5-564

C

US

5H080637A

December, 2008

INSTALLATION AND SERVICE MANUAL

gas-fired indoor power vented duct furnaces

model DFP

All models approved for use in California by the CEC

FOR YOUR SAFETY

IF YOU SMELL GAS:

1. Open windows.

2. Don’t touch electrical switches.

3. Extinguish any open flame.

4. Immediately call your gas supplier.

WARNING

Improper installation, adjustment, alteration,

service or maintenance can cause property

damage, injury or death, and could cause

exposure to substances which have been

determined by various state agencies to cause

cancer, birth defects or other reproductive

harm. Read the installation, operating and

maintenance instructions thoroughly before

installing or servicing this equipment.

CAUTION

To prevent premature heat exchanger failure do

not locate ANY gas-fired units in areas where

chlorinated, halogenated, or acid vapors are

present in the atmosphere.

FOR YOUR SAFETY

The use and storage of gasoline or other

flammable vapors and liquids in open containers

in the vicinity of this appliance is hazardous.

IMPORTANT

The use of this manual is specifically intended

for a qualified installation and service agency.

A qualified installation and service agency must

perform all installation and service of these

appliances.

Inspection on Arrival

1. Inspect unit upon arrival. In case of damage, report it

immediately to transportation company and your local factory

sales representative.

2.

Check rating plate on unit to verify that power supply meets

available electric power at the point of installation.

3. Inspect unit upon arrival for conformance with description of

product ordered (including specifications where applicable).

PLEASE BE SURE TO LEAVE IT WITH THE OWNER WHEN YOU LEAVE THE JOB.

THIS MANUAL IS THE PROPERTY OF THE OWNER.

5-564

SPECIAL PRECAUTIONS / TABLE OF CONTENTS

SPECIAL PRECAUTIONS

THE INSTALLATION AND MAINTENANCE INSTRUCTIONS

IN THIS MANUAL MUST BE FOLLOWED TO PROVIDE SAFE,

EFFICIENT AND TROUBLE-FREE OPERATION. IN ADDITION,

PARTICULAR CARE MUST BE EXERCISED REGARDING

THE SPECIAL PRECAUTIONS LISTED BELOW. FAILURE

TO PROPERLY ADDRESS THESE CRITICAL AREAS COULD

RESULT IN PROPERTY DAMAGE OR LOSS, PERSONAL

INJURY, OR DEATH. THESE INSTRUCTIONS ARE SUBJECT

TO ANY MORE RESTRICTIVE LOCAL OR NATIONAL CODES.

HAZARD INTENSITY LEVELS

1. DANGER: Indicates an imminently hazardous situation which,

if not avoided, WILL result in death or serious injury.

2. WARNING: Indicates a potentially hazardous situation which, if

not avoided, COULD result in death or serious injury.

3. CAUTION: Indicates a potentially hazardous situation which,

if not avoided, MAY result in minor or moderate injury.

4. IMPORTANT: Indicates a situation which, if not avoided,

MAY result in a potential safety concern.

DANGER

Appliances must not be installed where they may be

exposed to a potentially explosive or flammable atmosphere.

WARNING

1. Gas fired heating equipment must be vented - do not operate

unvented.

2. A built-in power exhauster is provided - additional external

power exhausters are not required or permitted.

3. If you are replacing an existing heater, it may be necessary to

resize the venting systems. Improperly sized venting systems

can result in vent gas leakage or the formation of condensate.

Refer to the National Fuel Gas Code ANSI Z223.1 or CSA

B149.1 latest edition. Failure to follow these instructions can

result in injury or death.

4. Under no circumstances should two sections of double wall

vent pipe be joined together within one horizontal vent system

due to the inability to verify complete seal of inner pipes.

5. All field gas piping must be pressure/leak tested prior to

operation. Never use an open flame. Use a soap solution or

equivalent for testing.

6. Gas pressure to appliance controls must never exceed 14"

W.C. (1/2 psi).

7. Disconnect power supply before making wiring connections

to prevent electrical shock and equipment damage.

8. All appliances must be wired strictly in accordance with

wiring diagram furnished with the appliance. Any wiring

different from the wiring diagram could result in a hazard

to persons and property.

9. To reduce the opportunity for condensation, the minimum

sea level input to the appliance, as indicated on the serial

plate, must not be less than 5% below the rated input, or

5% below the minimum rated input of duel rated units.

10. Ensure that the supply voltage to the appliance, as

indicated on the serial plate, is not 5% greater than the

rated voltage.

11. Any original factory wiring that requires replacement must

be replaced with wiring material having a temperature

rating of at least 105°C.

12.

When servicing or repairing this equipment, use only factory-

approved service replacement parts. A complete replacement

parts list may be obtained by contacting Modine Manufacturing

Company. Refer to the rating plate on the appliance for

complete appliance model number, serial number, and

company address. Any substitution of parts or controls not

approved by the factory will be at the owners risk.

2

2

5-564

CAUTION

1. Purging of air from gas lines should be performed as

described in ANSI Z223.1 - latest edition “National Fuel Gas

Code”, or in Canada in CAN/CGA-B149 codes.

2. Do not attempt to reuse any mechanical or electrical

controllers which have been wet. Replace defective controller.

3. Ensure that the supply voltage to the application, as indicated

on the serial plate, is not 5% less than the rated voltage.

IMPORTANT

1. To prevent premature heat exchanger failure, do not locate

ANY gas-fired appliances in areas where corrosive vapors

(i.e. chlorinated, halogenated or acid) are present in the

atmosphere.

2. To prevent premature heat exchanger failure, the input to

the appliance, as indicated on the serial plate, must not

exceed the rated input by more than 5%.

3. To prevent premature heat exchanger failure, observe heat

exchanger tubes by looking at the heat exchanger through

field installed access openings in connecting ductwork. If

the bottom of the tubes become red while blower and duct

furnace are in operation, additional baffles must be inserted

between blower and duct furnace to assure uniform air flow

across the heat exchanger.

4. To prevent premature heat exchanger failure, with all control

systems, a blower starting mechanism must be provided so

that the blower is running or energized within 45 seconds of

the gas control operation.

5. Start-up and adjustment procedures should be performed

by a qualified service agency.

6. To check most of the Possible Remedies in the troubleshooting

guide listed in Table 20.1, refer to the applicable sections

of the manual.

Table of Contents

Inspection on Arrival ................................................................. 1

Special Precautions .................................................................. 2

SI (Metric) Conversion Factors ................................................. 3

Unit Location ............................................................................. 3

Location Recommendations .............................................. 3

Combustible Material and Service Clearances ................. 3

Combustion Air Requirements ........................................... 3

Unit Suspension ....................................................................... 4

Installation ................................................................................ 4

Direction of Airflow ............................................................. 4

Duct Installation and Airflow Distribution ........................ 4-5

Venting ........................................................................... 5-6

Gas Connections ............................................................... 7

Electrical Connections ....................................................... 8

Start-Up Procedure ................................................................... 8

Pilot Burner and Main Burner Adjustment ......................... 9

Air Shutter Adjustment ..................................................... 10

Control Operating Sequence ...................................... 11-13

Variable Air Movement Applications ................................ 13

Gas Control Options ................................................... 13-14

Dimensional Data ................................................................... 15

Performance ........................................................................... 16

Air Temperature and External Static Pressure Limits ...... 16

Pressure Drop Curves ............................................................ 17

Maintenance ........................................................................... 18

Manifold Assembly Removal ........................................... 18

Burner and Pilot Assembly Removal .......................... 18-19

Service & Troubleshooting .................................................20-21

Replacement Parts Ordering .................................................. 22

Model Identification ................................................................. 22

Commercial Warranty ................................................ Back Page

SI (METRIC) CONVERSION FACTORS / UNIT LOCATION

SI (METRIC) CONVERSION FACTORS

Table 3.1

To Convert Multiply By To Obtain

"W.C. 0.24 kPa

psig 6.893 kPa

°F (°F-32) x 0.555 °C

inches 25.4 mm

feet 0.305 meters

CFM 0.028 m3/min

To Convert Multiply By To Obtain

CFH 1.699 m3/min

Btu/ft3 0.0374 mJ/m

pound 0.453 kg

Btu/hr 0.000293 kW/hr

gallons 3.785 liters

psig 27.7 "W.C.

3

UNIT LOCATION

DANGER

Appliances must not be installed where they may be exposed

to a potentially explosive or flammable atmosphere.

IMPORTANT

To prevent premature heat exchanger failure, do not locate

ANY gas-fired appliances in areas where corrosive vapors (i.e.

chlorinated, halogenated or acid) are present in the atmosphere.

Location Recommendations

1. When locating the furnace, consider general space and

heating requirements, availability of gas and electrical

supply, and proximity to vent locations.

2. Unit must be installed on the positive pressure side of the

circulating blower.

3. Be sure the structural support at the unit location site is

adequate to support the weight of the unit. For proper

operation the unit must be installed in a level horizontal

position.

4. Do not install units in locations where the flue products

can be drawn into the adjacent building openings such as

windows, fresh air intakes, etc.

5. Be sure that the minimum clearances to combustible

materials and recommended service clearances are

maintained. Units are designed for installation on noncombustible surfaces with the minimum clearances shown

in Figure 3.1 and Tables 3.2 and 3.3.

6. Units installed downstream of refrigeration systems, or

exposed to inlet air temperatures of 40°F or less, may

experience condensation, therefore, provisions should

be made for disposal of condensate. Means have been

provided in the bottom pan of the unit to accommodate a

condensate drain line connection flange.

7. When locating units, it is important to consider that the

exhaust vent piping must be connected to the outside

atmosphere.

8. In garages or other sections of aircraft hangars such as

offices and shops which communicate with areas used for

servicing or storage, keep the bottom of the unit at least 7”

above the floor. In public garages, the unit must be installed

in accordance with the Standard for Parking Structures

NFPA #88A and the Standard for Repair Garages NFPA

#88B. In Canada, installation of unit heaters in airplane

hangars must be in accordance with the requirements of

the enforcing authority, and in public garages in accordance

with the current CAN/CGA-B149 codes.

9. Do not install units in locations where gas ignition system is

exposed to water spray, rain, or dripping water.

