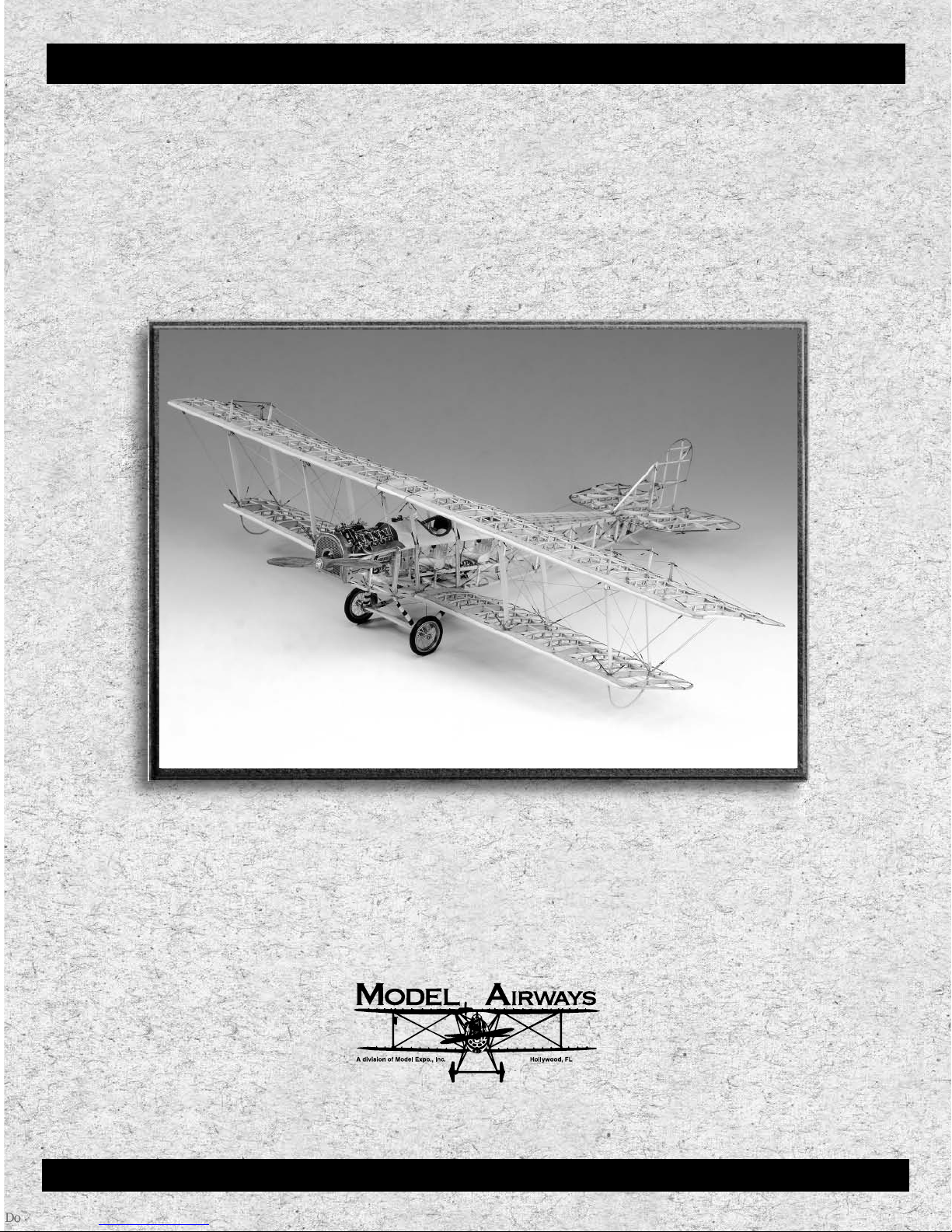

Model Airways CURTISS JN-4D JENNY, MA1010 Instruction Manual

INSTRUCTION MANUAL

MODELING THE

MODELING THE

C

C

URTISS

URTISS

JN-4D J

JN-4D J

✦

✦

1917

1917

✦

✦

ENNY

ENNY

PREPARED BY BEN LANKFORD

FUSELAGE LENGTH: 20-1/2" (521 mm)

Technical Characteristics

SCALE: 3/4" = 1' 0" (1:16)

WINGSPAN: 32-1/2" (826 mm)

Manufactured by Model Airways

Division of Model Expo, Inc., Hollywood, FL

A

http://www

Model Airways Kit No. MA1010

.modelexpo-online.com

HISTORY

The

Jenny

biplane was introduced in 1916 and manufactured by

the Curtiss Aeroplane and Motor Corporation in Hammondsport,

Jenny

New York. The

a combat aircraft in World War I, but it became an important

trainer for pilots of the United States Air Service. The aircraft

became more famous after the war, being used as a barnstormer

and mail carrier. More than 6000 aircraft were built. The most

produced and most popular model was the JN-4D. More than

3000 were built. Some 1200 were produced in Canada and known

as Canuck JN-4CAN. About 1000 aircraft, mostly JN-4D’s, were

built by other US firms such as Springfield Aircraft Corporation,

St. Louis Aircraft Corporation, and Liberty Iron Works.

The

Jenny

has a wingspan of 43 feet 7 inches and weighs 1430

pounds. She flies at a speed of 75 mph, has an endurance of 2.5

hours, climbs to 2000 feet in ten minutes, and the service ceiling

is 11,000 feet. The aircraft is manned by a crew of two and is

powered by a Curtiss OX-5 in-line V8, water-cooled engine.

Thousands of these 90 HP engines, first manufactured in 1910,

were used in the

Besides the JN-4D model, there were other minor variations in

the models JN-1, 2, 3, 4, and models JN-4A, 4B, 4C, JN-4D2, and

JN-6H. Some had engines mounted with no engine-prop down

thrust, some had wings with less stagger (10" to 12" as opposed

to 16" on JN-4D). Other variations included a different stabilizer

shape, more dihedral in the wings (up to 4 degrees), and a longer

lower wing length. All in all, however, all models looked pretty

much the same.

The prototype JN-4D had ailerons on both wings, but the production models eliminated the lower wing ailerons. Earlier

name was coined from the JN series. Not

Jenny

and other aircraft.

aircraft used a wheel for controlling the rudder, but the D model

used sticks. Quite a few

flying today. Restored aircraft can be found in museums around

the country, including the Smithsonian Institution’s Garber

Preservation Facility) in Suitland, Maryland outside Washington,

DC; College Park Aviation Museum in College Park, Maryland;

Curtiss Museum in Hammondsport, New York; and the History

and Traditions Museum at Lackland Air Force Base in San

Antonio, Texas, to name a few.

To see a

a Jenny

Association) Aviation Foundation’s Paul Harvey Audio-Video

Center, in Oshkosh, Wisconsin. It has a good history and vintage

footage of the

The video highlights Ken Hyde’s restoration of a

scenes of its initial flights. The video has some wonderful color

photography of several restored

These scenes are from a 1989 reunion of these historic aircraft

held in Oshkosh. Lots of different color schemes and markings.

Several photos of a

throughout these instructions. Refer to the credits below for

more information about Ken Hyde himself.

For more flight scenes and close-ups, look for the 1975 movie of

The Great Waldo Pepper

outstanding video available entitled

To T h e A i r, V olume III

training in

including Minneola Field, NY, and Kelly Field in Texas. The

video was copyrighted in 1993 by Aerofilm.

Jenny

in action, an outstanding video is

. This is a 1989 film by the EAA (Experimental Aircraft

Jenny

Jenny’s

Jenny’s

as a military trainer and a barnstormer.

Jenny

. This video has early film shots of pilots

. The film was shot at various locations,

have been restored and are still

It’s Gotta Be

Jenny

with

Jenny

’s close up and in flight.

restored by Ken Hyde are shown

with Robert Redford. There is also an

World W ar I: America Tak e s

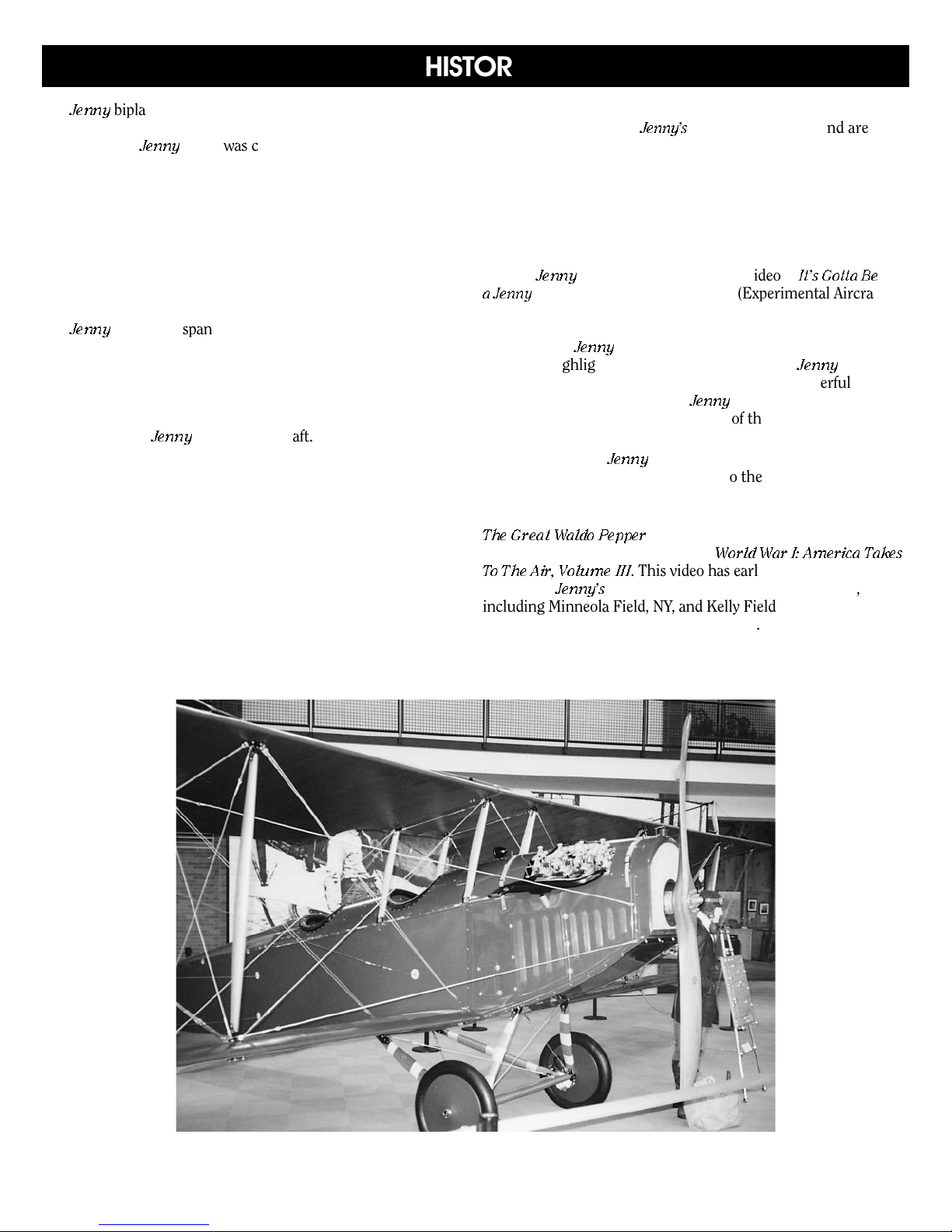

Ken Hyde’s restored Jenny at the Maryland Museum

2

TABLE OF CONTENTS

Technical Characteristics

History

Introduction and Credits

Before You Begin

Necessary Construction Tools

Working with the Plans and Parts

Painting and Staining the Model

Stage 1: Building the Wings

Stage 2: Building Vertical and Horizontal Stabilizers,

Stage 3: Building the Basic Fuselage

........................................................................................2

