INSTALLATION AND SERVICE MANUAL

low intensity gas-red pressurized infrared heaters

WARNING

1. Improper installation, adjustment,

alteration, service or maintenance can

cause property damage, injury or death,

and could cause exposure to substances

which have been determined by various

state agencies to cause cancer, birth

defects, or other reproductive harm. Read

the installation, operating, and

maintenance instructions thoroughly

before installing or servicing this

equipment.

2. Do not locate ANY gas-fired units in areas

where chlorinated, halogenated, or acidic

vapors are present in the atmosphere.

These substances can cause premature

heat exchanger failure due to corrosion

which can cause property damage, serious

injury or death.

3. For either indoor or outdoor installation.

Not for use in residential dwellings.

CAUTION

As with all infrared equipment, clearances to

combustible materials are critical. Be sure all

units have reflectors installed along the

entire length of the tube, and that they are not

mounted at an angle greater than 45° from

the horizontal plane. In locations used for

storage of combustible materials, signs shall

be clearly posted in the vicinity of the heater

where readily apparent to material handlers

to specify the maximum permissible stacking

height to maintain required clearances from the

heater to the combustibles.

9-511.4

5H0819050000

February, 2019

model IPT

FOR YOUR SAFETY

IF YOU SMELL GAS:

1. Open windows (indoor installation only).

2. Do not touch electrical switches.

3. Extinguish any open flame.

4. Immediately call your gas supplier.

FOR YOUR SAFETY

The use and storage of gasoline or other

flammable vapors and liquids in open

containers in the vicinity of this unit is

hazardous.

IMPORTANT

The use of this manual is specifically intended

for a qualified installation and service agency.

A qualified installation and service agency

must perform all installation and service of

these appliances.

Inspection upon Arrival

1. Inspect unit upon arrival. In case of damage, report it

immediately to transportation company and your local Modine

Sales Representative.

2. Check rating plate on unit to verify that power supply

meets available electric power at the point of installation.

3. Inspect unit upon arrival for conformance with description of

product ordered (including specifications where applicable).

THIS MANUAL IS THE PROPERTY OF THE OWNER.

PLEASE BE SURE TO LEAVE IT WITH THE OWNER WHEN YOU LEAVE THE JOB.

SPECIAL PRECAUTIONS

SPECIAL PRECAUTIONS

THE INSTALLATION AND MAINTENANCE INSTRUCTIONS IN

THIS MANUAL MUST BE FOLLOWED TO PROVIDE SAFE,

EFFICIENT AND TROUBLE-FREE OPERATION. IN ADDITION,

PARTICULAR CARE MUST BE EXERCISED REGARDING

THE SPECIAL PRECAUTIONS LISTED BELOW. FAILURE

TO PROPERLY ADDRESS THESE CRITICAL AREAS COULD

RESULT IN PROPERTY DAMAGE OR LOSS, PERSONAL

INJURY, OR DEATH. THESE INSTRUCTIONS ARE SUBJECT

TO ANY MORE RESTRICTIVE LOCAL OR NATIONAL CODES.

HAZARD INTENSITY LEVELS

1. DANGER: Indicates an imminently hazardous situation

which, if not avoided, WILL result in death or serious injury.

2. WARNING: Indicates a potentially hazardous situation which,

if not avoided, COULD result in death or serious injury.

3. CAUTION: Indicates a potentially hazardous situation which,

if not avoided, MAY result in minor or moderate injury.

4. IMPORTANT: Indicates a situation which, if not avoided,

MAY result in a potential safety concern.

DANGER

Appliances must not be installed where they may be

exposed to a potentially explosive or flammable atmosphere.

WARNING

10. Disconnect power supply before making wiring connections

to prevent electrical shock and equipment damage.

11. All appliances must be wired strictly in accordance with

the wiring diagram furnished with the unit. Any wiring

different from the wiring diagram could result in a hazard

to persons and property.

12. Any original factory wiring that requires replacement

must be replaced with wiring material having a

temperature rating of at least 105°C.

13. Ensure that the supply voltage to the appliance, as

indicated on the serial plate, is not 5% greater than rated

voltage.

14. When servicing or repairing this equipment, use only

factory-approved service replacement parts. A complete

replacement parts list may be obtained by contacting

Modine Manufacturing Company. Refer to the rating

plate on the unit for complete unit model number, serial

number, and company address. Any substitution of parts

or controls not approved by the factory will be at owner’s

risk.

CAUTION

WARNING

1. Do not locate ANY gas-fired units in areas where

chlorinated, halogenated, or acidic vapors are present in

the atmosphere. These substances can cause premature

heat exchanger failure due to corrosion which can cause

property damage, serious injury or death.

2. To prevent risk of fire or improper unit operation, radiant

tube baffle must be properly selected from Table 10.1

according to fuel type, burner input, and tube system length

and it must also be properly assembled and installed.

3. To prevent tube sections from separating during unit

operation, tube clamps must be centered over the joints

of adjoining tube sections and tightened to 50 ft. - lb. and

the clamp fastened to the tubes using (2) self-tapping

screws. Failure to do so may result in separation of tube

sections which could fall and result in death or serious injury.

4. All field gas piping must be pressure/leak tested prior to

operation. Never use an open flame. Use a soap solution

or equivalent for testing.

5. Gas pressure to appliance controls must never exceed

14" W.C. (1/2 psi).

6. Do not join two sections of Type B double wall vent pipe

within the vent system. A compromised pipe joint/liner pipe

may or not be detected, resulting in serious injury or

death.

7. A built-in combustion air blower is provided – additional

external draft hoods (diverters) or power exhausters are

not required or permitted.

8. To reduce the opportunity for condensation, the minimum

sea level input to the appliance, as indicated on the serial

plate, must not be less than 5% below the rated input.

9. A certified flexible connector must be used (local codes

permitting) as a the method of connecting the heaters to

the gas supply to avoid placing stress on the gas supply

line due to the expansion of the low intensity infrared

tubes during operation.

1. As with all infrared equipment, clearances to combustible

materials are critical. Be sure all units have reflectors

installed along the entire length of the tube, and that they

are not mounted at an angle greater than 45° from the

horizontal plane. In locations used for storage of

combustible materials, signs shall be clearly posted in the

vicinity of the heater where readily apparent to material

handlers to specify the maximum permissible stacking

height to maintain required clearances from the heater to

the combustibles.

2. Installation must conform with local building codes or in

the absence of local codes, with Part 7, Venting of

Equipment, or the National Fuel Gas Code, ANSI Z223.1

(NFPA 54) – latest edition. In Canada installation must be

in accordance with CAN/CGA-B149.1 for natural gas

units, and CAN/CGA-B149.2 for propane units.

3. Purging of air from gas lines should be performed as

described in ANSI Z223.1 – latest edition "National Fuel

Gas Code" or in Canada in CAN/CGA-B149 codes.

4. When leak testing the gas supply piping system, the

appliance and its combination gas control must be

isolated during any pressure testing in excess of 14" W.C.

(1/2 psi).

5. The unit should be isolated from the gas supply piping

system by closing its field installed manual shut-off valve.

This manual shut-off valve should be located within 6' of

the heater.

6. Turn off all gas before installing appliance.

7. Ensure that the supply voltage to the appliance, as

indicated on the serial plate, is not 5% less than the rated

voltage.

8. Do not attempt to reuse any mechanical or electrical

controllers which have been wet. Replace defective

controller.

2

9-511.4

SI (METRIC) CONVERSION FACTORS/UNIT LOCATION

Table 3.1 - SI (Metric) Conversion Factors

IMPORTANT

1. Approval requirements for infrared heaters specify that

the suspended type heaters shall be installed in

accordance with certain sections of the National Fire

Codes published by the National Fire Protection

Association and various ANSI standards. SOME of the

requirements are listed below.

Aircraft Hangars: Approval requirements are contained

in the current edition of ANSI/NFPA 409 (or in

accordance with the enforcing authority for Canada).

Public Garages: Approval requirements are contained in

the current edition of NFPA 88B (CAN/CGA B149 for

Canada).

Parking Structures: Approval requirements are

contained in the current edition of NFPA 88A.

General: All installations must be in accordance with the

current edition of ANSI Z-223.1 (NFPA 54) National Fuel

Gas Code and the current edition of the National Electric

Code, ANSI/NFPA 70. For Canada, installations must

conform with local building codes, or in the absence of

local codes, in accordance with the current edition of

CAN/CGA B149 and the Canadian Electric Code, C22.1.

2. Start-up and adjustment procedures should be performed

by a qualified service agency.

3. To check most of the Possible Remedies in the

troubleshooting guide listed in Table 23.1, refer to the

applicable sections of the manual.

To Convert Multiply By To Obtain

"W.C. 0.249 kPa

°F (°F-32) x 5/9 °C

Btu 1.06 kJ

Btu/ft3 37.3 kJ/m

Btu/hr 0.000293 kW

CFH (ft3/hr) 0.000472 m3/min

CFH (ft3/hr) 0.00000787 m3/s

CFM (ft3/min) 0.0283 m3/min

CFM (ft3/min) 0.000472 m3/s

UNIT LOCATION

Appliances must not be installed where they may be

exposed to a potentially explosive or flammable atmosphere.

Do not locate ANY gas-fired units in areas where chlorinated,

halogenated, or acidic vapors are present in the atmosphere.

These substances can cause premature heat exchanger

failure due to corrosion which can cause property damage,

serious injury or death.

To Convert Multiply By To Obtain

feet 0.305 m

Gal/Hr. 0.00379 m3/hr

Gal/Hr. 3.79 l/hr

3

gallons 3.79 l

Horsepower 746 W

inches 25.4 mm

pound 0.454 kg

psig 6.89 kPa

psig 27.7 "W.C.

DANGER

WARNING

Table of Contents

General Information/Installation Codes ...................1

Inspection upon Arrival ................................1

Special Precautions ..................................2

SI (Metric) Conversion Factors .........................3

Unit Location........................................4

Location Recommendations ........................4

Combustion Air Requirements ..........................4

Ventilation Air Requirements ........................4

Clearances to Combustibles ........................4

Installation .........................................5

Pre-Installation Notes .............................5

Removal of Burner Side Access Panels ...............5

Rotation of Gas Valve .............................5

Straight Tube Components .........................6

U-Tube Components..............................7

Unit Mounting – Tube System.......................8

UnitMounting–TurbulatorBafe ...................10

Unit Mounting – Burner ...........................10

UnitMounting–Reector .........................11

Additional Recommendations for Outdoor Installation ...11

Venting .......................................12

Gas Connections................................15

High-Altitude Accessory Kit ........................16

Electrical Connections............................18

Start-Up Procedure..................................19

Main Burner Adjustment ..........................19

Primary Air Shutter(Propane Only) ..................19

Control Operating Sequence ......................19

Dimensional Data ...................................20

Performance.......................................21

Maintenance.......................................22

Service & Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Replacement Parts Ordering ..........................24

Model Number Designations ..........................24

Serial Number Designations...........................24

Wiring Diagram..................................25,26

Warranty..........................................28

9-511.4

CAUTION

As with all infrared equipment, clearances to combustible

materials are critical. Be sure all units have reflectors

installed along the entire length of the tube, and that they are

not mounted at an angle greater than 45° from the horizontal

plane. In locations used for storage of combustible materials,

signs, shall be clearly posted in the vicinity of the heater

where readily apparent to material handlers to specify the

maximum permissible stacking height to maintain required

clearances from the heater to the combustibles.

IMPORTANT

Approval requirements for infrared heaters specify that the

suspended type heaters shall be installed in accordance

with certain sections of the National Fire Codes published

by the National Fire Protection Association and various

ANSI standards. SOME of the requirements are listed

below.

Aircraft Hangars: Approval requirements are contained in

the current edition of ANSI/NFPA 409 (or in accordance with

the enforcing authority for Canada).

Public Garages: Approval requirements are contained in

the current edition of NFPA 88B (CAN/CGA B149 for

Canada).

Parking Structures: Approval requirements are contained

in the current edition of NFPA 88A.

General: All installations must be in accordance with the

current edition of ANSI Z-223.1 (NFPA 54) National Fuel

Gas Code and the current edition of the National Electric

Code, ANSI/NFPA 70. For Canada, installations must

conform with local building codes, or in the absence of local

codes, in accordance with the current edition of CAN/CGA

B149 and the Canadian Electric Code, C22.1.

3

UNIT LOCATION /AIR REQUIREMENTS

"B"

"C"

"A"

0° MOUNTING ANGLE

"B"

"C"

"C"

CHAIN LOCATION

45° MOUNTING ANGLE

(MAXIMUM)

"A"

Location Recommendations

1. When locating the heater, consider the general space and

heating requirements and availability of gas and electrical

supply.

2. Be sure the structural support and chain at the unit location is

adequate to support the weight of the unit.

3. Be sure that the minimum clearances to combustible

materials and are maintained. The minimum clearances to

combustibles are shown in Table 4.1, and Figures 4.1 and

4.2, as well as affixed to the burner Model Identification plate.

4. Maintain a recommended minimum of 18" clearance from the

access side of the burner box and also on the combustion air

inlet end of the burner box.

5. Mounting height (measured from the bottom of unit) at which

heaters are installed is important to maintain proper occupant

comfort levels. Please refer to mounting height information in

Table 21.1.

6. Do not locate units in areas where chlorinated, halogenated,

or acid vapors are present in the atmosphere.

7. Unit gas control can be field configured for right or left access,

depending on unit location. See general instructions for

"Rotation of Gas Control" on page 5.

Combustion Air Requirements

Units installed in tightly sealed buildings or confined spaces

must be provided with two permanent openings, one near the

top of the confined space and one near the bottom. Each

opening should have a free area of not less than one square

inch per 1,000 BTU per hour of the total input rating off all units

in the enclosure, freely communicating with interior areas

having, in turn adequate infiltration from the outside.

For further details on supplying combustion air to a confined

(tightly sealed) space or unconfined space, see the National

Fuel Gas Code ANSI Z223.1 of CAN/CGA B149.1 or .2

Installation Code, latest edition.

An accessory combustion air intake collar can be used to bring

outside combustion air to the unit using 4" pipe. Refer to the

venting section "Utilizing Outside Combustion Air" on page 14

for details on pipe length and location.

Clearance to Combustibles

Ensure that:

1. Clearances to combustibles (as shown on the Model

Identification plate and in Table 4.1) are maintained. These

Clearances also apply to vehicles parked below the heater.

2. Adequate clearances to sprinkler heads are maintained. As a

guideline, certified minimum distance to combustible material

is based on the combustible material surface not exceeding

90˚Faboveambient(160˚Ftypical).

3. The stated clearance to combustibles represents a surface

temperature of 90°F (50°C) above room temperature.

Building materials with a low heat tolerance (such as plastics,

vinyl siding, canvas, tri-ply, etc.) may be subject to

degradation at lower temperatures. It is the installer's

responsibility to assure that adjacent materials are protected

from degradation.

