installation and service manual

gas-fired unit heaters

models PDE

G20, G31

6-592

55HH7755004477AA

CCoonntteennttss

Pages

Inspection on arrival..............................................................1

Special precautions ..............................................................2

General introduction .............................................................3

Technical data....................................................................3-4

Installation .........................................................................4-6

Positioning heater..............................................................4

Ventilation..........................................................................5

Unit suspension.................................................................5

Flue system....................................................................5-6

Piping ................................................................................6

Gas supply........................................................................6

Electrical supply................................................................6

Commissioning .....................................................................7

Servicing...............................................................................8

Wiring Diagram.....................................................................9

Major Component Location ..................................................9

Replacement of parts .........................................................10

Fault finding........................................................................11

Spare parts list ..............................................................11-12

WARNING

IImmpprrooppeerr iinnssttaallllaattiioonn,, aaddjjuussttmmeenntt,,

aalltteerraattiioonn,, sseerrvviiccee oorr mmaaiinntteennaannccee ccaann ccaauussee

pprrooppeerrttyy ddaammaaggee,, iinnjjuurryy oorr ddeeaatthh,, aanndd ccoouulldd

ccaauussee eexxppoossuurree ttoo ssuubbssttaanncceess wwhhiicchh hhaavvee

bbeeeenn ddeetteerrmmiinneedd bbyy vvaarriioouuss aaggeenncciieess ttoo

ccaauussee ccaanncceerr,, bbiirrtthh ddeeffeeccttss oorr ootthheerr

rreepprroodduuccttiivvee hhaarrmm.. RReeaadd tthhee iinnssttaallllaattiioonn,,

ooppeerraattiinngg aanndd mmaaiinntteennaannccee iinnssttrruuccttiioonnss

tthhoorroouugghhllyy bbeeffoorree iinnssttaalllliinngg oorr sseerrvviicciinngg tthhiiss

eeqquuiippmmeenntt..

FFOORR YYOOUURR SSAAFFEETTYY

IIff yyoouu ssmmeellll ggaass::

11.. OOppeenn wwiinnddoowwss

22.. DDoonn''tt ttoouucchh eelleeccttrriiccaall sswwiittcchheess..

33.. EExxttiinngguuiisshh aannyy ooppeenn ffllaammee..

44.. IImmmmeeddiiaatteellyy ccaallll yyoouurr ggaass ssuupppplliieerr..

FFOORR YYOOUURR SSAAFFEETTYY

TThhee uussee aanndd ssttoorraaggee ooff ggaassoolliinnee oorr ootthheerr

ffllaammmmaabbllee vvaappoouurrss aanndd lliiqquuiiddss iinn ooppeenn

ccoonnttaaiinneerrss iinn tthhee vviicciinniittyy ooff tthhiiss aapppplliiaannccee iiss

hhaazzaarrddoouuss..

THIS MANUAL IS THE PROPERTY OF THE OWNER.

PLEASE BE SURE TO LEAVE IT WITH THE OWNER WHEN

YOU LEAVE THE JOB.

!

TToo pprreevveenntt pprreemmaattuurree hheeaatt eexxcchhaannggeerr ffaaiilluurree

ddoo nnoott iinnssttaallll AANNYY ggaass ffiirreedd uunniittss iinn aarreeaass

wwhheerree cchhlloorriinnaatteedd,, hhaallooggeennaatteedd oorr aacciidd vvaappoouurrss

aarree pprreesseenntt iinn tthhee aattmmoosspphheerree..

IInnssppeeccttiioonn oonn AArrrriivvaall

1. Inspect unit upon arrival. In case of damage, report

immediately to transportation company , and y our local sales

representative.

2.

Inspect unit received for conformance with description of

product ordered.

IMPORTANT

TThhee uussee ooff tthhiiss mmaannuuaall iiss ssppeecciiffiiccaallllyy iinntteennddeedd

ffoorr aa qquuaalliiffiieedd iinnssttaallllaattiioonn aanndd sseerrvviiccee aaggeennccyy..

AAllll iinnssttaallllaattiioonn aanndd sseerrvviiccee ooff tthheessee uunniittss mmuusstt

bbee ppeerrffoorrmmeedd bbyy aa qquuaalliiffiieedd iinnssttaallllaattiioonn aanndd

sseerrvviiccee aaggeennccyy..

August, 1999

0120

22

TTHHEE IINNSSTTAALLLLAATTIIOONN AANNDD MMAAIINNTTEENNAANNCCEE IINNSSTTRRUUCCTTIIOONNSS

IINN TTHHIISS MMAANNUUAALL MMUUSSTT BBEE FFOOLLLLOOWWEEDD TTOO EENNSSUURREE SSAAFFEE,,

EEFFFFIICCIIEENNTT AANNDD TTRROOUUBBLLEE-FFRREEEE OOPPEERRAATTIIOONN.. IINN

AADDDDIITTIIOONN,, PPAARRTTIICCUULLAARR CCAARREE MMUUSSTT BBEE EEXXEERRCCIISSEEDD

RREEGGAARRDDIINNGG TTHHEE SSPPEECCIIAALL PPRREECCAAUUTTIIOONNSS LLIISSTTEEDD BBEELLOOWW..

FFAAIILLUURREE TTOO PPRROOPPEERRLLYY AADDDDRREESSSS TTHHEESSEE CCRRIITTIICCAALL

AARREEAASS CCOOUULLDD RREESSUULLTT IINN PPRROOPPEERRTTYY DDAAMMAAGGEE OORR LLOOSSSS,,

PPEERRSSOONNAALL IINNJJUURRYY,, OORR DDEEAATTHH..

1. Any power supply must be disconnected before making

wiring connections to prevent electrical shock and

equipment damage. All units must be wired strictly in

accordance with the wiring diagram (see Fig. 6 page 9).

2. The gas supply must be turned off before commencing

installation of the heaters. An isolating union gas cock or

union and isolating gas cock

MMUUSSTT

be fitted before the inlet

to the gas valve to allow replacement of parts.

3. The gas supply pressure to the unit heater controls must

never exceed 45mbar.

When leak testing the gas supply system, the unit, and its

combination gas control, must be isolated during any

pressure testing in excess of 45mbar. The unit should be

isolated from the gas supply system by closing the manual

shutoff valve.

4. Start-up and adjustment procedures should be performed

by a qualified engineer.The gas inlet pressure should be

checked upstream of the combination gas control.The inlet

pressure should be at least 20mbar on natural gas or 37mbar

on propane.Purging of gas piping should be perf ormed as

described in IM2. Supply pressure and setting pressure must

be checked with heater in operation when making final

adjustments.

5. All units must be flued to outside.

6. The units

MMUUSSTT NNOOTT bbee

installed in potentially explosive or

flammable atmospheres laden with grain dust, sawdust or

similar airborne materials.

7. Installation of units in high humidity or salt water

atmospheres should be avoided as this will cause

accelerated corrosion resulting in a reduction of the normal

life span of the units.

8. To prevent premature heat exchanger failure do not locate

AANNYY

gas fired unit in areas where chlorinated, halogenated

or acid vapours are present in the atmosphere.

9. Do not install units in extremely draughty locations.

Draughts can cause burner flames to impinge on the heat

exchanger thereby shortening its life.Separation between

units should be maintained to avoid discharge from one unit

entering the inlet of another.

10. Do not install units in tightly sealed rooms or small

compartments without provision for adequate combustion

air and venting. Combustion air must have access to the

space through a minimum of two permanent openings in

the enclosure, one near the bottom and the other near the

top.They should provide a free area of at least the values

given in Section 2.2 ‘Ventilation’.

11. Do not install units outdoors

12. For all sizes, required minimum clearance to combustible

materials from the bottom of the unit is 300mm (however

see page 2 section 16 which may require greater

clearances for servicing) and from the sides 450mm. For

PDE units sizes 30-50 minimum clearance from the top is

25mm and from the flue collar 50mm; for PDE units sizes

75-300 minimum clearance from the top is 50mm and from

the flue collar is 75mm; for PDE unit 350 minimum

clearance from the top is 75mm and from the flue collar is

100mm, for PDE unit 400 minimum clearance from the top

is 100mm and from the flue collar is 125mm.

13. At least 150mm clearance at the sides and 300mm

clearance at rear (or 150mm beyond end of motor at rear of

unit, whichever is greater) must be allowed to provide

sufficient air for combustion and correct operation of the

fan.However see page 2 section 12 for clearances to

combustible material.

