Modine Manufacturing HD 30, HD 45, HD 60, HD 75, HD 100 Product & Performance Data

...

Gas-Fired Power Vented Unit Heaters

Propeller & Blower Models

MODEL HD MODEL HDB

6-189.5

July, 2009

MODEL PDP

MODEL BDP

6-189.5

TABLE OF CONTENTS

Modine’s power vented unit heaters are designed for the heating

requirements of commercial and industrial buildings with select

models available for residential garage heating as well.

For locations where negative pressure may be an issue or

energy savings over older gravity vented units may be desired,

Modine power vented gas fired unit heaters are your solution.

Table of Contents Page

Design Features - All Models...............................................................................3

Design Features - Model HD/HDB...........................................................................4

Design Features - Model PDP/BDP..........................................................................5

General Performance Data - Propeller Models HD/PDP..........................................................6

General Performance Data - Blower Models HDB/BDP ..........................................................7

Blower Performance Data - Blower Model HDB ................................................................8

Blower Performance Data - Blower Model BDP .............................................................9-11

Gas Control Data - All Models .............................................................................12

Field Installed Accessories................................................................................13

Downturn Hood Performance Data - Propeller Models HD/PDP ...................................................14

Velocity Generating Nozzle Performance Data - Blower Model BDP ...............................................15

Unit Selection.......................................................................................16-17

Dimensional Data - Models HD/HDB........................................................................18

Dimensional Data - Model PDP ............................................................................19

Dimensional Data - Model BDP ............................................................................20

Specifications - Models PDP/BDP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21-22

Model Nomenclature - All Models ..........................................................................23

With 13 propeller and 11 blower model sizes available, the

units cover a wide variety of applications with input ranges

from 30,000 to 400,000 Btu/Hr in either natural or propane gas.

This catalog describes the design benefits, construction

features, performance data, unit selection procedure, and

the optional and accessory devices available.

WARNING

Do not locate ANY gas-fired unit in areas where chlorinated,

halogenated or acid vapors are present in the atmosphere.

As Modine Manufacturing Company has a continuous product improvement program, it reserves the right to change design and specifications without notice.

!

WARNING

Do not install in potentially explosive or flammable atmosphere

laden with dust, sawdust, or similar airborne materials.

!

2

6-189.5

DESigN FEATURES - ALL UNiTS

Tubular Heat Exchanger Power Vented Unit

Heaters, 30-125MBH

For residential, commercial or industrial applications that require

a low profile unit, Modine offers the Hot Dawg®. Capable of

being installed just one inch below the ceiling, the superior

quality of the Hot Dawg makes it a preferred choice for a

variety of applications, including garages and workshops.

