Modine Manufacturing PD/BD, PDP/BDP, PV/BV, DJE/DHE, IJE/IHE Installation Instructions Manual

SELECTION AND INSTALLATION INSTRUCTIONS

conversion from natural gas to propane gas for

models PD/BD, PDP/BDP, PV/BV, DJE/DHE, IJE/IHE

with control codes 11-14 or 30-33 and built 4/91 or after,

“D” and “I” series duct furnace/make up air units with

1. All field gas piping must be pressure/leak tested prior to

operation. Never use an open flame. Use a soap solution

or equivalent for testing.

2. Gas supply shall be shut-off and the electrical power

disconnected before proceeding with the conversion.

Failure to do so could result in re, explosion or electrical

shock.

WARNING

IMPORTANT

75-511.13

5H0722980000

December, 2016

digits 11 & 12 = N1 or S1

The propane kits appearing in this bulletin are for use with units

which are going to be installed between 0 and 2000 ft. elevation.

If a unit is to be installed at higher elevations, a special “high

altitude” propane orifice kit must be ordered in addition to the

propane conversion kits shown here. See Bulletin 75-535 for

selection of “high altitude” orifice kits.

When converting units to propane at elevations over 2000 ft.,

the main burner orifices in the propane conversion kit must

be replaced with the orifices from the “high altitude” orifice kit.

The remaining components of the propane kit, those other

than the main burner orifices, are still required to complete the

conversion to propane gas, regardless of the elevation at which

the unit is installed.

1. The use of this manual is specifically intended for a

qualified installation and service agency. All installation

and service of these kits must be performed by a qualified

installation and service agency.

2. These instructions must also be used in conjunction with

the Installation and Service manual originally shipped

with the appliance being converted, in addition to any

other accompanying component supplier literature.

As Modine Manufacturing Company has a continuous

product improvement program, it reserves the right to

change design and specifications without notice.

