Modine POR 100, POR 145, POR 185 Installation Manual

INSTALLATION AND SERVICE MANUAL

oil-fired unit heaters

model POR

4-522.3

5H75804 Rev.C

Inspection on Arrival

1. Inspect unit upon arrival. In case of damage, report

immediately to transportation company and you local Modine

sales representative.

2. Check rating plate on unit and motor to verify that power

supply and motor specification requirements meet available

electric power at the point of installation.

3. Inspect unit received for conformance with description of

product ordered (including specifications where applicable).

November, 2003

THIS MANUAL IS THE PROPERTY OF THE OWNER.

PLEASE BE SURE TO LEAVE IT WITH THE OWNER WHEN YOU LEAVE THE JOB.

WARNING

Improper installation, adjustment,

alteration, service or maintenance can

cause property damage, injury or death,

and could cause exposure to substances

which have been determined by various

state agencies to cause cancer, birth

defects or other reproductive harm. Read

the installation, operating and maintenance

instructions thoroughly before installing or

servicing this equipment.

CAUTION

To prevent premature heat exchanger

failure do not locate ANY gas-fired units in

areas where chlorinated, halogenated or

acid vapors are present in the atmosphere.

FOR YOUR SAFETY

WHAT TO DO IF YOU SMELL GAS:

1. Open windows.

2. Do not try to light any appliance.

3. Do not touch any electrical switch; do

not use any phone in your building.

4. Immediately call your gas supplier.

FOR YOUR SAFETY

The use and storage of gasoline or other

flammable vapors and liquids in open

containers in the vicinity of this appliance

is hazardous.

IMPORTANT

The use of this manual is specifically

intended for a qualified installation and

service agency. All installation and service

of these units must be performed by a

qualified installation and service agency.

2

SPECIAL PRECAUTIONS / TABLE OF CONTENTS

SPECIAL PRECAUTIONS

THE INSTALLATION AND MAINTENANCE INSTRUCTIONS IN

THIS MANUAL MUST BE FOLLOWED TO PROVIDE SAFE,

EFFICIENT AND TROUBLE-FREE OPERATION. IN

ADDITION, PARTICULAR CARE MUST BE EXERCISED

REGARDING THE SPECIAL PRECAUTIONS LISTED BELOW.

FAILURE TO PROPERLY ADDRESS THESE CRITICAL

AREAS COULD RESULT IN PROPERTY DAMAGE OR LOSS,

PERSONAL INJURY, OR DEATH. THESE INSTRUCTIONS

ARE SUBJECT TO ANY MORE RESTRICTIVE LOCAL OR

NATIONAL CODES.

HAZARD INTENSITY LEVELS

1. DANGER: Indicates an imminently hazardous situation

which, if not avoided, WILL result in death or serious injury.

2. WARNING: Indicates a potentially hazardous situation

which, if not avoided, COULD result in death or serious injury.

3. CAUTION: Indicates a potentially hazardous situation

which, if not avoided, MAY result in minor or moderate

injury.

4. IMPORTANT: Indicates a situation which, if not avoided,

MAY result in a potential safety concern.

DANGER

Appliances must not be installed where they may be exposed

to a potentially explosive or flammable atmosphere.

WARNING

1. Disconnect power supply before making wiring connections to

prevent electrical shock and equipment damage.

2. All appliances must be wired strictly in accordance with wiring

diagram furnished with the appliance. Any wiring different

from the wiring diagram could result in a hazard to persons

and property.

3. Any original factory wiring that requires replacement must

be replaced with wiring material having a temperature

rating of at least 105°C.

4. When servicing or repairing this equipment, use only

factory-approved service replacement parts. A complete

replacement parts list may be obtained by contacting

Modine Manufacturing Company. Refer to the rating plate

on the appliance for complete appliance model number,

serial number, and company address. Any substitution of

parts or controls not approved by the factory will be at the

owner’s risk.

