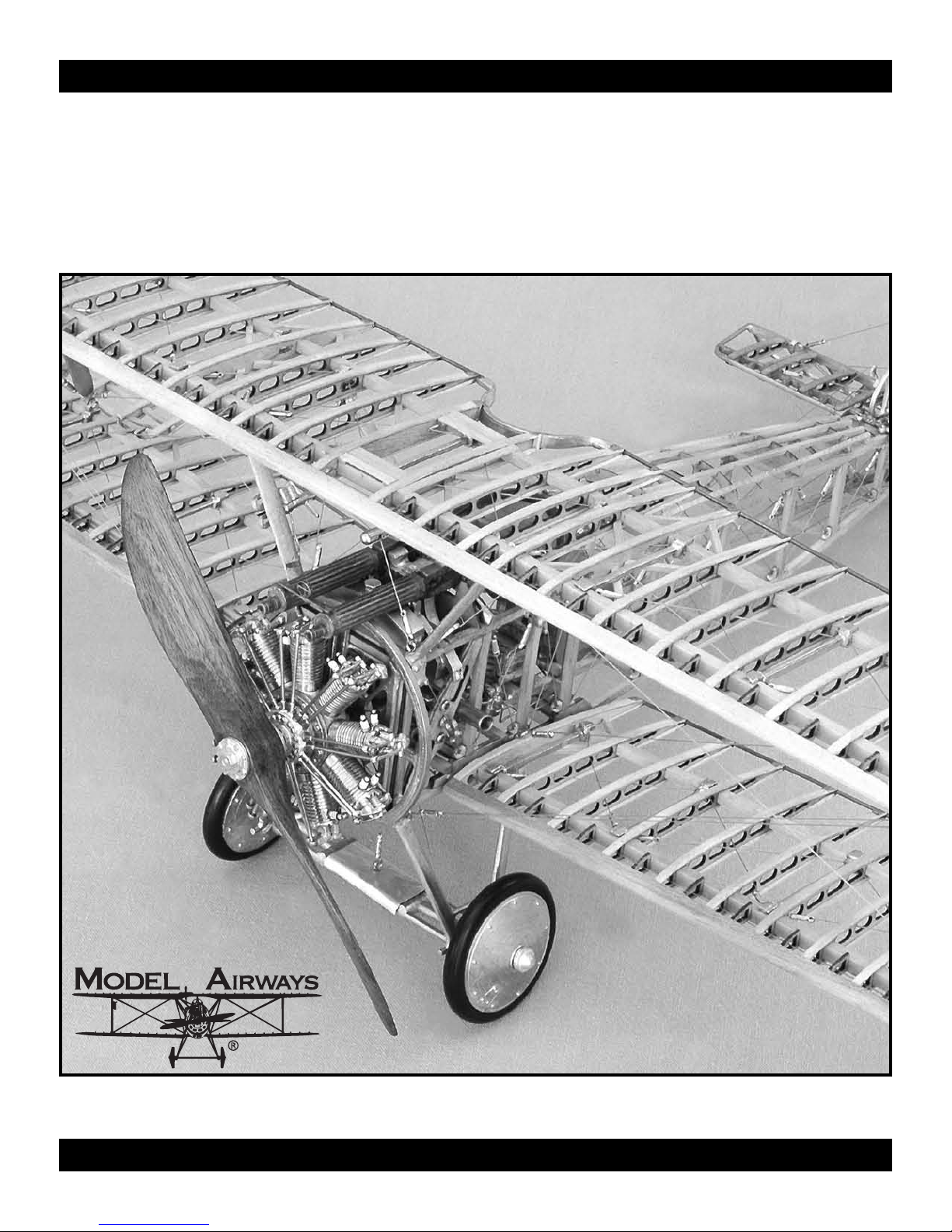

Model Airways SOPWITH CAMEL F.1, MA1030 Instruction Manual

INSTRUCTION MANUAL

MODELING THE

MODELING THE

SOPWITH CAMEL F. 1

SOPWITH CAMEL F. 1

✦

✦

WORLD WAR I BRITISH FIGHTER AIRCRAFT, 1917

WORLD WAR I BRITISH FIGHTER AIRCRAFT, 1917

Technical Characteristics

Scale: 3/4" = 1' (1:16)

Wingspan: 21" (534 mm)

Fuselage Length : 14-1/16""

(584.2 mm)

✦

✦

Manufactur

Model Airways Kit No. MA1030

Instructions and prototype by Kenneth H. Goldman

ed by Model Shipways, Inc. dba Model Expo • Hollywood, Florida

Sold by Model Expo, a division of Model Shipways, Inc.

http://www.modelexpo-online.com

HISTORY

HISTORY

T.O.M. Sopwith made his first solo flight in a Howard Wright Monoplane in 1910 and was forever hooked on aviation. A year later, after setting several records, he opened his own flying school. Not satisfied with other designers’ aircraft, he built his first biplane near the end of 1912, and at the beginning of 1913, The Sopwith Aviation Company

was in business. Combining his love of things nautical as well as aeronautical, his early production focused on float

planes. With the outbreak of the Great War, however, Sopwith’s efforts turned to the defense of the United Kingdom.

The company’s most famous creation was the F.1 Camel, so named after the humped fairing that enclosed its twin

Vickers machine guns each of which was fed by a disintegrating belt of 250 rounds. The prototype first flew in December 1916, and production models entered service in July 1917. The tight grouping of all the weight, including the

pilot, between the propeller and the center of the wings made the plane unforgiving in the hands of an inexperienced

pilot at low altitude but highly maneuverable at high altitude. Even with this late entry into combat, the Camel

accounted for 1,294 victories, more than any other Allied aircraft type. Surprisingly, less than 10% (503) of the total

production of 5,497 machines was actually accounted for by The Sopwith Aviation Co. The remainder were built

under license by Boulton & Paul Ltd. (1,550), British Caudron Co. Ltd. (100), Clayton & Shuttleworth Ltd. (575),

Hooper & Co. Ltd. (321), March, Jones & Cribb Ltd. (175) The Nieuport & General Aircraft Co. Ltd. (400),

Portholme Aerodrome Ltd. (300) and Ruston Proctor Ltd. (1,573).