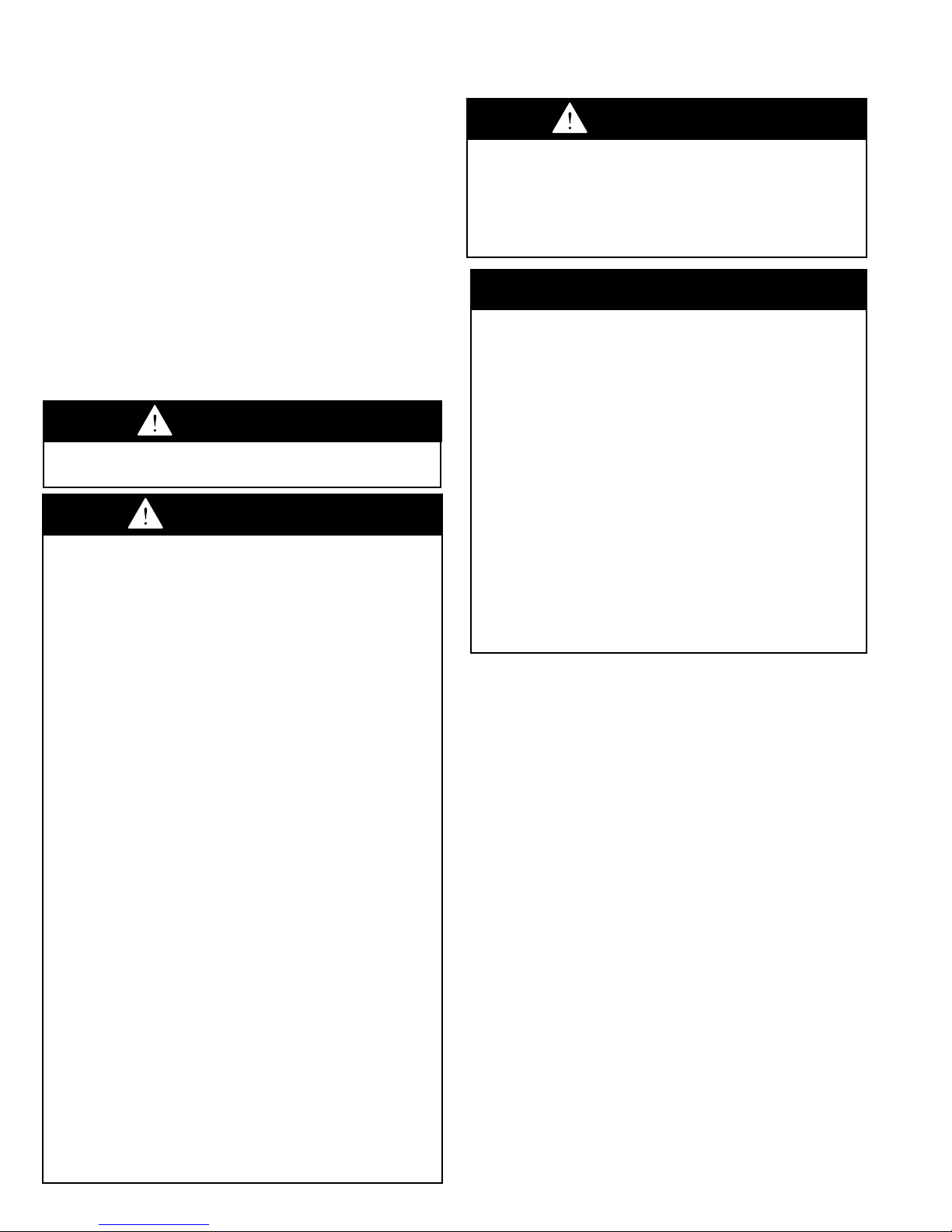

Figure 3.1 - Combustible Material and Service

Clearances

C

Access

Slide

B

A

D"

➀ A 3'' minimum clearance to combustible material is required from the vent collar.

Table 3.2 - Combustible Material Clearances

Clearance to

Combustible Materials

Model Access

Size Side Side (C) (D)

(A) (B)

75 12" 1" 3" 2"

100/125 12" 1" 3" 2"

150/175 12" 1" 3" 2"

200/225 12" 2" 3" 2"

250/300 12" 2" 3" 2"

350/400 12" 2" 3" 2"

Non-Access

Top Bottom

Table 3.3 - Service Clearances

Recommended

Service

Clearance

Model Access Non-Access Top Bottom

Size Side Side (C) (D)

(A) (B)

75 18" 6" 10" 0"

100/125 20" 6" 10" 0"

150/175 25" 6" 10" 0"

200/225 27" 6" 10" 0"

250/300 30" 6" 10" 0"

350/400 41" 6" 10" 0"

Combustion Air Requirements

Units installed in tightly sealed buildings or confined spaces

must be provided with two permanent openings, one near

the top of the confined space and one near the bottom. Each

opening should have a free area of not less than one square

inch per 1,000 BTU per hour of the total input rating off all

units in the enclosure, freely communicating with interior areas

having, in turn adequate infiltration from the outside.

For further details on supplying combustion air to a confined

(tightly sealed) space or unconfined space, see the National

Fuel Gas Code ANSI Z223.1 of CAN/CGA B149.1 or .2

Installation Code, latest edition.

5-564

33

UNIT SUSPENSION / INSTALLATION

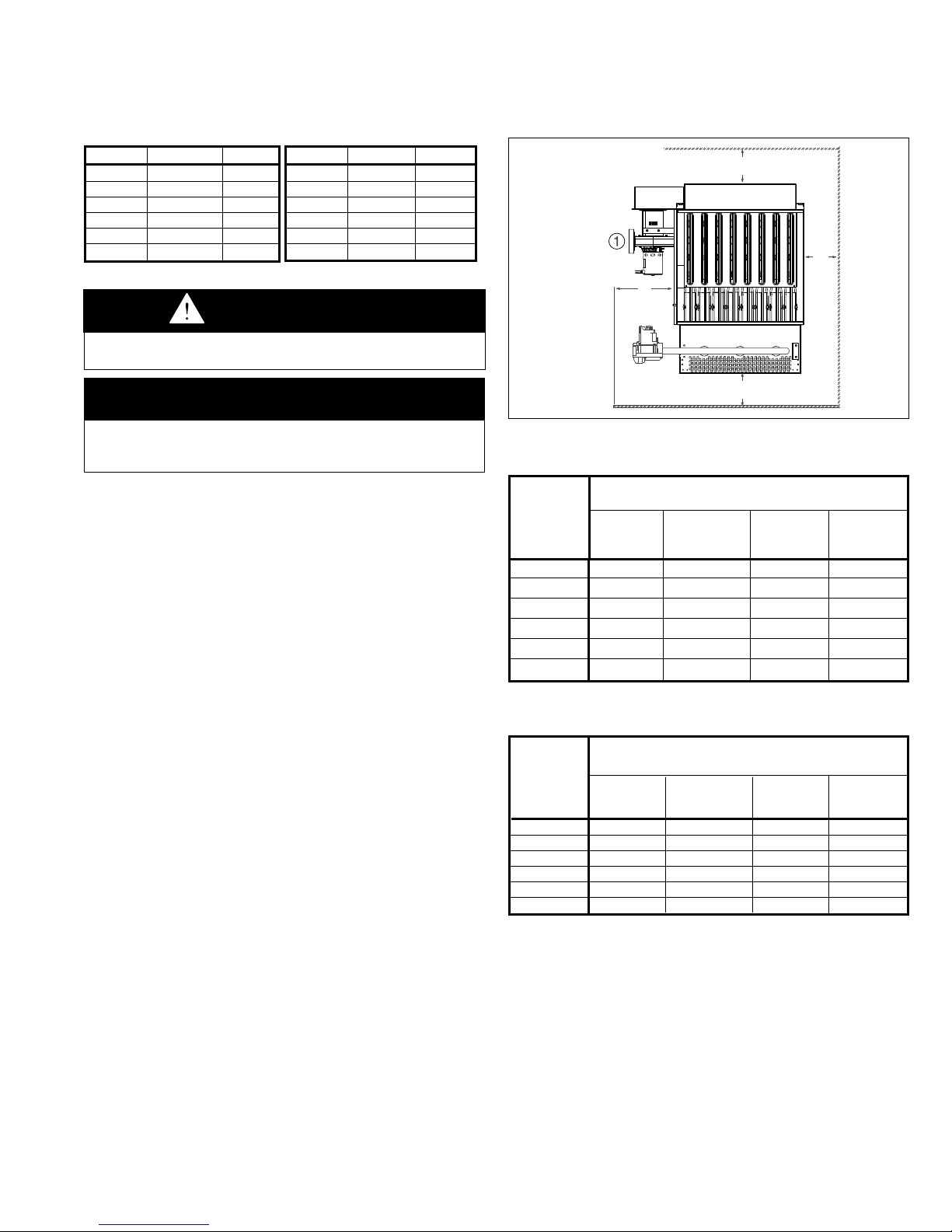

UNIT SUSPENSION

Be sure the means of suspension is adequate to support the

weight of the unit (see Dimensional Data for unit weights). For

proper operation, the unit must be installed in a level horizontal

position. Combustible material and service clearances as

specified in Figure 3.1 and Tables 3.2 and 3.3 must be strictly

maintained.

1. Four 1/2" - 13NC tapped holes in top of furnace are provided

to accept ceiling hangers. To assure that flames are directed

into the center of the heat exchanger tubes, the furnace must

be supported in a vertical position. Use a spirit level to ensure

that unit is suspended correctly.

2. NOTE: A pipe hanger adapter kit, shown in Figure 4.1, is

available as an accessory. One kit consists of two drilled

3/4" IPS pipe caps and two 1/2 - 13 x 1-3/4" capscrews to

facilitate threaded pipe suspension. Two kits are required for

mounting all duct furnace models.

Figure 4.1 - Suspension Methods

Duct Installation

1. The furnace is designed to accept straight ductwork. See

Figure 4.3. Provide an airtight seal between the ductwork

and the furnace. Seams with cracks in ductwork should be

caulked and/or taped and be of permanent type. All duct

connections MUST be airtight to prevent air leakage.

2. Provide removable access panels on both the upstream and

downstream sides of the ductwork; see Figure 4.3. These

openings should be large enough to view smoke or reflect

light inside the casing to indicate leaks in the heat exchanger

and to check for hot spots on heat exchangers due to poor air

distribution or lack of sufficient air (CFM)

Figure 4.3 - Duct Connections

C

INSTALLATION

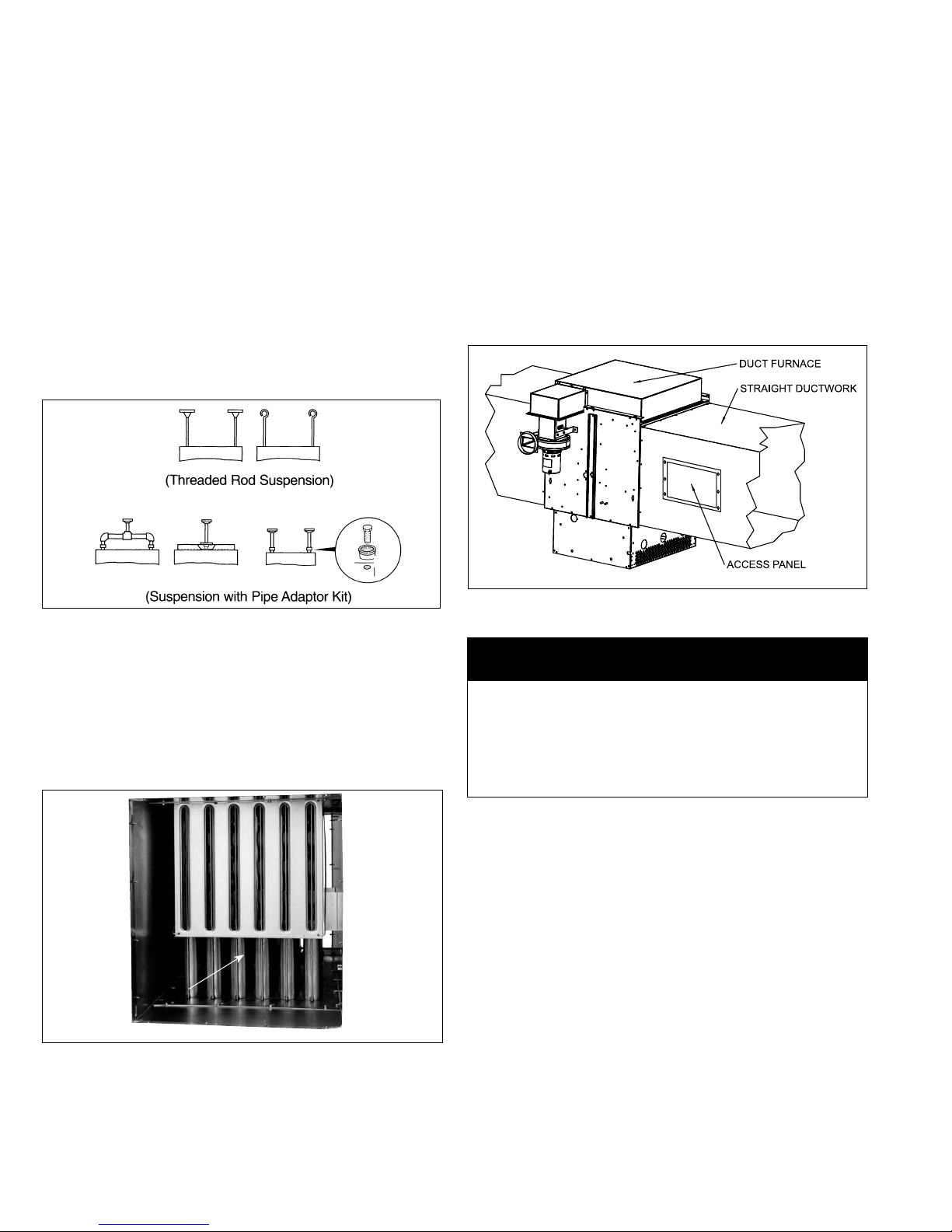

Direction of Airflow

Select proper direction of airflow. The air baffle must face the

air inlet direction as shown in Figure 4.2. If it is necessary to

reverse the airflow direction, remove the four screws securing

the air distribution baffle, reverse the air distribution baffle to the

air inlet side and replace the screws. See Airflow Reversal Note.

