DEMINERALIZZATORE D’ACQUA

WATER DEMINERALIZER

DEMINERALISATEUR D’EAU

UMKEHROSMOSEANLAGE

DESMINERALIZADO

R DE AGUA

Manuale Operatore

User Manual

Manuel d’utilisation

Bedienerhandbuch

Manual Operador

®

®

Via Saliceto, 22 • 40012 Castel Maggiore (BO) Italy • www.mocom.it

cod. 97050402

ITALIANO

DEMINERALIZZATORE D’ACQUA

Manuale Operatore

WATER DEMINERALIZER

User Manual

DEMINERALISATEUR D’EAU

Manuel d’utilisation

UMKEHROSMOSEANLAGE

Bedienerhandbuch

DESMINERALIZADOR DE AGUA

Manual Operador

ENGLISHFRANÇAIS DEUTSCH ESPAÑOL

i

ENGLISH

WATER DEMINERALIZER

USER MANUAL

REVISIONS

The following table lists subsequent editions/revisions of the manual.

The “Description” field brief explains the subject of the latest revision.

Code Rev. Date Description

D#0MDAA1000X 0 09-2005 First issue

D#0MDAA1000X 1 10-2006 Modified resin filter assembly and maintenance procedures

D#0MDAA1000X 2 06-2007 Modified the external graphics

D#0MDAA1000X 3 05-2008 New hydraulic and electrical drawing

New installation and maintenance procedures

97050402 4 05-2011 Address and code updating on Mocom use and maintenance manuals

97050402 5 07-2011 Correcting the board setting indication

TABLE OF CONTENTS

INTRODUCTION ................................................................................................................................................................ 1

APPLICABLE EUROPEAN DIRECTIVES ............................................................................................................... 1

INTENDED USE ...................................................................................................................................................... 1

PURPOSE OF THE MANUAL ................................................................................................................................. 2

GENERAL DIRECTIONS ........................................................................................................................................ 2

PACKAGE CONTENT........................................................................................................................................................ 3

SIZE AND WEIGHT ................................................................................................................................................. 3

HANDLING THE PRODUCT ................................................................................................................................... 3

CONTENT DESCRIPTION ...................................................................................................................................... 3

PRODUCT INFORMATION ................................................................................................................................................ 4

INTRODUCTION ..................................................................................................................................................... 4

GENERAL FEATURES ........................................................................................................................................... 4

FRONT PANEL ....................................................................................................................................................... 5

REAR PANEL .......................................................................................................................................................... 5

FUNCTIONING ........................................................................................................................................................ 5

INSTALLATION ................................................................................................................................................................. 6

INTRODUCTION ..................................................................................................................................................... 6

POWER SUPPLY .................................................................................................................................................... 6

SIZE OF EMBEDDING CHAMBER ......................................................................................................................... 6

GENERAL INSTALLATION PRECAUTIONS .......................................................................................................... 7

POWER SUPPLY .................................................................................................................................................... 7

INSTALLATION ONTO A WALL .............................................................................................................................. 8

HYDRAULIC AND ELECTRICAL CONNECTIONS ................................................................................................. 9

Initial installation ................................................................................................................................................. 9

Purging the internal hydraulic circuit .................................................................................................................. 9

Case 1: Direct connection to a sterilizer series Millenium ................................................................................ 11

ii

Case 2: Connection to an external feeding tank (optional) ............................................................................... 12

Case 3: Connection to an electric-type drawing tap (option) ............................................................................ 13

FIRST STARTUP .............................................................................................................................................................. 14

MILLDROP CONNECTED TO THE STERILIZER SERIES MILLENNIUM ............................................................ 14

MILLDROP CONNECTED TO THE FEEDING TANK ............................................................................................ 14

MILLDROP CONNECTED TO THE MANUAL DRAWING TAP ............................................................................. 15

STAND-BY STATUS .............................................................................................................................................. 15

APPENDIX A – TECHNICAL CHARACTERISTICS ........................................................................................................ 16

SUMMARY TABLE ................................................................................................................................................. 16

CHARACTERISTICS OF THE DEMINERALISED WATER ................................................................................... 17

APPENDIX B - MAINTENANCE ....................................................................................................................................... 18

INTRODUCTION .................................................................................................................................................... 18

ORDINARY MAINTENANCE PROGRAMME......................................................................................................... 18

GENERAL MAINTENANCE PROCEDURES ......................................................................................................... 18

REPLACING THE FILTERS ................................................................................................................................... 19

Resin filter cartridges ........................................................................................................................................ 19

Osmotic membrane and active carbon filter cartridge ....................................................................................... 20

REPLACING THE FLOW RESTRICTOR ............................................................................................................... 22

DISPOSAL AT END-OF-LIFE ................................................................................................................................ 22

APPENDIX C – TROUBLESHOOTING ............................................................................................................................ 23

INTRODUCTION .................................................................................................................................................... 23

ANALYSIS AND RESOLUTION OF PROBLEMS .................................................................................................. 23

APPENDIX D - DIAGRAMS .............................................................................................................................................. 25

ELECTRIC DIAGRAM ............................................................................................................................................ 25

HYDRAULIC DIAGRAM ......................................................................................................................................... 26

APPENDIX G – DECLARATION OF CONFORMITY ....................................................................................................... 27

APPENDIX H - NOTES ..................................................................................................................................................... 28

APPENDIX Z – TECHNICAL ASSISTANCE .................................................................................................................... 29

INTRODUCTION

1

ENGLISH

INTRODUCTION

Symbols

Dear Client

Thank you for choosing this product from M.O.COM. Srl. We hope that you will find it

completely satisfactory.

This manual describes all procedures for the correct installation and use of the

equipment.

Should you have any questions or suggestions concerning this product or our support, do

not hesitate to contact us.

NOTE

PAY SPECIAL ATTENTION; NOTES FOR PROPER INSTALLATION AND MAINTENANCE

PROCEDURES AND USE METHODS

.

WARNING

THIS SYMBOL INDICATES A POTENTIAL DANGER OF INJURY.

FOLLOW THE PROCEDURES DESCRIBED IN THE MANUAL TO

AVOID INJURING THE USER AND/OR OTHERS.

DANGER

THIS SYMBOL SIGNALS A POSSIBLE DANGER FOR PEOPLE.

FOLLOW THE SUGGESTED PROCEDURE IN ORDER TO PREVENT

POSSIBLE DAMAGE TO USERS AND/OR OTHERS.

THE MATERIAL THE DEMINERALIZER IS COMPOSED OF MUST BE

DISPOSED ACCORDING TO THE DIRECTIVE 2002/96/CEE

APPLICABLE

EUROPEAN

DIRECTIVES

The product described in this manual is manufactured in accordance with the highest

safety standards and doesn't represent any danger for the operator if used according to

the following instructions. The product is in accordance with the following European

Directive as applicable:

2006/95/CE

, for the approximation to the legislation of the Members States related to

low voltage equipment.

2004/108/CE, for the approximation to the legislation of the Members States related to

the electromagnetic compatibilità.

INTENDED USE

Important notes

The equipment is meant for professional use and can be employed only the purpose it

was designed for, that is the demineralization of the public water, and its use for the

water steam sterilizer feeding.

WARNING

THE DEVICE MUST ONLY BE USED BY QUALIFIED PERSONNEL.

IT MAY NOT BE USED OR HANDLED BY INEXPERT AND/OR

UNAUTHORIZED PERSONNEL FOR ANY REASON.

NOTES

THE INFORMATION INCLUDED IN THIS MANUAL IS SUBJECT TO CHANGE WITHOUT

NOTICE

.

M.O.COM. S

RL SHALL NOT BE RESPONSIBLE FOR DIRECT, INDIRECT,

ACCIDENTAL OR CONSEQUENTIAL DAMAGE OR OTHER DAMAGES RELATED TO

THE SUPPLY

/USE OF THIS INFORMATION.