CAUTION

1. Do not locate units in tightly sealed rooms or small

compartments (commonly referred to as confined spaces)

without provisions for adequate combustion air and

venting. Combustion air must have access to the confined

space through a minimum of two permanent openings in

the enclosure, at least one near the bottom. They should

provide a free area of not less than one square inch per

1,000 BTU/Hr input rating of all units in the enclosure with

a minimum of 100 square inches for each opening,

whichever is greater.

2. When oil-fired unit heaters are to be installed in areas

having negative pressure (for example - a space with

exhaust fan(s)) a power venter is recommended.

3. Do not install units below 7 feet, measured from the

bottom of the unit to the floor, unless properly guarded to

provide protection from moving parts.

IMPORTANT

1. To prevent premature heat exchanger failure, do not locate

ANY gas-fired appliances in areas where corrosive vapors (i.e.

chlorinated, halogenated or acid) are present in the

atmosphere.

2. To check most of the Possible Remedies in the troubleshooting

guide listed in Table 18.1, refer to the applicable sections of the

manual.

Table of Contents

Inspection on Arrival . . . . . . . . . . . . . . . . . . . . . . . . 1

Special Precautions . . . . . . . . . . . . . . . . . . . . . . . . . 2

SI (Metric) Conversion Factors . . . . . . . . . . . . . . . . 3

Unit Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Service Instructions . . . . . . . . . . . . . . . . . . . . . . . . . 14