Figure 2.1 - Hot Dawg

Propeller Unit Heater

Model HD Model HDB

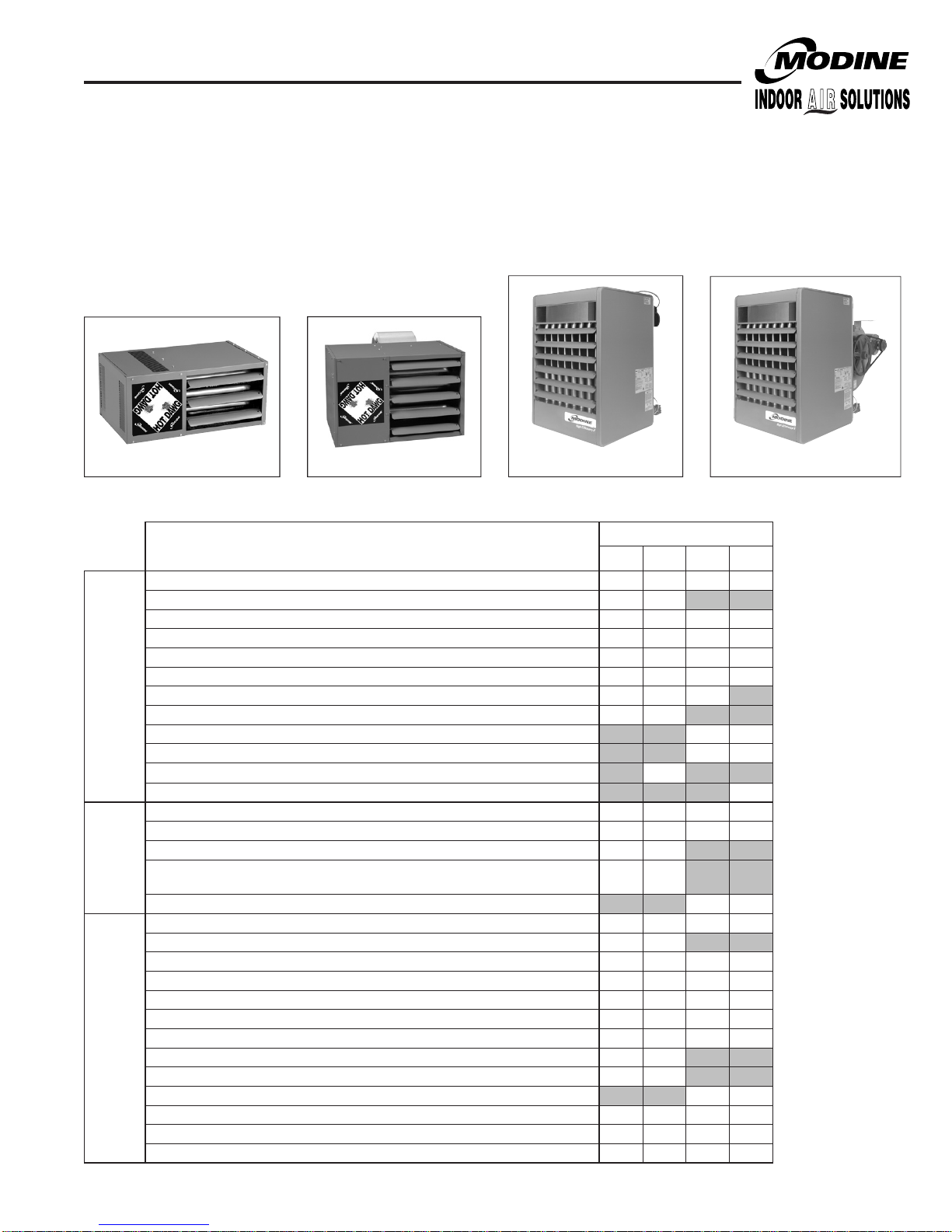

Table 3.1 - Standard Features and Factory Options ➀

Aluminized steel cabinet (gauge indicated)

Low profile casing design

Baked-on polyester powder paint for durability and corrosion resistence

Adjustable air-deflector blades

Fans engineered for quiet operation

Totally enclosed fan/blower motors (standard on sizes 100-400)

Fingerproof fan guard (optional on PDP units)

Two L-shaped mounting brackets (standard on sizes 30-75, accessory on sizes 100-125)

Adjustable mounting brackets for level hanging

Hinged tool-less bottom pan entry

Cabinet and Air Mover

Multi-tap 3-speed motors, certified to 0.8” W.C. external static pressure

Adjustable motor sheaves, certified to 0.5” W.C. external static pressure

80% thermally efficient

Aluminized steel heat exchanger (409 stainless steel optional)

Tubular heat exchanger

Heat

See page 13 for Field Installed Accessories

➀

In-shot burner on each heat exchanger tube for reliable performance, ease of

serviceability and low sound level on flame ignition/extinction

Exchanger

and Burner

Aluminized steel burner (409 stainless steel optional)

CSA certification for commericial and industrial use in the US and Canada

CSA certification for residential use in the US and Canada

Factory-installed power exhauster

Controls for natural gas (propane optional)

Single stage gas controls (two stage and mechanical modulation optional)

High limit safety control

Differential pressure switch for proof of venting

Flame roll-out safety switch

Controls

Direct spark ignition with continuous retry control system

Intermittent pilot ignition with continuous retry control system

Control terminal board and low voltage terminal connections

Gas control step down transformer with 24V gas controls

Fan delay timer

Figure 2.2 - Hot Dawg

Blower Unit Heater

Feature

6-189.5

Power Vented Unit Heater, 150-400MBH

For commercial or industrial applications that require higher

input ratings, the PDP/BDP is available in ratings that range

from 150,000 to 400,000 Btu/Hr in either natural or propane gas.

Figure 2.3 Propeller Unit Heater

Model PDP Model BDP

HD HDB PDP BDP

22 ga. 22 ga. 20 ga. 20 ga.

