®

GAS-FIRED HIGH AND LOW INTENSITY

INFRARED HEATERS

MODEL IHR

9-123.5 • FEBRUARY, 2021

MODEL OHP

MODEL IPT

2

9-123.539-123.5

TABLE OF CONTENTS

This catalog describes the design and construction features

and benefits, typical applications, dimensional data, and

configurations available for the IHR and ITP Series.

Modine’s IHR Series is a gas-fired, high intensity ceramic

infrared heater. Ideal for spot heating, the IHR series offers

simple gas and power connections, as well as inexpensive

maintenance.

Modine's IPT Series sets the industry standard for low intensity

infrared heating performance and installation versatility. The

comfort and uniform heating provided by the IPT Series are

second to none.

Table of Contents

General Unit Applications .......................................................... 2

Infrared Heating Defined ....................................................... 2

Advantages of Infrared Heating ............................................ 2

Typical Applications ............................................................... 2

Modine Breeze® AccuSpec Sizing and Selection Program ........ 3

Features and Benefits - Model IHR ............................................ 4

Features and Benefits - Model IHR ............................................ 5

Features and Benefits - Model IPT ............................................ 6

Performance and Dimensional Data - Model IHR ................... 7-8

Performance and Dimensional Data - Model OHP .................... 9

Performance, Utilities, and Clearance - Model IPT .................. 10

Dimensional Data - Model IPT ................................................. 11

Specifications and Model Nomenclature - Model IHR ............. 12

Specifications and Model Nomenclature - Model IPT .............. 13

Infrared Heating Defined

Infrared heating systems rely upon the transfer of radiant

energy from hot heat exchanger surfaces (up to 1850°F for high

intensity heaters) through the air to cooler surfaces, without the

use of an air mover. Since radiant energy always travels in a

straight line from its source, people and objects within a direct

line-of-sight of the heat exchanger become warmed immediately.

While capable of being used for total building heating or

large area heating, they are ideally suited for spot heating

applications. Spot heating involves small areas such as loading

dock doors and single person work cells.

Advantages of Infrared Heating

No air mover, reducing electricity and maintenance costs

while increasing worker comfort from the absence of drafts

and annoying fan noise.

Quick temperature recovery, as only objects need to be

heated, not large volumes of air.

Significant energy savings through use of zone control and/

or spot heating, which heats objects without the need to heat

large air volumes.

Typical Applications

The following are examples of applications that can benefit from

high-intensity infrared heating:

Manufacturing facilities

Vehicle repair centers

Warehouses and loading docks

Aircraft hangars

Indoor tennis courts

Indoor golf driving ranges

Emergency vehicle garages

Indoor stadium seating areas

The following are examples of applications that can benefit from

low-intensity infrared heating:

Manufacturing facilities

Vehicle repair centers

Refer to page 3 for information regarding the

Breeze® AccuSpec Sizing and Selection Program

WARNING

Do not locate ANY gas-fired unit in areas where chlorinated,

halogenated or acid vapors are present in the atmosphere.

As Modine Manufacturing Company has a continuous product improvement program, it reserves the right to change design and specifications without notice.

!

Warehouses and loading docks

Aircraft hangars

Tennis courts

Car washes

Golf driving ranges

Covered walkways

Emergency vehicle garages

Stadium seating areas

Vestibules

See Infrared Design and Engineering Guide 9-200 for additional

application information.

WARNING

Do not install in potentially explosive or flammable atmosphere

laden with dust, sawdust, or similar airborne materials.

!

MODINE BREEZE® ACCUSPEC SIZING & SELECTION PROGRAM

Modine Breeze® AccuSpec

Sizing and Selection Program

The Modine Breeze® AccuSpec is the fastest way to generate performance data based

on actual job conditions. The Breeze® AccuSpec program is a web-based sizing and

selection program. The program provides a series of step-by-step questions that allow

for the easy configuration of Modine products. After a model has been configured, the

program can generate Submittal Schedules, Submittal Data (including performance and

dimensional drawings), and Specifications.

