Modine Manufacturing Atherion MPR, Atherion ERM Service Manual

MCP15-525.0

MODINE CONTROL SYSTEM MANUAL

5H0837230000

September, 2012

commercial packaged ventilation system

Models MPR and ERM

WARNING IMPORTANT

1. Improper installation, adjustment, alt erat i on,

service or maintenance can cause property

damage, injury or death. Read the installat ion,

operating and maintenance instructions

thoroughly before installing or servicing thi s

equipment.

2. Improper control adjustments and manual

mode control can cause property damage,

injury or death. Read the installation,

operating and maintenance instructions

thoroughly before making adjustments.

3. Disconnect power supply before installing t he

accessory to prevent the unit from operating

during installation.

1. The use of this manual is specifically intended

for a qualified installation and service agency.

All installation and service of this unit must be

performed by a qualified installation and

service agency.

2. These instructions must also be used in

conjunction with the Installation and Service

Manual originally shipped with the appliance,

in addition to any other accompanying

component supplier literature.

3. This manual applies to Modine Control

System program version series 3 and 4 only.

For any other version, please contact Modine.

The program version that resides in the unit

controller can be found in the Information

section of the Service Sub Menu. Refer to the

manual for instructions on accessing this

screen.

THIS MANUAL IS THE PROPERTY OF THE OWNER.

PLEASE BE SURE TO LEAVE IT WITH THE OWNER WHEN YOU LEAVE THE JOB.

MODINE CONTROL SYSTEM MANUAL

Models MPR & ERM

2

MCP15-525.0

General Information

Controls are one of the most important c omponents of specialized HVAC equipment. The Modine Control System is designed

and engineered around the design of t he A therion™ to ensure that the unit operates safely, reliably, with optimized performance,

and maintaining maximum energ y ef ficiency.

Table of Contents

Model Nomenclature – Model MPR ............................................................. 4

Model Nomenclature – Model ERM ............................................................. 5

Identification of Superheat Cont rol..................................................................................................... 6

Controller Overview ...................................................................................... 7

Description and Features ................................................................................................................... 7

Standard and Optional Sensors Monitored ........................................................................................ 8

PCO3 Controller Layout ..................................................................................................................... 9

Display/Keypad Functions ......................................................................... 10

Standard Buttons ............................................................................................................................. 10

Extra Function Button Sequences ................................................................................................... 10

Menu Navigation .............................................................................................................................. 11

Navigation Sub Menus ..................................................................................................................... 11

Example Navigation to On/Off Sub Menus ...................................................................................... 11

Password Protection ........................................................................................................................ 12

Adjusting Customer Control Settings ............................................................................................... 12

Main Menu – Tree of Functions ................................................................. 13

Main Status Screen ..................................................................................... 14

Main Status Screen Parameters ...................................................................................................... 14

On/Off Sub Menu ......................................................................................... 18

Setpoint Sub Menu ..................................................................................... 19

Clock/Scheduler Sub Menu ........................................................................ 22

Input / Output Sub Menu ............................................................................ 23

Analog Inputs: .................................................................................................................................. 23

Digital Inputs: ................................................................................................................................... 23

Analog Outputs: ............................................................................................................................... 24

Digital Relay Outputs: ...................................................................................................................... 24

Data Logger Sub Menu ............................................................................... 25

Board Switch Sub Menu ............................................................................. 25

Programming the Remote Display Keypad to the Controller ........................................................... 26

Service Sub Menu ....................................................................................... 27

Information ....................................................................................................................................... 27

Working Hours ................................................................................................................................. 28

BMS Configuration ........................................................................................................................... 29

Working Hour Setpoint ..................................................................................................................... 30

Probe adjustment............................................................................................................................. 30

Control Settings ............................................................................................................................... 31

User DEV/Change PW1 .................................................................................................................. 39

Manual Management ....................................................................................................................... 40

MODINE CONTROL SYSTEM MANUAL

Models MPR & ERM

MCP15-525.0

3

Manual Control Reset ...................................................................................................................... 40

Analog Input: .................................................................................................................................... 40

Digital Input: ..................................................................................................................................... 41

Relay Output: ................................................................................................................................... 41

Analog Output: ................................................................................................................................. 41

Manufacturer Sub Menu ............................................................................. 42

Configuration .................................................................................................................................... 42

I/O Configuration – Digital Inp ut Configuration ................................................................................. 51

I/O Configuration – Analog Input Configuration ................................................................................ 56

I/O Configuration – Relay Output C onfiguration: .............................................................................. 63

I/O Configuration – Analog Output Configuration ............................................................................. 66

ERM ................................................................................................................................................. 67

Initialization ...................................................................................................................................... 70

pAD Settings .................................................................................................................................... 70

EVO -EVD Settings (Electronic Expansion Valve Driver) ................................................................. 73

Digital Scroll Compressors ........................................................................ 78

Starting Frequency and Minimum Compressor Running Time ......................................................... 78

Digital Scroll Compressor Operation ................................................................................................ 78

Electronic Expansion Valves Carel CDSS Mode ...................................... 79

Unit Alarms ................................................................................................. 80

Main Unit Controller Inputs/Outputs ......................................................... 83

pCO3 Inputs ...................................................................................................................................... 83

pCO3 Outputs ................................................................................................................................... 84

pCOe Expansion Module Inputs/Outputs (for Emerson EC3 Superheat Control only) ..................... 85

EVO/EVD Driver Module Inputs/Outputs (for Carel EVD Superheat Control only) ........................... 85

Energy Recovery Module Controller Inputs/Outputs (if equipped) ........ 86

pCOxs Inputs ................................................................................................................................... 86

pCOxs Outputs ................................................................................................................................. 86

Typical BMS – EMS – BAS System Variables .......................................... 87

MODINE CONTROL SYSTEM MANUAL

Models MPR & ERM

4

MCP15-525.0

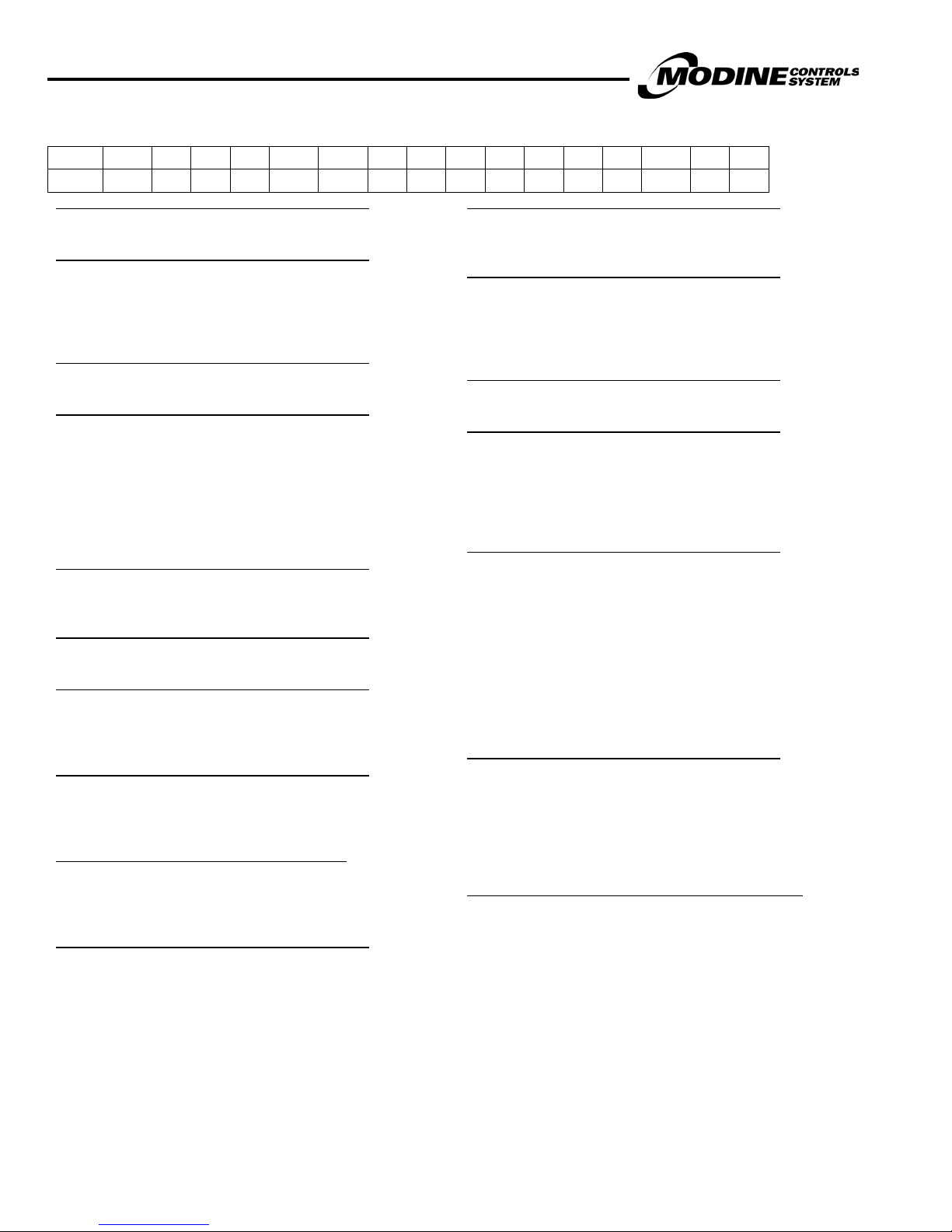

Model Nomenclature – Model MPR

1, 2, 3 4, 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20

UT UNC CS AC EC CMP HGR CA SB HP MT SV SA HT UNH TR HC

Digits 1, 2, 3 - Unit Type (UT)

MPR - Commercial Packaged Ventilation Unit

Digits 4, 5 - Unit Nominal Cooling (UNC)

15 - 15 ton

20 - 20 ton

26 - 26 ton

30 - 30 ton

6 - Cabinet Size (CS)

C - "C" Cabinet

7 - Air Control Configuration (AC)

A - Fresh & Return Air Dampers

D - Fresh Air Dampers (no Return Air)

E - Fresh Air Dampers (with Exhaust Air Opening and

Interface to Energy Recovery Module)

F - Fresh Air Dampers (with Exhaust Air Opening and

Interface to Power Exhaust Module)

G - Return Air Opening only (No Dampers or Fresh Air)

8 - Evaporator Coil (EC)

1 - High Capacity 4 Row, 14fpi DX Coil

2 - High Capacity 4 Row, 14fpi DX Coil with E-Coat

9 - Compressor Staging (CMP)

A - Tandem Digital Scroll Compressor

10 - Hot Gas Reheat (HGR)

0 - No Hot Gas Reheat

1 - Modulating Hot Gas Reheat

2 - Modulating Hot Gas Reheat with E-Coat

11 - Condenser Arrangement (CA)

A - Standard Fans, VFD Control, Microchannel Coils

B - Standard Fans, VFD Control, Microchannel Coils

with E-Coat and UV Top Coat

12 - Supply Blower Configuration (SB)

3 - 20" Backward Inclined Airfoil Plenum Fan

5 - 25” Backward Inclined Airfoil Plenum Fan

6 - 28" Backward Inclined Airfoil Plenum Fan

13 - Supply Blower Motor HP (HP)

C or Q - 1hp

D or R - 1-1/2hp

E or S - 2hp

F or T - 3hp

G o r U - 5hp

H or V - 7-1/2hp

J or W - 10hp

K or X - 15hp

C thru K include a factory mounted/wired motor starter.

Q thru X are Variable Frequency Drive (VFD) ready.

14 - Supply Blower Motor Type (MT)

1 - ODP - NEMA Premium Efficiency

2 - TE - NEMA Premium Efficiency

15 - Unit Supply Voltage (SV)

4 - 208V/3ph

5 - 230V/3ph

6 - 460V/3ph

7 - 575V/3ph

16 - Supply Blower Sheave Assy (SA)

Refer to AccuSpec

17 - Heating Section Type (HT)

0 - None

1 - Electric

2 - Natural Gas

3 - Natural Gas with 20kW Aux Elec Heat

- Nominal kW rating, derated for 208V/3ph.

18 - Nominal Heat Capacity (UNH)

N - No Heating

A - 20kW Electric

B - 40kW Electric

C - 60kW Electric

D - 80kW Electric

E - 100kW Electric

J - 300 MBH Gas - 80%

K 400 MBH Gas - 80%

L - 500 MBH Gas - 80%

- Nominal kW rating, derated for 208V/3ph.

19 - Temperature Rise (TR)

N - Not Applicable

(300MBH Gas Only and Electric)

H - High Air Temp Rise (75°F and Higher)

(400 and 500 MBH Gas Only)

L - Low Air Temp Rise (Under 75°F)

(400 and 500 MBH Gas Only)

20 - Heat Control (HC)

N - No Heating

A - Single Stage (Electric Only)

B - Two Stage (Electric Only)

C - Four Stage (Electric Only)

D - Modulating (Gas or Electric)

MODINE CONTROL SYSTEM MANUAL

Models MPR & ERM

MCP15-525.0

5

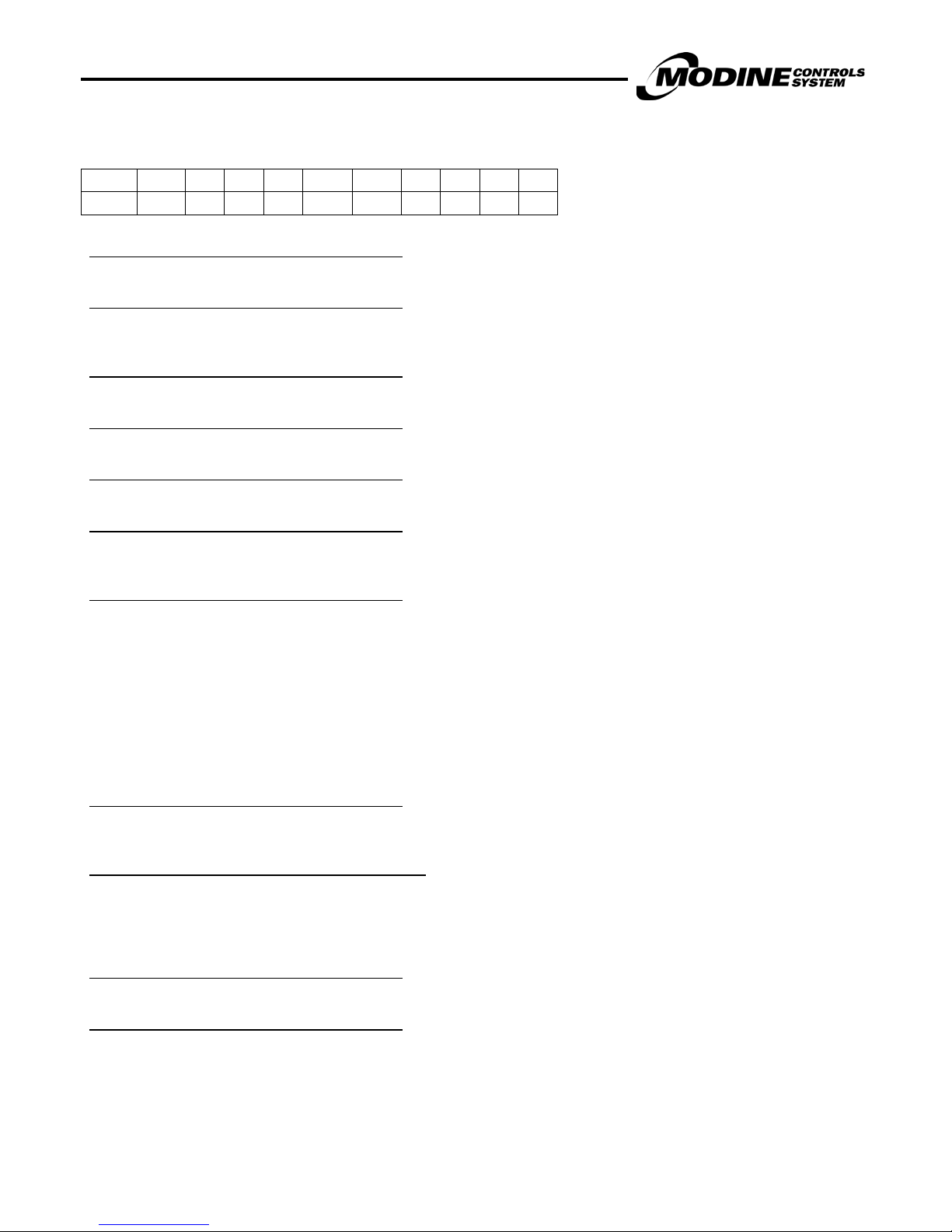

Model Nomenclature – Model ERM

1, 2, 3 4, 5 6 7 8 9 10 11 12 13 14

UT NWD CS ERT EBP EBC HP MT SV SA PH

Digits 1, 2, 3 - Unit Type (UT)

ERM - Energy Recovery Module

Digits 4, 5 – Nominal Wheel Diameter (NWD)

48 - 48” (6000 CFM limit )

58 - 58” (8700 CFM limit)

6 - Cabinet Size (CS)

C - "C" Cabinet

7 – Energy Recovery Type (ERT)

T - Total Energy Recovery Wheel

8 – Economizer Bypass (EBP)

E - Economizer Bypass

9 – Exhaust Blower Configuration (EBC)

3 - 20" Backward Inclined Airfoil Plenum Fan

6 - 28" Backward Inclined Airfoil Plenum Fan

10 - Exhaust Blower Motor HP (HP)

C or Q - 1hp

D or R - 1-1/2hp

E or S - 2hp

F or T - 3hp

G o r U - 5hp

H or V - 7-1/2hp

J or W - 10hp

C thru J include a factory mounted/wired motor starter.

