6-553.3

5H73889A (Rev. D)

April, 2002

NSTALLATION AND SERVICE MANUAL

I

gas-fired unit heaters

models PD and BD

All models approved for use in California by the CEC (when

equipped with IPI), in New York by the MEA division, and in

Massachusetts. Unit heater is certified for non-residential

applications.

WARNING

Improper installation, adjustment,

alteration, service or maintenance can cause

property damage, injury or death, and could

cause exposure to substances which have

been determined by various state agencies to

cause cancer, birth defects or other

reproductive harm. Read the installation,

operating and maintenance instructions

throroughly before installing or servicing this

equipment.

CAUTION

To prevent premature heat exchanger failure do

not locate ANY gas-fired units in areas where

chlorinated, halogenated, or acid vapors are

present in the atmosphere.

IMPORTANT

The use of this manual is specifically intended

for a qualified installation and service agency.

A qualified installation and service agency must

perform all installation and service of these

appliances.

Contents

Inspection on arrival ................................................................1

Installation (including venting)..............................................2-8

Operation ...........................................................................9-10

Checking input rate ...............................................................11

Dimensional data .............................................................12-13

Performance data.............................................................12-19

Service instructions – safety devices..............................20-21

Service instructions – general...............................................22

Troubleshooting................................................................22-24

Motor data........................................................................25-26

Model identification ...............................................................26

Control options ......................................................................27

Warranty ..................................................................Back cover

Pages

FOR YOUR SAFETY

IF YOU SMELL GAS:

1. Open windows.

2. Don’t touch electrical switches.

3. Extinguish any open flame.

4. Immediately call your gas supplier.

FOR YOUR SAFETY

The use and storage of gasoline or other

flammable vapors and liquids in open containers

in the vicinity of this appliance is hazardous.

Inspection on Arrival

1. Inspect unit upon arrival. In case of damage, report

immediately to transportation company and your local

Modine sales representative.

2.

Check rating plate on unit to verify that power supply meets

available electric power at the point of installation.

3. Inspect unit received for conformance with description of

product ordered (including specifications where applicable).

THIS MANUAL IS THE PROPERTY OF THE OWNER.

PLEASE BE SURE TO LEAVE IT WITH THE OWNER WHEN YOU LEAVE THE JOB.

Heater Parts from ACF Greenhouses

INSTALLATION

SPECIAL PRECAUTIONS

THE INSTALLATION AND MAINTENANCE INSTRUCTIONS IN THIS

MANUAL MUST BE FOLLOWED TO PROVIDE SAFE, EFFICIENT

AND TROUBLE-FREE OPERATION. IN ADDITION, PARTICULAR

CARE MUST BE EXERCISED REGARDING THE SPECIAL

PRECAUTIONS LISTED BELOW. FAILURE TO PROPERLY

ADDRESS THESE CRITICAL AREAS COULD RESULT IN

PROPERTY DAMAGE OR LOSS, PERSONAL INJURY, OR DEATH.

1. Disconnect power supply before making wiring connections to

prevent electrical shock and equipment damage. All units must be

wired strictly in accordance with wiring diagram furnished with the

unit.

2. Turn off all gas before installing unit heaters.

3. Gas pressure to unit heater controls must never exceed 14” W.C.

(1/2 psi).

When leak testing the gas supply piping system, the unit and its

combination gas control must be isolated during any pressure

testing in excess of 14" W.C. (1/2 psi).

The unit should be isolated from the gas supply piping system by

closing its field installed manual shut-off valve during any pressure

testing of the gas supply piping system.

4. Check gas inlet pressure at unit upstream from the combination gas

control. The inlet pressure should be 6”-7” W.C. on natural gas or

12”-14” W.C. on propane gas. Purging of gas piping should be

performed as described in ANSI Z223.1 Latest Edition, or in

Canada in CAN/CGA-B149 codes.

5. All units must be vented to the outside atmosphere.

6. Do not install in potentially explosive or flammable atmospheres

laden with grain dust, sawdust, or similar air-borne materials. In

such applications a blower type heater installed in a separate room

with ducting, including appropriate back flow prevention dampers, to

the dust-laden room is recommended.

7. Installation of units in high humidity or salt water atmospheres will

cause accelerated corrosion resulting in a reduction of the normal

life span of the units.

8. To prevent premature heat exchanger failure do not locate ANY gasfired unit in areas where chlorinated, halogenated or acid vapors

are present in the atmosphere.

9. Avoid installing units in extremely drafty locations. Drafts can cause

burner flames to impinge on heat exchangers which shortens life.

Maintain separation between units so discharge from one unit will

not be directed into the inlet of another.

10. Do not locate units in tightly sealed rooms or small compartments

without provision for adequate combustion air and venting.

Combustion air must have access to the confined space through a

minimum of two permanent openings in the enclosure, at least one

near the bottom. They should provide a free area of one square inch

per 1000 BTU per hour input rating of the unit with a minimum of

100 square inches for each opening, whichever is greater.

11. Do not install unit outdoors.

12. For all sizes, minimum clearance to combustibles from the bottom is

12" and from the sides 18"; for PD sizes 30-50 from the top is 1"

and from the flue collar 2"; for PD sizes 75-300 from the top is 2"

and from the flue collar is 3"; for PD 350 from the top is 3" and from

the flue collar is 4"; for PD 400 from the top is 4" and from the flue

collar is 5"; and for all BD sizes from the top and flue collar is 6".

13. Allow at least 6” clearance at the sides and 12” clearance at rear (or

6” beyond end of motor at rear of unit, whichever is greater) to

provide ample air for combustion and proper operation of fan.

14. The minimum distance from combustible materials based on the

combustible material surface not exceeding 160°F. Clearance from

the top of the unit may be required to be greater than 6” if heat

damage, other than fire, may occur to materials above the unit

heater at the temperature described.

15. Do not install units below 7 feet measured from the bottom of the

unit to the floor.

16. Modine unit heaters are designed for use in heating applications

with ambient temperatures between 32° F and 90° F If an

application exists where ambient temperatures can be expected to

fall outside of this range, contact factory for recommendations.

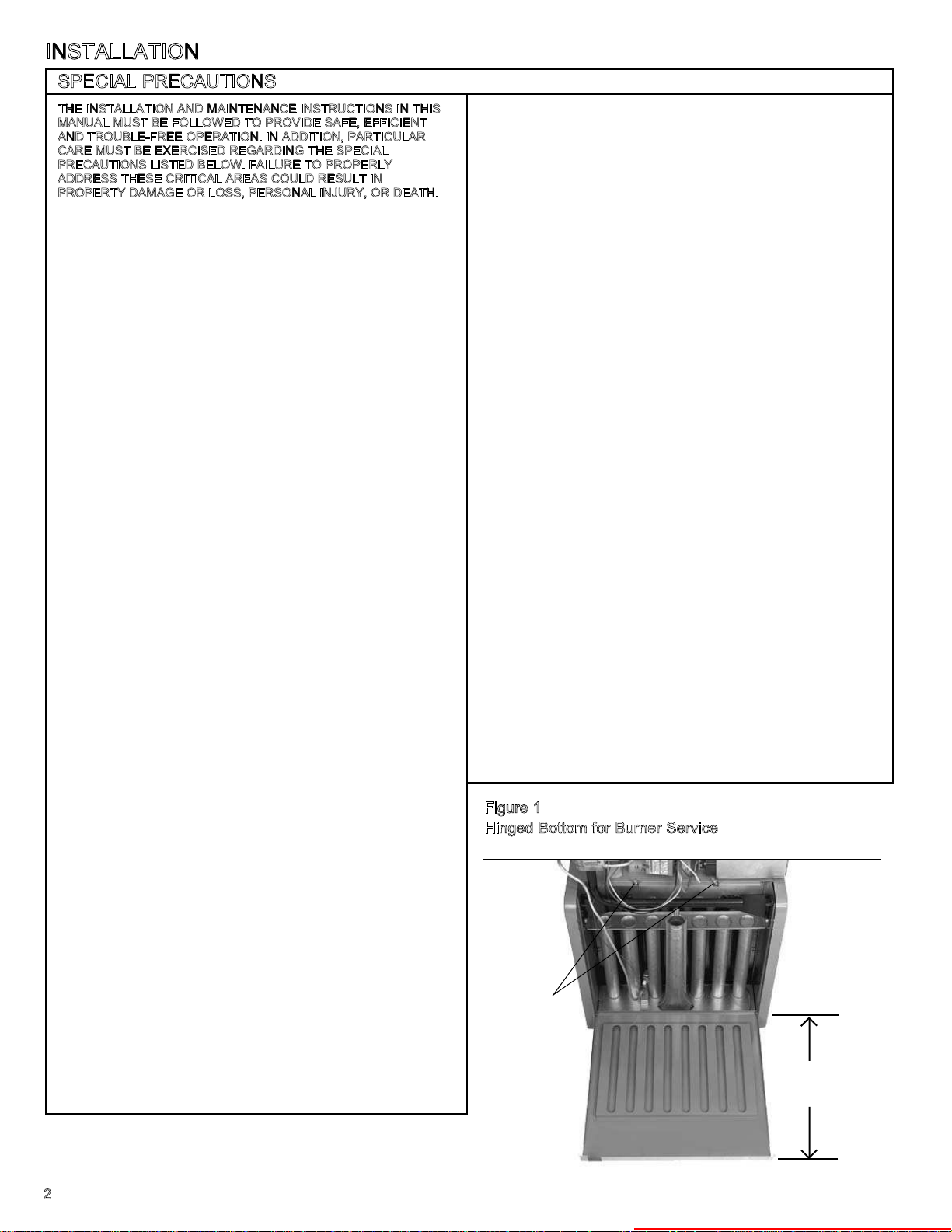

17. Provide clearance for opening hinged bottom for servicing. See

Figure 1. Do not set unit on its bottom.

18. To assure that flames do not impinge on heat exchanger surfaces,

the unit must be suspended in a vertical and level position. Failure

to suspend unit properly may shorten the life of the unit heater.

19. Do not lift unit heater by gas controls, gas manifold, or power

exhauster.

20.

Be sure no obstructions block air intake and discharge of unit heater.

21. Do not attach duct work, air filters, or polytubes to any propeller

(PD) model unit heaters.

22. In aircraft hangars, keep the bottom of the unit at least 10’ from the

highest surface of the wings or engine enclosure of the highest

aircraft housed in the hangar and in accordance with the

requirements of the enforcing authority and/or NFPA No. 409 –

Latest Edition .

23. In garages or other sections of aircraft hangars such as offices and

shops which communicate with areas used for servicing or storage,

keep the bottom of the unit at least 7’ above the floor. In public

garages, the unit must be installed in accordance with the Standard

for Parking Structures NFPA #88A and the Standard for Repair

Garages NFPA #88B. In Canada, installation of unit heaters in

airplane hangars must be in accordance with the requirements of

the enforcing authority, and in public garages in accordance with the

current CAN/CGA-B149 codes.

24. Consult piping, electrical, and venting instructions in this manual

before final installation.

25. All literature shipped with your unit should be kept for future use for

servicing or service diagnosis. Do not discard any literature shipped

with your unit.

26. Gas-fired heating equipment which has been improperly vented, or

which experiences a blocked vent condition may have the flue

gases accidentally spilled into the heating space. See page 20 for

specific information about the blocked vent safety switch supplied on

the unit.

27.

When servicing or repairing this equipment, use only Modine

approved service replacement parts. A complete replacement parts

list may be obtained by contacting Modine Manufacturing Company.

Refer to the rating plate on the unit for complete unit model number,

serial number and company address. Any substitution of parts or

controls not approved by Modine will be at owners risk.

Figure 1

Hinged Bottom for Burner Service

*(See Dimension "C", page 12)

WING SCREWS

THAT SECURE

HINGED

BOTTOM

THIS IS

DIMENSION C,

SEE PAGE 12

2

Heater Parts from ACF Greenhouses

INSTALLATION

In the U.S., the installation of these units must comply with the

“National Fuel Gas Code,” ANSI Z223.1, latest edition (also known

as NFPA 54) and other applicable local building codes.

In Canada, the installation of these units must comply with local

plumbing or waste water codes and other applicable codes and

with the current code CAN/CGA-B149.1, “Installation Code for

Natural Gas Burning Appliances and Equipment” or CAN/CGAB149.2, “Installation Code for Propane Burning Appliances and

Equipment.”

1. All installation and service of these units must be performed by

a qualified installation and service agency only as defined in

ANSI Z223.1, latest edition or in Canada by a licensed gas fitter.