Fast and Simple Unit/Thermostat/Accessory Selection

Job Specific

Specifications

Submittal Schedules

Unit Specific

Dimensional Drawings

For access to the Breeze® AccuSpec program, contact your local Modine sales representative.

4

9-123.5

FEATURES AND BENEFITS - MODEL IHR

Figure 4.1 - Construction Features - Model IHR

Features

1. High temperature cordierite-based grooved ceramic tiles

with perforations along both the top and bottom of the

grooves

2. Polished aluminum reflectors

3. 16 gauge aluminized steel frame

4. No air mover is utilized

5. Input ranges from 30,000 Btu/hr through 160,000 Btu/hr

in Natural or Propane gas

6. Direct spark or self-energizing standing pilot ignition

7. 115V, 25V, or millivolt controls

8. Externally-mounted controls

9. Burners are replaced by removing one fastener

10. CSA design certification for indoor, unvented operation in

commercial and industrial installations

Benefits

1. Increased temperature and surface area to provide maximum

heat transfer while maintaining lower gas input ratings.

2. Efficiently direct radiant heat to the desired area, for

increased comfort over wider areas.

3. Provides support for simple chain mounting.

4. Eliminates fan noise, drafts, maintenance and reduces

electrical energy costs.

5. Wide input range to accommodate a variety of heating

requirements

6. Maximize application flexibility.

7. Accommodate a wide range of electrical inputs.

8. Allow convenient access to gas valve, control system,

transformer, and gas orifices, increasing ease of installation

and service.

9. Eliminates the removal of the unit from its mounted position

for service.