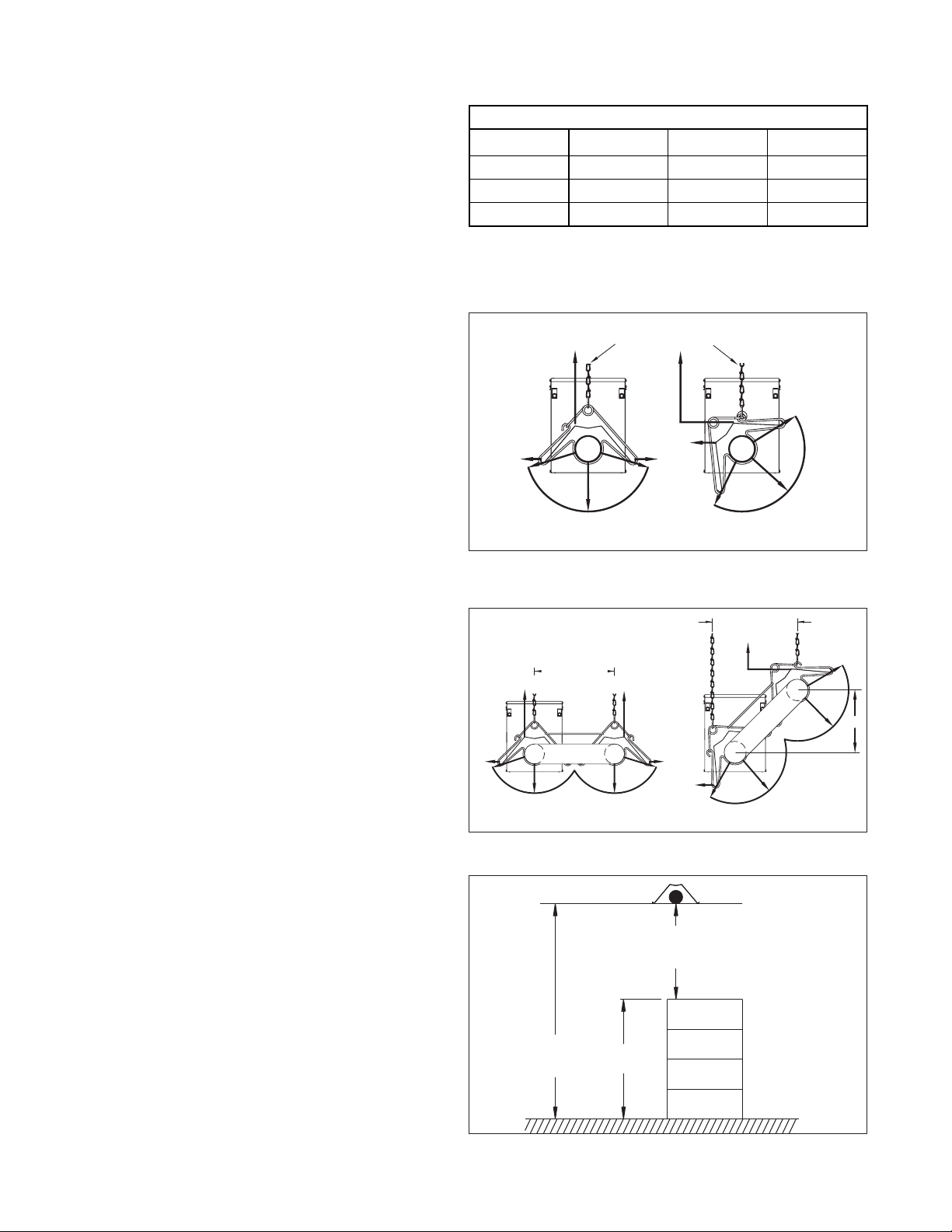

Storage of Combustible Materials

In locations used for storage of combustible materials, signs

shall be clearly posted in the vicinity of the heater where readily

apparent to material handlers to specify the maximum

permissible stacking height to maintain required clearances from

the heater to the combustibles. See Figure 4.3.

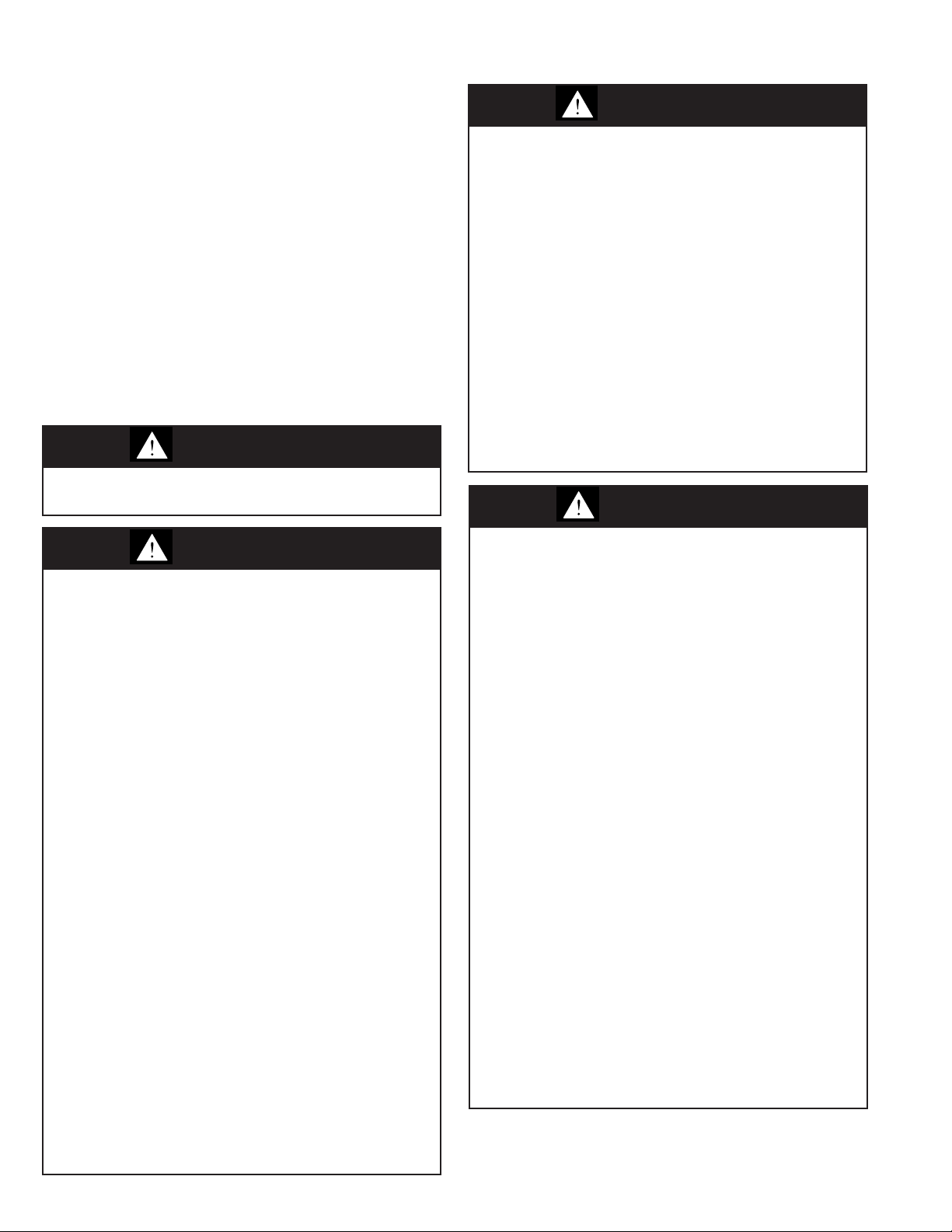

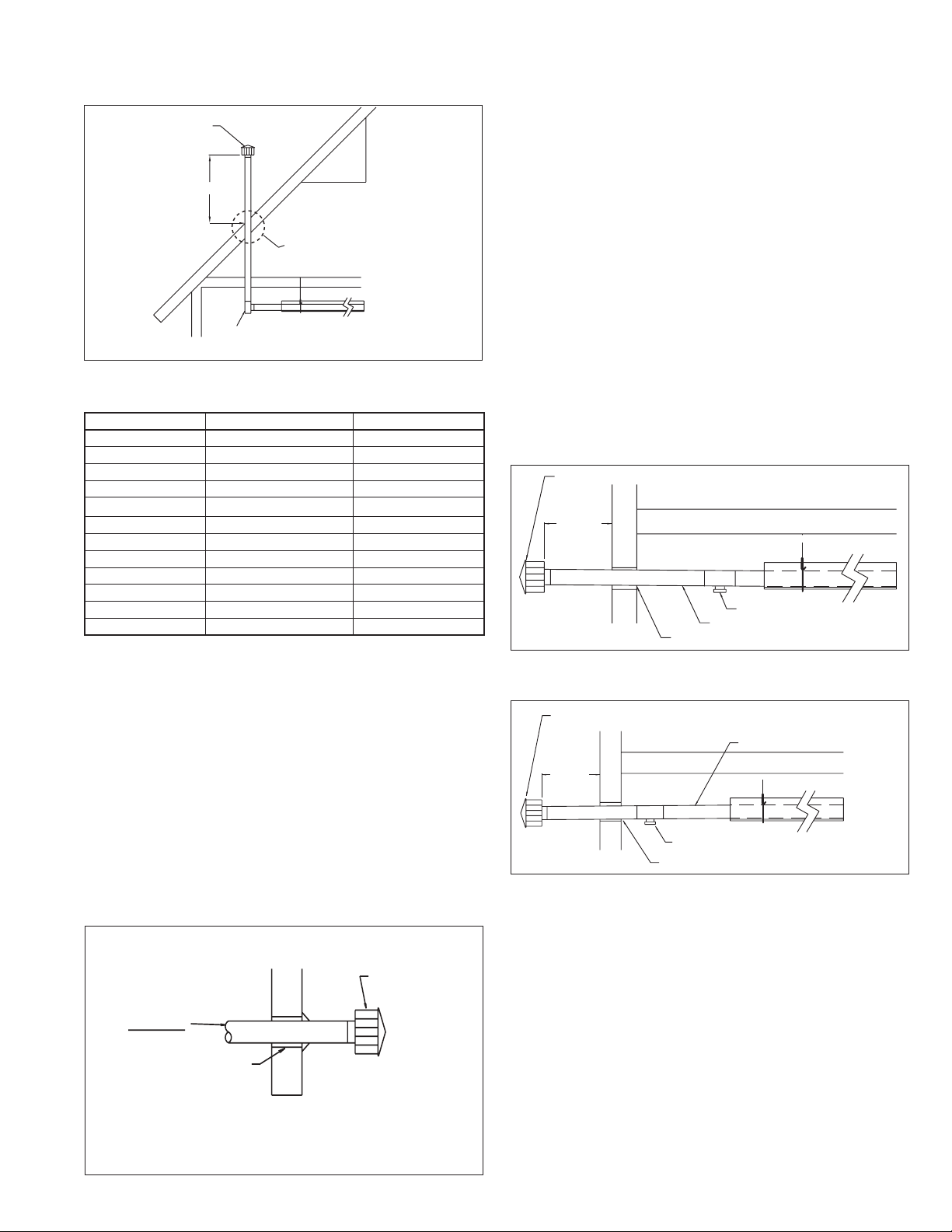

Table 4.1 - Combustible Material Clearances (inches) ➀

Combustible Material Clearances (inches)

Input MBH “A” ➀ “B” “C”

50/60 9 54 20

75/100/125 9 76 24

150/175/200 12 106 38

➀ Clearance to each end and above the U-Tube is 12 inches.

Refer to Figures 4.1 and 4.2.

Figure 4.1 - Combustible Material Clearances Straight Tube

CHAIN LOCATION

"A"

"C"

"B"

0° MOUNTING ANGLE

"A"

"C"

"C"

"B"

45° MOUNTING ANGLE

(MAXIMUM)

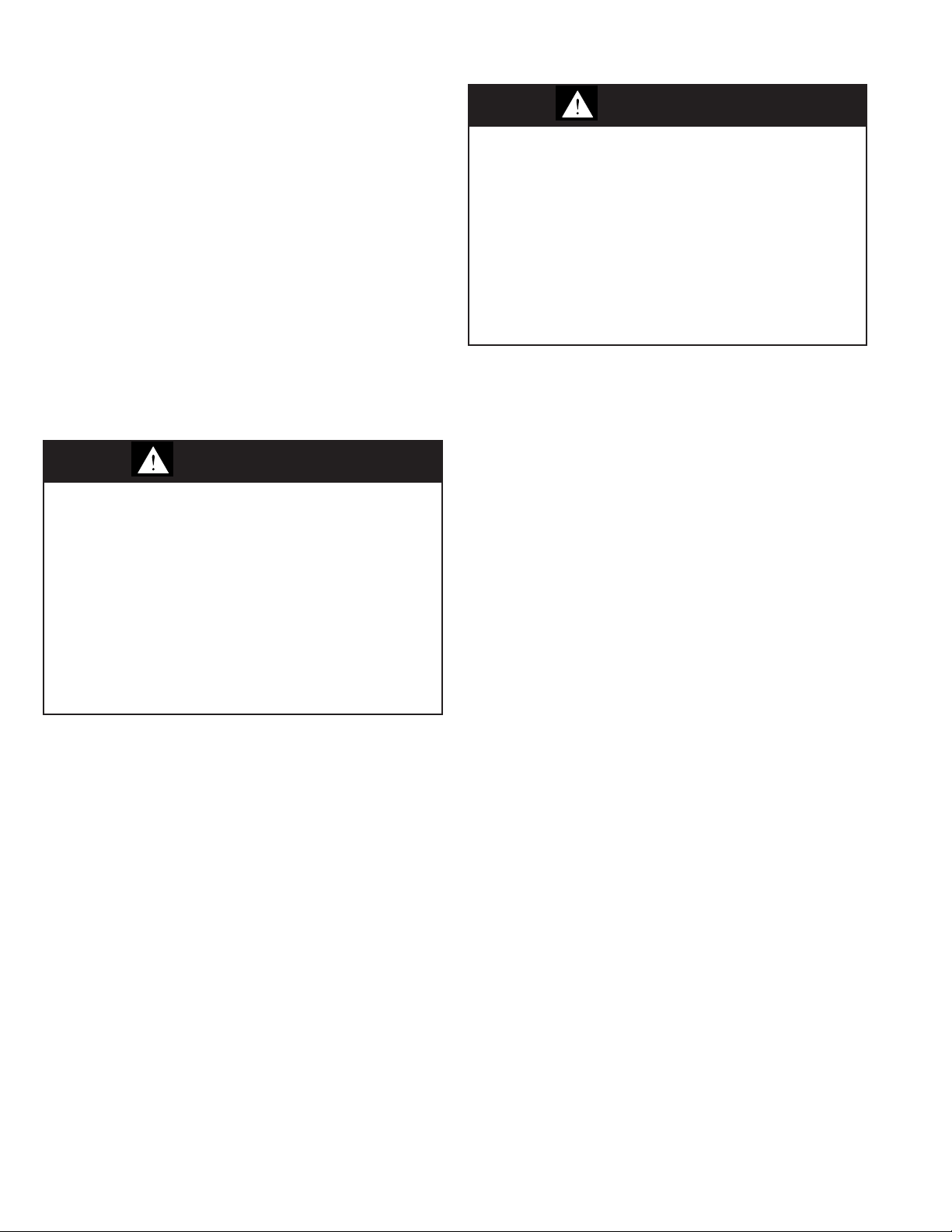

Figure 4.2 - Combustible Material Clearances -

U-Tube

CHAIN LOCATION

"A"

"C"

CHAIN LOCATION

"A"

"B"

"U" TUBE

0° MOUNTING ANGLE

"B"

"A"

"C"

"C"

"B"

"B"

"U" TUBE

45° MOUNTING ANGLE

(MAXIMUM)

12"

Figure 4.3 - Stacking Height

Minimum Clearance to

Combustible Materials

Unit Heater

Mounting

Height

Stacking

Height

4

9-511.4

INSTALLATION

Unit Mounting – Pre-Installation Notes

WARNING

1. To prevent risk of fire or improper unit operation, radiant

tube baffle must be properly selected from Table 10.1

according to fuel type, burner input, and tube system

length and it must also be properly assembled and installed.

2. To prevent tube sections from separating during unit

operation, tube clamps must be centered over the joints

of adjoining tube sections and tightened to 50 ft. - lb. and

the clamp fastened to the tubes using (2) self-tapping

screws. Failure to do so may result in separation of tube

sections which could fall and result in death or serious injury.

1. Be sure the method of unit suspension is adequate to support

the weight of the burner and tube system (see Tables 18.1

and 18.2 for system weights).