1,342 of the aircraft were equipped with Clerget engines, the rest had either a Gnome, Le Rhone or Bentley. The 130

hp Clerget 9B-powered F.1 Camels had a wingspan of 28 feet and a length of 18 feet nine inches. The aircraft weighed

957 pounds empty and 1455 loaded and could reach a speed of 101 to 113 mph at 10,000 feet. This performance fell

off somewhat at altitudes between that and its absolute ceiling of 24,000 feet. Fluid capacity of 26 gallons of fuel and

5.75 gallons of castor oil allowed 2.5 hours of flying time. The rate of climb was five minutes to 5,000 feet and twelve

minutes to 10,000 feet.

Although a lively dispute continues as to whether Canadian Captain A.R. Brown shot down the Red Baron on 21 April

1918 or whether Australian machine gunners firing up from the trenches fired the fatal shot, there is no dispute that

Roy Brown was flying a Sopwith Camel when he chased von Richthofen’s Fokker Dr.1 triplane that fateful day. Among

the other successful Camel pilots was Captain Arthur Harris, later Air Marshal and architect of the World War II carpet

bombing campaign against the Third Reich, which earned him the nickname “Bomber Harris.”

The SOPWITH CAMEL model plans and kit were completed in 2005. The model was designed for Model Airways by

Microfusioni - modellisimo of Milan, Italy, owned by Luigi Volonté and son Bruno. Model plans and original Instructions in Italian were developed by Luigi Volonté. The text was rewritten in English and expanded by Kenneth H. Goldman, who also built the model.

Copyright 2006 by Model Airways, Inc., a division of Model Shipways, Inc., dba Model Expo • Hollywood, Florida

INDEX

INDEX

Technical Specifications ...................................Cover

History / Introduction / Credits..............................2

Before You Begin.....................................................3

Working with the Plans & Parts ..............................3

What You’ll Need to Start Construction ..................3

Painting & Staining the Model................................4

Stage 1: Building The Engine & Propeller............4-7

Stage 2: Building The Wings ...............................7-11

Stage 3: Building The Empennage.........................23

Stage 4: Building The Fuselage.........................13-15

Stage 5: Building The Engine Mount ....................16

& Plumbing

Stage 6: Building The Cockpit & Controls ......17-19

Stage 7: Epennage Installation & Cabling........19-21

Stage 8: Attaching The Lower Wing.................20-22

& Undercarriage

Stage 9: Attaching The Upper Wing, ...............22-25

Cabling & Bracing

Stage 10: Finishing Touches .............................26-27

More Great Model Airways Kits............................28

2

Before You Begin

The SOPWITH CAMEL kit is intended as a

structural, non-flying, model without any fab-

vering. It is about as close as you can

ric co

come to being able to hold the r

our hand. Most every detail of the real air-

y

craft has been included as model scale permits.

Britannia castings and laser-cut wood fittings

eliminate creating many parts from scratch,

however, some final finishing is required

before they are suitable for the model.

Before starting the model, carefully examine

the kit and study the plans. Every effort has

been made to present the construction stages

in a clear, logical sequence. Nevertheless, it is

recommended that you think several steps

ahead and check the plans accordingly during assembly. This will help clarify what you

are doing now and will ensure proper fit of

the sub-assemblies later. The instructions

will help, but a thorough knowledge of the

plans at the outset is essential.

Determine if all the listed parts are present.

Handling them will produce a better understanding of the kit's requirements and will

help you visualize how every piece will look

on the completed model.

small fittings and hardware, sort them into

labeled containers with lids to keep the parts

in and dirt out.

Although each Stage in the instructions

results in a completed sub-assembly, it is recommended that you begin at Stage 1 and

proceed in order to the finish. Certain modeling techniques are described in full when

they first appear in the sequence and only are

referred to in subsequent steps. Always complete one construction stage before moving

to the next. In addition to the construction

figures that accompany the instructions,

ocess photographs thr

pr

clarify construction. If things still go awry,

take a br

eak, then consider doing them o

View color photo on our website!

www.modelexpo-online.com

eal thing in

To avoid losing

oughout will help

ver.

Plans

ways SOPWITH CAMEL is

odel Air

The M

manufactured to a scale of 1:16 or 3/4" equal

to one foot. I

appear throughout this instruction manual,

five full-size plan sheets are provided. Each

plan sheet is drawn to the actual siz

model except for some areas that have been

enlarged to better sho

imensions can be lifted dir

D

size plans by using draftsman dividers, a strip

of paper laid on the plans on which you make

at dot indicating each end of a part, or simply

by laying wood strips directly on the plans and

marking where to cut them.

n addition to the Figures that

e of the

w detail.

ectly off the full-

Parts

A parts list is included in each of the construction stages, noting the par

ticular stage. A MASTER PACKAGING

par

PARTS LIST (separate from these instructions) is provided that lists the quantities

included in the kit. F

wire and rigging, one or several pieces are provided in the kit as noted on the master packaging parts list. These are identified both by size

and by the names of the aircraft parts that will

be made from them. This material must be cut

to length or shape according to plan dimen-

ven though Model Airways supplies

sions. E

enough extra wood to complete the model

before running out, it is recommended that

you plan to measure and cut the required parts

so as to minimize waste. That way you are covered if you make a mistake.

ts required for that

or wood strips, brass rod,

Cast Metal Fittings

These parts will require final finishing before

mounting on the model. Remove mold joint

flash with a #10 or a #11 hobby blade, then

file or sand with fine sandpaper. Some of the

holes through which other parts fit, such as the

small eyes of a turnbuckle, may have filled in

during the casting process. Carefully clean

these out using a drill bit or reamer and check

the fit of the other parts. To ensure good glue

and paint bonds to these parts, wash off the

remaining traces of the mold release agent. A

spray of ammonia window cleaner and gentle

brushing with an old soft-bristle toothbrush

does the job nicely. Thoroughly rinse the parts

and allow them to dry.

