查询TSX07301022供应商

Modicon TSX Nano PLCs

Characteristics :

pages 40050/9 to 40050/11

References :

pages 40050/12 to 40050/14

Dimensions :

page 40050/15

Connections :

pages 40050/16 to 40050/19

Nano PLCs

Presentation

New features on Nano PLCs

The range of Nano PLCs includes new functions with :

i Non-extendable Nano PLC bases for small configurations.

i Nano PLC extensions which can be used to augment extendable Nano PLC bases at minimum cost.

i Analogue I/O extension modules (with c 100…240 V or a 24 V power supply) incorporating 3 inputs and 1 output.

Presentation

Nano PLCs are very compact and offer a cost-effective replacement for traditional solutions while increasing application

flexibility and ease of wiring.

Nano PLCs are available in 3 formats :

i Nano PLC bases with 10, 14, 16, 20 or 24 non-extendable I/O.

i Nano PLC bases with 10, 16 or 24 extendable I/O, which can be augmented with an I/O extension and up to 3 PLC

extensions.

i Nano PLC extensions with 16 or 24 I/O which can be used to augment extendable Nano PLC bases (1 extension per

base).

Non-extendable Nano PLC bases

Non-extendable Nano PLC bases will not accept any

extension. They all have a c 100…240 V power supply,

depending on the model :

i 10 I/O : 6 inputs + 4 outputs and 1 analogue input.

i 14 I/O : 8 inputs + 6 outputs.

i 16 I/O : 9 inputs + 7 outputs and 1 analogue input.

i 20 I/O : 12 inputs + 8 outputs.

Nano PLCs with 10 I/O

Nano PLCs with 14/16 I/O

i 24 I/O : 14 inputs + 10 outputs and 1 analogue input.

The following types of inputs and outputs are used :

i Inputs : a 24 V (sensor supply is not protected).

i Outputs : relay.

These PLCs incorporate extended communication : UniTelway master/slave link or ASCII link for transmission/

reception.

Models with 10, 14 and 20 I/O do not have a real-time clock.

40050/2

Nano PLCs with 20/24 I/O

Modicon TSX Nano PLCs

Characteristics :

pages 40050/9 to 40050/11

References :

pages 40050/12 to 40050/14

Dimensions :

page 40050/15

Connections :

pages 40050/16 to 40050/19

Nano PLCs

Description

Description

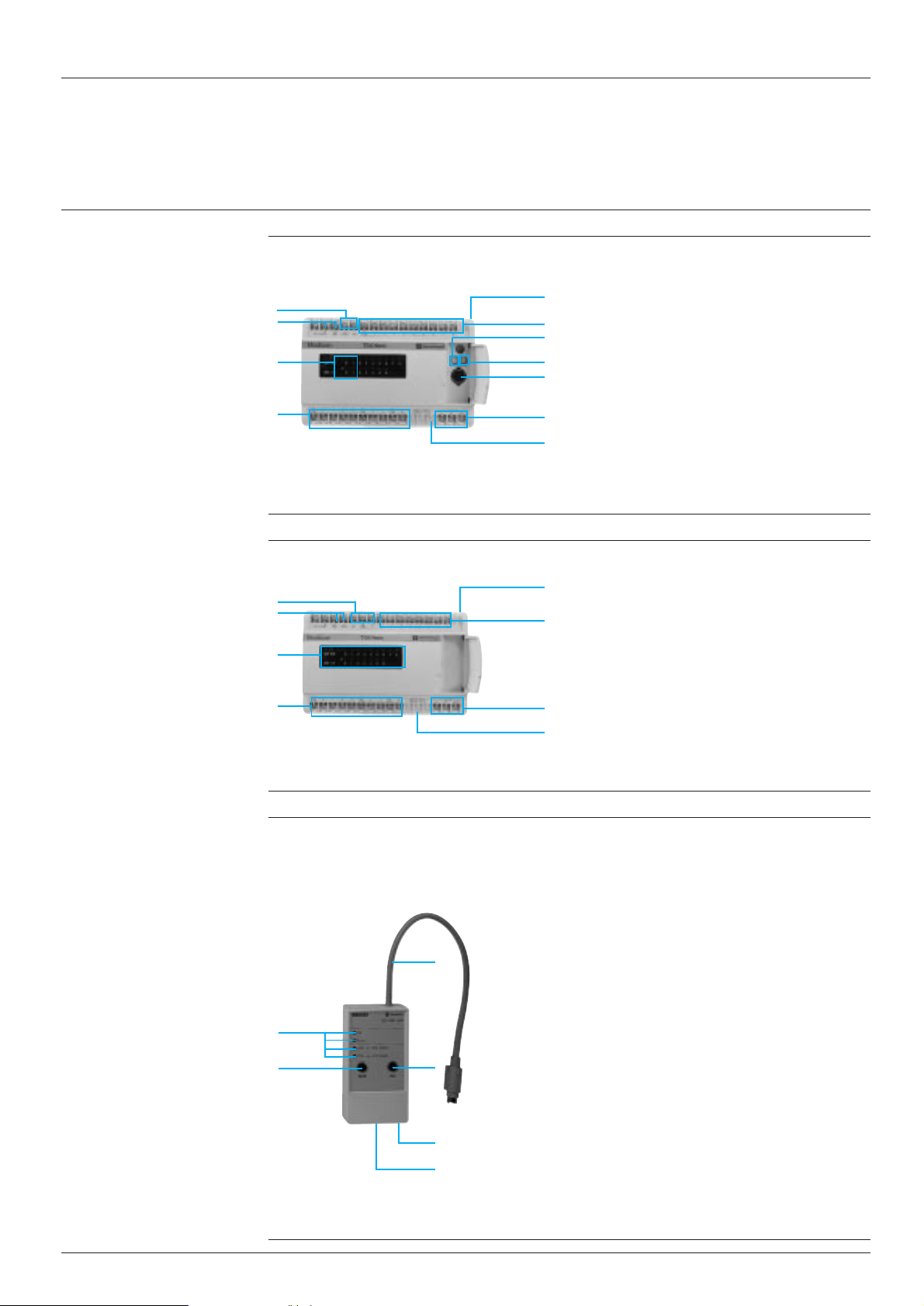

Non-extendable Nano PLCs

The front panels of TSX 07 3L ii28 non-extendable Nano PLCs comprise :

7

4

3

2

6

1 A port (1) for connecting a programming terminal (or

Uni-Telway bus or serial link)