• •

• • • •

• • • •

• • • •

• • • •

• • •

• •

•

• • • •

• • • •

• •

• •

• • • •

• •

• • • •

• • • •

• • • •

• • • •

• • • •

• •

• •

• • • •

• • • •

• • • •

Figure 2.4 Blower Unit Heater

Model

• •

• •

•

• •

• •

3

DESigN FEATURES - MODELS HD/HDB

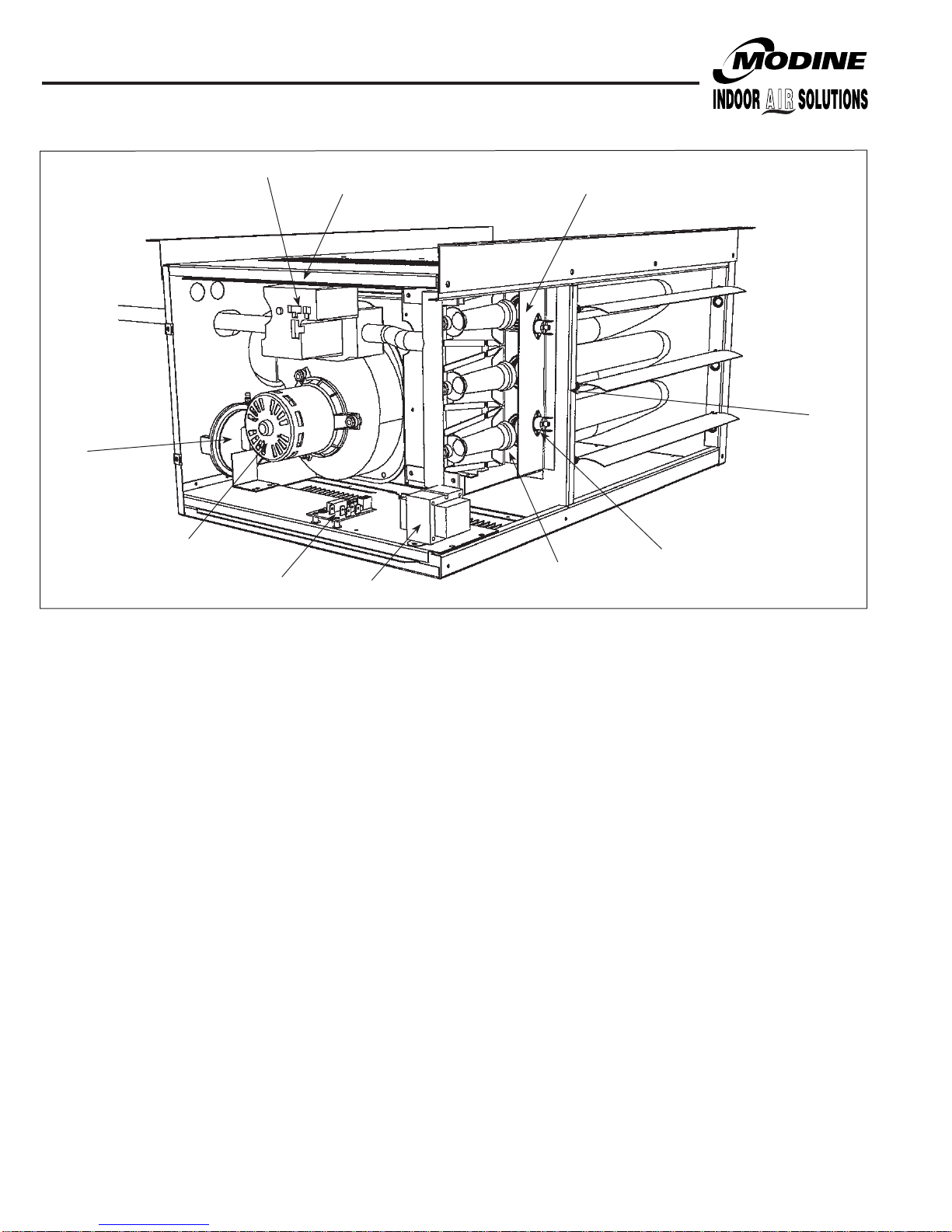

Figure 4.1 - Factory Mounted Standard and Optional Features (Models HD/HDB)

➁

➀

➃

➂

➉

➄

➈

➅

➇

➆

➀ Power Exhauster (STD)

All HD series (low profile) unit heaters are supplied with a

round vent pipe connection.

➁ Pressure Switch (STD)

An automatic reset vent pressure switch is supplied on

all HD series (low profile)unit heaters and is designed to

prevent operation of the main burner in the event there

is restricted venting of flue products. This restriction may

occur due to an improper vent diameter, long vent runs,

un-approved vent terminal, high winds, high negative

pressure within space, etc. After the cause of the

restriction has been corrected, the pressure switch will

reset automatically. See the trouble shooting section of the

installation and service manual for more information.

➂ integrated Direct Spark Control Board (STD)

The integrated direct spark ignition control combines all

furnace control functions. The integrated board provides

digital control of the air mover, inducer, ignition, gas valve

and flame sense as well as monitoring the safety circuit at

all times. The board includes LED diagnostics for trouble

shooting and a fused power supply.

➃ gas Valve - (See Table 12.2)

a) Single Stage gas Valve - (STD)

The main gas valve is factory installed on the unit

heater gas train. The main gas valve provides regulator,

main gas, and manual shutoff functions. The valve is

redundant and provides 100% shut off.

b) Two Stage gas Valve - (OPT)

The two-stage gas valve is factory installed on the unit

heater gas train. The two stage gas valve provides the

regulator, main gas (100% and 50% fire), and manual

shutoff functions. The valve is redundant and provides

100% shut off.

