Modine Manufacturing 6-558.6 User Manual

6-558.6

P/N 5H72256A Rev. F

October, 2002

INSTALLATION AND SERVICE MANUAL

separated combustion

high efficiency

gas-fired unit heaters

models PSH & BSH

All models approved for use in California by the CEC (when

equipped with IPI), in New York by the MEA division, and in

Massachusetts. Unit heater is certified for non-residential

applications.

WARNING

Improper installation, adjustment, alteration, service or

maintenance can cause property damage, injury or death,

and could cause exposure to substances which have been

determined by various state agencies to cause cancer, birth

defects or other reproductive harm. Read the installation,

operating and maintenance instructions thoroughly before

installing or servicing this equipment.

FOR YOUR SAFETY

The use and storage of gasoline or other flammable vapors

and liquids in open containers in the vicinity of this appliance

is hazardous.

Contents

Inspection on arrival . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Performance data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Dimensional data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Checking input rate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Propeller heaters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Service instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Troubleshooting guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Motor data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Control options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Rating plate identification . . . . . . . . . . . . . . . . . . . . . . . . . 27

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Back cover

Page

FOR YOUR SAFETY

If you smell gas:

1. Open windows

2. Don't touch electrical switches.

3. Extinguish any open flame.

4. Immediately call your gas supplier.

THIS MANUAL IS THE PROPERTY OF THE OWNER.

PLEASE BE SURE TO LEAVE IT WITH THE OWNER WHEN

YOU LEAVE THE JOB.

CAUTION

To prevent premature heat exchanger failure do not locate

ANY gas-fired units in areas where chlorinated, halogenated

or acid vapors are present in the atmosphere.

Inspection on Arrival

1. Inspect unit upon arrival. In case of damage, report

immediately to transportation company and your local

Modine sales representative.

2.

Check rating plate on unit to verify that power supply meets

available electric power at the point of installation.

3. Inspect unit received for conformance with description of

product ordered (including specifications where applicable).

Heater Parts from ACF Greenhouses

INSTALLATION

SPECIAL PRECAUTIONS

THE INSTALLATION AND MAINTENANCE INSTRUCTIONS

IN THIS MANUAL MUST BE FOLLOWED TO PROVIDE

SAFE, EFFICIENT AND TROUBLE-FREE OPERATION. IN

ADDITION, PARTICULAR CARE MUST BE EXERCISED

REGARDING THE SPECIAL PRECAUTIONS LISTED

BELOW. FAILURE TO PROPERLY ADDRESS THESE

CRITICAL AREAS COULD RESULT IN PROPERTY

DAMAGE OR LOSS, PERSONAL INJURY, OR DEATH.

1. Disconnect power supply before making wiring

connections to prevent electrical shock and equipment

damage. All units must be wired strictly in accordance

with wiring diagram furnished with the unit.

2. Turn off all gas before installing unit heaters.

3. Gas pressure to unit heater controls must never exceed

14" W.C. (1/2 psi).

When leak testing the gas supply piping system, the unit

and its combination gas control must be isolated during

any pressure testing in excess of 14" W.C. (1/2 psi).

The unit should be isolated from the gas supply piping

system by closing its field installed manual shut-off valve.

4. Check gas inlet pressure at unit upstream from

combination gas control. The inlet pressure should be 6" 7" W.C. on natural gas or 11" - 14" W.C. on propane gas.

Purging of gas piping should be performed as described

in ANSI Z223.1 - Latest Edition or in Canada in

CAN/CGA-B149 codes.

5. All units must be supplied with both combustion air and

exhaust piping to the outdoors.

6. Do not install in potentially explosive or flammable

atmospheres laden with grain dust, sawdust, or similar airborne materials. In such applications, a blower type heater

installed in a separate room with ducting, including

appropriate back flow prevention dampers to the dustladen room, is recommended.

7. Installation of units in high humidity or salt water

atmospheres will cause accelerated corrosion resulting in

a reduction of the normal life span of the units.

d

8. To prevent premature failure

unit heaters in areas where chlorinated, halogenated or

acid vapors are present in the atmosphere.

9. Maintain separation between units so discharge from one

unit will not be directed into the inlet of another.

10. Do not install unit outdoors.

11. Minimum clearance to combustibles is 12 inches from the

bottom; 18 inches from the sides; 6 inches from the top

and vent connector.

12. Allow at least 6" clearance at the sides and 12" clearance

at rear (or 6" beyond end of fan motor at rear of unit,

whichever is greater) to provide ample air for combustion

and proper operation of fan.

13. The minimum distance from combustible material is based

on the combustible material surface not exceeding 160°F.

Clearance from the top of the unit may be required to be

greater than 6" if heat damage, or other than fire, may

occur to materials above the unit heater at the

temperature described.

14. Do not install units below 7 feet, measured from the

bottom of the unit to the floor, unless properly guarded to

provide protection from moving parts.

15. Modine units are designed for use in heating applications

with ambient temperatures between 32°F and 90°F. If an

application exists where ambient temperatures can be

o not located ANY gas-fired

expected to fall outside of the is range, contact factory

for recommendations.

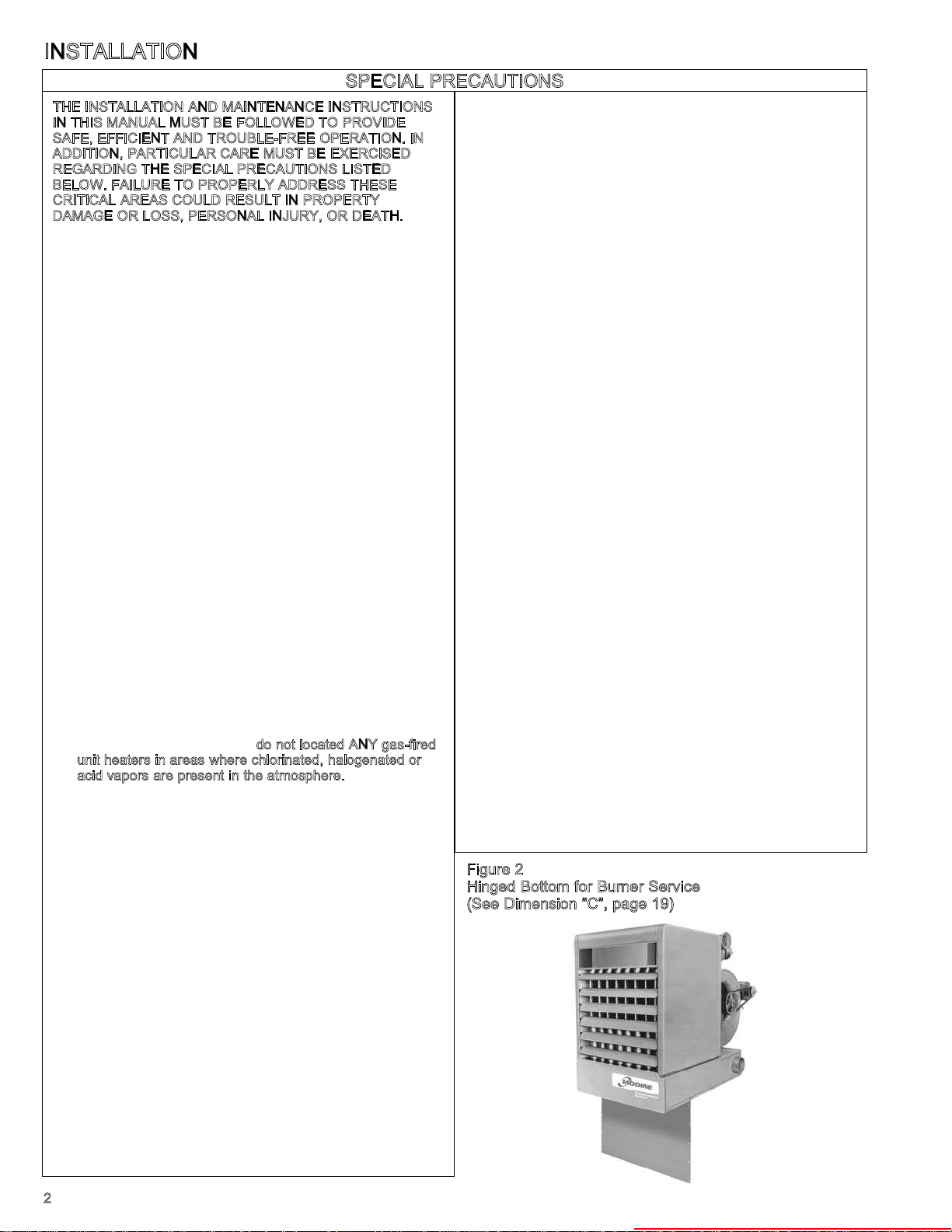

16. Provide clearance for opening hinged bottom pan for

servicing. See Figure 2. Do not set unit on its bottom.