2. This unit is certified by C.S.A., with the controls furnished. For

replacement parts, submit the complete model and serial

numbers shown on rating plate on the unit. Modine reserves the

right to substitute other authorized controls as replacements.

3. Unit is balanced for correct performance. Do not alter fan or

operate motors at reduced speed.

4. Information on controls is supplied separately.

5. Modine unit heaters use the same burner for natural and

propane gases.

L

ocating Unit Heaters

CAUTION

Units must not be installed in potentially explosive,

flammable, or corrosive atmosphere.

To prevent premature heat exchanger failure do not locate

ANY gas-fired unit in areas where chlorinated, halogenated

or acid vapors are present in the atmosphere.

In locating units, consider general space-heating requirements,

availability of gas, and proximity to vent locations. Unit heaters

should be located so heated air streams wipe exposed walls

without blowing directly against them. In multiple unit installations,

arrange units so that each supports the air stream from another,

setting up circulatory air movement in the area, but maintain

separation between units so discharge from one unit will not be

directed into the inlet of another. In buildings exposed to prevailing

winds, a large portion of the heated air should be directed along the

windward wall. Avoid interference of air streams as much as

possible.

Mounting height (measured from bottom of unit) at which unit

heaters are installed is critical. Maximum mounting heights are

listed in Table 7 on page 18. Alternate mounting heights for units

with deflector hoods or nozzles are shown on pages 14,16 and 17.

The maximum mounting height for any unit is that height above

which the unit will not deliver heated air to the floor.The maximum

mounting heights must not be exceeded in order to assure

maximum comfort.

Modine unit heaters are designed for use in heating applications

with ambient temperatures between 32° F and 90° F. If an

application exists where ambient temperatures can be expected to

fall outside of this range, contact factory for recommendations.

C

ombustion Air Requirements

Units installed in tightly sealed buildings or confined spaces should

be provided with two permanent openings, one near the top of the

enclosure and one near the bottom. Each opening should have a

free area of not less than one square inch per 1,000 BTU per hour

of the total input rating of all units in the enclosure, freely

communicating with interior areas having, in turn, adequate

infiltration from the outside.

U

nit Suspension

The most common method of hanging Modine gas unit heaters is

to utilize 3/8" threaded rod. On each piece of threaded rod used,

screw a nut a distance of about one inch onto the end of the

threaded rods that will be screwed into the unit heater. Then put a

washer over the end of the threaded rod and screw the threaded

rod into the unit heater weld nuts on the top of the heater at least 5

turns, and no more than 10 turns. Tighten the nut you first installed

onto the threaded rod to prevent it from turning. Drill holes into a

steel channel or angle iron at the same centerline dimensions as

the heater that is being installed. The steel channels or angle iron

pieces need to span and be fastened to appropriate structural

members. Cut the threaded rods to the preferred length, push

them through the holes in the steel channel or angle iron and

secure with washers and lock nuts or lock washers and nuts. A

double nut arrangement can be used here instead of at the unit

heater (a double nut can be used both places but is not necessary).

The entire means of suspension must of course be adequate to

support the weight of the unit (see page 14 and 15 for unit weights).

For proper operation, the unit must be installed in a level horizontal

position. Clearances to combustibles as specified above must be

strictly maintained. Do not install standard unit heaters above the

maximum mounting height shown in Table 7 on page 13, or below

seven feet from the bottom of the unit to the floor.

CAUTION

For all sizes, minimum clearance to combustibles from the

bottom is 12" and from the sides 18"; for PD sizes 30-50 from

the top is 1" and from the flue collar 2"; for PD sizes 75-300

from the top is 2" and from the flue collar is 3"; for PD 350

from the top is 3" and from the flue collar is 4"; for PD 400

from the top is 4" and from the flue collar is 5"; and for all BD

sizes from the top and flue collar is 6".

Allow at least 12" at the rear or 6" beyond the end of the

motor (whichever is greater), to provide ample air for

combustion and for proper operation of fan. Provide clearance

for opening at the hinged bottom for servicing - See Figure 1.

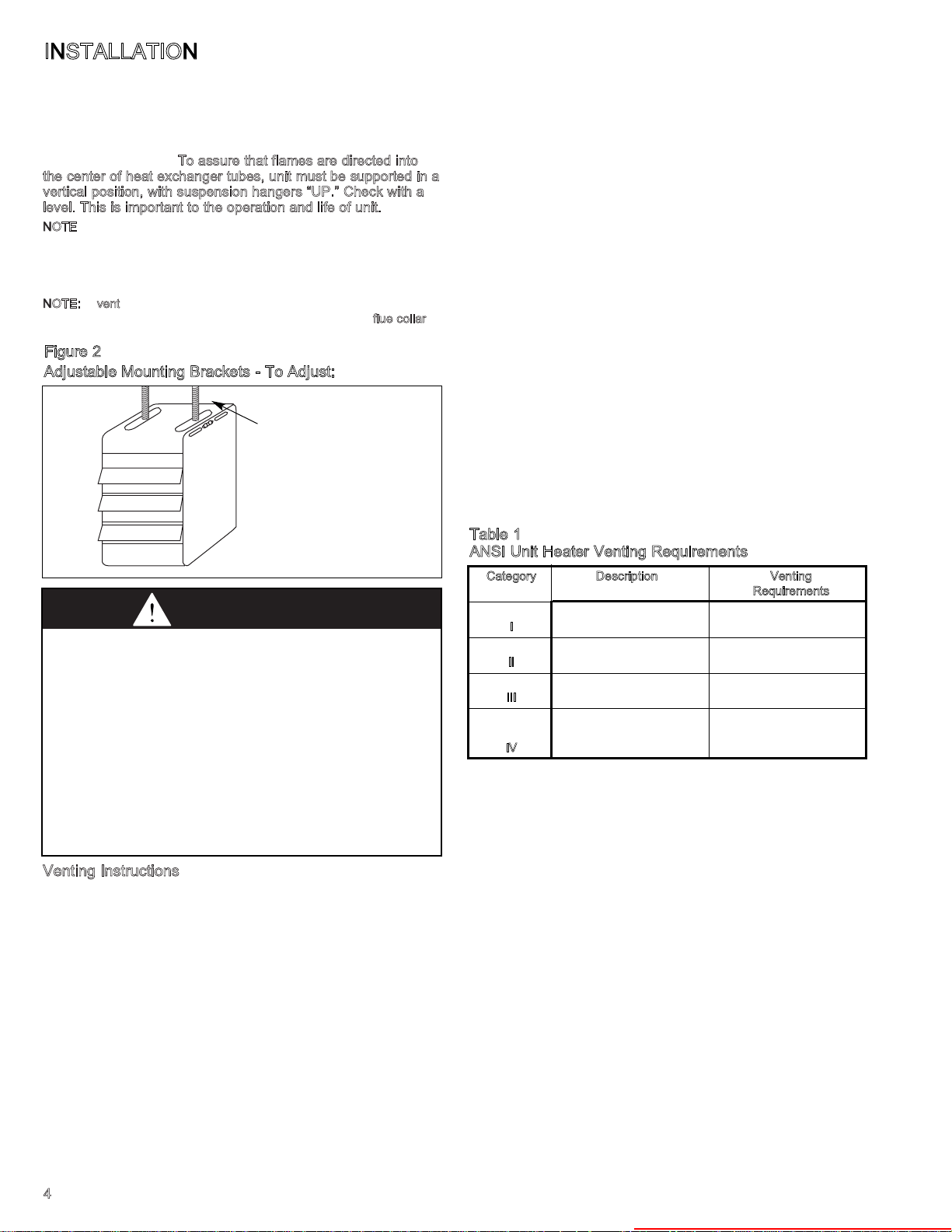

On all propeller units, except the PD 350 and PD 400, two tapped

holes (3/8-16) are located in the top of the unit to receive threaded

rods.

Units with two point suspension, models PD30 through PD300,

incorporate a level hanging feature. Depending on what options and

accessories are being used, the heater may not hang level as

received from the factory. Do not hang heaters with deflector hoods

until referring to the “installation manual for deflector hoods” and

making the recommended preliminary adjustments on the heater.

These preliminary adjustments need to be made with the heater

resting on the floor.

PD30 through PD300 units without deflector hoods that do not

hang level after being installed, can be corrected in place. Simply

remove both outer side panels (screws to remove are on back

flange of side panel) and you will see the (adjustable) mounting

brackets (Fig. 2). Loosen the set screws holding the mounting

brackets in place and using a rubber mallet or something similar,

tap the heater into a position where it does hang level. Re-tighten

set screws and replace the outer side panels.

3

Heater Parts from ACF Greenhouses

INSTALLATION

The PD 350 and PD 400 have four mounting holes. On all

blower units, except the PD 350 and PD 400, two tapped holes

are provided in the top of the unit and two holes in the blower

support bracket. The PD 350 and PD 400 have four tapped

holes in the top of the unit and two in the blower support

T

bracket for mounting.

o assure that flames are directed into

the center of heat exchanger tubes, unit must be supported in a

vertical position, with suspension hangers “UP.” Check with a

level. This is important to the operation and life of unit.

NOTE

: Pipe hanger adapter kits, are available as accessories from

Modine. The hardware allows for pipe caps to be secured into the top of

the unit heater with machine screws (machine screws are 3/8 - 16 x

1.75 UNC-2A THD). The pipe caps can then accommodate 3/4" NPT

pipe for mounting.

N

OTE:Avent

from the unit or the flue collar to the outside atmosphere. A

the pipe which connects the unit to a vent or chimney.

is the vertical passageway used to convey flue gases

flue collar

Figure 2

Adjustable Mounting Brackets - To Adjust:

1. Remove outer side panels.

2. “Set screws” - loosen and

position bracket where needed

– then tighten set screws.

3. Re-attach outer side panels.

CAUTION

Gas Unit Heaters must be vented – do not operate

unvented. A built-in draft hood (diverter) is provided –

additional external draft hoods (diverters) are not required

or permitted. Gas-fired heating equipment that has been

improperly vented or which experiences a blocked vent

condition may have flue gases accidentally spilled into the

heated space. See page 20 for specific information about

the blocked vent safety switch supplied on the unit.

Installation must conform with local building codes or in the

absence of local codes, with Part 7, Venting of Equipment,

of the National Fuel Gas Code, ANSI Z223.1 (NFPA 54) Latest Edition. In Canada installation must be in

accordance with CAN/CGA-B149.1 for natural gas units,

and CAN/CGA-B149.2 for propane units.

Venting Instructions

1. All units with single-stage controls are Category I.

2. All units with two-stage or modulating controls are Category

II. The installation of a Category II unit must conform to the

requirements from Table 1 in addition to those listed below.

3. Select size of vent pipe to fit vent pipe connection at rear of

appliance (see Page 12 and 13, Dimension J). Do not use a

vent pipe smaller than the vent pipe connection on the unit.

Vent pipe should be galvanized steel or other suitable

corrosion-resistant material. Follow the National Fuel Gas

Code for minimum thicknesses of vent material; minimum

thicknesses for flue collars vary depending on pipe

diameter.

4. Limit length of horizontal runs to 75% of vertical height.

Install with a minimum upward slope from unit of 1/4 inch

per foot and suspend securely from overhead structure at

points no greater than 3 feet apart. For best venting, put as

much vertical vent as close to the unit as possible. Fasten

individual lengths of vent together with at least three

corrosion-resistant sheet-metal screws.

4

5. Avoid venting through unheated space when possible. When

venting does pass through an unheated space, Modine

recommends the use of Type B double wall vent. If single

wall vent is used, insulate vent runs greater than 5 feet to

minimize condensation. Use insulation that is

noncombustible with a rating of not less than 350°F. Install a

tee fitting at the low point of the vent system to provide a

drip leg with a clean out cap as shown in Figure 3. The drip

leg should be cleaned annually.

6. Keep single wall vent pipe at least 6 inches from

combustible material. For double wall vent pipe, maintain

clearances listed on vent pipe (Category I and II units) (see

page 2, section 12 for allowable reductions). The minimum

distance from combustible material is based on the

combustible material surface not exceeding 160°F.

is

Clearance from the vent connector, vent, or top of unit may

be required to be greater than the minimum clearance if

heat damage other than fire (such as material distortion or

discoloration) may occur.

7. Where the vent passes through a combustible floor or roof,

a metal thimble 4 inches greater than the vent diameter is

necessary. If there is 6 feet or more of vent pipe in the open

space between the unit and where the vent pipe passes

through the floor or roof, the thimble need only be 2 inches

greater than the diameter of the vent pipe. If a thimble is not

used, all combustible material must be cut away to provide

the specified clearance to combustibles. Any material used

to close the opening must be noncombustible.

