Modine Manufacturing PDE, G31, G20 Service Manual

installation and service manual

gas-fired unit heaters

models PDE

G20, G31

6-592

55HH7755004477AA

CCoonntteennttss

Pages

Inspection on arrival..............................................................1

Special precautions ..............................................................2

General introduction .............................................................3

Technical data....................................................................3-4

Installation .........................................................................4-6

Positioning heater..............................................................4

Ventilation..........................................................................5

Unit suspension.................................................................5

Flue system....................................................................5-6

Piping ................................................................................6

Gas supply........................................................................6

Electrical supply................................................................6

Commissioning .....................................................................7

Servicing...............................................................................8

Wiring Diagram.....................................................................9

Major Component Location ..................................................9

Replacement of parts .........................................................10

Fault finding........................................................................11

Spare parts list ..............................................................11-12

WARNING

IImmpprrooppeerr iinnssttaallllaattiioonn,, aaddjjuussttmmeenntt,,

aalltteerraattiioonn,, sseerrvviiccee oorr mmaaiinntteennaannccee ccaann ccaauussee

pprrooppeerrttyy ddaammaaggee,, iinnjjuurryy oorr ddeeaatthh,, aanndd ccoouulldd

ccaauussee eexxppoossuurree ttoo ssuubbssttaanncceess wwhhiicchh hhaavvee

bbeeeenn ddeetteerrmmiinneedd bbyy vvaarriioouuss aaggeenncciieess ttoo

ccaauussee ccaanncceerr,, bbiirrtthh ddeeffeeccttss oorr ootthheerr

rreepprroodduuccttiivvee hhaarrmm.. RReeaadd tthhee iinnssttaallllaattiioonn,,

ooppeerraattiinngg aanndd mmaaiinntteennaannccee iinnssttrruuccttiioonnss

tthhoorroouugghhllyy bbeeffoorree iinnssttaalllliinngg oorr sseerrvviicciinngg tthhiiss

eeqquuiippmmeenntt..

FFOORR YYOOUURR SSAAFFEETTYY

IIff yyoouu ssmmeellll ggaass::

11.. OOppeenn wwiinnddoowwss

22.. DDoonn''tt ttoouucchh eelleeccttrriiccaall sswwiittcchheess..

33.. EExxttiinngguuiisshh aannyy ooppeenn ffllaammee..

44.. IImmmmeeddiiaatteellyy ccaallll yyoouurr ggaass ssuupppplliieerr..

FFOORR YYOOUURR SSAAFFEETTYY

TThhee uussee aanndd ssttoorraaggee ooff ggaassoolliinnee oorr ootthheerr

ffllaammmmaabbllee vvaappoouurrss aanndd lliiqquuiiddss iinn ooppeenn

ccoonnttaaiinneerrss iinn tthhee vviicciinniittyy ooff tthhiiss aapppplliiaannccee iiss

hhaazzaarrddoouuss..

THIS MANUAL IS THE PROPERTY OF THE OWNER.

PLEASE BE SURE TO LEAVE IT WITH THE OWNER WHEN

YOU LEAVE THE JOB.

!

TToo pprreevveenntt pprreemmaattuurree hheeaatt eexxcchhaannggeerr ffaaiilluurree

ddoo nnoott iinnssttaallll AANNYY ggaass ffiirreedd uunniittss iinn aarreeaass

wwhheerree cchhlloorriinnaatteedd,, hhaallooggeennaatteedd oorr aacciidd vvaappoouurrss

aarree pprreesseenntt iinn tthhee aattmmoosspphheerree..

IInnssppeeccttiioonn oonn AArrrriivvaall

1. Inspect unit upon arrival. In case of damage, report

immediately to transportation company , and y our local sales

representative.

2.

Inspect unit received for conformance with description of

product ordered.

IMPORTANT

TThhee uussee ooff tthhiiss mmaannuuaall iiss ssppeecciiffiiccaallllyy iinntteennddeedd

ffoorr aa qquuaalliiffiieedd iinnssttaallllaattiioonn aanndd sseerrvviiccee aaggeennccyy..