17. To assure that flames do not impinge on heat exchanger

surfaces, the unit must be suspended in a vertical and

level position. Failure to suspend unit properly may

shorten the life of the unit heater.

18. Do not life unit by power exhauster.

19. Be sure no obstructions block air intake and discharge of

unit.

20. Do not attach duct work, air filters, or polytubes to any

propeller (PSH) model unit.

21. In aircraft hangars, keep the bottom of the unit at least

10' from the highest surface of the wings or engine

enclosure of the highest aircraft housed in the hanger

and in accordance with the requirements of the enforcing

authority and/or NFPA No. 409 — Latest Edition.

22. In garages or other sections of aircraft hangars such as

offices and shops that communicate with areas used for

servicing or storage, keep the bottom of the unit at least

7' above the floor unless the unit is properly guarded to

provide user protection from moving parts. In parking

garages, the unit must be installed in accordance with

the standard for parking structures ANSI/NFPA 88A, and

in repair garages the standard for repair garages NFPA

#88B. In Canada, installation of unit heaters in airplane

hangars must be in accordance with the requirements of

the enforcing authority, and in public garages in

accordance with the current CAN/CGA-B149 codes.

23. Consult piping, electrical, and venting instructions in this

manual before final installation.

24. All literature shipped with your unit should be kept for

future use for servicing or service diagnosis. Do not

discard any literature shipped with your unit.

25. When servicing or repairing this equipment, use only

Modine-approved service replacement parts. A complete

replacement parts list may be obtained by contacting

Modine Manufacturing Company. Refer to the rating

plate on the unit for complete unit model number,

serial number and company address. Any substitution

of parts or controls not approved by Modine will be at

owners risk.

Figure 2

Hinged Bottom for Burner Service

(See Dimension “C”, page 19)

2

Heater Parts from ACF Greenhouses

INSTALLATION

Product Description

Modine PSH and BSH model unit heaters are listed as separated

combustion unit heaters and are defined as follows: A unit heater

for installation in non-residential structures which, when connected

to a sealed combustion air pipe and sealed exhaust vent, supplied

by the installer, constructed so that when installed according to the

manufacturer’s instructions, air for combustion is derived from the

outside atmosphere and the flue gases from the appliance are

discharged to the outside atmosphere and the flue gases from the

appliance are discharged to the outside atmosphere.

In the U.S., the installation of these units must comply with the

“National Fuel Gas Code,” ANSIZ223.1, latest edition (also known

as NFPA 54) and other applicable local building codes.

In Canada, the installation of these units must comply with local

plumbing or waste water codes and other applicable codes and

with the current code CAN/CGA-B149.1, “Installation Code for

Natural Gas Burning Appliances and Equipment” or CAN/CGAB149.2, “Installation Code for Propane Burning Appliances and

Equipment.”

1. All installation and service of these units must be performed by

a qualified installation and service agency only as defined in

ANSIZ223.1, latest edition or in Canada by a licensed gas fitter.

2. This unit is certified by C.S.A., with the controls furnished. For

replacement parts, submit the complete model, control code

and serial number shown on rating plate on the unit, Modine

reserves the right to substitute other authorized controls as

replacements.

3. Unit is balanced for correct performance. Do not alter fan or

operate motors at reduced speed.

4. Information on controls is supplied separately.

5. Modine unit heaters use the same burner for natural and

propane gases.

L

ocating Unit Heaters

CAUTION

Units must not be installed in potentially explosive, flammable or

corrosive atmosphere.

To prevent premature heat exchanger failure do not locate ANY

gas-fired unit in areas where chlorinated, halogenated or acid

vapors are present in the atmosphere.

In locating units, consider general space-heating requirements,

availability of gas, and proximity to vent locations. Unit heaters

should be located so heated air streams wipe exposed walls

without blowing directly against them. In multiple unit installations,

arrange units so that each supports the sir stream from another,

setting up circulatory air movement in the area. In buildings

exposed to prevailing winds, a large portion of the heated air

should be directed along with windward wall. Avoid interference of

air streams as much as possible.

Mounting height (measured from bottom of unit) at which unit

heaters are installed is critical. Maximum mounting heights for

standard units are listed in Tables 7 and 8 on page 18. Alternate

mounting heights for units with deflector hoods or nozzles are

shown on pages 10 and 12.The maximum mounting heights for

any unit is that heights above which the unit will not deliver heated

air to the floor.The maximum mounting heights must not be

exceeded in order to assure maximum comfort.

Motors and controls used on Modine unit heaters are designed for

use in ambient temperatures between 32°F and 90°F. If an

application exists where ambient temperatures can be expected to

fall outside of this range, contact factory for recommendations.

C

ombustion Air Requirements

Modine models PSH and BSH separated combustion units are

designed to receive air for combustion directly from the outside

atmosphere via field installed combustion air piping between the

unit and the outside atmosphere.

unit must be connected to the outside atmosphere.

The maximum equivalent length of combustion air piping cannot

exceed 30 feet. Keep this limitation in mind when locating units.

See page 5 for combustion air piping instructions.

U

nit Suspension

T

he combustion air inlet of the

CAUTION

Minimum clearance to combustibles is 12 inches from the

bottom; 18 inches from the sides; 6 inches from the top and vent

connector.

Allow at least 12" at the rear of unit or 6" beyond the end of the

motor (Whichever is greater) to provide ample air for proper

operation of fan.

Provide clearance for opening hinged bottom of servicing. See

Figure 2.

