Page 1

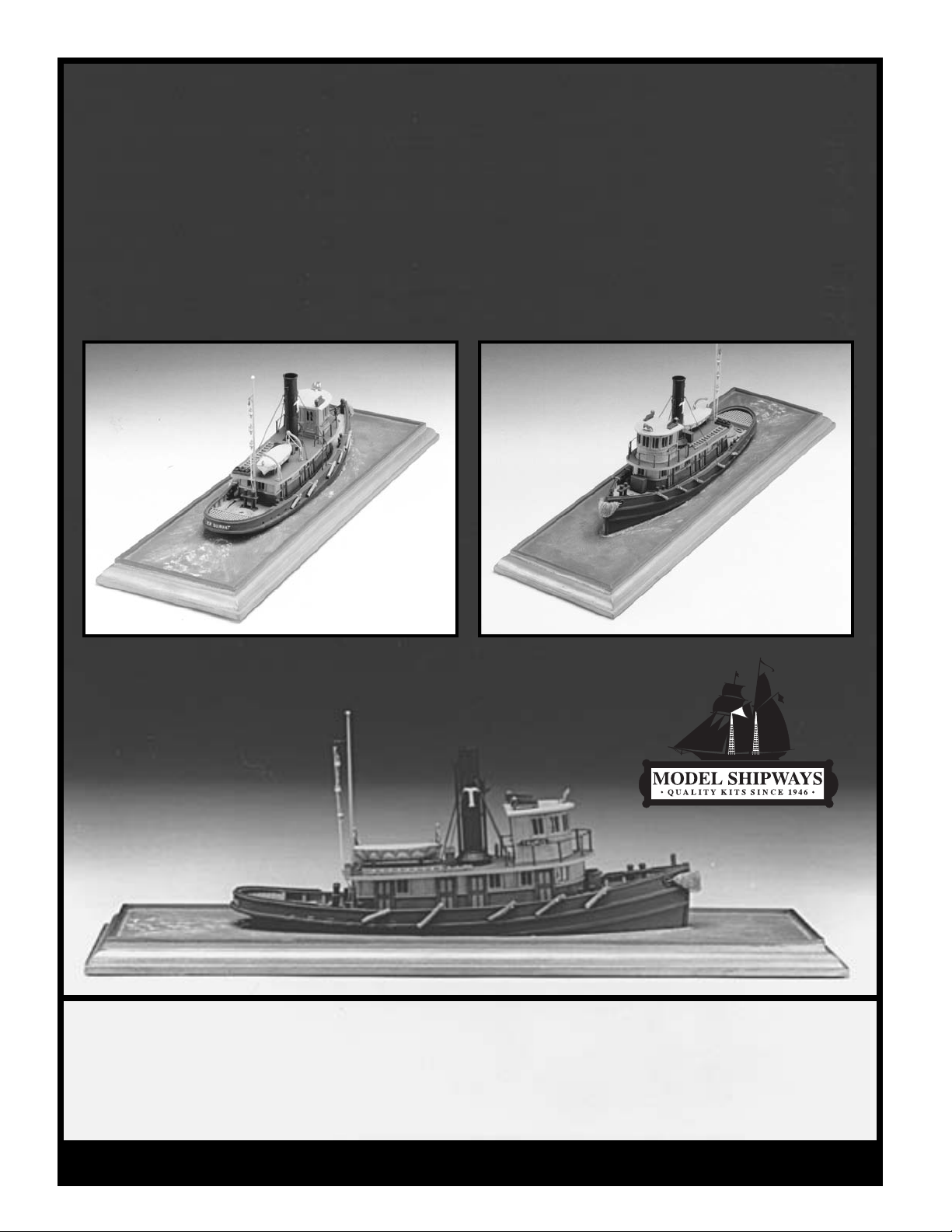

Steam Towboat

Steam Towboat

TAURUS

TAURUS

Towboats, like the TAURUS, were a

familiar sight in every American har

bor and navigable tidal flat at the turn

of the century. Graceful, yet functional, they pulled large liners and

pushed heavy barges with ease. Dur-

Model Shipways Kit No. 2021

ing the 1930's, steam engines lost

ground to Diesel propulsion, and

by the 1960's the steam units were

all but gone. A few steam tugs sur

vive today as museum relics.

Technical Characteristics:

Scale: 1/8" = 1' 0" (1:96)

Length: 9"

-

Height: 3-1/2"

Hull width: 2-1/4"

Page 2

Page 3

Instruction Manual

The Steam Towboat

Taurus

By Erik A. R. Ronnberg Jr., 1978

Instruction Manual Update By Ben Lankford, 1995

The Model Shipways kit is based on the tugs Betsy Ross of Philadelphia, 1903, and

the Sommers N. Smith of Boston,1887. Photos No. 2847 and 2156A, respectively, are in

the collection of the Steamship Historical Society, now in the library of the University

of Baltimore.

During the original development of the kit, Mr. Ronnberg was assisted by Mr. Willie

Dunne, Mr. Alan Frazer, and the librarians at the Historical Society. Their assistance is

greatly appreciated.

This new instruction manual expands on the original instructions prepared by Mr.

Ronnberg. The manual takes you through a step-by-step procedure for building a fine

ship model. Beginners and advanced modelers alike should find this a very rewarding project.

