SELECTION AND INSTALLATION INSTRUCTIONS

model HD/HDB, HDS/HDC, PTS/BTS, and PTC

1. All field gas piping must be pressure/leak tested prior to

operation. Never use an open flame. Use a soap solution

or equivalent for testing.

2. Gas supply shall be shut-off and the electrical power

disconnected before proceeding with the conversion.

Failure to do so could result in fire, explosion or electrical

shock.

WARNING

75-537.7

5H75697B

August, 2009

high altitude orifice kit

Identifying the Model and Control Code

Figure 1.1 explains the model number designations. To be

convertible, the first three characters in the model number must be

HD, HDB, HDS, HDC, PTS, BTS or PTC.

After obtaining this information, refer to the proper selection

chart. The selection charts are differentiated by product type,

altitude and fuel type. If you are converting from natural gas

to propane gas and want to operate at high altitude, both a

propane conversion kit and a propane high altitude kit must

be used. Selection charts include the proper kit suffix, the orifice

drill size, and the number of orifices required for the unit being

converted. Drill sizes are also stamped on each orifice.

IMPORTANT

1. The use of this manual is specifically intended for a

qualified installation and service agency. All installation

and service of these kits must be performed by a qualified

installation and service agency.

2. These instructions must also be used in conjunction with

the Installation and Service manual originally shipped with

the appliance being converted, in addition to any other

accompanying component supplier literature.

Modine gas-fired equipment ratings are certified by CSA or ETL.

For elevations above 2000 ft., ANSI Z223.1 requires ratings be

reduced 4 percent for each 1000 ft. above sea level. For units in

Canada CSA requires that ratings be reduced 10% at elevations

above 2000 ft. The high altitude kits appearing in this bulletin

are for use with units that will be installed over 2000 feet. These

kits comply with both ANSI Z223.1 and CSA requirements.

If a unit is to be installed at higher elevations AND converted

from natural gas to propane gas operation, a propane

conversion kit must be used in conjunction with the high altitude

kit. When converting units to propane at elevations over

2,000 ft., the main burner orifices in the propane conversion

kit must be replaced with the orifices from the “high altitude”

orifice kit. The remaining components of the propane gas kit,

other than the main burner orifices, are required to complete

the conversion to propane gas, regardless of the elevation at

which the unit is installed. For the Selection and Installation

Instructions for propane conversion kits, please see the latest

revision of Modine Bulletin 75-513 for Control Code 34 units

and 75-515 for Control Code 11 and 12 units.

