1-550.29

5H0707180000

February, 2015

INSTALLATION AND SERVICE MANUAL

steam/hot water unit heaters

Model HSB

Horizontal Delivery

Top/Bottom

Inlet/Outlet

Models V/VN

Vertical Delivery

Model HC

Horizontal Delivery

Side

Inlet/Outlet

Model PT/PTN

“Power-Throw”

IMPORTANT

The use of this manual is specifically intended

for a qualified installation and service agency.

A qualified installation and service agency must

perform all installation and service of these

appliances.

Inspection On Arrival

1. Inspect unit upon arrival. In case of damage, report it

immediately to transportation company and your local factory

sales representative.

2. Check rating plate on unit to verify that power supply meets

available electric power at point of installation.

3. Inspect unit received for conformance with description of

product ordered (including specifications where applicable).

C

US

General Information

Installation and service instructions in this manual are applicable

to the three types of steam/hot water unit heaters which should

be installed in their proper applications for their most effective

function as overhead heating units.

The copper coils are warranted for operation at steam or

hot water pressures up to 150 lbs. per sq. in. gauge, and

or temperatures up to 375°F, cupronickel tube units are

warranted for operating pressures up to 250 PSI and operating

temperatures up to 400°F. Canadian Standards Association

(CSA) requriements state that explosion-proof units may not

be used with a fluid temperature in excess of 329°F and still

maintain their explosion-proof rating, for national electric code

ignition temperature rating T3B for grain dust.

Motors are designed for continuous duty. They can operate in a

maximum ambient temperature of 104°F (40°C).

The unit heaters are listed by the Canadian Standards

Association as certified and Canadian Registered heat

exchangers CRN OH 9234.5C. *Does not apply to V/PT 952.

CAuTION

Do not remove outlet fan guard from vertical

type unit heaters.

Steam horizontal and vertical delivery unit heaters are available

in both standard and low-outlet temperature models. Low outlet

temperature models are recommended primarily for installation

on heating systems with steam pressures of 30 to 150 PSI.

When used at these steam pressures they provide lower outlet

air temperatures for longer heat throw and, because of wider

fin spacing, they are less susceptible to clogging in dusty

atmospheres.

The model number of each unit heater indicates its rated Btu/Hr.

capacity/1000 at 2 lbs. steam pressure and 60°F entering air

temperature. For example an HSB 63 has an output of 63,000

Btu/Hr. at 2 lbs. steam and 60°F entering air.

THIS MANUAL IS THE PROPERTY OF THE OWNER.

PLEASE BE SURE TO LEAVE IT WITH THE OWNER WHEN YOU LEAVE THE JOB.

SPECIAL PRECAUTIONS / TABLE OF CONTENTS / SI (METRIC) CONVERSION

FACTORS

SPECIAL PRECAUTIONS

THE INSTALLATION AND MAINTENANCE INSTRUCTIONS

IN THIS MANUAL MUST BE FOLLOWED TO PROVIDE SAFE,

EFFICIENT AND TROUBLE-FREE OPERATION. IN ADDITION,

PARTICULAR CARE MUST BE EXERCISED REGARDING

THE SPECIAL PRECAUTIONS LISTED BELOW. FAILURE

TO PROPERLY ADDRESS THESE CRITICAL AREAS COULD

RESULT IN PROPERTY DAMAGE OR LOSS, PERSONAL

INJURY, OR DEATH. THESE INSTRUCTIONS ARE SUBJECT

TO ANY MORE RESTRICTIVE LOCAL OR NATIONAL CODES.

HAZARD INTENSITY LEVELS

1. DANGER: Indicates an imminently hazardous situation

which, if not avoided, WILL result in death or serious injury.

2. WARNING: Indicates a potentially hazardous situation

which, if not avoided, COULD result in death or serious

injury.

3. CAUTION: Indicates a potentially hazardous situation which,

if not avoided, MAY result in minor or moderate injury.

4. IMPORTANT: Indicates a situation which, if not avoided,

MAY result in a potential safety concern.

dANgeR

Appliances with power codes 01, 02, 04, 05, and 10 must

not be installed where they may be exposed to a potentially

explosive or flammable atmosphere.

wARNINg

1. Disconnect power supply before making wiring connections

to prevent electrical shock and equipment damage.

2. All appliances must be wired strictly in accordance with

wiring diagram furnished with the appliance. Any wiring

different from the wiring diagram could result in a hazard to

persons and property.

3. Any original factory wiring that requires replacement must

be replaced with wiring material having a temperature

rating of at least 105°C.

4. Ensure that the supply voltage to the appliance as

indicated on the serial plate, is not 5% greater than the

rated voltage.

5. When servicing or repairing this equipment, use only

factory-approved service replacement parts. A complete

replacement parts list may be obtained by contacting

Modine Manufacturing Company. Refer to the rating plate

on the appliance for complete appliance model number,

serial number, and company address. Any substitution of

parts or controls not approved by the factory will be at the

owner’s risk.

1. Start-up and adjustment procedures must be performed

by a qualified service agency.

2. To check most of the Possible Remedies in the

troubleshooting guide listed in Table 15.1, refer to the

applicable sections of the manual.

Table of Contents

General Information .............................................................. 1

Special Precautions .............................................................. 2

SI (Metric) Conversion Factors ............................................. 2

Unit Location......................................................................... 3

Unit Mounting ....................................................................3-4

Unit Suspension ................................................................... 5

Installation .........................................................................5-6

Piping ................................................................................ 5

Electrical Connections ......................................................5

Operation .............................................................................. 6

Prior to Operation.............................................................. 6

Initial Start-up .................................................................... 6

Automatic Control Operations ........................................... 6

General ............................................................................. 7

Performance Data ........................................................... 8-11

Dimensional Data .......................................................... 12-13

Motor Ampere Ratings ........................................................ 14

Service................................................................................ 14

Service / Troubleshooting ................................................... 15

Warranty ................................................................Back Page

SI (METRIC) CONVERSION FACTORS

Table 2.1

To Convert Multiply By To Obtain

"W.C. 0.249 kPa

°F (°F-32) x 5/9 °C

Btu 1.06 kJ

Btu/ft

Btu/hr 0.000293 kW

CFH (ft

CFH (ft

3

/min) 0.0283 m3/min

CFM (ft

3

/min) 0.000472 m3/s

CFM (ft

IMPORTANT

3

37.3 kJ/m

3

/hr) 0.000472 m3/min

3

/hr) 0.00000787 m3/s

3

To Convert Multiply By To Obtain

feet 0.305 m

Gal/Hr. 0.00379 m

Gal/Hr. 3.79 l/hr

gallons 3.79 l

Horsepower 746 W

inches 25.4 mm

pound 0.454 kg

psig 6.89 kPa

psig 27.7 "W.C.

3

/hr

CAuTION

1. Do not remove outlet fan guard from vertical type unit heaters.

2. Do not install units below 8 feet measured from the bottom

of the unit to the floor.

3. Service or repair of this equipment must be performed by

a qualified service agency.

4. Do not reuse any electrical component which has been

wet. Replace component.

5. Ensure that the supply voltage to the appliance, as indicated

on the serial plate is not 5% less than the rated voltage.

6. Heaters are designed for use in heating applications with

ambient temperatures between 0°F and 100°F in hot water

applications and -10°F to 100°F in steam applications.

2

1-550.29

UNIT LOCATION / UNIT MOUNTING

UNIT LOCATION

dANgeR

Appliances with power codes 01, 02, 04, 05, and 10 must

not be installed where they may be exposed to a potentially

explosive or flammable atmosphere.

1. Units should not be installed in atmospheres where

corrosive fumes or sprays are present.

2. Be sure no obstructions block air intake or air discharge of

unit heater.

3. Locate horizontal delivery unit heaters so air streams of

individual units wipe the exposed walls of the building

with either parallel or angular flow without blowing directly

against the walls. Heaters should be spaced so the air

stream from one supports the air stream from another

heater. See Figure 3.1.

4. Columns, machinery, partitions, and other obstacles should

not interfere with air streams from unit heaters.

5. Unit heaters installed in a building exposed to a prevailing

wind should be located to direct a major volume of heated

air along the windward wall of the building.

6. Large expanses of glass, or large doors that are frequently

opened, should be covered by long-throw unit heaters such

as large horizontal delivery of “Power-Throw” unit heaters.

7. Vertical delivery unit heaters should generally be located in

the central area of the space to be heated. Place horizontal

delivery units along the walls of the same building where

heat loss is usually greatest. See Figure 3.3.

8. Arrange horizontal delivery units so they do not blow directly

at occupants. Air streams from this type of unit should be

directed down aisles, into open spaces on the floor, or along

exterior walls.

9. When only vertical delivery units are installed, they should

be located so exposed walls are blanketed by their air

streams. See Figure 3.2.

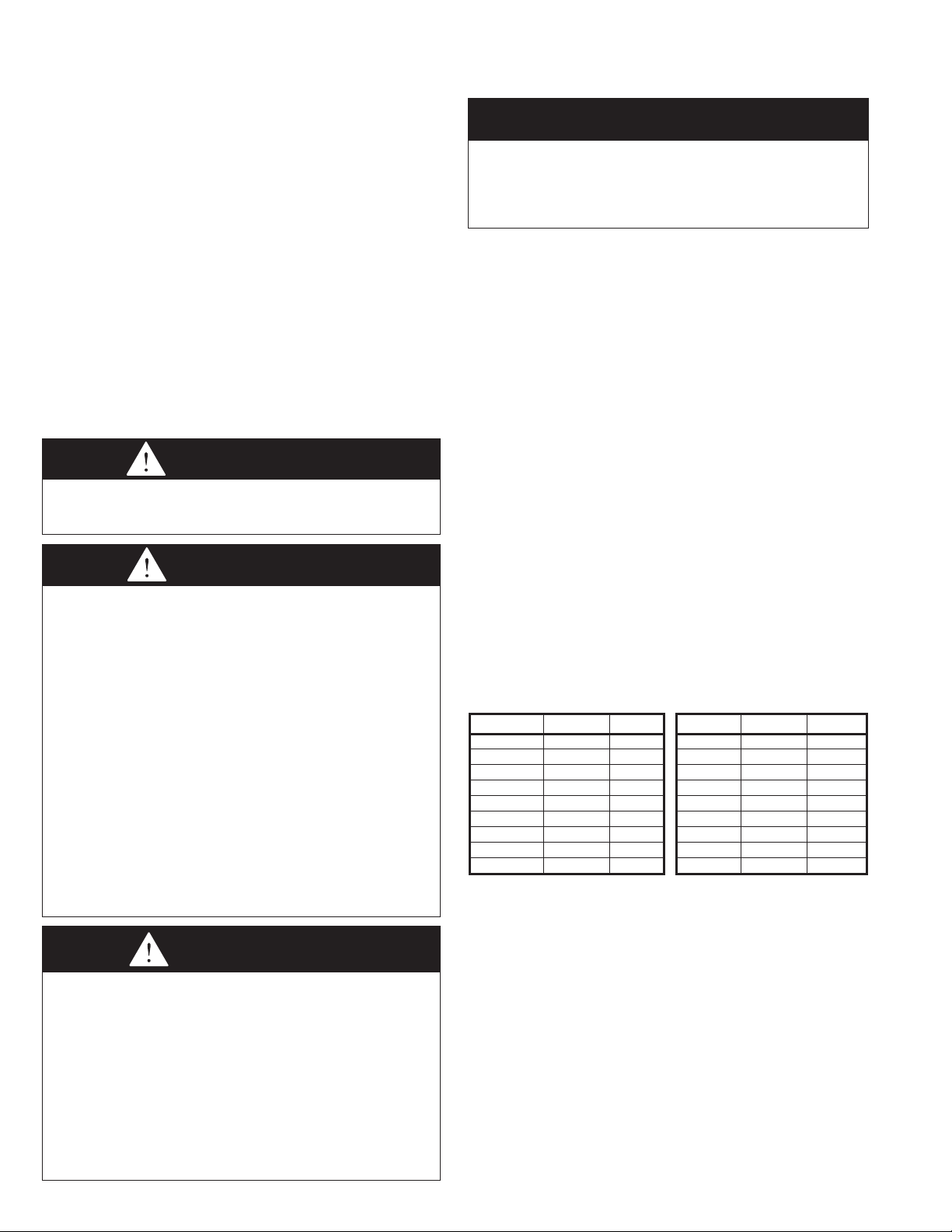

Figure 3.1 - Horizontal Delivery Unit Location

Figure 3.3 - Combination Horizontal and Vertical

Delivery Unit Installation

UNIT MOUNTING

CAuTION

Do not install units below 8 feet measured from the bottom of

the unit to the floor.