AAllll iinnssttaallllaattiioonn aanndd sseerrvviiccee ooff tthheessee uunniittss mmuusstt

bbee ppeerrffoorrmmeedd bbyy aa qquuaalliiffiieedd iinnssttaallllaattiioonn aanndd

sseerrvviiccee aaggeennccyy..

August, 1999

0120

22

TTHHEE IINNSSTTAALLLLAATTIIOONN AANNDD MMAAIINNTTEENNAANNCCEE IINNSSTTRRUUCCTTIIOONNSS

IINN TTHHIISS MMAANNUUAALL MMUUSSTT BBEE FFOOLLLLOOWWEEDD TTOO EENNSSUURREE SSAAFFEE,,

EEFFFFIICCIIEENNTT AANNDD TTRROOUUBBLLEE-FFRREEEE OOPPEERRAATTIIOONN.. IINN

AADDDDIITTIIOONN,, PPAARRTTIICCUULLAARR CCAARREE MMUUSSTT BBEE EEXXEERRCCIISSEEDD

RREEGGAARRDDIINNGG TTHHEE SSPPEECCIIAALL PPRREECCAAUUTTIIOONNSS LLIISSTTEEDD BBEELLOOWW..

FFAAIILLUURREE TTOO PPRROOPPEERRLLYY AADDDDRREESSSS TTHHEESSEE CCRRIITTIICCAALL

AARREEAASS CCOOUULLDD RREESSUULLTT IINN PPRROOPPEERRTTYY DDAAMMAAGGEE OORR LLOOSSSS,,

PPEERRSSOONNAALL IINNJJUURRYY,, OORR DDEEAATTHH..

1. Any power supply must be disconnected before making

wiring connections to prevent electrical shock and

equipment damage. All units must be wired strictly in

accordance with the wiring diagram (see Fig. 6 page 9).

2. The gas supply must be turned off before commencing

installation of the heaters. An isolating union gas cock or

union and isolating gas cock

MMUUSSTT

be fitted before the inlet

to the gas valve to allow replacement of parts.

3. The gas supply pressure to the unit heater controls must

never exceed 45mbar.

When leak testing the gas supply system, the unit, and its

combination gas control, must be isolated during any

pressure testing in excess of 45mbar. The unit should be

isolated from the gas supply system by closing the manual

shutoff valve.

4. Start-up and adjustment procedures should be performed

by a qualified engineer.The gas inlet pressure should be

checked upstream of the combination gas control.The inlet

pressure should be at least 20mbar on natural gas or 37mbar

on propane.Purging of gas piping should be perf ormed as

described in IM2. Supply pressure and setting pressure must

be checked with heater in operation when making final

adjustments.

5. All units must be flued to outside.

6. The units

MMUUSSTT NNOOTT bbee

installed in potentially explosive or

flammable atmospheres laden with grain dust, sawdust or

similar airborne materials.

7. Installation of units in high humidity or salt water

atmospheres should be avoided as this will cause

accelerated corrosion resulting in a reduction of the normal

life span of the units.

8. To prevent premature heat exchanger failure do not locate

AANNYY

gas fired unit in areas where chlorinated, halogenated

or acid vapours are present in the atmosphere.

9. Do not install units in extremely draughty locations.

Draughts can cause burner flames to impinge on the heat

exchanger thereby shortening its life.Separation between

units should be maintained to avoid discharge from one unit

entering the inlet of another.

10. Do not install units in tightly sealed rooms or small

compartments without provision for adequate combustion

air and venting. Combustion air must have access to the

space through a minimum of two permanent openings in

the enclosure, one near the bottom and the other near the

top.They should provide a free area of at least the values

given in Section 2.2 ‘Ventilation’.

11. Do not install units outdoors

12. For all sizes, required minimum clearance to combustible

materials from the bottom of the unit is 300mm (however

see page 2 section 16 which may require greater

clearances for servicing) and from the sides 450mm. For

PDE units sizes 30-50 minimum clearance from the top is

25mm and from the flue collar 50mm; for PDE units sizes

75-300 minimum clearance from the top is 50mm and from

the flue collar is 75mm; for PDE unit 350 minimum

clearance from the top is 75mm and from the flue collar is

100mm, for PDE unit 400 minimum clearance from the top

is 100mm and from the flue collar is 125mm.