Figure 4.2 - Air Distribution Baffle Location

Baffle location shown on entering air side of duct furnace.

AIR

DISTRIBUTION

BAFFLE

Airflow Distribution

IMPORTANT

To prevent premature heat exchanger failure, observe heat

exchanger tubes by looking at the heat exchanger through

field installed access openings in connecting ductwork. If

the bottom of the tubes become red while blower and duct

furnace are in operation, additional baffles must be inserted

between blower and duct furnace to assure uniform air flow

across the heat exchanger.

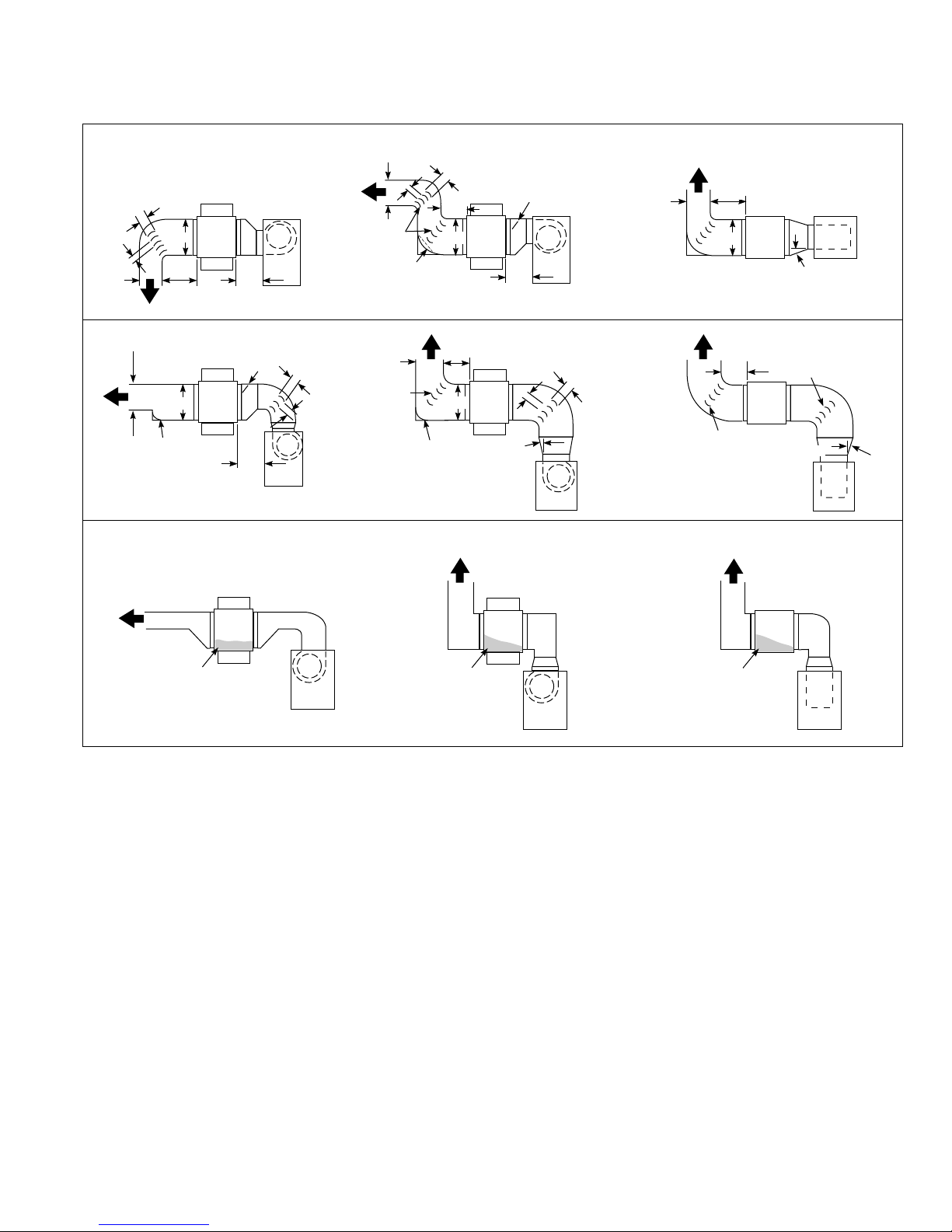

1. Provide uniform air distribution over the heat exchanger.

Use turning vanes where required (see Figure 5.1) to obtain

uniform air distribution. Avoid installing as in “G”, “H” & “J” of

Figure 5.1.

2. A bottom, horizontal discharge type blower should be

installed at least 12" from the furnace (See “A”, Figure 5.1).

3. A top, horizontal discharge type blower should be installed at

least 24" from the furnace (See “B”, Figure 5.1). Provide air

baffle at top of duct to deflect air down to the bottom of heat

exchanger.

Airflow Reversal Note: If factory installed discharge air options

(thermostat, freeze protection, etc.) were provided, these

options would have to be relocated to the discharge air side of

the duct furnace.

4

5-564

INSTALLATION

Figure 5.1 - Typical Duct & Airflow Installation

3" Max.

Turning

Vanes

3" Min.

B

B

A

12"

Min.

A

Baffle

SIDE VIEW

12"

Min.

SIDE VIEW

Air

Baffle

24"

Min.

G

POOR

3" Max.

RECOMMENCED INSTALLATIONS

RECOMMENDED INSTALLATIONS

3" Max.

B

Turning

Vanes

Baffle

12"

Min.

A

3" Min.

B

Air

Baffle

24"

Min.

SIDE VIEW

Turning

Vanes

3" Max.

15° Max.

Turning

Vanes

B

Baffle

12"

Min.

A

SIDE VIEW

INSTALLATIONS NOT RECOMMENDED

H

POOR

3" Min.

Turning

Van es

Dimensions “B” should never

be less than

CA

12"

Min.

B

A

15° Max.

TOP VIEW

FED

Turning

12"

Min.

Turning

Vanes

Van es

15° Max.

TOP VIEW

J

POOR

1

¼2 of “A”.

No Air

SIDE VIEW

No Air

SIDE VIEW

No Air

TOP VIEW

5-564

5

INSTALLATION

Venting

WARNING

1. Gas fired heating equipment must be vented - do not

operate unvented.

2. A built-in power exhauster is provided - additional external

power exhausters are not required or permitted.

3. If you are replacing an existing heater, it may be necessary

to resize the venting systems. Improperly sized venting

systems can result in vent gas leakage or the formation of

condensate. Refer to the National Fuel Gas Code ANSI

Z223.1 or CSA B149.1 latest edition. Failure to follow these

instructions can result in injury or death.

4. Under no circumstances should two sections of double wall

vent pipe be joined together within one horizontal vent system

due to the inability to verify complete seal of inner pipes.

NOTE: A vent is the vertical passageway used to convey

flue gases from the unit or the vent connector to the outside

atmosphere. A vent connector is the pipe which connects the

unit to a vent or chimney. Vent connectors serving Category

I appliances shall not be connected into any portion of

mechanical draft systems operating under positive pressure.

General Venting Instructions

1. Installation of venting must conform with local building codes,

or in the absence of local codes, with the National Fuel Gas

Code, ANSI Z223.1 (NFPA 54) - Latest Edition. In Canada,

installation must be in accordance with CAN/CGA-B149.1 for

natural gas units and CAN/CGA-B149.2 for propane units.

2. All vertically vented units are Category I. All horizontally vented

units are Category III. The installation must conform to the

requirements from Table 6.2 in addition to those listed below.

3. For units vented as Category I, refer to Table 6.1 for vent

sizing. Vent sizing for units vented as Category III are covered

in a later section on page 7. Do not use a vent pipe smaller

than the size of the outlet or vent transition of the appliance.

The pipe should be suitable corrosion resistant material.

Follow the National Fuel Gas Code for minimum thickness

and composition of vent material. The minimum thickness for

connectors varies depending on the pipe diameter.

Table 6.1 - Vertical Category I Vent Sizing Requirements

Vent Connector

Model Size

75-125

150-175 4" 5"

200 6" 6"

225-400

➀ Requires a 4" to 5" adapter for the larger vent pipe diameter.

4. For Category I vent systems limit length of horizontal runs to

75% of vertical height. Install with a minimum upward slope

from unit of 1/4 inch per foot and suspend securely from

overhead structure at points no greater than 3 feet apart.

For best venting, put vertical vent as close to the unit as

possible. A minimum of 12" straight pipe is recommended

from the power exhauster outlet before turns in the vent

system. Fasten individual lengths of vent together with at

least three corrosion-resistant sheet-metal screws.

5. It is recommended that vent pipes be fitted with a tee with a

drip leg and a clean out cap to prevent any moisture in the

vent pipe from entering the unit. The drip leg should be inspected

and cleaned out periodically during the heating season.

6. The National Fuel Gas Code requires a minimum clearance

of 6 inches from combustible materials for single wall vent

pipe. The minimum distance from combustible materials is

based on the combustible material surface not exceeding

160°F. Clearance from the vent pipe (or the top of the unit)

may be required to be greater than 6 inches if heat damage

other than fire (such as material distortion or discoloration)

could result.

Diameter

4" 4"

6” 6”

Minimum Vent Pipe

Diameter

➀

7. Avoid venting through unheated space. When venting does

pass through an unheated space, insulate runs greater than

5 feet to minimize condensation. Inspect for leakage prior to

insulating and use insulation that is noncombustible with a

rating of not less than 350°F. Install a tee fitting at the low

point of the vent system and provide a drip leg with a clean

out cap as shown in Figure 7.1.

Table 6.2 - ANSI Venting Requirements

Appliance Venting

Category Description Requirements

I Negative vent pressure Follow standard venting

Non-condensing requirements.

II Negative vent pressure Condensate must be

Condensing drained.

III Positive vent pressure Vent must be gastight.

Non-condensing

IV Positive vent pressure Vent must be liquid and

Condensing gastight. Condensate must

be drained.

8. When the vent passes through a combustible wall or floor,

a metal thimble 4 inches greater than the vent diameter is

necessary. If there is 6 feet or more of vent pipe in the

open space between the appliance and where the vent

pipe passes through the wall or floor, the thimble need only

be 2 inches greater than the diameter of the vent pipe. If a

thimble is not used, all combustible material must be cut

away to provide 6 inches of clearance. Any material used

to close the opening must be noncombustible.