10. Assures that the unit conforms to national safety standards.

9-123.5

5

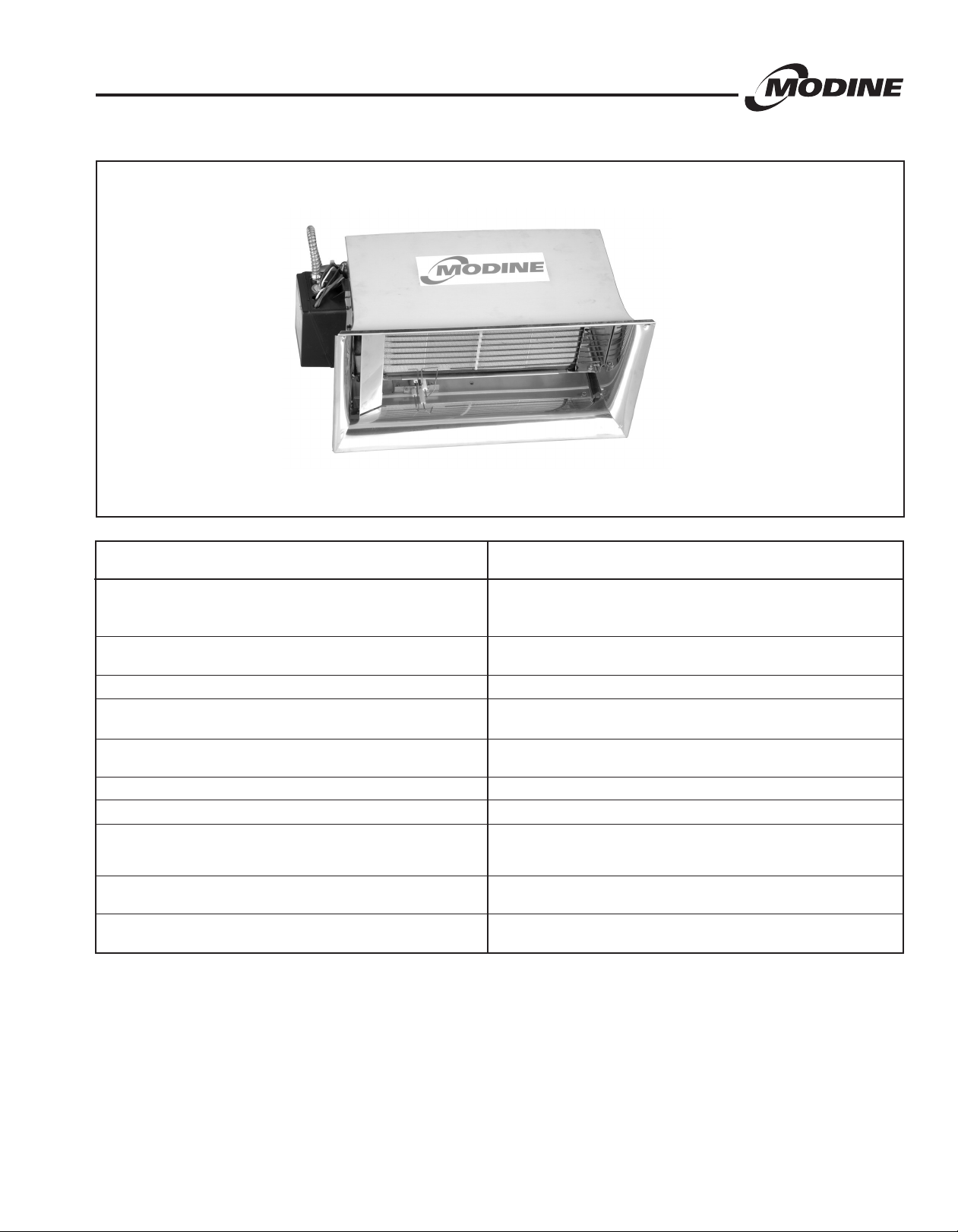

FEATURES AND BENEFITS - MODEL OHP

Figure 5.1 - Construction Features - Model OHP

Features

1.ETL Design Certified to ANSI Z83.26 Standard

2. Decorative stainless steel windscreen eggcrate grille

3. Wind and rain protected design

4. 31,000 and 34,000 BTU inputs.

5. No Fan Design.

6. Externally-mounted controls

7. Direct spark or self-energizing standing pilot ignition

8. Brushed 430 Stainless Steel Housing

Benefits

1. Assures that the unit conforms to national safety standards.

2. Prevents wind disturbance.

3. Input range to accommodate a variety of heating

requirements.

4. Flexible fuel type offering.

5.Eliminates fan noise, drafts, maintenance and reduces

electrical energy costs.

6. Allow convenient access to gas valve, control system,

transformer, and gas orifices, increasing ease of installation

and service.

7. Maximize application flexibility.

8. Provides maximum corrosion resistance.

6

9-123.5

FEATURES AND BENEFITS - MODEL IPT

Figure 6.1 - Construction Features

6

4, 13

8, 11

9

Features

1. Heat-treated darkened aluminized steel tubes

2. Polished aluminum reflectors

3. Removable side-access panels on both sides of the

burner box

4. Durable polyester-powder paint

5. Permanently-lubricated combustion blower motor

6. 180 degree-rotating gas valve

7. Sealed burner compartment

8. Flame sensor and ignitor mounted externally to the

combustion chamber

9. Flame observation window on underside of combustion

chamber

10. Gas valve operation light on back panel on the unit

11. Four-trial separate flame sensor

12. System approval for vented and common vented

installation

13. Weatherproof, water-resistant casing

14. ETL design certification

5

3 (not shown)

7

10

Benefits

1. Heat-treated darkening increases both radiant heat output for

more heat near the end of the tube system and eliminates

the scratching and flaking that can occur with painted tubes.

Aluminized steel provides corrosion resistance for longer life.

2. Direct radiant heat from the tubes to the desired area, for

increased comfort over wider areas.

3. Can be removed completely while accessing either side of the

unit.

4. Maintains life-long new appearance.

5. Reduces maintenance.

6. Allows convenient access from either side of the burner box.

7. Allows manifold pressure adjustments during unit operation,

which increases ease of installation and service.

8. Improve service access.

9. Provides a convenient visual check of unit operation from

ground level.

10. Indicates that the combustion blower is operating.

11. Provides reliable ignition.

12. Maximizes installation flexibility.

13. Maximizes application flexibility for both indoor and outdoor

installation.