2 A display of :

5

- inputs 0 to 7 or 0 to 11

- outputs 0 to 5 or 0 to 7

8

- PLC status (RUN, ERR, COM, I/O)

1

3 A mains power supply connection

4 A sensor power supply (a 24 V/150 mA)

5 An input sensor connection

6 An output preactuator connection

7 A removable cover for protecting the screw terminal

7

blocks

8 A potentiometer

Extendable Nano PLCs

The front panels of TSX 07 30 10ii extendable Nano PLCs with 10 I/O comprise :

1 A port (1) for connecting a programming terminal (or

6

5

4

8

The front panels of TSX 07 31 16/24ii extendable Nano PLCs with 16/24 I/O comprise :

6

5

4

8

10

7

2

3

1

9

10

Uni-Telway bus or serial link)

2 A selector switch for coding the base/extension function

3 A potentiometer

4 A display of :

- inputs 0 to 5 and outputs 0 to 3

- PLC status (RUN, ERR, COM, I/O)

5 A mains power supply connection

6 A sensor power supply (a 24 V/150 mA) on models

with a c 100…240 V supply

7 An input sensor connection

8 An output preactuator connection

9 An extension connection (I/O extension and/or PLC

extension) or Modbus slave connection

10 A removable cover for protecting the screw terminal

blocks

10

1 A port (1) for connecting a programming terminal (or

Uni-Telway bus or serial link)

7

2 A selector switch for coding the base/extension function

3 Two potentiometers

4 A display of :

2

3

- inputs 0 to 8 or 0 to 13 and outputs 0 to 6 or 0 to 9

1

- PLC status (RUN, ERR, COM, I/O)

5 A mains power supply connection

6 A sensor power supply (a 24 V/150 mA) on models

9

with a c 100...240 V supply

7 An input sensor connection

10

8 An output preactuator connection

9 An extension connection (I/O extension and/or PLC

extension) or Modbus slave connection

10 A removable cover for protecting the screw terminal

blocks

40050/4

(1) Female 8-way mini-DIN type connector.

Modicon TSX Nano PLCs

Characteristics :

pages 40050/9 to 40050/11

References :

pages 40050/12 to 40050/14

Dimensions :

page 40050/15

Connections :

pages 40050/16 to 40050/19

Nano PLCs

Presentation

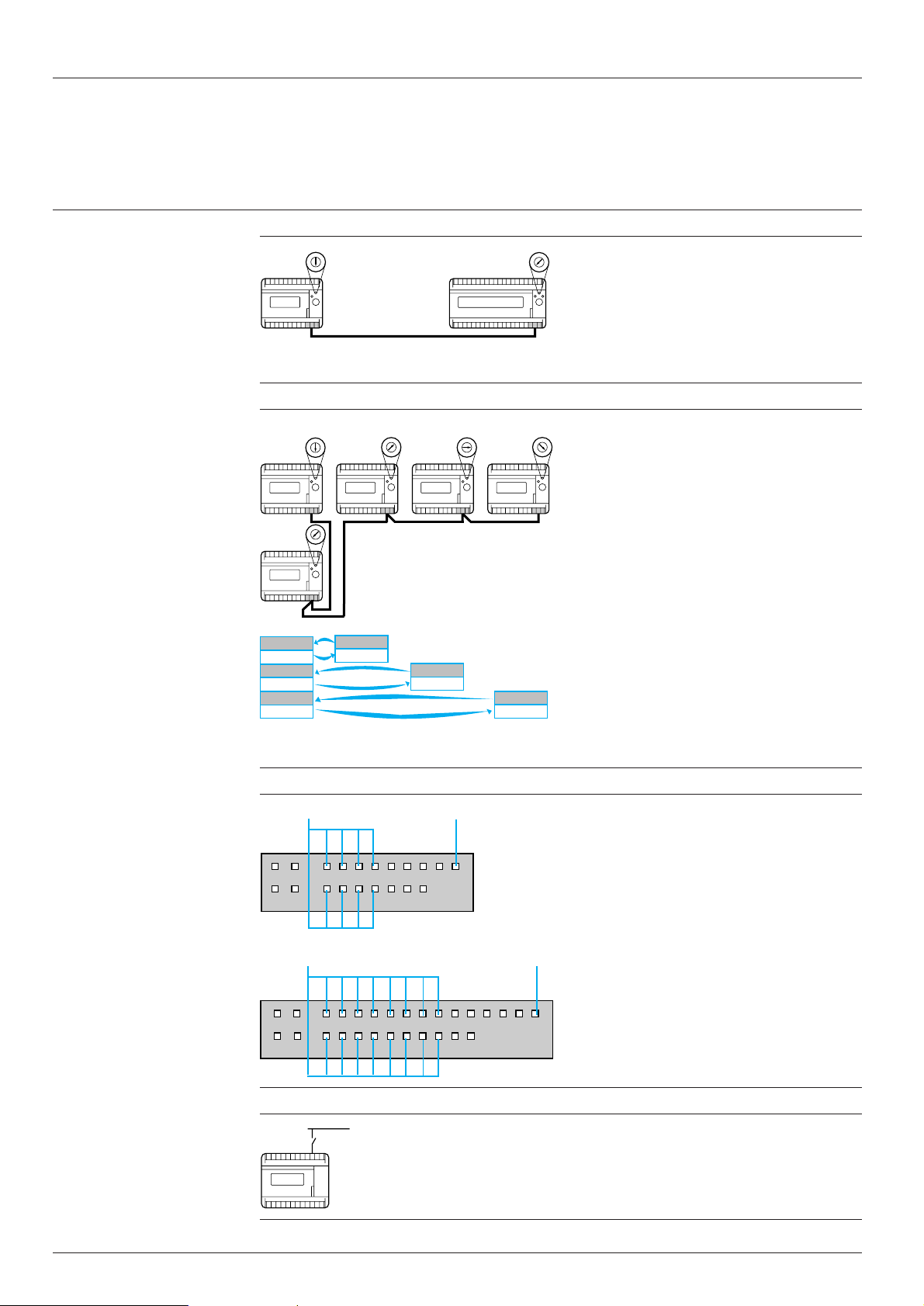

Extendable Nano PLC bases

Nano PLCs with 10 I/O

Nano PLCs with 16 I/O

(continued)

Nano PLCs, with a 24 V or c 100...240 V power supply,

are available with three different I/O combinations :

i 10 I/O : 6 inputs + 4 outputs.

i 16 I/O : 9 inputs + 7 outputs.

i 24 I/O : 14 inputs + 10 outputs.