9. Do NOT use dampers or other devices in the vent pipes.

10. Precautions must be taken to prevent degradation of

building materials by flue products.

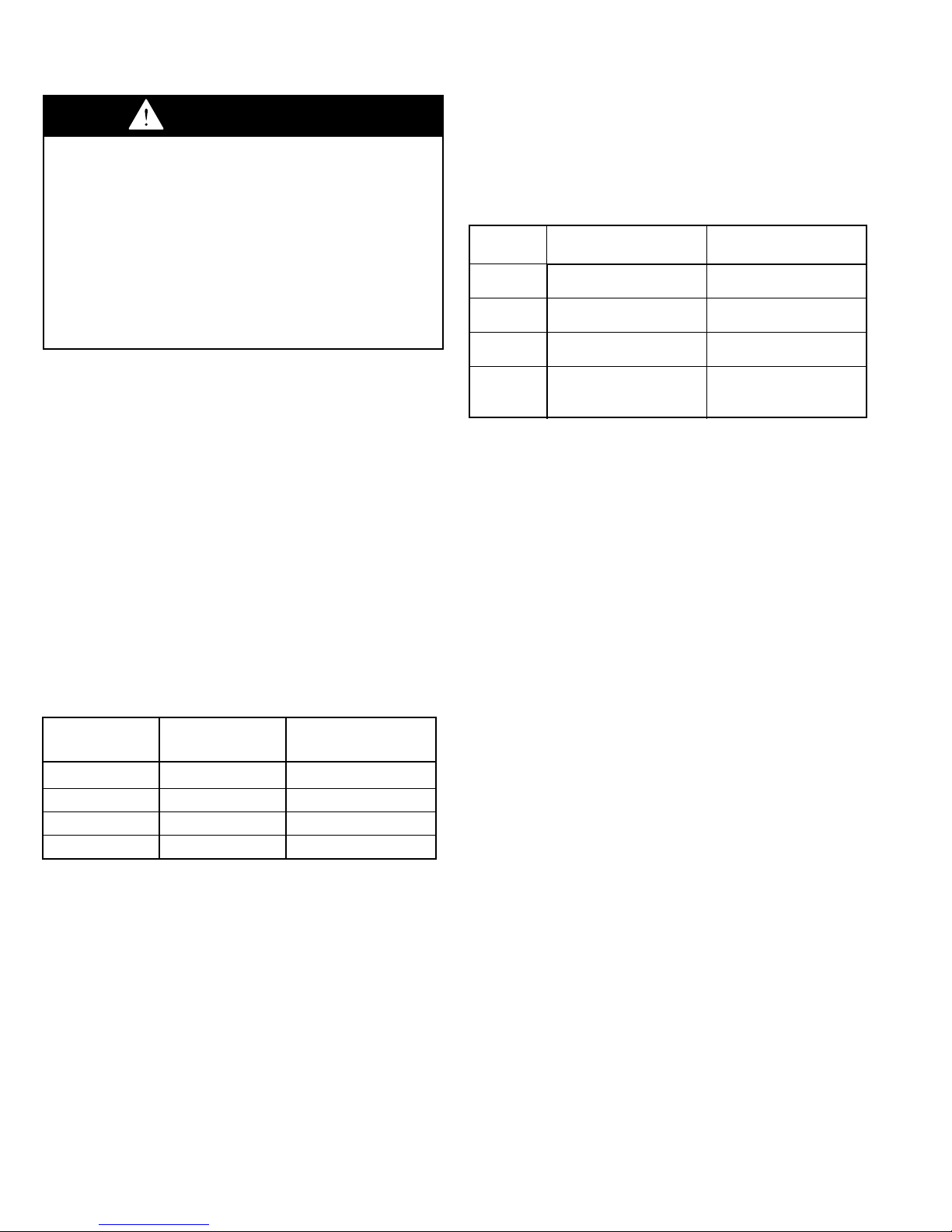

11. For category I vent systems the outlet of the vent should

extend as shown in Figure 7.1 and Table 7.1 if the following

conditions are met:

• Vent diameter is less than 12 inches, vent is of double

wall construction and is a listed product, and the vent

does not terminate within 2' of a vertical wall or similar

obstruction.

• For vents that have a diameter of 12 inches or larger,

constructed of single wall, or terminate within 2' of a

vertical wall or similar obstruction, the vent pipe shall

extend at least 2' higher than any portion of a building

within a horizontal distance of 10' (refer to Figure 7.1).

12. Use a listed vent terminal to reduce downdrafts and

moisture in vent.

13. For instructions on common venting refer to the National

Fuel Gas Code.

14. The vent must terminate no less than 5' above the vent

connector for Category I vent systems.

15. A unit located within an unoccupied attic or concealed space

shall not be vented with single wall vent pipe.

16. Single wall vent pipe must not pass through any attic, inside

wall, concealed space, or floor.

17. Do NOT vent this appliance into a masonry chimney.

18. When condensation may be a problem, the venting system

shall not terminate over public walkways or over an area

where condensation or vapor could create a nuisance or

hazard or could be detrimental to the operation of regulator

relief openings or other equipment.

19. In cold ambient conditions, such as Canada, the following

items are recommended for proper operation and

equipment life:

• The vent pipe must not pass through an unheated space

or interior part of an open chimney unless the vent pipe is

insulated.

• Where the vent pipe may be exposed to extreme cold, or

come into contact with snow or ice, the entire vent must

be insulated or double wall (includes outdoors). It is

preferred that the double wall vent is one continuous

piece but a joint is allowed outside the building.

• The heater system shall be checked at least once a year

by a qualified service technician.

6

5-564

TEE WITH DRIP LEG

AND CLEANOUT CAP

AT LOW POINT OF

VENT SYSTEM

POWER EXHAUSTER OUTLET

PITCH VENT PIPE DOWNWARD

FROM UNIT 1/4" PER FOOT

12"

Min.

GARY STEEL

MODEL 1092 TERMINAL

INSTALLATION

Figure 7.1 - Vertical Category I Vent System

LISTED TERMINAL

EXHAUST

12" MIN

4" MIN

* SIZE ACCORNING

TO EXPECTED

SNOW DEPTH.

"H" MIN*

ROOF FLASHING

TEE WITH DRIP LEG

AND CLEANOUT CAP

(SLOPE 1/4" PER

FOOT DOWNWARD

TOWARD DRIP LEG)

ROOF FLASHING

TEE WITH DRIP LEG

AND CLEANOUT CAP

(SLOPE 1/4" PER

FOOT DOWNWARD

TOWARD DRIP LEG)

X

ROOF PITCH IS:

X / 12

BACK VIEW

TO WALL OR ADJOINING BUILDING

12

USE LISTED THIMBLE

THROUGH ROOF AND

CEILING

2' MIN

TERMINAL

USE THIMBLE

THROUGH

CELLING

2' MIN*

4" MIN

EXHAUST

12" MIN

RECOMMENDED

RECOMMENDED

Table 7.1 - Minimum Height from Roof to Lowest

Discharge Opening

Rise X (in) Roof Pitch Min Height H (ft) ➀

0-6 Flat to 6/12 1.00

6-7 6/12 to 7/12 1.25

7-8 7/12 to 8/12 1.50

8-9 8/12 to 9/12 2.00

9-10 9/12 to 10/12 2.50

10-11 10/12 to 11/12 3.25

11-12 11/12 to 12/12 4.00

12-14 12/12 to 14/12 5.00

14-16 14/12 to 16/12 6.00

16-18 16/12 to 18/12 7.00

18-20 18/12 to 20/12 7.50

20-21 20/12 to 21/12 8.00

➀ Size according to expected snow depth.

Additional Requirements for Horizontally Vented

Category III Units

1. Seal the joints with a metallic tape or silastic suitable for

temperatures up to 350°F. (3M tapes 433 or 363 are

acceptable.) Wrap tape two full turns around the vent pipe.

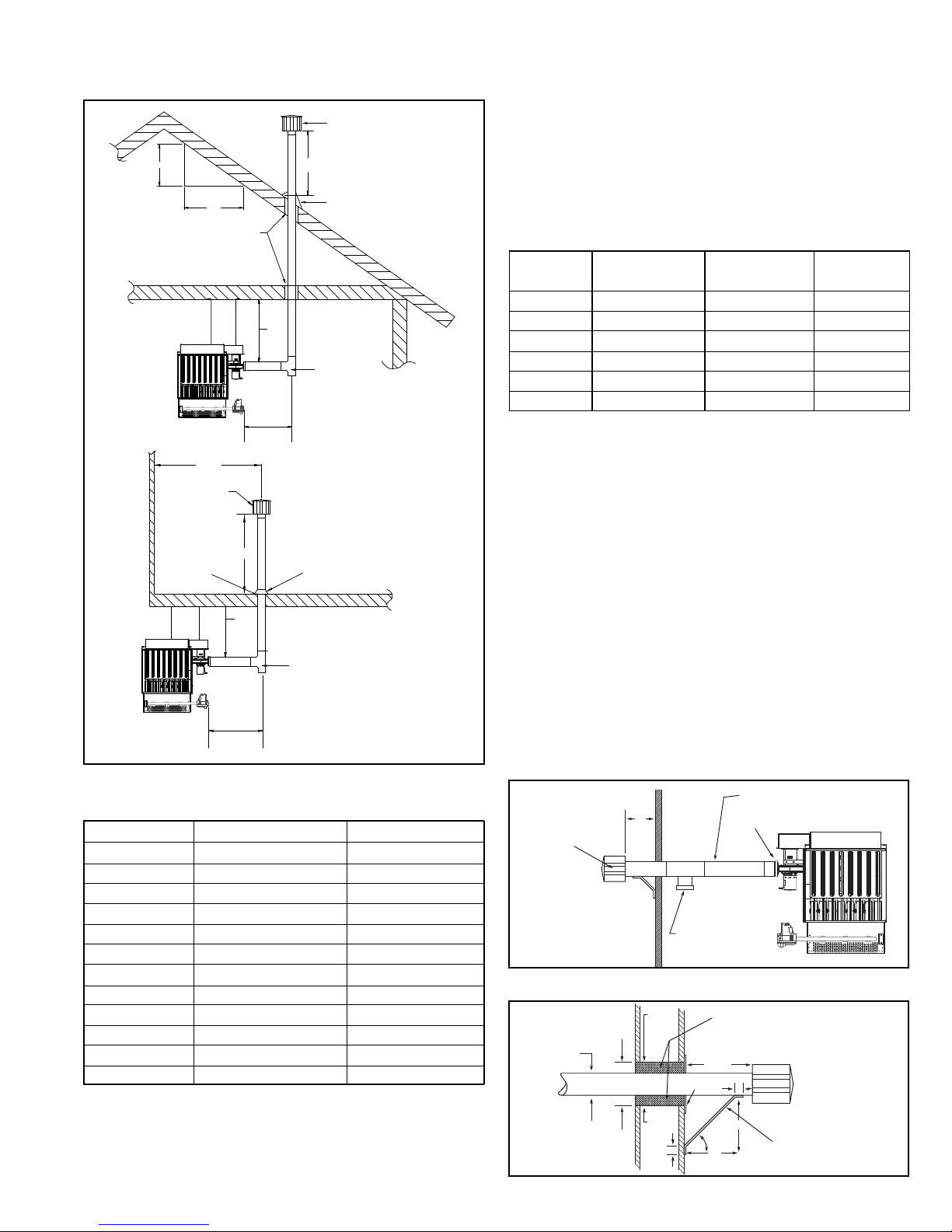

2. Refer to Table 7.2 for total minimum and maximum vent

lengths making the vent system as straight as possible.

