Page 1

LUKE Arm

User Guide

Part Number: LU-09012-001

Revision: 1.8

Date: December 05, 2016

Manufactured by:

Mobius Bionics

470 Commercial Street

Manchester, NH 03101

www.mobiusbionics.com

Page 2

Copyright

Copyright © 2016, Mobius Bionics LLC. All rights reserved.

Mobius Bionics LLC proprietary rights are included herein. This document contains

Mobius Bionics confidential information and may not be copied, transferred, or

disclosed, except as authorized by Mobius Bionics.

Trademarks

Bluetooth® is a registered trademark of Bluetooth SIG.

Wi-Fi® is a registered trademark of Wi-Fi Alliance.

Page 3

Contents

About This Guide

How to Use This Guide ................................................................................ 11

Conventions ................................................................................................ 12

Terminology................................................................................................ 14

Acronyms ................................................................................................... 14

Contacting Technical Support....................................................................... 15

Chapter 1 LUKE Arm System

Indications for Use ....................................................................................... 17

LUKE Arm System ...................................................................................... 18

Arm Types ............................................................................................ 19

Shoulder Configuration (SC) .............................................................. 19

Humeral Configuration (HC).............................................................. 19

Radial Configuration (RC).................................................................. 19

Batteries and Holster .............................................................................. 21

Internal Battery ................................................................................ 21

External Battery ............................................................................... 22

External Battery Holster .................................................................... 22

Battery Chargers and Charging Dock....................................................... 23

Charging Pad................................................................................... 24

AC Adapter ..................................................................................... 24

Charging Dock................................................................................. 25

ACI (Arm Control Interface) Module......................................................... 26

Input and Output Control Devices............................................................ 27

IMUs (Inertial Measurement Units)...................................................... 27

EMG (Surface EMG Electrodes).......................................................... 27

Pressure Switches............................................................................. 28

Rocker Switches............................................................................... 28

Pressure Transducers ........................................................................ 29

Linear Transducers ........................................................................... 29

Tactor ............................................................................................. 30

Contents

Chapter 2 Safety

Safety Guidelines - Arm................................................................................ 31

Electromagnetic Interference (EMI) Safety....................................................... 34

Safety Guidelines - Battery............................................................................ 35

Rev 1.8 -- Use or Disclosure of Data Contained on this Page is Subject to the Restrictions on the Inside Title Page of this Document 12/5/163

Page 4

Contents

Chapter 3 Arm Types and User Controls

System Battery Types................................................................................... 38

User Controls and Wrist Display.................................................................... 38

Power ON/OFF Button Location............................................................. 39

Turning the Arm ON and OFF ................................................................ 40

Wrist Display ......................................................................................... 40

Low Battery Icon and Low Battery Alert ......................................... 41

System Fault Icon .......................................................................... 41

Arm Mode LED and Grip Select LEDs ............................................ 42

Display Button ................................................................................. 43

Displaying the Battery Charge Level................................................... 43

Changing the Display Brightness........................................................ 44

Swapping IMUs................................................................................ 44

IMU LED Status ..................................................................................... 45

Hand Open Button................................................................................. 47

Orienting The Arm While Pressing The Hand Open Button ................. 48

Chapter 4 Setting Up the Arm

Installing IMUs............................................................................................. 49

Installing the IMU to the Shoe Clip .......................................................... 50

Installing the Shoe Clip to Your Shoe....................................................... 52

Location and Orientation of the IMUs ...................................................... 53

Waking a Sleeping IMU................................................................................ 53

Donning (Putting On) the Arm ...................................................................... 54

Chapter 5 Using the Arm

Key Concepts.............................................................................................. 56

Switching vs. Motion .............................................................................. 56

Operating Modes ................................................................................... 57

IMU - Walk Detect.................................................................................. 58

IMU - Angle Limit Detect ........................................................................ 58

Mode Change Interlock........................................................................... 59

Zeroing the IMUs ................................................................................... 59

Safe Operation of the System ....................................................................... 60

What To Do If the Arm Is Not In Proper Working Order............................ 60

Arm Is Not in Proper Working Order ................................................. 60

Unsure When Using the Arm............................................................. 60

Grasp Release .................................................................................. 61

Doffing the Arm ............................................................................... 61

Safe Motions ......................................................................................... 62

Taking It Slow........................................................................................ 62

Practicing Safe Operation of the System .................................................. 63

Lifting Heavy Objects ............................................................................. 63

Initializing the Arm....................................................................................... 64

Re-Initializing the Arm.................................................................................. 65

Improper Shutdowns.................................................................................... 65

4 Use or Disclosure of Data Contained on this Page is Subject to the Restrictions on the Inside Title Page of this Document -- Rev 1.8

Page 5

Contents

Operating Modes and Motions ...................................................................... 66

Standby Mode (No Motion) ..................................................................... 66

Hand Mode Motions............................................................................... 66

Opening or Closing the Hand............................................................ 67

Compound Wrist Motions ................................................................. 67

Rotating the Wrist ............................................................................ 69

Selecting a Grip ..................................................................................... 69

Power Grip (Grip Select LED 1)......................................................... 70

Tool Grip (Grip Select LED 2) ........................................................... 71

Fine Pinch Closed Grip (Grip Select LED 3) ........................................ 72

Fine Pinch Open Grip (Grip Select LED 4).......................................... 72

Lateral Pinch Grip (Grip Select LED 5) ............................................... 73

Chuck Grip (Grip Select LED 6)......................................................... 75

Grip Detents .................................................................................... 75

Arm Mode Motions ................................................................................ 75

SC Arm Motions .............................................................................. 76

Elbow Flexion - Extension (HC Arm) .................................................. 79

Humeral Internal - External Rotation (HC Arm) ................................... 80

Doffing (Removing) the Arm ......................................................................... 80

Chapter 6 Charging the Batteries

Battery Charging Safety ............................................................................... 82

Testing the Internal Battery Charge Level....................................................... 82

Charging the Internal Battery ........................................................................ 83

Testing the External Battery Charge Level...................................................... 85

Charging the External Battery ....................................................................... 86

Removing the External Battery from the Holster ................................. 88

Installing the External Battery in the Holster........................................ 88

Testing the IMU Battery Charge Level ........................................................... 89

Charging the IMU Battery............................................................................. 90

Chapter 7 Maintaining and Troubleshooting the Arm

Maintaining the Arm .................................................................................... 93

Removing and Replacing the Fingernails, Finger Covers and Hand Cover ... 94

Removing and Replacing Fingernails .................................................. 95

Removing and Replacing Finger Covers ............................................. 96

Removing and Replacing Hand Cover ................................................ 97

Cleaning the Arm................................................................................... 98

Troubleshooting the Arm............................................................................ 100

LUKE Arm System Alerts ..................................................................... 100

Troubleshooting ................................................................................... 101

Rev 1.8 -- Use or Disclosure of Data Contained on this Page is Subject to the Restrictions on the Inside Title Page of this Document 12/5/165