T

HIS DOCUMENT MAY NOT BE REPRODUCED, ADAPTED OR TRANSLATED, IN

WHOLE OR IN PART

, WITHOUT THE PRIOR, WRITTEN AUTHORIZATION OF

M.O.COM. SRL

IS REGISTERED TRADEMARK OF M.O.COM. SRL.

INTRODUCTION

2

PURPOSE OF THE

MANUAL

The purpose of this manual is to provide directions for:

- becoming familiar with the product;

- its appropriate installation;

- its secure and efficient employment.

The appendixes provide information regarding:

- technical characteristics;

- maintenance procedures;

- analysis and solution of problems;

- further miscellaneous documentation.

GENERAL

DIRECTIONS

The product must always be used in compliance with the procedures set out in this

manual and never for purposes that are different from the foreseen ones.

WARNING

THE USER IS RESPONSIBLE FOR ALL LEGAL OBLIGATIONS

LINKED TO THE PRODUCT’S INSTALLATION AND USE. IF THE

PRODUCT IS NOT INSTALLED OR USED PROPERLY, OR CORRECT

MAINTENANCE/ SERVICING IS NOT CARRIED OUT, IT SHALL NOT

BE POSSIBLE TO DEEM THE MANUFACTURER RESPONSIBLE FOR

ANY POSSIBLE BREAKAGE, MALFUNCTIONING, DAMAGES TO

THINGS, OR INJURIES TO PERSONS.

Please observe the following precautions in order to avoid injury or property damage; in

particular:

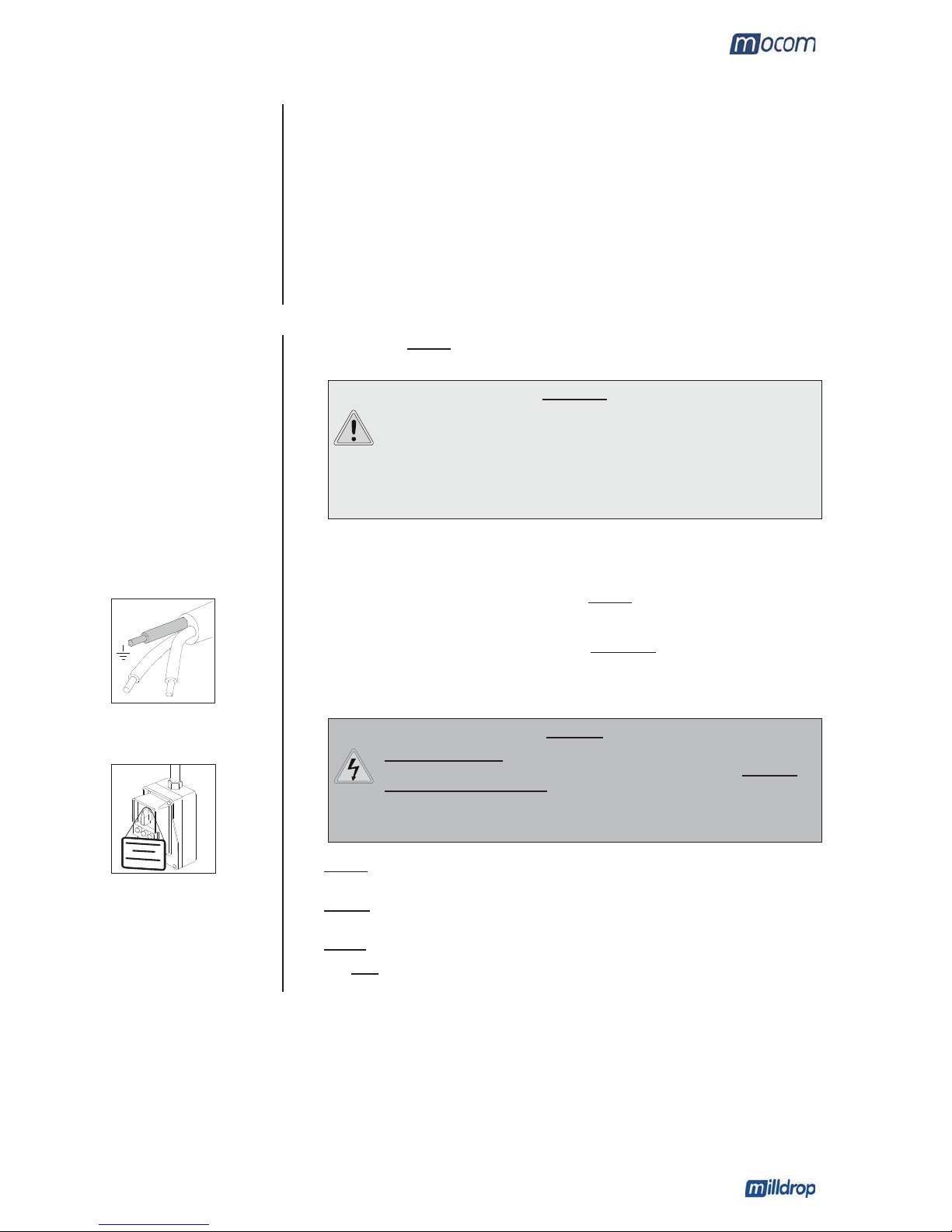

- Before connecting the power supply cable, ensure

that nominal mains voltage is

equal to the one indicated on the label. Voltages differing from indicated ones, may

damage the apparatus’s electric parts.

- Be sure the electric plant is provided with a grounding

conforming to laws and/or

rules in force.

- When getting started, carry out the “hydraulic circuit purging” so that possible

processing residuals will be expelled (see “Initial installation”).

DANGER

ALWAYS REMOVE THE MAINS CABLE FROM THE POWER OUTLET,

BEFORE CARRYING OUT ANY KIND OF MAINTENANCE. SHOULD

THAT NOT BE POSSIBLE, OR WHENEVER THE EXTERNAL

BREAKER IS FAR AWAY OR, AT ANY RATE, NOT VISIBLE TO THE

MAINTAINER, PLACE A WORK IN PROGRESS SIGN ON THE

EXTERNAL BREAKER AFTER TURNING IT OFF .

- Do not remove any label or nameplate from the device; should you need any new

ones, apply for them.

- Do not

use corrosive products, acids, steel wool or brushes for cleaning the

equipment.

- Do not

wash the equipment with direct water jets.

- Use only

original spare parts.

