Modine Manufacturing HD60, HD45, HD75, HD100, HD125 Installation And Service Manual

...

INSTALLATION AND SERVICE MANUAL

separated combustion gas-fired unit heaters

WARNING

1. Improper installation, adjustment, alteration,

service or maintenance can cause property

damage, injury or death, and could cause

exposure to substances which have been

determined by various state agencies

to cause cancer, birth defects or other

reproductive harm. Read the installation,

operating and maintenance instructions

thoroughly before installing or servicing this

equipment.

2. Do not locate ANY gas-fired units in areas

where chlorinated, halogenated, or acid

vapors are present in the atmosphere. These

substances can cause premature heat

exchanger failure due to corrosion, which

can cause property damage, serious injury,

or death.

FOR YOUR SAFETY

WHAT TO DO IF YOU SMELL GAS:

1. Open windows.

2. Do not try to light any appliance.

3. Do not touch any electrical switch; do

not use any phone in your building.

4. Immediately call your gas supplier

from a neighbor’s phone. Follow the gas

supplier’s instructions. If you can not reach

your gas supplier, call your fire department.

6-584.2

5H80002A Rev. B

March, 2009

model HDS and HDC

All models approved for use in California by the CEC, in New

York city by the MEA division, and in Massachusetts. Unit heater

is certified for residential and commercial applications.

FOR YOUR SAFETY

The use and storage of gasoline or other

flammable vapors and liquids in open containers

in the vicinity of this appliance is hazardous.

IMPORTANT

The use of this manual is specifically intended

for a qualified installation and service agency.

All installation and service of these units must

be performed by a qualified installation and

service agency.

Inspection on Arrival

1. Inspect unit upon arrival. In case of damage, report it

immediately to transportation company and your local

Modine sales representative.

2.

Check rating plate on unit to verify that power supply meets

available electric power at the point of installation.

3. Inspect unit upon arrival for conformance with description of

product ordered (including specifications where applicable).

Table of Contents

Inspection on Arrival. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Special Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

SI (Metric) Conversion Factors. . . . . . . . . . . . . . . . . . . . . . . . . 3

Before you Begin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Unit Location. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Combustible Material and Service Clearances

Unit Mounting

Venting

Gas Connections

Electrical

Operation

Unit Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Dimensions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Service/Trouble Shooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Unit Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Serial/Model Number/Replacement Parts . . . . . . . . . . . . . . . 19

Commercial Warranty. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

. . . . . . . . . 4

PLEASE BE SURE TO LEAVE IT WITH THE OWNER WHEN YOU LEAVE THE JOB.

THIS MANUAL IS THE PROPERTY OF THE OWNER.

SPECIAL PRECAUTIONS

SPECIAL PRECAUTIONS

THE INSTALLATION AND MAINTENANCE INSTRUCTIONS IN THIS

MANUAL MUST BE FOLLOWED TO PROVIDE SAFE, EFFICIENT

AND TROUBLE-FREE OPERATION. IN ADDITION, PARTICULAR

CARE MUST BE EXERCISED REGARDING THE SPECIAL

PRECAUTIONS LISTED BELOW. FAILURE TO PROPERLY ADDRESS

THESE CRITICAL AREAS COULD RESULT IN PROPERTY DAMAGE

OR LOSS, PERSONAL INJURY, OR DEATH. THESE INSTRUCTIONS

SUBJECT TO ANY MORE RESTRICTIVE LOCAL OR NATIONAL

CODES.

HAZARD INTENSITY LEVELS

1. DANGER: Indicates an imminently hazardous situation

which, if not avoided, WILL result in death or serious injury.

2. WARNING

which, if not avoided, COULD result in death or serious injury.

3. CAUTION: Indicates a potentially hazardous situation which,

if not avoided, MAY result in minor or moderate injury.

4. IMPORTANT: Indicates a situation which, if not avoided,

MAY result in a potential safety concern.

: Indicates a potentially hazardous situation

dANGER

Appliances must not be installed where they may be exposed

to a potentially explosive or flammable atmosphere.

WARNING

1. Gas fired heating equipment must be vented - do not

operate unvented.

2. A built-in power exhauster is provided - additional external

power exhausters are not required or permitted.

3. If you are replacing an existing heater, it may be necessary

to resize the venting systems. Improperly sized venting

systems can result in vent gas leakage or the formation of

condensate. Refer to the National Fuel Gas Code ANSI

Z223.1 or CSA B149.1 latest edition. Failure to follow these

instructions can result in injury or death.

4. Under no circumstances should two sections of double wall

vent pipe be joined together within one horizontal vent system

due to the inability to verify complete seal of inner pipes.

5. All field gas piping must be pressure/leak tested prior to

operation. Never use an open flame. Use a soap solution

or equivalent for testing.

6. Gas pressure to appliance controls must never exceed 14"

W.C. (1/2 psi).

7. To reduce the opportunity for condensation, the minimum

sea level input to the appliance, as indicated on the serial

plate, must not be less than 5% below the rated input,

or 5% below the minimum rated input of dual rated units.

8. Disconnect power supply before making wiring connections

to prevent electrical shock and equipment damage.

9. All appliances must be wired strictly in accordance with

wiring diagram furnished with the appliance. Any wiring

different from the wiring diagram could result in a hazard to

persons and property.

10. Any original factory wiring that requires replacement must

be replaced with wiring material having a temperature

rating of at least 105°C.

11. Ensure that the supply voltage to the appliance, as indicated

on the serial plate, is not 5% greater than the rated voltage.

12. When servicing or repairing this equipment, use only

factory-approved service replacement parts. A complete

replacements parts list may be obtained by contacting

the factory. Refer to the rating plate on the appliance for

complete appliance model number, serial number, and

company address. Any substitution of parts or controls not

approved by the factory will be at the owners risk.

cAUTION

1. All literature shipped with this unit should be kept for

future use for servicing or service diagnostics. Do not

discard any literature shipped with this unit.

2. Consult piping, electrical, and venting instructions in this

manual before final installation.

3. Do not attach ductwork, air filters, or polytubes to any

propeller unit heater.

4. Clearances to combustible materials are critical. Be sure to

follow all listed requirements.

5. Low profile heaters are designed for use in heating. applica tions with ambient temperatures between -40°F and 90°F.

6. Do not install unit outdoors.

7.

In garages or other sections of aircraft hangars such

as offices and shops that communicate with areas used for

servicing or storage, keep the bottom of the unit at least

7' above the floor unless the unit is properly guarded

to provide user protection from moving parts. In parking

garages, the unit must be installed in accordance with

the standard for parking structures ANSI/NFPA 88A, and

in repair garages the standard for repair garages NFPA

#88B. In Canada, installation of heaters in airplane

hangars must be in accordance with the requirements

of the enforcing authority, and in public garages in

accordance with the current CSA-B149 codes.

8. In aircraft hangars, keep the bottom of the unit at least 10'

from the highest surface of the wings or engine enclosure

of the highest aircraft housed in the hangars and in

accordance with the requirements of the enforcing authority

and/or NFPA 409-latest edition.

9. Installation of units in high humidity or salt water

atmospheres will cause accelerated corrosion resulting in a

reduction of the normal life of the units.

10. Do not install units below 7' measured from the bottom of

the unit to the floor in commercial applications (unless

unit is properly guarded to provide user protection from

moving parts) and 5' measured from the bottom of the unit

to the floor in residential applications.

11. Be sure no obstructions block air intake and discharge of

unit heaters.

12. The minimum distance from combustible material is based

on the combustible material surface not exceeding 160°F.

Clearance from the top of the unit may be required to be

greater then the minimum specified if heat damage, other

than fire, may occur to materials above the unit heater at

the temperature described.

13. Allow 18" of clearance at rear (or 6" beyond end of motor at

rear of unit, whichever is greater) and access side to

provide ample air for proper operation of fan.

14. Installation must conform with local building codes or in the

absence of local codes, with Part 7, Venting of Equipment,

of the National Fuel Gas Code, ANSI Z223.1 (NFPA 54) -

latest edition. In Canada installation must be in accordance

with CSA-B149.1.

15. The concentric vent adapter box must be installed inside

of the structure or building. Do not install this box on the

exterior of a building or structure.

16. Purging of air from gas supply line should be performed as

described in ANSI Z223.1 - latest edition “National Fuel

Gas Code”, or in Canada in CSA-B149 codes.

17. When leak testing the gas supply piping system, the

appliance and its combination gas control must be isolated

during any pressure testing in excess of 14" W.C. (1/2 psi).

2

6-584.2

SPECIAL PRECAUTIONS / SI (METRIC) CONVERSION FACTORS

BEFORE YOU BEGIN

cAUTION

18. The unit should be isolated from the gas supply piping

system by closing its field installed manual shut-off valve.

This manual shut-off valve should be located within 6' of

the heater.

19. Turn off all gas before installing appliance.

20. Ensure that the supply voltage to the appliance, as

indicated on the serial plate, is not 5% less than the rated

voltage.

21. Check the gas inlet pressure at the unit upstream of the

combination gas control. The inlet pressure should be

6-7" W.C. on natural gas or 12-14" W.C. on propane. If

inlet pressure is too high, install an additional pressure

regulator upstream of the combination gas control.

22. Servicing or repairing of this equipment must be

performed by a qualified service agency.

23. Do not attempt to reuse any mechanical or electronic

ignition controllers which has been wet. Replace defective

controller.

IMPORTANT

1. To prevent premature heat exchanger failure, do not locate

ANY gas-fired appliances in areas where corrosive vapors

(i.e. chlorinated, halogenated or acid) are present in the

atmosphere.

2. To prevent premature heat exchanger failure, the input to

the appliance as indicated on the serial plate, must not

exceed the rated input by more then 5%.

3. To prevent premature heat exchanger failure, observe

heat exchanger tubes. If the bottom of the tubes become

red while blower and furnace are in operation, check to

be sure the blower has been set to the proper rpm for the

application. Refer to page 13 for Blower Adjustments.

4. Start-up and adjustment procedures should be performed

by a qualified service agency.

5.