Page 6

Contents

Appendix A Technical Specifications

Arm Specifications..................................................................................... 107

Battery Specifications................................................................................. 112

AC Adapter Specifications.......................................................................... 113

Charging Pad Specifications........................................................................ 114

Arm Radio Specifications............................................................................ 115

Appendix B Guidance and Manufacturer’s Declaration

Electromagnetic Environment...................................................................... 117

Electromagnetic Emissions .................................................................... 117

Electromagnetic Immunity..................................................................... 118

Recommended Separation Distances ........................................................... 121

Essential Performance ................................................................................ 122

6 Use or Disclosure of Data Contained on this Page is Subject to the Restrictions on the Inside Title Page of this Document -- Rev 1.8

Page 7

Contents

List of Figures

Figure 1. Arm Types ............................................................................ 20

Figure 2. Internal Battery ......................................................................21

Figure 3. External Battery ..................................................................... 22

Figure 4. External Battery Holster..........................................................23

Figure 5. Charging Pad for IMU Battery................................................. 24

Figure 6. AC Adapter........................................................................... 24

Figure 7. Charging Dock ...................................................................... 25

Figure 8. ACI Module ........................................................................... 26

Figure 9. Example Inertial Measurement Unit ......................................... 27

Figure 10. Example EMG .......................................................................27

Figure 11. Example Pressure Switch ........................................................ 28

Figure 12. Example Rocker Switch .......................................................... 28

Figure 13. Example Pressure Transducer ................................................. 29

Figure 14. Example Linear Transducer ....................................................29

Figure 15. Example Tactor Output Device................................................ 30

Figure 16. Pinch Point Areas ..................................................................34

Figure 17. Power Button and LED - SC, HC, and RC Arms With External

Battery Only .......................................................................... 39

Figure 18. Power Button and LED - SC and HC Arms with Internal Battery 40

Figure 19. Wrist Display ......................................................................... 41

Figure 20. Hand Open Button ................................................................ 47

Figure 21. Attaching the IMU to the Shoe Clip......................................... 51

Figure 22. Attaching the Shoe Clip to the Shoe........................................ 52

Figure 23. Hand Open Button ................................................................ 61

Figure 24. Hand Open and Hand Closed ................................................. 67

Figure 25. Compound Wrist Motions ....................................................... 68

Figure 26. Rotating the Wrist .................................................................. 69

Figure 27. Power Grip............................................................................ 70

Figure 28. Tool Grip .............................................................................. 71

Figure 29. Fine Pinch Closed Grip........................................................... 72

Figure 30. Fine Pinch Open Grip ............................................................ 72

Figure 31. Lateral Pinch Grips ................................................................74

Figure 32. Chuck Grip............................................................................ 75

Figure 33. Moving the Hand Up or Down................................................ 77

Figure 34. Moving the Hand Left or Right................................................ 77

Figure 35. Moving the Hand Forward or Backward................................... 78

Figure 36. Voluntary Elbow Positioning (VEP) .......................................... 79

Figure 37. Elbow Flexion - Extension .......................................................79

Figure 38. Humeral Internal - External Rotation........................................ 80

Figure 39. Internal Battery Charging Port and Status Icon .........................84

Figure 40. Testing the External Battery Charge Level................................ 85

Figure 41. External Battery Charging Dock and Status LEDs ..................... 87

Figure 42. Removing and Replacing the External Battery .......................... 89

Figure 43. Charging the IMU Battery....................................................... 90

Figure 44. Lateral Pinch Grip - Fully Open ............................................... 94

Figure 45. Removing and Replacing the Fingernails .................................. 96

Rev 1.8 -- Use or Disclosure of Data Contained on this Page is Subject to the Restrictions on the Inside Title Page of this Document 12/5/167

Page 8

Contents

Figure 46. Lace - Securing Hand Cover ................................................... 97

Figure 47. Removing and Replacing the Finger and Hand Covers ..............98

Figure 48. Dimensions of Shoulder Configuration (In Centimeters) ........... 110

Figure 49. Dimensions of Humeral Configuration (In Centimeters)............ 111

Figure 50. Dimensions of Radial Configuration (In Centimeters) ............... 111

8 Use or Disclosure of Data Contained on this Page is Subject to the Restrictions on the Inside Title Page of this Document -- Rev 1.8

Page 9

Contents

List of Tables

Table 1. Arm System Icons ................................................................. 12

Table 2. Text Conventions.................................................................. 13

Table 3. Terminology ......................................................................... 14

Table 4. Acronyms............................................................................. 14

Table 5. Arm and Battery Types ......................................................... 38

Table 6. Arm Mode and Grip Select LEDs............................................ 42

Table 7. Wrist Display Battery Charge Levels ....................................... 43

Table 8. IMU LED Status.................................................................... 45

Table 9. Control Types - Switching vs. Motion ..................................... 56

Table 10. Arm and Operating Modes..................................................... 57

Table 11. Hand Mode — Motions ......................................................... 66

Table 12. Grip Select LEDs .................................................................. 69

Table 13. Arm Mode — Motions........................................................... 76

Table 14. Internal Battery Charging Port and Status Icon ........................ 84

Table 15. External Battery Charge Level................................................ 86

Table 16. External Battery Charging Dock Status LEDs........................... 87

Table 17. IMU Battery Charging LED Status .......................................... 91

Table 18. Troubleshooting - Try This First............................................ 101

Table 19. Troubleshooting - Wrist Display and System Faults................. 102

Table 20. Troubleshooting - Arm Function........................................... 104

Table 21. Troubleshooting - Power and Battery Charging...................... 105

Table 22. Arm System Specifications................................................... 107

Table 23. Operating Environmental Range........................................... 107

Table 24. Transport and Storage Environmental Range......................... 108

Table 25. Service Life Specifications.................................................... 108

Table 26. Mass of Arm Configurations................................................. 109

Table 27. Dimensions of Arm Configurations ....................................... 109

Table 28. Battery Charge and Operation Times.................................... 112

Table 29. Power Specifications - Internal Battery .................................. 112

Table 30. Power Specifications - External Battery ................................. 112

Table 31. Power Specifications - IMU Battery....................................... 113

Table 32. AC Adapter Specifications ................................................... 113

Table 33. Charging Pad Specifications................................................. 114

Table 34. Arm Radio Specifications..................................................... 115

Table 35. Guidance and Manufacturer’s Declaration -

Electromagnetic Emissions ................................................... 117

Table 36. Guidance and Manufacturer’s Declaration -

Electromagnetic Immunity.................................................... 118

Table 37. Recommended Separation Distances (Part I).......................... 121

Table 38. Recommended Separation Distances (Part II) ......................... 122

Rev. 1.8 -- Use or Disclosure of Data Contained on this Page is Subject to the Copyright Restrictions on the Inside Title Page of this Document 9

Page 10

Contents

10 Use or Disclosure of Data Contained on this Page is Subject to the Copyright Restrictions on the Inside Title Page of this Document -- Rev. 1.8

Page 11

About This Guide

The intent of this guide is to help guide you in the use of the LUKE arm system.