Table 1

ANSI Unit Heater Venting Requirements

Category Description Venting

I

II

III

I

V

Negative vent pressure Follow standard

Non-condensing venting requirements.

Negative vent pressure Condensate must be

Condensing drained.

Positive vent pressure Vent must be gastight.

Non-condensing

Positive vent pressure Vent must be liquid and

Condensing gastight. Condensate

8. Top of vertical vent should extend at least two feet above

the highest point where it passes through a roof and at least

2 feet higher than any portion of a building within a

horizontal distance of 10 feet (see Figure 3).

9. Use a vent terminal to reduce downdrafts and moisture in

vent. A vent terminal that is very open will avoid spillage at

unit’s diverter relief opening and tripping of the blocked vent

safety switch.

10.Check vent system to see that combustion products are

being vented properly. Operate unit for several minutes and

then pass a lighted match around the edge of the diverter

relief opening. If the flame is drawn into the opening, the

vent system is drawing properly. If not, make adjustments to

provide adequate draft (see page 21).

11.A drip leg with cleanout cap is recomended for all vent

systems to reduce the opportunity of damage to unit due to

condensation.

ADDITIONAL VENTING REQUIREMENTS FOR CATEGORY II

UNITS

Vent system must provide for drainage of condensate. At the

low point of the vent system, install a tee fitting with a

connector and attach flexible tubing, minimum 3/8 inch I.D., and

run to a drain. Tee fitting and associated condensate disposal

system must be periodically cleaned.

Requirements

must be drained.

Heater Parts from ACF Greenhouses

INSTALLATION

ADDITIONAL VENTING REQUIREMENTS FOR VENTING

INTO AN EXISTING MASONRY CHIMNEY OR COMMON

VENT (CATEGORY I and II UNITS ONLY)

1. Do not vent a Category I or II unit into a common vent with

mechanical draft systems operating under positive pressure

(Category III or IV units).

2. When connecting vent to an existing chimney, do not push

vent pipe beyond internal surface of chimney.

3. When venting into a common vent, the area of the common

vent should be equal to or greater than the area of the

largest vent plus 50 percent of the area of all additional

vents.

4. When venting into a common vent, the individual vents

should enter at different levels.

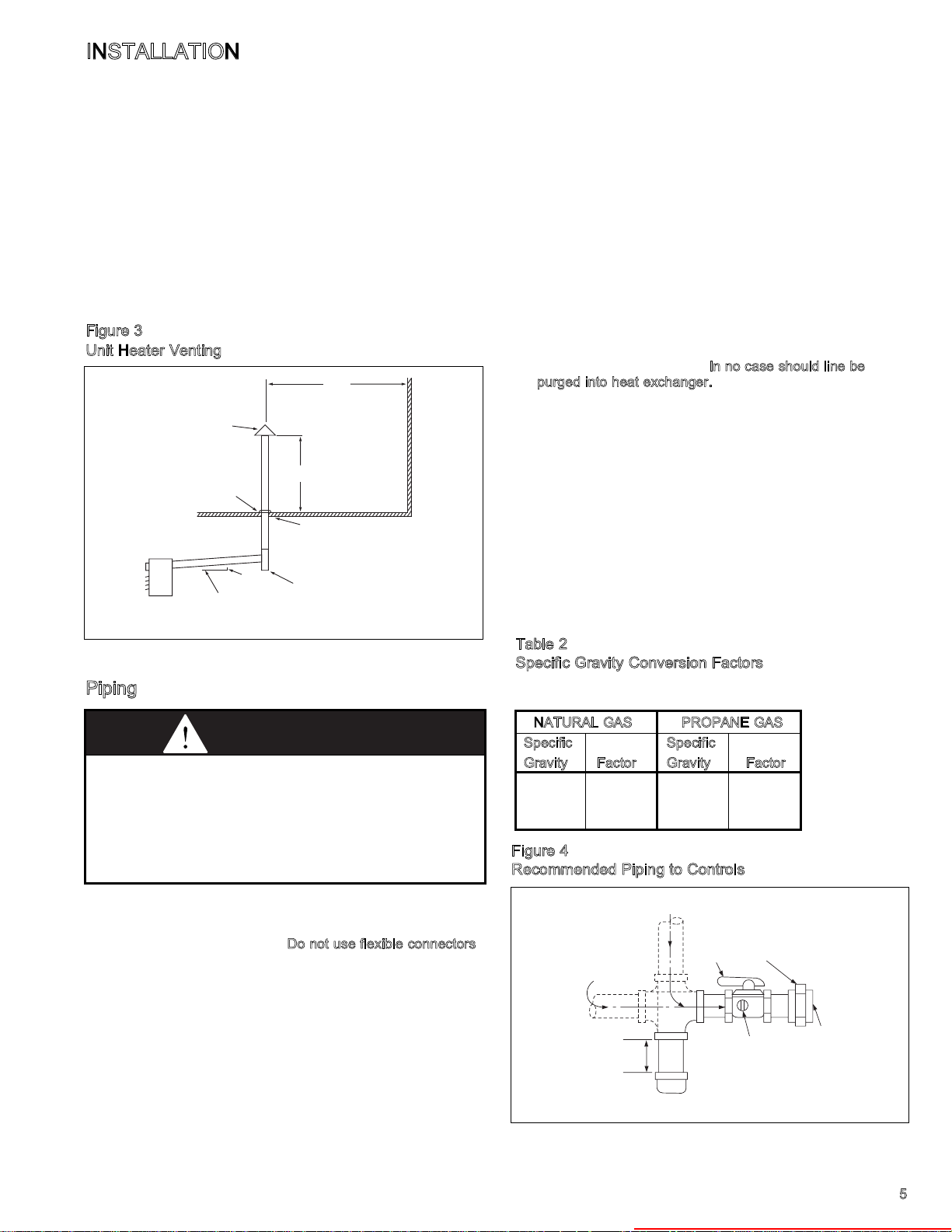

Figure 3

Unit Heater Venting

10' MIN.

TO WALL OR ADJOINING BUILDING

APPROVED

TERMINAL

2'

*

MIN.

ROOF FLASHING

USE THIMBLE

THROUGH CEILING

1/4"

DRIP LEG WITH

CLEANOUT CAP

P

iping

UNIT

1'0"

SLOPE 1/4" TO

THE FOOT

*SIZE ACCORDING TO EXPECTED SNOW DEPTH.

CAUTION

Gas pressure to unit heater controls must never exceed 14"

W.C. (1/2 psi).

When leak testing the gas supply piping system, the

appliance and its combination gas control must be isolated

during any pressure testing in excess of 14" W.C. (1/2 psi).

The appliance should be isolated from the gas supply piping

system by closing its field installed manual shut-off valve

during any pressure testing of the gas supply piping system.

1. Installation of piping must be in accordance with local

codes, and ANSI Z223.1, “National Fuel Gas Code,” or

CAN/CGA-B149 in Canada.

2. Piping to units should conform with local and national

requirements for type and volume and gas handled, and

pressure drop allowed in the line. Refer to Table 4, to

determine the cubic feet per hour (cfh) for the type of gas

and size of unit to be installed. Using this cfh value and the

length of pipe necessary, determine the pipe diameter from

Table 3. Where several units are served by the same main,

the total capacity, cfh, and length of main must be

considered. Avoid pipe sizes smaller than 1/2”. Table 3

allows for the usual number of fittings with a 0.3” W.C.

pressure drop. Where the gas supplied has a specific

gravity other than 0.60, apply the multiplying factor as given

in Table 2.

D

o not use flexible connectors

3. After threading and reaming the ends, inspect piping and

remove loose dirt and chips.

4. Support piping so that no strains are imposed on unit or

controls.

5. Use two wrenches when connecting piping to unit controls.

6. Provide a sediment trap before each unit and in the line

where low spots cannot be avoided. (See Figure 4).

7. Take-off to unit should come from top or side of main to

avoid trapping condensate.

8. Piping, subject to wide temperature variations, should be

insulated.

9. Pitch piping up toward unit at least 1/4” per 15’ of horizontal

run.

10. Compounds used on threaded joints of gas piping must be

resistant to action of liquefied petroleum gases.

11. Purge air before lighting unit by disconnecting pilot tubing

I

at combination gas control.

n no case should line be

purged into heat exchanger.

12. After installation, check system for gas leaks, using a soap

solution.

13. Install a ground joint union and a manual shut off valve

immediately upstream of the unit including a 1/8” NPT

plugged tapping accessible for test gage connection. (See

Figure 4).

14. Allow at least 5 feet of piping between any pressure

regulator and unit control string.

15. When Pressure/Leak testing, pressures above 14'' W.C.

(1/2 psi), close the field installed shut-off valve, disconnect

the appliance and its combination gas control from the gas

supply line, and plug the supply line before testing. When

testing pressures 14" W.C. (1/2 psi) or below, close the

manual shut-off valve on the appliance before testing.

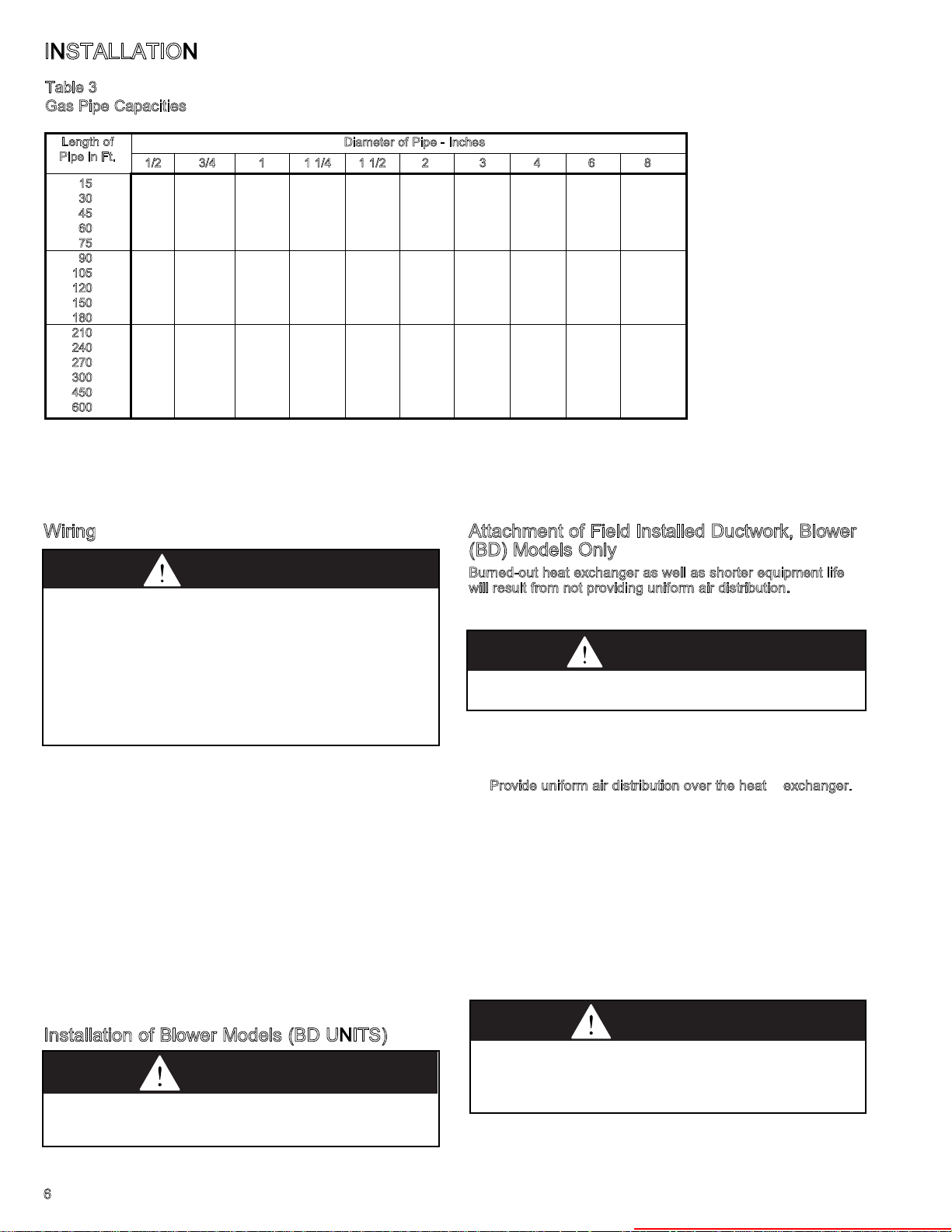

Table 2

Specific Gravity Conversion Factors

Multiplying factors to be used with Table 3 cubic ft./hr. values when the specific

gravity of gas is other than 0.60.

