Modine Manufacturing 1-500, HOT DAWG H2O HHD Service Manual

1-500

5H081501

HOT DAWG H2O® - Low Profile Hot Water Unit Heater

WARNING

Improper installation, adjustment, alteration,

service or maintenance can cause property

damage, injury or death. Read the installation,

operating and maintenance instructions

thoroughly before installing or servicing this

equipment.

IMPORTANT

The use of this manual is specifically intended

for a qualified installation and service agency. A

qualified installation and service agency must

perform all installation and service of these

appliances.

General Information

Installation and service instructions in this manual are

applicable to model HHD, low profile hot water unit heaters,

which should be installed in their proper applications for their

most effective function as heating units.

The water coils are warranted for operation at water pressures

up to 150 psi and temperatures up to 200°F.

Motors are designed for continuous duty. They can operate in

a maximum ambient temperature of 104°F (40°C).

The unit heaters are listed by ETL as certified. Units not

approved for use in potable water systems.

THIS MANUAL IS THE PROPERTY OF THE OWNER.

PLEASE BE SURE TO LEAVE IT WITH THE OWNER WHEN YOU LEAVE THE JOB.

October, 2010

INSTALLATION AND SERVICE MANUAL

Model HHD

Table of Contents

General Information……………………………………..

Inspection on Arrival…………………………………….

Special Precautions……………………………………..

SI (Metric) Conversion Factors………………………...

Installation

Unit Location…………………………………………

Unit Mounting………………………………………..

Hot Water Piping…………………………………….

Electrical Connections………………………………

Start-Up Procedure

Prior to Operation……………………………………

Initial Start-Up………………………………………..

Typical Sequence of Operation……………………

Troubleshooting……………………………………..

Unit Data

Dimensions…………………………………………..

Electrical Data……………………………………….

Mechanical Data…………………………………….

Performance Data…………………………………...

Maintenance/Replacement Parts……………………...

Warranty………………………………………………….

Inspection upon Arrival

1. Inspect unit upon arrival. In case of damage, report

immediately to transportation company and your local

factory sales representative.

2. Check rating plate on unit to verify that the power supply

meets available electric power at the point of installation.

3. Inspect unit received for conformance with description of

product ordered (including specifications where

applicable).

Note: Modine Manufacturing Company has a continuous

product improvement program, and therefore reserves the right

to change design and specifications without notice.

1

1

2

2

3

4-5

6

6

7

7

7

7

8

8

8

9

10

12

SPECIAL PRECAUTIONS

THE INSTALLATION AND MAINTENANCE INSTRUCTIONS IN

THIS MANUAL MUST BE FOLLOWED TO PROVIDE SAFE,

EFFICIENT, AND TROUBLE-FREE OPERATION. IN ADDITION,

PARTICULAR CARE MUST BE EXERCISED REGARDING THE

SPECIAL PRECAUTIONS LISTED BELOW. FAILURE TO

PROPERLY ADDRESS THESE CRITICAL AREAS COULD

RESULT IN PROPERY DAMAGE OR LOSS, PERSONAL INJURY,

OR DEATH. THESE INSTRUCTIONS ARE SUBJECT TO ANY

MORE RESTRICTIVE LOCAL OR NATIONAL CODES.

HAZARD INTENSITY LEVELS

1. DANGER: Indicates an imminently hazardous situation which,

if not avoided, WILL result in death or serious injury.

WARNING: Indicates a potentially hazardous situation which,

2.

if not avoided, COULD result in death or serious injury.

CAUTION: Indicates a potentially hazardous situation which, if

3.

not avoided, MAY result in minor or moderate injury.

IMPORTANT: Indicates a situation which, if not avoided, MAY

4.

result in a potential safety concern.

DANGER

Units must not be installed where they may be exposed to

potentially explosive or flammable atmosphere.

WARNING

1. Disconnect power supply before making wiring

connections to prevent electrical shock and equipment

damage.

2. All appliances must be wired strictly in accordance with

the wiring diagram furnished with the appliance. Any

wiring different from the wiring diagram could result in a

hazard to persons and property.

3. Any original factory wiring that requires replacement

must be replaced with wiring material having a

temperature rating of at least 105°C.