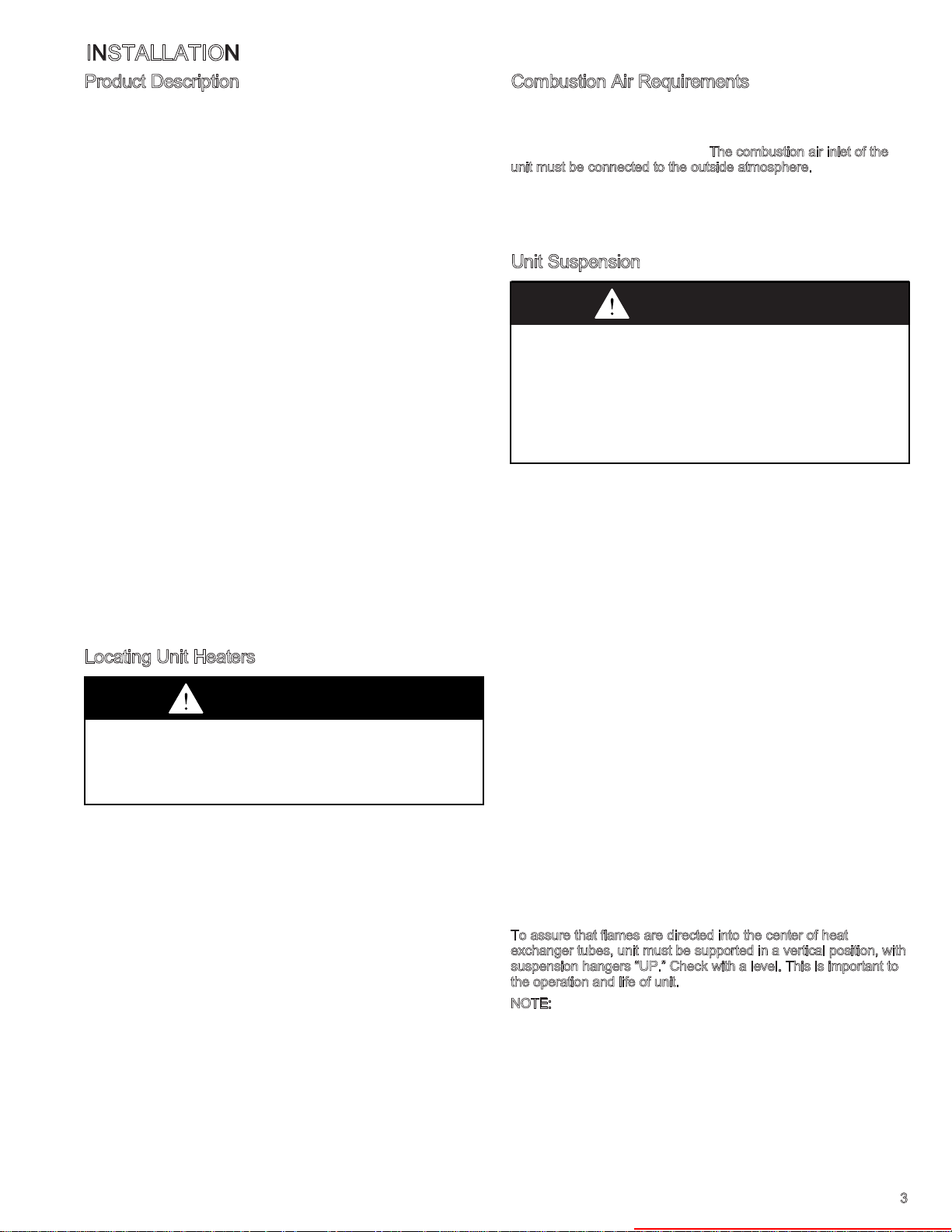

Be sure the means of suspension is adequate to support the

weight of the unit. (See page 19 for unit weights.) For proper

operation, the unit must be installed in a level horizontal position.

Clearances to combustibles as specified above must be strictly

maintained.

On all propeller units except the PSH280 and PSH340, two tapped

holes (3/8 - 16) are located in the top of the unit to receive ceiling

hangers. Units with two point suspension, models PSH130 through

PSH225, incorporate a level hanging feature. Depending on what

options and accessories are being used, the heater may not hang

level as received from the factory. Do not hang heaters with

deflector hoods until referring to the "installation manual for

deflector hoods" and making the recommended preliminary

adjustments on the heater.These preliminary adjustments need to

be made with the heater resting on the floor.

PSH130 through PSH225 units without deflector hoods that do not

hang level after being installed, can be corrected in place. Simply

remove both outer side panels (screws to remove are on back

flange of side panel) and you will see the (adjustable) mounting

brackets (Figure 3). Loosen the set screws holding the mounting

brackets in place and using a rubber mallet or something similar,

tap the heater into a position where it does hang level. Re-tighten

set screws and replace the outer side panels.

The PSH280 and PSH340 have four mounting holes. On all blower

units, except the BSH280 and BSH340, two tapped holes are

provided in the top of the unit and two holes in the blower support

bracket. The BSH280 and BSH340 have four tapped holes in the

top of the unit and two in the blower support bracket for mounting.

T

o assure that flames are directed into the center of heat

exchanger tubes, unit must be supported in a vertical position, with

suspension hangers “UP.” Check with a level. This is important to

the operation and life of unit.

NOTE:

Pipe hanger adapter kits, as shown in Figure 3, are

available as accessories from Modine. The hardware allows for

pipe caps to be secured into the top of the unit heater with

machine screws (as illustrated - machine screws are 3/8 - 16 x

1.75 UNC-2A THD). The pipe caps can then accommodate 3/4"

NPT pipe for mounting. Three different kits are available with either

2, 4, or 6 adapters per kit. See price sheet to determine proper kit.

3

Heater Parts from ACF Greenhouses

INSTALLATION

Figure 2

Suspension Methods

Remove Side Panels

to Adjust Mounting Brackets

(Suspension w/ Pipe Adapter Kit)

Venting

General Venting and Combustion Air

Instructions

CAUTION

Gas-fired heating equipment must be vented — do not operated

unvented.

A built-in power exhauster is provided — additional external

draft hoods (diverters) or power exhausters are not required or

permitted.

Installation must conform with local building codes or in the

absence of local codes, with the National Fuel Gas Code, ANSI

Z223.1 (NFPA 54) — Latest Edition. In Canada installation must

be in accordance with CAN/CGA-B149.1 for natural gas

appliances, and CAN/CGA-B149.2 for propane appliances.

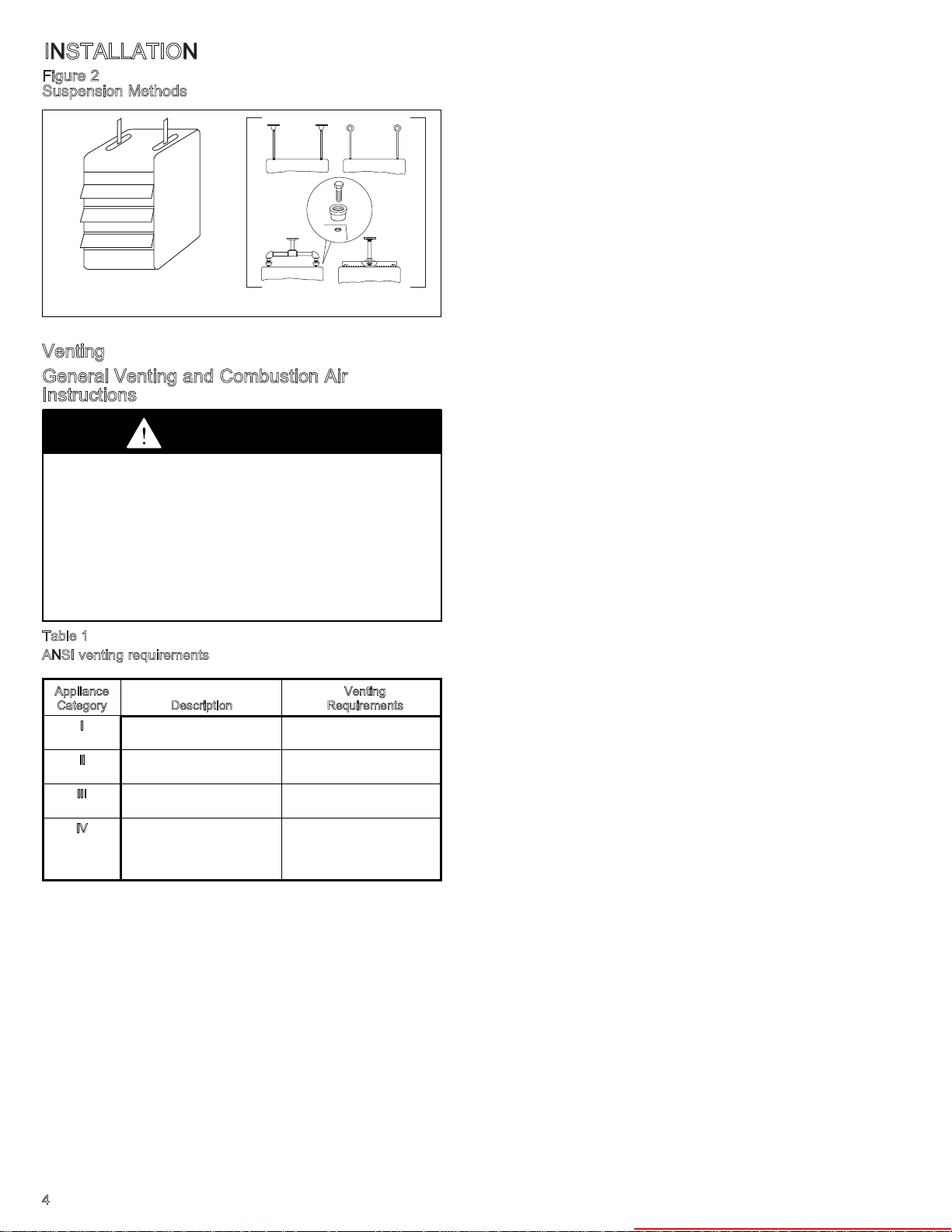

Table 1

ANSI venting requirements

Appliance Venting

Category Description Requirements

I

I

I

II

I

I

V

1. Table 1 summarizes the ANSI venting requirements for the

various appliance categories. All PSH/BSH models are

category III appliances. The venting requirements for a

category III appliance are included in these instructions.