Do not install unit above recommended maximum mounting

heights. Height at which unit heaters are installed is critical.

Maximum mounting heights for all units are listed in Table 4.1

and the height dimensions are shown in Figures 4.3 through

4.7. Maximum mounting heights for vertical models are given

for units with or without optional air deflectors. The data in

Table 4.1 is based on operating conditions of 2 lbs. steam or

220°F entering water with 60°F entering air. When operating

conditions are other than those above, refer to Figure 4.2 for

maximum mounting height correction factor. To obtain the

maximum mounting at actual operating conditions, multiply

the appropriate factor from Figure 4.2 by the mounting height

in Table 4.1. The maximum mounting height for all units is that

height above which the unit heater will not deliver heated air

to the floor at standard rating conditions.

Figure 3.2 - Unit Locations of Vertical Units In

Narrow Buildings

Deflector Mounting

If an optional air deflector has been furnished for vertical units,

it is always shipped separately and can be attached to the unit

before suspension. Vertical louvers for horizontal units and

horizontal louvers for “Power-Throw” units can also be added

and positioned before installation. Cone-jet and louver-type

deflectors must be attached with angle brackets and machine

screws to the bottom cover of the unit. Refer to mounting

instructions which are furnished with each deflector.

Depending on supply or return piping arrangement, there is

a possibility of interference between certain anemostat air

deflectors and piping on some vertical air delivery unit heaters.

Check dimensions.

1-550.29

3

1.3

1.2

1.1

1.0

.9

.8

.7

.6

.5

Correction Factor "R"

150 160 170 180 190 200 210 220 230 240 250 260 270 280 290 300 310 320 330 340 350 360 370

Steam Pressure

25 10 20 30 50 70 100

150

UNIT MOUNTING

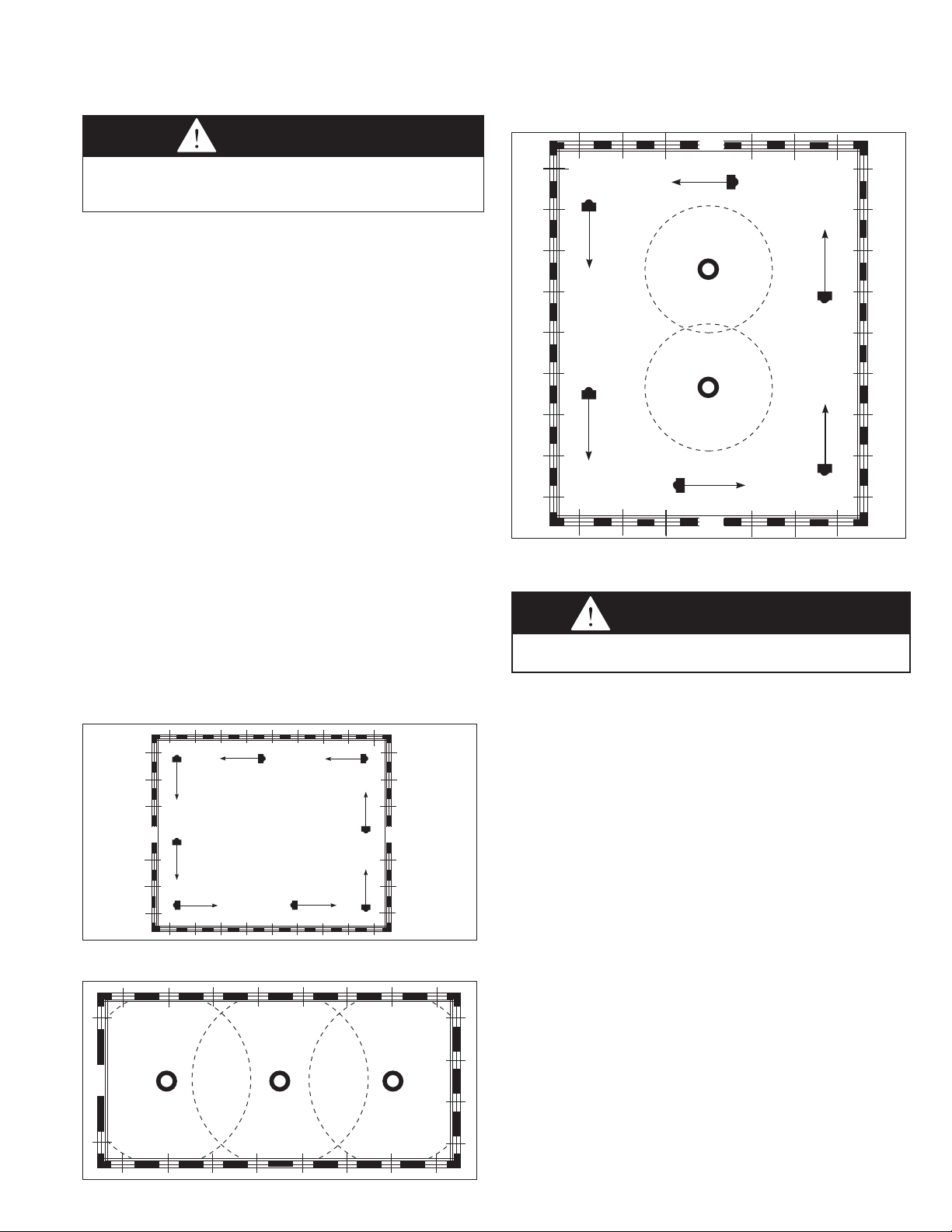

Table 4.1 - Maximum Mounting Heights

Vertical Type with Deectors

Horizontal Type Power-Throw Type

Height (ft)

Model No.

HSB/HC 18 8 9 — — — V/VN 42 11 13 15 17 8 9 13 15

HSB/HC 24 9 11 — — — V/VN 59 14 16 19 22 9 11 16 18

HSB/HC 33 10 12 — — — V/VN 78 15 19 20 26 11 14 17 22

HSB/HC 47 12 14 — — — V/VN 95 15 19 20 26 11 14 17 22

HSB/HC 63 14 16 — — — V/VN 139 18 23 24 31 13 17 21 26

HSB/HC 86 15 17 — — — V/VN 161 20 26 27 35 14 18 23 30

HSB/HC 108 17 19 — — — V/VN 193 22 27 30 36 16 19 25 31

HSB/HC 121 16 18 — — — V/VN 212 22 27 30 36 16 19 25 31

HSB/HC 165 19 21 — — — V/VN 247 26 32 34 42 17 21 30 37

HSB/HC 193 18 — PT/PTN 279 16 — V/VN 279 30 36 37 45 18 22 35 41

HSB/HC 258 19 22 PT/PTN 333 17 — V/VN 333 30 36 37 45 17 20 35 41

HSB/HC 290 20 23 PT/PTN 385 17 — V/VN 385 30 36 36 43 17 20 35 41

HSB/HC 340 20 23 PT/PTN 500 18 — V/VN 500 37 45 44 54 19 24 42 51

— — — PT/PTN 610 20 22 V/VN 610 36 44 43 52 19 24 41 50

— — — PT 952 21 — V 952 37 45 — — — — — —

➀ With horizontal louvers opened 30° from the vertical plane. HSB units have top and bottom piping connections, HC units have side connections. All have copper tubes.

➁ V and PT models have copper tubes, VN and PTN models have cupronickel tubes. Mounting heights are maximum for heaters operating at standard conditions

(2 lbs. steam or 220°F water with 60°F entering air). Heights listed for Louver or Cone-Jet are with deflectors in fully-opened position. Refer to Figure 4.2 for correction of

mounting heights under other operating conditions. Maximum mounting height will be reduced as entering air temperatures exceed 60°F.

Std. L.O.T. Std. L.O.T. Std. L.O.T. Std. L.O.T. Std. L.O.T. Std. L.O.T.

Model No.

Height (ft)

No Deector Cone-Jet Truncone Louvers

Height (ft) Height (ft) Height (ft) Height (ft)

Model No.

Figure 4.2 - Maximum Mounting Heights Correction Factors

These correction factors are to be used as multipliers to correct the maximum recommended mounting heights of unit heaters when operated with steam pressures other

than 2 pounds or with water at other than average temperature of 220°F.