N

ATURAL GAS

Specific

Gravity Factor

0.55 1.04

0.60 1.00

0.65 0.962

PROPANE GAS

Specific

Gravity Factor

1.50 0.633

1.53 0.626

1.60 0.612

Figure 4

Recommended Piping to Controls

GAS

SUPPLY LINE

GROUND

JOINT

VALVE

UNION

PLUGGED

1/8" NPT TEST

GAGE CONNECTION

CONTROLS

TRAP

MANUAL

SHUT-OFF

.

GAS

SUPPLY LINE

3"

MIN.

SEDIMENT

TO

5

Heater Parts from ACF Greenhouses

INSTALLATION

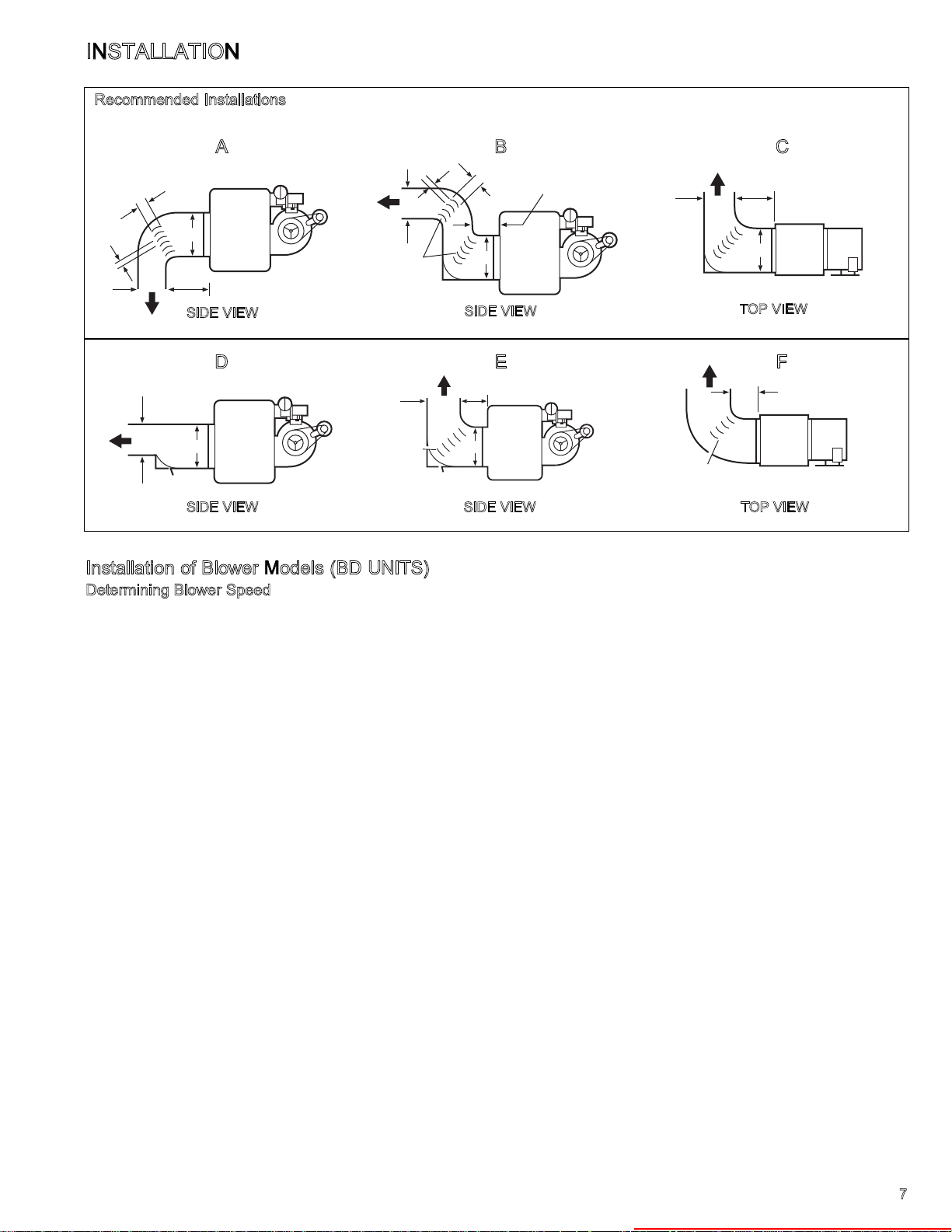

Table 3

Gas Pipe Capacities

In Cu. Ft. per Hour with Pressure Drop pf 0.3 in. W.C. with Specific Gravity 0.60.

Length of

Pipe in Ft.

15

0

3

45

60

75

90

105

120

150

180

210

240

270

300

450

600

1/2 3/4 1 1 1/4 1 1/2 2 3 4 6 8

76 218 440 750 1220 2480 6500 13880 38700 79000

73 152 285 590 890 1650 4700 9700 27370 55850

44 124 260 435 700 1475 3900 7900 23350 45600

50 105 190 400 610 1150 3250 6800 19330 39500

97 200 345 545 1120 3000 6000 17310 35300

88 160 320 490 930 2600 5400 15800 32250

80 168 285 450 920 2450 5100 14620 29850

158 270 420 860 2300 4800 13680 27920

120 242 380 710 2000 4100 12240 25000

128 225 350 720 1950 4000 11160 22800

Diameter of Pipe - Inches

205 320 660 1780 3700 10330 21100

190 300 620 1680 3490 9600 19740

178 285 580 1580 3250 9000 18610

170 270 545 1490 3000 8500 17660

140 226 450 1230 2500 7000 14420

119 192 380 1030 2130 6000 12480

Wiring

CAUTION

Disconnect power supply before making wiring connections

to prevent electrical shock and equipment damage. ALL

UNITS MUST BE WIRED STRICTLY IN ACCORDANCE

WITH WIRING DIAGRAM FURNISHED WITH UNIT.

ANY WIRING DIFFERENT FROM WIRING DIAGRAM MAY

BE HAZARDOUS TO PERSONS AND PROPERTY.

Any damage to or failure of Modine units caused by incorrect

wiring of the units is not covered by MODINE’S STANDARD

WARRANTY (see Back Cover).

All field installed wiring must be done in accordance with the

National Electrical Code ANSI/NFPA 70 – Latest Edition or

Canadian Electrical Code CSA C22.1 Part 1 or local codes.

Unit must be electrically grounded according to these codes.

See wiring diagram shipped with unit.

The power to these unit heaters should be protected with a

circuit breaker. Units for use with single-phase electric power,

should be provided with a manual motor starter, having

properly sized overload protection. Units for use with threephase electric power must be provided with a motor starter

having properly sized overload protection.

Location of thermostat should be determined by heating

requirements and be mounted on an inside wall about 5' above

floor level where it will not be affected by heat from the unit or

other sources, or drafts from frequently opened doors. See

instructions packed with thermostat.

I

nstallation of Blower Models (BD UNITS)

CAUTION

Proper air flow and distribution, across the heat exchanger

must be provided to prevent early failure of the blower unit

heater.

Attachment of Field Installed Ductwork, Blower

(BD) Models Only

Burned-out heat exchanger as well as shorter equipment life

will result from not providing uniform air distribution.

When installing heater always follow good duct design practices

CAUTION

Do not attempt to attach ductwork of any kind to propeller PD

models.

for even distribution of the air across the heat exchanger.

Recommended layouts are shown below. When installing

blower units with ductwork the following must be done.

rovide uniform air distribution over the heat exchanger.

P

1.

Use turning vanes where required. See figures below.

2. Provide removable access panels in the ductwork on the

downstream side of the unit heater. These openings should

be large enough to view smoke or reflect light inside the

casing to indicate leaks in the heat exchanger and to check

for hot spots on exchanger due to poor air distribution or

lack of sufficient air.

3.

If ductwork is connected to the rear of the unit use Modine

blower enclosure kit or if using field designed enclosure

maintain dimensions of blower enclosure as shown on page 13.

CAUTION

Check for red heat exchanger tubes. If bottom of tubes

become red while blower unit is in operation, check for

proper air volume and air distribution. Adjust blower speed or

correct discharge duct design to correct problem.

6

Heater Parts from ACF Greenhouses

INSTALLATION

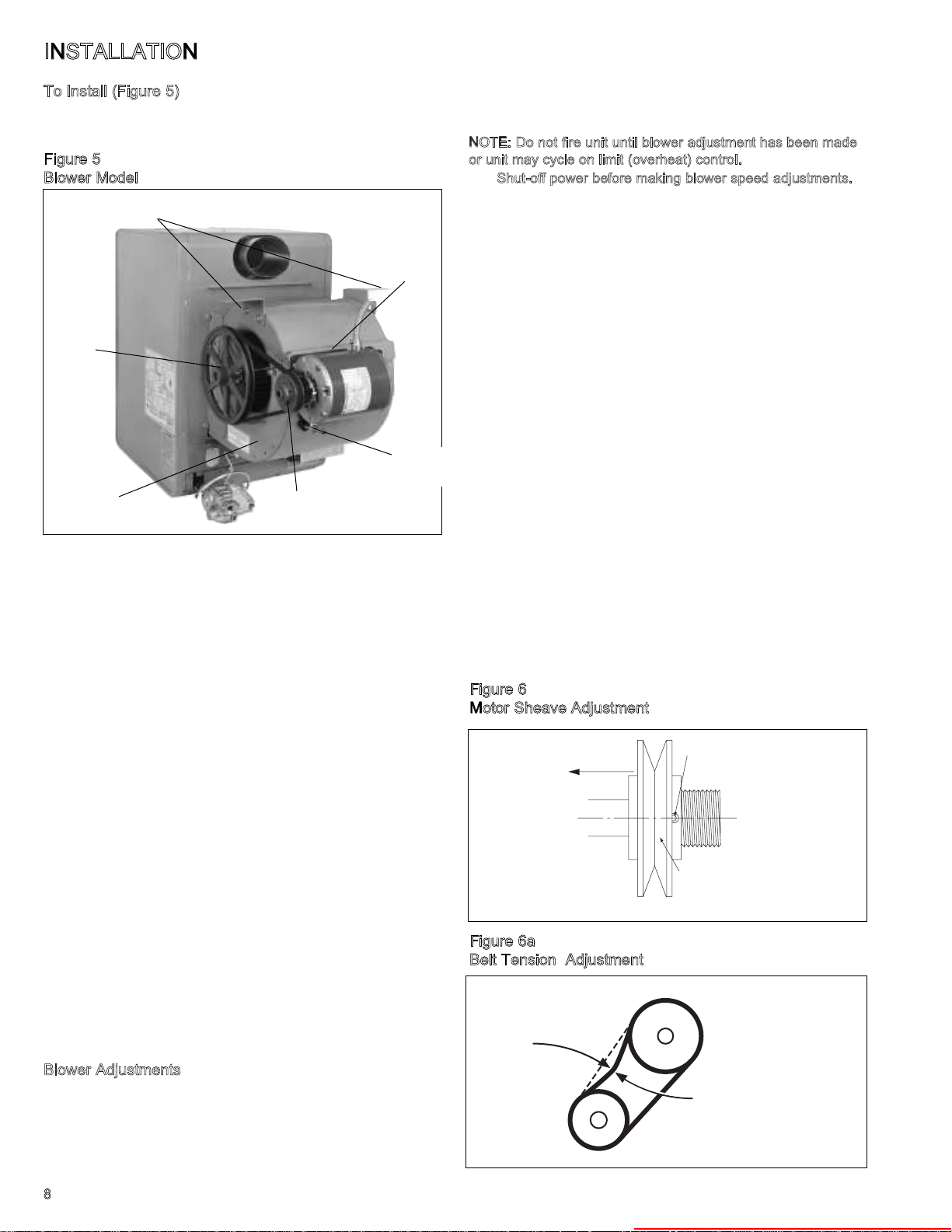

Recommended Installations

TURNING

VANES

3" MIN.

3" MAX.

B

A

B

12" MIN.

SIDE VIEW

A

BAFFLE

SIDE VIEW SIDE VIEW TOP VIEW

3" MAX.

B

TURNING

VANES

TURNING

VANES

BAFFLE

BAFFLE

SIDE VIEW

12"

MIN.

B

A

BA

3" MIN.

12"

A

12"

MIN.

