STEAM/HOT WATER UNIT HEATERS

MODEL HSB/HC MODEL V/VN

MODEL HCH

MODEL PT/PTN

MODEL GLW

1-150.16 • OCTOBER, 2019

TABLE OF CONTENTS

Table of Contents Page

I. Design Benefits

A. Application, Design, Construction Overview ....................................................3

B. Unit Features – Horizontal Delivery Unit Heaters............................................4

C. Unit Features – Vertical Delivery Unit Heaters ................................................5

D. Unit Features – Power-Throw

E. Unit Features – Low Water Temperature Greenhouse Heating Units .............6

F. Options and Accessories .................................................................................7

G. Power Code Descriptions & Control Sequence ...............................................8

II. Performance Data

A. Breeze

B. Steam Conversion Tables ..............................................................................10

C. Steam Performance Data – Standard Models ...............................................13

D. Steam Performance Data – Low Outlet Temperature Models .......................14

E. Steam Conversion Tables – Example Calculations .......................................15

F. Hot Water Conversion Tables ........................................................................16

G. Hot Water Performance Data – Standard Models .........................................19

H. Hot Water Performance Data – Low Outlet Temperature Models .................20

I. Hot Water Performance Data – High Efficiency Low EWT Models ...............21

J. Hot Water Conversion Tables – Example Calculations .................................22

K. Maximum Mounting Heights for Outlet Accessories, Dimensions .................23

L. Motor Data, Step-Down Transformer Accessory Data ..................................24

III. Dimensional Data

A. Dimensions – Horizontal Air Delivery Models ................................................25

B. Dimensions – Horizontal Air Delivery High Effeciency Models .....................26

C. Dimensions – Vertical Air Delivery Models ....................................................27

IV. Model Identification .................................................................................................28

V. Specifications .........................................................................................................29

™

Horizontal Delivery Unit Heaters ...................5

TM

AccuSpec Sizing and Selection Program ..........................................9

Refer to page 9 for information regarding the

TM

Breeze

AccuSpec Sizing and Selection Program

Canadian Registered

heat exchangers

CRN

OH 9234.5C

*Does not apply to V/

PT 952

As Modine Manufacturing Company has a continuous product improvement program,

it reserves the right to change design and specifications without notice.

2

1-150.16

DESIGN BENEFITS

Application, Design, Construction Overview - All Units

Wide Product Selection

• Ratings as low as 11,300 Btu/hr for hot water to as high as 952,000 Btu/hr for steam, based on standard conditions.

• Horizontal, Vertical, and Power-Throw™ (high velocity horizontal air delivery) models offer maximum application flexibility.

• Ratings are shown as Btu/hr (based on 2 PSI steam, 60°F entering air conditions), eliminating the need to convert from EDR.

This simplifies the matching of unit ratings to building heat loss.

Application Flexibility

• Horizontal and Power-Throw™ units are furnished with louvers for directional control of heated air. Vertical units are available

with various louver, truncone, and cone-jet deflector options to accommodate many different air distribution patterns. See

page 22 for more information.

• Units are available as low outlet temperature (LOT) models. LOT models have coils with fewer fins per inch to reduce the

output rating. This is a benefit for applications where the steam pressure exceeds 30 PSI and mounting height is critical; the

lower output results in outlet air temperatures that approximate that of standard coils at standard steam pressure. LOT models

are also well suited for dirty environments where the increased fin spacing decreases the build-up of foreign particles. Finally,

LOT models offer lower airside resistance resulting in greater allowable mounting heights and greater heat throw.

• Vertical and Power-Throw™ units are available with 90/10 cupro-nickel coils for high pressure/temperature applications, up to

250 PSI or 400°F.

• Side piping connections on the HC/HCH horizontal air delivery model allow for low clearance installations.

• Explosion-proof motors are available for use in hazardous areas. See page 8 for additional details.

• Design assures the correct relationship between air temperature, velocity, and air volume for greater heat throw; air is delivered

to the floor at maximum mounting height, increasing comfort and reducing fuel costs.

Ease of Installation/Maintenance = Reliability

• Units are compact and lightweight, requiring fewer contractor hours to install.

• All units include an electrical junction box, either integral to the motor or mounted on the unit casing, to allow for easy electrical

connections.

• All motors are totally enclosed. All single phase and explosion-proof motors include internal overload protection to protect the

motor from insulation damaging heat, resulting in longer motor life.

• Different suspension options are available for most units including threaded rod or pipe hanger adapters.

• All units are component tested for proper motor function and the coils are leak tested under pressure to ensure proper function

when the unit arrives at the jobsite.

• Fins on all units are vertical to limit build-up of foreign particles, prolonging periods between cleanings. Fins on vertical and

Power-Throw™ units are exposed for easy cleaning.

Blends with the Environment

• Quiet operation is assured through the use of carefully selected motors, fans, and scientifically designed venturi fan shrouds.

• HSB/HC/HCHC models have squared off corners for a clean, defined appearance. Vertical and Power-Throw™ units have a

pleasing circular symmetry.

• Casings are treated for corrosion resistance and finished with a neutral gray-green baked-on, electrostatically applied polyester

powder coat paint finish.

• HCH Casings are treated for corrosion resistance and finished with a Hammertone Beige baked-on, electrostatically applied

polyester powder coat paint finish.

1-150.16

3

DESIGN BENEFITS

CONNECTIONS

SIDE CONNECTIONS

Unit Features - Horizontal Delivery Unit Heaters

Horizontal delivery unit heaters are the most popular of all types.

These units are ideal for heating buildings with large open areas

and low ceilings. They are used to counter heat loss along outside

building walls, especially where windows are present.

In addition to the features noted on page 2, features that enhance the

popularity of the horizontal delivery unit heater are:

• HSB units have top and bottom supply and return connections.

This permits the unit to be rotated 360° without piping changes.

• HC units have side supply and return connections.

This permits the unit to be installed in low clearance areas.

• HCH high efficiency units have side supply and return

connections. This permits the unit to be installed in low clearance

areas.

• Units have a 2-piece casing for easy coil access.

• All models have tapped holes for suspension by threaded rod or

optional pipe hanger adapter kit, except HSB 18 and HSB 24

which mount directly to and are supported by the supply and

return piping.

• Serpentine copper tube coil design has high resistance to thermal

shock, even under high steam pressures.

• Absence of coil headers eliminates potential leaks and increases

coil face area without increasing overall size of unit.

• Coil designed for greater water carrying capacity with lower

friction loss.

HSB MODEL

TOP/BOTTOM CONNECTIONS

HCH MODEL

SIDE CONNECTIONS

HC MODEL

SIDE CONNECTIONS

Figure 4.1 - Unit Features

Connections – Female type permits direct connection of unit heater to the piping and eliminates the need for additional

fittings.

Vertical Fins – Less opportunity for dust and dirt to collect. Reduces cleaning. Fins die-formed for added strength and heat

transfer.

Coil – All air passes through coil. Heating is uniform. Design assures maximum control over air delivery and temperature

of air leaving the heater. Aluminum fins die-formed for added strength – increased heat transfer. Fins mechanically

bonded to serpentine copper tube.

Motor – All motors are totally enclosed. Single phase and explosion-proof types include built in thermal overload

protection. Selected and tested for operation on specific unit heater models. All motor wiring is terminated in an electrical

junction box either supplied on the unit heater casing, or as an integral part of the motor.

Fan – Lightweight. Blades accurately balanced and pitched to move air quietly and positively – with minimum power

requirement.

Deflector Blades – Adjustable horizontal air-deflector blades are standard. Vertical blades are also standard on models

HC/HSB-258, HC/HSB-290 and HC/HSB-340 and are optional on other models. Both horizontal and vertical blades are

illustrated.

Safety Fan Guard – Standard equipment. Bolted to rear casing, steel rod fan guard completely surrounds the fan

offering constant protection.

Casings – Baked-on gray-green polyester or Hammertone Beige powdercoat paint is applied over rust-and corrosionresistance-treated steel

for long life.

4

1-150.16

DESIGN BENEFITS

Unit Features - Vertical Delivery Unit Heaters

Vertical delivery unit heaters are ideal for heating buildings with high ceilings or areas

that require the heater to be mounted above obstructions such as craneways. Selection

from a variety of heat throw patterns is made easy by choosing from four types of air

deflectors. Heat throw patterns range from a high-velocity narrow jet to a gentle-velocity

broad based cone of heated air.

In addition to the features noted on page 2, features that enhance the popularity of the vertical

delivery unit heater are:

• Extended motor life with the use of the standard motor cooling cone. The cooling cone

protects the motor from intense radiant and convection heat from the coil when the fan

is not running. The cone also meters a controlled volume of ambient air over the motor

to reduce motor temperature, when the motor is running.

• All models through V/VN 279 have tapped holes for threaded rod or optional pipe

hanger adapter kit.

• All models V/VN 333 and larger have angle-iron mounting bracket with 5/8" diameter hanger holes.

• All vertical units are supplied with an outlet fan guard covering the opening in the bottom of the unit.

Figure 5.1 - Unit Features

Motor-Cooling Cone – Shields motor from coil

heat - prolongs life of insulation, windings, and

lubricant. Prolongs motor life (V/VN models only).

Coil – Aluminum fins firmly bonded to tubes

for maximum heat transfer. Steam and watercarrying passages between extra-heavy steel

pipe connections are copper for model V/PT

and cupro-nickel for model VN/PTN.

Motor – All motors are totally enclosed. Single

phase and explosion-proof types include built

in thermal overload protection. Selected and

tested for operation on specific unit heater

models.

Fan – Accurately balanced to operate quietly

and at lowest possible power cost.

Junction Box – All motor wiring is terminated in an

electrical junction box either supplied on the unit

heater casing or as an integral part of the motor.

Motor Easily Removable – Modine design permits

motor to be removed through opening below the

unit especially important where heaters are installed

close to ceiling (V/VN models only).

Vertical Fins – Less opportunity for dust and dirt to

collect. Exposed for easy cleaning with air hose

and brush.

Casings – Baked-on, gray-green polyester powder

coat paint applied over rust- and corrosionresistance treated steel lasts longer.

Unit Features - Power-ThrowTM Horizontal Delivery Unit Heaters

Power-Throw™ horizontal delivery unit heaters are ideal for heating large buildings where

a number of smaller units can be replaced by a few larger Power-Throw

results in a more economical installation. Their high velocity air delivery results in the

greatest heat throw available.

™

Power-Throw

units are also ideally suited for blanketing doors that frequently open.

Because of high velocity air delivery, care must be taken to avoid directing the air stream

at building occupants.

In addition to the features noted on page 2, features that enhance the popularity of the Power-Throw

horizontal delivery unit heater are:

• All models through PT/PTN 279 have hanger brackets with 5/8" diameter hanger holes

for 3-point suspension.

• All models larger than PT/PTN 279 have hanger brackets with 5/8" diameter hanger

holes for 2-point suspension and angle supports for 4-point suspension.

• Air distribution is controlled by a standard adjustable position horizontal louver assembly.

• The air stream can be concentrated into a high velocity jet or broadened to cover a greater area.

• Fan blades are properly balanced and pitched to move large volumes of high velocity air at relatively low sound levels.

• Refer to Figure 5.1 for features similar to the V/VN vertical models.

™

units. This

™

1-150.16

5

DESIGN BENEFITS

Unit Features - Low Water Temperature Greenhouse Heating Units

The Modine model GLW units are specifically designed to heat greenhouses

with low-temperature water. They can be successfully used in applications

where waste or reject heat from steam-electric power plants, refineries,

pumping stations, distilleries, and other industrial or processing plants can

be utilized for heating. With the ever-increasing cost of fossil fuel, utilizing

reject heat as a heat source for greenhouses is a sensible solution with the

model GLW.