There are many types of I/O :

i Inputs : a 24 V, c 115 V, analogue 0/10 V.

i Outputs : relay outputs, transistor outputs a 24 V/0.5 A

(positive logic : load common at “-”), transistor outputs

a 24 V/0.5 A (negative logic : load common at “+”).

Nano PLCs are programmed in lists of instructions using

the FTX 117 programming terminal, in Ladder or Instruction list language using software on an FT 2000, FTX 517

terminal or PC compatible. Instruction list and Ladder

programs are reversible on FTX terminals or PC compatibles.

Nano PLCs are easy to set up and have numerous built-in

functions (EEPROM memory for storing programs, batterybacked RAM, real-time clocks for models with 16 and 24

I/O). They can be installed easily on a mounting rail or base

plate, in a vertical or horizontal position.

Nano PLCs with 24 I/O

Nano PLCs with 16 I/O (c inputs)

Nano PLC extensions

Nano PLC extensions can be used to augment extendable

Nano PLCs using a single extension per base.

They all have a c 100…240 V or a 24 V power supply

and, depending on the model :

i 16 I/O : 9 inputs + 7 outputs.

i 24 I/O : 14 inputs + 10 outputs.

Nano PLC extensions with 16 I/O

The following types of inputs and outputs are used :

i Inputs : a 24 V.

i Outputs : relay outputs for models with c 100…240 V

power supply, transistor outputs with positive logic for

models with a 24 V power supply.

Nano PLC extensions with 24 I/O

Each extendable Nano base PLC 1 can be augmented using an I/O extension 2, made up of one of the extendable Nano

PLCs or a Nano extension.

In addition, up to three PLC extensions 3, 4 and 5 communicating via exchange words can be connected to the base PLC.

Only the base PLC can receive an I/O extension.

I/O extensionBase PLC PLC extension PLC extension PLC extension

123 45

200 m maximum

This extension link can be used exclusively as a Modbus slave link.

40050/3

Modicon TSX Nano PLCs

Characteristics :

pages 40050/9 to 40050/11

References :

pages 40050/12 to 40050/14

Dimensions :

page 40050/15

Connections :

pages 40050/16 to 40050/19

Nano PLCs

Description

Nano PLCs (with integrated analogue input)

The front panels of TSX 07 32/33 ii28 Nano PLCs with 10/16/24 I/O and 1 integrated analogue input comprise :

6

5

4

8

Nano PLC extensions

(continued)

1 A port (1) for connecting a programming terminal (or

10

7

2

3

1

9

10

Uni-Telway bus or ASCII link)

2 A point for adjusting the analogue input error

3 A potentiometer (for TSX Nano with 16/24 I/O)

4 A display of :

- discrete relay outputs and inputs

- PLC status (RUN, ERR, COM, I/O)

5 A mains power supply connection c 100…240 V

6 A sensor power supply a 24 V/150 mA

7 An input sensor connection

8 An output preactuator connection

9 An analogue input connection 0-10 V

10 A removable cover for protecting the screw terminal

blocks

The front panels of TSX 07 EX iiii Nano PLC extensions comprise :

1 A display of :

3

2

1

5

Program loader

The TSX PGR LDR module is designed to simplify duplicating or updating applications on Nano and Micro PLCs without

the need for a programming terminal. An application (in internal RAM) can be transferred from a PLC to the TSX PGR LDR

module (and saved within it), then transferred from the TSX PGR LDR module to a PLC.

1

2

7

4

6

7

- inputs 0 to 8 or 0 to 13

- outputs 0 to 6 or 0 to 9

- PLC status (RUN, ERR, COM, I/O)

2 A mains power supply connection

3 A sensor power supply (a 24 V/150 mA) on models

with a c 100...240 V supply

4 An input sensor connection

5 An output preactuator connection

6 A connection to the Nano base PLC

7 A removable cover for protecting the screw terminal

blocks

The front panel of the TSX PGR LDR module comprises :

1 A cord for connecting to the PLC programming port

2 Four operation indicator lights

3 A W/R button which selects the program transfer direction

(PLC v module or module v PLC).

4 A GO button to start the transfer

5 A Write Only switch which prevents PLC v module

transfer

6 A Program Protect switch which protects the PLC appli-

cation as read-only after the transfer

3

(1) Female 8-way mini-DIN type connector.

4

5

6

40050/5

Modicon TSX Nano PLCs

Characteristics :

pages 40050/9 to 40050/11

References :

pages 40050/12 to 40050/14

Dimensions :

page 40050/15

Connections :

pages 40050/16 to 40050/19

Nano PLCs

Functions

I/O extension (1)

Base

PLC

Peer PLCs (1)

Base

PLC

I/O

extension

345

6

2

1

7

0

PLC 2

345

6

2

1

7

0

345

6

2

1

7

0

Extension link

345

6

2

1

7

0

Peer PLC & extension link

PLC 3

I/O

extension

345

6

2

1

7

0

PLC 4

345

Each Nano base PLC can be extended using an I/O

6

2

1

7

0

extension. This extension is created by one of the PLCs

with 10, 16 or 24 I/O. The function of each PLC is defined

by the position of the coding selector switch :

i Position 0 : base PLC

i Position 1 : I/O extension

The extension link cable between the base PLC and the

I/O extension is a shielded, twisted pair and is no more than

200 metres long.

Up to 3 peer PLCs, communicating via common words, can

345

be connected to the base PLC. In this case, only the base

6

2

1

7

0

PLC can receive an I/O extension. The function of each

PLC is defined by the position of the coding selector switch.

I/O addressing of peer PLCs is identical to that of the base

PLC.

The extension link cable between the base PLC and PLC

extensions is a shielded, twisted pair and is no more than

200 metres long.

Base

PLC

IW

QW

IW

QW

IW

QW

PLC 2

QW

IW

PLC 3

QW

IW

QW

IW

PLC 4

Displaying the I/O, internal bits and PLC status

State of 8 internal bits if %S69 = 1

RUN

COM

State of 16 internal bits if %S69 = 1

RUN

COM

I

ERR

012345678

O

I/O

0123456

Nano PLCs with 10 and 16 I/O

I

ERR

012345678910111213

O

I/O

0123456789

System bit % S69

System bit % S69

Nano PLCs with 24 I/O

Inter-PLC communication

Each PLC has 2 reserved (IW) and 2 reserved (QW) words

for exchanging data between PLCs. These exchange words

are updated automatically. For each PLC, the user program

is only able to :

i Write to the 2 %QW output words

i Read the 2 %IW input words

The results of the self-tests performed continuously by the

base PLC, peer PLCs and I/O extensions are displayed on

the front panel by 4 indicator lamps :

i RUN : PLC status

i ERR : internal fault

i COM : data exchange on the extension link

i I/O : I/O fault

I/O display

The state of each I/O is displayed on the front panel of the

PLC by an indicator lamp : when the lamp is on, the I/O is

active, when the lamp is off, the I/O is inactive.

