INSTALLATION AND SERVICE MANUAL

separated combustion gas-fired unit heaters

WARNING

1. Improper installation, adjustment, alteration,

service or maintenance can cause property

damage, injury or death, and could cause

exposure to substances which have been

determined by various state agencies

to cause cancer, birth defects or other

reproductive harm. Read the installation,

operating and maintenance instructions

thoroughly before installing or servicing this

equipment.

2. Do not locate ANY gas-fired units in areas

where chlorinated, halogenated, or acidic

vapors are present in the atmosphere. These

substances can cause premature heat

exchanger failure due to corrosion, which

can cause property damage, serious injury,

or death.

FOR YOUR SAFETY

WHAT TO DO IF YOU SMELL GAS:

1. Open windows.

2. Do not try to light any appliance.

3. Do not touch any electrical switch; do

not use any phone in your building.

4. Immediately call your gas supplier

fromaneighbor’sphone.Followthegas

supplier’sinstructions.Ifyoucannotreach

your gas supplier, call your fire department.

6-584.8

5H0800020000

September, 2015

model HDS and HDC

All models approved for use in California by the CEC and

in Massachusetts. Unit heater is certified for residential and

commercial applications.

FOR YOUR SAFETY

The use and storage of gasoline or other

flammable vapors and liquids in open containers

in the vicinity of this appliance is hazardous.

IMPORTANT

The use of this manual is specifically intended

for a qualified installation and service agency.

All installation and service of these units must

be performed by a qualified installation and

service agency.

Inspection on Arrival

1. Inspect unit upon arrival. In case of damage, report it

immediately to transportation company and your local

Modine sales representative.

2.

Check rating plate on unit to verify that power supply meets

available electric power at the point of installation.

3. Inspect unit upon arrival for conformance with description of

product ordered (including specifications where applicable).

Table of Contents

Inspection on Arrival ................................. 1

Special Precautions ................................. 2

SI (Metric) Conversion Factors......................... 3

Before you Begin ................................... 3

Unit Location....................................... 4

Combustible Material and Service Clearances ......... 4

Unit Mounting .................................. 5

Venting ....................................... 6

Gas Connections............................... 12

High Altitude Accessory Kit . . . . . . . . . . . . . . . . . . . . . . . 13

Electrical ..................................... 15

Operation..................................... 16

Unit Components .................................. 17

Dimensions....................................... 18

Service/Troubleshooting............................. 19

Unit Wiring Diagram ................................ 20

Serial/Model Number/Replacement Parts ............... 21

Commercial Warranty........................Back Cover

PLEASE BE SURE TO LEAVE IT WITH THE OWNER WHEN YOU LEAVE THE JOB.

THIS MANUAL IS THE PROPERTY OF THE OWNER.

SPECIAL PRECAUTIONS

SPECIAL PRECAUTIONS

THE INSTALLATION AND MAINTENANCE INSTRUCTIONS IN THIS

MANUAL MUST BE FOLLOWED TO PROVIDE SAFE, EFFICIENT

AND TROUBLE-FREE OPERATION. IN ADDITION, PARTICULAR

CARE MUST BE EXERCISED REGARDING THE SPECIAL

PRECAUTIONS LISTED BELOW. FAILURE TO PROPERLY ADDRESS

THESE CRITICAL AREAS COULD RESULT IN PROPERTY DAMAGE

OR LOSS, PERSONAL INJURY, OR DEATH. THESE INSTRUCTIONS

SUBJECT TO ANY MORE RESTRICTIVE LOCAL OR NATIONAL

CODES.

HAZARD INTENSITY LEVELS

1. DANGER: Indicates an imminently hazardous situation

which, if not avoided, WILL result in death or serious injury.

2. WARNING: Indicates a potentially hazardous situation

which, if not avoided, COULD result in death or serious injury.

3. CAUTION: Indicates a potentially hazardous situation which,

if not avoided, MAY result in minor or moderate injury.

4. IMPORTANT: Indicates a situation which, if not avoided,

MAY result in a potential safety concern.

DANGER

Appliances must not be installed where they may be exposed

to a potentially explosive or flammable atmosphere.

WARNING

1. Gas fired heating equipment must be vented - do not

operate unvented.

2. A built-in power exhauster is provided - additional external

power exhausters are not required or permitted.

3. If an existing heater is being replaced, it may be necessary

to resize the venting systems. Improperly sized venting

systems can result in vent gas leakage or the formation of

condensate. Refer to the National Fuel Gas Code ANSI

Z223.1 (NFPA 54) or CSA B149.1 latest edition. Failure to

follow these instructions can result in injury or death.

4. Under no circumstances should two sections of double wall

vent pipe be joined together within one horizontal vent system

due to the inability to verify complete seal of inner pipes.

5. All field gas piping must be pressure/leak tested prior to

operation. Never use an open flame. Use a soap solution

or equivalent for testing.

6. Gas pressure to appliance controls must never exceed

14" W.C. (1/2 psi).

7. To reduce the opportunity for condensation, the minimum

sea level input to the appliance, as indicated on the serial

plate, must not be less than 5% below the rated input,

or 5% below the minimum rated input of dual rated units.

8. Disconnect power supply before making wiring connections

to prevent electrical shock and equipment damage.

9. All appliances must be wired strictly in accordance with

wiring diagram furnished with the appliance. Any wiring

different from the wiring diagram could result in a hazard to

persons and property.

10. Any original factory wiring that requires replacement must

be replaced with wiring material having a temperature

rating of at least 105°C.

11. Ensure that the supply voltage to the appliance, as indicated

on the serial plate, is not 5% greater than the rated voltage.

12. When servicing or repairing this equipment, use only

factory-approved service replacement parts. A complete

replacements parts list may be obtained by contacting

the factory. Refer to the rating plate on the appliance for

complete appliance model number, serial number, and

company address. Any substitution of parts or controls not

approved by the factory will be at the owner's risk.

CAUTION

1. All literature shipped with this unit should be kept for

future use for servicing or service diagnostics. Do not

discard any literature shipped with this unit.

2. Consult piping, electrical, and venting instructions in this

manual before final installation.

3. Do not attach ductwork, air filters, or polytubes to any

propeller unit heater.

4. Clearances to combustible materials are critical. Be sure to

follow all listed requirements.

5. Low profile heaters are designed for use in heating applica tions with ambient startup temperatures between -40°F and

90°F, and ambient operating temperatures between 40°F

and 90°F.

6. Do not install unit outdoors.

7. In garages or other sections of aircraft hangars such

as offices and shops that communicate with areas used for

servicing or storage, keep the bottom of the unit at least

7' above the floor unless the unit is properly guarded

to provide user protection from moving parts. In parking

garages, the unit must be installed in accordance with

the standard for parking structures ANSI/NFPA 88A latest

edition, and in repair garages the standard for repair garages

NFPA 30A - latest edition (Formerly NFPA 88B). In Canada,

installation of heaters in airplane hangars must be in

accordance with the requirements of the enforcing authority,

and in public garages in accordance with the current CSAB149 codes.

8. In aircraft hangars, keep the bottom of the unit at least 10'

from the highest surface of the wings or engine enclosure

of the highest aircraft housed in the hangars and in

accordance with the requirements of the enforcing authority

and/or NFPA 409-latest edition.

9. Installation of units in high humidity or salt water

atmospheres will cause accelerated corrosion resulting in a

reduction of the normal life of the units.

10. Do not install units below 7' measured from the bottom of

the unit to the floor in commercial applications (unless

unit is properly guarded to provide user protection from

moving parts) and 5' measured from the bottom of the unit

to the floor in residential applications.

11. Be sure no obstructions block air intake and discharge of

unit heaters.

12. The minimum distance from combustible material is based

on the combustible material surface not exceeding 160°F.

Clearance from the top of the unit may be required to be

greater then the minimum specified if heat damage, other

than fire, may occur to materials above the unit heater at

the temperature described.

13. Allow 18" of clearance at rear (or 6" beyond end of motor at

rear of unit, whichever is greater) and access side to

provide ample air for proper operation of fan.

14. Installation must conform with local building codes or in the

absence of local codes, with the National Fuel Gas

Code, ANSI Z223.1 (NFPA 54) - latest edition. In Canada

installation must be in accordance with CSA-B149.1.

15. The concentric vent adapter box must be installed inside

of the structure or building. Do not install this box on the

exterior of a building or structure.

16. Purging of air from gas supply line should be performed as

described in the National Fuel Gas Code, ANSI Z223.1

(NFPA 54) - latest edition, or, or in Canada in CSA-B149

codes.

17. When leak testing the gas supply piping system, the

appliance and its combination gas control must be isolated

during any pressure testing in excess of 14" W.C. (1/2 psi).

2

6-584.8

SPECIAL PRECAUTIONS / SI (METRIC) CONVERSION FACTORS

BEFORE YOU BEGIN

CAUTION

18. The unit should be isolated from the gas supply piping

system by closing its field installed manual shut-off valve.

This manual shut-off valve should be located within 6' of

the heater.

19. Turn off all gas before installing appliance.

20. Ensure that the supply voltage to the appliance, as

indicated on the serial plate, is not 5% less than the rated

voltage.

21. Check the gas inlet pressure at the unit upstream of the

combination gas control. The inlet pressure should be

6-7" W.C. on natural gas or 12-14" W.C. on propane. If

inlet pressure is too high, install an additional pressure

regulator upstream of the combination gas control.

22. Service or repair of this equipment must be performed by

a qualified service agency.

23. Do not attempt to reuse any mechanical or electronic

ignition controllers which has been wet. Replace defective

controller.

IMPORTANT

1. To prevent premature heat exchanger failure, do not locate

ANY gas-fired appliances in areas where corrosive vapors

(i.e. chlorinated, halogenated or acid) are present in the

atmosphere.

2. To prevent premature heat exchanger failure, the input to

the appliance as indicated on the serial plate, must not

exceed the rated input by more then 5%.

3. To prevent premature heat exchanger failure, observe

heat exchanger tubes. If the tubes become red while

blower and furnace are in operation, check to be sure the

blower has been set to the proper rpm for the application.

Refer to page 15 for blower adjustments.

4. Start-up and adjustment procedures must be performed

by a qualified service agency.

CAUTION

1. All literature shipped with this unit should be kept for future

use for servicing or service diagnostics. Leave manual with

the owner. Do not discard any literature shipped with this unit.

2. Consult piping, electrical, and venting instructions in this

manual before final installation.

3. Do not attach ductwork, air filters, or polytubes to any

propeller unit heater.

In the U.S., the installation of these units must comply with the

National Fuel Gas Code, ANSI Z223.1 - latest edition (NFPA

54) and other applicable local building codes. In Canada, the

installation of these units must comply with local plumbing or

waste water codes and other applicable codes and with the

current code CSA-B149.1.

1. All installation and service of these units must be

performed by a qualified installation and service agency

only as defined in ANSI Z223.1, latest edition or in

Canada by a licensed gas fitter.

2. This unit is certified with the controls furnished. For

replacements parts, please order according to the

replacement parts list on serial plate. Always know your

model and serial numbers. The right is reserved to

substitute other authorized controls as replacements.

3. Unit is balanced for correct performance. Do not alter fan

or operate motors at speeds below what is shown in this

manual.