13. At least 150mm clearance at the sides and 300mm

clearance at rear (or 150mm beyond end of motor at rear of

unit, whichever is greater) must be allowed to provide

sufficient air for combustion and correct operation of the

fan.However see page 2 section 12 for clearances to

combustible material.

14. The minimum distance required from combustible materials

is based on the combustible material surface not exceeding

70°C.Clearance from the top of the unit may be required to

be greater than 150mm if heat damage, other than fire,

may occur to materials above the unit heater at the

temperature described.

15. PDE unit heaters are designed for use in heating

applications with ambient temperatures between 0°C

and 32°C.If an application exists where ambient

temperatures can be expected to fall outside of this range,

contact your local sales representative for

recommendations.

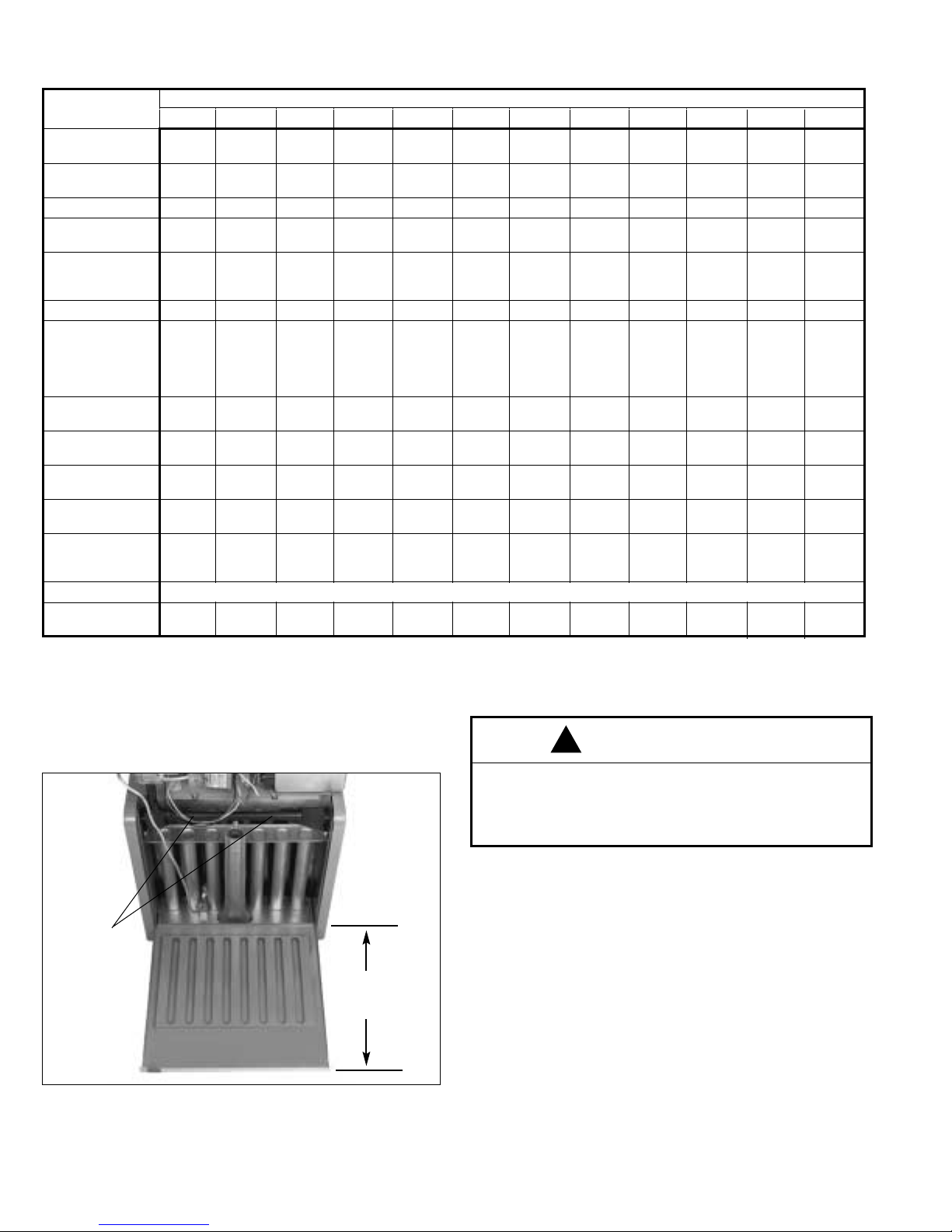

16. Clearance must be provided for opening hinged bottom for

servicing. See Figure 1. Do not stand unit on its base.

17. To ensure that flames do not impinge on heat exchanger

surfaces, the unit must be suspended in a ver tical and level

position. Failure to suspend a unit properly may shorten its

life.

18. The unit heater must not be lifted by its gas controls or gas

manifold.

19. Ensure there are no obstructions which block air intake and

discharge of the unit heater.

20. Do not attach duct work or air filters to any PDE model unit

heaters.

21. In aircraft hangars, the bottom of the unit must be at least

3m from the highest surface of the wings or engine

enclosures of the highest aircraft housed in the hangar and

the installation must be in accordance with the

requirements of the enforcing authority.

22. In garages or other sections of aircraft hangars such as

offices and shops which communicate with areas used for

servicing or storage, the bottom of the unit must be at least

1.8m above the floor.

23. The piping, electrical, ventilation and flueing instructions in

this manual should be carefully read before commencing

installation.

24. All literature shipped with the unit should be kept for future

use for servicing or service diagnosis. None of the literature

shipped with the unit should be discarded.

25. Only approved service replacement parts should be used