2. Combustible material and service clearances as specified in

Table 4.1 and Figures 4.1 through 4.3 must be strictly

maintained.

3. Maintain a recommended minimum of 18" clearance from the

access side of the burner box and also on the combustion air

inlet end of the burner box.

4. Before installing, review the components to be installed

against Figure 6.1 and Table 6.1 for straight tube systems or

Figure 7.1 and Table 7.1 for U-Tube systems. Ensure that all

parts are identified and available before proceeding with

installation of the unit.

5. It is recommended that the uninstalled system components

be arranged on the floor, where possible, to match the

intended layout. This can help ensure the layout matches the

intended design.

6. The standard gas control access is on the left side when

looking at the back end of the burner (combustion air inlet

end). If the intended installation requires access from the

opposite side, please follow the instructions in the section

titled "Rotation of Gas Control" prior to burner installation.

7. For proper operation, the burner and tube system must be

installed in a level horizontal position. Use a spirit level during

installation to ensure that the unit is suspended level.

8. Under no circumstances should the gas supply line or the

electrical supply line to the heater provide any assistance in

the suspension of the heater. Do not locate any gas or

electric service line directly above or below the heater.

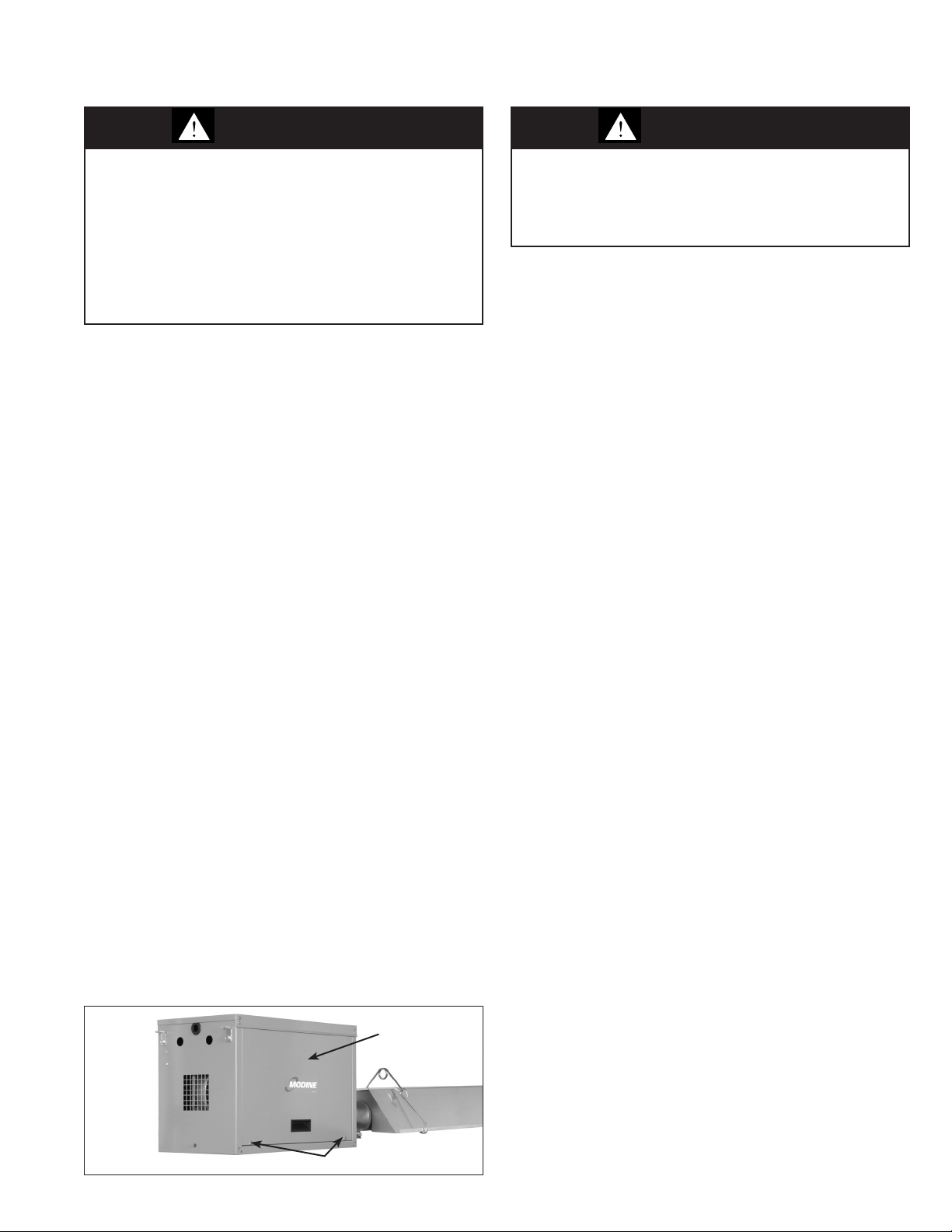

Removal of Burner Side Access Panels

Each of the two side access panels are held in place by two (2)

screws, as shown in Figure 5.1. Once the screws are removed,

the panels slide down, where they can either hang on the

hooks shown in Figure 22.1 or be removed completely during

service or maintenance. The unit is designed to operate without

these panels in place so that adjustments of the controls can

be made. The panels must be returned to the unit once

installation is complete.

Figure 5.1 - Side Access Panels

Rotation of Gas Control

WARNING

1. All field gas piping must be pressure/leak tested prior to

operation. Never use an open flame. Use a soap solution

or equivalent for testing.

2. Gas pressure to appliance controls must never exceed

14" W.C. (1/2 psi).

This section is only required if opposite side gas control access

is required. The standard access is on the left side when looking

at the back of the burner box (combustion air inlet end).

In order to install the heater so that the gas valve's controls can

be accessed from the opposite side of the burner box, the valve

may be rotated 180° by following the procedure below.

1. Remove burner side access panels as described in the

previous section.

2. Unplug all wires from the valve.

3. Using two wrenches, loosen the factory-supplied union in

the burner box and remove the gas valve. Do not apply

the wrenches directly to either the gas valve or the

gas manifold.

4. Remove the plug from the factory-supplied "tee" fitting and

screw it into the opposite leg of the tee. Be sure to properly

seal the threads of this connection.

5. Seat the gas valve onto the factory-supplied union, so that

the valve faces the opposite side of the burner box.

Tighten the union using two wrenches, without applying

them directly to either the gas valve or the gas manifold.

6. Plug-in all wires removed from the valve in step 2.

7. The gas piping/fitting connections must be pressure/leak

tested as outlined in the section titled "Gas Connections"

on page 15.

8. Replace the burner side access panels.

Remove Screws (2)

Side Access

Panel

9-511.4

5

INSTALLATION

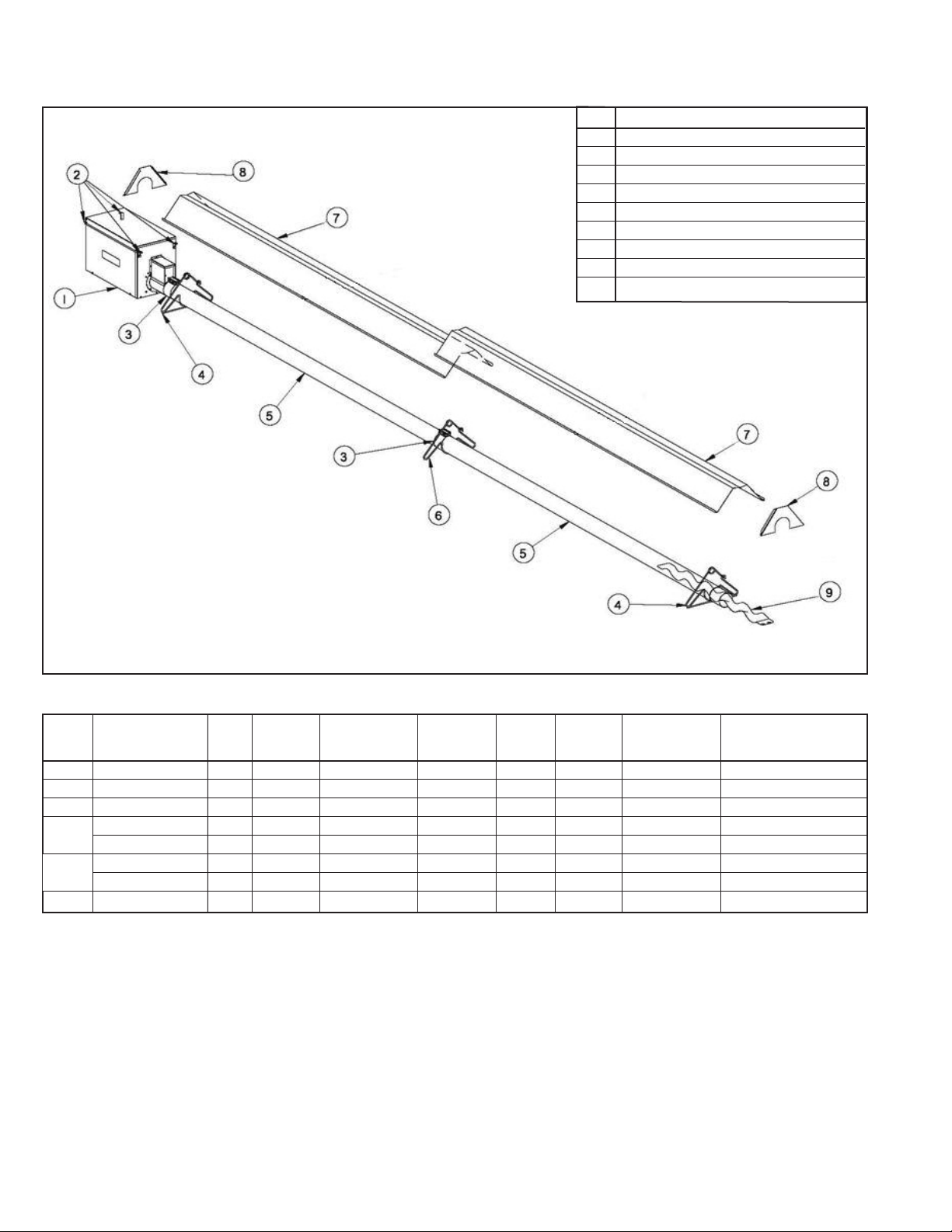

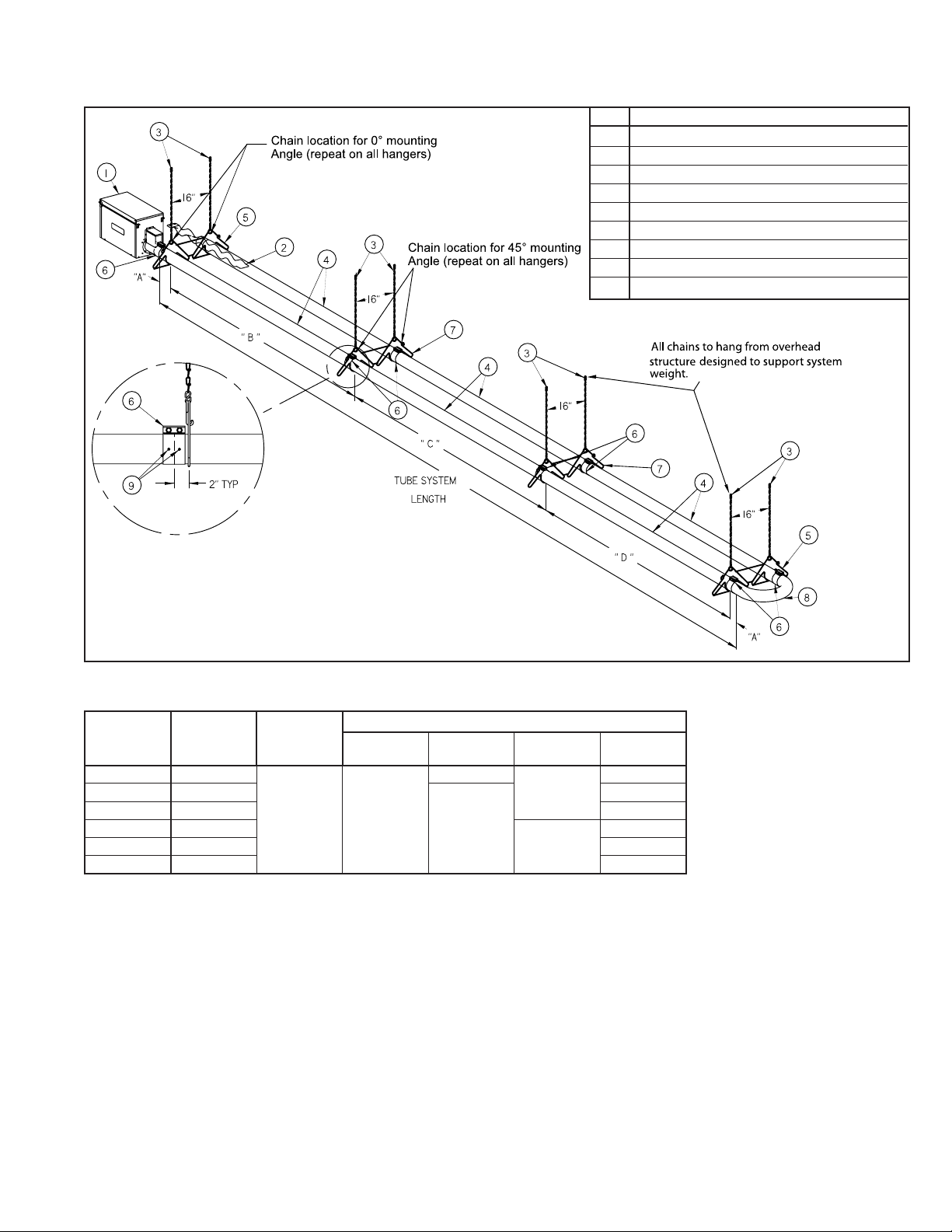

Figure 6.1 - Straight Tube System Components

Ref # Part Description

1 Burner

2 Burner Support Bracket (Qty. 4)

3 Tube Clamp

4 Tube&ReectorHangerw/ReinforcingBar

5 Radiant Tube

6 Tube&ReectorHanger

7 Reector

8 ReectorEndCap

9 TurbulatorBafe

Table 6.1 - Straight Tube System Component List

Tube Single-Tube Single-Tube Stocking Kit

Length Available Burner 10' 10' Hangers with Hangers Tube Reector Turbulator Option Requires the

(ft.) Input MBH Tubes Reectors Reinforcing Bar (regular) Clamps End Cap Bafe Sections Following Tube Kits ➁:

20 50, 60, 75 2 2 2 1 3 2 4 A

30 50, 60, 75, 100 3 3 2 2 4 2 4 E

40 60, 75, 100, 125 4 4 2 3 5 ➀ 2 4 A + D

50 100, 125 5 5 2 4 6 ➀ 2 4 E + D

50

150, 175, 200 5 ➀ 5 2 4 6 ➀ 2 4 B + C

60 125 - 1-Stage Only 6 6 2 5 7 ➀ 2 4 A + D + D

60

60 150, 175, 200 6 ➀ 6 2 5 7 ➀ 2 4 B + D

70 175, 200 7 ➀ 7 2 6 8 ➀ 2 4 B + E

➀ Tube systems for input ratings of 150MBH and higher utilize a 409 Aluminized Stainless Steel First tube section with stainless steel tube clamps.

➁ Tube systems can be ordered as either Modular (complete system) or Stocking Kits (combination of kits to form complete system).