To check most of the Possible Remedies in the trouble-

shooting guide listed in Table 17.1 refer to the applicable

sections of the manual.

cAUTION

1. All literature shipped with this unit should be kept for future

use for servicing or service diagnostics. Leave manual with

the owner. Do not discard any literature shipped with this unit.

2. Consult piping, electrical, and venting instructions in this

manual before final installation.

3. Do not attach ductwork, air filters, or polytubes to any

propeller unit heater.

In the U.S., the installation of these units must comply with the

“National Fuel Gas Code,” ANSI Z223.1, latest edition (also

known as NFPA 54) and other applicable local building codes.

In Canada, the installation of these units must comply with local

plumbing or waste water codes and other applicable codes and

with the current code CSA-B149.1.

1. All installation and service of these units must be

performed by a qualified installation and service agency

only as defined in ANSI Z223.1, latest edition or in

Canada by a licensed gas fitter.

2. This unit is certified with the controls furnished. For

replacements parts, please order according to the

replacement parts list on serial plate. Always know your

model and serial numbers. The right is reserved to

substitute other authorized controls as replacements.

3. Unit is balanced for correct performance. Do not alter fan

or operate motors at speeds below what is shown in this

manual.

4. Information on controls is supplied separately.

5. The same burner is used for natural and propane gas.

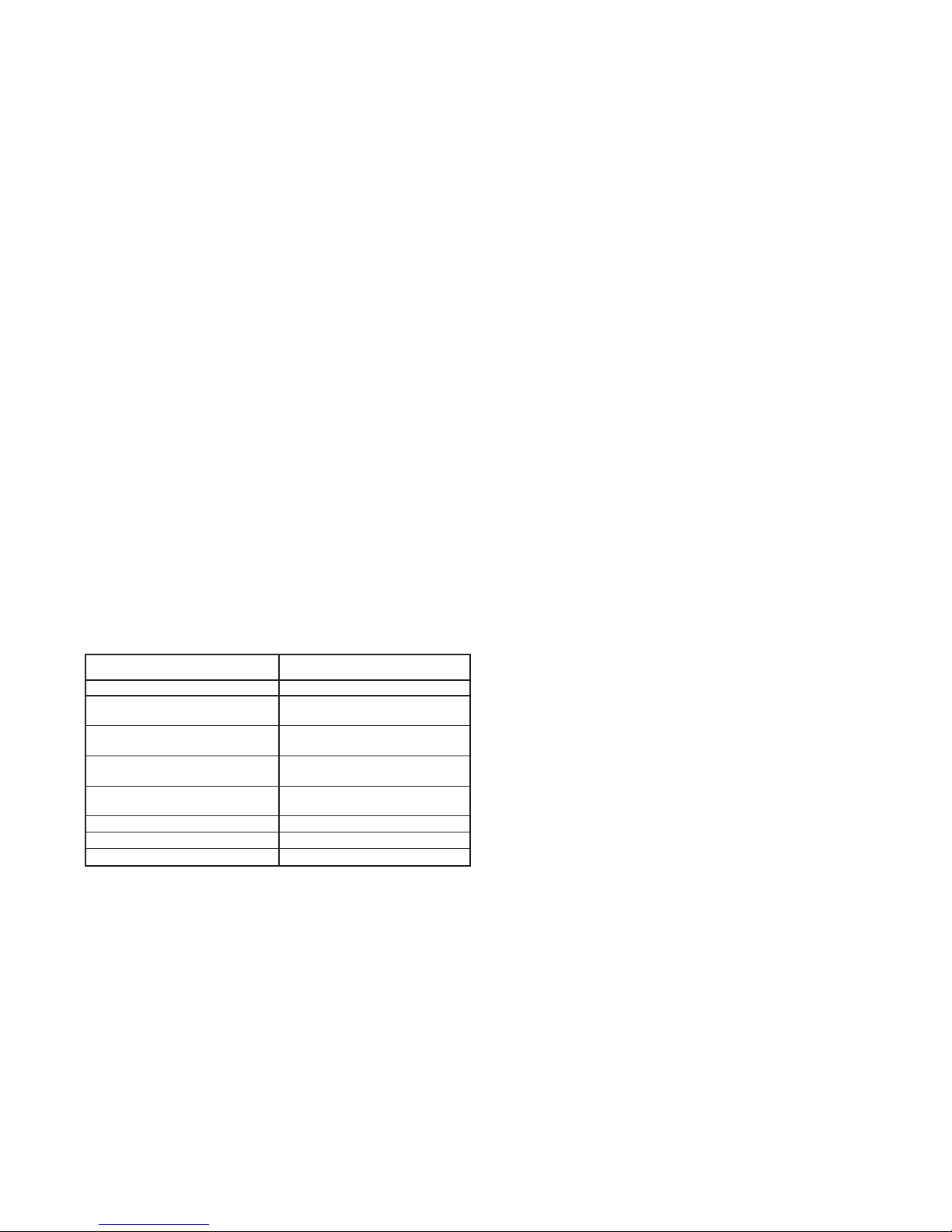

SI (METRIC) CONVERSION FACTORS

To Convert Multiply By To Obtain

"W.C. 0.249 kPa

°F (°F-32) x 5/9 °C

Btu 1.06 kJ

3

Btu/ft

Btu/hr 0.000293 kW

CFH (ft

CFH (ft

CFM (ft

CFM (ft

37.3 kJ/m

3

/hr) 0.000472 m3/min

3

/hr) 0.00000787 m3/s

3

/min) 0.0283 m3/min

3

/min) 0.000472 m3/s

To Convert Multiply By To Obtain

feet 0.305 m

Gal/Hr. 0.00379 m

Gal/Hr. 3.79 l/hr

3

gallons 3.79 l

Horsepower 746 W

inches 25.4 mm

pound 0.454 kg

psig 6.89 kPa

psig 27.7 "W.C.

3

/hr

6-584.2

3

UNIT LOCATION

UNIT LOCATION

dANGER

Appliances must not be installed where they may be exposed

to a potentially explosive or flammable atmosphere.

cAUTION

1. Clearances to combustible materials are critical. Be sure to

follow all listed requirements.

2. Low profile heaters are designed for use in heating applica tions with ambient temperatures between -40°F and 90°F.

3. Do not install unit outdoors.

4. In garages or other sections of aircraft hangars such

as offices and shops that communicate with areas used for

servicing or storage, keep the bottom of the unit at least

7' above the floor unless the unit is properly guarded.

In parking garages, the unit must be installed in accordance

with the standard for parking structures ANSI/NFPA 88A,

and in repair garages the standard for repair garages NFPA

#88B. In Canada, installation of heaters in airplane

hangars must be in accordance with the requirements

of the enforcing authority, and in public garages in

accordance with the current CSA-B149 codes.

5. In aircraft hangars, keep the bottom of the unit at least 10'

from the highest surface of the wings or engine enclosure

of the highest aircraft housed in the hangars and in accor dance with the requirements of the enforcing authority

and/or NFPA 409-latest edition.

6. Installation of units in high humidity or salt water

atmospheres will cause accelerated corrosion resulting in a

reduction of the normal life of the units.

Table 4.1 - Clearances

Unit Side Clearance To Recommended

Combustible Materials Service Clearance

Top and Bottom 1" 1"

Access Side 1" 18"

Non-Access Side 1" 1"

Rear 18" 18"

Vent Connector 4" 4"

6. Do not install units in locations where gas ignition system is

exposed to water spray, rain, or dripping water.

7. Mounting Height (measured from bottom of unit) at which

unit heaters are installed is critical. Refer to mounting

height and heat throw data on page 16 of this manual. The

maximum mounting height for any unit is that height above

which the unit will not deliver heated air to the floor.

Turning The Unit 180° (Model Sizes 30-75 Only)

All units are produced at the factory with left-side controls (when

looking at the unit). If the installation requires the controls to

be on the right side, all HDS/HDC heaters - with the exception

of the 100 and 125 - can be turned-over by following the

instructions below.

• By turning the unit 180° from the way it was received from

the factory, the sides become opposite but the front and

back remain in the same relative position. The bottom panel

now becomes the top panel and vice-versa.

• Remove the access panel, turn it 180°, and re-attach it to

the unit so that all the information labels can be read.

• Remove the spring loaded deflector blades, turn them over,

replace, and adjust so they are open and in a position to

direct the heated air down to the floor.

IMPORTANT

To prevent premature heat exchanger failure, do not locate

ANY gas-fired appliances in areas where corrosive vapors

(i.e. chlorinated, halogenated or acid) are present in the

atmosphere.

Location Recommendations

1. When locating the heater, consider general space and

heating requirements, availability of gas and electrical

supply, and proximity to vent locations.

2. When locating units, it is important to consider that the

combustion air and exhaust vent piping must be connected

to the outside atmosphere. Vent terminals should be located

adjacent to one another. Maximum equivalent vent lengths

are listed in “Section A - General Instruction - All Units” of the

Venting instructions.

3. Be sure the structural support at the unit location site is

adequate to support the unit's weight. For proper operation

the unit must be installed in a level horizontal position.

4. Do not install units in locations where the flue products

can be drawn into the adjacent building openings such as

windows, fresh air intakes, etc.

5. Be sure that the minimum clearances to combustible

materials and recommended service clearances are

maintained. Units are designed for installation with the

minimum clearances as shown in Table 4.1.

4

6-584.2

UNIT MOUNTING

cAUTION

1.

Do not install units below 7' measured from the bottom of

the unit to the floor in commercial applications (unless

unit is properly guarded to provide user protection from

moving parts) and 5' measured from the bottom of the unit

to the floor in residential applications.

2. Be sure no obstructions block air intake and discharge

of unit heaters.

3. The minimum distance from combustible material is

based on the combustible material surface not exceeding

160°F. Clearance from the top of the unit may be required

to be greater than the minimum specified if heat damage,

other than fire, may occur to materials above the unit

heater at the temperature described.

4. Allow 18" clearance at rear (or 6" beyond end of motor

at rear of unit, whichever is greater) and access side to

provide ample air for proper operation of fan.