4. Ensure that the supply voltage to the appliance, as

indicated on the serial plate, is not 5% greater than the

rated voltage.

5. When servicing or repairing of this equipment, use only

factory-approved service replacement parts. A

complete replacement parts list may be obtained by

contacting Modine Manufacturing Company. Refer to

the rating plate on the unit for complete model and serial

number and Company address. Any substitution of

parts or controls not approved by the factory will be at

the owner’s risk.

CAUTION

1. All literature shipped with this unit should be kept for

future use for servicing or service diagnostics. Leave

manual with the owner. Do not discard any literature

shipped with this unit.

2. Consult piping and electrical instructions in this manual

before final installation.

CAUTION

3. Units are designed for use in heating applications with

ambient temperatures between 40°F and 100°F.

Heaters should not be used in applications where the

heated space temperature is below 40°F unless a glycol

anti-freeze solution has been added.

4. Units not approved for use in potable water systems.

5. Do not install units below 7' measured from the bottom

of the unit to the floor in commercial applications (unless

unit is properly guarded to provide user protection from

moving parts) and 5' measured from the bottom of the

unit to the floor in residential applications.

6. Do not reuse any mechanical or electrical components

which have been wet. Replace defective components.

7. Do not operate the unit with steam. The coil is not

designed for steam condensate removal which can

damage the unit.

8. Ensure the supply voltage to the appliance, as indicated

on the serial plate, is not 5% less than the rated voltage.

IMPORTANT

1. Start-up and adjustment procedures should be

performed by a qualified service agency.

2. Be sure no obstructions block air intake and discharge

of unit heaters. Do not attach ductwork or air filters to

this unit heater. Maintain a minimum of 6” clearance to

inlet openings.

3. When mounting the unit to the joists, do not compress

the vibration isolators by over tightening the lag bolt

screws into the joist. Doing so will greatly reduce the

ability of the isolator to dampen vibration.

4. No water-flow can cause a freeze condition resulting in

damage to the coil.

5. Never leave the unit filled with water in a building

without heat unless antifreeze has been added.

6. To check most of the Possible Remedies in the

troubleshooting guide listed in Table 7.1, refer to the

applicable sections of the manual.

Table 2.1 – SI (Metric) Conversion Factors

To Convert Multiply By To

Obtain

“W.C. 0.249 kPa feet 0.305 m

ºF (ºF-32) x 5/9 ºC Gal/hr 0.00379 m³/hr

BTU 1.06 kJ Gal/hr 3.79 l/hr

BTU/ft3 37.3 kJ/m³ gallons 3.79 l

BTU/hr 0.000293 kW Horsepower 746 W

CFH (ft3/hr) 0.000472 m³/min inches 25.4 mm

CFH (ft3/hr) 0.00000787 m³/s pound 0.454 kg

CFM (ft3/min) 0.0283 m³/min psig 6.89 kPa

CFM (ft3/min) 0.000472 m³/s psig 27.7 “W.C.

To Convert Multiply

By

To

Obtain

2 1-500

INSTALLATION – UNIT LOCATION

DANGER

Units must not be installed where they may be exposed to

potentially explosive or flammable atmosphere.

CAUTION

1. All literature shipped with this unit should be kept for

future use for servicing or service diagnostics. Leave

manual with the owner. Do not discard any literature

shipped with this unit.

2. Consult piping and electrical instructions in this manual

before final installation.

3. Units are designed for use in heating applications with

ambient temperatures between 40°F and 100°F.

Heaters should not be used in applications where the

heated space temperature is below 40°F unless a glycol

anti-freeze solution has been added.

4. Units not approved for use in potable water systems.

IMPORTANT

the unit can be flipped 180° from the way it was received

from the factory. By doing so, the sides become opposite

but the front and back remain in the same relative position.

The bottom panel now becomes the top panel and viceversa. Be sure to remove the spring loaded deflector

blades, turn them over, replace, and adjust so they are open

and in a position to direct the heated air down to the floor.

Note that the labels on the front of the unit will be upside

down. New stickers can be purchased from Modine.