Dimensional/Performance Data . . . . . . . . . . . . . . . . 17

Service & Troubleshooting . . . . . . . . . . . . . . . . . . . . 18

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Back Page

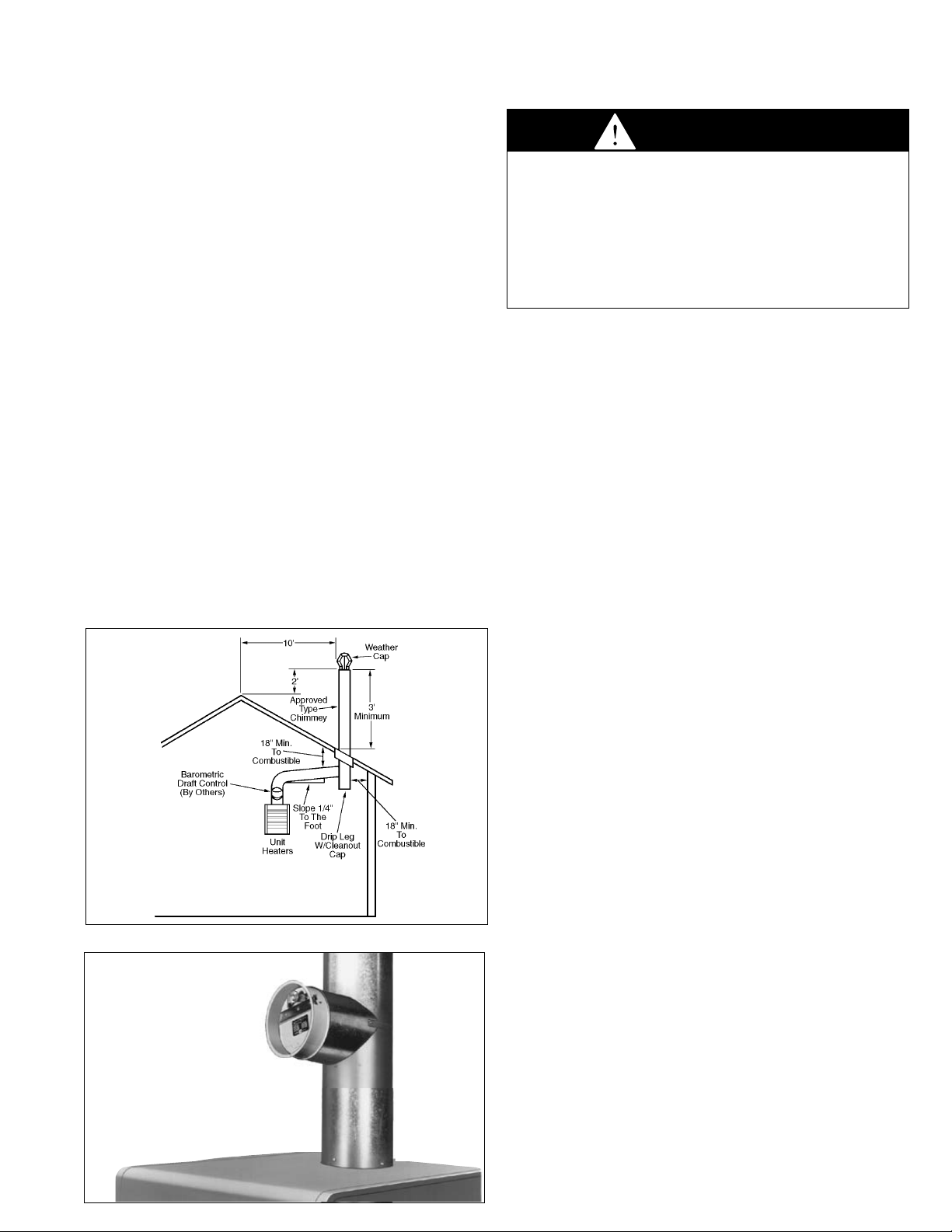

CAUTION

4. Do not install unit heater or vent pipe closer than 18

inches to combustible materials in any direction, except

the front of the unit heater, which must be unobstructed.

5. A barometric draft control must be installed on each unit

heater, in the same space as the unit heater and as close

to the unit as possible. See Figure 5.1.

6. Remove bypass plug from fuel unit when unit is connected

to one pipe oil system. Failure to do so will permanently

damage fuel unit and void warranty.

7. Do not mount the OSV more than three feet above the

burner inlet or above the lowest point in fuel line pipings

between burner and OSV. In-line mounting is recommended.

8. Start-up and adjustment procedures should be performed

by a qualified oil serviceman.

9. Do not reset primary control if heat exchanger is hot. If

unit fails to operate properly after resetting twice, consult

qualified oil serviceman.

10. Never use a nozzle size or type other than specified in

Service Instructions.

11. Do not attempt to start the burner when excess oil has

accumulated in the combustion chamber, when the heat

exchanger is full of oil vapor or very hot.

12. Burner adjustments should only be performed by qualified

oil serviceman.

13. Do not reset primary control if heat exchanger is warm.

Wait till cool.

14. To prevent unusual thermal stress and eventual harm to

the heat exchanger, do not operate unit heater without fire pot

or with a damaged fire pot that does not enclose the flame.

15. Do not attempt to reuse any mechanical or electrical

controllers which have been wet. Replace defective controller.

3

GENERAL INFORMATION

Install and wiring of these oil-fired unit heaters must conform to all

applicable local codes, the National Electric Code, and NFPA No.

31 “Installation of Oil Burning Equipment” by the National Fire

Protection Association. Installation of these unit heaters should

only be performed by a qualified oil serviceman.

1. These unit heaters are listed by Underwriters Laboratories,

Inc., with components as furnished.

2. Fuel oil grade No. 1 or 2, with a flash point not less than

100°F, is approved for these unit heaters as specified by

(ASTM) D396-73 Standard Specification for Fuel Oils, or the

Canadian Government Specification Board, 3-GP-28,

(American Society for Testing and Materials).

SI (METRIC) CONVERSION FACTORS / UNIT LOCATION

CAUTION

1. Do not locate units in tightly sealed rooms or small

compartments (commonly referred to as confined spaces)

without provisions for adequate combustion air and

venting. Combustion air must have access to the confined

space through a minimum of two permanent openings in

the enclosure, at least one near the bottom. They should

provide a free area of not less than one square inch per

1,000 BTU/Hr input rating of all units in the enclosure with

a minimum of 100 square inches for each opening,

whichever is greater.

2. When oil-fired unit heaters are to be installed in areas

having negative pressure (for example - a space with

exhaust fan(s)) a power venter is recommended.