Dimension “B” Should Never

Be Less than 1/2 of “A”

C

12"

B

MIN.

A

TOP VIEW

FED

12"

MIN.

TURNING

VANES

Installation of Blower Models (BD UNITS)

Determining Blower Speed

The drive assembly and motor on all gas-fired blower unit

heaters are factory assembled. The adjustable motor sheave

has been pre-set to permit operation of this unit under average

conditions of air flow and without any external static pressure.

The motor sheave should be adjusted as required when the

unit is to be operated at other than average air flows and/or

with external static pressures. Adjustment must always be

within the performance range shown on pages 18 and 19 and

the temperature rise range shown on the unit’s rating plate.

To determine the proper blower speed and motor sheave turns

open, the conditions under which the unit is to operate must be

known. If the blower unit is to be used without duct work,

nozzles or filters, the only criteria for determining the motor

sheave turns open and blower speed is the amount of air to be

delivered. The performance tables for blower models are shown

on pages 18 and 19. As an example, a model BD 350 unit,

operating with no external static pressure, that is, no duct work,

nozzles, etc., and is to deliver an air volume of 6481 cfm (cfm =

cubic feet of air per minute) requires that the unit be supplied

with a 5 hp motor, a C207 drive, and the drive sheave must be

set at 2.5 turns open to achieve a blower speed of 960 rpm

(see performance table for units with or without blower

enclosure, page 18). See "Blower Adjustments" on page 8 for

setting of drive pulley turns open.

If a blower unit is to be used with ductwork or nozzles, etc., the

total external static pressure under which the unit is to operate,

and the required air flow must be known before the unit can be

properly adjusted. Any device added externally to the unit, and

which the air must pass through, causes a resistance to air

flow. This resistance is called pressure loss. The total of the

pressure losses must be determined before adjusting the

blower speed.

If Modine filters are used, the expected pressure loss through

the filters is included in the performance data on page 19. If

Modine supplied discharge nozzles are used, the expected

pressure drop of the nozzles can be found footnoted at the

bottom of page 14. If filters, nozzles or ductwork are to be used

with the unit, and they are not supplied by Modine, the design

engineer or installing contractor must determine the pressure

loss for the externally added devices or ductwork to arrive at

the total external static pressure under which the unit is to

operate.

Once the total static pressure and the required air flow are

known, the operating speed of the blower can be determined

and the correct motor sheave adjustments made. As an

example, let's say, a model BD 350 is to be used with a Modine

supplied blower enclosure and Modine supplied filters attached

to someone else's ductwork. The unit is to move 6481 cfm or

air flow against an external static pressure of 0.2" W.C. Also,

0.2" W.C. must be added for the filter pressure drop for a total

of 0.4" W.C. total pressure drop. Entering the performance table

on page 18 for a BD 350, at 6481 cfm and 0.4" W.C. static

pressure, it is seen that the unit will require a 5 hp motor using

a C207 drive, and the motor sheave should be set at .5 turns

open to achieve a blower speed of 1050 rpm. You can see this

example differs from similar conditions in paragraph 2 by the

number of turns open and a higher rpm, which is needed to

overcome the added external static pressure from the filters.

7

Heater Parts from ACF Greenhouses

INSTALLATION

To Install (Figure 5)

1. Remove and discard the motor tie down strap and the

shipping block beneath the belt tension adjusting screw

(Not used on all models.)

Figure 5

Blower Model

THREADED ROD MOUNTING

BRACKETS ON BLOWER ASSEMBLY

MOTOR

MOUNTING

BRACKET

BLOWER

SHEAVE

MOTOR

ADJUSTMENT

BLOWER

HOUSING

MOTOR SHEAVE

2. Adjust motor adjusting screw for a belt deflection of

approximately 3/4" with five pounds of force applied midway

between the sheaves (refer to Figure 6a). Since the belt

tension will decrease dramatically after an initial run-in

period, it is necessary to periodically re-check the tension.

Excessive tension will cause bearing wear and noise.

3. The blower bearings are lubricated for life; however, before

initial unit operation the blower shaft should be lubricated at

the bearings with SAE 20 oil. This will reduce initial friction

and start the plastic lubricant flowing.

4. Make electrical connections according to the wiring

diagram.

5. Check rotation of the blower. Motor should be in clockwise

rotation when facing motor pulley. If rotation is incorrect,

correction should be made by interchanging wiring within

the motor. See wiring diagram on the motor.

6. The actual current draw of the motor should be determined.

Under no condition should the current draw exceed that

shown on the motor rating plate.

7. It is the installers responsibility to adjust the motor sheave

to provide the specified blower performance as listed on

pages 18 & 19 for blower settings different from the factory

set performance. The drive number on the unit may be

identified by referring to the Power Code number on the

serial plate of the unit (see page 26 for model number

nomenclature) and matching that number with those shown

on page 25. From the listing, the drive number can be

determined.

8. Blower sheave and motor sheave should be measured to

assure correct drive is on unit. Refer to page 26 for drive

sizes.

SCREW

adjustable motor sheave is supplied with these units. If blower

fan speed changes are required, adjust motor sheave as

follows:

N

OTE: Do not fire unit until blower adjustment has been made

or unit may cycle on limit (overheat) control.

Shut-off power before making blower speed adjustments.

1.

Refer to Determining Blower Speed on page 7 and to

Performance Date on pages 18 and 19 to determine

proper blower RPM.

2. Loosen belt and take belt off of motor sheave.

3. Loosen set screw on outer side of adjustable motor sheave

(see Figure 6).

4. To reduce the speed of the blower, turn outer side of motor

sheave counterclockwise.

5. To increase the speed of the blower, turn outer side of

motor sheave clockwise.

6. Retighten motor sheave set screw, replace belt and

retighten motor base. Adjust motor adjusting screw such

that there is 3/4” belt deflection when pressed with 5

pounds of force midway between the blower and motor

sheaves (see Figure 6a). Since the belt tension will

decrease dramatically after an initial run-in period, it is

necessary to periodically re-check the tension to assure

continual proper belt adjustment.

7. Check to make certain motor sheave and blower sheave

are aligned. Re-align if necessary.

8. Re-check blower speed after adjustment.

9. Check motor amps. Do not exceed amps shown on motor

nameplate. Slow blower if necessary.

10. Check air temperature rise across unit. Check temperature

rise against values shown in Performance Tables on

pages18 and19 to assure actual desired air flow is being

achieved.

11. If adjustments are required, recheck motor amps after final

blower speed adjustment.

Figure 6

Motor Sheave Adjustment

TOWARD MOTOR

SET SCREW

ADJUSTABLE HALF

OF SHEAVE

Figure 6a

Belt Tension Adjustment

B

lower Adjustments

Following electrical connections, check blower rotation to

assure blow-through heating. If necessary interchange wiring to

reverse blower rotation. Start fan motor and check blower

sheave RPM with a hand-held or strobe-type tachometer. RPM

should check out with the speeds listed in Performance Data

shown on pages 18 and 19. A single-speed motor with an

8

3/4" DEFLECTION

WITH 5# FORCE

Heater Parts from ACF Greenhouses

OPERATION

CAUTION

Start-up and adjustment procedures should be performed by

a qualified serviceman.

Check the gas inlet pressure at the unit upstream of the

combination gas control. The inlet pressure should be 6"-7"

W.C. on natural gas or 12"-14" W.C. on propane. If inlet

pressure is too high, install an additional pressure regulator

upstream of the combination gas control.

The pilot flame must be adjusted as described below. Purging

of air from gas lines, piping, and lighting the pilot should be

performed as described in ANSI Z223.1-latest edition

“National Fuel Gas Code” (CAN/CGA-B149 in Canada).

Be sure no obstructions block air intake and discharge of unit

heater.

Prior to Operation

Although this unit has been assembled and fire-tested at the

factory, the following pre-operational procedures should be

performed to assure proper on-site operation:

1. Turn off all electric power to the unit.

2. Check burner to insure proper alignment.

3. Check fan clearance. Fan should not contact casing when

spun by hand.

4. Check all electrical connections to be sure they are secure.

5. If you are not familiar with the unit’s controls (i.e.

combination gas control), refer to the control manufacturer’s

literature supplied with the unit.

6. Check that all horizontal deflector blades are open a

minimum of 30° as measured from vertical.

L

ighting Instructions (also on unit)

For Units with Standing Pilot

1. Set thermostat to lowest setting. Move gas control knob (or

lever) to off and wait 5 minutes.

2. Move gas control knob to PILOT (or move gas control lever

to SET) and depress reset button while lighting the pilot and

hold for 1 minute after pilot is lit.

3. Move gas control knob (or lever) to ON.

4. Set thermostat to desired setting.

F

or Units with Intermittent Pilot

1. Set thermostat to lowest setting. Move gas control knob (or

lever) to off and wait 5 minutes.

2. Move gas control knob (or lever) to ON.

3. Set thermostat to desired setting (pilot and main burner will

light automatically when thermostat calls for heat).

S

hut Down Instructions

Turn off power and close manual gas valve.

A

fter Initial Start Up

1. Check pilot flame adjustment as discussed below.

2. Check gas piping for leaks with a soap bubble solution to

insure safe operation.

3. Check gas input rate to assure proper gas flow and

pressure.

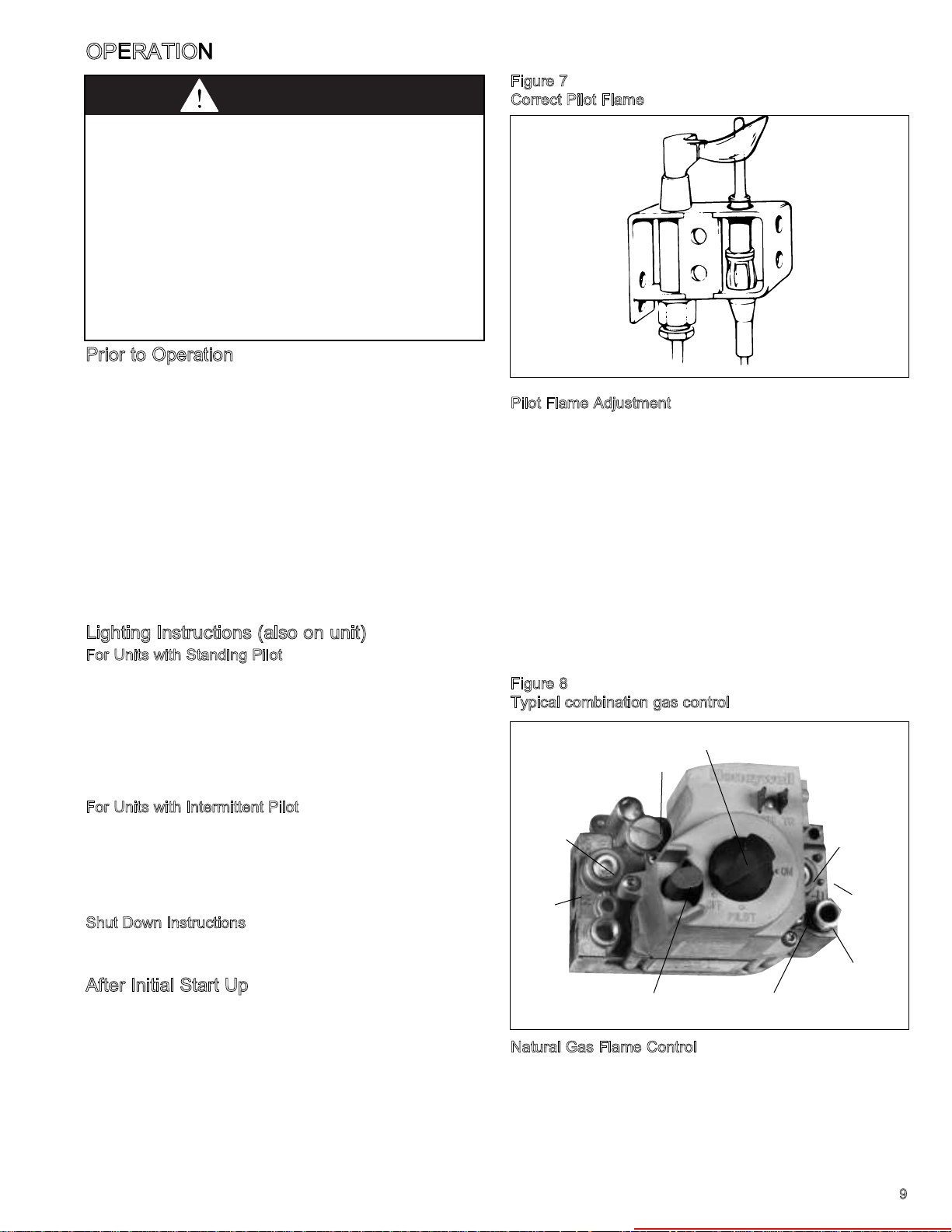

Figure 7

Correct Pilot Flame

ilot Flame Adjustment

P

The pilot burner is orificed to burn properly with an inlet

pressure of 6-7" W.C. on natural gas and 12-14" W.C. on

propane gas, but final adjustment must be made after

installation. Adjust to have a soft steady flame 3/4" to 1" long

and encompassing 3/8"-1/2" of the tip of the thermocouple or

flame sensing rod. Normally this flame will produce satisfactory

results. To adjust flame use pilot adjustment screw on

combination gas control (for location, see the combination gas

control literature supplied with unit). If the pilot flame is longer

and larger than shown by Figure 7, it is possible that it may

cause soot and/or impinge on the heat exchanger causing

burnout. If the pilot flame is shorter than shown it may cause

poor ignition and result in the controls not opening the

combination gas control. A short flame can be caused by a

dirty pilot orifice. Pilot flame condition should be observed

periodically to assure trouble-free operation.