6

9-511.4

INSTALLATION

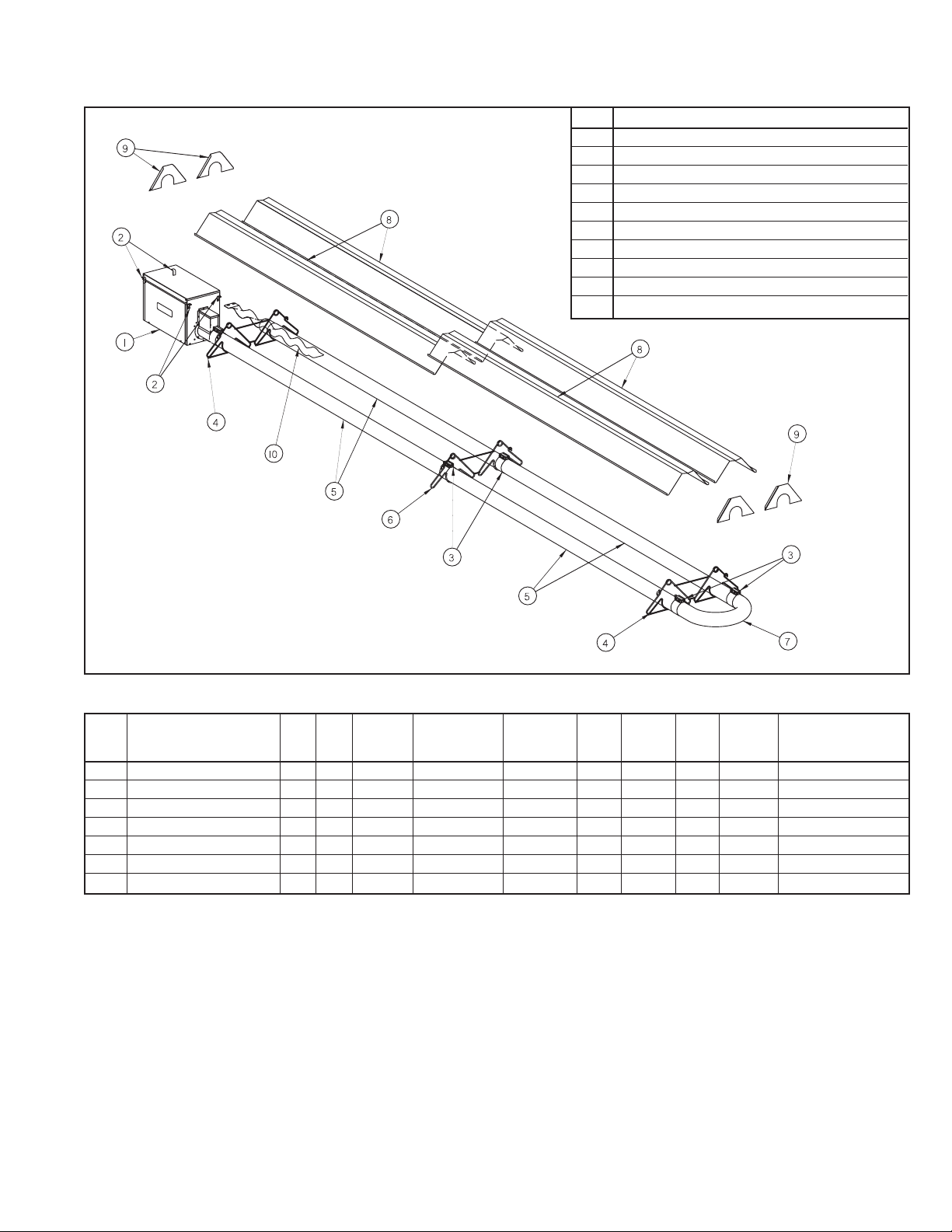

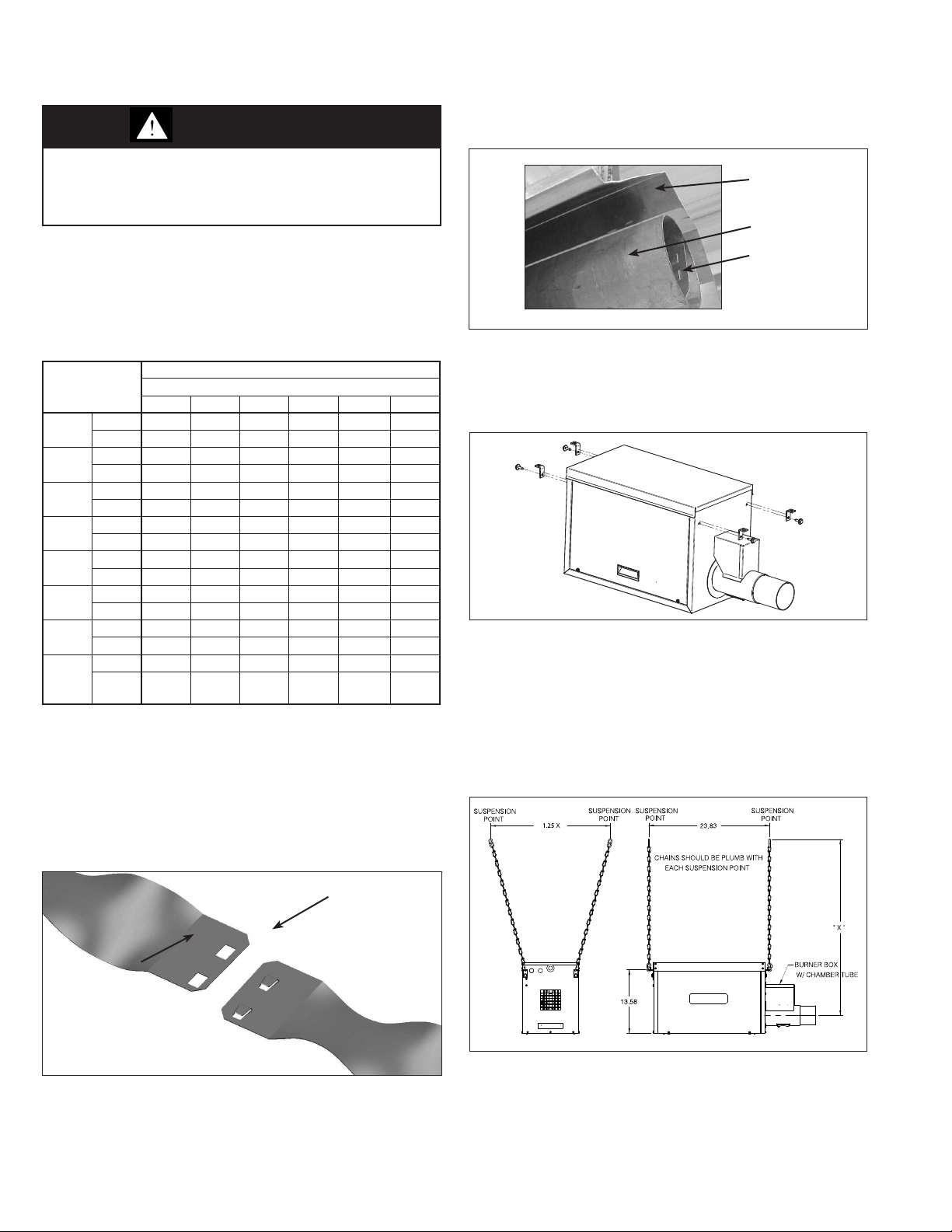

Figure 7.1 - U-Tube System Components

Ref # Part Description

1 Burner

2 Burner Support Bracket (Qty. 4)

3 Tube Clamp

4 DoubleTube&ReectorHangerw/ReinforcingBar

5 Radiant Tube

6 DoubleTube&ReectorHanger

7 U-Tube

8 Reector

9 ReectorEndCap

10 TurbulatorBafe

Table 7.1 - U-Tube System Component List

Tube Double-Tube Double-Tube Turbulator Stocking Kit

Length Available Burner 5' 10' 10' Hangers with Hangers Tube Reector Bafe Option Requires the

(ft.) Input MBH Tubes Tubes Reectors Reinforcing Bar (regular) Clamps End Cap U-Tube Sections ➂ Following Tube Kits ➁

20 50, 60, 75 - 2 2 2 - 4 4 1 4 A + U-Tube

30 50, 60, 75, 100 2 2 4 2 1 6 4 1 4 N/A

40 60, 75, 100, 125 - 4 4 2 1 6 4 1 4 A + D + U-Tube

50 100, 125, 150, 175, 200 2 4 ➀ 6 2 2 8 ➀ 4 1 4 N/A

60 125 - 1-Stage Only - 6 6 2 2 8 4 1 4 A + D + D + U-Tube

60 150, 175, 200 - 6 ➀ 6 2 2 8 ➀ 4 1 4 B + D + U-Tube

70 175, 200 2 6 ➀ 8 2 3 10 ➀ 4 1 4 N/A

➀ Tube systems for input ratings of 150MBH and higher utilize a 409 Aluminized Stainless Steel First tube section with stainless steel tube clamps.

➁ Tube systems can be ordered as either Modular (complete system) or Stocking Kits (combination of kits to form complete system).

➂ Forinstallationswhere4bafesareneedonstraighttubesetups,U-tubeinstallationswillonlyrequire3bafes.

9-511.4

7

INSTALLATION

Unit Mounting – Tube System

WARNING

To prevent tube sections from separating during unit

operation, tube clamps must be centered over the joints of

adjoining tube sections and tightened to 50 ft. - lb. and the

clamp fastened to the tubes using (2) self-tapping screws.

Failure to do so may result in separation of tube sections

which could fall and result in death or serious injury.

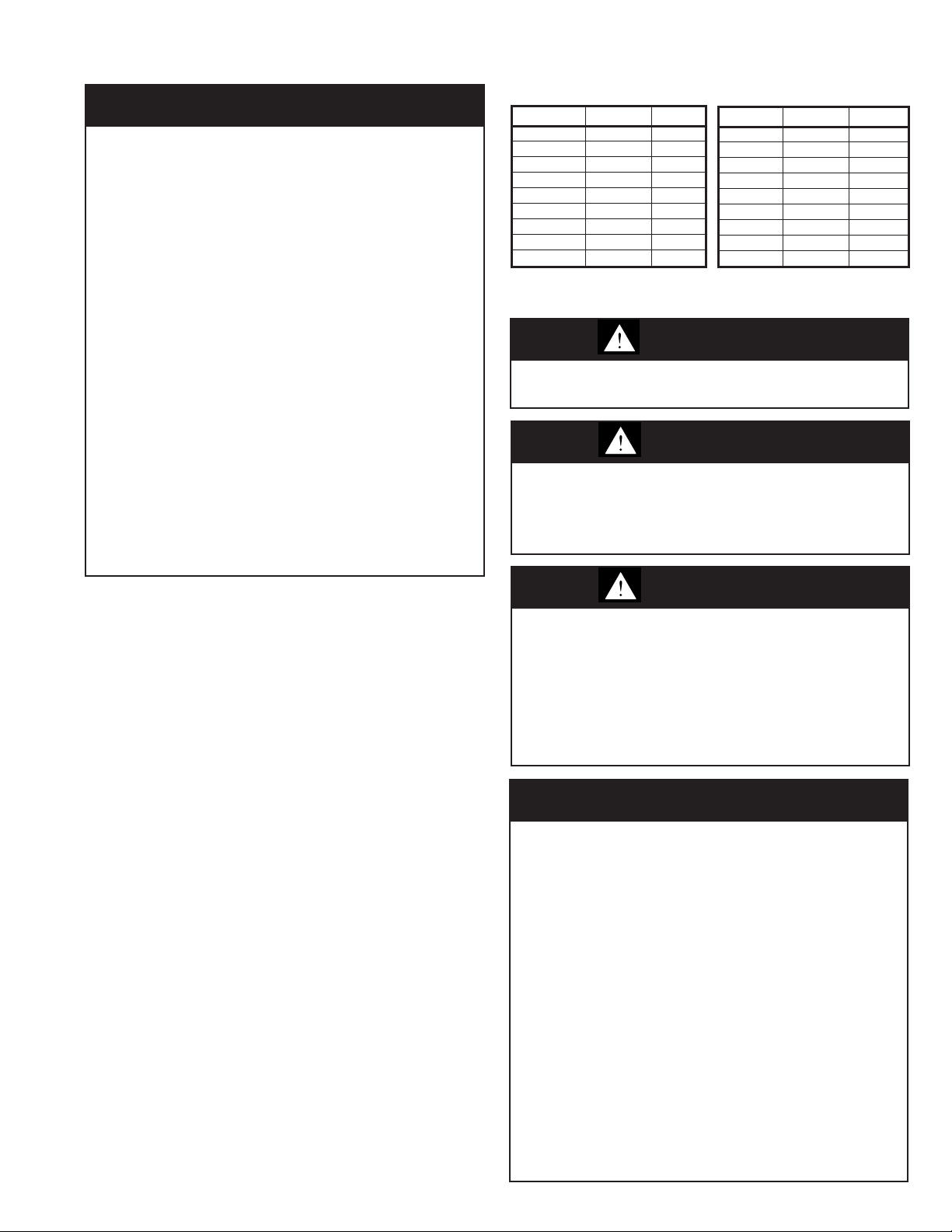

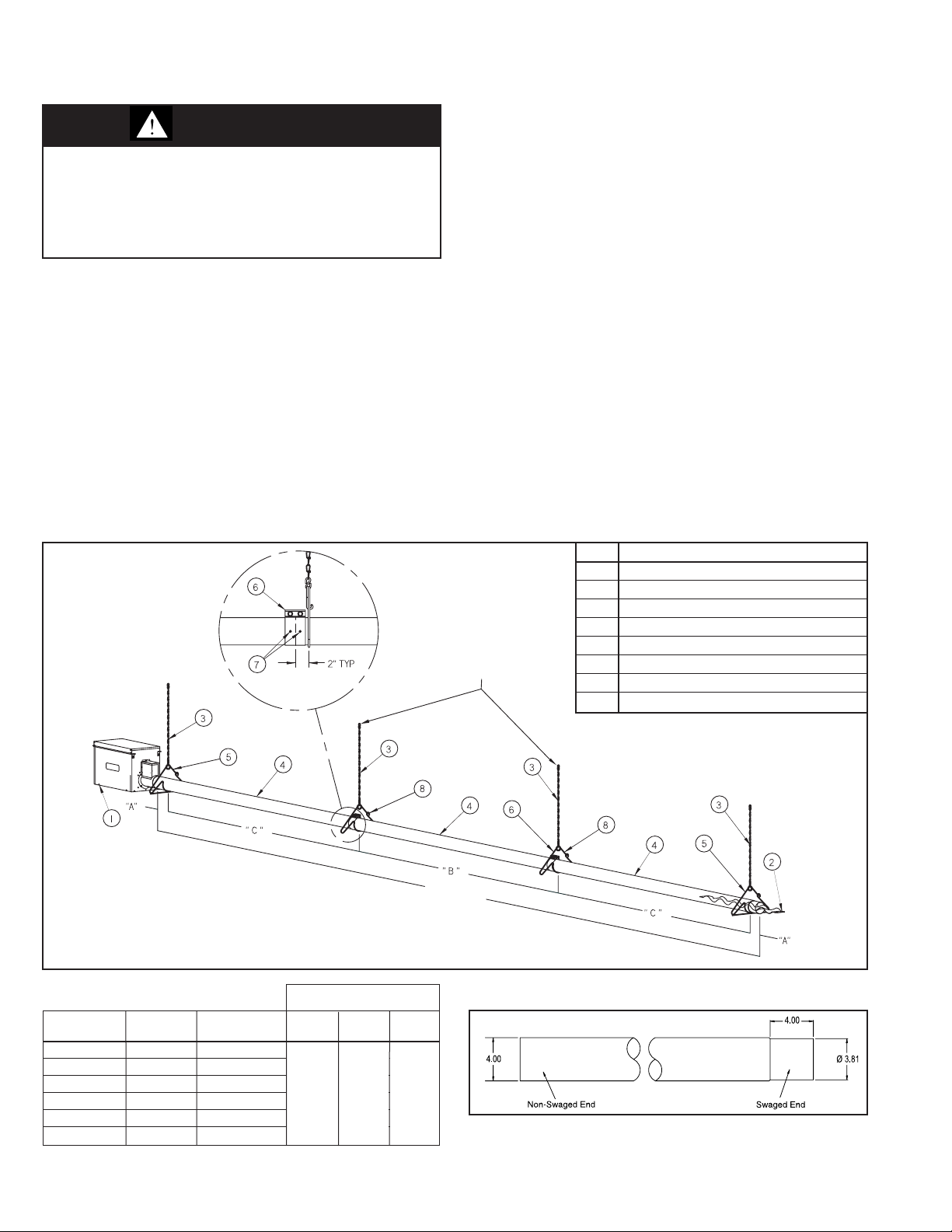

For steps 1-8 of this section, please refer to Figures 8.1 and 9.1

1. Locate and install tube and reflector system hanging chains

(200 lb. minimum working load) as shown, following spacing

indicated in Table 8.1 or 9.1.