Q thru W are Variable Frequency Drive (VFD) ready.

11 - Exhaust Blower Motor Type (MT)

1 - ODP - NEMA Premium Efficiency

2 - TE - NEMA Premium Efficiency

12 - ERM Supply Voltage (SV) (must match base model MPR unit)

4 - 208V/3ph

5 - 230V/3ph

6 - 460V/3ph

7 - 575V/3ph

13 - Exhaust Blower Sheave Assy (SA)

Refer to AccuSpec

14 – Electric Preheat (PH)

0 - No Heating

A - 20kW Electric (Nominal kW rating, derated for 208V/3ph.)

MODINE CONTROL SYSTEM MANUAL

Models MPR & ERM

6

MCP15-525.0

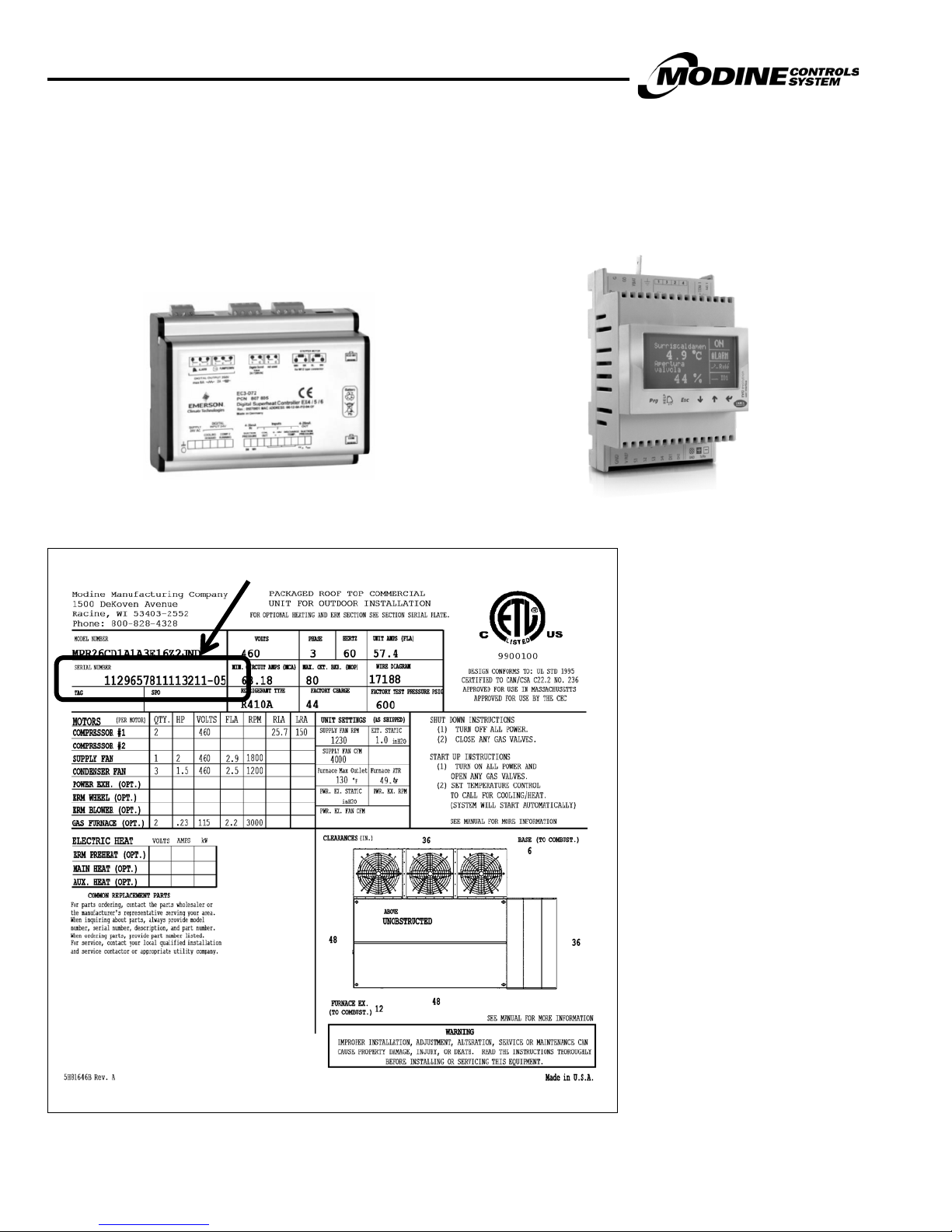

Identification of Superheat Control

This manual includes information that varies based on the superheat contr oll er used. The Atherion uses one of two dif ferent

superheat controllers. The controller can be identified in the unit serial number as follows:

If Digit 12=1, Emerson EC3 Superheat Control is used: If Digit 12=2, Carel EVD Superheat Control is used:

Sample Unit Serial Plate

MODINE CONTROL SYSTEM MANUAL

Models MPR & ERM

MCP15-525.0

7

Controller Overview

Description and Features

The Modine Control System utilizes a Carel pCO3 programmable microprocessor cont roller. Highly advanced with a powerful

microprocessor and fast processing speed, the controller features a hi gh number of I/O’s for complex HVAC/R applications.

The main controller board is housed in a plastic case that ensures a high index of protection and reduces the risk of electrostatic

discharges due to incorrect handling. The controller offers greater s afety due to the optical isolation of the serial pLAN, protection

of the analog inputs in the event of incorrect connections, and an extended range of operating temperatures. Given the increasing

demand for integration, pCO3 can interface with BMS systems via many of the most commonly-used serial communication

standards, using optional boards.

Some of the features of the Carel pCO3 programmable microprocessor controller include:

• 10 Analog Inputs

o Uses 10K NT C temperature sensors

o 4-20ma Humidity and CO2 sensors for reliability

• 6 Analog Outputs

o 0-10vdc for easy fault finding

• 18 Digital inputs

o Used to monitor all aspects of the unit

• 18 Digital Outputs

o True relayed outputs for reliability

• Real Time Clock

o With batt ery backup and day light savings adjustment

• pLAN Communication

o To allow connectivity to space sensors and o ther controllers

• Built In Display

o Backlit easy to use and easy to read

• Alarm Logging

o With a snapshot of the unit sensors

• Run Hours logging

o With maintenance setpoints

• Password Protection

o Three levels of password protection

• Manual Control

o For easy startup and service

• Simple Interface

o Easy to und er stand menus and settings

• Built in Scheduler

o Up to 7 periods per day – Either On/Off control or Occ upied/Unoccupied

o Holiday Scheduler with up to 20 holiday periods

• Remote Display option

o Can be 100ft from unit using standard RJ12 cable

• All reset points fully adjustable

MODINE CONTROL SYSTEM MANUAL

Models MPR & ERM

8

MCP15-525.0

Standard and Optional Sensors Monitored

The Modine Control System monitors a number of sensors within the Atheri on unit as follows:

Standard sensors monitored:

• Supply Air (Field Installed – see main unit Installation Manual)

o Main DOAS – HOAS control

• Outside Temperature (Unit Mounted) and Outside Humidity (Unit Mounted)

o Used to calculate OA enthalpy and dew point

• Suction Pressure (Unit Mounted)

o Used for superheat and dehumidification control

• Liquid Lin e Pr e ssure (Unit Mounted)

o Used for head pressure control

• Compressor High Pressure Switch (Unit Mounted)

o With retry control

• Compre ss or Low Pressure Switch (Unit Mounted)

o With retry control

• Supply Fan Air Proving Switch (Unit Mounted)

o Pressure differential switch

• Damper End Switch (Unit Mounted)

o Used to enab l e the supply fan

• Digital Compressor Alarm (Unit Mounted)

o Monitors the compressor protection and sup er heat modules

• Cooling Coil Condensate High Level Alarm (Unit Mounted)

o Disables the compressors if the drain pan is not draining properly

Optional sensors available:

• CO

• Building Pressure Sensor (Field Installed)

• Duct Pressure Sensor (Field Installed)

• Return Air Sensor (Unit Mounted)

• pAD Space Temperature and Humidity (Field Installed)

• Filter Dirty Switch (Unit Mounted)

Sensor (Field Installed)

2

o Used for demand ventilation control

o Used to control supply fan, exhaust fan, or dampers

o Used to control supply fan

o Only applicable if the unit has return air

o Used for spac e temperature and humidity control

o Pressure differential switch

MODINE CONTROL SYSTEM MANUAL

Models MPR & ERM

MCP15-525.0

9

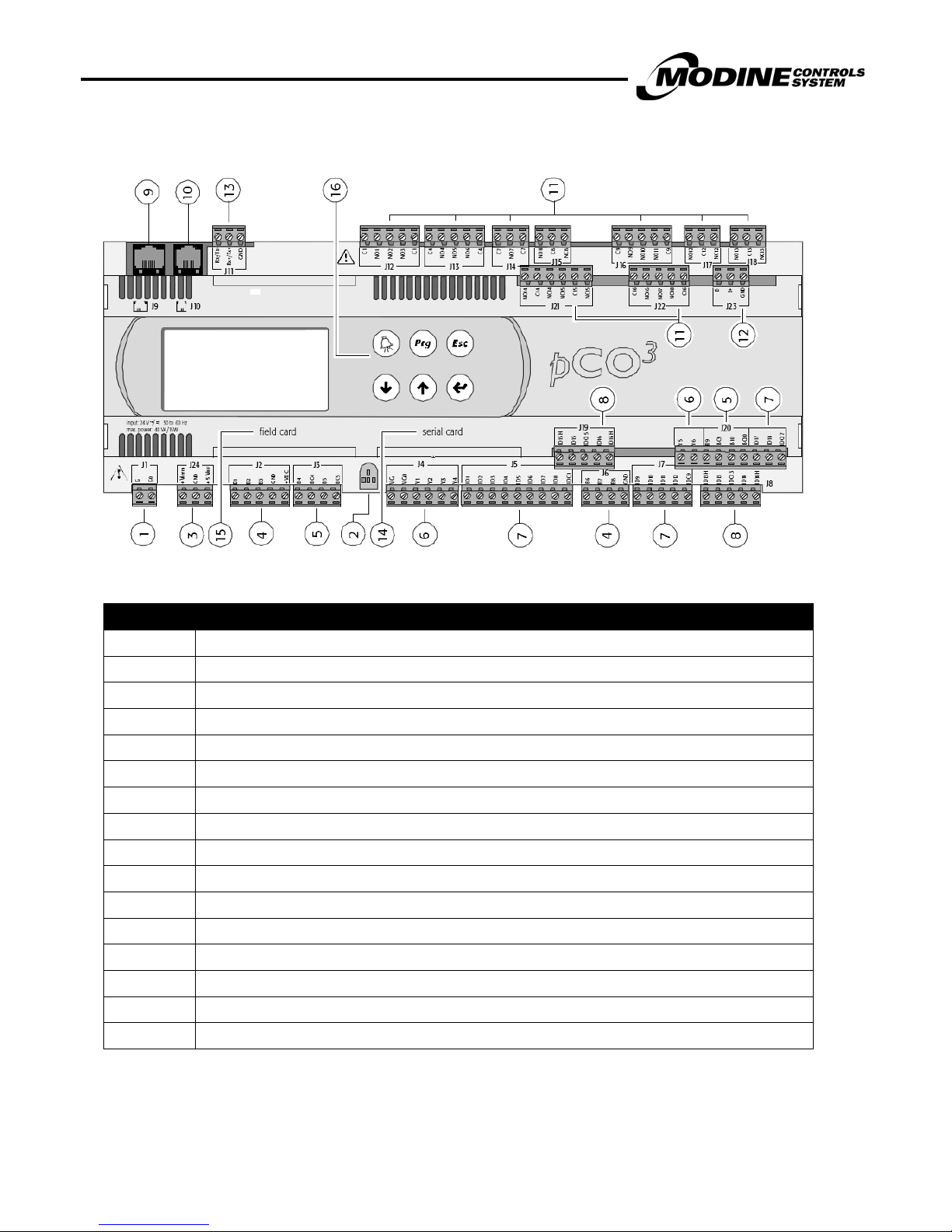

PCO3 Controller Layout

Reference Description

1 Power supply connector [G (+), G 0 (-)]

2 Yellow power LED and 3 status LEDs

3 Additional power supply for the t erminal and 0 to 5 V ratiometric probes

4 Universal analogue inputs: NT C, 0 to 1 V, 0 to 5 V ratiometric, 0 to 10 V, 0 to 20 mA, 4 to 20 mA

5 Passive analog inputs: NTC, PT 1000, ON/OFF

6 0 to 10 V analog outputs

7 24 Vac/Vdc digital inputs

8 230 Vac or 24 Vac/Vdc digital inputs

9 Connector for the display panel (exter nal panel with direct signals)

10 Connector for all standard pCO series terminals and for downloading the applicat i on program

11 Relay digital outputs

12 Connector for connection to the I/O expansion board

13 pLAN network connector

14 Cover for inserting the supervisor and maintenance option

15 Cover for inserting the field card option

16 Built-In terminal (LCD, buttons and LEDs)

MODINE CONTROL SYSTEM MANUAL

Models MPR & ERM

10

MCP15-525.0

Prg

Esc

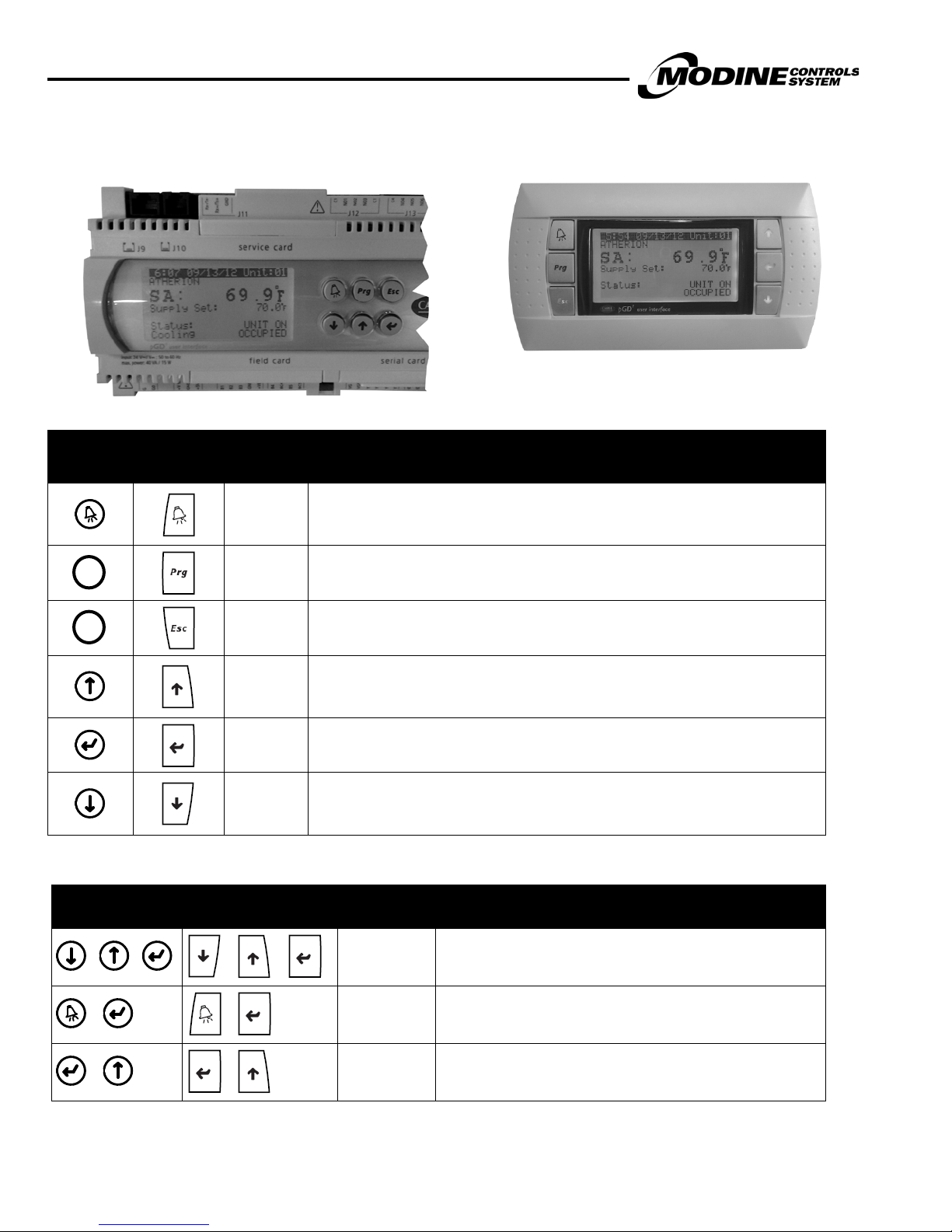

Display/Keypad Functions

pCO3 Display Keypad pGD1 Remote Display Keypad (Optional)

Standard Buttons

pCO3 Built-

in Display

pGD1

Remote

Display

Function Description

When one or more alarms are active the ALARM button will illuminate red.