PACKAGE CONTENT

3

ENGLISH

PACKAGE

CONTENT

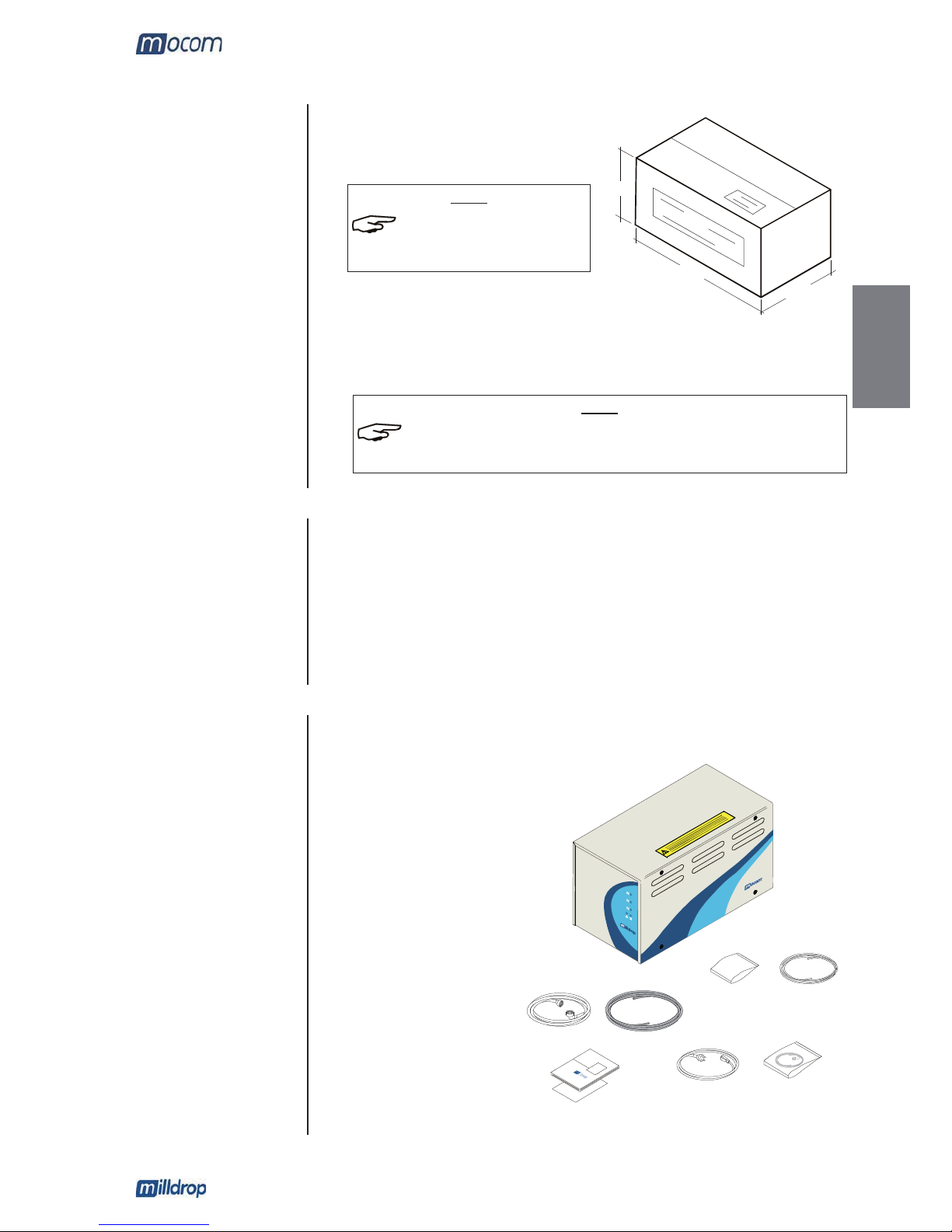

SIZE AND WEIGHT

Package:

Overall weight about 18 Kg

Once the package is opened, check that:

- the supply matches the specifications of the order (see the accompanying

document);

- there is no obvious product damage.

NOTE

SHOULD THE SUPPLY BE ERRONEOUS, ANY PART BE MISSING OR THERE BE

DAMAGES OF ANY KIND

, INFORM THE RETAILER AND THE TRANSPORTER THAT

CARRIED OUT DELIVERY AT ONCE AND IN DETAIL

.

HANDLING THE

PRODUCT

The product must be handled according to directions provided on the packaging.

We recommend to transport and store the device at temperatures not lower than 5°C.

Prolonged exposure to low temperature can damage the product.

Keep the original packaging and use it whenever the device is to be transported. The use

of different packaging could damage the product during shipment.

Keep the plugs mounted on the demineralizer’s pipe fittings (to be reapplied in case of

subsequent shipment).

CONTENT

DESCRIPTION

The package contains the following items:

• Demineralizer equipment (Ref. 1):

• Kit for the installation of the

draining pipe (Ref. 2);

• Draining pipe (red) - Ref. 3;

• Feeding pipe (blue),

complete with gaskets –

Ref. 4;

• Reinforced silicone pipe

(Ref. 5) for connecting

Milldrop to sterilizer,

external tank or tap;

• Power supply cable – Ref.

6;

• Kit (Ref. 7) containing:

start/stop signal cable, nr. 2

pipes union, nr. 4 clamps,

jack plug and key for

purging tap;

• Operator’s Manual and

Warranty Certificate – Ref.

8.

NOTE

C

HECK THE INTEGRITY OF THE

PACKAGE UPON RECEIPT

.

330

570

320

4

5

6

7

8

1

2

3

PRODUCT INFORMATION

4

PRODUCT

INFORMATION

INTRODUCTION

“Milldrop” is M.O.COM.’s proposal in the field of water demineralization for water steam

sterilizer.

It is a sophisticated apparatus but easy to use, and adaptable to the user requirements by

means of different installation possibilities.

Thanks to the reverse osmosis membrane and resin filter, the equipment “transforms” the

water coming from water works into qualitatively excellent demineralized water.

“Milldrop” – which is considerably easy to use and small in size - represents the ideal

equipment to be put next to any water steam sterilizer.

GENERAL

FEATURES

“Milldrop” is a water demineralizer based on the reverse osmosis principle.

The equipment includes:

- active carbon filter, having a duration of about 800 liters of demineralized water

produced;

- two resin filters having a duration of about 500 liters of demineralized water

produced,

- osmotic membrane which, if regularly checked, can last more than 800 liters of

demineralized water produced.

NOTE

T

HE LIFETIME OF FILTERS AND OSMOTIC MEMBRANE DEPENDS ON THE QUALITY OF

THE WATER FEEDING THE

MILLDROP.

The limit values for the feeding water are reported in the following table:

Element/Feature Value

Turbidity < 1 NTU

Cholrine < 0.1 ppm

Ph 2-11

Salt density < 5 SDI

Specific conductivity at 20°C < 1000 µS/cm

Iron < 0.1 ppm

Temperature < 35°C

Total hardness < 30°F

NOTE

FOR A SPECIFIC HARDNESS HIGHER THAN 25°F, THE USE OF A RESIN SWEETENER

AND SALTS REGENERATION IS RECOMMENDED

; THIS IS REQUIRED IF THE

HARDNESS IS HIGHER THAN

30°F.

The equipment operation is controlled by an electronic board which also monitors any

alarm (leak and lack of water, quality of the output water, etc.).

“Milldrop” may be installed on a work plane, hung to a wall or set inside the washbasin

piece of furniture.

“Milldrop” offers different installation possibilities:

- direct connection to the sterilizer series Millennium (provided with automatic filling

feature and start/stop interface);

- direct connection to an external tank with automatic water filling feature (possibility

to connect up to 3 sterilizers);

- direct connection to a drawing tap (provided with electric button), to fill manually little

tanks.

For extra details please refer to chapter “Hydraulic connections”.