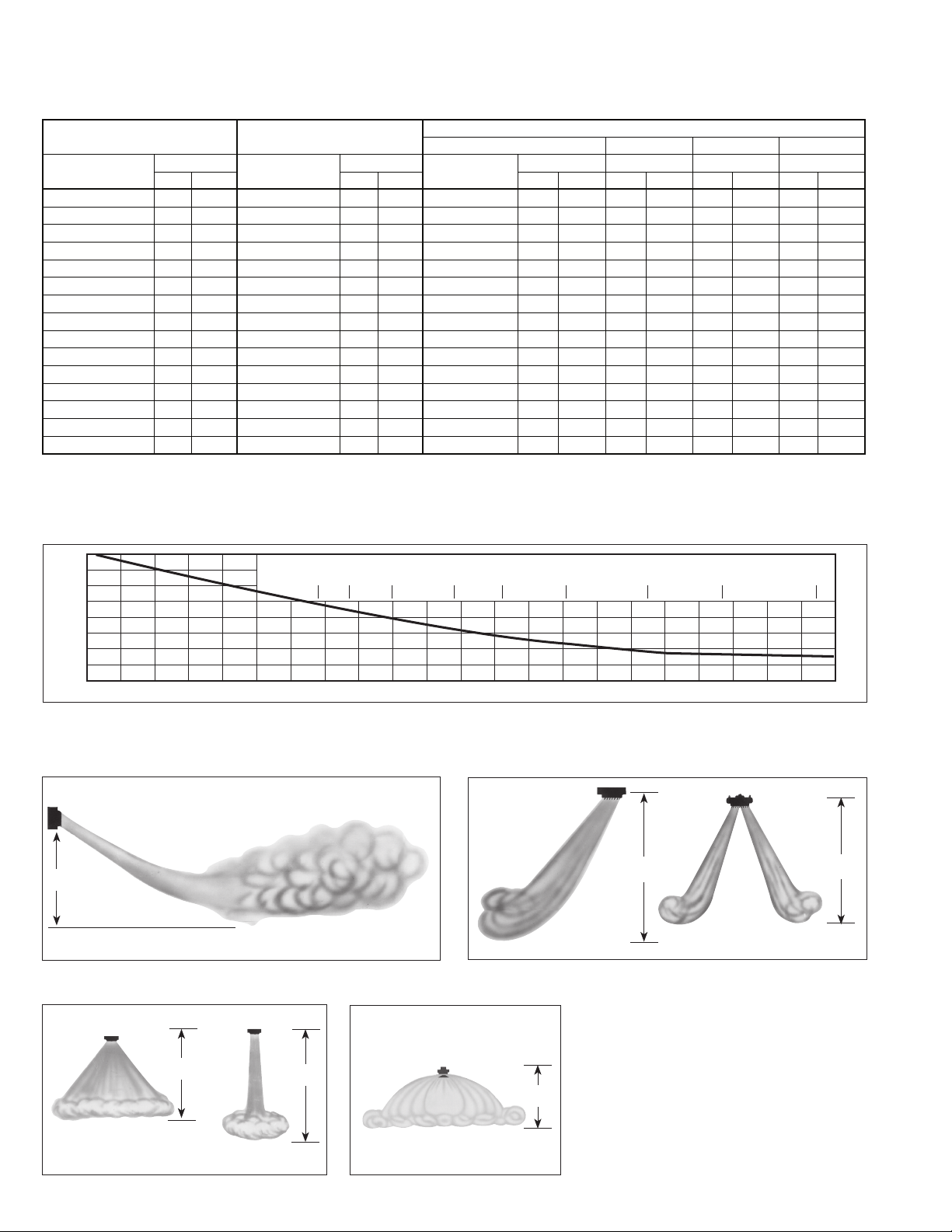

Figure 4.3 - Horizontal Unit Delivery

H

Figure 4.4 - Vertical One-Way & Two-Way Louvers

H

H

Figure 4.3 - Vertical Cone Jet

H

4

H

Figure 4.6 - Vertical Truncone

H

1-550.29

UNIT SUSPENSION / INSTALLATION

UNIT SUSPENSION

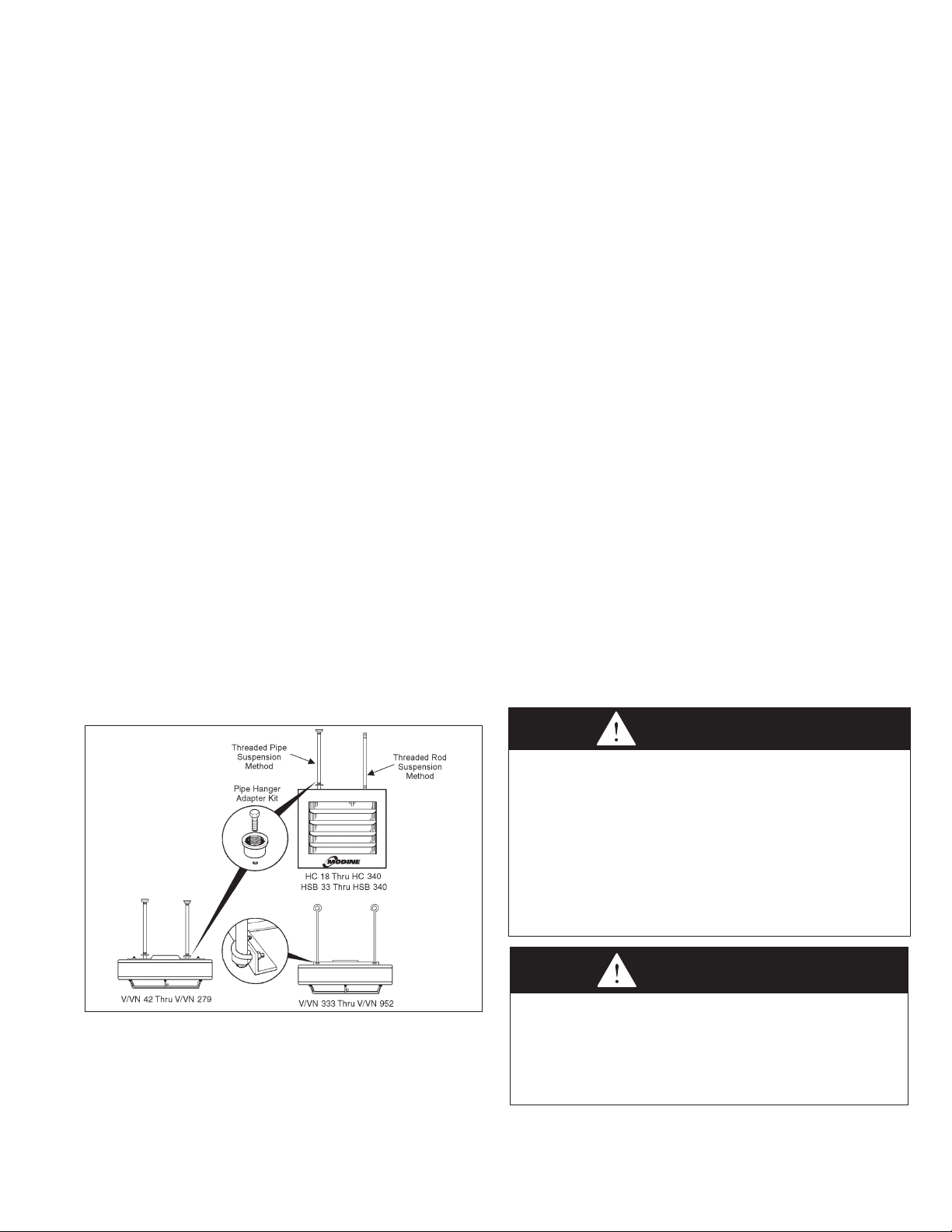

Horizontal delivery units, Model HSB/HC Series. All horizontal

delivery units, except Models HSB 18 and HSB 24, have two

tapped holes in the top for unit suspension. HSB 18 and HSB 24

models do not require independent suspension and are installed

directly on their supply piping. Models HSB 33-86 and HC 18-86

have 3/8"-16 tapped holes, model sizes 108 and larger have

1/2"-13 tapped holes. Piping support hangers or clamps are

recommended and should be placed as close to the unit heater

as possible. For other models, independent suspension can be

made with threaded rods, pipes, or ceiling hanger brackets. See

Figure 5.1.

Vertical delivery units. Vertical delivery Models V/VN 42

through V/VN 279 have four tapped holes (1/2"-13) in the top

cover for unit suspension. Unit suspension for these models can

be made with threaded rods, pipes or ceiling hanger brackets.

Models V/VN 333 through V/VN 952 are equipped with an angleiron mounting bracket that has eight 5/8" diameter hanger holes

permitting hook-hoisting and suspension with cables, if desired.

A 1/2" x 3" center U-bolt can be inserted in the two holes at

each end of the bracket to accommodate suspension with four

threaded rods, pipes or hanger brackets.

"Power-Throw" horizontal delivery units. “Power-Throw”

units are designed for horizontal air delivery and are equipped

with hanger brackets for suspension. Three hanger brackets

are supplied for Model PT/PTN 279, one on the front, and two

on the rear panel for three-point suspension. Only two hanger

brackets are furnished on the front panel of Models PT/PTN 333

through PT/PTN 952 (for required four-point suspension use the

two hanger brackets on the front panel and the two holes on the

ends of the upper angle supports at the rear of the unit). Each

hanger bracket has a 5/8" diameter mounting hole for hookhoisting and suspension with threaded rods, pipes, or cables.

Note: A pipe hanger adapter kit as illustrated in Figure 5.1

is available as an accessory from Modine. The kit consists of

two drilled 3/4" I.P.S. pipe caps and two capscrews to facilitate

threaded-pipe suspension. One kit will mount applicable HSB or

HC models, two kits are required for V/VN models.

Figure 5.1 - Unit Suspension

water systems, include a balancing valve in return line for

water flow regulation. A drain valve should also be provided

below each unit heater to allow removal of water from the

heating coil if located in an area subject to freezing.

3. In steam or hot water systems, rapid air removal is required

because entrained air is a cause of corrosion. Hot water

systems should be equipped with suitable air vent valves for

rapid and complete removal of air at the high points and ends

of both supply and return mains. Proper air venting for steam

systems can be achieved by use of a steam trap with an

internal air vent.

4. Traps must be located below the outlet of the unit. Consult

trap manufacturer for specific recommendations. Each steam

unit heater should be provided with a trap of sufficient size

and capacity to pass a minimum of two times the normal

condensate released by the unit at the minimum differential

pressure in the system. Trap capacity is based on the

pressure differential between supply and return mains. Steam

systems should be equipped with a float and thermostatic trap

or an inverted bucket trap with an air bypass.

5. It is advisable to use a pipe line strainer before each steam

trap draining a unit heater. This protection will reduce the

maintenance of the steam trap. When strainers are used they

should be installed between the unit heater and the trap and

be the same size as the trap tapping. In order to catch dirt

and scale, the strainer should have a screen perforation size

smaller than the trap orifices.

6. On systems where the steam supply to the unit heater is

modulated or controlled by a motorized valve, a vacuum

breaker should be installed between unit outlet and the trap.

If a vacuum breaker is used, it should be in conjunction with a

float and thermostatic trap.

7. Install a scale pocket at bottom of unit heater to collect dirt

and scale as shown in illustrations. Pipe diameter must be the

same size as unit connections and about 6" long.

8. Provide adequate pipe hangers, supports, or anchors to

secure the piping system independently of the unit heater.

Electrical Connections

Piping - See Figure 6.1

1. Branch piping to and from unit heater should include swing

joints to allow for expansion and contraction of the piping

without placing a strain on the unit heater element. On steam

systems, the branch piping should be taken off and returned

above the centerline of the supply and return lines.

2. Install pipe unions and shut-off valves in lines to and from

each unit heater to allow maintenance or replacement of unit

without shutting down and draining entire system. For hot

wARNINg

1. Disconnect power supply before making wiring connections

to prevent electrical shock and equipment damage.

2. All appliances must be wired strictly in accordance with

wiring diagram furnished with the appliance. Any wiring

different from the wiring diagram could result in a hazard

to persons and property.

3. Any original factory wiring that requires replacement must

be replaced with wiring material having a temperature

rating of at least 105°C.

4. Ensure that the supply voltage to the appliance as indicated

on the serial plate is not 5% greater than the rated voltage.

CAuTION

1. Do not install units below 8 feet measured from the bottom

of the unit to the floor.

2. Do not reuse any electrical component which has been

wet. Replace component.

3. Ensure that the supply voltage to the appliance, as indicated

on the serial plate is not 5% less than the rated voltage.

1. Installation of wiring must conform with local building codes,

or in the absence of local codes, with the National Electric

Code ANSI/NFPA 70 - Latest Edition. Unit must be electrically

grounded in conformance to this code. In Canada, wiring must

comply with CSA C22.1, Electrical Code.