Necessary Construction Tools

-

ecom

The follo

mended for the construction

process. Modelers who have built before may

have their own favorites.

A.

blades

B. Files - Set of needle files

F

R

C. Clamps and Pins

D. Boring Tools

wing tools and supplies ar

Knives and saws

1. Hobby knife with No. 11 and No. 10

or saw

2. Raz

lat, fine-tooth, mill bastar

ound riffler file

1. Assorted Bulldog clips

2. Wooden clothespins

ubber bands

3. R

4. Package of T-pins

et of miniatur

1. S

2. Pin vise

tandard set of twist drills

3. S

d file

e drills (#60 to #80)

e r

iscellaneous

E. M

1. Tweezers (a few)

Small fine pointed scissors

2.

3. Miniature pliers

a. small round

b. flat nose

Wire cutters

4.

5. Mechanics rule graduated in 1/64"

6. Brass brush for polishing cast parts

7. Small block plane

. Sandpaper

F

#120 aluminum oxide paper for shaping wood

parts

et/dry silicon carbide paper for

#200 w

intermediate sanding

#400 wet/dry silicon carbide paper for fit-

tings and finishing

G. Glue

Yellow (tan) carpenter's glue for wood parts

Cyanoacrylate (CA or Super Glue) for metal

parts, metal to wood, and rapid assembly of

wood par

3. OPTIONAL

C

have to take something apart)

Cyanoacrylate Accelerator for an instant bond

Five-minute epoxy provides extra strength for

gluing fittings.

H. Building Board

A soft, but stiff board such as acoustic ceiling

tile or insulation wallboard to easily take

straight pins for holding parts during assembly. This soft board should be nailed or glued

to a hard board so it will be flat. You can use a

table, but a portable board is good for turning

it around to make the work easier. You will

also need assorted scrap lumber, as indicated

on Plan 05 to build some of the suggested

special jigs.

ts.

yanoacrylate De-Bonder (just in case you

(for shaping wing leading edges)

Setting Up The Plans

t is easiest to build flat subassemblies dir

I

on the full-siz

building boar

or plastic wrap

especially super glue. Although the waxed

paper or plastic wrap protects the plan

somewhat, you could accidentally glue the

protective sheet to the model parts, or even to

the plan itself.

An alternative, if you have a dedicated

modeling area, is to lay a sheet of glass over the

full-siz

glass, using tape and w

in position. I

for sharp edges on the glass.

e plans. P

d and cover it with waxed paper

. Be careful applying glue,

e plan sheet and build dir

f y

lace the plan on your

ectly on the

eights to hold the par

ou use this method, watch out

ectly

ts

3

Getting Started

Before commencing each stage of construction, have all the parts for that stage identified and ready to use. It helps to lay each

part on its corresponding location on the

full-size plan to facilitate identification as

ou proceed. Lightly sand wood parts as

y

required to remove any fuzziness and prepare

the castings par

ts as noted above.

Painting and Staining

Your Sopwith Camel model need not be

painted or finished at all. H

ommended that you seal the wood parts and

Britannia castings for protection. Due to the

owever, it is rec-

STAGE 1: BUILDING THE ENGINE AND PROPELLER

intricacy of the finished model, this is best

done as you go. Using carpenter’s glue on

raw wood allows the strongest bond, but

inevitable glue smears and r

wood essentially impervious to staining, and

end grain will stain darker than the rest. A

good compr

varnish onto completed wood subassemblies,

follo

color or darken the tone, followed by a finish

coat of varnish to even out the gloss. The

first, sealer coat, is especially important if

you use water base products.

Britannia castings parts may be left polished

or painted a steel or gunmetal color

suggested during constr

insulators can be painted white. Other fit-

omise is to airbrush or brush

wed by a tinted coat to even out the

uns leave the

, or as

uction. Sparkplug

tings, such as turnbuckles and instr

castings, can be painted black. Varying the

tones on the various parts will add a nice

contrast to the finished model.

The distinctive wicker seat back is provided

ritannia casting to simplify construc-

as a B

tion. You will need to paint this, after gluing

it to the seat, to give it an appropriate rattan

finish. A tan base coat followed by light and

dark washes will give you a good effect.

After you have shaped and finish sanded the

laminated propeller, you can achieve a more

authentic look b

mahogany and then building up two or

three thinned layers of varnish or shellac.

y staining it golden

uments

Although a counter-intuitive design by today’s standards, fixing the

propellers to a spinning engine on a stationary crankshaft simplified

cooling, had an excellent weight to horsepower ratio and allowed

greater flexibility in locating the aircraft’s center of gravity – affecting maneuverability - over the in-line engines of the time. One

drawback, however, was the pronounced gyroscopic effect that

pulled the aircraft to the right. To fly in a straight line, pilots had to

compensate for this by applying constant left rudder.