Read this guide before using the arm.

This guide is shipped with the LUKE arm system.

How to Use This Guide

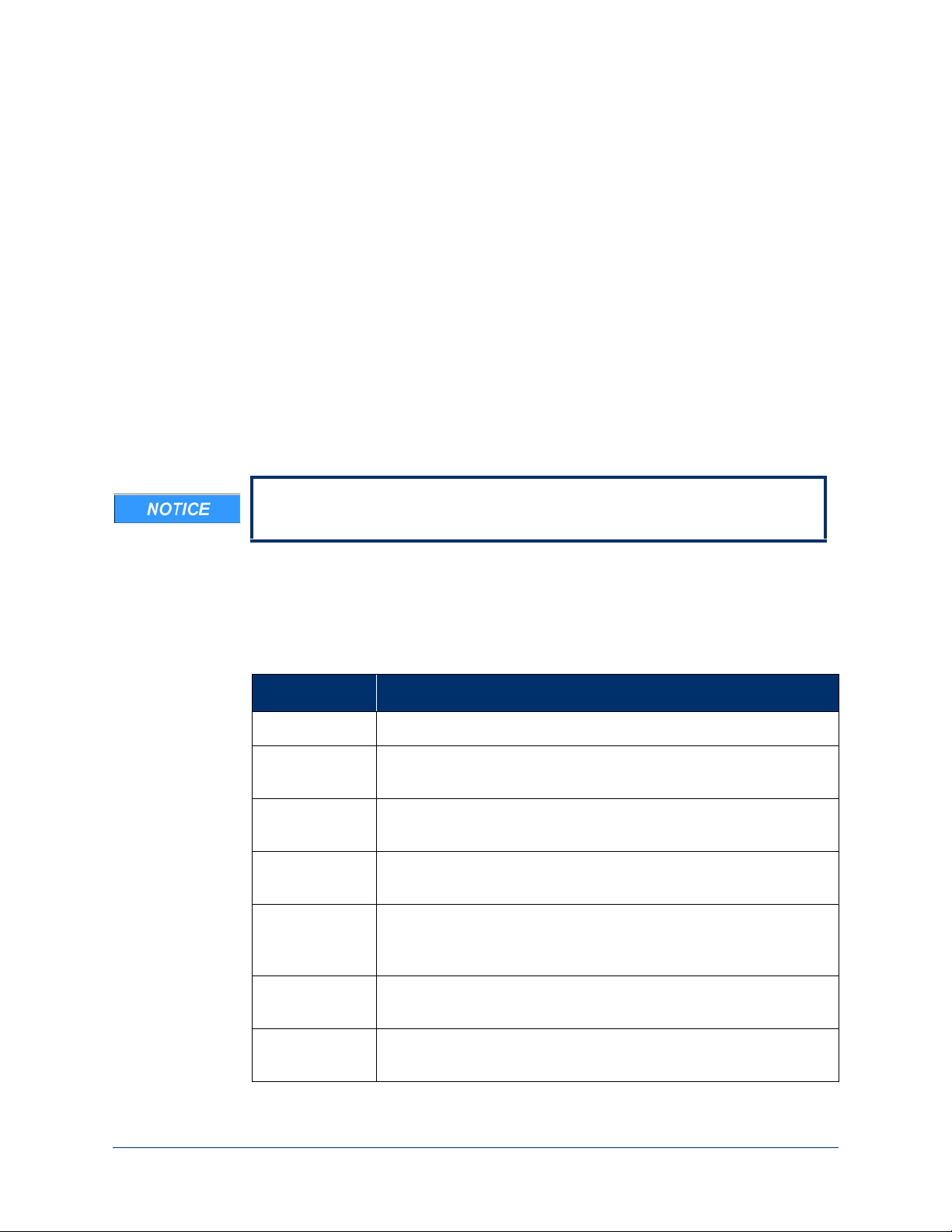

To learn about the arm and how to use the arm read the chapters in the table

below.

Read To Learn About...

Chapter 1 Overview — Provides a summary of the arm and arm parts.

Chapter 2 Safety — Provides WARNINGS and CAUTIONS on using the

arm and batteries.

Chapter 3 Arm Types and User Controls — Provides information about

arm types, batteries, and user controls and displays.

Chapter 4 Setting Up the Arm— Tells you how to install the IMUs and don

the arm.

Chapter 5 Using the Arm— Provides information on key concepts as well

as how to safely initialize the arm, change operating modes, and

command hand and arm motions.

Chapter 6 Charging the Batteries — Provides steps on how to charge all

batteries.

Chapter 7 Maintenance and Troubleshooting — Tells you how to

maintain the arm as well as troubleshoot problems.

Rev 1.8 -- Use or Disclosure of Data Contained on this Page is Subject to the Restrictions on the Inside Title Page of this Document r11