PRODUCT INFORMATION

5

ENGLISH

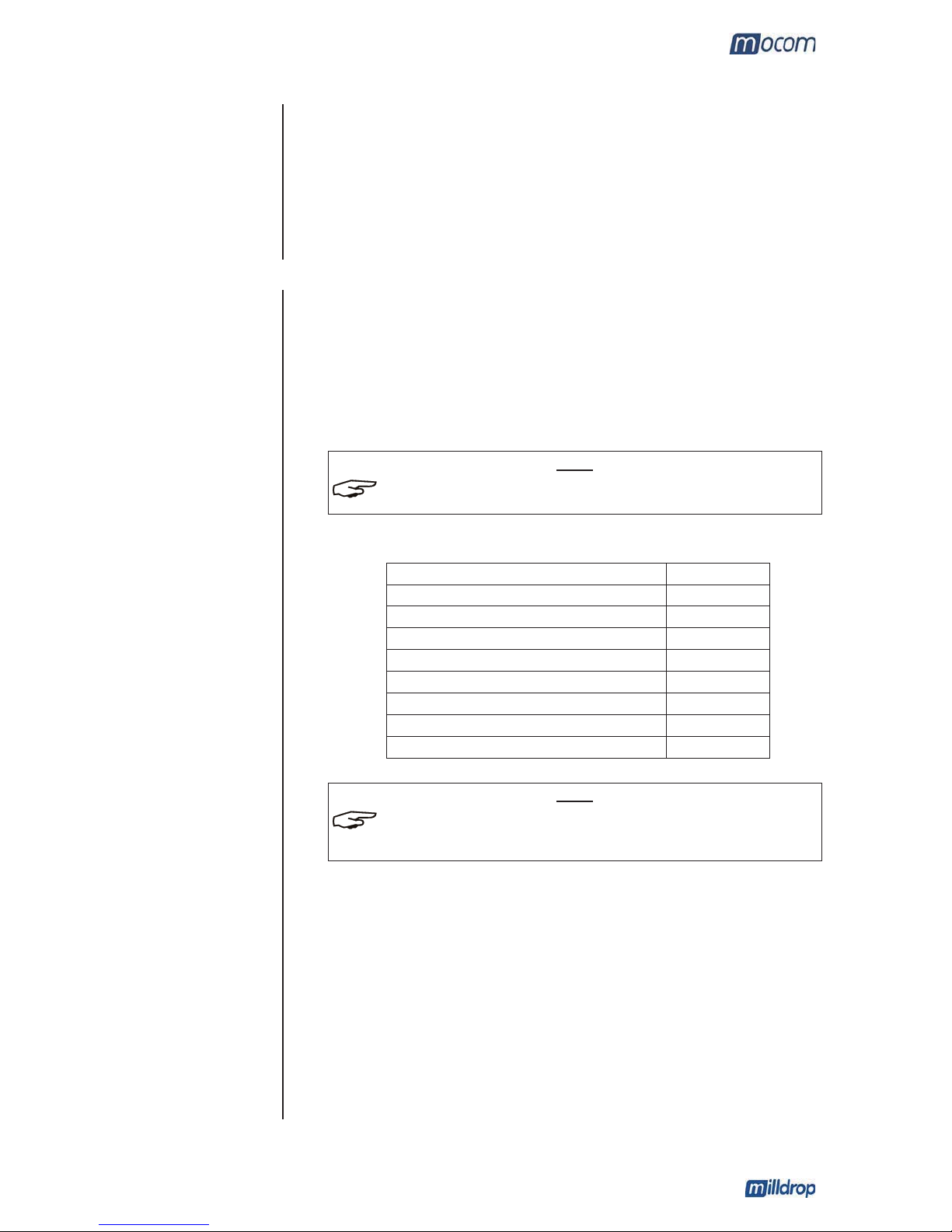

FRONT PANEL

REAR PANEL

A

C

B

S

L

T

MILLDROP

08 MD 0021

WWMD00D000 Year: 2008

FUNCTIONING

The Milldrop operation is very easy and automatic in any use.

1) Directly connected to a Millennium series sterilizer, it operates at the start of the

sterilizer’s water feeding pump, and until the pump stops.

2) Connected to the external tank, it starts working as the water level in the tank goes

down the maximum threshold, and stops as it is again reached.

3) Connected to the drawing tap (provided with electric device), it starts working as you

press the tap’s button and stops pressing it again.

NOTE

IF CONTINUALLY RUNNING FOR A TIME EXCEEDING 20 MINUTES, MILLDROP SHALL

STOP AUTOMATICALLY

.THE STOP IS SIGNALED BY THE BLINKING OF THREE

QUALITY WATER LED

’S AND THE ACOUSTIC INTERMITTENT ALARM.

TO RESTART THE DEMINERALIZER FROM A STOP STATUS, TURN IT OFF AND ON

AGAIN

.

t

green LED – good quality of the outlet water

yellow LED– sufficient quality

red LED– poor quality

red LED– lack of inlet water or low pressure

red LED– internal water leak

Solenoid valve filter

A - Connector and solenoid valve of the

water inlet

C – Quick connector for permeation product

S – Connector for sterilizer’s start/stop

cable

T – Connector for feeding tank/drawing tap

start/stop cable or purging jack plug

(service)

220Vac input – Fuses – Mains switch

B - Draining quick connector

L - Purging tube quick connector

INSTALLATION

6

INSTALLATION

INTRODUCTION

The correct and careful installation is the first

and fundamental step in achieving the good

demineralizer operation, long life and complete utilization of its features.

Moreover, this precaution will avoid the danger for physical injury or property damage, not

to mention equipment malfunctions and faults. So, please follow the instructions in this

chapter scrupulously

.

NOTE

T

HE TECHNICAL SERVICE (SEE APPENDIX Z) IS AT YOUR DISPOSAL FOR ANY

DOUBT YOU MAY HAVE OR FURTHER INFORMATION YOU MAY REQUIRE

.

THE DEMINERALIZER HAS PASSED THE REQUIRED TESTS BEFORE BEING

DELIVERED

.SO IT DOES NOT REQUIRE ANY ADDITIONAL CALIBRATION AT THE

GETTING IN SERVICE

.

POWER SUPPLY

The electrical system the demineralizer will be connected to, must be suitably

dimensioned basing on the power requirements of the device. See the nameplate located

on the backside of the equipment.

WARNING

VERIFY THE ELECTRIC PLANT’S CONFORMITY, AND THAT IT IS

GROUNDING PROVIDED.

SIZE OF

EMBEDDING

CHAMBER

When installing the demineralizer inside a cabinet, adequate space all around the device

must be foreseen in order to provide an effective ventilation, as well as an opening in the

back to allow the passage of the power cord and piping.

The built-in compartment should have the following minimum dimensions:

- Height 280 mm

- Width 270 mm

(free space on the ventilation grid

side)

- Depth 480 mm

(plus a space for rear connections

and front panel free view)

WARNING

COMPARTMENT DIMENSIONS LESS THAN THOSE SHOWN MAY

COMPROMISE THE CORRECT AIR CIRCULATION AROUND THE

DEVICE AND AN ADEQUATE COOLING, CAUSING CONSEQUENT

PERFORMANCE DETERIORATION AND/OR POSSIBLE DAMAGE.

NOTE

I

F THE MAINS SWITCH REMAINS INACCESSIBLE, USE A MAINS SOCKET

INCORPORATING AN ON

/OFF SWITCH.

REFER TO APPENDIX A(TECHNICAL CHARACTERISTICS) FOR COMPLETE

TECHNICAL DATA

.

280

270

480

INSTALLATION

7

ENGLISH

GENERAL

INSTALLATION

PRECAUTIONS

Obey the following warnings for the correct operation of the device and/or avoid

dangerous situations

:

- Install the demineralizer on a flat surface

;

- Leave adequate space for ventilation (at least 5 cm on the of the ventilation grid

side).

- Do not install near cisterns, wash-basins, etc. to avoid direct contacts with water or

liquids, possible short circuits and/or potentially dangerous situations for the

operator;

- Do not install in excessively humid

or poorly ventilated places;

- Do not install in places with gas

or inflammable and/or explosive vapors;

- Install the unit so that the power cord is not

bent or crushed. It must run freely all

the way to the mains socket.

- Install the unit so that any external fill/drain piping is not

bent or crushed. The length

of the reinforced silicone tube connecting Milldrop to the sterilizer or tank, shall not

exceed 2 meters, otherwise performance quality could fall or, what is worse, the

demineralizer itself could not operate properly.

POWER SUPPLY

The demineralizer must be connected to a mains socket of power adequate for the

absorption required, and provided with ground connection in compliance with current laws

and/or standards.

The mains socket must be suitably protected by a circuit breaker having the following

characteristics:

- Nominal current 5 A

- Differential current 0,03 A

NOTE

THE MANUFACTURER WILL NOT BE LIABLE FOR DAMAGES CAUSED BY INSTALLING

THE UNIT ON INADEQUATE ELECTRICAL SYSTEM AND

/OR NOT GROUNDED.

If you need to replace the power cord plug, use a type of equal characteristics or, at any

rate, adequate to the equipment power requirements. The user is entirely responsible for

the choice and replacement of the plug.

DANGER

CONNECT THE POWER CORD DIRECTLY TO THE SOCKET.

DO NOT USE EXTENSIONS CORDS, ADAPTERS OR OTHER

ACCESSORIES.