Copyright 1995

Model Shipways, Inc.

Sold and distributed by Model Expo, a division of Model Shipways, Inc.

Hollywood, FL 33020

www.modelexpo-online.com

3

Page 4

CONSTRUCTION STAGES & TABLE OF CONTENTS

Brief History Cover

Introduction/Credits Pg 3

Before You Begin Pg 5

What You'll Need to Start Construction Pg 6

How to Work With the Plans & Parts Pg 6

Painting & Staining the Model Pg 7

Stage A: Shaping the Pre-Carved Hull Pg 8

1. Shaping the Outside of the Hull Pg 8

2. Carving the Bulwarks and Deck Pg 8

Stage B: Completing the Basic Hull Pg 9

1. Installing the Stem Pg 9

2. Installing the Rubbing Strakes Pg 9

3. Planking the Deck Pg 9

4. Installing the Bulwark Stanchions and Rails Pg 9

Stage C: Mounting the Hull Pg 10

Stage D: Adding the Hull Details Pg 10

1. Stern Grating Pg 10

2. Hawse Pipe Lips Pg 10

3. Bow Fender Pg 10

4. Bitts and Bow Post Pg 10

5. Deck Plates Pg 10

6. Main Cabin Pg 10

7. Pilot House Pg 11

8. Smoke Stack, Whistle and Steam Vent Pipe Pg 11

9. Boat and Davits Pg 11

10. Mast and Towing Lanterns Pg 11

11. Ladders Pg 11

12. Stowage Chests Pg 11

13. Rail Stanchions Pg 12

14. Running Lights and Eagle Pg 12

15. Name Boards and Lettering Pg 12

16. Side Fenders Pg 12

Bibliography Pg 13

4

Page 5

BEFORE YOU BEGIN

The model is a waterline type ( no hull

below the waterline ). At 1/8" scale, it

makes a fine shelf model mounted on a

"sea" baseboard. It can also be used ef-

fectively in an HO gauge model railroad

setting. Although HO is 1/87 scale, 1/8"

( or 1/96) is close enough for the HO

layout. What you will have is slightly

smaller boat.

This kit contains a solid hull which has

been machined carved from select,

medium hard, fine grained basswood.

This style hull provides a quick and easy

lesson in the basic shapes and propor-

tions of hull design and helps to develop

woodworking skills. The exterior of the

TAURUS hull has been carved close to

the intended shape, so a simple sanding

is all that is required. Some carving is re-

quired for the bulwarks. Shaping and

finishing the hull to its final shape are

discussed in the instructions.

If you are a beginner, take your time. This

model is fairly simple to build but still re-

quires some time and concentration.

Make sure you complete one stage before

moving to the next. When things go

awry, consider doing it over. Completing

this model will prepare you for a more

complicated solid hull model such as the

Fishing Schooner ELSIE or the Colonial

Schooner SULTANA. Good luck!

