March, 2002

IINNSSTTAALLLLAATTIIOONN AANNDD SSEERRVVIICCEE MMAANNUUAALL

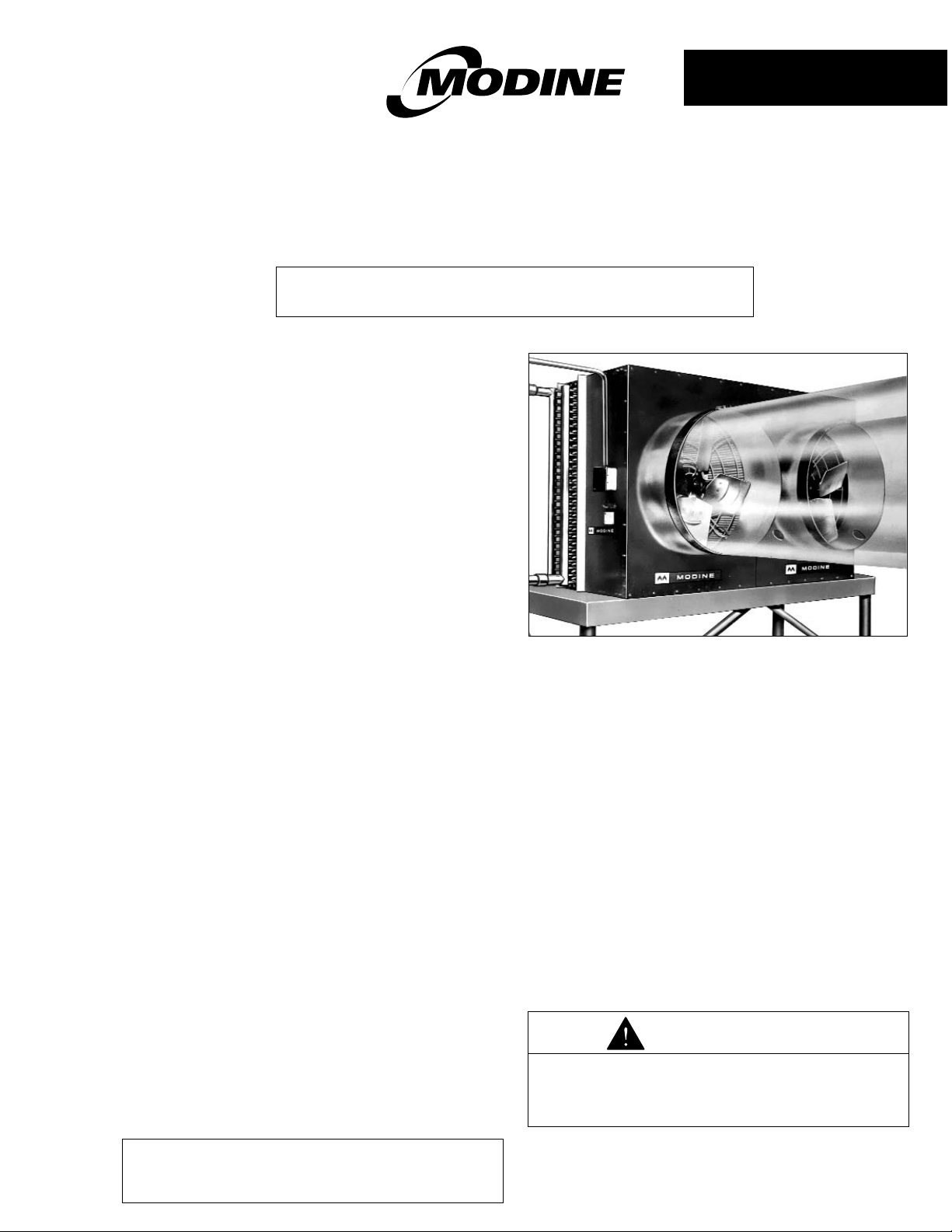

TTyyppee GGLLWW –– LLooww WWaatteerr TTeemmppeerraattuurree

GGrreeeennhhoouussee HHeeaattiinngg aanndd VVeennttiillaattiinngg UUnniittss

10-520.3

55HH7711775599 RReevv.. AA

IInnssppeeccttiioonn oonn AArrrriivvaall

1. Inspect unit upon arrival. In case of damage, report

immediately to transportation company and your local

Modine sales representative.

2. Check rating plate on unit and motor to verify that power

supply and motor specification requirements meet

available electric power at the point of installation.