....................................................................5

1. The Plans ...............................................................................5

2. Parts.......................................................................................5

3. Kit Lumber.............................................................................6

4. Britannia Metal Parts..............................................................6

5. Photo-Etched Parts................................................................6

6. Rigging Cord ........................................................................6

7. Setting Up the Plans ..............................................................6

8. Part Identification and Readiness .........................................6

9. Bending Wood Strips.............................................................6

1. Preparing the Wing Ribs........................................................7

2. Setting Up the Wing Spars ....................................................7

3. Installing the Wing Ribs..........................................................8

4. Installing the Beam Webs and Web Blocks...........................8

5. Installing the Wing Tips, Trailing Edge,

and Upper Beam Flanges....................................................9

6. Installing the Small Wing Stringers .........................................9

7. Adding Miscellaneous Stiffeners

and Lower Wing Walk..........................................................10

8. Installing the Leading Edge Cover Sheet ...........................10

9. Installing the Cap Strips.......................................................10

10. Installing Wing Strut, Kingpost, and Wing Skid

Support Pads and Fittings ...................................................11

11. Building and Installing the Upper Wing Ailerons..................11

12. Installing the Aileron Control Sheaves.................................11

13. Installing the Drag Wires......................................................12

14. Installing the Fake Hinge Rods

in the Upper and L

15. Building and Installing the Lower Wing Skids .......................12

16. Building , Installing, and Rigging the Kingposts...................12

Building the Upper Wing Center Section

17.

18. Rounding the Leading Edge and Wing Tips.......................13

19. Building the Wing Struts .......................................................13

Rudder, and Elevator

1. Building the Vertical Stabilizer..............................................14

2. Building the Rudder ............................................................14

3. Building the Horizontal Stabilizer..........................................15

4. Building & Installing the Elevator .........................................15

5. Mounting the Vertical Stabilizer...........................................16

Building the F

1.

Building the Sides of the F

2.

3. Placing the Sides in the Building Jig....................................17

Building and Installing the Horizontal Struts

4.

ongeron Splices

L

5.

6. Building & Installing the Tailpost ..........................................18

Installing the F

7.

Plates and Engine Bearers ..................................................18

ower Wings............................................12

uselage Jig

................................................................

ront and Side Nose

............................................Cover

......................................................4

............................................5

.......................................5

.......................................6

................................................7

............................

..........................................14

.............................16

....................................................16

uselage

......................................

.........................17

13

17

18

Stage 3: Building the Basic Fuselage (continued)

8. Installing the Cockpit Floor Board Supports

and Floor Boards ................................................................19

9. Installing the Longitudinal Side Seat Rails............................19

10. Installing Forward and Rear Cockpit Instrument

Panels, and Shelf Behind Rear Cockpit ..............................19

11. Installing the Fuselage Strut Clips........................................20

12. Installing Cross Brace Wires.................................................21

13. Building and Installing the Turtleback..................................21

14. Installing the Step Plate.......................................................21

Stage 4: Installing Cockpit Controls and Seats,

1. Installing the Joysticks and Other Flight

2. Building and Installing the Seat Supports,

3. Rigging More Fuselage Cross Brace Wires .........................23

Stage 5: Building and Installing the OX-5 Engine,

1. Assembly and Installation of the Fuel Tank .........................24

2. Building the OX-5 Engine ....................................................25

3. Installing the Engine and Radiator......................................28

4. Installing Engine Piping, Tubing,

5. Rigging Final Fuselage Cross Brace Wires ..........................30

6. Building and Installing the Prop...........................................30

Stage 6: Building and Installing the Landing Gear

1. Installing the Tail Skid and Supports.....................................30

2. Building and Installing the Landing Gear............................31

Stage 7: Installing the Cockpit Cowl, Wings,

1. Installing the Cockpit Cowl, Windshields,

2.

3. Rigging the Rudder and Elevator Control Wires .................34

4. Installing and Rigging the Upper Wing

5.

6. Installing the Interplane Wing Struts

7. Rigging the Interplane Strut Cross Brace Wires,

8. Rigging the Aileron Control Wires........................................37

Finishing Touches

Bibliography

Photos of Model Air

and Additional Rigging

Control Fittings ....................................................................22

Seats, and Rail Cross Strut...................................................23

Radiator, Fuel Tank,and Prop, and Final

Rigging of Cross Brace Wires

and Control Linkages..........................................................29

and Tail Skid

Stabilizers, Rudder, and Elevator,

and Completing the Rigging

and Cockpit Edging ...........................................................33

Installing the V

Rudder

Center Section and Struts

Installing the L

and Upper Wings ................................................................35

Flying Wires, Landing Wires, Drag Wires, and

Kingpost Wires

ertical and Horizontal Stabilizers

, and Elevator..........................................................33

ower Wings

..........................................................................38

A Division of Model Expo, Inc., Hollywood, FL

.........................................................30

..................................................

...................................................

.....................................................................

.................................................................37

ways’

Jenny

©2002 Model Airways, Inc.

.....................................22

...........................24

..........................33

,

......................................

34

35

36

39

3

C

URTISS

C

URTISS

INTRODUCTION

MODELING THE

MODELING THE

JN-4D J

JN-4D J

ENNY

ENNY

✦

✦

1917

1917

PLANS AND INSTRUCTIONS BY BEN LANKFORD, VIENNA, VA

PROTOTYPE MODEL BY BOB WERNER, HOLLYWOOD, FL

Model Airways developed its

The design is based on factory drawings of

along with historical photographs, and photographs of

restored

are still flying today. Because of varying dates on many of the

references, and knowing that changes were made over a period of time, the design depicted by Model Air

represent any one particular aircraft. Most modifications

found in the various references were minor detail changes,

so the overall design is representative of a typical

Many thanks to the subscribers of the

E-mail List

the aircraft. The Internet home page address for the list is

http://www.pease1.sr.unh.edu/1/index.html, and the site is

Jenny’s

in museums and private owned aircraft that

for their assistance with various details of

Jenny

kit between 1999 and 2001.

Jenny

ways may not

World War I Model

aircraft,

Jenny

.

✦

✦

maintained by Allan Wright. You will find some great information and a gallery of some fine WWI models on these pages.

The home page provides instructions for joining the mailing

list if you are interested.

Thanks also to Ken Hyde from Warrenton, VA, an expert builder

and restorer of full-size antique aircraft, including the

Ken answer

oping the kit design. Ken, who is 61 years of age at this writing,

is a former American Airlines captain and Boeing 727 pilot.

Ken’s interest in antique planes obviously came from his father,

John “Captain Johnny” Hyde, a barnstormer in the early 1900s.

Ken’s latest project is a replica of the Wright 1903 Flyer, which

he intends to fly at Kitty Hawk at 10:35 a.m., December 17,

2003, as the Wright brothers did 100 years earlier.

ed many questions that had me puzzled while devel-

Jenny

.