Standard features include:

• Hot water coil with 1/2" O.D. copper tubes, aluminum fins, and 1-1/2" MPT

copper connections.

• Maximum operating pressure is 300 PSI, maximum operating water

temperature is 180°F

• Frame, enclosure panels, and 24" polytube transitions are galvanized steel

for corrosion resistance in humid environments.

• 1/2 HP, totally enclosed motors (1 for GLW330S, 2 for GLW660S), available for single phase or three phase voltages.

• High airflow, 3850CFM for GLW330S and 7700CFM for GLW660S, based on 150 feet of polytube duct.

Unit Sizing

Figure 6.1 - Model GLW Performance Curves

Unit performance is based on the flow rate and the temperature of

the water relative to the ambient air temperature. Refer to Figure 6.1

and the following example for determining performance.

Example:

6000

Model GLW660S

5000

Determine heating capacity in BTU/hr for model GLW660S at

20GPM, 100°F entering water, and 70°F entering air.

4000

1. Figure 6.1 shows output in terms of BTU/hr per °F of ETD

(Entering Temperature Difference). ETD is the difference between

the entering water temperature and the entering air temperature.

For this example, ETD = 100°F – 70°F = 30°F.

2. From Figure 6.1, at 20GPM, the BTU/hr per °F of ETD for the

3000

Heating capacity

BTU/HR/ F of ETD

2000

Model GLW330S

GLW660S is 5000.

3. The heating capacity = 5000 x 30 = 150,000 BTU/hr.

1000

GLW660

4. The water temperature drop = (heating capacity)/(500 x GPM) =

150,000/(500 x 20) = 15°F.

10

5. The water pressure drop from the curve is 0.7 Ft. of water.

20 30 40 50

Water flow rate

gallons per minute

Dimensions and Specifications - Model GLW660S, GLW330S (All dimensions in inches)

Figure 6.2 - Top View Figure 6.3 - Discharge and Side Views

23.88" O.D.

23.88" O.D.

GLW330

4.0

3.0

2.0

ft. of water

1.0

Water pressure drop

GLW330S

15.75" 31.0"

GLW660S

62.5" - GLW660S

32.5" - GLW330S

8.0"

MAX

14.0"

31.5"

Weight: GLW330S=200 lbs., GLW660S=380 lbs.

Note: Information on this page applies only to Model GLW units. Information contained in Catalog that is not on this page does not apply to Model GLW units.

6

1-150.16

38.0"

19.0"

10.0"

DESIGN BENEFITS

Options and Accessories

Table 7.1

Factory Mounted Options

Factory Mounted Option Description

Standard fan guard may be factory replaced with fingerproof fan guard. For HSB/HC/HCH units only. Not

Fingerproof Fan Guard

available for units with explosion-proof motors.

Table 7.2

Field Installed Accessories for Horizontal Models

Field Installed Accessories Description

Blades used to deflect airflow in directions left or right of unit heater. Used in addition to standard

horizontal deflector blades. Vertical deflector blades are standard on HSB/HC models 258 through 340.

Vertical Deflector Blades

Not available for Power-Throw

Allows for remote control of airflow volume by controlling fan speed. Available only on HSB/HC models 18

Solid State Speed Control

through 108 with Power Code 01.

Available for HCH units.

Discharge Hoods

30°, 60°, and 90° downward deflector hoods

Table 7.3

Field Installed Accessories for Vertical Models

Field Installed Accessories Description

The cone-jet allows the discharge air stream to be adjusted from a concentrated high velocity jet to a

Cone-Jet

broadened air stream to cover a larger area. See page 22 for additional information.

The truncone causes a broad discharge air stream covering a larger area than possible with the cone-jet.

Truncone

See page 22 for additional information.

The one-way louver allows the discharge air stream to be adjusted in one direction. See page 22 for

One Way Louver

additional information.

The two-way louver allows the discharge air stream to be adjusted in two directions. See page 22 for

Two Way Louver

additional information.

™

models.

Table 7.4

Field Installed General Accessories

Field Installed Accessories Description

Thermostat

Honeywell T4051A1003, 50-80°F range, 16A @ 115V, 8A @ 230V

Thermostat

Honeywell T451A3005, 44-86°F range, 9.8A @ 115V, 4.9A @ 230V

Thermostat

Johnson Controls T22BBC-1, 40-90°F range, Auto/Off/Fan switch, 10A @ 115V, 4.9A @ 230V

Explosion-proof Thermostat

Honeywell T6051B1006, 46-84° range, 10.2A @ 115V, 6.5A @ 230V

Aquastat, 10 amps @ 115V; 6 amps @ 230V; 100°-240°F range, SPDT, 10°F Diff. Fixed,

Aquastat

Johnson A19DAC-1

Clear plastic locking guard with tumbler lock and two keys. Available only on thermostat Item Codes

Thermostat Guard

23124, 23125 and 90348.

Allows unit heater to be suspended by threaded pipe instead of threaded rod. Two kits are required for V

Pipe Hanger Adapter Kit

and VN models. Kits are not available for HSB-18 and HSB-24 models or Power-Throw

Toggle switch starter with thermal overload protection for remote on/off control of unit fan operation.

Manual Starter

Available for power codes 01 and 02 only.

For supply voltages of 208V/60Hz/1ph and all non-explosion-proof 3 phase voltages of 208, 230, 460 and

575, certain Model Numbers require that a 115V/60Hz/1 phase Power Code 01 unit heater be used with a

Step-Down Transformer

shipped loose accessory transformer. See page 23 for additional information.

™

models.

1-150.16

7

DESIGN BENEFITS

Power Code Descriptions & Control Sequence

Table 8.1

Power Code Descriptions

Power Thermal Overload

Code Protection

01 115/60/1 Totally Enclosed M Yes N/A

02 230/60/1 Totally Enclosed M Yes N/A

04 200-208/60/3 Totally Enclosed Polyphase Induction No Field Supplied/Installed

05 230/460/60/3 Totally Enclosed Polyphase Induction No Field Supplied/Installed

06 115/60/1 Explosion-proof N Split Phase Yes N/A

09 230/460/60/3 Explosion-proof N

10 575/60/3 Totally Enclosed Polyphase Induction No Field Supplied/Installed

M Motors are shaded pole for models HSB/HC 18-33 and V/VN 42-95. Models HSB/HC 47-340 and V/VN 139-333 are permanent split capacitor.

N Explosion-proof motors are suitable for Class I, Group D, Class II, Groups F and G, and Class III, Division 1 and 2 environments. Canadian Standard Association

(CSA) requirements state that the explosion-proof units may not be used with a fluid temperature in excess of 329°F or pressures greater than 87 psig and still

maintain their T3B temperature rating.

Class I, Group D motors are for operations in areas containing gasoline, petroleum, naphtha, benzene, butane, propane, alcohol, acetone, lacquer solvent or

natural gas.

Class II, Group F motors are for operations in areas containing carbon black, coal or coke dust.

Class II, Group G motors are for operations in areas containing flour, starch or grain dust.

Class III motors are for operations in areas containing easily ignitable fibers and flyings.

Supply Voltage

Motor Enclosure

Polyphase Induction Yes Field Supplied/Installed

Motor Type

Motor Starter

Control Sequence

The following control sequence descriptions are typical for steam/hot water unit heaters:

Intermittent Fan Operation - Hot Coil

When a room thermostat calls for heat, the motor is energized. Hot water or steam is continuously supplied to the unit heater, even

when the motor is not running. When the thermostat is satisfied, the motor is de-energized.

Continuous Fan Operation - Intermittent Hot/Cold Coil

When a room thermostat calls for heat, a valve is opened, allowing steam or hot water to enter the unit heater. When the

thermostat is satisfied, the valve is closed. The fan runs continuously.

Intermittent Fan Operation - Intermittent Hot/Cold Coil

When a room thermostat calls for heat, the motor is energized. At the same time, a valve is opened allowing steam or hot water to

enter the unit heater. An aquastat may be attached to the supply or return piping to prevent fan operation until the coil is adequately

heated to avoid cold air delivery. When the thermostat is satisfied, the valve closes and the motor is de-energized.

8

1-150.16

PERFORMANCE DATA

Modine Breeze™ AccuSpec

Sizing and Selection Program

The Modine Breeze AccuSpec is the fastest way to generate performance data based

on actual job conditions. The Breeze AccuSpec program is a web-based sizing and

selection program. The program provides a series on step-by-step questions that allow

for the easy configuration of Modine products. After a model has been configured, the

program can generate Submittal Schedules, Submittal Data including performance and

dimensional drawings, and Specifications.

Pictures for Visual

Selection

[HSB/HC/V/VN/PT/PTN]

Submittal Schedules

Dimensional Drawings

Capacities at

Job Conditions

[HSB/HC/V/VN/PT/PTN]

Job Specific

Specifications

Unit Specific

For access to the Breeze AccuSpec program, contact your local Modine sales representative.

1-150.16

9

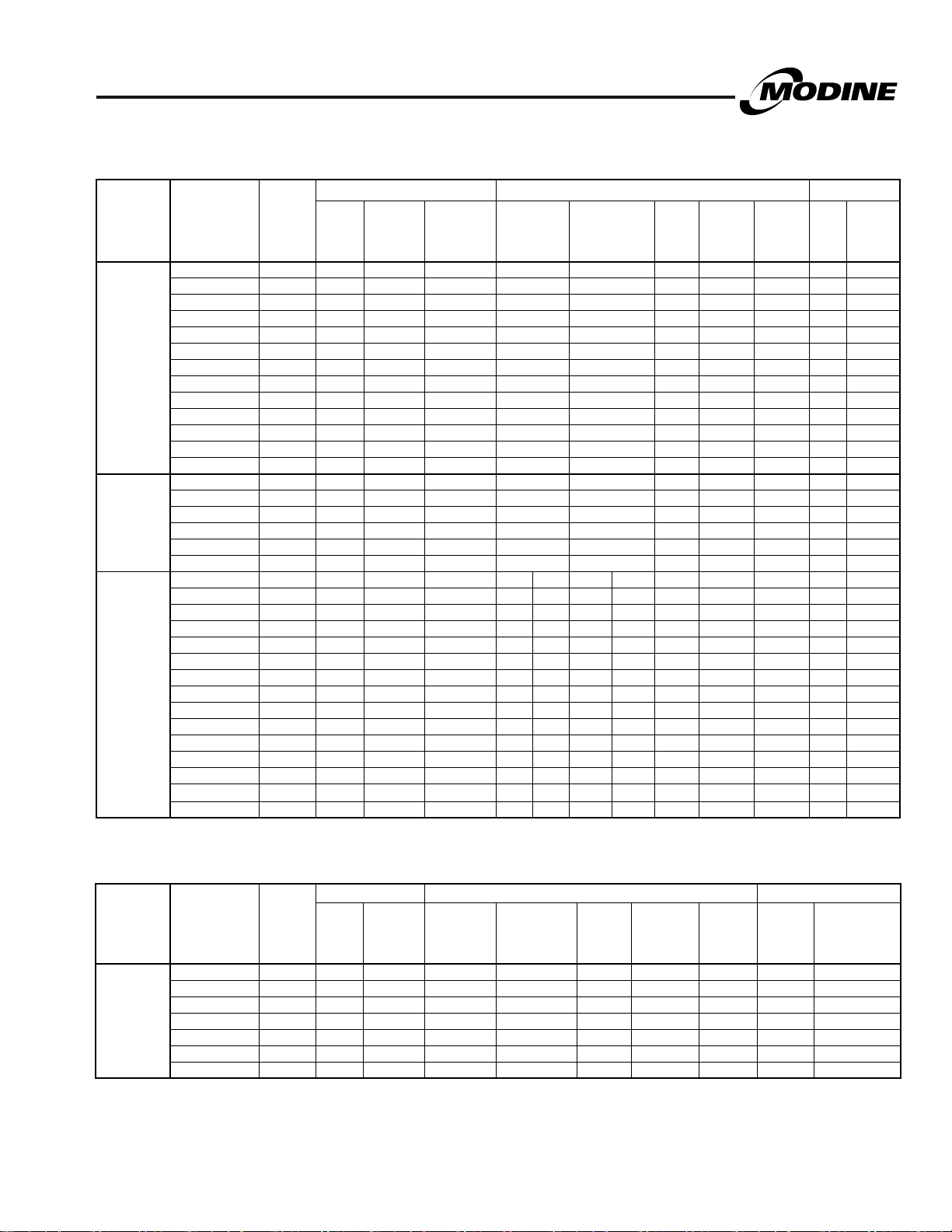

PERFORMANCE DATA

Steam Conversion Tables

Table 10.1 and the formulas below are used to determine the heating capacity (Btu/hr) of a unit heater at a steam pressure and/or

entering air temperature other than standard conditions of 2 lb. steam, 60°F entering air temperature.