2. Select the size of vent and combustion air pipe that fits the

power exhauster and combustion air intake on the rear of

the appliance (see pages 14 and 15 for dimensions). Do

not use a vent or combustion air pipe smaller than the size

of the outlet or inlet on the appliance. The pipe should be

single wall galvanized steel or other suitable corrosion

resistant material. Follow the National Fuel Gas Code for

minimum thickness of vent material. The minimum

thickness for connectors varies depending on the pipe

diameter.

3. A minimum of 12 inches straight pipe is recommended from

the power exhauster outlet before turns in the vent pipe.

Negative vent pressure Follow standard venting

Non-condensing requirements.

Negative vent pressure Condensate must be

Condensing drained.

Positive vent pressure Vent must be gastight.

Non-condensing

Positive vent pressure Vent must be liquid and

Condensing gastight.

Condensate must be

drained.

4. Install the vent and combustion air pipes with a downward

slope from the appliance of 1/4 inch per foot and suspend

securely from overhead structures at points no greater than

3 feet apart. Fasten individual lengths of vent together with

at least three corrosion resistant sheet metal screws.

5. Keep the vent pipe at least 6 inches from combustible

material. The minimum distance from combustible material

is based on the combustible material surface not exceeding

160F. Clearance from the vent pipe (or the top of the unit)

may be required to be greater than 6 inches if heat damage

other than fire (such as material distortion or discoloration)

could result.

6. Avoid venting through unheated space when possible.

When venting does pass through an unheated space,

insulate runs greater than 5 feet to minimize condensation.

Inspect for leakage prior to insulating and use insulation

that is noncombustible with a rating of not less than 350F.

Install a tee fitting at the low point of the vent system and

provide a drip let with a clean out cap as shown in figure

01. The drip leg should be cleaned annually.

7. When the vent passes through an INTERIOR wall or floor, a

metal thimble 4 inches greater than the vent diameter is

necessary. If there is 6 feet or more of vent pipe in the

open space between the unit heater and where the vent

pipe passes through the wall or floor, the thimble need only

be 2 inches greater than the diameter of the vent pipe. If a

thimble is not used, all combustible material must be cut

away to provide a 6 inches clearance. Any material used to

close the opening must be noncombustible.

8. Limit the total equivalent vent pipe length to a minimum of 5

feet and a maximum of 30 feet, making the vent system as

straight as possible. (The equivalent length of a 4 inch

elbow is 5 feet and a 6 inch elbow is 10 feet).

9. Seal the joints with a metallic tape suitable for temperatures

up to 350F. (3M tapes 433 or 363 are acceptable.) Wrap

the tape two full turns around the vent pipe.

10. Do NOT vent this appliance into a masonry chimney.

11. Do NOT use dampers or other devices in the vent or

combustion air pipes.

12. The venting system must be exclusive to a single appliance,

and to other appliance is allowed to be vented into it.

13. Long runs of horizontal or vertical combustion air pipes may

require insulation in very cold climates to prevent the

buildup of condensation on the outside of the pipe where

the pipe passes through conditioned spaces.

14. Vertical combustion air pipes should be fitted with a tee with

a drip leg and a clean out cap to prevent against the

possibility of any moister in the combustion air pipe from

entering the unit. The drip leg should be inspected and

cleaned periodically during the heating season.

15. When condensation may be a problem, the vent system

shall not terminate over public walkways or over an area

where condensate or vapor could create a nuisance or

hazard or could be detrimental to the operation of regulator,

relief openings or other equipment.

16. Precautions must be taken to prevent degradation of

building materials by flue products.

17. The vent cap for vertically vented appliances should extend

above any portion of a building within a horizontal distance

of 2 feet. Refer to figures 7 and 8.

4

Heater Parts from ACF Greenhouses

INSTALLATION

Venting Instructions for Concentric Vent

Options

The concentric vent concept allows for the vent pipe and the

combustion air pipe to pass through one hole in an

EXTERIOR wall or roof. The concentric vent kits offered are

horizontal or vertical. Venting with 2 pipes; a combustion air

pipe and flue product vent pipe remains an option, primarily

for replacement heaters where two holes through the exterior

of a building already exist.

When utilizing the concentric vent option, you have already

pre-determined whether the unit heater will be horizontal vent

or vertical vent and have received the appropriate kit. At this

time, you need to verify that you have all the components

required for the venting option chosen. The components for

each kit are as follows:

Horizontal Concentric Vent Kit:

• concentric adapter assembly

• specially designed vent termination cap

• specially designed inlet air guard

Vertical Concentric Vent Kit:

• concentric adapter assembly

• standard Briedert Type L or Gary Steel 1092 vent

termination cap

• specially designed inlet terminal

Although the first installation you will make will be the

concentric adapter assembly, you should now

the instructions for the type of venting option you’ve already

chosen - i.e. horizontal concentric, vertical concentric, 2 pipe

horizontal or 2 pipe vertical. These instructions can be found

on pages 5, 6,or 7 of these installation instructions. After

reading your specific instructions, come back to “Installing the

Concentric Vent Adapter Box” section and begin.

“

read ahead”