2. Fasten tube and reflector hangers to the hanging chains

installed in the previous step using ¼" diameter S-Hooks (70

lb. minimum working load). The hangers must be positioned

so that the tube system to be installed will be in the horizontal

plane and level. Refer to Figures 8.1 and 9.1 for chain

location on tube systems mounted at a 45° angle. Also note

that the first and last hangers are to be the type with

reinforcing bar. Do not close ends until the tube system

installed in subsequent steps is confirmed to be level.

3. Identify the first burner tube and first and second tube clamps

as follows:

Figure 8.1 - Straight Tube System Suspension

All chains to hang from

overhead structure designed

to support system weight.

• For units under 150,000 Btu/hr, all tubes and clamps

are the same.

• For units 150,000 Btu/hr and over, the first tube is

shinier than the other tubes and is stenciled with the

words “First Tube”. The first two tube clamps have a

shiny, mirror-like appearance.

4. Loosely slide the second tube clamp approximately 6" past

the swaged end (see Figure 8.2 for identification of tube ends).

5. Starting from the end of the tube system where the burner will

be installed (done in later steps), slide the first burner tube

through the first and second tube hangers. The non-swaged

end is to go through the first tube hanger and the swaged end

is to go through the second tube hanger. Position the tube so

the welded seam is directed toward the floor.

6. Loosely slide the next tube clamp over the swaged end of the

next tube and slide the non-swaged end over the swaged end

of the preceding tube, ensuring that the welded seam on the

tube is directed toward the floor. The other end is to be

inserted through the following tube hanger.

7. Center the tube clamp on the preceding tube over the joint of

the two tubes as shown in Figures 8.1 or 9.1 and tighten the

tube clamp bolts to 50 ft.-lb. Secure the tube clamp to both

tubes using (2) self-tapping sheet metal screws.

8. Repeat steps 6 and 7 until all tube sections are installed.

9. Verify that the tube system is level. If the tube is not level,

adjust the position of the hanger on the hanging chain. Once

level, crimp the ends of the S-hooks on the hangers closed.

Ref # Part Description

1 Burner (Installed In Later Steps)

2 TurbulatorBafe

3 Chain & “S” Hooks

4 Radiant Tube

5 Tube&ReectorHangerw/ReinforcingBar

6 Tube Clamp

7 Self-Tapping Sheet Metal Screws

8 Tube&ReectorHanger

TUBE SYSTEM

LENGTH

Table 8.1 -

Straight Tube Chain Spacing

Tube System Number of Minimum "A" "B" "C"

Length (ft) Chains Chain Length ➀ ➁ ➂

20 3 18"

30 4 18"

40 5 18"

50 6 18"

60 7 24"

70 8 24"

➀"A"Dimensionisspacingfromthetubesystemendstotherstandlasthangers.

➁ "B" Dimension is spacing between hangers for tubes between "C" dimensions.

➂"C"Dimensionisspacingbetweenthersttwohangersandthelast2hangers.

Chain to Chain

Spacing Dimensions

N/A

6"

9' 8"

9' 4"

8

Figure 8.2 - Tube Ends (Dimensions in inches)

9-511.4

INSTALLATION

Figure 9.1 - U-Tube System Suspension

Ref # Part Description

1 Burner (installed In later steps)

2 Turbulator Baffle

3 Chain & “S” Hooks

4 Radiant Tube

5 DBL Tube & Reflector Hanger w/ Reinforcing Bar

6 Tube Clamp

7 Double Tube & Reflector Hanger

8 U-Tube

9 Self-Tapping Sheet Metal Screws

Table 9.1 - U-Tube Chain Spacing

Tube System

Length (ft)

20 4

30 6

40 6 4' 4"

50 8

60 8 4' 4"

70 10 4' 4"

➀ “A” Dimension is spacing from the tube system ends to the first hanger and from the U-tube ends to the last hanger.

➁ “B” Dimension is spacing between first and second hangers away from burner.

➂ “C” Dimension is spacing between hangers for tubes between “B” and “D” dimensions.

➃ “D” Dimension is spacing between first and second hangers away from U-tube.

Number of

Chains

Maximum

Chain

Length

18" 6"

"A"

Dimension ①

Espacement des chaînes

"B"

Dimension ②

N/A

9' 4"

"C"

Dimension ③

N/A

9' 8"

"D"

Dimension ④

Sans objet

4' 4"

4' 4"

9-511.4

9

INSTALLATION

Unit Mounting – Turbulator Baffle

WARNING

To prevent risk of fire or improper unit operation, radiant

tube baffle must be properly selected from Table 10.1

according to fuel type, burner input, and tube system length

and it must also be properly assembled and installed.

1. The last section of radiant tube is to include a turbulator baffle

assembly. Determine the quantity of baffle sections to be

installed based on the burner rating and tube system length,

per Table10.1. Discard any baffle sections that will not be

required for the assembly.

Table 10.1 - Turbulator Baffle Assembly Section Qty.

Determination

Bafe Quantity

Input MBH

20 30 40 50 60 70

NG 2 2 - - - -

50

60

75

100

125

150

175

200

* Max. tube length on 125MBH 2-Stage units is 50'

* Note - Tube lengths shown are for units installed at elevations of 0-2001'.

Allowable tube lengths may differ upon elevation changes.

* Note - Forinstallationswhere4bafesareneedon straighttubesetups,

U-tubeinstallationswillonlyrequire3bafes.

2. Assemble the turbulator baffle assembly by mating the

LP 1 1 - - - -

NG 3 1 0 - - -

LP 3 1 0 - - -

NG 4 2 2 - - -

LP 4 2 - - - -

NG - 4 3 2 - -

LP - 4 3 - - -

NG - - 3 2 2 -

LP - - 4 3 1 -

NG - - - 3 2 -

LP - - - 3 2 -

NG - - - 3 2 2

LP - - - 3 2 0

NG - - - 4 2 0

LP - - - 4 2 0

sections determined in the previous step as shown in

Figure 10.1.

Tube Length (ft)

3. Insert the completed turbulator baffle assembly into the last

radiant tube, flush with the end as shown in Figure 10.2.

Figure 10.2 - Insertion of Turbulator Baffle Assembly

Reflector

Last Tube

Baffle

Unit Mounting – Burner

1. Install four burner support brackets as shown in Figure 10.3

with the bolts supplied.

Figure 10.3 - Burner Support Bracket Installation

2. The burner must be suspended with four chains (200 lb.

minimum working load) to allow for system expansion and

contraction during unit operation, as shown in Figure 10.4.

Note that for U-tube systems mounted at a 45° angle, the

exiting side of the tube system is 12" higher than the burner

(see Figure 4.2). Locate and mount burner to ensure that

Clearance to Combustibles are maintained (refer to

"Clearance to Combustibles" on page 4).

Figure 10.4 - Burner Suspension

Figure 10.1 - Assembly of Turbulator Baffle Assembly

Tabs

Slots

10

9-511.4

INSTALLATION

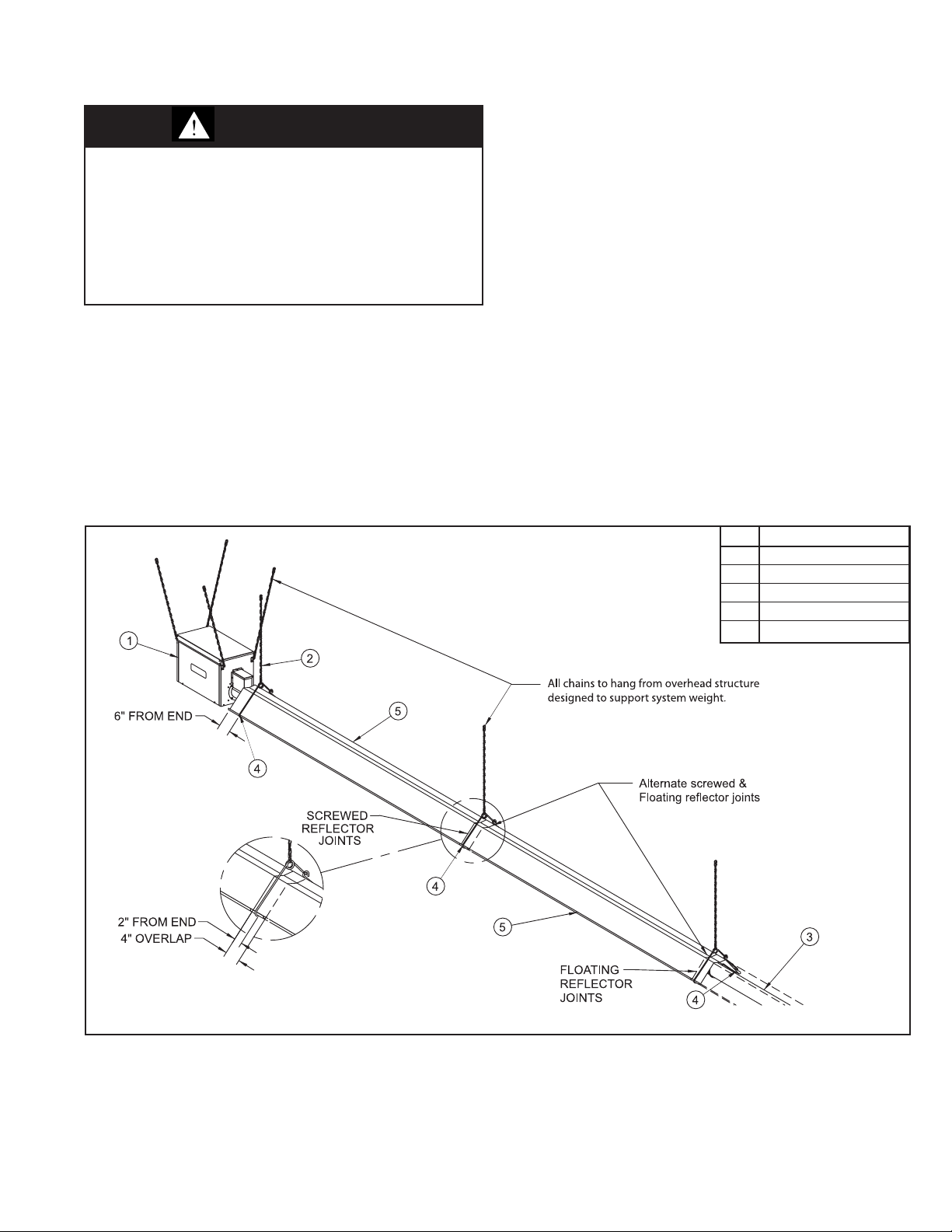

Unit Mounting – Radiant Reflector

CAUTION

As with all infrared equipment, clearances to combustible

materials are critical. Be sure all units have reflectors

installed along the entire length of the tube, and that they are

not mounted at an angle greater than 45° from the horizontal

plane. In locations used for storage of combustible materials,

signs, shall be clearly posted in the vicinity of the heater

where readily apparent to material handlers to specify the

maximum permissible stacking height to maintain required

clearances from the heater to the combustibles.

For steps 1-7, refer to Figure 11.1.

1. The entire radiant tube length must have radiant reflector

installed. The only exception is that on U-tube systems, a

reflector is not installed over the U-tube.

2. Remove any protective plastic covering the reflectors.

3. Starting from the burner, slide a reflector through the tube and

reflector hangers and position the reflector so that it is

centered over the tube. The end closest to the burner should

be 6" from the first tube and reflector hanger.

Figure 11.1 - Installation of the Radiant Reflectors

4. Slide the next reflector through the tube and reflector hangers

and center over the next tube. The reflector should overlap

the previous reflector by 4". Repeat until all reflectors are

installed (alternating top and bottom overlaps).

5. Starting from the burner end and working toward the vent end

of the tube system, overlapping reflector joints are to be either

secured or remain unsecured as follows:

• Every odd numbered reflector to even numbered

reflector joint (reflectors 1 to 2, 3 to 4, etc.) is to be

secured with self-tapping sheet metal screws.

• Every even numbered reflector to odd numbered

reflector joint (reflectors 2 to 3, 4 to 5, etc.) is to remain

unsecured to allow for expansion and contraction during

operation.

6. Reflector end caps are to be fastened to both ends of the

reflector system using sheet metal screws.

Additional Recommendations for Outdoor Installation

Complies with Canadian Standard CAN1-2.21

When utilized in an outdoor installation or in aircraft hangars, the

following is required:

1. A screened combustion air intake cap.

2. All electrical connections must be water tight and suitable for

outdoor use.

Ref # Part Description

1 Burner

2 Chain & “S” Hooks

3 Radiant Tube

4 Tube&ReectorHanger

5 Reector

9-511.4

11

INSTALLATION

Venting

WARNING

1. A built-in combustion air blower is provided – additional

external draft hoods (diverters) or power exhausters are

not required or permitted.

CAUTION

Installation must conform with local building codes or in the

absence of local codes, with Part 7, Venting of Equipment, or

the National Fuel Gas Code, ANSI Z223.1 (NFPA 54) – latest

edition. In Canada installation must be in accordance with

CAN/CGA-B149.1 for natural gas units, and CAN/

CGA-B149.2 for propane units.