4

➄ Control Step Down Transformer - (STD)

The control step down transformer is located in the

electrical junction box. The transformer is used to step down

the supply power (115V, 208V, 230V, 460V, 575V) to 24V

for the gas controls, fan delay relay, field supplied motor

starter, etc. To determine the control transformer supplied

as well as any accessory/field supplied transformers

required, refer to Table 12.1

➅ Flame Sensor – (hidden, STD)

Remote flame sensor verifies ignition of all burners,

monitors the flame signal and communicates with the

integrated circuit board.

➆ Flame Roll Out Switch - (STD)

Flame roll out switches are mounted near the burners and

will shut off the gas supply in the event of an unsafe flame

roll out condition.

➇ Auto High Limit Switch - (hidden, STD)

The limit control is mounted in the air stream and will shut

off the gas supply in the event of overheating.

➈ Direct Spark igniter - (hidden, STD)

Provides spark for direct ignition of the burners.

➉ Manual Reset Control - (hidden, propeller 100-125 only)

6-189.5

DESigN FEATURES - MODELS PDP/BDP

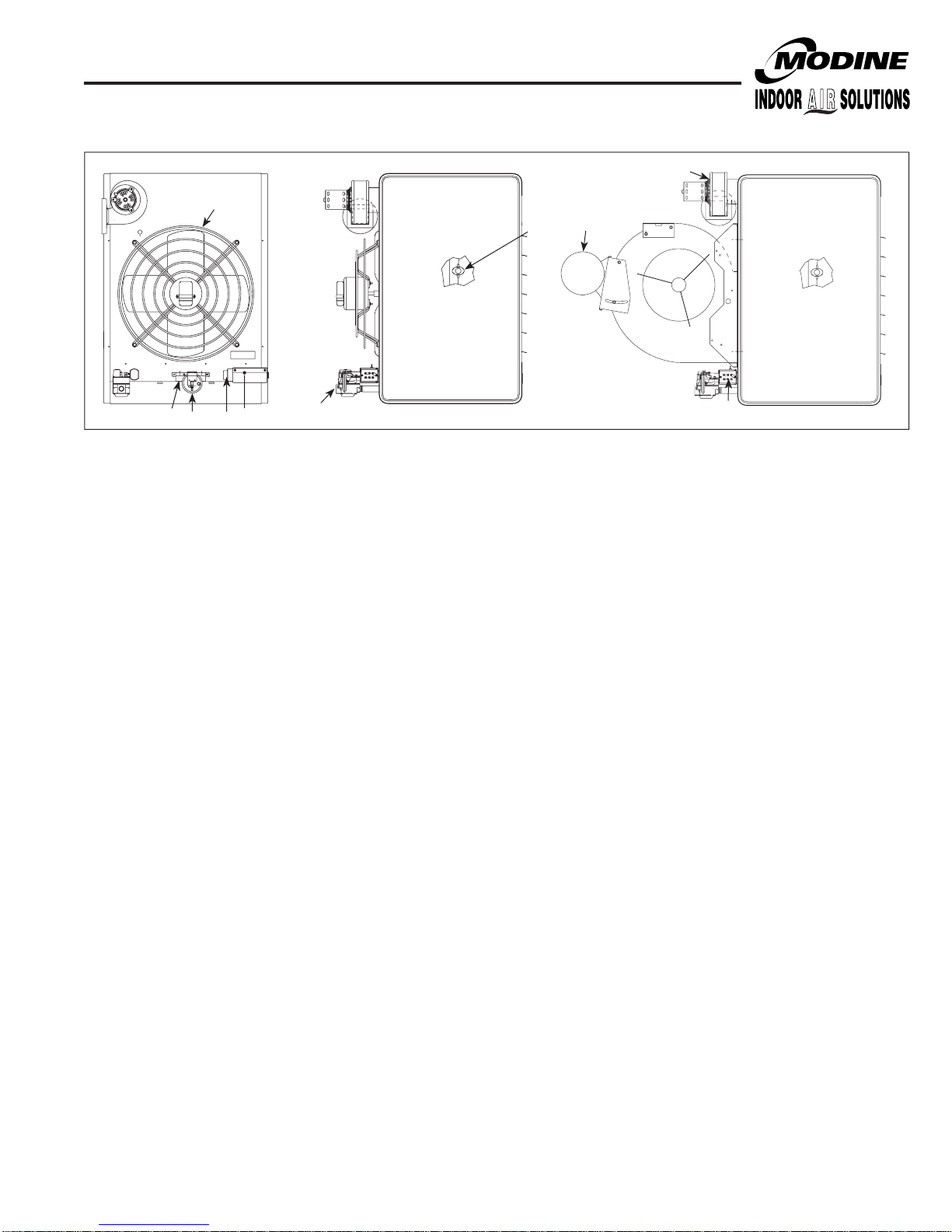

Figure 5.1 - Factory Mounted Standard and Optional Features (Models PDP/BDP)

➉

➆

➅

➈

➁

➇

All units include the standard (STD) features, and may include

the optional (OPT) features shown.