3. Inspect unit received for conformance with description of

product ordered (including specifications where

applicable).

GGeenneerraall IInnffoorrmmaattiioonn

The heat exchanger is warranted for operation at hot water

pressures up to 300 lbs. per sq. in. gauge, and/or

temperatures up to 180°F.

SSppeecciiaall PPrreeccaauuttiioonnss

1. Disconnect power supply before making wiring

connections to prevent electrical shock and equipment

damage. All units must be wired strictly in accordance

with wiring diagram furnished with unit.

2. Units should not be installed in atmospheres where

corrosive fumes or sprays are present.

3. Units with power codes 01, 02, 03, 04, or 05 must not

be installed in potentially explosive or flammable

atmospheres.

4. Be sure no obstructions block air intake or air discharge

of unit.

LLooccaattiinngg GGLLWW UUnniittss

In locating units consider the general heating and ventilating

requirements of the greenhouse. Arranging units to simplify

piping and electrical supply systems should also be given

consideration.

IInnssttaalllliinngg GGLLWW UUnniittss

Because of their weight it is generally not feasible to

suspend a GLW unit from the roof supports of a

greenhouse. No provision for overhead suspension is

provided on GLW660S units. Brackets to facilitate overhead

suspension of model GLW330S units can be provided.

Normal practice is to place this GLW unit on a field

fabricated stand or platform that is fastened to the floor. Be

sure the means of support is adequate to suppor t the weight

of the unit. For proper operation the unit must be installed in

a level horizontal position.

MMOODDEELL GGLLWW666600SS

PPiippiinngg

Proper operation of the GLW greenhouse heating unit is

dependent on correct arrangement of unit piping.The points

listed below generally outline the areas which must be

considered. For more complete coverage on the subject of

piping, reference should be made to a reputable engineer’s

handbook or the ASHRAE guide.

1. Piping should be sized to properly handle the required

flow (GPM) of water.

2. In the absence of engineered data on an individual

application, piping the full size of the GLW unit

connections should be used. Supply and return runouts

must be the same size.The inlet is on the bottom. Inlet

and outlet connections are clearly marked on each GLW

unit.

3. Air must be continuously eliminated from the GLW unit

to secure rated performance and avoid premature coil

failure.

WWiirriinngg

All wiring must be done in accordance with the National

Electric Code and applicable local codes. In Canada, wiring

must conform to the Canadian Electric Code. Power supply

TTHHIISS MMAANNUUAALL IISS TTHHEE PPRROOPPEERRTTYY OOFF TTHHIISS OOWWNNEERR,, PPLLEEAASSEE

BBEE SSUURREE TTOO LLEEAAVVEE IITT WWIITTHH HHIIMM WWHHEENN YYOOUU LLEEAAVVEE TTHHEE JJOOBB..

As Modine Manufacturing Company has a continuous

product improvement program, it reserves the right to

change design and specifications without notice.

CAUTION

Disconnect power supply before making wiring

connections to prevent electrical shock and equipment

damage. All units must be wired strictly in accordance

with wiring diagram furnished with this unit.

22

IINNSSTTAALLLLAATTIIOONN//OOPPEERRAATTIIOONN

to these unit heaters must be protected by a fused disconnect

switch. It is recommended that all wiring be adequately

grounded.

WWiirriinngg

Electric wiring must be sized to carry the full load amp draw of

the motor, starter, and any controls that are used with the unit

heater.All units with power codes 04, 05, 08, or 09 (polyphase

motors) must be provided with suitable overcurrent protection

in circuit supplying heater at installation. Overcurrent

protectors should be sized based on motor current rating

shown on motor rating plate, and applicable national electric

code procedures.

All units are provided with electrical junction boxes.The

GLW660 may be field wired from either junction box.Any

damage to or failure of Modine units caused by incorrect

wiring of the units is not covered by Modine’s standard

warranty.See Page 4.

PPrriioorr ttoo OOppeerraattiioonn

1. Make sure fuses are installed in fused disconnect

switches.

2. Check all electrical connections to assure they are secure.

3. Check rigidity of unit mounting.Tighten all fasteners, if

necessary.

4. Inspect piping, strainers, fittings, etc.

IInniittiiaall SSttaarrtt--UUpp

1. Set thermostat to lowest position.

2. Turn on power supply to unit.

3. Open return gate valve, and then open supply gate valve

to unit.

4. Raise thermostat setting to desired position.

5. To insure proper sequence of operation, cycle unit on and

off a few times by raising and lowering thermostat setting.