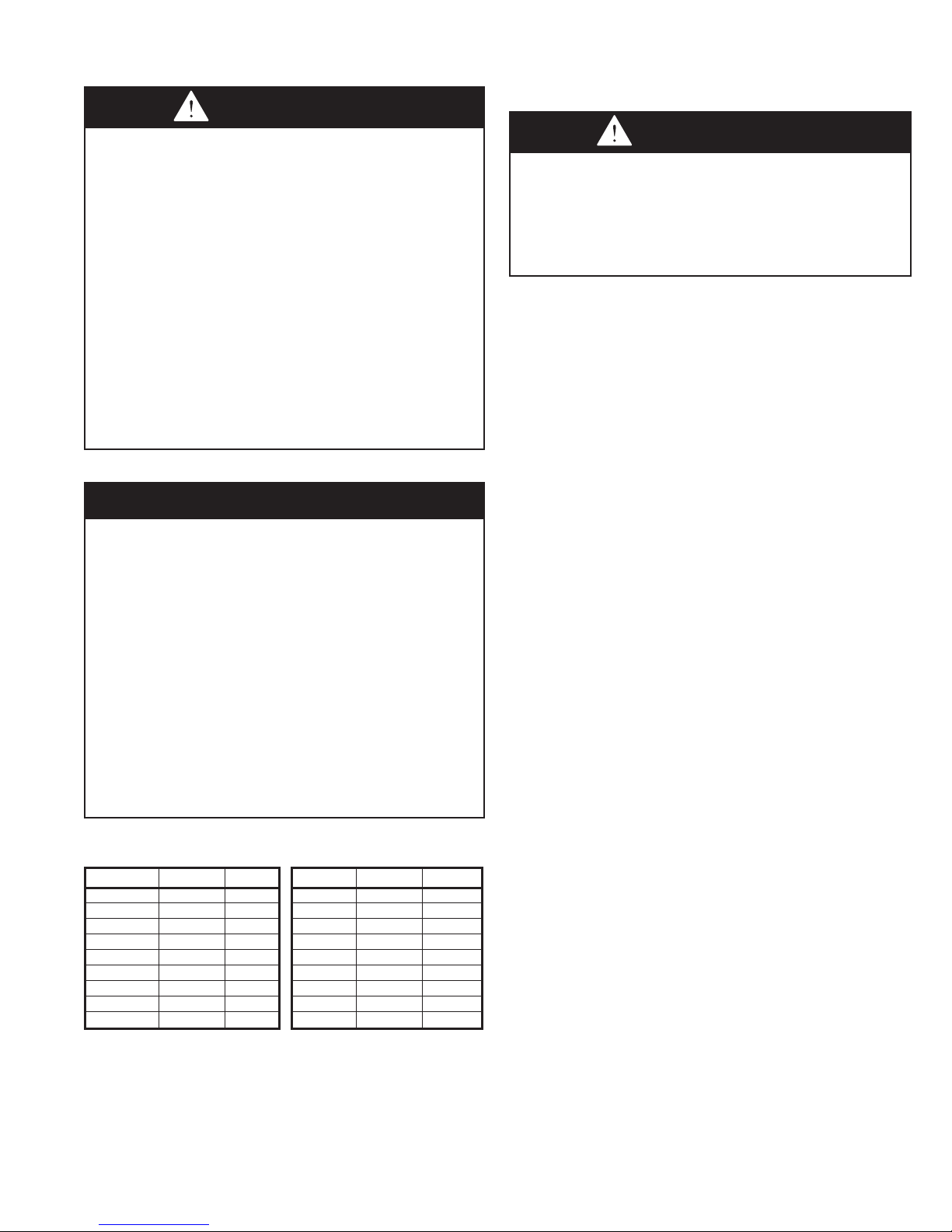

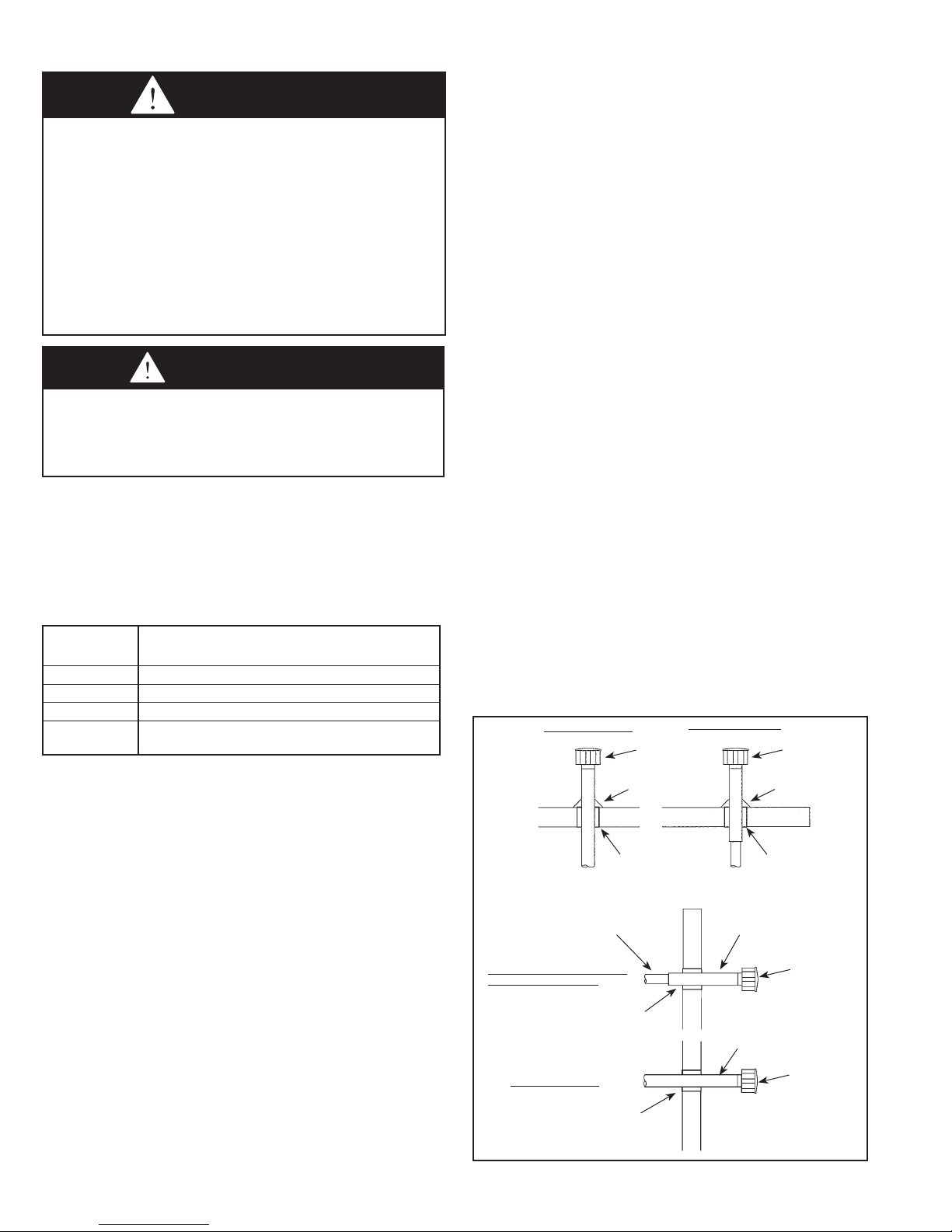

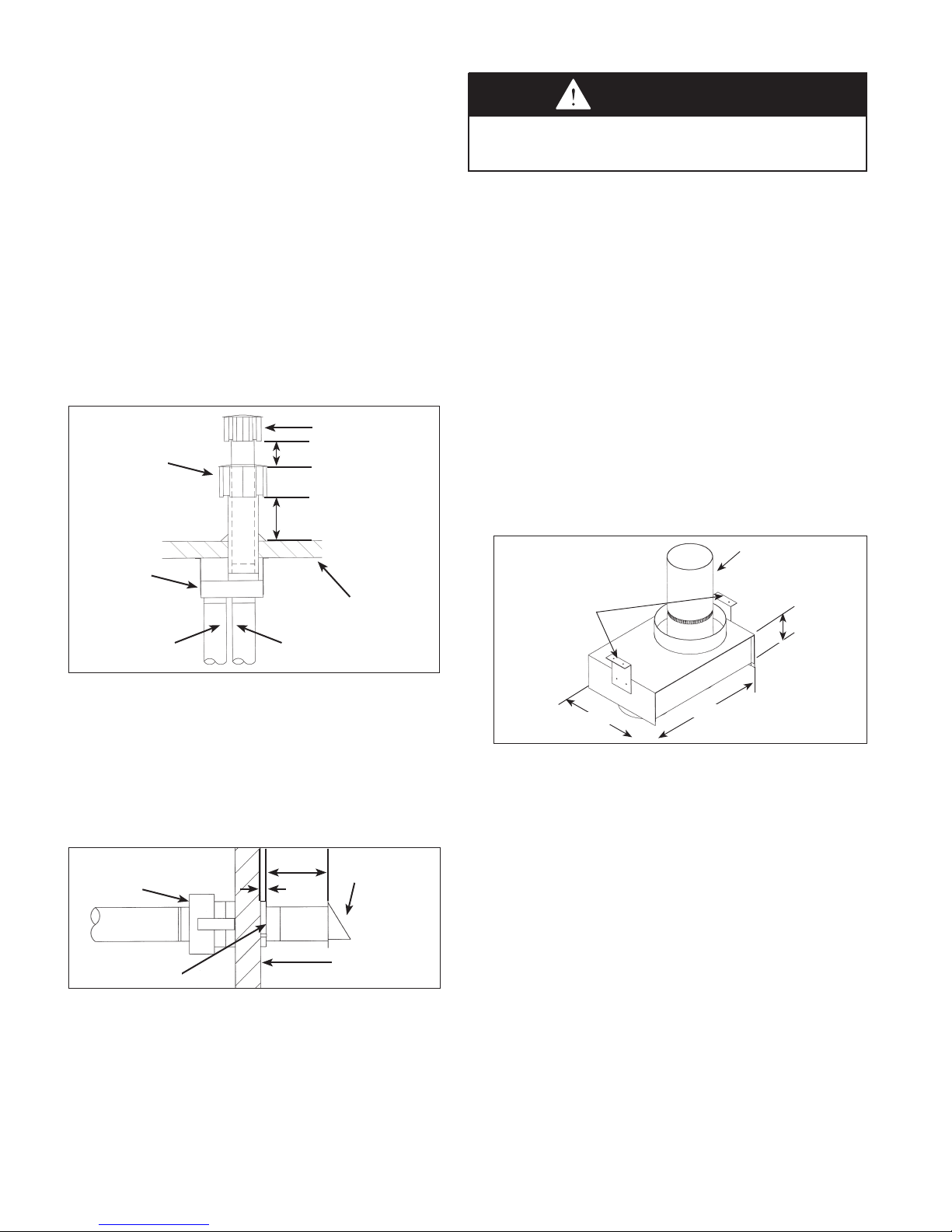

Figure 5.2 - Unit Heater Turned 180° (30-75 units only)

(Access panel and heated air outlet change sides)

1. Be sure the means of suspension is adequate to support

the weight of the unit (see page 16 for unit weights).