Table 10.1

Steam Heating Capacity Conversion Factors

Unit Steam Entering Air Temperature (°F)

Heater Pressure

Type (PSIG)

0 1.54 1.45 1.37 1.27 1.19 1.11 1.03 0.96 0.88 0.81 0.74 0.67

2 1.59 1.50 1.41 1.32 1.24 1.16 1.08 1.00 0.93 0.85 0.78 0.71

5 1.64 1.55 1.46 1.37 1.29 1.21 1.13 1.05 0.97 0.90 0.83 0.76

10 1.73 1.64 1.55 1.46 1.38 1.29 1.21 1.13 1.06 0.98 0.91 0.84

15 1.80 1.71 1.61 1.53 1.44 1.34 1.28 1.19 1.12 1.04 0.97 0.90

20 1.86 1.77 1.68 1.58 1.50 1.42 1.33 1.25 1.17 1.10 1.02 0.95

30 1.97 1.87 1.78 1.68 1.60 1.51 1.43 1.35 1.27 1.19 1.12 1.04

40 2.06 1.96 1.86 1.77 1.68 1.60 1.51 1.43 1.35 1.27 1.19 1.12

50 2.13 2.04 1.94 1.85 1.76 1.67 1.58 1.50 1.42 1.34 1.26 1.19

60 2.20 2.09 2.00 1.90 1.81 1.73 1.64 1.56 1.47 1.39 1.31 1.24

70 2.26 2.16 2.06 1.96 1.87 1.78 1.70 1.61 1.53 1.45 1.37 1.29

Horizontal Delivery

75 2.28 2.18 2 09 1.99 1.90 1.81 1.72 1.64 1.55 1.47 1.40 1.32

80 2.31 2.21 2.11 2.02 1.93 1.84 1.75 1.66 1.58 1.50 1.42 1.34

90 2.36 2.26 2.16 2.06 1.97 1.88 1.79 1.71 1.62 1.54 1.46 1.38

100 2.41 2.31 2.20 2.11 2.02 1.93 1.84 1.75 1.66 1.58 1.50 1.42

12 5 2.51 2.41 2.31 2.21 2.11 2.02 1.93 1.84 1.76 1.68 1.59 1.51

150 2.60 2.50 2.40 2.30 2.20 2.11 2.02 1.93 1.84 1.76 1.67 1.59

0 1.49 1.41 1.33 1.25 1.18 1.11 1.03 0.96 0.90 0.83 0.76 0.69

2 1.52 1.45 1.37 1.29 1.22 1.15 1.07 1.00 0.93 0.86 0.80 0.73

5 1.58 1.50 1.42 1.34 1.27 1.20 1.12 1.05 0.98 0.91 0.85 0.78

10 1.64 1.57 1.49 1.41 1.34 1.27 1.19 1.12 1.05 0.98 0.91 0.85

15 1.70 1.62 1.55 1.47 1.40 1.32 1.25 1.18 1.11 1.04 0.97 0.90

20 1.75 1.67 1.60 1.52 1.45 1.37 1.30 1.23 1.16 1.09 1.02 0.96

30 1.83 1.75 1.68 1.61 1.53 1.46 1.39 1.32 1.25 1.18 1.11 1.04

40 1.90 1.82 1.75 1.68 1.61 1.53 1.46 1.39 1.32 1.25 1.18 1.11

50 1.96 1.87 1.81 1.74 1.67 1.59 1.52 1.45 1.38 1.31 1.24 1.17

60 2.02 1.94 1.87 1.79 1.72 1.64 1.57 1.50 1.43 1.36 1.29 1.22

70 2.07 1.99 1.92 1.84 1.76 1.69 1.62 1.55 1.47 1.40 1.33 1.27

75 2.10 2.02 1.94 1.86 1.79 1.71 1.64 1.57 1.49 1.42 1.36 1.29

80 2.11 2.04 1.96 1.88 1.80 1.73 1.66 1.59 1.51 1.44 1.38 1.31

90 2.15 2.08 2.00 1.92 1.84 1.77 1.69 1.62 1.55 1.48 1.41 1.34

100 2.19 2.11 2.03 1.95 1.88 1.80 1.73 1.66 1.59 1.52 1.45 1.38

Vertical Delivery and Power-Throw

150 2.34 2.26 2.18 2.10 2.03 1.95 1.88 1.81 1.74 1.67 1.60 1.53

17 5 2.40 2.32 2.24 2.16 2.09 2.01 1.94 1.87 1.80 1.73 1.66 1.59

200 2.45 2.37 2.29 2.22 2.14 2.07 1.99 1.92 1.85 1.78 1.71 1.64

225 2.50 2.42 2.34 2.26 2.19 2.12 2.04 1.97 1.90 1.83 1.76 1.69

250 2.54 2.46 2.38 2.31 2.23 2.16 2.09 2.01 1.94 1.87 1.80 1.73

-10 0 10 20 30 40 50 60 70 80 90 100

125 2.27 2.19 2.11 1.99 1.91 1.88 1.81 1.74 1.67 1.60 1.53 1.46

Applicable formulas (examples on page 15):

To find actual unit heater capacity when operated at non-standard (actual) conditions:

= BtuS x Heating Capacity Factor

Btu

A

To select a heater capacity based on standard conditions to meet a heating capacity at non-standard (actual) conditions:

= BtuA ÷ Heating Capacity Factor

Btu

S

Where:

= Capacity at standard conditions (2 lb. steam, 60°F entering air temperature) from Tables 13.1 through 14.2

Btu

S

= Capacity at non-standard (actual) conditions

Btu

A

10

1-150.16

PERFORMANCE DATA

Steam Conversion Tables

Table 11.1 and the formulas below are used to determine the air temperature rise of a unit heater at a steam pressure and/or

entering air temperature other than standard conditions of 2 lb. steam, 60°F entering air temperature.

Table 11.1

Air Temperature Rise Conversion Factors

Unit Steam Entering Air Temperature (°F)

Heater Pressure

Type (PSIG)

0 1.33 1.28 1.24 1.17 1.12 1.07 1.01 0.96 0.90 0.84 0.78 0.72

2 1.38 1.33 1.27 1.22 1.17 1.11 1.06 1.00 0.94 0.88 0.83 0.76

5 1.43 1.38 1.33 1.27 1.21 1.16 1.11 1.05 1.00 0.93 0.88 0.82

10 1.50 1.45 1.40 1.35 1.29 1.24 1.19 1.13 1.07 1.02 0.95 0.90

15 1.56 1.51 1.46 1.42 1.36 1.31 1.24 1.19 1.14 1.08 1.02 0.97

20 1.61 1.56 1.52 1.46 1.41 1.36 1.30 1.25 1.19 1.14 1.08 1.02

30 1.70 1.65 1.61 1.55 1.51 1.46 1.40 1.35 1.29 1.24 1.18 1.12

40 1.78 1.73 1.68 1.62 1.58 1.54 1.48 1.43 1.38 1.32 1.26 1.21

50 1.84 1.79 1.74 1.69 1.65 1.60 1.55 1.50 1.45 1.39 1.33 1.28

60 1.91 1.86 1.81 1.75 1.71 1.66 1.61 1.56 1.50 1.45 1.40 1.33

70 1.95 1.91 1.86 1.81 1.76 1.71 1.66 1.61 1.56 1.51 1.45 1.39

Horizontal Delivery

75 1.97 1.93 1.89 1.84 1.79 1.74 1.69 1.64 1.58 1.53 1.47 1.42

80 2.00 1.95 1.91 1.86 1.82 1.76 1.72 1.66 1.61 1.56 1.49 1.44

90 2.04 2.00 1.95 1.90 1.86 1.81 1.75 1.70 1.65 1.60 1.54 1.49

100 2.08 2.04 1.99 1.95 1.89 1.85 1.79 1.75 1.69 1.64 1.59 1.53

12 5 2.17 2.13 2.09 2.04 1.99 1.94 1.89 1.84 1.79 1.74 1.68 1.63

150 2.25 2.21 2.17 2.12 2.07 2.03 1.98 1.93 1.87 1.83 1.77 1.71

0 1.36 1.31 1.25 1.19 1.13 1.08 1.02 0.96 0.90 0.84 0.78 0.72

2 1.41 1.35 1.29 1.24 1.18 1.12 1.06 1.00 0.94 0.88 0.82 0.76

5 1.46 1.40 1.35 1.29 1.23 1.17 1.12 1.06 1.00 0.94 0.88 0.82

10 1.54 1.48 1.43 1.37 1.31 1.25 1.20 1.14 1.08 1.02 0.96 0.89

15 1.61 1.55 1.49 1.44 1.38 1.32 1.26 1.20 1.14 1.09 1.02 0.97

20 1.67 1.61 1.55 1.50 1.44 1.38 1.32 1.26 1.20 1.15 1.08 1.02

30 1.77 1.71 1.65 1.60 1.54 1.48 1.42 1.36 1.30 1.25 1.18 1.12

40 1.85 1.79 1.74 1.68 1.62 1.56 1.51 1.45 1.39 1.33 1.27 1.21

50 1.92 1.86 1.81 1.75 1.69 1.64 1.58 1.52 1.46 1.40 1.34 1.28

60 1.99 1.93 1.88 1.82 1.76 1.70 1.65 1.58 1.53 1.47 1.41 1.35

70 2.05 1.99 1.94 1.88 1.82 1.76 1.70 1.65 1.59 1.53 1.47 1.41

75 2.08 2.02 1.96 1.91 1.85 1.79 1.73 1.67 1.62 1.56 1.50 1.43

80 2.10 2.04 1.99 1.93 1.87 1.81 1.75 1.70 1.64 1.58 1.52 1.46

90 2.15 2.09 2.04 2.00 1.92 1.86 1.80 1.74 1.69 1.63 1.57 1.51

100 2.19 2.14 2.08 2.02 1.97 1.91 1.85 1.79 1.73 1.67 1.61 1.55

Vertical Delivery and Power-Throw

150 2.39 2.33 2.27 2.22 2.16 2.10 2.04 1.99 1.93 1.87 1.81 1.75

17 5 2.46 2.41 2.35 2.29 2.24 2.18 2.12 2.06 2.00 1.94 1.88 1.82

200 2.54 2.48 2.42 2.37 2.31 2.25 2.19 2.13 2.07 2.02 1.96 1.89

225 2.60 2.54 2.49 2.43 2.37 2.32 2.26 2.20 2.14 2.08 2.02 1.96

250 2.66 2.60 2.55 2.49 2.43 2.38 2.32 2.26 2.20 2.14 2.08 2.02

-10 0 10 20 30 40 50 60 70 80 90 100

125 2.29 2.24 2.18 2.12 2.07 2.01 1.95 1.89 1.83 1.77 1.71 1.65

Applicable formulas (examples on page 15):

To find actual air temperature rise of unit heater when operated at non-standard (actual) conditions:

= (FATS - EATS ) x Air Temperature Rise Factor

ATR

A

To find actual final air temperature of unit heater when operated at non-standard (actual) conditions:

= EATA + ATR

FAT

A

A

Where:

= Standard conditions entering air temperature (60°F)

EAT

S

= Non-standard (actual) entering air temperature

EAT

A

= Final air temperature at standard conditions from Tables 13.1 through 14.2

FAT

S

= Final air temperature at non-standard (actual) conditions

FAT

A

= Air temperature rise at non-standard (actual) conditions

ATR

A

1-150.16

11

PERFORMANCE DATA

Steam Conversion Tables

Table 12.1 is used to determine how steam pressures other than 2 lb. affect mounting height.