The equivalent length of a 90° elbow is 5 feet for 4" diameter

and 7 feet for 6" diameter.

Table 7.2 - Horizontal Category III Vent Sizing

Requirements

Vent Connector

Model Size

75

100-175

200

225

250-300

350-400

➀ Unit can be vented with 5" diameter pipe if a 6" to 5" reducer is used.

Otherwise, use 6" pipe.

Diameter

4" 4" 48'

4" 4" 55'

6"

6"

6" 6" 63'

6" 6" 70'

3. The vent terminal must be a Gary Steel 1092.

4. The vent must extend a minimum of 12" beyond the exterior

wall surface as shown in Figure 7.2. The vent must be

supported as shown in Figure 7.3. Precautions must be taken

to prevent degradation of building materials by flue products.

5. The vent system shall terminate at least 3 feet above any

forced air inlet (except direct vent units) located within 10 feet,

and at least 4 feet below, 4 feet horizontally from, or 1 foot

above any door, window, or gravity air inlet into any building.

The bottom of the vent terminal shall be located above the

snow line or at least 1 foot above grade; whichever is greater.

When located adjacent to public walkways the vent system

shall terminate not less than 7 feet above grade.

6. The venting system must be exclusive to a single unit, and

no other unit is allowed to be vented into it.

7. Horizontally vented units must use single wall vent pipe

although one continuous section of double wall vent pipe

may be used with the vent system. Under no circumstances

should two sections of double wall vent pipe be joined

together within one vent system due to the inability to verify

complete seal of inner pipes.

Minimum Vent

Pipe Diameter

5" ➀ 70'

6" 70'

Maxium Vent

Length

Figure 7.2 - Horizontal Venting

Figure 7.3 - Venting Through Combustible Walls

METAL FACE

PLATE

45

1"

FIBER GLASS

INSULATION

MIN. 2"

12" min

1"

9"

9"

VENT TERMINATION

SUPPORT BRACKET

(where required)

(Make from 1" x 1" steel angle)

VENT PIPE

DIAMETER

2" MIN.

2" MIN.

METAL

SLEEVE

METAL

SLEEVE

5-564

7

INSTALLATION

Gas Connections

WARNING

1. All field gas piping must be pressure/leak tested prior to

operation. Never use an open flame. Use a soap solution or

equivalent for testing.

2. Gas pressure to appliance controls must never exceed 14"

W.C. (1/2 psi).

3. To reduce the opportunity for condensation, the minimum sea

level input to the appliance, as indicated on the serial plate,

must not be less than 5% below the rated input, or 5% below

the minimum rated input of duel rated units.

CAUTION

Purging of air from gas lines should be performed as

described in ANSI Z223.1 - latest edition “National Fuel Gas

Code”, or in Canada in CAN/CGA-B149 codes.

IMPORTANT

To prevent premature heat exchanger failure, the input to the

appliance, as indicated on the serial plate, must not exceed

the rated input by more than 5%.

1. Installation of piping must conform with local building codes,

or in the absence of local codes, with the National Fuel Gas

Code, ANSI Z223.1 (NFPA 54) - Latest Edition. In Canada,

installation must be in accordance with CAN/CGA-B149.1 for

natural gas units and CAN/CGA-B149.2 for propane units.

2. Piping to units should conform with local and national

requirements for type and volume of gas handled, and

pressure drop allowed in the line. Refer to Table 10.1 to

determine the cubic feet per hour (cfh) for the type of gas

and size of unit to be installed. Using this cfh value and the

length of pipe necessary, determine the pipe diameter from

Table 8.1. Where several units are served by the same main,

the total capacity, cfh and length of main must be considered.

Avoid pipe sizes smaller than 1/2". Table 8.1 allows for a 0.3"

W.C. pressure drop in the supply pressure from the building

main to the unit. The inlet pressure to the unit must be 6-7"

W.C. for natural gas and 11-14" W.C. for propane gas. When

sizing the inlet gas pipe diameter, make sure that the unit

supply pressure can be met after the 0.3" W.C. has been

subtracted. If the 0.3" W.C. pressure drop is too high, refer to

the Gas Engineer’s Handbook for other gas pipe capacities.

3. The gas piping to the unit can enter the unit from the side of

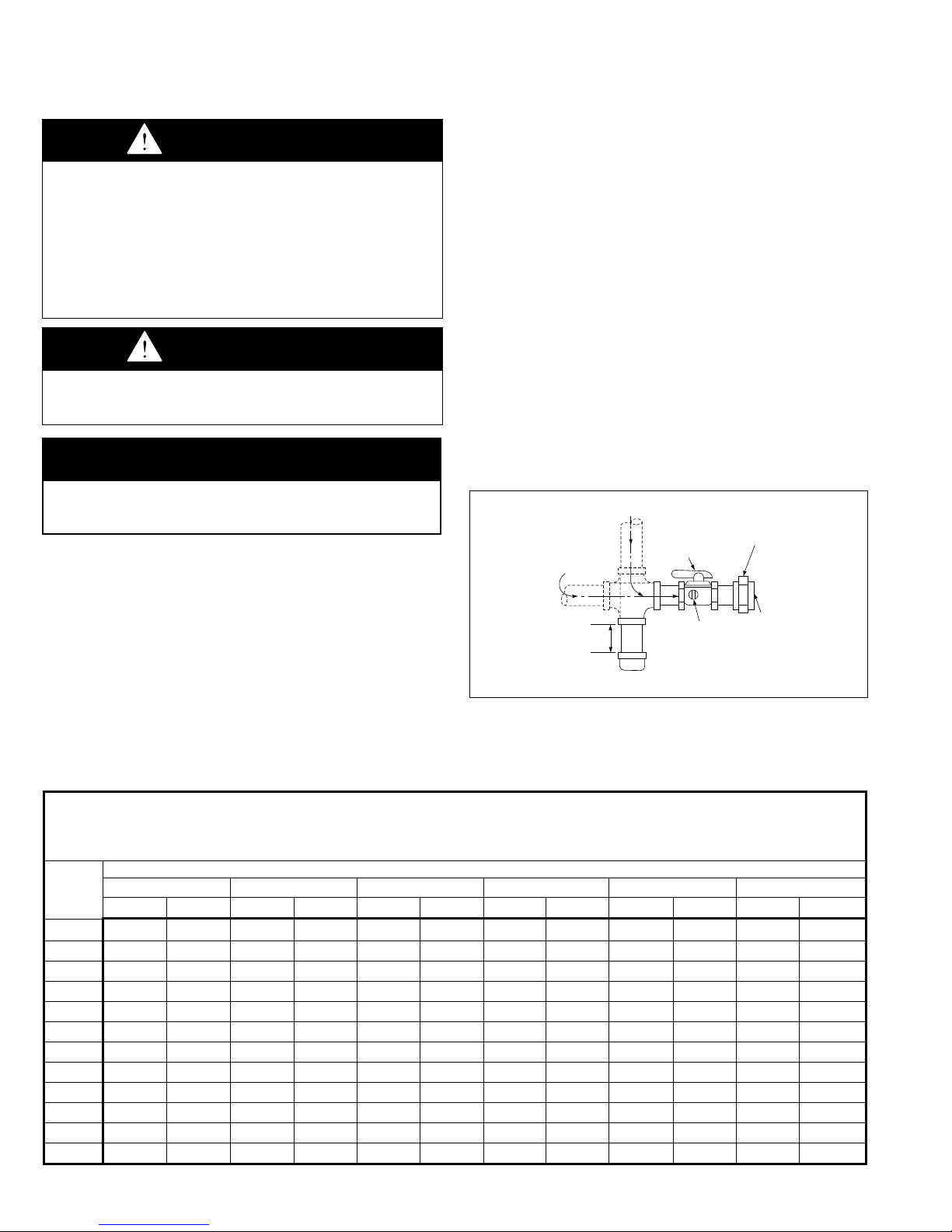

the unit or from below. Install a ground joint union with brass

seat and a manual shut-off valve external of the unit casing,

and adjacent to the unit for emergency shut-off and easy

servicing of controls, including a 1/8" NPT plugged tapping

accessible for test gauge connection (See Figure 8.1).

4. Provide a sediment trap before each unit in the line where low

spots cannot be avoided. (See Figure 8.1).

5. When Pressure/Leak testing, pressures above 14" W.C. (1/2

psi), close the field installed shut-off valve, disconnect the

appliance and its combination gas control from the gas supply

line, and plug the supply line before testing. When testing

pressures 14" W.C. (1/2 psi) or below, close the manual shutoff valve on the appliance before testing.

Figure 8.1 - Recommended Sediment Trap/Manual

Shut-off Valve Installation - Side or Bottom Gas

Connection

GAS

SUPPLY LINE

MANUAL GAS

TRAP

SHUT-OFF VALVE

PLUGGED

1/8" NPT TEST

GAGE CONNECTION

GAS

SUPPLY LINE

3"

MIN.

SEDIMENT

➀ Manual shut-off valve is in the “OFF” position when handle is perpendicular to

pipe.

➀

GROUND

JOINT

UNION

W/ BRASS

SEAT

TO

CONTROLS

Table 8.1 - Gas Pipe Capacities

Gas Pipe Capacities (Up to 14” W.C. Gas Pressure through Schedule 40 Pipe)

Length Pipe Diameter

Of Pipe 1/2" 3/4" 1" 1-1/4" 1-1/2" 2"

(feet) Natural Propane Natural Propane Natural Propane Natural Propane Natural Propane Natural Propane

10 132 83 278 175 520 328 1050 662 1600 1008 3050 1922

20 92 58 190 120 350 221 730 460 1100 693 2100 1323

30 73 46 152 96 285 180 590 372 890 561 1650 1040

40 63 40 130 82 245 154 500 315 760 479 1450 914

50 56 35 115 72 215 135 440 277 670 422 1270 800

60 50 32 105 66 195 123 400 252 610 384 1150 725

70 46 29 96 60 180 113 370 233 560 353 1050 662

80 43 27 90 57 170 107 350 221 530 334 990 624

90 40 25 84 53 160 101 320 202 490 309 930 586

100 38 24 79 50 150 95 305 192 460 290 870 548

125 34 21 72 45 130 82 275 173 410 258 780 491

150 31 20 64 40 120 76 250 158 380 239 710 447

8

Cubic Feet per Hour with Pressure Drop of 0.3” W.C.

Natural Gas - Specific Gravity - 0.60

Propane Gas - Specific Gravity - 1.50

5-564

INSTALLATION / START-UP PROCEDURE

Electrical Connections

WARNING

1. Disconnect power supply before making wiring connections

to prevent electrical shock and equipment damage.

2. All appliances must be wired strictly in accordance with

wiring diagram furnished with the appliance. Any wiring

different from the wiring diagram could result in a hazard

to persons and property.

3. Any original factory wiring that requires replacement must

be replaced with wiring material having a temperature

rating of at least 105°C.

4. Ensure that the supply voltage to the appliance, as indicated

on the serial plate, is not 5% greater than rated voltage.

CAUTION

Ensure that the supply voltage to the appliance, as indicated

on the serial plate, is not 5% less than rated voltage.

1. Installation of wiring must conform with local building codes,

or in the absence of local codes, with the National Electric

Code ANSI/NFPA 70 - Latest Edition. Unit must be electrically

grounded in conformance to this code. In Canada, wiring

must comply with CSA C22.1, Part 1, Electrical Code.

2. All duct furnaces are provided with a wiring diagram located

on the inside door of the electrical junction box. Refer to this

wiring diagram for all wiring connections. For factory installed

options and field installed accessory wiring, refer to Set A and

Set B on the provided wiring diagram.