IMPORTANT

To prevent premature heat exchanger failure, do not locate ANY

gas-fired appliances in areas where corrosive vapors (i.e.

chlorinated, halogenated or acid) are present in the atmosphere.

DANGER

Appliances must not be installed where they may be exposed

to potentially explosive or flammable atmosphere.

To Convert Multiply By To Obtain

"W.C.

(inches water column)

0.24 kPa

psig 6.893 kpa

°F (°F-32) × 0.555 °C

inches 25.4 mm

feet 0.305 meters

CFM 0.028 m3/min

CFH 1.699 m3/min

btu/ft

3

0.0374 mJ/m

3

pound 0.453 kg

btu/hr 0.000293 kW/hr

gallons 3.785 liters

SI (METRIC) CONVERSION FACTORS

Table 3.1

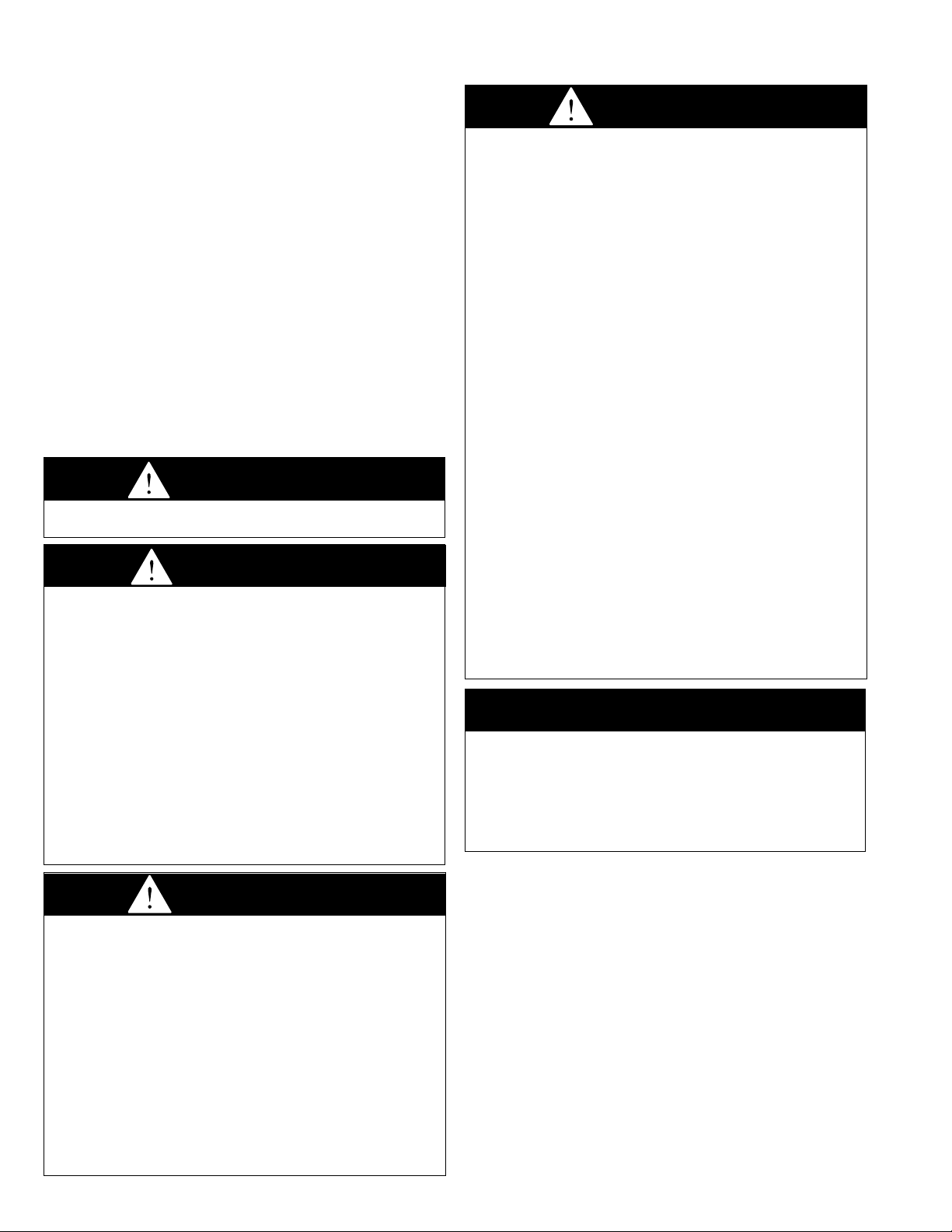

UNIT LOCATION

Location Recommendations

1. When location the furnace, consider general space and

heating requirements, availability of gas and electrical

supply, and proximity to vent locations.

2. Unit heaters should be located so they discharge air nearly

parallel to exposed walls. Arrange units so they do not blow

directly at occupants. Interference of air streams by

columns, beams, partitions, or other obstructions should be

avoided as much as possible.

3. In multiple unit installations, arrange units so that each

supports the air stream of the next unit, thus creating

circulatory air movement in the area. See Figure 3.1. A

large portion of the heated air should be directed toward

the side of the building exposed to prevailing winds.

4. When locating units, it is important to consider that the

exhaust vent piping must be connected to the outside

atmosphere.

5. Be sure the structural support at the unit location site is

adequate to support the weight of the unit. For proper

operation the unit must be installed in a level horizontal

position.

6. Do not install units in locations where the flue products can

be drawn into the adjacent building openings such as

windows, fresh air intakes, etc.

7. Be sure that the minimum clearances to combustible

materials and recommended service clearances are