Table 12.1

Steam Unit Heater Mounting Height Correction Factors MN

Steam Pressure, PSIG

2 5 10 15 20 30 40 50 60 70 80 90 100 125 150 175 200 225 250

Correction Factor 1.00 0.97 0.94 0.92 0.89 0.86 0.84 0.82 0.80 0.79 0.77 0.76 0.76 0.74 0.72 0.71 0.70 0.69 0.68

M Factors are for use with entering air temperatures that range from 50° to 70°F.

N While all units are capable of operation on steam pressures greater than 30 lb., low outlet temperature models are ideally suited for steam pressures above

30 lb. when mounting height is critical.

Applicable formula (examples on page 15):

Max. Mounting Height

= Max. Mounting HeightS x Correction Factor

A

Where:

Max. Mounting Height

Max. Mounting Height

= Maximum mounting height at actual conditions

A

= Maximum mounting height at standard conditions

S

Table 12.2 is used to determine the rate of condensate production at steam pressures other than 2 lb.

Table 12.2

Properties of Steam

Gauge Latent Gauge Latent Gauge Latent Gauge Latent

Pressure Temp Heat Pressure Temp Heat Pressure Temp Heat Pressure Temp Heat

(PSIG) (°F) (Btu/lb.) (PSIG) (°F) (Btu/lb.) (PSIG) (°F) (Btu/lb.) (PSIG) (°F) (Btu/lb.)

0 212.0 970.3 34 279.4 924.7 70 316.0 897.3 109 343.6 875.4

2 218.5 966.2 36 281.9 922.9 72 317.7 896.0 11 2 345.4 873.9

4 224.4 962.4 38 284.3 921.1 74 319.3 894.8 115 347.2 872.5

5 227.2 960.6 40 286.7 919.3 76 320.9 893.5 118 348.9 871.0

6 229.8 958.8 42 289.0 917.6 78 322.4 892.3 121 350.7 869.6

8 234.8 955.6 44 291.3 915.9 80 323.9 891.1 124 352.4 868.2

10 239.4 952.5 46 293.5 914.3 82 325.4 889.9 125 352.9 867.8

12 243.7 949.6 48 295.6 912.7 84 326.9 888.8 127 354.0 866.9

14 247.8 946.8 50 297.7 911.2 86 328.4 887.6 13 0 355.7 865.5

16 251.6 944.2 52 299.7 909.7 88 329.8 886.5 133 357.3 864.1

18 255.3 941.7 54 301.7 908.2 90 331.2 885.4 136 358.9 862.9

20 258.8 939.3 56 303.6 906.7 92 332.5 884.3 139 360.4 861.5

22 262.1 936.9 58 305.5 905.3 94 333.9 883.2 142 362.0 860.3

24 265.3 934.7 60 307.3 903.9 96 335.2 882.1 14 5 363.5 859.0

26 268.3 932.5 62 309.1 902.5 98 336.6 881.1 150 365.9 856.9

28 271.3 930.5 64 310.9 901.2 100 337.9 880.0 175 377.4 846.8

30 274.1 928.5 66 312.6 899.9 103 339.8 878.5 200 387.9 837.2

32 276.8 926.6 68 314.4 898.6 106 341.7 876.9 225 397.3 828.5

- - - - - - - - - 250 406.1 820.0

Applicable formula (examples on page 15):

Condensate rate = Btu

÷ Latent Heat of Steam

A

Where:

= Capacity at actual operating conditions

Btu

A

12

1-150.16

PERFORMANCE DATA

Steam Performance Data - Standard Models

Table 13.1 - Performance Data for Standard Units at Standard Conditions of

2 lb. Steam and 60°F Entering Air High Motor Speed

Type Model No. Btu/hr Sq. Ft. EDR

Horizontal

Delivery

Power Throw™

e

Vertical

Delivery

e

HSB/HC 18

HSB/HC 24

HSB/HC 33

HSB/HC 47

HSB/HC 63

HSB/HC 86

HSB/HC 108

HSB/HC 121

HSB/HC 165

HSB/HC 193

HSB/HC 258

HSB/HC 290

HSB/HC 340

PT/PTN 279

PT/PTN 333

PT/PTN 385

PT/PTN 500

PT/PTN 610

PT 952

V/VN 42

V/VN 59

V/VN 78

V/VN 95

V/VN 139

V/VN 161

V/VN 193

V/VN 212

V/VN 247

V/VN 279

V/VN 333

V/VN 385

V/VN 500

V/VN 610

V 952

18,000 75 8 17 340 625 107 19 1/60 1,550

24,000 100 9 18 370 695 119 25 1/25 1,550

33,000 138 10 21 630 690 108 34 1/25 1,550

47,000 196 12 28 730 810 119 49 1/12 1,550

63,000 263 14 29 1,120 690 111 65 1/12 1,550

86,000 358 15 31 1,340 835 118 89 1/8 1,625

108,000 450 17 31 2,010 790 109 112 1/8 1,625

121,000 504 16 25 1,775 715 122 125 1/5 1,075

165,000 688 19 40 3,240 880 106 171 1/3 1,075

193,000 804 18 38 2,900 810 121 200 1/3 1,075

258,000 1,075 19 44 4,560 750 111 267 1/2 1,075

290,000 1,208 20 46 4,590 765 117 300 1/2 1,075

340,000 1,417 20 46 5,130 735 120 352 1/2 1,075

279,000 1,163 16 100 5,460 2,165 111 289 1/2 1,075

333,000 1,388 17 110 5,980 2,165 116 345 3/4 1,140

385,000 1,604 17 115 7,680 1,860 110 398 1 1,140

500,000 2,083 18 130 10,390 2,520 108 517 1 1/2 1,140

610,000 2,542 20 140 11,750 2,315 112 631 1 1/2 1,140

952,000 3,967 21 145 12,170 2,321 139 985 2 1,140

42,000 175 11

59,000 246 14

78,000 325 15

95,000 396 15

139,000 579 18

161,000 671 20

193,000 804 22

212,000 883 22

247,000 1,029 26

279,000 1,163 30

333,000 1,388 30

385,000 1,604 30

500,000 2,083 37

610,000 2,542 36

952,000 3,967 37

Maximum

Mounting

Height (ft.)

c

15

19

20

20

24

27

30

30

34

37

37

36

44

43

Heat Throw or

Spread @ Max.

Height c

11

17

14

21

15

23

15

23

18

27

20

30

22

33

22

33

26

39

30

45

30

45

30

45

37

56

36

54

56

Air Data Motor Data

CFM

d

950 825 103 43 1/30 1,050

1,155 1,005 111 61 1/30 1,050

1,590 1,065 109 81 1/15 1,050

1,665 1,120 118 98 1/15 1,050

2,660 1,285 112 144 1/6 1,075

2,945 1,420 115 167 1/3 1,075

3,500 1,690 116 200 1/3 1,075

3,610 1,740 120 219 1/3 1,075

4,820 1,910 111 256 1/2 1,075

5,460 2,165 111 289 1/2 1,075

5,980 2,165 116 345 3/4 1,140

7,680 1,860 110 398 1 1,140

10,390 2,520 108 517 1 1/2 1,140

11,750 2,315 112 631 1 1/2 1,140

12,170 2,321 139 985 2 1,140

Outlet

Velocity

(Fpm)

Final Air

Temp. (°F)

Condensate

lb/hr

Hp

Approx.

RPM

Table 13.2 - Performance Data for Standard Units at Standard Conditions of

2 lb. Steam and 60°F Entering Air Reduced Motor Speed P

Air Data Motor Data

Type Model No. Btu/hr

HSB/HC 18

HSB/HC 24

Horizontal

Delivery

M Horizontal units with horizontal louvers open 30° from vertical plane. Vertical types equipped with cone jet deflector, blades fully opened are shown in bold. Please see

page 22 for additional outlet accessory performance data.

N Cfm for horizontal types is entering Cfm. Cfm for vertical and Power-Throw™ types is leaving Cfm.

O V and PT models have copper tubes, VN and PTN models have 90/10 cupro-nickel tubes.

P Requires Solid State Motor Speed Controller.

HSB/HC 33

HSB/HC 47

HSB/HC 63

HSB/HC 86

HSB/HC 108

14,000 58 8 10 220 415 118 14 1/60 1,000

18,000 75 9 11 230 440 131 19 1/25 1,000

25,000 104 10 13 395 440 118 26 1/25 1,000

38,000 158 12 17 450 515 137 39 1/12 1,000

47,000 195 14 17 685 430 122 49 1/12 1,000

64,000 265 15 19 825 525 131 66 1/8 1,000

81,000 340 17 19 1,255 500 119 84 1/8 1,000

Sq. Ft.

EDR

Maximum

Mounting

Height (ft.)

c

Heat Throw or

Spread @

Max. Height

c

CFM

d

Outlet

Velocity

(Fpm)

Final Air

Tem p.

(°F)

Condensate

lb/hr

Hp

Approx.

RPM

1-150.16

13

PERFORMANCE DATA

Steam Performance Data - Low Outlet Temperature Models

Table 14.1 - Performance Data for Low Outlet Temperature Units at Standard Conditions of

2 lb. Steam and 60°F Entering Air High Motor Speed

Air Data Motor Data

Type Model No. Btu/hr Sq. Ft. EDR

Horizontal

Delivery

Power Throw™

e

Vertical

Delivery

e

HSB/HC 18L

HSB/HC 24L

HSB/HC 33L

HSB/HC 47L

HSB/HC 63L

HSB/HC 86L

HSB/HC 108L

HSB/HC 121L

HSB/HC 165L

HSB/HC 258L

HSB/HC 290L

HSB/HC 340L

PT/PTN 610L

V 42L

V 59L

V 78L

V 95L

V/VN 139L

V/VN 161L

V/VN 193L

V/VN 212L

V/VN 247L

V/VN 279L

V/VN 333L

V/VN 385L

V/VN 500L

V/VN 610L

V 952L

15,900 66 9 20 364 655 100 16 1/60 1,550

19,300 80 11 21 435 795 100 20 1/25 1,550

29,500 123 12 24 695 745 99 31 1/25 1,550

32,000 133 14 32 855 910 94 33 1/12 1,550

52,500 219 16 33 1,170 710 101 54 1/12 1,550

61,500 256 17 36 1,510 910 97 64 1/8 1,625

86,500 360 19 36 2,150 825 97 90 1/8 1,625

88,000 367 18 29 2,070 800 98 91 1/5 1,075

143,000 596 21 45 3,480 930 97 148 1/3 1,075

190,000 792 22 51 4,655 750 98 197 1/2 1,075

207,000 863 23 53 5,040 805 94 214 1/2 1,075

255,000 1,063 23 53 5,575 775 102 264 1/2 1,075

470,000 1,958 22 154 2,400 2,445 97 486 1-1/2 1,140

33,000 138 13

44,000 183 16

62,000 258 19

71,000 296 19

103,000 429 23

127,000 529 26

149,000 621 27

163,000 679 27

190,000 792 32

215,000 896 36

256,000 1,067 36

296,000 1,233 36

385,000 1,604 45

470,000 1,958 44

733,000 3,055 45

Maximum

Mounting

Height (ft.)

c

17

22

26

26

31

35

36

36

42

45

45

43

54

52

-

Heat Throw or

Spread @ Max.