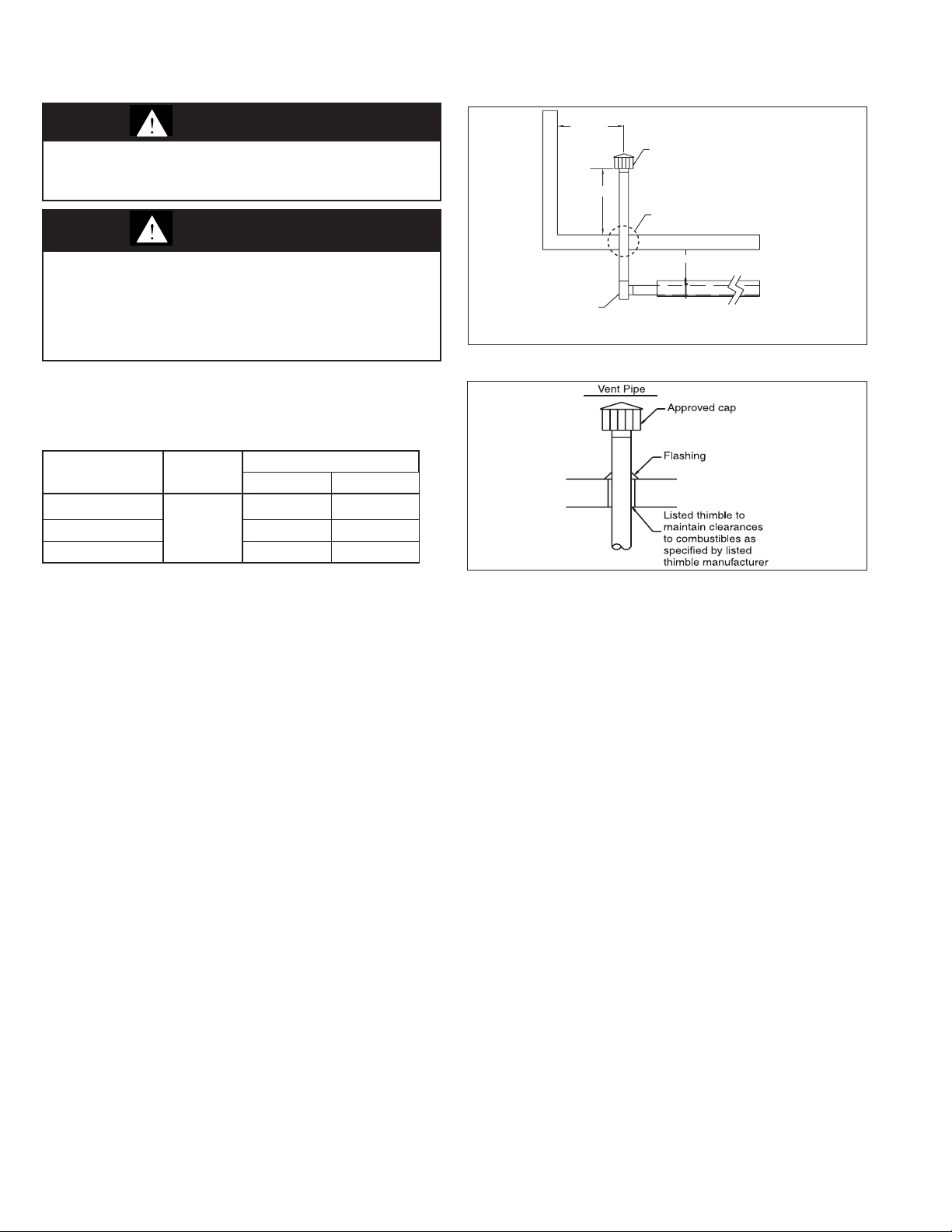

General Venting Instructions

The vent pipe may be installed in either a vertical or horizontal

method. Certified vent pipe lengths are as follows:

Table 12.1 - Maximum Vent Length

Input MBH

50, 60, 75, 100

125 30' 30'

150, 175, 200 40' 30'

Min Vent

Lenght (ft.)

5'

Maximum Vent Length (ft.)

1-Stage 2-Stage

20' 20'

Figure 12.2 - Vertical Venting

2' Min.

Approved cap

1' Min.*

See Figure 12.2

Drip Leg

Downward slope 1/4" towards drip leg.

* Size according to expected snow depth.

Figure 12.3 - Construction through Combustible Roof

1. All systems are considered a Category III appliance and the

vent system must be approved for Category III application in

accordance with UL1738 or ULCS636.

2. Use either a certified Category III vent system with a

maximum flue temperature of up to 550°F, or single wall vent

pipe with all joints (fastened with 3 corrosion resistant sheet

metal screws) and seams sealed with a 550°F or greater

sealant. Follow the vent manufacturers instructions for

clearance to combustibles.

3. Refer to the National Fuel Gas Code for the minimum

material thickness and composition of the vent material.

4. If single wall vent systems are used, Type B vent can be used

to terminate the vent system. The Type B double wall vent

must be one continuous section. Under no circumstances

should two sections of double wall vent pipe be joined

together within one vent system due to the inability to verify

complete seal at inner pipes.

5. All seams and joints must be inspected to ensure gas

tightness after installation. Vent system (connections, joints,

and seems) must be leak checked using a soap solution

6. Models 50-75 use 3" venting. Models 100-200 use 4". For

models 50-75, a 4" to 3" reducer must be used to connect the

last tube section to the 3" vent pipe. It is recommended that

vent pipes be fitted with a tee with a drip leg and a clean out

cap to prevent any moisture in the vent pipe from entering the

unit. The drip leg should be inspected and cleaned out

periodically during the heating season See figure 13.1 & 13.3.

7. The National Fuel Gas Code requires a minimum clearance

of 6 inches from combustible materials for single wall vent

pipe. The minimum distance from combustible materials is

based on the combustible material surface not exceeding

160°F. Clearance from the vent pipe (or the top of the unit)

may be required to be greater than 6 inches if heat damage

other than fire (such as material distortion or discoloration)

could result.

8. Avoid venting through unheated space when possible. When

single wall pipe does pass through an unheated space, insulate

runs greater than 5' to minimize condensation. Inspect for

leakage prior to insulating and use insulation that is

noncombustible with a rating of not less than 550°F. Install a

tee fitting at the low point of the vent system and provide a drip

leg with a clean out cap as shown in Figure 12.2. The drip leg

should be cleaned annually.

9. Where the vent passes through a combustible wall or floor or

ceiling, a listed metal thimble 4" greater than the vent

diameter is necessary. If there are six feet or more of vertical

vent pipe in the open space between the unit heater and

where the vent pipe passes through the floor or roof, the

thimble need only be 2" greater than the diameter of the vent

pipe. If a thimble is not used, all combustible material must be

cut away to provide a 6 inch clearance. Any material used to

close an opening must be noncombustible. Vent pipes must

be adequately supported and sealed with a 550°F or greater

sealant.

10. The vent termial must be Modine part number:

- 5H0722850005 (item code 27865) 3" vent pipe

- 5H0722850001 (item code 27866) 4" vent pipe

11. Do NOT vent this appliance into a masonry chimney.

12. Do NOT use dampers or other devices in the vent pipes.

13. Do NOT use PVC pipe.

14. Precautions must be taken to prevent degradation of

building materials by flue products.

15. The top of the vertical stack should extend at least 2' above

any portion of a building within a horizontal distance of 2'.

16. For pitched roof vertical venting, refer to Figure 13.1 and

Table 13.1 for the vertical distance that the cap must extend

above the pitched roof.

17. Common venting is not allowed for Category III appliances.

12

9-511.4

INSTALLATION

A

Listed thimble

to maintain

clearances as

specified by

listed thimble

manufacturer

Vent Pipe

vent terminal

Figure 13.1 - Vertical Venting through Sloped Roof

pproved Cap

Roof Pitch

x

is x/12

H

Drip Leg

Downward slope 1/4" towards drip leg.

12"

See Figure 12.2

Table 13.1 - Minimum Height from Roof to Lowest

Discharge Opening

Rise X (inches) Roof Pitch

0-6 Flat to 6/12 1

6-7 6/12 to 7/12 1.25

7-8 7/12 to 8/12 1.50

8-9 8/12 to 9/12 2

9-10 9/12 to 10/12 2.50

10-11 10/12 to 11/12 3.25

11-12 11/12 to 12/12 4

12-14 12/12 to 14/12 5

14-16 14/12 to 16/12 6

16-18 16/12 to 18/12 7

18-20 18/12 to 20/12 7.50

20-21 20/12 to 21/12 8

* Size according to expected snow depth.

MIn. Height (ft)*

Additional Requirements for Horizontal Venting

1. All horizontal termial must be Modine part number:

- 5H0722850005 (item code 27865) 3" vent pipe

- 5H0722850001 (item code 27866) 4" vent pipe

In the United States, the vent cap must be 24" from wall,

while in Canada, a distance of 48" from the wall is required.

2. When horizontal vents pass through a combustible wall (up to

8 inches thick), use a thimble with 2" clearances to the vent

and insulate between thimble and vent. The vent passage

may also be constructed and insulated as shown in Figure

13.2. Where horizontal vents pass through a non-combustible

wall, no clearances to the wall are required.

3. The vent system shall terminate at least 3' above any forced

air inlet (except direct vent units) located within 10', and at

least 4' below, 4' horizontally from, or 1' above any door,

window or gravity air inlet into any building. The bottom of the

vent terminal shall be located above the snow line or at least

1' above grade; whichever is greater. When located adjacent

to public walkways the vent system shall terminate not less

than 7' above grade.

4. Vent must extend beyond any combustible overhang of the

building.

5. The vent system shall not terminate over public walkways,

building entrances, or where condensate or vapor could

cause a nuisance or hazard or could be detrimental to the

operation of regulators, relief openings, or other equipment.

6. Precautions must be taken to prevent degradation of building

materials by flue products.

7. When vented horizontally, maintain a 1/4" per foot rise away

from the heater. Place a drain tee and clean out near the vent

connector (see Figure 13.3). Where local authorities have

jurisdiction, a 1/4" downward slope is acceptable. Use a drain

tee with a clean out near the exit of the vent (see Figure 13.4)

or allow the condensate to drip out the end.

Figure 13.3 - Horizontal Venting with Upward Pitch

vent terminal

24" min.

(48" min.

in Canada)

Clean out/drip leg

1/4" Slope up towards termination

Listed thimble

Figure 13.4 = Horizontal Venting w/Downward Pitch

(with drip leg)

vent terminal

1/4" Slope down towards termination

24" min.

(48" min.

in Canada)

Tee with drip leg and cleanout cap at low

point of vent system

Listed Thimble

Figure 13.2 - Vent Construction through

Combustible Wall

9-511.4

13

INSTALLATION

Utilizing Outside Combustion Air (Optional)

1. An accessory combustion air intake collar is required for

connecting the combustion air piping to the burner box. For

outdoor installation, the air intake collar connects directly to

the accessory air intake cap.

2. All units may utilize a maximum of 20' of 4" O. D. fresh air

intake pipe with two (2) 90° elbows, 25' with one (1) elbow, or

30' with no elbows.

3. Modine recommends using 4" insulated (sealed) pipe or

Schedule 40 PVC pipe to provide fresh air and limit

condensation from forming on outer surface. A Modinespecified accessory screened combustion air intake cap is

required.

4. Insure that air intake cap is protected from snow blockage.

5. Keep intake opening at least 5 feet from any exhaust vent

opening.

6. Where practical, the outside combustion air intake is

recommended to be in the same pressure zone as the vent

termination.

Gas Connections

WARNING

1. All field gas piping must be pressure/leak tested prior to

operation. Never use an open flame. Use a soap solution

or equivalent for testing.

2. Gas pressure to the appliance controls must never exceed

14” W.C. (1/2 psi).

3. To reduce the opportunity for condensation, the minimum

sea level input to the appliance, as indicated on the serial

plate, must not be less than 5% below the rated input.

4. A certified flexible connector must be used (local codes

permitting) as the method of connecting the heaters to the

gas supply to avoid placing stress on the gas supply line

due to the expansion of the low intensity infrared tubes

during operation.

1. Installation of piping must conform with local building codes,

or in the absence of local codes, of the National Gas Fuel

Code, ANSI Z223.1 (NFPA 54) – Latest Edition. In Canada,

installation must be in accordance with CAN/CGA-B149.1 for

natural gas units and CAN/CGA-B149.2 for propane units.

2. Piping to units should conform with local and national

requirements for type and volume of gas handled, and

pressure drop allowed in the line. Refer to Table 19.1 to

determine the cubic feet per hour (cfh) for the type of gas and

size of unit to be installed. Using this cfh value and length of

pipe necessary, determine the pipe diameter from Table 19.1.

Where several units are served by the same main, the total

capacity, cfh, and length of main must be considered. Avoid

pipe sizes smaller than 1/2". Table 19.1 allows for a 0.3" W.C.

pressure drop in the supply pressure from the building main

to the unit. The inlet pressure to the unit must be 6" W.C. for

natural gas and 11-14" W.C. for propane gas. The gas supply

pressure must never exceed 14" W.C. If the pressure exceeds

14" W.C., a gas pressure regulator must be added upstream

of the combination gas valve. When sizing the inlet gas pipe

diameter, make sure that the unit supply pressure can be met

after the 0.3" W.C. has been subtracted. If the 0.3" W.C.

pressure drop is too high, refer to the Gas Engineer’s

Handbook for other gas pipe capacities.

CAUTION

1. Purging of air from gas supply line should be performed

as described in ANSI Z223.1 - latest edition “National Fuel

Gas Code”, or in Canada in CAN/CGA-B149 codes.

2. When leak testing the gas supply piping system, the

appliance and its combination gas control must be

isolated during any pressure testing in excess of 14" W.C.

(1/2 psi).

3. The unit should be isolated from the gas supply piping

system by closing its field installed manual shut-off

valve.This manual shut-off valve should be located within

6' of the heater.

4. Turn off all gas before installing appliance.

3. Install a ground joint union with brass seat and a manual

shutoff valve adjacent to the unit for emergency shut-off and

easy servicing of controls, including a 1/8" NPT plugged

tapping immediately upstream of the gas supply connection

to the heater, accessible for test gauge connection. See

Figure 15.1.

4. Provide a sediment trap before each unit and in the line

where low spots cannot be avoided. (See Figure 15.1).

5. A certified, metallic stainless steel connector (local codes

permitting) of at least ¾” minimum ID by 36” long, must be used

as the method of connecting the heater to the gas supply line.

The connector must be certified to ANSI Z21.24/CSA 6.10. A

flexible connector avoids placing stress on the gas supply line

due to the thermal expansion of the unit while operating

Canadian installation codes do not permit the use of flexible

metallic connectors. In Canada, Installation Code CAN/

CSA-B149.1-05 requires the use of a Type I hose connector

certified to CSA CAN/CGA-8.1. Use a hose that is of the same

diameter and length as noted above. The certified flexible

connectors must be installed as illustrated in Figure 15.2, in one

plane, without any sharp bends, kinks, or twists. The gas

take-off from the drop line must be parallel to the burner gas

inlet connection.

6. Under no circumstances should the gas supply line to the

heater provide any assistance in the suspension of the

heater. Do not locate any gas service line directly above or

below the heater.

14

9-511.4

INSTALLATION

7. When pressure/leak testing pressures above

14" W.C. (1/2 psi), close the field installed shut-off valve,

disconnect the unit, and its combination gas control from the

gas supply line, and plug the supply line before testing. When

testing pressures 14" W.C. (1/2 psi) or below, close the

manual shut-off valve on the unit before testing.