6. Check for proper rotation of fan. All fans must rotate in a

counter-clockwise direction when viewed from the back of

the GLW unit.Do not attach polytubes to GLW unit until

proper rotation of fans is assured.

IInnssttaallllaattiioonn ooff PPoollyyeetthhyylleennee AAiirr

DDiissttrriibbuuttiinngg TTuubbee ((PPoollyyttuubbee))

TTuubbee IInnssttaallllaattiioonn

The polyethylene tube providing air distribution throughout the

greenhouse, is simply and directly connected to the heater

outlet transition with a gasket and a clamp.The clamp and

gasket are shipped attached to the unit.To install:

1. Remove clamp.

2. Thread a tube end through the clamp about 2 to 4 inches.

3. Orient the tube so that the distribution holes are in the

desired position.

4. Fit tube end clamp over the gasketed outlet transition and

secure clamp with a screwdriver.

5. Unroll tube to length desired and tie up opposite end.

6. Add air distribution holes as needed if polytube has been

shortened from standard length.

7. A minimum number of 100-3" diameter holes are required

for a 24" diameter polytube.

TTuubbee SSuussppeennssiioonn

For optimum air distribution the tube should be suspended

about 7 to 9 feet above the floor with the hoops and key rings

supplied.The tube must be hung without sharp bends or

twists.The hoops supplied are special straps of crosslaminated plastic for durability that include eyelets at each end

for clipping into key ring.The key rings, with strap and tube,

may be clipped onto either a long lead wire or an eyebolt in

the truss construction of the greenhouse. Because of the

variety of greenhouse constructions, no further provisions for

suspension are provided other than the hoops and key rings.

Recommended tube suspension with hoops is approximately

eight feet apart, which will be adequate for polytube weight

(12 lbs. per 100 feet) and sufficient to dampen out snapping

action when the tube is initially inflated. For wire suspension,

make sure the key rings are properly anchored, i.e., either

tied, taped, or looped into the wire to prevent shifting.While

the tube is inflated, stretch tube slightly and tie end to

greenhouse frame.This will reduce the chance of tube flutter

and increase the life of the tube.

RReeppllaacceemmeenntt PPaarrttss

All replacement parts and controls are proprietar y in that all

have been designed, tested, and approved for the particular

application to insure both physical and electrical fit and

performance. Any substitution of parts or controls not

approved by Modine will be at customer’s risk.

NNOOTTEE::

Modine Manufacturing Company reserves the right

to substitute parts of advanced design and to

change specifications or prices without advance

notice or without incurring obligations.

Replacement parts can be obtained by submitting the model

number, power code control code and serial number shown on

the rating plate attached to the unit, along with a description of

the part, to the Service Dept., Modine Manufacturing

Company, West Kingston, Rhode Island 02892.

33

PPEERRFFOORRMMAANNCCEE//DDIIMMEENNSSIIOONNSS

PPeerrffoorrmmaannccee DDaattee

Example of computing heating capacity in BTU/HR for model

GLW660S.

ETD is the difference between the entering water temperature

and the entering air temperature.

At 20 GPM with 100°F entering water temperature and 70°F

entering air temperature.

ETD = 100-70 = 30°F.

BTU/HR/°F of ETD from the curve = 4900

Heating capacity = 4900 x 30 = 147,000 BTU/HR.

Water pressure drip = 0.7 Ft. of water

Water temperature drop in °F =

DDiimmeennssiioonnss aanndd SSppeecciiffiiccaattiioonnss ––

MMooddeell GGLLWW666600SS,, GGLLWW333300SS

(All dimensions in inches)

HHoott WWaatteerr CCooiill

– 1/2" O.D.copper tubes; aluminum fins

– 1-1/2" MPT copper connections

– Frame - galvanized steel

– Maximum operating pressure - 300 PSI

– Maximum operating water temperature -

180°F

PPaanneellss aanndd TTrraannssiittiioonnss

– Galvanized steel

MMoottoorrss

– 1/2 H.P.; Single- or three-phase available (two

motors on GLW660S)

PPoollyyttuubbeess aarree AAvvaaiillaabbllee ffoorr SSppeecciiffiicc AApppplliiccaattiioonnss

–

24" diameter

AAiirr FFllooww

– GLW660S-7700 CFM;GLW330S-3850 CFM

WWeeiigghhtt

– GLW660S-380 Lbs.; GLW330S-200 Lbs.