1-550.29

5

INSTALLATION / OPERATION

Figure 6.1 - Suggested Piping Arrangements ➀

Hot Water Systems

Horizontal Unit Heater Connected to

Overhead Hot Water Mains

Vertical Unit Heater Connected to

Lower Hot Water Mains

Steam Systems

Unit Heater Connection for High Pressure Steam

➀ Arrangements shown are recommendations only. Where horizontal units are shown, vertical units can be substituted or vice versa. For modifications to piping

suggestions shown, refer to your local plumbing authority.

Electrical Connections (Cont.)

2. Electric wiring must be sized to carry the full load amp draw

of the motor, starter, and any controls that are used with

the unit heater. All units with power codes 04, 05, 09, or

10 (polyphase motors) must be provided with suitable

overcurrent protection in circuit supplying heater at

installation. Overcurrent protectors should be sized based

on motor current rating shown on the unit serial plate, and

applicable national electric code procedures.

All units are provided with an electrical junction box.

Junction boxes are either integral to the motor or attached

to the unit casing. Units with explosion-proof motors have

an explosion-proof junction box attached to the motor.

Any damage to or failure of Modine units caused by

incorrect wiring of the units is not covered by Modine’s

standard warranty.

3. Location of room thermostat, when supplied, should be in

the natural circulating path of room air. Mount thermostat

about five feet above floor level where it will not be affected

by heat from the unit or other sources of drafts that would

prevent it from properly controlling room temperature. See

instructions packed with the thermostat.

4. Speed controllers furnished with specified unit heater fan

motors, are packed separately and must be connected

according to wiring diagram with each controller.

OPERATION

Prior to Operation

1. Make sure fuses are installed in fused disconnect switches.

2. Check all electrical connections to assure they are secure.

3. Check rigidity of unit mounting. Tighten all fasteners,

4. Inspect piping, strainers, traps, fittings, etc.

Initial Start-Up

1. Set thermostat to lowest position.

2. Turn on power supply to unit.

3. Open return gate valve, and then open supply gate valve

4. Raise thermostat setting to desired position.

5. Adjust louvers (if provided) for desired heat distribution.

6. To insure proper sequence of operation, cycle unit on and off

7. Check for proper rotation of fan. All fans must rotate in a

Automatic Control Operations

Install one of the following operating systems for continuous

automatic control.

Intermittent Fan Operation — Hot Coil

A room thermostat starts and stops the fan motor. An aquastat

is sometimes strapped to the return piping to prevent fan

operation when heat is not being supplied to the unit heater.

Unit Heater Connection for Low-Pressure Steam

Open Gravity or Vacuum Return System

if necessary.

to unit.

a few times by raising and lowering thermostat setting.

counterclockwise direction when viewed from the back

(HSB/HC, PT/PTN) or top (V/VN) of the unit heater.

Continuous Fan Operation — Intermittent Hot/Cold Coil

A room thermostat controls a valve which opens to allow steam

or hot water to supply the unit and closes to shut off the supply

when the thermostat is satisfied.

6

1-550.29

OPERATION

Figure 7.1 - Horizontal Delivery Unit Cutaway

Connections — Female-type permits direct connection of unit heater to the

piping. HC models have copper connectors at side of the unit.

Vertical fins — Less opportunity for dust and dirt to collect. Reduces cleaning.

Fins die-formed for added strength and heat transfer.

Coil — All air passes through coil. Heating is uniform. Design assures maximum

control over air delivery and temperature of air leaving the heater. Aluminum

fins die-formed for added strength — increased heat transfer. Fins mechanically

bonded to serpentine copper tube.

Motor — All motors are totally enclosed. Single phase types include built-in

thermal overload protection. All motor wiring is terminated in an electrical junction

box either supplied on the unit heater or as an integral part of the motor.

Fan — Lightweight. Blades accurately balanced and pitched to move air quietly

and positively — with minimum power requirement.

Safety fan guard — Standard equipment. Bolted steel rod fan guard completely

surrounds the fan offering constant protection.

Deflector blades — Adjustable horizontal air-deflector blades are standard —

vertical blades are optional.

Casings — Electrostatically applied, gray-green polyester powder coat paint

finish is applied over rust- and corrosion-treated steel for long life.

Figure 7.2 - Typical Horizontal Unit with

Standard Junction Box

Figure 7.4 - Vertical Delivery Unit Cutaway

Motor-Cooling Cone — Shields

motor from coil heat — prolongs life

of insulation, windings, and lubricant.

Prolongs motor life.

Coil — Aluminum fins mechanically

bonded to tubes for maximum heat

transfer. All steam- and watercarrying passages between heavy

steel pipe connections are copper, or

cupronickel.

Motor — All motors are totally

enclosed. Single phase types include

built-in thermal overload protection.

Figure 7.3 - Horizontal Unit with Optional

Fingerproof Fan Guard

Junction Box — Easier installation

with single point electrical connection.

Motor easily removable — Modine

design permits motor to be removed

through opening below the unit —

especially important where heaters are

installed close to ceiling.

Vertical fins — Less opportunity for

dust and dirt to collect. Exposed for

easy cleaning with air hose and brush.

Fan — Accurately balanced to

operate quietly and at lowest possible

power consumption.

1-550.29

Casings — Electrostatically applied,

gray-green polyester powder coat paint

finish applied over rust- and corrosiontreated steel lasts longer.

7

STEAM PERFORMANCE DATA - STANDARD MODELS

Table 8.1 - Performance Data for Standard Units at Standard Conditions of

2 lb. Steam and 60°F Entering Air High Motor Speed

Air Data Motor Data

Type Model No. Btu/hr

HSB/HC 18 18,000 75 8 17 340 625 107 19 1/60 1,550

HSB/HC 24 24,000 100 9 18 370 695 119 25 1/25 1,550

HSB/HC 33 33,000 138 10 21 630 690 108 34 1/25 1,550

HSB/HC 47 47,000 196 12 28 730 810 119 49 1/12 1,550

HSB/HC 63 63,000 263 14 29 1,120 690 111 65 1/12 1,550

Horizontal

Delivery

Power-

Throw™

Vertical

Delivery

HSB/HC 86 86,000 358 15 31 1,340 835 11 8 89 1/8 1,625

HSB/HC 108 108,000 450 17 31 2,010 790 109 11 2 1/8 1,625

HSB/HC 121 121,000 504 16 25 1,775 715 122 125 1/5 1,075

HSB/HC 165 165,000 688 19 40 3,240 880 106 171 1/3 1,075

HSB/HC 193 193,000 804 18 38 2,900 810 121 200 1/3 1,075

HSB/HC 258 258,000 1,075 19 44 4,560 750 111 267 1/2 1,075

HSB/HC 290 290,000 1,208 20 46 4,590 765 11 7 300 1/2 1,075

HSB/HC 340 340,000 1,417 20 46 5,130 735 120 352 1/2 1,075

PT/PTN 279 279,000 1,163 16 100 5,460 2,165 111 289 1/2 1,075

PT/PTN 333 333,000 1,388 17 110 5,980 2,165 11 6 345 3/4 1,140

PT/PTN 385 385,000 1,604 17 115 7,680 1,860 11 0 398 1 1,140

PT/PTN 500 500,000 2,083 18 130 10,390 2,520 108 517 1 1/2 1,140

PT/PTN 610 610,000 2,542 20 140 11,750 2,315 11 2 631 1 1/2 1,140

PT 952 952,000 3,967 21 145 12,170 2,321 139 985 2 1,140

V/VN 42 42,000 175 11 15 17 11 950 825 103 43 1/30 1,050

V/VN 59 59,000 246 14 19 21 14 1,155 1,005 111 61 1/30 1,050

V/VN 78 78,000 325 15 20 23 15 1,590 1,065 109 81 1/15 1,050

V/VN 95 95,000 396 15 20 23 15 1,665 1,120 118 98 1/15 1,050

V/VN 139 139,000 579 18 24 27 18 2,660 1,285 112 144 1/6 1,075

V/VN 161 161,000 671 20 27 30 20 2,945 1,420 115 167 1/3 1,075

V/VN 193 193,000 804 22 30 33 22 3,500 1,690 116 200 1/3 1,075

V/VN 212 212,000 883 22 30 33 22 3,610 1,740 120 219 1/3 1,075

V/VN 247 247,000 1,029 26 34 39 26 4,820 1,910 111 256 1/2 1,075

V/VN 279 279,000 1,163 30 37 45 30 5,460 2,165 111 289 1/2 1,075

V/VN 333 333,000 1,388 30 37 45 30 5,980 2,165 116 345 3/4 1,140

V/VN 385 385,000 1,604 30 36 45 30 7,680 1,860 110 398 1

V/VN 500 500,000 2,083 37 44 56 37 10,390 2,520 108 517 1 1/2 1,140

V/VN 610 610,000 2,542 36 43 54 36 11,750 2,315 112 631 1 1/2 1,140

V 952 952,000 3,967 37 56 12,170 2,321 139 985 2 1,140

Sq. Ft.

EDR

Maximum

Mounting

Height (ft.)

Heat Throw

or Spread @

Max. Height

CFM

Outlet

Velocity

(Fpm)

Final Air

Temp.

(°F)

Condensate

lb/hr

lbs.

2

STEAM

60° ENT. AIR

Approx.

Hp

RPM

1,140

Table 8.2 - Performance Data for Standard Units at Standard Conditions of

2 lb. Steam and 60°F Entering Air Reduced Motor Speed ➃

Air Data Motor Data

Type Model No. Btu/hr

HSB/HC 18 14,000 58 8 10 220 415 11 8 14 1/60 1,000

HSB/HC 24 18,000 75 9 11 230 440 131 19 1/25 1,000

Horizontal

Delivery

➀ Horizontal units with horizontal louvers open 30° from vertical plane. Vertical types equipped with cone jet deflector, blades fully opened are shown in bold.

➁ CFM for horizontal types is entering CFM. CFM for vertical and "Power-Throw" types is leaving CFM.

➂ V and PT models have copper tubes, VN and PTN models have 90/10 cupro-nickel tubes.

➃ Requires Solid State Motor Speed Controller.

HSB/HC 33 25,000 104 10 13 395 440 118 26 1/25 1,000

HSB/HC 47 38,000 158 12 17 450 515 137 39 1/12 1,000

HSB/HC 63 47,000 195 14 17 685 430 122 49 1/12 1,000

HSB/HC 86 64,000 265 15 19 825 525 131 66 1/8 1,000

HSB/HC 108 81,000 340 17 19 1,255 500 11 9 84 1/8 1,000

Sq. Ft.

EDR

Maximum

Mounting

Height (ft.)

8

Heat Throw

or Spread @

Max. Height

1-550.29

CFM

Outlet

Velocity

(Fpm)

Final Air

Temp.

(°F)

Condensate

lb/hr

Hp

Approx.

RPM

STEAM PERFORMANCE DATA - LOW OUTLET TEMPERATURE MODELS

2

lbs.