INSTALLATION

8

INSTALLATION

ONTO A WALL

Milldrop can be placed on a working plane, mounted on the Millrack system (see the

relating User Manual) or installed on a wall (see Fig. A-B-C). In this last case, proceed as

follows:

1. Remove the screws (1) and the lid (A). Figure A

2. Remove the screws (2-3) and the side panel (B). Figure A

3. Position the panel (B) on the wall where Milldrop has to be installed and mark the

wall by a pencil in the mounting slots (C). Figure B

NOTE

THE DEMINERALIZER MUST BE INSTALLED PERFECTLY HORIZONTAL, OTHERWISE

THE ANTI

-FLOODING SYSTEM COULD NOT PROPERLY FUNCTION.ON CHOOSING

THE INSTALLATION POINT

, CONSIDER THE ROOM NECESSARY FOR REAR PIPING,

FOR THE FRONT PANEL FREE VISION AND FOR THE ADEQUATE VENTILATION (SEE

PARAGRAPH

GENERAL INSTALLATION PRECAUTIONS).

4. Bore the holes corresponding the marks just made. Figure C.

NOTE

B

EFORE DRILLING, BE SURE THAT NO PIPING OR ELECTRIC CABLES ARE INSIDE

THE WALL

.

5. Reassemble the side panel (B), fasten the screws (2 and 3).

6. Insert the screw anchors (4) in the holes, the screws (5) in the panel’s slots and

screw down. (Note: items 4 and 5 are not supplied) – see Figure C.

7. Reassemble the lid (A) and fasten the screws (1).

A

B

2

3

1

Figure A Figure B

Figure C

INSTALLATION

9

ENGLISH

HYDRAULIC AND

ELECTRICAL

CONNECTIONS

Initial installation

Purging the internal

hydraulic circuit

See Figures D, E:

1. Use the kit supplied (Page 3, Ref. 2) and install the draining bracket onto the

washbasin’s siphon where you wish to install the Milldrop draining pipe; carry out an

hole Ø 6 mm in the siphon across the bracket’s fitting.

2. Insert the red pipe in the ring nut , plug it in the bracket’s fitting, and fasten the ring

nut.

Figure D

3. Cut the red pipe long enough to reach the draining connection B on the rear panel of

the demineralizer.

NOTE

THE PIPING MUST NOT BE BENT, SQUASHED OR HAVE A PARTICULARLY TORTUOUS

ROUTE

, OTHERWISE PERFORMANCE WILL BE QUALITATIVELY VERY LOW OR, WHAT

IS WORSE

, THE DEMINERALIZER ITSELF SHOULD MALFUNCTION.

4. Take the plug out the draining quick connector (see picture) and connect the red pipe

(keep the plug!).

5. Install a tap (not supplied) provided with male connector ¾” on the water outlet and

near the demineralizer. Check the pressure value of the water works (see Appendix

A).

6. Connect the feeding blue pipe (supplied) between the tap outlet and the water inlet

“A” on the rear panel of the demineralizer, check for the presence of gaskets, and

fasten both the pipe’s ring nuts.

7. Open the tap and check for no leaks.

1. Remove the plastic plug from the quick connector “C” on the rear panel of the

demineralizer and connect the supplied pipe-union.

2. Mount the reinforced silicone pipe on the pipe-union, tight by clamps.

3. Place the opposite end of the silicone pipe inside a wash-basin.

Figure E

Gasket

Blue pipe

Pipe-union

Red pipe

to draining siphon

to wash-basin

Reinforced

silicon

pip

e

TAP

Clamp

drill Ø6

red pipe

Siphon

Plug

Take out the plug by

keeping the ring still

Quick connector

ring nut

INSTALLATION

10

See Figure F:

4. Plug the key (supplied with the kit - page 3, Ref. 7) in the fitting of the purging tap

positioned under the Milldrop equipment and turn the tap on "Service Mode" position.

5. Plug the purging jack (supplied with the kit - Page 3, Ref. 7) in the connector "T".

6. Connect the mains cable and switch on the demineralizer.

7. The water will start to flow from the silicone tube connected to the quick connector “L”;

let to drain for about 10 minutes.

WARNING

This hydraulic circuit purging procedure allows to eliminate the

maintenance liquids from the osmotic membrane, avoiding that the

liquids are passing from and damaging the resin filter.

8. Switch off the equipment.

9. Take the purging jack out the connector “T”.

10. Plug again the key in the fitting of the purging tap and back it on "Normal Mode"

position.

11. Take the plastic plug out the quick connector “C” (keep the plug!)

12. Remove the pipe-union and silicone tube from the quick connector “L” and connect it

to the quick connector “C”.

WARNING

Close the quick connector “L” with the plastic plug.

Check for the tightness.

Continue the installation by carrying out the specific hydraulic connections according to

the use required.

Figure F

ke

y

purging jack

purging tap fitting

ended the purging,

move pipe-union and

silicone tube to the

quick connector “C”

INSTALLATION

11

ENGLISH

Case 1:

Direct connection to a

sterilizer series

Millenium

See Figure G:

Keep the DIP1 position on the electronic board unchanged (see diagram on page 25):

- Make sure that the position is as indicated in the

figure. If not, correct it.

1. Cut the silicone pipe (connected to the quick connector “C” on the demineralizer rear

panel) long enough to reach the pipe-union installed on the sterilizer’s automatic

feeding point, connect and tight by clamps.

NOTE

THE PIPES MUST NOT BE BENT, SQUASHED OR HAVE A PARTICULARLY TORTUOUS

ROUTE

.THE LENGTH OF THE FEEDING SILICONE TUBE MUST NOT EXCEED 2

METRES, OTHERWISE THE GENERAL PERFORMANCE SHOULD DECREASE OR THE

DEMINERALIZER ITSELF SHOULD MALFUNCTION

.

2. Connect the supplied start/stop signal cable between the connector “S” on the

demineralizer rear panel and the female jack connector on the sterilizer.

Figure G

(from the tap)

water inlet

to draining siphon

Start/Stop

cable

Clamp

Silicone pipe

jack

j

ack connecto

r

Sterilizer series

Millennium

ON

OFF

DIP1

1

2

3

4

INSTALLATION

12

Case 2:

Connection to an

external feeding tank

(optional)

See Figure H:

Keep the DIP1 position on the electronic board unchanged (see diagram on page 25):

- Make sure that the position is as indicated in the

figure. If not, correct it.

1. Plug the supplied pipe fitting in the inlet point (label “Milldrop”) of the tank.

2. Cut the silicone pipe (connected to the quick connector “C” on the demineralizer rear

panel) long enough to reach the pipe-union installed on the tank’s inlet (label

“Milldrop”), fit and tight by clamps.

NOTE

T

HE PIPES MUST NOT BE BENT, SQUASHED OR HAVE A PARTICULARLY TORTUOUS

ROUTE

.THE LENGTH OF THE FEEDING SILICONE TUBE MUST NOT EXCEED 2

METRES, OTHERWISE THE GENERAL PERFORMANCE SHOULD DECREASE OR THE

DEMINERALIZER ITSELF SHOULD MALFUNCTION

.

3. Plug a supplied pipe-union in one of the three outlets available on the tank (label M1,

M2 or M3), fit a silicone pipe and tight by clamps.

4. Cut the silicone pipe long enough to reach the pipe-union installed on the sterilizer’s

automatic feeding point, fit and tight by clamps.

5. Connect the start/stop signal cable (provided with the demineralizer) between the

jack connector “T” on the demineralizer rear panel and the female jack connector on

the tank’s level sensor cabling.

6. The tank is provided with a tap for drawing manually the permeation product. If the

user wishes to use also this feature, connect the supplied pipe fitting to the drawing

tap.

F

M

I

L

L

D

R

O

P

Figure H

Feeding tank

Clamps

Silicone pipe

Silicone pipe

Start/Stop cable

to draining siphon

Clamps

(from the tap)

water inlet

Drawing tap

pipeunion

j

ack

connecto

r

« T »

ON

OFF

DIP1

1

2

3

4

INSTALLATION

13

ENGLISH

Case 3:

Connection to an

electric-type drawing

tap (option)

See Figure I:

Configure DIP1 on the Milldrop electronic board as follows (see diagram on page 25):

- Remove the external cover and the protection of the

electronic board.