4. Information on controls is supplied separately.

5. The same burner is used for natural and propane gas.

To check most of the possible remedies in the troubleshooting

guide listed in Table 19.1, refer to the applicable sections of the

manual.

SI (METRIC) CONVERSION FACTORS

To Convert Multiply By To Obtain

"W.C. 0.249 kPa

°F (°F-32) x 5/9 °C

Btu 1.06 kJ

Btu/ft

Btu/hr 0.000293 kW

CFH (ft

CFH (ft

CFM (ft

CFM (ft

3

37.3 kJ/m

3

/hr) 0.000472 m3/min

3

/hr) 0.00000787 m3/s

3

/min) 0.0283 m3/min

3

/min) 0.000472 m3/s

To Convert Multiply By To Obtain

feet 0.305 m

Gal/Hr. 0.00379 m

Gal/Hr. 3.79 l/hr

3

gallons 3.79 l

Horsepower 746 W

inches 25.4 mm

pound 0.454 kg

psig 6.89 kPa

psig 27.7 "W.C.

3

/hr

6-584.8

3

UNIT LOCATION

UNIT LOCATION

DANGER

Appliances must not be installed where they may be exposed

to a potentially explosive or flammable atmosphere.

CAUTION

1. Clearances to combustible materials are critical. Be sure to

follow all listed requirements.

2. Low profile heaters are designed for use in heating

applications with ambient startup temperatures between

-40°F and 90°F, and ambient operating temperatures

between 40°F and 90°F.

3. Do not install unit outdoors.

4. In garages or other sections of aircraft hangars such

as offices and shops that communicate with areas used for

servicing or storage, keep the bottom of the unit at least

7' above the floor unless the unit is properly guarded.

In parking garages, the unit must be installed in accordance

with the standard for parking structures ANSI/NFPA

88A-latest edition, and in repair garages the standard for

repair garages NFPA 30A - latest edition (Formerly NFPA

88B). In Canada, installation of heaters in airplane

hangars must be in accordance with the requirements

of the enforcing authority, and in public garages in

accordance with the current CSA-B149 codes.

5. In aircraft hangars, keep the bottom of the unit at least 10'

from the highest surface of the wings or engine enclosure

of the highest aircraft housed in the hangars and in

accordance with the requirements of the enforcing authority

and/or NFPA 409-latest edition.

6. Installation of units in high humidity or salt water

atmospheres will cause accelerated corrosion, resulting in

a reduction of the normal life of the units.

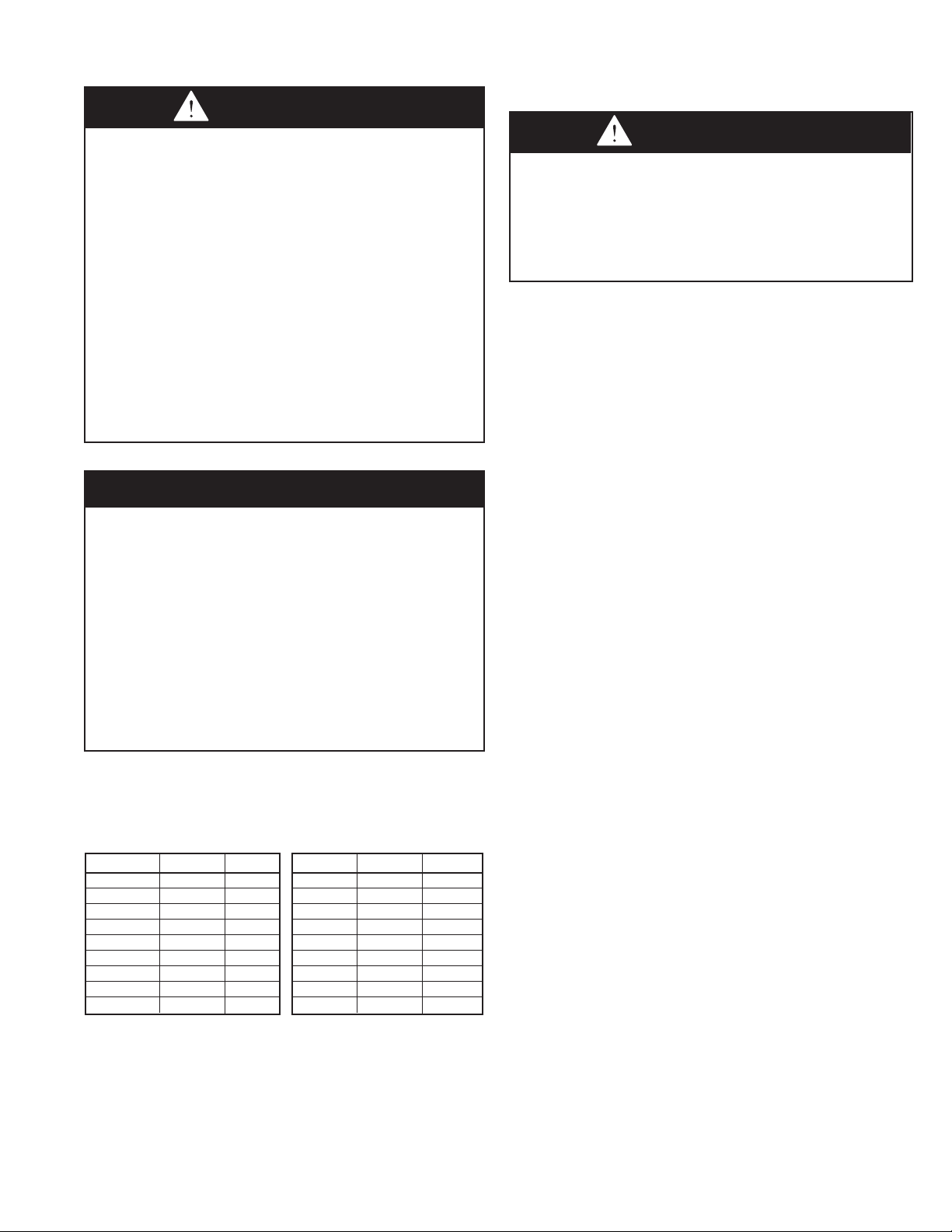

Table 4.1 - Clearances

Unit Side

Combustible Materials Service Clearance

Top and Bottom 1" 1"

Access Side 1" 18"

Non-Access Side 1" 1"

Rear 18" 18"

Vent Connector 4" 4"

6. Do not install units in locations where gas ignition system is

exposed to water spray, rain, or dripping water.

7. Mounting height (measured from bottom of unit) at which unit

heaters are installed is critical. Refer to mounting height and

heat throw data on page 16 of this manual. The maximum

mounting height for any unit is that height above which the

unit will not deliver heated air to the floor.

Clearance To Recommended

Turning The Unit 180° (Model sizes 30-75 only)

All units are produced at the factory with left-side controls (when

looking at the unit). If the installation requires the controls to

be on the right side, all HDS/HDC heaters - with the exception

of the 100 and 125 - can be turned-over by following the

instructions below.

• By turning the unit 180° from the way it was received from

the factory, the sides become opposite but the front and

back remain in the same relative position. The bottom

panel now becomes the top panel and vice-versa.

• Remove the access panel, turn it 180°, and re-attach it to

the unit so that all the information labels can be read.

• Remove the spring-loaded deflector blades, turn them over,

replace, and adjust so they are open and in a position to

direct the heated air down to the floor.

IMPORTANT

To prevent premature heat exchanger failure, do not locate

ANY gas-fired appliances in areas where corrosive vapors

(i.e. chlorinated, halogenated or acid) are present in the

atmosphere.

Location Recommendations

1. When locating the heater, consider general space and

heating requirements, availability of gas and electrical

supply, and proximity to vent locations.

2. When locating units, it is important to consider that the

combustion air and exhaust vent piping must be connected

to the outside atmosphere. Vent terminals should be located

adjacent to one another. Maximum equivalent vent lengths

are listed in “Section A - General Instruction - All Units” of the

venting instructions.

3. Be sure the structural support at the unit location site is

adequate to support the unit's weight. For proper operation

the unit must be installed in a level horizontal position.

4. Do not install units in locations where the flue products

can be drawn into the adjacent building openings such as

windows, fresh air intakes, etc.

5. Be sure that the minimum clearances to combustible

materials and recommended service clearances are

maintained. Units are designed for installation with the

minimum clearances as shown in Table 4.1.

4

6-584.8

UNIT MOUNTING

CAUTION

1.

Do not install units below 7' measured from the bottom of

the unit to the floor in commercial applications (unless

unit is properly guarded to provide user protection from

moving parts) and 5' measured from the bottom of the unit

to the floor in residential applications.

2. Be sure no obstructions block air intake and discharge

of unit heaters.

3. The minimum distance from combustible material is

based on the combustible material surface not exceeding

160°F. Clearance from the top of the unit may be required

to be greater than the minimum specified if heat damage,

other than fire, may occur to materials above the unit

heater at the temperature described.

4. Allow 18" clearance at rear (or 6" beyond end of motor

at rear of unit, whichever is greater) and access side to

provide ample air for proper operation of fan.

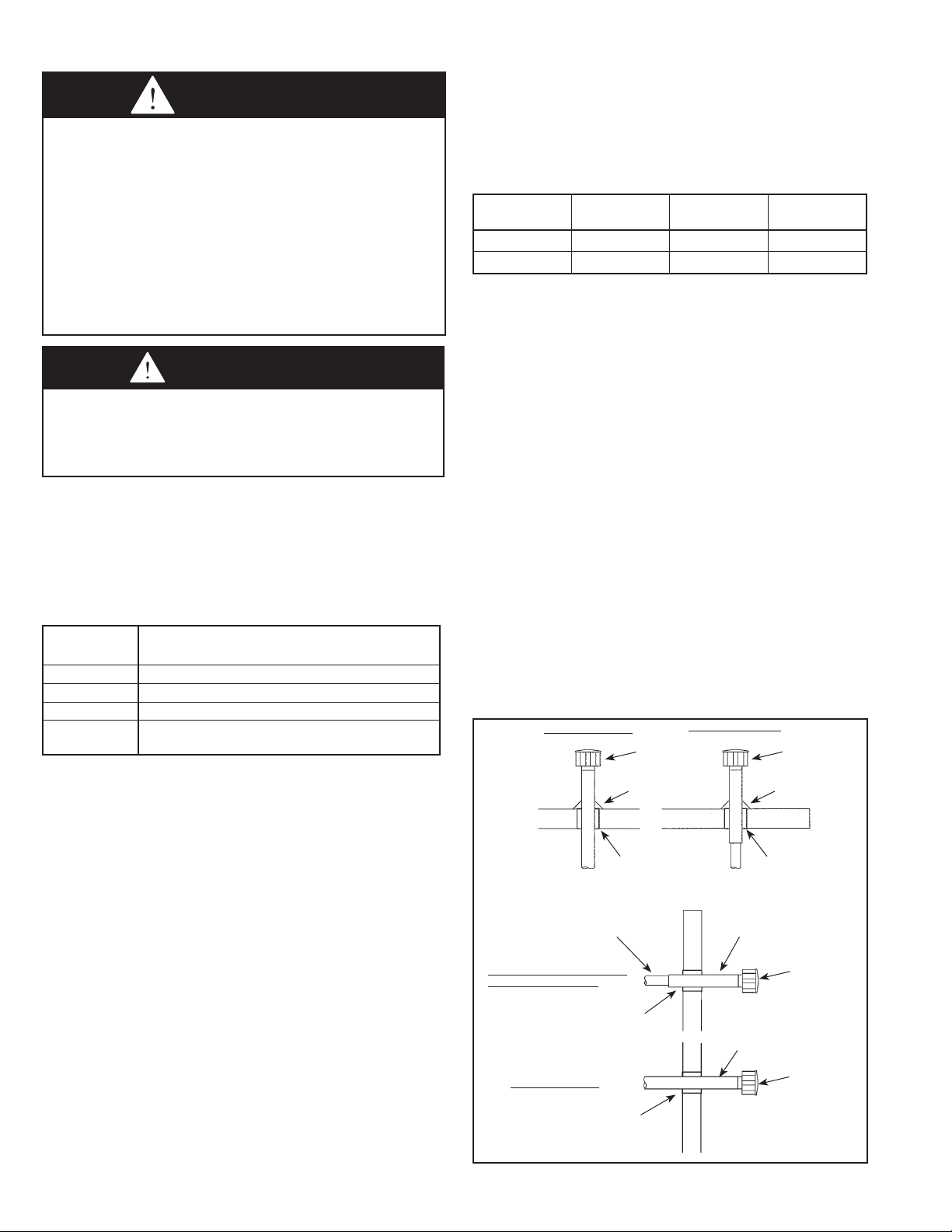

Figure 5.2 - Unit Heater Turned 180° (30-75 units only)