Identifying the Model, Control Code and

Date of Manufacture

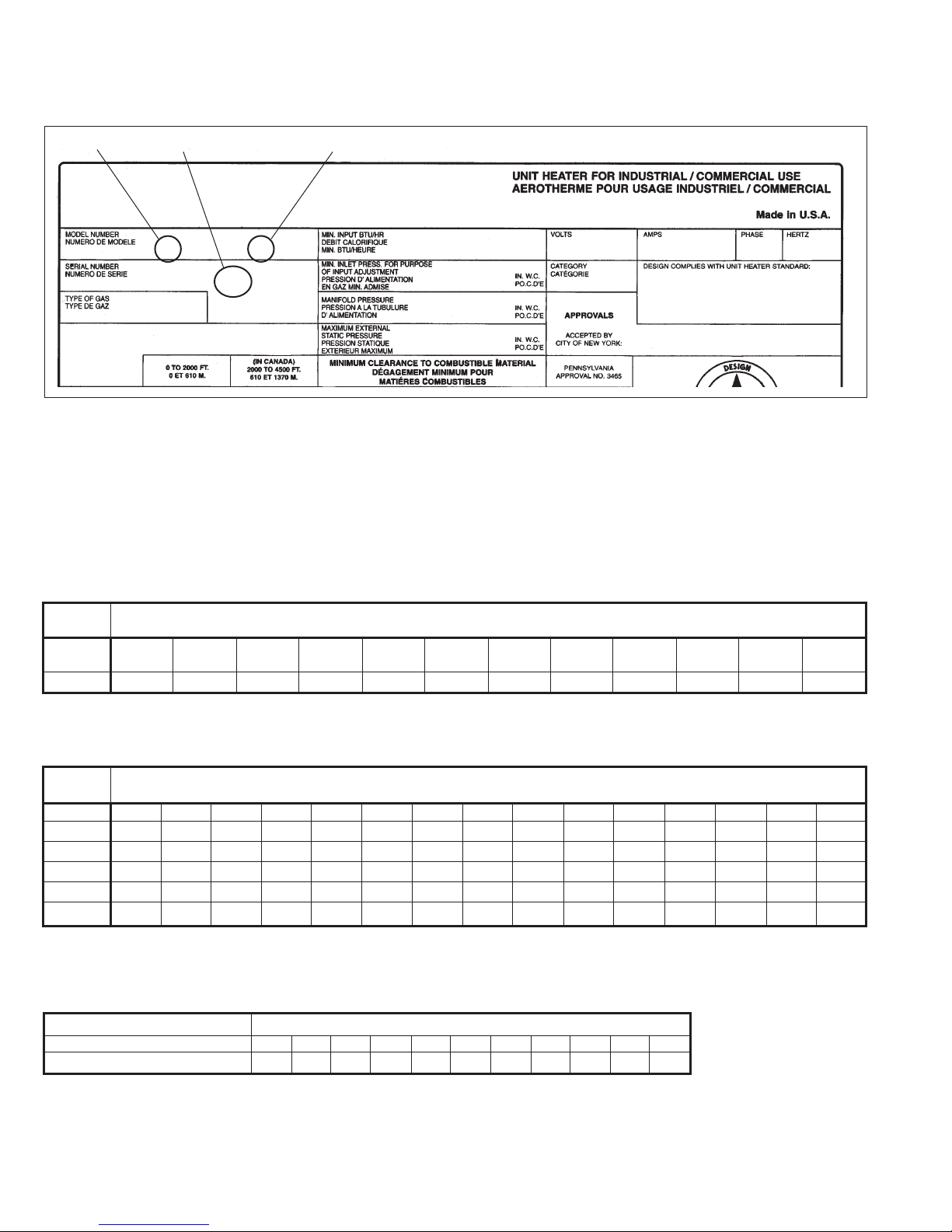

Figure 2.1, shown on the next page, is an example of a typical

serial plate. Markings pertinent to verifying correct application

of the conversion kit are identified and explained in detail. All

prerequisites must be satisfied before the unit is deemed

convertible.

1. The first two or three characters in the model number box

are letters. These letters identify the style of the heater. If

any of the following model prefixes appear in this box, the

unit is potentially convertible: PD/BD, PDP/BDP, PV/BV,

DJE, IJE, DFG, IFG, NFG, DFP, IFP, DFS, IFS.

2. Next, the number 11, 12, 13, 14, 30, 31, 32, or 33 must be

the control code or digits 11 and 12 of the model number

are N1 or S1. This is item (2) in Figure 2.1. Any other

number code disqualifies the unit for conversion.

3. Item (3) in Figure 2.1 in the serial number box designates

the date the unit was built. In Figure 2.1, the numbers

3601 are shown. This number is interpreted as the thirty

sixth week of 2001. Prior to January 1995, the digits

preceding the year represent month of manufacture. After

January 1995, the (2) digits proceeding the year represent

the week of manufacture. Any serial number dated 4/91 or

after is acceptable for conversion.

THIS MANUAL IS THE PROPERTY OF THE OWNER. PLEASE BE SURE TO LEAVE IT WITH THE OWNER WHEN YOU LEAVE THE JOB.

NATURAL TO PROPANE CONVERSION KIT SELECTION GUIDE

Figure 2.1

Typical Serial Plate

j lk

Modine Manufacturing Company

1221 Magnolia Ave., Buena Vista, VA 24416; Phone: 540-261-2166

PD 250AA0111 115 5.7 1 60

30011013601-0978 6.0 I ANS Z83.8 - 96

Natural 3.5 CGA-2.6-M96

0.0 MEA 293-96-E

Selection of the Proper Kit

Referring to the model number box on the serial plate in Figure

2.1 (above), the prefix letters and succeeding numbers which are

needed for kit selection are PD250.

The letters identify the model, and the numbers indicate the size

of the unit. Referring to Tables 2.1, 2.2, or 2.3 locate the model

type column (i.e. PD, BD, etc.). Working with Table 2.1 and the

row labeled PD/BD, move right searching for the proper model

size. Read the kit number suffix directly below the model size

for a PD250. Add this suffix (-9) to the base part number for the

propane conversion kit shown in the heading of Table 2.1. The

correct kit for a PD250 with Control Code 11, is 3H034670-9.