5

Page 6

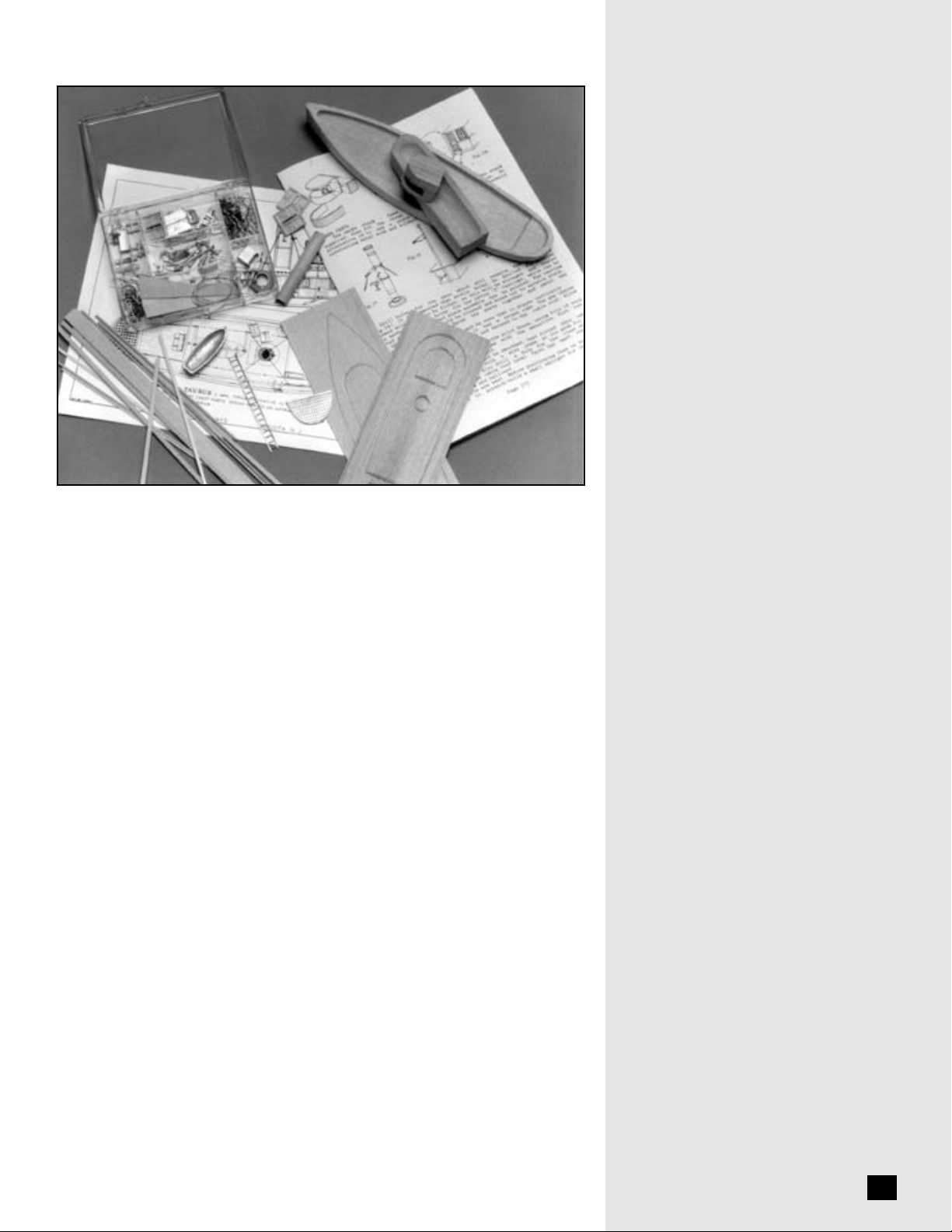

HOW TO WORK WITH

PLANS AND PARTS

Before starting model construction, exam

ine the kit and study the plan carefully. Fa

miliarizing yourself with the kit will serve

two purposes. First, it will let you determine that all parts have been supplied as

listed. And second, you'll be surprised at

just how quickly handling the parts allows

you to better understand the kit requirements. Try to visualize how every part will

look on the completed model. Also, deter

mine ahead of time what must be done

first. The instructions will help you in this

regard, but a thorough knowledge of the

plan at the outset is essential.

It is suggested that all small fittings and

hardware be sorted into labeled boxes or

compartments to avoid loss during the

building process.

1. The Plan

One Plan Sheet is provided. However,

many sketches throughout this manual

further illustrate the various stages of

construction.

The TAURUS kit is manufactured to a

scale of 1/8" = 1'0". The plan is drawn to

the exact scale that the model is to be built.

Dimensions can be lifted directly off the

plan by using a set of draftsman dividers

or by using a "tick" strip, which is simply a

piece of paper used to "pick up" the dimensions (a roll of calculator tape works

very well). Lay your paper strip over the

plan and mark the lengths of items carefully with a sharp pencil. Then use the

strip to transfer the marks to the wood or

item to be made to scale.

2. Kit Lumber

Your kit may contain limewood, a Euro

pean wood, as a substitute for the basswood. Both woods are similar in workability and grain.

3. Cast Metal Fittings

The kit is supplied with Britannia metal

castings. The Britannia metal is a great

improvement over the white metal that

was used in some older kits. Unlike

white metal and pewter, Britannia does

not contain lead, so there are no possible

corrosion problems. The fittings, however, will require final finishing before they

are suitable for installing on the model.

Before painting the cast metal fittings,

clean them up by removing all the mold

joint flash. To do this, use a No. 11 hobby

blade to cut the flash, then file or sand with

fine sandpaper. It is also suggested that

you clean the fittings thoroughly with

warm soapy water before applying primer.

Make sure they are rinsed thoroughly and

allowed to dry before painting.

-

-

WHAT YOU’LL NEED TO START CONSTRUCTION

The following tools and supplies are recommended for the construction process.

-

Modelers who have built before may

have their own favorites.

A. Knives & Saws

1. Hobby knife with No. 11 blades

2. Coping saw (or jeweler's saw

frame) and fine blades

B. Files

Set of needle files

C. CarvingTools

Small chisel and gouge for shaping

the bulwarks

D. Sharpening Stone

Necessary to keep the tools razor

sharp

E. Clamps

1. Several wooden clothespins

3. Rubber bands

F. Wire Cutters & Tin Snips

For cutting fine wire & chain; for

cutting brass sheet

G. Boring Tools

1. Set of miniature drills: #60 to #80

2. A pin vise

3. Larger bits: 1/16", 3/32", and 1/8"

H. Miscellaneous

1. Tack hammer

2. Tweezers (a few)

3. Miniature pliers

a. small round for forming rings

and eyes

b. flat nose (with serrated jaws)

4. 1/2" or 3/4" masking tape

I. Sandpaper

Fine and medium grit garnet or

aluminum oxide sandpaper

(#100 to #220 grit)

J. Finishing:

Paint brushes

a. fine point for details

b. 1/4 flat square for hull

K. Supplies:

(will be covered in detail in the

Painting & Staining section and

throughout instructions.)

1. Paints

2. Primer

3. Stains/varnish

4. White or Carpenter's (yellow)

wood glue

5. Five minute epoxy

6. Super glue

7. Model airplane type glue

Note about Glues: White or Carpenter's

yellow wood glue will suffice for most

of the model. Five-minute epoxy provides extra strength for gluing fittings.

Cyanoacrylate (Super) glue such as Jet,

can be used for quick adhesion. The best

cyanoacrylate glue for most applications

is a medium viscosity gap-filling type.