(Access panel and heated air outlet change sides)

1. Be sure the means of suspension is adequate to support

the weight of the unit (see page 18 for unit weights).

2. For proper operation, the unit must be installed in a level

horizontal position.

3. Clearances to combustibles as previously specified must be

strictly maintained.

4. For model sizes 30-75, before lifting the heater for

suspension, the mounting brackets must be installed as

follows (for bracket accessory installation on model sizes

100-125, see the latest revision of literature 6-594):

• For standard (left side) control access, remove the 3

screws and mounting bracket along the top edge of both

the front and back of the unit. Install the front bracket as

shown in Figure 5.1 by aligning the screw holes on the

bracket with the screw holes on the top edge of the unit.

Repeat for the bracket on the back of the unit.

• For right side control access, remove the 3 screws and

mounting bracket along the top edge of both the front and

back of the unit. Turn the unit over and install the front

bracket as shown in Figure 5.2 by aligning the screw holes

on the bracket with the screw holes on the top edge of the

unit (originally the bottom edge). Repeat for the bracket on

the back of the unit.

5a. Suspension by screws/lag bolts: Secure the mounting

brackets to the ceiling joists or truss, using 1/4" screws with

1/2" washers. These unit mounting brackets are slotted to

accommodate joists on 16" or 24" centerlines. See page 18

for mounting bracket dimensions.

Figure 5.1 - Unit Heater in Standard Mounting

Configuration (30-75 units only)

5b. Suspension by threaded rod: The unit can also be hung

with threaded rod utilizing the same mounting brackets.

Attach the threaded rod to the unit mounting brackets,

securing with a top and bottom nut. For model sizes

100-125, the units are designed to be suspended by

threaded rod without the use of brackets. On each piece of

3/8" threaded rod used, screw a nut a distance of about 1"

onto the end of the threaded rods that will be screwed into

the unit heater. Place a washer over the end of the threaded

rod and screw the threaded rod into the unit heater weld nuts

on the top of the heater at least 5 turns, and no more than

10 turns. Tighten the nut first installed onto the threaded rod

to prevent the rod from turning.

Next, drill holes into a steel channel or angle iron at the

same centerline dimensions as those chosen for the heater

being installed. The steel channels or angle iron pieces need

to span and be fastened to appropriate structural members.

Cut the threaded rods to the preferred length, push them

through the holes in the steel channel or angle iron and

secure with washers and lock nuts, lock washers and nuts,

or a washer with double nut arrangement.

NOTE: A pipe hanger adapter kit, shown in Figure 5.3, is

available as an accessory. One kit consists of two drilled

3/4" IPS pipe caps and two 3/8" - 16 x 1-3/4" capscrews

to facilitate threaded pipe suspension. Two kits would be

required.

5c. Shelf mounted units: The unit heater can also be installed

on a shelf. The mounting brackets will need to be attached

to the heater the same manner as explained in note #4,

however, to mount on a shelf the brackets must go on the

bottom of the heater. The brackets must be affixed to the

shelf using similar screws (1/4" screw with 1/2" washer) as

overhead joist or truss mounting. Be sure all clearance to

combustible requirements are met.

Figure 5.3 - Unit Heater Suspension Methods

(Threaded Rod) (Pipe Adaptor Kit)

6-584.8

5

INSTALLATION - VENTING

WARNING

1. Gas fired heating equipment must be vented - do not

operate unvented.

2. A built-in power exhauster is provided - additional external

power exhausters are not required or permitted.

3. If an existing heater is being replaced, it may be necessary

to resize the venting systems. Improperly sized venting

systems can result in vent gas leakage or the formation of

condensate. Refer to the National Fuel Gas Code ANSI

Z223.1 (NFPA 54) or CSA-B149.1 Installation Code - latest

edition. Failure to follow these instructions can result in

serious injury or death.

4. Under no circumstances should 2 sections of double wall

vent pipe be joined together within 1 horizontal vent system

due to the inability to verify complete seal of inner pipes.

CAUTION

Installation must conform with local building codes or in the

absence of local codes, with Part 7, Venting of Equipment, of

the National Fuel Gas Code, ANSI Z223.1 (NFPA 54) - latest

edition. In Canada installation must be in accordance with

CSA B149.1.

Model HDS/HDC unit heaters must be vented with the proper

passageway as described in these instructions to convey

flue gases from the unit or the vent connector to the outside

atmosphere. The heaters must also have a separate combustion

air intake pipe to bring in fresh air for combustion from the

outside atmosphere.

The venting instructions are organized in sections, based on

installation type. The sections are identified as follows:

Instructions Applicable Installation Instructions

Section by Vent System Type

A General instructions for ALL installations

B VERTICAL 2-PIPE vent systems ➀

C HORIZONTAL 2-PIPE vent systems ➀

D HORIZONTAL AND VERTICAL

CONCENTRIC vent systems ➀

➀ The differences between vertical and horizontal vent systems in 2-Pipe or

concentric vent configurations will be identified in “Section A - General

Instructions – All Units”.

A4. Refer to Table 6.1 for total equivalent vent pipe lengths,

making the vent system as straight as possible. Refer to

Table 6.1 for total equivalent vent pipe lengths, making the

vent system as straight as possible.

Table 6.1 - Vent Pipe Diameters, Transitions, and

Total Equivalent Vent Pipe Lengths For Horizontal

and Vertical Venting Systems

Model

Size

30-45 3" 3' 25'

60-125 4" 3' 25'

A5. A minimum of 12" straight pipe is recommended from the

flue outlet before turns in the vent pipe.

A6. Horizontal sections of vent pipe are to be installed with a

minimum downward slope from the appliance of 1/4" per foot

and suspended securely from overhead structures at points

not greater than 3' apart.

A7. Fasten individual lengths of vent together with at least 3

corrosion-resistant sheet metal screws.

A8. Keep single wall vent pipe at least 6" from combustible

materials. For double wall vent pipe, follow the vent

pipe manufacturer’s clearances to combustibles. The

minimum distance from combustible materials is based

on the combustible material surface not exceeding 160°F.

Clearance from the vent pipe (or the top of the unit) may be

required to be greater than 6" if heat damage other than fire

could result (such as material distortion or discoloration).

A9. Avoid venting through unheated space when possible.

When venting does pass through an unheated space or

if the unit is installed in an environment that promotes

condensation, insulate runs greater than 5' to minimize

condensation. Inspect for leakage prior to insulating and use

insulation that is noncombustible with a rating of not less

than 400°F. Install a tee fitting at the low point of the vent

system and provide a drip leg with a clean out cap as shown

in Figure 8.1.

Vent Pipe

Sizes

Minimum

Eqv. Length

Maximum

Eqv. Length

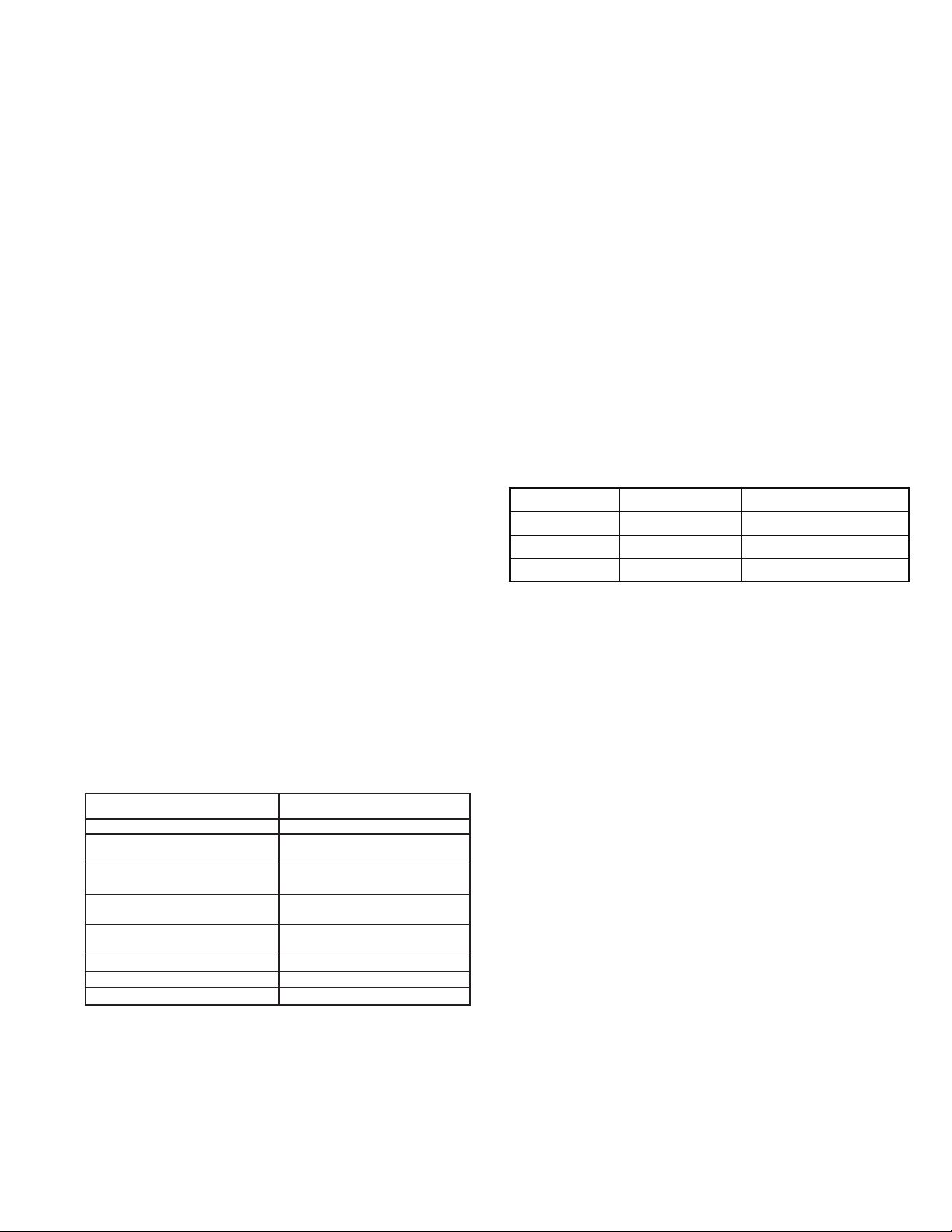

Figure 6.1 - Venting Through Combustible Roof or Wall

Single Wall Vent Pipe

Flashing

Listed

Terminal

Double Wall Vent Pipe ➀

Flashing

Listed

Terminal

Section A – General Instructions – All Units

A1. If the unit heater being installed is replacing existing

equipment and using the existing vent system from that

equipment, inspect the venting system for proper size and

horizontal pitch, as required in the National Fuel Gas Code

ANSI Z223.1 or CSA B149.1 Installation Code-latest edition

and these instructions. Determine that there is no blockage

or restriction, leakage, corrosion and other deficiencies,

which could cause an unsafe condition.