3. The power supply to the duct furnace should be protected

with a fused disconnect switch.

4. Refer to Table 9.1 to determine the amp draw of the duct

furnace by adding the amp draw for the control transformer

(includes ignition controllers, gas valves, control relays, and

amplifiers) and power exhauster together, based on the

voltage and model size. Size the disconnect switch to cover

the amp draw of the unit.

5. Refer to the unit dimensional drawing on page 15 for the

electrical knockout locations.

Table 9.1 - Unit Amps

Digit 14

Supply Voltage

A 115/60/1 0 0.35 0.65 1.3 2.17 1.4 2.4

B 208/60/1 0 0.19 0.36 0.72 1.2 0.7 1.4

C 230/60/1 0 0.17 0.33 0.65 1.09 0.6 1.3

D 208/60/3 0 0.19 0.36 0.72 1.2 0.7 1.4

E 230/60/3 0 0.17 0.33 0.65 1.09 0.6 1.3

F 460/60/3 ➃ 0 0.09 0.16 0.33 0.54

G 575/60/3 ➃ 0 0.07 0.13 0.26 0.43 0.24 ➁ 0.52 ➂

➀ Unit controls amp draw is included in master unit amp draw.

➁ Requires a 250 VA transformer.

➂ Requires a 500 VA transformer.

➃ For Digits F (460V) and G (575V), amp draw shown is on primary (line) side of

required step-down transformer.

Control Step Down

Transformer Amp Draw

Digit 15 - Transformer Model Size

0 ➀ 1 2 3 4 75-175 200-400

Power Exhauster

Amp Draw

0.30 ➁ 0.65 ➂

START-UP PROCEDURE

IMPORTANT

Start-up and adjustment procedures should be performed by a

qualified service agency.

1. Turn off power to the unit at the disconnect switch. Check

that fuses or circuit breakers are in place and sized

correctly. Turn all hand gas valves to the “OFF” position.

2. Check that the supply voltage matches the unit supply

voltage listed on the serial plate. Verify that all wiring is

secure and properly protected. Trace circuits to insure that

the unit has been wired according to the wiring diagram.

3. Check to insure that the venting system is installed and free

from obstructions.

4. Check to see that there are no obstructions to the intake

and discharge of the duct furnace.

5. Perform a visual inspection of the unit to make sure no

damage has occurred during installation.

6. Turn on power to the unit at the disconnect switch. Check to

insure that the voltage between terminals 1 and 2 is 24V.

7. Check the thermostat, ignition control, gas valve, power

exhauster motor, and supply fan blower motor for electrical

operation. If these do not function, recheck the wiring

diagram. Check to insure that none of the Gas Control

Options & Accessories (see page 14) have tripped.

8. Recheck the gas supply pressure at the field installed

manual-shut-off valve. The inlet pressure should be 6"-7”

W.C. on natural gas and 11"-14” W.C. on propane gas.

If inlet pressure is too high, install an additional pressure

regulator upstream of the combination gas control.

9. Open the field installed manual gas shut-off valve.

10. Open the manual main gas valve on the combination gas

control. Call for heat with the thermostat. On a call for heat,

the power exhauster relay will energize the power exhauster

motor. Once the power exhauster motor has reached full

speed, the differential pressure switch will close. Once

closed, the ignition controller will attempt to light the pilot.

If the pilot does not light, purge the pilot line. If air purging

is required, disconnect the pilot line at outlet of pilot valve.

In no case should the line be purged into heat exchanger.

Check the pilot flame length (See Pilot Burner Adjustment).

11. Once the pilot has been established, check to make sure

that the main gas valve opens. Check the manifold gas

pressure (See Main Burner Adjustment) and flame length

(See Air Shutter Adjustment) while the circulating air blower

is operating.

12. Check to insure that gas controls sequence properly

(See Control Operating Sequence). Verify if the unit has

any additional control devices and set according to the

instructions in the Gas Controls Options.

13. Once proper operation of the duct furnace has been

verified, remove any jumper wires that were required for

testing.

14. Close the electrical compartment door.

5-564

9

START-UP PROCEDURE

Pilot Burner Adjustment

The pilot burner is orificed to burn properly with an inlet pressure

of 6-7" W.C. on natural gas and 11-14" W.C. on propane gas, but

final adjustment must be made after installation. If the pilot flame

is too long or large, it is possible that it may cause soot and/or

impinge on the heat exchanger causing failure. If the pilot flame

is shorter than shown, it may cause poor ignition and result in

the controls not opening the combination gas control. A short

flame can be caused by a dirty pilot orifice. Pilot flame condition

should be observed periodically to assure trouble-free operation.

To Adjust the Pilot Flame

1. Create a call for heat from the thermostat.

2. Remove the cap from the pilot adjustment screw. For location,

see the combination gas control literature supplied with unit.

3. Adjust the pilot length by turning the screw in or out to achieve

a soft steady flame 3/4" to 1" long and encompassing 3/8"1/2" of the tip of the thermocouple or flame sensing rod (See

Figure 10.1).

4. Replace the cap from the pilot adjustment screw.

Figure 10.1 - Correct Pilot Flame

3/4" to 1"

Main Burner Adjustment

The gas pressure regulator (integral to the combination gas

control) is adjusted at the factory for average gas conditions. It is

important that gas be supplied to the duct furnace in accordance

with the input rating on the serial plate. Actual input should

be checked and necessary adjustments made after the duct

furnace is installed. Over-firing, a result of too high an input,

reduces the life of the appliance and increases maintenance.

Under no circumstances should the input exceed that shown on

the serial plate.

Measuring the manifold pressure is done at the tee in the

manifold for premium gas controls (Digit 13=0, 1, 2, or 3) or

at the pressure tap on the gas valve for standard gas controls

(Digit 13=4)." (See Figure 10.2).

To Adjust the Manifold Pressure

1. Move the field installed manual shut-off valve to the “OFF”

position.

2. Remove the 1/8" pipe plug in the pipe tee or gas valve and

attach a water manometer of “U” tube type which is at least

12" high.

3. Move the field installed manual gas shut-off valve to the “ON”

position.

4. Create a high fire call for heat from the thermostat.

5. Determine the correct high fire manifold pressure. For

natural gas 3.5” W.C., for propane gas 10” W.C. Adjust the

main gas pressure regulator spring to achieve the proper

manifold pressure (for location, see the combination gas

control literature supplied with unit).

6. If the unit has Electronic Modulation gas controls (determine

from the Model Identification Digit 12), the low fire gas

pressure needs to be adjusted. Using Figure 10.3 for item

number locations, this is accomplished as follows:

a. Disconnect power.

b. Remove all wires from Maxitrol Amplifier terminal “3” or

duct furnace terminal “43” (if available).

c. Turn on power at the disconnect switch.

d. Remove the maximum adjustment screw (4), spring

(5), and plunger (8). A small magnet is useful for this

purpose. CAUTION - The plunger is a precision part.

Handle carefully to avoid marring or picking up grease

and dirt. Do not lubricate.

e. Using minimum adjusting screw (9), adjust low fire

manifold pressure to 0.56" W.C. for natural gas and

1.6" W.C. for propane gas.

f. Replace plunger and spring retainer, spring, and

maximum adjusting screw in proper order.

g. Using maximum adjustment screw (4), adjust high fire

manifold pressure to 3.5" W.C. for natural gas and 10"

W.C. for propane gas.

h. Disconnect power.

i. Replace cover plate (2) and re-install all wires from

Maxitrol amplifier terminal “3” or duct furnace terminal “43”.

7. After adjustment, move the field installed manual shut-off

valve to the “OFF” position and replace the 1/8" pipe plug.

8. After the plug is in place, move the field installed manual

shut-off valve to the “ON” position and recheck pipe plugs for

gas leaks with soap solution.

Figure 10.3 - Maxitrol Modulating Valve Adjustments

Figure 10.2 - Manifold Pressure Test Points

Premium Controls

Manifold Pressure Test Point

Standard Controls

10

5-564

1. TOP HOUSING

2. COVER PLATE

3. SEAL GASKET

4. MAXIMUM ADJUSTMENT SCREW

5. MAXIMUM ADJUSTMENT SPRING

6. SOLENOID

7. MINIMUM ADJUSTMENT SPRING

8. PLUNGER

9. MINIMUM ADJUSTMENT SCREW

10. MINIMUM ADJUSTMENT SCREW STOP

START-UP PROCEDURE

Air Shutter Adjustment

Proper operation provides a soft blue flame with a well-defined

inner core. A lack of primary air will reveal soft yellow-tipped

flames. Excess primary air produces short, well-defined flames

with a tendency to lift off the burner ports. For both natural

and propane gas, the air shutters can be adjusted to control

the burner flame height. The air shutters can be accessed by

reaching behind the gas valve in Figure

may require the removal of the manifold (see Manifold Assembly

Removal).

Natural Gas Flame Control

Control of burner flames on duct furnaces utilizing natural gas

is achieved by resetting the primary air shutters (See Figure

19.1) to either increase or decrease primary combustion air.

Prior to flame adjustment, operate duct furnace for about fifteen

minutes. The main burner flame can be viewed after loosening

and pushing aside the gas designation disc on the side of the

burner box.

To increase primary air, loosen the air shutter set screws and

move the air shutters closer to the manifold until the yellowtipped flames disappear. (See Figure 19.1 for air shutter and

heat exchanger support locations.) To decrease primary air,

move the air shutters away from the manifolds until flames

no longer lift from burner ports, but being careful not to cause

yellow tipping. Retighten set screws after adjustment.

Propane Gas Flame Control

An optimum flame will show a slight yellow tip. Prior to flame

adjustment, operate furnace for at least fifteen minutes. Loosen

air shutter set screws and move the air shutters away from the

manifold to reduce the primary air until the yellow flame tips

appear. Then increase the primary air until yellow tips diminish

and a clean blue flame with a well defined inner cone appears.

10.3. The larger models

Table 11.1 - Manifold Pressure and Gas Consumption

Model Size Type of Gas Natural Propane

Btu/Cu. Ft. 1040 2500

Specific Gravity 0.60 1.53

High Fire Manifold Pressure No. of

Inches of Water Column 3.5 10 Orifices

Cfh 72.1 30.0

75

Orifice Drill Size 20 37

Cfh 96.1 40.0

100

Orifice Drill Size 30 45

Cfh 120.2 50.0

125

Orifice Drill Size 25 42

Cfh 144.2 60.0

150

Orifice Drill Size 30 45

Cfh 168.3 70.0

175

Orifice Drill Size 27 43

Cfh 192.3 80.0

200

Orifice Drill Size 23 40

Cfh 216.3 90.0

225

Orifice Drill Size 20 37

Cfh 240.4 100.0

250

Orifice Drill Size 25 42

Cfh 288.7 120.0

300

Orifice Drill Size 20 37

Cfh 336.5 140.0

350

Orifice Drill Size 27 43

Cfh 384.6 160.0

400

Orifice Drill Size 23 40

1

2

2

3

3

3

3

4

4

6

6

5-564

11

START-UP PROCEDURE

IMPORTANT

To prevent premature heat exchanger failure, with all control

systems, a blower starting mechanism must be provided so

that the blower is running or energized within 45 seconds of

the gas control operation.

Control Operating Sequence

Indoor power vented duct furnaces are supplied with intermittent

pilot systems with continuous retry as standard. On mechanical

modulation systems the main burner is turned off 100%

when the thermostat is satisified, but the pilot remains lit. For

intermittent pilot systems, except mechanical modulation both

the main burner and pilot burner are turned off 100% when

the thermostat is satisfied. Intermittent pilot systems, for both

natural and propane gas, the ignition controller is 100% shut-off

with continuous retry. On a call for heat, the system will attempt

to light the pilot for 70 seconds. If the pilot is not sensed for

any reason, the ignition control will wait for approximately six

minutes with the combination gas control closed and no spark.