ALARM

Pressing the ALARM button once will indicate information regarding any active alarms.

Pressing the ALARM button twice will reset any active manual-reset alarms.

Refer to Literature #MCP15-543 for installation instructions. Refer to

the Board Settings section for instructions on programming the remote

display keypad to the controller.

PRG Pressing the PRG button will select the main navigation menu.

ESC

UP

ENTER

DOWN

Pressing the ESC button will return the user to the main display screen showing unit

status.

Pressing the UP button can either:

Scroll through the various display screens, providing the cursor is in the top left position.

Increase the value of a set point adjustment.

Pressing the ENTER button will confirm any set point adjustments and move the cursor to

the next available set point.

Pressing the DOWN button can either:

Scroll through the various display screens, providing the cursor is in the top left position.

Decrease the value of a set point adjustment.

Extra Function Button Sequences

pCO3

Built-in Display

+ +

+

pGD1

Remote Display

.+. .+.

+

Combinations

UP + DOWN+

ENTER

ALARM +

ENTER

Key

Description

Allows access to controller address.

Allows access to controller system information.

+

+

ENTER + UP Change unit on remote display keypad. (ERM Only)

MODINE CONTROL SYSTEM MANUAL

Models MPR & ERM

MCP15-525.0

11

Prg

Prg

Esc

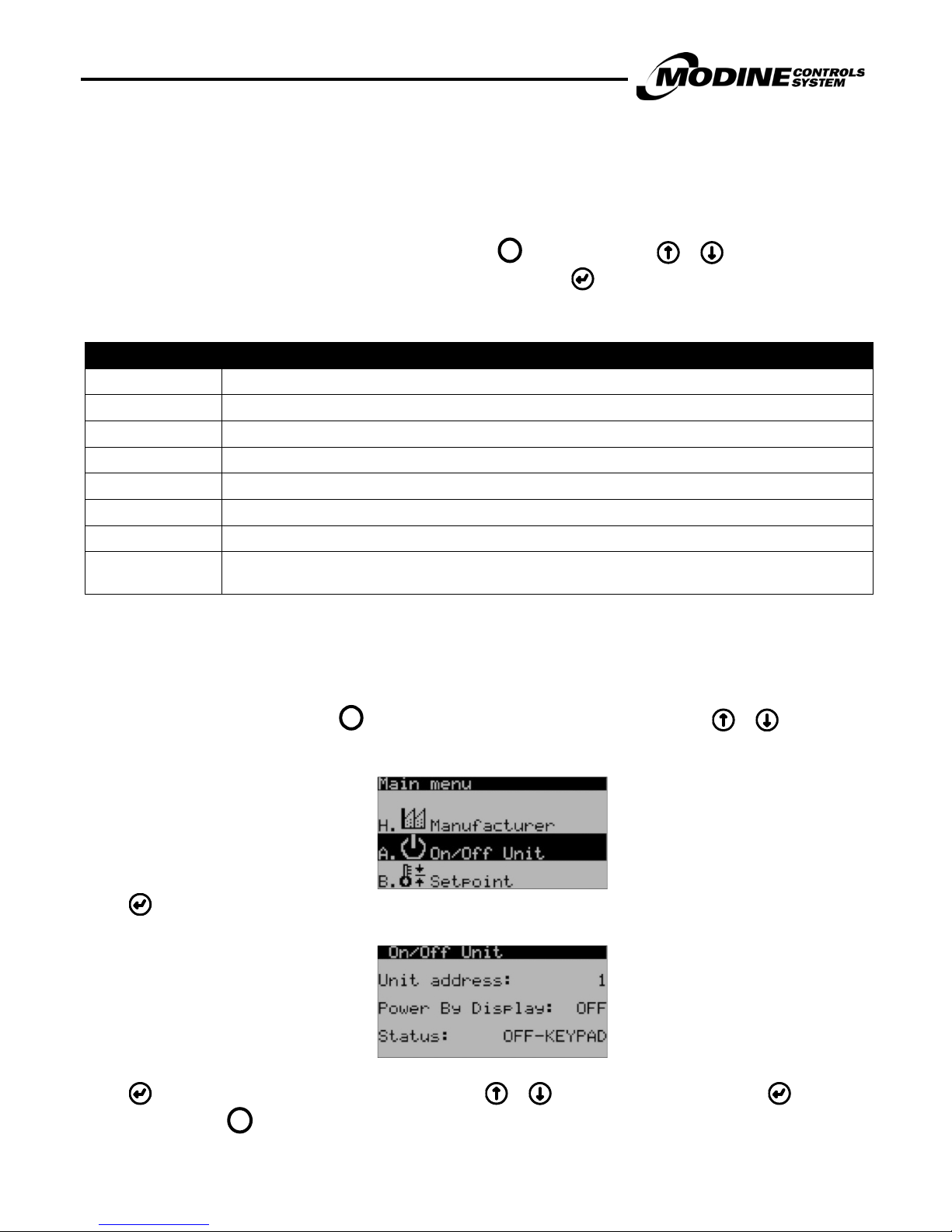

Menu Navigation

The following instructions ref er to the built-in display keypad buttons . See the table on the previous page for the corresponding

buttons if using the remote keypad.

The Main Status Screen is displayed when the unit is first turned on or after one minute of keypad inactivity. Fr om this Main

Status Screen, eight sub menus can be accessed by pressing the button and using the or buttons t o move to the

desired menu. The selected menu will be highlighted with a black bar. Press to enter the selected menu.

Navigation Sub Menus

Sub Menu Description

A. Unit On/Off

B. Setpoints

C. Clock/Scheduler

D. Input/Output

E. Alarm Log

F. Board Switch

G. Service

H. Manufacturer

Details on the Main Status Screen and each sub menu will be covered in the following sections of this manual.

Example Navigation to On/Off Sub Menus

(Similar for all other sub menus):

Switch on or switch off the unit.

View the user setpoints.

View the current time and date and set o n/off time zones.

View the status of the controller inputs and outputs.

View the alarm log.

Change the controller pLAN board address.

View maintenance related parameters, such as hours run, sensor calibration and manual overrides.

Manufacturer menu and adjustment of various manufacturer related parameters, such as unit

configuration and timing settings.

From the Main Status Screen, press the key to access the Sub Menu sele c tion screen. Use the or buttons to

navigate to the On/Off sub menu as shown in the following picture:

Press to access the On/Off sub menu screen:

Press to navigate to the parameter to chan ge, then use the or button to change the value. Press again to confirm

the setting. Press the button to exit the sub menu screen, back to the Main Status Screen.

MODINE CONTROL SYSTEM MANUAL

Models MPR & ERM

12

MCP15-525.0

Esc

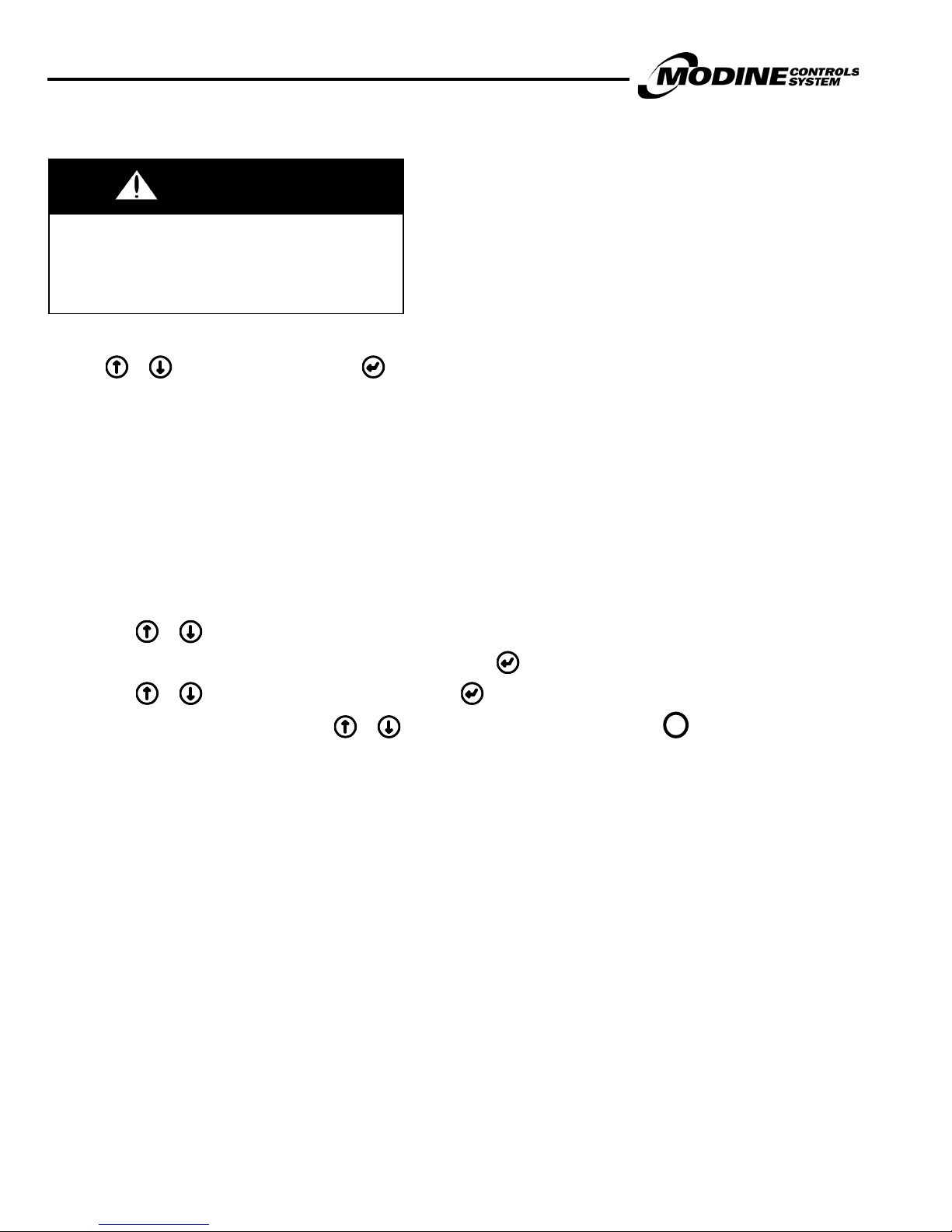

Password Protection

WARNING

Improper control adjustments and manual m ode

control can cause property damage, injury or

death. Read the installation, operating and

maintenance instructions thoroughly before

making adjustments.

To prevent unauthorized adjustments, a password is required to gain access to certain menus. When a password is requested

use the or keys to enter the number and to access the page. The passwords for the sub menus are as follows:

SETPOINTS: None

CLOCK/SCHEDULER: None

SERVICE SETTINGS: 0001

MANUFACTURER: Contact Modine

Adjusting Customer Control Settings

The following procedure is used to access and adjust control parameters (refer to Parameters List and Factory Values).

1. After entering the correct pas sword the cursor will appear at the top left corner (Home location).

2. Use the or keys to move to the desired menu.

3. To move the flashing cursor to the r equired adjustable fields press .

4. Use the or keys to change t he values and press the key to move the cursor to the next field or Home location.

5. When the cursor is Home either us e the or keys to scroll to the next sub-menu or the key to exit and return to

the Main Menu page.

MODINE CONTROL SYSTEM MANUAL

Models MPR & ERM

MCP15-525.0

13

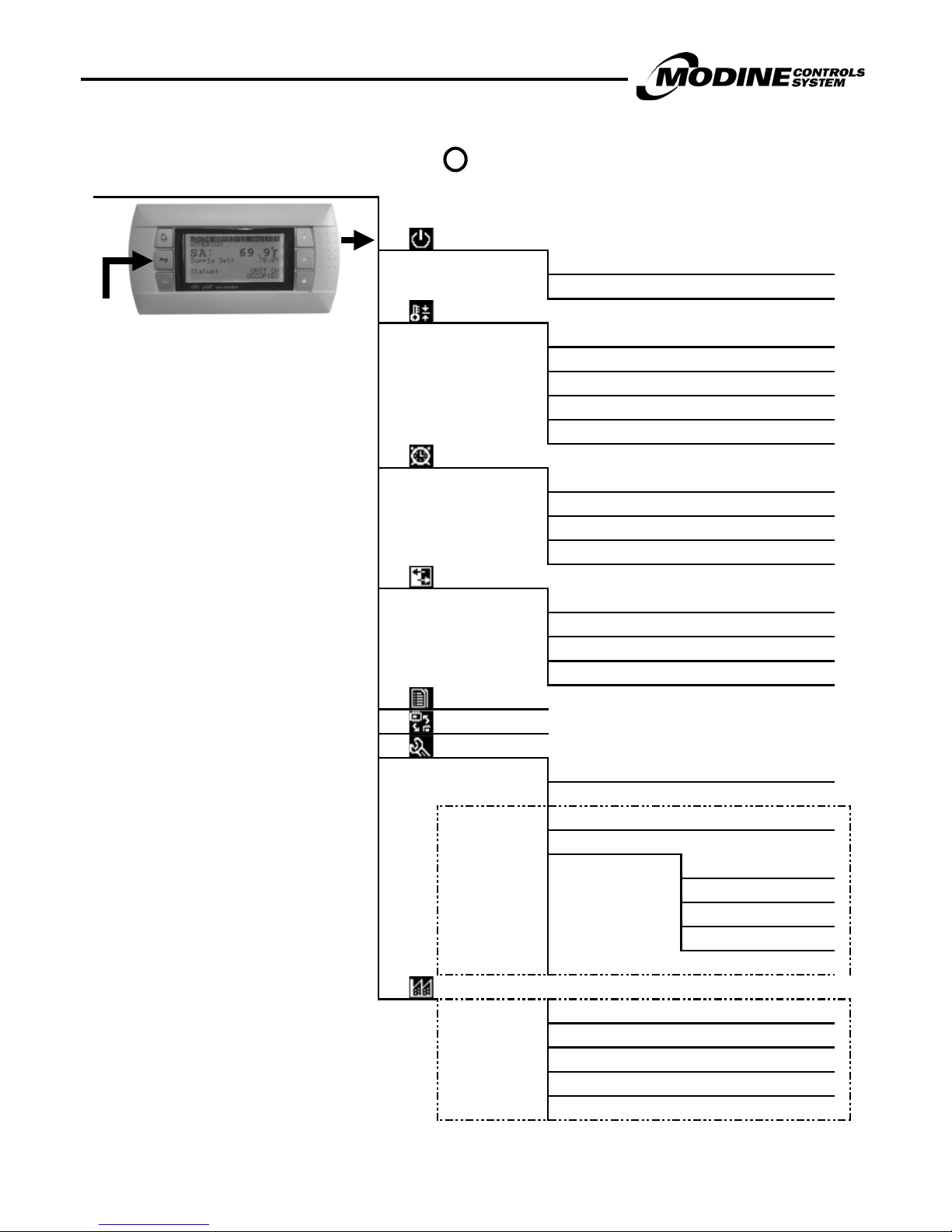

Unit Sta tu s

A.

