Page 1

®

Quality System certified by

®

STEAM

STERILIZER

®

OPERATING MANUAL

Ed. 1

Rev. 5

Date: January 2008

Page 2

TABLE OF CONTENTS

REVISIONS

The following table lists subsequent editions/revisions of the manual.

The “Description” field brief explains the subject of the latest revision.

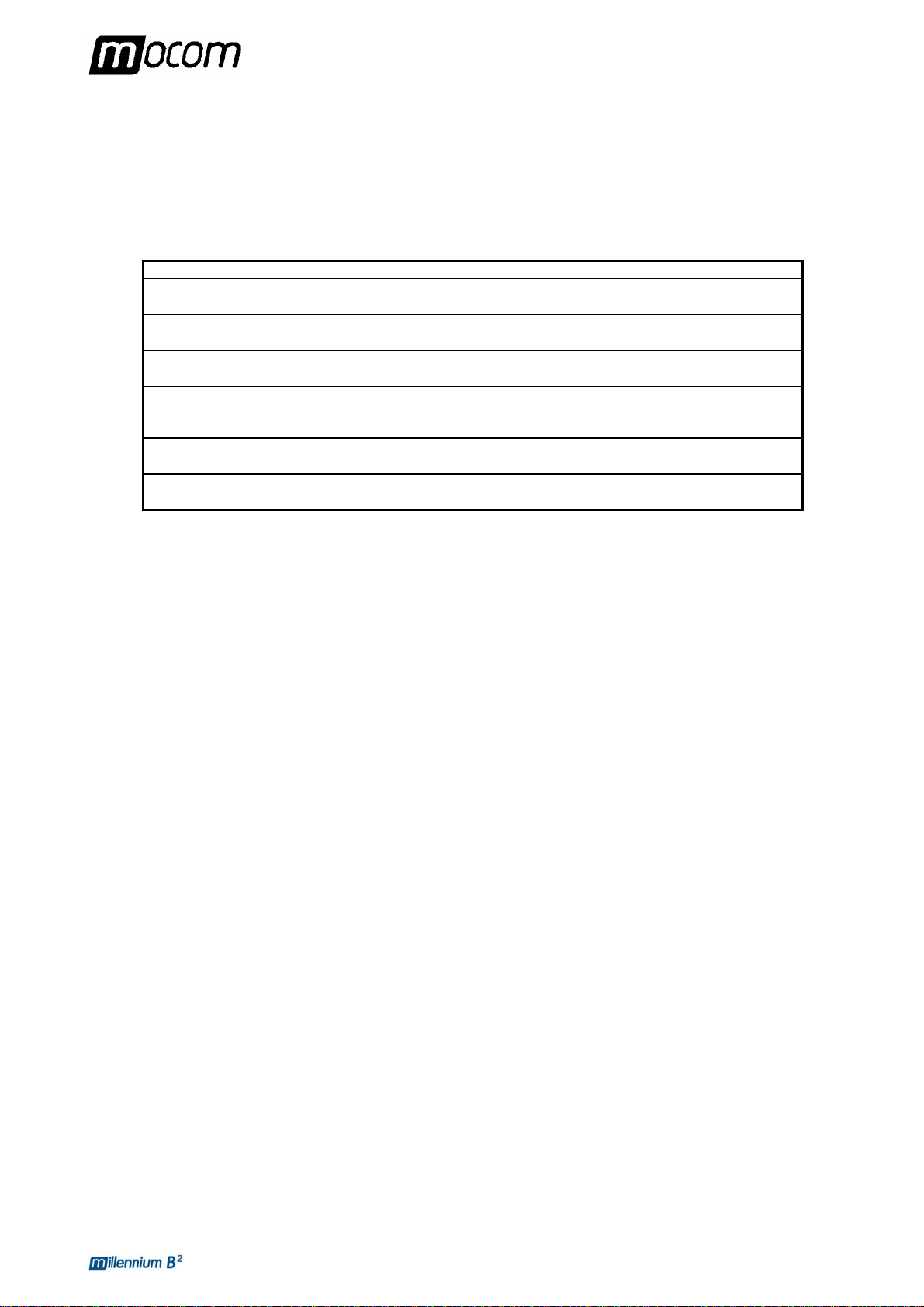

Ed. Rev. Date Description

1 0 11-02 First issue

1 1 02-03 A few modifications; added new chapter “Replacing the printer paper”

1 2 03-04 A few small modifications; photo on the cover

1 3 11-04 A few small modifications;

Added the menu option “Password”

1 4 01-06 Upgrade (software, interface with Milldrop and Millflash)

1 5 01-08 EEC standards reference updating

TABLE OF CONTENTS

1 - INTRODUCTION............................................................................................................................1

APPLICABLE EUROPEAN DIRECTIVES........................................................................................................1

INTENDED USE.................................................................................................................................................1

PURPOSE OF THE MANUAL...........................................................................................................................2

GENERAL WARNINGS...................................................................................................................................... 2

2 - CONTENTS OF THE PACKAGE...................................................................................................3

DIMENSIONS AND WEIGHT............................................................................................................................ 3

DESCRIPTION OF THE CONTENTS................................................................................................................3

HANDLING THE PRODUCT..............................................................................................................................4

3 - PRODUCT INTRODUCTION..........................................................................................................5

INTRODUCTION................................................................................................................................................5

GENERAL CHARACTERISTICS.........................................................................................................................5

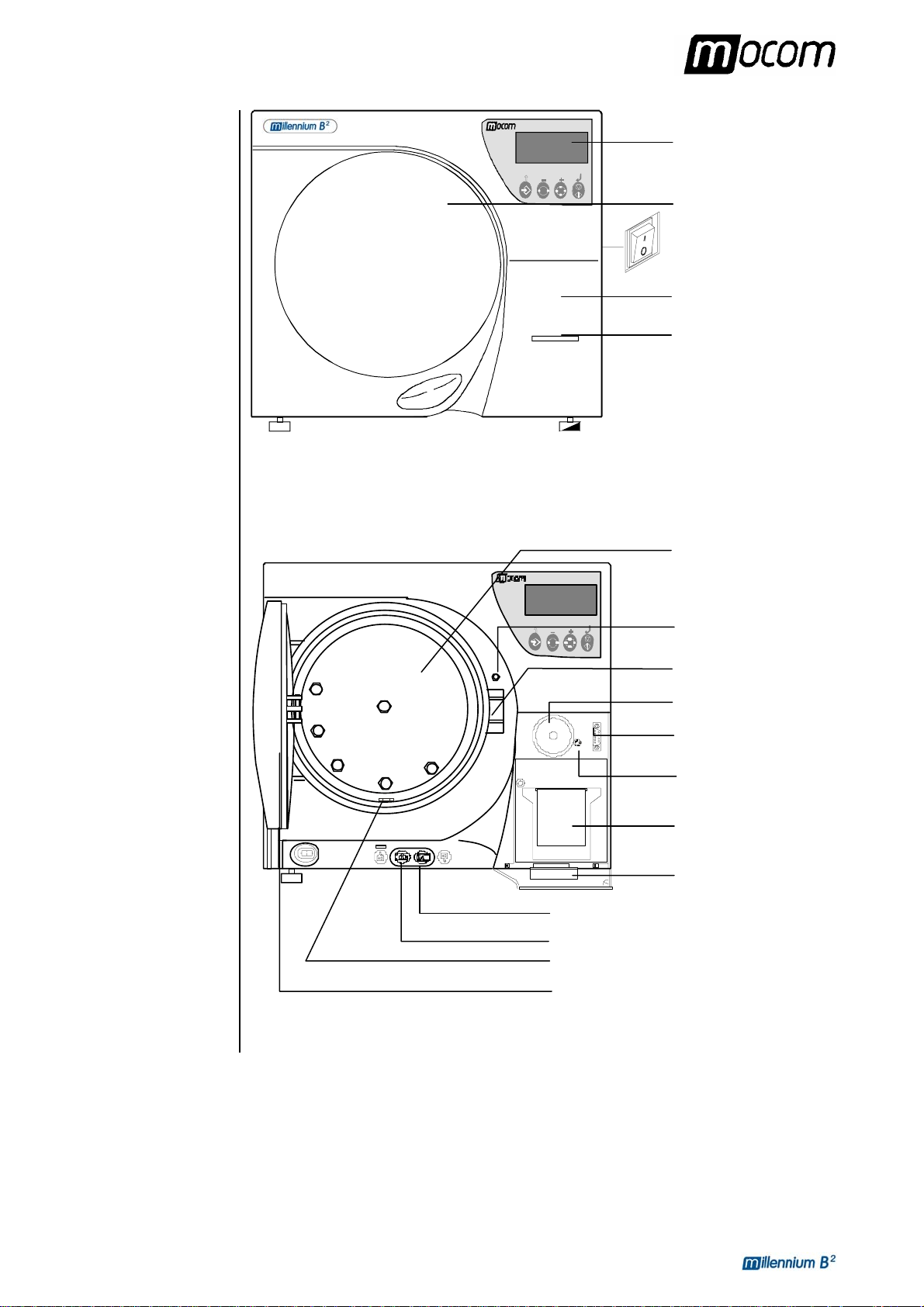

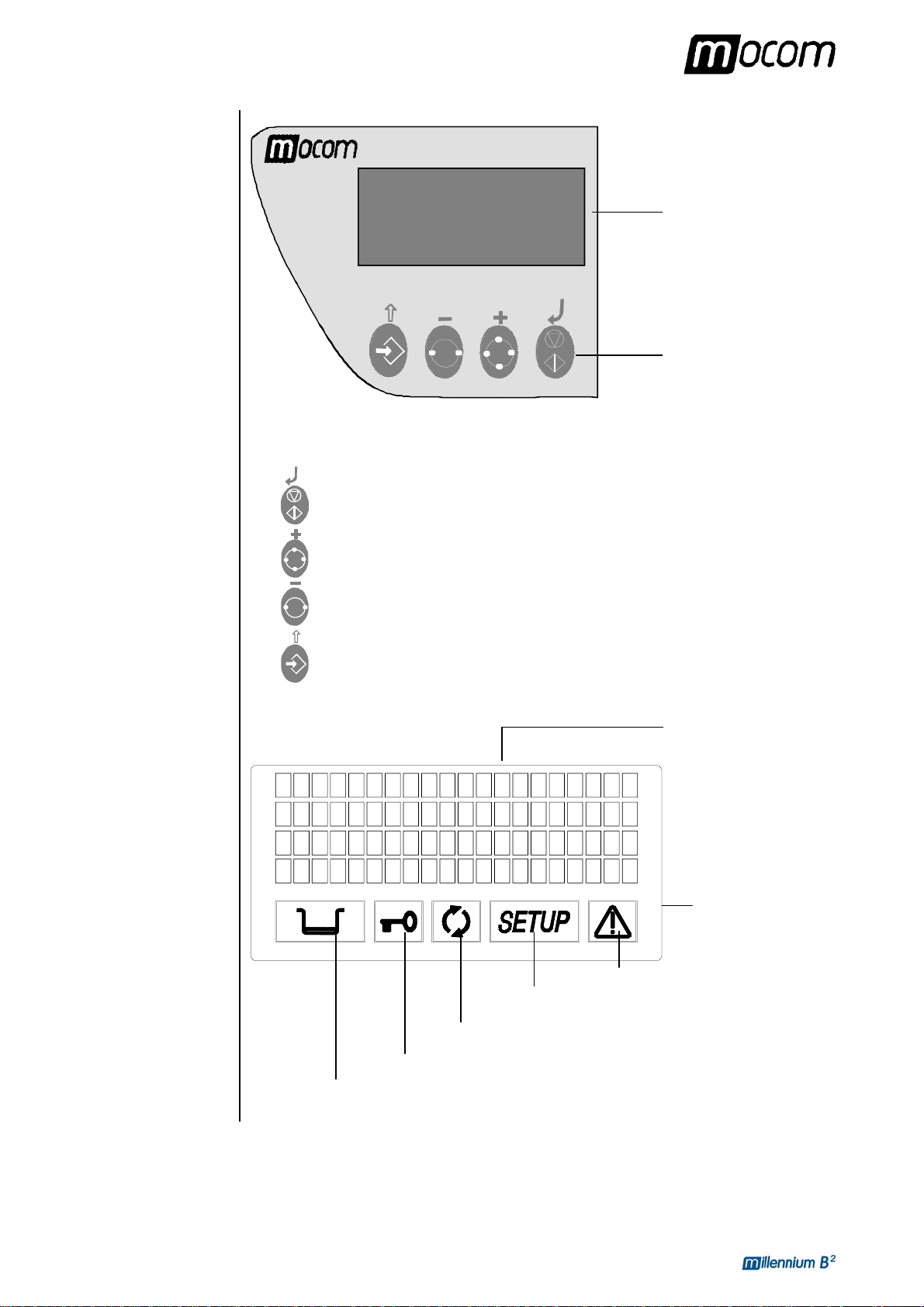

FRONT............................................................................................................................................................... 6

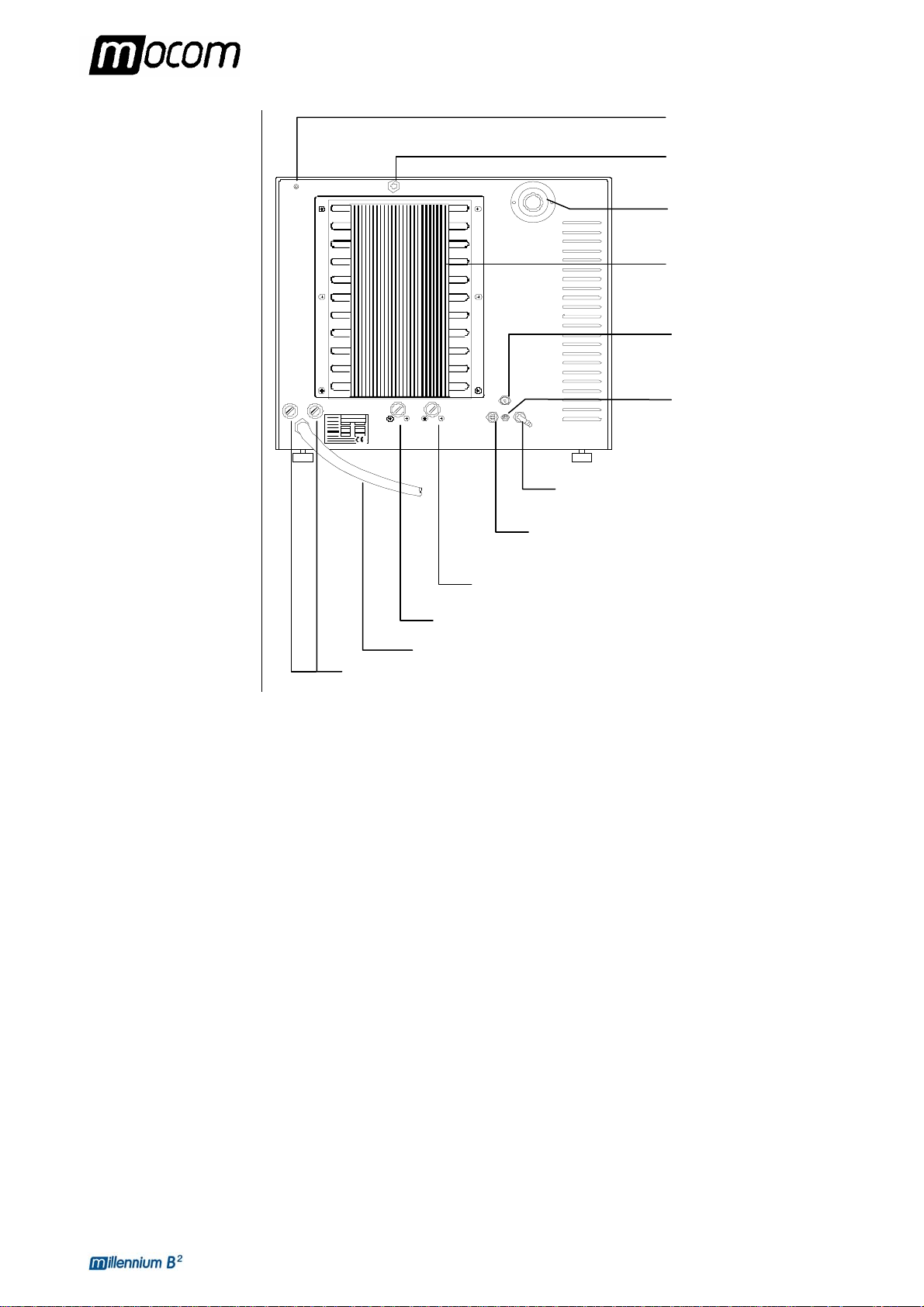

REAR .................................................................................................................................................................7