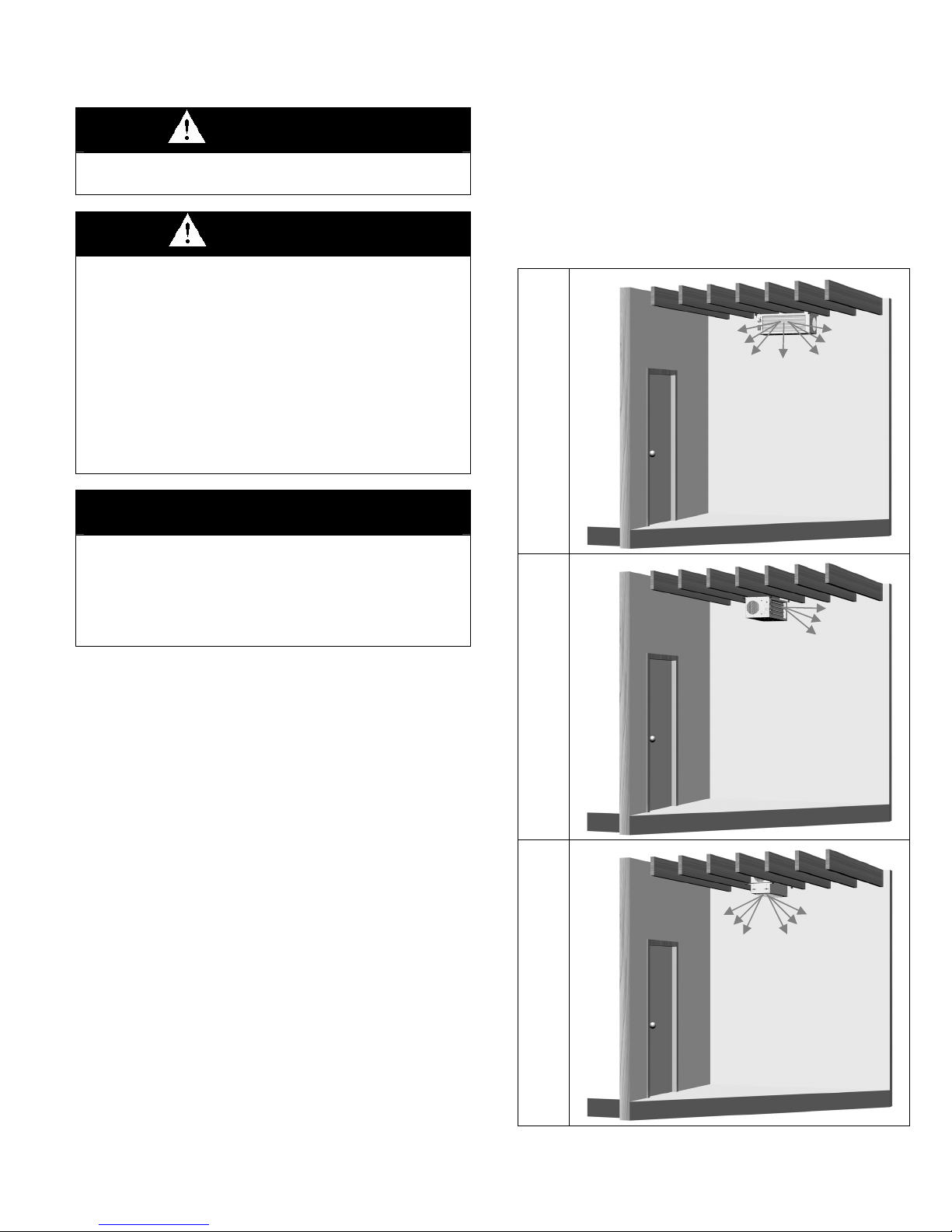

Figure 3.1 – Model HHD Mounting Orientations

Horizontal Air Delivery,

Perpendicular to Joists

1. Start-up and adjustment procedures should be

performed by a qualified service agency.

2. Be sure no obstructions block air intake and discharge

of unit heaters. Do not attach ductwork or air filters to

this unit heater. Maintain a minimum of 6” clearance to

inlet openings.

1. Units should not be installed in atmospheres where

corrosive fumes or sprays are present.