A2. The combustion air pipe and vent pipe should be galvanized

steel or other suitable corrosion resistant material. Follow

the National Fuel Gas Code for minimum thickness of vent

material. The minimum thickness for connectors varies

depending on the pipe diameter. Do not vent unit with PVC

or other forms of plastic venting material.

A3. All heaters come with factory installed vent and combustion

air adapters for attaching the vent pipe to the heater. Attach

the vent pipe to the adapter with 3 corrosion resistant

screws. (Drill pilot holes through the vent pipe and adapter

prior to screwing in place). Vent pipe must not be smaller

than the connector size.

6

Listed

Thimble

Single

Wall

Single Wall Vent Pipe Terminating

with Double wall vent pipe. ➀

Clearance Specified

by Type B Vent Mfg.

Single Wall Vent Pipe

Listed

Thimble

➀ See Instruction A12 for attaching single wall pipe to double wall pipe.

6-584.8

Clearance Specified

by Type B Vent Mfg.

Double

Wall

Listed

Terminal

Single

Wall

Listed

Terminal

INSTALLATION - VENTING

A10. When the vent passes through a combustible INTERIOR

wall or floor, a metal thimble 4" greater than the vent

diameter is necessary. If there is 6' or more of vent pipe in

the open space between the appliance and where the vent

pipe passes through the wall or floor, the thimble need only

be 2" greater than the diameter of the vent pipe. If a thimble

is not used, all combustible material must be cut away

to provide 6" of clearance. Where authorities have

jurisdiction type B vent may be used for the last section

of vent pipe to maintain clearance to combustibles while

passing through wall or floor (see Figure 6.1). Any material

used to close the opening must be noncombustible.

A11. All seams and joints of the single wall pipe must be sealed

with metallic tape or silastic suitable for temperatures up to

400°F. Wrap the tape 2 full turns around the vent pipe. One

continuous section of double wall vent pipe may be used

within the vent system to pass through the wall to a listed

vent cap. Refer to instruction A12 in “Section A – General

Instructions – All Units” for attaching double wall pipe to

single wall pipe.

A12. The following are general instructions for double wall (type

B) terminal pipe installation:

How to attach a single wall vent terminal to double wall

(type B) vent pipe:

1. Look for the “flow” arrow on the vent pipe.

2. Slide the vent terminal inside the exhaust end of the

double wall vent pipe.

3. Drill 3 holes through the pipe and the vent terminal.

Using 3/4" long sheet metal screws, attach the cap to

the pipe. Do not overtighten.

How to connect a single wall vent system to a double

wall (type B) vent pipe:

1. Slide the single wall pipe inside the inner wall of the

double wall pipe.

2. Drill 3 holes through both walls of the single and double

wall vent pipes. Using 3/4" sheet metal screws, attach

the 2 pieces of pipe. Do not overtighten.

3. The gap between the single and double wall pipe must

be sealed but it is not necessary to fill the full volume

of the annular area. To seal, run a large bead of 400°F

silastic around the gap.

A13. Vent termination clearances must be maintained:

Table 7.1 - Vent Termination Clearances

Minimum Clearances for

Structure Vent Terminal Location

Forced air inlet within 10 feet 3 feet above

Combustion air inlet of another

appliance 6 feet all directions

Door, window, gravity air inlet, 4 feet horizontal and below

or any building opening 1 foot above

Electric meter, gas meter, gas 4 feet horizontal (U.S.)

regulator, and relief equipment ➀ 6 feet horizontal (Canada)

Gas regulator ➀ 3 feet horizontal (U.S.)

6 feet horizontal (Canada)

Adjoining building or parapet wall 6 feet all directions

Adjacent public walkways 7 feet all directions

Grade (ground level) 3 feet above

➀

Do not terminate the vent directly above a gas meter or regulator.

A14. Do NOT vent this appliance into a masonry chimney.

A15. Do NOT use dampers or other devices in the vent or

combustion air pipes.

A16.

The venting system must be exclusive to a single

appliance, and no other appliance is allowed to be vented

into it.

A17. Precautions must be taken to prevent degradation of

building materials by flue products.

A18. Single wall vent pipe must not pass through any

unoccupied attic, inside wall, concealed space, or floor.

A19. Uninsulated single wall vent pipe must not be used

outdoors for venting appliances in regions where the 99%

winter design temperature is below 32°F.A19. Long runs

of horizontal or vertical combustion air pipes may require

insulation in very cold climates to prevent the buildup of

condensation on the outside of the pipe where the pipe

passes through conditioned spaces.

A20. Vertical combustion air pipes should be fitted with a tee

with a drip leg and a clean out cap to prevent against the

possibility of any moisture in the combustion air pipe from

entering the unit. The drip leg should be inspected and

cleaned out periodically during the heating season.

A21. The vent terminal must be:

Table 7.2 - Vent Terminals (two pipe)

Model Size Modine PN Other Listed Terminals

30-45 5H0722850005 Gary Steel 1092

60-75 5H0722850001 Gary Steel 1092

100-125 5H0722850001 Gary Steel 1092

A22. In addition to following these general instructions, specific

instructions for vertical and horizontal vent systems in

2-Pipe or concentric vent configurations must also be

followed. The following outlines the differences:

Vertical Category III Vent System Determination

• Vertical vent systems terminate vertically (up) (an example is

shown in Figure 8.1).

• Determine the venting configuration as follows:

> For two building penetrations through the wall or roof (one

for the combustion air inlet pipe and one for the vent pipe),

proceed to “Section B - Vertical 2-Pipe Venting”.

> For a single larger building penetration through the wall or

roof, through which both the combustion air inlet and vent

pipes will pass, proceed to “Section D - Horizontal and

Vertical Concentric Venting”.

> For all other cases, proceed to the next section for

Horizontal Vent System Determination.

Horizontal Category III Vent System Determination

• Horizontal vent systems terminate horizontally (sideways)

(an example is shown in Figure 9.1).

• Determine the venting configuration as follows:

> For two building penetrations through the wall or roof (one

for the combustion air inlet pipe and one for the vent pipe),

proceed to “Section C - Horizontal 2-Pipe Venting”.

> For a single larger building penetration through the wall or

roof, through which both the combustion air inlet and vent

pipes will pass, proceed to “Section D - Horizontal and

Vertical Concentric Venting”.

6-584.8

7

INSTALLATION - VENTING

Section B – Vertical 2-Pipe Vent System

Installation

B1. This section applies to vertically vented 2-pipe (one

combustion air inlet pipe and one vent pipe) vent systems

and is in addition to “Section A – General Instructions – All

Units”.

B2. Vertical vent systems terminate vertically (up).

B3. It is recommended to install a tee with drip leg and clean out

cap as shown in Figure 8.1.

B4. The combustion air and vent pipes must be terminated with

2 listed vent caps.

B5. Vertical vents must terminate a minimum horizontal and

vertical distance from roof lines and adjacent walls or

obstructions. These minimum distances are outlined in

Figure 8.1 and Table 8.1.

B6. The vent must terminate at least 1' above and 6" horizontally

from the combustion air inlet.