After six minutes, the cycle will begin again. After three cycles,

some ignition controllers lockout for approximately one hour

before the cycle begins again. This will continue indefinitely until

the pilot flame is sensed or power is interrupted to the system.

NOTE: Gas Control Options (see page 14) could change the

listed sequence of operation based on their function.

The descriptions given are for the basic duct furnace.

Single-Stage Gas Controls

Utilizes a single-stage combination gas, an ignition control, and

a single-stage low voltage thermostat.

1. The thermostat calls for heat.

2. The power exhauster relay is energized starting the power

exhauster motor. Once the motor has reached full speed, the

differential pressure switch closes. The power exhauster relay

pre-purge timer closes after 20 to 40 seconds energizing the

gas control circuit.

3. The pilot valve opens and the spark ignitor sparks in an

attempt to light the pilot. (If the unit was not provided with a

time delay relay, the blower starts at this time.)

4. Once the pilot is lit, the flame sensor proves the pilot and

stops the spark ignitor from sparking.

5. The main gas valve is opened and the main burner is lit to

100% full fire.

6. If the unit was provided with a time delay relay, the blower

starts after 30 to 45 seconds.

7. The unit continues to operate until the thermostat is satisfied,

at which time both the main and pilot valves close 100%. (If

the unit was not provided with a time delay relay, the blower

stops at this time).

8. If the unit was provided with a time delay relay, the blower

stops after 30 to 45 seconds.

Two-Stage Gas Controls

Utilizes a two-stage combination gas control, an ignition control,

and a two-stage low voltage thermostat. The unit fires at 50%

fire on low stage and 100% fire on high stage.

1. The thermostat calls for low stage heat.

2. The power exhauster relay is energized starting the power

exhauster motor. Once the motor has reached full speed, the

differential pressure switch closes. The power exhauster relay

pre-purge timer closes after 20 to 40 seconds energizing the

gas control circuit.

3. The pilot valve opens and the spark ignitor sparks in an

attempt to light the pilot. (If the unit was not provided with a

time delay relay, the blower starts at this time.)

4. Once the pilot is lit, the flame sensor proves the pilot and

stops the spark ignitor from sparking.

5. The main gas valve is opened and the main burner is lit to

50% fire.

6. If the unit was provided with a time delay relay, the blower

starts after 30 to 45 seconds.

7. If the temperature at the thermostat continues to fall, the

thermostat will call for high stage heat.

8. The main gas valve is opened completely and the main

burner is lit to 100% full fire.

9. The unit continues to operate until the high stage of the

thermostat is satisfied, at which time the main valve closes

to 50% fire.

10. The unit continues to operate until the low stage thermostat

is satisfied, at which time both the main and pilot valves

close 100%. (If the unit was not provided with a time delay

relay, the blower stops at this time.)

11. If the unit was provided with a time delay relay, the blower

stops after 30 to 45 seconds.

Mechanical Modulating Gas Controls (Natural Gas Only)

Dial Number

Lo 1 2 3 4 5 6 7 8 Hi

Discharge

Air Temp. 58 62 65 69 72 76 79 83 86 90

(°F)

Utilizes a mechanical modulating gas control and an ignition

control. The mechanical modulating gas control is designed

for use in constant blower applications. The discharge air

temperature is maintained by setting the control dial of the

modulating gas valve in one of ten positions. A hydrostatic

sensing bulb located in the discharge air stream controls the gas

flow between 40% through 100% full fire. When the discharge

air hydrostatic sensing bulb is satisfied, the modulating valve

closes completely, but the pilot remains lit.

This control cannot be used with a room override thermostat.

1. Power is supplied to the unit through either an exhaust fan

interlock contact or a start/stop switch.

2. The power exhauster relay is energized starting the power

exhauster motor. Once the motor has reached full speed, the

differential pressure switch closes. The power exhauster relay

pre-purge timer closes after 20 to 40 seconds energizing the

gas control circuit.

3. The pilot valve opens and the spark ignitor sparks in an

attempt to light the pilot. (If the unit was not provided with a

time delay relay, the blower starts at this time.)

4. Once the pilot is lit, the flame sensor proves the pilot and

stops the spark ignitor from sparking.

5. The hydrostatic sensing bulb, integral to the mechanical

modulating gas valve, calls for heat. The main gas valve is

opened and the main burner is lit. The burner modulates

between 40% through 100% fire based on the call for heat.

6. If the unit was provided with a time delay relay, the blower

starts after 30 to 45 seconds.

7. The unit continues to operate until the hydrostatic sensing

bulb is satisfied, at which time the main valve closes 100%,

but the pilot remains lit.

8. The unit blower (and pilot) continues to operate until either an

exhaust fan interlock contact or a start/stop switch is opened.

If the unit was provided with a time delay relay, the blower

stops after 30 to 45 seconds.

12

5-564

START-UP PROCEDURE

Electronic Modulating Gas Controls

Single Furnace

Utilizes an electronic modulating/regulating gas control,

combination gas valve, an ignition control, modulating amplifier,

and either a modulating room thermostat or modulating duct

thermostat with remote temperature set point adjuster. The

thermostat controls can modulate the gas flow between 40%

through 100% full fire. When the thermostat is satisfied, the amplifier

cuts power to the combination gas valve which prevents gas

flow to both the main and pilot burners.

When duct sensing is utilized, a room override thermostat can

be added. When calling for heat, the room override thermostat

provides full fire operation until the space temperature is

satisfied. Control is then returned to the duct sensing control.

In this situation, either the duct sensor or the room override

thermostat can call for heat.

1. The thermostat calls for heat.

2. The power exhauster relay is energized starting the power

exhauster motor. Once the motor has reached full speed, the

differential pressure switch closes. The power exhauster relay

pre-purge timer closes after 20 to 40 seconds energizing the

gas control circuit.

3. The pilot valve opens and the spark ignitor sparks in an

attempt to light the pilot. (If the unit was not provided with a

time delay relay, the blower starts at this time.)

4. Once the pilot is lit, the flame sensor proves the pilot and

stops the spark ignitor from sparking.

5. The main gas valve is opened and the main burner is lit to

100% full fire.

6. If the unit was provided with a time delay relay, the blower

starts after 30 to 45 seconds.

7. The modulating gas valve can be controlled by either an

electronic modulating room or duct thermostat. The thermostat

can modulate the firing rate between 40% through 100% full fire.

The call for heat is created by a resistance signal (8000 to 12000

ohms) in the thermostat. The amplifier converts this resistance

into a DC voltage (0 to 12 volts DC with 0 volts high fire and 12

volts low fire). The output voltage is applied to the modulating

gas valve to control the gas flow to the main burner. As the

temperature drops, the voltage drops causing the modulating

valve to open further. If the discharge air temperature increases,

the voltage increases causing the modulating valve to close

allowing less gas flow to the main burner. For further information

regarding the operation of the electronic modulating system,

consult the literature provided with the unit.

8. The unit continues to operate in this manner until the

thermostat is satisfied, at which time both the main and pilot

valves close 100%. (If the unit was not provided with a time

delay relay, the blower stops at this time.)

9. If the unit was provided with a time delay relay, the blower

stops after 30 to 45 seconds.

Electronic Modulating Gas Controls - Master/Slave

One Master furnace is provided with up to three Slave furnaces

that utilize electronic modulating/regulating gas controls,

combination gas valves, ignition controls, one multiple furnace

modulating amplifier, and either a modulating room thermostat

or modulating duct thermostat with remote temperature adjuster.

The thermostat controls can modulate the gas flow of all the

furnaces between 40% through 100% full fire. The amplifier

sends a signal to all of the gas valves so that they modulate

at the same percentage. When the thermostat is satisfied,

the amplifier cuts power to the combination gas valves which

prevents gas flow to both the main and pilot burners.

When duct sensing is utilized, a room override thermostat can

be added. When calling for heat, the room override thermostat

provides full fire operation until the space temperature is

satisfied. Control is then returned to the duct sensing control.

In this situation, either the duct sensor or the room override

thermostat can call for heat.

5-564

The sequence of operation for Electronic Modulating Gas

Controls - Master/Slave is the same as Electronic Modulating

Gas Controls - Single Furnace.

Electronic Modulating Gas Controls - Building

Management Control (0-10Vdc or 4-20 mA Signal)

Utilizes an electronic modulating/regulating gas control,

combination gas valve, an ignition control, modulating signal

conditioner, and an inverted (0 Vdc or 4 mA being high fire and

10 Vdc or 20 mA being low fire) 0-10 Vdc or 4-20 mA input

signal provided by a Building Management System (BMS). The

signal conditioner can modulate the gas flow between 40%

through 100% full fire. When the BMS thermostat (field supplied)

is satisfied, the BMS heat contact (field supplied) opens to cut

power to the combination gas valve which prevents gas flow to

both the main and pilot burners.

1. The BMS thermostat (field supplied) calls for heat and closes

the BMS heat contact (field supplied).

2. The power exhauster relay is energized starting the power

exhauster motor. Once the motor has reached full speed, the

differential pressure switch closes. The power exhauster relay

pre-purge timer closes after 20 to 40 seconds energizing the

gas control circuit.

3. The pilot valve opens and the spark ignitor sparks in an

attempt to light the pilot. (If the unit was not provided with a

time delay relay, the blower starts at this time.)

4. Once the pilot is lit, the flame sensor proves the pilot and

stops the spark ignitor from sparking.

5. The main gas valve is opened and the main burner is lit to

100% full fire.

6. If the unit was provided with a time delay relay, the blower

starts after 30 to 45 seconds.

7. The modulating gas valve is controlled by the BMS

thermostat. The thermostat can modulate the firing rate

between 40% through 100% full fire by modulating the input

signal between either 0-10 Vdc or 4-20 mA (The signal

conditioner can accept a 0-10 Vdc signal when all the dip

switches are in the “OFF” position and 4-20 mA signal when

all the dip switches are in the “ON” position). The signal

conditioner converts the input signal into a DC voltage (0

to 12 volts DC with 0 volts high fire and 12 volts low fire).

The output voltage is applied to the modulating gas valve to

control the gas flow to the main burner. As the temperature

drops, the voltage drops causing the modulating valve to open

further. If the discharge air temperature increases, the voltage

increases causing the modulating valve to close allowing less

gas flow to the main burner. For further information regarding

the operation of the electronic modulating system, consult the

literature provided with the unit.

8. The unit continues to operate in this manner until the

thermostat is satisfied, at which time the BMS heat contact

opens resulting in both the main and pilot valves closing

100%. (If the unit was not provided with a time delay relay, the

blower stops at this time.)

9. If the unit was provided with a time delay relay, the blower

stops after 30 to 45 seconds.

Variable Air Movement Applications

When the air mover supplied by others can provide variable

air movement (i.e. 2-speed or variable frequency drive units),

the allowable minimum CFM of the duct furnace can be 66% of

the minimum listed CFM in Table 16.1 if the unit is applied as

follows:

1. The unit is provided with 2-stage, mechanical modulation, or

electronic modulating gas controls. (see Model Identification).

2. The unit is provided with a factory installed discharge air

controller.

3. The system does not include a room thermostat.

The factory installed discharge air thermostat will prevent the

unit from firing above the allowable 100°F rise when the unit is

at or above the minimum CFM by monitoring the discharge air

and going to low fire. A room thermostat, because it is located

remote from the unit, could cause the unit to over-fire.

