Modine Manufacturing PD/BD, PDP/BDP, PV/BV, DJE/DHE, IJE/IHE Installation Instructions Manual

SELECTION AND INSTALLATION INSTRUCTIONS

conversion from natural gas to propane gas for

models PD/BD, PDP/BDP, PV/BV, DJE/DHE, IJE/IHE

with control codes 11-14 or 30-33 and built 4/91 or after,

“D” and “I” series duct furnace/make up air units with

1. All field gas piping must be pressure/leak tested prior to

operation. Never use an open flame. Use a soap solution

or equivalent for testing.

2. Gas supply shall be shut-off and the electrical power

disconnected before proceeding with the conversion.

Failure to do so could result in re, explosion or electrical

shock.

WARNING

IMPORTANT

75-511.13

5H0722980000

December, 2016

digits 11 & 12 = N1 or S1

The propane kits appearing in this bulletin are for use with units

which are going to be installed between 0 and 2000 ft. elevation.

If a unit is to be installed at higher elevations, a special “high

altitude” propane orifice kit must be ordered in addition to the

propane conversion kits shown here. See Bulletin 75-535 for

selection of “high altitude” orifice kits.

When converting units to propane at elevations over 2000 ft.,

the main burner orifices in the propane conversion kit must

be replaced with the orifices from the “high altitude” orifice kit.

The remaining components of the propane kit, those other

than the main burner orifices, are still required to complete the

conversion to propane gas, regardless of the elevation at which

the unit is installed.

1. The use of this manual is specifically intended for a

qualified installation and service agency. All installation

and service of these kits must be performed by a qualified

installation and service agency.

2. These instructions must also be used in conjunction with

the Installation and Service manual originally shipped

with the appliance being converted, in addition to any

other accompanying component supplier literature.

As Modine Manufacturing Company has a continuous

product improvement program, it reserves the right to

change design and specifications without notice.