On/Off By Display

On/Off By pAD (Optional)

B.

Supply Air Setpint

Dampe r Mi n Position

Room Space Te m perature (Optional )

Room Space Humidi ty (Optional)

Building Pre ssure (Optional)

C.

Date/time

Daylight Savings

Scheduler

Holidays

D.

a. Ana log i nputs

b. Digital i nputs

c. Analog outputs

d. Digital outputs

E.

F.

G. Service

b. Information

d. Working Hours

e. BMS config.

f. S ervice S etti n g s

a. Working hours set

b. Probe adjustment

c. Control Settings

d. User Dev/Change PW 1

g. Manual Management

H. Manufacturer

a. Configuration

b. I/O Configuration

c. ERM (Optional)

d. Initialization

e. pAD settings (Optional)

To acces s the

branches i n t hi s

area, enter pass word

PW1

To acces s the

branches i n t hi s

area, enter pass word

PW2

Data Logge r

Board Swi tch

On/ Off Un it

Setpoints

Clock/Scheduler

Input/Output

Prg

Main Menu – Tree of Functions

Irrespective of the current screen displayed, pressing the key accesses the main menu, as shown below:

MODINE CONTROL SYSTEM MANUAL

Models MPR & ERM

14

MCP15-525.0

Unit On

Wait Sup Fan

Unoccupied

Occupied

Dehum

Main Status Screen

The Main Status Screen is displayed when the unit is first turned on or after one minute of keypad inactivity.

The following information is displayed on t he Main Status Screen:

• Time/date

• Unit number

• Supply Air Temperature

• Current Supply Air Setpoint

• Unit Status

• Unit Mode

Once this screen is displayed, t he user can navigate up and down through the list of Main Status Screen Parameters by using the

+ buttons. These screens are described in further detail in the next sec tion.

Note that the main unit controller will always show as Unit: 01. If the unit i s al s o equipped with an ERM module, it has its own

controller, which is Unit: 02. The ke ypad at the main controller or the remote key pad can be used to change the Main Status

Screen to display either Unit 01 or 02.

To change the controller being disp l ayed, press the + buttons. If you are viewing the main controller display, pressing

those buttons will switch to displa ying the ERM controller. Pressing thos e buttons again will revert back t o displaying the main

controller.

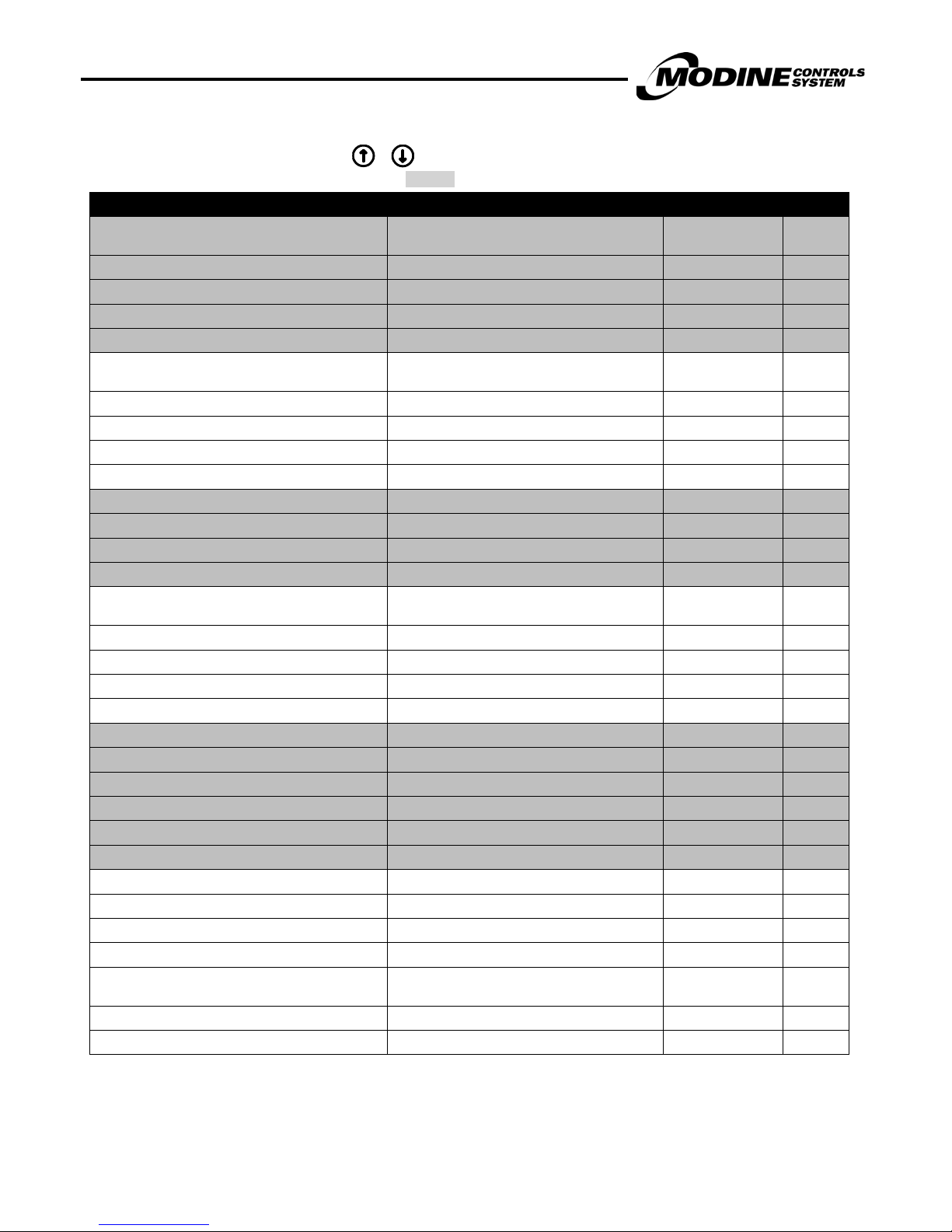

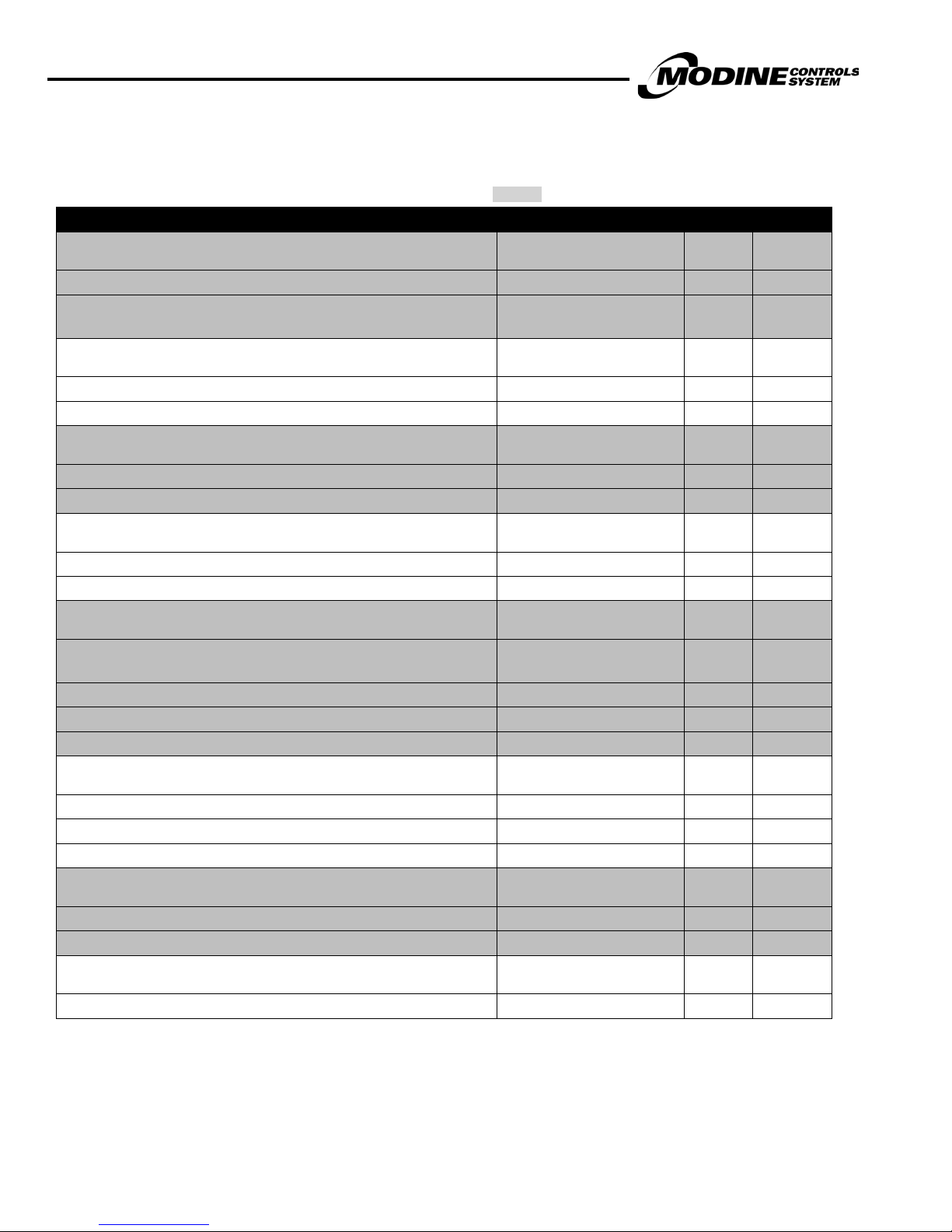

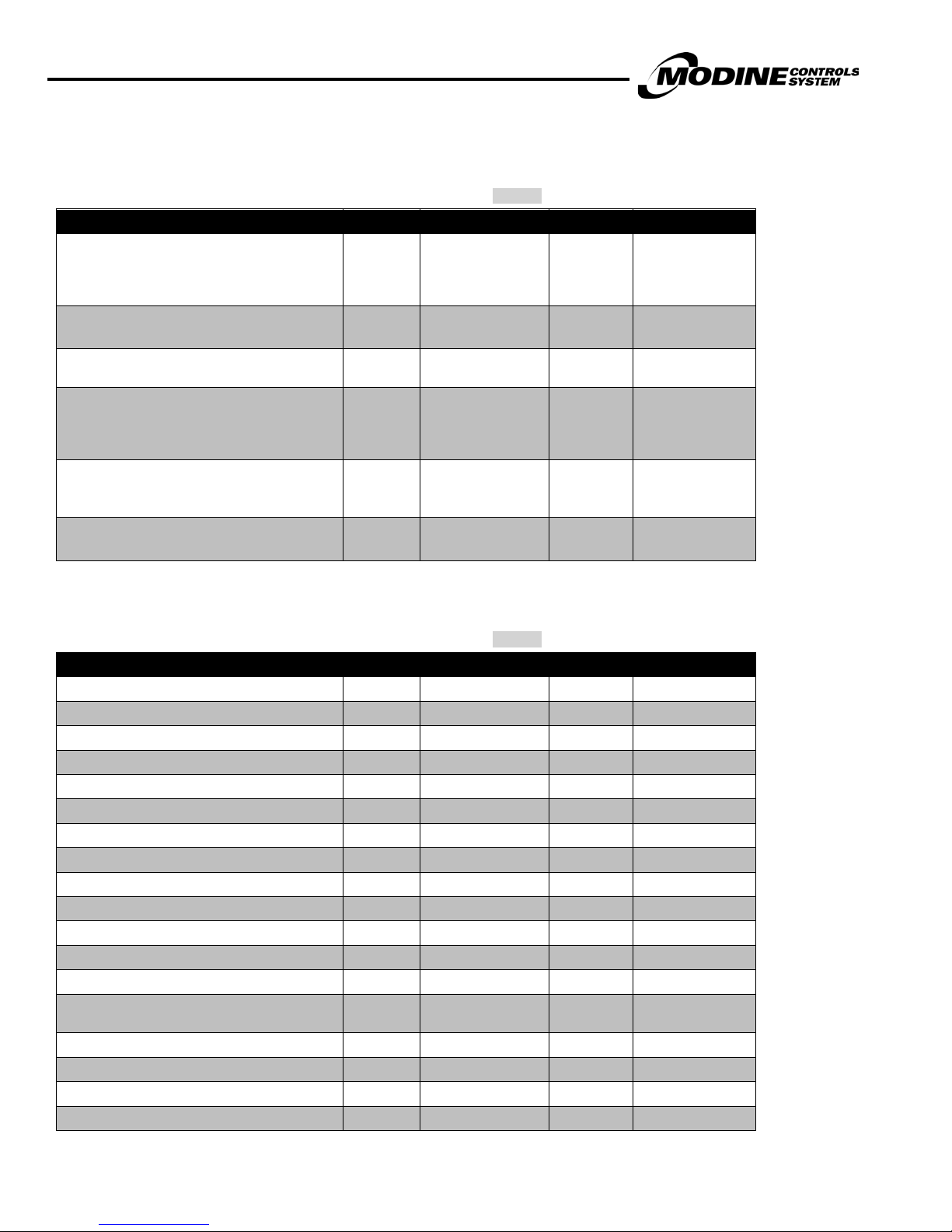

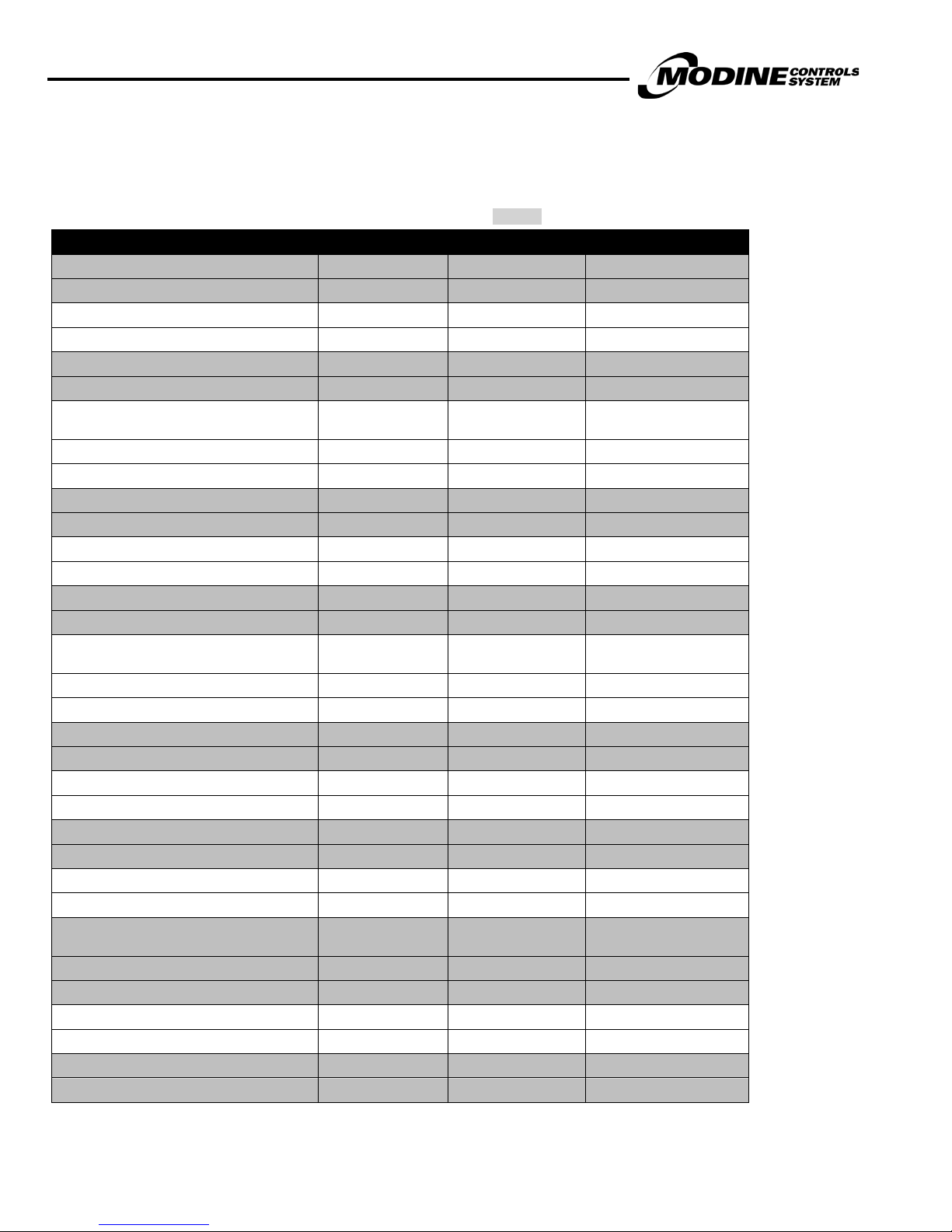

Main Status Screen Parameters

The status screens can be seen when the + buttons are pressed on the Main Status Screen. The following table

describes the menu parameters (Note: Change in shading indicates change to next screen):