2. For proper operation, the unit must be installed in a level

horizontal position.

3. Clearances to combustibles as previously specified must be

strictly maintained.

4. For model sizes 30-75, before lifting the heater for

suspension, the mounting brackets must be installed as

follows (for bracket accessory installation on model sizes

100-125, see the latest revision of literature 6-594):

• For standard (left side) control access, remove the (3)

screws and mounting bracket along the top edge of both

the front and back of the unit. Install the front bracket as

shown in Figure 5.1 by aligning the screw holes on the

bracket with the screw holes on the top edge of the unit.

Repeat for the bracket on the back of the unit.

• For right side control access, remove the (3) screws and

mounting bracket along the top edge of both the front and

back of the unit. Turn the unit over and install the front

bracket as shown in Figure 5.2 by aligning the screw holes

on the bracket with the screw holes on the top edge of the

unit (originally the bottom edge). Repeat for the bracket on

the back of the unit.

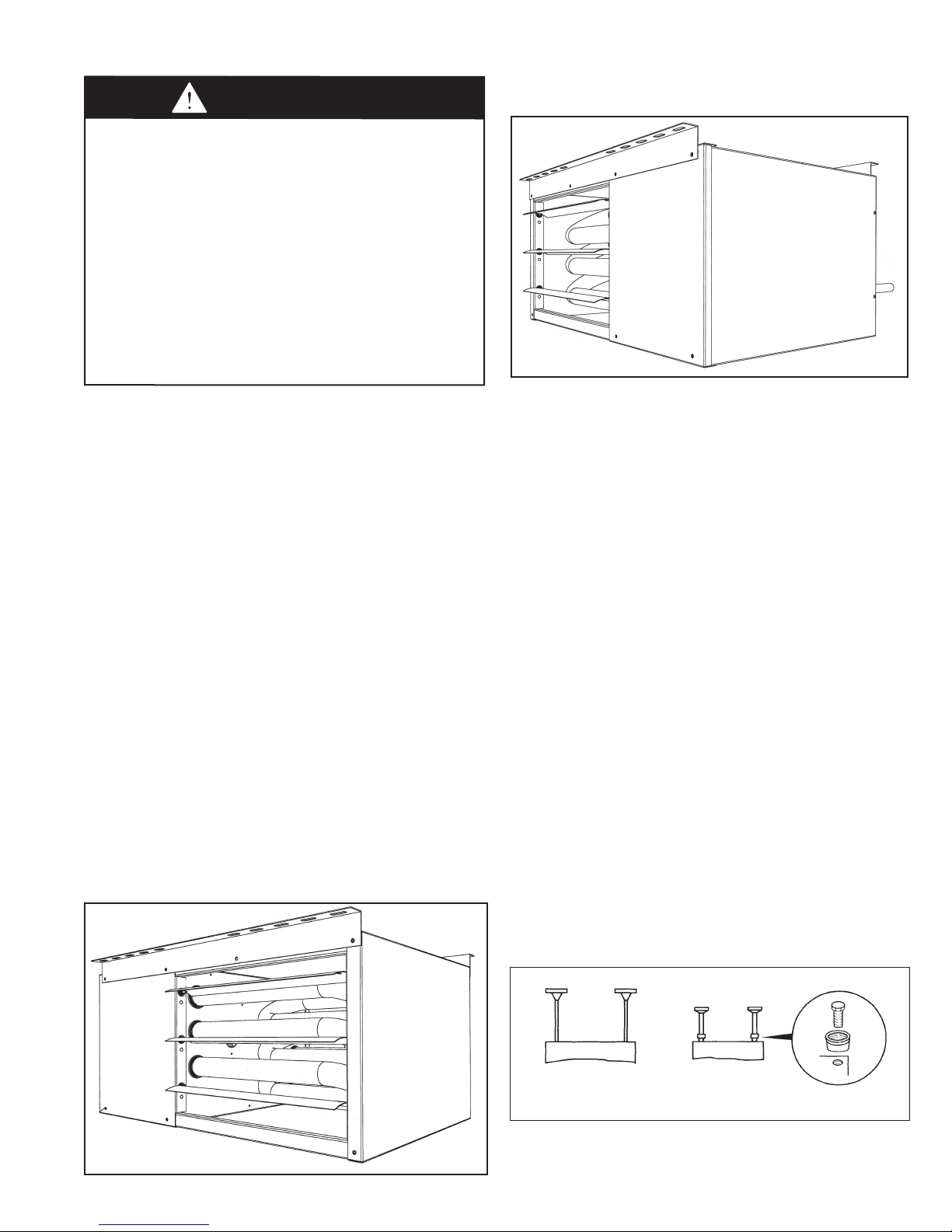

5a. Suspension by screws/lag bolts:

brackets to the ceiling joists or truss, using 1/4" screws with

1/2" washers. These unit mounting brackets are slotted to

accommodate joists on 16" or 24" centerlines. See page 16

for mounting bracket dimensions.

Secure the mounting

Figure 5.1 - Unit Heater in Standard Mounting

Configuration (30-75 Units Only)

5b. Suspension by threaded rod:

with threaded rod utilizing the same mounting brackets.

Attach the threaded rod to the unit mounting brackets,

securing with a top and bottom nut. For model sizes

100-125, the units are designed to be suspended by

threaded rod without the use of brackets. On each piece of

3/8" threaded rod used, screw a nut a distance of about one

inch onto the end of the threaded rods that will be screwed

into the unit heater. Place a washer over the end of the

threaded rod and screw the threaded rod into the unit heater

weld nuts on the top of the heater at least 5 turns, and no

more than 10 turns. Tighten the nut first installed onto the

threaded rod to prevent the rod from turning.

Next, drill holes into a steel channel or angle iron at the

same centerline dimensions as those chosen for the heater

being installed. The steel channels or angle iron pieces need

to span and be fastened to appropriate structural members.

Cut the threaded rods to the preferred length, push them

through the holes in the steel channel or angle iron and

secure with washers and lock nuts, lock washers and nuts,

or a washer with double nut arrangement.

NOTE

: A pipe hanger adapter kit, shown in Figure 5.3, is

available as an accessory. One kit consists of two drilled

3/4" IPS pipe caps and two 3/8 - 13 x 1-3/4" capscrews

to facilitate threaded pipe suspension. Two kits would be

required.

5c. Shelf mounted units:

on a shelf. The mounting brackets will need to be attached

to the heater the same manner as explained in note #4,

however, to mount on a shelf the brackets must go on the

bottom of the heater. The brackets must be affixed to the

shelf using similar screws (1/4" screw with 1/2" washer) as

overhead joist or truss mounting. Be sure all clearance to

combustible requirements are met.

The unit heater can also be installed

The unit can also be hung

Figure 5.3 - Unit Heater Suspension Methods

(Threaded Rod) (Pipe Adaptor Kit)

6-584.2

5

INSTALLATION - VENTING

WARNING

1. Gas fired heating equipment must be vented - do not operate

unvented.

2. A built-in power exhauster is provided - additional external

power exhausters are not required or permitted.

3. If you are replacing an existing heater, it may be necessary

to resize the venting systems. Improperly sized venting

systems can result in vent gas leakage or the formation of

condensate. Refer to the National Fuel Gas Code ANSI

Z223.1 or CSA B149.1 latest edition. Failure to follow these

instructions can result in serious injury or death.

4. Under no circumstances should two sections of double wall

vent pipe be joined together within one horizontal vent system

due to the inability to verify complete seal of inner pipes.

cAUTION

Installation must conform with local building codes or in the

absence of local codes, with Part 7, Venting of Equipment, of

the National Fuel Gas Code, ANSI Z223.1 (NFPA 54) - latest

edition. In Canada installation must be in accordance with CSA

B149.1.

Model HDS/HDC unit heaters must be vented with the proper

passageway as described in these instructions to convey

flue gases from the unit or the vent connector to the outside

atmosphere. The heaters must also have a separate combustion

air intake pipe to bring in fresh air for combustion from the

outside atmosphere.

The venting instructions are organized in sections, based on

installation type. The sections are identified as follows:

Instructions Applicable Installation Instructions

Section by Vent System Type

A General instructions for ALL

B VERTICAL 2-PIPE

vent systems ➀

C HORIZONTAL 2-PIPE

D HORIZONTAL AND VERTICAL

CONCENTRIC

➀The differences between Vertical and Horizontal vent systems in 2-Pipe or

Concentric Vent configurations will be identified in “Section A - General

Instructions – All Units”.

vent systems ➀

installations

vent systems ➀

A4. Limit the total equivalent vent pipe length to a minimum

of 3' and a maximum of 25', making the vent system as

straight as possible. The equivalent length of a 3" elbow is

1' and for a 4" elbow is 5'.

A5. A minimum of 12" straight pipe is recommended from the

flue outlet before turns in the vent pipe.