The Clerget rotaries provided improved speed control over the

Gnome and Le Rhone rotaries by replacing the standard “blip”

switch that temporarily grounded the magneto (killing the ignition)

with a selector switch that restricted the engine to run on 9, 7, 5 or

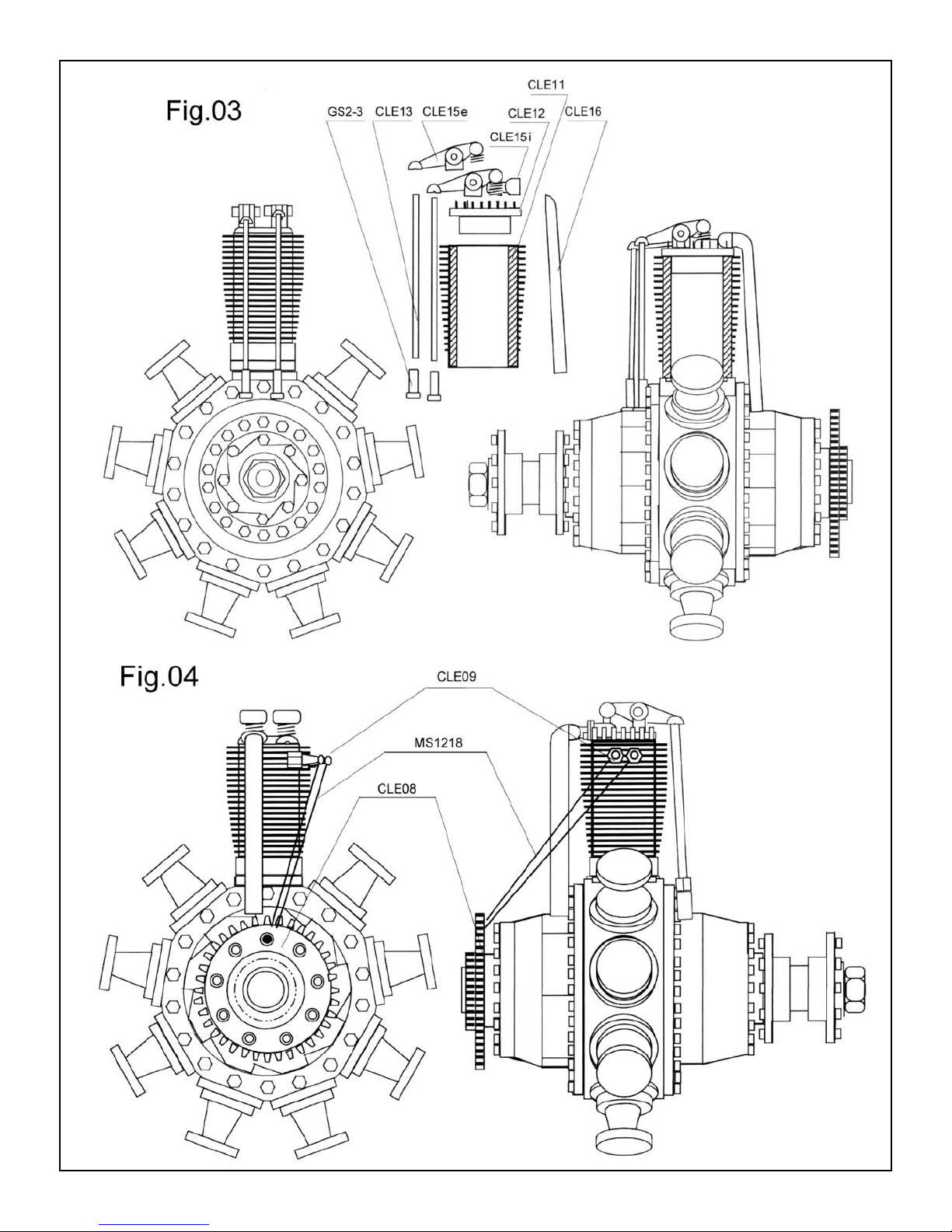

Parts List For Stage 1

WP129K-1.5

CLE02 Crankcase 1 Britannia casting

CLE03 Crankcase covers 2 Britannia castings

CLE04 Front propeller flange 1 Britannia casting

CLE05 Rear propeller flange 1 Britannia casting

CLE06 Camshaft box 1 Britannia casting

CLE07 Induction box 1 Britannia casting

CLE08 Igniter ring 1 Britannia casting

CLE09 Spark plugs 18 Britannia castings

CLE11 Cylinders 9 Britannia castings

Crankshaft tube 1 3/16" diameter x

1-1/2" brass tube

even 3 cylinders. Like the earlier rotaries, the Clerget spewed

unburned castor-oil from the exhaust, adding to the pilot’s discomfort. Pilots were issued a small bottle of blackberry brandy to counteract the smoke’s laxative effect.

The completed engine subassembly slips onto the fixed crankshaft

at a later construction stage. Super glue and/or epoxy should be

used to assemble the parts. Care must be exercised with the many

small parts. Refer to Figures 01 through 05. For clarity, drawings

may show a single cylinder. It is a simple matter to repeat the assembly for the other eight cylinders. The key to success is to carefully

clean up all of the castings and then to dry fit everything before

applying glue.

Parts List For Stage 1

CLE12 Cylinder heads 9 Britannia castings

WP162-1.2 Valve lifters 18 15/16" x 1/16" d.

brass rods

GS2-3 Tappet seats 18 Small brass eyelets

CLE15i Intake rocker arms 9 Britannia castings

CLE15e Exhaust rocker arms 9 Britannia castings

CLE16 Induction pipes 9 Britannia castings

CLE17 Propeller 3 Laser-cut basswood

5/32" thick

WP1218 Ignition wires 9 cut from 72"

black thr

ead

Engine group:

Begin by attaching the front and back

ers (CLE-03) to the crankcase

crankcase co

(CLE-02). N

the castings to help y

one side in place, then make sure the bolts

heads line up on both covers before gluing

the second co

bly onto the crankshaft tube, which you must

cut from (WP129K-1.5) to ensure that the

engine parts line up properly, but do not glue

the cast par

Slip the nine cylinders (CLE-11) over the

pistons on the crankcase so that the pair

v

e tiny notches in

ote that ther

er in place. S

v

ts to the tube at this stage.

e ar

ou align the par

lip this subassem

ts. G

lue

-

ed

sparkplug holes all face the same way, perpendicular to the central axis of the

w hold the subassembly facing

crankcase. N

ou so that the spar

y

on the cylinder at the top

of the engine. Slip the camshaft box (CLE-

06) onto the brass sleeve and align it so the

paired depressions for the tappet seats (GS2-

3) are centered in front of each cylinder.