14. Assures that the unit conforms to national safety standards.

9-123.5

7

PERFORMANCE AND DIMENSIONAL DATA - MODEL IHR

Table 7.1 - Performance and Dimensional Data

Recommended Mounting Height (ft.) ➀

Model

IHR 30 Single Stage or Millivolt 30,000 12 - 14 12 - 15 12 3/4 14 1/4 44 85

IHR 60 Single Stage or Millivolt 60,000 14 - 16 18 - 21 19 1/8 15 1/4 60 170

IHR 90 Single Stage or Millivolt 90,000 16 - 18 21 - 25 26 5/8 15 1/4 81 255

IHR 130 Single Stage or Millivolt 130,000 21 - 24 26 - 32 32 15 1/4 55 340

IHR 160 Single Stage or Millivolt 160,000 24 - 28 29 - 35 38 1/2 15 1/4 65 425

➀ See Table 8.1 for allowable mounting angles.

➁ See Figure 7.1.

➂ Single stage controls are direct spark ignition with 100% safety shutoff and are available as either 115V or 24V

④ Millivolt thermostat and 35 feet of wire.

Gas Controls

➂ ➃

Input Rating (Btu/hr)

Natural Propane

Standard

Reflector

30°

Angle

Parabolic

Reflector

30°

Angle

Dimensions

(in) ➁

A B

Ship

Wt.

(lbs)

Radiating

(sq. in.)