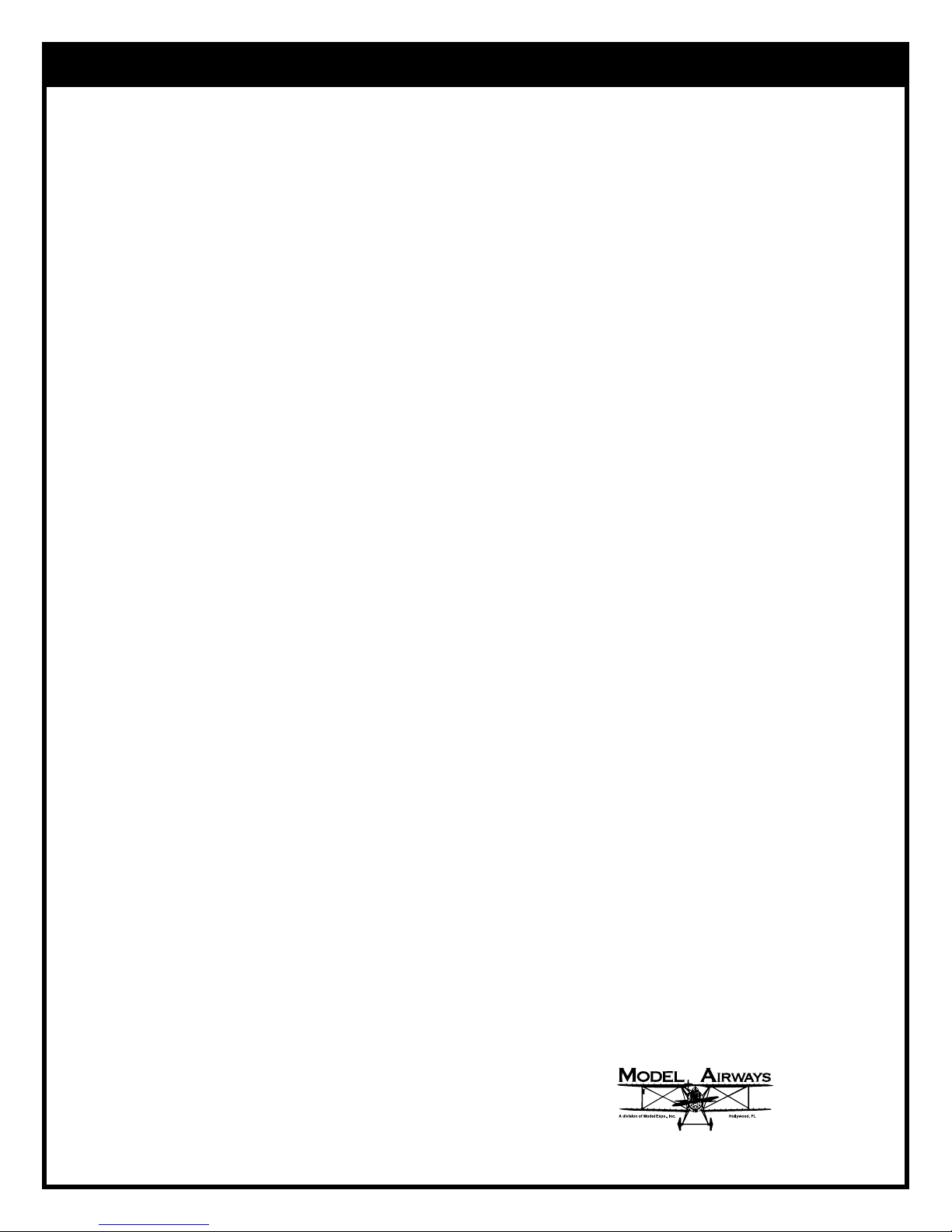

Clockwise from upper left: Interplane Wing Strut Fitting, Carburetor, and Tail Surface

and Rigging, as they appear on restored examples of the Jenny airplane

4

Before You Begin

The

Curtiss JN-4D Jenny

is an interesting

aircraft and makes a splendid model. The

kit is intended as a str

uctural model without any fabric covering. Most every detail of

the real aircraft has been included as model

scale permits. While your model structure

will be glued together, the original real aircraft had little glue if any. Most of the wooden structure was joined with many small

wood screws and metal clips. However,

some of the restored

Jenny’s

now use glue

in addition to the screws, since better glue

is now available.

Britannia, photo-etched metal, and wooden

fittings eliminate creating many parts from

scratch. However, some require final finishing before they are suitable for the model.

This is especially true for the britannia castings and will be discussed later.

Always complete one construction stage

before moving to the next. When things

go awry, consider doing them over.

Necessary Construction Tools

The following tools and supplies are recommended for the construction process.

Modelers who have built before may have

their own favorites.

A. Knives and Saws

1. Hobby knife with No. 11 blades

2. Razor saw or jeweler’s saw

B. Files

Set of needle files

C. Clamps and Pins

1. Alligator clips (some with and some

without teeth)

2. Wooden clothespins (craft shops have

small versions of the design)

Rubber bands

3.

4. Package of straight pins or florist pins

with plastic heads

Boring T

D.

1. Set of miniature drills

2. Pin vise

Miscellaneous

E.

1.

2. Tweezers (a few)

3.

4. Miniature pliers

5.

F. Sandpaper

Fine and medium grit garnet or aluminum

oxide sandpaper (#100 to #220), and

#400 wet-or-dry paper for fittings and

final wood sanding

Glue

G.

White glue, Carpenter’s wood glue (yellow in color), and Cyanoacrylate glue

(super glue) can be used for most of the

ools

ack hammer

T

Small fine-pointed scissors

a. small round

b. flat nose

Wire cutters (for cutting steel and

brass or copper wire, rod, and strip

metal)

model. Five-minute epoxy provides extra

strength for gluing fittings. The best super

glue for most applications is a medium

viscosity gap-filling type. The watery thin

type is recommended to fill a narrow

crack by capillary action.

H. Power Tools

While not really necessary, one power

tool would be advantageous for this kit.

The kit contains several sizes of steel

music wire that is extremely hard. A

Dremel or other rotary tool fitted with a

small fiberglass-reinforced cut-off wheel

is ideal for cutting off and flattening the

ends of steel music wire.

I. Building Board

A soft but stiff board, such as acoustic

ceiling tile or insulation wallboard, to easily

take straight pins for holding parts during

assembly. This soft board should be

nailed or glued to a hard board so it will be

flat. You can use a table, but a portable

board is good for turning it around to make

the work easier.

Working with the Plans & Parts

Before starting the model, carefully examine the kit and study the plans. First, determine if all the listed parts are present.

Handling them will produce a better understanding of the kit’s requirements. Try to

visualize how every piece will look on the

completed model. Also, determine the

building sequence – what must be done

first – ahead of time. The instructions will

help, but a thorough knowledge of the plans

at the outset is essential. Be especially

aware of when to rig the many brace wires

in the fuselage. There are a lot of parts that

must be added inside the fuselage. The

brace wires would get in the way if rigged

too soon.

To avoid losing small fittings and hardware,

sort them into labeled boxes or compartments.

These should have lids to keep out dirt.

1.

The Plans

Six plan sheets are provided:

1. Laser-Cut Wood Patterns and

Fitting Sketches

Assembly

Upper and Lower W

2.

and Details

3. Basic Fuselage Assembly and Details

4. Tail Surfaces and Landing Gear

Assembly and Details

OX-5 Engine and Cockpit Controls

5.

Assembly and Details

Component

6.

Details

Model Airways’

Assembly and Rigging

Jenny

to a scale of 3/4" = 1' 0" (1:16). Each sheet is

drawn to that scale except areas enlarged to

show detail. Most of the enlarged details are

double scale, and designated 2X (1-1/2" =

1'0"). Most dimensions can be lifted directly

off the plans by using draftsman dividers or

a “tick” strip (piece of paper such as an

adding machine roll). Lay the paper strip

ing

kit is manufactured

over the plan, carefully mark the item’s

length with a sharp pencil, then transfer the

marks to the wood.

Because these are model building plans,

actual measurements were converted to

model inches. For comparison, 1/16" on the

model is equal to 1" on the real aircraft, 1/8"

is 2", and so on. The table below compares

full-size dimensions with scale model inches

and millimeters:

SCALE CONVERSION TABLE

Full Size Model Scale Model Scale

Inches Inches Millimeters

1/4" 1/64" 0.40mm

1/2" 1/32" 0.79mm

3/4" 3/64" 1.19mm

1" 1/16" 1.59mm

1-1/4" 5/64" 1.98mm

1-1/2" 3/32" 2.38mm

1-3/4" 7/64" 2.78mm

2" 1/8" 3.17mm

2-1/4" 9/64" 3.57mm

2-1/2" 5/32" 3.97mm

2-3/4" 11/64" 4.37mm

3" 3/16" 4.76mm

6" 3/8" 9.53mm

9" 9/16" 14.29mm

12" 3/4" 19.05mm

2. Parts

Laser-cut wood parts, photo-etched parts, and

britannia castings are designated by a letternumber (such as

W1, F4, R2

sketches. A part noted such as

would indicate a right or left hand part. You

may also see some similar parts labeled, for

example,

R3A

and

R3B

generally in the following letter categories:

C

– CONTROLS: AILERONS, RUDDER,

ELEVATOR

E

– ENGINE, ENGINE PIPING, ENGINE

CONTROLS, RADIATOR, FUEL

TANK, PROPELLER

F

– FUSELAGE

L

– LANDING GEAR, T

RIGGING FITTINGS COMMON TO

R

–

VARIOUS LOCATIONS

ABILIZERS, RUDDER, ELEVATOR

S

– ST

WINGS

W

–

Wood strips and sheets, rod, wire, tubing,

rigging cord, and similar parts which must

be cut from longer pieces have no letter designation. Rather, only the dimension of these

items is shown on the plans.

A parts list is included in each of the construction stages, noting the parts required

for that particular stage. A

ts List

Par

(separate fr

is provided that lists the quantities included

in the kit. For wood strips, sheets, r

tubing, and rigging, one or several pieces ar

ovided in the kit as noted on the master

pr

packaging par

ts list. Each of these have been

assigned a Model Expo (Model Airways) WP

stock part number. These parts must be cut

to length or shape according to the dimensions shown on the plan.

) on plans and

L2R

or

L2L

. Parts are classified

AIL SKID

Master Packaging

om these instructions)

e,

od, wir

e

5

3. Kit Lumber

Strips and sheets of solid basswood or birch

plywood are supplied in the kit. Sort the

wood in the kit by thickness to save time.

After selecting and cutting what you need,

return the remaining stock to the proper

thickness and wood-type pile. Don’t worry

about using a piece for one item intended for

another. Model Airways supplies enough

extra wood to complete the model before

unning out.

r

4. Britannia Metal Parts

These parts will require final finishing before

mounting on the model. First, remove mold

joint flash with a #11 hobby blade, then file

or sand with fine sandpaper. Clean out any

holes using a drill bit or reamer. Some of the

smaller holes may not be completely formed.

Also, if another part must fit in the hole,

ream the hole if necessary for the parts to fit.

Wash fittings in dishwashing liquid and

warm water to remove traces of mold release

agent and the body oils your fingers deposit.

Allow to dry thoroughly.

5. Photo-Etched Parts

Cut the sprues off the parts with a sharp

hobby blade on a hardwood backing, or use a

sprue cutter. File any remaining sprue to

smooth out the part. Some photo-etched

parts must be bent to conform to the shape

shown on the plans, and lengths or configuration may be modified for the same part to

fit different locations. Bend parts using flat

nose or needle nose pliers. Don’t try bending

with your fingers.

6. Rigging Cord

On the real aircraft, the flying and landing

wire rigging and cross brace wires are 1/8"or 5/32"-diameter stranded steel wire. For

the kit, however, gray nylon cord is provided to make it easier to rig. All of the cord

should be beeswaxed to protect it and cut

down fuzz.

7. Setting Up the Plans

Build the wings, vertical and horizontal stabilizers, elevator, and fuselage sides directly

on the plan. Place the plan on your building

board and cover the plan with waxed paper

or plastic wrap. Be careful applying glue,

especially super glue. Although the waxed

paper or plastic wrap pr

what, you could accidentally glue the pr

tive sheet to the model par

otects the plan some-

otec-

ts, or even to the

plan itself. Plastic wrap is really a bear to

remove if it is accidentally glued to the

model with super glue. Use small applicators

such as a commercial Microbrush or toothpick for applying the glue. You don’t need a

lot of glue for the aircraft’s fragile parts.