14. The minimum distance required from combustible materials

is based on the combustible material surface not exceeding

70°C.Clearance from the top of the unit may be required to

be greater than 150mm if heat damage, other than fire,

may occur to materials above the unit heater at the

temperature described.

15. PDE unit heaters are designed for use in heating

applications with ambient temperatures between 0°C

and 32°C.If an application exists where ambient

temperatures can be expected to fall outside of this range,

contact your local sales representative for

recommendations.

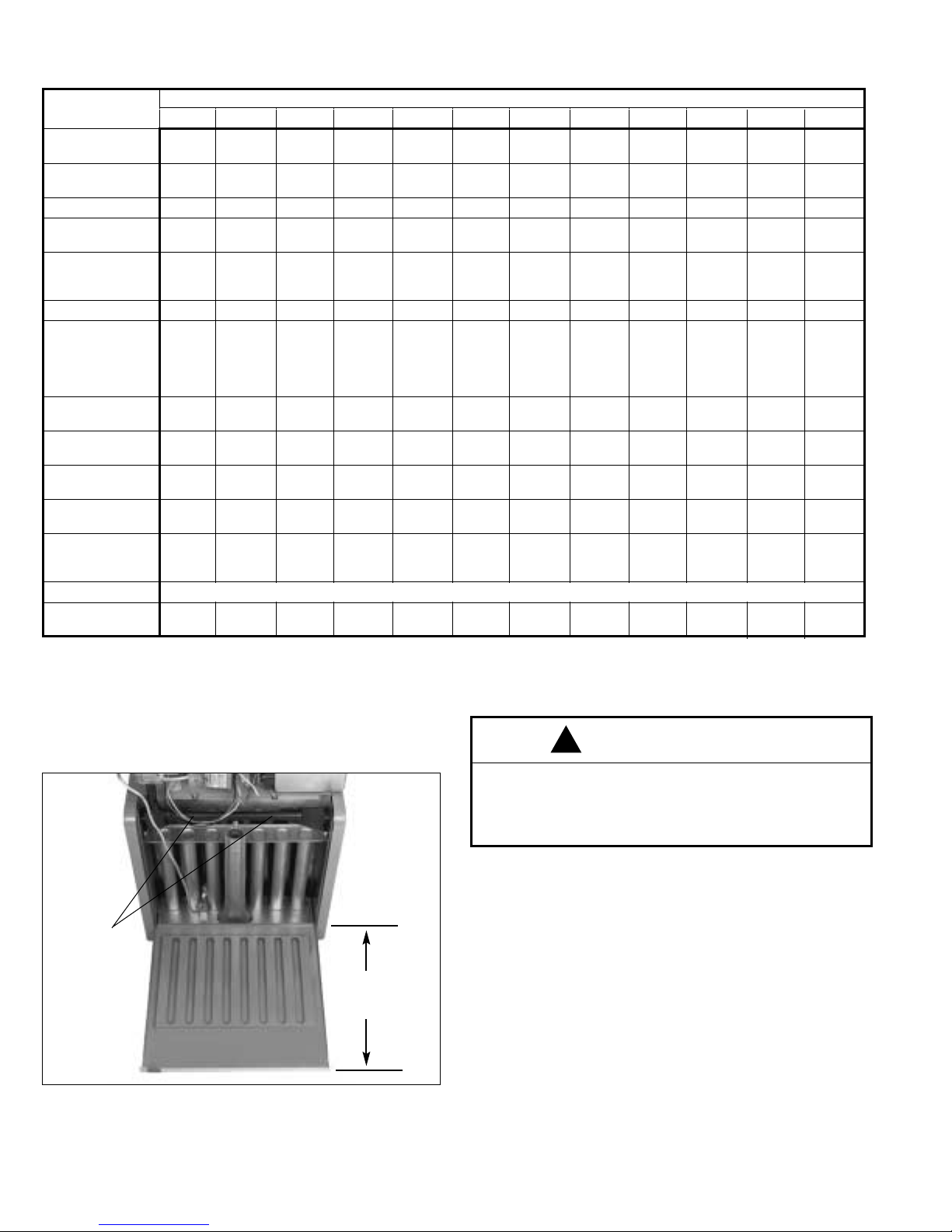

16. Clearance must be provided for opening hinged bottom for

servicing. See Figure 1. Do not stand unit on its base.

17. To ensure that flames do not impinge on heat exchanger

surfaces, the unit must be suspended in a ver tical and level

position. Failure to suspend a unit properly may shorten its

life.

18. The unit heater must not be lifted by its gas controls or gas

manifold.

19. Ensure there are no obstructions which block air intake and

discharge of the unit heater.

20. Do not attach duct work or air filters to any PDE model unit

heaters.

21. In aircraft hangars, the bottom of the unit must be at least

3m from the highest surface of the wings or engine

enclosures of the highest aircraft housed in the hangar and

the installation must be in accordance with the

requirements of the enforcing authority.

22. In garages or other sections of aircraft hangars such as

offices and shops which communicate with areas used for

servicing or storage, the bottom of the unit must be at least

1.8m above the floor.

23. The piping, electrical, ventilation and flueing instructions in

this manual should be carefully read before commencing

installation.

24. All literature shipped with the unit should be kept for future

use for servicing or service diagnosis. None of the literature

shipped with the unit should be discarded.

25. Only approved service replacement parts should be used

when servicing or repairing these unit heaters. A complete

replacement parts list may be obtained by contacting your

appliance supplier.The data plate on the unit gives the unit

model number, serial number and company address. Any

substitution of non-approved parts or controls is at the

owners risk and may invalidate the EC Certification.

26. Always turn off the gas supply at the gas cock and

disconnect the electricity supply to the appliance before

servicing or replacing any components.

27. These unit heaters will normally be controlled by a room

thermostat. Harry Taylor have available a proportional

temperature controller (PTC-1) which can be used to

provide this control. If a room thermostat is to be used

contact Harry Taylor for details of suitable models.

IINNSSTTAALLLLAATTIIOONN

SSPPEECCIIAALL PPRREECCAAUUTTIIOONNSS

33

These instructions are for the PDE unit set up as a Category

I

2H

heater to use natural gas (G20) at a nominal supply

pressure of 20mbar.This is one of its many CE certified forms.

Information on the PDE unit set up as a Catergory I

3+

heater to

use propane (G31) at a nominal suppy pressure of 37mbar,

another certified form, is given in Table 4, page 12.

HHeeaatteerrss

mmuusstt nnoott uussee ggaasseess ootthheerr tthhaann tthhoossee ffoorr wwhhiicchh tthheeyy wweerree

ddeessiiggnneedd aanndd bbuuiilltt..

These instructions should be read thoroughly before

commencing installation of the appliance.

It is the law that all gas appliances are installed by competent

persons, e.g. CORGI Registered, in accordance with the Gas

Safety (Installation and Use) Regulations 1984 (As Amended).

Failure to install the appliance correctly could lead to

prosecution and it is therefore in your interest, and that of

safety, to ensure the law is complied with.

The installation of the appliance must be in accordance with

the current I.E.E. Regulations (BS 7671), and relevant

requirements of the local gas region, local authority, British

Standard Codes of Practice and Building Regulations.

SSeeee aallssoo::

BS 6891 Installation of Low Pressure Pipework.

BS 6230 Installation of Gas Fired Forced Convection Air

Heaters for Commercial and Industrial Space Heating.

BBrriittiisshh GGaass PPuubblliiccaattiioonnss::

IM 2 Purging Procedures of Non-Domestic Gas Boilers.

IM 5 Soundness Testing Procedures for Non-Domestic Gas

Installations.

IM 11 Flues for Commercial and Industrial Gas Fired Boilers

and Air Heaters.

IM 16 Guidance Notes for the Installation of Gas Pipework.