A6. Horizontal sections of vent pipe are to be installed with a

minimum downward slope from the appliance of 1/4 inch

per foot and suspended securely from overhead structures

at points not greater than 3' apart.

A7. Fasten individual lengths of vent together with at least three

corrosion resistant sheet metal screws.

A8. Keep single wall vent pipe at least 6" from combustible

materials. For double wall vent pipe, follow the vent

pipe manufacturer’s clearances to combustibles. The

minimum distance from combustible materials is based

on the combustible material surface not exceeding 160°F.

Clearance from the vent pipe (or the top of the unit) may be

required to be greater than 6" if heat damage other than fire

could result (such as material distortion or discoloration).

A9. Avoid venting through unheated space when possible.

When venting does pass through an unheated space or

if the unit is installed in an environment that promotes

condensation, insulate runs greater than 5' to minimize

condensation. Inspect for leakage prior to insulating and

use insulation that is noncombustible with a rating of not

less than 400°F. Install a tee fitting at the low point of the

vent system and provide a drip leg with a clean out cap as

shown in Figure 8.1.

A10. When the vent passes through a combustible INTERIOR

wall or floor, a metal thimble 4" greater than the vent

diameter is necessary. If there is 6' or more of vent pipe

in the open space between the appliance and where the

vent pipe passes through the wall or floor, the thimble need

only be 2" greater than the diameter of the vent pipe. If a

thimble is not used, all combustible material must be cut

away to provide 6" of clearance. Where authorities have

Figure 6.1 - Venting Through Combustible Roof

or Wall

Single Wall Vent Pipe

Flashing

Specified

Terminal

Double Wall Vent Pipe ➀

Flashing

Specified

Terminal

Section A – General Instructions – All Units

A1. If the unit heater being installed is replacing existing

equipment and using the existing vent system from that

equipment, inspect the venting system for proper size and

horizontal pitch, as required in the National Fuel Gas Code

ANSI Z223.1 or CSA B149.1 Installation Code-latest edition

and these instructions. Determine that there is no blockage

or restriction, leakage, corrosion and other deficiencies,

which could cause an unsafe condition.

A2. The vent pipe should be galvanized steel or other suitable

corrosion resistant material. Follow the National Fuel

Gas Code for minimum thickness of vent material. The

minimum thickness for connectors varies depending on the

pipe diameter. Do not vent unit with PVC or other forms of

plastic venting material.

A3. All heaters come with factory installed vent and combustion

air adapters for attaching the vent pipe to the heater (3" for

model sizes 30-45, 4" for model sizes 60-125). Attach the

vent pipe to the adapter with 3 corrosion resistant screws.

(Drill pilot holes through the vent pipe and adapter prior to

screwing in place). Vent pipe must not be smaller than the

connector size.

6

Listed

Thimble

Single

Wall

Single Wall Vent Pipe Terminating

with Double wall vent pipe. ➀

Clearance Specified

by Type B Vent Mfg.

Single Wall Vent Pipe

Listed

Thimble

➀ See Instruction A12 for attaching single wall pipe to double wall pipe

6-584.2

Clearance Specified

by Type B Vent Mfg.

Double

Wall

Specified

Terminal

Single

Wall

Specified

Terminal

INSTALLATION - VENTING

jurisdiction type B vent may be used for the last section

of vent pipe to maintain clearance to combustibles while

passing through wall or floor. See Figure 6.1. Any material

used to close the opening must be noncombustible.

A11. All seams and joints of the single wall pipe must be sealed

with metallic tape or silastic suitable for temperatures up to

400°F. Wrap the tape two full turns around the vent pipe.

One continuous section of double wall vent pipe may be

used within the vent system. Refer to instruction A12 in

“Section A – General Instructions – All Units” for attaching

double wall pipe to single wall pipe.

A12. The following are General Instructions for Double Wall

(Type B) Terminal Pipe Installation:

How to attach a single wall vent terminal to double wall

(type B) vent pipe:

1. Look for the “flow” arrow on the vent pipe.

2. Slide the vent terminal inside the exhaust end of the

double wall vent pipe.

3. Drill (3) holes through the pipe and the vent terminal.

Using 3/4" long sheet metal screws, attach the cap to

the pipe. Do not over tighten.

How to connect a single wall vent system to a double

wall (type B) vent pipe:

1. Slide the single wall pipe inside the inner wall of the

double wall pipe.

2. Drill (3) holes through both walls of the single and

double wall vent pipes. Using 3/4" sheet metal screws,

attach the two pieces of pipe. Do not over tighten.

3. The gap between the single and double wall pipe must

be sealed but it is not necessary to fill the full volume

of the annular area. To seal, run a large bead of 400°F

silastic around the gap.

A13. Vent termination clearances must be maintained:

Table 7.1 - Vent Termination Clearances

Minimum Clearances for

Structure Vent Terminal Location

Forced air inlet within 10 feet 3 feet above

Combustion air inlet of another

appliance 6 feet all directions

Door, window, gravity air inlet, 4 feet horizontal and below

or any building opening 1 foot above

Electric meter, gas meter, gas 4 feet horizontal (U.S.)

regulator, and relief equipment ➀ 6 feet horizontal (Canada)

Gas regulator ➀ 3 feet horizontal (U.S.)

6 feet horizontal (Canada)

Adjoining building or parapet wall 6 feet all directions

Adjacent public walkways 7 feet all directions

Grade (ground level) 3 feet above

➀

Do not terminate the vent directly above a gas meter or regulator.

➁

The vent must be at least 6" higher than anticipated snow depth.

➁

A20. Long runs of horizontal or vertical combustion air pipes

may require insulation in very cold climates to prevent the

buildup of condensation on the outside of the pipe where

the pipe passes through conditioned spaces.

A21. Vertical combustion air pipes should be fitted with a tee

with a drip leg and a clean out cap to prevent against the

possibility of any moisture in the combustion air pipe from

entering the unit. The drip leg should be inspected and

cleaned out periodically during the heating season.

A22. In addition to following these General Instructions, specific

instructions for Vertical and Horizontal vent systems in

2-Pipe or Concentric Vent configurations must also be

followed. The following outlines the differences:

Vertical Vent System Determination

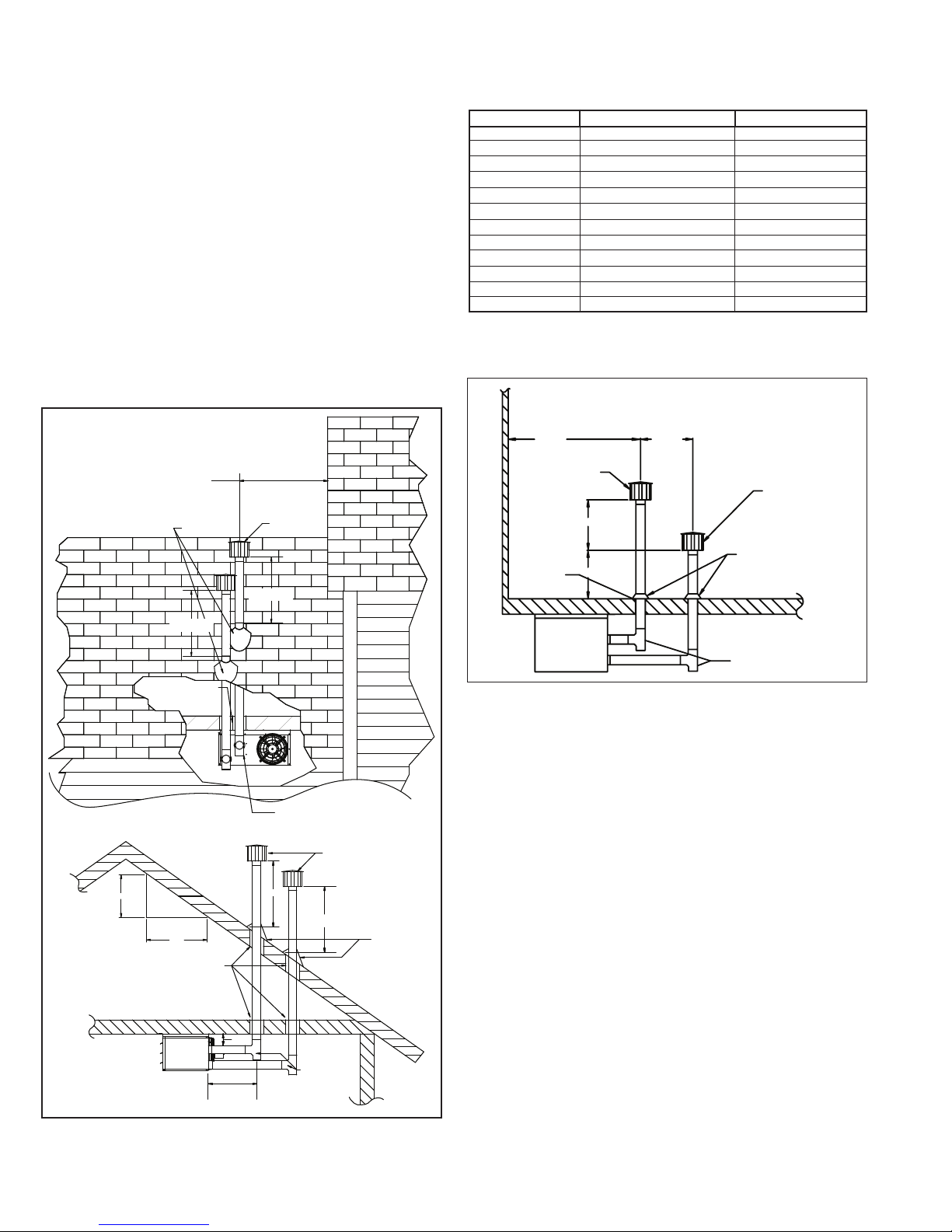

• Vertical vent systems terminate vertically (up) (an example is

shown in Figure 8.1).

• Determine the venting configuration as follows:

> For two building penetrations through the wall or roof (one

for the combustion air inlet pipe and one for the vent pipe),

proceed to “Section B - Vertical 2-Pipe Venting”.