Internal bits display

When the PLC system bit %S69 is set to 1, the first

indicator lamps show the state of 8 or 16 defined internal

bits (%M120…%M127 or %M112…%M127).

40050/6

Dedicated I/O

Base PLC

RUN/STOP

123450C

The RUN/STOP input will launch or stop program execution

from an external order. After configuration, one of the first

6 inputs (%I0.0 to %I0.5) can be assigned to this function.

One of the first 4 outputs (%Q0.0 to %Q0.3) can be

configured to indicate to the user that the PLC program is

120C

not running (STOP or fault).

(1) TSX 07 30/31 PLCs can no longer receive an I/O extension or peer PLC when the integrated Modbus link is in use.

TSX 07 32/33 ii28 and TSX 07 3L ii28 PLCs cannot take an I/O extension or peer PLC.

Modicon TSX Nano PLCs

Characteristics :

pages 40050/9 to 40050/11

References :

pages 40050/12 to 40050/14

Dimensions :

page 40050/15

Connections :

pages 40050/16 to 40050/19

Nano PLCs

Functions

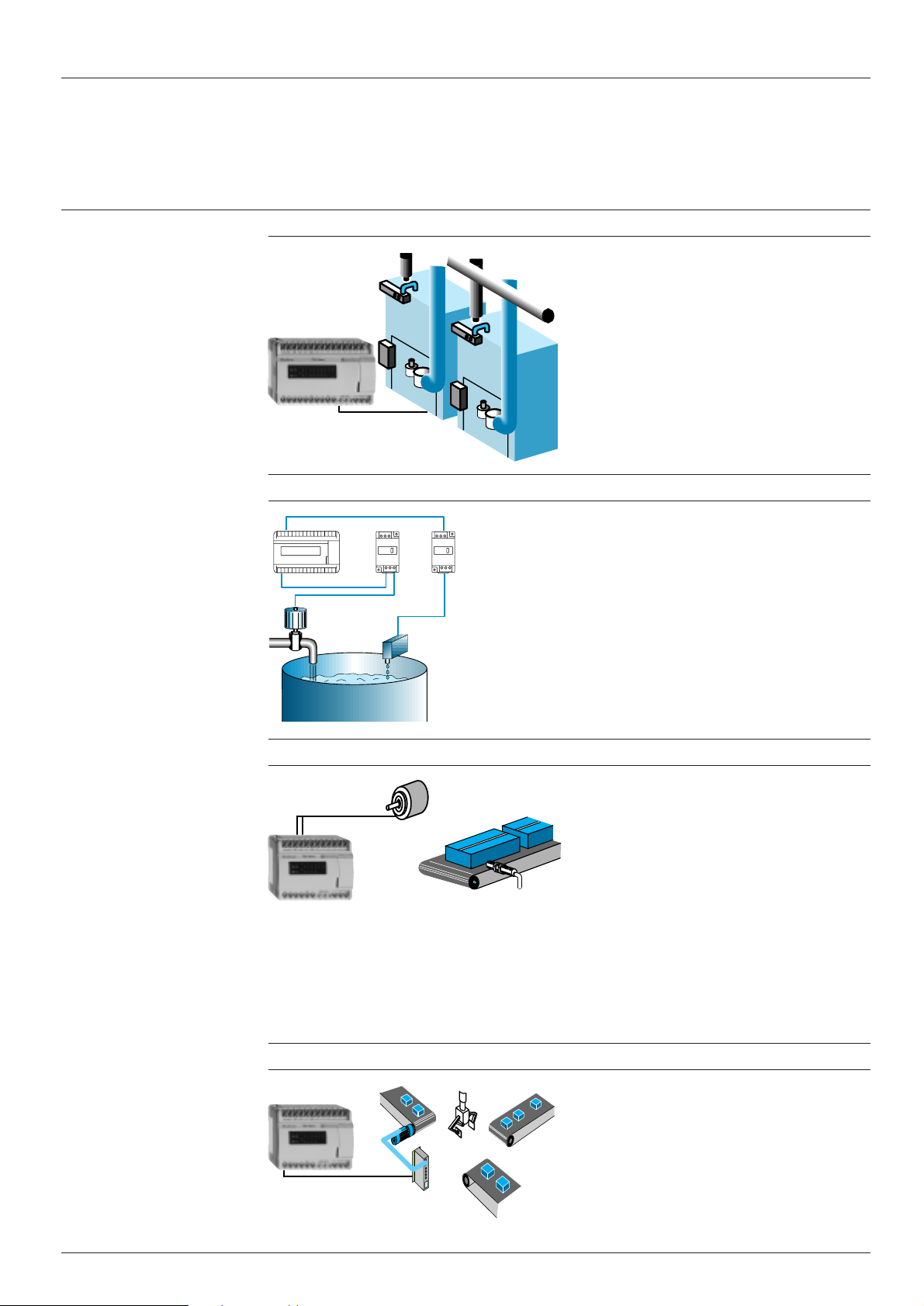

Real-time based programming

Nano PLC

Analogue I/O

TSX 073i ii12

(continued)

ASN

AEN

Nano PLCs with 16 or 24 I/O integrate 16 user-definable

real-time clocks which can be used to :

i Control the outputs directly (opening and closing electrical

circuits) or act on the user program according to the time

(month, day, hour and minute).

i Program time setpoints which can be modified via an

operator panel or calculated by the program.

i Program event time-stamping or perform time

calculations.

The Nano PLC is designed for simple process control

applications (level, temperature, flow rate control, etc) with

speed controller or servo-valve control.

TSX AEN/ASN modules are used with Nano PLCs to

process 1 analogue input and 1 analogue output respectively :

i The input module, 0/10 V - 10/+ 10 V or 4/20 mA is

connected to the a 24 V input %I0.0 of the PLC and is

configured in frequency meter mode.

i The output module, 0/10 V - 10/+ 10 V or 4/20 mA uses

the pulse width modulation transistor output %Q0.0.