MMOODDIINNEE GGAASS FFIIRREEDD UUNNIITT HHEEAATTEERRSS PPDDEE MMOODDEELLSS

GGEENNEERRAALL IINNTTRROODDUUCCTTIIOONN

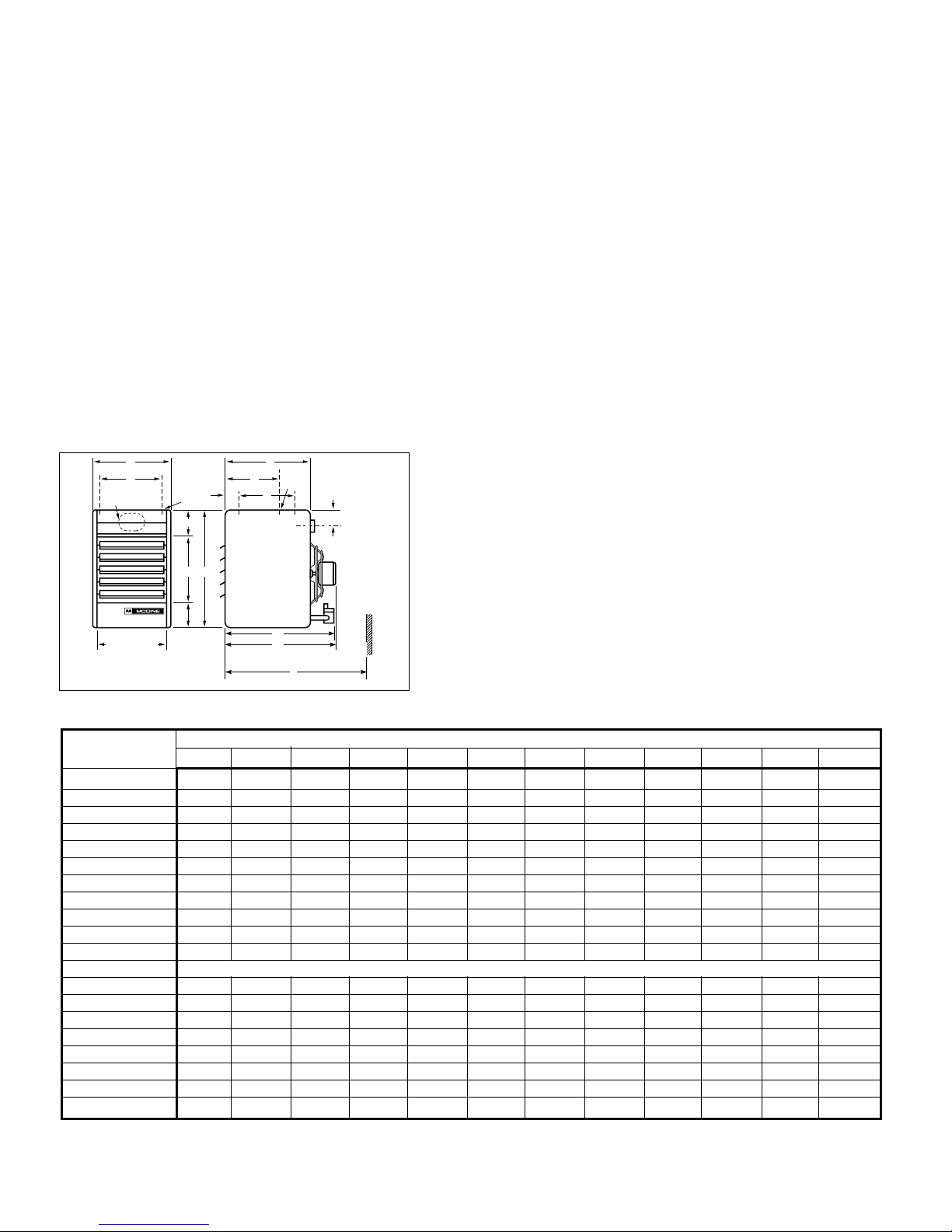

TTAABBLLEE 11..TTEECCHHNNIICCAALL DDAATTAA

A

H

D (OPENING)

BB

E

AA

B

K

W

X

F

C

K

G

L - Approx

MIN. DISTANCE

TO WALL IS L + 6"

J VENT PIPE

EE

(MIN. DISTANCE TO WALL)

L

LL

DDiimmeennssiioonnss ((mmmm))

DDiimmeennssiioonn MMooddeell NNuummbbeerr -PPDDEE

SSyymmbbooll 3300 5500 7755 110000 112255 115500 117755 220000 225500 330000 335500 440000

AA

327 438 438 489 489 533 597 651 651 727 854 1,016

BB

616 616 730 730 895 895 895 1,022 1,022 1,022 1,022 1,022

CC

375 375 508 508 559 559 559 635 635 635 635 635

DD

265 376 376 427 427 472 535 589 589 665 792 953

EE

330 330 406 406 508 508 508 610 610 610 610 610

FF

235 235 279 279 305 305 305 343 343 356 ––

GG

51 51 70 70 92 92 92 111 111 111 108 108

HH

235 346 346 397 397 448 505 559 559 635 762 924

AAAA

127 127 159 159 203 203 203 229 229 229 229 229

BBBB

159 159 165 165 184 184 184 184 184 184 184 184

JJ ((IInncchheess))

3" 4" 5" 6" 6" 7" 7" 7" 8" 9" 10" 10"

KK

11

M10

GGaass CCoonnnn.. ""

1/2 1/2 1/2 1/2 1/2 1/2 1/2 1/2 1/2 3/4 3/4 3/4

WW

––––––– –––127 127

XX

––––––– –––406 406

LL

22

718 718 914 914 927 943 943 1,038 1,041 1,073 1,073 1,200

LLLL

448 457 590 599 650 669 699 775 775 797 797 797

EEEE

565 565 737 737 775 775 775 835 835 835 835 835

FFaann DDiiaammeetteerr

228 305 305 348 348 408 458 508 508 560 560 650

AApppprrooxx.. WWeeiigghhtt ((kkgg))

26.4 32.7 46.4 52.7 69.1 73.6 76.8 105 105 118.6 150 186.4

1

PDE30 to PDE300 inclusive - 2 holes (and the level hanging adjustment feature). PDE350 and PDE400 - 4 holes.

2

Dimension equals overall plus 150mm.

NNOOTTEE:: NNOOTT AALLLL MMOODDEELLSS AARREE AAVVAAIILLAABBLLEE IINN TTHHEE UUKK.. CCHHEECCKK WWIITTHH YYOOUURR SSUUPPPPLLIIEERR..

DDIIMMEENNSSIIOONNSS PPEERRFFOORRMMAANNCCEE —— PPDDEE

44

IINNSSTTAALLLLAATTIIOONN

22..11 PPoossiittiioonniinngg UUnniitt HHeeaatteerrss

When siting units, consider general spaceheating requirements,

availability of gas, and proximity to flue locations. Unit heaters

should be positioned so heated air streams wipe exposed walls

without blowing directly against them.In multiple unit

installations, arrange units so that each supports the air stream

from another, setting up circulatory air movement in the area,

but maintain separation between units so discharge from one

unit will not be directed into the inlet of another.In buildings

exposed to prevailing winds, a large portion of the heated air

should be directed along the windward wall.Avoid interference

to air streams as much as possible.Mounting height (measured

from bottom of unit) at which unit heaters are installed is critical.

Maximum mounting heights are listed in the Table 1 on page 3.

The maximum mounting height for any unit is that height above

which the unit will not deliver heated air to the floor. The

maximum mounting heights must not be exceeded in order to

ensure maximum comfort. PDE unit heaters are designed for

use in heating applications with ambient temperatures between

O°C and 32°C.If an application exists where ambient

temperatures can be expected to fall outside this range, contact

your local sales representative for recommendations.

CAUTION

Units must not be installed in potentially explosive,

flammable, or corrosive atmosphere. To prevent premature

heat exchanger failure do not locate ANY gas fired unit in

areas where chlorinated, halogenated or acid vapours are

present in the atmosphere.

!

FFiigguurree 11

HHiinnggeedd BBaassee ffoorr SSeerrvviicciinngg

(See Dimension "C", page 3)

WING SCREWS

THAT SECURE

HINGED

BOTTOM

THIS IS

DIMENSION C,

SEE PAGE 3

PPeerrffoorrmmaannccee —— nnaattuurraall ggaass oonnllyy.. SSeeee ppaaggee 1122 ffoorr pprrooppaannee ddeettaaiillss..

*

Based on natural gas - typical calorific value 37.78 MJ/M3.

**

At 18°C ambient and unit fired at full-rated input. Mounting height as measured from bottom of unit.

NNOOTTEE:: NNOOTT AALLLL MMOODDEELLSS AARREE AAVVAAIILLAABBLLEE IINN TTHHEE UUKK.. CCHHEECCKK WWIITTHH YYOOUURR SSUUPPPPLLIIEERR..