PARAMETER DESCRIPTION FACTORY VALUE RANGE UNITS

Time and date Current time and date

Unit network address Actual Value 1

Supply Air Temperature Actual Value °F / °C

Supply Air Setpoint Actual Value °F / °C

OFF by Alarm

OFF by pLAN

OFF by BMS

OFF by Clock

Unit Status Current status of unit

Current Occupied Mode

Occupied Mode

Unit Mode Current Mode of operation

Note: Unless a pAD Wall Stat is installed the

unit only operate in Occupied Mode

OFF by Digital In

OFF by Keypad

OFF by Demand

OFF - Door Open

Off Manually

Wait - Damper

Occupied – BMS

Occupied – CLK

Occupied – DIG

Venting

Cooling

Heating

(continued on next page)

MODINE CONTROL SYSTEM MANUAL

Models MPR & ERM

MCP15-525.0

15

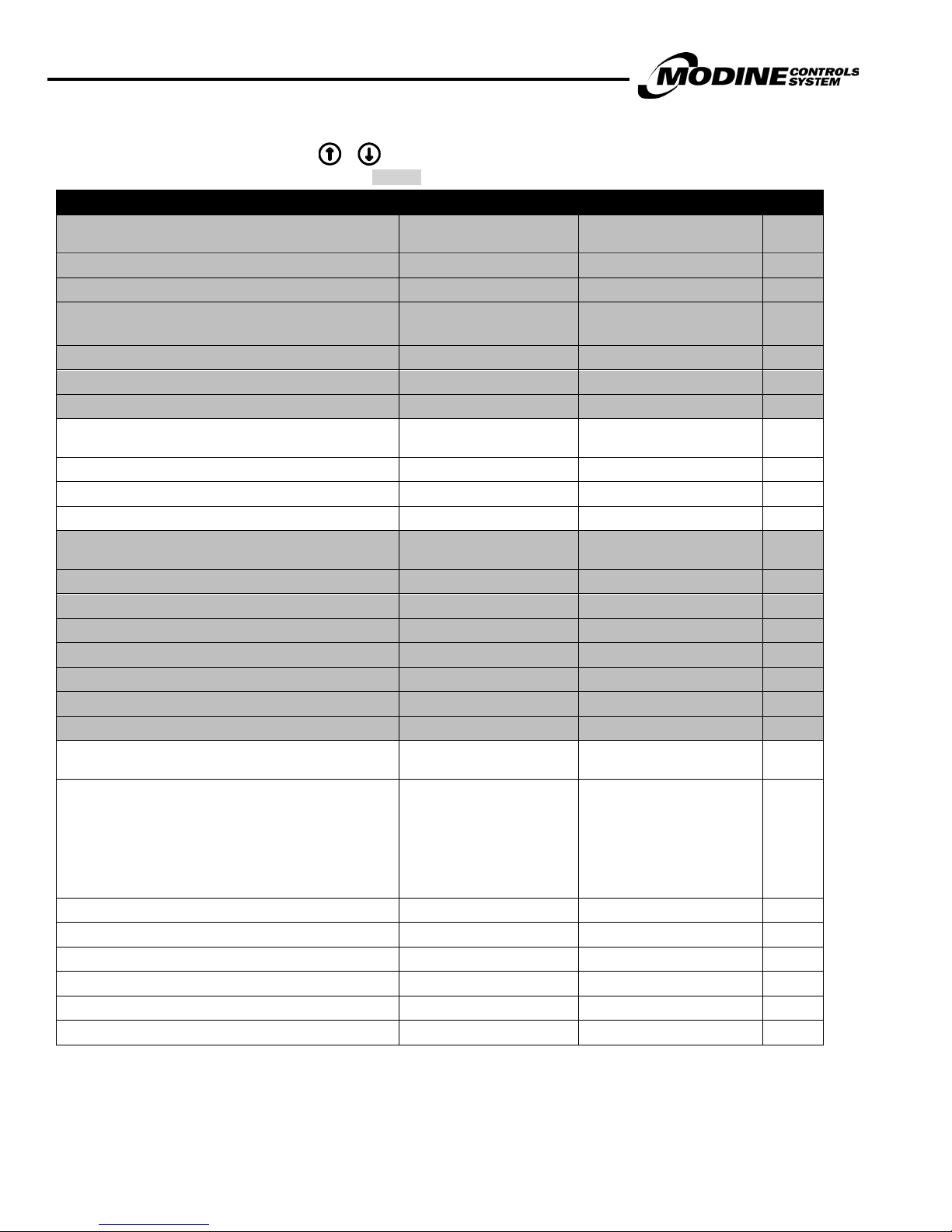

Main Status Screen Parameters (continued)

The status screens can be seen when the + buttons are pressed on the main status screen. The following table

describes the menu parameters (Note: Change in shading indicates change to next screen):

PARAMETER DESCRIPTION FACTORY VALUE RANGE UNITS

Note: The screen below will only be displayed if

the optional Space wall stat is installed (pAD)

pAD Space Temperature Actual Value °F / °C

pAD Space Humidity Actual Value %RH

pAD Space Enthalpy Actual Value (Calculated) BTU/Lb

pAD Space Dew Point Actual Value (Calculated) °F / °C

Note: The screen below will only be displayed if

the unit has a Return Air Damper or ERM

Return Temperature Actual Value °F /°C

Return Air Humidity Actual Value %RH

Return Air Enthalpy Actual Value (Calculated) BTU/Lb

Return Air Dew Point Actual Value (Calculated) °F /°C

Outside Air Temperature Actual Value °F /°C

Outside Air Humidity Actual Value %RH

Outside Air Enthalpy Actual Value (Calculated) BTU/Lb

Outside Air Dew Point Actual Value (Calculated) °F /°C

Note: The screen below will only be displayed if

the unit has an ERM module

ERM Leaving Air Temperature Actual Value °F /°C

ERM Leaving Air Humidity Actual Value %RH

ERM Leaving Air Enthalpy Actual Value (Calculated) BTU/Lb

ERM Leaving Air Dew Point Actual Value (Calculated) °F /°C

Cooling Demand Actual Value 0-100 %

Heating Demand Actual Value 0-100 %

Outside Air Damper Position Actual Value 0-100 %

Return Air Damper Position (Optional) Actual Value 0-100 %

Hot Gas Reheat Valve (If Enabled) Actual Value 0-100 %

Dehum Demand (If Enabled) Actual Value 0-100 %

Supply Fan Actual Value On or Off

Supply Fan Modulation (If Enabled) Actual Value 0-100 %

Exhaust Fan (If Enabled) Actual Value On or Off

Exhaust Fan Modulation (If Enabled) Actual Value 0-100 %

Note: The screen below will only be displayed if

the unit has an ERM module

ERM Exhaust Fan (If Enabled) Actual Value On or Off

ERM Exhaust Fan Modulation (If Enabled) Actual Value 0-100 %

(continued on next page)

MODINE CONTROL SYSTEM MANUAL

Models MPR & ERM

16

MCP15-525.0

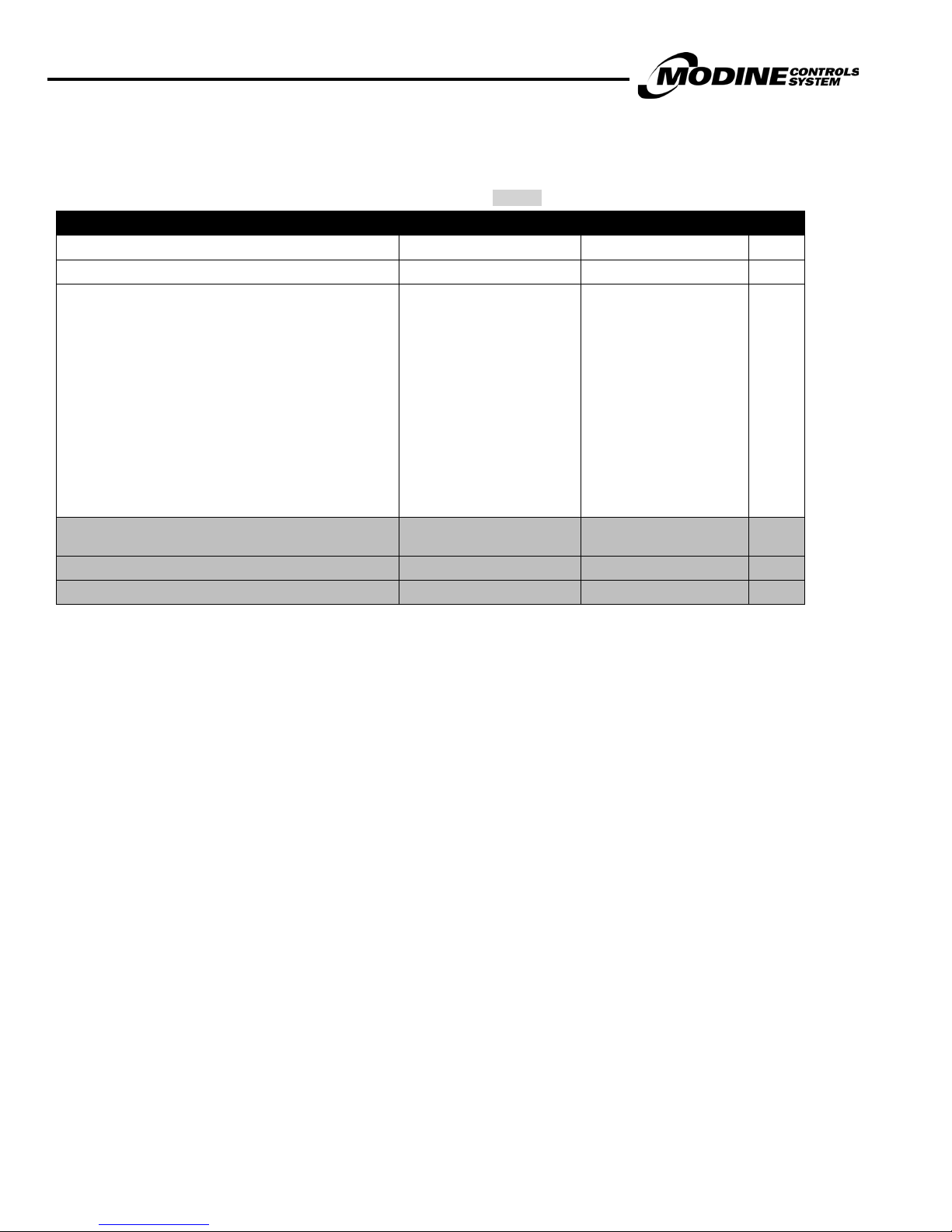

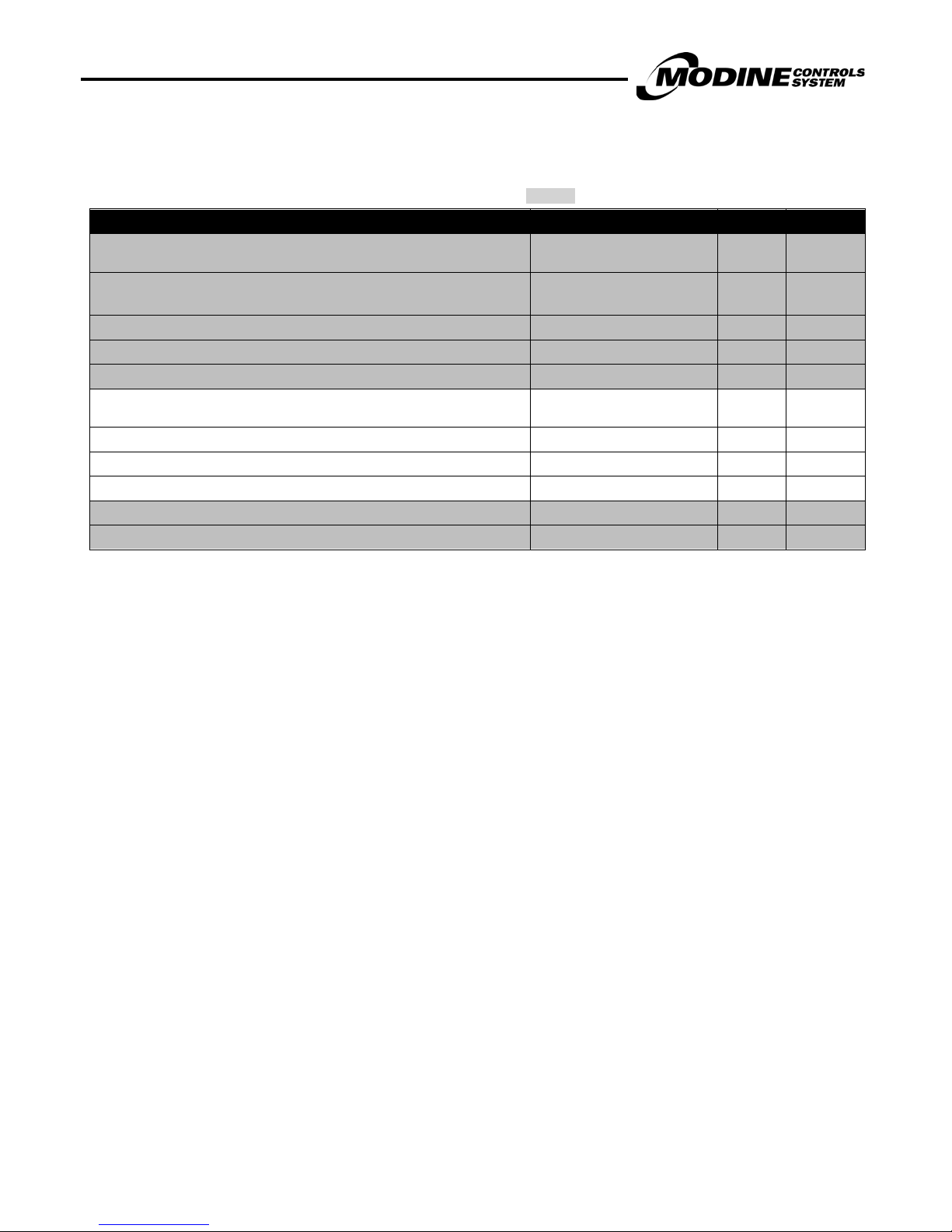

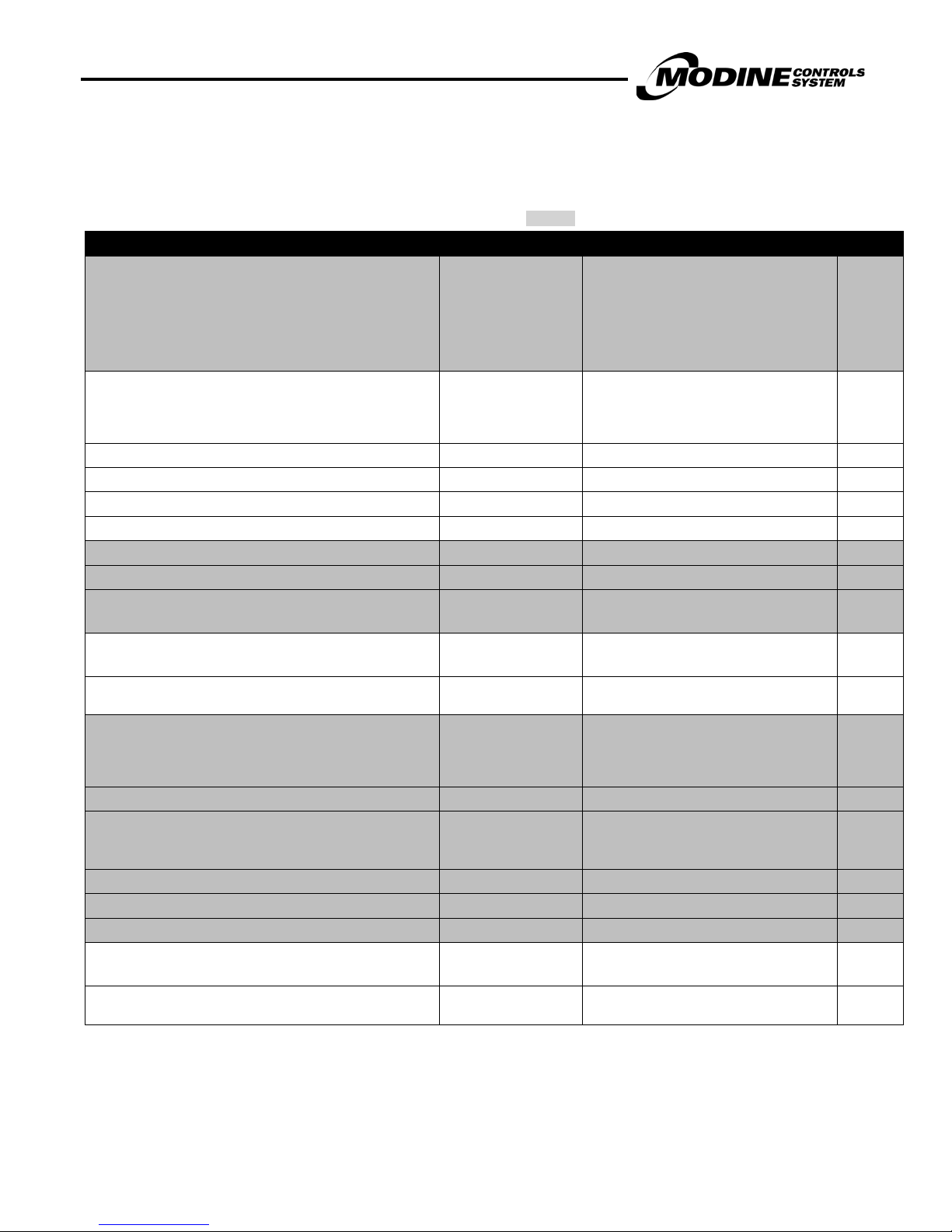

Main Status Screen Parameters (continued)