when servicing or repairing these unit heaters. A complete

replacement parts list may be obtained by contacting your

appliance supplier.The data plate on the unit gives the unit

model number, serial number and company address. Any

substitution of non-approved parts or controls is at the

owners risk and may invalidate the EC Certification.

26. Always turn off the gas supply at the gas cock and

disconnect the electricity supply to the appliance before

servicing or replacing any components.

27. These unit heaters will normally be controlled by a room

thermostat. Harry Taylor have available a proportional

temperature controller (PTC-1) which can be used to

provide this control. If a room thermostat is to be used

contact Harry Taylor for details of suitable models.

IINNSSTTAALLLLAATTIIOONN

SSPPEECCIIAALL PPRREECCAAUUTTIIOONNSS

33

These instructions are for the PDE unit set up as a Category

I

2H

heater to use natural gas (G20) at a nominal supply

pressure of 20mbar.This is one of its many CE certified forms.

Information on the PDE unit set up as a Catergory I

3+

heater to

use propane (G31) at a nominal suppy pressure of 37mbar,

another certified form, is given in Table 4, page 12.

HHeeaatteerrss

mmuusstt nnoott uussee ggaasseess ootthheerr tthhaann tthhoossee ffoorr wwhhiicchh tthheeyy wweerree

ddeessiiggnneedd aanndd bbuuiilltt..

These instructions should be read thoroughly before

commencing installation of the appliance.

It is the law that all gas appliances are installed by competent

persons, e.g. CORGI Registered, in accordance with the Gas

Safety (Installation and Use) Regulations 1984 (As Amended).

Failure to install the appliance correctly could lead to

prosecution and it is therefore in your interest, and that of

safety, to ensure the law is complied with.

The installation of the appliance must be in accordance with

the current I.E.E. Regulations (BS 7671), and relevant

requirements of the local gas region, local authority, British

Standard Codes of Practice and Building Regulations.

SSeeee aallssoo::

BS 6891 Installation of Low Pressure Pipework.

BS 6230 Installation of Gas Fired Forced Convection Air

Heaters for Commercial and Industrial Space Heating.

BBrriittiisshh GGaass PPuubblliiccaattiioonnss::

IM 2 Purging Procedures of Non-Domestic Gas Boilers.