Page 12

About This Guide

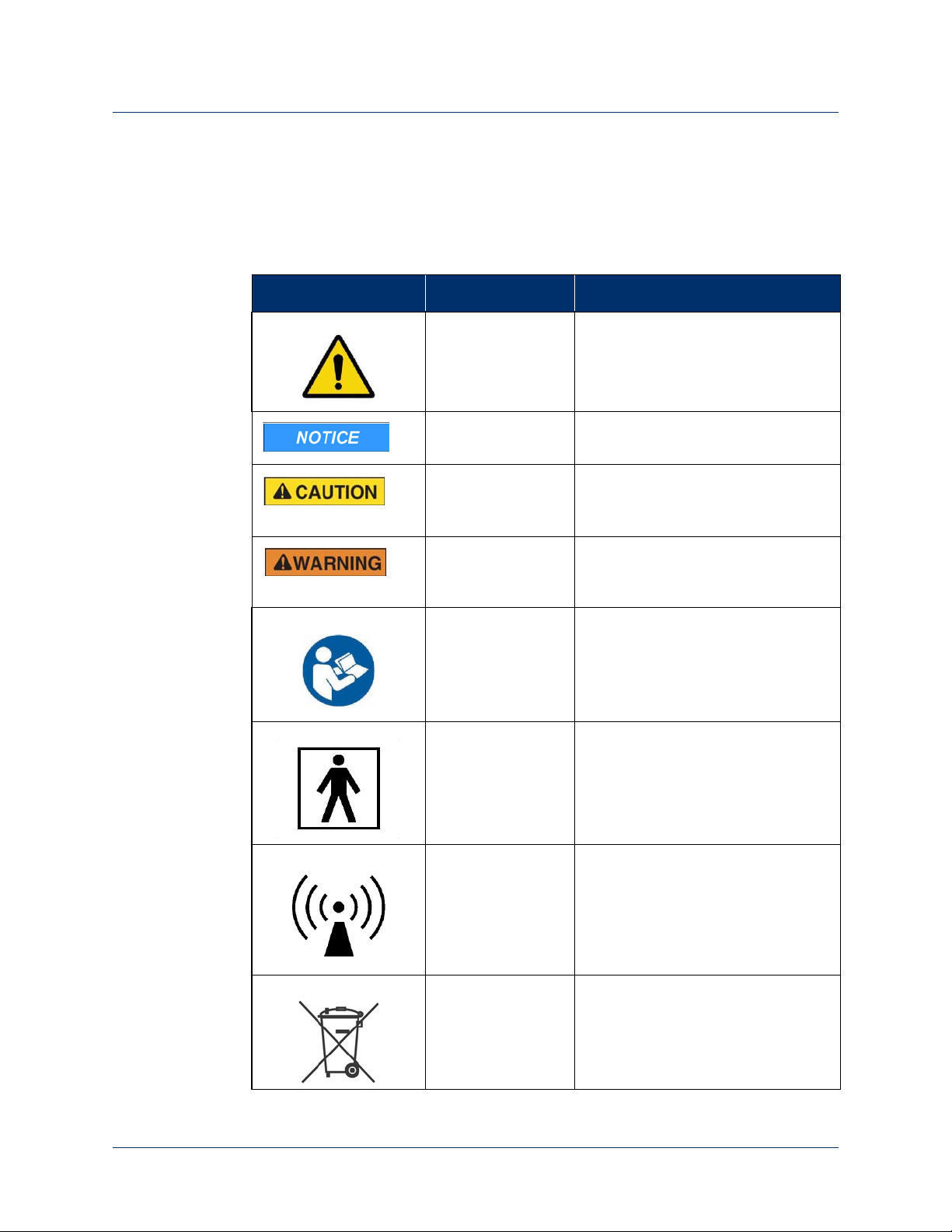

Conventions

Table 1 describes the arm system icons and Table 2 describes text conventions used

throughout this guide.

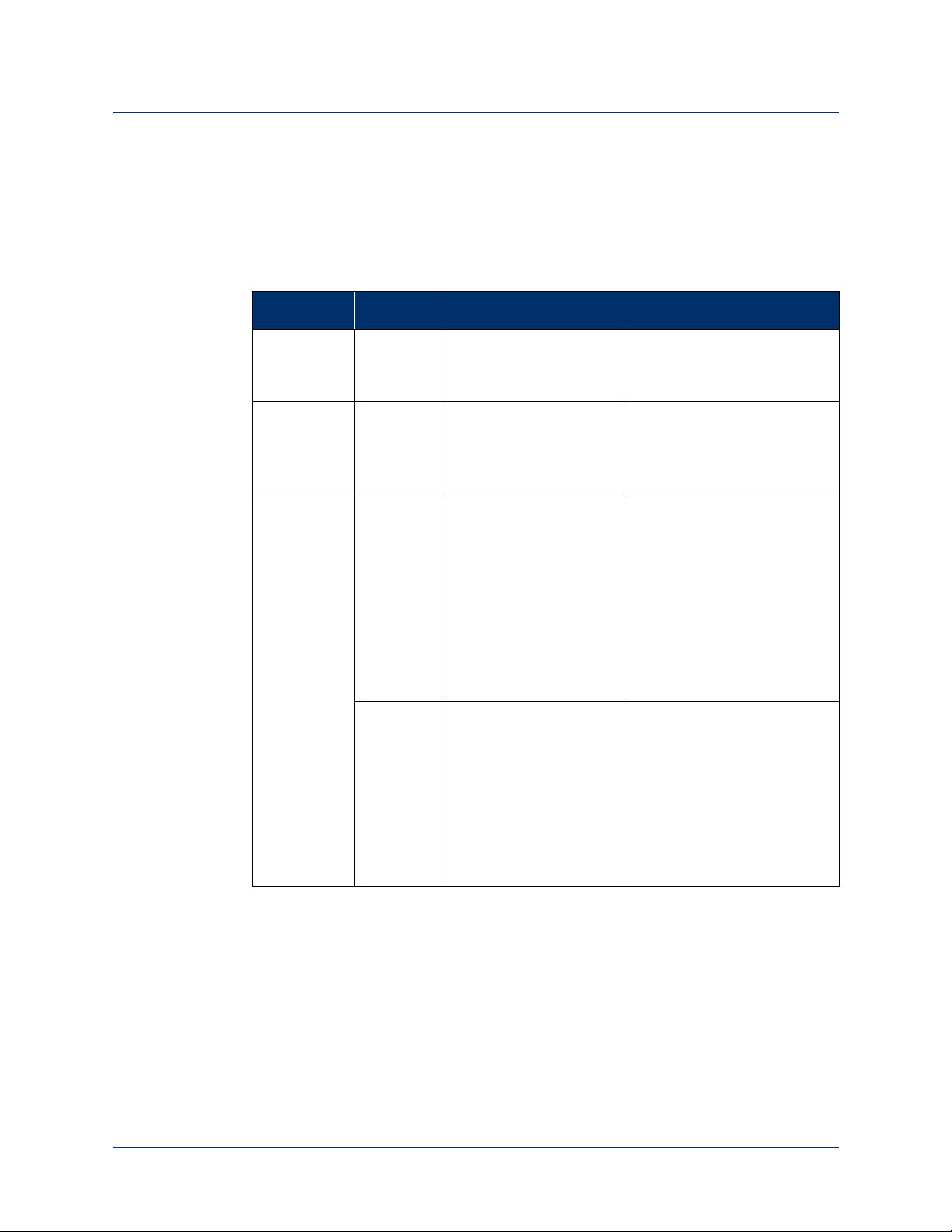

Table 1. Arm System Icons

Icon Meaning Description

Alert Alerts you to potential injury

hazards. Obey all safety messages

that follow this symbol to avoid

possible injury.

Information Note Notice is used to address practices

not related to personal injury.

CAUTION Cautions indicate a hazardous

situation which, if not avoided, could

result in minor or moderate injury.

WARNING Warnings indicate a hazardous

situation which, if not avoided, could

result in death or serious injury.

Read This Guide Used to instruct you to refer to this

guide prior to using the LUKE arm

system.

Electrically Isolated

Equipment

Radio Transmitter Indicates that equipment contains a

Disposal of

Equipment

Indicates Type BF equipment which

is electrically isolated and can safely

contact a person’s skin without the

risk of electric shock.

radio transmitter.

Indicates that equipment should not

be disposed of in the trash.