The status screens can be seen when the + buttons are pressed on the main status screen. The following table

describes the menu parameters (Note: Change in shading indicates change to next screen):

PARAMETER DESCRIPTION FACTORY VALUE RANGE UNITS

Note: The screen below will only be displayed if the unit

has an ERM module

ERM Wheel Actual Value On or Off

ERM Wheel Status (Optional) Actual Value Stopped or Running

Count On: Off:

Wheel minimum on and off counter

ERM By-Pass Damper Actual Value Open or Closed

ERM Pre-Heater On or Off

ERM Door Switch Open or Closed

Note: The screen below will only be displayed if the unit

has Gas or Electric Heat

Gas Or Electric Stages On Actual Value 0-2 (gas) 0-4 Elec. Heat

Heat Modulation Actual Value 0-100 %

Heating Lockout Warning Heating is locked out

Note: The screen below will only be displayed if the unit

is in EC3 Mode

Compressor 1 Status On or Off

Compressor 1 Minimum On Time Actual Value (Counts Down) 0-120 S

Compressor 1 Minimum Off Time Actual Value (Counts Up) 0-120 S

Compressor 2 Status On or Off

Compressor 2 Minimum On Time Actual Value (Counts Down) 0-120 S

Compressor 2 Minimum Off Time Actual Value (Counts Up) 0-120 S

Digital Compressor Modulation Actual Value 0-100 %

Note: The screen below will only be displayed if the unit

is in CDSS mode

Status (Digital Compressor)

Countdown Actual value S

Maximum Power Admitted Actual Value 0-100 %

Digital Compressor Actual Value On or Off

Valve Actual Value On or Off

Requested Capacity Actual Value 0-100 %

Current Capacity Actual Value 16.6-100 %

(continued on next page)

Actual Value Sec

Off

Start-up

On

Alarm

Off By Time

On By Time

MODINE CONTROL SYSTEM MANUAL

Models MPR & ERM

MCP15-525.0

17

No Enthalpy Lockout

Enthalpy LO Comp 1&2

Stand-By

I/O Automatic or

Reset Manual Controls

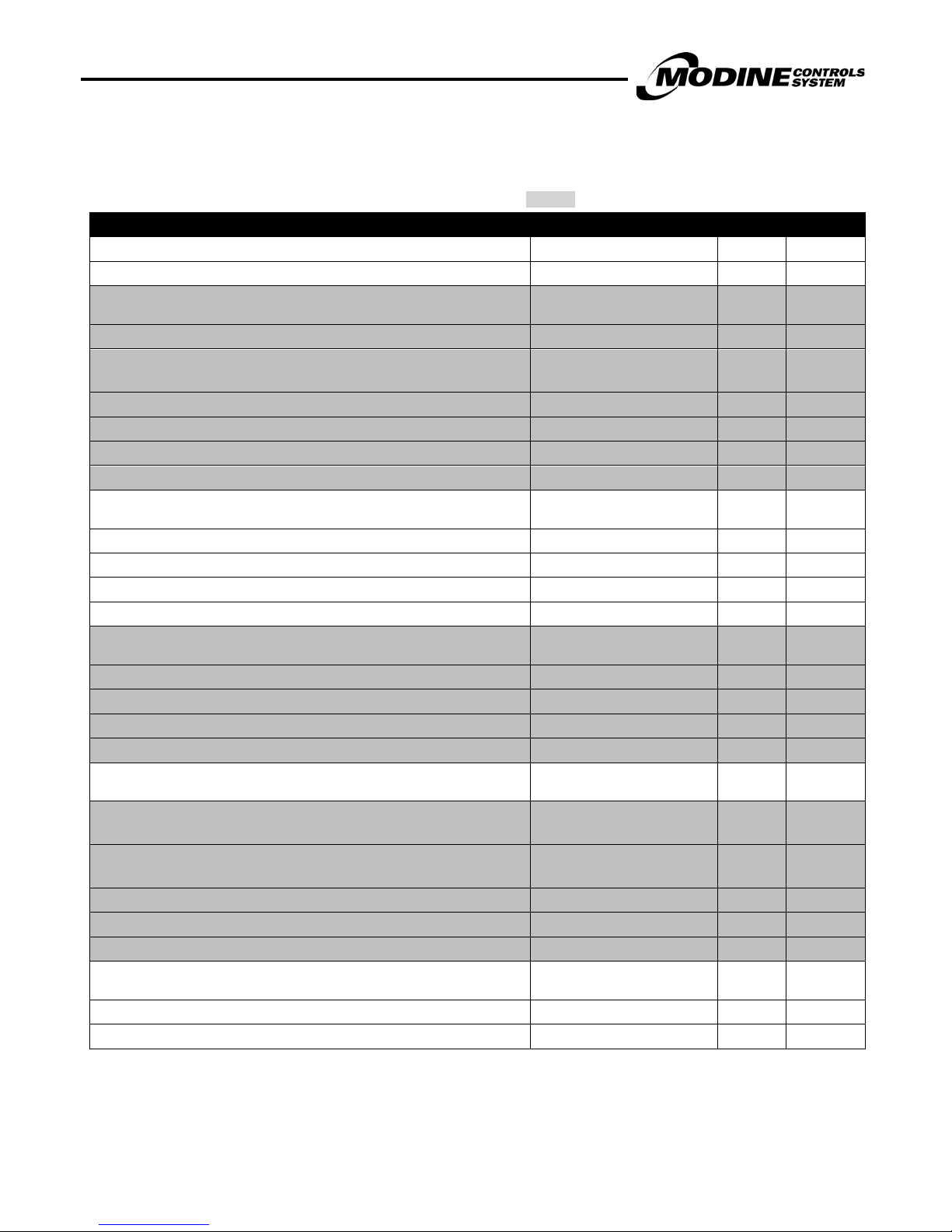

Main Status Screen Parameters (continued)

The status screens can be seen when the + buttons are pressed on the main status screen. The following table

describes the menu parameters (Note: Change in shading indicates change to next screen):

PARAMETER DESCRIPTION FACTORY VALUE RANGE UNITS

Note: The screen below will only be displayed if the unit

is in CDSS mode

Compressor 2 Status On or Off

Compressor 2 Minimum On Time Actual Value (Counts Down) 0-120 S

Compressor 2 Minimum Off Time Actual Value (Counts Up) 0-120 S

Note: The screen below will only be displayed if the unit

is in CDSS mode

Cooling Lockout

Compressor Enthalpy Lockout

Compressor Lockout

Condenser Fan Modulation Actual Value 0-100 %

Discharge Pressure Actual Value PSIG

Discharge Temperature (If in CDSS Mode) Actual value °F /°C

Suction Pressure Actual Value PSIG

Note: The screen below will only be displayed if the unit

is in CDSS mode

Liquid Line Temperature Actual value F /°C

Condensing Temperature Calculated F /°C

Sub-Cool Calculated F /°C

Capacity Reduction Actual Value 0-100 %

Note: The screen below will only be displayed if the unit

is in CDSS mode

Super-Heat Calculated F /°C

Suction Line Temperature Actual Value F /°C

Suction Pressure Actual Value PSIG

Evaporating Temperature Calculated F /°C

EEV Valve Steps Actual Value Depends On Valve Type Steps

EEV Value Percentage Actual Value 0-100 %

Valve Regulation

Enthalpy LO Comp 1

Enthalpy LO Comp 2

Compressor Held Off by

Lockout timers

Close

On

Position

Wait

Note: The next screen will only be displayed if a clock

schedule is enabled

Clock Override On or Off

Override Time 1-9 Hrs.

Manual Control Status & Reset Actual Value

I/O Manual

MODINE CONTROL SYSTEM MANUAL

Models MPR & ERM

18

MCP15-525.0

On/Off Sub Menu

Main Status Screen On/Off

The following table describes the menu parameters (Note: Change in shading indicates change to next s c reen):

PARAMETER DESCRIPTION FACTORY VALUE RANGE UNITS

Unit Address 1

Power By Display Actual Value On or Off

Unit On

OFF by Alarm

OFF by pLAN

OFF by BMS

OFF by Clock

Status Actual Value

Note: The screen below will only be displayed if the

optional Space wall stat is installed (pAD)

pAD Number Actual Value 1

On / Off Permanently Off - On or Off

OFF by Digital In

OFF by Keypad

OFF by Demand

OFF - Door Open

Off Manually

Wait - Damper

Wait Sup Fan

MODINE CONTROL SYSTEM MANUAL

Models MPR & ERM

MCP15-525.0

19

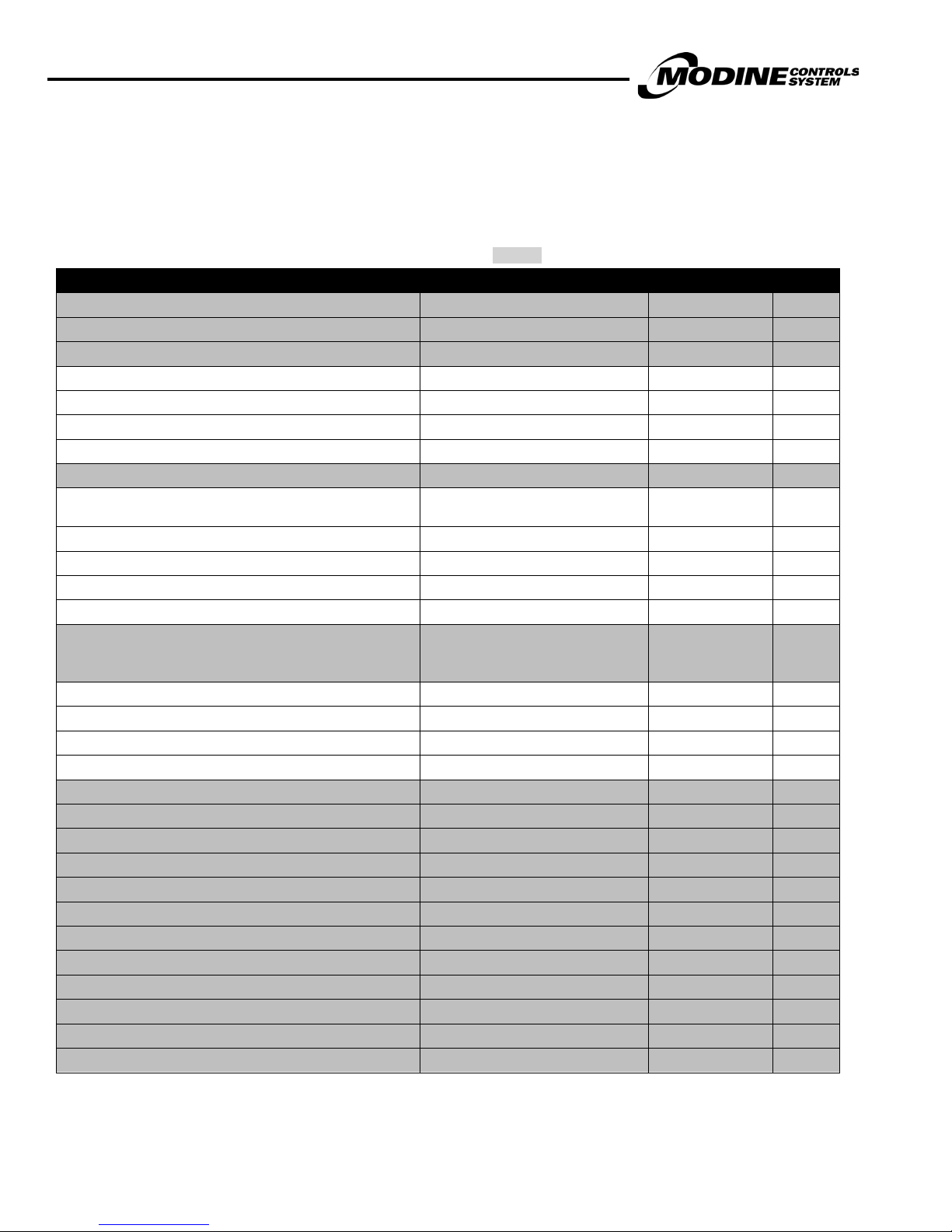

Setpoint Sub Menu

Main Status Screen Setpoint

The following table describes the menu parameters (Note: Change in shading indicates change to next s c reen):

PARAMETER DESCRIPTION FACTORY VALUE RANGE UNITS

Supply Air Setpoint 70 50-99 °F /°C

Current Setpoint Actual Value °F /°C

Note: The screen below will only be displayed if the optional Space wall

stat is installed (pAD)

pAD Thermostat Number Actual Value

Space Cooling Temperature Setpoint

Note: Heating Setpoint equals cooling setpoint minus 4°F

Space Humidity Setpoint 60 30-100 %RH

Space Humidity Differential 5 0-10 %

Unoccupied Cooling Setpoint 85 60-100 °F / °C

Unoccupied Heating Setpoint 62 40-100 °F / °C

Note: The screen below will only be displayed if Dew Point

Dehumidification is enabled

Occupied OA Dew point Setpoint 55 40-70 °F /°C

Occupied OA Dew point Differential 3 0-10 °F /°C

Unoccupied Space Dew point Setpoint 55 40-70 °F /°C

Unoccupied Space Dew point Differential 3 0-10 °F /°C

Note: The screen below will only be displayed if the optional space wall

stat is installed (pAD)

Occupied Space Humidity Setpoint 60 30-100 %RH

Occupied Space Humidity Differential 5 0-10 %

Unoccupied Space Humidity Setpoint 60 30-100 %RH

Unoccupied Space Humidity Differential 5 0-10 %

Note: The screens below will only be displayed if the unit is setup for

HOAS damper control

Outside Air Minimum Damper Position

Note: The Return Air Damper (Optional) will be the inverse of this value

OA Damper Position 1

Note: The Return Air Damper (Optional) will be the inverse of this value

OA Damper Position 2 50% ID15 Closed ID 16 Open 0-100 %

OA Damper Position 3 75% ID15 Open ID 16 Closed 0-100 %

OA Damper Position 4 100% ID15 and ID 16 Closed 0-100 %

Note: The Screen below will only be displayed if Damper CO2 Control is

selected

CO2 Setpoint 800 0-2000 PPM

CO2 Level Actual Value 0-2000 PPM

(continued on next page)

74 50-100 °F / °C

Setting depends on Unit type 0-100 %

30% ID15 and ID 16 Open 0-100 %

MODINE CONTROL SYSTEM MANUAL

Models MPR & ERM

20

MCP15-525.0

Setpoint Sub Menu (continued)

Main Status Screen Setpoint

The following table describes the menu parameters (Note: Change in shading indicates change to next s c reen):

PARAMETER DESCRIPTION FACTORY VALUE RANGE UNITS

Note: The Screen below will only be displayed if Damper Building

Pressure Control is selected

Building Pressure Setpoint 0.2 0-0.5 Inch W.G.