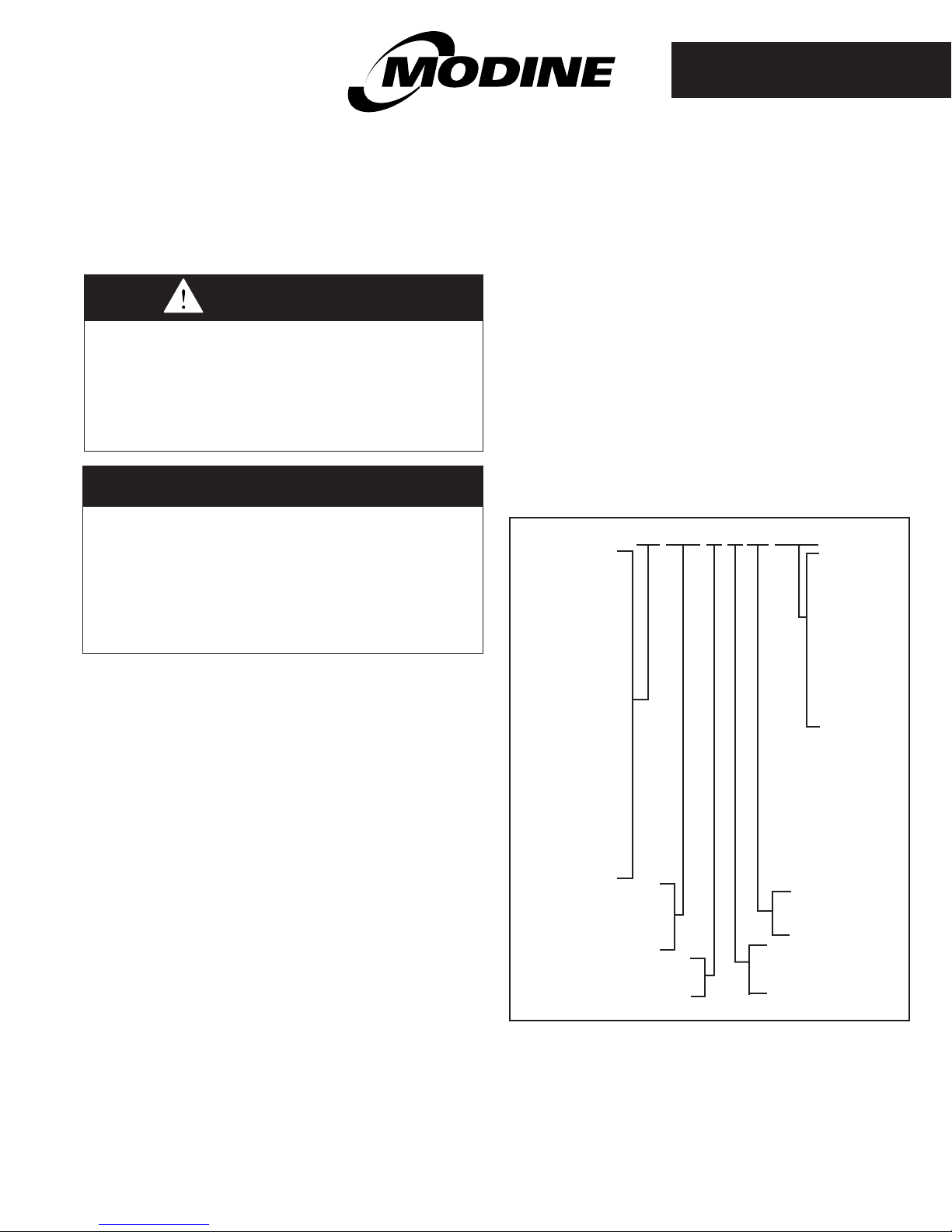

Figure 1.1 - Model Number Designations

HD 45 A S 01 1 1

Model Type

(Tubular HX)

HD - Power Vented

Propeller Unit

(30-125MBH)

HDB - Power Vented

Blower Unit

(60-125MBH)

HDS - Separated

Combustion

Propeller Unit

(30-125MBH)

HDC - Separated

Combustion Blower

Unit (60-125MBH)

PTS - Separated

Combustion Propeller

Unit (150-400MBH)

BTS - Separated

Combustion Blower

Unit (150-400MBH)

PTC - High Efficiency,

Separated Combustion

Propeller Unit

(135-310MBH)

MBH Input

30 - 30,000 Btu/hr input

through

400 - 400,000 Btu/hr input

Heat Exchanger Type

A - Aluminized

S - Stainless Steel

Power Code

01 - 115 volt, 60 hertz,

single phase

Ignition Type

H - Hot Surface

S - Direct Spark

Control Code

11 - Single Stage,

Natural Gas

12 - Two Stage,

Natural Gas

21 - Single Stage,

Propane Gas

22 - Two Stage,

Propane Gas

34 - Single Stage,

Natural Gas

74 - Single Stage,

Propane Gas

PLEASE BE SURE TO LEAVE IT WITH THE OWNER WHEN YOU LEAVE THE JOB.

THIS MANUAL IS THE PROPERTY OF THE OWNER.