8. Part Identification and Readiness

All the laser-cut wood, britannia castings,

and photo-etched copper and aluminum

parts can be identified by the patterns and

sketches shown on Plan Sheet 1.

Before starting each stage, have all the parts

required for the stage, such as laser-cut

parts, britannia castings, photo-etched parts,

stripwood, rod, and rigging, identified and

ready to use. Sand wood parts as required

to get rid of any fuzziness and prepare the

castings and photo-etched parts as noted

in Paragraph 4 and 5 above.

9. Bending Wood Strips

During the process of building the model,

you will be advised to heat-bend some wood,

such as fuselage longerons, wing tips, and

wing skids, to conform to a specific curve. A

good way to do this is to use an aluminum

tip with a flat end filed to a 45-degree angle.

Fit the tip in a 20- to 30-watt soldering iron.

First, soak the wood in cold water for 5 or 10

minutes. Remove the wood and let it sit and

dry out a bit for another 5 minutes. It won’t

completely dry out. Then take the soldering

iron an press on the wood, moving along

bending the wood to shape as you go. If

necessary, press over a form shaped to the

curve. The heat applied will easily bend the

wood, and the formed shape will remain after

the wood is dry.

Painting & Staining the Model

The

Jenny

model need not be painted or finished at all. However, it is recommended that

you stain the wood parts and seal the britannia castings for protection. A light tan stain

on all wooden parts will help to make the

entire structure uniform in color.

Some parts could be painted, such as the

radiator and the fuselage cockpit cowl. This

would add a nice contrast to the otherwise

unpainted model. Since many color schemes

were used on various models, you will need

to do a little research on your own for proper

colors. You could also paint fittings such as

wing strut fittings and fuselage clips copper

color or black for contrast. If black is your

choice, consider using Blacken-It, a chemical

rather than paint. Steel rod represents steel

tubing on the real aircraft. These can be left

as is or painted a light gray color. Cast cockpit fittings can also be painted gray or just

varnished.

Sanding and cleaning:

faces with 220-grit dry sandpaper, followed

by 400-grit, and wipe off all dust thoroughly.

A tack rag would be helpful.

Brushing and stains:

brush can be used to apply stain to the parts.

Model Shipways or Minwax brand stains are

excellent for staining. For the castings, a

clear flat finish is suggested. This finish

could also be applied over the stained wood

parts as added protection.

Painting:

If parts are to be painted, use

a primer first, then paint. Any of the model

paints are satisfactory. For this model,

flat paints will pr

gloss paints.

Sand all wood sur-

A soft artist quality

obably look better than

View of

wing

uts

str

on

Ken

s

Hyde’

restored

Jenny

6

Plan Sheet 2 shows all the details for con

structing the wings, wing struts, and rigging

drag wires within the wings. In addition,

refer to Sheet 6 and Stage 7 for rigging the

kingposts on top of the upper wing that can

be done during this stage if desir

ed. The

following parts are required for this stage:

Laser-Cut Wood Parts

Upper wing ribs – 2 of W1

Upper and lower wing ribs – 4 of W2

Upper and lower wing ribs – 22 of W3

Upper and lower wing ribs – 12 of W4

Upper wing ribs – 10 of W5

Upper wing ribs – 6 of W6

Upper and lower wing ribs – 4 of W7

Lower wing ribs – 2 of W8

Lower wing ribs – 2 of W9

Upper wing ribs – 2 of W10

Lower wing ribs – 2 of W11

Upper wing ribs – 2 of W12

Aileron ribs – 4 of W13

Aileron ribs – 16 of W14

Center section ribs – 1 of W15

Center section ribs – 2 of W16

Center section wing struts – 4 of W17

Interplane wing struts – 8 of W18

Kingposts on upper wing – 4 of W19

Lower wing handhold blocks – 2 of W23

Wing building jig shims – 20 of W24

Britannia Castings

Aileron control horns – 4 of C1

Aileron control cable sheaves – 4 of C3

Aileron control cable sheave bodies –

4 of C4

Wing strut end fittings – 20 of W20

Wing skid end fittings – 4 of W21

Photo-Etched Copper Parts

Single eye rig fittings for drag wires

and kingpost wires – 128 of R1

Double eye rig fittings for aileron

control horn brace wires – 6 of R2

Drag wire and kingpost wire turnbuckles –

54 of R3A(short)

Wing wire rigging plates at struts –

20 of W22

Wood Strips

Rib vertical web stiffeners and cap strips –

0.020" x 1/16"

Wing strut and kingpost support pads –

0.020" x 1/8"

Stringers and miscellaneous wing stiffeners – 1/32" x 1/32" and 3/64" x 3/64"

Front beam flanges, and shims for wing

building jig setup – 1/32" x 3/32"

Rear beam flanges – 1/32" x 1/8"

Front beam webs, and web blocks at

compression ribs – 1/32" x 5/32"

Support stringers for lower wing walk and

wing tip stiffener – 3/64" x 3/64"

Rear beam webs, and web blocks at

compression ribs – 3/64" x 1/8"

Wing tips – 1/16" x 3/32"

Aileron leading edges – 1/16" x 5/32"

Upper wing rear web in way of ailerons –

5/64" x 1/8"

Wing skids – 3/32" x 3/32" flexible

beech wood

(cut to length as required)

STAGE 1:

Front beam web between first two ribs

inboard and center section – 3/32" x

5/32"

Leading edge – 3/32" x 3/16"

Rear beam webs between first two ribs

inboard and center section – 1/8" x 1/8"

Blocks (to be carved) at leading edge

wing tips and handholds – 3/16" x 5/16"

W

ood Sheet

Leading edge cover sheet and lower

wing walk – 1/64" plywood

Steel Rod

Wing trailing edge and struts between

kingposts – 1/32"-diameter

Fake wing hinges at center wing section

and fuselage – 1/16"-diameter

Brass Rod

Pins for kingposts – 1/32"-diameter

Brass Strip

Aileron fake hinges – 1/64" x 1/16"

Self-Adhesive Copper Tape

BUILDING THE WINGS

(cut to length as required)

(cut to length as required)

(cut to length as required)

(cut to length as required)

(cut to shape as required)

Bands securing trailing edge to ribs

and stiffeners

Rigging Cord

Drag wires in wings and kingpost wires –

0.010"-diameter gray nylon cord

Wrapping cord for splices – 0.008"

diameter black nylon cord

(cut to length as required)

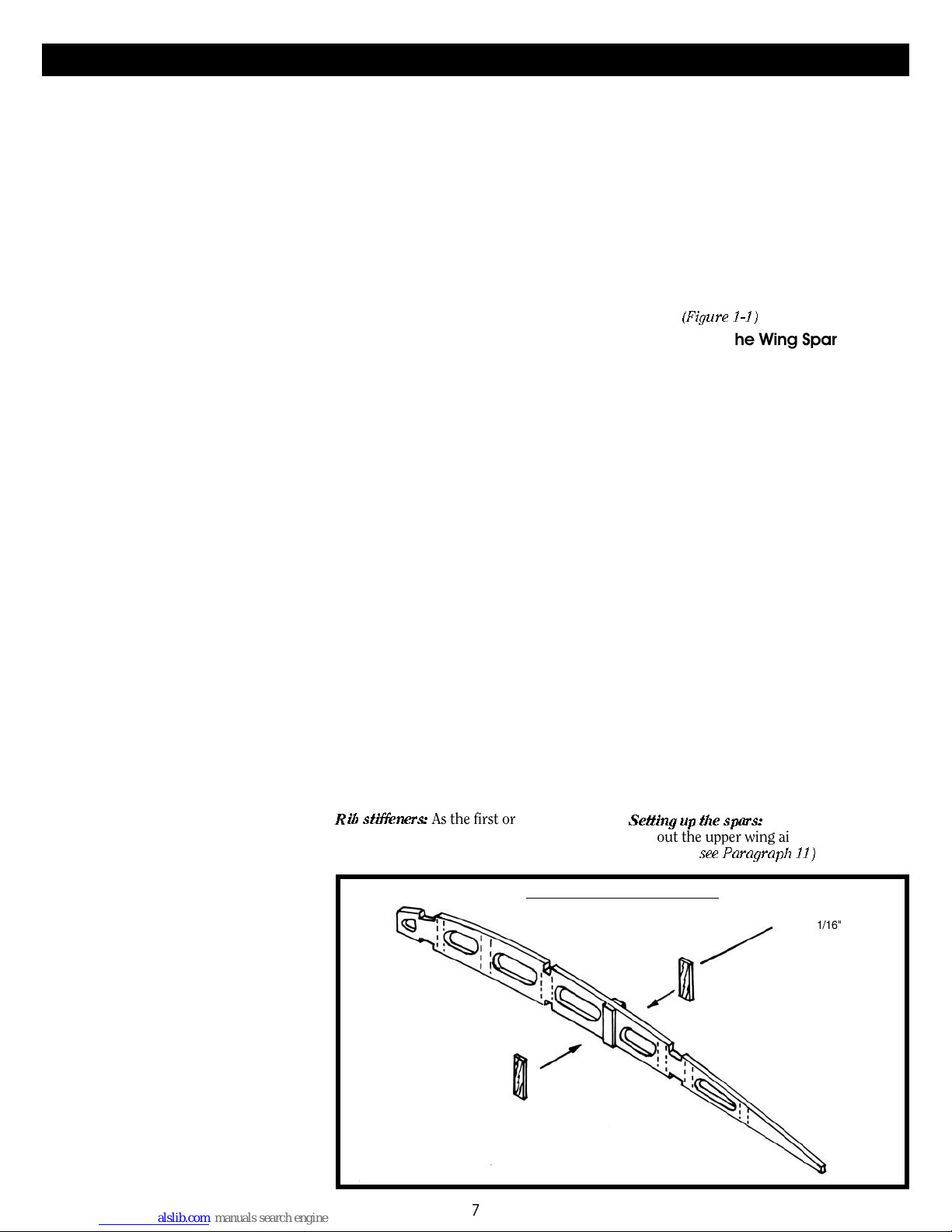

1. Preparing the Wing Ribs

All wing ribs are laser-cut. For your information, the airfoil is an Eiffel 36. There are several different types of ribs, such as solid

compression ribs, where the drag wire fittings are located, basic ribs with lightening

holes, shorter ribs in the upper wing center

section in way of the upper wing ailerons,

and the aileron ribs. The outboard rib near

the wing tip is a solid rib, more narrow than

the others since the wing tapers at the tip.