maintained. Units are designed for installation on with the

minimum clearances shown in Table 3.2.

8. Do not install units in locations where gas ignition system is

exposed to water spray, rain, or dripping water.

9. Mounting Height (measured from bottom of unit) at which

unit heaters are installed is critical. Refer to mounting

height information and heat throw data on page 17 of this

manual. The maximum mounting height for any unit is that

height above which the unit will not deliver heated air to the

floor.

Figure 3.1

Typical Unit Locations

Table 3.2

Combustible material and Service Clearances

All Model Sizes

Top Sides Back Front Bottom Flue

18” 18” 18” Unobstructed 18” 18”

4

INSTALLATION

Combustion Air Requirements

For complete combustion, 14-1/2 lbs. of air is required for each

pound of No. 2 fuel oil. Lack of combustion air can cause erratic

burner operation, noisy combustion, fuel odors and soot

deposits on heat exchanger walls resulting in lowered efficiency

and high fuel consumption.

Units installed in tightly sealed buildings or confined spaces

must be provided with two permanent openings, one near the

top of the confined space and one near the bottom. Each

opening should have a free area of not less than one square

inch per 1,000 BTU per hour of the total input rating of all units

in the enclosure with a minimum of 100 square inches for each

opening, whichever is greater, freely communicating with

interior areas having, in turn adequate infiltration from the

outside.

For further details on supplying combustion air to a confined

(tightly sealed) space or unconfined space, see the National

Fuel Gas Code ANSI Z223.1 of CAN/CGA B149.1 or .2

Installation Code, latest edition.

Confined of Unconfined Spaces

The National Fuel Gas Code defines an “unconfined space” as

a space whose volume is greater than 50 cubic feet per 1000

Btu/Hr input of the installed appliance(s). A confined space is 50

cubic feet or less per 1000 Btu/Hr input of the installed

appliance(s).