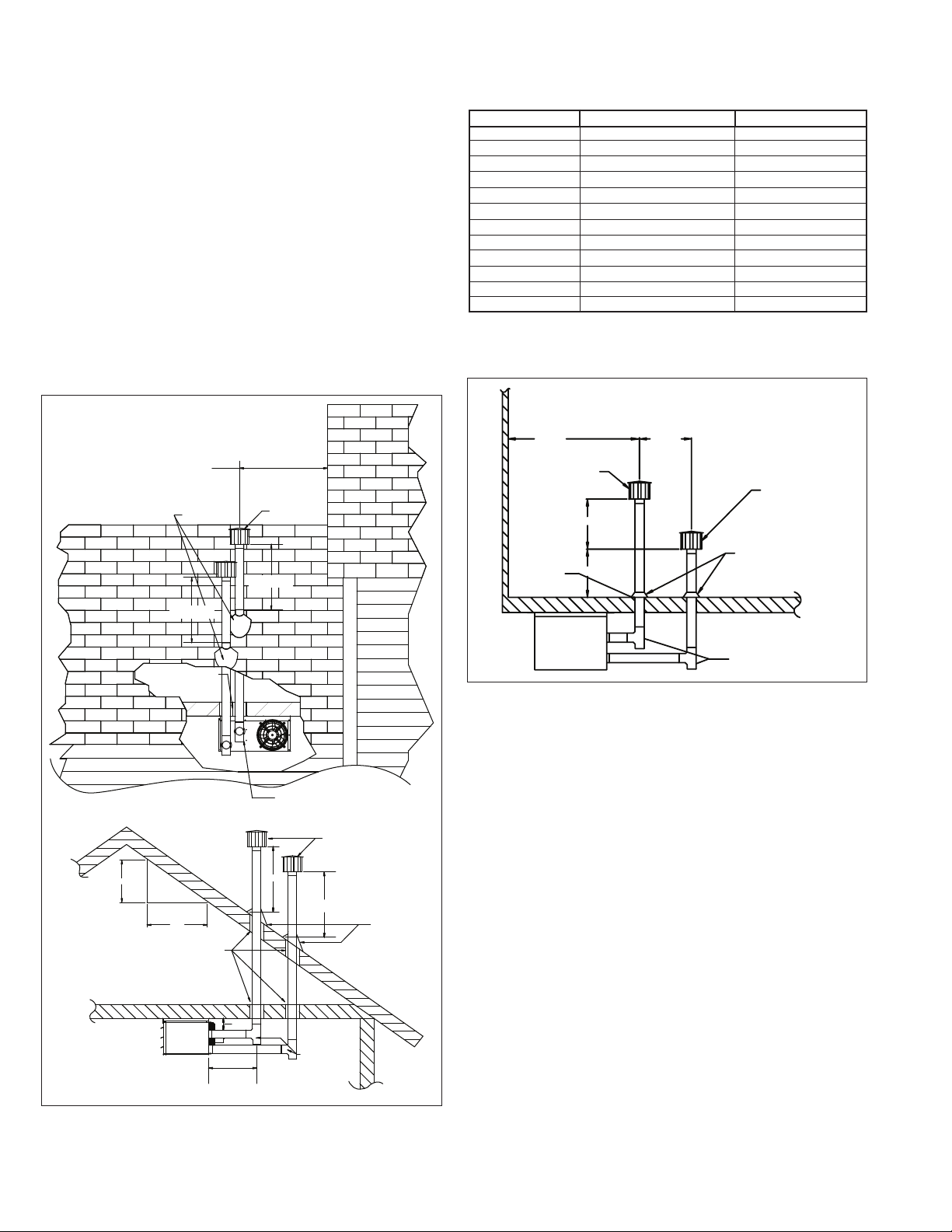

Figure 8.1 - Vertical 2-Pipe Vent System - Sloped Roof

Table 8.1 - Minimum Height from Roof to Lowest

Discharge Opening

Rise X (in) Roof Pitch Min Height H (ft) ➀

0-6 Flat to 6/12 1.00

6-7 6/12 to 7/12 1.25

7-8 7/12 to 8/12 1.50

8-9 8/12 to 9/12 2.00

9-10 9/12 to 10/12 2.50

10-11 10/12 to 11/12 3.25

11-12 11/12 to 12/12 4.00

12-14 12/12 to 14/12 5.00

14-16 14/12 to 16/12 6.00

16-18 16/12 to 18/12 7.00

18-20 18/12 to 20/12 7.50

20-21 20/12 to 21/12 8.00

➀ Size according to expected snow depth.

Figure 8.2 - Vertical 2-Pipe Vent System - Flat Roof

TO WALL OR ADJOINING BUILDING

MINIMUM DISTANCE TO ADJOINING WALL

OR BUILDING IS 2 FEET.

REFER TO TABLE 8.1 FOR "H" DIMENSION.

ROOF FLASHING

"H" MIN*

(SEE TABLE 8.1)

USE LISTED THIMBLES

THROUGH CEILING

AND ROOF

X

ROOF PITCH IS:

X / 12

12

USE LISTED THIMBLE

THROUGH ROOF AND

CEILING

"H" MIN*

(SEE TABLE 8.1)

EXHAUST

COMBUSTION AIR

"H" MIN*

LISTED

TERMINAL

TEE WITH DRIP LEG

AND CLEANOUT CAP

(SEE TABLE 8.1)

LISTED

TERMINAL

"H" MIN*

ROOF FLASHING

2' MIN

LISTED

TERMINAL

6" MIN

LISTED

TERMINAL

12" MIN

USE THIMBLE

THROUGH

CELLING

12" MIN*

Exhaust

ROOF FLASHING

* SIZE ACCORNING

TO EXPECTED

Combustion Air

SNOW DEPTH.

TEE WITH DRIP LEG

AND CLEANOUT CAP

B9. Once venting is complete, proceed section titled “Installation

– Gas Connections”.

BACK VIEW

4" MIN

EXHAUST

COMBUSTION AIR

12" MIN

RECOMMENDED

8

TEE WITH DRIP LEG

AND CLEANOUT CAP

(SLOPE 1/4" PER

FOOT DOWNWARD

TOWARD DRIP LEG)

6-584.8

INSTALLATION - VENTING

Section C – Horizontal 2-Pipe Vent System

Installation

C1. This section applies to horizontally vented 2-pipe vent

systems (one combustion air inlet pipe and one vent

pipe) and is in addition to “Section A – General

Instructions – All Units”.

C2. Horizontal vent systems terminate horizontally

(sideways).

C3. All horizontal vents must be terminated with a listed vent

cap. The cap must terminate a minimum distance from

the external wall, as summarized in Figure 9.1.

C4

. The termination of horizontally vented system must

extend 16" beyond the exterior surface of an exterior

wall.

C5

. The combustion air pipe must be a minimum of 6" below

the vent pipe, and 4" from the exterior wall.

C6. Construct the vent system as shown in Figure 9.1.

Figure 9.1 - Horizontal Venting with Downward Pitch

ADJACENT

BUILDING

2' MIN

12"

SLOPE 1/4" PER FOOT

DOWNWARD FROM UNIT

C11. For a vent termination located under an eave, the

distance of the overhang must not exceed 24". The

clearance to combustibles above the exterior vent must

be maintained at a minimum of 12". Consult the National

Fuel Gas Code for additional requirements for eaves that

have ventilation openings.

C12. Once venting is complete, proceed to section titled

“Installation – Gas Connections”.

6" MIN

LISTED

TERMINAL

SUPPORT BRACKET

. When horizontal vents pass through a combustible wall

C7

4" MIN

EXHAUST

COMBUSTION AIR

TEE WITH DRIP LEG AND

CLEANOUT CAP AT LOW

POINT OF VENT SYSTEM

(up to 22" thick), the vent passage must be constructed

and insulated as shown in Figure 9.2.

C8. The vent must be supported as shown in Figure 9.2.

Figure 9.2 - Exhaust Vent Construction Through

Combustible Walls and Support Bracket

METAL FACE

PLATE

45

FIBER GLASS

INSULATION

MIN. 2"

1"

9"

9"

VENT TERMINATION

SUPPORT BRACKET

(where required)

(Make from 1" x 1" steel angle)

VENT PIPE

DIAMETER

2" MIN.

2" MIN.

METAL

SLEEVE

METAL

SLEEVE

1"

C9. When condensation may be a problem, the vent system

shall not terminate over public walkways or over an area

where condensate or vapor could create a nuisance or

hazard or could be detrimental to the operation of

regulators, relief openings, or other equipment.

C10. Maintain a 1/4" per foot downward slope away from the

heater and place a drip leg with clean out near the exit of

the vent as shown in Figure 9.1, or allow the condensate

to drip out the end.

6-584.8

9

INSTALLATION - VENTING

Section D – Concentric Vent System

Installation

D1.

This section applies to both horizontally and vertically

vented concentric vent systems as defined in “Section A –

General Instructions – All Units”, and is in addition to the

instructions in that section.

D2. When utilizing the concentric vent option, it should have

been predetermined whether the appliance will be

horizontally or vertically vented. Before proceeding, verify

that the concentric vent kit received contains the correct

components for the installation:

For Vertically Vented Units (Refer to Figure 10.1):

➀ Concentric adapter assembly (same for horizontal and

vertical kits)

➁ Standard listed vent cap

➂ Specially designed inlet terminal (part #5H0751540001)

Figure 10.1 - Vertical Concentric Vent Kit

Components

Outlet Vent

Combustion Air

Inlet Terminal

Concentric

Vent Adapter

Box

Combustion Air Exhaust

For Horizontally Vented Units (Refer to Figure 10.2):

➀ Concentric adapter assembly (same for horizontal and

vertical kits)

➁ Special vent termination cap (part #5H0751500001)

➂ Special inlet air guard

Figure 10.2 - Horizontal Concentric Vent Kit

Components

6" Min.

12" Min.*

Termination Cap

* Size according

to expected

snow depth.

Building

Roof / Ceiling

CAUTION

The concentric vent adapter box must be installed inside of

the structure or building. Do not install this box on the exterior

of a building or structure.

D3. Once the kit contents have been verified as correct for the

direction of venting, the concentric vent adapter box is to

be installed. Determine the location of the box. Be sure to

maintain all clearances as listed in these instructions.

D4. The adapter box is to be mounted on the interior side of

the building. It must not be mounted outside the building.

The adapter box has integral mounting holes for ease of

installation.

D5. The adapter box can be mounted flush to the wall (for

horizontal kits) or to the ceiling (for vertical kits). The box

can also be offset from the wall or ceiling by using field

supplied brackets. When mounting the box, consider

serviceability and access to the vent and combustion air

pipes. If the box is to be mounted using field supplied

brackets, these brackets must be strong enough to rigidly

secure the box to the wall or ceiling, and should be made

from corrosion resistant material.

D6. Determine the length of the vent pipe and combustion air

inlet pipe for the selected location. THE VENT PIPE WILL

PASS THROUGH THE CONCENTRIC VENT BOX. THE

LAST SECTION OF VENT PIPE IS A CONTINUOUS

LENGTH OF DOUBLE WALL “B” VENT. See section A12

for attaching and terminating double wall pipe. Begin with

pipe lengths on the concentric pipe side of the adapter box

referring to Figures 10.1 and 10.2. These pipes will extend

through the building wall or roof as well as any added length

for the thickness of the wall and the offset from any field

installed brackets.

For Vertical Concentric Vent Kits

(refer to Figure 10.1):

• The bottom of the combustion air intake pipe must

terminate above the snow line, or at least 12" above the

roof, whichever distance is greater.

• The bottom of the vent cap must terminate at least 6"

above the top of the combustion air intake cap.

For Horizontal Concentric Vent Kits

(refer to Figure 10.2):

• The combustion air intake pipe must terminate at least

1" from the wall to prevent water from running down the

wall and into the pipe.

• The back of the vent cap must terminate at least 14" from

the combustion air intake pipe.

D7. Cut the concentric side vent and combustion air pipes to

the proper length as determined in the previous step. See

Table 11.1 for combustion air and vent pipe sizes. The pipes

must be single wall galvanized or stainless steel material,

except for the last section of vent pipe, which must be one

continuous length of double wall B-vent extended through

the concentric vent box and combustion air inlet pipe on the

concentric side of the box.

D8. Allow the concentric side vent pipe to pass through the

concentric vent adapter box, as shown in Figure 11.1.

Attach the double wall vent pipe to the single wall vent pipe

that goes to the unit. Be sure to seal the joint and the open

area around the double wall vent. Seal all joints and seams

using sealant suitable for temperatures up to 400°F.

10

6-584.8

INSTALLATION - VENTING

D9. Slide the combustion air pipe over the vent pipe and attach

to the air inlet of the concentric adapter box, as shown

in Figure 11.1, using at least 3 corrosion-resistant sheet

metal screws. Seal the joint and seam using sealant

suitable for temperatures up to 400°F.

Figure 11.1 - Adapter Box with Combustion Air Intake

Pipe Attached

Outlet Vent

Pipe Extended

Through Box

Combustion Air

Pipe Attached

4.57”

Table 11.1 - Concentric Vent Pipe Sizes

Single Wall Pipe Type B Vent Pipe

Model

Size

30-45

60-125 4" 6" 4"

B-Vent must have 1/4" air gap (OD is 1/2" larger than ID).

➁ Use vent transitions included in concentric vent kit as described in D13.

Combustion Air

(To Unit)

3" ➁

Combustion Air

(External)

6"

Vent

(Pass-Through)

4" ➁

Figure 11.2 - Adapter Box Exploded Assembly

13.33"

18.84"

D10. Place this assembly (the adapter box, vent pipe and

combustion air pipe) through the wall or roof and verify that

the distance requirements as defined in Step D7 are met.

Securely attach the assembly building.

D11. From outside the building, caulk the gap between the

combustion air intake pipe and the building penetration.