CONTROL PANEL............................................................................................................................................8

LCD DISPLAY....................................................................................................................................................8

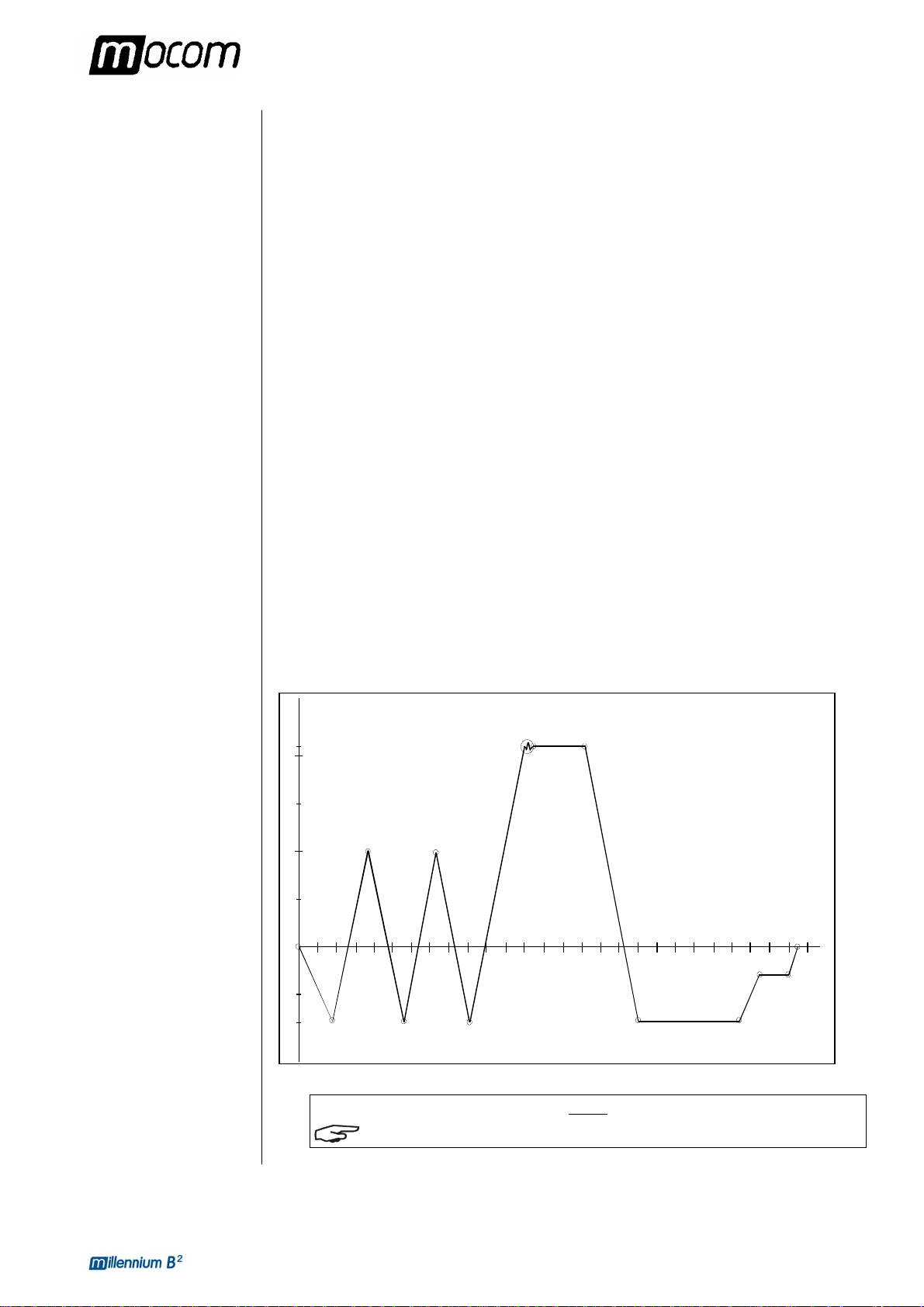

OPERATING CYCLE EXAMPLE........................................................................................................................9

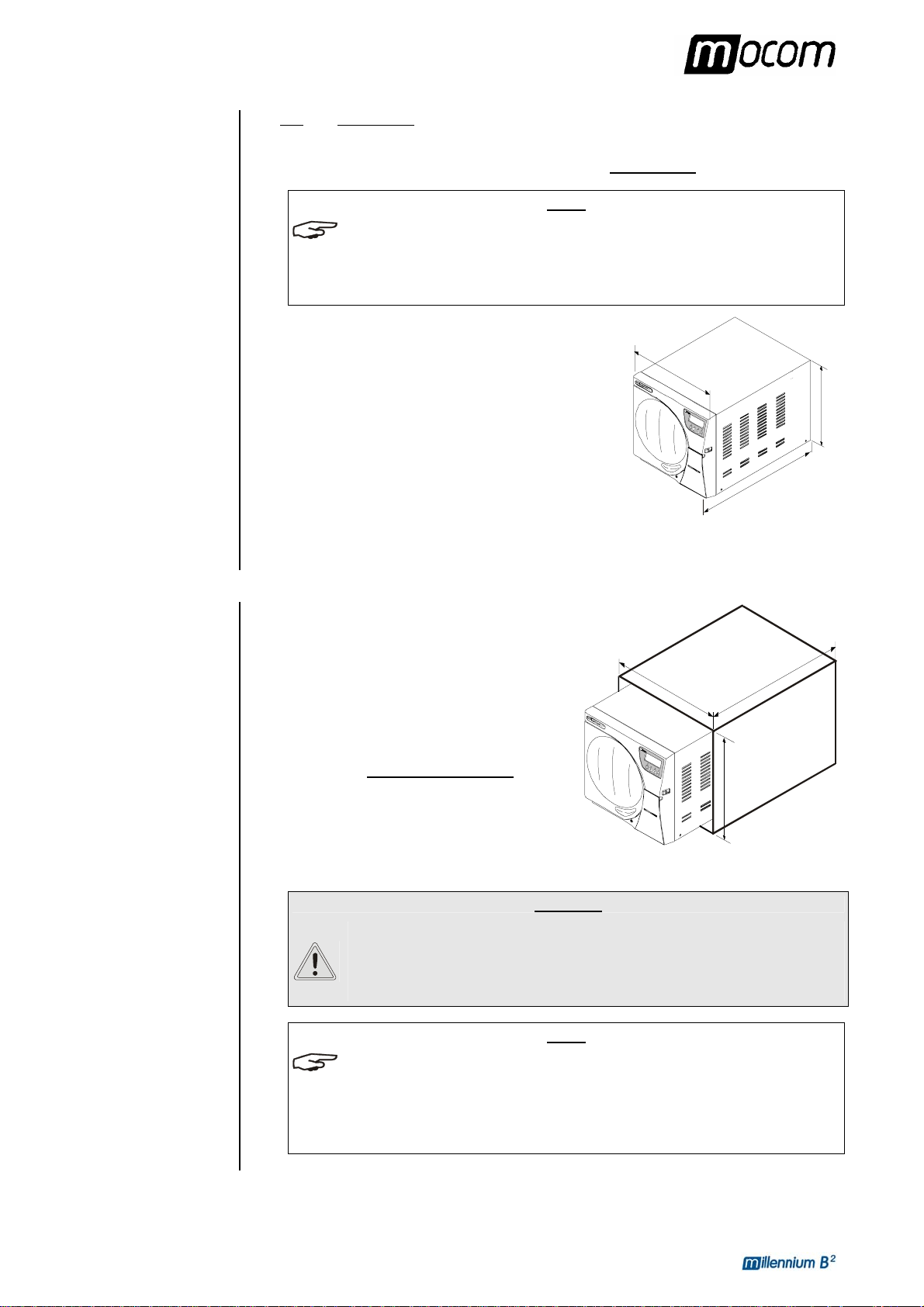

4 - INSTALLATION...........................................................................................................................10

INTRODUCTION..............................................................................................................................................10

COMPARTMENT DIMENSIONS FOR BUILT-IN INSTALLATIONS................................................................10

GENERAL INSTALLATION PRECAUTIONS.................................................................................................. 11

ELECTRICAL CONNECTIONS........................................................................................................................11

CONNECTING THE DATA RECORDING MILLFLASH ...................................................................................11

CONNECTING AN EXTERNAL WATER FILLING TANK................................................................................12

CONNECTING DEMINERALIZER MILLDROP...............................................................................................12

CONNECTING AN EXTERNAL DRAIN TANK.................................................................................................13

DIRECT CONNECTION TO A CENTRALIZED DRAINING POINT..................................................................14

I

Page 3

TABLE OF CONTENTS

5 - FIRST START-UP........................................................................................................................ 15

TURNING ON THE EQUIPMENT.....................................................................................................................15

INITIAL AUTOMATIC TEST.............................................................................................................................15

ACQUISITION AND UPDATING OF THE AMBIENT PRESSURE VALUES.................................................... 15

STAND-BY MODE............................................................................................................................................16

FILLING DISTILLED WATER ...........................................................................................................................17

Manual filling.............................................................................................................................................17

Automatic filling........................................................................................................................................17

MAX LEVEL IN THE INTERNAL/EXTERNAL DRAIN TANK............................................................................18

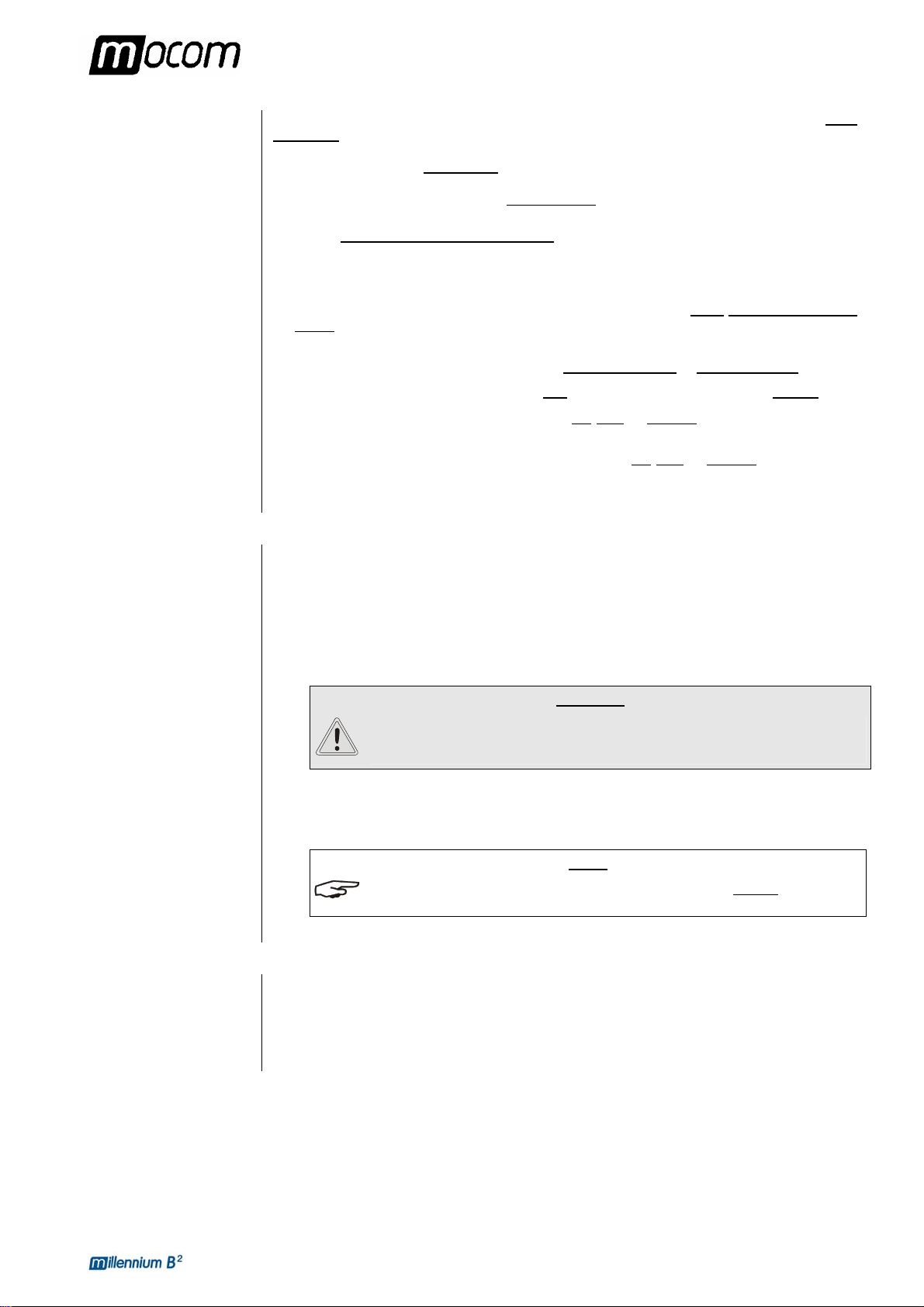

6 - CONFIGURATION....................................................................................................................... 19

INTRODUCTION...............................................................................................................................................19

STARTING AND ENTERING THE SETUP MODE...........................................................................................19

MEANING OF THE KEYS IN SETUP MODE ................................................................................................... 19

DESCRIPTION OF THE MENU ITEMS ............................................................................................................21

DEFAULTS SETTINGS ....................................................................................................................................23

ACTIVATING CONFIGURATION OPTIONS ...................................................................................................23

Setting the language.................................................................................................................................23

Setting the date........................................................................................................................................23

Setting the time.........................................................................................................................................24

Setting the password................................................................................................................................24

Setting the sterilization programs .............................................................................................................25

Setting the STAND-BY mode...................................................................................................................29

Setting the printing mode..........................................................................................................................30

Setting the tank filling mode......................................................................................................................32

Setting the water draining mode..............................................................................................................32

Acquisition of the ambient pressure..........................................................................................................33

Adjusting the contrast of the liquid crystal display ................................................................................... 34

EXIT THE CONFIGURATION MODE..............................................................................................................34

7 - PREPARING THE MATERIAL .................................................................................................... 35

INTRODUCTION...............................................................................................................................................35

TREATING THE MATERIAL BEFORE STERILIZATION..................................................................................35

ARRANGING THE LOAD .................................................................................................................................36

8 - PROGRAM SELECTION............................................................................................................. 38

INTRODUCTION...............................................................................................................................................38

PROCEDURE...................................................................................................................................................38

9 - RUNNING THE CYCLE.............................................................................................................. 40

INTRODUCTION...............................................................................................................................................40

STARTING THE CYCLE..................................................................................................................................40

PROGRAM EXECUTION..................................................................................................................................41

RESULT OF THE CYCLE................................................................................................................................45

CHECK OF THE CYCLE DATA REPORT........................................................................................................46

MANUAL CYCLE INTERRUPTION..................................................................................................................46

10 - STORING STERILIZED MATERIALS ....................................................................................... 48

INTRODUCTION...............................................................................................................................................48

HANDLING .......................................................................................................................................................48

STORAGE ........................................................................................................................................................48

11 - TEST PROGRAMS.................................................................................................................... 49

INTRODUCTION...............................................................................................................................................49

BOWIE & DICK TEST.......................................................................................................................................49

VACUUM TEST................................................................................................................................................50

APPENDIX A – TECHNICAL CHARACTERISTICS......................................................................... 53

SUMMARY TABLE...........................................................................................................................................53

II

Page 4

TABLE OF CONTENTS

SAFETY DEVICES........................................................................................................................................... 54

WATER SUPPLY CHARACTERISTICS...........................................................................................................55

APPENDIX B – PROGRAMS............................................................................................................56

INTRODUCTION..............................................................................................................................................56

PROGRAM SUMMARY TABLE....................................................................................................................... 57