2. When locating the heater, consider general space and

heating requirements and availability of hot water and

electrical supply.

3. Be sure the structural support at the unit location site is

adequate to support the unit’s weight.

4. Determine mounting orientation of the unit heater.

Figure 3.1 shows three typical orientations. Additional

details can be seen in Figure 5.2.

5. Be sure no obstructions block air intake and discharge

of unit heaters. Do not attach ductwork or air filters to

this unit heater. Maintain a minimum of 6” clearance to

inlet openings. Failure to do so will result in poor unit

performance.

6. Unit heaters installed in a building exposed to a

prevailing wind should be located to direct a major

volume of heated air along the windward wall.

7. Vertical delivery unit heaters should generally be

located in the central area of the space to be heated.

Place horizontal delivery units along the walls of the

same building where heat loss is usually greatest.

8. Locate units so they do not blow directly at occupants.

9. Locate units so their air streams blanket exposed walls.

Reversing Electrical/Piping Connection Access

Units feature electrical access on the left and piping

connections on the right as standard (when looking at the

unit). If the installation requires the access to be reversed,

Parallel to Joists

Horizontal Air Delivery,

Vertical Air Delivery,

Recessed Between Joists

1-500 3

INSTALLATION – UNIT MOUNTING

CAUTION

Do not install units below 7' measured from the bottom of the

unit to the floor in commercial applications (unless unit is

properly guarded to provide user protection from moving

parts) and 5' measured from the bottom of the unit to the

floor in residential applications.

IMPORTANT

When mounting the unit to the joists, do not compress the

vibration isolators by over tightening the lag bolt screws into

the joist. Doing so will greatly reduce the ability of the

isolator to dampen vibration.

1. Be sure the means of suspension is adequate to

support the weight of the unit (see Table 8.1 for unit

weights).

2. Before lifting the heater for suspension, based on the

mounting orientation selected (refer to Figure 3.1), the

mounting brackets must be installed on the unit as

follows:

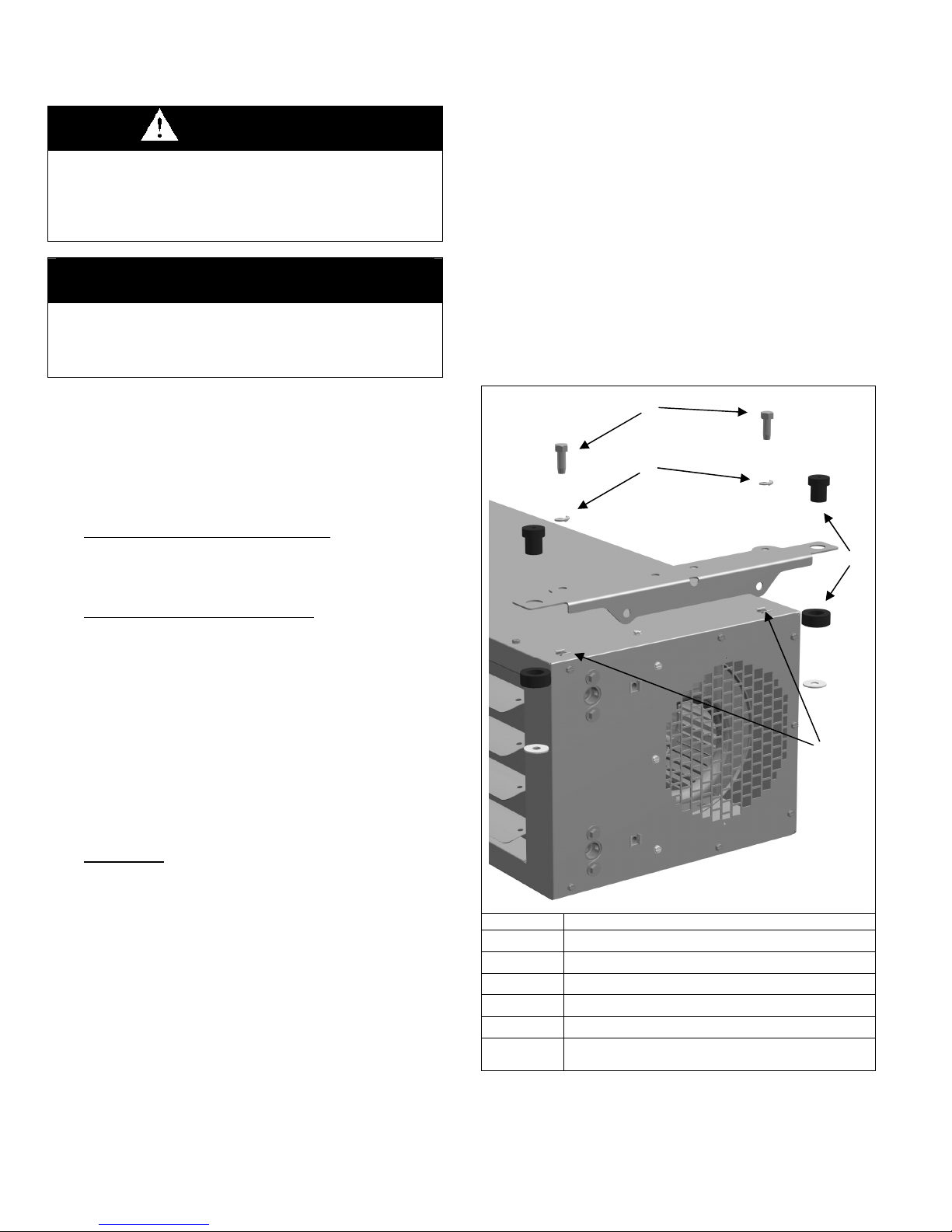

For Horizontal Air Delivery Orientations:

a) Position the brackets on the top of the unit as

shown in Figure 4.1.

For Vertical Air Delivery Orientations:

a) Position the brackets on the side of the unit as

shown in Figure 5.1. Note the following:

• For 10” or 12” deep joists, the bracket can be

oriented as shown in the top picture.

• For 12” deep joists, the bracket can be oriented

as shown in the bottom picture for additional

headroom. Refer also to Figure 5.2.

• If required, louver blades can be flipped to

change the direction of airflow control. To do

so, remove the spring loaded deflector blades,

turn them over, replace, and adjust so they are

open and in a position to direct the heated air.

For All Units:

b) Secure the brackets to the unit with the 3/8”-16 x 1”

Hex Bolts and 3/8” Lock Washers included with the

bracket kit. The bolts thread into the retaining nuts

that are located in the top of the unit casing.

c) Repeat for the bracket on the left side of the unit

(not pictured).

d) Install the vibration isolators that were supplied with

the unit (see Figure 4.1) by inserting the smaller

diameter pieces through the ¾” diameter holes from

the top side of the bracket. The larger diameter

pieces are fitted from the bottom side. The outer

diameter of the top mounted pieces will friction fit

into the inside diameter of the bottom pieces.

3. With the brackets installed on the unit, the unit can be

installed to the ceiling joists or trusses as follows (refer

to Figure 5.2):

• The bracket mounting hole locations accommodate

joists on 16" centerlines.

• Use (4) 1/4" lag bolt screws (supplied by others) that

are at least 3” long. The (4) 1-1/2” x 1/4” Fender

Washers (supplied by Modine) must be placed

between the lag bolt screw and bottom vibration

isolation piece

• Install the lag bolt screws until the top of the isolator

just touches the bottom of the joist. Do not

compress the isolator by over tightening the lag bolt

screw. Doing so will greatly reduce the ability of the

isolator to dampen vibration.

Figure 4.1

Bracket Installation for Horizontal Air Delivery

c

d

e

h

f

Item Qty (total for unit) - Description

c

d

e

f

g

h

Note: Figure 4.1 shows the unit with standard right hand piping

connections. See page 3 for instructions on reversing the piping

access side.

Qty (4) – Hex Bolts, 3/8"-16 x1"

Qty (4) – 3/8” Lock Washers

Qty (2) – Mounting Brackets

Qty (4) – Retainer Nuts , 3/8"-16

Qty (4) – Two-Piece Vibration Isolators

Qty (4) – 1-1/2” x 1/4” Fender Washers

(used when the unit is installed to the joists)

g

4 1-500

Loading...

Loading...