Figure 8

Typical combination gas control

GAS CONTROL KNOB

PRESSURE REGULATOR

ADJUSTMENT SCREW

(UNDER CAP SCREW)

INLET

PRESSURE TAP

INLET

RESET BUTTON

N

atural Gas Flame Control

Control of burner flames on units utilizing natural gas is

achieved by moving the gas manifold to either increase or

decrease primary combustion air. Prior to flame adjustment,

operate unit with casing closed for about five minutes.

Operation can be viewed after loosening and pushing aside

the blue gas designation disc on rear of unit.

PILOT ADJUSTMENT

SCREW

OUTLET

PRESSURE

TAP

OUTLET

PILOT TUBING

CONNECTION

9

Heater Parts from ACF Greenhouses

OPERATION

Lack of primary air will cause soft yellow-tipped flames. Excess

primary air produces short, well-defined flames with a tendency

to lift off the burner ports. Proper operation with natural gas

provides a soft blue flame with a well-defined inner core.

To increase primary air, loosen the manifold mounting screws

and tap the manifold away from the mixer tubes until yellowtipped flames disappear. See Figure 14. To decrease primary

air move the manifold closer to the mixer tubes until flames no

longer lift from burner ports, but being careful not to cause

yellow tipping. Retighten manifold mounting screws after

adjustment.

P

ropane Gas Flame Control

Adjustable primary air shutters are attached to the orifices on

the gas manifold for units equipped for propane gas operation.

See Figure 15.

Prior to flame adjustment, operate unit heater with casing

closed for at least five minutes. Then lower hinged bottom and

adjust primary air shutters. Loosen wing screws and push

shutters forward to reduce primary air until yellow flame tips

appear. Then increase primary air until yellow tips diminish to

just a slightly yellow tip and a clean blue flame with a welldefined inner cone appears.

It may also be necessary to adjust the manifold position in

addition to adjusting air shutters to obtain proper flame. Follow

the instructions under "Natural Gas Flame Control" for adjusting

the manifold.

n optimum flame will show a slightly yellow tip

A

Checking Input Rate

CAUTION

Check the gas inlet pressure at the unit upstream of the

combination gas control. The inlet pressure should be 6"-7"

W.C. on natural gas or 12"-14" W.C. on propane. If inlet

pressure is too high, install an additional pressure regulator

upstream of the combination gas control.

Important

checked with unit in operation when making final adjustments.

I

nput Adjustments

The gas pressure regulator (part of the combination gas

control) is adjusted at the factory for average gas conditions. It

is important that gas be supplied to the heater in accordance

with the input rating stamped on the serial plate. Actual input

should be checked and necessary adjustments made after the

heater is installed. Over-firing, a result of too high an input,

reduces the life of the unit, and increases maintenance. Under

no circumstances should the input exceed that shown on the

rating plate.

Input can be determined by the meter-timing method provided

other gas equipment connected to the meter is off during the

test. If this is not possible, use the pressure method.

(

A) Meter Timing Method

1. Shut off all other gas-burning equipment, including other

2. Start the heater and determine the number of seconds it

– Inlet pressure and manifold pressure must be

pilot lights served by the gas meter.

takes to consume 1 cu. ft. of gas. Two basic formulas are

useful:

F1 = 3600 C/T

F2 = F1/C

where:

F1 = input to heater, Btuh.

F2 = input to heater, cu. ft. per hr.

C = heating value of gas, Btu per cu. ft.

T = time to consume 1 cu. ft. of gas in sec.

The heating value of gas may be determined from the local

utility or gas dealer.

These are representative values:

GAS

Natural 1000-1150

Propane 2500

3. If the seconds for 1 cu. ft. are more (input less) than shown

.

in Table 4 for model being tested, locate the combination

gas control and pressure regulator adjustment screw (see

Figure 8). Remove the cap screw from the pressure

regulator and make one clockwise turn at a time on the

adjustment screw until the correct time is obtained. If the

seconds are less (input greater) than indicated in the table,

follow the same procedure in a

If the correct number of seconds cannot be obtained check

orifice size. Correct orifices can be obtained from Modine

Manufacturing Company, Buena Vista, Virginia. When

requesting orifices, state type of gas, heating value, and its

specific gravity. Also give model number of unit.

For example, if the input to the heater is 100,000 Btuh and the

heating value of the gas is 1000 Btu per cu. ft., then, by the

second formula, the input is 100 cu. ft. per hr. Table 4 indicates

the time for one revolution of various size meter dials with

various input rates. If a 1 cu. ft. meter dial is used, we proceed

down the cu. ft. column to 100 cu. ft. per hr. and then

horizontally to the left to determine a time of 36 seconds for

one revolution of the dial. Similarly, if the 1/2 cu. ft. dial is used,

we determine a time of 18 seconds for one revolution at the

required input.

(

B) Pressure Method

The pressure method determines input by measuring the

pressure of the gas in the manifold in inches of water.

1. Determine correct manifold pressure from Table 6.

2. Locate combination gas control.

3. Move gas control knob (or lever) to off.

4. Remove the 1/8" pipe plug in outlet pressure tap in

combination gas control (see Figure 9) and attach water

manometer or “U” tube which is at least 12" high.

5. Follow lighting instructions and turn thermostat up to get

unit to fire.

6. If pressure as indicated by “U” tube is less than 1/2" higher

or lower than indicated in Table 6, adjust regulator as

described under “Meter-Timing Method,” Step 3.

If pressure as indicated by “U” tube is more than 1/2" higher

or lower than indicated in Table 6, check inlet pressure at

unit. The inlet pressure should be 6"-7" W.C. pressure on

natural gas and 12"-14" W.C. on propane gas.

After adjustment move gas control knob (or lever) to off and

replace 1/8" pipe plug. With the plug in place, follow the lighting

instructions to put unit back in service.

Btu per cu. ft.

c

ounter-clockwise

direction.

10

Heater Parts from ACF Greenhouses

CHECKING INPUT RATE

Figure 9

Major Gas and Electric Components

FAN MOTOR

FAN

GUARD

PILOT TUBING

COMBINATION

GAS CONTROL

IGNITION

CONTROL

CONTROL

TRANSFORMER

Table 4

Meter-Timing Gas

(Time required for one revolution is charted for various size

meter dials and various rates of gas input in cu. ft. per hour. To

convert to Btuh, multiply by the heating value of the gas used.)

Time for 1

Revolution,

Sec.

10

12

14

16

18

20

22

24

26

28

30

35

40

45

50

55

60

70

80

90

100

120

Input, Cu. Ft. per Hour, When Meter Dial Size is:

1/2 cu. ft. 1 cu. ft. 2 cu. ft. 5 cu. ft.

180

150

129

112

100

90

82

75

69

64

60

51

45

40

36

33

30

26

22

20

18

15

360

300

257

225

200

180

164

150

138

129

120

103

90

80

72

65

60

51

45

40

36

30

ENTRANCE FOR

COMBUSTION AIR

720

600

514

450

400

360

327

300

277

257

240

206

180

160

144

131

120

103

90

80

72

60

JUNCTION

BOX

1800

1500

1286

1125

1000

900

818

750

692

643

600

514

450

400

360

327

300

257

225

200

180

150

TERMINAL

BOARD

Table 6

Manifold Pressure & Gas Consumption *

Natural Propane

BTU/Cu. Ft. 1050 2500 No. of

Model Specific Gravity 0.60 1.53 Orifices

Manifold Pressure In. W.C. 3.5 10.0

CFH 28.6 12.0

Gal/Hr. Propane – .33

PD 30 Sec/cu. ft. 126 300 1

Orifice Drill Size 38 52

CFH 47.6 20.0

PD 50 Gal/Hr. Propane – .55

BD 50 Sec/cu. ft. 76 180 1

Orifice Drill Size 30 45

CFH 71.4 30.0

PD 75 Gal/Hr. Propane – .82

BD 75 Sec/cu. ft. 50 120 1

Orifice Drill Size 21 39

CFH 95.2 40.0

PD 100 Gal/Hr. Propane – 1.15

BD 100 Sec/cu. ft. 38 90 2

Orifice Drill Size 30 45

CFH 119.0 50.0

PD 125 Gal/Hr. Propane – 1.43

BD 125 Sec/cu. ft. 30 72 2

Orifice Drill Size 26 43

CFH 138.1 58.0

PD 150 Gal/Hr. Propane – 1.64

BD 150 Sec/cu. ft. 26 62 2

Orifice Drill Size 21 39

CFH 166.7 70.0

PD 175 Gal/Hr. Propane – 1.86

BD 175 Sec/cu. ft. 22 51 3

Orifice Drill Size 28 43

CFH 190.5 80.0

PD 200 Gal/Hr. Propane – 2.19

BD 200 Sec/cu. ft. 19 45 3

Orifice Drill Size 25 42

CFH 238.1 100.0

PD 250 Gal/Hr. Propane – 2.74

BD 250 Sec/cu. ft. 15 36 3

Orifice Drill Size 18 36

CFH 285.7 120.0

PD 300 Gal/Hr. Propane – 3.29

BD 300 Sec/cu. ft. 13 30 4

Orifice Drill Size 21 39

CFH 333.3 140.0

PD 350 Gal/Hr. Propane – 3.84

BD 350 Sec/cu. ft. 11 26 5

Orifice Drill Size 23 41

CFH 381.0 160.0

PD 400 Gal/Hr. Propane – 4.38

BD 400 Sec/cu. ft. 9 23 6

Orifice Drill Size 25 42

*Above gases based on average standards. Units can be furnished

for gases of different values and specific gravities. (Gal./Hr. based

on 60°F. 30" Hg., 91,500 BTU/Gal.) In Canada, refer to rating plate

on side of unit for orifices at high altitude.

Table 5

Orifice Drill Sizes with Decimal Equivalents

Main Burner Orifices

Dia. Dia.

Drill Decimal Drill Decimal

Size Equivalent Size Equivalent

18 .1695 38 .1015

21 .1590 39 .0995

23 .1540 41 .0960

25 .1495 42 .0935

26 .1470 43 .0890

28 .1405 45 .0820

30 .1285 52 .0635

36 .1065

Pilot Orifice Identity Numbers

Pilot Burner Identity No. Identity No.

Manufacturer Natural Gas Propane Gas

Honeywell

R

obertshaw

Johnson

① As number appears on top of pilot orifice.

BCR-18 BBR-11

1 8

①

N

L

1 O

P

7715 4710

Heater Parts from ACF Greenhouses

Figure 10

Dials of Typical Gas Meter

①

11

DIMENSIONS/PERFORMANCE – PD

A

H

D (OPENING)

BB

E

AA

B

K

W

X

F

C

K

G

L - Approx

MIN. DISTANCE

TO WALL IS L + 6"

J VENT PIPE

EE

(MIN. DISTANCE TO WALL)

L

LL

For clearance to combustibles, see page 3.

Dimensions (inches) — PD Do not use propeller units with duct work.

Dimension Model Number

Symbol PD 30 PD 50 PD 75 PD 100 PD 125 PD 150 PD 175 PD 200 PD 250 PD 300 PD 350 PD 400

A

B

C

D

E

F

G

H

AA

BB

J

① 3 4 5 6 6 7 7 7 8 9 10 10

K

(Mounting

Holes)

➂

Gas Connections

W

X

L

➃ 28-1/4 28-1/4 36 36 36-1/2 37-1/8 37-1/8 40-7/8 41 42-1/4 42-1/4 47-1/4

LL

EE

Fan Diameter

pprox. Weight

A

Diameter of round vent pipe to fit oval opening.