STERILIZATION PROGRAM DIAGRAM..........................................................................................................59

DIAGRAMS OF THE TEST PROGRAMMES...................................................................................................64

EXAMPLES OF PRINTED REPORTS.............................................................................................................65

APPENDIX C – MAINTENANCE.......................................................................................................67

INTRODUCTION..............................................................................................................................................67

ORDINARY MAINTENANCE PROGRAM........................................................................................................ 67

MAINTENANCE DESCRIPTION......................................................................................................................68

Clean gasket and porthole....................................................................................................................... 68

Clean external surfaces...........................................................................................................................68

Clean sterilization chamber and accessories........................................................................................... 68

Disinfect external surfaces....................................................................................................................... 68

Clean internal distilled water tank ............................................................................................................69

Clean external distilled water tank ...........................................................................................................69

Safety valve maintenance........................................................................................................................69

Clean/replace the drain filter.................................................................................................................... 69

Replace bacteriological filter....................................................................................................................70

Replacing the paper in the printer............................................................................................................70

PERIODIC STERILIZER VALIDATION............................................................................................................71

RECYCLING / DISPOSAL INSTRUCTIONS....................................................................................................71

APPENDIX D – GENERAL PROBLEMS...........................................................................................72

INTRODUCTION..............................................................................................................................................72

ANALYSIS AND RESOLUTION OF PROBLEMS............................................................................................72

APPENDIX E – ALARMS..................................................................................................................75

INTRODUCTION..............................................................................................................................................75

ALARM INTERVENTION .................................................................................................................................75

Alarm during a cycle.................................................................................................................................75

Alarm outside the cycle........................................................................................................................... 76

RESETTING THE SYSTEM............................................................................................................................ 77

ALARM CODES ............................................................................................................................................... 78

ANALYSIS AND RESOLUTION OF PROBLEMS............................................................................................80

APPENDIX F – DIAGRAMS..............................................................................................................86

ELECTRICAL DIAGRAM (BOARD TYPE “G”)................................................................................................. 86

ELECTRICAL DIAGRAM (BOARD TYPE “T”)..................................................................................................87

PLUMBING DIAGRAM..................................................................................................................................... 88

APPENDIX G – DECLARATION OF CONFORMITY ........................................................................89

APPENDIX H – NOTES PER THE OPERATOR ...............................................................................90

APPENDIX Z – TECHNICAL SUPPORT...........................................................................................91

III

Page 5

Page 6

1. INTRODUCTION

INTRODUCTION

Symbols used in the

manual

Dear Customer

Thank you for choosing a product from M.O.COM. Srl. We hope that you will find it completely

satisfactory.

This manual describes all procedures for the correct use of the device and instructions for

deriving the full benefit from its features.

In any case, we will be available to provide explanations and to receive any suggestions you

may have for improving our products or services.

NOTE

PAY SPECIAL ATTENTION TO PARAGRAPHS INDICATED BY THE POINTING FINGER.

WARNING

THIS SYMBOL INDICATES A POTENTIAL DANGER OF INJURY. FOLLOW THE

PROCEDURES DESCRIBED IN THE MANUAL TO AVOID INJURING THE USER

AND/OR OTHERS.

DANGER

THIS SYMBOL INDICATES A POTENTIAL DANGER OF PROPERTY DAMAGE.

FOLLOWS THE INSTRUCTIONS IN THE MANUAL TO PREVENT POTENTIAL

DAMAGE TO MATERIALS, EQUIPMENT OR OTHER PROPERTY.

DANGER

THIS SYMBOL INDICATES A POTENTIAL DANGER DUE TO HIGH TEMPERATURE.

APPLICABLE

EUROPEAN

DIRECTIVES

INTENDED USE

THE MATERIAL THE STERILIZER IS COMPOSED OF MUST BE DISPOSED

ACCORDING TO THE DIRECTIVE 2002/96/CEE

The product described in this manual is manufactured in accordance with the highest safety

standards and doesn't represent any danger for the operator if used according to the following

instructions. The product is in accordance with the following European Directive as applicable:

73/23/CEE, for the approximation to the legislation of the Members States related to low

voltage equipment (and following modifications).

2004/108/CEE, for the approximation to the legislation of the Members States related to the

electromagnetic compatibility (and following modifications);

93/42/CEE, concerning the medical devices (and following modifications

).

The product described in this manual is exclusively intended for the sterilization of solid and

hollow re-usable instruments and porous materials.

WARNING

THE DEVICE MUST ONLY BE USED BY QUALIFIED PERSONNEL. IT MAY

NOT BE USED OR HANDLED BY INEXPERT AND/OR UNAUTHORIZED

PERSONNEL FOR ANY REASON.

THIS DEVICE MUST NOT BE USED FOR THE STERILIZATION OF FLUIDS,

LIQUIDS OR PHARMACEUTICAL PRODUCTS.

NOTE

THE MANUAL INFORMATION ARE SUBJECT TO CHANGES WITHOUT ANY NOTICE.

MO.COM. LTD. CO. WON'T BE RESPONSIBLE FOR DIRECT, INDIRECT, ACCIDENTAL,

CONSEQUENT DAMAGES OR OTHER DAMAGES RELATED TO THE SUPPLY OR THE USE OF

AND

.

ARE REGISTERED TRADEMARKS OF M.O.COM. SRL

SUCH INFORMATION

HIS DOCUMENT MAY NOT BE REPRODUCED, ADAPTED OR T RANSLATED, IN WHOLE OR IN

T

PART, WITHOUT THE PRIOR, WRITTEN AUTHORIZATION OF M.O.COM. SRL

1

Page 7

1. INTRODUCTION

PURPOSE OF THE

MANUAL

GENERAL

WARNINGS

The purpose of this manual is to provide instructions for:

– becoming generally familiar with the product;

– its correct installation and configuration;

– its safe, efficient use ;

– handling materia ls before and after sterilization.

Its appendices also provide:

– the product's general technical specifications;

– sterilization program specifications;

– maintenance;

– troubleshooting;

– a variety of other documentation.

When using this product, always

anything other than its intended purpose.

THE USER IS RESPONSIBLE FOR ALL LEGAL REQUIREMENTS RELATED

TO THE INSTALLATION AND USE OF THIS PRODUCT. THE

MANUFACTURER WILL NOT BE RESPONSIBLE FOR ANY BREAKAGE,

MALFUNCTIONS, PROPERTY DAMAGE OR INJURY IN THE EVENT THAT

THE PRODUCT IS NOT INSTALLED OR USED CORRECTLY.

Please observe the following precautions in order to avoid injury or property damage:

– Use ONLY

– Do not

– Do not

– Do not

distilled water of high quality.

THE USE OF WATER OF INADEQUATE QUALITY CAN SEVERELY

DAMAGE THE DEVICE.

SEE APPENDIX A, TECHNICAL CHARACTERISTICS IN THIS REGARD .

pour water or other liquids on the device;

pour inflammable substances on the device;

use the device in the presence of gas or explosive or inflammable vapors;

follow the instructions in the manual and never use for

WARNING

WARNING

– Before performing any maintenance or cleaning, ALWAYS DISCONNECT the electricity.

WARNING

WHENEVER IT IS NOT POSSIBLE TO DISCONNECT THE ELECTRICITY TO

THE DEVICE, OR IF THE EXTERNAL POWER GRID SWITCH IS FAR AWAY

OR, AT ANY RATE, NOT VISIBLE TO THE MAINTAINER, PLACE A WORK

IN PROGRESS SIGN ON THE EXTERNAL POWER GRID SWITCH AFTER

TURNING IT OFF .

– Make sure the electrical system is grounded

– Do not

– Use only

remove any label or nameplate from the device; request new ones, if necessary.

original replacement parts.

THE FAILURE TO OBSERVE THE ABOVE, RELEASES THE

MANUFACTURER FROM ALL LIABILITY.

conforming to current laws and/or standards;

WARNING

2

Page 8

2. CONTENTS OF THE PACKAGE

CONTENTS OF

THE PACKAGE

DIMENSIONS

AND WEIGHT

DESCRIPTION OF

THE CONTENTS

Total weight about 75 kg

NOTE

CHECK THE INTEGRITY OF THE PACKAGE UPON

RECEIPT

.

Once the package is opened, check that:

– the supply matches the specifications of the order (see the

accompanying document);

– that there is no obvious product damage;

NOTE

IN THE CASE OF A WRONG PRODUCT, MISSING PARTS OR ANY TYPE OF DAMAGE,

IMMEDIATELY PROVIDE A DETAILED DESCRIPTION TO THE RESELLER AND THE

TRANSPORTER THAT MADE THE DELIVERY

.

610

690

560

The package contains:

– Steam sterilizer

– Stainless steel wire instrument tray (5 pcs.) (Ref. 1);

– Stainless steel wire tray support (Ref. 2);

– Instruction manual (Ref. 3);

– Warranty certificate (Ref. 4) (see note).

– Tray extractor (Ref. 5);

– Container with quick connector for adding distilled water (about 2 l ) (Ref. 6);

– Extra bacteriological filter (Ref. 7)

– Silicone tube (2 m) for draining water, with quick connector (Ref. 8).

– Spare roll of printer paper (Ref. 9).

NOTE

THE CUSTOMER MUST KEEP THE WARRANTY CERTIFICATE TOGETHER WITH THE

RECEIPT

.

3

Page 9

2. CONTENTS OF THE PACKAGE

HANDLING THE

PRODUCT

Where possible, the packaged product must be handled using suitable mechanical means

(forklift truck, transpallet, etc.) and following the instructions shown on the package.

In the case of manual handling, the product must be lifted by two persons using the handles

cut in the side of the box.

Once removed from the box, the sterilizer must be lifted by two persons and transported on a

cart or other similar device.

WARNING

WE RECOMMEND THAT THE DEVICE BE TRANSPORTED AND STORED

AT A TEMPERATURE NO LOWER THAN 5 °C. PROLONGED EXPOSURE

TO LOW TEMPERATURE AN DAMAGE THE PRODUCT.

NOTE

KEEP THE ORIGINAL PACKAGING AND USE IT WHENEVER THE DEVICE IS TO BE

TRANSPORTED

DURING SHIPMENT.

. THE USE OF DIFFERENT PACKAGING COULD DAMAGE THE PRODUCT

DANGER

BEFORE TRANSPORT, LEAVE THE DEVICE TURNED-OFF FOR ABOUT 30

MINUTES AFTER THE LAST PROGRAM FINISHES AND DRAIN THE

DISTILLED WATER AND USED WATER TANKS SO THAT THE ALL THE

HOT INTERNAL PARTS WILL HAVE TIME TO COOL.

4

Page 10

3. PRODUCT INTRODUCTION

PRODUCT

INTRODUCTION

INTRODUCTION

GENERAL

CHARACTERISTICS

Millennium B² is MO.COM.'s revolutionary type B (EN 13060) small steam sterilizer and a

new de facto standard for safety, performance, flexibility and ease of use.

It is a sophisticated but, at the same time, easy to use device that, thanks to its wide range of

configuration options and patented operating devices, satisfies every need for sterilizing

medical devices, guaranteeing the maximum performance under all conditions.

It also features a better way of relating to users who, rather than having to adapt to the

machine and its characteristics, are able to "converse" with it and configure it to meet their

own needs.

Thanks to its remarkable ease of use, small size and pleasant appearance, it is the ideal

partner for all professional who demand the maximum sterilization safety.

Millennium B² is a completely microprocessor-controlled steam sterilizer with a large (21-

liter) sterilization chamber made of stamped stainless steel.

It is characterized by an advanced fractionated vacuum system for the complete removal of

air, even from hollow, porous materials, and an effective final vacuum drying phase capable of

eliminating all traces of humidity from any load.

Its exclusive steam generation system, effective plumbing circuit and electronic management

(supplemented by high-precision sensors) guarantees high process execution speeds and

excellent thermodynamic parameter stability.

Moreover, its Process Evaluation System constantly monitors all the machine's “vital”

parameters in real-time, guaranteeing absolute safety and a perfect result.

It offers users 11 sterilization programs (of which one completely programmable), all equipped

with customizable, optimized drying for the fast, effective sterilization of the various types of

loads (instruments and materials) use d in a medica l enviro n ment.

Four of these can be selected directly from the control panel, which has a new simplified,

design.

And then, there are interesting options for configuring the preheating mode (based on the

sterilizer's frequency of use), printing the end of cycle report, methods for filling the water

supply, draining the used water and more.

Please refer to the chapter, “Configuration” for more detail.

Finally, Millennium B² has one of the most complete, sophisticated and advanced safety

systems available today to protect users in the case of any electrical, mechanical, thermal or

biological operating anomaly .

NOTE

PLEASE REFER TO APPENDIX A (TECHNICAL CHARACTERISTICS) FOR A DESCRIPTION

OF THE SAFETY DEVICES.

5

Page 11

3. PRODUCT INTRODUCTION

Millflash

interface

FRONT

LCD display and

control panel

Door

On/Off switch

Service compartment

access panel

Printer paper

output slot

Sterilization

Door microswitch

Motorized

closing system

Bacteriological filter

RS232 serial port

Built-in printer

Used water drain qu ick connector

Distilled water fill quick connector

Water drain plug and filter

Door

Service

6

Page 12

3. PRODUCT INTRODUCTION

used water tank

distilled water tank

REAR

Connection for automatically filling the

Mains fuses

Power cord

Band heating element safety thermostat and manual

rearm

Steam generator safety thermostat and manual rearm

Connection for directly draining the

Jack for Milldrop

Start/Stop cable

Distilled water tank vent

hole

Safety valve

Heat exchanger

Distilled water tank

draining point

(maintenance)

Jack socket for the

external tank level

sensor (option)

7

Page 13

3. PRODUCT INTRODUCTION

CONTROL

PANEL

LCD DISPLAY

Liquid Crystal Display

(LCD)

Command keys

The function of the command keys differ according to operating mode of the equipment.

Key NORMAL mode SETUP mode

Cycle Start/Stop

Sterilization cycle selectio n

Test cycle selection

Enter Setup mode ESC, quit the current menu

Enter, confirmation of the value/option

selected

Value increment / Forward scroll of

the menu options

Value decrement / Backward scroll of

the menu options

4 lines of 20 characters

Illuminated icon

8

Water level

Door status

Process status

Setup status

ALARM

Page 14

3. PRODUCT INTRODUCTION

OPERATING

CYCLE EXAMPLE

The Millennium B² sterilization program can be described as a succession of phases, each

with a specific purpose.

For example, after loading the material in the chamber, closing the door, selecting the program

and starting the cycle (and the consequent locking of the door opening mechanism), the

standard program (for porous materials, 134 °C - 4’) offers the following sequence (see chart,

below):

1. preheating the generator and sterilization chamber;

2. removing the air and penetration of the material by steam through a series of vacuum

(extraction of the fluid from the sterilization chamber) and pressure(injection of steam into

the chamber) phases;

3. raising the pressure, with the consequent increase in the temperature of the steam, until

reaching the conditions required for sterilization (in the example, 134 °C);

4. stabilizing the pressure and temperature;

5. sterilizing for the required time (in the example, 4 minutes);

6. depressurizing the sterilization chamber ;

7. vacuum-drying phase;

8. ventilating the load with sterile air;

9. bringing the pressure of the sterilization chamber back to the atmospheric level.

After reaching atmospheric pressure, the door is automatically unlocked and it can be opened

to remove the load from the sterilization chamber.

It should be emphasized that phases 1, 3, 4, 6 and 9 are identical in all cycles, with slight

variations of duration that are solely dependent on the quantity and consistency of the load

and the heating conditions of the sterilizer while phases 2, 5, 7 and 8 clearly vary their

configuration and/or duration on the basis of the cycle selected (and, as a consequence, the

type of load) and the choices made by the user.

Pressione (bar)

2.10

2.00

1.00

0.00

-0.80

VUOTO FRAZIONATO

PROCESSO

ASCIUGATURA SOTTO VUOTO

Tempo (min)

NOTE

PLEASE REFER TO APPENDIX B (PROGRAMS) FOR MORE DETAIL.