TTAABBLLEE 22

MMooddeell NNuummbbeerr-PPDDEE

3300 5500 7755 110000 112255 115500 117755 220000 225500 330000 335500 440000

HHeeaatt IInnppuutt

((ggrroossss)) kkWW**

8.8 14.7 22.0 29.3 36.6 44.0 51.3 58.6 73.3 87.9 102.6 117.2

HHeeaatt IInnppuutt

((nneett)) kkWW**

7.9 13.2 19.8 26.4 32.6 39.6 46.2 52.7 66.0 79.1 92.3 105.5

OOuuttppuutt kkWW**

7.0 11.7 17.6 23.4 29.3 35.1 41.0 46.9 58.6 70.3 82.0 93.8

BBuurrnneerr sseett..

7.0 6.7 6.8 6.7 6.5 6.1 5.7 7.1 5.5 7.2 6.5 6.4

pprreessss.. mmbbaarr

IInnjjeeccttoorr - NNoo..

111222333456

DDiiaamm.. mmmm

2.71 3.45 4.30 3.45 3.91 4.30 3.86 3.86 4.7 4.22 4.22 4.09

MMaarrkkiinngg

36 29 18 29 23 18 24 24 13 19 19 20

GGaass rraattee mm33//hh

0.82 1.36 2.04 2.72 3.39 4.08 4.76 5.43 6.8 8.15 9.51 10.87

AApppprrooxx.. fflluuee

9 14 21 29 36 43 50 57 71 86 100 114

ggaass vvooll.. iinn

sseeccoonnddaarryy fflluuee**

33..77%% CCOO22&&

110000°°CC 11//sseecc

AAiirr ffllooww

0.21 0.35 0.51 0.69 0.87 1.03 1.20 1.36 1.75 2.10 2.34 2.66

mm33//sseecc

OOuuttlleett vveelloocciittyy

2.6 3.2 3.7 4.3 4.4 4.7 4.8 4.1 5.3 5.7 5.6 5.3

mm//sseecc

AAiirr TTeemmpp rriissee

27 27 28 27 27 28 28 28 27 27 28 28

°°CC

MMoouunnttiinngg hhtt..

2.1 2.7 3.7 4.3 4.3 4.9 5.2 4.6 5.8 6.4 6.1 6.7

((mmaaxx)) mm

HHeeaatt tthhrrooww

7.6 10.1 12.5 14.9 15.5 16.8 18.0 15.5 20.4 22.6 21.9 23.2

((aatt mmaaxx mmoouunntt.. hhtt..))

mm****

PPoowweerr ssuuppppllyy

230V 50Hz

PPoowweerr uussee

125 150 200 225 400 450 450 400 750 850 950 1,200

((wwaattttss))

55

Safe, efficient and trouble free operation of conventionally flued

appliances is vitally dependent on the provision of an adequate

supply of fresh air to the room in which the appliance is installed.

In buildings having a design air change rate of less than 0.5/h,

and where indirect fired heaters are to be installed in heated

spaces having volume less than:

(a) 4.7 m

3

per kilowatt of total rated heat input for heaters

fitted with natural draught burners: or

(b) 2.2 m

3

per kilowatt of total rated heat input for heaters

fitted with forced or induced draught burners;

grilles shall be provided at low level (i.e. below the level

of the appliance flue connection); except that:

(1) for heaters of heat input less than 60 kW, the total

minimum free area shall be not less than 4.5 cm

2

per

kilowatt of rated heat input;or

(2) for heaters of heat input 60 kW or more, the total mini-

mum free area shall not be less than 270 cm

2

plus 2.25

cm

2

per kilowatt in excess of 60 kW rated heat input.

Most traditional building constructions will provide air changes

of at least 0.5/h without the need for ventilation openings. In the

case of a building having an air change rate less than 0.5/h, low

level ventilation will be necessary.

For indirect heaters installed in buildings with a design air

change rate of 0.5/h or greater, and where the volume of the

heated space is greater than 4.7 m

3

per kilowatt of total rated

heat input, as appropriate, additional high and low level

ventilation will not be required.

22..33 UUnniitt SSuussppeennssiioonn

The most common method of hanging PDE unit heaters is to

utilize M10 threaded rod. On each piece of threaded rod used,

screw a nut about 25mm onto the end of the rods that will be

screwed into the unit heater. Then put a washer over the end of

the threaded rod and screw the rod at least 5 turns, and no

more than 10 turns, into the weld nuts on the top of the heater.

Tighten the nut first installed onto the threaded rod to prevent it

from turning. Drill holes into a steel channel or angle iron at the

same centreline dimensions as the heater that is being installed.

The steel channels or angle iron pieces need to span and be

fastened to appropriate structural members.Cut the threaded

rods to the preferred length, push them through the holes in the

steel channel or angle iron and secure with washers and lock

nuts or lock washers and nuts.A double nut arrangement can be

used here instead of at the unit heater (a double nut can be

used at both places but is not necessary).The entire means of

suspension must be adequate to support the weight of the unit

(see page 3 for unit weights).

For proper operation, the unit must be installed in a level

horizontal position. Clearances to combustibles as specified

below must be strictly maintained.The heaters must not be

installed above the maximum mounting height shown in Table 2

on page 4.

On all units, except the PDE 350 and PDE 400, two M10

tapped holes are located in the top of the unit to receive

threaded rods.

Units with two point suspension, models PDE30 to PDE300,

incorporate a level hanging feature.

PDE30 to PDE300 units that do not hang level after being

installed, can be corrected in place. Remove both outer side

panels (screws are on back flange of side panel) exposing the

(adjustable) mounting brackets (Fig.2).Loosen the set screws

holding the mounting brackets in place and using a rubber

mallet or something similar, tap the heater into a position where

it does hang level.Tighten set screws and replace the outer

side panels.

The PDE 350 and PDE 400 have four mounting holes in the top

of the unit.

TToo eennssuurree tthhaatt ffllaammeess aarree ddiirreecctteedd iinnttoo tthhee cceennttrree ooff tthhee hheeaatt

eexxcchhaannggeerr ttuubbeess,, tthhee uunniitt mmuusstt bbee ssuuppppoorrtteedd iinn aa vveerrttiiccaall

ppoossiittiioonn,, wwiitthh ssuussppeennssiioonn hhaannggeerrss ““UUPP””..

CChheecckk wwiitthh aa lleevveell..

This is important to the operation and life of the unit.

22..44 FFlluuee SSyysstteemm

To ensure safe and satisfactory operation of the heater, the flue

system must be capable of the complete evacuation of flue

products at all times.The height of the flue ter minal above the

draught diverter must be at least 2m and for this height no more

than 0.6m horizontal run may be installed immediately after the

appliance outlet. For greater heights 0.3m horizontal run may be

added for each extra metre of flue height.

The chimney must terminate in a downdraught free zone.

Compliance with the recommendations made in BS.6644;

British Gas publication IMII Flues for Commercial and Industrial

Gas fired boilers and gas heaters’ and the ‘Third Edition of the

1956 Clean Air Memorandum’ should be strictly observed

where applicable.

The flue/chimney design should avoid the formation of excessive

quantities of condensate and for this reason it is recommended

that all chimneys are suitably insulated and lined.

Drain points should be fitted at the bottom of all vertical flue

sections. Drain pipes must be a minimum of 25mm internal

diameter and manufactured from acid condensate resistant

materials (e.g. stainless steel) and positioned so that pipe runs

and discharge points are not subject to the effects of frost and

that flue gases cannot leak into the room.

Any terminal fitted must be an approved type.

22..22 VVeennttiillaattiioonn

CAUTION

For all sizes, required minimum clearance to combustible

materials from the bottom of the unit is 300mm (but see

2.1.16) and from the sides 450mm. For PDE units sizes

30-50 minimum clearance from the top is 25mm and from

the flue collar 50mm; for PDE units sizes 75-300 minimum

clearance from the top is 50mm and from the flue collar is

75mm; for PDE unit 350 minimum clearance from the top is

75mm and from the flue collar is 100mm; for PDE unit 400

minimum clearance from the top is 100mm and from the flue

collar is 125mm. Allow at least 300mm clearance at the rear

or 150mm beyond the end of motor (whichever is greater) to

provide sufficient air for combustion and correct operation of

the fan.Provide clearance for opening at the hinged bottom

for servicing. See Figure. 1.

!

FFiigguurree 22

AAddjjuussttaabbllee MMoouunnttiinngg BBrraacckkeettss

Remove side panels to adjust

mounting brackets

CAUTION

PDE unit heaters must be flued to outside – do not operate

without a flue. A built in draught diverter is fitted – additional

external draught diverters are not required or permitted.