Building Pressure Actual Value 0-0.5

Note: The screen below will only be displayed if Supply Fan CO2 Control

is selected

CO2 Setpoint 800 0-2000 PPM

CO2 Level Actual Value 0-2000 PPM

Note: The Screen below will only be displayed if Supply Fan Building

Pressure Control is selected

Building Pressure Setpoint 0.2 0-0.5 Inch W.G.

Building Pressure Actual Value 0-0.5 Inch W.G.

Note: The screen below will only be displayed if Supply Fan Duct Static

Pressure Control is selected

Duct Static Pressure Setpoint 1.0 0-5 Inch W.G.

Duct Pressure Actual Value 0-5 Inch W.G.

Note: The Screen below will only be displayed if Supply Fan Constant

Volume Control is selected

Supply Fan Speed 1

Supply Fan Speed 2 85% ID15 Closed ID 16 Open 0-100 %

Supply Fan Speed 3 75% ID15 Open ID 16 Closed 0-100 %

Supply Fan Speed 4 50% ID15 and ID 16 Closed 0-100 %

Note: The screen below will only be displayed if Exhaust Fan Building

Pressure On/Off Control is selected

Building Pressure Setpoint 0.2 0-0.5 Inch W.G.

Building Pressure Differential 0.1 0-0.5 Inch W.G.

Building Pressure Actual Value 0-5 Inch W.G.

Note: The Screen below will only be displayed if Exhaust Fan Building

Pressure Control is selected

Building Pressure Setpoint 0.2 0-0.5 Inch W.G.

Building Pressure Actual Value 0-0.5 Inch W.G.

Note: The screen below will only be displayed if Exhaust Fan Offset

(from Supply Fan) Control is selected

Exhaust Fan Offset Setpoint (From Sup. Fan) 20 0-100 %

(continued on next page)

Inch W.G.

100% ID15 and ID 16 Open 0-100 %

MODINE CONTROL SYSTEM MANUAL

Models MPR & ERM

MCP15-525.0

21

Setpoint Sub Menu (continued)

Main Status Screen Setpoint

The following table describes the menu parameters (Note: Change in shading indicates change to next s c reen):

PARAMETER DESCRIPTION FACTORY VALUE RANGE UNITS

Note: The Screen below will only be displayed if Exhaust Fan Constant

Volume Control is selected

Exhaust Fan Speed 1

Exhaust Fan Speed 2 85% ID15 Closed ID 16 Open 0-100 %

Exhaust Fan Speed 3 75% ID15 Open ID 16 Closed 0-100 %

Exhaust Fan Speed 4 50% ID15 and ID 16 Closed 0-100 %

Note: The screen below will only be displayed if ERM Exhaust Fan

Building Pressure Control is selected

Building Pressure Setpoint 0.2 0-0.5 Inch W.G.

Building Pressure Actual Value 0-5 Inch W.G.

ERM Exhaust Fan Minimum Speed 50 0-100 %

Note: The Screen below will only be displayed if ERM is Enabled

ERM Exhaust Fan Minimum Speed 50 0-100 %

100% ID15 and ID 16 Open 0-100 %

MODINE CONTROL SYSTEM MANUAL

Models MPR & ERM

22

MCP15-525.0

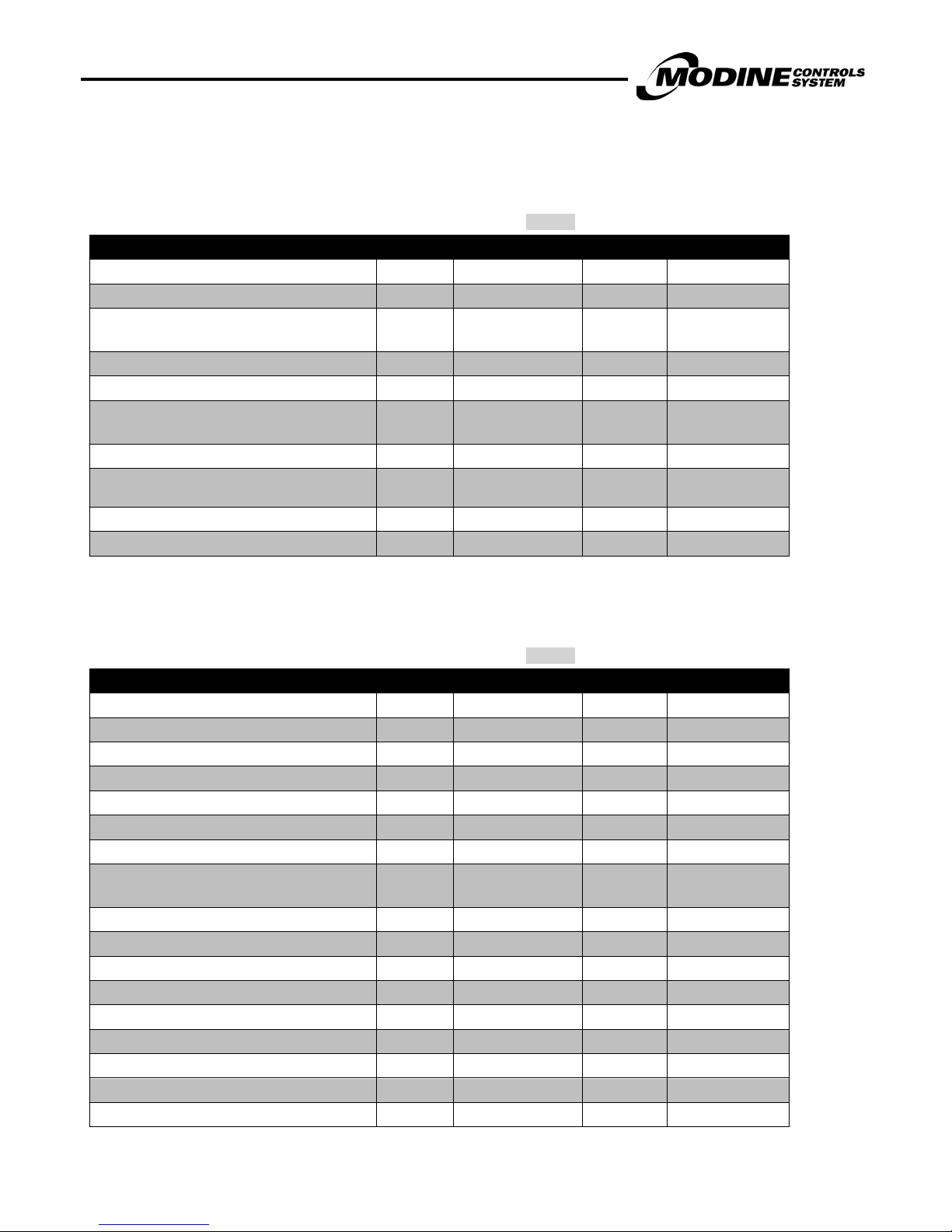

Clock/Scheduler Sub Menu

Main Status Screen Clock/Scheduler

Note: The Schedule/Holidays can be used to either turn the unit On/Off or t o Cycle the unit from Occupied to Unoccupied (when

an Optional Space Sensor is installed).

The following table describes the menu parameters (Note: Change in shading indicates change to next screen):

PARAMETER DESCRIPTION FACTORY VALUE RANGE UNITS

Day Actual day Monday – Sunday -

Date Actual date MM/DD/YY -

Hour (Military Time) Actual time 00:00-23:59 -

Daylight Savings On On / Off

Transition Time 60 0-60 S

Start (Spring) Second Sunday in March @ 2:00am

End (Fall) First Sunday In November @ 3:00am

Number Of Schedules 0 0-7 -

Note: The screen below will only be shown if at least one

schedule is set

Schedule Number 1-7 Time On 00:00 00:00 – 23:59 Hrs:Min

Time Off 00:00 00:00 – 23:59 Hrs:Min

Days Enabled – Selects the days the schedule is to take effect. None MTWTFSS Days

Number of Holidays

Note: If a Holiday is one day the Start – Stop will be the same

e.g. 7/4 – 7/4

Holiday 1 Start - Stop 0 1/1/ - 12/31 Days

Holiday 2 Start - Stop 0 1/1/ - 12/31 Days

Holiday 3 Start - Stop 0 1/1/ - 12/31 Days

Holiday 4 Start - Stop 0 1/1/ - 12/31 Days

Holiday 5 Start - Stop 0 1/1/ - 12/31 Days

Holiday 6 Start - Stop 0 1/1/ - 12/31 Days

Holiday 7 Start - Stop 0 1/1/ - 12/31 Days

Holiday 8 Start - Stop 0 1/1/ - 12/31 Days

Holiday 9 Start - Stop 0 1/1/ - 12/31 Days

Holiday 10 Start - Stop 0 1/1/ - 12/31 Days

Holiday 11 Start - Stop 0 1/1/ - 12/31 Days

Holiday 12 Start - Stop 0 1/1/ - 12/31 Days

Holiday 13 Start - Stop 0 1/1/ - 12/31 Days

Holiday 14 Start - Stop 0 1/1/ - 12/31 Days

Holiday 15 Start - Stop 0 1/1/ - 12/31 Days

Holiday 16 Start - Stop 0 1/1/ - 12/31 Days

0 0-16 Days

MODINE CONTROL SYSTEM MANUAL

Models MPR & ERM

MCP15-525.0

23

Input / Output Sub Menu

Analog Inputs:

Main Status Screen Input/Output Analog Inputs

The following table describes the menu parameters (Note: Change in shading indicates change to next s c reen):

PARAMETER DESCRIPTION INPUT FACTORY VALUE RANGE UNITS

Return Air Humidity (Optional) B1 Actual 0-100 %RH

CO2 (Optional) B2 Actual 0-2000 PPM

Building Pressure (Optional) or

Duct Static Pressure

Outside Air Temperature B4 -999.9-999.9 °F / °C

Return Air Temperature (Optional) B5 Actual -999.9-999.9 °F / °C

Discharge Line Temperature (In CDSS Mode)

or Liquid Line Pressure (In EC3 Mode)

Outside Air Humidity B7 Actual 0-100 %RH

Not Used (In CDSS Mode) or Suction Pressure

(In EC3 Mode)

Mixed Air Temperature B9 Actual -999.9-999.9 °F / °C

Supply Air Temperature B10 Actual -999.9-999.9 °F / °C

Digital Inputs:

Main Status Screen Input/Output Digital Inputs

The following table describes the menu parameters (Note: Change in shading indicates change to next s c reen):

PARAMETER DESCRIPTION INPUT FACTORY VALUE RANGE UNITS

High Pressure ID1 Actual C/O Normally Closed

Low Pressure ID2 Actual C/O Normally Closed

Supply Fan Air Flow Switch ID3 Actual C/O Closed Fan On

Smoke Detector ID4 Actual C/O Normally Closed

Filter Dirty ID5 Actual C/O Normally Open

Damper End Switch ID6 Actual C/O Cls = Damp. Open

Occupied ID7 Actual C/O Cls = Occupied

Not Used In CDSS Mode or

Digital Compressor EC3 Alarm (In EC3 Mode)

Condensate Pan Float ID9 Actual C/O Normally Closed

Gas Valve 1 ID10 Actual C/O Cls = Valve Open

Gas Valve 2 ID11 Actual C/O Cls = Valve Open

Freeze Stat ID12 Actual C/O Not Used

Supply Fan Door Switch ID13 Actual C/O Cls = Door Closed

Remote On Off ID14 Actual C/O Cls = Unit On

Supply Fan Speed 2 or Damper Position 2 ID15 Actual C/O See Setpoints

Supply Fan Speed 3 or Damper Position 2 ID16 Actual C/O See Setpoints

Exhaust Fan Air Flow Switch ID17 Actual C/O Closed on Fan On

(continued on next page)

B3 Actual 0-4 “WG

B6 Actual

B8 Actual 0-500 PSIG

ID8 Actual C/O Normally Closed

-999.9-999.9

0-650

°F / °C

PSIG

MODINE CONTROL SYSTEM MANUAL

Models MPR & ERM

24

MCP15-525.0

Input / Output Sub Menu (continued)

Analog Outputs:

Main Status Screen Input/Output Analog Outputs

The following table describes the menu parameters (Note: Change in shading indicates change to next s c reen):

PARAMETER DESCRIPTION OUTPUT FACTORY VALUE RANGE UNITS

Not Used (In CDSS Mode) or Compressor

Modulation (EC3 Mode)

Digital Compressor Control Signal to the EC3

Module

Condenser Fan

Control Signal to the Condenser Fan VFD Drive

Note: The screen below will only be displayed

if Dehumidification Control is Enabled

Supplemental Electric Heat (In CDSS Mode) or

Hot Gas Re-Heat (EC3 Mode)

Control Signal to the Modulating Hot Gas Re-Heat

Interface Board (In EC3 Mode)

Heat

Control Signal to Either the Modulating Gas

Valves or the Electric Heat SCR controller

Supply Fan

Control Signal for the Supply Fan VFD (Optional)

Digital Relay Outputs:

Main Status Screen Input/Output Digital Outputs

The following table describes the menu parameters (Note: Change in shading indicates change to next screen):

PARAMETER DESCRIPTION OUTPUT FACTORY VALUE RANGE UNITS

Supply Fan DO7 Actual On/Off Condenser Fans DO8 Actual On/Off Compressor 1 DO3 Actual On/Off Compressor 2 DO4 Actual On/Off Outside Air Damper Open DO5 Actual On/Off Outside Air Damper Closed DO6 Actual On/Off Electric Heat 3 DO1 Actual On/Off Electric Heat 4 DO2 Actual On/Off Gas or Electric Heat 1 DO9 Actual On/Off Gas or Electric Heat 2 DO10 Actual On/Off Hot Gas Re-Heat Stage 2 DO11 Actual On/Off Gas Heat 1 Exhaust Fan High DO12 Actual On/Off Gas Heat 2 Exhaust Fan High DO13 Actual On/Off Digital Compressor Valve (In CDSS Mode) or

Hot Gas Re-Heat Close Off Valve (EC3 Mode)

General Alarm DO15 Actual On/Off -

Return Air Damper Open (Optional) DO16 Actual On/Off -

Return Air Damper Close (Optional) DO17 Actual On/Off -

Exhaust Fan (Optional) DO18 Actual On/Off -

AO1 Actual 0-10 Volts DC

AO2 Actual 0-10 Volts DC

AO3 Actual 0-10 Volts DC

AO4 Actual 0-10 Volts DC

AO5 Actual 0-10 Volts DC

DO14

Actual

Actual

On/Off

On/Off

-

MODINE CONTROL SYSTEM MANUAL

Models MPR & ERM

MCP15-525.0

25

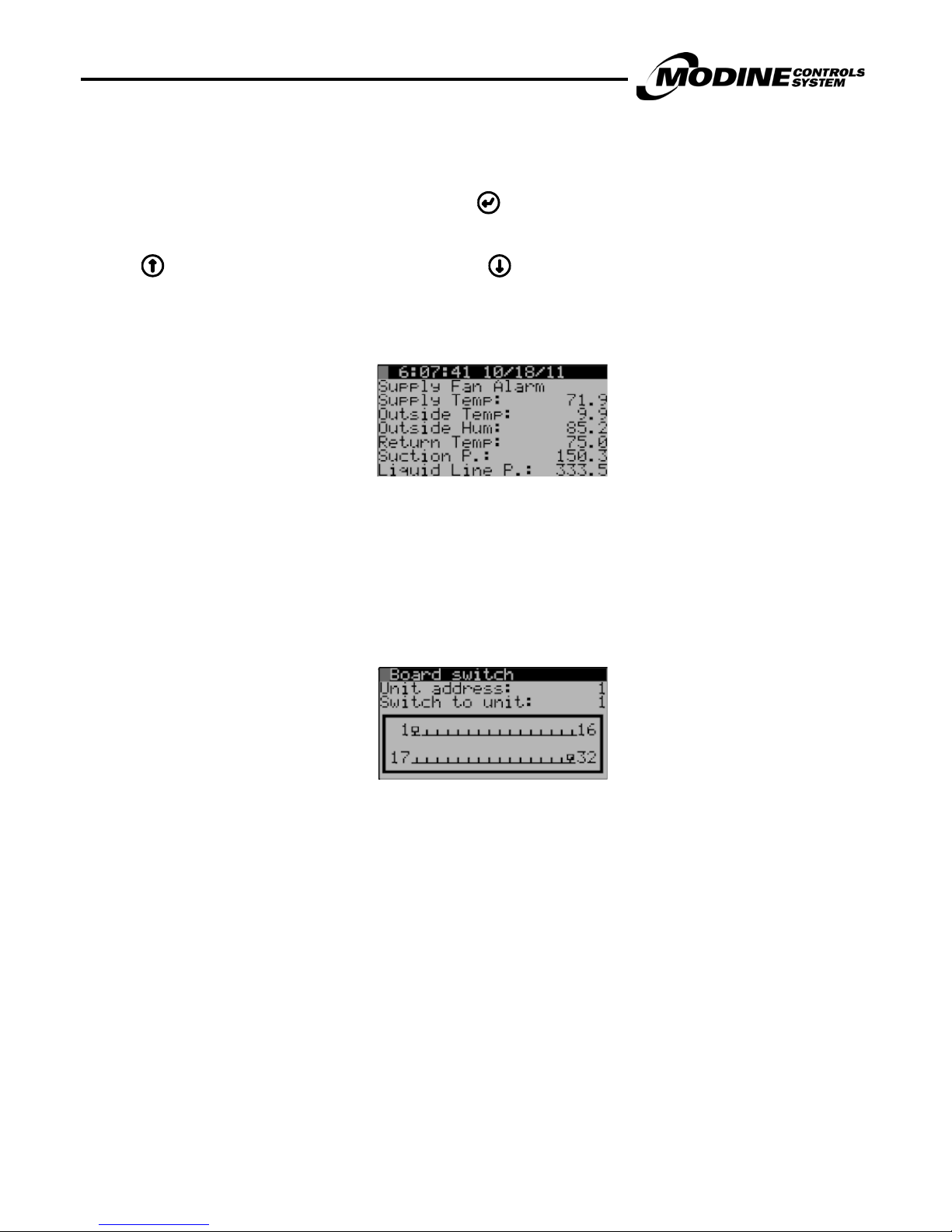

Data Logger Sub Menu

Main Status Screen Data Logger

To access contents of the Data Logger m enu simply press the button. The most recent alarm will be displayed on the screen.