- Change the setting of the DIP1 switches as shown in

the figure

- Refit the covers.

1.

Install the drawing tap (with electric button) where desired (anyhow, near the

demineralizer).

2.

Plug the supplied pipe fitting on the drawing tap’s outlet, cut the silicone pipe

installed on the outlet C of the demineralizer so that it is long enough to reach

the pipe fitting of the tap, and tight by clamps.

NOTE

THE PIPING MUST NOT BE BENT, SQUASHED OR HAVE A PARTICULARLY TORTUOUS

ROUTE

.THE SILICONE TUBE’S LENGTH MUST NOT EXCEED 2 METRES, OTHERWISE

PERFORMANCE WILL BE QUALITATIVELY VERY LOW OR

, WHAT IS WORSE, THE

DEMINERALIZER ITSELF SHOULD MALFUNCTION

.

3. Connect the start/stop signal cable of the drawing tap between to the connector “T” on

the demineralizer rear panel p.

Figure I

Clamp

Drawing tap

Silicone pipe

To the draining

siphon

Start/Stop cable

Pipe-union

(from the tap)

water inlet

ON

OFF

DIP1

1

2

3

4

FIRST STARTUP

14

FIRST STARTUP

MILLDROP

CONNECTED TO

THE STERILIZER

SERIES

MILLENNIUM

Once properly installed, proceed with the following additional startup operations and

checks according with the Milldrop use.

Turn on the demineralizer and then the sterilizer.

Ended the initial test of the sterilizer, enter the SETUP menu, select “Filling Options” and

the mode “AUTOMATIC” (see the Operating Manual of the sterilizer).

Check that demineralizer starts to work as the sterilizer’s automatic feeding pump starts,

and stops at the same time as the pump.

NOTE

T

HE EQUIPMENT WILL STOP AUTOMATICALLY IF THE DELIVERY OF WATER LASTS

UNINTERRUPTEDLY FOR MORE THAN

20 MINUTES.TO RESTART THE MILLDROP

OPERATION TURN OFF AND ON THE EQUIPMENT AGAIN

.

MILLDROP

CONNECTED TO

THE FEEDING TANK

The demineralizer starts immediately as turned on (if the tank is empty or with water

under the maximum level).

As reached the maximum water level in the tank (signaled through the level sensor), the

demineralizer stops automatically.

NOTE

S

TARTING AT EMPTY TANK, THE MILLDROP OPERATION MIGHT BE STOPPED BY

THE PROTECTION TIME

-OUT OF 20 MINUTES AND BEFORE THE WATER INSIDE THE

TANK HAS REACHED THE MAXIMUM LEVEL

.IN THIS CASE, TURN OFF AND ON AGAIN

TO RESTART THE EQUIPMENT OPERATION AND WATER FILLING UP

.

Turn on the sterilizer.

Ended the sterilizer initial test, enter the SETUP menu, select “Filling Options” and the

mode “AUTOMATIC” (see the Operating Manual of the sterilizer).

If the water level into the sterilizer’s internal tank is lower the minimum, the automatic

feeding pump starts promptly.

In this case, the demineralizer will start a few seconds after the start of the sterilizer’s

pump (i.e. as the tank’s float, by lowering, triggers the demineralizer by the start/stop

command), and will stop as the tank’s float reaches again the maximum level.

NOTE

THE EQUIPMENT WILL STOP AUTOMATICALLY IF THE DELIVERY OF WATER LASTS

UNINTERRUPTEDLY FOR MORE THAN

20 MINUTES.TO RESTART THE MILLDROP

OPERATION TURN OFF AND ON THE UNIT AGAIN

.

In case of manual water drawing also from the tank’s tap, ensure that the water remaining

in the tank is sufficient to warrant the water need of sterilizer(s) connected to the tank,

considering also the time necessary to restore a sufficient level into the tank:

- one sterilizer connected, the remaining water must be at least 2 liters .

- two sterilizers connected, the remaining water must be at least 4.5 liters.

- three sterilizers connected, the remaining water must be at least 7 liters.

FIRST STARTUP

15

ENGLISH

MILLDROP

CONNECTED TO

THE MANUAL

DRAWING TAP

Press the tap’s button to start the water delivery.

Press 2 seconds again the tap’s button to stop the water delivery.

NOT

A

WAIT 10 SECONDS BEFORE PRESSING AGAIN THE TAP’S BUTTON TO RESTART

WITH THE WATER DELIVERY

.

NOTE

THE EQUIPMENT WILL STOP AUTOMATICALLY IF THE DELIVERY OF WATER LASTS

UNINTERRUPTEDLY FOR MORE THAN

20 MINUTES.TO RESTART THE MILLDROP

OPERATION TURN OFF AND ON THE UNIT AGAIN

.

STAND-BY STATUS

Over the first startup operations, the demineralizer sets in stand-by status.

In such a condition, the turning on of alarm LED will have no influence on the

demineralizer subsequent starting, except the alarm “Internal leak” that will stop the

demineralizer and prevents it from operating.

In this case, turn off the demineralizer and call the Technical Service.

NOTE

THE TECHNICAL SERVICE (SEE APPENDIX Z) IS AT YOUR DISPOSAL FOR ANY

DOUBT YOU MAY HAVE OR FURTHER INFORMATION YOU MAY REQUIRE

.

APPENDIX A – TECHNICAL DATA

16

APPENDIX A – TECHNICAL CHARACTERISTICS

SUMMARY TABLE

Device REVERSE OSMOSIS WATER DEMINERALIZER

Model

Milldrop

Manufacturer

C.M.F. S.r.l.

Via E.Ellero, 9

33080 Cusano di Zoppola (PN [=Province of Pordenone]) -

ITALY

for

M.O.COM. Srl

Via Saliceto, 22

40013 Castel Maggiore (BO)

Italy

Power supply voltage

220 – 240 V ~

Mains frequency

50/60 Hz

Mains fuses

2x F 3,15A 250V

Protection fuse on the electronic board

T 3,15A 250V

External size (LxHxD) 220 x 235 x 415 mm (rear connections excluded)

Nominal power

130 W, 2A max

Insulation class

Class I

Utilization

Internal use

Environment operating conditions

Temperature: +15°C ÷ +35°C

Relative humidity: 90% non-condensing

Net weight

14 Kg

Outlet flow rate

25 lt/h

Inlet pressure

1 ÷ 4 bar

Working pressure

Max 10 bar (at pump outlet)

Tap water temperature

+10°C ÷ + 35°C

Resin filter cartridge life (average value) about 500 l (depending on the quality of the inlet water)

Osmotic membrane and active carbon filter

life (average value)

about 800 l (depending on the quality of the inlet water)

APPENDIX A – TECHNICAL DATA

17

ENGLISH

CHARACTERISTICS OF THE DEMINERALISED WATER

FILTERING CHARACTERISTICS

The following table shows the demineralizer’s average filtering characteristics, compared with values stated

by the standards EN 285 and EN 13060.

Element/Characteristic

Unit of

measure

Value at the

inlet

Value at the

outlet

Value according

to

EN 13060/EN 285

Ph value - 7,6

6,3

5 - 7

Conductivity at 20°C µS/cm 435

1,8

<15

Dry residue mg/l 345

2

<10

Cadmium mg/l Cd <0.01

<0.003

<0.005

Iron mg/l Fe 0.32

0.03

<0.2

Manganese mg/l Mn 0.03

<0.003

<0.1

Nickel mg/l Ni <0.01

<0.003

<0.1

Lead mg/l Pb <0.05

<0.02

<0.05

Copper mg/l Cu 0.02

0.006

<0.1

Zinc mg/l Zn 0.56

0.02

<0.1

Chlorides mg/l Cr 3.7

<0.05

<2

Phosphates mg/l P 0.01

<0.01

<0.5

Silicon oxide mg/l SiO2 5,7

<0.10

<1

Appearance - colorless, transparent, without sediments

Hardness mmol/l 2.57

<0.005

<0.02

NOTE

T

HE VALUES SHOWN IN THE COLUMN “OUTLET WATER” ARE INDICATIVE AND REFERRED TO VALUES OF

THE COLUMN

“INLET WATER”.