Analogue processing is also possible using three

TSX 07 32/33 ii28 bases which consist of 1 analogue

input 0-10 V.

High-speed processing applications

Nano PLC

Pulse outputs

Nano PLC

On a base PLC or peer PLC, each of the first 6 inputs (%I0.0

to %I0.5) can be assigned to the latching function after

configuration. This function is used to take account of input

pulses with short durations, 100 µs minimum.

Nano PLCs include standard functions which are easy to

set up and can be used for adaptation to control systems

requiring counting capacity or short response times :

i Fast counter (maximum frequency 10 kHz)

i Fast up/down counter (maximum frequency 1 kHz)

i Frequency meter (maximum frequency 10 kHz)

Sensors which are used on the up/down counter inputs

(%I0.0 and %I0.3) must have solid state outputs.

2 reflex outputs (%Q0.1 and %Q0.2) are controlled directly

by the fast counter (without waiting for outputs to be

updated at the end of the scan) according to a matrix

predefined during configuration.

After configuration, the first output %Q0.0 (if it is a transistor

output) of the Nano PLC can be used with :

i The PWM software function, as a pulse width modulation

output at a predefined frequency of up to 4.9 kHz

designed for use in applications with light or sound

intensity control (dimmer function).

i The PULSE software function, as a pulse generator

output of up to 4.9 kHz designed for use for controlling

stepper motors.

40050/7

Modicon TSX Nano PLCs

Characteristics :

pages 40050/9 to 40050/11

References :

pages 40050/12 to 40050/14

Dimensions :

page 40050/15

Connections :

pages 40050/16 to 40050/19

Nano PLCs

Functions

Uni-Telway communication

Modbus slave communication

(continued)

Micro

Nano

The Nano PLC can communicate with other Uni-Telway

devices via the terminal port : speed controllers, operator

terminals, compact or modular PLCs.

The ability to send and receive messages means that Nano

PLCs can be integrated in distributed architectures.

In slave mode, for example, the Nano PLC can initiate

communication and send updated variables to the bus

master (local reflex processing).

28 Nano slave PLCs can be connected to the Uni-Telway

bus over a distance of 1 km (isolated for speeds of 1.2 to 9.6

K bits/s).

CCX 17

Nano PLCs have an RS 485 serial link extension port,

supporting the Modbus protocol (depending on the model).

It is used to perform the following requests :

ASCII communication

Bar

code

reader

Modem application (Modbus or Uni-Telway protocol)

Micro

Nano

i Read/write bits and words

i Read PLC status (via Uni-TE request)

i Set to RUN or STOP mode (via Uni-TE request)

i Initialise the PLC (via Uni-TE request)

Up to 28 Nano PLCs can be connected over a distance of

200 m for user-definable speeds of 1.2 to 19.2 K bits/s.

The ability to send and receive characters enables the

Nano PLC to communicate in point-to-point mode with a

large number of ASCII devices, such as PCs (directly or via

modem), printers, bar code readers, etc.

Frame speed and format can be configured. Connection to

the Nano PLC terminal port is via an RS 232/485 converter

cable powered by the PLC.

A PLC fitted with a Modbus or Uni-Telway master module

interrogates Nano PLCs via the switched telephone network.

When connected to a Modem in RS 485 mode, the master

can use the link to generate dialling sequences for remote

sites.

Each Nano PLC responds to requests from the master, but

is also able to trigger a call by activation of a discrete input

on the Modem.

40050/8

Nano

Nano

Target applications (with Modbus or Uni-Telway) :

i System teleprocessing

i Telemonitoring of remote sites

i Water, energy, environment control

The Uni-Telway slave link of Nano PLCs can also be used

for :

i Up/down loading programs

i Programming and remote diagnostics

Modicon TSX Nano PLCs

Nano PLCs

References :

pages 40050/12 to 40050/14

Dimensions :

page 40050/15

Connections :

pages 40050/16 to 40050/19

Environment

Conforming to standards IEC 1131-2, IEC 664, UL 508, UL 746 C, UL 94, CSA 22-2 no. 142, EN 50081/class B

Characteristics

Temperature Operation

Storage

Humidity Without condensation % 5…95

Altitude m 0…2000

Vibration resistance Conforming to IEC 68-2-6 FC tests

Mechanical shock resistance Conforming to IEC 68-2-27 EA tests

°

C 0…+ 60

°

C - 25…+ 70

Power supply characteristics

Type of PLC TSX 07 30/31/32/33 iii8, TSX 07 3L ii28, TSX 07 30/31 iii2, TSX 07 EX ii12

Supply Nominal V c 100…240 a 24

voltage

Limit V 85…264 19.2…30

Frequency Nominal Hz 50/60 –

Limit Hz 47…63 –

Power required ≤ 30 VA ≤ 14 W

Sensor protected power supply V 24/150 mA –

Primary/earth isolation Vrms 2000/50-60 Hz 2000/50-60 Hz

Microbreaks Duration ms ≤ 10 ≤ 1

TSX 07 EX ii28

Discrete input characteristics

Type of input V

Nominal Voltage V a 24 c 110/120

input

values Current mA 710

Sensor supply V a 19.2…30 (including ripple) –

Limit input At state 1 Voltage V ≥ 11 ≥ 79

values

Current mA ≥ 2.5 for 11 V ≥ 4 for 79 V

At state 0 Voltage V ≤ 5 ≤ 20

Current mA ≤ 1.2 ≤ 2

Logic Positive or negative depending on wiring –

Filter time 12 ms, 3 ms or 100 µs (on I0.0 to I0.7)/375 µs 12 ms

Isolation Betw. grps of I/O points Vrms 1500/50-60 Hz 1500/50-60 Hz

Type Optoelectronic module –

aa

a 24 (resistive)

aa

(on I0.8 to I0.13)

cc

c 115 (capacitive)

cc

40050/9

Modicon TSX Nano PLCs

Nano PLCs

References :

pages 40050/12 to 40050/14

Dimensions :

page 40050/15

Connections :

pages 40050/16 to 40050/19

Characteristics

Discrete output characteristics

Type of output Relay Transistor, positive logic Transistor, negative logic

Output description 1 normally open contact Protected Non-protected

Loads Voltage V c 24…220 a 24 a 24

(nominal

values) Nominal current A – 0.5 0.5

Tungsten lamp W – ≤ 10 ≤ 10

aa

a loads Voltage V 24 19.2…30 19.2…30

aa

Current A DC-12 : 1-24 V (0.3 x 10

c c

c loads AC-12 resistive A 1-110/220 V (0.5 x 106 op. cycles) – –

c c

duty 0.5-110/220 V (2 x 106 op. cycles)