The inner most rib on each wing panel is

thicker than the others.

Rib stif

feners:

As the first or

der of business,

glue the vertical rib stiffeners on each side

of ribs where lightening holes are located, as

1-1 RIB STIFFENERS

FIG.

7

shown on the plan. These stif

feners prevent

rib cracking on the real aircraft. The thickness of the rib plus the vertical rib stiffeners

on each side should equal the width of the

cap strips that are 1/16" wide. However, the

tical stiffener wood supplied is 0.020"

ver

thick (1/64" not available). Before gluing the

vertical stiffeners, block sand the strips down

to 1/64" thick if necessary. Test fit a cap strip

to make sure it is flush with the stiffeners.

Hard to do after the wing is assembled. Cut

the stiffeners flush with the top and bottom

of the ribs, except cut the one at the center

flush with the underside of the stringer

notches

(Figure 1-1)

.

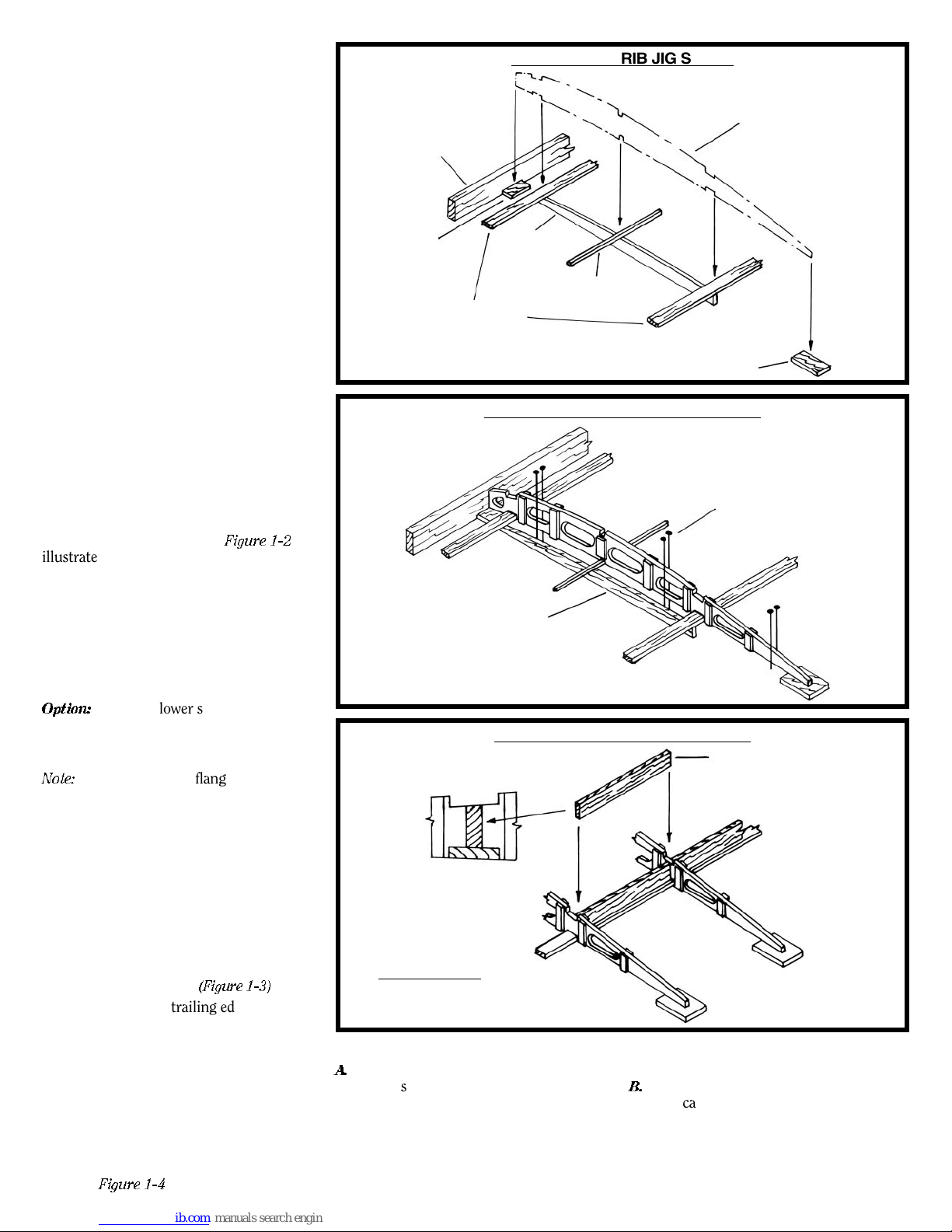

2. Setting Up the Wing Spars

In addition to the ribs, the wings basic construction consists of a heavy main front and

rear beam, two small stringers (upper and

lower) in between the main beams, a trailing

edge, and a leading edge. On the real aircraft

the main beams are a solid “eye” beam continuous through the ribs. However, for the

model these beams are composed of an upper

and lower continuous wooden flange with a

separate web fitted in between each wing rib.

The leading edge is a solid continuous wooden spar, with the addition of a strengthening

cover sheet back to the center of the front

beam on the top side of each wing panel.

Small stringers fit into the notches at the top

and bottom of the ribs. These stringers are to

prevent rib twist on the real aircraft.

The trailing edge is a steel rod on the model

(tubing on the real aircraft). The rod splices

into a wooden wing tip on the lower wings.

For the upper wings, the rod is continuous

around the ailerons and is wood on the main

part of the wing.

Both the upper wing and lower wing panels

are similar in construction, so the instructions to follow are applicable to both except

for specific details which will be noted.

Setting up the spars:

without the upper wing ailerons. Build these

separately (

see Paragraph 11)

Lay out the basic wings

.

TYPICAL STIFFENER

.020" X 1/16"

Since the wing ribs have undercamber, jig

shims are required to correctly locate the

beam flanges at their pr

oper angles. The

shims are laser-cut parts.

The leading edge is a r

ectangular spar and is

deeper than necessary so it can sit directly on

the plan without any shim strips. Pin the

leading edge to the plan first. Later, when the

wings are removed from the building board,

the leading edge will be r

ounded to its cor-

rect shape.

Next, lay a 1/32"-thick shim just behind the

leading edge in way of each rib. This will

hold the ribs off the work surface to allow for

the thickness of the cap strips. Also, lay a

1/32"-thick shim under the trailing edge.

Both of the 1/32" shims can be short pieces

in way of each rib or a long strip.

Laser-cut jig shims, W24, are used to hold

the beam flanges at the correct height and

angle. It is suggested that these shims be laid

just to one side of each wing rib rather than

under it, so you can still see the rib locations

on the plan. Pin the shims to the plan. Note

that there are only enough of the laser-cut

parts to build one wing panel at a time. If you

want to build more, you must make your

own additional shims.

Lay down the lower beam flanges and pin

them on top of the jig shims.

Figure 1-2

illustrates the setup. Out near the wing tips,

both of the beam flanges must be tapered as

shown on the plans. Also, the flanges are

angled toward the wing tips outboard of the

last full-size rib. Consequently, you can take

the flanges during this step only out to the

full-size rib and then add the remaining

portion of the flanges when you do the wing

tips (to be discussed later).

Option:

The small lower stringer at the middle of the wing ribs could also be installed

along with the beam flanges. Refer to Paragraph 6 for a discussion on the stringers.

Note:

When pinning the flanges (and the

stringer if the option is chosen) to the shims,

use one of the full-length lightened ribs to

check the fit as you go. The fr

ont end of the

rib will butt against the leading edge, and the

bottom slots in the rib must fit the lower

beam flanges (and stringer).

3. Installing the Wing Ribs

Position and glue each wing rib to the leading

edge, and to the fr

ont and r

ear beam lower

flanges (and the center stringer if this option

is used). Use pins if necessary to hold the ribs

tically at each location

ver

The shor

t ribs at the trailing edge, W7, can

be installed now

, or wait until the trailing

(Figur

e 1-3)

.

edge is in place.

Installing the Beam W

4.

ebs

and Web Blocks

With the ribs in place add the webs at the

ont and r

fr

must be shaped so they ar

bottom of the slots for the upper flanges.

Glue the webs to the lower flanges and to

each rib.

ear beams. The top of the webs

e flush with the

e 1-4

Figur

illustrates the basic

FIG. 1-2 WING RIB JIG SETUP

3/32" X 3/16"

LEADING

EDGE

1/32" SHIM

LOWER BEAM FLANGES

1/32" X 3/32" FRONT

1/32" X 1/8" REAR

JIG W24

1/32" X 1/32" STRINGER

(OPTION – INSTALL NOW)

FIG. 1-3 INSTALLING THE WING RIBS

THIS SHOWS OPTION WITH

W24 OFFSET FROM RIBS

FIG. 1-4 INSTALLING BEAM WEBS

REAR WEB SHOWN

(FRONT SIMILAR)

webs between ribs. Variances are as follows:

A.

The webs between the inboard two ribs

are the same thickness as the flanges.

This thick web suppor

ts the fake hinge

pins that connect the lower wings to the

fuselage and upper wings to the center

section. For the model, drill a hole in the

ends of each web for inserting a fake

hinge made of steel rod. The inboard ribs

8

TYPICAL WING RIB

1/32" SHIM

PINS

BEAM WEB –

1/32" FRONT WEB

3/64" REAR BEAM

5/64" IN WAY OF

AILERONS

already have a laser-cut guide hole (more

on this later).

B.

The rear web outboard where the ailerons

e located is a continuous piece and is set

ar

flush with the aft side of the flange. Like

the flanges, the beam webs outboard of

the last full depth rib ar

e not installed at

this time. They will be done with the wing

tip construction per Paragraph 5.

Option:

The web blocks to be described in

the next paragraph can be glued to the beam

webs before the beam webs are glued

between the ribs.