Identifying the Model, Control Code and

Date of Manufacture

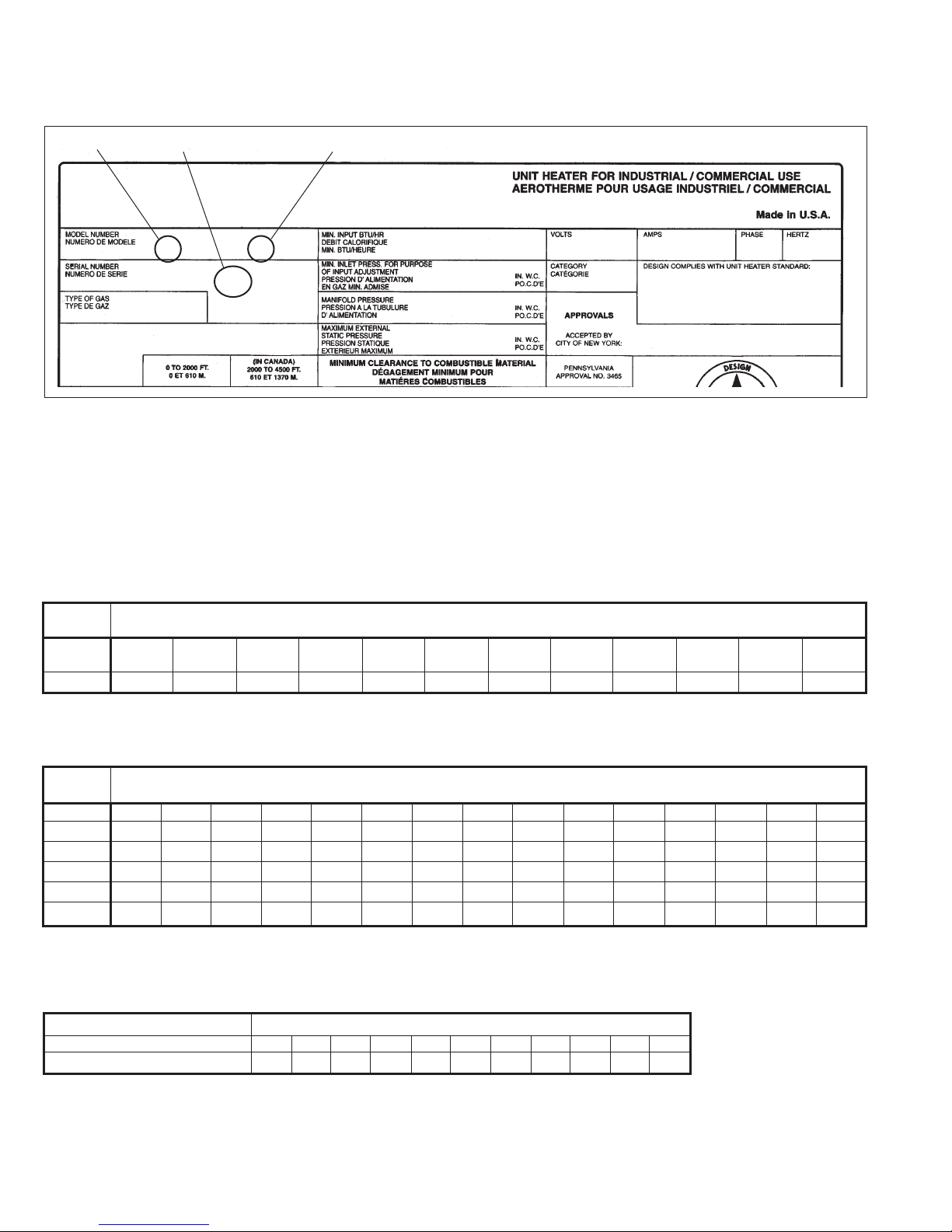

Figure 2.1, shown on the next page, is an example of a typical

serial plate. Markings pertinent to verifying correct application

of the conversion kit are identified and explained in detail. All

prerequisites must be satisfied before the unit is deemed

convertible.

1. The first two or three characters in the model number box

are letters. These letters identify the style of the heater. If

any of the following model prefixes appear in this box, the

unit is potentially convertible: PD/BD, PDP/BDP, PV/BV,

DJE, IJE, DFG, IFG, NFG, DFP, IFP, DFS, IFS.

2. Next, the number 11, 12, 13, 14, 30, 31, 32, or 33 must be

the control code or digits 11 and 12 of the model number

are N1 or S1. This is item (2) in Figure 2.1. Any other

number code disqualifies the unit for conversion.

3. Item (3) in Figure 2.1 in the serial number box designates

the date the unit was built. In Figure 2.1, the numbers

3601 are shown. This number is interpreted as the thirty

sixth week of 2001. Prior to January 1995, the digits

preceding the year represent month of manufacture. After

January 1995, the (2) digits proceeding the year represent

the week of manufacture. Any serial number dated 4/91 or

after is acceptable for conversion.

THIS MANUAL IS THE PROPERTY OF THE OWNER. PLEASE BE SURE TO LEAVE IT WITH THE OWNER WHEN YOU LEAVE THE JOB.

NATURAL TO PROPANE CONVERSION KIT SELECTION GUIDE

Figure 2.1

Typical Serial Plate

j lk

Modine Manufacturing Company

1221 Magnolia Ave., Buena Vista, VA 24416; Phone: 540-261-2166

PD 250AA0111 115 5.7 1 60

30011013601-0978 6.0 I ANS Z83.8 - 96

Natural 3.5 CGA-2.6-M96

0.0 MEA 293-96-E

Selection of the Proper Kit

Referring to the model number box on the serial plate in Figure

2.1 (above), the prefix letters and succeeding numbers which are

needed for kit selection are PD250.

The letters identify the model, and the numbers indicate the size

of the unit. Referring to Tables 2.1, 2.2, or 2.3 locate the model

type column (i.e. PD, BD, etc.). Working with Table 2.1 and the

row labeled PD/BD, move right searching for the proper model

size. Read the kit number suffix directly below the model size

for a PD250. Add this suffix (-9) to the base part number for the

propane conversion kit shown in the heading of Table 2.1. The

correct kit for a PD250 with Control Code 11, is 3H034670-9.