IM 5 Soundness Testing Procedures for Non-Domestic Gas

Installations.

IM 11 Flues for Commercial and Industrial Gas Fired Boilers

and Air Heaters.

IM 16 Guidance Notes for the Installation of Gas Pipework.

MMOODDIINNEE GGAASS FFIIRREEDD UUNNIITT HHEEAATTEERRSS PPDDEE MMOODDEELLSS

GGEENNEERRAALL IINNTTRROODDUUCCTTIIOONN

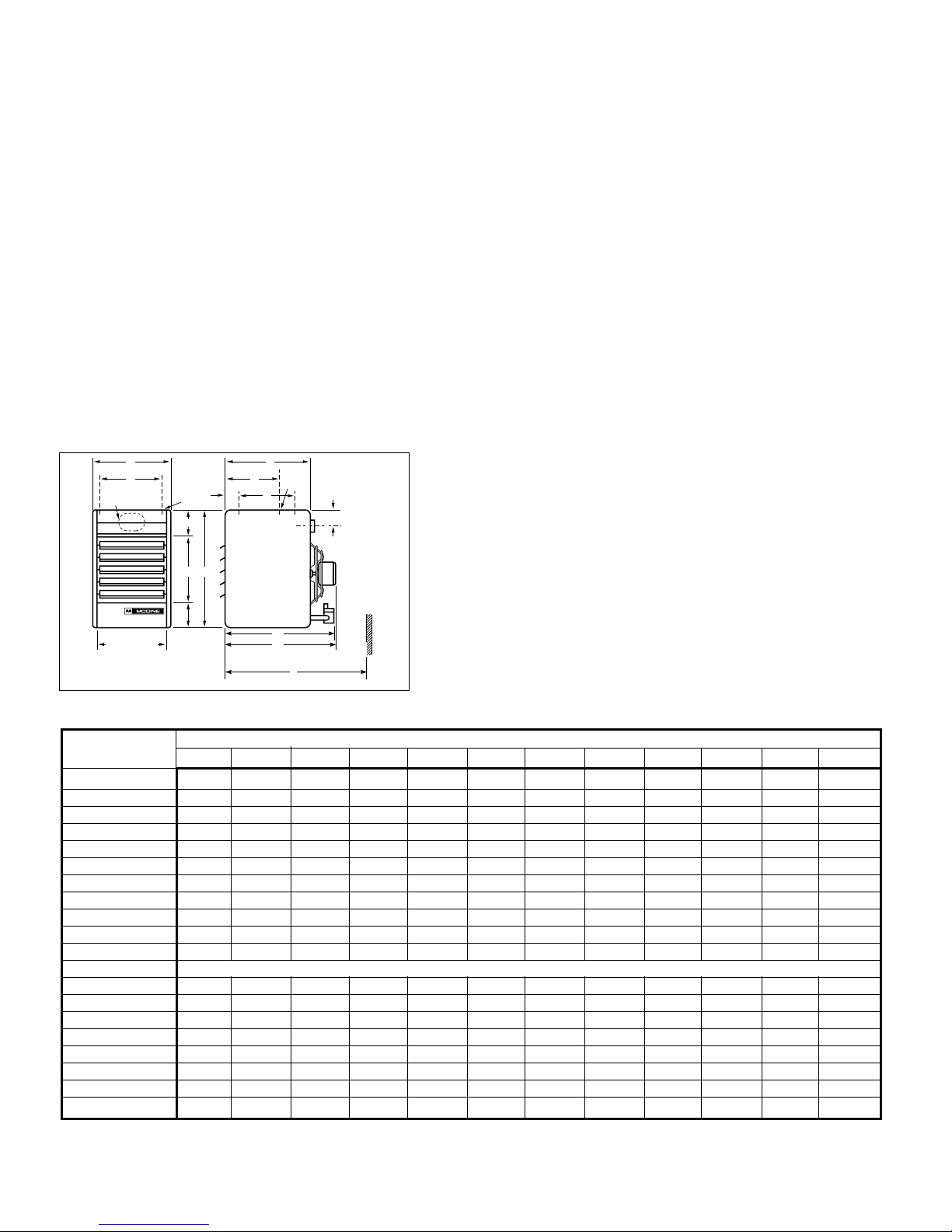

TTAABBLLEE 11..TTEECCHHNNIICCAALL DDAATTAA

A

H

D (OPENING)