!

66

Do not use a flue smaller than the flue pipe connection on the

unit. Flue should be stainless steel, aluminum or other suitable

corrosion resistant material.

Install with a minimum upward slope from unit of 20mm per

metre and suspend securely from overhead structure at points

no greater than 1 metre apart. For best flue operation, install

the vertical flue as close to the unit as possible. Avoid running

flue through unheated space when possible.When it does pass

through an unheated space, it is recommended that double

walled flue pipe is used. If single wall is used, insulate runs of

greater than 1.5m to minimize condensation. Use insulation that

is noncombustible with a rating of not less than 200°C.

Keep single wall flue pipe at least 150mm from combustible

material (see page 2 section 12 for permissible reductions). For

double wall pipe maintain clearances listed in manufacturer’s

literature.The minimum distance from combustible material is

based on the combustible material surface not exceeding 70°C.

Clearance from the flue connector, or top of unit may be

required to be greater than the minimum clearance if heat

damage other than fire (such as material distortion or

discoloration) may occur. Where the flue passes through a

combustible floor or roof, a metal sleeve 100mm greater than

the flue diameter is necessary.If there is 2m or more of flue

pipe in the open space between the unit and where the flue

pipe passes through the floor or roof, the sleeve need only to be

50mm greater than the diameter of the flue pipe. If a sleeve is

not used, all combustible material must be cut away to provide

the specified clearance to combustibles.Any material used to

close the opening must be noncombustible.

The top of the vertical flue should extend at least 600mm above

the highest point where it passes through a roof and at least

600mm higher than any portion of a building within a horizontal

distance of 3m (see Figure 3).

Use a flue terminal to reduce downdraughts and moisture in the

flue.

Check flue system to see that combustion products are being

satisfactorily cleared. Operate unit for several minutes and then

pass a lighted match around the edge of the diverter relief

opening. If the flame is drawn into the opening, the system is

drawing properly. If not, make adjustments to provide adequate

draught.

AADDDDIITTIIOONNAALL RREEQQUUIIRREEMMEENNTTSS FFOORR FFLLUUEEIINNGG IINNTTOO AANN

EEXXIISSTTIINNGG MMAASSOONNRRYY CCHHIIMMNNEEYY

In the case of brick or similar structures a stainless steel rigid or

flexible flue liner (grade 304/316) may be used in conjunction

with a 50mm (minimum) thick layer of vermiculite or perlite

granules between the liner and the inner skin of the chimney

body. Liners should be sealed at both the top and the bottom.

In situations where a conventional flue is inappropriate, a flue

boost kit is available for all PDE models allowing up to 10

metres (or equivalent length) of horizontal flue.

22..55 PPiippiinngg

22..66 GGaass SSuuppppllyy

If there is any doubt regarding the capacity of the gas meter,

the available gas pressure, the adequacy of existing service

pipes or the size required for new service pipes then the advice

of the gas supplier should be requested. Installation pipework

should be fitted and tested for gas soundness in accordance

with BS. 6891 for small installations or IGEUP1 and IGEUP2 for

large installations.

The local gas supplier must be consulted if it is necessary to

employ a gas pressure booster.

An isolating union gas cock or union and isolating gas cock

MMUUSSTT

be fitted before the inlet to the gas valve to allow

replacement of parts.

Before installation, check that the local distribution conditions,

nature of gas and pressure, and the current state of adjustment

of the appliance are compatible.

22..77 EElleeccttrriiccaall SSuuppppllyy

A 230V~50 Hz mains supply is required, fused at 5 amps

(PDE 350 and 400 10 amps).

Wiring external to the appliance

MMUUSSTT

be in accordance with

I.E.E. (BS. 7671) Wiring Regulations and any local regulations

which apply.

The mains wiring to the appliance must be fixed, PVC insulated

and the wires should be between 1 and 2.5 mm

2

cross sectional

area.

The mains wiring inlet to the junction box is in the base of the

box and the installer MUST fit a suitable strain relief bush to this

hole.

CAUTION

Gas pressure to unit heater controls must never exceed

45mbar.

When leak testing the gas supply system, the appliance and

its combination gas control must be isolated during any

pressure testing in excess of 45mbar. The appliance should

be isolated from the gas supply system by closing the inlet

manual shutoff valve.

!

FFiigguurree 33

UUnniitt HHeeaatteerr IInnssttaallllaattiioonn

CAUTION

Disconnect power supply before making wiring connections

to prevent electrical shock and equipment damage.ALL

UNITS MUST BE WIRED STRICTLY IN ACCORDANCE

WITH WIRING DIAGRAM SUPPLIED WITH HEATER. ANY

WIRING DIFFERENCE FROM WIRING DIAGRAM MAY BE

HAZARDOUS TO PERSONS AND PROPERTY.

TTHHIISS AAPPPPLLIIAANNCCEE MMUUSSTT BBEE CCOORRRREECCTTLLYY EEAARRTTHHEEDD..

!

3.5m MIN.

TO WALL OR ADJOINING BUILDING

APPROVED

TERMINAL

1 METER*

MIN.

ROOF FLASHING

USE THIMBLE

THROUGH CEILING

DRIP LEG WITH

UNIT

.635cm

SLOPE TO

30.5cm

*SIZE ACCORDING TO EXPECTED SNOW DEPTH.

CLEANOUT CAP

77

Before commencing commissioning:

Ensure that the electrical supply is off.

Extinguish all naked lights and open all doors and windows.

DDOO

NNOOTT SSMMOOKKEE

. Check that the gas supply is turned on at the

meter and that the main gas cock is open. Loosen the union

and allow air to be purged from the gas line until gas is

smelled.Tighten the union.See BS 6891 and/or IM 2 for fur ther

details.Turn off the gas supply and connect a manometer to the

test point at the outlet of the combination gas control.Tur n on

the gas supply. Check for gas soundness.

33..11 PPrree-ooppeerraattiioonnaall CChheecckkss

Although this unit has been assembled and fired at the factory,

the following pre-operational procedures should be performed to

ensure correct on site operation:

Check burner for alignment.

Check fan clearance.Fan should not contact casing when spun

by hand.

Check all electrical connections to ensure they are secure.

Check that all horizontal deflector blades are open a minimum of

30° as measured from vertical.

33..22 LLiigghhttiinngg IInnssttrruuccttiioonnss

3.2.1. Set room thermostat to lowest setting

3.2.2. Drop down the bottom pan (see 4.1.1 page 8).Set gas

control knob to PILOT and push in while lighting the pilot

with gas match or taper.

Hold in for 1/2 minute after pilot is lit.

3.2.3. Check pilot flame adjustment.The pilot burner is fitted with

an injector such that it will operate correctly with an inlet

pressure of 15-20 mbar on natural gas and 37mbar on

propane but final adjustment must be made after

installation. Adjust to have a soft steady flame 20-25mm

long and encompassing 8 to 12mm of the tip of the

thermocouple. Normally this flame will produce satisfactory

results.To adjust flame use the pilot adjustment screw on

combination gas control (for location, see Figure 4).

If the pilot flame is longer and larger than shown by Figure

5 it is possible that this will cause soot and/or impinge on

the heat exchanger causing burnout.If the pilot flame is

shorter than shown it may cause poor ignition and result in

the controls not opening the combination gas control. A

short flame can be caused by a dirty pilot injector. Pilot

flame condition should be observed periodically to ensure

trouble free operation.

3.2.4. Move gas control knob to ON.

3.2.5. Set room thermostat to desired setting.

3.2.6. Check gas piping for leaks as described in IM 5.

3.2.7. Check gas input rate by measuring burner pressure using

the manometer fitted to test point at the outlet of the

combination gas control. Allow unit to operate for 15

minutes to stabilize.Check the pressure and if necessary

adjust to the figure shown in Table 2 on page 4 for the

particular model. The location of the pressure setting

adjuster on the combination gas is shown in Figure 4.

Remove the dust cover over the adjuster and, using a

small screwdriver turn the screw beneath clockwise to

increase and anti-clockwise to decrease the pressure.

Allow the unit to operate for 15 minutes then check the

pressure again. Replace the dust cover when finished.

Disconnect the manometer from the test point and replace

the sealing screw in the pressure test nipple.