The watery-thin type is recommended

to fill a narrow crack by capillary action.

For scribed decking sheets, it is best to

use a contact cement or model airplane

type cement. White glue tends to warp

thin sheet wood and makes it difficult to

install.

6

Page 7

PAINTING & STAINING THE MODEL

It may seem strange to begin an instruction manual with directions on applying

the finishes to the model. Not so! Much

time and effort can be saved, and a more

professional result can be obtained, if

the finishing process is carried out dur

ing construction. Paint the various small

parts before they are installed on the

model.

The painting sequence must be a well

thought out procedure, otherwise you

may have difficulty as you proceed with

assembly. For example, it is easier to

paint a cabin or hatch coaming before it

is glued to the deck. Put the parts aside

until they are ready to be installed.

Proper timing in application of finishes

and the use of masking tape to define

painted edges should eliminate unsightly glue marks and splotchy stained surfaces. In the end, following these general

suggestions will be to your advantage.

-

1. Preliminaries

Before painting, rub down all external

surfaces with 220 grit dry sandpaper

and wipe off all dust thoroughly. Give

all unprimed surfaces two coats of

primer. A very light sanding is recommended after the last coat of primer, but

don't sand down to bare wood. With

clean hands, a soft brush, and a clean,

soft rag or tack rag, gently dust and

wipe off the hull.

Choosing paint:

a flat finish paint. Glossy finishes are not

desirable. A satin finish will give the

most satisfactory results, but the undercoat (primer) paint should be dead flat.

Floquil marine color paints are ideal. If

you object to solvent based paints, Floquil's Polly-S is an excellent water-based

acrylic and brushes and covers well.

Clear finishes are available for both

types of paint so you can get the gloss or

flatness you desire.

Masking off surfaces

tricky to mask off the surfaces you don't

want to paint. Some brands of masking

tape are absolutely no good because

they allow paint to bleed under them, so

be selective. The Scotch Brand remov

able magic tape is a good tape. The adhesive is low-tack, the same adhesive

used for their Post-It note paper. A

graphic design tape, such as the Chart

Pak brand, is also good but the adhesive

grips rather securily. If you use it, make

sure your paint is thoroughly dry. It is

available in widths as fine as 1/32" and

1/64". Black plastic electrician's tape is

also acceptable.

A secret to good masking is to lightly

paint a clear finish along the tape first.

For hand brushing, use

: It can be very

-

This seals the edges so the color paints

won't run under the tape. Floquil flat

finish or crystal cote will do the trick.

Spray Painting

work best with fast drying lacquers. The

Floquil paints spray very well when

thinned about 25%, used in an airbrush

such as the Testors and Badger units.

You will also find many brands of paint

available in aerosol cans which give

good results. Test them on a wood block

as previously described before using

them on the model. The aerosol cans put

out much more paint than an airbrush,

so you must spray lightly and fast. Don't

let the paint build too heavily, or you

will have a mess of runs.

Brush painting

bristle brushes is probably best for the

beginner. And many highly skilled

modelmakers prefer the brushed on

technique because a brushed surface,

with its fine imperfections, imparts a

more life like appearance to the model.

Choosing Brushes

soft and of the highest quality. Artist

grade sable or synthetics are the best.

They should be a littler wider for painting the surface. A brush that's too narrow will cause excessive streaking of the

finish.

Brushing Technique

paint or stain with a brush, lay down one

thin coat in a single stroke, then move the

brush over to coat the adjacent areas with

single strokes. Never make repeat strokes

over fresh paint or you will tear up the

surface of the first brush stroke. Wait

until the paint has dried to a hard finish

before applying a second coat.

: Spraying techniques

: Painting with fine, soft

: Brushes must be very

: When applying

2. TAURUS Color Scheme

Color schemes on tugs varied considerably. Here are some of the more common ones.

Hull: Black, or dull or weathered black;

Boston tugs often were white.

Cap rails: Always black.

Deck: Well maintained but not fancy;

use a greyish-umber, or teak stain.

Cabin and pilot house sides: Red was a

favorite; Boston owned tugs may have a

cherry or mahogany stained cabin to

contrast with white hull. The box photo

shows a cabin with mahogany for half

the cabin and natural or oak finish for

the upper half.

Cabin and pilot house top: Canvas covered, paint light grey or buff.

Doors and windows: Bright varnished

oak.

Bulwarks inboard: Buff, grey or red

oxide.

Stern grating: Dark brown holes and

lighter brown top surface.

Quarter bitts: Black or red oxide

Stack, rail stanchions, and deck plates:

Black

Running lights: Brown box; port light is

red, starboard light is green.

Eagle on pilot house: Gold

Boat: White with tan or light grey cover.

7

Page 8

STAGE A

FIG. 1 – Hull Sections at the Bow, Amidships and Stern

SHAPING THE

PRE-CARVED HULL

1. Shaping the Outside

of the Hull

The outside of the pre-carved hull can

be shaped very easily with a sanding

block. About all you need do is even up

both sides with a sanding block. The

stern has vertical sides down to a sharp

edge, then tapers back to the waterline.

Sand the bottom slope to obtain the

sharp edge. Figure 1 illustrates a section

at the bow, amidships, and at the stern.