Looking at the top cylinder, the left hand of

each pair should be closer to you. Glue CLE06 against the crankcase. For the best fit of

the tappet seats (GS2-3) later on, use a 3/32"

twist drill to clean the 18 depr

CLE-06. F

o

kplug holes ar

.

inish up with a quick twist fr

4

e to the left

This is the fr

essions in

ont

om a

7/64" drill to bevel the edges. Be careful not

to drill too deep.

Refer to Engine Photograph 1 to align the

cylinder heads (CLE-12) on the cylinders

ou glue them in place. NOTE that

e y

befor

the two flats on the top do not match: the

larger one, with straighter sides, also has the

larger hole; it is for the intake rocker arm,

-

which goes to the side opposite the spar

plug holes.

central axis of the engine, which will set the

two holes at an angle to that axis. N

the intake rocker arms (CLE-15i) to the

cylinder heads so that the flanged pipe on

each goes to the r

The flats should line up with the

ear of the engine.

k

ext, glue

lip the induction box (CLE-07) onto the

S

brass tube at the rear of the engine. Referring

to Engine Photograph 2, holding an induction pipe (CLE-16) in place, flanged end

against a flat on the CLE-07, position the

flat on the induction bo

x so that the flat side

of the other end of the pipe meets the center

of the flanged pipe on the intake r

ocker arm.

Properly aligned, it will be at a slight angle.

Glue CLE-07 to the crankcase. Dry fit each

induction pipe and adjust the flat as neces-

y to fit against the pipe on each CLE-15i

sar

and glue them into place. F

each induction pipe that extends abo

ile off any part of

ve the

edge of the flanged pipe on parts CLE-15i.

lue the igniter ring (CLE-08) to the induc-

G

tion box so that the holes line up between

each pair of cylinders and the small gear faces

om the engine. Now glue the engine

away fr

subassembly to the crankshaft tube so that

one end of the tube is flush with the outer

surface of the small gear on the igniter ring.

Glue the exhaust rocker arms (CLE-15e) in

place on the cylinder heads. C

ut the 18 valve

lifters (CLE-13) from the provided lengths

of 1/16" brass r

od. It is suggested that you

cut them to 15/16" and then file them down

to achieve the best fit. Slide a tappet seat

(CLE-14) onto the brass r

od and glue into

place, referring to Engine Photograph 3.

Complete the engine gr

ignition wir

es (WP1218) from the igniter

oup by attaching the

ring to the spark plugs, referring to Engine

hotograph 4. Cut 18 4" lengths of black

P

thread. Feed each pair of threads through

one of the nine holes in the igniter ring and

tie them to the spar

kplug terminals. Alligator

clips or other small clamps can be used on

the thread ends that emerge from the hole to

eights to keep the threads taut as you

act as w

fix them and the knots with a drop of glue.

Trim off the excess thread and repeat the

process for the other eight cylinders.