DC-13 : 0.4-24 V (1 x 106 op. cycles) common to “-” loads common to “+” loads

1-48 V (0.5 x 106 op. cycles)

2-24 V (0.3 x 106 op. cycles)

1-24 V (0.5 x 106 op. cycles)

(continued)

6

op. cycles) 0.625 (at 30 V) 0.625 (at 30 V)

AC-15 inductive A 0.22-220 V (1 x 106 op. cycles) – –

duty 0.5-24/48/110 V (1 x 106 op. cycles)

Response State 0 to 1 ms ≤ 5 ≤ 1 ≤ 1

time

State 1 to 0 ms ≤ 10 ≤ 1 ≤ 1

Leakage

current At state 0 mA – ≤ 1 ≤ 1

Voltage

drop At state 1 V – ≤ 2 (for I = 0.5 A) ≤ 1.5 (for I = 0.5 A)

Built-in Overloads None (fit one fuse per I/O point or Yes None (fit a fuse on the preactuator

protection and short-circuits group of I/O points) common)

Overvoltages None (fit RC or GMOV peak limiter circ. Yes Yes

Polarity

inversions – Yes Yes

1-24 V (0.2 x 106 op. cycles)

for c and a freewheel diode for a )

Integrated analogue input characteristics

Type of PLC TSX 07 32/33 ii28

Analogue Number of points 1

input

Input range V 0…10

Input impedance k

Max. voltage V ± 16

without destruction

Type of protection Against short-circuits

Ω

16…18

Conversion Method Successive approximations

Isolation Analogue input V None

Wiring Isolated sensor m 30 max.

distance with

shielded cable Non-isolated sensor m 10 max.

40050/10

Resolution 8 bits

Conversion time PLC scan time

Precision at 25 °C % FS ± 0.8

at 60 °C % FS ± 2

Drift 0.34 % per 10 °C

Repeatability V ± 0.8 % of 0 to 60 °C (at full scale)

and processor

Modicon TSX Nano PLCs

Nano PLCs

References :

pages 40050/12 to 40050/14

Dimensions :

page 40050/15

Connections :

pages 40050/16 to 40050/19

Modbus characteristics

Type of PLC TSX 07 30/31 iiii

Characteristics

(continued)

Structure Description Heterogeneous industrial bus

Transmission Mode Asynchronous in base band, RTU/ASCII frame

Configuration Number of devices 28 devices maximum, 98 link addresses maximum

Available Modbus/Jbus slave Code Description Code Description

functions 01 Reading of n consecutive output bits 05 Writing of 1 output bit

Services Sending requests Bits : 120 bits maximum per request

Physical interface RS 485 non-isolated

Method of access Master/slave type

Bit rate 1.2 K bits/s to 19.2 K bits/s

Medium Double shielded twisted pair

Bus length 200 m maximum

Drop cable 15 m maximum

02 Reading of n consecutive input bits 06 Writing of 1 output word

03 Reading of n consecutive output words 15 Writing of n output bits

04 Reading of n consecutive input words 16 Writing of n output words

Words : 120 words maximum per request

Safety One CRC 16 check parameter on each frame

Monitoring Diagnostics counters, event counters

ASCII asynchronous serial link characteristics

Type of PLC TSX 07 30/31/32/33 iiii, TSX 07 3L iiii

Physical layer Terminal port RS 485 non-isolated Half-duplex (10 m max)

Flow rate 1.2 K bits/s to 9.6 K bits/s

Transmission Type Point-to-point, without flux control (Xon-Xoff, RTS/CTS)

Services 120 character messages Transmission/reception

Uni-Telway integrated link characteristics

Type of PLC TSX 07 30/31/32/33 iiii, TSX 07 3L iiii

Structure Physical interface RS 485 terminal port Half-duplex non-isolated

Configuration Number of devices Master : 3 devices maximum (5 link addresses maximum)

Services Uni-TE server Writing or reading Nano master data after a request is sent by a connected

Data 7 or 8 bits

Stop bit 1 or 2 bits

Parity bit Even, odd or no parity

(general characteristics, see page 43594/2)

Bit rate 1.2 to 9.6 K bits/s

Functions Master/slave

Slave : 28 devices maximum

(96 link addresses max.)

Bus length 10 m max, 1000 m when using the TSX P ACC 01 terminal port cable connector

client device

Reception of messages from all

devices on the bus (master or slave)

128 bytes maximum

Uni-TE client Sending requests (128 bytes maximum) to :

(master function) - all slave devices on the bus

Uni-TE client Sending messages to every device on

(slave function) the bus (master or slave), 128 bytes

maximum

40050/11

Characteristics :

pages 40050/9 to 40050/11

Dimensions :

page 40050/15

Connections :

pages 40050/16 to 40050/19

TSX 07 3L 1428

Modicon TSX Nano PLCs

Nano PLCs

References

Non-extendable Nano PLC bases

These bases will not accept any extension. They incorporate extended communication : Uni-Telway master/slave link or

ASCII link for transmission/reception.

a 24 V/150 mA sensor power supply is not protected.

Number Inputs Relay Transistor outputs Reference Weight

of I/O outputs 24 V/0.5 A (1) kg

cc

c 100…240 V power supply

cc

14 8 a 24 V 6 – TSX 07 3L 1428 0.320

20 12 a 24 V 8 – TSX 07 3L 2028 0.340

TSX 07 3L 2028

ii

TSX 07

i 010ii

ii

ii

TSX 07

i1 16ii

ii

Extendable Nano PLC bases

These Nano PLC bases are used as base PLCs (1 per configuration), as I/O extensions (maximum 1 per configuration)

or as peer PLCs (maximum 3 per configuration). They integrate an extended communication function : Uni-Telway master/

slave link or ASCII link in transmission/reception and Modbus slave link.

Number Inputs Relay Transistor outputs Reference Weight

of I/O outputs 24 V/0.5 A (1) kg

aa

a 24 V power supply

aa

10 6 a 24 V 4 – TSX 07 30 1022 0.290

– 4 protected, TSX 07 30 1012 0.270

16 9 a 24 V 7 – TSX 07 31 1622 0.350

– 7 protected, TSX 07 31 1612 0.325

positive logic

4 unprotected, TSX 07 30 1002 0.270

negative logic

positive logic

ii

TSX 07

i1 24ii

ii

40050/12

7 unprotected, TSX 07 31 1602 0.325

negative logic

24 14 a 24 V 10 – TSX 07 31 2422 0.400

– 10 protected, TSX 07 31 2412 0.370

positive logic

10 unprotected, TSX 07 31 2402 0.370

negative logic

(1) Multilingual quick reference guide included as standard (English, French, German, Italian and Spanish).