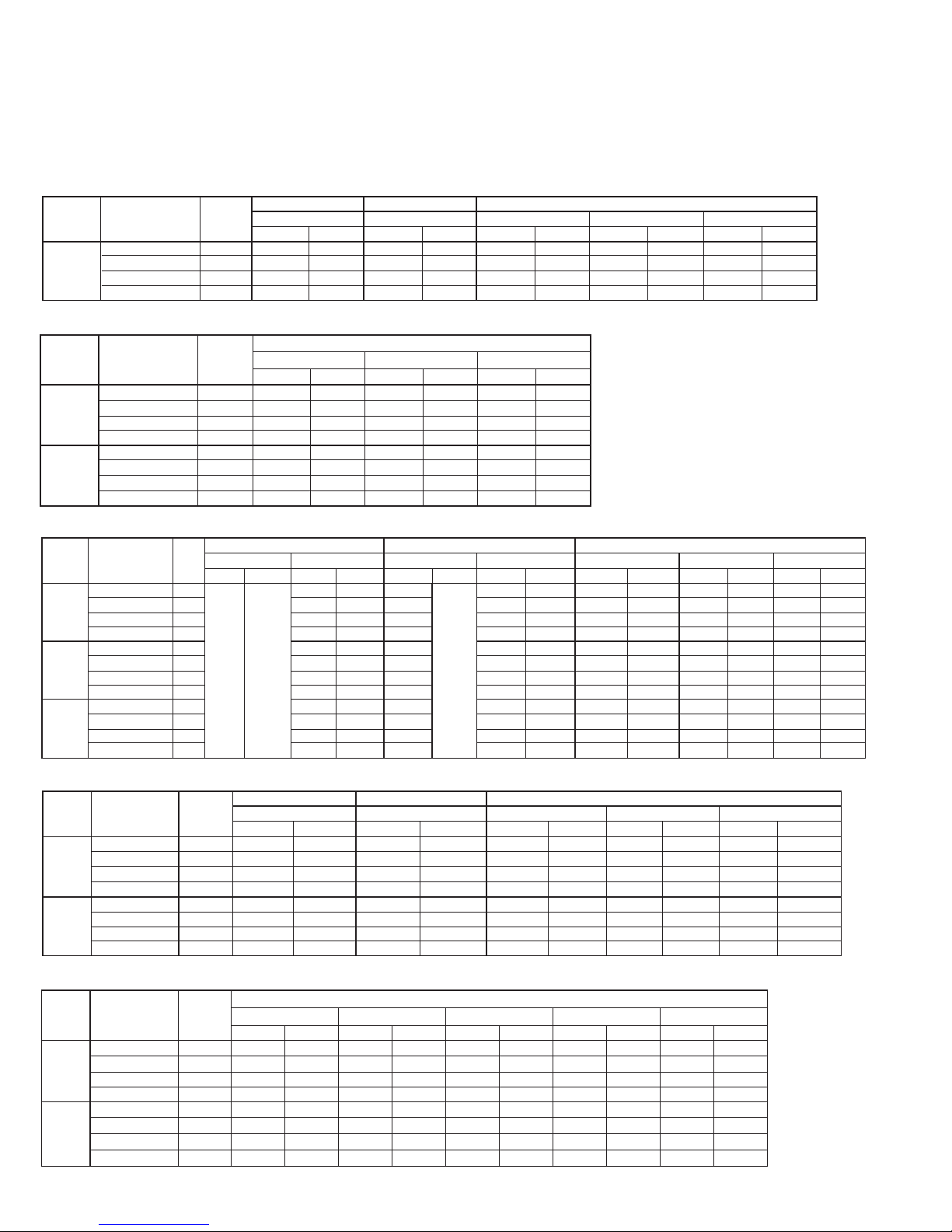

SELECTION OF THE PROPER KIT

Model

Size

Kit Details

Qty per

Kit

U.S.A. and Canada

7501-8000 ft

8001 - 8500 ft

8501-9000 ft

9001 - 9500 ft

9501-10000 ft

NAT

PROP

NAT

PROP

NAT

PROP

NAT

PROP

NAT

PROP

100

Kit Suffix

-

-40

-42

-40

-42

-40

-42

-40

-20

-43

-20

Item Code

-

53184

53213

53184

53213

53184

53213

53184

47336

55576

47336

Orifice

5

49

56

49

56

49

56

49

57

50

57

Pressure Sw

1

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

125

Kit Suffix

-

-37

-41

-37

-41

-37

-41

-38

-42

-38

-42

Item Code

-

53178

53212

53178

53212

53178

53212

53182

53213

53182

53213

Orifice

5

45

55

45

55

45

55

46

56

46

56

Pressure Sw

1

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Example: Convert a HDS125AS0112 for at 6000 feet elevation.

The appropriate model size is HDS125 with a Control Code of 12, which is for natural gas. Referring to Tables 2.1 through 3.2, it

can be identified that Table 2.4 should be used as it applies to HDS125 models for the elevation and gas type of this example.

In the column for 5501 - 6500 feet elevation and natural gas, it can be seen that the kit suffix is -30. All conversion kits have the same

base number, only the suffix of the part number changes by model size. The full kit number is 3H035031-30. The Item Code is 53165.