Table 2.1

Natural Gas to Propane Gas Conversion Kit Selection Guide

Base Kit Number – 3H034670…(Choose correct suffix -1, -2, -3, etc…)

Model

Type

PD/BD,

PDP/BDP 30 50 75 100 125 150 175 200 250 300 350 400

Suffix -1 -2 -3 -4 -5 -6 -7 -8 -9 -10 -11 -12

Model Size

Table 2.2

Natural Gas to Propane Gas Conversion Kit Selection Guide (For units manufactured after April 1, 1991)

Base Kit Number – 3H33749…(Choose correct suffix -1, -2, -3 etc., per instructions, before ordering propane conversion kits.)

Model

Type

PAE/BAE 30 50 75 100 125 145 – 175 200 225 – 250 300 350 400

Suffix -1 -2 *-14 -4 -5 -6 – -7 -8 -9 – -10 -11 -12 -13

PV/BV 30 50 75 100 125 145 – 175 200 – – 250 300 350 400

Suffix -1 -2 -14 -4 -5 -6 – -7 -8 – – -10 -11 -12 -13

DJE/DHE – – 75 100 125 – 150 – 200 225 – 250 300 350 400

Suffix – – -14 -15 -16 – -6 – -8 -17 – -10 -11 -18 -13

Model Size

* For units manufactured after September, 1993. For units manufactured prior to this date, consult the factory.

Table 2.3

Natural Gas to Propane Gas Conversion Kit Selection Guide

Base Kit Number – 3H036483…(Choose correct suffix -1, -2, -3 etc...)

Model Type Model Size

DFG/IFG/NFG, DFP/IFP, DFS/IFS 75 100 125 150 175 200 225 250 300 350 400

Suffix -1 -2 -3 -4 -5 -6 -7 -8 -9 -10 -11

2

75-511.13

INSTALLATION

Installation of Kit

Conversion of any unit is the responsibility of, and the

risk of the person making the conversion.

1. All field gas piping must be pressure/leak tested prior to

operation. Never use an open flame. Use a soap solution

or equivalent for testing.

2. Gas supply shall be shut-off and the electrical power

disconnected before proceeding with the conversion.

Failure to do so could result in re, explosion or electrical

shock.

General

1. Shut off gas supply to the unit. Disconnect the electrical

power to the unit.

2. For codes 11, 12, 13, 14 or if digit 11 of the model number

is S or T and digit 12 is 1, disconnect the pilot gas tube

and thermocouple lead at the combination gas control. For

codes 30, 31, 32, 33 or if digit 11 of the model number is

N or P and if digit 12 is 1, disconnect the pilot gas tube at

the combination gas control and the ignition cable(s) at the

ignition control.

3. Remove burner assembly.

For PD/BD, PDP/BDP, and PV/BV Models

Lower bottom pan to expose burner and manifold (see Figure

3.1).

For codes 11, 12, 13, or 14, disconnect pilot gas tube and

thermocouple lead at the controls. For codes 30, 31, 32, or 33,

disconnect the pilot gas tube at the combination gas control and

the ignition cable(s) at the ignition control.

Remove the two burner retaining pins holding the burner in place

(see Figure 3.2). The burner can then be easily lowered from

the unit. In replacing the burner, be certain that the slots at the

front of the burner are located properly on their shoulder rivets

and that the burner retaining pins are put back into their proper

locations.

After removing burner assembly, proceed with step #4, page 4.

WARNING

Figure 3.1

Hinged Bottom for Burner Service

Figure 3.2

Manifold Adjustment

MIXER

TUBES

BURNER

RETAINING PIN

For Indoor Duct Furnace Models

On DHE/IHE models, lower the controls enclosure cover and

disconnect the pilot gas supply line and thermocouple at the gas

valve. On models DJE/IJE, DFG/IFG/NFG, DFP/IFP, DBG/IBG,

DCG/ICG, DBP/IBP, and DCP/ICP models, the gas controls are

exposed. On models DFS/IFS, remove lower assess door to

expose gas controls and burner.

The burner may be removed from either side of the duct furnace.

To remove the burner, remove all of the sheet metal screws

holding the side burner access panel in place. (Note: with the

side access panel screws removed, the access panel is free to

move, be careful not to drop the panel.)

Figure 3.3

75-511.13

BURNER SIDE

ACCESS PANEL

BURNER

ALIGNMENT PINS

PILOT

TUBE

THERMOCOUPLE

GAS

VALV E

LEAD

3

Loading...

Loading...