13

OPTIONS

Units with Standard

Control Panel

Units with Premium Control Box

13

48

6

46

6

8

57

9

13

49

2

3

50

5

4

1

10

9

8

12

46

47

55

51

52

12

300

FM

R

LISTED

PRESSURE

OPERATED

SWITCH

504H

ADDISON

IL. U.S.A.

MODEL

RLGP-A

M1

LOW

PRESSURE

50

100

150

200

350

250

mm.

W.C.

2

4

6

8

10

14

IN.

12

300

FM

R

LISTED

PRESSURE

OPERATED

SWITCH

504H

ADDISON

IL. U.S.A.

MODEL

RLGP-A

M1

LOW

PRESSURE

50

100

150

200

350

250

mm.

W.C.

2

4

6

8

10

14

IN.

12

3

456

A1010 Amplifier

89101114

GH

T

PV

MV

LED

TH

PV/MV

GND

TR

SENSE

Gas Control Options

The unit must be reviewed to determine if any of the listed gas

control options were supplied.

➀ Time Delay Relay

The Time Delay Relay is factory installed in the duct furnace

electrical junction box. The standard duct furnace is provided

for instantaneous fan operation. On a call for heat, the blower is

energized at the same time as the gas controls. The optional time

delay relay allows the gas controls to operate for approximately 30

seconds before the blower starts. This allows the heat exchanger

a warm up period so that the initial delivered air coming out of the

ductwork is not cool. The time delay relay also keeps the motor

running for approximately 30 seconds after the call for heat has

been satisfied to remove the residual heat from the heat exchanger.

➁ Low Gas Pressure Switch

The low gas pressure switch is factory installed in the duct furnace

above the gas train. The switch monitors the gas pressure upstream

of all the gas controls and shuts off the electric supply to the

ignition controller and combination gas valve if low gas pressure is

experienced. This will shut off all gas flow to the burner. The switch

has an automatic reset so that if the gas pressure is interrupted

and then is returned, the switch will automatically allow the unit to

operate when gas conditions are returned to the allowable range

of the pressure switch. The pressure switch range is 2" to 14" W.C.

and should be set to insure that the minimum inlet gas pressure is

available (6" W.C. for natural gas, 11" W.C. for propane gas).

➂ High Gas Pressure Switch

The high gas pressure switch is factory installed in the duct

furnace above the gas train. The switch monitors the gas pressure

downstream of all the gas controls and shuts off the electric supply

to the ignition controller and combination gas valve if high gas

pressure is experienced right before the manifold. This will shut off

all gas flow to the burner. The switch has a manual reset so that if

the gas pressure is too high, a service person must check the unit

to make sure that none of the gas controls have been damaged

by the high gas pressure and then reset the switch to allow the

unit to operate when gas conditions are returned to the allowable

range of the pressure switch. The pressure switch range is 2" to 16"

W.C. and should be set to insure that the maximum manifold gas

pressure is not exceeded (3.5" W.C. for natural gas, 10" W.C. for

propane gas).

➅ Air Flow Proving Switch

The air flow proving switch is factory installed in the duct furnace

electrical junction box. The air flow proving switch monitors the

pressure differential between the duct furnace and the atmosphere.

The purpose of the air flow proving switch is to cut power to the

gas controls if a positive pressure is not measured by the switch.

This could be caused by a lack of air movement through the heat

exchanger.

NOTE: The air flow proving switch will prevent any heat

exchanger warm-up (the unit should not be equipped with

a time delay relay) because the gas controls can not be

energized until air flow is proven.

Setting the Air Flow Proving Switch

The range of the air flow proving switch is adjustable between 0.17"

to 5.0" W.C.

1. Set the thermostat so that there is a call for heat. This should fire

the burner and the blower should start.

2. Turn the set screw of the pressure switch clockwise until it stops.

This will set the pressure at 5.0" W.C.

3. Turn the screw counter-clockwise until the gas controls light and

then one additional full turn (This is approximately 0.25'' W.C.).

This will allow for dirty filters or any other slight static pressure

increases in the system.

➆ Manual Reset High Limit

The manual reset high limit switch is factory installed in place

of the standard automatic reset high limit switch located in the

duct furnace electrical junction box. In case of a failure of the

blower motor, blockage of the inlet air, etc., the manual reset

switch prevents the unit from cycling on the high limit. If the limit

temperature is exceeded, a service person must inspect the unit for

the cause of the high discharge temperature, take corrective action,

and then reset the switch.

Figure 14.1 - Location of Gas Control Options

➃ Supply Air Fire Stat

The fire stat is factory installed in the duct furnace electrical junction

box with the sensor in the discharge air stream. In case of elevated

temperatures in the supply air, the manual reset switch shuts

down the entire unit. If the limit temperature is exceeded, a service

person must inspect the unit for the cause of the high discharge

temperature, take corrective action, and then reset the switch.

➄ Timed Freeze Protection

The timed freeze protection system is factory installed in the duct

furnace electrical junction box with the sensor (30°-75°F adjustable)

factory installed in discharge air stream. On initial start-up, the

timed delay in the system allows the unit to go through the normal

ignition sequence. The timed delay is an automatic reset switch and

adjustable for 1-10 minutes. In the event that the unit fails to fire

after this period, the discharge air sensor will sense the cold air and

will shut down the entire unit.

14

Note: Wrap around gas train on

premium and electronic

modulation units only.

1. Discharge Thermostat

2. Low Gas Pressure Switch

3. High Gas Pressure Switch

4. Power Exhauster

5. Timed Freeze Protection

6. Ignition Controller

8. Control Relay

9. Time Delay Relay

10. Furnace Low Voltage Terminal Strip

12. Furnace Supply Power Terminal Strip

13. Control Step Down Transformer

46. Electronic Modulating Amplifier

47. Electronic Modulating Gas Valve

48. Air Flow Proving Switch

49. High Limit Switch

50. Supply Air Fire Stat

51. Main Gas Valve

52. Burner Box

55. Differential Pressure Switch

57. Control Terminal Board

5-564

DIMENSIONAL DATA

Figure 15.1 - Indoor Power Vented Duct Furnace Dimensions

18.39

(MOUNTING

HOLES)

J (ROUND)

H

A

F (MOUNTING HOLES)

G

E (DUCT SIZE)

8.965

1.41

P

10.50

I

22.907

C

PREMIUM

CONTROL

BOX

M

O

K

D (DUCT SIZE)

Table 15.1 - Indoor Power Vented Duct Furnace Dimensions

(All Dimensions in inches)

Dimensions 75 100/125 150/175 200/225 250/300 350/400

A 15.41 17.90 22.16 24.29 27.33 38.83

C (standard) 22.43 22.43 22.43 24.09 24.09 24.09

B 33.05 33.05 33.05 37.05 37.05 37.05

D 15.21 17.70 21.96 24.09 27.13 38.63

E 19.07 19.07 19.07 23.07 23.07 23.07

F 14.09 16.59 20.85 22.98 26.01 37.51

G 12.65 15.14 19.41 21.60 24.60 36.14

H 23.75 26.26 30.51 32.78 35.79 47.32

I 17.83 17.83 17.83 20.68 20.68 20.68

J 4 4 4 6 6 6

K 14.55 17.04 21.31 23.26 26.44 37.80

M 2.01 2.01 2.01 1.94 1.94 1.94

N 29.65 29.65 29.65 33.65 33.65 33.65

O (max. approx.) (standard) 5.6 5.6 5.6 6.8/6.2 6.2 8.3/8.6

P 14.03 14.03 14.03 17.40 17.40 17.40

Gas Connection Pipe Size (max. std.) 1/2 1/2 1/2 1/2 / 3/4 3/4 3/4

Gas Connection Pipe Size (max. prem.) 3/4 3/4 3/4 3/4 3/4 3/4

Approx. Unit Shipping 101# 125# 152# 187# 225# 296#

Weight Unit Net 85# 107# 133# 167# 193# 263#

Model Size

N

B

5-564

15

PERFORMANCE

Table 16.1 - Air Temperature Rise - Power Vented Indoor Duct Furnaces ➀ ➁

Air Temperature Rise Through Unit (°F)

Model Btu/Hr 20

Size Input Output Max Min

75 75,000 60,000 2778 1389 1111 926 855 794 741 694 654 617 585 556

100 100,000 80,000 3704 1852 1481 1235 1140 1058 988 926 871 823 780 741

125 125,000 100,000 4630 2315 1852 1543 1425 1323 1235 1157 1089 1029 975 926

150 150,000 120,000 5556 2778 2222 1852 1709 1587 1481 1389 1307 1235 1170 1111

175 175,000 140,000 6481 3241 2593 2160 1994 1852 1728 1620 1525 1440 1365 1296

200 200,000 160,000 7407 3704 2963 2469 2279 2116 1975 1852 1743 1646 1559 1481

225 225,000 180,000 8333 4167 3333 2778 2564 2381 2222 2083 1961 1852 1754 1667

250 250,000 200,000 9259 4630 3704 3086 2849 2646 2469 2315 2179 2058 1949 1852

300 300,000 240,000 11111 5556 4444 3704 3419 3175 2963 2778 2614 2469 2339 2222

350 350,000 280,000 11111➄ 6481 5185 4321 3989 3704 3457 3241 3050 2881 2729 2593

400 400,000 320,000 11111➄ 7407 5926 4938 4558 4233 3951 3704 3486 3292 3119 2963

➀

Ratings are shown for elevations up to 2000 feet. For higher elevations, the input rating should be reduced at the rate of 4% per 1000 feet elevation above sea level. For Canada, in

elevations between 2000 and 4500 feet, the unit must be derated to 90% of the rating listed above.

➁

Units approved for use in California by CEC.

➂

Power vented indoor duct furnaces are supplied with a factory installed air baffle. For applications where an air tempature rise less than 60°F is desired, it is recomended to remove

this baffle to reduce system pressure drop.

➃

For Variable Air Movement Applications, see page 13.

➄

The maximum CFM for the 350 and 400 results in a 23°F and a 27°F air temperature rise (respectively) based on the maximum unit pressure drop.

➂

40 ➂ 50 ➂ 60 65 70 75 80 85 90 95 100

➃

CFM

Air Temperature and External Static Pressure Limits

The maximum allowable discharge air temperature is 150°F. The maximum allowable air temperature rise for all Power Vented Units

is 100°F. All duct furnaces are designed for a maximum allowable static pressure of 3.0" W.C. on the heat exchanger.

Figure 16.1 - Recommended Unit Configurations

SINGLE TOP VIEW

2279 CFM

60°F ENTERING

AIR TEMP.

TANDEM TOP VIEW

2279 CFM

20°F ENTERING

AIR TEMP.

TEMP. RISE

160,000

BTU/HR

OUTPUT

65°F

TEMP. RISE

PREHEAT

UNIT

160,000

BTU/HR

OUTPUT

65°F

OUTPUT

TEMP. RISE

REHEAT

160,000

BTU/HR

65°F

UNIT

125°F DISCHARGE

AIR TEMP.

150°F DISCHARGE

AIR TEMP.

PARALLEL TOP VIEW

5698 CFM

20°F ENTERING

AIR TEMP.

200,000

BTU/HR

OUTPUT 65°F

TEMP. RISE

SEE SERVICE

CLEARANCES

200,000

BTU/HR

OUTPUT 65°F

TEMP. RISE

85°F DISCHARGE

AIR TEMP.

16

5-564

PRESSURE DROP CURVES

0

0.2

0.4

0.6

0.8

1

1.2

1.4

0

1000

2000

3000

4000

5000

6000

7000

8000

9000

10000

11000

12000

13000

14000

15000

CFM