Engine Photograph 1

5

6

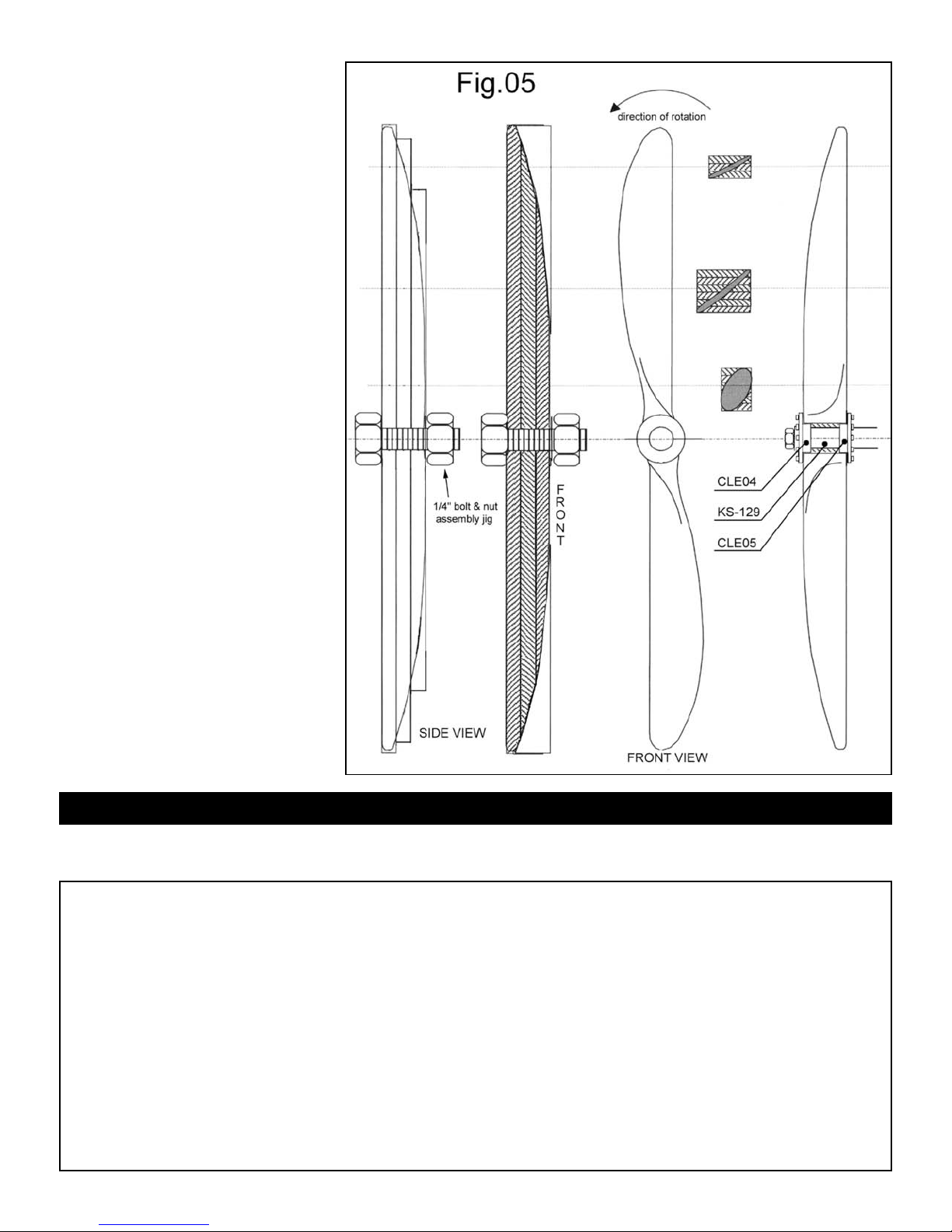

Propeller group:

Referring to Fig.05, laminate the propeller

layers (CLE17). Take care to stack the layers

in the correct order. When viewed from the

front in a vertical position, the stack goes

om longest to shortest with the shortest

fr

layer closest to you. Curved edges would

then be upper left and lo

diameter bolt and nut make a handy center

clamp that helps align the layers while the

glue dries.

Remove the bolt and whittle and sand the

propeller to its refined shape. The front of

the finished propeller curves toward the back

when viewed from the side. Begin with the

overall lengthwise curve, then proceed to the

cross-sectional shaping. This will result in a

curved leading edge and a straight trailing

edge after the final shaping. Shape the front

first, then the back to follow the front. Note

that the front surface is slightly convex and

the back is slightly concave.

When you are satisfied with the result, apply

a gold-mahogany stain. If using a water-base

stain you might have to lightly re-sand the

opeller with #400 paper to remove any

pr

raised wood grain, then apply a couple of

coats of varnish.

Attach the front (CLE04) and rear( CLE05)

flanges to the propeller. Make sure the front

and rear bolt heads/nuts line up before

gluing. Dry fit this assembly onto the

crankshaft mount. There should be a space

of about 1/16" between the rear propeller

flange and the camshaft box.

DO NOT glue the propeller to the

crankshaft mount until final fitting of the

engine to the completed aircraft. This will

allow you to make any needed adjustment so

the prop will clear the machine gun muzzles.

wer right. A 1/4"