F

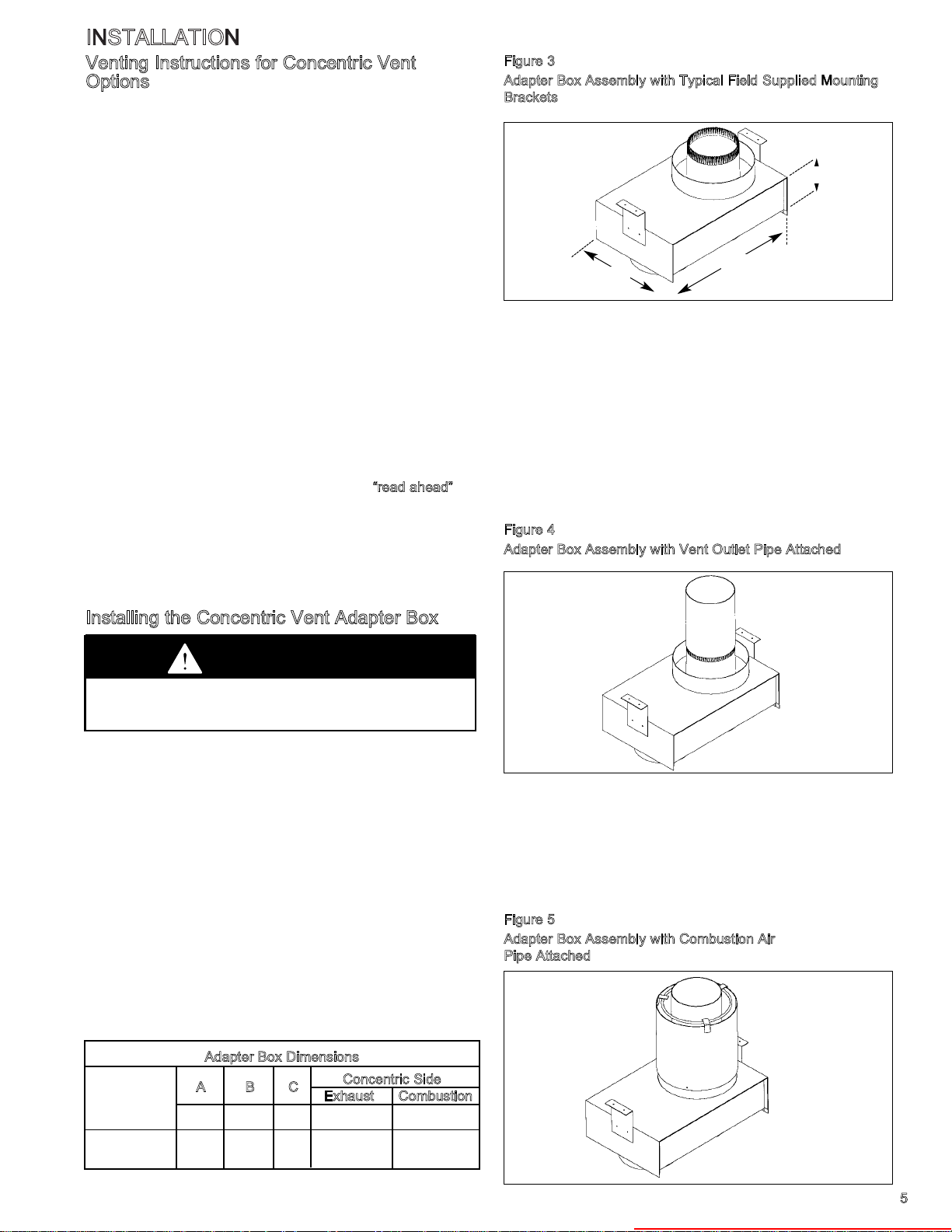

igure 3

Adapter Box Assembly with Typical Field Supplied Mounting

Brackets

C

A

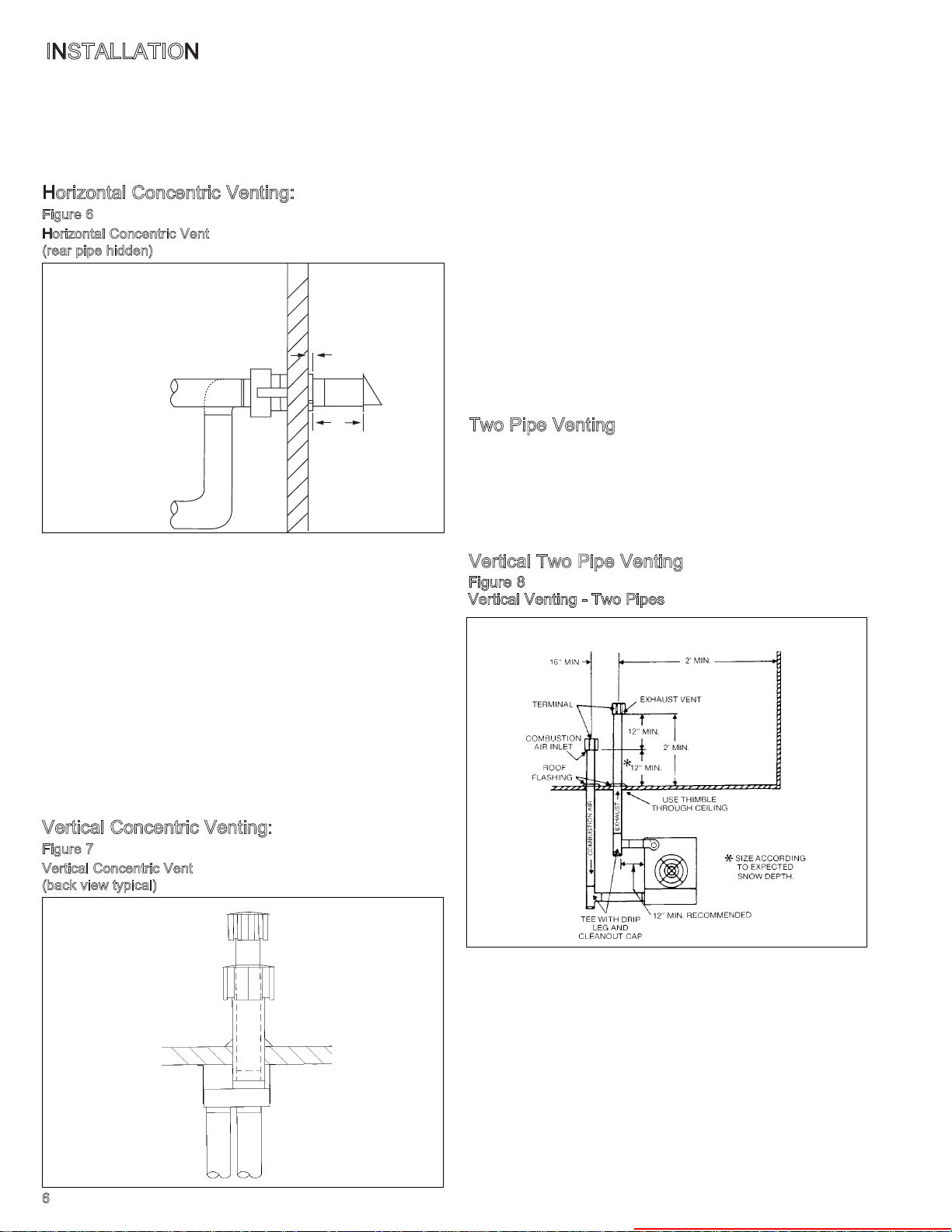

4. Determine the appropriate length of vent pipe that must be

attached to the vent outlet (the concentric side) of the box.

Refer to the following sections for the minimum length of

vent pipe to be used for the method of venting (vertical or

horizontal). Make sure to add the length of the field

supplied brackets if used, and the thickness of the wall or

roof.

5. Cut the vent pipe to the proper length and attach it to the

vent outlet of the concentric vent adapter box using at

least 3 corrosion resistant sheet metal screws. Seal this

joint using metallic tape suitable for temperatures up to

350° F. Wrap the tape two full turns around the vent pipe.

See figure 4.

F

igure 4

Adapter Box Assembly with Vent Outlet Pipe Attached

B

I

nstalling the Concentric Vent Adapter Box

CAUTION

The concentric vent adapter box must be installed inside of

the structure or building. Do not install this box on the

exterior of a building or structure.

1. Determine the location of the box. Refer to the instructions

in the following sections for the method of venting to be

used (vertical or horizontal). Maintain all clearances as

listed in these instructions.

2. This box can be mounted flush to the wall or roof, or the

box can be offset from the wall or roof by using field

supplied brackets. When mounting the box, consider

serviceability and access to the vent and combustion air

pipes.

3. If the box is to be mounted using field supplied brackets,

these brackets must be strong enough to rigidly secure

the box to the wall or roof, and should be made from

corrosion resistant material. After determining the length

of the field supplied brackets, attach them to the sides of

the box using several corrosion resistant sheet metal

screws. See figure 3 for typical installation and brackets.