BTU/HR

500 x GPM

6000

Model GLW660S

5000

4000

3000

Heating capacity

BTU/HR/ F of ETD

2000

1000

Model GLW330S

GLW660

GLW330

10

20 30 40 50

Water flow rate

gallons per minute

4.0

3.0

2.0

1.0

ft. of water

Water pressure drop

CCoommmmeerrcciiaall HHVVAACC&&RR DDiivviissiioonn

Modine Manufacturing Company

604 Liberty Lane

West Kingston, Rhode Island 02892

Phone: 1.800.828.4328 (HEAT)

FAX: 401.792.9041 (Service & Parts)

www.modine.com

3/02 - Litho in USA

MMooddiinnee wwaarrrraannttss iittss pprroodduuccttss ttoo bbee ffrreeee ffrroomm ddeeffeeccttss iinn mmaatteerriiaall aanndd

wwoorrkkmmaannsshhiipp,, eexxcclluussiivvee,, hhoowweevveerr,, ooff ffaaiilluurreess aattttrriibbuuttaabbllee ttoo tthhee uussee ooff

mmaatteerriiaallss ssuubbssttiittuutteedd uunnddeerr eemmeerrggeennccyy ccoonnddiittiioonnss ffoorr mmaatteerriiaallss nnoorrmmaallllyy

eemmppllooyyeedd.. TThhiiss wwaarrrraannttyy ccoovveerrss rreeppllaacceemmeenntt ooff aannyy ppaarrttss ffuurrnniisshheedd ffrroomm tthhee

ffaaccttoorryy ooff MMooddiinnee,, bbuutt ddooeess nnoott ccoovveerr llaabboorr ooff aannyy kkiinndd aanndd mmaatteerriiaallss nnoott

ffuurrnniisshheedd bbyy MMooddiinnee,, oorr aannyy cchhaarrggeess ffoorr aannyy ssuucchh llaabboorr oorr mmaatteerriiaallss,, wwhheetthheerr

ssuucchh llaabboorr,, mmaatteerriiaallss oorr cchhaarrggeess tthheerreeoonn aarree dduuee ttoo rreeppllaacceemmeenntt ooff ppaarrttss,,

aaddjjuussttmmeennttss,, rreeppaaiirrss,, oorr aannyy ootthheerr wwoorrkk ddoonnee.. TThhiiss wwaarrrraannttyy ddooeess nnoott aappppllyy ttoo

aannyy eeqquuiippmmeenntt wwhhiicchh sshhaallll hhaavvee bbeeeenn rreeppaaiirreedd oorr aalltteerreedd oouuttssiiddee tthhee ffaaccttoorryy

ooff MMooddiinnee iinn aannyy wwaayy ssoo aass,, iinn tthhee jjuuddggeemmeenntt ooff MMooddiinnee,, ttoo aaffffeecctt iittss ssttaabbiilliittyy,,

nnoorr wwhhiicchh hhaass bbeeeenn ssuubbjjeecctteedd ttoo mmiissuussee,, nneegglliiggeennccee,, oorr ooppeerraattiinngg ccoonnddiittiioonnss

iinn eexxcceessss ooff tthhoossee ffoorr wwhhiicchh ssuucchh eeqquuiippmmeenntt wwaass ddeessiiggnneedd..

BUYER AGREES THAT MODINE’S WARRANTY OF ITS PRODUCTS TO BE

FREE FROM DEFECTS IN MATERIAL AND WORKMANSHIP, AS LIMITED

HEREIN, SHALL BE IN LIEU OF AND EXCLUSIVE OF ALL OTHER

WARRANTIES, EITHER EXPRESS OR IMPLIED, WHETHER ARISING

FROM LAW, COURSE OF DEALING, USAGE OF TRADE, OR OTHERWISE.

TTHHEERREE AARREE NNOO OOTTHHEERR WWAARRRRAANNTTIIEESS,, IINNCCLLUUDDIINNGG WWAARRRRAANNTTYY OOFF

MMEERRCCHHAANNTTAABBIILLIITTYY OORR FFIITTNNEESSSS FFOORR PPUURRPPOOSSEE,, WWHHIICCHH EEXXTTEENNDD

BBEEYYOONNDD TTHHEE DDEESSCCRRIIPPTTIIOONN OONN TTHHEE FFAACCEE HHEERREEOOFF..