12 Use or Disclosure of Data Contained on this Page is Subject to the Restrictions on the Inside Title Page of this Document -- Rev 1.8

Page 13

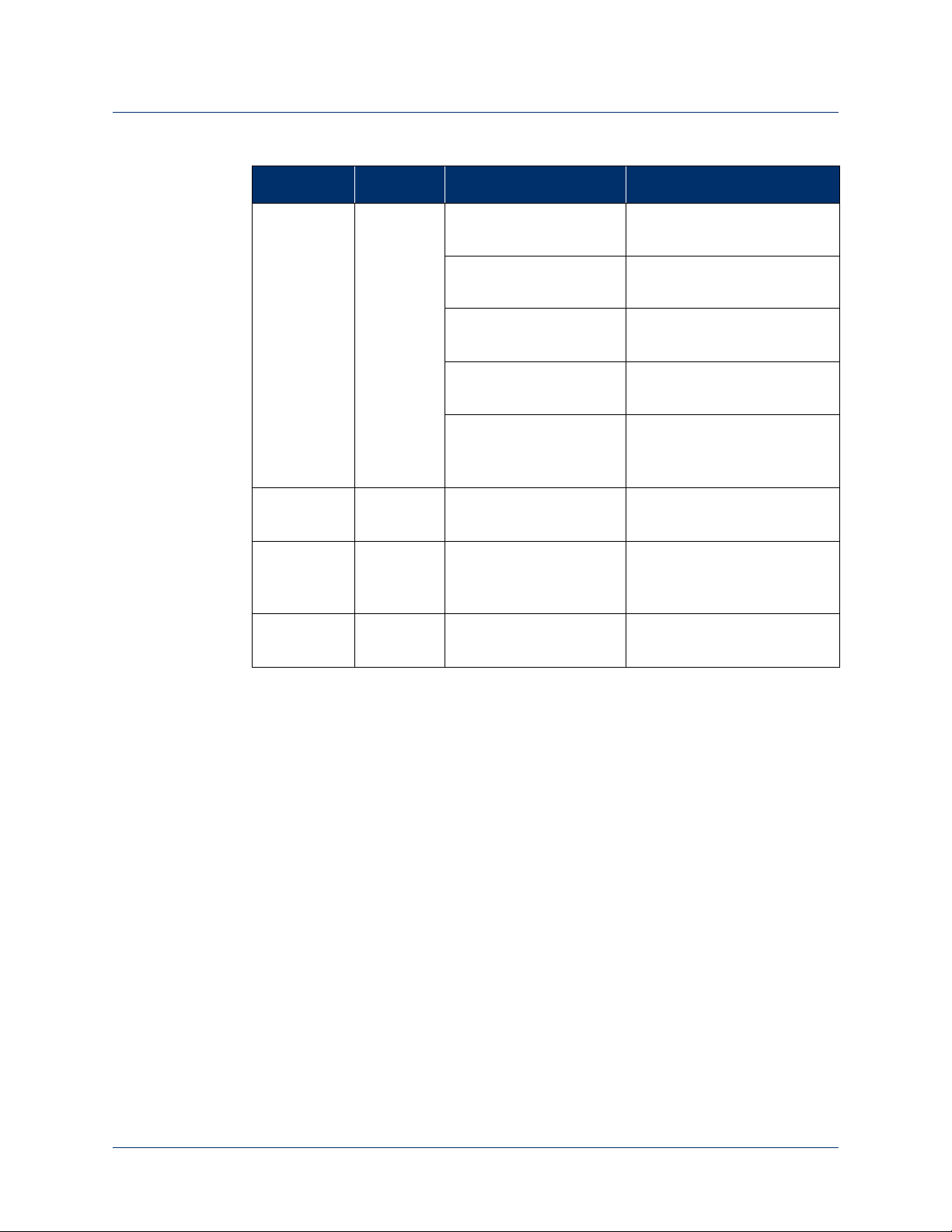

Icon Meaning Description

Recycle Equipment Indicates that equipment should be

recycled.

Use Indoors Identifies electrical equipment

designed for indoor use and should

be kept dry.

Conventions

Meets Class II

Safety

Requirements

MR Unsafe Indicates that equipment is not

Table 2. Text Conventions

Convention Appearance in Text Example

Key concepts and

Appear in bold type. Inertial Measurement

emphasized text

Book titles, directories,

Appear in italic typeface. LUKE Arm User Guide

pathnames, and filenames

Identifies equipment that meets the

safety requirements specified for

Class II equipment according to IEC

61140.

compatible with magnetic resonance

(MRI) environment.

Unit

Rev 1.8 -- Use or Disclosure of Data Contained on this Page is Subject to the Restrictions on the Inside Title Page of this Document 12/5/1613

Page 14

About This Guide

Terminology

Table 3 describes the terminology used in this guide to describe the arm, socket,

and accessories.

Table 3. Terminology

Arm Refers to the arm hardware in isolation.

Prosthesis Refers to the combination of the socket and the arm.

Arm System Refers to the socket, arm, and all related accessories.

Acronyms

Table 4 lists the acronyms used in this guide.

Table 4. Acronyms

Ter m Description

Acronym Description

ACI Arm Control Interface — Controls the interface between you and

the Master Arm Controller.

EMG Electromyograph — A sensor that is placed on the skin and senses

the activation signal of a muscle.

EMI Electromagnetic Interference — Interference to the arm’s

electronics caused by external electrical sources.

HC Humeral Configuration — A type of arm.

IMU Inertial Measurement Unit — A control input that is placed on top

of a foot or lower appendage.

LED Light Emitting Diode — A light that displays a status.

MAC Master Arm Controller — The main processing unit of the arm.

RC Radial Configuration — A type of arm.

SC Shoulder Configuration — A type of arm.

SOC State of Charge — The battery charge level.

USB Universal Serial Bus — A standard way for a computer to talk to

other devices.

VEP Voluntary Elbow Positioning — A type of arm motion of the

LUKE arm.

14 Use or Disclosure of Data Contained on this Page is Subject to the Restrictions on the Inside Title Page of this Document -- Rev 1.8

Page 15

Contacting Technical Support

To contact technical support use the following address, web site URL or telephone:

Mobius Bionics

470 Commercial Street

Manchester, NH 03101

www.mobiusbionics.com

603-239-3834

855-MOBIUS1 (855-662-4871)

Contacting Technical Support

Rev 1.8 -- Use or Disclosure of Data Contained on this Page is Subject to the Restrictions on the Inside Title Page of this Document 12/5/1615

Page 16

About This Guide

16 Use or Disclosure of Data Contained on this Page is Subject to the Restrictions on the Inside Title Page of this Document -- Rev 1.8

Page 17

LUKE Arm System

This chapter provides an overview of the LUKE arm system which includes the

socket, arm, batteries, AC Adapter, charging pad, and arm inputs and outputs.

Prior to using the LUKE arm system you must have met with your prosthetist.

During the meeting(s) the prosthetist will have performed a number of steps such as:

• design and build a custom socket to attach the arm

• pick the arm configuration and arm parts to best fit your needs

• set up and configure the arm

• allow you to test the arm system in a controlled setting

Once the prosthetist feels that you have met all demands in order to use the arm

they will allow you to use the arm. You should clearly understand how the

prosthetist has set up your arm prior to using the arm.

1

Indications for Use

The LUKE arm system consists of a prosthetic arm and accessories which are used

by a certified prosthetist to create a full upper extremity prosthesis indicated for

individuals, age 18 years and older, who have partial or full upper limb amputations

or congenital defects. The device is used to assist in activities of daily living (ADLs).

Rev 1.8 -- Use or Disclosure of Data Contained on this Page is Subject to the Restrictions on the Inside Title Page of this Document r17

Page 18

Chapter 1: LUKE Arm System

LUKE Arm System

The LUKE arm system is comprised of a specific arm type and several accessories

depending on the arm type. The arm system is described below.