9

Page 15

4. INSTALLATION

660

480

420

5006705

INSTALLATION

INTRODUCTION

COMPARTMENT

DIMENSIONS FOR

BUILT-IN

INSTALLATIONS

The first and fundamental step in achieving good sterilizer operation, long life and complete

use of its features is a correct, careful installation. Moreover, this precaution will avoid the

danger of physical injury or property damage, not to mention malfunctions and damage to the

machine. So, please follow the instructions in this chapter scrupulously

.

NOTE

M.O.COM. CUSTOMER SUPPORT (SEE APPENDIX Z) WILL ANSWER YOUR QUESTIONS

AND PROVIDE ADDITIONAL INFORMATION

HE STERILIZER HAS PASSED ALL REQUIRED INSPECTIONS BEFORE BEING PLACED ON

T

THE MARKET. IT DOES NOT REQUIRE ANY ADDITIONAL CALIBRATION BEFORE BEING

PLACED IN SERVICE

.

.

Dimensions and weight

– Height (total) 420 mm

– Width (total) 480 mm

– Depth

(excluding rear connections) 660 mm

– Total weight 63 kg

Electricity

The electrical system to which the sterilizer will be connected must be suitably dimensioned

based on the electrical characteristics of the device. This information is shown on the back of

the machine.

When installing the sterilizer inside a cabinet, you

must provide adequate space all around the device

(>10cm, specially in the rear part) to provide

effective ventilation as well as a large enough

opening in the back that, in addition to allow the

passage of the power cord will also provide an

50

adequate air flow and the consequent optimum

cooling of the heat exchanger.

It is indispensable that the built-in compartment

have the following minimum dimensions

shown in

the figure.

WARNING

COMPARTMENT DIMENSIONS LESS THAN THOSE SHOWN MAY

COMPROMISE THE CORRECT CIRCULATION OF AIR AROUND THE

DEVICE AND MAY NOT PROVIDE ADEQUATE COOLING, WITH THE

CONSEQUENT DETERIORATION OF PERFORMANCE AND/OR POSSIBLE

DAMAGE.

NOTE

IF THE MAIN SWITCH IS INACCESSIBLE WHEN INSTALLED IN THE COMPARTMENT, USE AN

ELECTRIC PLUG THAT INCORPORATES AN ON/OFF SWITCH.

O NOT REMOVE THE UPPER COVER OR ANY OTHER EXTERNAL PART. WHEN INSTALLED

D

IN THE COMPARTMENT

LEASE REFER TO APPENDIX A (TECHNICAL CHARACTERISTICS) FOR COMPLETE

P

TECHNICAL DATA

, THE DEVICE MUST BE COMPLETE WITH ALL ITS PARTS.

.

10

Page 16

4. INSTALLATION

GENERAL

INSTALLATION

PRECAUTIONS

ELECTRICAL

CONNECTIONS

Obey the following warnings for the correct operation of the device and/or to avoid risky

situations:

Install the sterilizer on a flat surface

an irregular surface and to slightly tilt lower the front part of the sterilizer.

Make sure that the support surface is strong enough to support the device's weight (about 65

kg);

– Leave adequate space for ventilation

sterilizer, especially in back.

If the device is built-in to a cabinet, be sure to respect the warnings in the preceding

paragraph, avoiding an obstructions to the air intake;

– Do not install the sterilizer near tubs, sinks or similar places, to avoid

liquids. This could cause short circuits and/or potentially dangerous situations for the

operator;

– Do not install the sterilizer in a place that is excessively humid or poorly ventilated;

– Do not install the machine were there is gas

– Install the device so that the power cord is not

way to the socket.

– Install the device that any external fill/drain tubing is not

freely to the drain tank.

The sterilizer's must be connected to a socket of the electrical system of adequate capacity for

the device's absorption and ground provided, in conformity with current laws and/or standards.

The socket must be suitably protected by a breaker having the following characteristics:

– Nominal current In 16 A

; if necessary, adjust the leveling feet to compensate for

(at least 10 cm on each side) all around the

contact with water or

or inflammable and/or explosive vapors;

bent or crushed. It must run freely all the

bent or crushed. They must run

CONNECTING THE

DATA RECORDING

MILLFLASH

– Differential current I∆n 0.03 A

WARNING

THE MANUFACTURER WILL NOT BE LIABLE FOR DAMAGES CAUSED BY

INSTALLING THE STERILIZER ON AN INADEQUATE ELECTRICAL

SYSTEM AND/OR NOT EQUIPPED WITH A GROUND.

If it is necessary to replace the plug on the power cord, use one with equal characteristics or,

at any rate, adequate to the device's electrical characteristics. The user is entirely responsible

for the selection and replacement of the plug.

NOTE

ALWAYS CONNECT THE POWER CORD DIRECTLY TO THE SOCKET. DO NOT USE

EXTENSION CORDS

The sterilizer can be connected to MILLFLASH allowing the recording of the cycle data on .txt

format file and its management by PC.

The connectors of the service box are used for interfacing; refer to MILLFLASH Operating

Manual for the installation instructions.

, ADAPTERS OR OTHER ACCESSORIES.

11

Page 17

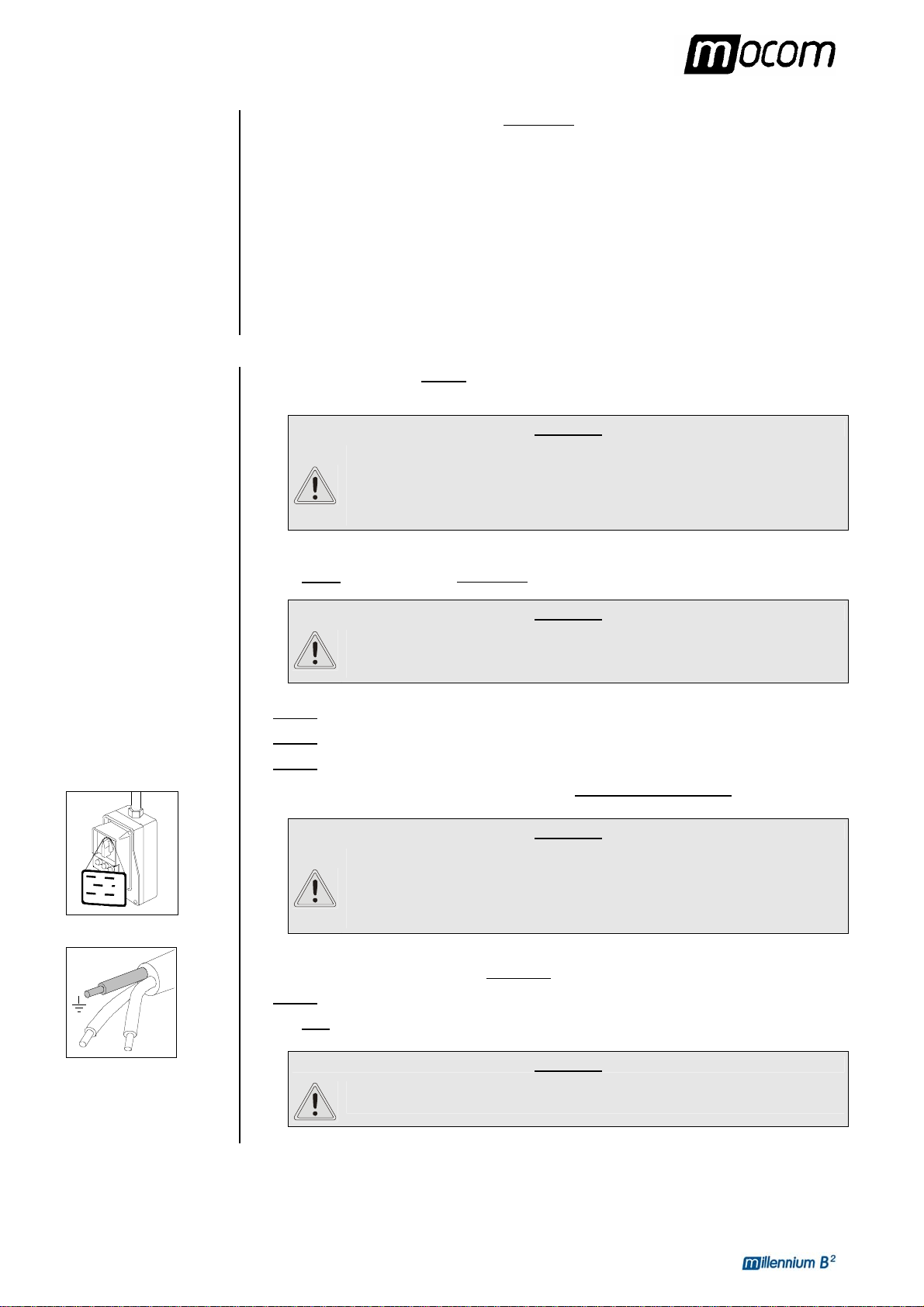

4. INSTALLATION

CONNECTING AN

EXTERNAL

WATER FILLING

TANK

(OPTIONAL, automatic

filling function)

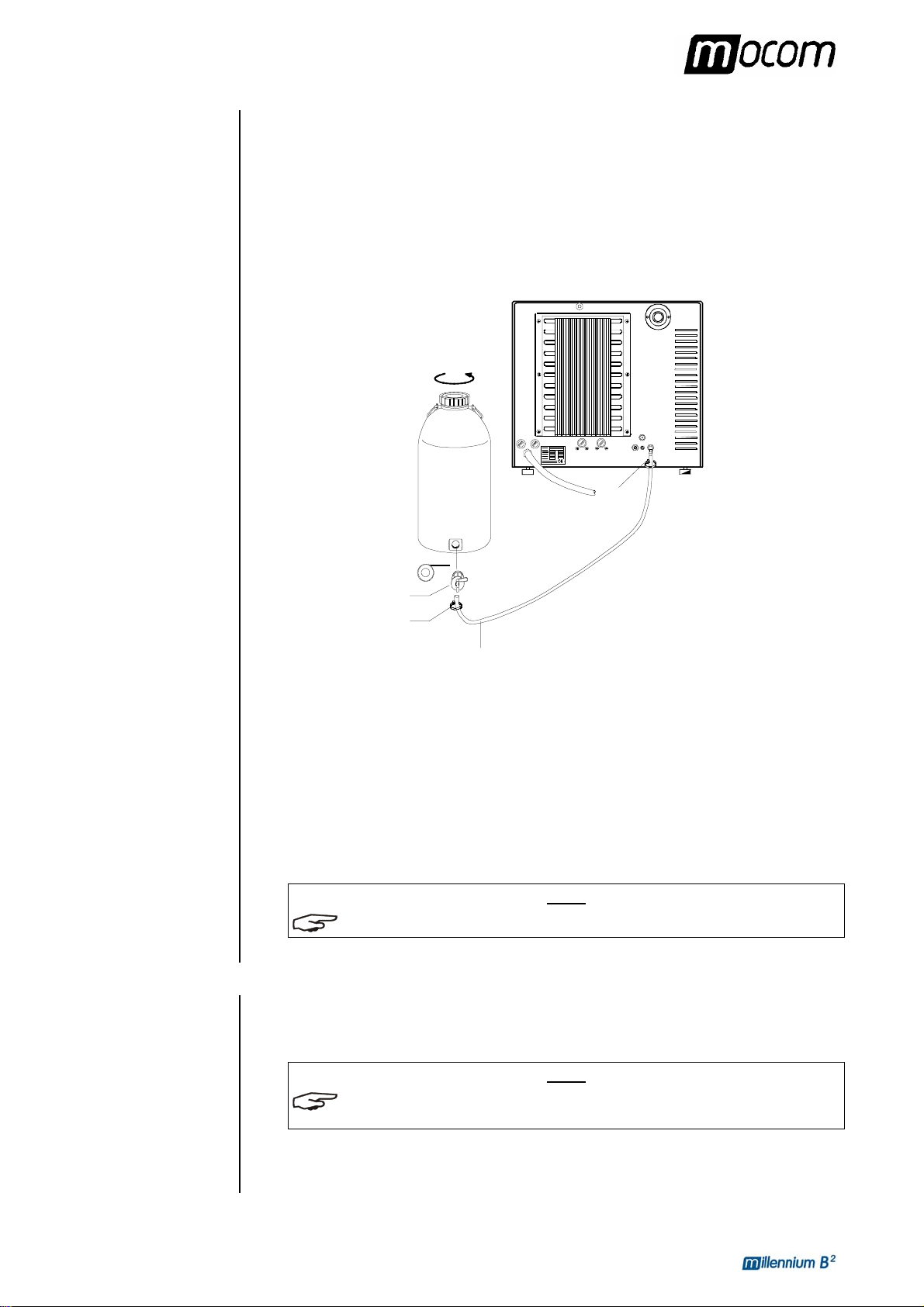

To avoid having to periodically fill the water tank (see Chapter 5, “First Start-Up”), it is

possible to connect the sterilizer to an external filling tank (supplied as an option), that the user

will periodically fill, or to a commercially-available, reverse-osmosis water purification system

with accumulation tank.

In that case, when the internal water tank reaches the MIN level, the autoclave activates a

pump that automatically fills the internal tank.

Follow the instructions below for the correct connection of the external tank:

– Install the tap provided on the filling tank; use Teflon tape or connector sealant for a perfect

seal.

Filling

tank

Clip

CONNECTING

DEMINERALIZER

MILLDROP

Teflon

Tap

Clip

Silicon pipe

– Use the filling tanks silicone tube (or other suitable tube, max length 2m) and insert it on

the filling connector taking care to push it completely on.

– Lock the tube to connector with the plastic tie provided.

– Insert the other end of the tube on the tap of the filling tank.

– Make sure that the tube runs freely from the device to the filling tank, without being bent,

crushed or obstructed in any way.

– Loosen the upper plug to facilitate the flow of water (also remove any gasket or under-

plug);

– Open the tap on the filling tank.

NOTE

REFER TO THE CHAPTER, “CONFIGURING THE DEVICE – AUTOMATIC FILLING OPTION ”.

The sterilizer can be connected to MILLDROP (water treatment system by reverse osmosis)

warranting the automatic reservoir filling with high quality demineralized water.

Refer to MILLDROP operating manual for the installation instructions.

NOTE

FOR THIS OPTION SETTING, REFER TO CHAPTER “CONFIGURING THE DEVICE –

AUTOMATIC FILLING OPTION”.

For additional information and advice about the correct connection of the sterilizer to the

various water purification systems, contact M.O.COM. customer support (see Appendix Z).