Figure 7.1 - Unit Dimensional Drawing

Area

8

9-123.5

PERFORMANCE AND DIMENSIONAL DATA - MODEL IHR

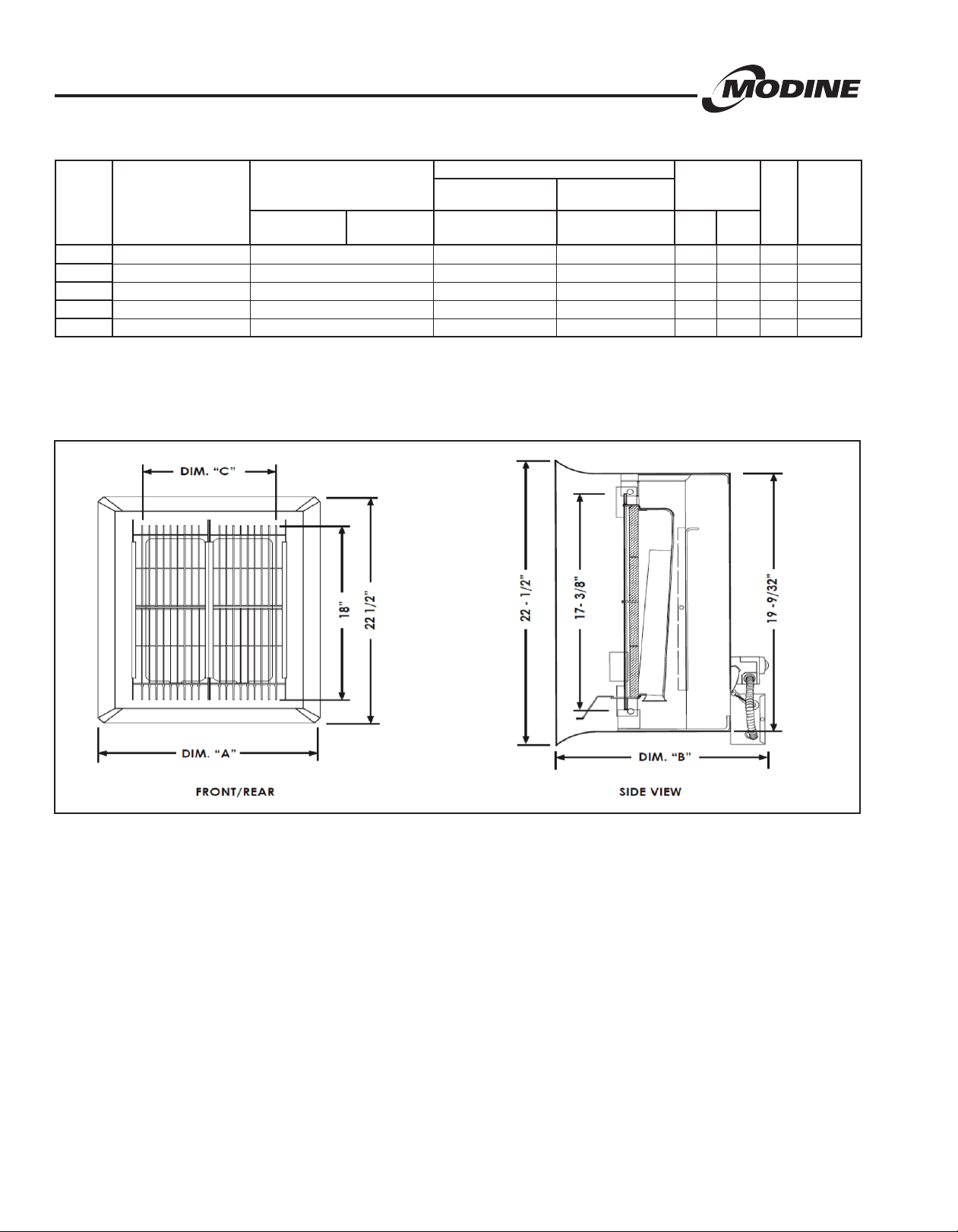

Table 8.1 - Allowable Mounting Angle Range

Model Size Allowable Mounting Angle Range

30 – 160 20° – 35°

Table 8.2 - Clearances to Combustible Materials (See Figure 8.3)

Model Sizes

Side of Heater

Back of Heater 18 18 30 30 32

Top of Heater 28 40 42 52 60

Below Front 72 72➀ 98 120 132

➀ Clearance is 80 in. when heater is fitted with a parabolic reflector.

Figure 8.3 - Clearances to Combustibles (See Table 8.2)

30 60 90 130 160

30 32 48 48 50

9-123.5

9

PERFORMANCE AND DIMENSIONAL DATA - MODEL OHP

Table 9.1 - Performance and Dimensional Data

Model

OHP 31 430 SS 31,000 59 lbs 8.0' to 12.0' 8' x 8' 24 vac

OHP 34 430 SS 34,000 59 lbs 8.5' to 13.0' 9' x 9' 24 vac

➀ Clearance is 80 in. when heater is fitted with a parabolic reflector.

Housing BTU/Hr input Ship Weight

Figure 9.1 - Unit Dimensional Drawing

Recommended Mounting

Heights ➀

Approx. Area

Heated

Control Voltage

Table 9.2 - Clearances to Combustible Materials

Model Sizes

31,000 (N,P)

34,000 (N) 34,000 24 vac

➀ Heaters mounted on an angle between 1° to 30° must maintain clearances posted for 0° or 30°; whichever is greater.

BTU'Hr Voltage

31,000 24 vac

Mounting

Angle ➀

0° 18 N/A 13 48 12 N/A

30° N/A 18 18 40 12 36

0° 18 N/A 13 48 12 N/A

30° N/A 18 18 40 12 36

Side Back Top Below End(s) Front

Figure 9.2 - Clearance to Combustibales

10

9-123.5

Mounting

Height

Minimum Clearance to

Combustible Materials

Stacking

Height

"B"

"C"

"A"

0° MOUNTING ANGLE

"B"

"C"

"C"

CHAIN LOCATION

45° MOUNTING ANGLE

(MAXIMUM)

"A"

PERFORMANCE, UTILITIES AND CLEARANCE - MODEL IPT

Electrical Rang Gas Connecon (inch)

Minimum Gas Inlet

Pressure (" W.C.)

Maximum Gas

Inlet Pressure

("W.C.)

Manifold Gas Pressure (' W.C.)

Tube/Vent Diameter

(inch)

60Hz/1Ph 1/2 NPT

7.0 (natural gas)

11.0 (propane gas)

14.0

3.5 (natural gas-single stage)

2.5 (natural gas-two stage)

10.0 (propane gas-single stage)

6.2 (propane gas-two stage)

4 (O.D.)

Table 10.1 - Performance

Input MBH 50 60 75 100 125 150 175 200

Certified Tube Lengths (ft.)