Table 2.1 - High Altitude Kits for HD/HDB 30-75 Models ONLY (7501 ft. and up in Table 2.2)

Model

Size

30-75

Kit Details

Kit Suffix

Item Code - 31669 31671 34503 31671 31669 31671 31669 31672 31670 31673

Orifice

Pressure Sw

Qty per

Kit

- -1 -3 -6 -3 -1 -3 -1 -4 -2 -5

5 51 57 50 57 51 57 51 58 52 59

1 NA NA NA NA NA NA NA NA NA NA

Table 2.2 - High Altitude Kits for HD/HDB 30-75 Models ONLY

Model

Size

30-60

75

Kit Details

Kit Suffix

Item Code

Orifice

Pressure Sw

Kit Suffix

Item Code

Orifice

Pressure Sw

Qty per

Kit

- -2 -5 -7 -11 -9 -13

5 52 59 52 60 53 61

1 NA NA NA NA NA NA

- -2 -5 -8 -12 -10 -14

5 52 59 52 60 53 61

1 NA NA Yes Yes Yes Yes

U.S.A Canada U.S.A. and Canada

2001-4500 ft 2001-4500 ft 4501-5500 ft 5501-6500 ft 6501-7500 ft

NAT PROP NAT PROP NAT PROP NAT PROP NAT PROP

U.S.A. and Canada

7501-8500 ft 8501 - 9500 ft 9501-10000 ft

NAT PROP NAT PROP NAT PROP

31670 31673 45406 45411 45408 45413

31670 31673 45407 45412 45409 45414

Table 2.3 - High Altitude Kits for HDS/HDC 30-75 Models ONLY

Model

Size

30

45

60-75

Kit Details

Kit Suffix

Item Code

Orifice

Pressure Sw

Kit Suffix

Item Code

Orifice

Pressure Sw

Kit Suffix

Item Code

Orifice

Pressure Sw

Qty

per

2001-2500 ft 2501-4500 ft 2001-2500 ft 2501-4500 ft

Kit

NAT PROP NAT PROP NAT PROP NAT PROP

-

5 51 57 50 51 57

1 NA NA NA NA NA

- -15 -16 -6 -15 -17

5 51 51 50 51 57

1 Yes Yes NA Yes Yes

Not Required

- -16 -18 -6 -16 -18

5 51 57 50 51 57

1 Yes Yes NA Yes Yes

U.S.A Canada

-1 -3 -6

31669 31671 34503 31669 31671

47331 47332 34503 47331 47333

Not Required

47332 47334 34503 47332 47334

-1 -3

Not Required

4501-5500 ft 5501-6500 ft 6501-7500 ft

NAT PROP NAT PROP NAT PROP

-16 -18 -21 -22 -23 -26

47332 47334 47337 47338 47339 47342

51 57 51 57 52 59

Yes Yes Yes Yes Yes Yes

-19 -20 -16 -18 -24 -27

47335 47336 47332 47334 47340 47343

51 57 51 57 52 59

Yes Yes Yes Yes Yes Yes

-16 -18 -21 -22 -25 -28

47332 47334 47337 47338 47341 47344

51 57 51 57 52 59

Yes Yes Yes Yes Yes Yes

U.S.A and Canada

Table 2.4 - High Altitude Kits for HD/HDB, HDS/HDC Model Sizes 100 and 125 (7501 ft. and up in Table 2.5)