D12. Attach the combustion air intake and vent pipe

terminations as follows:

For Vertical Concentric Vent Kits

(refer to Figure 10.1):

• Slide the combustion air cap down over the vent pipe

and fasten it to the combustion air pipe with at least 3

corrosion-resistant sheet metal screws.

• Attach the vent cap to the vent pipe using at least

3 corrosion-resistant sheet metal screws. Refer to

instruction A12 for connecting terminal to double wall

pipe.

• Caulk the gap between the combustion air cap and the

vent pipe with silicone sealant, or other appropriate

sealants suitable for metal to metal contact and for

temperatures up to 400° F.

For Horizontal Concentric Vent Kits

(refer to Figure 10.2):

• Attach the combustion air intake guard using corrosion-

resistant screws at the end of the combustion air intake

pipe to prevent animals and debris from entering.

• Attach the vent cap to the vent pipe using at least

3 corrosion-resistant sheet metal screws.

D13. For model sizes 30 and 45, attach the 3" to 4" vent

transitions on the non-concentric side vent and combustion

air connections using 3 corrosion resistant sheet metal

screws.

D14. Install vent pipe and combustion air pipe between unit

heater and concentric vent adapter box as outlined in

“Section A – General Instructions – All Units”.

D15. Once venting is complete, proceed to the section titled

“Installation - Gas Connections”.

Table 11.2 - Vent Terminals (Concentric)

Model Size Modine PN

30-45 Horizontal Concentric

30-45 Vertical Concentric

60-125 Horizontal Concentric

60-125 Vertical Concentric

5H0751500001 Vent Cap

3H034930004 Intake Guard Assembly

5H072280001 Vent Cap

5H0751540004 Intake Cap

5H0751500001 Vent Cap

3H034930004 Intake Guard Assembly

5H072280001 Vent Cap

5H0751540004 Intake Cap

6-584.8

11

INSTALLATION - GAS CONNECTIONS

GAS CONNECTIONS

WARNING

1. All field gas piping must be pressure/leak tested prior to

operation. Never use an open flame. Use a soap solution or

equilavent for testing.

2. Gas pressure to appliance controls must never exceed

14" W.C. (1/2 psi).

3. To reduce the opportunity for condensation, the minimum

sea level input to the appliance, as indicated on the serial

plate, must not be less than 5% below the rated input, or

5% below the minimum rated input of dual rated units.

CAUTION

1. Purging of air from gas lines should be performed as

described in ANSI Z223.1 - latest edition “National Fuel

Gas Code”, or in Canada CSA-B149 codes.

2. When leak testing the gas supply piping system, the

appliance and its combination gas control must be isolated

during any pressure testing in excess of 14" W.C. (1/2 psi).

3. The unit should be isolated from the gas supply piping

system by closing its field installed manual shut-off

valve. This manual shut-off valve should be located within

6' of the heater.

4. Turn off all gas before installing appliance.

IMPORTANT

To prevent premature heat exchanger failure, the input to the

appliance, as indicated on the serial plate, must not exceed

the rated input by more than 5%.

1. Installation of piping must conform with local building codes,

or in the absence of local codes, with the National Fuel Gas

Code, ANSI Z223.1 (NFPA 54) - latest Edition. In Canada,

installation must be in accordance with CSA-B149.1.

2. Piping to units should conform with local and national

requirements for type and volume of gas handled, and

pressure drop allowed in the line. Refer to Table 12.1 to

determine the cubic feet per hour (CFH) for the type of gas

and size of unit to be installed. Using this CFH value and the

length of pipe necessary, determine the pipe diameter from

Table 12.2. Where several units are served by the same

main, the total capacity, CFH and length of main must be

considered. Avoid pipe sizes smaller than 1/2". Table 12.2

allows for a 0.3" W.C. pressure drop in the supply pressure

from the building main to the unit. The inlet pressure to the

unit must be 6-7" W.C. for natural gas and 11-14" W.C. for

propane gas. When sizing the inlet gas pipe diameter, make

sure that the unit supply pressure can be met after the

0.3" W.C. has been subtracted. If the 0.3" W.C. pressure drop

is too high, refer to the Gas Engineer’s Handbook for other

gas pipe capacities.

3. Install a ground joint union with brass seat and a manual

shut-off valve adjacent to the unit for emergency shut-off

and easy servicing of controls, including a 1/8" NPT plugged

tapping accessible for test gauge connection (see Figure 12.1).

4. Use 2 wrenches when connecting field piping to units.

5. Provide a sediment trap before each unit in the line where

low spots cannot be avoided (see Figure 12.1).

6. When pressure/leak testing, pressures above 14" W.C.

(1/2 psi), close the field installed shut-off valve, disconnect

the appliance and its combination gas control from the gas

supply line, and plug the supply line before testing. When

testing pressures 14" W.C. (1/2 psi) or below, close the

manual shut-off valve on the appliance before testing.

12

Figure 12.1 - Recommended Sediment Trap/Manual

Shut-off Valve Installation - Side or Bottom Gas

Connection ➀

➀ Manual shut-off valve is in the “OFF” position when handle is perpendicular to pipe.

Table 12.1 - Sea Level Manifold Pressure &

Gas Consumption

Natural Propane

Model BTU/Cu. Ft. 1050 2500 No. of

Size Specific Gravity 0.60 1.53 Orifices

Manifold Pressure In. W.C. 3.5 10.0

CFH 28.6 12.0 2

Gal/Hr. Propane .33

30

Sec/cu. ft. 126 300

Orifice Drill Size 49 56

CFH 42.9 18.0 3

Gal/Hr. Propane .50

45

Sec/cu. ft. 84 200

Orifice Drill Size 49 56

CFH 57.1 24.0 4

Gal/Hr. Propane .66

60

Sec/cu. ft. 63 150

Orifice Drill Size 49 56

CFH 71.4 30.0 5

Gal/Hr. Propane .83

75

Sec/cu. ft. 50 180

Orifice Drill Size 49 56

CFH 95.2 40 5

Gal/Hr.Propane 1.09

100

Sec/cu. ft. 38 90

Orifice Drill Size 45 55

CFH 119 50 5

Gal/Hr.Propane 1.37

125

Sec/cu. ft. 30 72

Orifice Drill Size 42 53

Table 12.2 - Gas Pipe Capacities - Natural Gas ➀ ➁

Pipe

Length (ft)

10 132 278 520 1050 1600 3050

20 92 190 350 730 1100 2100

30 73 152 285 590 890 1650

40 63 130 245 500 760 1450

50 56 115 215 440 670 1270

60 50 105 195 400 610 1150

70 46 96 180 370 560 1050

80 43 90 170 350 530 930

100 38 79 150 305 460 870

125 34 72 130 275 410 780

150 31 64 120 250 380 710

➀ Capacities in cubic feet per hour through Schedule 40 pipe with maximum

0.3" W.C. pressure drop with up to 14" W.C. gas pressure. Specific gravity is

0.60 for natural gas and 1.50 for propane gas.

➁ For pipe capacity with propane gas, divide natural gas capacity by 1.6. Example:

What is the propane gas pipe capacity for 60' of 1-1/4" pipe? The natural gas

capacity is 400 CFH. Divide by 1.6 to get 250 CFH for propane gas.

6-584.8

1/2" 3/4" 1" 1-1/4" 1-1/2" 2"

Natural Gas

INSTALLATION - HIGH ALTITUDE ACCESSORY KIT

HIGH ALTITUDE ACCESSORY KIT

Modine’s gas-fired equipment standard input ratings are

certified by ETL. For elevations above 2,000', ANSI Z223.1

requires ratings be reduced 4 percent for each 1000' above sea

level. For units in Canada, CSA requires that ratings be reduced

10 percent at elevations above 2,000'. The high altitude

adjustment instructions and pressure switch kits listed in this

manual are for use with units that will be installed over 2,000'

These methods and kits comply with both ANSI Z223.1 and

CSA requirements.

If a unit is to be installed at higher elevations AND converted from

natural gas to propane gas operation, a propane conversion kit

must be used in conjunction with the pressure adjustment

methods and pressure switch kits listed herein. For the selection

Manifold Pressure Adjustment

The inlet pressure to the unit must be confirmed to be within

acceptable limits (6-7" W.C. for natural gas and 11-14" W.C. for

propane gas) before opening the shutoff valve or the

combination gas valve may be damaged.

Heaters for the use with natural gas have gas valves that need

to be field adjusted to 3.5" W.C. manifold pressure at 7.0" W.C.

inlet pressure.

Units for use with propane gas have gas valves that need to be

field adjusted to 10.0" W.C. manifold pressure at 14.0" W.C.

inlet pressure.

Installation above 2,000' elevation requires adjustment of the

manifold pressure as described.

and installation instructions for propane conversion kits, please

see the latest revision of Modine Manual 75-515.

Derated BTU Content Gas and Manifold Pressure

Calculation

Selection of the Proper Pressure and Kit

To determine the proper manifold pressure at altitude and if

required, the proper combustion air pressure switch kit, the full

model number of the heater, the fuel to be used, and the

altitude the unit will be installed at must be known. Refer to the

unit serial plate or carton label to obtain the necessary

information about the unit.

After obtaining this information, refer to the gas pressure and

selection charts shown in Tables 13.1 through 13.3. The pressure

charts are differentiated by elevation, fuel type, and country

the product is being installed in. The selection charts are

differentiated by product type, altitude and fuel type. If

converting from natural gas to propane gas and operation

at high altitude, both a propane conversion kit and a

pressure switch kit must be used (if applicable). Selection

charts include the proper kit suffix, when required.