50 ➁ 70 ➂ 70 ➂

Recommended

10 – 12 10 – 12 12 – 14 12 – 14 15 – 22 15 – 22 18 – 28 20 - 30

Mounting Height (ft.) ➀

Recommended

Tube System

Application ➀

➀ Recommended Mounting Height and Tube System Applications are meant as a general guide and are adjusted to meet the requirements of the actual application.

The applications are as follows:

-- Spot or Area Heating is an application where occupant comfort is the goal and occupant(s) are either relatively stationary (Spot - Example: small work cell or

dispersed over a slightly wilder range than with Spot Heating (Area - Example: assembly line). Mounting height is typically at the low end of the range shown above.

-- Total Building Heating is an application where average space temperature is to be maintained, however due to the significant temperature gradient differences

on long straight tube systems, areas may exist where direct occupant comfort is not achieved.

➁ IPT 100 not available for Propane Gas operation at 50 ft. tube system length.

➂ IPT 75 not available for Propane Gas operation at 40 ft. tube section length.

Spot or Area

Heating

Total Building

Heating

Table 10.2 - Utilities

20, 30

20, 30, 40 20, 30, 40

30, 40,

Straight Tube

40, 50, 60 50, 60

U-Tube

50, 60, 50, 60,

Table 10.3 - Combustible Material

Clearances ➀ ➁ ➂

Combusble Material Clearances (inches)

Input MBH

50/60

75/100/125

150/175/200 12 106 38

➀ Clearance to each end and above the U-Tube is 12 inches.

➁ In unvented applications, clearance from radiant tube end

is 36" in all directions.

➂ Refer to Figures 8.1 through 8.3.

Figure 10.2 - Stacking Height

1

➀ ➁ ➂

"A"

9 54 20

9 76 24

IPT

2

"B"

"C"

Figure 10.1 - Combustible Material Clearances -

Straight Tube

CHAIN LOCATION

3

"A"

"C"

"B"

0° MOUNTING ANGLE

"A"

"C"

"C"

"B"

45° MOUNTING ANGLE

(MAXIMUM)

Figure 8.3 - Combustible Material Clearances - U-Tube

CHAIN LOCATION

"A"

CHAIN LOCATION

"A"

"C"

"B"

"U" TUBE

0° MOUNTING ANGLE

9-123.5

"A"

"C"

"B"

"C"

"B"

"B"

"U" TUBE

45° MOUNTING ANGLE

(MAXIMUM)

12"

11

TOP VIEW

TOP VIEW

FRONT VIEW

SIDE VIEW

BACK VIEW

12.39

12.00

1.36

2.61

6.00

4.00

4.00

O

1.000

GAS CONNECTION

O

.875

THERMOSTAT

CONNECTION

O

.875

LINE VOLTAGE

CONNECTION

10.00

23.12

21.91

11.00

13.58

14.99

6.00

3.65

B

A

11"

28"

DIMENSIONAL DATA - MODEL IPT

Figure 11.1 - Casing Dimensions

Figure 11.2 - Burner and Tube System Dimensions

14"

Center-to-center of tubes = 16 inches.

Table 11.1 - Tube Systems Data

Straight Tube U-Tube System

Tube Length (ft.) System Length “A” (ft.) System Weight (lb.) System Length “B” (ft.) System Weight (lb.)

20 23 78 13 89

30 33 112 18 132

40 43 146 23 157

50 53 180 28 200

60 63 214 33 225

70 73 252 38 277

Table 11.2 - Burner Shipping Weights

Model Shipping Wt. (lb.)

All Burners 43

12

9-123.5

SPECIFICATIONS, MODEL NOMENCLATURE - MODEL IHR

General

The heater reflector housing shall be constructed of one-side

bright polished aluminum. The emitter shall be composed of a

perforated ceramic tile on which combustion takes place on the

surface. The burner plenum shall be constructed of aluminized

steel of one-piece drawn construction. The heater shall be

of a modular design employing multiple burners to achieve the

specified input.

• The venturi is constructed of stainless or aluminized

steel.

• The secondary re-radiating rods shall be constructed

of high temperature stainless steel alloy placed in

close proximity of the ceramic burner face.

• Parabolic reflectors shall be used when units are

installed in high mounting applications or when

focusing of the infrared heating pattern is desirable.