STEAM

60° ENT. AIR

Table 9.1 - Performance Data for Low Outlet Temperature Units at Standard Conditions of

2 lb. Steam and 60°F Entering Air High Motor Speed

Air Data Motor Data

Type Model No. Btu/hr

HSB/HC 18L 15,900 66 9 20 364 655 100 16 1/60 1,550

HSB/HC 24L 19,300 80 11 21 435 795 100 20 1/25 1,550

HSB/HC 33L 29,500 123 12 24 695 745 99 31 1/25 1,550

HSB/HC 47L 32,000 133 14 32 855 910 94 33 1/12 1,550

HSB/HC 63L 52,500 219 16 33 1,170 710 101 54 1/12 1,550

Horizontal

Delivery

Power-

Throw™PT/PTN 610L 470,000 1,958 22 154 2,400 2,445 97 486 1-1/2 1,140

HSB/HC 86L 61,500 256 17 36 1,510 910 97 64 1/8 1,625

HSB/HC 108L 86,500 360 19 36 2,150 825 97 90 1/8 1,625

HSB/HC 121L 88,000 367 18 29 2,070 800 98 91 1/5 1,075

HSB/HC 165L 143,000 596 21 45 3,480 930 97 148 1/3 1,075

HSB/HC 258L 190,000 792 22 51 4,655 750 98 197 1/2 1,075

HSB/HC 290L 207,000 863 23 53 5,040 805 94 214 1/2 1,075

HSB/HC 340L 255,000 1,063 23 53 5,575 775 102 264 1/2 1,075

Sq. Ft.

EDR

Maximum

Mounting

Height (ft.)

Heat Throw

or Spread @

Max. Height

CFM

Outlet

Velocity

(Fpm)

Final Air

Temp.

(°F)

Condensate

lb/hr

Hp

Approx.

RPM

V 42L 33,000 138 13 17 20 13 960 835 94 34 1/30 1,050

V 59L 44,000 183 16 22 24 16 1,190 1,035 96 45 1/30 1,050

V 78L 62,000 258 19 26 29 19 1,740 1,070 95 65 1/15 1,050

V 95L 71,000 296 19 26 29 19 1,760 1,180 99 73 1/15 1,050

V/VN 139L 103,000 429 23 31 35 23 2,860 1,380 95 106 1/6 1,075

V/VN 161L 127,000 529 26 35 39 26 3,400 1,640 96 132 1/3 1,075

Vertical

Delivery

V/VN 193L 149,000 621 27 36 41 27 3,710 1,790 99 154 1/3 1,075

V/VN 212L 163,000 679 27 36 41 27 3,830 1,845 102 169 1/3 1,075

V/VN 247L 190,000 792 32 42 48 32 5,110 2,030 96 197 1/2 1,075

V/VN 279L 215,000 896 36 45 54 36 5,790 2,300 96 222 1/2 1,075

V/VN 333L 256,000 1,067 36 45 54 36 6,340 2,300 100 265 3/4 1,140

V/VN 385L 296,000 1,233 36 43 54 36 8,140 1,970 95 307 1 1,140

V/VN 500L 385,000 1,604 45 54 68 45 11,000 2,670 94 400 1-1/2 1,140

V/VN 610L 470,000 1,958 44 52 66 44 12,400 2,445 97 485 1-1/2 1,140

V 952L 733,000 3,055 45 - 68 - 12,940 2,450 115 759 2 1,140

Table 9.2 - Performance Data for Low Outlet Temperature Units at Standard Conditions of

2 lb. Steam and 60°F Entering Air Reduced Motor Speed ➃

Air Data Motor Data

Type Model No. Btu/hr

HSB/HC 18L 12,000 51 9 12 230 425 108 12 1/60 1,000

HSB/HC 24L 14,400 60 11 13 265 490 109 15 1/25 1,000

Horizontal

Delivery

➀ Horizontal units with horizontal louvers open 30° from vertical plane. Vertical types equipped with cone jet deflector, blades fully opened are shown in bold.

➁ CFM for horizontal types is entering CFM. CFM for vertical and "Power-Throw" types is leaving CFM.

➂ V and PT models have copper tubes, VN and PTN models have 90/10 cupro-nickel tubes.

➃ Requires Solid State Motor Speed Controller.

HSB/HC 33L 22,000 92 12 14 430 470 107 23 1/25 1,000

HSB/HC 47L 24,300 101 14 19 540 580 101 25 1/12 1,000

HSB/HC 63L 39,500 164 16 20 725 445 109 41 1/12 1,000

HSB/HC 86L 46,000 192 17 22 925 565 105 48 1/8 1,000

HSB/HC 108L 65,000 270 19 22 1,330 520 104 67 1/8 1,000

Sq. Ft.

EDR

Maximum

Mounting

Height (ft.)

Heat Throw

or Spread @

Max. Height

CFM

Outlet

Velocity

(Fpm)

Final Air

Temp.

(°F)

Condensate

lb/hr

Hp

Approx.

RPM

1-550.29

9

HOT WATER PERFORMANCE DATA - STANDARD MODELS

Table 10.1 - Performance Data for Standard Units at Standard Conditions of

200°F Entering Water and 60°F Entering Air High Motor Speed

Water Data Air Data Motor Data

Type Model No. Btu/hr

HSB/HC 18 12,600 1.3 0.5 0.3 / 5.0 9 18 340 615 93 1/60 1,550

HSB/HC 24 16,200 1.7 0.8 0.3 / 5.0 10 19 370 675 100 1/25 1,550

HSB/HC 33 21,700 2.3 0.2 0.4 / 10.0 11 23 630 675 91 1/25 1,550

HSB/HC 47 30,900 3.2 0.4 0.4 / 10.0 13 30 730 785 98 1/12 1,550

HSB/HC 63 45,600 4.7 0.6 0.5 / 20.0 15 31 1,120 680 97 1/12 1,550

Horizontal

Delivery

HSB/HC 86 60,200 6.3 1.0 0.5 / 20.0 16 33 1,340 820 101 1/8 1,625

HSB/HC 108 83,700 8.7 2.8 0.5 / 30.0 18 33 2,010 775 98 1/8 1,625

HSB/HC 121 93,000 9.7 3.3 0.7 / 30.0 17 27 1,775 700 107 1/5 1,075

HSB/HC 165 130,900 13.6 8.6 2.0 / 30.0 20 43 3,240 870 96 1/3 1,075

HSB/HC 193 143,000 14.9 1.4 2.0 / 50.0 19 41 2,900 790 105 1/3 1,075

HSB/HC 258 201,900 21.0 5.7 2.5 / 70.0 20 47 4,560 740 100 1/2 1,075

HSB/HC 290 228,600 23.8 7.1 2.5 / 70.0 22 50 4,590 750 105 1/2 1,075

HSB/HC 340 271,100 28.2 11.3 2.8 / 70.0 22 50 5,130 720 108 1/2 1,075

PT/PTN 279 192,300 20.0 0.2 4.5 / 60.0 17 108 5,460 2,165 94 1/2 1,075

Power-

Throw™

PT/PTN 333 238,500 24.8 0.4 4.5 / 100.0 18 11 7 5,980 2,165 99 3/4 1,140

PT/PTN 385 276,100 28.8 0.6 4.5 / 100.0 18 124 7,680 1,860 95 1 1,140

PT/PTN 500 358,000 37.3 0.5 6.0 / 100.0 19 138 10,390 2,520 93 1 1/2 1,140

PT/PTN 610 450,400 46.9 1.0 6.0 / 100.0 22 151 11,750 2,315 97 1 1/2 1,140

PT 952 721,600 75.2 1.1 14.0 / 200.0 23 150 12,166 2,321 120 2 1,140

V/VN 42 30,100 3.1 0.6 0.5 / 10.0 12 16 18 12 950 825 90 1/30 1,050

V/VN 59 42,600 4.4 0.5 0.8 / 15.0 15 20 22 15 1,155 1,005 96 1/30 1,050

V/VN 78 57,000 5.9 0.5 1.0 / 20.0 16 22 24 16 1,590 1,065 95 1/15 1,050

V/VN 95 69,300 7.2 0.5 1.3 / 25.0 16 22 24 16 1,665 1,120 101 1/15 1,050

V/VN 139 106,600 11.1 2.6 1.0 / 30.0 19 26 29 19 2,660 1,285 99 1/6 1,075

V/VN 161 123,200 12.8 2.2 1.3 / 40.0 21 29 32 22 2,945 1,420 101 1/3 1,075

Vertical

Delivery

V/VN 193 147,200 15.3 2.2 1.5 / 50.0 23 32 35 24 3,500 1,690 101 1/3 1,075

V/VN 212 161,700 16.8 1.5 2.0 / 60.0 23 32 35 24 3,610 1,740 104 1/3 1,075

V/VN 247 188,700 19.7 2.1 2.0 / 60.0 28 37 41 28 4,820 1,910 98 1/2 1,075

V/VN 279 212,600 22.2 2.1 2.3 / 75.0 32

V/VN 333 260,100 27.1 3.8 2.8 / 75.0 32 40 48 32 5,980 2,165 102 3/4 1,140

V/VN 385 302,100 31.5 5.0 3.3 / 75.0 32 39 48 32 7,680 1,860 98 1 1,140

V/VN 500 391,700 40.8 4.8 3.0 / 100.0 39 47 59 40 10,390 2,520 96 1 1/2 1,140

V/VN 610 450,400 46.9 1.0 6.0 / 100.0 38 46 57 39 11,750 2,315 97 1 1/2 1,140

V 952 721,600 75.2 1.1 14.0 / 200.0 39 59 12,166 2,321 120 2 1,140

GPM

Pressure

Drop

(Ft. of

Water)

Min/Max

GPM

Maximum

Mounting

Height (ft.)

Heat Throw

or Spread @

Max. Height

CFM

40 48 32 5,460 2,165 98 1/2 1,075

Outlet

Velocity

(Fpm)

Final Air

Temp.

(°F)

200°F ENTERING

WATER

60°F ENTERING

AIR

20°F WATER

TEMPERATURE

DROP

Approx.

Hp

RPM

Table 10.2 - Performance Data for Standard Units at Standard Conditions of

200°F Entering Water and 60°F Entering Air Reduced Motor Speeds

Water Data Air Data Motor Data

Type Model No. Btu/hr

GPM

Pressure

Drop (Ft.

of Water)

Maximum

Mounting

Height (ft.)

HSB/HC 18 9,900 1.3 0.5 9 11 220 400 101 1/60 1,000

HSB/HC 24 12,400 1.7 0.8 10 12 230 425 109 1/25 1,000

Horizontal

Delivery

HSB/HC 33 16,700 2.3 0.2 11 14 395 430 98 1/25 1,000

HSB/HC 47 23,600 3.2 0.4 13 18 450 490 107 1/12 1,000

HSB/HC 63 34,600 4.7 0.6 15 18 685 420 106 1/12 1,000

HSB/HC 86 45,900 6.3 1.0 16 20 825 515 11 0 1/8 1,000

HSB/HC 108 64,300 8.7 2.8 18 20 1,255 490 106 1/8 1,000

➀ Horizontal units with horizontal louvers open 30° from vertical plane. Vertical types equipped with cone jet deflector, blades fully opened are shown in bold.

Non-bolded mounting height/spread data is for units without deflectors.

➁ CFM for horizontal types is entering CFM. CFM for vertical and "Power-Throw" types is leaving CFM.

➂ V and PT models have copper tubes, VN and PTN models have 90/10 cupro-nickel tubes.

➃ Requires Solid State Motor Speed Controller.

10

Heat Throw

or Spread @

Max. Height

1-550.29

➃

CFM

Outlet

Velocity

(Fpm)

Final Air

Temp.

(°F)

Hp

Approx.