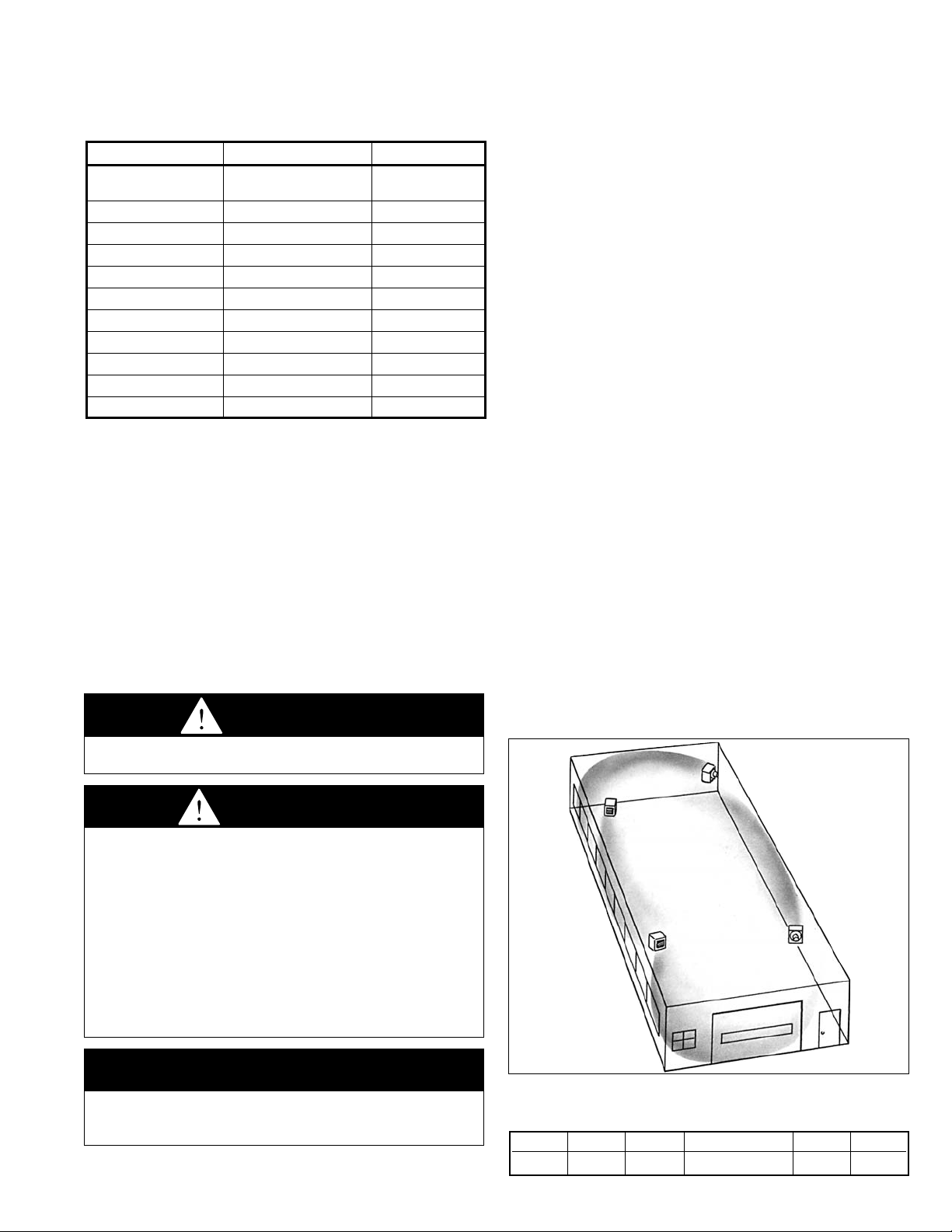

Unit Suspension

1. Be sure the means of suspension is adequate to support

the weight of the unit (see Table 17.1 for unit weights).

2. For proper operation, the unit must be installed in a level

horizontal position.

3. Clearances to combustibles as previously specified must

be strictly maintained.

4. It is recommended that adequate service access in access

of 18 inches be provided for the burner and fan limit switch.

5. Do not install unit heater above the maximum mounting

height shown in Table 17.2.

Four tapped holes (1/2" - 13) in the top of the unit are provided

for unit heater suspension. Suspension can be made with

threaded rods, pipes, or ceiling hanger brackets furnished by

others. See Figure 17.1 for hanger hole locations and Figure

4.1 for suspension methods.