• Protective screens shall be used in facilities where

debris may damage the heater.

Burner

The ceramic burner face shall operate at a temperature range

of 1660 degrees F to 1810 degrees F and shall incorporate a

secondary re-radiating surface of stainless steel rods to obtain

optimum operating temperature and radiant output.

Reflectors

The heater reflector housing shall be constructed of one-side

bright polished aluminum. The emitter shall be composed of a

perforated ceramic tile on which combustion takes place on the

surface. The burner plenum shall be constructed of aluminized

steel of one-piece drawn construction. The heater shall be

of a modular design employing multiple burners to achieve the

specified input.

Controls shall be exterior mounted for easy accessibility.

All controls shall be rated for a maximum inlet pressure of 1/2

PSI gas pressure. Controls shall be designed for Natural gas

having a specific gravity of 0.60, a Btu content of 1050 Btu/ft3

(Alternate: Propane gas having a specific gravity of 1.53, a Btu

content of 2500 Btu/ft3) at 0-2000 feet elevation.

Accessories

The following field installed accessories shall be included

(check those that apply):

Chain mounting set - 5’ chain set with 4 “S” hooks. Preset

mounting angle of 30°.

Horizontal parabolic reflector - Directs rays directly

downward. Can be used for matching horizontal mounting

specifications.

Full parabolic reflector - Directs rays in a more focused

pattern. Typically used in high mounting applications.

Full parabolic reflector with screen - Directs rays in a more

focused pattern. Outer screen protects ceramic grids from

objects striking the heater.

DR heater screen - Screen slips on the outside of the

reflectors and protects the ceramic grids.

Warning plaque - Hung below heater, restates the

clearance to combustible warning.

• The venturi is constructed of stainless or aluminized

steel.

• The secondary re-radiating rods shall be constructed

of high temperature stainless steel alloy placed in

close proximity of the ceramic burner face.

• Parabolic reflectors shall be used when units are

installed in high mounting applications or when

focusing of the infrared heating pattern is desirable.

• Protective screens shall be used in facilities where

debris may damage the heater.

Controls

Heater(s) shall be equipped with (check one):

• Heaters shall be equipped with one of the following control

systems:

Standing Manual Pilot System with 100% safety shut-off

of pilot and main burner in case of pilot outage, operating

with no external electrical connection but on milli-voltage

generated by the pilot flame (NMV-2 or PMV-2).

Direct Spark Ignition System with direct spark ignition

of the main burner through a solid state ignition module

operating a spark electrode. Loss of power causes 100%

safety shut-off of main burner(s). System operates on 120

or 24 volts (NFS-2 or PFS-2). 24V/60Hz/1ph with 6VA

maximum power consumption.

Figure 12.1 - Model Number Designations

IHR 9 0 G 4 7

Control Code

IHR - High Intensity

Infrared Heater

MBH Input

30 - 30,000 Btu/hr

60 - 60,000 Btu/hr

90 - 90,000 Btu/hr

130 - 130,000 Btu/hr

160 - 160,000 Btu/hr

Direct Spark Ignition

47 = Natural, 115V, Direct

Spark, 1-Stage

48 = Natural, 24V, Direct

Spark, 1-Stage

97 = Propane, 115V, Direct

Spark, 1-Stage

98 = Propane, 24V, Direct

Spark, 1-Stage

27 = Natural, Millivolt,

1-Stage

67 = Propane, Millivolt,

1-Stage

S - Spark Ignition System

M - Standing Pilot,

Milivolt System

9-123.5

13

SPECIFICATIONS, MODEL NOMENCLATURE - MODEL IPT

MODEL NUMBER

1, 2, 3 4, 5, 6 7 8, 9 10, 11

IPT

200 S 01 11

S: DIRECT SPARK

MODEL PREFIX:

IMPROVED PRESSURE TUBE: IPT

MBH INPUT: 50, 60, 75,100, 125, 150, 175, 200

MODEL SIZE:

IGNITION TYPE:

11: SINGLE STAGE, NATURAL GAS

21: SINGLE STAGE, PROPANE GAS

CONTROL CODE:

POWER CODE:

01: 115V/60HZ/1PH

DIGIT SEQUENCE

12: TWO STAGE, NATURAL GAS

22: TWO STAGE, PROPANE GAS

General

Contractor shall furnish and install Modine model __________

low intensity infrared heater(s). The low intensity infrared

system shall be straight tube________, U-tube_______

configuration. Performance shall be as indicated on the

equipment schedule in the plans. The infrared heater(s) shall be

certified for indoor and outdoor installations. Infrared heater(s)

shall have ETL design certification for use in both the US and

Canada.