➀ gas Valve (See Table 12.2)

a) Single Stage gas Valve - (STD)

The main gas valve is factory installed on the unit heater

gas train. The main gas valve provides the pilot, regulator,

main gas, and manual shutoff functions.

b) Two Stage gas Valve - (OPT)

The two-stage gas valve is factory installed on the unit

heater gas train. The two stage gas valve provides the

pilot, regulator, main gas (100% and 50% fire), and manual

shutoff functions. See the supplier literature included with

the unit.

c) Mechanical Modulating - (OPT)

Mechanical modulation utilizes a main gas valve as well

as a mechanical modulating gas valve (not shown).

The mechanical modulating valve includes a hydrostatic

sensing bulb that is to be field installed in ductwork. The

discharge air temperature is field set by the control dial on

the modulating gas valve. Refer to Installation and Service

manual for set point temperatures.

➁ ignition controller - (STD)

The ignition controller is factory installed on the back of the

unit heater with the spark igniter and sensor located on the

burner. For both natural and propane gas units, the ignition

controller is 100% shut-off with continuous retry. On a call for

heat, the system will attempt to light the pilot for 70 seconds.

If the pilot is not sensed for any reason, the ignition control

will wait for approximately six minutes with the combination

gas control closed and no spark. After six minutes, the cycle

will begin again. After three cycles, some ignition controllers

lockout for approximately one hour before the cycle begins

again. This will continue indefinitely until the pilot flame is

sensed or power is interrupted to the system.

➂ Time Delay Relay - (STD on all but Mech. Mod.)

The time delay relay is factory installed in electrical junction

box. The time delay relay allows the gas controls to operate

for approximately 30 to 90 seconds before the blower starts.

This allows the heat exchanger a warm up period so that the

initial delivered air is not cool. The time delay relay also keeps

the motor running for approximately 30 - 90 seconds after the

call for heat has been satisfied to remove the residual heat

from the heat exchanger.

Note: Mechanical modulation units are used on make-up air

only and do not require or include time delay relays.

➂

➄

➀

6-189.5

➃

➃ Low Voltage Terminal Board - (STD)

The low voltage terminal board is located in electrical junction

box. The terminal board is labeled to match the electrical

wiring diagram provided with the unit.

➄Control Step Down Transformer - (STD)

The control step down transformer is located in the electrical

junction box. The transformer is used to step down the supply

power (115V, 208V, 230V, 460V, 575V) to 24V for the gas

controls, fan delay relay, field supplied motor starter, etc.

To determine the control transformer supplied as well as any

accessory/field supplied transformers required, refer to

Table 12.1

➅Blower Motor - (OPT)

The blower motor is factory installed on the blower housing.

The blower motor can be provided in a variety of supply

voltages and motor horsepowers. The blower motor is

supplied with an adjustable sheave that can be used to

increase/decrease the blower RPM.

➆High Limit Switch - (STD)

The automatic reset high limit switch is factory installed on the

side of the unit heater. If the limit temperature is exceeded,

the gas controls are de-energized until the switch is cooled.

➇Pressure Switch (STD)

A automatic reset vent pressure switch is supplied on all

power vented unit heaters to prevent operation of the main

burner in the event there is restricted venting of flue products.

This restriction may occur due to an improper vent diameter,

long vent runs, un-approved vent terminal, high winds, high

negative pressure within space, etc. After the cause of the

restriction has been corrected, the pressure switch will reset

automatically.

➈Power Exhauster (STD)

All power vented unit heaters are supplied with a round vent

pipe connection. The power exhauster may be rotated 180° to

allow for various venting directions.

➉Finger Proof Fan guard (OPT)

Propeller units may be equipped with an optional finger proof

fan guard for added protection. The finger proof fan guard is

installed at the factory in place of the standard fan guard.

Standard fan guard is shown.