Adapter Box Dimensions

Concentric Side

Exhaust Combustion

Heater Sizes

130-225 8

Heater Sizes

280-340

A B C

1

/4" 113/4" 4" 4" 6"

101/2" 16" 4" 6" 8"

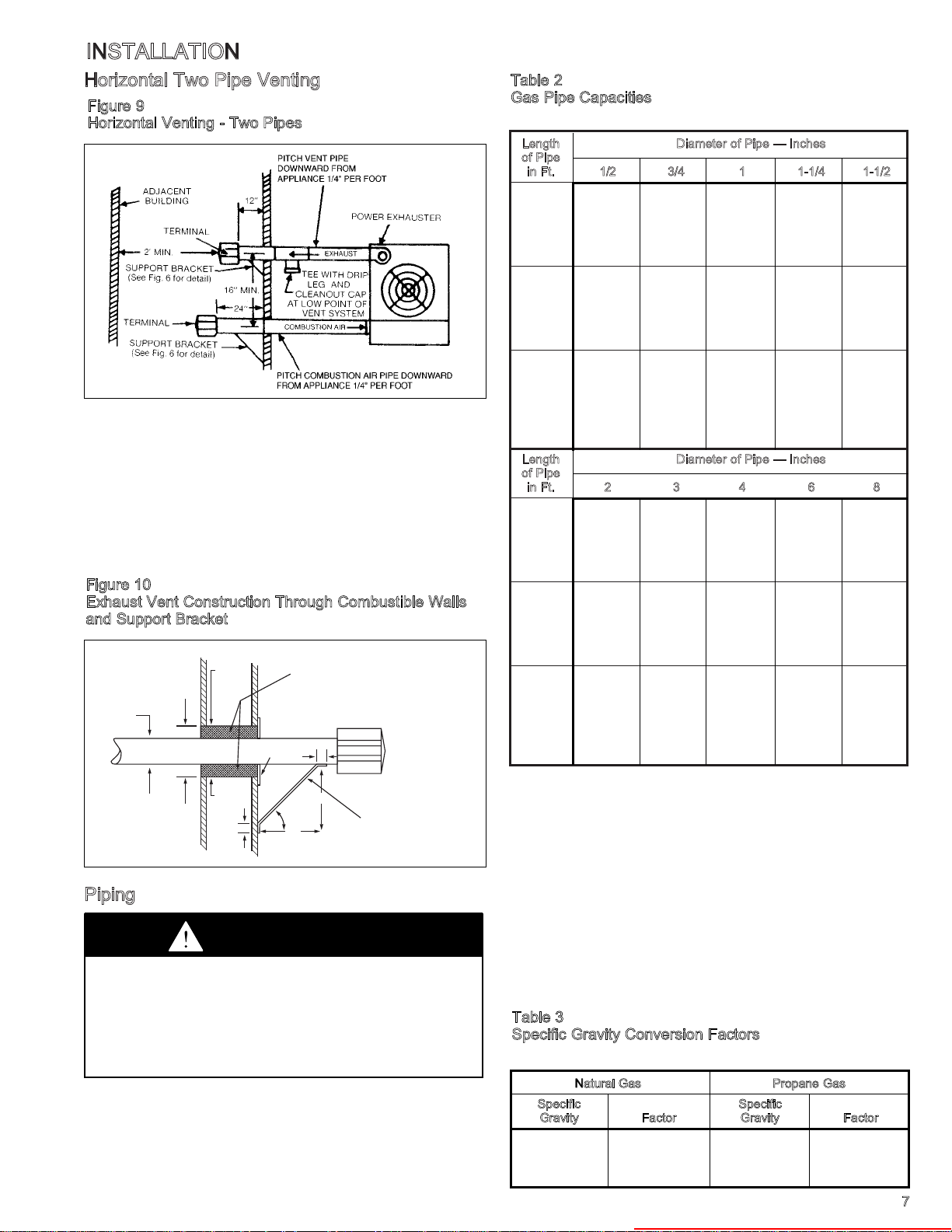

6. Determine the length of the combustion air pipe to extend

through the wall. Refer to the following sections for the

minimum length of combustion air pipe to be used for the

method of venting being used, vertical or horizontal. Cut

the pipe to the proper length.

7. Slide the combustion air pipe over the vent pipe. Attach

the combustion air pipe to the adapter box using at least 3

non corrosive sheet metal screws. See figure 5.

F

igure 5

Adapter Box Assembly with Combustion Air

Pipe Attached

5

Heater Parts from ACF Greenhouses

INSTALLATION

T

8. Place this assembly (the adapter box, vent pipe and

combustion air pipe) through the wall or roof and verify that

the distance requirements as defined in the following

sections are met. Securely attach the assembly (adapter

box and vent and combustion air pipe) to the wall or roof

using appropriate fasteners.

H

orizontal Concentric Venting:

Figure 6

Horizontal Concentric Vent

(rear pipe hidden)

1"

To Exhaust

1. The vent must terminate with a Gary Steel Model 1092 or

Briedert Type L cap for the appropriate pipe size.

2. The combustion air pipe must terminate with the cap

supplied by the manufacturer. This cap is specially

designed to work with the concentric vent system. Refer to

the parts list on page 5 for the appropriate part.

3. The bottom of the air intake pipe must terminate above the

snow line, or at least 12 inches above the roof, which ever

distance is greater.

4. The bottom of the vent cap must terminate at least 6 inches

above the top of the air intake cap.

5. To attach the caps, slide the combustion air cap over the

vent pipe and fasten it to the combustion air pipe with at

least 3 non corrosive fasteners. Then, attach the vent cap

to the vent pipe, also using at least 3 non corrosive

fasteners.

6. Caulk the gap between the combustion air cap and the vent

pipe with silicone sealant, or other appropriate sealants

suitable for metal to metal contact and for temperatures of

350° F.

12"

o Combustion

Air Inlet

1. The vent pipe must terminate with the terminal supplied by

the manufacture for horizontal venting. Refer to the parts

list on page 5 for the appropriate part.

2. The combustion air pipe must terminate at least 1 inch from

the wall. This will prevent water from running down the wall

and into the pipe and allows for easy installation of the

combustion air intake guard.

3. Caulk between the wall and the air intake pipe.

4. Maintain 12 inches from the combustion air inlet to the back

of the vent terminal.

5. Attach the combustion air intake guard using non corrosive

screws as shown in figure 5. This guard must be placed at

the end of the pipe on the exterior of the building. This

guard helps to prevent animals and debris from entering the

combustion air pipe.

V

ertical Concentric Venting:

Figure 7

Vertical Concentric Vent

(back view typical)

wo Pipe Venting

T

Two pipe venting refers to using two penetrations through an

exterior wall or roof. This method of venting is primarily used

for replacement heaters where two holes through the exterior of

a building exist. To vent using this method, either (2) Briedert

Type L caps or (2) Gary Steel Model 1092 caps provided with

your unit heater must be used. These caps are used for both

vertical and horizontal venting of the heater.

V

ertical Two Pipe Venting

Figure 8

Vertical Venting - Two Pipes

1. The bottom of the combustion air cap must be located

above the snow line or 12 inches above the roof, which ever

is greater.

2. The vent must terminate at least 1 foot above and 16

inches horizontally from the combustion air inlet.

3. When the vent passes through a combustible roof, a metal

thimble 4 inches greater than the vent diameter is

necessary. If there is 6 feet or more of vertical vent pipe in

the open space between the unit heater and where the vent

pipe passes through the roof, the thimble need only be 2

inches greater than the diameter of the vent pipe. If a

thimble is not used, all combustible material must be cut

away to provide a 6 inch clearance. Any material used to

close the opening must be noncombustible.

6

Heater Parts from ACF Greenhouses

INSTALLATION

Horizontal Two Pipe Venting

Figure 9

Horizontal Venting - Two Pipes

1. When horizontal vents pass through a combustible wall (up

to 8 inches thick), the vent passage must be constructed

and insulated as shown in Figure 10.

2. The termination of horizontally vented system must extend

12 inches beyond the exterior surface of an exterior wall.

3. The combustion air pipe must be a minimum of 16 inches

below the vent pipe, and 24 inches from the exterior wall.

4. Support the vent and combustion air pipe as shown in

Figure 10.

Figure 10

Exhaust Vent Construction Through Combustible Walls

and Support Bracket

PLATE

45

FIBER GLASS

INSULATION

MIN. 2"

1"

9"

9"

VENT TERMINATION

SUPPORT BRACKET

(where required)

(Make from 1" x 1" steel angle)

VENT PIPE

DIAMETER

iping

P

2" MIN.