Using the sanding block, smooth out

the top of the bulwarks so you have a

smooth curve (hull profile) and maintain a sharp edge along the bulwark.

Next, decide on how you want the stem

to look. Figure 2 shows three variations

that you can use. Using a sanding block,

shape the bow to accept a stem piece.

The "catboat" stem (Figure 2c) was very

popular among tugs designed with a lot

of barge pushing in mind.

2. Carving the Bulwarks

and Deck

The machine-carved hull has bulwarks

approximately 1/8" thick. They are

thicker than required so they won't

break while inside the kit box. The inboard sides of the bulwarks need to be

cut down to a uniform thickness of

about 1/32". However, this will be difficult and leave the bulwarks very weak.

Although a little thick, you can cut

them down to only 1/16". If you want

to simplify the bulwarks and omit the

timberheads, the bulwarks can be thicker. If timberheads will be added, strive

for a thinner bulwark. The cap rail must

cover the bulwark plank plus the top of

each timberhead. If both are too wide

the cap rail will be wider than scale and

look very bulky. Figure 3 shows a

method for cutting the bulwark thickness down. Use a gouge to cut to the

depth, then smooth the surface with a

flat chisel. A small sanding block will

complete the task.

As you proceed around the stern, use

the grating casting provided in the kit

and test fit it as you go so the grating

will fit snugly against the bulwarks.

The deck will be covered with the

scored deck sheet included in the kit,

unless you desire to lay individual

planks as an option. In any case, you

must first take a chisel and square up

the corners at the bow and at the deck

Keep

bottom

Sharp

edge

Softer

edge

edge sharp

FIG. 2 – Variations of the Stem

ABC

FIG. 3 – Cutting the Bulwark Thickness

Mark width

Gouge

FIG. 4 – Carving the Deck

Square

corners at

stern grate

FIG. 5 – Installing the Rubbing Strakes

Cut from

sheet

Straight

strips

Smooth

with

chisel

Catboat stem

1/32" to

1/16"

Cut out

at bow

Sand to shape

8

Page 9

grating step aft. Square these areas and

sand the deck smooth (see Figure 4).

At this stage, the hull is fully shaped. Go

over the entire hull with sandpaper,

using #220 grit for the final smoothing.

Be careful not to round the upper edges

of the rail, the hull angle aft, and the bot

tom (waterline). These should be sharp

corners.

Before proceeding to the next stage, it

would be a good idea to drill a couple of

pilot holes in the bottom of the hull if

you intend to have the boat mounted on

a baseboard.

STAGE B

COMPLETING THE BASIC HULL

1. Installing the Stem

Precut the stem and glue it to the bow.

The stem should have a very slight

taper to it. Make sure the grain of the

wood is in line with the piece.

FIG. 6 – Planking the Deck

Decking

-

Waterway strip

Scupper slot

FIG. 7 – Installing the Rails

Rough

File to shape

2. Installing the

Rubbing Strakes

Using a 1/16" strip, pre-shape the rubbing strakes. The straight sticks can be applied from the stem back to about the

front of the deck grating (the lower strake

feathers out at the waterline). Mark the

location of the rubbing strakes on the hull

with a pencil. For the stern you can cut

the strakes out of a 1/6" sheet. Make it a

little wider than necessary. After it is installed, sand it down to match the other

section of strake (see Figure 5).

As an option for the stern, you could

steam-bend or ammonia soak a strip to

soften it for bending around the stern.

Also, you may want to try laminating

several thin strips to obtain the shape.

3. Planking the Deck

For this model, you can lay individual

planks as an option, or use the scored

decking included in the kit. For the

scored sheets, first make a paper template to fit snugly against the bulwarks.

Place the template on the scored sheet

and cut the sheet with a hobby knife.

Glue the deck sheets down with model

airplane type cement or contact cement.

White or Carpenters wood glue tends to

warp the wood. Make sure you have

the scored lines lined up with the centerline of the boat.

The waterway along the bulwarks were

generally planks flush with the deck.

For the model they can be faked by

adding a 1/8" wide paper strip, glued

FIG. 8 – Installing the Rub Rail and Spray Rail

Spray rail

Rubrail

on top of the scored decking (see Figure

6). If you prefer a wood waterway, you

can trim 1/8" off the edge of the scored

decking and glue on a waterway piece.

After the waterway is in place, cut the

scupper slots through the bulwarks (also

shown in Figure 6). Use a small drill and

needle file to shape up the slots. The

plan also shows a larger hole aft which is

a freeing port. This is optional. The vertical lines are bars, added in the hole to

prevent loosing a tow line through them.

4. Installing the Bulwark

Stanchions and Rails

If you are going to add them, the bulwark stanchions should be about 1/32"

square. Starting at the bow, space them

about 1/4" apart. At the scuppers, the

stanchions should be at the end of the

slot, not in way of the slot. Cut each bulwark stanchion to length and glue in

place. Cutting and mounting the stan

chions is tedious work, so exercise great

care in the installation.

-

Glue the main rail atop the bulwark and

stanchions, making sure it extends

slightly beyond the bulwark outboard

and stanchions inboard. The rail portion

around the stern can be made the same

way as discussed for the rubbing strakes

(see Figure 7 ). Finally, add the rub rail

at the stern and spray rail forward (see

Figure 8 ).