Table 2.1

Natural Gas to Propane Gas Conversion Kit Selection Guide

Base Kit Number – 3H034670…(Choose correct suffix -1, -2, -3, etc…)

Model

Type

PD/BD,

PDP/BDP 30 50 75 100 125 150 175 200 250 300 350 400

Suffix -1 -2 -3 -4 -5 -6 -7 -8 -9 -10 -11 -12

Model Size

Table 2.2

Natural Gas to Propane Gas Conversion Kit Selection Guide (For units manufactured after April 1, 1991)

Base Kit Number – 3H33749…(Choose correct suffix -1, -2, -3 etc., per instructions, before ordering propane conversion kits.)

Model

Type

PAE/BAE 30 50 75 100 125 145 – 175 200 225 – 250 300 350 400

Suffix -1 -2 *-14 -4 -5 -6 – -7 -8 -9 – -10 -11 -12 -13

PV/BV 30 50 75 100 125 145 – 175 200 – – 250 300 350 400

Suffix -1 -2 -14 -4 -5 -6 – -7 -8 – – -10 -11 -12 -13

DJE/DHE – – 75 100 125 – 150 – 200 225 – 250 300 350 400

Suffix – – -14 -15 -16 – -6 – -8 -17 – -10 -11 -18 -13

Model Size

* For units manufactured after September, 1993. For units manufactured prior to this date, consult the factory.

Table 2.3

Natural Gas to Propane Gas Conversion Kit Selection Guide

Base Kit Number – 3H036483…(Choose correct suffix -1, -2, -3 etc...)

Model Type Model Size

DFG/IFG/NFG, DFP/IFP, DFS/IFS 75 100 125 150 175 200 225 250 300 350 400

Suffix -1 -2 -3 -4 -5 -6 -7 -8 -9 -10 -11

2

75-511.13

INSTALLATION

Installation of Kit

Conversion of any unit is the responsibility of, and the

risk of the person making the conversion.

1. All field gas piping must be pressure/leak tested prior to

operation. Never use an open flame. Use a soap solution

or equivalent for testing.

2. Gas supply shall be shut-off and the electrical power

disconnected before proceeding with the conversion.

Failure to do so could result in re, explosion or electrical

shock.

General

1. Shut off gas supply to the unit. Disconnect the electrical

power to the unit.

2. For codes 11, 12, 13, 14 or if digit 11 of the model number

is S or T and digit 12 is 1, disconnect the pilot gas tube

and thermocouple lead at the combination gas control. For

codes 30, 31, 32, 33 or if digit 11 of the model number is

N or P and if digit 12 is 1, disconnect the pilot gas tube at

the combination gas control and the ignition cable(s) at the

ignition control.

3. Remove burner assembly.

For PD/BD, PDP/BDP, and PV/BV Models

Lower bottom pan to expose burner and manifold (see Figure

3.1).

For codes 11, 12, 13, or 14, disconnect pilot gas tube and

thermocouple lead at the controls. For codes 30, 31, 32, or 33,

disconnect the pilot gas tube at the combination gas control and

the ignition cable(s) at the ignition control.

Remove the two burner retaining pins holding the burner in place

(see Figure 3.2). The burner can then be easily lowered from

the unit. In replacing the burner, be certain that the slots at the

front of the burner are located properly on their shoulder rivets

and that the burner retaining pins are put back into their proper

locations.

After removing burner assembly, proceed with step #4, page 4.

WARNING

Figure 3.1

Hinged Bottom for Burner Service

Figure 3.2

Manifold Adjustment

MIXER

TUBES

BURNER

RETAINING PIN

For Indoor Duct Furnace Models

On DHE/IHE models, lower the controls enclosure cover and

disconnect the pilot gas supply line and thermocouple at the gas

valve. On models DJE/IJE, DFG/IFG/NFG, DFP/IFP, DBG/IBG,

DCG/ICG, DBP/IBP, and DCP/ICP models, the gas controls are

exposed. On models DFS/IFS, remove lower assess door to

expose gas controls and burner.

The burner may be removed from either side of the duct furnace.

To remove the burner, remove all of the sheet metal screws

holding the side burner access panel in place. (Note: with the

side access panel screws removed, the access panel is free to

move, be careful not to drop the panel.)

Figure 3.3

75-511.13

BURNER SIDE

ACCESS PANEL

BURNER

ALIGNMENT PINS

PILOT

TUBE

THERMOCOUPLE

GAS

VALV E

LEAD

3

INSTALLATION

Remove the side access panel to expose the furnace burner

assembly.