BB

E

AA

B

K

W

X

F

C

K

G

L - Approx

MIN. DISTANCE

TO WALL IS L + 6"

J VENT PIPE

EE

(MIN. DISTANCE TO WALL)

L

LL

DDiimmeennssiioonnss ((mmmm))

DDiimmeennssiioonn MMooddeell NNuummbbeerr -PPDDEE

SSyymmbbooll 3300 5500 7755 110000 112255 115500 117755 220000 225500 330000 335500 440000

AA

327 438 438 489 489 533 597 651 651 727 854 1,016

BB

616 616 730 730 895 895 895 1,022 1,022 1,022 1,022 1,022

CC

375 375 508 508 559 559 559 635 635 635 635 635

DD

265 376 376 427 427 472 535 589 589 665 792 953

EE

330 330 406 406 508 508 508 610 610 610 610 610

FF

235 235 279 279 305 305 305 343 343 356 ––

GG

51 51 70 70 92 92 92 111 111 111 108 108

HH

235 346 346 397 397 448 505 559 559 635 762 924

AAAA

127 127 159 159 203 203 203 229 229 229 229 229

BBBB

159 159 165 165 184 184 184 184 184 184 184 184

JJ ((IInncchheess))

3" 4" 5" 6" 6" 7" 7" 7" 8" 9" 10" 10"

KK

11

M10

GGaass CCoonnnn.. ""

1/2 1/2 1/2 1/2 1/2 1/2 1/2 1/2 1/2 3/4 3/4 3/4

WW

––––––– –––127 127

XX

––––––– –––406 406

LL

22

718 718 914 914 927 943 943 1,038 1,041 1,073 1,073 1,200

LLLL

448 457 590 599 650 669 699 775 775 797 797 797

EEEE

565 565 737 737 775 775 775 835 835 835 835 835

FFaann DDiiaammeetteerr

228 305 305 348 348 408 458 508 508 560 560 650

AApppprrooxx.. WWeeiigghhtt ((kkgg))

26.4 32.7 46.4 52.7 69.1 73.6 76.8 105 105 118.6 150 186.4

1

PDE30 to PDE300 inclusive - 2 holes (and the level hanging adjustment feature). PDE350 and PDE400 - 4 holes.

2

Dimension equals overall plus 150mm.

NNOOTTEE:: NNOOTT AALLLL MMOODDEELLSS AARREE AAVVAAIILLAABBLLEE IINN TTHHEE UUKK.. CCHHEECCKK WWIITTHH YYOOUURR SSUUPPPPLLIIEERR..

DDIIMMEENNSSIIOONNSS PPEERRFFOORRMMAANNCCEE —— PPDDEE

44

IINNSSTTAALLLLAATTIIOONN

22..11 PPoossiittiioonniinngg UUnniitt HHeeaatteerrss

When siting units, consider general spaceheating requirements,

availability of gas, and proximity to flue locations. Unit heaters

should be positioned so heated air streams wipe exposed walls

without blowing directly against them.In multiple unit

installations, arrange units so that each supports the air stream

from another, setting up circulatory air movement in the area,

but maintain separation between units so discharge from one

unit will not be directed into the inlet of another.In buildings

exposed to prevailing winds, a large portion of the heated air

should be directed along the windward wall.Avoid interference

to air streams as much as possible.Mounting height (measured

from bottom of unit) at which unit heaters are installed is critical.

Maximum mounting heights are listed in the Table 1 on page 3.

The maximum mounting height for any unit is that height above

which the unit will not deliver heated air to the floor. The

maximum mounting heights must not be exceeded in order to

ensure maximum comfort. PDE unit heaters are designed for

use in heating applications with ambient temperatures between

O°C and 32°C.If an application exists where ambient

temperatures can be expected to fall outside this range, contact

your local sales representative for recommendations.