BUYER’S REMEDY FOR BREACH OF WARRANTY, EXCLUSIVE OF ALL

OTHER REMEDIES PROVIDED BY LAW, IS LIMITED TO REPAIR OR

REPLACEMENT AT THE FACTORY OF MODINE, ANY PART OF PARTS

WHICH SHALL, WITHIN ONE YEAR FROM DATE OF FIRST BENEFICIAL

USE BY BUYER OR ANY OTHER USER, WITHIN ONE YEAR FROM DATE

OF RESALE BY BUYER IN ANY UNCHANGED CONDITION, OR WITHIN

EIGHTEEN MONTHS FROM DATE OF SHIPMENT FROM MODINE,

WHICHEVER OCCURS FIRST, BE RETURNED THERETO WITH

TRANSPORTATION CHARGES PREPAID AND WHICH THE EXAMINATION

OF MODINE SHALL DISCLOSE TO HAVE BEEN DEFECTIVE;EXCEPT

THAT WHEN THE PRODUCT IS TO BE USED BY BUYER AS A

COMPONENT PART OF EQUIPMENT MANUFACTURED BY BUYER,

BUYER’S REMEDY FOR BREACH, AS LIMITED HEREIN, SHALL BE

LIMITED TO ONE YEAR FROM DATE OF SHIPMENT FROM MODINE.

BUYER AGREES THAT IN NO EVENT WILL MODINE BE LIABLE FOR

COSTS OF PROCESSING, LOST PROFITS, INJURY TO GOODWILL, OR

ANY OTHER CONSEQUENTIAL OR INCIDENTAL DAMAGES OF ANY KIND

RESULTING FROM THE ORDER OR USE OF ITS PRODUCT, WHETHER

ARISING FROM BREACH OF WARRANTY, NONCONFORMITY TO

ORDERED SPECIFICATIONS, DELAY IN DELIVERY, OR ANY LOSS

SUSTAINED BY THE BUYER.

Modine warrants Polytube (Air Distribution Tubes) for a period of three

months from date of first beneficial use by buyer or any other user, within

three months from date of resale by Buyer in any unchanged condition, or

within six months from date of shipment from Modine, whichever occurs first.

IInnssppeecctt RReegguullaarrllyy

Under average conditions, it is recommended that GLW

units be inspected before every heating season. Check for

dirty, clogged condensers, excessive vibration and loose

connections.

MMoottoorrss

AA.. CClleeaanniinngg

Remove grease and dirt on motor during each

inspection or lubrication, or whenever condensers are

cleaned, whichever is sooner.

BB.. LLuubbrriiccaattiioonn

1. Lubricate motor according to manufacturer’s

instructions located on the motor.

2. When no motor oiling instructions are on the motor,

oil the motor every two thousand hours of operation

with SAE20 motor oil for units in normal

applications. Adjust oiling according to usage and

atmosphere.

3. Some motors do not have oil fittings.These motors

are lubricated for long life and do not require further

lubrication.

CC.. OOvveerrllooaadd PPrrootteeccttiioonn

A change in line voltage higher or lower than motor

nameplate rating may cause overheating and serious

motor damage. Check voltage conditions.A separate

manual starter with thermal overload protection device is

recommended for those units that do not have motors

with built-in overload protection.

CCoonnddeennsseerrss

AA.. CClleeaanniinngg

Clean condenser at least once a year; more often under

unfavorable conditions.Unless condenser is kept

reasonably free of dirt, lint and grease, its original

heating capacity will be reduced…possibly to a serious

degree, and motor damage may result.

BB.. IInntteerrnnaall CCoorrrroossiioonn SSaaffeegguuaarrddss

Provide controlled water treatment…Contact your

compound supplier for proper usage or the services of a

water treatment laboratory.

Periodic internal flushing of the coils is recommended in

areas where water supply is suspected of causing scale.

CCaassiinnggss

AA.. CClleeaanniinngg

Periodic cleaning of casings is recommended to remove

dirt, grease and corrosive substances that may injure

finish.

BB.. GGeenneerraall IInnssppeeccttiioonn

Tighten fan guard and motor bracket, Check fan for

proper clearance, free rotation and firm connection to

shaft.

When servicing is complete, tag unit to indicate date of

inspection, lubrication and cleaning.

MMAAIINNTTEENNAANNCCEE

WARNING

Using inorganic or mineral acids such as muriatic

(hydrochloric) acid, even though inhibited, may lead to

severe damage, including corrosion and leakage.

WWAARRRRAANNTTYY

© Modine Manufacturing Company 2002

Loading...

Loading...