5

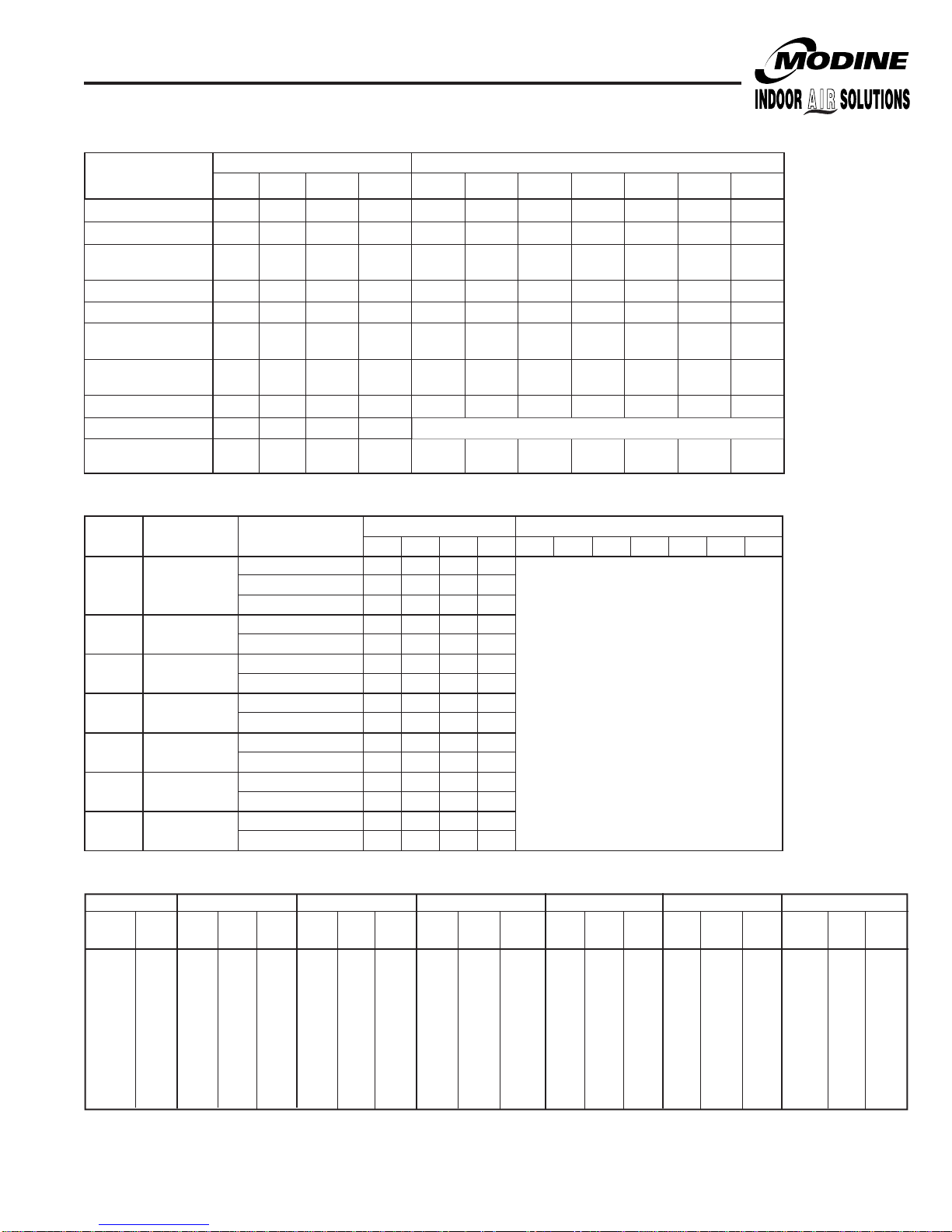

gENERAL PERFORMANCE DATA - MODELS HD & PDP

Table 6.1 - Propeller Unit Model HD and PDP general Performance Data

Model HD Sizes Model PDP Sizes

30 45 60 75 100 125 150 175 200 250 300 350 400

Btu/Hr Input ➀

Btu/Hr Ouput ➀

Entering Airflow (CFM)

@ 70°F

Outlet Velocity (FPM) 523 725 653 769 565 747 931 959 819 1053 1123 1068 1016

Air Temp. Rise (°F) 44 46 45 48 50 47 51 51 52 50 50 53 54

Max. Mounting

Height (Ft.) ➁

Heat Throw (Ft.) @

Max Mtg Ht ➁

Motor Type ➂

Motor HP 1/15 1/15 1/12 1/12 1/12 1/8 1/8 1/6 1/6 1/3 1/2 3/4 3/4

Motor RPM 1550 1550 1625 1625 1050 1625 1625 1075 1075 1075 1075 1125 1125

30,000 45,000 60,000 75,000 100,000 125,000 150,000 175,000 200,000 250,000 300,000 350,000 400,000

24,000 36,000 48,000 60,000 80,000 100,000 120,000 140,000 160,000 200,000 240,000 280,000 320,000