APPENDIX B – MAINTENANCE

18

APPENDIX B - MAINTENANCE

INTRODUCTION

In addition to the procedures for the correct use, it needs the user performs an ordinary

maintenance in order to guarantee safe and efficient operation over the entire life of the

equipment.

The ordinary maintenance hereafter described consists in easy manual activities and

preventive maintenance interventions.

ORDINARY

MAINTENANCE

PROGRAMME

The table summarizes the maintenance required to maintain the demineralizer operating

at its peak efficiency.

WEEKLY

Clean and disinfect the external surfaces

YEARLY

(or earlier if the limit of

500 litres has been

reached

Replace the resin filter cartridges

YEARLY

(or earlier if the limit of

800 litres has been

reached

Replace osmotic membrane and

active carbon filter

DANGER

ALWAYS REMOVE THE MAINS CABLE FROM THE POWER OUTLET,

BEFORE CARRYING OUT ANY KIND OF MAINTENANCE.

SHOULD THAT NOT BE POSSIBLE, OR WHENEVER THE EXTERNAL

BREAKER IS FAR AWAY OR, AT ANY RATE, NOT VISIBLE TO THE

MAINTAINER, PLACE A WORK IN PROGRESS SIGN ON THE

EXTERNAL BREAKER AFTER TURNING IT OFF .

GENERAL

MAINTENANCE

PROCEDURES

With reference to the above table, let's take a summary look at the various maintenance

to be performed:

- Clean all the external surfaces using a clean cotton cloth dampened with water plus,

possibly, a neutral detergent. Dry the surfaces and remove any residue before using

the equipment.

- To disinfect the external surfaces, use denatured alcohol, as well as detergents

containing a minimum percentage of sodium hypoclorite (or equivalent substances).

- Yearly or whenever necessary, replace the exhausted filters with new ones having

the same characteristics. For this maintenance, call the Technical Service (see

Appendix Z).

NOTE

S

HOULD THE DEMINERALIZER BE FORESEEN UNUSED FOR A TIME LONGER THAN

20 DAYS, WE SUGGEST TO EMPTY THE EXTERNAL FEEDING TANK, IF CONNECTED.

.

APPENDIX B – MAINTENANCE

19

ENGLISH

REPLACING THE

FILTERS

Resin filter cartridges

For filters replacement follow the procedures reported below.

See Figures L and M:

1. Turn off Milldrop, remove the mains cable and disconnect pipes and cable from the

use side (sterilizer, feeding tank or drawing tap).

2. Turn off the water tap feeding the Milldrop.

3. Remove the screws (1) and take off the lid (A).

4. Remove the screws (2) and take off the side panel (B) (if possible).

5. Lift and extract the filters assembly (C) from its bearings, disconnect pipes Ø8 (3

and 4) from the quick connectors on both ends of the resin filter cartridges.

6. Replace both cartridges, taking care to install them in the correct position and with

the arrows towards the bottom of the unit (Fig. M).

NOTE

T

O DISCONNECT A PIPE FROM ITS QUICK CONNECTOR, PULL OUT THE PIPE WHILE

KEEPING THE LOCK RING STILL

.

A

B

2

3

1

C

3

4

Figure L

Figure M

7. Reconnect the pipes respecting the original positions, open the water tap feeding

the Milldrop.

8. Carry out the purging of the hydraulic circuit as follows:

a: pull the pipe-union (and its connected pipe) out the quick connector “C”.

b: plug an other supplied pipe-union in the quick connector “C”, mount a silicon

pipe (not supplied) and place the opposite end inside a wash-basin.

c verify that the jack of the start/stop cable coming from the sterilizer, tank or

drawing tap is disconnected from the Milldrop; plug the purging jack in the “T”

connector.

d. connect the mains cable and switch on the Milldrop.

e. the water will start to flow from the silicone tube connected to the quick

connector “C”; let to drain for about 10 minutes.

9. Turn off Milldrop, remove the purging jack from the “T” connector, mount the

equipment lids and restore the hydraulic and electric connections.

C

A

rrows

APPENDIX B – MAINTENANCE

20

Osmotic membrane

and active carbon filter

cartridge

The osmotic membrane and the active carbon filter cartridge have the same duration, and

therefore must be both replaced at the expiry.

Replace first the osmotic membrane

.

See Figure N

1. Turn off Milldrop, remove the mains cable and the hydraulic and electric connection

with the equipment (sterilizer, tank or drawing tap).

2. Proceed as for the resin filter cartridges, and remove the whole filter assembly (A)

from its supports to access the osmotic membrane assembly (B).

3. Disconnect the pipes Ø8 (1) and (2) from their quick connectors and replace the

osmotic membrane.

NOTE

T

O DISCONNECT A PIPE FROM ITS QUICK CONNECTOR, PULL OUT THE PIPE WHILE

KEEPING THE LOCK RING STILL

.

4. Reconnect the pipes respecting their original position.

Figure N

5. Carry out the purging of the hydraulic circuit as for the first installation (see page 9);

let to drain the water for about 10 minutes.

WARNING

The hydraulic circuit purging procedure allows to eliminate the

maintenance liquids from the osmotic membrane, avoiding that the

liquids are passing from and damaging the resin filter

6. Check for no leaks in the equipment and on the quick connectors.

A

B

1

2

1

APPENDIX B – MAINTENANCE

21

ENGLISH

Replace now the active carbon filter cartridge.

See Figure O

1. Turn off MILLDROP and remove the mains cable.

2. Disconnect the quick elbow Ø10 (1) and “T” Ø10 (2) connectors and replace the

carbon filter cartridge (A) taking care to install it in the correct position and with the

arrow towards the bottom of the unit (Fig. O).

NOTE

T

O DISCONNECT A PIPE FROM ITS QUICK CONNECTOR, PULL OUT THE PIPE WHILE

KEEPING THE LOCK RING STILL

.

3. Reconnect the pipes respecting their original position.

Figure O

4. Carry out the purging of the hydraulic circuit as for the resin filter cartridges:

a: pull the pipe-union (and its connected pipe) out the quick connector “C”.

b: plug an other supplied pipe-union in the quick connector “C”, mount a silicon

pipe (not supplied) and place the opposite end inside a wash-basin.

c verify that the jack of the start/stop cable coming from the sterilizer, tank or

drawing tap is disconnected from the Milldrop; plug the purging jack in the “T”

connector.

d. connect the mains cable and switch on the Milldrop.

e. the water will start to flow from the silicone tube connected to the quick

connector “C”; let to drain for about 10 minutes.

5. Turn off Milldrop, remove the purging jack from the “T” connector, mount the

equipment lids and restore the hydraulic and electric connections.

A

1

2

A

rrow

APPENDIX B – MAINTENANCE

22

REPLACING THE

FLOW RESTRICTOR

See Figure P:

1. Turn off Milldrop and remove the mains cable.

2. Turn off the water tap feeding the Milldrop, remove the equipment lid and the side

panel.

3. Disconnect the “flow restrictor” from the red pipes Ø6 and replace with a new one.

NOTE

T

O DISCONNECT A PIPE FROM ITS QUICK CONNECTOR, PULL OUT THE PIPE WHILE

KEEPING THE LOCK RING STILL

.

WARNING

Install the new device with the arrow marking the flow direction

towards the bottom of the equipment.