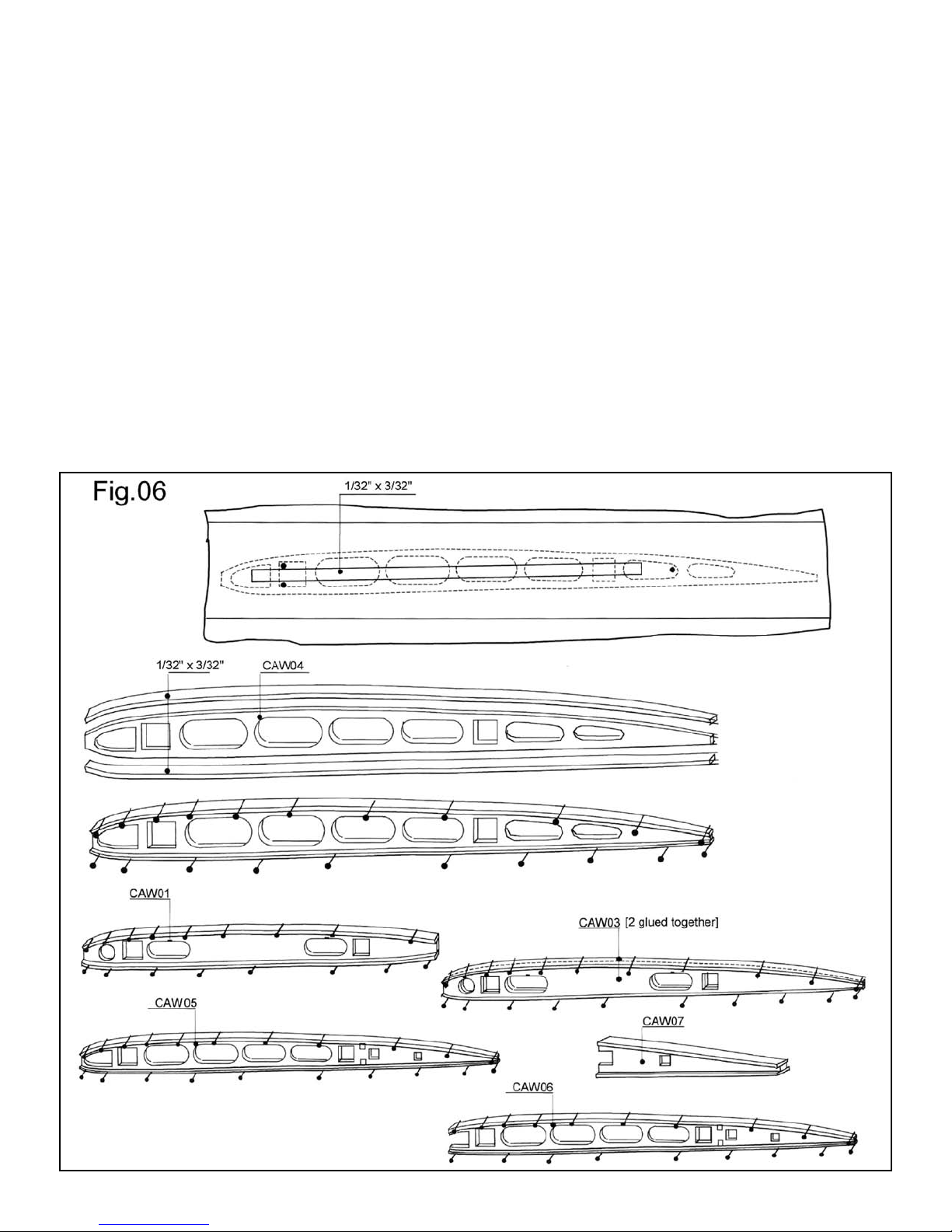

STAGE 2: BUILDING THE WINGS

The upper and lower wings are built in essentially the same manner,

referring primarily to full-size Plan 03. The primary differences are

Parts List For Stage 2

CA

W01

Ribs 2 laser-cut plywood 3/64" thick

CAW02 Ribs 28 laser-cut plywood 3/64" thick

CAW03 Ribs 8 laser-cut plywood 3/64" thick

CAW04 Ribs 4 laser-cut plywood 3/64" thick

CAW05 Ribs 16 laser-cut plywood 3/64" thick

Ribs 4 laser-cut plywood 3/64" thick

W06

CA

Ribs

W07

CA

Nose ribs 50 laser-cut plywood 3/64" thick

W08

CA

CAW18 Wingtips 4 Britannia castings

op center trailing edge 1 Britannia casting

T

W19

CA

4 laser-cut plywood 3/64" thick

the center trailing edges and that the lower wing will be cut in two

and rejoined to create its correct dihedral angle.

CA

W20

Compression bars 15 Britannia castings

CAW21a/b

CAW22 Aileron horns 4 Britannia castings

CAW23

CAW24 Aileron pulleys 4 Britannia castings

CA

CA

CA

W042 Turnbuckles 36 Britannia castings

WP3603

7

Aileron hinges 12 each Britannia castings

Aileron cable anchors

W25

W38

W39

ession bars w/ey

Compr

wer wing joint

ont lo

r

F

Rear lower wing joint 1 Britannia casting

Rib caps

4 Britannia castings

es

ritannia castings

B

6

ritannia casting

B

1

1/32" x 3/32" basswood strips

Parts List For Stage 2 (continued)

WP3671 Leading edges 5/32" x 3/16" basswood strips

WP3648

WP3631 Rear spars 1/8" x 1/8" basswood strips

WP3625

WP3618 Rear aileron spars 1/16" x 1/16" basswood strips

WP1205 Rigging cable Metal-gray thread

WP161K

WP0976 Trailing edge bands 1/4" Adhesive copper tape

Wing ribs; rib caps:

After cutting loose all of the above referenced ribs, lightly sand them to remove surface char from the laser, then sort them by

number.

To facilitate making the cap strips overlap

ribs CAW02, 04, 05, 06 and 07 equally to

each side, make a simple jig by gluing a 2

1/2" length of the 1/32" x 3/32" rib cap

stock to a scrap block of soft wood, as in

Fig.06. Pin the rib to be glued onto the

strip through some of the cutouts, apply

carpenter’s wood glue to the rib edge and

use T-pins against the rib cap to clamp the

cap to the rib. Repeat for the opposite edge.

Note the photograph “Rib Pins”. Use of a

hair drier will speed up the process. The

“waist” on ribs CAW05 and CAW06 make

them particularly fragile, requiring extra

care when gluing on their cap strips.

The 8 parts CAW03 are laminated in pairs

to make 4 double-thick ribs befor

strips are glued on, and the 2 ribs CAW01

are glued flush to one edge of the cap strip

to make left and right capped ribs. Fig.06

shows the left hand one (looking from back

to front of the finished airplane). Therefore,

instead of using the jig, lay a piece of waxed

paper on the scrap wood to avoid gluing

those ribs to it.

Inserting the spars; leading edges;

nose ribs:

Slight variation in the provided wood strips

is to be expected, ther

spars, including the ailer

ribs and sand down the spars as needed to

attain a snug fit.

eferring to P

R

upper wing ribs, except CAW 06, 07 and

08 onto the fr

ear (1/8" squar

r

that the flush sides of ribs CAW01 face the

center of the wing. O

, glue the ribs into place using a small

up

brush and thinned wood glue.

nce the glue is dr

O

length and taper the ends outboard of the

first rib at each end to fit the narrower slot

in ribs CA

Front spars 5/32" x 5/32" basswood strips

Front aileron spars 3/32" x 3/32" basswood strips

ing braces

W

ing trailing edges 3/64" brass rod

W

nsert the aileron spars (3/32" and 1/16"

I

square stock) through the holes in ribs

W05 and 06, then glue and cut to

CA

length accor

rib CAW07, being careful to leave a gap

een it and the next inboard rib. This

betw

w the ailerons to move when they

will allo

later are cut free. Locate the wing angle

braces on P

e lumber and glue into place.

squar

Dry fit the leading edge lumber (5/32" x

3/16" x 24") against the front edge of the

ribs to check for uniform fit and to make

sure that the nose ribs (CAW08) will fit

snugly between the front spar and the leading edge. If necessary, use a long strip of

sandpaper, affixed to the same length

straight, flat piece of wood, to lightly sand

the leading edges of the ribs.