RPM

HOT WATER PERFORMANCE DATA - LOW OUTLET TEMPERATURE MODELS

200°F ENTERING

WATER

60°F ENTERING

AIR

20°F WATER

TEMPERATURE

DROP

Table 11.1 - Performance Data for Low Outlet Temperature Units at Standard Conditions of

200°F Entering Water and 60°F Entering Air – High Motor Speed

Water Data Air Data Motor Data

Type Model No. Btu/hr

GPM

Pressure

Drop

(Ft. of

Min/Max

GPM

Water)

HSB/HC 18L 11,300 1.2 0.4 0.3 / 5.0 10 21 364 650 88 1/60 1,550

HSB/HC 24L 13,700 1.4 0.6 0.3 / 5.0 12 22 435 775 88 1/25 1,550

HSB/HC 33L 19,300 2.0 0.2 0.4 / 10.0 13 26 695 730 85 1/25 1,550

HSB/HC 47L 21,100 2.2 0.2 0.4 / 10.0 15 34 855 890 82 1/12 1,550

HSB/HC 63L 37,900 4.0 0.4 0.5 / 20.0 17 35 1,170 695 89 1/12 1,550

Horizontal

Delivery

HSB/HC 86L 44,600 4.6 0.6 0.5 / 20.0 18 38 1,510 890 87 1/8 1,625

HSB/HC 108L 66,100 6.9 1.8 0.8 / 30.0 20 38 2,150 815 88 1/8 1,625

HSB/HC 121L 66,700 6.9 1.9 0.8 / 30.0 19 31 2,070 785 89 1/5 1,075

HSB/HC 165L 113,200 11.8 6.6 2.0 / 30.0 23 48 3,480 920 89 1/3 1,075

HSB/HC 258L 147,400 15.4 3.2 2.5 / 70.0 23 54 4,655 735 89 1/2 1,075

HSB/HC 290L 161,100 16.8 3.7 2.5 / 70.0 25 57 5,040 800 89 1/2 1,075

HSB/HC 340L 200,900 20.9 6.6 2.5 / 70.0 25 57 5,575 760 93 1/2 1,075

Power-

Throw™PT/PTN 610L 344,900 35.9 0.6 6.0 / 100.0 24 158 12,400 2,445 86 1-1/2 1,140

Maximum

Mounting

Height (ft.)

Heat Throw

or Spread @

Max. Height

CFM

Outlet

Velocity

(Fpm)

Final Air

Temp.

(°F)

Hp

Approx.

RPM

V 42L 23,000 2.4 0.4 0.5 / 10.0 14 18 21 14 960 835 83 1/30 1,050

V 59L 32,600 3.4 0.3 0.8 / 15.0 17 23 25 17 1,190 1,035 86 1/30 1,050

V 78L 43,600 4.5 0.3 1.0 / 20.0 20 28 31 21 1,740 1,170 84 1/15 1,050

V 95L 53,100 5.5 0.3 1.3 / 25.0 20 28 31 21 1,760 1,180 89 1/15 1,050

V/VN 139L 81,200 8.5 1.6 1.0 / 30.0 24 33 37 25 2,860 1,380 87 1/6 1,075

V/VN 161L 93,900 9.8 1.3 1.3 / 40.0 28 37 41 28 3,400 1,640 86 1/3 1,075

Vertical

Delivery

V/VN 193L 112,500 11.7 1.3 1.5 / 50.0 29 38 43 29 3,710 1,790 89 1/3 1,075

V/VN 212L 123,400 12.9 0.9 2.0 / 60.0 29 38 43 29 3,830 1,845 91 1/3 1,075

V/VN 247L 143,600 15.0 1.2 2.0 / 60.0 34 45 51 35 5,110 2,030 87 1/2 1,075

V/VN 279L 162,200 16.9 1.2 2.3 / 75.0 38 48 57 39 5,790 2,300 87 1/2 1,075

V/VN 333L 198,300 20.7 2.3 2.3 / 75.0 38 48 57 39 6,340 2,300 90 3/4 1,140

V/VN 385L 229,100 23.9 3.0 2.3 / 75.0 38 46 57 49 8,140 1,970 87 1 1,140

V/VN 500L 295,000 30.7 2.8 3.0 / 100.0 48 57 72 49 11,000 2,670 85 1-1/2 1,140

V/VN 610L 344,900 35.9 0.6 6.0 / 100.0 47 55 70 48 12,400 2,445 86 1-1/2 1,140

V 952L 546,700 56.9 0.7 14.0 / 100.0 48 - 72

- 12,800 2,440 102 2 1,140

Table 11.2 - Performance Data for Low Outlet Temperature Units at Standard Conditions of

200°F Entering Water and 60°F Entering Air – Reduced Motor Speeds ➃

Water Data Air Data Motor Data

Type Model No. Btu/hr

GPM

Pressure

Drop

(Ft. of

Water)

HSB/HC 18L 8,700 1.2 0.4 10 13 230 410 94 1/60 1,000

HSB/HC 24L 10,400 1.4 0.6 12 14 265 475 95 1/25 1,000

Horizontal

Delivery

HSB/HC 33L 14,700 2.0 0.2 13 16 430 455 91 1/25 1,000

HSB/HC 47L 16,300 2.2 0.2 15 21 540 570 87 1/12 1,000

HSB/HC 63L 29,000 4.0 0.4 17 21 725 435 96 1/12 1,000

HSB/HC 86L 33,900 4.6 0.6 18 23 925 550 93 1/8 1,000

HSB/HC 108L 50,500 6.9 1.8 20 23 1,330 510 94 1/8 1,000

➀ Horizontal units with horizontal louvers open 30° from vertical plane. Vertical types equipped with cone jet deflector, blades fully opened are shown in bold.

Non-bolded mounting height/spread data is for units without deflectors.

➁ CFM for horizontal types is entering CFM. CFM for vertical and "Power-Throw" types is leaving CFM.

➂ V and PT models have copper tubes, VN and PTN models have 90/10 cupro-nickel tubes.

➃ Requires Solid State Motor Speed Controller.

Maximum

Mounting

Height (ft.)

Heat Throw

or Spread @

Max. Height

CFM

Outlet

Velocity

(Fpm)

Final Air

Temp.

(°F)

Hp

Approx.

RPM

1-550.29

11

DIMENSIONAL DATA

SIZES 108-193, 1/2"-13 TAP

SIZES 108-165, 1/2"-13 TAP

F

G

H

5"

Min.

D

C

B

E

A

Wall

Pipe

Connections

Mounting Holes

Mounting Holes

1/2" - 13 Tap

F

G

5"

Min.

D

C

B

E

A

Wall

Mounting Holes

1/2" - 13 Tap

Mounting Holes

Pipe

Connections

Horizontal Air Delivery Models — Two Styles

Figure 12.1 - Model Dimensions HSB 18-193

MOUNTING HOLES

SIZES 33-86, 3/8"-16 TAP

B

E

A

G (MOUNTING

HOLES)

F (PIPE

CONNECTIONS)

C

Figure 12.3 - Model Dimensions HC 18-165

MOUNTING HOLES

SIZES 33-86, 3/8"-16 TAP

B

E

A

G (MOUNTING

HOLES)

H (PIPE

CONNECTION)

Figure 12.2 - Model Dimensions HSB 258-340

5"

D

MIN

Figure 12.4 - Model Dimensions HC 193-340 ➀

C

MIN

5"

D

➀ Vertical deflector blades shown are standard on models HC 258-340

Table 12.1 - Model HSB and HC Dimensions ➀ ➁

and optional on model HC 193.

D Female Approx.

Model 115 Std. 115V Exp. Connections Fan Shipping

Number A B C Motor Motor E F G H NPT Diameter Wt. lb.

HSB 18 12-3/8 13 6 5 12 - 3 - - 3/4 9 16

HSB 24 12-3/8 13 6 6-1/2 12 - 3 - - 3/4 9 20

HSB 33 16-3/8 17-1/2 8-3/4 6-1/2 12-1/4 11 3-5/8 6 - 1-1/4 12 34

HSB 47 16-3/8 17-1/2 8-3/4 8 12-1/4 11 3-5/8 6 - 1-1/4 12 36

HSB 63 20-7/16 21-1/2 8-3/4 8 12-3/4 15 3-5/8 6 - 1-1/4 14 48

HSB 86 20-7/16 21-1/2 8-3/4 9 12-3/4 15 3-5/8 6 - 1-1/4 14 52

HSB 108 24-7/16 25-1/2 9-1/2 8 11-1/2 18 3-3/4 6-3/8 - 1-1/4 18 74

HSB 121 24-7/16 25-1/2 9-1/2 7-1/2 11 18 3-3/4 6-3/8 - 1-1/4 18 76

HSB 165 30-1/2 30-1/2 9-1/4 9-1/2 14 21-1/4 3-3/4 6-3/8 - 1-1/4 22 92

HSB 193 30-1/2 30-1/2 9-1/4 9-1/2 14 21-1/4 3-3/4 6-3/8 - 1-1/4 22 98

HSB 258 38-1/2 38-1/2 12-1/2 10-1/2 14 18-1/2 3-5/8 7-7/8 - 1-1/4 22 162

HSB 290 38-1/2 38-1/2 12-1/2 10-1/2 14 18-1/2 3-5/8 7-7/8 - 1-1/4 24 168

HSB 340 38-1/2 44-1/2 12-1/2 10-1/2 14 18-1/2 3-5/8 7-7/8 - 1-1/4 24 176

HC 18 11-1/2 12-3/4 6 5 12 5-5/8 2-1/4 4-1/8 7-1/2 1/2 9 16

HC 24 11-1/2 12-3/4 6 6-1/2 12 5-5/8 2-1/4 4-1/8 7-1/2 1/2 9 20

HC 33 15 17-1/2 8-3/4 6-1/2 12-1/4 11 3-5/8 6 10 3/4 12 34

HC 47 15 17-1/2 8-3/4 8 12-1/4 11 3-5/8 6 10 3/4 12 35

HC 63 18-1/2 21-1/2 8-3/4 8 12-3/4 15 3-5/8 6 14 3/4 12 48

HC 86 18-1/2 21-1/2 8-3/4 9 12-3/4 15 3-5/8 6 14 3/4 14 52

HC 108 22-1/2 25-1/2 9-1/2 8 11-1/2 18 3-5/8 6-3/8 18 3/4 18 74

HC 121 22-1/2 25-1/2 9-1/2 7-1/2 11 18 3-5/8 6-3/8 18 3/4 18 76

HC 165 26-1/2 29-1/2 9-1/4 9-1/2 14 21-1/4 3-5/8 6-3/8 22 3/4 22 92

HC 193 30-1/2 32-1/2 9-1/4 9-1/2 14 21-1/4 3-5/8 4-3/4 26 1-1/4 22 98

HC 258 38-1/2 38-1/2 12-1/2 10-1/2 14 18-1/2 3-5/8 8 34 1-1/4 22 163

HC 290 38-1/2 38-1/2 12-1/2 10-1/2 14 18-1/2 3-5/8 8 34 1-1/4 24 168

HC 340 38-1/2 44-1/2 12-1/2 10-1/2 14 18-1/2 3-5/8 8 34 1-1/4 24 176

➀ All dimensions in inches.

Dimensions shown are for Standard and Low Outlet Temperature Models.

12

1-550.29

DIMENSIONAL DATA

Figure 13.1 - Model Dimensions V/VN and PT/PTN

Vertical Air Delivery

“Power-Throw” Air Delivery

Air Deflectors (Optional)

Table 13.1 - Model V/VN and PT/PTN Dimensions ➀ ➁ ➂

Male

Connections Approx.