CAUTION

Units must not be installed in potentially explosive,

flammable, or corrosive atmosphere. To prevent premature

heat exchanger failure do not locate ANY gas fired unit in

areas where chlorinated, halogenated or acid vapours are

present in the atmosphere.

!

FFiigguurree 11

HHiinnggeedd BBaassee ffoorr SSeerrvviicciinngg

(See Dimension "C", page 3)

WING SCREWS

THAT SECURE

HINGED

BOTTOM

THIS IS

DIMENSION C,

SEE PAGE 3

PPeerrffoorrmmaannccee —— nnaattuurraall ggaass oonnllyy.. SSeeee ppaaggee 1122 ffoorr pprrooppaannee ddeettaaiillss..

*

Based on natural gas - typical calorific value 37.78 MJ/M3.

**

At 18°C ambient and unit fired at full-rated input. Mounting height as measured from bottom of unit.

NNOOTTEE:: NNOOTT AALLLL MMOODDEELLSS AARREE AAVVAAIILLAABBLLEE IINN TTHHEE UUKK.. CCHHEECCKK WWIITTHH YYOOUURR SSUUPPPPLLIIEERR..

TTAABBLLEE 22

MMooddeell NNuummbbeerr-PPDDEE

3300 5500 7755 110000 112255 115500 117755 220000 225500 330000 335500 440000

HHeeaatt IInnppuutt

((ggrroossss)) kkWW**

8.8 14.7 22.0 29.3 36.6 44.0 51.3 58.6 73.3 87.9 102.6 117.2

HHeeaatt IInnppuutt

((nneett)) kkWW**

7.9 13.2 19.8 26.4 32.6 39.6 46.2 52.7 66.0 79.1 92.3 105.5

OOuuttppuutt kkWW**

7.0 11.7 17.6 23.4 29.3 35.1 41.0 46.9 58.6 70.3 82.0 93.8

BBuurrnneerr sseett..

7.0 6.7 6.8 6.7 6.5 6.1 5.7 7.1 5.5 7.2 6.5 6.4

pprreessss.. mmbbaarr

IInnjjeeccttoorr - NNoo..

111222333456

DDiiaamm.. mmmm

2.71 3.45 4.30 3.45 3.91 4.30 3.86 3.86 4.7 4.22 4.22 4.09

MMaarrkkiinngg

36 29 18 29 23 18 24 24 13 19 19 20

GGaass rraattee mm33//hh

0.82 1.36 2.04 2.72 3.39 4.08 4.76 5.43 6.8 8.15 9.51 10.87

AApppprrooxx.. fflluuee

9 14 21 29 36 43 50 57 71 86 100 114

ggaass vvooll.. iinn

sseeccoonnddaarryy fflluuee**

33..77%% CCOO22&&

110000°°CC 11//sseecc

AAiirr ffllooww

0.21 0.35 0.51 0.69 0.87 1.03 1.20 1.36 1.75 2.10 2.34 2.66

mm33//sseecc

OOuuttlleett vveelloocciittyy

2.6 3.2 3.7 4.3 4.4 4.7 4.8 4.1 5.3 5.7 5.6 5.3

mm//sseecc

AAiirr TTeemmpp rriissee

27 27 28 27 27 28 28 28 27 27 28 28

°°CC

MMoouunnttiinngg hhtt..

2.1 2.7 3.7 4.3 4.3 4.9 5.2 4.6 5.8 6.4 6.1 6.7

((mmaaxx)) mm

HHeeaatt tthhrrooww

7.6 10.1 12.5 14.9 15.5 16.8 18.0 15.5 20.4 22.6 21.9 23.2

((aatt mmaaxx mmoouunntt.. hhtt..))

mm****

PPoowweerr ssuuppppllyy

230V 50Hz

PPoowweerr uussee

125 150 200 225 400 450 450 400 750 850 950 1,200

((wwaattttss))

Loading...

Loading...