NOTE: A pipe hanger adapter kit, shown in figure 4.1 is

available as an accessory from Modine, or can be selffabricated. Kit consists of two drilled 3/4" I.P.S. pipe caps and

two 1/2" - 13 x 1-3/4" capscrews to facilitate threaded-pipe

suspension. Two kits are required for mounting each unit.

Figure 4.1

Suspension Methods

Venting

1. To dispose of flue gasses, all oil-fired heaters must be

vented per NFPA No. 31 “Installation of Oil Burning

Equipment” and all local codes.

2. Do not install chimney connector closer than 18 inches to

combustible materials in any direction. Where chimney

connector passes through a wall or partition, a metal

ventilated thimble not less than 12 inches larger in diameter

than the connector must be used.

3. All Modine oil-fired heaters have an 8 inch vent connection.

Never use a chimney connector smaller than 8 inches,

except a 7 inch adapter may be used on Model POR100 to

accomodate a 7 inch vent.

4. Install a barometric draft control the same size and on the

vent pipe as close to the unit as possible. Installing a

barometric draft control is essential for proper operation of

the unit. Excessive over fire draft can cause unburned fuel

to accumulate in the stack creating a potentially explosive

condition. To install barometric draft control, refer to

instructions furnished by draft control manufacturer. The air

flow opening of the barometric draft control should face the

front of the unit heater or away from air currents in the

vicinity of the heater.

THE BAROMETRIC DRAFT CONTROL MUST BE ADHUSTED

TO PROVIDE MINUS 0.02 INCHES W.C. (WATER COLUMN)

OVERFIRE DRAFT AS MEASURED BETWEEN THE DRAFT

CONTROL AND THE UNIT AND AS CLOSE TO THE UNIT AS

POSSIBLE.

CAUTION

A barometric draft control must be installed on each unit

heater, in the same space as the unit heater and as close to

the unit as possible. See Figure 5.1.

CAUTION

1. Do not install units below 7 feet, measured from the

bottom of the unit to the floor, unless properly guarded to

provide protection from moving parts.

2. Do not install unit heater or vent pipe closer than 18

inches to combustible materials in any direction, except

the front of the unit heater, which must be unobstructed.

Venting - continued

5. If it is necessary to have an excessively high stack or if the

stack is located such that it is susceptible to updraft

conditions caused by wind, then oversized barometric

dampers should be installed. In extremely windy locations, a

Breidert type vent cap is recommended.

6. For the best venting, the chimney should be as close to the

unit as possible. Keep flue pipes as straight as possible,

avoiding sharp bends. Limit horizontal runs to 75% of

vertical height or a maximum of 10 feet. Horizontal runs in

excess of 10 feet require a draft booster. Chimney

connector must be pitched at a minimum upward slope of

1/4 inch per foot.

7. Condensed flue products will cause rapid corrosion of vent

pipes and heat exchanger. Where possible, avoid venting

through unheated or unoccupied spaces. When necessary,

insulate pipe from cold to maintain draft head and prevent

condensation. Provide a drip leg with a clean-out cap at

bottom of vertical pipe. See Figure 5.1.

8. The chimney must be high enough to provide a minus 0.02

inches W.C. (water column) overfire draft. The top of the

chimney must be at least 3 feet above the highest point

where it passes through the roof and at least 2 feet higher

than any portion of a building within 10 feet of the chimney.

See Figure 5.1.

9. When connecting vent to existing chimney, do not push vent

pipe beyond internal surface of chimney.

10. If making more than one connection into the same chimney,

the chimney connectors must enter at different levels and

the area of the chimney must be equal to or greater than the

combined areas of the individual connectors.

Figure 5.1 - Typical Venting Arrangement

Figure 5.2 - Barometric Draft Control Above Unit

Wiring

General

All wiring must be done in accordance with the National Electric

Code, latest edition, (NFPA No. 70). Canadian electrical code

C22.1 applies in Canada.