4. Reassembly the equipment lids, connect the mains cable and turn on the unit.

5. Open the water feeding tap and check for no leaks.

6. Reassemble the board protection panel and the lid, fasten the screws.

Figure P

DISPOSAL AT ENDOF-LIFE

In accordance with Directives 2002/95/ EC, 2002/96/ EC and 2003/108/ EC, regarding

the reduction in use of dangerous substances in electrical and electronic equipment, as

well as waste disposal, such equipment may not be disposed of as normal urban waste

and must be separated accordingly. When purchasing a new, equivalent piece of

equipment, the old piece of equipment that has reached its end-of-life must be handed

over to the reseller for proper disposal. As regards reuse, recycling and other forms of

recovery of the above mentioned waste, the manufacturer carries out the functions

defined in the individual national legislations.

The proper collection and separation of such equipment for recycling, treatment and

disposal helps avoid any possible negative effects on the environment and health and

facilitates the recycling of the materials of which the equipment is made. The crossed out

rubbish can symbol indicates that the product, at the end-of-life, must be collected

separately from other types of waste.

WARNING!

Improper disposal of the product results in the application of sanctions which are

defined by individual national laws.

“Flow restrictor”

Red pipes Ø6

APPENDIX C – TROUBLESHOOTING

23

ENGLISH

APPENDIX C – TROUBLESHOOTING

INTRODUCTION

If you run into a problem or alarm while using the equipment, you should not be immediately concerned.

It may not, in fact, be related to a breakdown but, more probably to an anomalous situation, often merely transitory (such

as a blackout), or incorrect use.

In any case, it is important to first identify the cause of the anomaly and then take suitable corrective action, either

autonomously or with the help of the Technical Support Department (see Appendix Z).

For this purpose, below, we provide instructions for diagnosing and resolving general problems.

At the starting on

It is possible that at the start of operation, and also in normal condition, the red LED (signaling poor outlet water quality)

lights for a few seconds; this situation is normal.

On the contrary, if the LED remains lit for a time longer than 45 seconds (matched with the acoustic alarm), the

equipment enters in blocking status; in this case it will be necessary to replace the resin filter and/or the osmotic

membrane.

This fault condition is preceded by an intermediate phase during which Milldrop, even if correctly operating, turns on the

yellow LED (matched with the acoustic alarm) to signal that the filter replacement is coming near.

Milldrop unused for a few days

Should the equipment be unused for a few days, the red LED could remain lit for a time longer than 45 seconds at the

subsequent starting on, so resulting in the blocking of the equipment. In this case switch off the unit and switch on it

again. If the problem occurs again, replace the filter.

NOTE

SHOULD YOU FORESEE NOT TO USE THE EQUIPMENT FOR MORE THAN 20 DAYS, WE SUGGEST TO EMPTY

THE EXTERNAL TANK WHENEVER PROVIDED

.

ANALYSIS AND RESOLUTION OF PROBLEMS

If your demineralizer is not working correctly, please make the following checks before calling the Technical Support

Department:

PROBLEM POSSIBLE CAUSE PROPOSED SOLUTION

The demineralizer

does not

power-on.

The power cord is not plugged-in. Plug it in.

There is no voltage at the socket.

Check the cause of the lack of voltage at

the socket and fix it.

The main switch and/or differential switch are

OFF.

Turn the switch ON.

The mains fuses or the on-board fuse are

blown.

Replace with new fuses of same rating

value. (See Summary Table in Appendix

A).

Alarm:

water leak (red LED

blinking)

Water leak inside the equipment.

Remove the water leak cause and dry the

internal parts well.

Electronic board failure. Replace the electronic board.

APPENDIX C – TROUBLESHOOTING

24

PROBLEM POSSIBLE CAUSE PROPOSED SOLUTION

Alarm:

lack of water (red

LED blinking)

Entry tap closed. Open the tap.

Water work pressure insufficient. Check the water pressure.

Solenoid valve filter clogged up Clean the filter (see rear view, page 5).

Pressure switch failure. Replace the pressure switch.

Inlet solenoid valve failure. Replace the solenoid valve.

Active carbon filter clogged up. Replace the active carbon filter.

Alarm:

Poor outlet water

quality (red LED

blinking)

Resin filters depleted. Replace the resin filter assembly.

Osmotic membrane depleted.

Prepare to replace the osmotic membrane

shortly

Alarm:

Sufficient outlet

water quality (yellow

LED blinking)

Resin filters almost depleted. Prepare to replace the resin filters shortly.

Osmotic membrane almost depleted.

Prepare to replace the osmotic membrane

shortly.

Alarm:

Continuous operation

over 20 minutes

(water quality LED’s

are flashing and

intermittent buzzer

sounds)

Purging jack in the quick connector “T”

Remove the jack and plug in the start/stop

cable

Starting on with tank empty Turn off and on the demineralizer

Feeding tank’s float failure. Replace the float.

Pump failure. Replace the pump.

Drawing tap button failure Check the cause.

Osmotic membrane clogged up.

Carry out the hydraulic circuit purging or

replace the osmotic membrane it

Alarm:

Conductivity probe

disconnected or

probe sensor without

water (green LED

flashing and

intermittent buzzer)

Water not yet in circulation Effettuare un prelievo di acqua

Conductivity sensor without water

Check the connection of the pipe on the

quick connector “C” and perform a water

drawing

Conductivity probe cable disconnected Reconnect the cable

Conductivity probe failure Replace the probe

The demineralizer

does not deliver any

water.

Continuous working time exceeding 20

minutes.

Turn off the demineralizer and turn on

again (or push again the tap’s button).

Start/stop signal cable detached Connect the cable.

Feeding tank’s float failure. Replace the float.

Alarm signaling for inlet water lack or internal

leak

Remove the problem.

Lack of the power supply. Remove the cause.

Alarm signaling for poor outlet water quality. Replace the resin filter assembly.

Pump failure. Replace the pump.

Low outlet flow rate

Pump failure. Replace the pump.

Resin filter and/or active carbon filter clogged

up.

Replace the resin filter and/or the active

carbon filter.

Osmotic membrane clogged up.

Cleanse the osmotic membrane or replace

it.

APPENDIX D - DIAGRAMS

25

ENGLISH

APPENDIX D - DIAGRAMS

ELECTRIC DIAGRAM

Probe terminal

board

+5V

Ground

Tem

p

erature

Water leak sensor

Pressure switch –NC contact

Start/Stop signal (tank/tap)

Sonda

Probe

Electric valve

Pump

230 Vac

Transformer

Fusible

Start/Stop signal (sterilizer)

Configuration

dip-switch

APPENDIX D - DIAGRAMS

26

HYDRAULIC DIAGRAM

8

9

10

11

1

2

3

4

5

6

7

Legend:

1 – Water inlet solenoid valve 5 – Membrane assembly 9 – Conductivity probe

2 – Activated carbon filter assembly 6 – Resin filter assembly 10 – Purging tap

3 – Pressure switch 7 – Flow restrictor 11 – Quick connector plug

4 – Pump assembly 8 – Draining union

WATER INLET

DEMINERALIZED

WATER OUTLET

FLOW

Drain

FLOW

FLOW

APPENDIX G – DECLARATION OF CONFORMITY

27

ENGLISH

APPENDIX G – DECLARATION OF CONFORMITY

APPENDIX H - NOTES

28

APPENDIX H - NOTES

APPENDIX Z – TECHNICAL ASSISTANCE

29

ENGLISH

APPENDIX Z – TECHNICAL ASSISTANCE

FOR ANY REQUEST FOR

TECHNICAL SERVICE FOR THE PRODUCT,

WHETHER IN OR OUT OF WARRANTY,

DIRECTLY CONTACT THE

TECHNICAL SUPPORT DEPARTMENT

OF THE DEALER OR RESELLER

THAT SUPPLIED THE PRODUCT.

M.O.COM. Srl is completely available to customers to provide any technical information about the product as well as to

offer suggestions and advice on steam sterilization procedures.

In this regard, please refer to the following address:

M.O.COM. Srl

Via Saliceto, 22

40013 Castel Maggiore (BO)

Italy

website www.mocom.it

Loading...

Loading...