33..33 CCoonnttrrooll OOppeerraattiinngg SSeeqquueennccee

With pilot alight, when the thermostat calls for heat, power is

supplied to the combination gas control and at the same time

power is supplied to the fan timer.The main burner should light

immediately.The fan motor will start in 15 to 45 seconds.When

the thermostat has been satisfied, power is turned off to the

combination gas control and fan timer. The main burner will go

out but the pilot will continue to burn.The fan motor will continue

to operate for 45 to 75 seconds to allow the heat exchanger to

cool down.

FFiigguurree 55

PPiilloott FFllaammee AAddjjuussttmmeenntt

33.. CCOOMMMMIISSSSIIOONNIINNGG

FFiigguurree 44

CCoommbbiinnaattiioonn GGaass CCoonnttrrooll

20/25mm

CAUTION

Start-up and adjustment procedures should be performed by

a qualified engineer.

!

CAUTION

Important – Supply pressure and setting pressure must be

checked with heater in operation when making final adjustments.

!

GAS CONTROL KNOB

INLET PRESSURE

TEST FITTING

PRESSURE REGULATOR

ADJUSTMENT SCREW

(UNDER CAP SCREW)

INLET

PILOT TUBING

PILOT ADJUSTMENT

SCREW

THERMOCOUPLE / INTERRUPTER

CONNECTION

PROTECTIVE COVER

OUTLET

OUTLET

PRESSURE

TEST

FITTING

88

It is recommended that a full service be carried out at least

once a year by a qualified heating engineer (CORGI

Registered).

44..11 CClleeaanniinngg tthhee HHeeaatteerr

44..11..11 MMaaiinn BBuurrnneerr

Lower bottom pan by removing wing screws on the unit base.

Disconnect pilot pipe, and thermocouple lead from multifunctional

control.

Remove the two burner retaining pins holding the burner

assembly in place.

IIMMPPOORRTTAANNTT:: DDoo nnoott aatttteemmpptt ttoo rreemmoovvee tthhee ggaass mmaanniiffoolldd ttoo

eeaassee rreemmoovvaall ooff tthhee bbuurrnneerr aass tthhiiss ccoouulldd sseerriioouussllyy aaffffeecctt tthhee

ccoorrrreecctt ooppeerraattiioonn ooff tthhee aapppplliiaannccee iiff iitt iiss nnoott rree-ppoossiittiioonneedd eexxaaccttllyy

aass iinntteennddeedd.. TThhee aasssseemmbbllyy ccaann nnooww bbee lloowweerreedd ffrroomm tthhee uunniitt..

NNOOTTEE:: OOnn rreeffiittttiinngg tthhee bbuurrnneerr aasssseemmbbllyy eennssuurree tthhaatt tthhee sslloottss aatt

tthhee ffrroonntt ooff tthhee bbuurrnneerr aarree ccoorrrreeccttllyy llooccaatteedd oonn tthheeiirr sshhoouullddeerr

rriivveettss aanndd tthhaatt tthhee rreettaaiinniinngg ppiinnss aarree rreeffiitttteedd iinn tthhee ccoorrrreecctt

llooccaattiioonn..

Clean the burner ports (avoid using hard, sharp instruments

capable of damaging the ports) and check the injector (s) for

blockage.Clean carefully as necessary.

44..11..22 PPiilloott BBuurrnneerr

Inspect the pilot burner and thermocouple. Ensure they are clean

and in good condition.

CChheecckk::

(a) The pilot burner is securely fixed.

(b) The thermocouple tip is not burned or cracked.Replace if

necessary.

(c) The pilot burner head is undamaged.

(d) The pilot pipe/pilot connection is gastight.

44..11..33 HHeeaatt EExxcchhaannggeerr

After removing the burner assembly clean heat exchanger tubes

from bottom using a stiff brush

((nnoott wwiirree))

.

44..11..44 FFaann aanndd MMoottoorr

Remove fan guard.Check fan is securely fitted to motor shaft

and for damage to blades.Clean fan blades as necessary taking

care not to damage them.

NNOOTTEE:: EEnnssuurree aallll ffoouurr ffiixxiinnggss sslleeeevveess aarree ffiitttteedd bbeeffoorree rree-ffiixxiinngg

ffaann aass oovveerrttiigghhtteenniinngg ccoouulldd rreessuulltt iinn rreedduucceedd ffaann lliiffee..

44..11..55 GGeenneerraall

Check wiring for possible loose connections paying par ticular

attention to the overheat thermostat interrupter leads.

Check air louvres in bottom pan are clean and unobstructed.

Clean as necessary.

44..22 OOvveerrhheeaatt TThheerrmmoossttaatt

The overheat thermostat, bulb mounted on the left inner side

panel (when facing front of unit) – body in junction box, will shut

off the gas supply to the main burner in the event of overheating.

The manual reset button is located beneath a black screw off cap

positioned on the side of the junction box.See Figs.6 and 7.

It is a single pole single throw switch.The contacts open to shut

the combination gas control in the event of the unit overheating.

This overheat thermostat should operate only when something is

wrong with the unit.Whenever this thermostat operates, the

problem should be identified and corrected immediately or

serious damage may result. If the overheat thermostat cuts off

the gas supply during normal operation:

1. Make sure deflector blades are open and that there are not

any obstructions in the air inlet or discharge outlet.

2. Check actual input to unit against rated input.

3. Check motor is operating.

4. Check fan is not loose on motor shaft.

5. Check fan speed against motor data plate.

6. Check flue system is not damaged or blocked. Also check

unit is flued correctly and that there is not a negative

pressure in the building adversely affecting draught.

7. Clean heat exchanger tubes inside and out if necessary.

8. Check operation of fan delay timer.

9. If items 1 to 8 do not solve the problem, check overheat

thermostat and replace if necessary.

IIMMPPOORRTTAANNTT NNOOTTEE:: TThhee oovveerrhheeaatt tthheerrmmoossttaatt oonn tthhiiss uunniitt

hheeaatteerr wwiillll sshhuutt ooffff tthhee ggaass sshhoouulldd eexxcceessssiivvee ddiisscchhaarrggee

tteemmppeerraattuurreess ooccccuurr.. DDoo nnoott aatttteemmpptt ttoo ccoonnttrrooll tthhee ffaann wwiitthh tthhee

oovveerrhheeaatt tthheerrmmoossttaatt.. AAnnyy cchhaannggee iinn wwiirriinngg ttoo aatttteemmpptt ttoo ccoonnttrrooll

tthhee ffaann wwiitthh tthhee oovveerrhheeaatt tthheerrmmoossttaatt wwiillll rreessuulltt iinn hhaazzaarrddoouuss

ccoonnddiittiioonnss aanndd iinnvvaalliiddaattee tthhee wwaarrrraannttyy..

44..33 TTeessttiinngg aafftteerr SSeerrvviicciinngg

After re-assembly restore the electrical and gas supplies. Light

the appliance (see Lighting Instructions on inside of casing) and

check the gas connections for soundness as follows:

Close gas supply cock at the meter.

Remove the screw in the inlet pressure test point and connect a

manometer to the test nipple. Open the gas supply cock at the

meter and the appliance gas cock. Record the static pressure.

Close the gas supply cock at the meter and watch the pressure

gauge for approximately 3 minutes. Any decrease in pressure

(after the first minute of temperature stabilization) indicates a

gas leak which must be cured (first check connection of

manometer to test nipple).When satisfied remove manometer

and refit test nipple sealing screw.

44.. SSEERRVVIICCIINNGG

CAUTION

Always turn off the gas supply at the gas cock and

disconnect the electricity supply to the appliance before

servicing or replacing any components.

!

99

FFiigguurree 66

AAiirr HHeeaatteerr WWiirriinngg DDiiaaggrraamm

FFiigguurree 77

MMaajjoorr CCoommppoonneenntt LLooccaattiioonn

OVERHEAT

THERMOSTAT

BULB

LOUVRES

FFRROONNTT

VVIIEEWW

FLUE RELIEF

OPENING

SERIAL NUMBER

PLATE

FAN & MOTOR

DIMPLED HEAT

EXCHANGER

COMBINATION

GAS CONTROL

FAN MOTOR

CONDENSER

MANUAL RESET FOR

OVERHEAT

THERMOSTAT

BENEATH BLACK CAP.