2" MIN.

METAL

SLEEVE

METAL

SLEEVE

METAL FACE

1"

CAUTION

Gas pressure to unit heater controls must never exceed 14"

W.C. (1/2 psi).

When leak testing the gas supply piping system, the appliance

and its combination gas control must be isolated during any

pressure testing in excess of 14" W.C. (1/2 psi).

The appliance should be isolated from the gas supply piping

system by closing its field installed manual shut-off valve.

1. Installation of piping must be in accordance with local

codes, and ANSI Z223.1, “National Fuel Gas Code,” or

CAN/CGA-B149 in Canada.

2. Piping to units should conform with local and national

requirements for type and volume and gas handled, and

pressure drop allowed in the line. Refer to Table 5, to

determine the cubic feet per hour (cfh) for the type of gas

Table 2

Gas Pipe Capacities

In Cu. Ft. per Hour with Pressure Drop of 0.3 in W.C. with Specific Gravity 0.60.

Length Diameter of Pipe — Inches

of Pipe

in Ft. 1/2 3/4 1 1-1/4 1-1/2

15 76 218 440 750 1220

30 73 152 285 590 890

45 44 124 260 435 700

60 50 105 190 400 610

75 97 200 345 545

90 88 160 320 490

105 80 168 285 450

120 158 270 420

150 120 242 380

180 128 225 350

210 205 320

240 190 300

270 178 285

300 170 270

450 140 226

600 119 192

ength Diameter of Pipe — Inches

L

of Pipe

in Ft. 2 3 4 6 8

15 2480 6500 12880 38700 79000

30 1650 4700 9700 27370 55850

45 1475 3900 7900 23350 45600

60 1150 3250 6800 19330 39500

75 1120 3000 6000 17310 35300

90 930 2600 5400 15800 32250

105 920 2450 5100 14620 29650

120 860 2300 4800 15680 27920

150 710 2000 4100 12240 25000

180 720 1950 4000 11160 22800

210 660 1780 3700 10330 21100

240 620 1680 3490 9600 19740

270 580 1580 3250 9000 18610

300 545 1490 3000 8500 17660

450 450 1230 2500 7000 14420

600 380 1030 2130 6000 12480

and size of unit to be installed. Using this cfh value and the

length of pipe necessary, determine the pipe diameter from

Table 2. Where several units are served by the same main,

the total capacity, cfh, and length of main must be

considered. Avoid pipe sizes smaller than 1/2". Table 2

allows for the usual number of fittings with a 0.3; W.C.

pressure drop. Where the gas supplied has a specific

gravity other than 0.60, apply the multiplying factor as given

in Table 3.

3. After threading and reaming the ends, inspect piping and

remove loose dirt and chips.

4. Support piping so that no strains are imposed on unit or

controls.

5. Use two wrenches when connecting piping to unit controls.

Table 3

Specific Gravity Conversion Factors

Multiplying factors to be used with Table 1 when the specific gravity of gas is

other than 0.60.

Natural Gas Propane Gas

Specific Specific

Gravity Factor Gravity Factor

0.55 1.04 1.50 0.633

0.60 1.00 1.53 0.626

0.65 0.962 1.60 0.612

Heater Parts from ACF Greenhouses

7

INSTALLATION

6. Provide a drip pocket before each unit and in the line where

low spots cannot be avoided. (See Figure 7).

7. Take-off to unit should come fro top or side of main to avoid

trapping condensate.

8. Piping, subject to wide temperature variations, should be

insulated.

9. Pitch piping up toward unit at least 1/4" per 15' of horizontal

run.

10. Compounds used on threaded joints of gas piping must be

resistant to action of liquefied petroleum gases.

11. Purge air before lighting unit by disconnecting pilot tubing at

combination gas control.

into heat exchanger.

12. After installation, check system for gas leaks, using a soap

solution.

13. Install a ground joint union and a manual shut off valve

immediately upstream of the unit including a 1/8" NPT

plugged tapping accessible for test gage connection. (See

Figure 7).

14. Allow at least 5 feet of piping between any high pressure

regulator and unit control string.

15. When Pressure/Leak testing, pressures above 14'' W.C. (1/2

psi), close the field installed shut-off valve, disconnect the

appliance and its combination gas control from the gas

supply line, and plug the supply line before testing. When

testing pressures 14" W.C. (1/2 psi) or below, close the

manual shut-off valve on the appliance before testing.

Figure 7

Recommended Piping to Controls

GAS

SUPPLY LINE

GAS

SUPPLY LINE

3"

MIN.

I

n no case should line be purged

A manual shut off valve with

1/8' N.P.T. plugged tapping,

accessible for test gage

GROUND

JOINT

UNION

PLUGGED

1/8" NPT TEST

GAGE CONNECTION

connection must be installed

immediately upstream of the

gas supply connection to the

appliance.

TO

CONTROLS

The power to these units should be protected with a fused

disconnect. Units for use with three-phase electric power must

be provided with a motor starter having properly sized overload

protection.

Location of thermostat should be determined by heating

requirements and be mounted on an inside wall about 5' above

floor level . . . where it will not be affected by heat from the unit

or other sources, or drafts from frequently opened doors. See

instructions packed with thermostat.

I

nstallation of Blower Models (BSH Units)

CAUTION

Proper air flow and distribution, across the hat exchanger must

be provided to prevent early failure of the blower unit heater.

Attachment of Field Installed Ductwork,

Blower BSH Models Only

Burned-out heat exchanger and shorter equipment life will

result from not providing uniform air distribution.

CAUTION

Do not attempt to attach ductwork of any kind to propeller PSH

models.

When installing unit, always follow good duct design practices

for even distribution of the air across the heat exchanger.

Recommended layouts are shown below. When installing blower

units with ductwork, the following must be done.

P

rovide uniform air distribution over the heat exchanger.

1.

Use turning vanes where required. See figures below.

2. Provide removable access panels in the ductwork on the

downstream side of the unit. These openings should be

large enough to view smoke or reflect light inside the casing

to indicate leaks in the heat exchanger and to check for hot

spots on exchanger due to poor air distribution or lack of

sufficient air (cfm).

3. If ductwork is connected to the rear of the unit, use Modine

blower enclosure kit, or if using field designed enclosure,

maintain dimensions of proper blower enclosure as shown.

on page 19.

DRIP

POCKET

iring General

W

CAUTION

Disconnect power supply before making wiring connections to

prevent electrical shock and equipment damage. ALL UNITS

MUST BE WIRED STRICTLY IN ACCORDANCE WITH

WIRING DIAGRAM FURNISHED WITH UNIT.

ANY WIRING DIFFERENT FROM WIRING DIAGRAM MAY BE

HAZARDOUS TO PERSONS AND PROPERTY.

Any damage to or failure of Modine units caused by incorrect

wiring of the units is not covered by MODINE’S STANDARD

WARRANTY (see Back Cover).

All field installed wiring must be done in accordance with the

National Electrical Code ANSI/NFPA 70 — Latest Edition or

Canadian Electrical Code CSA C22.1 Part 1 or local codes.

Unit must be electrically grounded according to these codes.

See wiring diagram shipped with unit. For optional wiring

diagrams see Bulletin 6-453.

8

CAUTION

Check for red heat exchanger tubes. If bottom of tubes become

red while blower unit is in operation, check for proper air volume

and air distribution. Adjust blower speed or correct discharge

duct design to correct problem.

nstallation of Blower Units (BSH)

I

Determining Blower Speed

The drive assembly and fan motor on all gas-fired blower units

are factory assembled. The adjustable motor sheave has been

pre-set to obtain maximum air flow without any external static

pressure. The motor sheave should be adjusted as required

when the unit is to be operated at other air flows and/or with

external static pressures. Adjustment must always be within the

performance range shown on pages 14 and 15 and the

temperature rise range shown on the unit’s rating plate.