12

Page 18

4. INSTALLATION

D

R

e

CONNECTING AN

EXTERNAL DRAIN

TANK

OPTIONAL, external

drain function)

Connecting the tank to

a central draining point

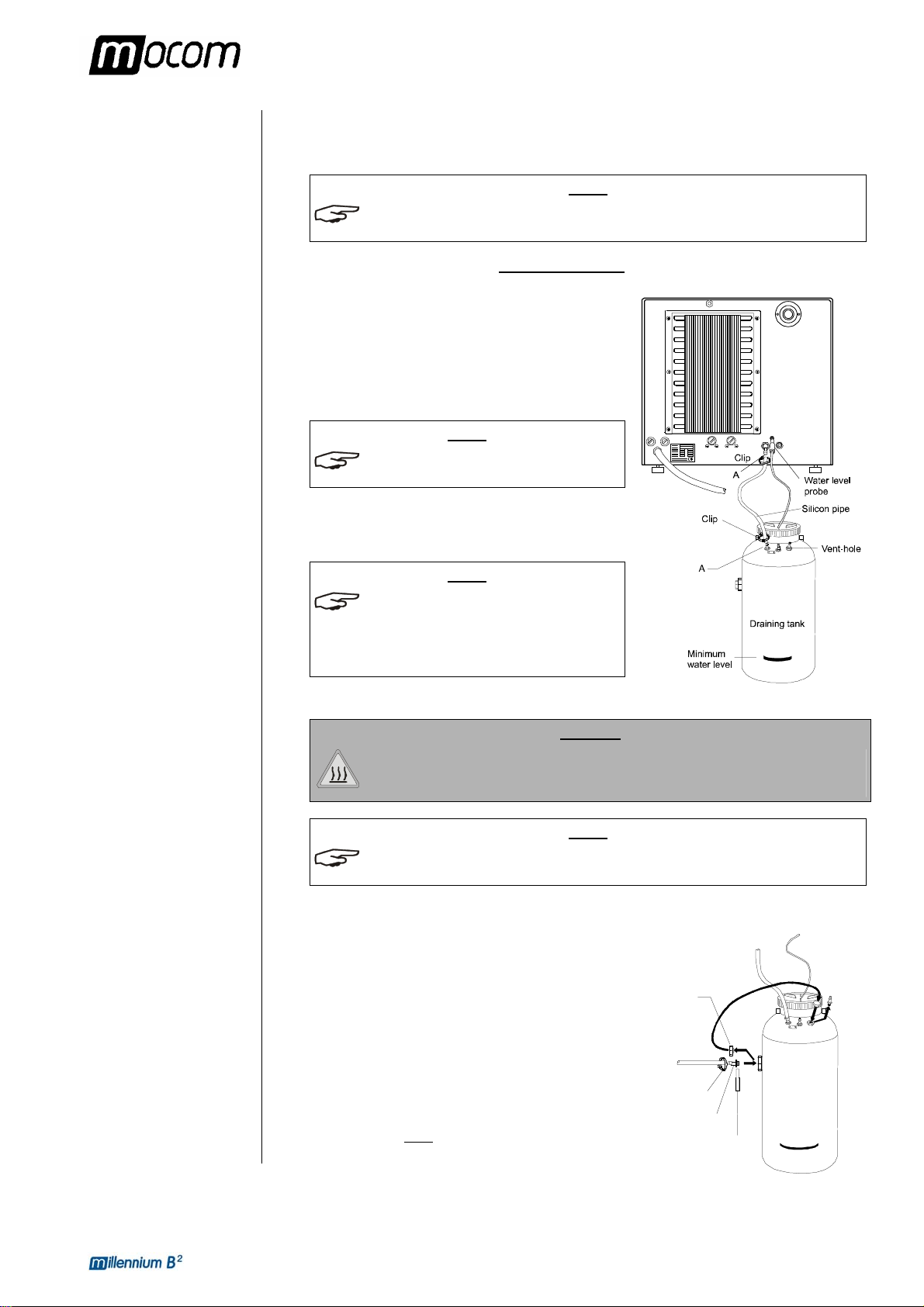

An external drain tank (supplied as an option) can be used to avoid having to periodically

empty the internal used water tank, which is then manually emptied or connected to central

drain system.

NOTE

CHECK THAT THE DRAIN SILENCER IS CORRECTLY INSTALLED INSIDE THE TANK,

CORRESPONDING TO CONNECTION

“A”.

Follow the instructions below for the correct connection of the tank:

– Insert the silicone tube (provided with the option) on

connector A on the machine; push the tube all the

way on and lock it with the plastic tie;

– Cut the silicone tube to measure, push the free end

on connector A on the drain tank and lock it with the

plastic tie;

NOTE

MAKE SURE THE TUBE IS NOT BENT,

CRUSHED OR OBSTRUCTED IN ANY WAY

.

– Connect the plug of the level sensor to the jack

(optional) on the back of the device (see figure);

NOTE

MAKE SURE THE PLUG IS CORRECTLY

INSERTED

INTERPRETED AS A MAX LEVEL SIGNAL,

WITH A CONSEQUENT ALARM WHENEVER

YOU INSIST ON STARTING THE CYCLE

. A POOR CONNECTIN IS

.

– Fill the tank with normal tap water up to the level marked on the container.

DANGER

HOT WATER AND STEAM UNDER PRESSURE COME OUT OF THE DRAIN

CONNECTORS. CONNECT ALL THE ELEMENTS OF THE DRAIN CIRCUIT

CAREFULLY TO AVOID PROPERTY DAMAGE AND/OR INJURY.

NOTE

FOR THIS OPTION SETTING, REFER TO CHAPTER “CONFIGURING THE DEVICE – SETTING

THE WATER DRAINING MODE

”..

To avoid having to periodically empty the draining tank, it

is possible to connect it directly to a central drain.

– Insert the screw plug in place of the free vent hose

union on the side connector of the draining tank;

Plug

eplace th

pipe-fitting

by the plug

– Screw the 1/8" hose union, supplied, on the side

connector; use a wrench to hold the connector to be

tightened;

– Use Teflon tape or connector sealant for a perfect

seal.

– On this tube union, insert a tube of suitable material

and dimensions (NOT

SUPPLIED); push the tube all

the way on and lock with the plastic tie provided.

To the draining

plant

Clip

Pipe-fitting

raining tank

Teflon

13

Page 19

4. INSTALLATION

DIRECT

CONNECTION TO A

CENTRALIZED

DRAINING POINT

– Connect the other end of the tube to the centralized draining point, checking the seal.

NOTE

MAKE SURE THE TUBE IS NOT BENT, CRUSHED OR OBSTRUCTED IN ANY WAY.

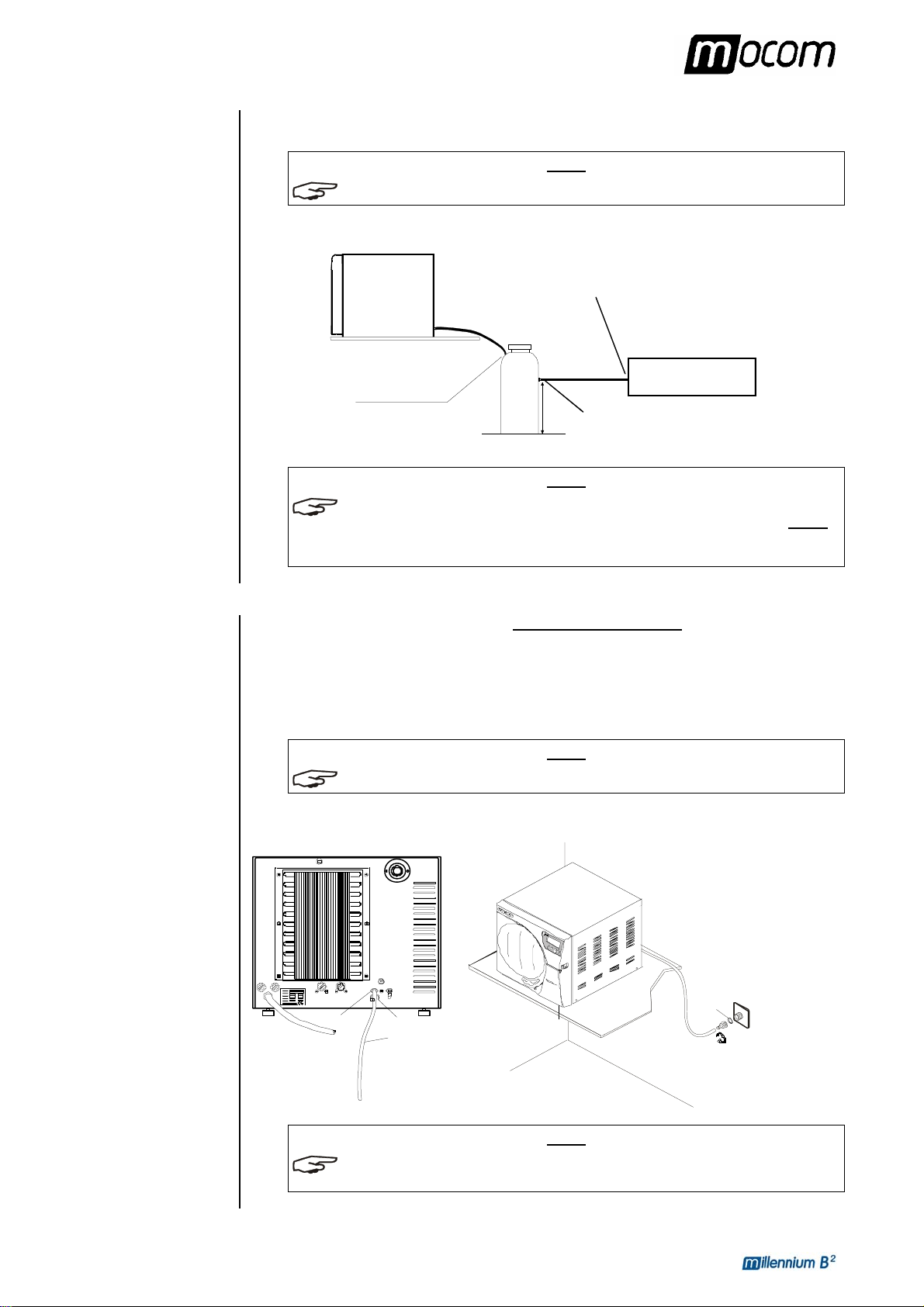

The following diagram provides an indicative arrangement of the components:

Connection point

Sterilizer

Support plane

This point must be lower

than the support pla ne

Draining ta n k

of the centralized draining plant

CENTRALIZED

X

Connection point

of the draining tank

DRAIN

NOTE

DIMENSION X IS THE HEIGHT OF THE SIDE CONNECTOR OF THE TANK ABOVE THE FLOOR.

THE CONNECTION BETWEEN THE TANK AND THE CENTRALIZED DRAINING POINT MUST

NO HIGHER THAN X

EMPTYING OF THE TANK

+30 MM. HIGHER CONNECTIONS COULD COMPROMISE THE CORRECT

.

Follow the instructions shown below for a correct direct connection to a centralized draining

point:

– Insert the silicone tube (provided) or other suitable plastic tube on hose union A; push the

tube all the way on and lock with the plastic tie or other means;

– Cut the tube to measure, push the free end on the connection provided on the centralized

draining point and lock with the plastic tie or other means;

NOTE

MAKE SURE THE TUBE IS NOT BENT, CRUSHED OR OBSTRUCTED IN ANY WAY.

The following diagram provides an indicative arrangement of the components:

Centralized

A

Clip

Pipe

To the centralized

draining point

Su pport plane

This point must be at level lower

than the steri l izer’s support plane

Washer

draining point

Clip

NOTE

THE CONNECTION POINT TO THE CENTRAL DRAIN MUST BE LOWER THAN THE

STERILIZER

'S SUPPORT SURFACE. OTHERWISE, THE TANK MAY NOT EMPTY CORRECTLY.

14

Page 20

5. FIRST START-UP

FIRST START-UP

TURNING ON THE

EQUIPMENT

INITIAL

AUTOMATIC

TEST

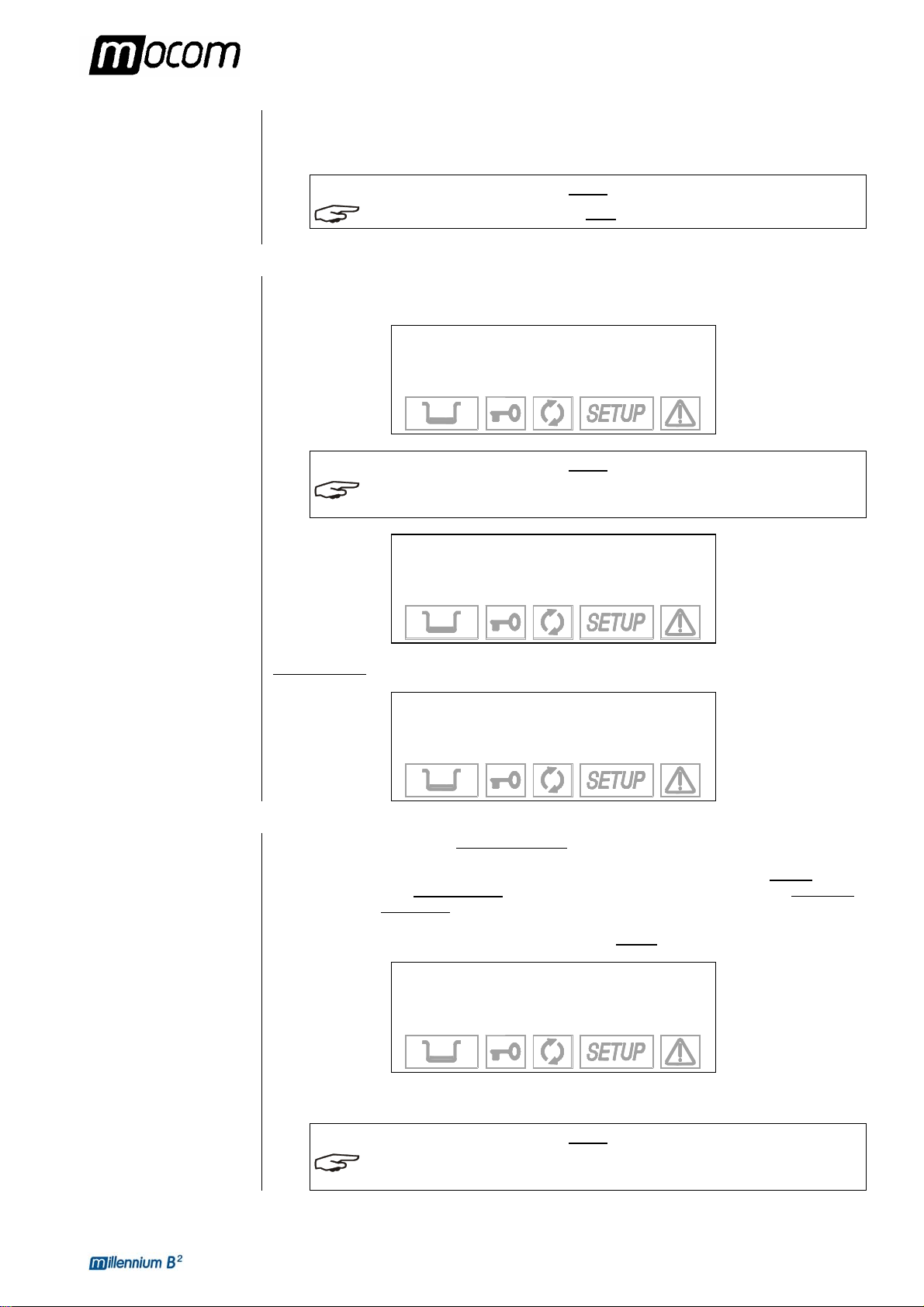

Once the sterilizer has been correctly installed, it may be turned on and prepared for use.

Turn on the equipment by the main (luminous) switch located on the right side of the machine.

NOTE

DO THIS WITH THE STERILIZER'S DOOR OPEN.

When turned on, the control panel lights up and beeps so you can visually check its correct

operation. The panel then displays this message:

MILLENNIUM B2

R. Exxxx/BGyyyyyy

DEVICE CHECK-UP

NOTE

IF THE DOOR IS CLOSED, THE TEST IS INTERRUPTED. THE PANEL THEN BEEPS AND

DISPLAYS THE FOLLOWING MESSAGE

OPEN DOOR

TO CONTINUE

.

ACQUISITION AND

UPDATING OF THE

AMBIENT

PRESSURE

VALUES

Open the door to allow the test to continue. At the end of the test you will see:

MILLENNIUM B2

R. Exxxx/BGyyyyyy

CHECK-UP COMPLETE

The sterilizer measures the ambient pressure for the correct operation of several auxiliary

devices. Whenever the difference between the value read and that previously stored (see the

Chapter, “Configuring the Device - Acquisition the ambient pressure) is higher than a

set value, the system automatically

the data remains unchanged

After updating, the device performs the initial automatic test procedure (see the preceding

paragraph). At the end, the display shows the following notice (accompanied by a beep):

When ↵ is pressed, the device goes to STAND-BY mode (see the following paragraph).

ALSO SEE THE PARAGRAPH, “ACQUIRING THE AMBIENT PRESSURE VALUE” IN THIS

REGARD

without updating.

AMBIENT PRESSURE

-0.01 bar

↵ to continue

.

updates the stored value after a brief delay. Otherwise,

VALUE UPDATED

NOTE

15

Page 21

5. FIRST START-UP

STAND-BY MODE

After the initial test, the sterilizer goes to STAND-BY mode and the display shows:

Counter xxxxx/yyyyy

Stand-by HIGH

23.6 °C 30/08/02

-0.01 bar 18:13:05

The upper line is the cycle counter for sterilizations performed, with the number of correctly

completed cycles on the left

and the total number started on the right. The line below shows

the Stand-by status and the preheating mode (High-Low-Off). The two lower lines show the

temperature and pressure of the sterilization chamber on the left and current date and time on

the right.