①

For natural gas; may vary depending on control availability.

➁

PD 30 through PD 300 — 2 holes (and the level hanging adjustment feature). PD 350 through PD 400 — 4 holes.

➂

Dimension equals overall plus 6".

➃

Performance — PD Inputs and outputs are the same for BD as PD

Standard Model Number

Btu/Hr. Input

Btu/Hr. Output

Entering Airflow CFM

Outlet Velocity

Air Temp. Rise °F

ounting Hgt.

M

(Max. Ft.) ① 7 9 12 14 14 16 17 15 19 21 20 19

eat Throw Ft.

H

(Max. Mtg. Hgt.)

Motor

Data

➁

U

Power (amps)

Ratings shown are for elevations up to 2,000 ft. For elevations above 2,000 feet, ratings should be reduced at the rate of 4% for each 1,000 feet above sea level. (In Canada see rating plate.)

At 65°F ambient and unit fired at full-rated input. Mounting height as measured from bottom of unit, and without deflector hoods.

①

All single phase motors are totally enclosed and thermal overload protected. Data listed is for standard 115-volt, 60 hertz, single-phase motors.

➁

12

Horsepower

nit total

12-7/8 17-1/4 17-1/4 19-1/4 19-1/4 21 23-1/2 25-5/8 25-5/8 28-5/8 33-5/8 40

24-1/4 24-1/4 28-3/4 28-3/4 35-1/4 35-1/4 35-1/4 40-1/4 40-1/4 40-1/4 40-1/4 40-1/4

14-3/4 14-3/4 20 20 22 22 22 25 25 25 25 25

10-7/16 14-13/16 14-13/16 16-13/16 16-13/16 18-9/16 21-1/16 23-3/16 23-3/16 26-3/16 31-3/16 37-1/2

13 13 16 16 20 20 20 24 24 24 24 24

9-1/4 9-1/4 11 11 12 12 12 13-1/2 13-1/2 14 – –

2 2 2-3/4 2-3/4 3-5/8 3-5/8 3-5/8 4-3/8 4-3/8 4-3/8 4-1/4 4-1/4

9-1/4 13-5/8 13-5/8 15-5/8 15-5/8 17-3/8 19-7/8 22 22 25 30 36-3/8

5 5 6-1/4 6-1/4 8 8 8 9 9 9 9 9

6-1/4 6-1/4 6-1/2 6-1/2 7-1/4 7-1/4 7-1/4 7-1/4 7-1/4 7-1/4 7-1/4 7-1/4

3/8-16 3/8-16 3/8-16 3/8-16 3/8-16 3/8-16 3/8-16 3/8-16 3/8-16 3/8-16 3/8-16 3/8-16

➁ 1/2 1/2 1/2 1/2 1/2 1/2 1/2 1/2 1/2 1/2 3/4 3/4

– – – – – – – – – – 5 5

– – – – – – – – – – 16 16

19-1/2 20-1/8 30 30 30 31-1/8 31-1/8 34-7/8 34-7/8 36-1/4 35-1/2 40-1/2

22-1/4 22-1/4 29 29 30-1/2 30-1/2 30-1/2 32-7/8 32-7/8 32-7/8 32-7/8 32-7/8

9 12 12 14 14 16 18 20 20 22 22 24

58# 72# 102# 116# 152# 162# 169# 231# 231# 261# 330# 410#

PD 30 PD 50 PD 75 PD 100 PD 125 PD 150 PD 175 PD 200 PD 250 PD 300 PD 350 PD 400

30,000 50,000 75,000 100,000 125,000 150,000 175,000 200,000 250,000 300,000 350,000 400,000

24,000 40,000 60,000 80,000 100,000 120,000 140,000 160,000 200,000 240,000 280,000 320,000

440 740 1100 1460 1850 2180 2550 2870 3700 4460 4870 5440

515 610 736 860 870 931 959 819 1053 1123 1068 1016

51 50 51 51 50 51 51 52 50 50 53 54

①

RPM

ype

T

25 33 41 49 51 55 59 51 67 74 70 69

1/40 1/40 1/12 1/12 1/8 1/8 1/6 1/6 1/3 1/2 3/4 3/4

1550 1550 1550 1550 1625 1625 1075 1075 1075 1075 1125 1125

Shaded Shaded Shaded Shaded Perm. Perm. Perm. Perm. Perm. Perm. Perm. Perm.

Pole Pole Pole Pole Split Cap. Split Cap. Split Cap. Split Cap. Split Cap. Split Cap. Split Cap. Split Cap.

1.3 1.3 2.5 2.5 2.6 2.6 3.1 3.1 5.7 7.8 8.3 8.3

Heater Parts from ACF Greenhouses

DIMENSIONS/PERFORMANCE – BD

A

H

J VENT PIPE

K

AA

B

E

C

F

W

N

X

K

S

G

O

EE

P

4-5/8''

For clearance to combustibles,

see page 3.

QxV

RxT

D (OPENING)

BB

M (APPROX.)

L (MIN. DISTANCE TO WALL)

BLOWER

ENCLOSURE

(OPTIONAL)

FILTER RACK

(OPTIONAL)

Dimensions (inches) — BD

Dimension

Symbol

A

B

C

D

E

F

G

H

AA

BB

J

① 4 5 6 6 7 7 7 8 9 10 10

K➃ Mounting Holes

Gas Connections

W

X

EE

L w/ Blwr Encl & Filt Rk

L w/o Blwr Encl & Filt Rk

M

➂ 32 37-1/8 39-3/4 43-7/8 47-1/8 47-1/8 55 55 55 55 59

N

➄ 11-3/4 14-7/8 17-5/8 18-5/8 21-1/2 21-1/2 25-7/16 25-7/16 24-15/16 17-15/16 22

O

P

Q Blower Encl Ht

V Blower Encl Width

R Inlet Duct Height

T Inlet Duct Width

C

enter to Center

Blower Mtg. Holes S

Std. Mtr. Sheave Dia.

Std. Blower Sheave Dia.

Blower Wheel Diameter

Approx. Weight

Diameter of round vent pipe to fit oval opening.

①

For natural gas;may vary depending on control availability.

➁

This is an approximate dimension for standard motors, allow 3" for sheave and optional motors.

➂

BD 50 thru BD 300 — 4 holes (2 on blower and 2 on unit).

➃

BD350 and BD 400 — 6 holes (2 on blower and 4 on unit).

Distance between mounting hole in unit casing and mounting hole on blower. On the BD 350 and BD 400, the distance is from rear mounting hole in casing to the mounting hole on blower.

➄

Motor pulley is adjustable.

➅

Standard Blower Motor Data — BD

BD 50 BD 75 BD 100 BD 125 BD 150 BD 175 BD 200 BD 250 BD 300 BD 350 BD 400

17-1/4 17-1/4 19-1/4 19-1/4 21 23-1/2 25-5/8 25-5/8 28-5/8 33-5/8 40

24-1/4 28-3/4 28-3/4 35-1/4 35-1/4 35-1/4 40-1/4 40-1/4 40-1/4 40-1/4 40-1/4

14-3/4 20 20 22 22 22 25 25 25 25 25

14-13/16 14-13/16 16-13/16 16-13/16 18-9/16 21-1/16 23-3/16 23-3/16 26-3/16 31-3/16 37-1/2

13 16 16 20 20 20 24 24 24 24 24

9-1/4 11 11 12 12 12 13-1/2 13-1/2 14 – –

2 2-3/4 2-3/4 3-5/8 3-5/8 3-5/8 4-3/8 4-3/8 4-3/8 4-1/4 4-1/4

13-5/8 13-5/8 15-5/8 15-5/8 17-3/8 19-7/8 22 22 25 30 36-3/8

5 6-1/4 6-1/4 8 8 8 9 9 9 9 9

6-1/4 6-1/2 6-1/2 7-1/4 7-1/4 7-1/4 7-1/4 7-1/4 7-1/4 7-1/4 7-1/4

3/8-16 3/8-16 3/8-16 3/8-16 3/8-16 3/8-16 3/8-16 3/8-16 3/8-16 3/8-16 3/8-16

➁ 1/2 1/2 1/2 1/2 1/2 1/2 1/2 1/2 1/2 3/4 3/4

– – – – – – – – – 5 5

– – – – – – – – – 16 16

41-3/8 46-5/8 49-5/8 56-5/8 56-5/8 56-5/8 63-5/8 63-5/8 63-5/8 63-5/8 63-5/8

47-5/8 52-5/8 55-5/8 51-5/8 62-5/8 62-5/8 69-5/8 69-5/8 69-5/8 69-5/8 69-5/8

38 43-1/8 45-3/4 49-7/8 53-1/8 53-1/8 61 61 61 61 65

4-1/2 5-3/4 5-3/4 7-1/2 7-1/4 7-1/4 8-1/2 8-1/2 8-1/2 8-1/2 8-1/2

22 22 25 25 30 30 34 34 34 34 34

14-1/8 17-1/8 17-1/8 21-3/8 21-3/8 21-3/8 25-1/8 25-1/8 25-1/8 25-1/8 25-1/8

17-1/2 17-1/2 21-1/4 21-1/4 29 29 34-1/4 34-1/4 34-1/4 44-3/8 44-3/8

15-3/4 15-3/4 15-3/4 20 20 20 23-3/4 23-3/4 23-3/4 23-3/4 23-3/4

16 16 19-3/4 19-3/4 27-1/2 27-1/2 32-3/4 32-3/4 32-3/4 42-7/8 42-7/8

10-15/16 13-15/16 18-7/16 18-7/16 17-5/16 17-3/8 20-3/8 20-3/8 20-3/8 20-3/8 20-3/8

➅ 3 3 3 3 3 3 3 3 3 3 4-1/2

8 10 8 7 11 7 14 10 7 6 10

8 8 9 9 13 13 15 15 15 15 15

116# 146# 158# 205# 215# 231# 307# 307# 331# 420# 490#

Note: Mounting heights and throws for BD models, without ductwork or nozzles, and at a cfm

yielding a 55° temperature rise are the same as those listed for equivalent size PD units.

Standard Model Number

BD 50 BD 75 BD 100 BD 125 BD 150 BD 175 BD 200 BD 250 BD 300 BD 350 BD 400

Motor

Data

Horsepower

RPM

Type

1/4 1/4 1/4 1/4 1/4 1/3 1/4 1/3 3/4 1 1-1/2

1725 1725 1725 1725 1725 1725 1725 1725 1725 1725 1725

Split Split Split Split Split Split Split Split Split Cap. Cap.

Phase Phase Phase Phase Phase Phase Phase Phase Phase Start Start

Total Unit

Power Amps

Data listed is for standard 115-volt, 60-Hertz, single-phase motors.

①

5.7 5.7 5.7 5.7 5.7 4.9 5.7 4.9 11.3 13.7 15.6

Model Number

13

Heater Parts from ACF Greenhouses

PERFORMANCE DATA – NOZZLES

S

T

T

H

S

S

S

T

H

A choice of four air discharge nozzles

accommodate various heat throw

patterns illustrated. Equipped with

adjustable louver blades, nozzles are

fabricated from galvanized steel and

are offered either unpainted or

painted to match the finish of the

blower unit heaters. Nozzles are

flanged for easy attachment over

the air discharge opening of the

blower unit heater.

40° DOWNWARD

NOZZLE

90° VERTICAL

NOZZLE

H

S

S

5-WAY

NOZZLES

40° SPLITTER

NOZZLE

Mounting Height, Heat Throw, Heat Spread (in feet)

Nozzle

Type

40°

Downward

Nozzle

90° Vertical

Nozzle

40° Splitter

Nozzle

5-Way

Nozzle

The above table is based on an inlet air temperature of 70°F and an air temperature rise of 55°F. Air deflectors on, 40° and 90° discharge nozzles set perpendicular to the

face of the air discharge opening. On 5-way nozzles all air deflectors set perpendicular to floor. Static pressure measured at 0.1" W.C. for 90° nozzle, 0.2" W.C. for 40°

downward and 5-way nozzle, and 0.3" W.C. for 40° splitter nozzle. Outlet velocities are approximately 1750 FPM for the 40° nozzles, 1000 FPM for the 90° nozzle and 1300

FPM for 5-way. For motor size, drive and blower rpm refer to pages 18 and 19. Mounting height measured from bottom of unit.