For DJE, IJE, DHE, and IHE carefully thread the pilot tube and

the thermocouple leads through the combustion air slot (at the

rear of the unit) into the burner box so they may be drawn out

with the burner.

Slide the complete burner assembly out of the burner box. The

complete burner and pilot assembly are now free for service

(see Fig. 4.1).

To replace the burner, follow the above steps in reverse order,

being careful to align the burner assembly properly on the

alignment pins on the access panels on both sides of the duct

furnace (see Fig. 3.3).

4. Remove pilot gas tube at the pilot, and exchange pilot

orifice (see Figures 4.2 and 4.3) as follows:

• For Robertshaw pilots, replace the pilot orifice stamped

N18 with the pilot orifice supplied in the conversion kit

stamped LP10.

• For Honeywell pilots, replace the pilot orifice stamped

BCR-18 with the pilot orifice supplied in the conversion

kit stamped BBR - 11 or 12.

• For PSE pilots, replace the pilot orifice stamped 018N

with the pilot orifice supplied in the conversion kit

stamped 012LP.

Figure 4.3 - Pilot Assembly

PILOT

BURNER

PILOT

ORIFICE

THERMOCOUPLE

5. Verify that pilot is oriented to main burner as shown in

Fig. 4.3.

6. Exchange main burner orifice(s) and install air shutters

(see Figure 4.4). Check the orifice number stamped on

each orifice. Be sure that this number is the same number

indicated on the kit parts list for the kit being installed. (See

Table 5.1 or 5.2).

Figure 4.1 - Burner Assembly Figure 4.4 - Burner Orifices and Air Shutters

BURNER

ASSEMBLY

PILOT

ASSEMBLY

THERMOCOUPLE

LEAD

GAS VALVE

PILOT

TUBE

AIR

SHUTTERS

MANIFOLD

MIXER

TUBES

MAIN BURNER

ORIFICES

Figure 4.2 - Pilot Assemblies & Orifices

Robertshaw Pilot Assembly

PILOT BURNER ASSEMBLY

(standing pilot shown)

Honeywell Pilot Assembly PSE Pilot Assembly

PILOT ORIFICE IDENTITY

NUMBER STAMPED HERE

(Natural Gas N18,

Propane Gas 10 LP)

PILOT TUBE WITH

COMPRESSION

SLEEVE AND NUT

4

PILOT ORIFICE IDENTITY

NUMBER STAMPED HERE

(Natural Gas BCR-18,

Propane Gas BBR-11 or 12)

PILOT TUBE WITH

COMPRESSION

SLEEVE AND NUT

75-511.13

PILOT ORIFICE IDENTITY

NUMBER STAMPED HERE

(Natural Gas 018N,

Propane Gas 012 LP)

PILOT TUBE WITH

COMPRESSION

SLEEVE AND NUT

INSTALLATION

Table 5.1 – Conversion Kit Parts List, Natural to Propane for Base Kit 3H034670-xxxx (Refer to Table 2.1)

Qty Part Number -1 -2 -3 -4 -5 -6 -7 -8 -9 -10 -11 -12

Regulator Kit for

Honeywell VR8200, 1 393691 x x x x x x x x x x x

VR8300, VR8204, VR8304

Regulator Kit for Honeywell

V800, VR800, VR8440

Regulator Kit for Robertshaw

7200ER, 7200IPER

Regulator Kit for Robertshaw

7000BER/BDER/ERHC/DERHC

Regulator Kit for

Robertshaw 7222IPER

Regulator Kit for

White-Rogers 36E, 36C

Main Burner Orifice ( ) 5H54751 52 45 39 45 43 39 43 42 36 39 41 42

Drill Size Qty (1) (1) (1) (2) (2) (2) (3) (3) (3) (4) (5) (6)

Table 5.2 – Conversion Kit Parts List, Natural to Propane for Base Kit 3H033749-xxxx (Refer to Table 2.2)