Height c

13

20

16

24

19

29

19

29

23

35

26

39

27

41

27

41

32

48

36

54

36

54

36

54

45

68

44

66

-

68

CFM

d

960 835 94 34 1/30 1,050

1,190 1,035 96 45 1/30 1,050

1,740 1,070 95 65 1/15 1,050

1,760 1,180 99 73 1/15 1,050

2,860 1,380 95 106 1/6 1,075

3,400 1,640 96 132 1/3 1,075

3,710 1,790 99 154 1/3 1,075

3,830 1,845 102 169 1/3 1,075

5,110 2,030 96 197 1/2 1,075

5,790 2,300 96 222 1/2 1,075

6,340 2,300 100 265 3/4 1,140

8,140 1,970 95 307 1 1,140

11,000 2,670 94 400 1-1/2 1,140

12,400 2,445 97 485 1-1/2 1,140

12,940 2,450 115 759 2 1,140

Outlet

Velocity

(Fpm)

Final Air

Temp. (°F)

Condensate

lb/hr

Hp

Approx.

RPM

Table 14.2 - Performance Data for Low Outlet Temperature Units at Standard Conditions of

2 lb. Steam and 60°F Entering Air Reduced Motor Speed P

Air Data Motor Data

Type Model No. Btu/hr Sq. Ft. EDR

HSB/HC 18L

HSB/HC 24L

Horizontal

Delivery

M Horizontal units with horizontal louvers open 30° from vertical plane. Vertical types equipped with cone jet deflector, blades fully opened are shown in bold. Please see

page 22 for additional outlet accessory performance data.

N Cfm for horizontal types is entering Cfm. Cfm for vertical and Power-Throw™ types is leaving Cfm.

O V and PT models have copper tubes, VN and PTN models have 90/10 cupro-nickel tubes.

P Requires Solid State Motor Speed Controller.

HSB/HC 33L

HSB/HC 47L

HSB/HC 63L

HSB/HC 86L

HSB/HC 108L

12,000 51 9 12 230 425 108 12 1/60 1,000

14,400 60 11 13 265 490 109 15 1/25 1,000

22,000 92 12 14 430 470 107 23 1/25 1,000

24,300 101 14 19 540 580 101 25 1/12 1,000

39,500 164 16 20 725 445 109 41 1/12 1,000

46,000 192 17 22 925 565 105 48 1/8 1,000

65,000 270 19 22 1,330 520 104 67 1/8 1,000

Maximum

Mounting

Height (ft.)

c

14

Heat Throw or

Spread @ Max.

Height c

1-150.16

CFM

d

Outlet

Velocity

(Fpm)

Final Air

Temp. (°F)

Condensate

lb/hr

Hp

Approx.

RPM

PERFORMANCE DATA

Steam Conversion Tables - Example Calculations

Conversion factor example #1:

For an HSB340S operating at 30 lb. steam and 50°F entering air temperature, determine the following:

x Capacity (Btu/hr)

x Final air temperature (°F)

x Condensate (lb./hr)

x Maximum mounting height

Solution:

The factors/data necessary to solve this problem are as follows:

x Steam heating capacity conversion factor for 30 lb. steam and 50°F entering air is 1.43, from Table 10.1.

x Air temperature rise conversion factor is 1.40, from Table 11.1.

x The latent heat of steam at 30 lb. is 928.5 Btu/lb., from Table 12.2.

x The mounting height correction factor is 0.86, from Table 12.1.

x The standard rated capacity of an HSB 340 is 340,000 Btu/hr, from Table 13.1.

x The final air temperature of an HSB 340 at standard conditions is 120°F, from Table 13.1.

x The maximum mounting height at standard conditions is 20 feet, from Table 13.1.

= BtuS x Heating Capacity Factor = 340,000 x 1.43 = 486,200 Btu/hr

Btu

A

= (FATS - EATS ) x Air Temp Rise Factor = (120°F - 60°F) x 1.40 = 84°F

ATR

A

= EATA + ATRA = 50°F + 84°F = 134°F

FAT

A

Condensate rate = Btu

Max. Mounting Height

÷ Latent Heat of Steam = 486,200 ÷ 928.5 = 523.6 lb./hr

A

= Max. Mounting HeightS x Correction Factor = 20 feet x 0.86 = 17.2 feet

A

Conversion factor example #2:

Which vertical unit heater model is required to deliver 155,500 Btu/hr at 20 lb. steam and 60°F entering air temperature. What will

be the actual capacity and rate of condensate production for the selected unit?

Solution:

The factors/data necessary to solve this problem are as follows:

x Steam heating capacity conversion factor for 20 lb. steam and 60°F entering air is 1.23, from Table 10.1.

x The latent heat of steam at 20 lb. is 939.3 Btu/lb. from Table 12.2.

= BtuA ÷ Heating Capacity Factor = 155,500 ÷ 1.23 = 126,423 Btu/hr (at standard conditions)

Btu

S

From Table 13.1, a V 139 model meets the requirement with a rated capacity of 139,000 Btu/hr at standard conditions.

The capacity of the V 139 at actual conditions will be Btu

139,000 x 1.23 = 170,970 Btu/hr.

Condensate rate = Btu

÷ Latent Heat of Steam = 170,970 ÷ 939.3 = 182.0 lb./hr.

A

Alternate Solution:

Low Outlet Temperature models are normally recommended for steam pressures above 30 lb. However, the use of these

models with steam pressure less than 30 lb. is acceptable.

Based on the example above, a V 161L model, from Table 14.1, meets the requirement with a rated capacity of 127,000 Btu/hr

at standard conditions.

= BtuS x Heating Capacity Factor =

A

The capacity of the V 161L at actual conditions will be Btu

127,000 x 1.23 = 156,210 Btu/hr.

Condensate rate = Btu

÷ Latent Heat of Steam = 156,210 ÷ 939.3 = 166.3 lb./hr.

A

1-150.16

= BtuS x Heating Capacity Factor =

A

15

PERFORMANCE DATA

Hot Water Conversion Tables

Table 16.1 and the formulas below are used to determine the heating capacity (Btu/hr) of a unit heater at a water temperature and/

or entering air temperature other than standard conditions of 200° entering water temperature, 60° entering air temperature.

Table 16.1

Hot Water Heating Capacity Conversion Factors

Entering Water Entering Air Temperature (°F)

Temp. (°F) 0 10 20 30 40 50 60 70 80 90 100

60 0.462 0.380 0.300 0.222 0.146 0.072 0 0 0 0 0

70 0.539 0.456 0.375 0.296 0.219 0.145 0.071 0 0 0 0

80 0.615 0.531 0.450 0.370 0.293 0.217 0.143 0.071 0 0 0

90 0.692 0.607 0.524 0.444 0.366 0.289 0.214 0.141 0.070 0 0

100 0.769 0.683 0.599 0.518 0.439 0.361 0.286 0.212 0.140 0.069 0

11 0 0.846 0.759 0.674 0.592 0.512 0.434 0.357 0.283 0.210 0.138 0.068

120 0.923 0.835 0.749 0.666 0.585 0.506 0.429 0.353 0.279 0.207 0.137

130 1.000 0.911 0.824 0.740 0.658 0.578 0.500 0.424 0.349 0.276 0.205

14 0 1.077 0.987 0.899 0.814 0.731 0.651 0.571 0.494 0.419 0.345 0.273

150 1.154 1.063 0.974 0.888 0.805 0.723 0.643 0.565 0.489 0.414 0.342

160 1.231 1.139 1.049 0.962 0.878 0.795 0.714 0.636 0.559 0.483 0.410

17 0 1.308 1.215 1.124 1.036 0.950 0.867 0.786 0.706 0.629 0.552 0.478

180 1.385 1.291 1.199 1.110 1.024 0.940 0.857 0.777 0.699 0.621 0.547

190 1.462 1.367 1.274 1.184 1.097 1.012 0.929 0.848 0.768 0.690 0.615

200 1.539 1.443 1.349 1.258 1.170 1.084 1.000 0.918 0.838 0.759 0.684

210 1.615 1.519 1.424 1.332 1.243 1.157 1.071 0.989 0.908 0.828 0.752

220 1.692 1.594 1.499 1.406 1.312 1.229 1.143 1.060 0.978 0.897 0.820

230 1.769 1.670 1.573 1.480 1.390 1.301 1.214 1.130 1.048 0.966 0.889

240 1.846 1.746 1.649 1.554 1.463 1.373 1.286 1.201 1.118 1.035 0.957

250 1.923 1.822 1.723 1.628 1.536 1.446 1.357 1.272 1.188 1.104 1.025

260 2.000 1.898 1.798 1.702 1.609 1.518 1.429 1.342 1.257 1.173 1.094

270 2.077 1.974 1.873 1.776 1.682 1.590 1.500 1.413 1.327 1.242 1.162

280 2.154 2.050 1.948 1.850 1.755 1.663 1.571 1.483 1.397 1.311 1.230

290 2.231 2.126 2.023 1.924 1.829 1.734 1.643 1.554 1.467 1.380 1.300

300 2.308 2.202 2.098 1.998 1.902 1.807 1.714 1.625 1.537 1.449 1.367

310 2.385 2.278 2.173 2.072 1.974 1.879 1.786 1.695 1.607 1.518 1.436

320 2.462 2.354 2.248 2.146 2.048 1.952 1.857 1.766 1.677 1.587 1.504

330 2.539 2.430 2.323 2.220 2.121 2.024 1.929 1.837 1.746 1.656 1.572

340 2.615 2.506 2.398 2.294 2194 2.096 2.000 1.907 1.816 1.725 1.641

350 2.962 2.581 2.473 2.368 2.267 2.168 2.071 1.978 1.886 1.794 1.709

360 2.769 2.657 2.548 2.442 2.340 2.241 2.143 2.049 1.956 1.863 1.778

370 2.846 2.733 2.622 2.516 2.413 2.313 2.214 2.119 2.026 1.932 1.846

380 2.923 2.809 2.697 2.590 2.486 2.385 2.286 2.190 2.096 2.001 1.914

390 3.000 2.885 2.772 2.664 2.560 2.458 2.357 2.261 2.165 2.070 1.983

400 3.077 2.961 2.847 2.738 2.633 2.530 2.429 2.331 2.235 2.139 2.051

Applicable formulas (examples on page 21):

To find actual unit heater capacity when operated at non-standard (actual) conditions:

Btu

= BtuS x Heating Capacity Factor

A

To select a heater capacity based on standard conditions to meet a heating capacity at non-standard (actual) conditions:

Btu

= BtuA ÷ Heating Capacity Factor

S

Where:

Btu

= Capacity at standard conditions (200°F entering water temperature, 60°F entering air temperature) from Tables 19.1

S

through 20.2

= Capacity at non-standard (actual) conditions

Btu

A

16

1-150.16

PERFORMANCE DATA

Hot Water Conversion Tables

Table 17.1 - Minimum Water Flow and Water Volume (gallons) M

TYPE Model Min. GPM Max. GPM

18 0.25 5 0.13

24 0.25 5 0.13 39 1.40 18 0.50 333 4.50 100 1.24 59 0.75 15 0.23

33 0.40 10 0.41 67 2.60 31 0.77 385 4.50 100 1.24 78 1.00 20 0.31

47 0.40 10 0.41 104 4.10 48 1.10 500 6.00 100 1.66 95 1.25 25 0.38

63 0.50 20 0.66 170 6.80 77 1.80 610 6.00 100 1.98 139 1.00 30 0.43

86 0.50 20 0.66 195 8.00 88 2.14 952 14.00 200 6.50 161 1.25 40 0.54

HORIZONTAL

DELIVERY

M Water flow and water volume is the same for standard coils and low-outlet temperature coils

108 0.50 30 0.98 193 1.50 50 0.65

121 0.50 30 0.98 212 2.00 60 0.86

HSB/HC

165 2.00 30 1.35 247 2.00 60 0.86

193 2.00 50 1.45 279 2.25 75 0.97

258 2.50 70 2.20 333 2.25 75 1.24

290 2.50 70 2.20 385 2.25 75 1.24

340 2.50 70 2.50 500 3.00 100 1.66

Coil Volume

Type Model Min. GPM Max. GPM

(gals)

22 0.80 10 0.30

HORIZONTAL

DELIVERY

HCH

Coil Volume

(gals)

Type Model Min. GPM Max. GPM

POWER-

THROW

PT/PTN

279 4.50 60 0.97

Coil Volume

(gals)

Type Model Min. GPM Max. GPM

42 0.50 10 0.15

VERTICAL

DELIVERY

V/VN

610 6.00 100 1.98

952 14.00 200 6.50

Table 17.2 - Ethylene Glycol Correction Factors N

Table 17.2 is used to determine how glycol solutions affect heater capacity. These factors should be applied to the heater capacity at

actual entering water and air temperature conditions.