NOTE

A CYCLE BEGINS WITH THE START OF THE STERILIZATION CYCLE (FIRST VACUUM

), EXCLUDING THE PREHEATING PHASE. A CYCLE ENDS AT THE END OF THE

PHASE

PROGRAM

(SEE THE CHAPTER, “PROGRAM EXECUTION”).

O SET THE DATE AND TIME AS WELL AS SELECT THE PREHEATING MODE, PRINT THE

T

DATA AND FILL THE TANK

”.

DEVICE

, PLEASE REFER TO THE CHAPTER, “CONFIGURING THE

At regular intervals, the first two lines on the display alternate with the modes set for printing

(ON/OFF) and filling (Manual/Automatic):

Print ON

Filling MANUAL

23.6 °C 30/08/02

-0.01 bar 18:13:05

The icons in the lower part of the LCD screen remain off with the exception of the door status

and/or water level indicators, which light-up if the door is closed and/or the level in the filling

tank reaches its MIN or MAX values (or the MAX value in the drain tank).

During the first start-up, the MIN water level icon in the filing tank is normally on.

The device waits for the selection of the desired sterilization program (see the Chapter,

“Program Selection”).

DANGER

WHEN THE DOOR IS OPEN IN STAND-BY MODE, A LONG BEEP OF

ABOUT 30 SEC. INDICATES THAT THE SURFACES INSIDE THE DEVICE

ARE HOT. TO AVOID BURNS, TAKE CARE NOT TO TOUCH THE

STERILIZATION CHAMBER, THE SUPPORTS PROVIDED OR THE INSIDE

OF THE DOOR WITH YOUR BARE HANDS.

16

Page 22

5. FIRST START-UP

FILLING DISTILLED

WATER

Manual filling

Automatic filling

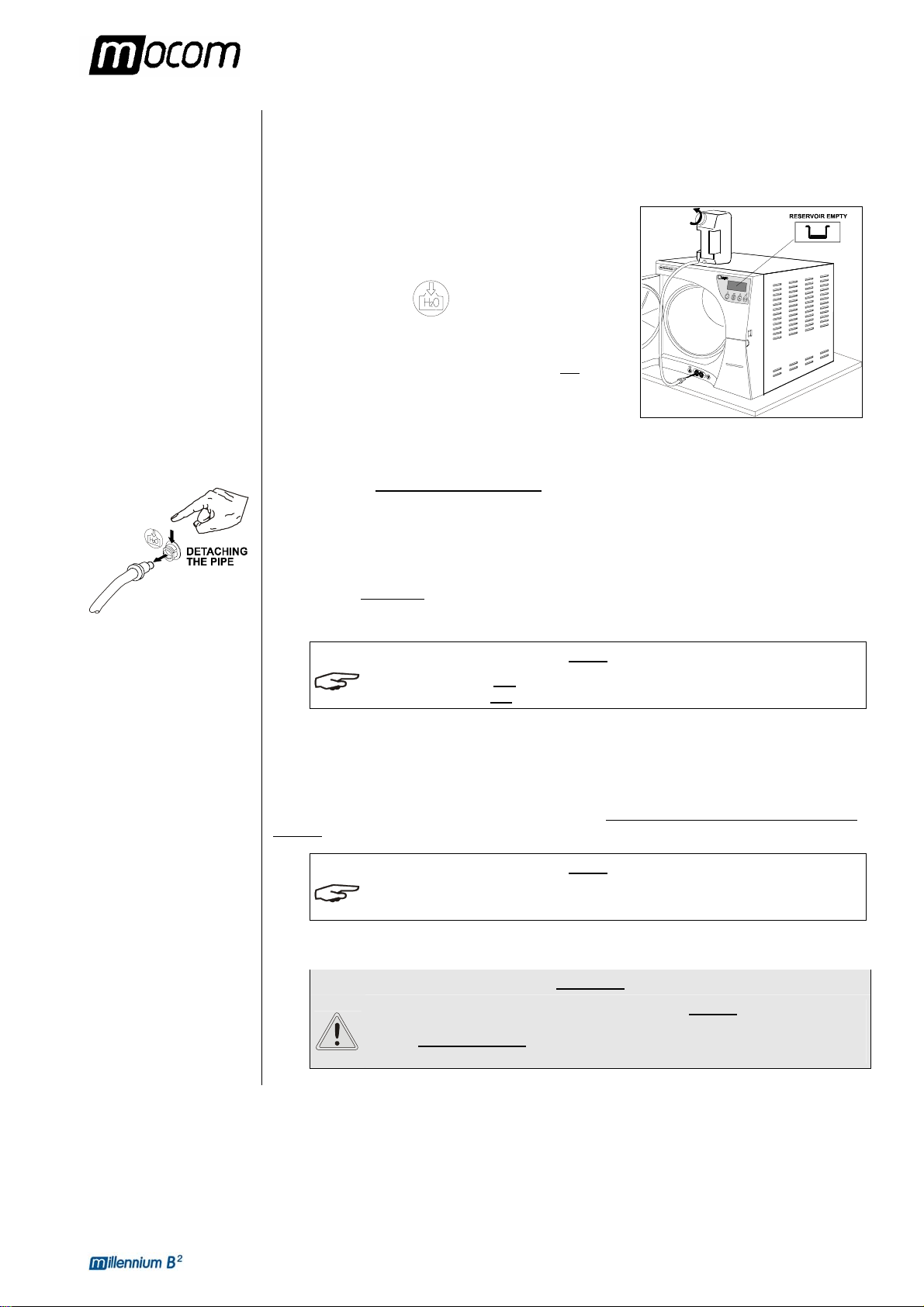

The first time the sterilizer is used, and later when the MIN water level indicator comes on, you

will have to fill, or top-off, the internal distilled water tank.

With reference to the figure (and with the door open), proceed as follows:

1. Fill the manual container (2 l) with distilled water,

keeping it horizontal;

2. Connect the tube’s quick connector to the

corresponding female connector under the chamber

entrance (marked

click;

3. Place the container in a vertical position, at the same

time, loosening the plug and taking care not

water on the machine.

4. The water will begin to flow into the tank;

5. Continue filling until the MIN level indicator turns off.

6. Continue until the water is drained from the container;

7. At this point, lower the connector below

8. While pinching the tube with your fingers, press the metal lever located on the side of the

connector and detach the quick connector;

9. Refill the container (2 l) and repeat the operations described in points 2, 3 and 4 a second

time;

10. W hen the MAX level

quick connector as described in points 7 and 8.

THE ICON MAX DOES NOT HAVE TO BE ON TO START A STERILIZATION PROGRAM. THE

MIN INDICATOR OFF IS SUFFICIENT.

ICON

In the event of sterilizer installation for automatic filling from an external tank or demineralizer

Milldrop (see the Chapter, “Installation”), the filling will occur automatically after the automatic

filling option has been selected.

Obviously, for the correct operation, the user must fill the external tank or switch on the

Milldrop in advance.

USE ONLY HIGH QUALITY DISTILLED WATER. FOR THE SPECIFICATIONS OF THE WATER

SUPPLY

To set the automatic filling option, please refer to the Chapter, “Configuring the Device”.

THE AUTOMATICALLY FILLING SYSTEM MUST NEVER RUN DRY; THIS

CAUSES PREMATURE WEAR TO THE AUXILIARY WATER-INJECTION

PUMP. PERIODICALLY CHECK THE WATER LEVEL IN THE EXTERNAL

TANK.

), pushing until you hear a

to spill

the connection point, keeping it horizontal;

icon comes on (accompanied by a beep), stop filling and detach the

NOTE

NOTE

, SEE APPENDIX A (TECHNICAL CHARACTERISTICS).

WARNING

17

Page 23

5. FIRST START-UP

MAX LEVEL IN THE

INTERNAL/

EXTERNAL DRAIN

TANK

Emptying the internal

tank

Emptying the external

tank (option)

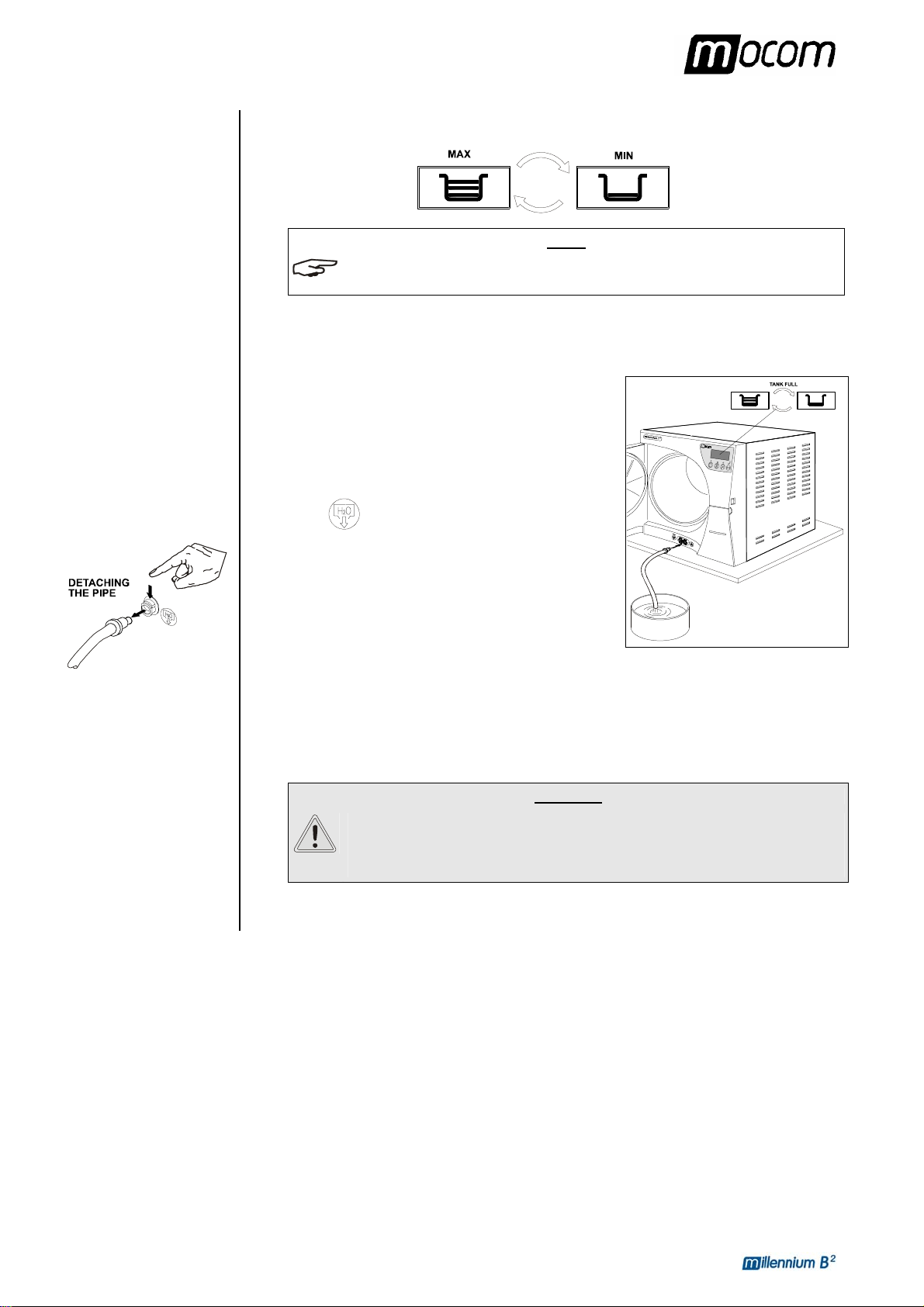

When the water level in the internal or external drain tank reaches the MAX level, the LCD

display alternatively lights the MAX and MIN icons.

NOTE

IN THIS CONDITION THE UNIT WILL GENERATE AN ALARM INDICATION (SEE APPENDIX E -

ALARM) AS YOU ATTEMPT TO LAUNCH A STERILIZATION CYCLE.

In this case, empty the internal or external draining tank.

Referring to the figure, open the door and operate in the

following way:

1. Arrange an empty tank on the floor near the sterilizer

and put the free end of the supplied tube into the tank;

2. Connect the quick connector to the corresponding

female connector under the chamber entrance

(marked

3. Wait for the complete empty of the internal tank; then

while pinching the tube with your fingers, press the

metal lever located on the side of the connector and

detach the quick connector.

Remove the top cap from the external tank and empty into a sink the water exceeding the

signed level.

Refer to chapter “CONNECTING AN EXTERNAL DRAINING TANK” for more details.

), pushing until you hear a click;

WARNING

DO NOT EMPTY THE TANK COMPLETELY, BUT KEEP A QUANTITY OF

WATER UP TO THE MARKED LEVEL. OTHERWISE THE WATER DRAINING

SOUND AND THE STEAM ESCAPE FROM THE VENT-HOLE WILL

INCREASE CONSIDERABLY.

18

Page 24

6. CONFIGURATION

CONFIGURATION

INTRODUCTION

STARTING AND

ENTERING THE

SETUP MODE

MEANING OF THE

KEYS IN SETUP

MODE

Millennium B² offers personalization options never previously seen on any steam sterilizer.

Users may configure the device to meet their own needs. For example, the device's

performance may be adapted on the basis of the type of activity, the type of material to be

sterilized or its frequency of use.

The SETUP program allows selecting from numerous options that users activate through an

intuitive, easy-to-use menu.

NOTE

USE THE SETUP PROGRAM WHENEVER NECESSARY. A CORRECTLY PERSONALIZED

DEVICE PROVIDES THE BEST PERFORMANCE AND THE MOST SATISFACTORY USE

M.O.COM.

PROVIDING SUGGESTIONS OR ADVICE ON THE BEST WAY TO USES THE OPTIONS IN THE

SETUP PROGRAM

To start the SETUP program, hold down the Ç key on the control panel for several seconds,

until the display shows:

ICON SETUP ON THE DISPLAY LIGHTS-UP AND STAYS ON OR THE ENTIRE

CONFIGURATION PHASE.

When you press the ↵ key, you enter the SETUP mode. The screen shows the first-level menu

items (see the paragraph, SETUP flowchart).

Pressing the ESC key Ç quits the SETUP program and takes you back to normal operation

(stand-by mode).

THE SETUP PROGRAM CAN ONLY BE STARTED IN STAND-BY MODE. IT IS NOT

ACCESSIBLE DURING STERILIZATION OR TEST CYCLES

In SETUP mode the control panel keys have different functions than in normal mode.

Key SETUP mode

CUSTOMER SUPPORT (SEE APPENDIX Z) IS AVAILABLE TO HELP USERS BY

MILLENNIUM B2

SETUP

↵ to continue

Ç to exit

NOTE

NOTE

.