9

Page 10

FIG. 9 – Installing the Bitts

and Bow Post

FIG. 10 – Main Cabin Panel Construction

Mark with pencil

Belt rail

Coaming

Vertical panel

Horizontal panel

Window Door

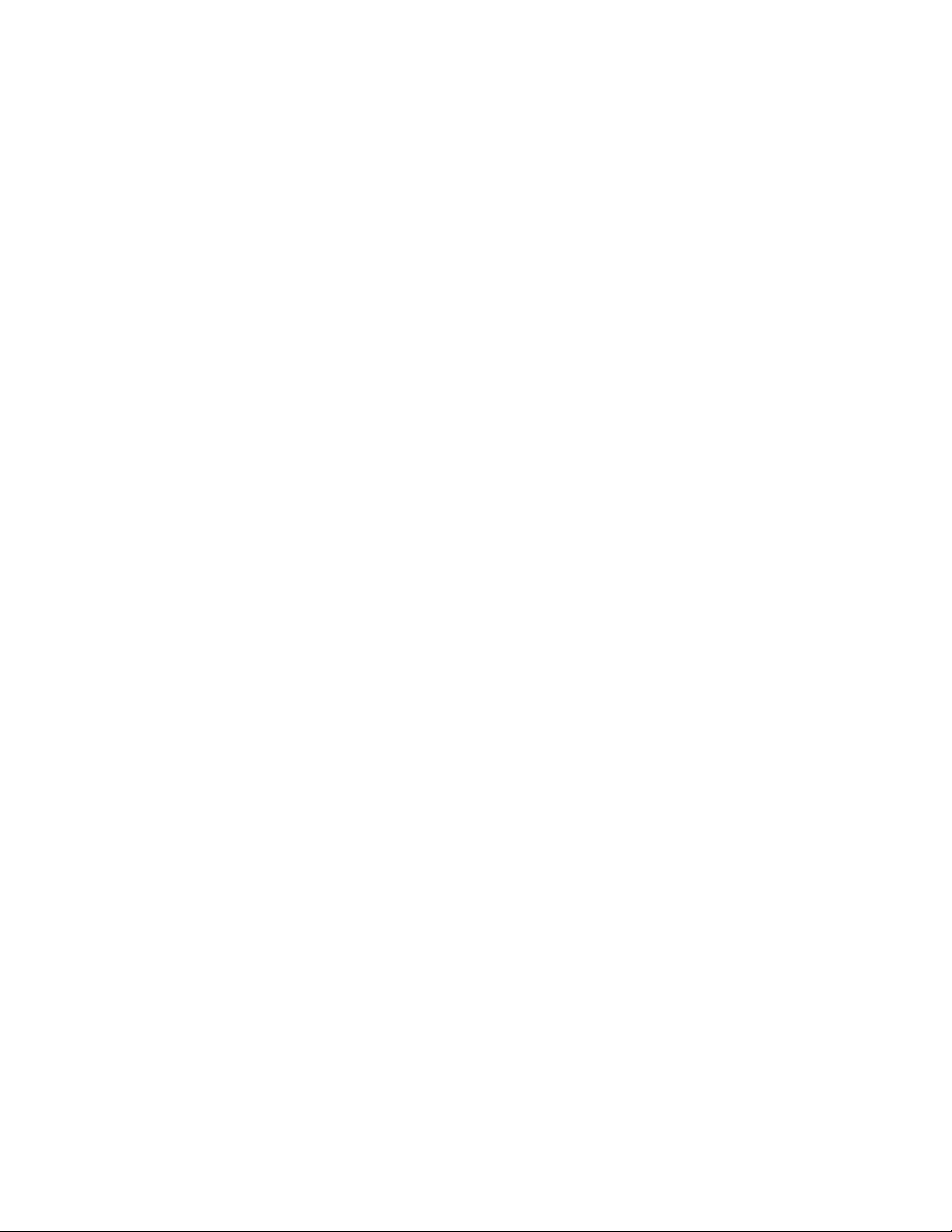

STAGE C

MOUNTING THE HULL

If you are going to mount your model on

a baseboard, as opposed to using it in a

model railroad layout, now would be a

good time to do it to prevent details from

becoming damaged during handling.

The kit includes a wooden baseboard.

For a boat sitting in the water you can

add some strips of wood along the edge

of the baseboard, projecting 1/8" or so

above. The model can be mounted with

screws into the pilot holes you drilled in

the hull. For water, you can use paint, or

paint the baseboard, then pour casting

resin or acrylic gel over the paint. This

makes a realistic looking sea bed. The

photo on the kit box shows how it looks.

STAGE D

ADDING THE HULL DETAILS

Before beginning with the details, outline all topside items on the deck by

marking their locations with a pencil.

Take all measurements from the plans

using tick strips.

1. Stern Grating

The stern grating is a Britannia casting.

Clean it up, prime it and paint it before

installation. If you carved the bulwarks

using the casting as a pattern, it should

fit nicely.

2. Hawse Pipe Lips

Drill holes in the bow and glue the Bri

tannia hawse pipe lips over the hole.

Shape the hole with a file so it blends in

with the hawse pipe lips.

3. Bow Fender

The bow fender is provided as a Britannia casting but should be enhanced by

adding "rope whiskers"; for the model

glue on some short pieces of thread so it

appears nice and fuzzy like the real

fender.