8. If the gas valve was rotated to change control access side,

leak test fittings

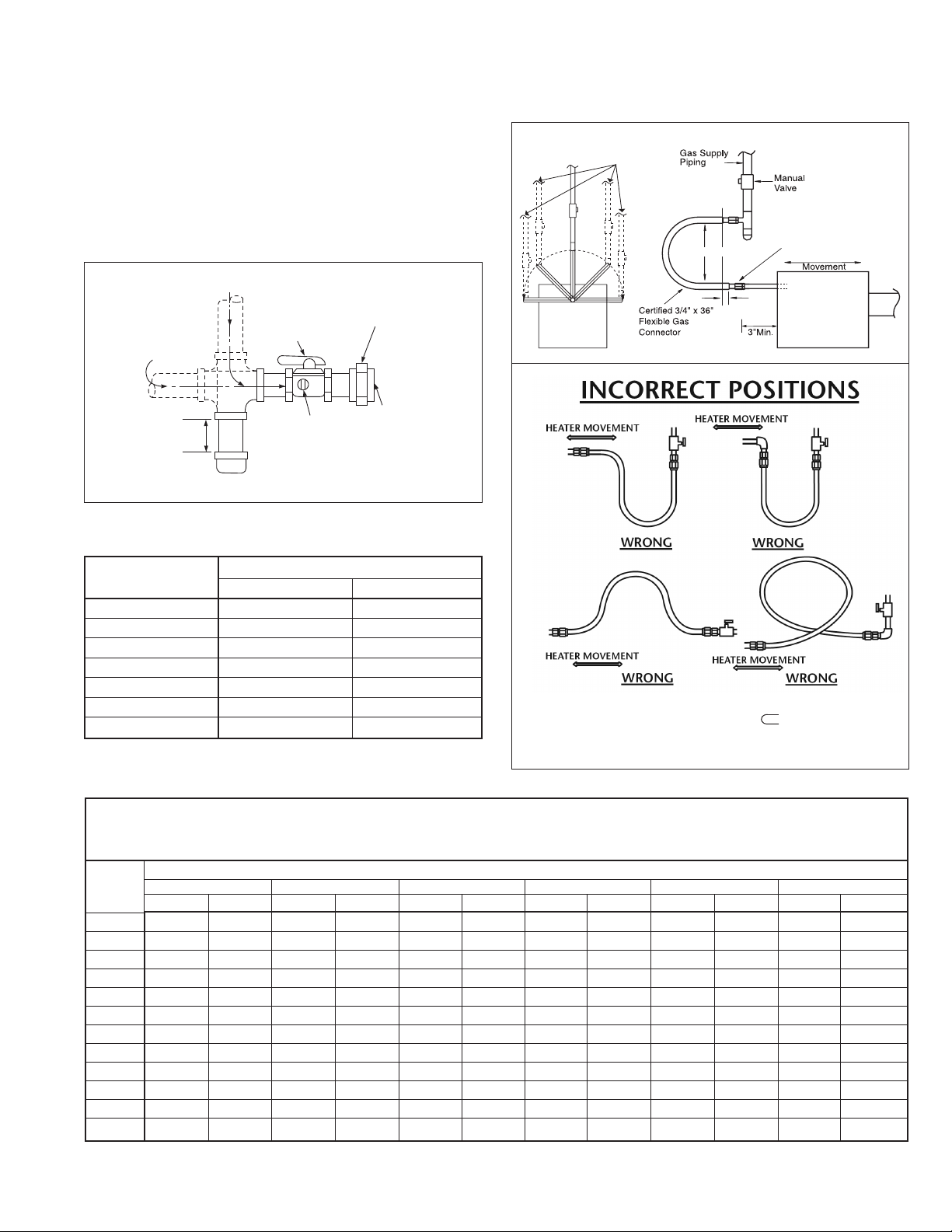

Figure 15.1 - Recommended Sediment Trap/

Manual Shut-Off Valve Installation

SUPPLY LINE

Table 15.1 -

GAS

SUPPLY LINE

MANUAL GAS

TRAP

SHUT-OFF VALVE

PLUGGED

1/8" NPT TEST

GAGE CONNECTION

GAS

3"

MIN.

SEDIMENT

3/4" x 36" Flexible GasConnector Pressure

GROUND

JOINT

UNION

W/ BRASS

SEAT

TO

CONTROLS

Drop ("W.C.)

Input MBH

Natural Propane

50 0.03 0.02

60 0.04 0.02

75 0.05 0.03

100 0.08 0.04

150 0.14 0.07

175 0.18 0.09

200 0.23 0.11

Gas Type

Figure 15.2 - Recommended Installation of Flexible

Gas Connector

Alternate Supply Locations

should be maintained on a

12" radius arc

Field Supplied Gas Piping

Note: The gas supply nipple

must be parallel to the

12"

2"

Burner Box

(End View)

Warning:Connectormustbeinstalledinaconguration.Use

only a 36" long connector of 3/4" nominal ID with this heater. This is

offeredasafactorysupplied,eldinstalledaccessory.

heater movement.

Burner Box

(Side View)

Table 15.2 - Gas Pipe Capacities

Gas Pipe Capacities (Up to 14" W.C. Gas Pressure through Schedule 40 Pipe)

Cubic Feet per Hour with Pressure Drop of 0.3" W.C.

Natural Gas - Specific Gravity - 0.60

Propane Gas - Specific Gravity - 1.50

Length Pipe Diameter

Of Pipe 1/2" 3/4" 1" 1-1/4" 1-1/2" 2"

(feet) Natural Propane Natural Propane Natural Propane Natural Propane Natural Propane Natural Propane

10 132 83 278 175 520 328 1050 662 1600 1008 3050 1922

20 92 58 190 120 350 221 730 460 1100 693 2100 1323

30 73 46 152 96 285 180 590 372 890 561 1650 1040

40 63 40 130 82 245 154 500 315 760 479 1450 914

50 56 35 115 72 215 135 440 277 670 422 1270 800

60 50 32 105 66 195 123 400 252 610 384 1150 725

70 46 29 96 60 180 113 370 233 560 353 1050 662

80 43 27 90 57 170 107 350 221 530 334 990 624

90 40 25 84 53 160 101 320 202 490 309 930 586

100 38 24 79 50 150 95 305 192 460 290 870 548

125 34 21 72 45 130 82 275 173 410 258 780 491

150 31 20 64 40 120 76 250 158 380 239 710 447

9-511.4

15

INSTALLATION - HIGH ALTITUDE ACCESSORY KIT

HIGH ALTITUDE ACCESSORY KIT

Modine’s gas-fired equipment standard input ratings are

certified by ETL. For elevations above 2,000', ANSI Z223.1

requires ratings be reduced 4 percent for each 1000' above sea

level. For units in Canada, CSA requires that ratings be reduced

10 percent at elevations above 2,000'. The high altitude

adjustment instructions and pressure switch kits listed in this

manual are for use with units that will be installed over 2,000'

These methods and kits comply with both ANSI Z223.1 and

CSA requirements.

If a unit is to be installed at higher elevations AND converted from

natural gas to propane gas operation, a propane conversion kit

must be used in conjunction with the pressure adjustment

methods and pressure switch kits listed herein. For the Selection

and Installation Instructions for propane conversion kits, please

see the latest revision of Modine Manual 75-538.

Selection of the Proper Pressure and Kit

To determine the proper manifold pressure at altitude and if

required, the proper combustion air pressure switch kit, the full

model number of the heater, the fuel to be used, and the

altitude the unit will be installed at must be known. Refer to the

unit serial plate or carton label to obtain the necessary

information about the unit.

After obtaining this information, refer to the gas pressure and

selection charts shown in Tables 16.1 through 17.1. The

pressure charts are differentiated by elevation, fuel type, and

country the product is being installed in. The selection charts

are differentiated by product type, altitude and fuel type.

Selection charts include the proper kit suffix, when required.

Manifold Pressure Adjustment

The inlet pressure to the unit must be confirmed to be within

acceptable limits (6-7" W.C. for natural gas and 11-14" W.C.

for propane gas) before opening the shutoff valve or the

combination gas valve may be damaged.

Heaters for use with natural gas, the manifold pressure must

be set at 3.5” W.C. for high fire and 2.5" W.C. for low fire.

Units for use with propane gas, the manifold pressure must be

set at 10.0" W.C. for high fire and 6.2" W.C. for low fire.

Installation above 2,000'. elevation requires adjustment of the

manifold pressure as described.

Derated BTU Content Gas and Manifold Pressure

Calculation

Some utility companies may derate the BTU content (heating

value) of the gas provided at altitude to a value other than 1,050

BTU/ft3 for natural gas or 2,500 BTU/ft3 for propane gas to allow

certain heating appliances to be used with no manifold pressure

adjustments. For this reason it is necessary that the supplying

utility be contacted for detailed information about the gas type

and BTU content (heating value) before operating any heater.

Tables 16.1 and 16.2 show the standard derated heating values

(4% per 1,000' of elevation in the USA and 10% between 2,001’

and 4,500' elevation in Canada) of natural and propane gases

at various altitudes. If the utility is supplying gas with heating

values as shown in Tables 16.1 and 16.2, the manifold pressure

should be set to 3.5" W.C for natural gas and 10.0" W.C. for

propane gas.

NOTE: Both the high fire and low fire gas pressure must be

adjusted for proper operation.

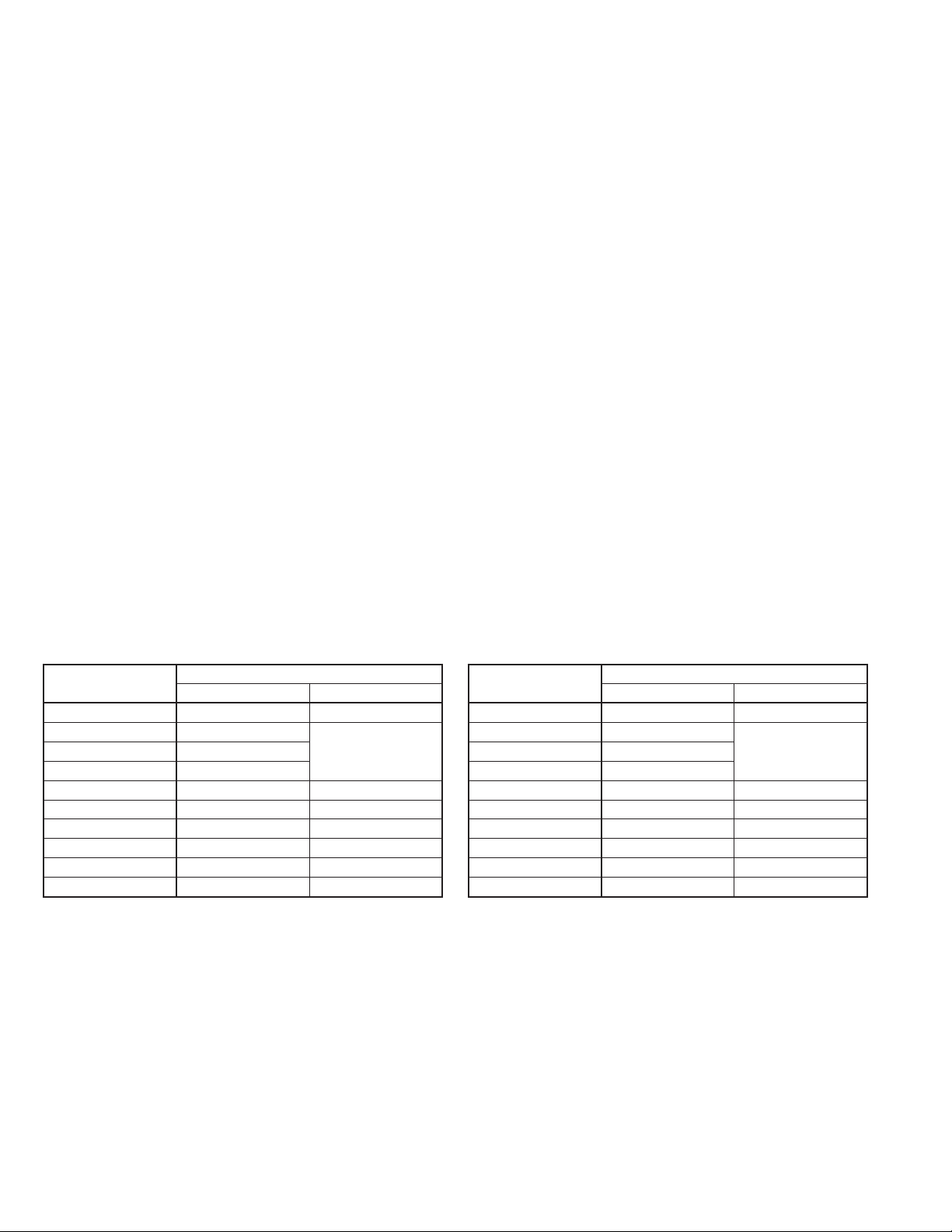

Table 16.1 - Natural Gas Heating Values at

Altitude

Altitude (ft)

0-2,000 1,050 1,050

2,001-3,000 929

4,001-4,500 874

4,501-5,000 856 856

5,001-6,000 822 822

6,001-7,000 789 789

7,001-8,000 757 757

8,001-9,000 727 727

9,001-10,000 698 698

Values shown are for 3.5" W.C. manifold pressure, for other BTU content values (available from local utility) use Equation 17.1 to calculate manifold pressure.

Values shown are for 10.0" W.C. manifold pressure, for other BTU content values (available from local utility) use Equation 17.1 to calculate manifold pressure.

When installed at altitudes above 2,000', a pressure switch may need to be changed. Refer to Table 17.1 to determine if a switch change is required.

Gas heating values are derated 4% per 1,000' of elevation in the USA and 10% between 2,000' and 4,500' elevation in Canada in accordance with ANSI Z223.1

and CSA-B149, respectively.

Gas Heating Values at Altitude (BTU/ft3)

USA Canada

9453,001-4,000 892

Table 16.2 - Propane Gas Heating Values at

Altitude

Altitude (ft)

0-2,000 2,500 2,500

2,001-3,000 2,212

4,001-4,500 2,080

4,501-5,000 2,038 2,038

5,001-6,000 1,957 1,957

6,001-7,000 1,879 1,879

7,001-8,000 1,803 1,803

8,001-9,000 1,731 1,731

9,001-10,000 1,662 1,662

Gas Heating Values at Altitude (BTU/ft3)

USA Canada

2,2503,001-4,000 2,123

16

9-511.4

INSTALLATION - HIGH ALTITUDE ACCESSORY KIT

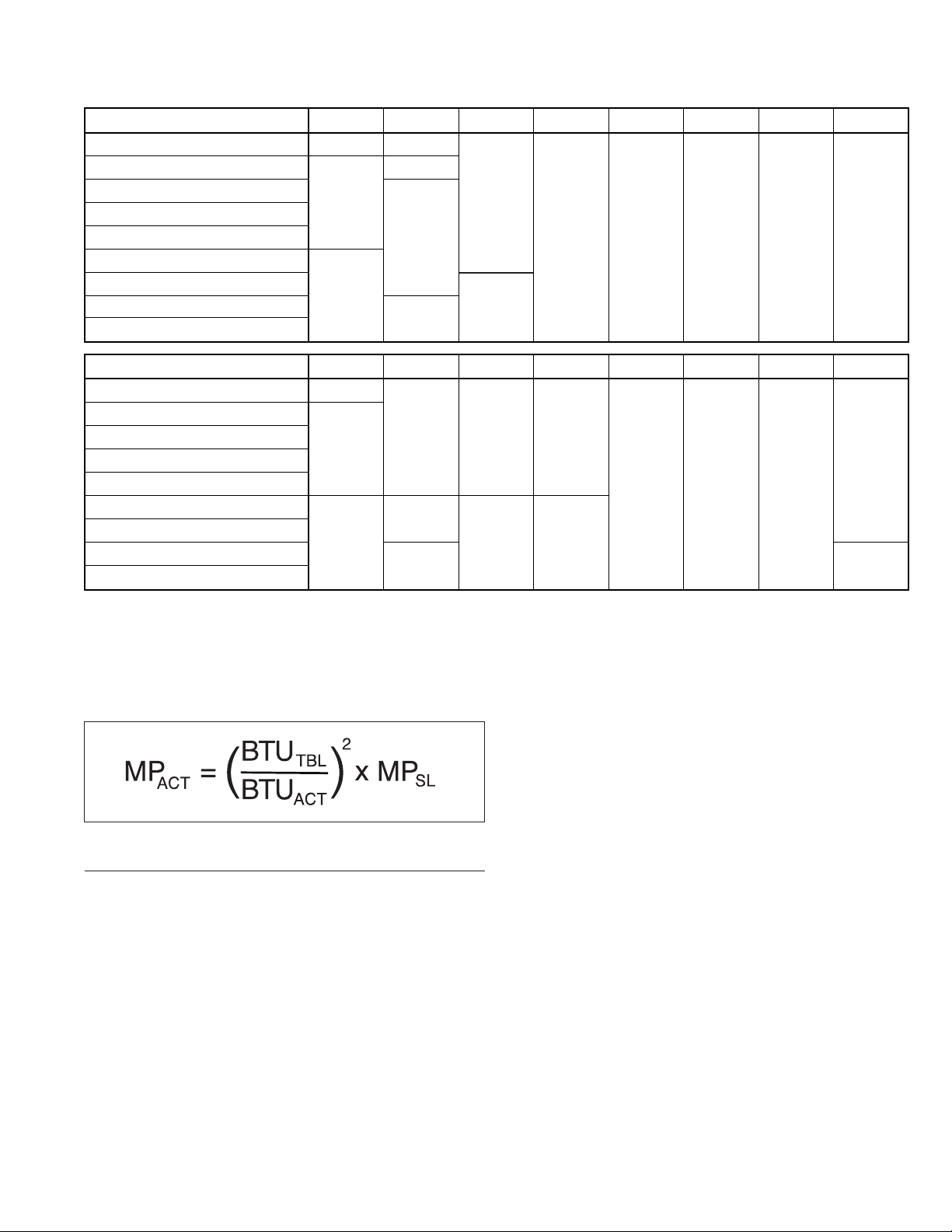

Table 17.1 - High Altitude Kits for IPT

Conversion IPT - Natural Gas 50 60 75 100 125 150 175 200

0-2000 FT 77823 77824

2001-3500 FT

3501-4000 FT

4001-4500 FT

4501-5000 FT

5001-5500 FT

5501-6000 FT

6001-6500 FT

6501-7500 FT

Conversion IPT - LP 50 60 75 100 125 150 175 200

0-2000 FT

2001-3500 FT

3501-4000 FT

4001-4500 FT

4501-5000 FT

5001-5500 FT

5501-6000 FT

6001-6500 FT

6501-7500 FT

77831

77836

77839

77847

77850

77832

77825

77834

77838

77840 77841 77842

77851

77854 77855

77837

77852 77853

77826 77827 77828 77829 77830

77843 77844 77845

77846

If the heating value of the gas being supplied is different than

the values shown in Tables 16.1 and 16.2, use the following

equation to determine the appropriate manifold pressure for the

altitude and gas heating value being supplied.