To determine the proper blower speed and motor shave turns

open, the conditions under which the unit is to operate must be

know. If the blower unit is to be used without duct work, nozzles

or filters, the only criteria for determining the motor sheave

turns open and blower speed is the amount of air flow to be

delivered. The performance tables for blower models are shown

on pages 14 and 15. As an example, a model BSH150 unit

Heater Parts from ACF Greenhouses

INSTALLATION

A

3" MIN.

12"

MIN.

3" MAX.

TURNING

VANES

12"

B

BAFFLE

12"

MIN.

A

B

BAFFLE

TURNING

VANES

12" MIN.

B

3" MAX.

TURNING

VANES

3" MIN.

A

Recommended Installations

A B C

SIDE VIEW SIDE VIEW TOP VIEW

D E F

B

without filters operating with one external static pressure, that

is, no duct work, nozzles, etc., and is to deliver an air flow of

2071 cfm (cfm = cubic feet of air) requires that the unit be

supplied with a 1/2 hp motor, a C25 drive and, the motor

sheave set at 5 turns open to achieve a blower speed of 255

rpm (see performance table for units

page 14). See “Blower Adjustments” for setting of motor sheave

turns open.

If a blower unit is to be used with ductwork or nozzles, etc., the

total external static pressure under which the unit is to operate,

and the required air flow must be known before the unit can be

properly adjusted. Any device added externally to the unit, and

which the air must pass through, causes a resistance to air

flow. This resistance is called pressure loss. The total of the

pressure losses must be determined before adjusting the

blower speed.

If Modine filters are used, the expected pressure loss through

the filters is included in performance data on page 15. If Modine

supplied discharge nozzles are used, the expected pressure

loss of the nozzles can be found footnoted at the bottom of

page 10. If filters, nozzles, or ductwork are to be used with the

unit, and they are not supplied by Modine, the design engineer

or installing contractor must determine the pressure loss for the

externally added devices, or ductwork, to arrive at the total

external static pressure under which the unit is to operate.

Once the total external static pressure and the required air flow

are known, the operating speed of the blower can be

determined and the correct motor sheave adjustments made.

As an example, let’s say a model BSH150 is to be used with a

Modine supplied blower enclosure, Modine supplied filters, are

to be attached to ductwork supplied by others, and the unit is to

move 2071 cfm of air flow against an external static pressure of

0.2" W.C. static pressure, it is seen that the unit will require a

1/2 hp motor using a C22 drive, and the motor sheave should

be set at 1 turn open to achieve a blower speed of 415 rpm.

See “Blower Adjustments” for setting of motor sheave turns

open.

T

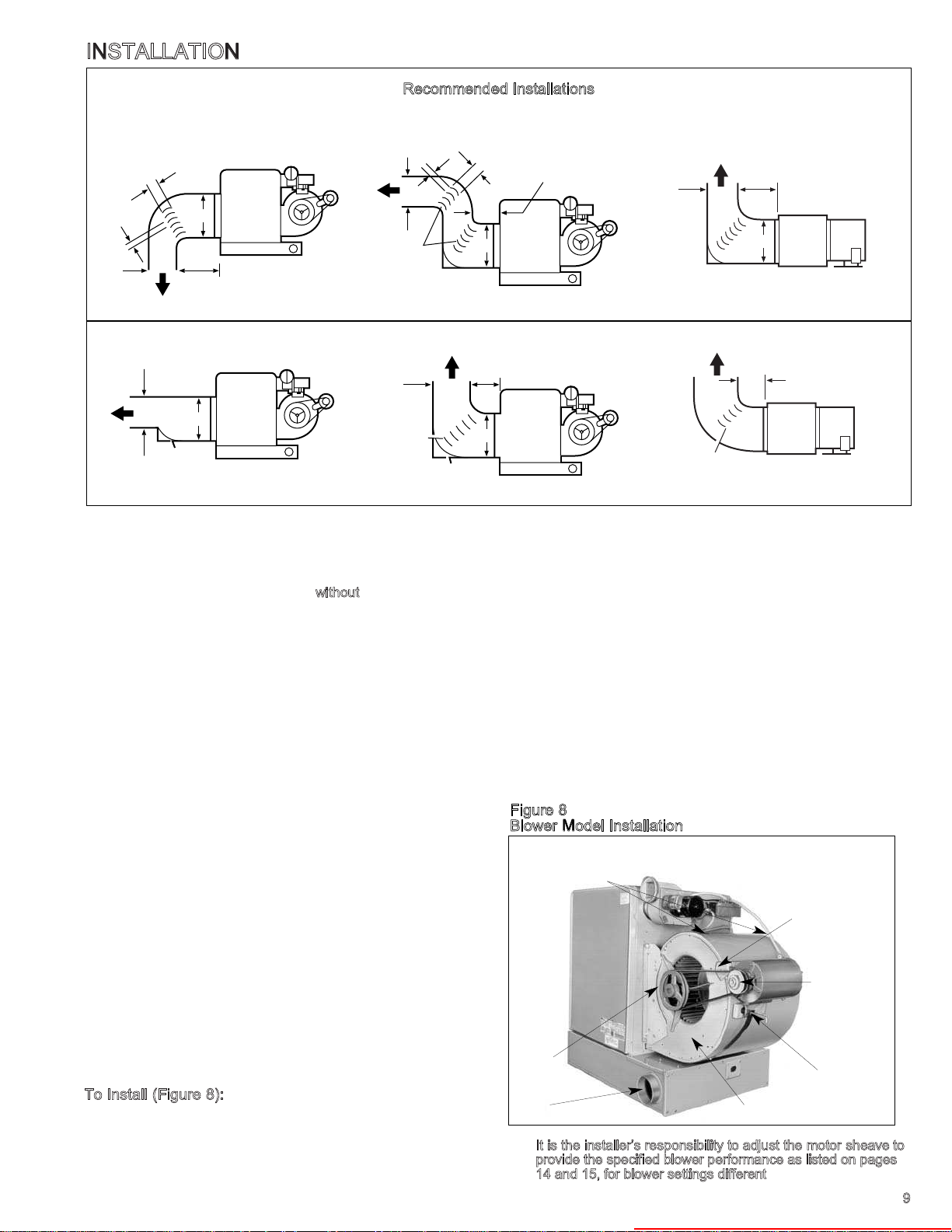

o Install (Figure 8):

1. Remove and discard the tie down strap and the shipping

block beneath the belt tension adjusting screw. (Not used

on all models.)

2. Adjust belt tension adjusting screw for a belt deflection of

approximately 3/4" with five pounds of force applied midway

A

BAFFLE

SIDE VIEW SIDE VIEW TOP VIEW

without

blower enclosure,

Dimension “B” Should Never

Be Less than 1/2 of “A”

12"

B

MIN.

A

12"

MIN.

TURNING

VANES

between the sheaves (refer to Figure 9a). Since the belt

tension will decrease dramatically after an initial run-in

period, It is necessary to periodically re-check the tension.

excessive tension will cause bearing wear and noise.

3. The blower bearings are lubricated for life; however, before

initial unit operation the blower shaft should be lubricated at

the bearings with SAE20 oil. This will reduce initial friction

and start the plastic lubricant flowing.

4. Make electrical connections according to the wiring

diagram.

5. Check rotation of the blower. Motor should be in clockwise

rotation when facing motor pulley. If rotation is incorrect,

correction should be made by interchanging wiring within

the motor. See wiring diagram on the motor.

6. The actual current draw of the motor should be determined.

Under no condition should the current draw exceed that

shown on the motor rating plate.

Figure 8

Blower Model Installation

Threaded Rod

Mounting Brackets on

Blower Assembly

Motor Mounting

Bracket

Motor Sheave

(Movable Face

to Outside)

Blower

Sheave

Combustion Air Inlet

I

t is the installer’s responsibility to adjust the motor sheave to

7.

Blower Housing

Motor

Adjustment

Screw

provide the specified blower performance as listed on pages

14 and 15, for blower settings different

Heater Parts from ACF Greenhouses

9

Loading...

Loading...