JUNCTION

BOX

RREEAARR

VVIIEEWW

FLUE

CONNECTION

VVIIEEWW FFRROOMM BBEELLOOWW

((BBOOTTTTOOMM PPAANN OOPPEENN))

TAPPED MOUNTING

HOLES

Overheat Thermostat with

interupter to gas valve &

capillary with sensor to

heat exchanger

(Manual reset button

located beneath black

screw off cap)

230V Thermostat

(By Others on

installation)

230V/50 Hz

Supply

Gas Valve

Fan

Motor

TD Relay

Capacitor

Junction Box

CAUTION

FAILURE TO WIRE THIS UNIT ACCORDING

TO THIS WIRING DIAGRAM MAY RESULT

IN INJURY TO THE INSTALLER OR USER.

FOR DEVIATIONS CONTACT THE FACTORY.

MANIFOLD

MIXER

TUBES

BURNER

RETAINING PIN

MAIN

BURNER

ORIFICES

MANIFOLD MOUNTING

SCREW AND PIN

1100

TToo rreeppllaaccee::

55..11 BBuurrnneerr//ppiilloott//tthheerrmmooccoouuppllee

Lower bottom pan by removing wing screws on the unit base.

Disconnect pilot pipe, and thermocouple lead from multifunctional

control.

Remove the two burner retaining pins holding the burner

assembly in place.

IIMMPPOORRTTAANNTT:: DDoo nnoott aatttteemmpptt ttoo rreemmoovvee tthhee ggaass mmaanniiffoolldd ttoo

eeaassee rreemmoovvaall ooff tthhee bbuurrnneerr aass tthhiiss ccoouulldd sseerriioouussllyy aaffffeecctt tthhee

ccoorrrreecctt ooppeerraattiioonn ooff tthhee aapppplliiaannccee iiff iitt iiss nnoott rree-ppoossiittiioonneedd eexxaaccttllyy

aass iinntteennddeedd.. TThhee aasssseemmbbllyy ccaann nnooww bbee lloowweerreedd ffrroomm tthhee uunniitt..

NNOOTTEE:: OOnn rreeffiittttiinngg tthhee bbuurrnneerr aasssseemmbbllyy eennssuurree tthhaatt tthhee sslloottss aatt

tthhee ffrroonntt ooff tthhee bbuurrnneerr aarree ccoorrrreeccttllyy llooccaatteedd oonn tthheeiirr sshhoouullddeerr

rriivveettss aanndd tthhaatt tthhee rreettaaiinniinngg ppiinnss aarree rreeffiitttteedd iinn tthhee ccoorrrreecctt

llooccaattiioonn..

55..11..11 BBuurrnneerr

It is not possible to replace single burner bars.The complete burner

assembly must be replaced.Remove the pilot and thermocouple (see

5.1.2.) and refit to the new assembly.

55..11..22 PPiilloott

Remove the burner assembly as detailed above. Unscrew the

thermocouple. Undo the pilot bracket retaining the nut.The pilot gas pipe

can now be unscrewed (take care not to lose the pilot injector) and the

pilot assembly released by removing the two retaining screws. Replace

defective component and reassemble in reverse order.

55..22 TThheerrmmooccoouuppllee

Lower bottom pan by removing wing screws on the unit base.

The thermocouple can be unscrewed.

55..33 MMaaiinn BBuurrnneerr IInnjjeeccttoorr

Lower bottom pan by removing wing screws on the unit base.

The main injector can be unscrewed from the manifold and

replaced.

55..44 GGaass VVaallvvee

Disconnect pilot gas pipe, thermocouple and thermocouple

interrupter from the gas valve.

Remove green cover from the solenoid actuator on the valve

and detach flying leads from the terminal block, noting their

position.

Having ensured isolation of the gas supply uncouple the union

gas cock and unscrew the gas valve from the appliance inlet

gas pipe.

Replace gas valve and reassemble in reverse order.

55..55 TThheerrmmooccoouuppllee IInntteerrrruupptteerr

Unscrew thermocouple from top of gas valve and extract

thermocouple interrupter from the gas valve. Release spade

connections on interrupter cable from the overheat thermostat in

the heater junction box and feed back through the cable

grommet. Replace component and reassemble in reverse order.

55..66 DDeellaayy TTiimmeerr

The delay timer is located in the junction box.Remove the

junction box front cover by taking out the two retaining screws.

Remove the single retaining screw from beneath the junction

box, pull off the electrical connectors (taking care to note their

positions) and lift out the timer.Replace defective component

and reassemble in reverse order. If in doubt regarding the

electrical connections consult the wiring diagram on page 9.

55..77 OOvveerrhheeaatt TThheerrmmoossttaatt

The overheat thermostat body is located in the junction box.

Remove the junction box cover by taking out the two retaining

screws.Remove the thermostat cover retaining nut from the

outside of the junction box and pull back into the box. Remove

the left hand side casing of the heater (looking from the front)

by taking out the two retaining screws at the rear and pull the

side panel clear.The overheat thermostat bulb is mounted in the

air stream at the bottom left of the appliance. Remove the two

screws holding it in place and feed it back through the hole in

the inner casing.To refit remove the two lower front louvres

which can be sprung out.The thermostat bulb can now be

positioned and the retaining screws fitted.

55..88 FFaann//FFaann MMoottoorr//CCaappaacciittoorr

The capacitor is mounted alongside the junction box.Remove

the junction box front cover by taking out two retaining screws.

Disconnect the wires from the terminal block noting their

position.The capacitor retaining nut can be seen on the left hand

side of the junction box and should be removed.Replace the

defective component and reassemble in reverse order.If in doubt

regarding the electrical connections consult the wiring diagram

on page 9.

The fan/fan motor is mounted in the centre of the guard.Remove

the junction box front cover by taking out two retaining screws.

Disconnect the fan motor wires from the terminal block noting

their position and feed back through the grommet.Remove the

four guard mounting bolts and lift assembly clear.The fan and

motor can be removed from the guard by undoing the four bolts.

IIMMPPOORRTTAANNTT:: CCaarree mmuusstt bbee ttaakkeenn ttoo nnoottee iiff tthhee gguuaarrdd iiss

mmoouunntteedd oonn tthhee ffrroonntt oorr rreeaarr ffiixxiinngg ppooiinnttss ooff tthhee mmoottoorr.. IInnccoorrrreecctt

rree-aasssseemmbbllyy wwiillll ccaauussee ddaammaaggee ttoo tthhee uunniitt..

The fan can be removed from the motor by removing the

retaining screw.

Reassemble in reverse order making sure the fan and guard are

correctly mounted using the four sleeves to prevent

overtightening, and that the fan spins freely without catching on

the casing. If in doubt as to the correct electrical connection

consult the wiring diagram on page 9.

55.. RREEPPLLAACCEEMMEENNTT OOFF PPAARRTTSS

CAUTION

Always turn off the gas supply at the gas cock and

disconnect the electricity supply to the appliance before

servicing or replacing any components.

!

1111

66..11 IIff ppiilloott ddooeess nnoott lliigghhtt::

PPOOSSSSIIBBLLEE CCAAUUSSEESS AANNDD RREEMMEEDDIIEESS

a. Check that manual gas control knob on combination gas

control is in the pilot position.

b.Bleed air from the pilot line (take special care when bleeding

propane units).

c. If pilot splutters, check pilot line for condensate or other

obstruction.

d. If pilot flame is feeble or short, check orifice for cleanliness.

Replace if necessary.See page 7 for pilot flame adjustment.

e. If the above steps do not correct the condition, consult your

qualified installation and service contractor or gas supplier.

66..22 IIff ppiilloott ddooeess nnoott rreemmaaiinn aalliigghhtt::

PPOOSSSSIIBBLLEE CCAAUUSSEESS AANNDD RREEMMEEDDIIEESS

a. Check inlet pressure with all units operating, making certain

that there is correct pressure.

b.Check pipe size to unit.

c. Be sure all pilot connections are tight.

d. Check for excessive draughts.

e. Check for blocked pilot orifice or pilot line.

f. Check for leaks around pilot fittings. If leaks cause flame

impingement on thermocouple lead, thermocouple may

become inoperative.

g. Ensure thermocouple and interrupter connections are both

clean and tight at the gas valve.

h. Ensure all connections between overheat thermostat and

thermocouple are clean and secure.

i. Check the overheat thermostat for correct operation. See page

8.

j. If the above steps do not correct the condition, consult your

qualified installation and service contractor or gas supplier.