.

function ENTER, confirm the selected option or value

Increase the value /scroll down

Decrease the value /scroll up the menu items

ESC, exit the selected menu option

19

Page 25

6. CONFIGURATION

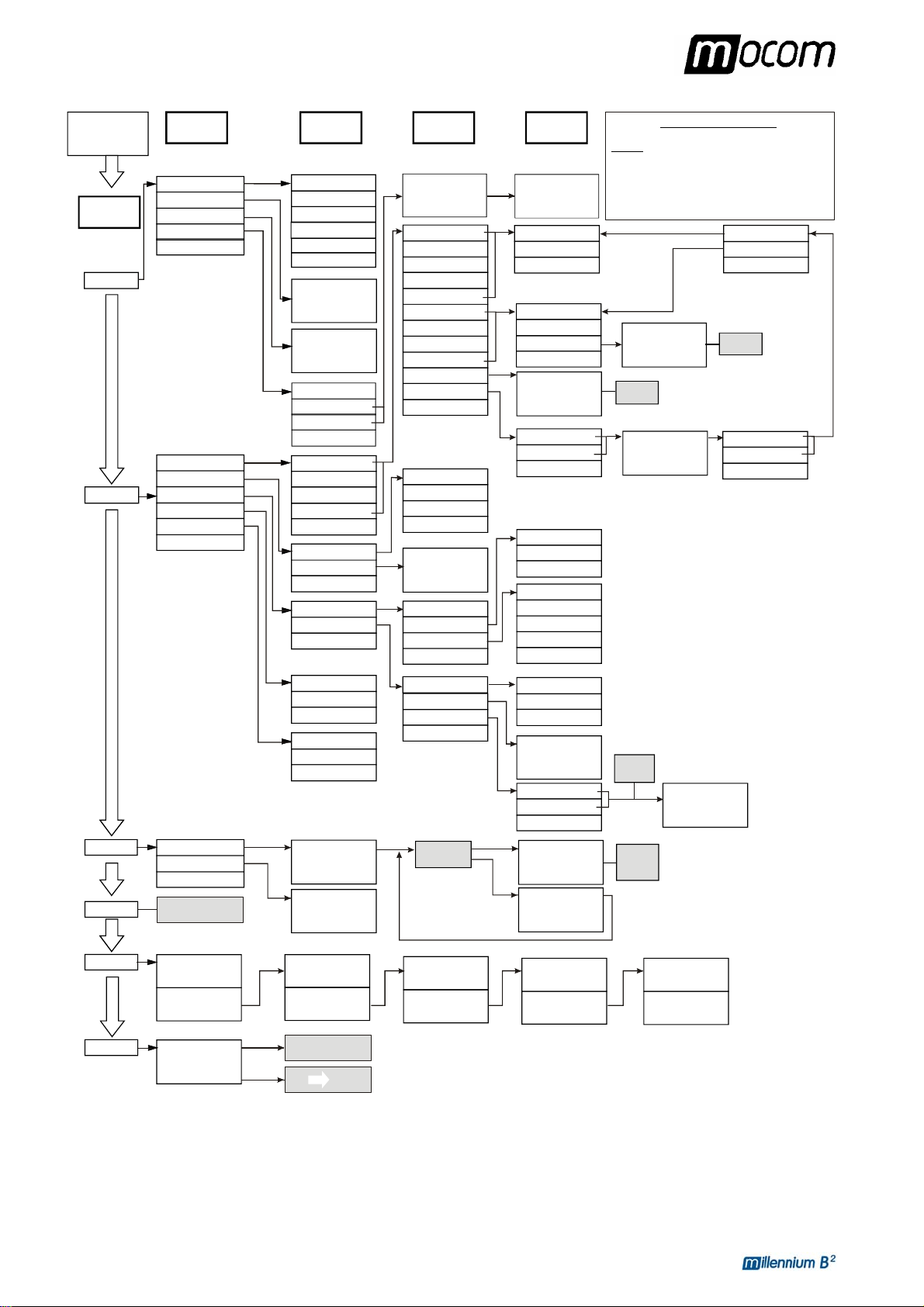

YES

EXIT

EXTRA

: XX mi n

to enter

MANUAL

EXIT

REPORT

EXIT

NORMAL

PRINT

EXTENDED

EXIT

COPIES

to set to enter

NR

. COPIES

EXIT

INTERNAL

EXTERNAL

EXIT

134c

PROCESS

121c

PROCESS

EXIT

MILLENNIUM B2

NOTES

REPORT

NOW PRINTING

PLEASE WAIT...

SHORT

DRYI N G

LONG

DRYING

EXIT

FRACTION

. VACUUM

SINGLE

VACUUM

EXIT

EXTRA

DRYING

DRYING

REVIEW

PRESSURE VALUE

SET INTO MEMORY

WARNING!

OPEN THE DOOR

Is the door

time

limited

(+ beep)

AMBIENT PRESSURE

EXIT

LCD CONTRAST

CR

TYPE CR

+LF TYPE

EXIT TYPE 1

TYPE 2

EXIT

ACQUISITION OF THE

starting

Firmware

release

Date

dd/mm/yyyy

STANDARD

Stand

by option

Print

option

EXTERNAL

Filling

option

AUTOMATIC

EXIT

REVIEW

to confirm

WRAPPED

EMERGENCY

INTERNAL

AT CYCLE END

EXTERNAL

STEP BY STEP

EXIT

EXIT

TIME

TIME

: XX min

: XX min

to enter

to enter

starting

CR

TYPE (+FF)

CR

+LF TYPE (+FF)

CONFIRM

PASSWORD

Setup Layout

Selecting the last option of the current menu (or the item

1st MENU LEVEL

MILLENNIUM B2

SETUP

to continue

↵

⇑

to exit

1st MENU

LEVEL

BASIC

ADVANCED

2nd MENU

LEVEL

LANGUAGE

DATE SETTING

TIME SETTING

PASSWORD

EXIT

PROGRAMS

STANDBY OPTIONS

PRINT OPTIONS

FILLING OPTIONS

DRAIN OPTIONS

EXIT

3rd MENU

ITALIANO

ENGLISH

FRANCAIS

DEUTSCH

ESPANOL

EXIT

+/-

to set

to enter

↵

to exit

⇑

+/-

to set

to enter

↵

⇑

to exit

DISABLED

ANY POWER ON

ANY CYCLE START

EXIT

1st PRESET

2nd PRESET

3rd PRESET

4th PRESET

EXIT

ST-BY MODE

ST-BY TIMEOUT

EXIT

PRINTER

LEVEL

dd/mm/yyyy

hh:mm:ss

4th MENU

LEVEL

INSERT PASSWORD

* * * * * * * * * * * * * * *

↵

to enter

⇑

to exit

134c HOLLOW

121c HOLLOW

134c SOLID

121c SOLID

134c EMERGENCY

134c WRAPPED

121c WRAPPED

134c POROUS

121c POROUS

134c PRION

XXXc CUSTOM

EXIT

OFF

LOW

HIGH

TIMEOUT: XXX min

+/- to set

↵

to enter

⇑

to exit

OFF

5th MENU

LEVEL

* * * * * * * * * * * * * * *

↵

to enter

⇑

to exit

STANDARD DRYING

FAST

EXIT

STANDARD DRYING

INTELL. DRYING

EXIT

+/+/-- to set

↵

⇑

to exit

Selecting the item, the previous menu is displayed

ESC

( key has the same effect of EXIT command)

EXIT

TO ENTER), the previous menu is displayed

+/- to set

↵

to exit

⇑

from 18’

to set

↵

⇑

to exit

from 01’

SPECIAL

SERVICE

EXIT SETUP

ONLY AVAILABLE FOR

MOCOM SERVICE

Exxxx / BP yyyyyy

Language

ENGLISH

Time

hh:mm:ss

MILLENNIUM B2

EXIT SETUP?

to confirm

↵

to resume

⇑

+/ to scroll

confirm

resume

AUTOMATIC

AMBIENT PRESSURE

to enter

↵

to exit

⇑

ADJUSTMENT OF THE

LCD CONTR A S T

+/- to set

to exit

⇑

1st PRESET

134c POROUS

DRYING

2nd PRESET

134c HOLLOW

FAST DRYING

EXIT SETUP AND

GO TO STAND-BY MODE

BACK TO

+/to scroll

PRINTOUT MODE

PRINT LAST

open?

3rd PRESET

134c

EXTRA DRYING (+05)

4th PRESET

134c

FAST DRYING

: XX

+/-

↵

⇑

to exit

PRINT

NO

TO CONTINUE

+/to scroll

HIGH

120 min

1 copy

CR+LF

PRINT

THE REPORT

+/to scroll

Drain option

INTERNAL

20

Page 26

6. CONFIGURATION

DESCRIPTION OF

THE MENU ITEMS

Now, we describe the meaning of the various main menu and second-level menu items.

MAIN MENU

The main menu has 6 entries that open additional (second-level) menus:

BASIC (basic options)

ADVANCED (advanced options)

SPECIAL (special options

SERVICE (menu not accessible to users)

DATA REVIEW (summary

EXIT SETUP (exit the SETUP program and return to normal operation. In

this regard, see the paragraph, Exiting the SETUP

program)

THE METHODS FOR CHANGING THE VARIOUS ITEM SETTINGS ARE FOUND IN THE

PARAGRAPH

BASIC Menu

The Basic menu (basic options) consists of the items:

LANGUAGE (language setting

DATE SETTING (setting the current date

TIME SETTING (setting the current time

PASSWORD (setting the password)

EXIT (exit

ADVANCED Menu

The Advanced menu (advanced options) consists of the items:

PROGRAMMES (setting preselected sterilization programs

STAND-BY OPTIONS (stand-by

PRINT OPTIONS (setting printer and printing options)

FILLING OPTIONS (setting modes for filling

DRAIN OPTIONS (setting the modes for emptying

EXIT (exit

SPECIAL Menu

The Special menu (special options) consists of the following items:

AMBIENT PRESSURE (acquisition of the ambient pressure

LCD CONTRAST (adjusting the contrast

EXIT (exit

SERVICE Menu

The Service menu can ONLY

DATA REVIEW Menu

The Data Review displays a summary of the device's current settings

verify their correctness.

It has the following screens (shown by way of example):

, ACTIVATING CONFIGURATION OPTIONS.

the BASIC menu and return to the main menu)

LCD display)

the ADVANCED menu and return to the main menu)

the SPECIAL menu and return to the main menu)

be accessed by the Service department.

)

of options selected)

NOTE

)

);

)

, shown on the

mode settings)

the distilled water tank)

the used water tank)

)

of the Liquid Crystal Display)

, allowing users to

21

Page 27

6. CONFIGURATION

MILLENNIUM B2

R. Exxxx/BGyyyyyy

LANGUAGE

ENGLISH

Firmware version

Use the keys

1st PRESET

134°C POROUS

STANDARD DRYING

Use the keys

3rd PRESET

134°C WRAPPED

EXTRA DRYING +05

Use the keys

Stand-by option

HIGH

120 min

Use the keys

Filling option

AUTOMATIC

Drain option

INTERNAL

Use the keys

EXIT

DATA REVIEW

↵ to continue

DATE

dd/mm/yyyy

TIME

hh:mm:ss

+ / - to scroll through the menu

2nd PRESET

134°C HOLLOW

FAST DRYING

+ / - to scroll through the menu

4th PRESET

134°C EMERGENCY

FAST DRYING

+ / - to scroll through the menu

Print option

INTERNAL

1 COPY(ies)

+ / - to scroll through the menu

+ / - to scroll through the menu

Press ↵ to confirm

NOTE

FOR THE MEANING OF THE TERMS SHOWN, SEE THE PARAGRAPH, ACTIVATING

CONFIGURATION OPTIONS.

22

Page 28

6. CONFIGURATION

DEFAULTS

SETTINGS

ACTIVATING

CONFIGURATION

OPTIONS

Setting the language

(LANGUAGE on the

BASIC Menu)

Setting the date

(DATE SETTING on the

BASIC Menu)

The sterilizer leaves the factory with the following settings:

DATE: current date

TIME: current time

PROGRAMS: Preset 1: 134°C POROUS (standard drying)

Preset 2: 134°C HOLLOW (standard drying)

Preset 3: 134°C SOLID (standard drying)

Preset 4: 134°C EMERGENCY

NOTE

THE PROGRAMS INDICATED SHOULD BE CONSIDERED AS PREFERENTIAL SETTINGS.

HOWEVER, OTHER COMBINATIONS ARE POSSIBLE BASED ON THE DESTINATION MARKET.

ST-BY MODE: HIGH (preheating)

PRINT OPTIONS: INTERNAL

1 copy

FILLING OPTIONS: MANUAL

DRAIN OPTIONS: INTERNAL

Now, we provide a detailed explanation of how to select the various available options,

proceeding in the shown in the previous paragraph.

Select LANGUAGE using the ↵ key. The following screen will appear:

ITALIANO +

→

ENGLISH ↑

FRANÇAIS ↓

DEUTSCH ESPAÑOL

Select the desired language. Move using the + or – keys and confirm using the ↵ key to store

the selection. After the data is confirmed, you return to the second-level menu.

NOTE

AS SOON AS THE SELECTION IS CONFIRMED, ALL THE MENUS OF THE SETUP PROGRAM

WILL BE DISPLAYED IN THE LANGUAGE SET

When DATE SETTING is selected with the ↵ key, you will see:

dd/mm/yyyy

+/- to set

↵ to enter

Ç to exit

.

Proceed as follows:

– The day flashes: set the current date with the + and - keys. Confirm with ↵.

– The month flashes: set the current month with the + and - keys. Confirm with ↵.

– The year flashes: set the current year with the + and - keys. Confirm with ↵.

The date is stored. Once the last confirmation is given, you return to the second-level menu.

23

Page 29

6. CONFIGURATION

Setting the time

(TIME SETTING on the

BASIC menu)

Setting the password

(PASSWORD on the

BASIC menu)

When TIME SETTING is selected with the ↵ key, you will see:

hh:mm:ss

+/- to set

↵ to enter

Ç to exit

Proceed as follows:

– The hours flash: set the current hour with the + and - keys. Confirm with ↵.

– The minutes flash: set the current value with the + and - keys. Confirm with ↵.

The time is stored. Once the last confirmation is given, you return to the second-level menu.

When PASSWORD is selected with the ↵ key, you will see this menu:

DISABLED +

→

ANY POWER ON ↑

ANY CYCLE START ↓

EXIT -

Select DISABLED to use the device freely, without any limitation on operator access.

Select ANY P OWER-ON to protect the machine with a password at the time it is turned-on

(power-on from the main switch).

This makes sure that the machine can only be powered-on by authorized personnel, but

afterwards it can be used by others without limitation.

Select ANY CYCLE START to protect the autoclave with a password to be entered both at

power-on and at the start of every sterilization program.

Only authorized personnel will be able to use it.

NOTE

ENTERING A PASSWORD PROVIDES MORE CONTROLLED USE OF THE PRODUCT BUT, AT

THE SAME TIME, INEVITABLY MAKES IT MORE CUMBERSOME. SO AS NOT TO OVERLY

COMPLICATE USING THE DEVICE

IT IS REALLY NEEDED

.

, WE RECOMMEND ONLY ACTIVATING THIS OPTION WHEN

When the ANY POWER-ON or ANY CYCLE START options are selected, the following

screen is displayed:

INSERT PASSWORD

↵ to enter

Ç to exit

Enter the password with the + and – keys (fixed length, 8 characters).

Confirm with the ↵ key. Then, the following message will appear:

CONFIRM PASSWORD

↵ to enter

Ç to exit

Enter the password again using the + and – keys.

24

Page 30

6. CONFIGURATION

Confirm with the ↵ key.

NOTE

TO CHANGE THE PASSWORD, FIRST SELECT THE DISABLE OPTION, WHICH CANCELS

THE PREVIOUS PASSWORD

, AND THEN SELECT THE ANY POWER-ON OR ANY

CYCLE START OPTION, ENTERING THE NEW PASSWORD AS DESCRIBED ABOVE.

Setting the sterilization

programs

(PROGRAMS on the

ADVANCED menu)

The program setting and their storing in four pre-set positions is achieved in various steps

using several menus in sequence.

Each pre-set position can be associated to a standard or user configurable cycle (CUSTOM).

Let's look at the two cases separately.

To associate a standard program and define several of its parameters, proceed as follows:

1. Select PROGRAMS using the ↵ key; the following menu appears:

1st PRESET +

→

2nd PRESET ↑

3rd PRESET ↓

4th PRESET EXIT

Define the position (1, 2, 3 or 4) to which the sterilization program will be associated using

the + and - keys. Confirm with the ↵ key.

2. From here, you enter the list of available cycles:

134 °C HOLLOW +

→

121 °C HOLLOW ↑

134 °C SOLID ↓

121 °C SOLID -

134 °C EMERGENCY

134 °C WRAPPED

121 °C WRAPPED

134 °C POROUS

121 °C POROUS

134 °C PRION

XXX °C CUSTOM

EXIT

Using the + and - keys, scroll the list until you identify the sterilization program desired.

3. Confirm the selection with the ↵ key.

When the PRION program is selected, you will go to a screen for selecting the sterilization time.

TIME: XX min

+/- to set

↵ to enter

Ç to exit

A value can be set, starting from 18 minutes.

25

Page 31

6. CONFIGURATION

As a function of the choices made, you will go to one of two alternative menus that allow selecting

the type of drying to associate to the selected program.

a) Programs with short drying (HOLLOW, SOLID, EMERGENCY):

→ STANDARD DRYING +

FAST DRYING ↑

EXIT ↓

-

It is possible to select STANDARD mode (the default setting) or FAST (reduced drying,

recommended for light loads). Move using the + and - keys and confirm with the ↵ key.