The upper bar will display the time and date of the most recent alarm. The second line will indicate the alarm generated. The rest

of the page will contain readings of certain variables at the time of the alarm.

Use the button to navigate through previous alarms and the butt on to navigate to the most recent. The alarms are

chronologically stored and the most recent alarm will be the first di s pl ayed.

An example of an alarm log is shown bel ow:

Board Switch Sub Menu

Main Status Screen Board Switch

The Board Switch screen will indic ate the current devices connected to the pLAN network (Keypad, pAD Wall S tat, and/or ERM

unit). In the screen below, the main controller is on address 1.

The pCO

In the situation that module addresses need to be set up, the board address c an be c hanged within the Board Switch sub menu.

3

controller is factory defaulted to th e following for modules communicat ed with on the pLAN:

3

• pCO

• ERM Module: Address 2

• Remote Wall Stat (pAD): Address 4

• Superheat Control (EVD only): Address 30

• Remote Display (pGD1): Address 32

Controller: Address 1

MODINE CONTROL SYSTEM MANUAL

Models MPR & ERM

26

MCP15-525.0

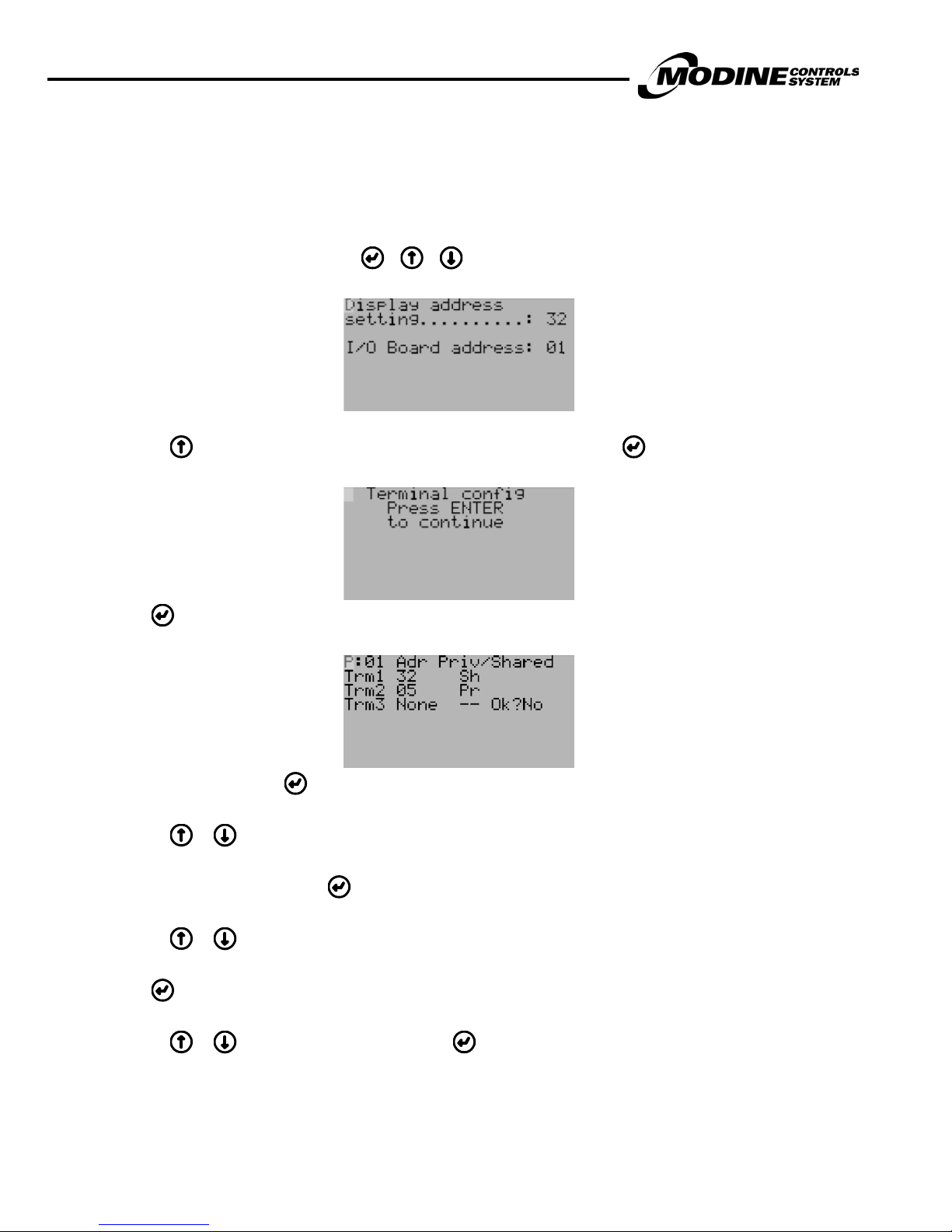

Programming the Remote Display Keypad to the Controller

In the situation that the terminal display address is required to be set up, t he following procedure applies:

1. Set the correct address on the display, connect to the controller and then power up the unit.

2. By simultaneously pressing a nd holding + + , the display will sh ow the Display Address screen.

3. Pressing will change the I/O board address to the controller address 1. Press to display the following screen:

4. Press again. The display will s how the following terminal configuration screen:

5. To select Terminal 1, press until the cursor is underneath Trm1 00 Pr.

6. Pressing or will change the 00 to the required value 32.

7. To set as Private or Shared, press until the cursor is underneath the Pr (PRIVATE) symbol.

8. Pressing or will change the Pr to Sh (SHARED) symbol. Pr For Normal – Sh if the unit has and ERM unit.

9. Press until the cursor is underneat h the NO.

10. Pressing or will change the NO to YE S. Press and the display is programmed.

MODINE CONTROL SYSTEM MANUAL

Models MPR & ERM

MCP15-525.0

27

PARA

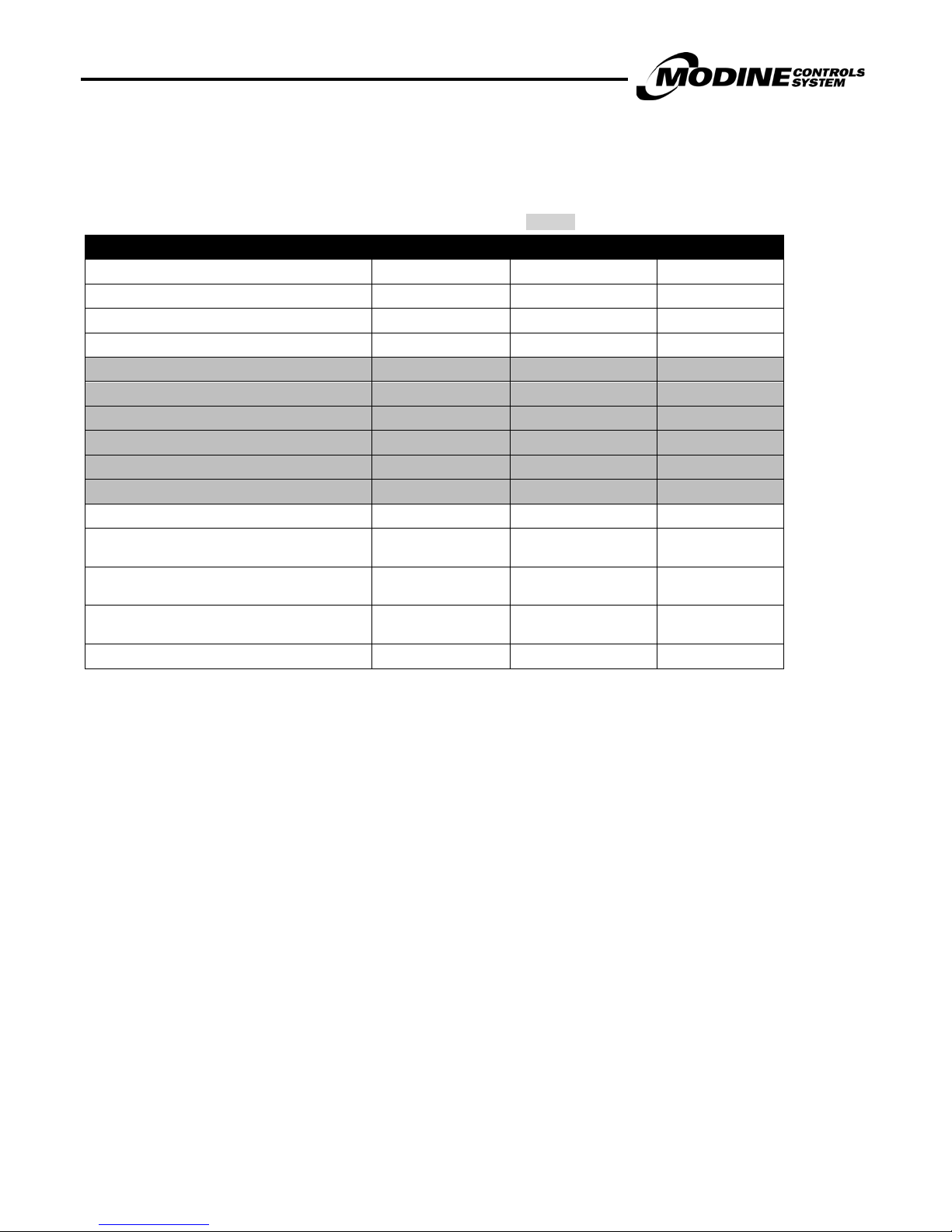

Service Sub Menu

Information

Main Status Screen Service Information

The following table describes the menu parameters (Note: Change in shading indicates change to next screen):

METER DESCRIPTION FACTORY VALUE RANGE UNITS

Code (Name of Program) Actual Value - -

Software Version Actual Value - -

Bios Version Actual Value 0 – 99.99 -

Boot Version Actual Value 0 – 99.99 -

pCO Typ e pCO3 Large - -

Total flash Actual Value 0-9999 KB

RAM Actual Value 0-9999 KB

Built-In type Actual Value - -

T memory writes Actual Value - -

Main cycle Actual Value 0-9999 Cycle/s

Control Power Status - -

Last Off Time Actual Value

Last On Time Actual Value

Note: The screen below will only be displayed

if the unit is in CDSS mode

EVO Firmware Version Actual Value

(continued on next page)

MM/DD/YY –

HH:MM:SS

MM/DD/YY –

HH:MM:SS

MODINE CONTROL SYSTEM MANUAL

Models MPR & ERM

28

MCP15-525.0

Service Sub Menu (continued)

Working Hours

Main Status Screen Service Working Hours

The following table describes the menu parameters (Note: Change in shading indicates change to next s c reen):

PARAMETER DESCRIPTION FACTORY VALUE RANGE UNITS

Supply Fan Hours Actual Value 0-999,999 Hours

Supply Fan Number of Starts Actual Value 0-999,999 Compressor 1 Hours Actual Value 0-999,999 Hours

Compressor 1 Number of Starts - 0-999,999 Compressor 2 Hours Actual Value 0-999,999 Hours

Compressor 2 Number of Starts - 0-999,999 -

Note: The following three screens will only

be displayed if Gas Heat is enabled

Heat Exhaust Fan 1 Hours Actual Value 0-999,999 Hours

Heat Exhaust Fan 1 Number of Starts - 0-999,999 Heat Exhaust Fan 2 Hours Actual Value 0-999,999 Hours

Heat Exhaust Fan 2 Number of Starts - 0-999,999 Gas Heat 1 Hours Actual Value 0-999,999 Hours

Gas Heat 1 Number of Starts - 0-999,999 Gas Heat 2 Hours Actual Value 0-999,999 Hours

Gas Heat 2 Number of Starts - 0-999,999 -

Note: The following four screens will only

be displayed if Electric Heat is enabled

Electric Heat 1 Hours Actual Value 0-999,999 Hours

Electric Heat 1 Number of Starts - 0-999,999 Electric Heat 2 Hours Actual Value 0-999,999 Hours

Electric Heat 2 Number of Starts - 0-999,999 Electric Heat 3 Hours Actual Value 0-999,999 Hours

Electric Heat 3 Number of Starts - 0-999,999 Electric Heat 4 Hours Actual Value 0-999,999 Hours

Electric Heat 4 Number of Starts - 0-999,999 Exhaust Fan Hours Actual Value 0-999,999 Hours

Exhaust Fan Number of Starts - 0-999,999 -

Note: The following four screens will only

be displayed if the ERM Module is enabled

ERM Exhaust Fan Hours Actual Value 0-999,999 Hours

ERM Exhaust Fan Number of Starts - 0-999,999 ERM Wheel Hours Actual Value 0-999,999 Hours

ERM Wheel Number of Starts - 0-999,999 ERM Preheater Hours Actual Value 0-999,999 Hours

ERM Preheater Number of Starts - 0-999,999 -

(continued on next page)

MODINE CONTROL SYSTEM MANUAL

Models MPR & ERM

MCP15-525.0

29

PARAMETER DESCRIPTION

CAREL

9600

Service Sub Menu (continued)

BMS Configuration

Main Status Screen Service BMS Configuration ( requires password PW1)

The following table describes the menu parameters (Note: Change in shading indicates change to next screen):

FACTORY VALUE RANGE UNITS

NA

Lon

BACnet IP\Eth

Protocol

Note: The following three screens will only be displayed if

BACnet IP/Ethernet is selected and Enable Plugin is Yes.

The information set must be supplied by the controls

integrator.

Device Instance Actual Value 0-99,000 -

IP Address of the Device Actual Value 0.0.0.0 – 255.255.255.255 -

SubNet Actual Value 255.0.0.0 – 255.255.255.0 -

Gateway 0.0.0.0 – 255.255.255.255 DNS 1 Actual Value 0.0.0.0 – 255.255.255.255 -

DNS 2 Actual Value 0.0.0.0 – 255.255.255.255 -

Type IP

Function Read

Update No

Note: The following two screens will only be displayed if

BACnet MSTP is selected and Enable Plugin is Yes.

The information set must be supplied by the controls

integrator.

Device Instance Actual Value 0-99,000 -

BACnet MSTP

PCOLOAD

MODBUS

MODEM

The Modine Control System supports the

following Protocols:

Lon

BACnet IP/Eth

BACnet MSTP

IP

Ethernet

Read: Reads the settings from the card

Write: Write the setting to the card

Yes: Sends a Read or Write request to the

card (depending on the Function setting)

-

-

-

Baud Rate (of the MSTP Network) 38400

MAC Ad dres s (MSTP Station) 0 0-127

MaxMasters 0 0-127

MaxInfoFrames 0 1-99

Function Read

Update No

19200

38400

76800

Read: Reads the settings from the card

Write: Write the setting to the card

Yes: Sends a Read or Write request to the

card (depending on the Function setting)

bps

-

-

Loading...

Loading...