-

FIG. 11 – Adding the Steering Linkage

Roller

4. Bitts and Bow Post

The bitts and bow castings could be

added later, but it is probably a good

idea to get these in place before adding

the cabin. Again, these are best painted

before being installed (see Figure 9).

5. Deck Plates

The four deck plates on the deck, the

round circles adjacent to the stack, are

for passing coal to the bunkers located

on both sides of the boiler. These plates

are iron set flush with the deck planking. For the model, simple paper punchings from a 1/4" paper punch will serve

the purpose, or you can cut out holes in

the scored decking and insert a piece of

wood cut to the correct diameter.

6. Main Cabin

The cabin is provided machine-carved.

However, check the shape. The cabin

should be about 1/16" smaller all

around than the plan. To the sides of the

cabin, you will add covering sheets and

door and window castings. When

added, the cabin should be the correct

dimension.

With a pencil, lay out lines to locate all

the doors, windows, and a horizontal

line for the side panelling. The panelling

is to represent tongue and groove

sheathing on the real craft. Cut the panelling from the scored sheet provided in

the kit. Arrange the panelling as shown

on the plans and in Figure 10. Notice the

panels are horizontal below the scribed

line, and vertical above. As an option,

Chain

Eye

Rod

you could glue individual strips of

wood to form each panel plank.

Glue each door and window casting in

place. Since the windows are open, paint

the cabin behind the windows black, or

light blue to simulate the glass. Do this

before installing the windows. You

could also be daring and insert some

plastic sheet in the window openings to

create some reflection like real glass.

Your choice.

Along the separation of the vertical and

horizontal panels, and at the deck, you

need to add a belt rail and coaming.

Thin, stiff paper like bristol board is

ideal. Make the rail about 1/32" wide,

and the coaming at the deck 1/16" wide.

Next, center the cabin and glue it to the

deck. At this point, it would be a good

idea to add the steering linkage which

connects the steering gear in the pilot

house with the steering quadrant which is

under the stern grating ( see Figure 11).

The linkage has a short chain on each end,

with a connecting rod going through deck

eyebolts. Although you can't see it, the

forward chain is connected to a rope or

light chain which passes over rollers up to

the pilot house steering wheel drum.

Make another pattern for the cabin top

and cut the top from sheet wood. Do not

use scored sheet. The top is canvas cov

ered so the plank seams do not show.

For the edge of the cabin top, you can

leave it as is, or glue a thin strip of paper

or wood around the edge (see Figure

12). Glue the top in place, being careful

to align it evenly. When it is set, mark

the locations of the topside items in pen

-

-

10

Page 11

FIG. 12 – Adding the Cabin Top

FIG. 13 – Beveling the Pilot House

FIG. 14 – Completing Assembly of the Pilot House

cil, then drill holes for the rail stanchions

and the towing light mast.

FIG. 15 – Vent Pipe FIG. 16 – Boat Covering

Shape to fit window

Mark

Fit

Window

Step

7. Pilot House

The pilot house is also a machine-carved

structure. It is cut out in way of the windows so you can look through the opening. You may need to trim the opening

so the windows fit properly. Paint the

interior black so you can't see the wood.

For the windows, leave open or add

clear plastic sheet in each pane.The rest

of the pilot house is done exactly like the

main cabin. Check for fit on the main

cabin, and sand the bottom if necessary

to fit. Finally, glue the completed pilot

house on top of the main cabin, and

make a small step at the door (see Fig

ures 13 and 14 ).

-

8. Smoke Stack, Whistle, and

Steam Vent Pipe

Smoke stack parts include a wooden

stack dowel, Britannia casting base and

"T" emblems, brass rings and chain guys,

and Britannia whistle and vent pipe (see

Figure 15 ).

You may need to bore out the base a little

to receive the stack dowel. Fit the brass

rings over the dowel as shown. Drill a

hole for the "T" emblems, and holes for

the guy chain eyes at the mid ring. Insert

a U-shaped staple of brass in the holes for

attaching the chain. Install the whistle and

vent pipe in the holes in the stack base.

Prime and paint the entire unit.

Install the stack, making sure it is verti

cal and has the proper rake aft (see the

-

plan). File the bottom of the base if necessary. Attach the chains to the cabin top

with similar staples.

9. Boat and Davits

The boats can be positioned as shown on

the plan or moved closer to the cabin

edge.The boat can be either on the port

or starboard side. If at the cabin edge,

you could scratch build a small skylight

for the engine room. The kit box photo

shows an old wooden ladder atop the

cabin. Be inventive!

Make a cover for the boat out of fine

cloth or paper (see Figure 16). The boat

can be hung from the davits using

thread or a piece of brass wire.

10. Mast and Towing Lanterns

Fit the mast through a hole in the cabin

top, but first install a hanger from brass

wire into the mast for the lantern halliard (see Figure 17). The halliard can be

thread or brass wire. Notice on the kit

box photo, a small block was added at

Cover

FIG. 17 – Lantern Halliard

the top for the halliard. It gives the

model that extra touch.

11. Ladders

Add the port and starboard ladder going

up to the cabin top. The top should be

curved as a hand rail.