Model Fan NPT Shipping

Number A B C D E F G Diameter Top Bottom Wt. (lb.)

V/VN 42 24-3/4 3-5/8 11-3/8 2-1/8 4-3/8 14-1/2 - 14 1-1/4 1-1/4 36

V/VN 59 24-3/4 5-1/8 11-3/8 2-1/8 4-3/8 14-1/2 - 14 1-1/4 1-1/4 42

V/VN 78 24-3/4 6-5/8 11-3/8 2-1/8 2-5/8 16-1/2 - 16 1-1/4 1-1/4 46

V/VN 95 24-3/4 8-1/8 11-3/8 2-1/8 2-5/8 16-1/2 - 16 1-1/4 1-1/4 48

V/VN 139 34-3/4 6-7/8 18-3/8 2-1/8 3 19-1/2 - 19 1-1/2 1 70

V/VN 161 34-3/4 8-3/8 18-3/8 2-1/8 3 19-1/2 - 19 1-1/2 1 80

V/VN 193 34-3/4 9-7/8 18-3/8 2-1/8 3 19-1/2 - 19 1-1/2 1 86

V/VN 212 34-3/4 12-7/8 18-3/8 2-1/2 3 19-1/2 - 19 2 1-1/4 94

V/VN 247 34-3/4 12-7/8 18-3/8 2-1/2 3 21-1/2 - 21 2 1-1/4 108

V/VN 279 34-3/4 14-3/8 18-3/8 2-1/2 3 21-1/2 - 21 2 1-1/4 112

V/VN 333 43-1/4 14-5/8 31-1/2 2-7/8 3-1/8 22-1/2 18-1/5 22 2-1/2 1-1/2 166

V/VN 385 43-1/4 14-1/2 31-1/2 2-7/8 3-1/2 27-1/2 18-1/5 27 2-1/2 1-1/2 168

V/VN 500 43-1/4 19 31-1/2 2-7/8 3-1/2 27-1/2 18-1/5 27 2-1/2 1-1/2 360

V/VN 610 51-1/2 19-1/8 31-3/8 - 3-3/4 30-1/2 31-3/8 30 2-1/2 1-1/2 450

V 952 53-3/4 21-1/8 30 - 3-1/2 31 30 30 3 3 487

PT/PTN 279 34-3/4 22-5/8 25-1/4 16-3/4 16-3/4 - - 21 2 1-1/4 122

PT/PTN 333 43-1/4 23-7/8 30 15-3/4 14-3/8 - - 22 2-1/2 1-1/2 176

PT/PTN 385 43-1/4 25-3/4 30 15-3/4 14-3/8 - - 27 2-1/2 1-1/2 184

PT/PTN 500 43-1/4 29 30 20-1/4 14-3/8 - - 27 2-1/2 1-1/2 376

PT/PTN 610 51-1/2 29-5/8 30 20-3/8 21 - - 30 2-1/2 1-1/2 472

PT 952 53-3/4 26-3/8 30 23-1/8 26-7/8 - - 30 3 3 487

➀All dimensions in inches.

➁Dimensions shown are for Standard and Low Outlet Temperature Models.

➂See Table 13.2 for optional air outlet accessory dimensions.

Table 13.2 - Vertical Air Outlet Accessories Dimensions ➀

Model Cone-Jet Truncone Louvers

Number L T M X P Z

V 42, V 59 6-1/2 18-7/8 12 22 6-1/2 16-7/8

V 78, V 95 6-1/2 18-7/8 12 22 6-1/2 16-7/8

V 139, V 212 7-1/2 24-3/4 13 27 7-1/2 19-3/4

V 247, V 279 8 26-7/8 16 34 8 22-3/4

V 333 8-1/2 28 16 34 8-1/2 22-3/4

V 385, V 500 10 22-3/4 21 41 10 27-3/4

V 610 10-1/2 36-3/4 21 41 10-1/2 30-3/4

V 952 - - - - 19-1/2 32

➀ All dimensions in inches.

1-550.29

13

MOTOR DATA / SERVICE

Table 14.1 - Motor Amp Draw Data ➀ ➁

Amp Draw by Motor Type, Voltage and Power Code

Totally Enclosed

115/60/1 208/60/1 230/60/1 208/60/3 230/460/3 575/60/3 115/60/1 230/460/60/3

Model Number Motor HP ➂ 01 N/A 02 04 05 10 06 09

HSB/HC 18 1/60 0.8 ➃ 0.44 ➃ ➃ ➃ 4.3 -

HSB/HC 24, 33 1/25 1.6 ➃ 1.0 ➃ ➃ ➃ 4.3 -

HSB/HC 47, 63 1/12 3.0 ➃ 1.0 ➃ 1.4/0.7 ➄ ➃ 4.3 -

HSB/HC 86, 108 1/8 2.3 ➃ 1.0 ➃ 1.4/0.7 ➄ ➃ 4.3 -

HSB/HC 121 1/5 2.8 ➃ 1.5 1.9 ➄ 2.1/1.05 ➄ ➃ 4.0 1.4/0.7

HSB/HC 165, 193 1/3 5.4 ➃ 2.5 1.9 ➄ 2.1/1.05 ➄ ➃ 6.5 1.4/0.7

HSB/HC 258-340 1/2 6.7 ➃ 3.5 2.6 ➄ 3.0/1.5 ➄ ➃ 9.0 2.0/1.0

V/VN 42, 59 1/30 2.1 ➃ 0.6 1.9 ➄ 2.1/1.05 ➄ ➃ 4.0 -

V/VN 78, 95 1/15 2.5 ➃ 1.3 1.9 ➄ 2.1/1.05 ➄ ➃ 4.0 -

V/VN 139 1/5 2.8 ➃ 1.5 1.9 ➄ 2.1/1.05 ➄ ➃ 4.0 1.4/0.7

V/VN 161-212 1/3 5.4 ➃ 2.5 1.9 ➄ 2.1/1.05 ➄ ➃ 6.5 1.4/0.7

V/VN 247 1/2 6.7 ➃ 3.5 2.6 ➄ 3.0/1.5 ➄ ➃ 9.0 2.0/1.0

V/VN, PT/PTN 279 1/2 6.7 ➃ 3.5 2.6 ➄ 3.0/1.5 ➄ ➃ 9.0 2.0/1.0

V/VN, PT/PTN 333 3/4 8.8 ➃ 4.4 3.7 ➄ 3.4/1.7 ➄ ➃ - -

V/VN, PT/PTN 385 1 - - - 4.2 4.0/2.0 1.5 - 3.5/1.75

V/VN, PT/PTN 500, 610 1-1/2 - - - 7.4 6.6/3.3 2.0 - 5.8/2.9

V, PT 952 2 - - - 7.4 6.8/3.4 - - 6.2/3.1

➀ Ratings shown are for Standard and Low Outlet Temperature Models.

➁ All motors include thermal overload protection except for units with power code 04, 05, or 10.

➂ All HSB/HC units, V/VN 42 thru V/VN, PT/PTN 333 motor HP listed for power code 01. V/VN, PT/PTN 333 thru V/VN, PT/PTN 610 motor HP listed for power code 04

and V/PT 952 motor HP listed for power code 05.

➃ For supply voltages of 208V/60Hz/1ph and all non-explosion proof 3 phase voltages of 208, 230, 460 and 575, Model Numbers indicated with Note ➃, require that a

115V/60Hz/1 phase power code 01 unit heater be used with a shipped loose accessory transformer. See literature #1-556 for Transformer Sizes. See Note ➄.

➄ Model numbers indicated with Note ➄, can be ordered with a power code (208V/3ph=04, 230/460V/3ph=05) that provides a motor matched to the supply voltage with

amp draw as shown. Alternately, a 115V/60Hz/1 phase power code 01 unit heater could be used with a shipped loose accessory transformer. See literature #1-556 for

Transformer Sizes.

Explosion Proof

SERVICE

wARNINg

When servicing or repairing this equipment, use only

factory-approved service replacement parts. A complete

replacement parts list may be obtained by contacting Modine

Manufacturing Company. Refer to the rating plate on the unit

for complete unit substitution of parts or controls not approved

by the factory will be at the owner’s risk.

CAuTION

1. Service or repair of this equipment must be performed by a

qualified service agency.

2. Do not reuse any electrical component which has been wet.

Replace component.

IMPORTANT

To check most of the Possible Remedies in the troubleshooting

guide listed in Table 15.1, refer to the applicable sections of

the manual.

Heating equipment should be serviced before each heating

season to assure proper operations. The following items may be

required more frequently based on the environment in which the

unit is installed and frequency of equipment operation.

All installation and service of these units must be

performed by a qualified installation and service agency.

Before any service, BE SURE TO TURN OFF THE STEAM

OR WATER SUPPLY AT THE MANUAL SHUT-OFF VALVES

AND TURN OFF ALL ELECTRIC POWER TO THE HEATER.

14

1-550.29

Motors

1. Remove grease and dirt on motor during each inspection or

lubrication. Open frame motors should be blown clean every

heating season, or whenever coils are cleaned, whichever is

sooner.

2. Lubricate motor according to manufacturer’s instructions

located on the motor. When no motor oiling instructions are

on the motor, oil the motor every two thousand hours of

operation with SAE20 motor oil for units in normal

applications. Adjust oiling according to usage and atmosphere.

3. Some motors do not have oil fittings. These motors are

lubricated for long life and do not require further lubrication.

4. A change in line voltage higher or lower than motor nameplate

rating may cause overheating and serious motor damage.

Check plant voltage conditions. A separate manual starter

with thermal overload protection device is recommended for

those units that do not have motors with built-in overload

protection.

Coils

1. Clean coil at least once a year; more often under unfavorable

conditions. Unless coil is kept reasonably free of dirt, lint and

grease, its original heating capacity will be reduced —

possibly to a serious degree, and motor damage may result.

Two commonly used cleaning methods are:

• Loosen dirt by brushing fins on side where air enters coil

and then turn on fan to blow dirt from unit.

• Use high pressure air hose to loosen dirt by blowing from

side where air leaves coil (side adjacent to louvers on blowthrough units; side adjacent to fan on draw-through units).

SERVICE / TROUBLESHOOTING

2. For thorough cleaning of coil, remove motor and fan and

spray a mild alkaline cleaning solution over the coil. After a

few minutes, follow by a hot water rinse. (A steam gun can be

used for spraying cleaning solution and hot water.)

3. Coils subjected to corrosive fumes should be checked and

cleaned frequently.

4. Provide controlled water treatment — don’t use excess of

boiler compounds. Contact your boiler compound supplier for

proper usage or the services of a water treatment laboratory.

5. Periodic internal flushing of the coils is recommended in

areas where water supply is suspected of causing scale. Use

an alkaline-chelant solution and introduce it at the main pump

of the hydronic system. Flush thoroughly.

WARNING: USING INORGANIC OR MINERAL ACIDS SUCH

AS MURIATIC (HYDROCHLORIC) ACID, EVEN THOUGH

INHIBITED, MAY LEAD TO SEVERE DAMAGE, INCLUDING

CORROSION AND LEAKAGE.

6. De-aerate boiler feed-water (particularly if large amount of

new water is used).

7. Ensure rapid continuous and adequate condensate drainage

by properly sized and installed traps and piping. Check traps

for sticking. Clean strainers ahead of traps. (When traps

don’t work, condensate accumulates in unit heater coil; water

hammer results.)