Characteristics :

pages 40050/9 to 40050/11

Dimensions :

page 40050/15

Connections :

pages 40050/16 to 40050/19

Modicon TSX Nano PLCs

Nano PLCs

References

(continued)

ii

TSX 07

i1 16ii

ii

ii

TSX 07

i1 24ii /TSX 07 21 1648

ii

Extendable Nano PLC bases

Number Inputs Relay Transistor outputs Reference Weight

of I/O outputs 24 V/0.5 A (1) kg

cc

c 100…240 V power supply

cc

10 6 a 24 V 4 – TSX 07 30 1028 0.300

16 9 c 115 V 7 – TSX 07 31 1648 0.390

9 a 24 V 7 – TSX 07 31 1628 0.360

24 14 a 24 V 10 – TSX 07 31 2428 0.410

Nano PLC bases

cc

c 100…240 V power supply

cc

Number Inputs Relay Integrated Reference Weight

of I/O outputs analogue input (1) kg

(with an integrated analogue input) (2)

(continued)

– 4 unprotected, TSX 07 30 1008 0.280

negative logic

– 7 unprotected, TSX 07 31 1608 0.335

negative logic

– 10 unprotected, TSX 07 31 2408 0.380

negative logic

TSX 07 33 1628

TSX 07 EX 16ii

TSX 07 EX 24ii

10 6 a 24 V 4 1 x 0…10 V TSX 07 32 1028 0.290

16 9 a 24 V 7 1 x 0…10 V TSX 07 33 1628 0.290

24 14 a 24 V 10 1 x 0…10 V TSX 07 33 2428 0.290

Nano PLC extensions

These extensions can be used to augment extendable Nano PLC bases at minimum cost (maximum 1 extension per base).

Number Inputs Relay Transistor outputs Reference Weight

of I/O outputs 24 V/0.5 A (1) kg

aa

a 24 V power supply

aa

16 9 a 24 V – 7 protected, TSX 07 EX 1612 0.325

24 14 a 24 V – 10 protected, TSX 07 EX 2412 0.370

cc

c 100…240 V power supply

cc

16 9 a 24 V 7 – TSX 07 EX 1628 0.360

24 14 a 24 V 10 – TSX 07 EX 2428 0.410

positive logic

positive logic

(1) Multilingual quick reference guide included as standard (English, French, German, Italian and Spanish).

(2) TSX 07 32/33 ii28 PLCs do not have I/O extension and/or PLC extension links or the Modbus slave link.

40050/13

Characteristics :

pages 40050/9 to 40050/11

Dimensions :

page 40050/15

Connections :

pages 40050/16 to 40050/19

TSX PRG LDR

Modicon TSX Nano PLCs

Nano PLCs

References

Separate parts

Description Use with Length Reference Weight

Program Simplifies duplicating or 0.3 m TSX PRG LDR 0.150

loader updating applications

with programming (program and constants

port in internal RAM)

connecting cable

Input Nano PLC with 10 I/O – TSX 07 SIM 06 0.050

simulator

a 24/c 115 V

(continued)

kg

Nano PLC with 16 I/O – TSX 07 SIM 09 0.070

TSX P ACC 01

Nano PLC with 24 I/O – TSX 07 SIM 14 0.080

Connecting cables I/O extension 0.3 m TSX CA0 003 0.015

between

Nano PLC bases

PLC extension 50 m TSX STC 050 1.710

200 m TSX STC 200 6.790

Connecting cable Nano PLC terminal port 2,5 m TSX PCX 1130 0.240

for Modem connection to the Modem

(DCE) device (with 25-way male

SUB-D connector)

Terminal port Isolation of Uni-Telway signals 1 m TSX P ACC 01 0.690

cable for distances > 10 m

connector and < 1 km, line termination,

bus drop cable

40050/14

Description Composition Reference Weight

kg

Self-instruction 1 Nano PLC (16 I/O), TSX SDC 07 30 117 0.950

cases (1) 1 input simulator and 1 FTX 117

1 Nano PLC (16 I/O), TSX SDC 07 30 DSF 0.600

1 input simulator

and software under DOS for FT 2000/FTX 517

1 Nano PLC (16 I/O), TSX SDC 07 30 DSP 0.600

1 input simulator

and software under DOS for PC compatible

(1) Multilingual quick reference guide included as standard (English, French, German, Italian and Spanish).

Characteristics :

pages 40050/9 to 40050/11

References :

pages 40050/12 to 40050/14

Connections :

pages 40050/16 to 40050/19

Modicon TSX Nano PLCs

Nano PLCs

Dimensions, mounting

Dimensions

Mounting

85

a60

TSX 07 3i 10ii 105 86

TSX 07 3i 16ii, TSX 07 3L 1428 135 116

TSX 07 3i 24ii, TSX 07 31 1648, TSX 07 3L 2028 165 146

(1) 2 knock-outs Ø 4

G

a G

77

(1)

Mounting

By clicking onto 35 mm

Mounting Removal

Mounting positions on vertical plane

Possible mounting positions Incorrect mounting position

""

" DIN rail, or by screwing onto panel using Ø M3 screws

""

1 1

Installation rules

2

2

1

2

a

2

1

1 End stop AB1-AB8P35

2 Access cover

b

a

1 Switchgear, enclosure or machine frame

2 Cable ducting or clips

a ≥ 20 mm

b ≥ 40 mm

Warning : Avoid placing heat generating devices

a

(transformers, power supplies, contactors, etc)

beneath the Nano PLC.

40050/15

Modicon TSX Nano PLCs

Nano PLCs

Characteristics :

pages 40050/9 to 40050/11

References :

pages 40050/12 to 40050/14

Connection of inputs

Power supply

TSX 07 30/31 iii2, TSX 07 EX iii12

Positive logic Negative logic

24 V

aa

a 24 V, 6, 9 or 14 inputs

aa

–

3-wire prox. sens. 2-wire prox. sens. 3-wire prox. sens. 2-wire prox. sens.