Do not take apart or change the arm or connected parts. This could lead to

harm.

Based on your arm’s type and setup you may not have some of the following

parts.

Note the following concerning the LUKE arm system:

• The arm is internally powered (when under battery power).

RISK OF DEATH OR SERIOUS HARM

• The arm is designated Class II (when plugged into the AC Adapter).

• The arm and all body worn accessories are Type BF applied parts.

The IMUs have an IP57 rating. The other body worn components of the arm

system, when installed and covers are in place, have an IP52 rating. The IP

rating specifies the strength of the enclosure against solids (such as dust) and

liquids. An IP52 rating provides resistance to light rain and fine dust. An IP57

rating provides resistance to fine dust and submersion to depths of 1 m.

18 Use or Disclosure of Data Contained on this Page is Subject to the Restrictions on the Inside Title Page of this Document -- Rev 1.8

Page 19

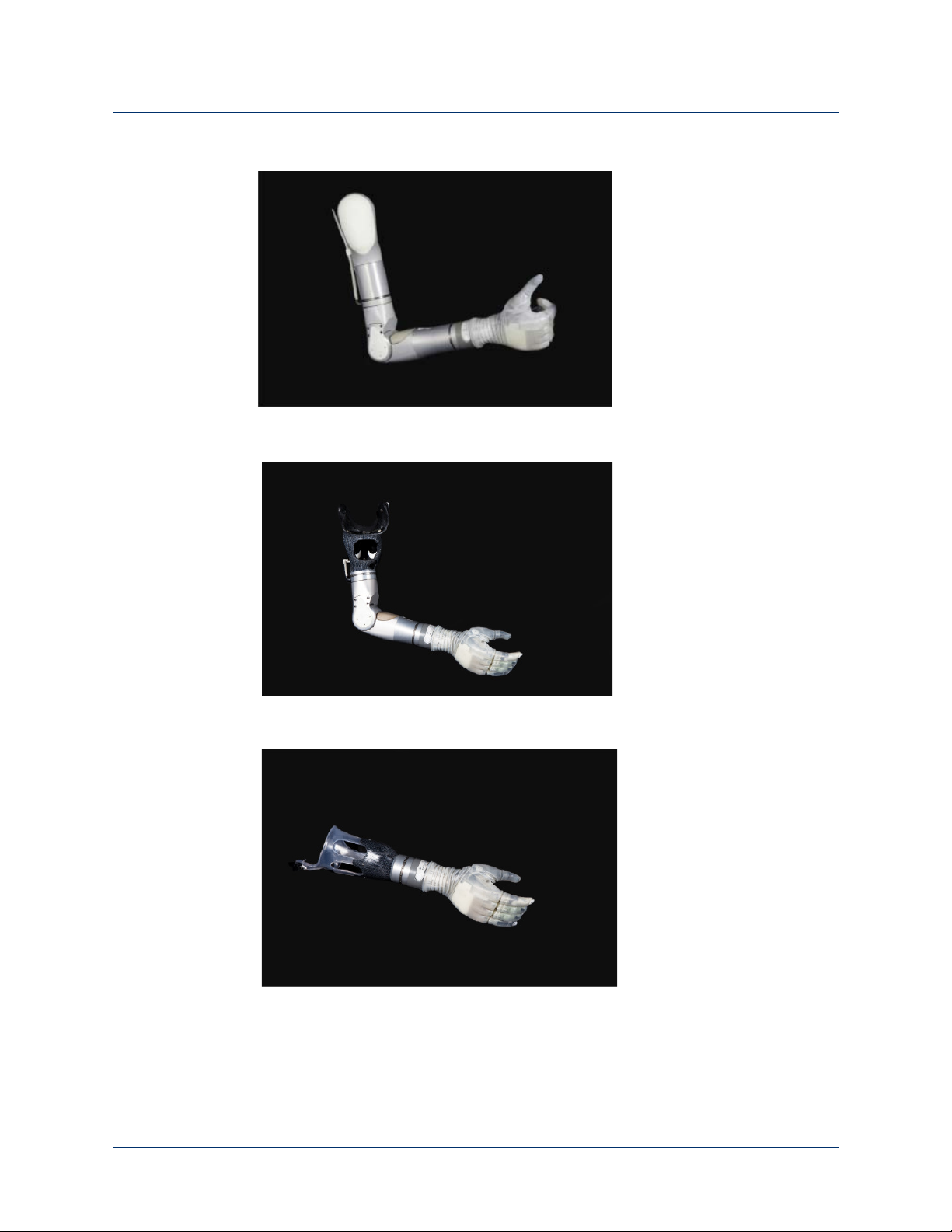

Arm Types

LUKE Arm System

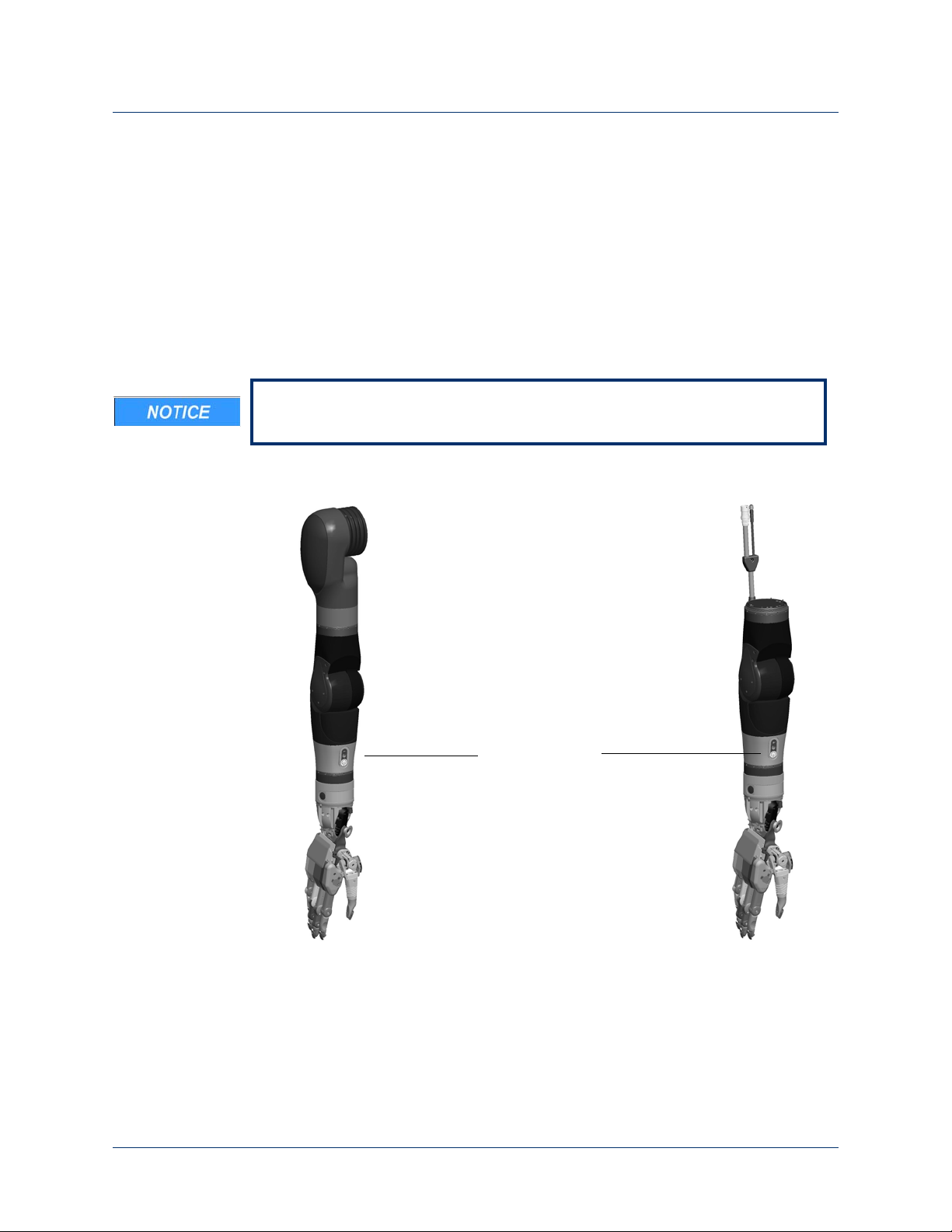

Your LUKE arm is one of the three types listed below and shown in Figure 1. Your

prosthetist will have chosen the arm type that best fits your needs and set up the

arm for the right or left side as well as proper length.

Shoulder Configuration (SC)

This arm type is for those amputees with little or no residual limb or for those

amputees with limited movement or other restricting factors in their residual limb.

Humeral Configuration (HC)

This arm type is for those amputees with a residual limb below the shoulder but not

including the elbow.

Radial Configuration (RC)

This arm type is the shortest of the three and is for amputees with a residual limb

below the elbow.

Rev 1.8 -- Use or Disclosure of Data Contained on this Page is Subject to the Restrictions on the Inside Title Page of this Document 12/5/1619

Page 20

Chapter 1: LUKE Arm System

Shoulder Configuration (SC)

Humeral Configuration (HC)

Radial Configuration (RC)

Figure 1. Arm Types

20 Use or Disclosure of Data Contained on this Page is Subject to the Restrictions on the Inside Title Page of this Document -- Rev 1.8

Page 21

Batteries and Holster

Internal Battery

Shoulder Configuration (SC)

Humeral Configuration (HC)

SC and HC Arms

(Inside the Arm)