Ethylene Glycol Solution %

Solution Temperature (°F) 20% 30% 40% 50% 60% 70% 80%

60 0.99 0.96 0.93 0.89 0.85 0.81 0.76

10 0 0.99 0.96 0.93 0.89 0.85 0.81 0.76

15 0 0.99 0.96 0.94 0.90 0.87 0.83 0.78

200 0.99 0.96 0.94 0.92 0.88 0.85 0.81

250 0.98 0.96 0.94 0.92 0.89 0.86 0.82

300 0.98 0.95 0.95 0.92 0.90 0.87 0.83

350 0.98 0.95 0.95 0.93 0.91 0.88 0.84

400 0.97 0.95 0.95 0.93 0.92 0.89 0.85

N For Propylene Glycol solution correction factor, multiply Ethylene Glycol correction factor by 0.95.

Applicable formulas (examples on page 21):

To find actual unit heater capacity when operated with glycol solution:

Btu

= BtuS (or BtuA) x Glycol Correction Factor

AG

To select a heater capacity based on standard conditions to meet a heating capacity with a glycol solution:

(or BtuA) = BtuAG ÷ Glycol Correction Factor

Btu

S

Where:

Btu

= Capacity at standard conditions (200°F entering water temperature, 60°F entering air temperature) from Tables 19.1 through 20.2

S

= Capacity at non-standard (actual) conditions

Btu

A

Btu

= Capacity with glycol solution

AG

Table 17.3 - Hot Water Unit Heater Mounting Height Correction Factors O

Table 17.3 is used to determine how hot water temperatures other than 200°F affect mounting height.

Entering Water Correction Entering Water Correction Entering Water Correction

Temperature, °F Factor Temperature, °F Factor Temperature, °F Factor

140 1.33 230 0.91 320 0.74

150 1.25 240 0.89 330 0.72

160 1.19 250 0.86 340 0.71

170 1.13 260 0.84 350 0.70

180 1.08 270 0.82 360 0.69

190 1.04 280 0.80 370 0.67

200 1.00 290 0.78 380 0.66

210 0.97 300 0.77 390 0.65

220 0.94 310 0.75 400 0.64

O Factors are for use with entering air temperatures that range from 50° to 70°F

Applicable formula (examples on page 21):

Max. Mounting Height

= Max. Mounting HeightS x Correction Factor

A

Where:

Max. Mounting Height

Max. Mounting Height

= Maximum mounting height at actual conditions

A

= Maximum mounting height at standard conditions

S

1-150.16

Coil Volume

(gals)

17

PERFORMANCE DATA

Hot Water Conversion Tables - Miscellaneous Formulas

Table 18.1 is used to determine how water temperature drop affects heater capacity in Btu, water flow rate in GPM and pressure

drop in feet of water. These factors should be applied to the values at actual entering water and air temperature conditions.

Table 18.1

Correction Factors for Varying Water Temperature Drop M

Water Temperature Drop, °F

5 10 15 20 25 30 35 40 45 50 55 60

Btu Correction Factor 1.23 1.13 1.06 1.00 0.95 0.90 0.86 0.82 0.78 0.72 0.69 0.67

GPM Correction Factor 4.64 2.21 1.40 1.00 0.76 0.61 0.50 0.42 0.36 0.30 0.26 0.23

WPD Correction Factor 17.24 4.32 1.85 1.00 0.61 0.41 0.30 0.22 0.18 0.14 0.12 0.11

M Water temperature drop correction factors valid only for standard 200°F entering water and 60°F air temperature conditions.

Applicable formulas (examples on page 21):

To find actual unit heater capacity or flow rate or water pressure drop when operated at non-standard (actual) conditions:

= BtuS x Btu Correction Factor

Btu

A

= GPMS x GPM Correction Factor

GPM

A

= WPDS x WPD Correction Factor

WPD

A

To select a heater capacity based on standard conditions to meet a heating capacity at non-standard (actual) conditions:

= BtuA ÷ Btu Correction Factor

Btu

S

Where:

= Capacity at standard conditions (200°F entering water temperature, 60°F entering air temperature) from Tables 19.1

Btu

Btu

GPM

GPM

WPD

WPD

S

A

through 20.2

= Capacity at non-standard (actual) conditions

= Flow rate at standard conditions (200°F entering water temperature, 60°F entering air temperature) from Tables 19.1

S

through 20.2

= Flow rate at non-standard (actual) conditions

A

= Water pressure drop at standard conditions (200°F entering water temperature, 60°F entering air temperature) from

S

Tables 19.1 through 20.2

= Water pressure drop at non-standard (actual) conditions

A

Other miscellaneous useful formulas:

= EATA + [(460 + EATA) x (BtuA) ÷ (573 x Cfms)] for HSB and HC units only

FAT

A

= EATA + [(460 + EATA) ÷ ((573 x Cfms ÷ BtuA) - 1)] for V/VN and PT/PTN units only

FAT

A

= BtuA ÷ (480 x GPMA)

WTD

A

Where:

= Entering air temperature at actual conditions

EAT

A

= Final air temperature at actual conditions

FAT

A

= Capacity at actual conditions

Btu

A

= Unit airflow as found in Tables 19.1 through 20.2

Cfm

S

= Water flow rate at actual conditions in GPM

GPM

A

= Water temperature drop at actual conditions

WTD

A

18

1-150.16

PERFORMANCE DATA

Hot Water Performance Data - Standard Models

Table 19.1 - Performance Data for Standard Units at Standard Conditions of

200°F Entering Water and 60°F Entering Air High Motor Speed

Water Data Air Data Motor Data

Type Model No. Btu/hr

HSB/HC 18

HSB/HC 24

HSB/HC 33

HSB/HC 47

HSB/HC 63

Horizontal

Delivery

Power Throw™

e

Vertical

Delivery

e

HSB/HC 86

HSB/HC 108

HSB/HC 121

HSB/HC 165

HSB/HC 193

HSB/HC 258

HSB/HC 290

HSB/HC 340

PT/PTN 279

PT/PTN 333

PT/PTN 385

PT/PTN 500

PT/PTN 610

PT 952

V/VN 42

V/VN 59

V/VN 78

V/VN 95

V/VN 139

V/VN 161

V/VN 193

V/VN 212

V/VN 247

V/VN 279

V/VN 333

V/VN 385

V/VN 500

V/VN 610

V 952

Pressure

GPM

12,600 1.3 0.5 0.3 / 5.0 9 18 340 615 93 1/60 1,550

16,200 1.7 0.8 0.3 / 5.0 10 19 370 675 100 1/25 1,550

21,700 2.3 0.2 0.4 / 10.0 11 23 630 675 91 1/25 1,550

30,900 3.2 0.4 0.4 / 10.0 13 30 730 785 98 1/12 1,550

45,600 4.7 0.6 0.5 / 20.0 15 31 1,120 680 97 1/12 1,550

60,200 6.3 1.0 0.5 / 20.0 16 33 1,340 820 101 1/8 1,625

83,700 8.7 2.8 0.5 / 30.0 18 33 2,010 775 98 1/8 1,625

93,000 9.7 3.3 0.7 / 30.0 17 27 1,775 700 107 1/5 1,075

130,900 13.6 8.6 2.0 / 30.0 20 43 3,240 870 96 1/3 1,075

143,000 14.9 1.4 2.0 / 50.0 19 41 2,900 790 105 1/3 1,075

201,900 21.0 5.7 2.5 / 70.0 20 47 4,560 740 100 1/2 1,075

228,600 23.8 7.1 2.5 / 70.0 22 50 4,590 750 105 1/2 1,075

271,100 28.2 11.3 2.8 / 70.0 22 50 5,130 720 108 1/2 1,075

192,300 20.0 0.2 4.5 / 60.0 17 108 5,460 2,165 94 1/2 1,075

238,500 24.8 0.4 4.5 / 100.0 18 117 5,980 2,165 99 3/4 1,140

276,100 28.8 0.6 4.5 / 100.0 18 124 7,680 1,860 95 1 1,140

358,000 37.3 0.5 6.0 / 100.0 19 138 10,390 2,520 93 1-1/2 1,140

450,400 46.9 1.0 6.0 / 100.0 22 151 11,750 2,315 97 1-1/2 1,140

721,600 75.2 1.1 14.0 / 200.0 23 150 12,166 2,321 120 2 1,140

30,100 3.1 0.6 0.5 / 10.0 12

42,600 4.4 0.5 0.8 / 15.0 15

57,000 5.9 0.5 1.0 / 20.0 16

69,300 7.2 0.5 1.3 / 25.0 16

106,600 11.1 2.6 1.0 / 30.0 19

123,200 12.8 2.2 1.3 / 40.0 21

147,200 15.3 2.2 1.5 / 50.0 23

161,700 16.8 1.5 2.0 / 60.0 23

188,700 19.7 2.1 2.0 / 60.0 28

212,600 22.2 2.1 2.3 / 75.0 32

260,100 27.1 3.8 2.8 / 75.0 32

302,100 31.5 5.0 3.3 / 75.0 32

391,700 40.8 4.8 3.0 / 100.0 39

450,400 46.9 1.0 6.0 / 100.0 38

721,600 75.2 1.1 14.0 / 200.0 39

Drop

(Ft. of

Water)

Min/Max

GPM

Maximum

Mounting

Height (ft.)

Heat Throw or

Spread @ Max.

c

16

20

22

22

26

29

32

32

37

40

40

39

47

46

Height

c

18

22

24

24

29

32

35

35

41

48

48

48

59

57

-

59

CFM

12

15

1,155 1,005 96 1/30 1,050

16

1,590 1,065 95 1/15 1,050

16

1,665 1,120 101 1/15 1,050

19

2,660 1,285 99 1/6 1,075

22

2,945 1,420 101 1/3 1,075

24

3,500 1,690 101 1/3 1,075

24

3,610 1,740 104 1/3 1,075

28

4,820 1,910 98 1/2 1,075

32

5,460 2,165 98 1/2 1,075

32

5,980 2,165 102 3/4 1,140

32

7,680 1,860 98 1 1,140

40

10,390 2,520 96 1-1/2 1,140

39

11,750 2,315 97 1-1/2 1,140

-

12,166 2,321 120 2 1,140

Outlet

Velocity

d

(Fpm)

950 825 90 1/30 1,050

Final Air

Tem p.