Qty. Part Number -1 -2 -3 -4 -5 -6 -7 -8 -9 -10 -11 -12 -13 -14 -15 -16 -17 -18

Regulator Kit for

Honeywell VR8200 1 393691 X X X X X X X X X

VR8300, VR8204, VR8304

Regulator Kit for Honeywell

V800, VR800, VR8440

Regulator Kit for Robertshaw

7200ER, 7200IPER

Regulator Kit for Robertshaw

7000BER/BDER/ERHC/DERHC

Regulator Kit for

Robertshaw 7222IPER

Main Burner Orifice ( ) 5H54751B… 52 45 49 45 42 45 43 40 43 42 43 39 40 37 45 48 37 43

Drill Size Qty. (1) (1) (2) (2) (2) (3) (3) (3) (4) (4) (5) (5) (6) (1) (2) (3) (3) (6)

Carton Label 1 5H73133C… 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18

Description Qty. Part Number

Honeywell Pilot Orifice 1 Orifice Stamp BBR-11

Parts Common To Kits: Robertshaw Pilot Orifice 1 Orifice Stamp 10 LP

(Table 5.1 and Table 5.2) PSE Pilot Orifice 1 Orifice Stamp 012 LP

Air Shutter Same As Main Burner Orifice Qty. 3H20634A2

Gas Designation Disc 1 5H604841A

Conversion Kit Rating Plate 1 5H73734A

Instruction Sheet 1 5H72298A

1 391937 x x

1 78776 x x x x x x x x

1 85478 x x x x

1 54302 x x x x x

1 92-0659 x x x x x x x x x x x x

1 391937 X X X X X X X X X X X X X X X X

1 78776 X X X X X

1 85478 X X X X X X X X

1 54302 X X X X X X X X X X X X X X

{

Table 5.3 – Conversion Kit Parts List, Natural to Propane for Base Kit 3H036483-xxxx (Refer to Table 2.3)

Qty. Part Number -1 -2 -3 -4 -5 -6 -7 -8 -9 -10 -11

Regulator Kit for

Honeywell VR8204, VR8200A, 1 5H71926A2 X X X X X X X X X X X

VR8300A

Regulator Kit for Honeywell

V800A

Regulator Kit for Robertshaw

7200IPER, 7200ER

Regulator Kit for Robertshaw

700BDER, 700DERHC, 1 5H73134A2 X X X X X

7000BER, 7000ERHC

Regulator Kit for White Rodgers

1 5H73134A2 X X X X X X X X X X X

36E36, 36C38, 36C03

Main Burner Orifice ( ) 5H54751B 37 45 42 45 43 40 37 42 37 43 42

Drill Size Qty (1) (2) (2) (3) (3) (3) (3) (4) (4) (6) (6)

Carton Label 1 5H78020B 1 2 3 4 5 6 7 8 9 10 11

Description Qty. Part Number

Robertshaw Pilot Orifice 1 5H71962A2

Parts Common To Kit: Air Shutter Same As Main Burner Orifice Qty. 3H20634A2

(Table 5.3) Gas Designation Disc 1 5H604841A

Conversion Kit Rating Plate 1 5H73734A

Instruction Sheet 1 5H72298A

1 5H7057A2 X

1 5H73135A2 X X X X X X

{

75-511.13

5

WARNING

MISE EN GARDE

VALVE CONVERTED FOR USE AT

4.2" - 11.0" W.C. IMPROPER OPERATION

COULD RESULT IN DEATH OR

SERIOUS INJURY.

SOUPAPE CONVERTIE POUR USAGE

A COLONNE D'EAU DE 10.6 A 28CM.

UN FONCTIONNEMENT INAPPROPRIE

PEUT PROVOQUER LA MORT OU DES

BLESSURES GRAVES

INSTALLATION

7. Reinstall the burner assembly making certain that the

retaining pins (and clips) are replaced and the burner is

correctly positioned.

8. For codes 11 or 12 or if digit 11 of model number is S and

digit 12 is 1, reconnect the pilot gas tube and thermocouple

at the combination gas control. For codes 30 or 31 or if

digit 11 of model number is N and digit 12 is 1, reconnect

the pilot gas tube at the combination gas control and the

ignition cable(s) at the ignition control.