There are two battery types used to power the arm. Which battery type is used

depends on your arm type and how your prosthetist configured the power to the

arm. The two batteries are:

Internal Battery

This battery may be used to power the SC and HC arms and is located within the

arm’s forearm. See

Depending on how your prosthetist configured your arm you may not have an

internal battery.

Figure 2. Internal Battery

LUKE Arm System

Figure 2.

Rev 1.8 -- Use or Disclosure of Data Contained on this Page is Subject to the Restrictions on the Inside Title Page of this Document 12/5/1621

Page 22

Chapter 1: LUKE Arm System

External Battery

SC, HC, and RC Arms

(Outside the Arm)

External Battery

This battery, see

Figure 3, is normally worn on a belt or in a pocket and is used in

one of two ways:

• In SC and HC arms, with an internal battery, it may be used to supplement

power to the arm.

• In RC arms and in SC and HC arms, without an internal battery, it is used

standalone to power the arm.

The external battery is used with an external battery holster to power the arm. See

External Battery Holster for more information.

Figure 3. External Battery

External Battery Holster

The external battery is mounted in a holster which in turn can be clipped to a belt or

worn in a pocket. See

the external battery is in either the vertical or horizontal position. There are two

versions of the holster; one with an ON/OFF button and power LED and one

without. For more information see

22 Use or Disclosure of Data Contained on this Page is Subject to the Restrictions on the Inside Title Page of this Document -- Rev 1.8

Figure 4. The belt clip can be attached to the holster so that

Power ON/OFF Button Location.

Page 23

Figure 4. External Battery Holster

Battery Holster with ON/OFF button

Battery Holster without ON/OFF button

LUKE Arm System

Battery Chargers and Charging Dock

There are three components used for charging the batteries: a charging pad, an AC

Adapter, and a charging dock. The AC Adapter is used with the charging dock to

charge the external battery. To charge an internal battery, the AC Adapter plugs

directly into the arm.

Rev 1.8 -- Use or Disclosure of Data Contained on this Page is Subject to the Restrictions on the Inside Title Page of this Document 12/5/1623