Equation 17.1 - Manifold Pressure for Derated Gas

WHERE:

M P

BTU

BTU

MPSL = Manifold Pressure (in. W.C.), at Sea Level –

NOTE: High and Low fire manifold pressure must both be

adjusted using the calculation shown in 17.1.

= Manifold Pressure (in. W.C.) at Altitude –

ACT

Manifold pressure setting for the heater

being installed

= BTU/ft3 Content of Gas –

TBL

Obtained from Tables 16.1 or 16.2

(whichever is applicable)

= BTU/ft3 Content of Gas –

ACT

Obtained from the local utility company

Use 3.5" W.C. for natural gas and 10.0" W.C. for

propane gas

9-511.4

17

INSTALLATION/START-UP PROCEDURE

Electrical Connections

WARNING

1. Disconnect power supply before making wiring connections

to prevent electrical shock and equipment damage.

2. All appliances must be wired strictly in accordance with

wiring diagram furnished with the appliance. Any wiring

different from the wiring diagram could result in a hazard

to persons and property.

3. Any original factory wiring that requires replacement must

be replaced with wiring material having a temperature

rating of at least 105°C.

4. Ensure that the supply voltage to the appliance, as indicated

on the serial plate, is not 5% greater than rated voltage.

CAUTION

Ensure that the supply voltage to the appliance, as indicated

on the serial plate, is not 5% less than the rated voltage.

1. Installation of wiring must conform with local building codes,

or in the absence of local codes, of the National Electric Code

ANSI/NFPA 70 - Latest Edition. Unit must be electrically

grounded in conformance to this code. In Canada, wiring

must comply with CSA C22.1 Part 1, Electrical Code.

2. Make sure all multi-voltage components (motors,

transform ers, etc.) are wired in accordance with the power

supply voltage.

3. The unit must be wired strictly in accordance with the wiring

diagram furnished with the unit.

4. The power supply to the unit should be protected with a fused

disconnect switch or circuit breaker.

5. The power supply must be within 5 percent of the voltage

rating and each phase must be balanced within 2 percent of

each other. If not, advise the utility company.

6. External electrical service connections that must be

installed include:

a. Supply power connection (120 volts).

b. Connection of thermostats, summer/winter switches, or

any other accessory control devices that may be supplied

(24 volts).

7. Control wire used to connect the heater to the thermostat

must have adequate ampacity and insulation temperature

rating for the total connected load, see Table 21.2.

8. Under no circumstances should the electrical supply or

control wiring to the heater provide any assistance in the

suspension of the heater. Do not locate any wiring directly

above or below the heater.

9. All outdoor electrical connections must be weatherized to

prevent moisture from entering the electrical compartment.

10. Ensure proper polarity of unit and power source.

11. Refer to the unit dimensional drawings on Figure 20.1 for

the electrical knockout locations.

START-UP PROCEDURE

CAUTION

Purging of air from gas lines should be performed as

described in ANSI Z223.1 - Latest Edition “National Fuel

Gas Code”, or in Canada, CAN/CGA-B149 codes.

IMPORTANT

Start-up and adjustment procedures should be performed

by a qualified service agency.

1. Turn off power to the unit at the disconnect switch. Check

that fuses or circuit breakers are in place and sized correctly.

Turn all hand gas valves to the “OFF” position.

2. Remove service access side burner access panel as outlined

on page 5 in section titled "Removal of Burner Side Access

Panels".

3. Check that the supply voltage matches the unit supply

voltage listed on the serial plate. Verify that all wiring is

secure and properly protected. Trace circuits to insure the

unit has been wired according to the wiring diagram.

4. If utilizing indoor air for combustion, ensure adequate

ventilation for intake of fresh air. Check to see that there are

no obstructions to the intake of the unit.

5. Perform a visual inspection of the unit to make sure no

damage has occurred during installation. Check reflectors to

ensure they are installed between 0° and 45° from the

horizontal plane.

6. Recheck the gas supply pressure. The inlet pressure to the

unit must be 6" W.C. for natural gas and 11-14" W.C. for

propane gas. The gas supply pressure must never exceed

14" W.C. If the pressure exceeds 14" W.C., a gas pressure

regulator must be added upstream of the combinations gas

valve.

7. Open the field installed manual shutoff valve and turn power

on to the unit.

8. Check to make sure that the main gas valve opens upon a

call for heat from the thermostat. Check the manifold gas

pressure (see main burner adjustment).

9. Check to insure that gas controls sequence properly (See

Control Operating Sequence).

During checkout procedure, use the following steps to

verify that the venting system is adequately sized:

1. Inspect the venting system for proper size and horizontal

pitch, as required in the National Fuel Gas Code ANSI

Z223.1 or CAN/CGA B149.1 or .2 Installation Code – latest

edition and these instructions. Determine that there is no

blockage or restriction, leakage, corrosion and other

deficiencies, which could cause an unsafe condition.

2. Insofar as practical, close all building doors and windows and

all doors between the space in which the unit(s) connected to

the venting system are located and other spaces of the

building. Turn on any exhaust fans so they shall operate at

maximum speed. Do not operate a summer exhaust fan.

3. Place the unit being inspected in operation. Adjust thermostat

so that the unit will operate continuously.

4. After it has been determined that each unit connected to the

venting system properly vents when tested as outlined above,

return doors, windows, exhaust fans, and any other gasburning unit to their previous condition of use.

5. If improper venting is observed during any of the above tests,

the venting system must be corrected.

6. If the venting system must be resized, it must conform with

the National Fuel Gas Code ANSI Z223.1 or CAN/CGA

B149.1 or .2 Installation Code – latest edition. If the venting

system must be resized, it should be resized to approach the

minimum size as determined using the appropriate table in

Appendix G of the National Fuel Gas Code ANSI Z223.1.

18

9-511.4

START-UP PROCEDURE

Main Burner Adjustment

The gas pressure regulator (integral to the combination gas

control) is adjusted at the factory for average gas conditions.

It is important that gas be supplied to the heater in accordance

with the input rating on the serial plate. Actual input should

be checked and necessary adjustments made after the heater

is installed. Over-firing, a result of too high an input, reduces the

life of the unit and increases maintenance. Under no circumstances

should the input exceed that shown on the serial plate.

Measuring the manifold pressure is done at the manifold

pressure tap on the main gas valve on the heater.

To adjust the manifold pressure:

1. The correct manifold pressure is 3.5" high fire and 2.5" W.C.

low fire for natural gas.10" high fire and 6.2" W.C. low fire for

propane gas. Adjust the main gas pressure regulator spring to

achieve the proper manifold pressure.

2. Move the field installed manual shut-off valve to the “OFF”

position.

3. Remove the 1/8" pipe plug in manifold pressure tap or use the

pressure tap tower in the combination gas control and attach

a water manometer of “U” tube type that is at least 12" high.

Instructions for units with the pressure tap towers:

The inlet (IN P) and outlet (OUT P) pressure ports accept a 5/16"

ID hose connection. Using a 3/32 (2.3mm) inch hex wrench,

rotate pressure tap screw one revolution counter-clockwise (when

measuring pressure, only loosen but do not remove screw).

4. Move the field installed manual shut-off valve to the “ON”

position.

5. Create a call for heat from the thermostat.

6. After adjustment, move the field installed manual shut-off

valve to the “OFF” position, remove manometer and hose

from the outlet boss. turn outlet pressure tap screw clockwise

to seal the pressure port. Tighten to 13 in. -lbs. minimum.

7. After the plug is in place, move the field installed manual shutoff valve to the “ON” position and recheck pipe plugs for gas

leaks with a soap solution.

8. Replace the side access panels.

Table 19.1 - Manifold Pressure and Gas Consumption

Type of Gas Natural Propane

Input MBH

Specic Gravity 0.6 1.53

Manifold Pressure " W.C. 3.5 10

50

60

75

100

125

150

175

200

Gal/Hr.Propane n/a 0.55

OriceDrillSize 3.3 mm 2.0 mm

Gal/Hr.Propane n/a 0.66

OriceDrillSize #27 #43

Gal/Hr.Propane n/a 0.83

OriceDrillSize #22 #38

OriceDrillSize #11 #32

OriceDrillSize #3 #30

OriceDrillSize #B #28

OriceDrillSize #F #23

Gal/Hr.Propane n/a 2.20

OriceDrillSize #L #18

3

Btu/ft

CFH 48.1 20.0

CFH 57.7 24.0

CFH 72.1 30.0

CFH 96.2 40.0

CFH 120.2 50.0

CFH 144.2 60.0

CFH 168.3 70.0

CFH 192.3 80.0

1040 2500

No. of

Orices

1

1

1

1 Gal/Hr.Propane n/a 1.10

1 Gal/Hr.Propane n/a 1.38

1 Gal/Hr.Propane n/a 1.65

1 Gal/Hr.Propane n/a 1.93

1

9-511.4

Primary Air Shutter (Propane Gas Only)

Propane gas models 75-200 are equipped with an adjustable

primary air shutter, mounted flush with the end of the gas

orifice, as shown in Figure 19.2. These are set at the factory;

do not adjust.

Figure 19.2 - Propane Gas Primary Air Shutter on

75-200 Models Only

Air

Shutter

Gas Orifice

Control Operating Sequence

These models utilize a combination gas valve/ignition controller

and a single or two stage thermostat.

1. The thermostat calls for heat.

2. The combustion air blower is energized and begins a fifteen

(15) second pre-purge cycle. The pre-purge clears any

residual gas left over from the previous operation.

3. The pressure switch closes during the pre-purge, energizing

the indicator light on the back of the burner box.

4. The ignition control board is energized and the spark igniter

attempts to light the gas at the burner. Ignition trial time is 7

seconds.

5. Upon proper ignition, the flame is visible through the

combustion chamber sight glass (see Figure 22.2). The unit

continues to operate until the thermostat is satisfied,

at which time the thermostat contacts open and the gas valve

is de-energized until the thermostat makes another call for

heat.

6. If a flame is not sensed for any reason, the main gas valve

will close and there will be a short purge period before ignition

is tried again.

7. If flame is not sensed after three re-tries (four total tries), there

will be at least a one hour wait before ignition is tried again.

Power can be interrupted during this one-hour lockout to reset

the sequence of operation.

8. On single stage units, the main gas valve is opened and the

main burner is lit to 100% full fire.

9. 2-stage High heat warm-up. The control will run in high fire for

the first 30 seconds following flame recognition period

regardless of W2 demand. If W2 is not energized, or is in auto

staging condition, at the end of this 30 second period the

control de-energizes the high gas output (low gas remains

energized). If W2 is energized the control remains on high

heat.

10. 2-stage Low heat operation, the control keeps the main gas

valve and induced draft motor energized while monitoring the

call for heat. .

11. 2-stage High heat opearation. If the P5 shunt jumper is in

place, the control will automatically stage into second stage

following 10 minutes of a steady call for heat.

19

DIMENSIONAL DATA

Figure 20.1 - Casing Dimensions (in.)

TOP VIEW

10.00

23.12

ø

.875

THERMOSTAT

CONNECTION

BACK VIEW

12.39

2.61

4.00

6.00

12.00

1.000

ø

GAS CONNECTION

4.00

1.36

ø

.875

LINE VOLTAGE

CONNECTION

14.99

SIDE VIEW

13.58

Figure 20.2 - Burner and Tube System Dimensions (inches)

A

14

11

B

21.91

11.00

FRONT VIEW

3.65

6.00

28

Table 20.1 - Tube Systems Data

Straight Tube U-Tube System

Tube Length (ft.)

System Length “A” (ft.) System Weight (lb.) System Length “B” System Weight (lb.) (ft.)

20 23 78 13 89

30 33 112 18 132

40 43 146 23 157

50 53 180 28 200

60 63 214 33 225

70 73 252 38 277

Table 20.2 - Burner Shipping Weights

Model Shipping Wt. (lb.)

All Burners 43

20

9-511.4

16

PERFORMANCE

Table 21.1 - Performance

Input MBH 50 60 75 100 125 150 175 200

20, 30, 30, 40, 40, 50, 50, 60, 50, 60,

Certified Tube Lengths (ft.)

40 50 ➁ 60 ➃ 70 70

Recommended

Mounting Height (ft.) ➀

Recommended

Tube System

Application ➀

➀ Recommended Mounting Height and Tube System Applications are meant as a general guide and are adjusted to meet the requirements of the actual application.

The applications are as follows:

-- Spot or Area Heating is an application where occupant comfort is the goal and occupant(s) are either relatively stationary (Spot - Example: small work cell or dispersed over

a slightly wilder range than with Spot Heating (Area - Example: assembly line). Mounting height is typically at the low end of the range shown above.

-- Total Building Heating is an application where average space temperature is to be maintained, however due to the significant temperature gradient differences on

long straight tube systems, areas may exist where direct occupant comfort is not achieved.

➁ IPT 100 not available for Propane Gas operation at 50 ft. tube system length.

➂ IPT 75 not available for Propane Gas operation at 40 ft. tube section length.

➃ IPT 125 only available for operation at 60 ft. tube section length for 1-Stage units.

Spot or Area

Heating

Total Building

Heating

Table 21.2 - Utilities

Electrical Rating

20, 30

10 – 12 10 – 12 12 – 14 ➂ 12 – 14 15 – 22 15 – 22 18 – 28 20 - 30

Gas Connection

(inch)

Minumum Gas Inlet

20, 30, 40 50, 60

U-Tube

Straight Tube

Pressure ("W.C.)

Maximum Gas

Pressure ('W.C.)

Manifold Gas

Pressure ("W.C.)

Tube/Vent

Diameter (inch)

115V/60Hz/1Ph 1/2 NPT

6.0 (natural gas)

11.0 (propane gas)

14.0

3.5" (natural gas, high fire)

2.5" (natural gas, low fire)

10.0" (propane gas, high fire)

6.2" (propane gas, low fire)

4 (O.D.)

9-511.4

21

MAINTENANCE/SERVICE & TROUBLESHOOTING

MAINTENANCE

Qualified gas service personnel should service all heating

equipment before each heating season to assure proper

operation. The following items may require more frequent

service based on the environment in which the unit is installed,

and how long the unit is operated.

Burner Assembly