66..33 EEffffeecctt ooff ppiilloott ooppeerraattiioonn oonn ssaaffeettyy ccoonnttrroollss::

PPOOSSSSIIBBLLEE CCAAUUSSEESS AANNDD RREEMMEEDDIIEESS

a. A short pilot flame may cause poor ignition or reduce heat on

thermocouple to the point where the automatic controls

become inoperative, thereby shutting off gas supply to main

burners.This may result from a blocked injector.

b.Check electrical connection from the thermocouple interrupter

to the safety valve to ensure good electrical contact. Also

check location of pilot flame in relation to thermocouple

element.

66..44 IIff mmaaiinn bbuurrnneerrss ddoo nnoott lliigghhtt::

PPOOSSSSIIBBLLEE CCAAUUSSEESS AANNDD RREEMMEEDDIIEESS

a. Check power to appliance is turned on.

b.Check room thermostat and time switch (if fitted) are calling

for heat.

c. Check that knob on combination gas control is in ON position.

d. Be sure pilot is lit, correctly positioned and strong enough to

ignite burner ports.

e. Check wiring (electrical power supply) to combination gas

control.

f.If the above steps do not correct the condition, consult your

qualified installation and service contractor or gas supplier.

WWhheenn sseerrvviicciinngg,, rreeppaaiirriinngg oorr rreeppllaacciinngg ppaarrttss oonn tthheessee uunniittss

aallwwaayyss ggiivvee tthhee ccoommpplleettee MMooddeell NNuummbbeerr aanndd SSeerriiaall NNuummbbeerr

ffrroomm aapppplliiaannccee ddaattaa ppllaattee..

66.. FFAAUULLTT FFIINNDDIINNGG GGUUIIDDEE

DDeessccrriippttiioonn NNuummbbeerr ppeerr uunniitt MMooddiinnee ppaarrtt

nnuummbbeerr

CCoommbbiinnaattiioonn ggaass vvaallvvee

1

Models 30 - 250 5H75043B

Models 300 - 400 5H75116B

CCoommpplleettee ffaann && mmoottoorr

1

30 HTPMG2304101

50 HTPMG31541xx

75 HTPMG3154107

100 HTPMG3504118

125 HTPMG3504106

150 HTPMG4104135

175 HTPMG45041xx

200 HTPMG5106130

250 HTPMG5106129

300 HTPMG5606116

350 HTPMG5606116

400 HTPMG61041xx

FFaann mmoottoorr

1

30 HTM44026112D

50 HTM44080195A

75 HTM44080195A

100 HTM44180189A

125 HTM44180189A

150 HTPMG4106141

175 HTM44180189A

200 HTM46370183A

250 HTM46370183A

300 HTM46500201A

350 HTM46500201A

400 HTM46500201A

FFaann gguuaarrdd

1

30 HTSFB2290004

50 HTSFB2290002

75 HTSFB2290002

100 HTSFB2290002

125 HTSFB2290002

150 HTSFB2290001

175 HTSFB2290005

200 HTSFB2290000

250 HTSFB2290000

300 HTSFB2290003

350 HTSFB2290003

400 HTSFB2290006

FFaann

1

30 HTFFF1241005

50 HTCF69200003

75 HTCF69218063

100 HTCF69224053

125 HTCF69200006

150 HTCF69218003

175 HTCF69218006

200 HTCF69231006

250 HTCF69227016

300 HTCF69227036

350 HTCF69227036

400 HTCF69212006

LLiimmiitt tthheerrmmoossttaatt

1 HTLM7P009062

DDeellaayy ttiimmeerr

1 5H7381CB

TThheerrmmooccoouuppllee

1 HTQ309A2754B

TThheerrmmooccoouuppllee

1

iinntteerrrruupptteerr

HT0000021609

TTAABBLLEE 33

SSPPAARREE PPAARRTTSS LLIISSTT

MMooddeell NNuummbbeerr-PPDDEE

3300 5500 7755 110000 112255 115500 117755 220000 225500 330000 335500 440000

HHeeaatt IInnppuutt

((ggrroossss)) kkWW

8.8 14.7 22 29.3 36.6 44 51.3 58.6 73.3 87.9 102.6 117.2

HHeeaatt IInnppuutt

((nneett)) kkWW

8 13.5 20.2 27 33.7 40.5 47.2 53.4 67.4 80.9 94.4 107.8

OOuuttppuutt kkWW

7 11.7 17.6 23.4 29.3 35.1 41 46.9 58.6 70.3 82 93.8

IInnlleett sseett..

37

pprreessss.. mmbbaarr

IInnjjeeccttoorr -NNoo..

111222333456

DDiiaamm.. mmmm

1.40 1.85 2.18 1.85 2.08 2.26 1.99 2.08 2.37 2.26 2.18 2.08

MMaarrkkiinngg

54 49 44 49 45 43 47 45 42 43 44 45

GGaass rraattee kkgg//hh

1.16 1.94 2.9 3.86 4.83 5.8 6.76 7.72 9.66 11.6 13.5 15.4

AApppprrooxx.. fflluuee

9 14 21 29 36 43 50 57 71 86 100 114

ggaass vvooll..iinn

sseeccoonnddaarryy fflluuee**

44..44%% CCOO22&&

112200°°CC 11//sseecc

AAiirr ffllooww

0.21 0.35 0.51 0.69 0.87 1.03 1.20 1.36 1.75 2.10 2.34 2.66

mm33//sseecc

OOuuttlleett vveelloocciittyy

2.6 3.2 3.7 4.3 4.4 4.7 4.8 4.1 5.3 5.7 5.6 5.3

mm//sseecc

AAiirr tteemmpp.. rriissee

27 27 28 27 27 28 28 28 27 27 28 28

°°CC

MMoouunnttiinngg hhtt..

2.1 2.7 3.7 4.3 4.3 4.9 5.2 4.6 5.8 6.4 6.1 6.7

((mmaaxx)) mm

HHeeaatt tthhrrooww

7.6 10.1 12.5 14.9 15.5 16.8 18 15.5 20.4 22.6 21.9 23.2

((aatt mmaaxx mmoouunntt.. hhtt..))

mm**

PPoowweerr ssuuppppllyy

230V 50Hz

PPoowweerr ccoonnssuupptt..

125 150 200 225 400 450 450 400 750 850 950 1,200

((wwaattttss))

TTAABBLLEE 44

PPeerrffoorrmmaannccee —— PPrrooppaannee UUnniittss OOnnllyy

*

Based on propane gas - typical calorific value 91.65 MJ/M3.

**

At 18°C ambient and unit fired at full-rated input. Mounting height as measured from bottom of unit.

Head Office

Kitson’s Works

Aylesbury Road

Bromley

Kent BR2 0QZ

Tel: 020 8464 0915

Fax: 020 8464 0916

Northern Sales Office

Units 1-3 Guide Bridge T/E

South Street

Ashton-under-Lyne

Lancashire OL7 0HU

0161 308 4550

0161 308 4551

DDeessccrriippttiioonn NNuummbbeerr ppeerr uunniitt MMooddiinnee ppaarrtt

nnuummbbeerr

CCaappaacciittoorr

1

30 Not required

50 HTFFE1049039

75 HTFFE1049039

100 HTFFE1049031

125 HTFFE1049031

150 HTFFE1049031

175 HTFFE1049031

200 HTFFE1049026

250 HTFFE1049027

300 HTFFE1049028

350 HTFFE1049028

400 HTFFE1049029

BBuurrnneerr aasssseemmbbllyy

1

30 3H33073B1

50 3H33073B2

75 3H33073B3

100 3H33073B4

125 3H33073B16

150 3H33073B5

175 3H33073B6

200 3H33073B7

250 3H33073B7

300 3H33073B9

350 3H33073B10

400 3H33073B11

DDeessccrriippttiioonn NNuummbbeerr ppeerr uunniitt MMooddiinnee ppaarrtt

nnuummbbeerr

PPiilloott aasssseemmbbllyy

1

30 3H31982B1

50 3H31982B1

75 3H31982B2

100 3H31982B2

125 3H31982B2

150 3H31982B5

175 3H31982B5

200 3H31982B5

250 3H31982B5

300 3H31982B5

350 3H31982B6

400 3H31982B6

MMaaiinn bbuurrnneerr iinnjjeeccttoorr

30 1 36

50 1 29

75 1 18

100 2 29

125 2 23

150 2 18

175 3 24

200 3 24

250 3 13

300 4 19

350 5 19

400 6 20

Harry Taylor

Harry Taylor of Ashton Limited - Sole Distributor in the British Isles

TTAABBLLEE 33 ccoonnttiinnuueedd

Loading...

Loading...