Model

Size

100

125

Kit Details

Kit Suffix

Item Code

Orifice

Pressure Sw

Kit Suffix

Item Code

Orifice

Pressure Sw

Qty per

Kit

- -32 -44 -31 -44 -32 -44 -33 -36 -39 -42

5 47 1.25mm 46 1.25mm 47 1.25mm 48 56 48 56

1 NA NA NA NA NA NA NA NA Yes Yes

- -29 -34 -29 -34 -29 -34 -30 -35 -37 -41

5 43 54 43 54 43 54 44 54 45 55

1 NA NA NA NA NA NA Yes Yes Yes Yes

U.S.A Canada U.S.A. and Canada

2001-4500 ft 2001-4500 ft 4501-5500 ft 5501-6500 ft 6501-7500 ft

NAT PROP NAT PROP NAT PROP NAT PROP NAT PROP

53170 55577 53166 55577 53170 55577 53171 53177 53183 53213

53164 53172 53164 53172 53164 53172 53165 53176 53178 53212

Table 2.5 - High Altitude Kits for HD/HDB, HDS/HDC Model Sizes 100 and 125

22

75-537.7

SELECTION OF THE PROPER KIT

Table 3.1 - High Altitude Kits for PTS/BTS Models

Model

Size

150

175

200

250

300

350

400

Kit Details

Kit Suffix

Item Code - 55776 55779 55776 55779 55776 55779 55777 55779 55778 55780

Orifice

Pressure Sw

Kit Suffix

Item Code - 55781 55784 55781 55784 55782 55784 55782 55784 55783 55785

Orifice

Pressure Sw

Kit Suffix

Item Code - 55786 55790 55786 55790 55787 55791 55788 55792 55789 55792

Orifice

Pressure Sw

Kit Suffix

Item Code - 55793 55798 55794 55799 55795 55800 55796 55800 55797 55801

Orifice

Pressure Sw

Kit Suffix

Item Code - 55802 55806 55802 55806 55803 55806 55804 55807 55805 55808

Orifice

Pressure Sw

Kit Suffix

Item Code - 55809 55813 55809 55813 55810 55813 55811 55814 55812 55815

Orifice

Pressure Sw

Kit Suffix

Item Code - 55816 55820 55816 55820 55817 55820 55818 55821 55819 55822

Orifice

Pressure Sw

Qty per

Kit

- -45 -48 -45 -48 -45 -48 -46 -48 -47 -49

6 43 54 43 54 43 54 44 54 45 55

1 NA NA NA NA NA NA NA NA NA NA

- -50 -53 -50 -53 -51 -53 -51 -53 -52 -54

7 43 54 43 54 44 54 44 54 45 55

1 NA NA NA NA NA NA NA NA NA NA

- -55 -59 -55 -59 -56 -60 -57 -61 -58 -61

7 41 53 41 53 42 1.50mm 2.35mm 1.45mm 2.30mm 1.45mm

1 NA NA NA NA NA NA NA NA NA NA

- -62 -67 -63 -68 -64 -69 -65 -69 -66 -70

9 42 1.50mm 2.40mm 53 2.35mm 1.45mm 2.30mm 1.45mm 43 54

1 NA NA NA NA NA NA NA NA NA NA

- -71 -75 -71 -75 -72 -75 -73 -76 -74 -77

9 37 52 37 52 38 52 39 1.60mm 40 53

1 NA NA NA NA NA NA Yes Yes Yes Yes

- -78 -82 -78 -82 -79 -82 -80 -83 -81 -84

12 2.45mm 53 2.45mm 53 2.40mm 53 42 1.50mm 2.30mm 1.45mm

1 NA NA NA NA NA NA NA NA NA NA

- -85 -89 -85 -89 -86 -89 -87 -90 -88 -91

12 37 52 37 52 38 52 39 1.60mm 40 53

1 Yes Yes Yes Yes Yes Yes Yes Yes Yes Yes

U.S.A Canada U.S.A. and Canada

2001-4500 ft 2001-4500 ft 4501-5500 ft 5501-6500 ft 6501-7500 ft

NAT PROP NAT PROP NAT PROP NAT PROP NAT PROP

Table 3.2 - High Altitude Kits for PTC Models

Model

Size

135

155

180

215

260

310

Kit Details

Kit Suffix

Item Code

Orifice

Pressure Sw

Kit Suffix

Item Code

Orifice

Pressure Sw

Kit Suffix

Item Code

Orifice

Pressure Sw

Kit Suffix

Item Code

Orifice

Pressure Sw

Kit Suffix

Item Code

Orifice

Pressure Sw

Kit Suffix

Item Code

Orifice

Pressure Sw

Qty per

Kit

- -92 -94 -92 -94 -47 -49 -47 -49 -93 -95

-

6 2.15mm 1.35mm 2.15mm 1.35mm 45 55 45 55 47 1.25mm

1 NA NA NA NA NA NA NA NA NA NA

- -45 -96 -45 -96 -45 -48 -46 -48 -46 -94

-

6 43 1.45mm 43 1.45mm 43 54 44 54 44 1.35mm

1 NA NA NA NA NA NA NA NA NA NA

- -50 -61 -50 -61 -50 -53 -51 -53 -51 -97

-

7 43 1.45mm 43 1.45mm 43 54 44 54 44 1.35mm

1 NA NA NA NA NA NA NA NA NA NA

- -98 -70 -98 -70 -98 -101 -99 -101 -100 -102

-

9 44 54 44 54 44 1.35mm 2.15mm 1.35mm 45 55

1 NA NA NA NA NA NA NA NA NA NA

- -103 -68 -103 -68 -62 -68 -62 -69 -66 -69

-

9 41 53 41 53 42 53 42 1.45mm 43 1.45mm

1 NA NA NA NA NA NA NA NA NA NA

- -104 -84 -104 -84 -104 -106 -105 -106 -105 -107

-

12 43 1.45mm 43 1.45mm 43 54 44 54 44 1.35mm

1 NA NA NA NA NA NA NA NA NA NA

U.S.A. Canada U.S.A. and Canada

2001-4500 ft 2001-4500 ft 4501-5500 ft 5501-6500 ft 6501-7500 ft

NAT PROP NAT PROP NAT PROP NAT PROP NAT PROP

58152 58154 58152 58154 55778 55780 55778 55780 58153 58155

55776 58156 55776 58156 55776 55779 55777 55779 55777 58154

55781 55792 55781 55792 55781 55784 55782 55784 55782 58157

58158 55801 58158 55801 58158 58161 58159 58161 58160 58162

58163 55799 58163 55799 55793 55799 55793 55800 55797 55800