(°F)

Hp

Approx.

RPM

Table 19.2 - Performance Data for Standard Units at Standard Conditions of

200°F Entering Water and 60°F Entering Air Reduced Motor Speeds

Water Data Air Data Motor Data

Type Model No. Btu/hr

HSB/HC 18

HSB/HC 24

Horizontal

Delivery

M Horizontal units with horizontal louvers open 30° from vertical plane. Vertical types equipped with cone jet deflector, blades fully opened are shown in bold. Please see

page 22 for additional outlet accessory performance data.

N Cfm for horizontal types is entering Cfm. Cfm for vertical and Power-Throw™ types is leaving Cfm.

O V and PT models have copper tubes, VN and PTN models have 90/10 cupro-nickel tubes.

P Requires Solid State Motor Speed Controller.

HSB/HC 33

HSB/HC 47

HSB/HC 63

HSB/HC 86

HSB/HC 108

9,900 1.3 0.5 9 11 220 400 101 1/60 1,000

12,400 1.7 0.8 10 12 230 425 109 1/25 1,000

16,700 2.3 0.2 11 14 395 430 98 1/25 1,000

23,600 3.2 0.4 13 18 450 490 107 1/12 1,000

34,600 4.7 0.6 15 18 685 420 106 1/12 1,000

45,900 6.3 1.0 16 20 825 515 110 1/8 1,000

64,300 8.7 2.8 18 20 1,255 490 106 1/8 1,000

GPM

Pressure

Drop (Ft. of

Water)

Maximum

Mounting

Height (ft.) c

P

Heat Throw or

Spread @ Max.

Height c

CFM

d

Outlet

Velocity

(Fpm)

Final Air

Temp. (°F)

Hp

Approx.

RPM

1-150.16

19

PERFORMANCE DATA

Hot Water Performance Data - Low Outlet Temperature Models

Table 20.1 - Performance Data for Low Outlet Temperature Units at Standard Conditions of

200°F Entering Water and 60°F Entering Air – High Motor Speed

Water Data Air Data Motor Data

Type Model No. Btu/hr

HSB/HC 18L

HSB/HC 24L

HSB/HC 33L

HSB/HC 47L

HSB/HC 63L

Horizontal

Delivery

Power Throw™

e

Vertical

Delivery

e

HSB/HC 86L

HSB/HC 108L

HSB/HC 121L

HSB/HC 165L

HSB/HC 258L

HSB/HC 290L

HSB/HC 340L

PT/PTN 610L

V 42L

V 59L

V 78L

V 95L

V/VN 139L

V/VN 161L

V/VN 193L

V/VN 212L

V/VN 247L

V/VN 279L

V/VN 333L

V/VN 385L

V/VN 500L

V/VN 610L

V 952L

Pressure

Drop

GPM

11,300 1.2 0.4 0.3 / 5.0 10 21 364 650 88 1/60 1,550

13,700 1.4 0.6 0.3 / 5.0 12 22 435 775 88 1/25 1,550

19,300 2.0 0.2 0.4 / 10.0 13 26 695 730 85 1/25 1,550

21,100 2.2 0.2 0.4 / 10.0 15 34 855 890 82 1/12 1,550

37,900 4.0 0.4 0.5 / 20.0 17 35 1,170 695 89 1/12 1,550

44,600 4.6 0.6 0.5 / 20.0 18 38 1,510 890 87 1/8 1,625

66,100 6.9 1.8 0.8 / 30.0 20 38 2,150 815 88 1/8 1,625

66,700 6.9 1.9 0.8 / 30.0 19 31 2,070 785 89 1/5 1,075

113,200 11.8 6.6 2.0 / 30.0 23 48 3,480 920 89 1/3 1,075

147,400 15.4 3.2 2.5 / 70.0 23 54 4,655 735 89 1/2 1,075

161,100 16.8 3.7 2.5 / 70.0 25 57 5,040 800 89 1/2 1,075

200,900 20.9 6.6 2.5 / 70.0 25 57 5,575 760 93 1/2 1,075

344,900 35.9 0.6 6.0 / 100.0 24 158 12,400 2,445 86 1 1/2 1,140

23,000 2.4 0.4 0.5 / 10.0 14

32,600 3.4 0.3 0.8 / 15.0 17

43,600 4.5 0.3 1.0 / 20.0 20

53,100 5.5 0.3 1.3 / 25.0 20

81,200 8.5 1.6 1.0 / 30.0 24

93,900 9.8 1.3 1.3 / 40.0 28

112,500 11.7 1.3 1.5 / 50.0 29

123,400 12.9 0.9 2.0 / 60.0 29

143,600 15.0 1.2 2.0 / 60.0 34

162,200 16.9 1.2 2.3 / 75.0 38

198,300 20.7 2.3 2.3 / 75.0 38

229,100 23.9 3.0 2.3 / 75.0 38

295,000 30.7 2.8 3.0 / 100.0 48

344,900 35.9 0.6 6.0 / 100.0 47

546,700 56.9 0.7 14.0 / 100.0 48

(Ft. of

Water)

Min/Max GPM

Maximum

Mounting

Height (ft.) c

Heat Throw or

Spread @ Max.

18

23

28

28

33

37

38

38

45

48

48

46

57

55

Height

c

21

25

31

31

37

41

43

43

51

57

57

57

72

70

72

Outlet

CFM

Velocity

d

(Fpm)

14

960 835 83 1/30 1,050

17

1,190 1,035 86 1/30 1,050

21

1,740 1,170 84 1/15 1,050

21

1,760 1,180 89 1/15 1,050

25

2,860 1,380 87 1/6 1,075

28

3,400 1,640 86 1/3 1,075

29

3,710 1,790 89 1/3 1,075

29

3,830 1,845 91 1/3 1,075

35

5,110 2,030 87 1/2 1,075

39

5,790 2,300 87 1/2 1,075

39

6,340 2,300 90 3/4 1,140

49

8,140 1,970 87 1 1,140

49

11,000 2,670 85 1 1/2 1,140

48

12,400 2,445 86 1 1/2 1,140

12,800 2,440 102 2 1,140

Final Air

Temp. (°F)

Hp

Approx.

RPM

Table 20.2 - Performance Data for Low Outlet Temperature Units at Standard Conditions of

c

1-150.16

P

Heat Throw or

Spread @ Max.

Height c

CFM

d

Outlet

Velocity (Fpm)

Final Air

Tem p.

(°F)

Hp

Approx.

RPM

200°F Entering Water and 60°F Entering Air – Reduced Motor Speeds

Water Data Air Data Motor Data

Type Model No. Btu/hr

HSB/HC 18L

HSB/HC 24L

Horizontal

Delivery

M Horizontal units with horizontal louvers open 30° from vertical plane. Vertical types equipped with cone jet deflector, blades fully opened are shown in bold. Please see

page 22 for additional outlet accessory performance data.

N Cfm for horizontal types is entering Cfm. Cfm for vertical and Power-Throw™ types is leaving Cfm.

O V and PT models have copper tubes, VN and PTN models have 90/10 cupro-nickel tubes.

P Requires Solid State Motor Speed Controller.

HSB/HC 33L

HSB/HC 47L

HSB/HC 63L

HSB/HC 86L

HSB/HC 108L

8,700 1.2 0.4 10 13 230 410 94 1/60 1,000

10,400 1.4 0.6 12 14 265 475 95 1/25 1,000

14,700 2.0 0.2 13 16 430 455 91 1/25 1,000

16,300 2.2 0.2 15 21 540 570 87 1/12 1,000

29,000 4.0 0.4 17 21 725 435 96 1/12 1,000

33,900 4.6 0.6 18 23 925 550 93 1/8 1,000

50,500 6.9 1.8 20 23 1,330 510 94 1/8 1,000

GPM

Pressure Drop

(Ft. of Water)

20

Maximum

Mounting

Height (ft.)

PERFORMANCE DATA

Hot Water Performance Data – High Efficiency Low EWT Models

Table 21.1 - Performance Data for Low Outlet Temperature Units at Standard Conditions of

140°F Entering Water and 60°F Entering Air – High Motor Speed

Water Data Air Data Motor Data

Type Model No. Btu/hr

HCH 22

HCH 39

Horizontal

Delivery

HCH 67

HCH 104

HCH 170

HCH 195

Pressure

Drop

GPM

21,688 2.2 4.9 0.8 / 10 8 27 370 408 113 1/25 1,550

38,547 3.9 1.5 1.4 / 18 8 28 660 409 113 1/25 1,550

66,875 6.8 2.6 2.6 / 31 9 33 1,150 456 113 1/6 1,075

104,204 10.4 4.8 4.1 / 48 11 39 1,830 503 112 1/6 1,075

169,564 17.0 7.4 6.8 / 77 11 42 2,870 475 115 1/3 1,140

194,917 19.5 10.4 8.0 / 88 11 40 3,200 455 115 1/3 1,140

(Ft. of

Water)

Min/Max GPM

Maximum

Mounting

Height (ft.) c

Heat Throw or

Spread @ Max.

Height

c

CFM

d

Outlet

Velocity

(Fpm)

Final Air

Temp. (°F)

Hp

Approx.

RPM

1-150.16

21

PERFORMANCE DATA

Hot Water Conversion Tables - Example Calculations

Conversion factor example #1:

What is the capacity (Btu/hr), water flow rate (GPM), water temperature drop (°F) and final air temperature (°F) for an HSB 86 at

240°F entering water temperature (EWT) and 70°F entering air temperature (EAT)? What is the maximum mounting height?

Solution:

The factors/data necessary to solve this problem are as follows:

xHot water heating capacity conversion factor for 240°F EWT and 70°F entering air is 1.201, from Table 16.1.

xThe standard rated capacity of an HSB 86 is 60,200 Btu/hr, from Table 19.1.

x The standard rated capacity of an HSB 86 is based on water flow rate of 6.3 GPM, from Table 19.1.

x The standard high motor speed airflow of an HSB 86 is 1340 CFM, from Table 19.1.

x The maximum mounting height, at standard conditions for an HSB 86 is 16 feet, from Table 19.1.

x The mounting height correction factor for 240°F EWT is 0.89 from Table 17.2.

= BtuS x Heating Capacity Factor = 60,200 x 1.201 = 72,300 Btu/hr

Btu

A

For water flow rate, since only the entering water and air temperature conditions have changed, the water flow rate will remain

6.3 GPM.

= BtuA ÷ (480 x GA) = 72,300 Btu/hr ÷ (480 x 6.3 GPM) = 23.9°F

WTD

A

= EATA + [(460 + EATA) x (BtuA) ÷ (576 x Cfms)] = 70°F + [(460 + 70°F) x (72,300) ÷ (576 x 1340)] = 120°F

FAT

A

Max. Mounting Height

= Max. Mounting HeightS x Correction Factor = 16 ft. x 0.89 = 14.2 feet

A

Conversion factor example #2:

Select a vertical unit heater model that can deliver at least 150,000 Btu/hr with 160°F EWT and 60°F EAT. What will be the required

water flow rate, water temperature drop, final air temperature and maximum mounting height?

Solution:

The factors/data necessary to solve this problem are as follows:

x Hot water heating capacity conversion factor for 160°F EWT and 60°F entering air is 0.714, from Table 16.1.

x The mounting height correction factor for 160°F EWT is 1.19, from Table 17.2.

= BtuA ÷ Heating Capacity Factor = 150,000 ÷ 0.714 = 210,084 Btu/hr (at standard conditions)

Btu

S

From Table 19.1, a V 279 model will meet the requirement with a rated capacity of 212,600 Btu/hr at standard conditions.