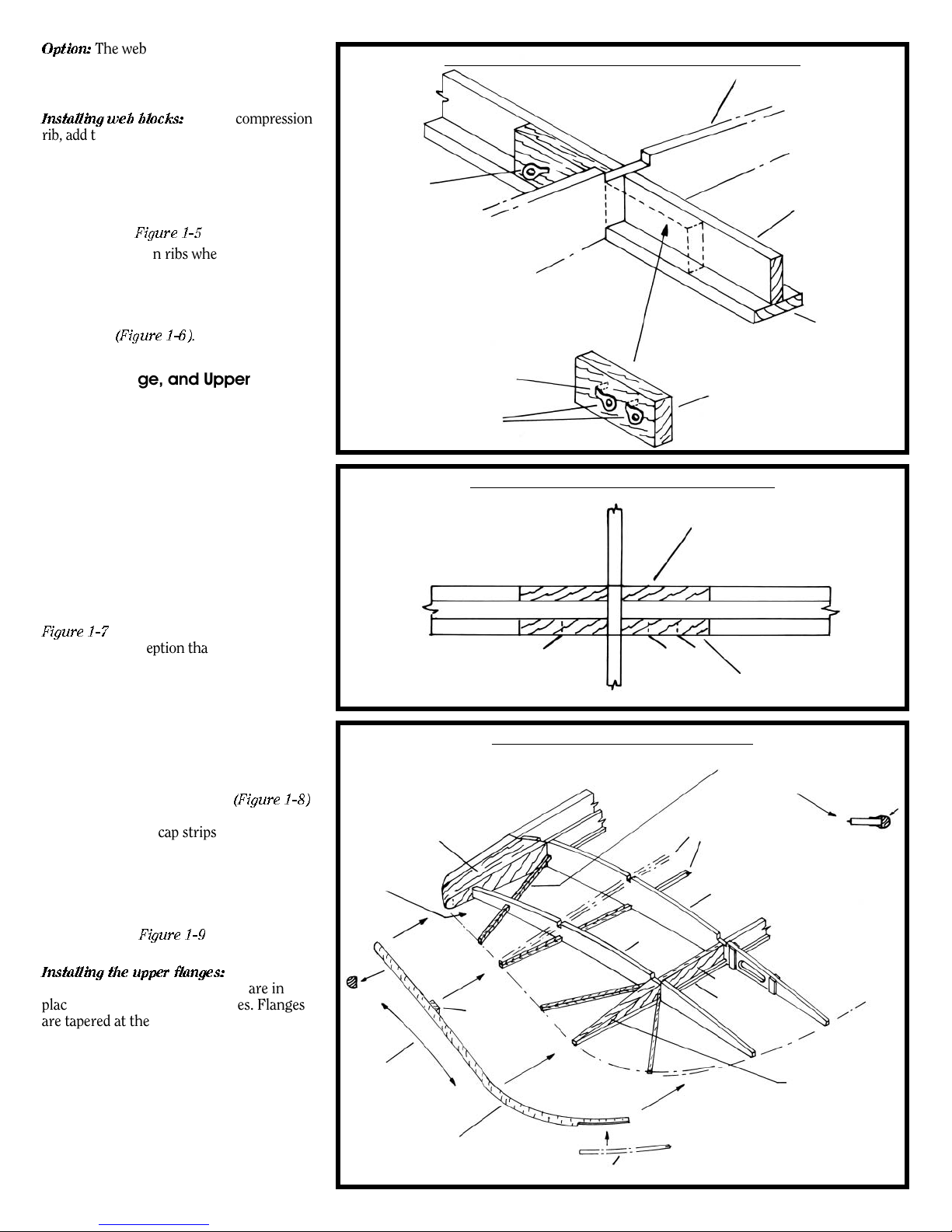

Installing web blocks:

At each compression

rib, add the web blocks on each side of the

ribs. Fit these blocks on the forward side of

the rear beam and aft side of the front beam.

These blocks hold the drag wire single eye rig

fittings (R1). The fittings should be installed

in the blocks befor

now than later.

e installing the block; easier

Figure 1-5

illustrates.

At the compression ribs where the wing

struts are located, add additional blocks on

the other side of the beam webs. The blocks,

now on all four corners of the rib juncture

provide support for the pads in way of the

wing struts

(Figure 1-6).

5. Installing the Wing Tips,

Trailing Edge, and Upper Beam

Flanges

The wing tips are made of wood. The rear

beam flange tapers aft, and its web tapers top

and bottom to the tip. The front beam flange

tapers forward, and its web tapers top and

bottom. See Detail 2-F and 2-G on the plan for

the correct tapers. There is a filler block at the

leading edge. It tapers like the front beam.

Outboard of the last full-size rib there is a narrow wing rib. Taper and fit the wing tips. On

the lower wing, the tip curves into the trailing

edge. Heat bend this curve. Note that the wing

tip follows the curvature of the undercambered wing ribs, so it is not a straight piece.

Figure 1-7

illustrates the wing tip construction, with the exception that the upper beam

flanges and stringer have not yet been added.

The trailing edge is a steel rod. It is tied into

the wooden wing tips of the lower wings.

Bend the trailing edge to shape. Splice the

steel trailing edge into the wooden lower

wing tip and wrap with thread. For the upper

wing, the ailerons have the rod. Position and

glue the trailing edge to the ends of the ribs

with just a touch of super glue

(Figure 1-8)

After the wings are removed from the building board, and the cap strips have been

added, the copper self stick bands will be

added at each rib over the trailing edge rod.

The lower wings have a handhold block

(W23). Install the laser-cut blocks and sand

to the taper of the wing tips and round the

hole edges. See

Figure 1-9

and Detail 2-H

on the plan.

Installing the upper flanges:

After all webs

and web blocks and the wing tips are in

place, add the beam upper flanges. Flanges

are tapered at the wing tips. See Detail 2-F

and 2-G on the plan.

6. Installing the Small Wing Stringers

The stringers on the real aircraft are very

small dowels (about 5/16" full-size). However

1/32" square strips are provided in the kit, as

a dowel this small is not available commercially. You can sand the edges of the square

to form a dowel or use a draw plate. Or, leave

the square strips as is for more strength (rec-

.

CURVE SIMILAR

TO CAMBER OF

,

SINGLE DRAG

WIRE FITTING

R1 THIS SIDE

RIGHT WING, REAR BEAM

BLOCKS SHOWN. FRONT

BEAM SIMILAR EXCEPT

SINGLE AND DOUBLE R1

FITTINGS REVERSE SIDES.

(SEE PLAN OF WINGS)

DRILL HOLES FOR R1

FILLER BLOCK

HANDHOLD

BLOCK HERE

(SEE FIG. 1-9)

DOWNWARD

WING RIB W11

1/16" X 3/32" WING TIP

TAPERED AND SHAPED

FIG. 1-5 WEB BLOCKS AT COMPRESSION RIBS

WING RIB W4 OR W6

WEB BLOCK –

DRAG WIRE

FITTINGS R1

FIG. 1-6

WEB BLOCKS AT WING STR

PLAN

1/32" THICK AT FRONT BEAM

3/64" THICK AT REAR BEAM

UTS

ADD WEB BLOCKS ON OPPOSITE

SIDE OF WEBS IN WAY OF WING

STRUT LOCATIONS

WEB BLOCKS

FIG. 1-7 WING TIP CONSTRUCTION

TYPICAL 3/64" X 3/64" STIFFENER.

WING

T

A

STICK TAPE AS SHOWN

STRINGERS

W4

1

W1

WEB

TAPERED

BLOCK

TRAILING EDGE ROD (SEE FIG. 1-8)

FLANGE

(SEE PLAN

DETAILS)

LOWER WING SHOWN

(UPPER WING SIMILAR EXCEPT

FOR CUT OUT FOR AILERONS)

BEAM WEB

PER FIG. 1-5

TIP, USE COPPER

THIS WEB SAME

THICKNESS AND

TAPER AS FLANGES

BEAM LOWER

FLANGE

TAPE

9

ommended). Fit the stringers in the precut

notches in the ribs. Fix with glue. The

stringers are rather delicate, so be careful

handling the strips. Out at the wing tips the

stringers angle towar

seen in

Figure 1-7

d the wing tip strip as

.

You should be able to slide the lower strip

through the notches, or you could lay them

down before installing the ribs (an option

noted in Paragraph 3).

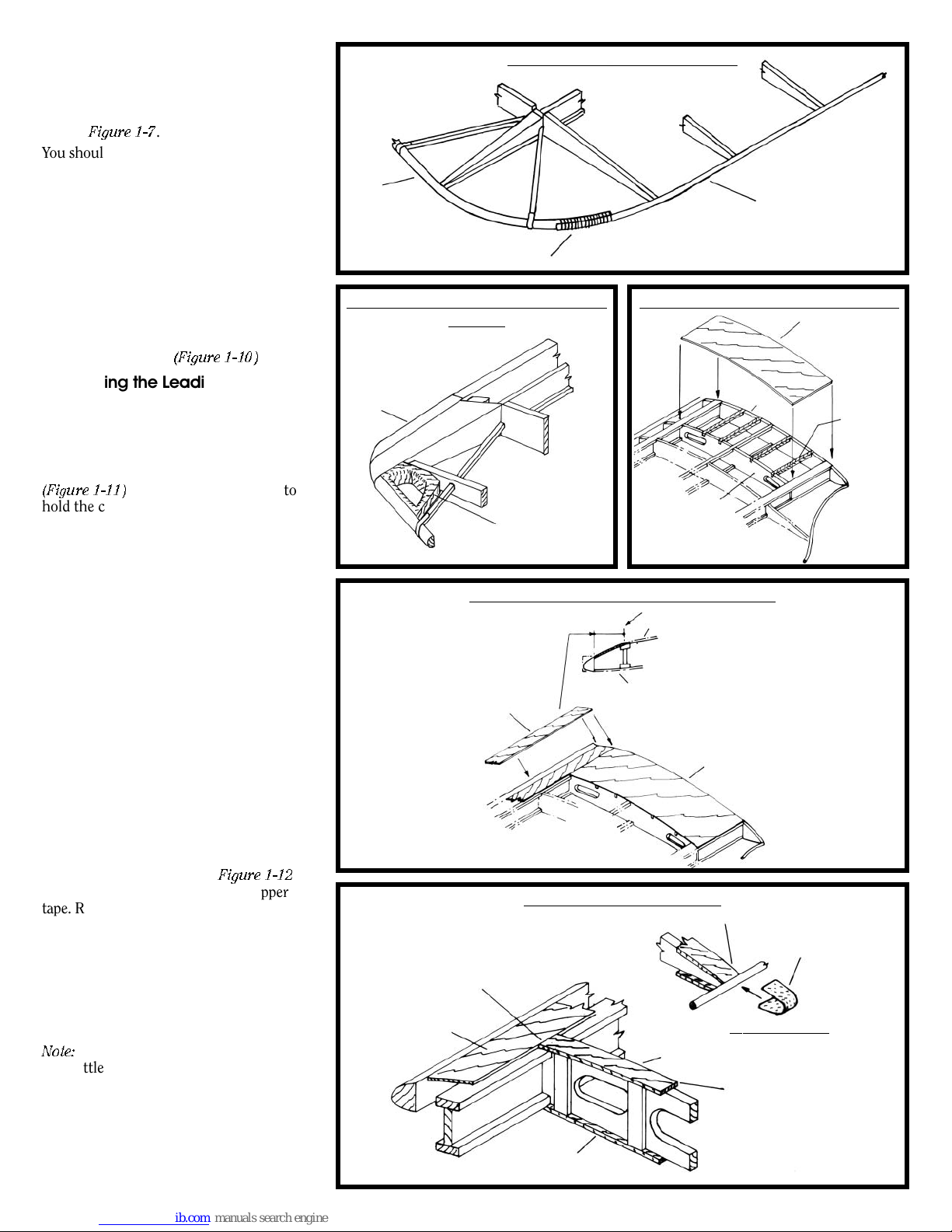

7. Adding Miscellaneous Stiffeners

and Lower Wing Walk

Install the 1/32" square stiffeners between

the ribs adjacent to the inboard edge of the

ailerons.