58164 55815 58164 55815 58164 58166 58165 58166 58165 58167

75-537.7

3

HIGH ALTITUDE KIT INSTALLATION

Installation of Kit

1. Read these instructions carefully. Failure to follow

instructions can damage product or cause a hazardous

condition.

2. This conversion kit must be installed by a qualified service

person. The qualified service agency performing this work

assumes responsibility for the proper conversion of this

appliance with this kit.

3. This kit contains the following:

•Highaltitudegasorifices

•Aconversionratingplate

•Apressureswitch(somemodels)

4. On the High Altitude Conversion Label (see Figure 4.1) write

the drill size, as stamped on the orifice, with a permanent

marker. Be sure to check correct orifice size using the

selection instructions beginning on page 1.

5. Remove the access panel to the heater.

6. Disconnect the gas supply piping to the heater.

7. Remove the electrical connections from the gas valve. This

should not require the use of tools.

8. Remove the four (4) screws holding the manifold to the

burner box. This will allow for the removal of the manifold

and gas valve assembly.

9. Remove the orifices from the manifold assembly and place

them where they can be used if the heater should need to be

converted back to natural gas.

10. Insert the orifices from the kit into the manifold assembly. If

you are converting a model size below 75 there will be extra

orifices, which should be discarded. Tighten the orifices

using a wrench so that they are gas tight.

11. Place the manifold assembly back on the burner box using

the four (4) screws.

12. Replace the electrical connections to the gas valve.

13. Verify that the igniter and sensor are in the same location

and have not been damaged.

14. Connect the gas supply piping to the heater using two

wrenches so as to not place strain on the heater gas

manifold.

15. For units requiring pressure switch change (refer to Tables

2.1 through 3.2), disconnect wires and remove screws.

Install new switch and attach wires. Note: wires are

interchangeable.

16. Affix the High Altitude Conversion Label that came with the

kit on the heater, near the serial plate on the same panel as

the common replacement parts label.

Check

1. See the original rating plate for the unit heater’s rated input

and verify by checking the correct main burner orifice size

and manifold pressure. This information is presented on the

conversion kit rating plate.

2. Remove the inlet and outlet pressure tap plugs and place

pressure taps on both the inlet and outlet pressure tap of the

gas valve.

3. Connect a pressure-measuring device capable of reading

inches of water column on both the inlet and outlet pressure

tap.

4. Follow lighting instructions on unit. Turn up thermostat setting

to call for heat. After the main burners light, measure the

outlet (manifold) pressure of the combination gas control.

The pressure should be 3.5" W.C. for natural gas and 10"

W.C. for propane gas. The outlet pressure can be adjusted at

the control’s regulator. Turning the adjustment clockwise will

increase the outlet pressure while turning it counterclockwise

will decrease the pressure.

5. There are no adjustments that can be made to the burner

flame. Some yellow in the flame is acceptable as long as no

carbon (black soot) is being formed.

6. Turn the heater off and replace the inlet and outlet pressure

tap plugs.

7. Place the heater back into service and leak test the inlet and

outlet pressure tap plugs as well as the connection between

the gas valve and the manifold pipe and supply piping to the

valve.

Figure 4.1 - High Altitude Conversion Label

NOTICE

THIS APPLIANCE EQUIPPED FOR HIGH ALTITUDE.

IN U.S. ACCORDING TO ANSI Z223.1

IN CANADA, ACCORDING TO C.G.A. CERTIFICATION

MAIN BURNER ORIFICES CHANGED TO

PLACE THIS LABEL ADJACENT TO SERIAL PLATE.

DRILL

SIZE.

5H70857A

As Modine Manufacturing Company has a continuous product improvement program, it reserves the right to change design and specifications without notice.

© Modine Manufacturing Company 2009

Commercial Products Group

Modine Manufacturing Company

1500 DeKoven Avenue

Racine, WI 53403

Phone: 1.800.828.4328 (HEAT)

www.modine.com

Litho in USA

Loading...

Loading...