The capacity of the V 279 at actual conditions will be Btu

151,796 Btu/hr.

= BtuS x Heating Capacity Factor = 212,600 x 0.714 =

A

Since the capacity was calculated based off standard conditions with factors for changes in entering water and air temperature

conditions, the water flow rate will remain 22.2 GPM.

= BtuA ÷ (480 x GPMA) = 151,796 Btu/hr ÷ (480 x 22.2 GPM) = 14.2°F

WTD

A

= EATA + [(460 + EATA) ÷ ((576 x Cfms ÷ BtuA) - 1)] = 60°F + [(460 + 60°F) ÷ ((576 x 5,460 ÷ 151,796) - 1)] = 86.4°F

FAT

A

Max. Mounting Height

= Max. Mounting HeightS x Correction Factor = 40 ft. (with cone-jet deflector) x 1.19 = 47.6 feet

A

22

1-150.16

22

PERFORMANCE DATA

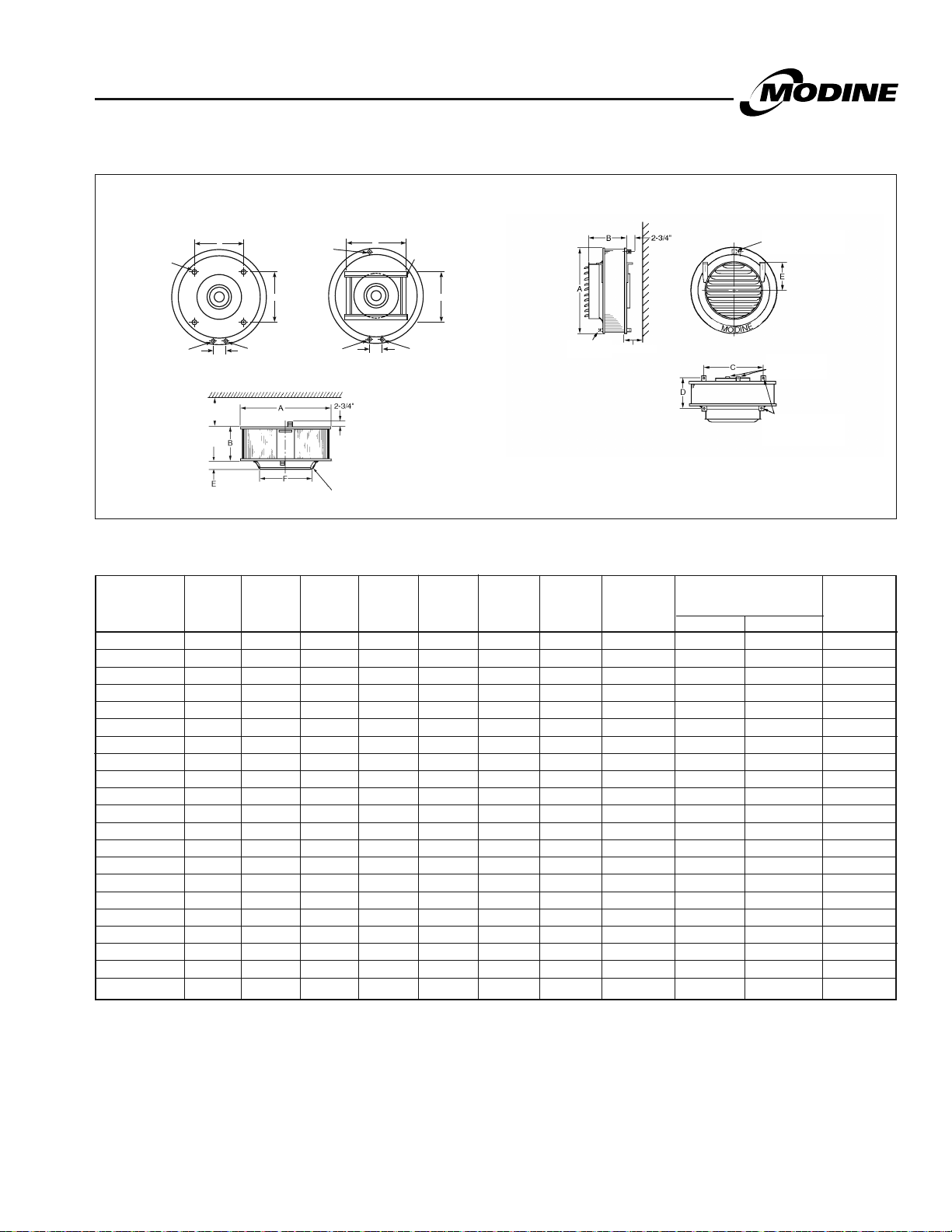

Maximum Mounting Heights for Vertical Outlet Accessories, Dimensions

CONE JET TRUNCONE ONE WAY LOUVERS TWO WAY LOUVERS

H

S

H

S

S

H

S

H

S

H

Table 23.1

Mounting Height/Spread for Vertical Unit Air Outlet AccessoriesMNOP

Cone-Jet Truncone One Way Louvers Two Way Louvers

Standard L.O.T. Standard L.O.T. Standard L.O.T. Standard L.O.T.

Model H S H S H S H S H S H S H S H S

V/VN 42 15 11 17 13 8 19 9 23 13 11 15 13 8 22 9 26

V/VN 59 19 14 22 16 9 25 11 28 16 14 18 16 10 28 11 32

V/VN 78 20 15 26 19 11 26 14 33 17 15 22 19 11 30 13 38

V/VN 95 20 15 26 19 11 26 14 33 17 15 22 19 11 30 13 38

V/VN 139 24 18 31 23 13 32 17 40 21 18 26 23 13 36 16 46

V/VN 161 27 20 35 26 14 35 18 46 23 20 30 26 14 40 18 52

V/VN 193 30 22 36 27 16 39 19 47 25 22 31 27 15 44 19 54

V/VN 212 30 22 36 27 16 39 19 47 25 22 31 27 15 44 19 54

V/VN 247 34 26 42 32 17 46 21 56 30 26 37 32 18 52 22 64

V/VN 279 37 30 45 36 18 53 22 63 35 30 41 36 21 60 25 72

V/VN 333 37 30 45 36 17 53 20 63 35 30 41 36 21 60 25 72

V/VN 385 36 30 43 36 17 53 20 63 35 30 41 36 21 60 25 72

V/VN 500 44 37 54 45 19 65 24 79 42 37 51 45 26 74 31 90

V/VN 610 43 36 52 44 19 63 24 77 41 41 50 44 25 72 30 88

V 952 - - - - - - - - 45 56 54 65 26 66 31 82

M Data shown for standard 2 lb. steam, 60°F entering air temperature conditions. For louvers or cone-jet, data shown for deflectors in fully-opened position.

For mounting height/spread at steam pressures other than 2 lb., multiply the value by the correction factor in Table 11.1.

N For mounting height and spread for hot water, multiple the values above by 1.06 to approximate the mounting height and spread at 200°F entering

water temperature. For entering water temperature other than 200°F, multiply the values above by 1.06 and than multiply the correction factor in Table 16.2

O All dimensions in feet.

P V models have copper tubes and VN models have 90/10 cupro-nickel tubes.

Figure 23.2 - Vertical Air Outlet Accessories

CONE-JET

L

T

TRUNCONE

X

LOUVER

M

Table 23.2 - Vertical Air Outlet Accessories Dimensions Q

Model Cone-Jet Truncone Louvers

Number L T M X P Z

V 42, V 59 6-1/2 18-7/8 12 22 6-1/2 16-7/8

V 78, V 95 6-1/2 18-7/8 12 22 6-1/2 16-7/8

V 139, V 212 7-1/2 24-3/4 13 27 7-1/2 19-3/4

V 247, V 279 8 26-7/8 16 34 8 22-3/4

V 333 8-1/2 28 16 34 8-1/2 22-3/4

V 385, V 500 10 22-3/4 21 41 10 27-3/4

V 610 10-1/2 36-3/4 21 41 10-1/2 30-3/4

V-952 - - - - 19-1/2 32

Q All dimensions in inches.

23

1-150.16

P

Z

23

PERFORMANCE DATA

Motor Data, Step-Down Transformer Accessory Data

Table 24.1 - Motor Data MN

Available Motor Type, Voltage and Power Code

Totally Enclosed

115/60/1 208/60/1 230/60/1 208/60/3 230/460/3 575/60/3 115/60/1 230/460/60/3

Model Number Motor HP O 01 N/A 02 04 05 10 06 09

HSB/HC 18 1/60 3 P 3 P P P 3 HSB/HC/HCH 22, 39, 24, 33 1/25 3 P 3 P P P 3 -

HSB/HC 47, 63 1/12 3 P 3 P 3 Q P 3 -

HSB/HC/HCH 67, 104, 86, 108 1/6, 1/8 3 P 3 P 3 Q P 3 -

HSB/HC 121 1/5 3 P 3 3 Q 3 Q P 3 3

HSB/HC/HCH 165, 170, 193, 195 1/3 3

HSB/HC 258-340 1/2 3 P 3 3 Q 3 Q P 3 3

V/VN 42, 59 1/30 3 P 3 3 Q 3 Q P 3 -

V/VN 78, 95 1/15 3 P 3 3 Q 3 Q P 3 -

V/VN 139 1/5 3 P 3 3 Q 3 Q P 3 3

V/VN 161-212 1/3

V/VN 247 1/2 3 P 3 3 Q 3 Q P 3 3

V/VN, PT/PTN 279 1/2 3 P 3 3 Q 3 Q P 3 3

V/VN, PT/PTN 333 3/4 3 P 3 3 Q 3 Q P - V/VN, PT/PTN 385 1 - - - 3 3 3 - 3

V/VN, PT/PTN 500, 610 1-1/2 - - - 3 3 3 - 3

V, PT 952 2 - - - - 3 - -

M Ratings shown are for Standard and Low Outlet Temperature Models.

N All HSB/HC units, V/VN 42 thru V/VN, PT/PTN 333 motor HP listed for power code 01. V/VN PT/PTN 333 thru V/VN, PT/PTN 610 motor HP listed for power code

04 and V/PT 952 motor HP listed for power code 05.

O For model sizes V/VN/PT/PTN 385 and above, motors for Power Codes 04, 05, and 10 do not have thermal overload protection.

P For supply voltages of 208V/60Hz/1ph and all non-explosion-proof 3 phase voltages of 208, 230, 460 and 575, Model Numbers indicated with Note P, require that a

115V/60Hz/1 phase Power Code 01 unit heater be used with a shipped loose accessory transformer. See Table 24.2 for Transformer Sizes.

Q For non-explosion-proof 3 phase supply voltages of 208, 230, and 460, Model Numbers indicated with Note Q, can be ordered with a Power Code (208V/3ph=04,

230/460V/3ph=05) that provides a motor matched to the supply voltage with amp draw as shown. Alternately, a 115V/60Hz/1 phase Power Code 01 unit heater could

be used with a shipped loose accessory transformer. See Table 24.2 for Transformer Sizes.

3 P 3 3 Q 3 Q P 3 3

P 3 3 Q 3 Q P 3 3

Explosion-proof

3

Figure 24.1

Field Installed Transformer Accessory

Table 24.2 - Step-Down Transformer Accessory Selection

208V/60Hz/1 230/460V/ 575V/60Hz/

or 3 phase 60Hz/3 phase 3 phase

Model Number kVA kVA kVA

HSB/HC 18-63 0.25 0.25

HSB/HC 86-121 0.50 0.50

HSB/HC 165-193 1.00 0.75 0.75

HSB/HC 258-340 1.00 1.00