> For a single larger building penetration through the wall or

roof, through which both the combustion air inlet and vent

pipes will pass, proceed to “Section D - Horizontal and

Vertical Concentric Venting”.

> For all other cases, proceed to the next section for

Horizontal Vent System Determination.

Horizontal Vent System Determination

• Horizontal vent systems terminate horizontally (sideways)

(an example is shown in Figure 9.1).

• Determine the venting configuration as follows:

> For two building penetrations through the wall or roof (one

for the combustion air inlet pipe and one for the vent pipe),

proceed to “Section C - Horizontal 2-Pipe Venting”.

> For a single larger building penetration through the wall or

roof, through which both the combustion air inlet and vent

pipes will pass, proceed to “Section D - Horizontal and

Vertical Concentric Venting”.

A14. Do NOT vent this appliance into a masonry chimney.

A15. Do NOT use dampers or other devices in the vent or

combustion air pipes.

A16.

The venting system must be exclusive to a single

appliance, and no other appliance is allowed to be vented

into it.

A17. Precautions must be taken to prevent degradation of

building materials by flue products.

A18. Single wall vent pipe must not pass through any

unoccupied attic, inside wall, concealed space, or floor.

A19. Uninsulated single wall vent pipe must not be used

outdoors for venting appliances in regions where the 99%

winter design temperature is below 32°F.

6-584.2

7

INSTALLATION - VENTING

"H" MIN*

12" MIN

RECOMMENDED

4" MIN

ROOF PITCH IS:

X / 12

MINIMUM DISTANCE TO ADJOINING WALL

OR BUILDING IS 2 FEET.

REFER TO TABLE 8.1 FOR "H" DIMENSION.

"H" MIN*

(SEE TABLE 8.1)

TEE WITH DRIP LEG

AND CLEANOUT CAP

(SLOPE 1/4" PER

FOOT DOWNWARD

TOWARD DRIP LEG)

COMBUSTION AIR

ROOF FLASHING

USE LISTED THIMBLE

THROUGH ROOF AND

CEILING

EXHAUST

USE LISTED THIMBLES

THROUGH CEILING

AND ROOF

12

X

ROOF FLASHING

COMBUSTION AIR

EXHAUST

TEE WITH DRIP LEG

AND CLEANOUT CAP

SPECIFIED

TERMINAL

SPECIFIED

TERMINAL

"H" MIN*

(SEE TABLE 8.1)

"H" MIN*

(SEE TABLE 8.1)

Combustion Air

Exhaust

* SIZE ACCORNING

TO EXPECTED

SNOW DEPTH.

TO WALL OR ADJOINING BUILDING

12" MIN

12" MIN*

2' MIN

6" MIN

USE THIMBLE

THROUGH

CELLING

TEE WITH DRIP LEG

AND CLEANOUT CAP

ROOF FLASHING

TERMINAL

TERMINAL

Section B – Vertical 2-Pipe Vent System

Installation

B1. This section applies to vertically vented 2-pipe (one

combustion air inlet pipe and one vent pipe) vent systems

and is in addition to “Section A – General Instructions – All

Units”.

B2. Vertical vent systems terminate vertically (up).

B3. It is recommended to install a tee with drip leg and clean out

cap as shown in Figure 8.1.

B4. The combustion air and vent pipes must be terminated with

(2) Gary Steel Model 1092 caps.

B5. Vertical vents must terminate a minimum horizontal and

vertical distance from roof lines and adjacent walls or

obstructions. These minimum distances are outlined in

Figure 8.1 and Table 8.1.

B6. The vent must terminate at least 1 foot above and 6 inches

horizontally from the combustion air inlet.

Figure 8.1 - Vertical 2-Pipe Vent System - Sloped Roof

Table 8.1 - Minimum Height from Roof to Lowest

Discharge Opening

Rise X (in) Roof Pitch Min Height H (ft) ➀

0-6 Flat to 6/12 1.00

6-7 6/12 to 7/12 1.25

7-8 7/12 to 8/12 1.50

8-9 8/12 to 9/12 2.00

9-10 9/12 to 10/12 2.50

10-11 10/12 to 11/12 3.25

11-12 11/12 to 12/12 4.00

12-14 12/12 to 14/12 5.00

14-16 14/12 to 16/12 6.00

16-18 16/12 to 18/12 7.00

18-20 18/12 to 20/12 7.50

20-21 20/12 to 21/12 8.00

➀ Size according to expected snow depth.

Figure 8.2 - Vertical 2-Pipe Vent System - Flat Roof

B9. Once venting is complete, proceed section titled “Installation

– Gas Connections”.

8

6-584.2

INSTALLATION - VENTING

METAL

SLEEVE

FIBER GLASS

INSULATION

MIN. 2"

2" MIN.

VENT TERMINATION

SUPPORT BRACKET

(where required)

(Make from 1" x 1" steel angle)

9"

9"

45°

1"

METAL

SLEEVE

2" MIN.

VENT PIPE

DIAMETER

METAL FACE

PLATE

1"

COMBUSTION AIR

EXHAUST

SLOPE 1/4" PER FOOT

DOWNWARD FROM UNIT

TEE WITH DRIP LEG AND

CLEANOUT CAP AT LOW

POINT OF VENT SYSTEM

SPECIFIED

TERMINAL

SUPPORT BRACKET

6" MIN

2' MIN

4" MIN

12"

ADJACENT

BUILDING

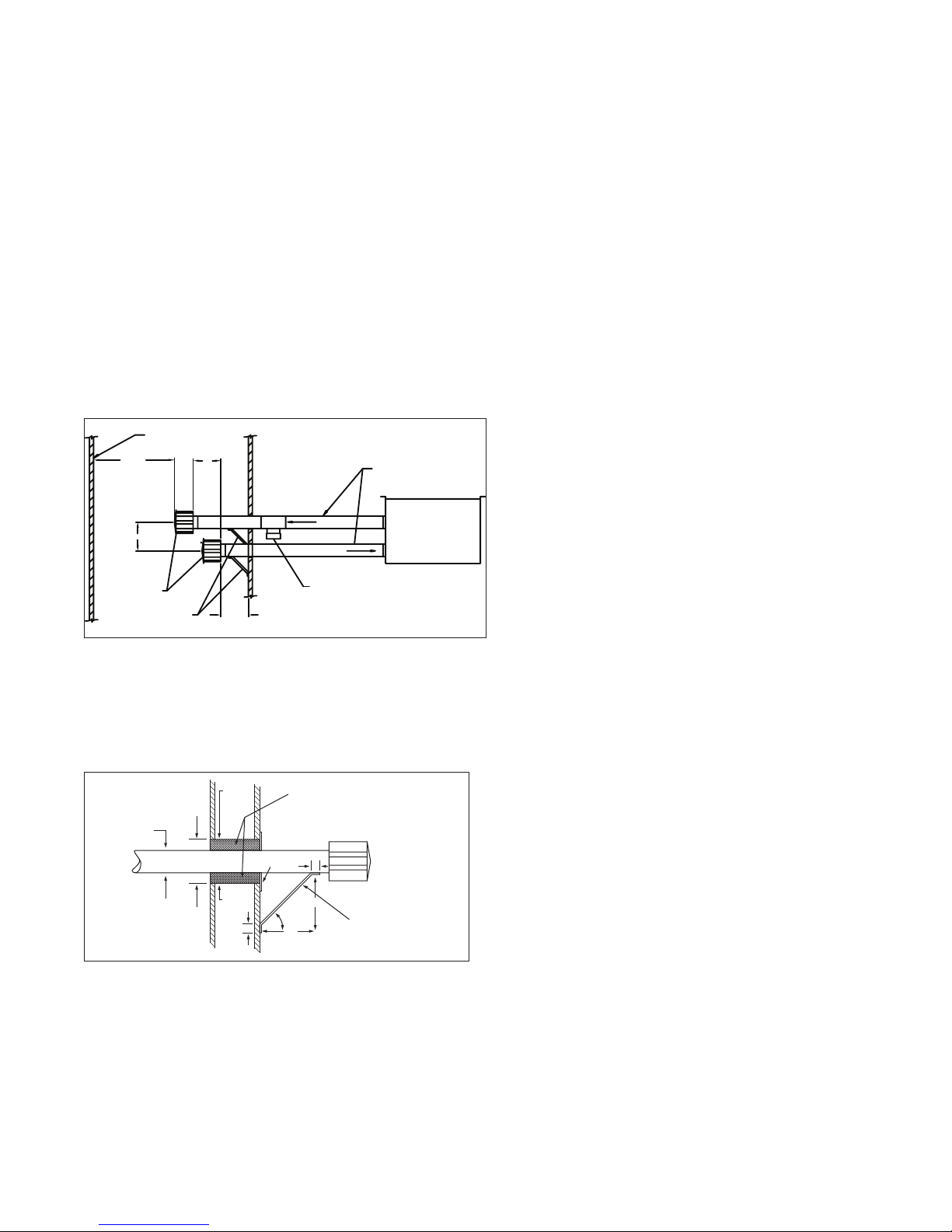

Section C – Horizontal 2-Pipe Vent System

Installation

C1. This section applies to horizontally vented 2-pipe

vent systems (one combustion air inlet pipe and one

vent pipe) and is in addition to “Section A – General

Instructions – All Units”.

C2. Horizontal vent systems terminate horizontally

(sideways).

C3. All horizontal vents must be terminated with a Gary Steel

1092 vent cap. The cap must terminate a minimum

distance from the external wall, as summarized in

Figure 9.1.

C4

. The termination of horizontally vented system must

extend 16 inches beyond the exterior surface of an

exterior wall.

C5

. The combustion air pipe must be a minimum of 6 inches

below the vent pipe, and 4 inches from the exterior wall.

C6. Construct the vent system as shown in Figure 9.1.

Figure 9.1 - Horizontal Venting with Downward Pitch

C11. For a vent termination located under an eave, the

distance of the overhang must not exceed 24". The

clearance to combustibles above the exterior vent

must be maintained at a minimum of 12". Consult the

National Fuel Gas Code for additional requirements for

eaves that have ventilation openings.