505 720 990 1160 1490 1980 2180 2550 2870 3700 4460 4870 5440

10 10 12 14 12 16 16 17 15 19 21 20 19

25 27 36 38 42 56 55 59 51 67 74 70 69

SP SP PSC PSC SP PSC PSC PSC PSC PSC PSC PSC PSC

Table 6.2 - Propeller Unit Model HD and PDP Operating Electrical Data

Supply

Voltage

115V

115V

1 Phase Total Amps 3.7 3.7 2.5 2.5 4.7 4.2 4.0 5.1 5.1 7.7 9.8 11.1 11.1

1 Phase

208V

1 Phase

230V

1 Phase

208V

3 Phase 208V Total Amps 2.05 2.05 1.38 1.38 2.60 2.32 2.21 2.82 2.82 4.26 5.42 6.14 6.14

230V

3 Phase 230V Total Amps 1.85 1.85 1.25 1.25 2.35 2.10 2.00 2.55 2.55 3.85 4.90 5.55 5.55

460V

3 Phase 460V Total Amps 0.93 0.93 0.63 0.63 1.18 1.05 1.00 1.28 1.28 1.93 2.45 2.78 2.78

575V

3 Phase 575V Total Amps 0.74 0.74 0.50 0.50 0.94 0.84 0.80 1.02 1.02 1.54 1.96 2.22 2.22

Ratings shown are for elevations up to 2,000 ft. For elevations above 2,000 feet, ratings should be reduced at the rate of 4% for each 1,000 feet above sea level. (In Canada see rating plate.)

➀

Reduction of ratings requires use of a high altitude kit.

Data taken at 55°F air temperature rise. At 65°F ambient and unit fired at full-rated input. Mounting height as measured from bottom of unit, and without deflector hoods.

➁

All motors used are produced, rated and tested by reputable manufacturers in accordance with NEMA standards and carry the standard warranty of both the motor manufacturer and Modine.

➂

All motors are 115V single phase motors with built-in thermal overload protection. Model sizes 30-75 are open motors, sizes 100-400 are totally enclosed.

Power Code

01 (115V)

01 (115V) with

Transformer

03 (208V)

01 (115V) with

Transformer

02 (230V)

01 (115V) with

Transformer

01 (115V) with

Transformer

01 (115V) with

Transformer

01 (115V) with

Transformer

30 45 60 75 100 125 150 175 200 250 300 350 400

Motor Amps 2.4 2.4 1.2 1.2 2.7 2.2 2.3 2.7 2.7 5.4 7.5 8.8 8.8

Transformer kVA n/a n/a n/a n/a n/a n/a n/a n/a n/a n/a n/a n/a n/a

Transformer kVA 0.5 0.5 0.5 0.5 1.0 1.0 0.5 1.0 1.0 1.0 1.5 1.5 1.5

208V Total Amps 2.05 2.05 1.38 1.38 2.60 2.32 2.21 2.82 2.82 4.26 5.42 6.14 6.14

Motor Amps

Total Amps 1.9 2.8 2.8

Transformer kVA 0.5 0.5 0.5 0.5 0.75 0.75 0.5 0.75 0.75 1.0 1.5 1.5 1.5

230V Total Amps 1.85 1.85 1.25 1.25 2.35 2.10 2.00 2.55 2.55 3.85 4.90 5.55 5.55

Motor Amps

Total Amps 1.9 2.8 2.8 3.7 4.7 5.5 5.5

Transformer kVA 0.5 0.5 0.5 0.5 1.0 1.0 0.5 1.0 1.0 1.0 1.5 1.5 1.5

Transformer kVA 0.5 0.5 0.5 0.5 0.75 0.75 0.5 0.75 0.75 1.0 1.5 1.5 1.5

Transformer kVA 0.5 0.5 0.5 0.5 0.75 0.75 0.5 0.75 0.75 1.0 1.5 1.5 1.5

Transformer kVA 0.5 0.5 0.5 0.5 0.75 0.75 0.5 0.75 0.75 1.0 1.5 1.5 1.5

n/a n/a n/a n/a n/a n/a

n/a n/a n/a n/a n/a n/a

Model HD Sizes Model PDP Sizes

1.0 1.5 1.5

1.0 1.5 1.5 2.5 3.5 4.4 4.4

n/a n/a n/a n/a

6

6-189.5

gENERAL PERFORMANCE DATA - MODELS HDB & BDP

Table 7.1 - Blower Unit Model HDB and BDP general Performance Data

Model HDB Sizes Model BDP Sizes

60 75 100 125 150 175 200 250 300 350 400

Btu/Hr Input ➀ 60,000 75,000 100,000 125,000 150,000 175,000 200,000 250,000 300,000 350,000 400,000

Btu/Hr Ouput ➀ 48,000 60,000 80,000 100,000 120,000 140,000 160,000 200,000 240,000 280,000 320,000

Entering Airflow

Range (CFM)

Outlet Velocity (FPM) 437-726 546-908 443-781 488-773 869 892 773 966 1026 1037 1008

Air Temp. Rise (°F) 40-70 40-70 35-65 45-75 40-70 40-70 40-70 40-70 40-70 40-70 40-70