14

Max. Mounting Ht. (ft.) H 16 20 21 24 26 25 27 29 31 32 32

Heat Throw (ft.) T 48 61 64 71 79 76 81 86 94 96 96

Heat Spread (ft.) S 16 20 21 24 26 25 27 29 31 32 32

Max. Mounting Ht. (ft.) H 14 22 23 24 26 26 24 29 31 32 32

Heat Spread (ft.) S 14 22 23 24 26 26 24 29 31 32 32

Max. Mounting Ht. (ft.) H – – – 23 24 24 23 25 28 30 32

Heat Throw (ft.) T – – – 56 60 59 59 62 70 75 80

Heat Spread (ft.) S – – – 113 120 118 117 124 140 151 160

Max. Mounting Ht. (ft.) H – 18 18 23 22 21 20 25 26 23 26

Heat Spread (ft.) S – 25 26 32 31 29 28 35 36 32 36

BD 50 BD 75 BD 100 BD 125 BD 150 BD 175 BD 200 BD 250 BD 300 BD 350 BD 400

Model Number

Heater Parts from ACF Greenhouses

DIMENSIONAL DATA

A

C

B

/

4"

D

B

A

/4"

3

C

D

3

/4"

B

D

A

C

Downward Nozzles

3

/4"

B

D

Downward Nozzles

40°

A

C

90°

40°

Splitter Nozzles

5-Way

Nozzle

Dimensions (in inches)

Nozzle

Type

40° Downward

Nozzle

90° Vertical

Nozzle

40° Splitter

Nozzle

5-Way

Nozzle

Dimension

Symbol

A 14-13/16 14-13/16 16-13/16 16-13/16 18-9/16 21-1/16 23-3/16 23-3/16 26-3/16 31-1/8 37-1/2

B 13 16 16 20 20 20 24 24 24 24 24

C 20 24 22 26 26 25 30 30 30 36 36

D 3-1/2 4 3 4 4 4 4 4 6 11 11

A 14-13/16 14-13/16 16-13/16 16-13/16 18-9/16 21-1/16 23-3/16 23-3/16 26-3/16 31-1/8 37-1/2

B 13 16 16 20 20 20 24 24 24 24 24

C 15 15 17 22 22 23 29 29 30 34 34

D 6 6 6 8 8 8 10 10 10 14 14

A – – – – 18-9/16 21-1/16 23-3/16 23-3/16 26-3/16 31-1/8 37-1/2

B – – – – 20 20 24 24 24 24 24

C – – – – 34 33 39 39 40 46 47

D – – – – 10 11 12 12 14 19 20

A 14-13/16 14-13/16 16-13/16 16-13/16 18-9/16 21 23-3/16 23-3/16 26-3/16 31-1/8 37-1/2

B 13 16 16 20 20 20 24 24 24 24 24

C 20-3/4 20-3/4 22-3/4 22-3/4 24-1/2 27 29 29 32 37 43-1/2

D 11 11 12 12 13 14 15 15 16 18 18

BD 50

BD 75 BD 100 BD 125 BD 150 BD 175 BD 200 BD 250 BD 300 BD 350 BD400

Model Number

15

Heater Parts from ACF Greenhouses

PERFORMANCE DATA – HOODS FOR PROPELLER MODELS

X

Y

Y

Z

Z

X

60 NOZZLE

30 NOZZLE

60

30

30 DOWNTURN NOZZLE

60 DOWNTURN NOZZLE

Performance Data — 30°, 60° and 90° Downward Deflector Hoods

ounting

M

Height to

Bottom of

Heater

Models

8'

10

' 6 15 22 9 23 22 13 30 41 14 31 43 15 34 47 17 37 51 14 31 43 20 43 59 23 48 66 21 45 62 21 44 61

12'

14'

16'

PD 50 PD 75 PD 100 PD 125 PD 150 PD 175 PD 200 PD 250 PD 300 PD 350 PD 400

X Y Z X Y Z X Y Z X Y Z X Y Z X Y Z X Y Z X Y Z X Y Z X Y Z X Y Z

8 19 26 11 25 34 14 31 43 15 32 44 16 36 49 18 38 52 15 33 45 21 44 60 24 49 67 22 46 63 22 45 62

4 12 17 7 20 28 11 28 39 12 29 40 14 33 45 15 35 49 12 30 41 19 42 58 21 47 65 20 44 61 19 43 59

5 14 21 10 25 35 10 26 37 12 30 42 14 33 46 11 27 37 17 40 56 20 46 63 19 43 59 18 42 57

5 17 25 7 21 30 10 27 38 12 31 43 8 22 31 16 38 53 19 44 61 17 41 56 16 40 55

18'

20'

22'

4'

2

Mounting

Height to

Bottom of

Heater

Models

8'

10'

12'

14'

16'

PD 50 PD 75 PD 100 PD 125 PD 150 PD 175 PD 200 PD 250 PD 300 PD 350 PD 400

X Y Z X Y Z X Y Z X Y Z X Y Z X Y Z X Y Z X Y Z X Y Z X Y Z X Y Z

0 19 26 0 26 36 0 33 45 0 34 47 0 38 52 0 40 55 0 35 47 0 47 65 0 52 72 0 49 68 0 48 66

0 14 19 0 23 32 0 31 42 0 32 44 0 36 49 0 39 53 0 33 45 0 46 63 0 51 70 0 48 66 0 47 64

0 18 25 0 28 38 0 29 40 0 33 46 0 36 50 0 30 41 0 44 60 0 50 68 0 46 64 0 45 62

0 10 14 0 23 33 0 25 35 0 30 41 0 33 46 0 26 36 0 41 57 0 48 65 0 44 61 0 43 59

0 13 19 0 18 25 0 25 35 0 29 41 0 19 27 0 38 53 0 45 62 0 41 57 0 40 55

18'

20'

22'

4'

2

30° Downward Hood For Propeller Units

➀

6 18 26 6 20 29 9 26 37 6 18 26 14 36 50 17 42 58 15 38 53 15 37 52

12 32 45 15 39 54 13 35 49 13 33 47

8 24 35 13 35 49 10 29 42 8 25 37

8 26 38 8 24 36 8 24 35

60° Downward Hood For Propeller Units

➀

0 12 17 0 13 19 0 23 32 0 12 17 0 35 48 0 42 58 0 38 52 0 36 50

0 29 40 0 38 52 0 33 46 0 31 43

0 16 23 0 32 45 0 25 35 0 21 30

0 19 28 0 16 24 0 16 23

Mounting

Height to

Bottom of

Heater

Models

8'

10'

12'

14'

16'

18'

20'

PD 50 PD 75 PD 100 PD 125 PD 150 PD 175 PD 200 PD 250 PD 300 PD 350 PD 400

S S S S S S S S S S S

10 23 30 34 38 42 36 54 62 58 56

11 20 27 30 34 37 32 48 56 52 50

12 19 24 27 31 34 29 44 51 47 46

17 23 25 29 32 27 41 47 44 42

16 21 24 27 29 25 38 44 41 39

20 22 25 28 24 36 42 38 37

19 21 24 26 23 34 40 36 35

22'

24'

26'

28'

0'

3

Data Based on units fired at full rated input with an entering air temperature of 60°-80°F. Maximum mounting heights higher versus units without outlet devices.

➀

90° Downward Hood For Propeller Units

23 25 22 33 38 35 34

THROW-FLOOR COVERAGE

➀

31 36 33 32

30 35 32 31

29 33 31 30

32 30 29

NOTE:

X = FEED FROM HEATER

TO START OF

FLOOR COVERAGE.

Y = FEET TO END OF

FLOOR COVERAGE.

Z = FEET TO END OF

THROW.

30° HOOD 60° HOOD

16

Heater Parts from ACF Greenhouses

PERFORMANCE DATA – HOODS FOR BLOWER MODELS

erformance Data — 30°, 60° and 90° Downward Deflector Hoods

P

Mounting

Height to

Bottom of

Heater

Models

8'

10'

12'

14'

16'

18'

20'

22'

BD 50 BD 75 BD 100 BD 125 BD 150 BD 175 BD 200 BD 250 BD 300 BD 350 BD 400

X Y Z X Y Z X Y Z X Y Z X Y Z X Y Z X Y Z X Y Z X Y Z X Y Z X Y Z

13 29 40 18 38 52 22 47 64 23 47 64 26 53 72 28 56 76 24 50 68 31 63 86 35 69 94 37 73 99 30 61 84

12 28 38 16 37 50 21 46 63 21 46 63 25 52 71 26 55 75 23 49 67 30 62 85 34 69 94 36 72 98 29 61 83

10 25 35 15 35 48 20 45 61 20 45 62 23 51 70 25 54 74 22 48 66 29 62 84 33 68 93 34 71 97 28 60 82

8 21 30 14 33 46 19 43 59 19 43 60 22 50 68 24 53 73 21 47 64 28 61 83 31 67 92 33 71 96 27 59 80

12 30 42 17 41 57 17 42 57 21 48 66 23 52 71 19 45 62 27 59 81 30 66 90 32 69 95 26 57 79

9 25 36 16 39 54 16 39 54 19 46 64 21 50 69 18 43 59 25 58 80 29 65 89 31 68 93 24 56 77

14 35 50 14 36 50 18 44 61 20 48 66 16 40 56 24 56 77 28 63 87 30 67 92 23 54 75

11 30 43 11 31 44 16 41 57 18 45 63 14 36 51 22 54 75 26 62 85 28 65 90 21 52 72

24'

26'

28'

3

0'

Mounting

Height to

Bottom of

Heater

Models

8'

10'

12'

14'

16'

18'

20'

22'

BD 50 BD 75 BD 100 BD 125 BD 150 BD 175 BD 200 BD 250 BD 300 BD 350 BD 400

X Y Z X Y Z X Y Z X Y Z X Y Z X Y Z X Y Z X Y Z X Y Z X Y Z X Y Z

0 31 42 0 40 55 0 50 68 0 50 69 0 56 77 0 60 82 0 53 73 0 68 93 0 74 102 0 78 107 0 66 90

0 28 39 0 38 52 0 48 66 0 49 67 0 55 76 0 59 81 0 52 71 0 67 91 0 74 101 0 77 106 0 65 88

0 25 34 0 36 49 0 47 64 0 47 65 0 54 74 0 57 79 0 50 69 0 65 90 0 72 99 0 76 104 0 63 87

0 19 27 0 33 45 0 44 61 0 45 62 0 52 71 0 56 76 0 48 67 0 64 88 0 71 97 0 75 102 0 62 85

0 11 16 0 29 40 0 42 57 0 42 58 0 50 68 0 54 74 0 46 63 0 62 85 0 69 95 0 73 100 0 60 82

0 22 31 0 38 53 0 39 53 0 47 64 0 51 70 0 43 59 0 60 82 0 68 93 0 72 98 0 58 79

0 33 46 0 34 47 0 43 60 0 48 66 0 39 54 0 58 79 0 65 90 0 70 95 0 55 76

0 26 36 0 27 38 0 39 54 0 44 61 0 34 47 0 55 75 0 63 86 0 67 92 0 52 72

24'

26'

28'

3

0'

Mounting

Height to

Bottom of

Heater

Models

8'

10'

12'

14'

16'

18'

20'

22'

24'

26'

28'

30'

BD 50 BD 75 BD 100 BD 125 BD 150 BD 175 BD 200 BD 250 BD 300 BD 350 BD 400

S S S S S S S S S S S

29 42 56 61 72 79 70 98 113 121 94

26 38 50 55 65 70 63 88 101 108 84

24 35 46 50 59 64 58 80 92 99 77

22 32 43 46 55 60 53 74 85 91 71

21 30 40 43 51 56 50 70 80 85 67

19 28 38 41 48 53 47 66 75 81 63

27 36 39 46 50 45 62 71 76 60

26 34 37 44 48 42 59 68 73 57

24 33 35 42 45 41 57 65 70 55

31 34 40 44 39 55 63 67 52

30 33 39 42 38 53 60 65 50

29 32 37 41 36 51 58 62 49

32'

34'

36'

38'

40'

2'

4

Data Based on unit fired at full rated input, 60°-80°F entering air temperature, and a 40°F temperature rise through

➁

unit. Maximum mounting heights higher versus units without outlet devises.

30° Downward Hood For Blower Units

➁

13 36 51 16 42 59 10 29 42 21 52 72 25 59 82 27 63 87 20 49 69

19 48 68 23 57 79 25 61 85 18 46 64

16 44 62 21 54 75 23 58 81 15 41 58

12 36 52 19 50 70 21 55 77 10 32 47