C12. Once venting is complete, proceed section titled

“Installation – Gas Connections”.

C7

. When horizontal vents pass through a combustible

wall (up to 22 inches thick), the vent passage must be

constructed and insulated as shown in Figure 9.2.

C8. The vent must be supported as shown in Figure 9.2.

Figure 9.2 - Exhaust Vent Construction Through

Combustible Walls and Support Bracket

C9. When condensation may be a problem, the vent system

shall not terminate over public walkways or over an area

where condensate or vapor could create a nuisance

or hazard or could be detrimental to the operation of

regulators, relief openings, or other equipment.

C10. Maintain a 1/4" per foot downward slope away from the

heater and place a drip leg with clean out near the exit of

the vent as shown in Figure 9.1, or allow the condensate

to drip out the end.

6-584.2

9

INSTALLATION - VENTING

Section D – Concentric Vent System

Installation

D1.

This section applies to both horizontally and vertically

vented concentric vent systems as defined in “Section A

– General Instructions – All Units”, and is in addition to the

instructions in that section.

D2. When utilizing the concentric vent option, it should have

been predetermined whether the appliance will be

horizontally or vertically vented. Before proceeding, verify

that the concentric vent kit received contains the correct

components for the installation:

For Vertically Vented Units (Refer to Figure 10.1):

➀ Concentric adapter assembly (same for horizontal and

vertical kits)

➁ Standard Gary Steel 1092 vent termination

➂ Specially designed inlet terminal (part #5H75154B1)

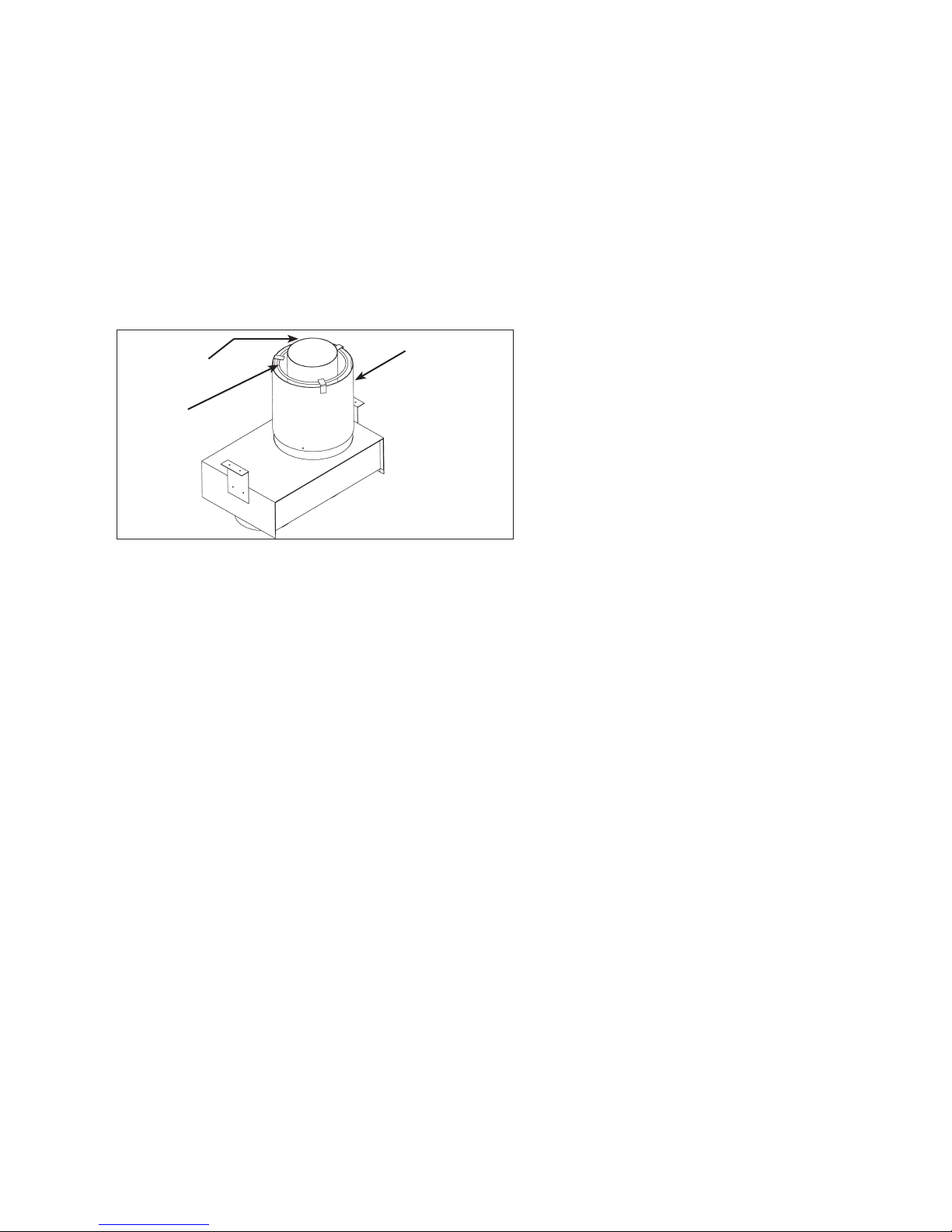

Figure 10.1 - Vertical Concentric Vent Kit

Components

Outlet Vent

Combustion Air

Inlet Terminal

Concentric

Vent Adapter

Box

4" Combustion Air 4" Exhaust

6" Min.

12" Min.*

Termination Cap

* Size according

to expected

snow depth.

Building

Roof / Ceiling

cAUTION

The concentric vent adapter box must be installed inside of

the structure or building. Do not install this box on the exterior

of a building or structure.

D3. Once the kit contents have been verified as correct for the

direction of venting, the concentric vent adapter box is to

be installed. Determine the location of the box. Be sure to

maintain all clearances as listed in these instructions.

D4. The adapter box is to be mounted on the interior side of the

building. It must not be mounted outside the building.

D5. The adapter box can be mounted flush to the wall (for

horizontal kits) or to the ceiling (for vertical kits). The box

can also be offset from the wall or ceiling by using field

supplied brackets. When mounting the box, consider

serviceability and access to the vent and combustion air

pipes.

D6. If the box is to be mounted using field supplied brackets,

these brackets must be strong enough to rigidly secure

the box to the wall or ceiling, and should be made from

corrosion resistant material. After determining the length of

the field supplied brackets, attach them to the sides of the

box using several corrosion resistant sheet metal screws.

See Figure 10.3 for typical installation and brackets.

Figure 10.3 - Adapter Box with Outlet Vent Pipe

Attached

4" Outlet Vent Pipe

Attached

Field Supplied

Mounting Brackets

4"

For Horizontally Vented Units (Refer to Figure 10.2):

➀ Concentric adapter assembly (same for horizontal and

vertical kits)

➁ Special vent termination cap (part #5H75150B1)

➂ Special inlet air guard

Figure 10.2 - Horizontal Concentric Vent Kit

Components

Concentric

Vent Adapter

Box

Combustion Air

Intake Guard

14" Min.

1" Min.

Outlet Vent

Termination Cap

Building Side Wall

8.25"

11.75"

D7. Determine the length of the vent pipe and combustion

air pipe that must be attached to the vent outlet and

combustion air inlet (on the concentric side) of the adapter

box (refer to Figure 10.3 and 11.1) to extend through the

building wall or roof. Be sure to add the length of the field

supplied brackets (if used) and the thickness of the wall or

roof. Note the following when determining the pipe lengths:

For Vertical Concentric Vent Kits

(refer to Figure 10.1):

• The bottom of the combustion air intake pipe must

terminate above the snow line, or at least 12 inches above

the roof, whichever distance is greater.

• The bottom of the vent cap must terminate at least 6 inches

above the top of the combustion air intake cap.

For Horizontal Concentric Vent Kits

(refer to Figure 10.2):

• The combustion air intake pipe must terminate at least

1 inch from the wall to prevent water from running down

the wall and into the pipe.

• The back of the vent cap must terminate at least 14 inches

from the combustion air intake pipe.

10

6-584.2

D8. Cut the concentric side vent and combustion air pipes to

the proper length as determined in the previous step. Note

that the vent pipe diameter is 4" and the combustion air

intake pipe diameter is 6". Both pipes must be single wall

galvanized or stainless steel material.

D9. Attach the concentric side vent pipe to the vent outlet

of the concentric vent adapter box, as shown in Figure

10.3, using at least 3 corrosion resistant sheet metal

screws. Seal the joint and seam using sealant suitable for

temperatures up to 400°F.

D10. Slide the combustion air pipe over the vent pipe and attach

to the air inlet of the concentric adapter box, as shown

in Figure 11.1, using at least 3 corrosion resistant sheet

metal screws. Seal the joint and seam using sealant

suitable for temperatures up to 400°F.

Figure 11.1 - Adapter Box with Combustion Air Intake

Pipe Attached

Outlet Vent

Pipe Attached

Combustion Air

Intake Guard

6" Combustion Air

Pipe Attached

D11. Place this assembly (the adapter box, vent pipe and

combustion air pipe) through the wall or roof and verify that

the distance requirements as defined in Step D7 are met.

Securely attach the assembly building.

D12. From outside the building, caulk the gap between the

combustion air intake pipe and the building penetration.

D13. Attach the combustion air intake and vent pipe

terminations as follows:

For Vertical Concentric Vent Kits

(refer to Figure 10.1):

• Slide the combustion air cap down over the vent pipe

and fasten it to the combustion air pipe with at least 3

corrosion resistant sheet metal screws.

• Attach the vent cap to the vent pipe using at least 3

corrosion resistant sheet metal screws.

• Caulk the gap between the combustion air cap and the

vent pipe with silicone sealant, or other appropriate

sealants suitable for metal to metal contact and for

temperatures up to 400° F.

For Horizontal Concentric Vent Kits

(refer to Figure 10.2):

• Attach the combustion air intake guard using corrosion

resistant screws at the end of the combustion air intake

pipe to prevent animals and debris from entering.