(1)

–

PNP

+

+ – C012345 13

Inputs Inputs

Power supply

TSX 07 30/31 iii8, TSX 07 32/33 iii8, TSX 07 EX iii28, TSX 07 3Lii28

Positive logic Negative logic

c

100/240 V

(1)

cc

c 100/240 V, 6, 8, 9, 12 or 14 inputs

cc

3-wire prox. sens. 2-wire prox. sens.

–

PNP

+

aa

a 24 V

aa

a

24 V

aa

a 24 V

aa

(1)

c

(1)

+

+

–

100/240 V

+

++

+

–

+

+

–

––

+

–

NPN

C012345 13

–

3-wire prox. sens.

–

NPN

–

+

2-wire prox. sens.

–

+

+

–

LN

Power supply

TSX 07 31 1648

c

100/240 V

(1)

Analogue input

TSX 07 32 1028/33 ii28

C012345 13

a

a

24 V

cc

c 100/240 V, 9 inputs

cc

Nano with analogue input

c

115 V

NL

C0

Inputs

cc

c 115 V

cc

(1)

1234 678LN 5

Inputs

0-10V

LN

+

–

C012345 13

a

a

24 V

Inputs

40050/16

+NC

–

(2)

(2)

Sensor

(1) 3 A fuse.

(2) Earth connection required for non-isolated sensor.

Modicon TSX Nano PLCs

Nano PLCs

Characteristics :

pages 40050/9 to 40050/11

References :

pages 40050/12 to 40050/14

Connection of relay outputs

Power supply

aa

a 24 V or

aa

TSX 07 30 1022/1028, TSX 07 32 1028 TSX 07 3L 1428

4 outputs

12C3C0

(2)

LN LN

c

(2)

24…240 V/a 24 V

TSX 07 31 1622/1628, TSX 07 33 1628, TSX 07 EX 1628

7 outputs

123CC0

(2)

LN LN

(2)

c

24…240 V/a 24 V

Preactuators

45C6

(2)

LN

cc

c 110…220 V (1)

cc

Preactuators

(2)

LN

c

6 outputs

123CC0

24…240 V/a 24 V

45

Preactuators

(2)

LN

TSX 07 3L 2028 TSX 07 31 2422/2428, TSX 07 33 2428, TSX 07 EX 2428

123CC0

8 outputs

4567

123CC0

Preactuators

10 outputs

4567

C8C9

Preactuators

(2)

(2)

LN

Power supply

(2)

LN

c 24…240 V/a 24 V

cc

c 110…220 V (1)

cc

(2)

LN LN

(2)

LN

c

24…240 V/a 24 V

(2)

LN

TSX 07 31 1648

7 outputs

123CC0

Preactuators

(2)

LN LN

c

45CC6

(2)

(2)

LN

LN

24…240 V/ a 24 V

(2)

(1) Provide an inductive overload protection device at the load terminals and for each output : an RC or GMOV type peak

limiter circuit for

cc

c, a flywheel diode for

cc

aa

a.

aa

(2) Fuse rated for load.

40050/17

Modicon TSX Nano PLCs

Nano PLCs

Characteristics :

pages 40050/9 to 40050/11

References :

pages 40050/12 to 40050/14

Connection of

Power supply

TSX 07 30 1012 TSX 07 31 1612, TSX 07 EX 1612

Outputs

123–VC0

(1)

+

–

a

TSX 07 31 2412, TSX 07 EX 2412

123 7C0 56

aa

a 24 V transistor outputs

aa

aa

a 24 V, positive logic transistor outputs

aa

Preactuators

24 V

Outputs

–

V894C

Preactuators

(1)

+

–

Outputs

123

(1)

a

24 V

–

VC0 56C4

Preactuators

(1)

+

–

Power supply

TSX 07 30 1002/1008 TSX 07 31 1602/1608

Outputs Outputs

123C0

(1)

a

24 V

+

–

TSX 07 31 2402/2408, TSX 07 31 2408

(1)

a

24 V

aa

a 24 V, negative logic transistor outputs

aa

+

V

Preactuators

Outputs

–

+

123C0 56C4

(1)

a

24 V

+

V

Preactuators

40050/18

123 7C0 56

(1)

a

24 V

+

–

(1) Fuse rated for load.

+

V894C

Preactuators

Modicon TSX Nano PLCs

Nano PLCs

Characteristics :

pages 40050/9 to 40050/11

References :

pages 40050/12 to 40050/14

Connection of extensions

Connection to Modbus and Uni-Telway buses

Connection of extensions

Nano

base PLC

BSG

A

(1)

(1) TSX CA0 003 cable (0.3 m long) or shielded twisted pair cable.

(2) Remote location (200 m max) of Nano PLC extensions requires either :

i TSX STC 050 cable (50 m long) or TSX STC 200 (200 m long), or

i Shielded twisted pair cable with the following main characteristics :

- Mechanical characteristics : tinned copper core, 18 to 24 gauge with tinned copper shielding

- Electrical characteristics : load resistance per unit length of one wire : ≤ 85 Ω/km, load resistance per unit length of

shielding : ≤ 12 Ω/Km

Nano

I/O extension

ABSG

Nano

PLC

extension

ABSG

(2)

Connection of Modbus bus

Nano

base PLC

Nano

base PLC

Nano

base PLC

BSG

A

(1)

(1) Shielded twisted pair cable

ABSG ABSG

To Modbus master

device

Connection of Uni-Telway bus

FT 2000

1

1 TSX CSA iii : bus cable, double twisted shielded pair. The shielding must be taken to earth at each device.

2

3

CCX 17 Nano ATV

4

TER AUX

5

2

4

2 TSX SCA 62 : passive 2-channel subscriber socket (see page 43594/5).

3 XBT-Z908 : connecting cable between the CCX 17 operator panel and the TSX SCA 62 subscriber socket (see page

43594/5).

4 TSX PCU 1030 : Uni-Telway connecting cable between the PC compatible FT 2000 terminal and the TER port of Nano

PLCs or TSX P ACC 01 connectors.

T FTX CBF 020 : Uni-Telway connecting cable between the FTX 517 terminal and the TER port of Nano PLCs or TSX

P ACC 01 connectors.

5 TSX P ACC 01 : cable connector from a Nano PLC to the Uni-Telway bus via the PLC terminal port. The connecting

cable (1 m long) is integrated in the cable connector. It isolates signals (over a distance > 10 m) and adapts line

termination impedance. It is also used to select the terminal port (Uni-Telway master/slave or character mode).

40050/19

Loading...

Loading...