9. Modify the combination gas control regulator to use

propane gas. Follow the instructions in the regulator kit

to convert the combination gas control. Some conversion

kits will have more than one regulator kit and they are

specific to the manufacturer of the combination gas control

(i.e. Honeywell, Robertshaw, etc.). Check the conversion

kit Parts List, Table 5.1, 5.2, or 5.3, for application of the

correct regulator kit. A second check can be made by

finding the model number on the combination gas control

and matching it with the correct kit. Do not attempt to

substitute one regulator kit for another.

10. Affix the propane conversion label to the combination gas

control. This label is supplied with the regulator conversion

kit (see Figure 6.2).

11. Affix the conversion Rating Plate adjacent to the unit's

original rating plate (see Figure 6.3). Be sure that all blanks

on the label are completely filled in (date of conversion,

kit number, and organization/individual performing the

conversion).

12. Remove the natural gas designation disc(s) and replace

with the propane gas designation disc(s) included with the

conversion kit (see Figure 7.1). Note that some units may

use several discs.

13. Turn on the gas supply to the unit.

14. Check the line pressure of the gas supply upstream of

the combination gas control either with a water column

manometer or with a gauge with water column scale. The

supply pressure should be no less than 12 in. w.c. and no

more than 14 in. w.c.

15. Connect the manometer or (gauge) to the outlet pressure

tap designated on the combination gas control.

16. Restore electric supply to unit.

17. Light unit following instructions on unit rating plate. Turn

up thermostat setting to call for heat. After the main

burners light, measure the outlet (manifold) pressure of

the combination gas control. The outlet pressure should

be 10 in. w.c. The outlet pressure can be adjusted at the

combination gas control's regulator. Turning the adjustment

clockwise will increase the outlet pressure while turning it

counterclockwise will decrease the pressure.

18. Verify normal operating sequence of ignition system

according to the Installation & Service Manual.

19. Check for leaks at all joints and connections in the gas

lines. This is most easily done with a soap/water solution.

Simply brush or spray some of the solution on a joint or

connection and look for bubble formation.

20. Observe the main burner flame. The flame should have a

well-defined conical shape with the base anchored to the

burner port. If the flame appears to be lifting or rising above

the burner port (see Figure 6.1), loosen the thumb screw

on the air shutter and slide the shutter forward toward the

mixer tube (see Figure 4.4).

21. If a majority of the flame is yellow, move the air shutter

back away from the mixer tube. Slight yellow tips on a

propane flame are common and are not objectionable.

Adjust pilot flame. Follow instructions in Installation and

Service Manual.

6

Figure 6.1

Lifting Flame

Figure 6.2

Typical Combination Gas Control Conversion Label

Figure 6.3

Conversion Rating Plate

MODINE MANUFACTURING COMPANY

CONVERSION KIT RATING PLATE

This appliance was converted on

to propane gas with kit no. __________________

by: _______________________________________

__________________________________________

which accepts the responsibility that this

conversion has been properly made. Use

parts supplied by Heating Division of Modine

Manufacturing Company. Conversion to be

performed by a qualified service technician.

Appliance model number and input rating: See

existing rating plate.

Inlet gas pressure: Minimum 12" W.C.

Maximum 14" W.C.

Manifold gas pressure: 10" W.C.

Burner orifice size: # __________ drill

Ce générateur d’air chaud a été converti le

___________ pour fonctionner au gaz propane à

l’aide de l’ensemble n° ______________________

par _______________________________________

__________________________________________

(nom et adresse de l’organisme qui a effectué la

conversion), qui accepte l’entière responsabilité

de la conversion.

5H73734A

75-511.13

EQUIPPED

FOR USE

WITH

PROPANE

GAS

NTRL

5H604841A

INSTALLATION

Figure 7.1

Gas Designation Disc

22. See the original rating plate for the unit heater's rated

input. The input can be verified at any time simply by

checking for the correct main burner orifice size and

manifold pressure. This information is presented on the

conversion kit rating plate.

75-511.13

7

Building HVAC Products • Modine Manufacturing Company • 1500 DeKoven Avenue • Racine, Wisconsin 53403-2552

"I" & "O" Model Series - Phone: 1.866.823.1631 (Toll Free) • All Other Model Series - Phone: 1.800.828.4328 (HEAT)

© Modine Manufacturing Company 2016

75-511.13

Loading...

Loading...