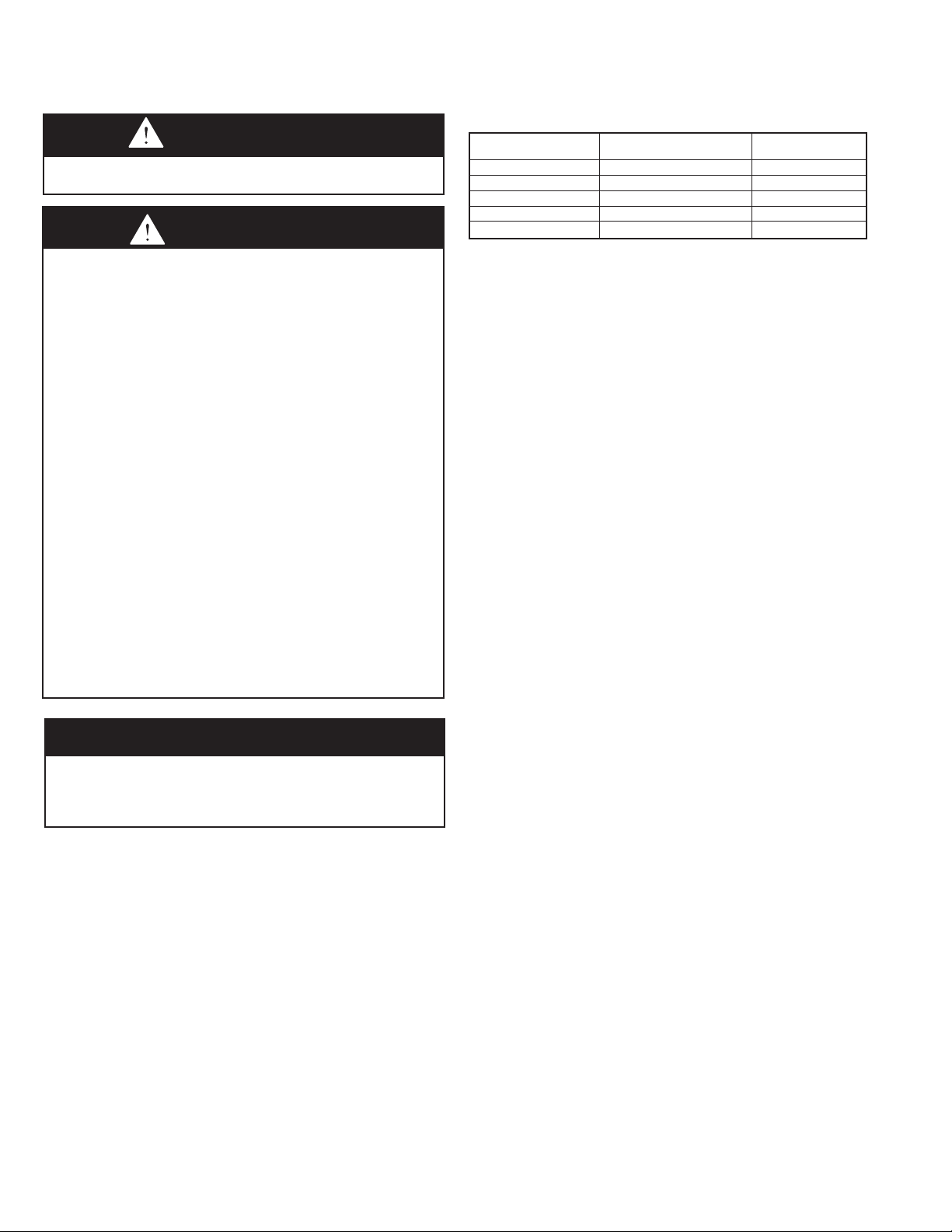

Table 13.1 - Natural Gas Heating Values at

Altitude

➀ Values shown are for 3.5" W.C. manifold pressure, for other BTU content values (available from local utility) use Equation 14.1 to calculate manifold pressure.

➁ Values shown are for 10.0" W.C. manifold pressure, for other BTU content values (available from local utility) use Equation 14.1 to calculate manifold pressure.

➂ When installed at altitudes above 2,000', a pressure switch may need to be changed. Refer to Table 13.3 to determine if a switch change is required.

➃ Gas heating values are derated 4% per 1,000' of elevation in the USA and 10% between 2,000' and 4,500' elevation in Canada in accordance with ANSI Z223.1

and CSA-B149, respectively.

➀ ➂ ➃

Altitude (ft)

0-2,000 1,050 1,050

2,001-3,000 929

4,001-4,500 874

4,501-5,000 856 856

5,001-6,000 822 822

6,001-7,000 789 789

7,001-8,000 757 757

8,001-9,000 727 727

9,001-10,000 698 698

Gas Heating Values at Altitude (BTU/ft

USA Canada

9453,001-4,000 892

3

Some utility companies may derate the BTU content (heating

value) of the gas provided at altitude to a value other than 1,050

3

for natural gas or 2,500 BTU/ft3 for propane gas to allow

BTU/ft

certain heating appliances to be used with no manifold pressure

adjustments. For this reason it is necessary that the supplying

utility be contacted for detailed information about the gas type

and BTU content (heating value) before operating any heater.

Tables 13.1 and 13.2 show the standard derated heating values

(4% per 1,000' of elevation in the USA and 10% between 2,001'

and 4,500' elevation in Canada) of natural and propane gases

at various altitudes. If the utility is supplying gas with heating

values as shown in Tables 13.1 and 13.2, the manifold pressure

should be set to 3.5" W.C for natural gas and 10.0" W.C. for

propane gas.

NOTE: Only the high fire gas pressure need be adjusted, low

fire gas pressure should remain the same.

Table 13.2 - Propane Gas Heating Values at

Altitude

)

➁ ➂ ➃

Altitude (ft)

0-2,000 2,500 2,500

2,001-3,000 2,212

4,001-4,500 2,080

4,501-5,000 2,038 2,038

5,001-6,000 1,957 1,957

6,001-7,000 1,879 1,879

7,001-8,000 1,803 1,803

8,001-9,000 1,731 1,731

9,001-10,000 1,662 1,662

Gas Heating Values at Altitude (BTU/ft

USA Canada

2,2503,001-4,000 2,123

Table 13.3 - High Altitude Kits for HDS/HDC ➀

Model

Size

30

45

60

75

100

125

➀ For Label Only kits, Modine part number 5H0807146005 is required to be lled out and attached to the unit by the installer. Please contact the local Modine

representative at 1.866.828.4328 (HEAT).

Details

KitSufx

Item Code 68407 68409 68409 68414 68414 68414

KitSufx

Item Code 68406 68408 68407 68410 68414 68414 68415

KitSufx

Item Code 68407 68407 68409 68411 68415 68415 68415

KitSufx

Item Code 68407 68407 68409 68411 68415 68415 68415

KitSufx

Item Code 68408 68408 68408 68408

KitSufx

Item Code 68408 68408 68408 68408 68408

0-2,000 ft 2,001-2,500 ft 2,501-4,500 ft 4,501-5,500 ft 5,501-6,500 ft 6,501-7,500 ft 7,501-8,500 ft 8,501 - 9,500 ft 9,501-10,000 ft

Not Required Label Only Label Only

Not Required Label Only

Not Required Label Only

Not Required Label Only

Not Required Label Only Label Only Label Only Label Only

Not Required Label Only Label Only Label Only

0002 0004 0003 0006 0010 0010 0011

0003 0003 0005 0007 0011 0011 0011

0003 0003 0005 0007 0011 0011 0011

U.S.A and Canada

0003 0005 0005 0010 0010 0010

0004 0004 0004 0004

0004 0004 0004 0004 0004

6-584.8

3

)

13

INSTALLATION - HIGH ALTITUDE ACCESSORY KIT

If the heating value of the gas being supplied is different than

the values shown in Tables 13.1 and 13.2, use the following

equation to determine the appropriate manifold pressure for the

altitude and gas heating value being supplied.

Equation 14.1 - Manifold Pressure for Derated Gas

WHERE:

MP

= Manifold Pressure (in. W.C.) at Altitude –

ACT

BTU

BTU

MP

SL

NOTE: Only the primary manifold pressure should be adjusted

on units equipped with two-stage or modulating gas controls.

No adjustments to the low Fire manifold pressure are necessary

on these units.

Manifold pressure setting for the heater being

installed

= BTU/ft3 Content of Gas –

TBL

Obtained from Tables 13.1 or 13.2 (whichever is

applicable)

= BTU/ft3 Content of Gas –

ACT

Obtained from the local utility company

= Manifold Pressure (in. W.C.), at Sea Level –

Use 3.5" W.C. for natural gas and 10.0" W.C. for

propane gas

14

6-584.8

INSTALLATION - ELECTRICAL CONNECTIONS

ELECTRICAL CONNECTIONS

W ARNING

1. Disconnect power supply before making wiring connections

to prevent electrical shock and equipment damage.

2. All appliances must be wired strictly in accordance with

wiring diagram furnished with the appliance. Any wiring

different from the wiring diagram could result in a hazard

to persons and property.

3. Any original factory wiring that requires replacement must

be replaced with wiring material having a temperature

rating of at least 105°C.

4. Ensure that the supply voltage to the appliance, as

indicated on the serial plate, is not 5% greater than rated

voltage.

CAUTION

Ensure that the supply voltage to the appliance, as indicated

on the serial plate, is not 5% less than the rated voltage.

1. Installation of wiring must conform with local building codes,

or in the absence of local codes, with the National Electric

Code ANSI/NFPA 70 - Latest Edition. Unit must be electri cally

grounded in conformance to this code. In Canada, wiring

must comply with CSA C22.1, Part 1, Electrical Code.

2. Two copies of the unit wiring diagram are provided with each

unit. One is located in the side access control compartment

and the other is supplied in the literature packet. Refer to

this diagram for all wiring connections.

3. Make sure all multi-voltage components (motors, transformers, etc.) are wired in accordance with the power supply

voltage.

4. The power supply to the unit must be protected with a fused

or circuit breaker switch.

5. The power supply must be within 5 percent of the voltage

rating and each phase must be balanced within 2 percent of

each other. If not, advise the utility company.

6. External electrical service connections that must be installed

include:

a. Supply power connection (115, 208, 230, 460, or 575 volts).

b. Connection of thermostats, or any other accessory control

devices that may be supplied (24 volts).

NOTE: All units with supply voltage 208V and greater must use

a field installed step-down transformer, available as a separate

accessory. Refer to Table 15.1 for additional information on the

required transformer.

7. Refer to Figures 18.1 and 18.2 for the side access control

compartment location.

8. All supply power electrical connections are made in the side

access control compartment of the unit. The low voltage

(thermostat and accessory control devices) can be wired to

the terminals in the side access control compartment. Refer

to the wiring diagram for the terminal location of all low

voltage wiring.