12. Stowage Chests

Install the forward stowage chest for

ward of the main cabin, and the lifebelt

-

11

Page 12

stowage chest aft of the smoke stack.

Glue with epoxy to set them securely.

13. Rail Stanchions

The rail stanchions fit into the holes you

drilled on the cabin top. After gluing, feed

the brass railing wire through the stanchions and touch with a little super glue.

14. Running Lights and Eagle

Make sure you have the lights painted

the correct color. Remember Port (like

wine) is red. The eagle is installed on the

pilot house front.

15. Name Boards and Lettering

You could name this boat anything you

like. TAURUS is Model Shipways name

for a typical tug. The name can be hand

painted, or you can use dry transfer lettering from an art store.

16. Side Fenders

On the real boats, fenders were made

from old railroad ties or sawed-off logs.

For the model, cut some twigs off your

favorite bush and stain them to look

weathered. These make nice realistic

fenders.Glue to the bulwarks and use

thread for the securing lines.

After all is done, look over your prize

and touch up paint if necessary. Make a

final check with the plan to see that you

have included all parts. Add the water

to your baseboard if you have not already done so.

Congratulations!

Your model is now complete. Don't

hesitate to call Model Expo when

you are ready to begin your next

modeling endeavor.

12

Page 13

BIBLIOGRAPHY

1. Brady, E. M., Tugs, Towboats, and Towing. Describes operation of modern

tugs with many glances backward at steam units. Good stuff on towing gear

and techniques.

2. Lang, Steven,

graphic overview of tugs through time and in most regions of America.

3. Campbell, G. F.,

Describes modelwork of a general nature, drawing examples from many

types of sailing ships. Contains some good hints on crafts techniques. Excellent for the beginner.

On the Hawser. A tugboat album offering a varied photo

The Neophyte Shipmodeler's Jackstay, Model Shipways, 1962.

-

13

Page 14

TAURUS INSTRUCTIONS

FOR LASER-CUT CABIN AND

PILOT HOUSE

The TAURUS kit has been modified to include

laser-cut lifts and cabin tops for the main cabin

and pilot house. These laser-cut parts replace

the solid wood machine carved structures supplied in earlier kits.

These instructions apply to assembly of the

laser-cut parts. Once assembled, refer back to

the Instruction manual for addition of siding,

windows, and doors.

MAIN CABIN

Cabin lifts

1/8” thick

8 required

Cabin top

1/32” thick

1 required

Step. 1

- Glue the 1/8" cabin lifts together.

Step. 2 - Shape the top and bottom of the

cabin lifts to follow the deck sheer line. The

front also needs to be sloped back a bit. This

can be done with a sanding block. See Figure

1.

Step. 3 - Glue on the 1/32" cabin top. The

cabin top is slightly smaller than the plan to

allow for adding the edge molding (see Instruction Manual).

Step. 4 - Return to the Instruction Manual for

instructions on installing the windows, doors,

and siding.

PILOT HOUSE

Step. 1 - Glue up the three 1/8" lifts with curved

front. On top of these glue on two of the 1/32"

lifts supplied in the kit. Glue the three 1/8" rectangular lifts on the aft side. Next, add two more

1/32" lifts. You now have a pilot house with a

cut-out in way of the windows, so you can see

through.

Step. 2 - Glue on the 1/32" thick pilot house

top. See Figure 2.

1/8” thick

3 required

Pilot house

lifts 1/8” thick

3 required

Pilot house lifts at

windows 1/32”

thick 4 required

1/8”

1/8”

Pilot house top

1/32” thick

1 required

1/32” top

2@1/32”

2@1/32”

FIGURE 2

Step. 3 - Return to the Instruction Manual for

instructions on installing the windows, doors,

and siding.

14

FIGURE 1

Shape profile

Page 15

MODELER'S LOG

Date Time Notes

15

Page 16

Other Fine Kits from

Model Shipways

SULTANA

Model Shipways Kit No. MS2016

WILLIE L. BENNETT

Model Shipways Kit No. MS2032

OUR GUARANTEE

If less than delighted, return your purchase within 30 days in original condition.

BLUENOSE

Model Shipways Kit No. MS2130

CHARLES MORGAN

Model Shipways Kit No. MS2140

RATTLESNAKE

Model Shipways Kit No. MS2028

BENJAMIN LATHAM

Model Shipways Kit No. MS2109

PHANTOM

Model Shipways Kit No. MS2027

NIAGARA

Model Shipways Kit No. MS2240

SAVE TIME & MONEY ...ORDER DIRECTLY FROM OUR WEBSITE!

EMMA C. BERRY

Model Shipways Kit No. MS2150

FLYING FISH

Model Shipways Kit No. MS2018

BEDFORD WHALEBOAT

Model Shipways Kit No. MS2645

PRINCE DE NEUFCHATEL

Model Shipways Kit No. MS2110

MODEL SHIPWAYS, INC.

Sold & Distributed by Model Expo, a division of Model Shipways, Inc.

race, Hollywood, FL 33020

3850 N. 29th T

er

Toll-Free 800-222-3876 Monday - Friday 9-6 ET • Fax 800-742-7171

http://www.modelexpo-online.com

USS CONSTITUTION

Model Shipways Kit No. MS2040

PRIDE OF BALTIMORE II

Model Shipways Kit No. MS2120

Loading...

Loading...