NOTE

THE EMERGENCY PROGRAM PROVIDES ONLY FAST DRYING.

b) Programs with long drying (POROUS, WRAPPED, EXTRA):

→ STANDARD DRYING +

INTELL. DRYING ↑

EXTRA DRYING ↓

EXIT -

It is possible to select STANDARD (default setting), INTELLIGENT (automatic drying that

adjusts its duration longer or shorter than standard drying on the basis of the volume

and/or quantity and type of load) or EXTRA (drying extended by a selectable value,

recommended for critical loads). Move using the + and - keys and confirm with the ↵ key.

NOTE

WITH LARGE LOADS OR SPECIAL MATERI ALS, THE STANDARD OPTION MAY NOT

PROVIDE A PERFECT RESULT. IN THIS CASE, EXTEND THE DRYING PHASE BY USING THE

EXTRA MODE.

ITH PARTICULARLY COMPLEX TYPES OF LOADS (SUCH AS WRAPPED INSTRUMENTS IN

W

"CONTAINER" FOR STERILIZATION) "INTELLIGENT" DRYING MAY NOT WORK

A

CORRECTLY, WITH WORSE THAN EXPECTED RESULTS. IN THESE CASES, USE THE

STANDARD OR EXTRA OPTIONS, DEPENDING ON THE NEED.

When the EXTRA option is activated, the following screen appears:

EXTRA: XX min

+/- to set

↵ to enter

Ç to exit

which permits setting the duration of extra drying from between 1 and 15 minutes (time to

be added to the STANDARD DRYING time). Set the value using the + and - keys and

confirm the selection with the ↵ key.

NOTE

THE SELECTION CAN BE CHANGED AT ANY TIME BY FOLLOWING THE PROCEDURE

DESCRIBED ABOVE

HENEVER AN IDENTICAL STERILIZATION PROGRAM IS ALREADY PRESENT IN ANOTHER

W

POSITION, THE SELECTION IS NOT ACCEPTED. THE FOLLOWING WARNING APPEARS ON

THE DISPLAY

.

, ALONG WITH A BEEP:

THIS PROGRAM

IS ALREADY PRESET

26

Page 32

6. CONFIGURATION

To define the CUSTOM program to associate to one of the pre-set position (1, 2, 3 or 4)

proceed as follows:

1. Select PROGRAMS, select the program number to which the program is to be associated

(see the previous description) and then select CUSTOM in the next screen; the following

menu appears:

→

134°C PROCESS +

121°C PROCESS ↑

EXIT ↓

-

Select 121 °C to perform a custom program with a sterilization process at 121 °C or 134 °C

for one at 134 °C. Move using the + and - keys and confirm with the ↵ key.

2. You will then go the screen:

TIME: XX min

+/- to set

↵ to enter

Ç to exit

Use the + and - keys to set the duration of the sterilization process and confirm with the ↵

key.

NOTE

THE DURATION OF THE STERILIZATION PROCESS IS VARIABLE FROM 4 TO 30 MINUTES

FOR THE PROGRAM AT 134 °C, AND FROM 20 TO 30 MINUTES FOR THE PROGRAM AT

121 °C.

3. After selecting the time, you go to the menu where you specify the type of initial vacuum:

→ FRACTION. VACUUM +

SINGLE VACUUM ↑

EXIT ↓

-

Select FRACTION. to perform a fractionated vacuum (indispensable for sterilizing hollow

bodies and porous materials), or SINGLE for a single preliminary vacuum phase (solid

instruments). Move using the + and - keys and confirm with the ↵ key.

4. At this point, you come to another menu

SHORT DRYING +

→

where you set the drying mode:

LONG DRYING ↑

EXIT ↓

-

Select LONG drying suitable for porous and/or wrapped loads, or SHORT if you need to

sterilize solid, loose materials (and even hollow so long as not wrapped). Move with the +

and - , confirm with the ↵ key.

27

Page 33

6. CONFIGURATION

5. Depending on the selection (SHORT or LONG) one of two different menus will open (these

menus are the same for the standard cycles), i.e.:

In SHORT mode the following is displayed:

→ STANDARD DRYING +

FAST DRYING ↑

EXIT ↓

-

In LONG mode the following is displayed:

STANDARD DRYING +

→

INTELL. DRYING ↑

EXTRA DRYING ↓

EXIT -

For the choice criteria, refer to the instruction of page 26.

Whenever the CUSTOM program is already present in another position, the selection

is not accepted. The following warning appears on the display, along with a beep:

THIS PROGRAM IS

ALREADY PRESET

NOTE

THE SELECTION CAN BE CHANGED AT ANY TIME BY FOLLOWING THE PROCEDURE

DESCRIBED ABOVE

.

HE LIST OF AVAILABLE PROGRAMS, THEIR SCREENS AND THE CHARACTERISTICS OF

T

STERILIZABLE MATERIALS

(IN RELATION TO THE PROGRAMS) ARE CONTAINED IN

APPENDIX B (PROGRAMS).

CCESS TO A CUSTOM CYCLE DOES NOT REQUIRE A PASSWORD. NONE OF THE

A

COMBINATIONS POSSIBLE IN THE CUSTOMIZATION PHASE CREATE ANY RISKS OR

DANGERS OF INJURY TO THE OPERATOR OR DAMAGE TOT HE DEVICE

.

28

Page 34

6. CONFIGURATION

Setting the STAND-BY

mode

(STAND-B Y OPTIO NS on

the ADVANCED menu)

Based on the equipment's frequency of use, or other considerations, it is possible to select the

heating level during the STAND-BY (preheating) phase and the time beyond which STAND-BY

is deactivated.

When you s elect STAND-BY OPTIONS with the ↵ key, you access the following menu:

ST-BY MODE +

→

ST-BY TIME-OUT ↑

EXIT ↓

-

When you select STAND-BY MODE, an additional menu appears where you can set the

heating level:

→

OFF +

LOW ↑

HIGH ↓

EXIT -

Select HIGH (high preheating level) for intense use or, at any rate, to reduce the wait time

between one cycle and the next to a minimum.

Select LOW (low

preheating) for normal use, since the wait time will be relatively shorter, in

any case.

Select OFF (deactivate

preheating) for occasional use. In this case, the wait time will be longer

(up to about 10-12 minutes for a "cold start").

Move using the + and - keys ; confirm with the ↵ key.

On the other hand, when the ST-BY TIME-OUT option is selected, it is possible to set the time

for deactivating STAND-BY, i. e., how many minutes after the last cycle the heating elements

are turned off.

The following screen appears:

TIMEOUT: XXX

min

+/- to set

↵ to enter

Ç to exit

It is possible to set a value between 0 and 300 minutes (in 30-minute increm ents), after which

the heating elements are turned off (a condition analogous to STAND-BY OFF), avoiding the

useless consumption of electricity.

Set using the + and - keys; confirm with the ↵ key.

NOTE

THIS OPTION IS ALSO ACTIVE WITH STAND-BY OFF. HOWEVER, IN THIS CONDITION

THE TIMER VALUE OBVIOUSLY HAS NO EFFECT SINCE THE HEATING ELEMENTS ARE

TURNED OFF ANYWAY AT THE END OF THE STERILIZATION PROGRAM

.

HEN ANY CYCLE SELECTION KEY (STERILIZATION OR TEST) IS PRESSED, OR THE

W

MACHINE IS TURNED OFF AND ON WITH THE MAIN SWITCH

MODE (HIGH OR LOW) IS IMMEDIATELY REACTIVATED.

, THE ORIGINAL STAND-BY

29

Page 35

6. CONFIGURATION

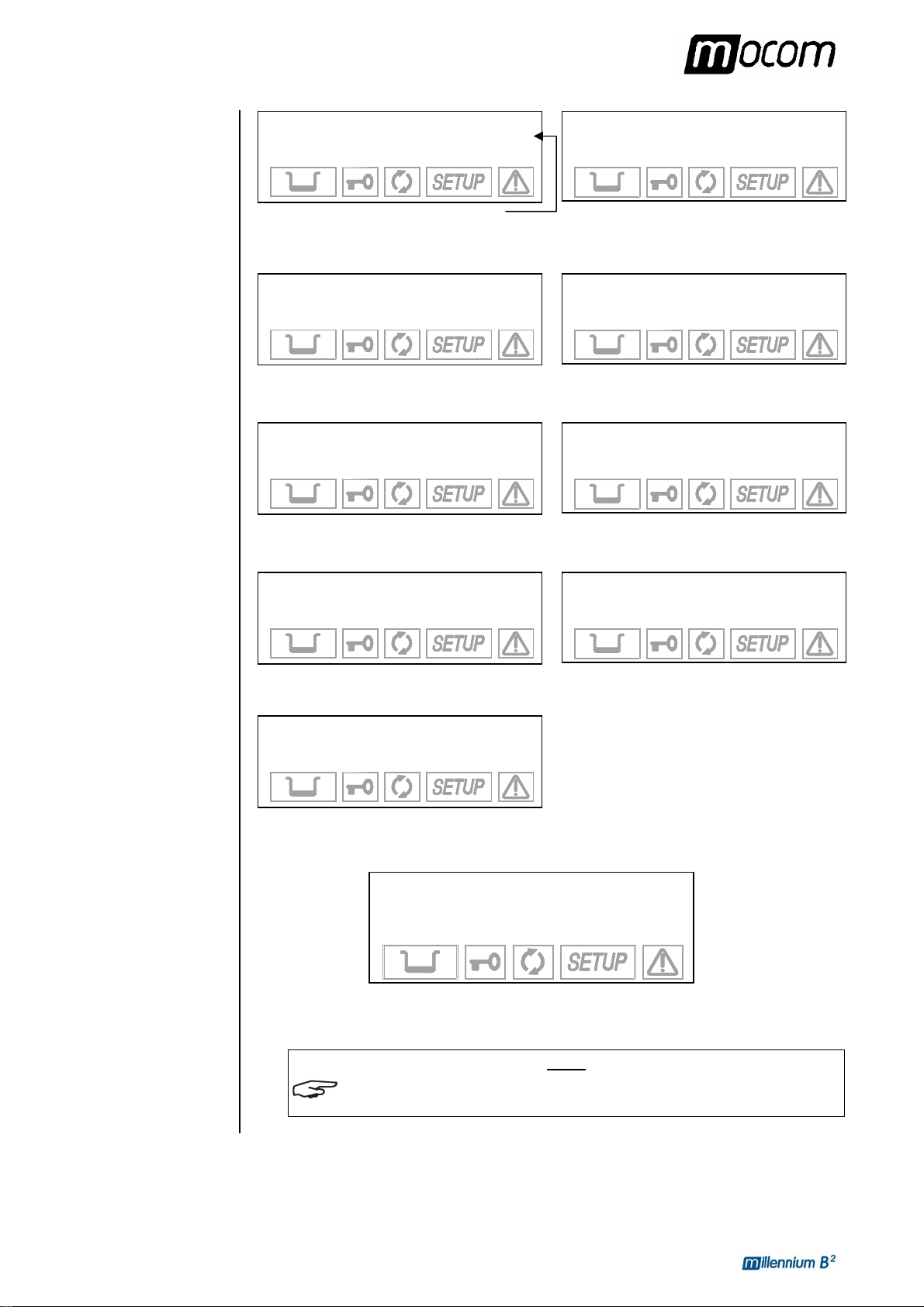

Setting the printing

mode

(PRINT OPTIONS on the

ADVANCED menu)

Printer model 1

The sterilizer is equipped wi th a printer for recording sterilization program data; it is necessary

to set the parameters required for its proper operation.

1. Select PRINT OPTIONS using the ↵ key and the following menu appears:

PRINTER +

→

REPORT ↑

EXIT ↓

-

Select PRINTER to select the settings for the printer used, or REPORT to set the number

of copies to print and to reprint data from the last program executed.

a) Item PRINTER

The following screen appears:

→

OFF +

INTERNAL ↑

EXTERNAL ↓

EXIT -

Select OFF to deactivate the printing of data at the end of a sterilization (or test) cycle.

Select INTERNAL to enable the thermal printer set inside the front of the sterilizer. In

this case, another menu opens:

→

TYPE 1 +

TYPE 2 ↑

EXIT ↓

-

Printer model 2

Select Type 1 for the model 1 of the printer installed.

Select Type 2 for the model 2 of the printer installed.

If, on the other hand, you choose EXTERNAL, the data will be printed on an external

peripheral. Following this selection, another menu opens:

CR TYPE +

→

CR+LF TYPE ↑

CR (+FF) TYPE ↓

CR+LF (+FF) TYPE EXIT

Activate CR to use printers that advance the paper only on the CR (Carriage Return)

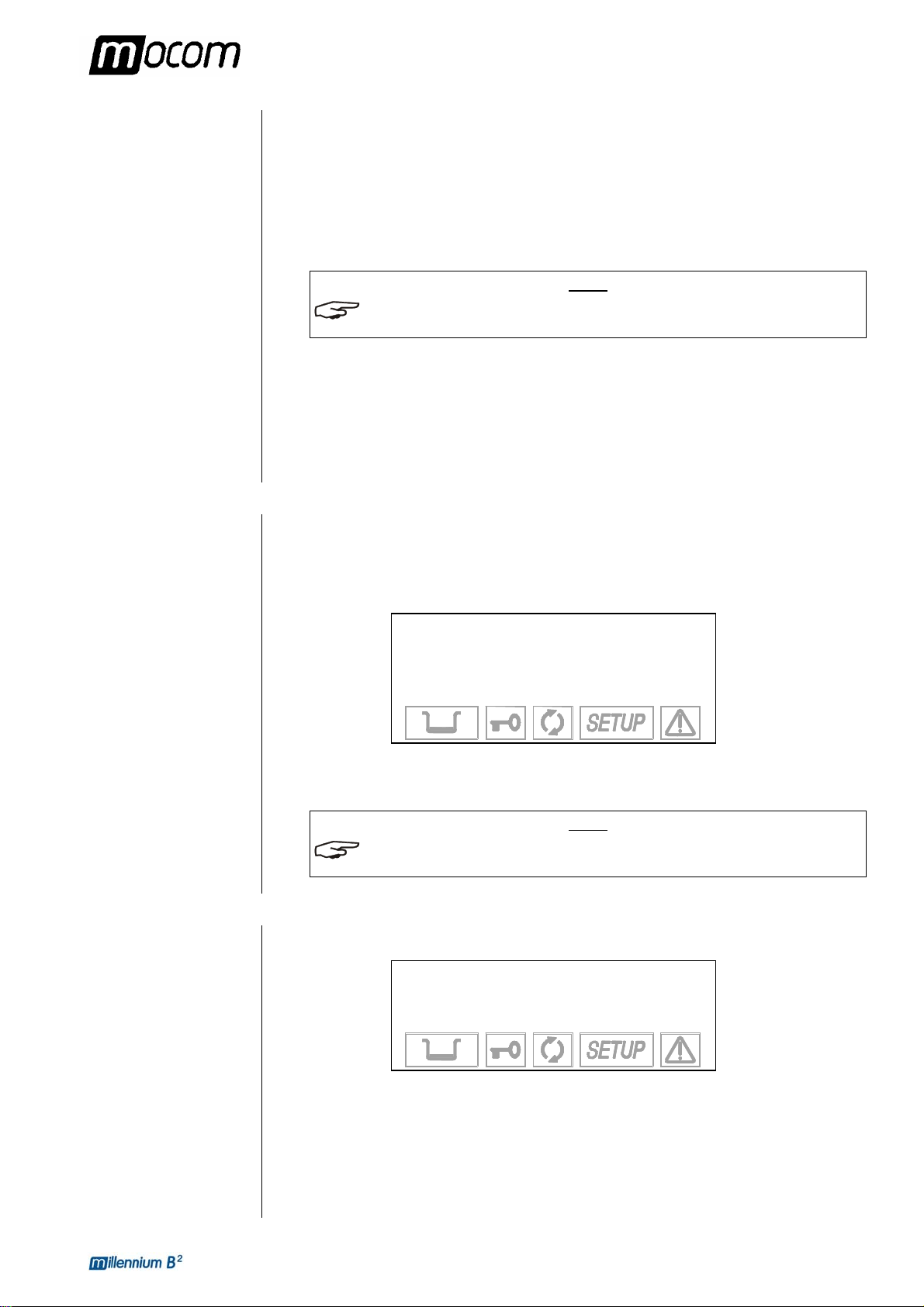

command, or CR+LF for that require the CR+LF (Carriage Return + Line Feed)