Casing

The controls, combustion air blower and burner shall be housed

in a water-resistant casing, providing weatherproof protection.

The burner and control box casing shall be constructed of not

less than 20 gauge aluminized steel. After forming, the casing

parts shall be cleaned of all oils and a phosphate coating

applied prior to painting. The phosphated parts shall then be

finished with an electrostatically applied, gray-green polyester

powder paint finish. The applied polyester powder paint shall

be baked on to provide an attractive finish on all of the exposed

casing parts.

Heat Exchanger

The heat exchanger tubes and combustion chamber shall be

constructed of 16 gauge, 4" O. D. aluminized steel, and the first

combustion tube for gas inputs 150,000 Btuh and greater shall

be 16 gauge 4" O. D. 409 Aluminized Stainless Steel. The last

heat exchanger tube shall incorporate a turbulator baffle for

maximum efficiency of heat transfer.

The heat exchanger tubes must be used in conjunction with

reflectors. The reflector can be adjusted from 0° to 45° from

the horizontal plane. Reflectors shall be of bright polished

aluminum.

Figure 13.1 - Model Number Designations

Controls

Input power to the infrared heater(s) shall be 115V/60Hz/1ph.

Heater(s) shall be equipped with a direct four-trial (three

re-trial), 100% shut-off eletronic ignition control system

with a separate flame sensor. Infrared heater(s) shall be

equipped with a 115V/25V control transformer. Thermostat

shall operate on 25V. Heater(s) will be equipped with a prepurge mode, a differential pressure switch, and an indicator

light to prove proper operation of the gas valve. All controls

shall be rated for a maximum inlet pressure of 1/2 PSI gas

pressure.

Controls shall be designed for natural_______,

propane_______ gas having a specific gravity of _______, a

Btu content of _______ Btu/ft3 at _______ feet elevation.

Motor

Each heater shall have a single motor. The combustion air

blower motor shall be totally enclosed in the control box and

the motor shall be protected by a thermal overload switch.

The motor shall be .03 H.P., 115 volt, 60 Hz, single phase,

with an operating speed of 3000 rpm.

14

9-123.5

9-123.5

15

The Modine brand has been the

industry standard since Arthur B.

Modine invented and patented

the first lightweight, suspended

hydronic unit heater in 1923.

No other manufacturer can

provide the combined application

flexibility, technical expertise and

fast delivery found at Modine.

Consult your local Modine

distributor for help in solving your

indoor air problems.

Products from Modine are designed to provide indoor air-comfort and ventilation

solutions for residential, commercial, institutional and industrial applications.

Whatever your heating, ventilating and air conditioning requirements, Modine

has the product to satisfy your needs, including:

H VA C

• Unit Heaters:

– Gas

– Hydronic

– Electric

– Oil

• Ceiling Cassettes

• Duct Furnaces

• Hydronic Cabinet Unit Heaters, Fin Tube, Convectors

• Infrared Heaters

• Make-up Air Systems

• Unit Ventilators

Ventilation

• Packaged Rooftop Ventilation

School Products

• Vertical Packaged Classroom HVAC:

– DX Cooling/Heat Pump

– Water/Ground Source Heat Pump

– Horizontal/Vertical Unit Ventilators

Specific catalogs are available for each product. Catalogs 75-136 and 75-137

provide details on all Modine HVAC equipment.

®

Modine Manufacturing Company

1500 DeKoven Avenue

Racine, Wisconsin 53403-2552

Phone: 1.800.828.4328 (HEAT)

www.modinehvac.com

© Modine Manufacturing Company 2021

9-123.5

Loading...

Loading...