Unit Heater Wiring

All internal wiring to the burner motor, fan motor and the fan and

limit control has been completed at the factory. Provide 115-volt

electric service from a fused disconnect switch to the octagon

junction box on the rear of the unit heater. Wire must be

insulated to 60°C and must be a minimum of 14-gauge (AWG)

copper in at least 1/2 inch thin-wall or flexible metal conduit.

Thermostat Wiring

The proper wiring for a single thermostat for each unit heater is

shown in Figure 6.1. The multiple unit wiring diagram shown in

Figure 6.2 illustrates typical wiring and connections used with a

centralized oil distribution system for multiple unit installations.

This diagram is provided as a reference only, and is not

intended to satisfy any particular local code requirements.

System operation and compliance with local codes is the

responsibility of the installer.

As shown, this system includes a relay for low voltage control of

the booster pump, and the line voltage power supply to the

booster pump motor. Figure 6.2 also shows the proper

connections for multiple unit heaters, each controlled by a

thermostat. In this arrangement, a 25V power source is

connected to pressure switches on each unit. Upon demand for

heat, a thermostat energizes the controls which start each

burner. Meanwhile, separate pressure switches, on the fuel unit,

sense an increase in oil pressure, and close their contacts to

activate the booster pump switching relay, which in turn starts

the booster pump. Optional high and low pressure controllers

can supply line pressure. Location of a remote, low-voltage

thermostat should be determined by the heating requirements

and be mounted on an inside wall approximately 5 feet above

the floor. It must not be located where it would be affected by

direct heat from the unit or other sources or drafts from

frequently opened doors or windows. See instructions packed

with thermostat. The unit may also be controlled by a remote

U.L. listed manual on-off switch.

5

INSTALLATION

WARNING

1. Disconnect power supply before making wiring connections to

prevent electrical shock and equipment damage.

2. All appliances must be wired strictly in accordance with wiring

diagram furnished with the appliance. Any wiring different

from the wiring diagram could result in a hazard to persons

and property.

3. Any original factory wiring that requires replacement must

be replaced with wiring material having a temperature

rating of at least 105°C.

6

A

N

A

X

D

A

INSTALLATION

Figure 6.1

Single Unit Wiring Diagram

Figure 6.2

Typical Multiple Unit Installation and Booster Pump Wiring Diagram

WARNING

All appliances must be wired strictly in accordance

with wiring diagram furnished with the appliance.

Any wiring different from the wiring diagram could

result in a hazard to persons and property.

FIELD WIRING

CONNECTIONS

(WIRE NUTS

BY OTHERS)

W

BK

FAN

MOTOR

Wiring Legend

FACTORY

FIELD

WIRE NUT

FAN & LIMIT

CONTROL

FAN LIMIT

BL

BK

115V/60HZ/1∅

FUSED DISCONNECT

SWITCH (BY OTHERS)

FAN

SWITCH

LIMIT

R

CONTROL

FAN

MOTOR

BURNER

MOTOR

GROUN

IN J-BO

BURNER

MOTOR

W

BK

W

W

CAD

IGNITOR

CELL

BURNER HOUSING

LL WIRING MUST CONFORM TO

ATIONAL ELECTRIC CODE NFPA #70

ND APPLICABLE LOCAL CODES

JUNCTION BOX

ON BURNER

GR

BK

W

OR

BL

T

PRIMARY

T

CONTROL

F

F

Single-phase, intermittent ignition,

low voltage thermostat

GROUND

EQUIPMENT

GROUND

LOW

VOLT.

THERM.

(BY OTHERS)

FUSED DISCONNECT

SWITCH (BY OTHERS)

115V/60 HZ/1∅

FIELD WIRING

JUNCTION BOX

(ON HEATER)

USE COPPER

CONDUCTORS ONLY

W

BK

BK

OR

PRIMARY

CONTROL

IGNITOR

WBL

T

LOW VOLT.

THERMOSTAT

T

F

CAD CELL

F

5H70833B REV.

Loading...

Loading...