8. Adequately vent each unit.

9. Use low pressure steam when possible.

Casings

1. Periodic cleaning of casings is recommended to remove

dirt, grease and corrosive substances that may injure finish.

Rusted or corroded spots should be cleaned and repainted.

2. Tighten fan guard and motor bracket. Check fan for proper

clearance, free rotation and firm connection to shaft.

When servicing is complete, tag unit to indicate date of

inspection, lubrication and cleaning.

Replacement Parts

When requesting parts please contact your local representative.

Please have full model and serial number available. See

Figure 15.1.

Figure 15.1 - Model Identification Plate

Table 15.1 - Troubleshooting

Fails to Maintain Temperature

1. Undersized unit heater, boiler, pump or piping.

2. Unit heater operating at low speed when sized for high speed.

3. Unit heater mounted too high — heated air not delivered to floor.

4. Thermostat — improper location or setting, or not functioning.

5. Dirty or clogged coil.

Unit Blows Cold Air

1. Manual shut-off valve closed.

2. Insufficient steam pressure of lack of hot water.

3. Aquastat not functioning.

4. Improper venting.

5. Steam trap not functioning.

6. Drip leg too short (steam system).

7. Return line plugged (steam system).

8. Pump undersized or not operating (hot water system).

Does Not Operate When Heat Needed

1. Defective motor or electrical connections.

2. Thermostat, aquastat or pressure limit control not functioning.

Fails to Deliver Heat to Floor

1. Units mounted too high.

2. Operating on low speed.

3. Final air temperature too high.

4. Louvers not adjusted properly.

5. Wrong type of diffuser (on verticals).

6. Undersized unit heater (insufficient air delivery).

7. Wrong type of unit (may require vertical delivery).

8. Cross ventilation or drafts.

9. Obstructions to air flow.

Noisy Unit

1. Loose bolts or screws.

2. Fan blade bent, out of balance.

3. Dirt accumulation on fan blades.

4. Fan hub or blade rivets loose.

5. Motor shaft bearing worn.

6. Motor mounting bent, fan not positioned properly in venturi.

7. Conduit too rigid, transmits vibration noise.

8. BX cable touching unit heater, chatters as casing vibrates.

Employees Complain of Hot Blast

1. Air stream aimed directly at employees.

2. Louvers not adjusted properly.

3. Wrong type of diffuser (on verticals).

4. Excessive final air temperature.

Unit Operates Too Long

1. Thermostat installed on cold wall or other improper location.

2. Aquastat or pressure limit control not functioning properly.

3. Unit is undersized.

Frequent Motor Failure

1. Voltage fluctuations too high or too low.

2. Excessive or insufficient lubrication.

3. Wiring to motor undersized.

4. Improper electrical connections.

5. Motor operating in too high air temperature.

6. Restricted air flow due to clogged coil or closed louvers.

7. Fan out of balance.

8. Unbalanced voltage on 3φ power.

Coil Failure/Unit Leaks

1. Severe internal corrosion from feedwater.

2. Type of boiler treatment.

3. Entrained air causing water hammer.

4. Continuous operation above 150 PSI (375°F)(steam systems).

5. Loose connection.

1-550.29

15

COMMERCIAL WARRANTY

Seller warrants its products to be free from defects in material and

workmanship, EXCLUSIVE, HOWEVER, of failures attributable to the use

of materials substituted under emergency conditions for materials normally

employed. This warranty covers replacement of any parts furnished from the

factory of Seller, but does not cover labor of any kind and materials not

furnished by Seller, or any charges for any such labor or materials, whether

such labor, materials or charges thereon are due to replacement of parts,

adjustments, repairs, or any other work done. This warranty does not apply to

any equipment which shall have been repaired or altered outside the factory of

Seller in any way so as, in the judgment of Seller, to affect its stability, nor

which has been subjected to misuse, negligence, or operating conditions in

excess of those for which such equipment was designed. This warranty does

not cover the effects of physical or chemical properties of water or steam or

other liquids or gases used in the equipment.

BUYER AGREES THAT SELLER’S WARRANTY OF ITS PRODUCTS TO BE

FREE FROM DEFECT IN MATERIAL AND WORKMANSHIP, AS LIMITED

HEREIN, SHALL BE IN LIEU OF AND EXCLUSIVE OF ALL OTHER

WARRANTIES, EITHER EXPRESS OR IMPLIED, WHETHER ARISING

FROM LAW, COURSE OF DEALING, USAGE OF TRADE, OR OTHERWISE,

THERE ARE NO OTHER WARRANTIES, INCLUDING WARRANTY OF

MERCHANTABILITY OR FITNESS FOR PURPOSE, WHICH EXTEND

BEYOND THE PRODUCT DESCRIPTION CONFIRMED BY BUYER AND

SELLER AS OF THE DATE OF FINAL AGREEMENT.

This warranty is void if the input to the product exceeds the rated input as

indicated on the product serial plate by more than 5% on gas-fired and oil-fired

units, or if the product in the judgment of SELLER has been installed in a

corrosive atmosphere, or subjected to corrosive fluids or gases, been subjected

to misuse, negligence, accident, excessive thermal shock, excessive humidity,

physical damage, impact, abrasion, unauthorized alterations, or operation

contrary to SELLER’S printed instructions, or if the serial number has been

altered, defaced or removed.

BUYER AGREES THAT IN NO EVENT WILL SELLER BE LIABLE FOR

COSTS OF PROCESSING, LOST PROFITS, INJURY TO GOODWILL, OR

ANY OTHER CONSEQUENTIAL OR INCIDENTAL DAMAGES OF ANY KIND

RESULTING FROM THE ORDER OR USE OF ITS PRODUCT, WHETHER

ARISING FROM BREACH OF WARRANTY, NONCONFORMITY TO

ORDERED SPECIFICATIONS, DELAY IN DELIVERY, OR ANY LOSS

SUSTAINED BY THE BUYER.

BUYER’S REMEDY FOR BREACH OF WARRANTY, EXCLUSIVE OF ALL

OTHER REMEDIES PROVIDED BY LAW, IS LIMITED TO REPAIR OR

REPLACEMENT AT THE FACTORY OF SELLER, ANY COMPONENT WHICH

SHALL, WITHIN THE APPLICABLE WARRANTY PERIOD DEFINED HEREIN

AND UPON PRIOR WRITTEN APPROVAL, BE RETURNED TO SELLER

WITH TRANSPORTATION CHARGES PREPAID AND WHICH THE

EXAMINATION OF SELLER SHALL DISCLOSE TO HAVE BEEN DEFECTIVE;

EXCEPT THAT WHEN THE PRODUCT IS TO BE USED BY BUYER AS A

COMPONENT PART OF EQUIPMENT MANUFACTURED BY BUYER,

BUYER’S REMEDY FOR BREACH, AS LIMITED HEREIN, SHALL BE

LIMITED TO ONE YEAR FROM DATE OF SHIPMENT FROM SELLER. FOR

GAS-FIRED PRODUCTS INSTALLED IN HIGH HUMIDITY APPLICATIONS

AND UTILIZING STAINLESS STEEL HEAT EXCHANGERS, BUYER’S

REMEDY FOR BREACH, AS LIMITED HEREIN, SHALL BE LIMITED TO

TEN YEARS FROM DATE OF SHIPMENT FROM SELLER.

These warranties are issued only to the original owner-user and cannot be

transferred or assigned. No provision is made in these warranties for any

labor allowance or field labor participation. Seller will not honor any expenses

incurred in its behalf with regard to repairs to any of Seller’s products. No

credit shall be issued for any defective part returned without proper written

authorization (including, but not limited to, model number, serial number,

date of failure, etc.) and freight prepaid.

OPTIONAL SUPPLEMENTAL WARRANTY

Provided a supplemental warranty has been purchased, Seller extends the

warranty herein for an additional four (4) years on certain compressors.

Provided a supplemental warranty has been purchased, Seller extends the

warranty herein for an additional four (4) years or nine (9) years on certain

heat exchangers.

EXCLUSION OF CONSUMABLES & CONDITIONS BEYOND SELLER’S

CONTROL

This warranty shall not be applicable to any of the following items: refrigerant

gas, belts, filters, fuses and other items consumed or worn out by normal wear

and tear or conditions beyond Seller’s control, including (without limitation as

to generality) polluted or contaminated or foreign matter contained in the air or

water utilized for heat exchanger (condenser) cooling or if the failure of the part

is caused by improper air or water supply, or improper or incorrect sizing of

power supply.

Component

Applicable Models

Heat Exchangers

Gas-Fired Units

Heat Exchangers

Low Intensity Infrared Units

Compressors

Condensing Units for Cassettes

Burners

Low Intensity Infrared Units

Other

Components excluding Heat Exchangers,

Coils, Condensers, Burners, Sheet Metal

Heat Exchangers/Coils

Indoor and Outdoor Duct Furnaces and

System Units, Steam/Hot Water Units,

Oil-Fired Units, Electric Units, Cassettes,

Vertical Unit Ventilators, Geothermal Units

Compressors

Vertical Unit Ventilators, Geothermal Units

Burners

High Intensity Infrared Units

Sheet Metal Parts

All Products

TEN YEARS FROM DATE OF FIRST BENEFICIAL USE BY BUYER OR ANY OTHER USER, WITHIN

TEN YEARS FROM DATE OF RESALE BY BUYER OR ANY OTHER USER, WITHIN TEN YEARS

FROM DATE OF RESALE BY BUYER IN ANY UNCHANGED CONDITION, OR WITHIN ONE

HUNDRED TWENTY-SIX MONTHS FROM DATE OF SHIPMENT FROM SELLER, WHICHEVER

OCCURS FIRST

FIVE YEARS FROM DATE OF FIRST BENEFICIAL USE BY BUYER OR ANY OTHER USER, WITHIN

FIVE YEARS FROM DATE OF RESALE BY BUYER OR ANY OTHER USER, WITHIN FIVE YEARS

FROM DATE OF RESALE BY BUYER IN ANY UNCHANGED CONDITION, OR WITHIN SIXTY-SIX

MONTHS FROM DATE OF SHIPMENT FROM SELLER, WHICHEVER OCCURS FIRST

TWO YEARS FROM DATE OF FIRST BENEFICIAL USE BY BUYER OR ANY OTHER USER, WITHIN

TWO YEARS FROM DATE OF RESALE BY BUYER IN ANY UNCHANGED CONDITION, OR WITHIN

THIRTY MONTHS FROM DATE OF SHIPMENT FROM SELLER, WHICHEVER OCCURS FIRST

ONE YEAR FROM DATE OF FIRST BENEFICIAL USE BY BUYER OR ANY OTHER USER, WITHIN

ONE YEAR FROM DATE OF RESALE BY BUYER IN ANY UNCHANGED CONDITION, OR WITHIN

EIGHTEEN MONTHS FROM DATE OF SHIPMENT FROM SELLER, WHICHEVER OCCURS FIRST

“APPLICABLE WARRANTY PERIOD”

As Modine Manufacturing Company has a continuous product improvement program, it reserves the right to change design and specifications without notice.

© Modine Manufacturing Company 2015

Modine Manufacturing Company

1500 DeKoven Avenue

Racine, WI 53403

Phone: 1.800.828.4328 (HEAT)

www.modinehvac.com

Loading...

Loading...