On the lower wings, fit the supports and

wood sheet over the two inboard ribs, which

provides a wing walk

(Figure 1-10)

.

8. Installing the Leading Edge Cover

Sheet

Install the plywood cover sheet (also plywood veneer on the real aircraft) on top of

the wings only. It fits from the leading edge

strip back to the middle of the front beam

(Figure 1-11)

. Use some small clamps to

hold the cover sheet in position while the

glue dries, or glue the front first, then glue

the sheet to the front beam with super glue

plus accelerator for a quick fix. The wood is

not as long as the upper wing, so you must

have one butt joint. Place the butt joint at

one of the ribs.

9. Installing the Cap Strips

The upper cap strips can be installed while

the wings are still pinned to the building

board. The wings must be removed from the

board to install the lower strips. To hold the

cap strips in position for gluing, use a bent

pin, or super glue the cap strip at the leading

edge and use super glue plus accelerator at

the trailing edge. Then add glue to the

remaining areas. The cap strips butt into the

ply sheet on top of the wing and to the leading edge on the bottom.

After the wings are removed from the building boar

the trailing edge at each rib.

shows the cap strips and also the copper

tape. Remember this figure so you don’t

forget to add the tape later.

Another method for gluing cap strips is to

coat the rib and cap strip with white glue,

let dry, then use an iron to heat-bond the

cap strips on. Though I have no personal

experience with this method, I am told this

works fine.

Note:

are a little thicker than the 1/64"-thick ply

sheet (1/64" basswood not available). Sand

the front of the cap strips flush with the top

of the ply sheet. Also, sand the cap strips at

the trailing edge down to the steel rod before

applying the self-adhesive copper tape. The

ribs are a little deeper at the trailing edge

than is found on the real aircraft.

d, add self-adhesive copper tape over

Figure 1-12

The basswood cap strips at 0.020" thick

FIG. 1-8 WING TRAILING EDGE

LOWER

WING TIP

SPLICE WITH THREAD

FIG. 1-9 LOWER WING HANDHOLD

BLOCK

LEADING EDGE

LASER-CUT BLOCK

W23 – SAND FLUSH

WITH TOP OF WING

AND ROUND

THE HOLE EDGES

FIG. 1-11 LEADING EDGE COVER SHEET

LEADING EDGE SHEET

1/64" PLYWOOD

(UPPER WING SIMILAR)

FIG. 1-12 RIB CAP STRIPS

SAND CAP STRIP FLUSH

WITH COVER PLY

COVER PLY

T

OP

ONL

Y

BUTT LOWER STRIP

O LEADING EDGE

INT

10

1/32"-DIA. STEEL ROD

TRAILING EDGE

(ON UPPER WING, ROD

IS ONL

Y ON AILERONS)

FIG. 1-10 WING WALK – LOWER WINGS

1/64" PLYWOOD

W8

3/64" X 3/64"

STIFFENERS

WING WALK

SUPPOR

W9

CENTER OF BEAM FLANGE

CAP STRIP LATER, OR WING WALK

CAP STRIP

LATER

–

Y

ALK PL

WING W

LOWER WING

SAND CAP STRIP ENDS

DOWN TO TRAILING

BUTT INTO

COVER PLY

EDGE ROD

A

T TRAILING EDGE

.020" X 1/16"

CAP STRIP

ADD SELFADHESIVE

COPPER TAPE

OVER ROD

TS

1

0.Installing Wing Strut, Kingpost,

and W

F

ing Skid Support Pads and

ittings

The support pads are fitted on each side of

the cap strips in way of the struts. For the

lower wing, the inboard pads are on top of

the wing. The outboar

d pads are on both the

top and bottom of the wing. The bottom pads

are supports for the wing skid fittings. On

the upper wing center section, the pads are

located only on the bottom side. On the main

upper wing panels, install the pads on both

sides at the outer wing strut location. The

underside is support for the wing struts, and

the top side provides support for the kingposts. At the inner strut location, locate the

pads only on the underside. The plan, Detail

2-I shows each pad required.

Glue the photo-etched copper wing strut

rigging plates (W22) to the pads, aligning

the center hole on the axis of the rib and

beam. A common photo-etched copper fitting is provided in the kit. However, all the

rigging eyes are not needed at every location. Cut off the eyes not required. The

plan, Detail 2-J, illustrates what each should

look like. Bend the remaining eyes to the

angle of the wing wires.

On the real aircraft, U bolts going under the

beams are used to hold the plates down. On

the model, glue the fitting to the wings. It

will also be held down when you insert the

struts in the holes.

After the fittings have been installed, or

before, drill a hole into the wing through the

center hole of the fitting for receiving the

wing strut, kingpost, and skid end fittings.

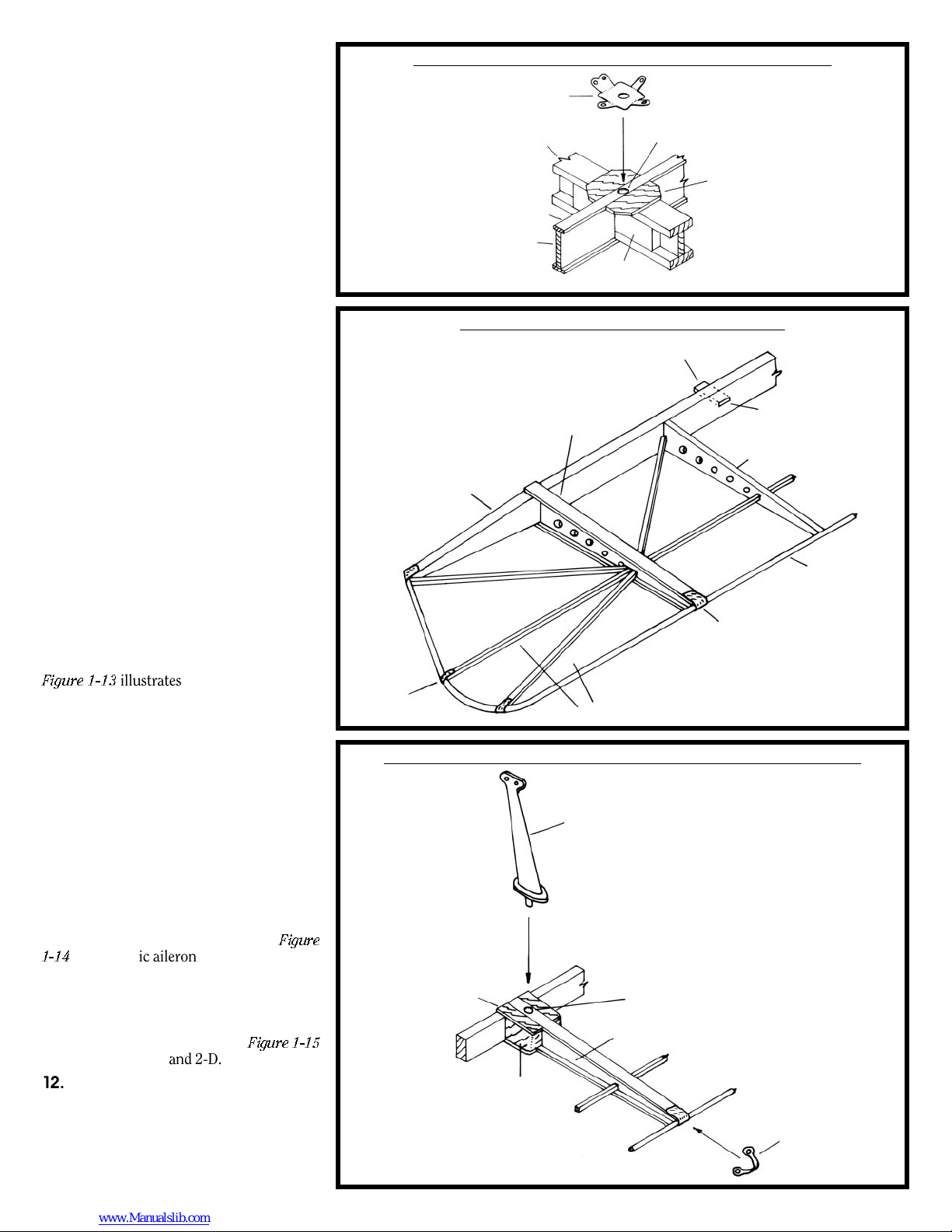

Figure 1-13

illustrates the installation of

pads and fitting.