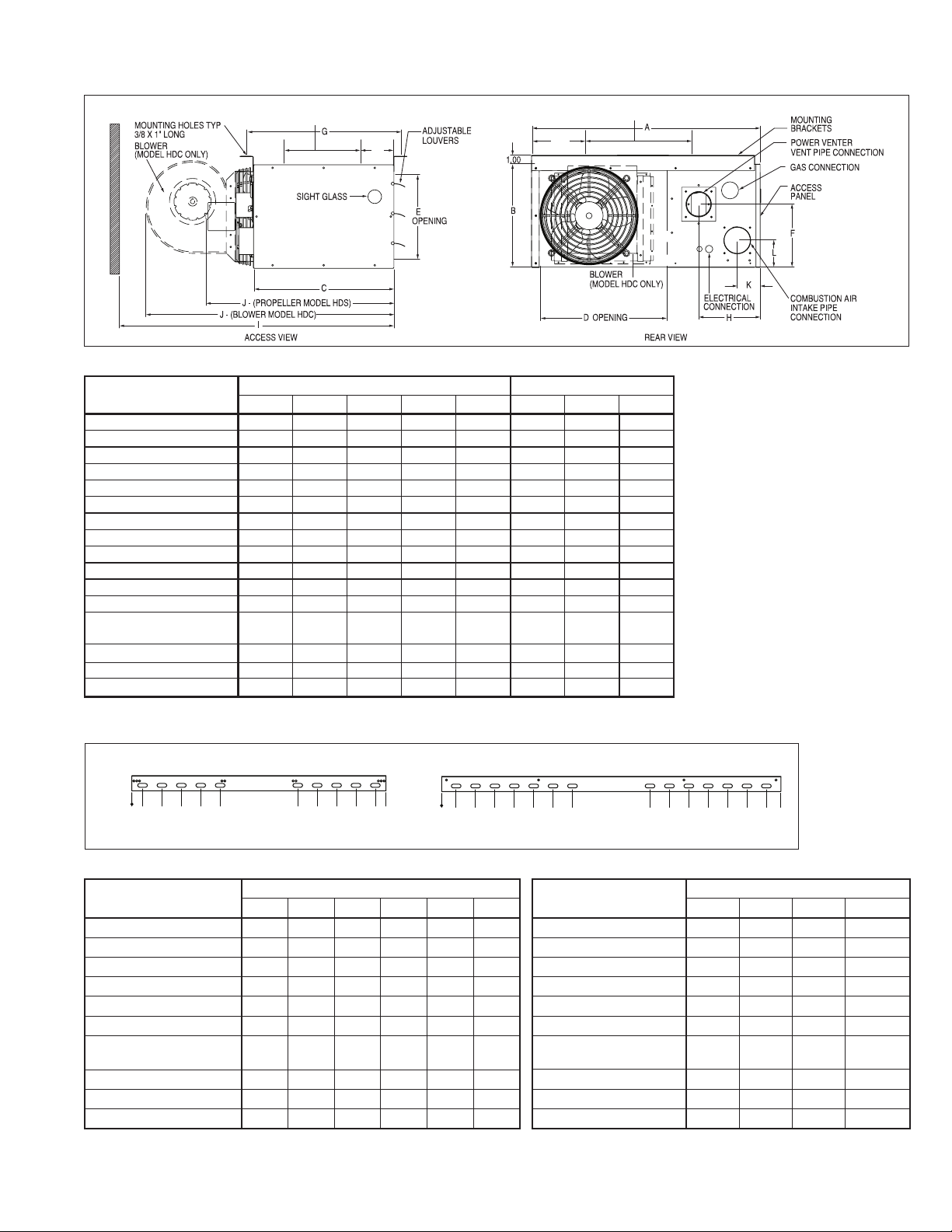

Table 15.1 - Propeller Unit Model HDS and Blower Unit Model HDC Operating Electrical Data

Supply

Voltage

115V

1 Phase

208V

1 Phase

230V

1 Phase

208V

3 Phase

230V

3 Phase

460V

3 Phase

575V

3 Phase

Amp draw data shown is operating amp draw at incoming power. For units that use a field installed accessory step-down transformer as noted, the amp draw shown is the primary side

operating amp draw. For sizing of circuit protection for equipment with transformers, please refer to the National Electric Code.

Power Code

01 (115V)

01 (115V) with

Transformer

01 (115V) with

Transformer

01 (115V) with

Transformer

01 (115V) with

Transformer

01 (115V) with

Transformer

01 (115V) with

Transformer

30 45 60 75 100 125 60 75 100 125

Motor Amps 2.40 2.40 1.95 1.95 2.50 2.20 5.70 7.10 9.50 9.50

Total Amps 3.70 3.70 3.75 3.75 5.05 4.75 7.50 8.90 12.05 12.05

Transformer kVA n/a n/a n/a n/a n/a n/a n/a n/a n/a n/a

Transformer kVA 0.50 0.50 0.50 0.50 1.00 1.00 1.00 1.50 1.50 1.50

208V Total Amps 2.05 2.05 2.07 2.07 2.79 2.63 4.15 4.92 6.66 6.66

Transformer kVA 0.5 0.5 0.5 0.5 0.75 0.75 1.00 1.50 1.50 1.50

230V Total Amps 1.85 1.85 1.88 1.88 2.53 2.38 3.75 4.45 6.03 6.03

Transformer kVA 0.50 0.50 0.50 0.50 1.00 1.00 1.00 1.50 1.50 1.50

208V Total Amps 2.05 2.05 2.07 2.07 2.79 2.63 4.15 4.92 6.66 6.66

Transformer kVA 0.50 0.50 0.50 0.50 0.75 0.75 1.00 1.50 1.50 1.50

230V Total Amps 1.85 1.85 1.88 1.88 2.53 2.38 3.75 4.45 6.03 6.03

Transformer kVA 0.50 0.50 0.50 0.50 0.75 0.75 1.00 1.50 1.50 1.50

460V Total Amps 0.93 0.93 0.94 0.94 1.26 1.19 1.88 2.23 3.01 3.01

Transformer kVA 0.50 0.50 0.50 0.50 0.75 0.75 0.50 0.50 1.00 1.00

575V Total Amps 0.74 0.74 0.75 0.75 1.01 0.95 1.50 1.78 2.41 2.41

Model HDS Sizes Model HDC Sizes

6-584.8

15

INSTALLATION - ELECTRICAL CONNECTIONS

Low Medium High

External Static Pressure (IN. WC)

Temperature Rise (Deg. F)

Temperature Rise (Deg. F)

Temperature Rise (Deg. F)

Temperature Rise (Deg. F)

ELECTRICAL CONNECTIONS

Location of thermostat should be determined by heating

requirements and be mounted on an inside wall about 5' above

floor level where it will not be affected by heat from the unit

or other sources, or drafts from frequently opened doors. See

instructions packed with thermostat.

Wiring Adjustments for Blower Motors

The blowers used on Modine HDC units are direct drive and

equipped with three speed motors. Air temperature rise of the

unit is determined by the speed setting and the amount of static

pressure in the system. Units are normally shipped with motors set

at high speed. Motor speed is changed by connecting the motor

lead for the desired fan speed to the “EAC” or “Blo” terminal of the

control board. Unused motor leads for other speeds are placed on

the “Park” terminals of the board. See the wiring diagram on

page 21.

When applying a blower equipped unit to a duct system or other

load, consult the performance curves on this page to determine

the air temperature rise for a given motor speed range and static

pressure. Verify that the static pressure on the outlet of the unit

does not exceed the maximum specified for the unit. If static

pressure is too high it must be reduced either by modifications to

the system or using the medium or low motor speed. If the unit

shuts down on high limit during normal operation, a higher motor

speed should be used.

Blower Curve Models (HDC 60-125 Only)

Speeds

70

65

60

55

50

45

40

35

0.00

0.10

70

65

60

55

50

45

40

35

0.00

0.10

HDC 60

0.30

0.20

External Static Pressure (IN. WC)

0.40

0.50

HDC 75

0.30

0.20

External Static Pressure (IN. WC)

0.40

0.50

0.60

0.60

635

684

741

808

889

988

1111

1270

0.70

794

855

926

1010

1111

1235

1389

1587

0.70

CFM

CFM

16

6-584.8

65

60

55

50

45

40

35

0.00 0.10 0.20 0.30 0.40 0.50 0.60 0.70 0.80

75

70

65

60

55

50

45

40

0.00 0.10 0.20 0.30 0.40 0.50 0.60 0.70 0.80

HDC 100

HDC 125

External Static Pressure (IN. WC)

1140

1235

1347

1481

1646

1852

2116

1235

1323

1425

1543

1684

1852

2058

2315

CFM

CFM

INSTALLATION - OPERATION

OPERATION

IMPORTANT

1. To prevent premature heat exchanger failure, observe

heat exchanger tubes. If the tubes become red while

blower and furnace are in operation, check to be sure the

blower has been set to the proper rpm for the application.

Refer to page 16 for blower adjustments.

2. Start-up and adjustment procedures must be performed

by a qualified service agency.

Prior to Operation

Although this unit has been assembled and fire-tested at the

factory, the following pre-operational procedures should be

performed to assure proper on-site operation.

1. Turn off power to the unit at the disconnect switch. Check that

fuses or circuit breakers are in place and sized correctly. Turn

all hand gas valves to the “OFF” position.

2. Remove the side control access panel.

3. Check that the supply voltage matches the unit supply voltage

listed on the Model Identification plate. Verify that all wiring

is secure and properly protected. Trace circuits to insure that

the unit has been wired according to the wiring diagram. If

installed at altitudes above 2,000' and the high altitude kit

includes a combustion air proving switch, replace the switch

in the unit with the switch provided in the kit. Take care to

ensure that the tubing and electrical connections are securely

fastened.

4. Check to insure that the venting system is installed correctly

and free from obstructions. Before you start use the following

steps to verify that the venting system is adequately sized:

a. Seal any unused openings in the venting system.

b. Inspect the venting system for proper size and horizontal

pitch, as required in the National Fuel Gas Code ANSI

Z223.1 (NFPA 54) or CSA B149.1 Installation Code-latest

edition and these instructions. Determine that there is

no blockage or restriction, leakage, corrosion and other

deficiencies, which could cause an unsafe condition.

c. In so far as practical, close all building doors and windows

and all doors between the space in which the appliance(s)

connected to the venting system are located and other

spaces of the building. Turn on clothes dryers and any

exhaust fans such as range hoods and bathroom exhausts,

so they shall operate at maximum speed. Do not operate a

summer exhaust fan. Close fireplace dampers.

d. Follow the lighting instructions. Place the appliance being

inspected in operation. Adjust thermostat so that the

appliance will operate continuously.

e. After it has been determined that each appliance connected

to the venting system properly vents when tested as outlined

above, return doors, windows, exhaust fans, fireplace

dampers and any other gas-burning appliance to their

previous conditions of use.

f. If improper venting is observed during any of the above

tests, the venting system must be corrected.

5. Check to see that there are no obstructions to the intake and

discharge of the unit.

Check fan clearance. Fan should not contact casing when

6.

spun by hand.

7. Check to make sure that all filters are in place and that

they are installed properly according to direction of air flow

(if applicable).

8. Perform a visual inspection of the unit to make sure no

damage has occurred during installation. Check to ensure all

fasteners are in place and the burner openings are properly

aligned with the heat exchanger tubes and that the gas

orifices are centered in the burner inspirator tube opening.

9. Check that all horizontal deflector blades are open a

minimum of 30° as measured from vertical.

10. Turn on power to the unit at the disconnect switch.

11. Check the thermostat, ignition control, gas valve, and supply

fan blower motor for electrical operation. If these do not

function, recheck the wiring diagram.

12. Check the blower wheel for proper direction of rotation when

compared to the air flow direction arrow on the blower

housing (if applicable). Blower wheel rotation, not air

movement, must be checked as some air will be delivered

through the unit with the blower wheel running backwards.

13. For blower units, check the blower speed (rpm). Refer to

blower adjustments for modification.

14. Check the motor speed (rpm).

15. Check the motor voltage.

16. Check the motor amp draw to make sure it does not exceed

the motor nameplate rating.

17. Recheck the gas supply pressure at the field installed

manual shut-off valve. The minimum inlet pressure should

be 6" W.C. on natural gas and 11" W.C. on propane gas.

The maximum inlet pressure for either gas is 14" W.C. If

inlet pressure exceeds 14" W.C., a gas pressure regulator

must be added upstream of the combination gas valve.

18. Open the field installed manual gas shut-off valve.

19. Place the manual main gas valve on the combination gas

valve in the “ON” position. Call for heat with the thermostat.

20. Check to make sure that the main gas valve opens. Check

the manifold gas pressure (see “Main Gas Adjustment”)

while the supply fan blower is operating.

21. Check to insure that gas controls sequence properly (see

“Control Operating Sequence”).

the unit’s controls (i.e. combination gas control), refer to the

control manufacturer’s literature supplied with the unit.

22. Once proper operation of the unit has been verified,

remove any jumper wires that were required for testing.

24. Replace the side control access panel.

25. If installed at altitudes above 2,000', affix label included with

high altitude kit and fill in all fields with a permanent marker.