Trim spar ends and notch them, using a

ound needle file, to fit the wingtips

r

e cap

e test fit all of the

efor

on spars, to the

lan 03.1, slide all of the

ont (5/32" squar

e stock) spars. Make sure

nce ev

, cut the front spar to

y

W06 and glue those ribs in place.

e stock) and

ything is lined

er

CAW18. You also will need to file a notch

in the front spar rib CAW05 meets it. File

and bend the wing tip if needed so that all

ends make contact with the spars and ribs.

Glue the wing tip in place using CA and

repeat for the other wing tip.

Next, hold the 3/16" side of the leading

edge lumber in place to determine its proper length and wher

er the end of the wing tip casting – see

v

o

Fig.10. Before gluing the leading edge to

the ribs, locate the ailer

W24) on P

(CA

priate holes in the leading edge of the front

lue the leading edge in place and

. G

spar

taper the ends do

the last rib the leading edge attaches to.

lue the leading edge in place, 3/16" edge

G

against the ribs and car

rounded profile, as in the ribs cross-sections

lan 03. Car

on P

will speed up the pr

ribs in place. Now is the time to varnish

and tint the wing assembly

steps will expose unv

can be touched up with a brush.

, build the lo

inally

F

stage of completion and saw apart per

Plan 03.2.

ding to the plan. Attach aileron

lan T.03. Cut them from 1/16"

Rib Pins

e to cut notches to fit

on pulleys

lan 03 and drill the appr

wn to the wingtips fr

efully sand it to a

eful use of a block plane

ocess. G

w

lue the nose

. Although later

arnished edges, these

er wing to the same

om

Compression bars; pulleys;

trailing edge; visibility cutout;

rigging:

Glue the aileron pulleys in place using

CA glue.

Drill #75 size holes through both ends of

the compression bars (CAW20 and 25)

where the round flange meets the angle

bracket – see Fig.12 detail. Next, locate and

glue the compression bars in place, hanging

bars CAW20 from the top and attaching

CAW25 from the bottom, so the eyes point

down from the upper wing. All of the

compression bars are hung from the top in

the lower wing, which positions the eyes on

CAW25 pointing up. It is important that

the outboard upper and lower parts

CAW25 line up on the two wings, because

this is where the wing struts will attach.

To frame the visibility cutout in the upper

wing, first make sure that tabs that overlap

the spars of the center compr

filed down to a maximum of 1/32" thick.

Next cut four 9/32" lengths of 1/32" x

3/32" wood strip and glue these supports to

the front and rear spars edges, against ribs

CAW01, so that they extend from the outer

spar edges into the center space. Cut six

roughly 3/4" lengths of the same wood

and plank three of them onto each pair

of supports.

The easiest way to rig the wing bracing

o-

wires is to run a continuous length of

WP1205 thread from one end of the wing

to the other and then repeat the process to

create the X-pattern on Plan 03. Each time

you come to the front end of a compression

bar, slip a turnbuckle (W042) onto the

thread, through both holes, before running

the thread through the holes you drilled in

the compression bars. After stringing the

thread all the way to the opposite end of

the wing, secure the end, then gently

tighten the thread, working backward to

wher

e you started. At each front end of a

compression bar, slide a turnbuckle up to

the bar then secure the thread and turnbuckle with CA glue. A

compression bar secure the thread with CA

ession bar ar

t each rear end of a

e

8

glue. The procedure basically is the same

for the lo

rigged separately.

Although this rigging technique provides

generally acceptable results, the more

demanding modeler might pr

the thread through each turnbuckle eye in

lieu of using a continuous run.

The casting for the upper wing’s center

trailing edge (CAW19) requires some

adjustment for a good fit. C

at the ends so that they nestle between the

cap strips where they meet ribs CAW02.

Y

round to achieve the best fit. Sand the ends

of ribs CAW01 if needed, then glue curved

section of CAW19 to the end of the center

ribs so that 3/64" of the casting extends

beyond the trailing ends of ribs CAW02.

This provides an end seat for the 3/64"

brass rod which is used to make the wing’s

trailing edge. See Fig.11. Cut the brass rod

to length before attaching it with CA glue,

and leave a gap between the wing and the

wer wing, except each half is

ou might hav

e to file the pins out of

efer to knot

ut the long pins

ailerons – Plan 03. Finish off the trailing

y wrapping the joints with 1/2"

edge b

lengths of copper tape, cut to the width of

the rib cap strips. Use four 1/4" long copper strips to co

joints between ribs CAW01 and the center

trailing edge.

Carefully separate the ailerons from the

wings b

the rear wing spar and the front aileron

. Continue the cut through the wing tip

spar

casting and sand as needed. Referring to

Plan 03-1 and Fig.13 attach the hinges

W21 a&b. The gudgeon half (has hole)

CA

attaches to the r

half (has pin) attaches to the fr

spar. In order to lock the aileron to the

wing, arrange the hinges so the pintles of

the middle and outside hinges face the aircraft center line and that of the inside

hinges face toward the wingtips.

Locate the aileron horns CAW22 and the

aileron cable anchors CAW23 on the

ailerons as indicated in the drawings. The

ver the top and bottom

y sawing through the ribs between

ear wing spar and the pintle

ont aileron

horns angle forward and are placed atop the

upper wing and belo

Before gluing in place, notch the rib cap

where each part goes so that the vertical tab

snugs up against its laser-cut rib

w the bottom wing.

.

Joining the lower wing halves:

Create the lower wing dihedral by tapering

the bottom ends of the front and rear spars

so that when they are rejoined by parts

W38 and CAW39 they will lie flat with-

CA

in the cast joints and the underside of the

outermost ribs(CAW06) will be elevated

e the work surface. Reference

25/32" abo

Plan 03.3. The easiest way to ensure both

sides come out the same is to cut blocks of

the right thickness to hold up the wing

ends while you gently push down on the

center joints. Before gluing this together,

check that the space between the inside flats

of the innermost ribs (CAW03) is 1

13/16".

v

9

Loading...

Loading...