• Attach the vent cap to the vent pipe using at least 3

corrosion resistant sheet metal screws.

D14. For model sizes 30 and 45, attach the 3" to 4" vent

transitions on the non-concentric side vent and combustion

air connections using 3 corrosion resistant sheet metal

screws.

D15. Install vent pipe and combustion air pipe between unit

heater and concentric vent adapter box as outlined in

“Section A – General Instructions – All Units”.

D16. Once venting is complete, proceed to the section titled

“Installation - Gas Connections”.

6-584.2

11

INSTALLATION - GAS CONNECTIONS

GAS

SUPPLY LINE

GAS

SUPPLY LINE

GROUND

JOINT

UNION

MANUAL

SHUT-OFF

VALVE

3"

MIN.

SEDIMENT

TRAP

PLUGGED

1/8" NPT TEST

GAGE CONNECTION

TO

CONTROLS

GAS CONNECTIONS

WARNING

1. All field gas piping must be pressure/leak tested prior to

operation. Never use an open flame. Use a soap solution

or equilavent for testing.

2. Gas pressure to appliance controls must never exceed 14"

W.C. (1/2 psi).

3. To reduce the opportunity for condensation, the minimum sea

level input to the appliance, as indicated on the serial plate,

must not be less than 5% below the rated input, or 5% below the

minimum rated input of dual rated units.

cAUTION

1. Purging of air from gas lines should be performed as

described in ANSI Z223.1 - latest edition “National Fuel

Gas Code”, or in Canada CSA-B149 codes.

2. When leak testing the gas supply piping system, the

appliance and its combination gas control must be isolated

during any pressure testing in excess of 14" W.C. (1/2 psi).

3. The unit should be isolated from the gas supply piping

system by closing its field installed manual shut-off

valve.This manual shut-off valve should be located within

6' of the heater.

4. Turn off all gas before installing appliance.

IMPORTANT

To prevent premature heat exchanger failure, the input to the

appliance, as indicated on the serial plate, must not exceed

the rated input by more than 5%.

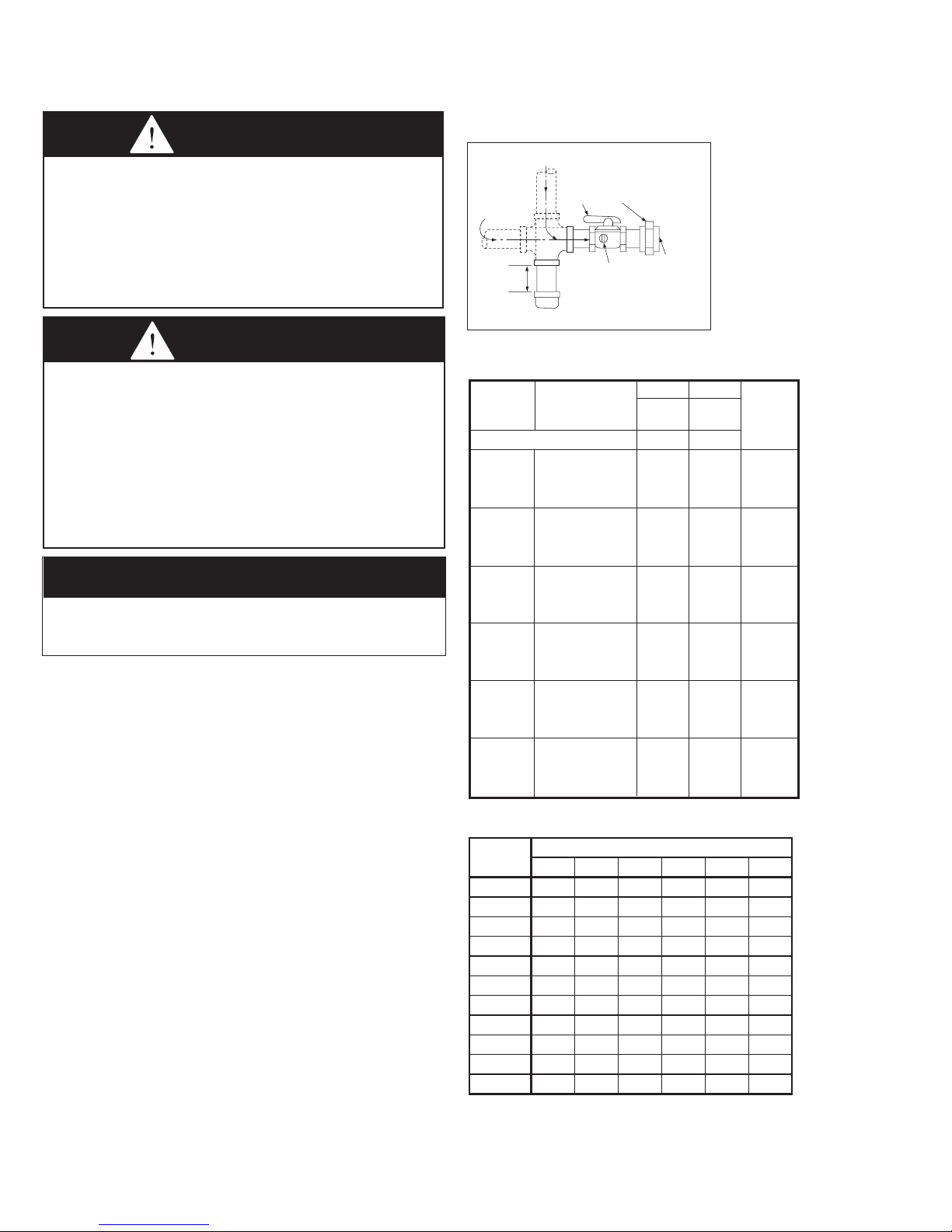

1. Installation of piping must conform with local building codes,

or in the absence of local codes, with the National Fuel Gas

Code, ANSI Z223.1 (NFPA 54) - latest Edition. In Canada,

installation must be in accordance with CSA-B149.1.

2. Piping to units should conform with local and national

requirements for type and volume of gas handled, and

pressure drop allowed in the line.Refer to Table 12.1 to

determine the cubic feet per hour (CFH) for the type of gas

and size of unit to be installed. Using this CFH value and the

length of pipe necessary, determine the pipe diameter from

Table 12.2. Where several units are served by the same

main, the total capacity, CFH and length of main must be

considered. Avoid pipe sizes smaller than 1/2". Table 12.2

allows for a 0.3" W.C. pressure drop in the supply pressure

from the building main to the unit. The inlet pressure to the

unit must be 6-7" W.C. for natural gas and 11-14" W.C. for

propane gas. When sizing the inlet gas pipe diameter, make

sure that the unit supply pressure can be met after the 0.3"

W.C. has been subtracted. If the 0.3" W.C. pressure drop is

too high, refer to the Gas Engineer’s Handbook for other gas

pipe capacities.

3. Install a ground joint union with brass seat and a manual

shut-off valve adjacent to the unit for emergency shut-off

and easy servicing of controls, including a 1/8" NPT plugged

tapping accessible for test gauge connection (See Figure 12.1).

4. Provide a sediment trap before each unit in the line where

low spots cannot be avoided. (See Figure 12.1).

5. When Pressure/Leak testing, pressures above 14" W.C.

(1/2 psi), close the field installed shut-off valve, disconnect

the appliance and its combination gas control from the gas

supply line, and plug the supply line before testing. When

testing pressures 14" W.C. (1/2 psi) or below, close the

manual shut-off valve on the appliance before testing.

12

Figure 12.1 - Recommended Sediment Trap/Manual

Shut-off Valve Installation - Side or Bottom Gas

Connection ➀

➀ Manual shut-off valve is in the “OFF” position when handle is perpendicular to pipe.

Table 12.1 - Manifold Pressure & Gas Consumption

Natural Propane

Model BTU/Cu. Ft. 1050 2500 No. of

Size Specific Gravity 0.60 1.53 Orifices

Manifold Pressure In. W.C. 3.5 10.0

CFH 28.6 12.0 2

Gal/Hr. Propane .33

30

Sec/cu. ft. 126 300

Orifice Drill Size 49 56

CFH 42.9 18.0 3

Gal/Hr. Propane .50

45

Sec/cu. ft. 84 200

Orifice Drill Size 49 56

CFH 57.1 24.0 4

Gal/Hr. Propane .66

60

Sec/cu. ft. 63 150

Orifice Drill Size 49 56

CFH 71.4 30.0 5

Gal/Hr. Propane .83

75

Sec/cu. ft. 50 180

Orifice Drill Size 49 56

CFH 95.2 40 5

Gal/Hr.Propane 1.09

100

Sec/cu.ft. 38 90

Orifice Drill Size 45 55

CFH 119 50 5

Gal/Hr.Propane 1.37

125

Sec/cu.ft. 30 72

Orifice Drill Size 42 53

Table 12.2 - Gas Pipe Capacities - Natural Gas ➀ ➁

Pipe

Length (ft)

1/2” 3/4” 1” 1-1/4” 1-1/2” 2”

10 132 278 520 1050 1600 3050

20 92 190 350 730 1100 2100

30 73 152 285 590 890 1650

40 63 130 245 500 760 1450

50 56 115 215 440 670 1270

60 50 105 195 400 610 1150

70 46 96 180 370 560 1050

80 43 90 170 350 530 930

100 38 79 150 305 460 870

125 34 72 130 275 410 780

150 31 64 120 250 380 710

➀ Capacities in Cubic Feet per Hour through Schedule 40 pipe with maximum

0.3"W.C. pressure drop with up to 14"W.C. gas pressure. Specific graivity is 0.60

for Natural gas and 1.50 for Propane gas.

➁ For Pipe Capacity with Propane Gas, divide Natural gas capacity by 1.6. Example:

What is the propane gas pipe capacity for 60 feet of 1-1/4" pipe? The Natural gas

capacity is 400 CFH. Divide by 1.6 to get 250 CFH for Propane gas.

Natural Gas

6-584.2

Loading...

Loading...