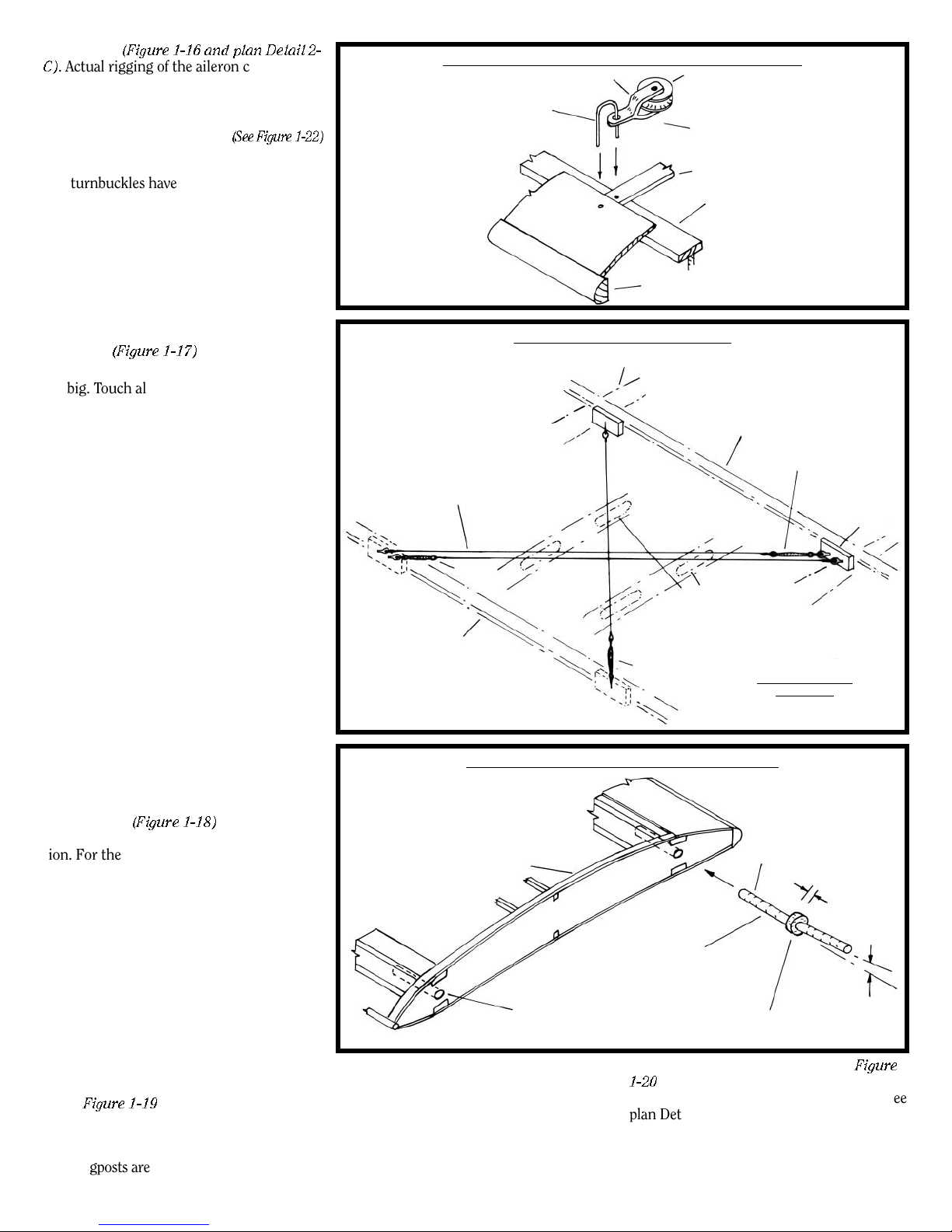

11. Building and Installing the Upper

Wing Ailerons

Build the ailerons flat on the plan. First, lay

down the leading edge and rod trailing edge,

then pin and glue the ribs to the leading and

trailing edge. Install the stif

fening between

ribs. Add the cap strips as you did the wing

panels, then add the copper bands at each

rib. Cut slots in the ailer

on leading edge and

the rear wing beam web for fake hinges. Use

a strip of brass for the fake hinges. The location of the hinges is fr

om factory plans. However, you could omit all but the two outer

hinges as an option on the model. See

1-14

for the basic ailer

In way of the contr

on construction.

ol horns, add the pads and

Figure

filler blocks on each side of the rib and drill a

hole for the fittings. Install the britannia

casting control horns (C1) and the three

back brace wire fittings (R2). See

Figure 1-15

and plan Details 2-A and 2-D.

12.Installing the Aileron Control

Sheaves

Pin or glue the sheaves (C3) into the sheave

body (C4) to assemble the sheaves. The

sheaves ar

e located on the fr

a U pin made fr

om brass r

ont beam. Inser

od into the beam

to attach the sheaves to the top and bottom

t

FIG. 1-13 STRUT SUPPORT PADS & WING WIRE FITTING

PHOTO-ETCHED FITTING W22 –

BEND EYES TO WING WIRE ANGLES.

CUT

OFF EYES NOT NEEDED

ATA GIVEN LOCATION.

BEAM

CAP STRIP

RIB

DRILL HOLE THROUGH

W22 INT

WEB

BLOCK

O BEAM

TYPICAL FULL .020" SUPPORT

PAD. (SEE PLAN DETAIL 2-I

FOR PARTIAL PADS)

FIG. 1-14 BASIC AILERON CONSTRUCTION

1/64" X 1/16" BRASS FLAT BAR FAKE HINGE

CUT SLOT FOR FAKE

HINGES – CUT MATCHING

SLOT IN REAR WING

W14

AT EACH RIB

COPPER

TAPE

.020" X 1/16"

CAP STRIPS

1/16" X 5/32"

LEADING

EDGE

SELF-ADHESIVE COPPER TAPE

TYPICAL 1/32" STIFFENERS

FIG. 1-15 AILERON CONTROL HORNS & BRACE WIRE FITTINGS

CONTROL HORN CASTING C1

(TOP AND BOTTOM)

.020" PAD

(TOP AND

OM)

BOTT

FILLER BLOCK

DRILL HOLE TOP AND BOTTOM

FOR CONTROL

SOLID RIB

W13

HORNS

PHOT

BACK BRACE

WIRE FITTING R2

11

BEAM WEB

1/32"-DIA. STEEL

ROD TRAILING

EDGE

O-ETCHED

of the wings

C)

. Actual rigging of the aileron control wires

e 1-16 and plan Detail 2-

(Figur

will be discussed in a later stage.

On the right side of the upper wing center sec-

tion add a similar U pin that will ser

lead for the aileron control wire

ve as a fair-

(See Figure 1-22)

13.Installing the Drag Wires

The turnbuckles have an eye on each end.

One end can be tied with thread to the rig eye

fittings (R1), or if you file out one side of the

eye they can be hooked into the fitting. On

the real aircraft the end is U-shaped for bolting to the fitting.

Add the short turnbuckles (R3A) and rig the

drag wires (nylon cord on the model). These

go between the compression ribs on the main

wing panels and also on the upper wing center section

(Figure 1-17)

.

Try to be neat with the cord. Don’t get knots

too big. Touch all knots with super or white

glue so they won’t come adrift.

14. Installing the Fake Hinge Rods in

the Upper and L

On the real aircraft, the lower wing was attached

to the fuselage and the upper wing was attached

to the center section by a pair of heavy hinges

bolted to the beam webs. Until such time as the

rigging wires were installed, the wings were not

supported and would rotate on the hinge. For

the model, the hinge has been faked to provide

a more rigid connection, so when the wings are

installed they don’t flop around, making installation of the struts and rigging easier. A simple

steel rod is provided as a fake hinge.

First, bend the steel rod to the angle of the wing

dihedral (1°). In order to maintain the 3/32" gap

between the outer wing panels and fuselage/

center wing section, an optional spacer inserted

onto the steel rod is suggested. This can be

made from a piece of wood, or of aluminum or

brass tubing with a 1/16" inside diameter.

Drill a hole in the end of the beams through

ecut guide holes in the inboar

the pr

ting the fake hinge pin. Glue the r

inser

into the holes

hole into the beams of upper wing center sec

tion. For the lower wing, ther

drilled in the fuselage. This will be shown in

the fuselage building stage.

(Figure 1-18)

ower Wings

d ribs for

od

. Drill a similar

-

e will be holes

15. Building and Installing the Lower

ing Skids

W

Using the 3/32" squar

e flexible beech wood,

shape the strip into a 1/16" dowel. The beech

bends rather easily, but can be easier and hold

its shape better if it is wet first. Pin the dowel

over the plan pattern and let dry. It may tend

to flex back a little, but that’s OK. When

installed in the skid fittings, it will be secur

e.

Fit the cast fitting (W21) at each end under

the lower wing, then glue the skids in the

holes.

Figure 1-19

shows the process.

16. Building , Installing, and

Rigging the Kingposts

The kingposts are laser-cut, but you must

taper them and shape to a streamline section.

FIG. 1-16 AILERON CONTROL CABLE SHEAVES

CASTING C4

BRASS ROD

.

FIG. 1-17 WING DRAG WIRES

.010"-DIA. GRAY

NYLON CORD

R3A

FRONT WING

BEAM

FIG. 1-18 INSTALLING FAKE HINGE RODS

WING)

OP

W1 (T

W8 (BOTTOM WING)

DRILL 1/16" HOLE INTO BEAMS

THROUGH PRE-CUT PILOT

HOLES IN LASER-CUT RIB

The end fittings ar

e so small they have been

omitted on the model. Paint the ends black or

copper color to “fake” a fitting that is similar

to the wing str

uts. Install the single eye rig fit

tings (R1) into the posts. Drill a hole in the

bottom of the posts and insert a brass pin.

Insert the kingposts into the holes on top of

the upper wing, then add the steel r

od at top

12

CASTING C3

FITTING AT TOPAND

BOTTOM OF WING

CAP

STRIP

WING FRONT

LEADING EDGE

COMPRESSION RIB

REAR WING BEAM

DRAG WIRES PASS

THROUGH HOLES

IN THESE

LIGHTENED RIBS

R3A

FAKE HINGE

(1/16"-DIA. STEEL

between the fr

Next, add the single eye rig fittings (R1)

1-20

.

ROD)

OPTIONAL SPACER

(WOOD OR

ont and r

BEAM

SHORT TURNBUCKLE

R3A

WEB BLOCK

FITTINGS

TYPICAL

GLUE ROD IN HOLE

PANEL IN

LEFT WING

3/32"

TUBING)

THICK

1 DEGREE

ear posts. See

WITH R1

on the wing for the kingpost brace wires. See

-

plan Detail 2-E.

The rigging for the kingposts can be accom

plished at this time or wait until later

to Stage 7 and Sheet 6 for details. The short

nbuckles (R3A) for the transverse wir

tur

Figur

. Refer

es

e

-

Loading...

Loading...