Max. Mounting

Height (Ft.) ➁ 7-13 7-16 8-19 8-17 14 15 13 16 18 19 19

Heat Throw (Ft.) @

Max Mtg Ht ➁ 20-45 24-57 27-68 27-59 49 52 47 58 64 67 68

Motor Type ➂ P.S.C. P.S.C. P.S.C. P.S.C. T.E T.E T.E T.E T.E T.E T.E

Motor HP 1/4 1/3 1/2 1/2

Motor RPM

Table 7.2 - Blower Unit Model HDB Operating Electrical Data

Supply

Voltage

115V

115V

1 Phase Total Amps 6.4 8.1 11.5 11.5

1 Phase

208V

1 Phase

230V

1 Phase

208V

208V

3 Phase

3 Phase 208V Total Amps 3.54 4.48 6.36 6.36

230V

230V

3 Phase

3 Phase 230V Total Amps 3.20 4.05 5.75 5.75

460V

460V

3 Phase

3 Phase 460V Total Amps 1.60 2.03 2.88 2.88

575V

575V

3 Phase

3 Phase 575V Total Amps 1.28 1.62 2.30 2.30

Power Code

01 (115V)

01 (115V) with

Transformer

01 (115V) with

Transformer

01 (115V) with

Transformer

01 (115V) with

Transformer

01 (115V) with

Transformer

01 (115V) with

Transformer

635-

794-

1111

1389

Max

1100

1100 Max 1100 Max 1100

Max

1140-

2116

1235-

2058

1587-

2778

1725 1725 1725 1725 1725 1725 1725

Model HDB Sizes Model BDP Sizes

60 75 100 125 150 175 200 250 300 350 400

Motor Amps 5.4 7.1 9.5 9.5

Transformer kVA n/a n/a n/a n/a

Transformer kVA 1.0 1.0 1.5 1.5

208V Total Amps 3.54 4.48 6.36 6.36

Transformer kVA 1.0 1.0 1.5 1.5

230V Total Amps 3.20 4.05 5.75 5.75

Transformer kVA 1.0 1.0 1.5 1.5

Transformer kVA 1.0 1.0 1.5 1.5

Transformer kVA 1.0 1.0 1.5 1.5

Transformer kVA 1.0 1.0 1.5 1.5

1852-

3241

2116-

3704

See Table 9.1

2646-

4630

See Table 7.3

3175-

5556

3704-

6481

4233-

6584

Table 7.3 - Blower Unit Model BDP Operating Electrical Data

Voltage 115/60/1 230/60/1 208/60/3 230/60/3 460/60/3 575/60/3

Motor Motor Total Total Motor Total Total Motor Total Total Motor Total Total Motor Total Total Motor Total Total

HP Rpm Amps Amps Watts Amps Amps Watts Amps Amps Watts Amps Amps Watts Amps Amps Watts Amps Amps Watts

1/4 1725 3.7 6.0 696 2.7 4.0 914 1.3 2.6 539 1.2 2.5 569 0.7 1.9 592 0.5 1.8 569

1/3 1725 5.0 7.3 845 2.5 3.8 868 1.2 2.5 518 1.2 2.5 569 0.6 1.9 569 0.8 2.1 753

1/2 1725 8.0 10.3 1190 4.0 5.3 1213 2.2 3.5 726 2.1 3.4 776 1.1 2.4 799 0.9 2.2 811

3/4 1725 11.0 13.3 1535 5.4 6.7 1535 2.8 4.1 851 2.7 4.0 914 1.4 2.6 937 1.1 2.3 926

1 1725 13.4 15.7 1811 6.7 8.0 1834 3.6 4.9 1018 3.5 4.8 1098 1.8 3.0 1121 1.5 2.6 1127

1-1/2 1725 15.2 17.5 2018 7.6 8.9 2041 4.8 6.1 1267 4.8 6.1 1397 2.4 3.6 1397 1.9 3.1 1386

2 1725 --- --- --- --- --- --- 6.8 8.1 1683 6.0 7.3 1673 3.0 4.3 1673 2.3 3.5 1616

3 1725 --- --- --- --- --- --- 9.9 11.2 2328 8.2 9.5 2179 4.1 5.4 2179 3.4 4.6 2248

5 1725 --- --- --- --- --- --- 15.2 16.5 3430 13.0 14.3 3283 6.5 7.8 3283 5.3 6.5 3341

Ratings shown are for elevations up to 2,000 ft. For elevations above 2,000 feet, ratings should be reduced at the rate of 4% for each 1,000 feet above sea level. (In Canada see rating plate.)

➀

Reduction of ratings requires use of a high altitude kit.

Data taken at 55°F air temperature rise. At 65°F ambient and unit fired at full-rated input. Mounting height as measured from bottom of unit, and without deflector hoods.

➁

All motors used are produced, rated and tested by reputable manufacturers in accordance with NEMA standards and carry the standard warranty of both the motor manufacturer and Modine.

➂

All motors are 115V single phase motors with built-in thermal overload protection. Model sizes 60-75 are open motors, sizes 100-400 are totally enclosed.

6-189.5

7

Loading...

Loading...