Page 24

Chapter 1: LUKE Arm System

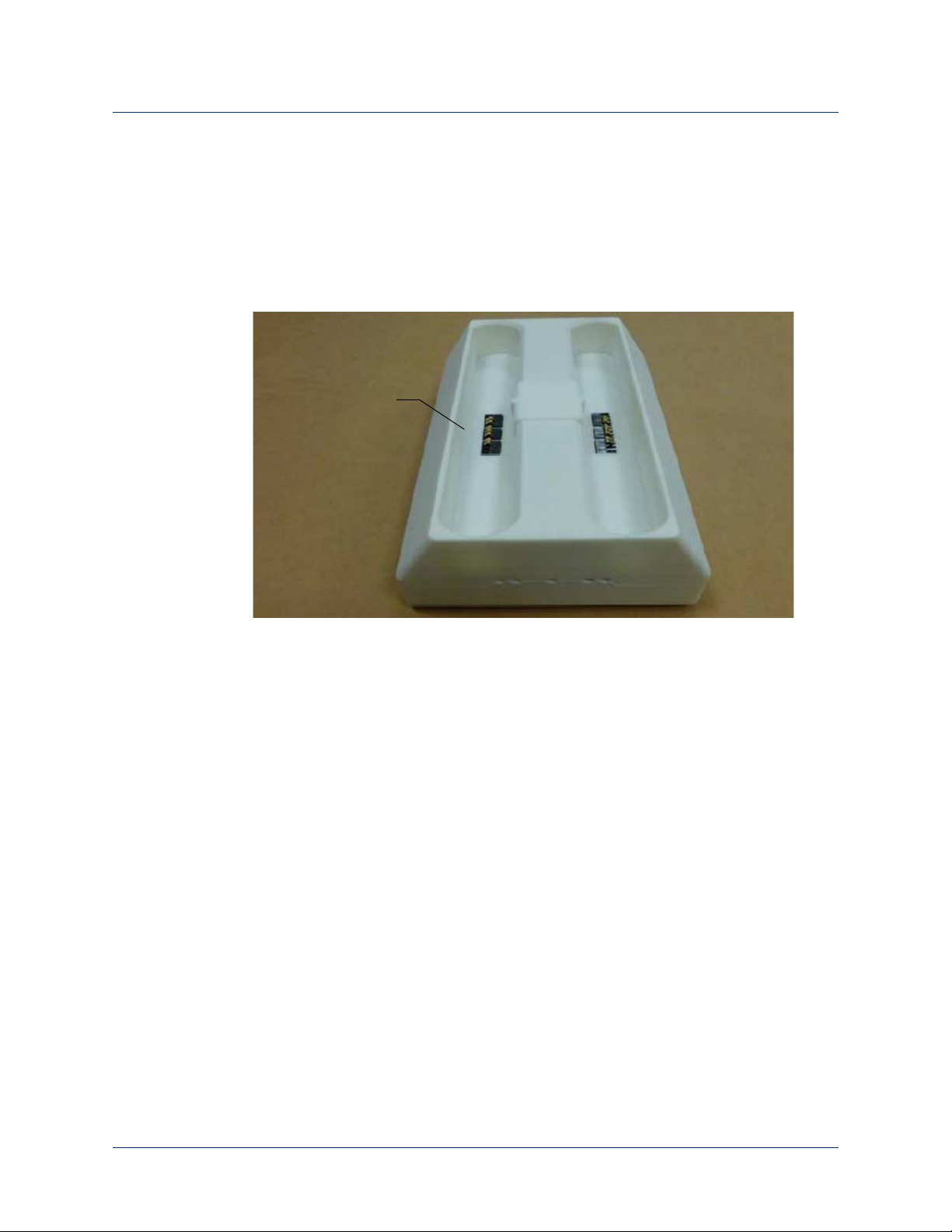

Charging Pad

AC Adapter

Charging Pad

A wireless charging pad is provided in order to charge the IMU battery.

shows the charging pad.

Figure 5. Charging Pad for IMU Battery

AC Adapter

Figure 5

The AC Adapter is used with the external battery charging dock and to directly

charge the internal battery within the arm. The AC Adapter comes with a line cord

for use in your country.

Figure 6 shows the AC Adapter.

Figure 6. AC Adapter

24 Use or Disclosure of Data Contained on this Page is Subject to the Restrictions on the Inside Title Page of this Document -- Rev 1.8

Page 25

LUKE Arm System

Charging Dock

Charging Dock

The charging dock is used to charge the external battery. The charging dock has

two slots allowing you to charge two batteries at once and is powered by the AC

Adapter. When charging the battery you should remove the battery from its holster

and place it in the charging dock.

Figure 7. Charging Dock

Figure 7 shows the charging dock.

Rev 1.8 -- Use or Disclosure of Data Contained on this Page is Subject to the Restrictions on the Inside Title Page of this Document 12/5/1625

Page 26

Chapter 1: LUKE Arm System

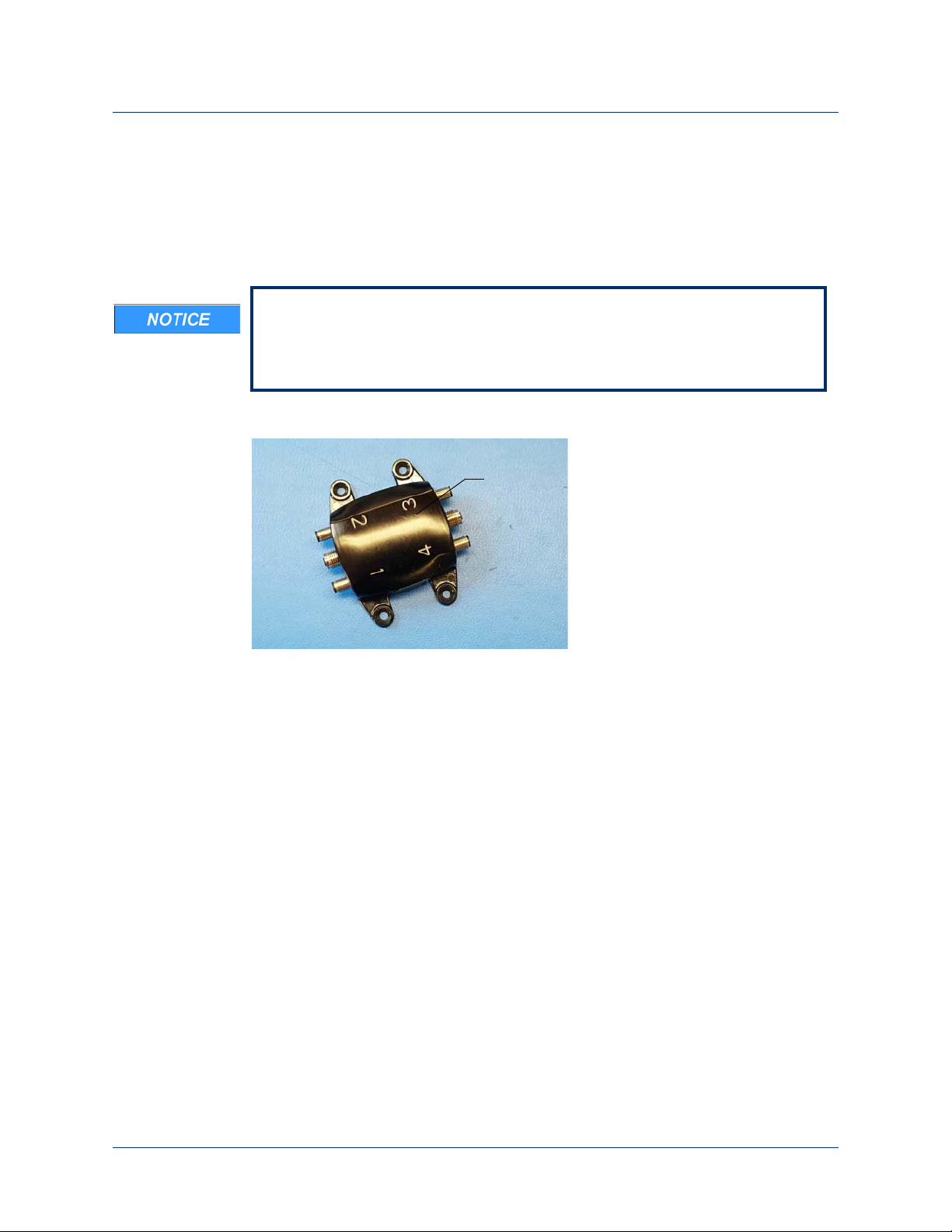

ACI Module

ACI (Arm Control Interface) Module

The ACI Module, see Figure 8, receives signals from user inputs (e.g., surface EMG

electrodes and pressure transducers) and sends them to the MAC which in turn

controls the arm. The ACI Module provides four user inputs and connects to the

arm.

The arm supports up to four IMU/ACI modules at a time in multiple

combinations, with a maximum of two IMUs. For example, your prosthetist

may configure the arm to support two IMU modules and two wired ACI

modules or four wired ACI modules and no IMUs.

Figure 8. ACI Module

26 Use or Disclosure of Data Contained on this Page is Subject to the Restrictions on the Inside Title Page of this Document -- Rev 1.8

Page 27

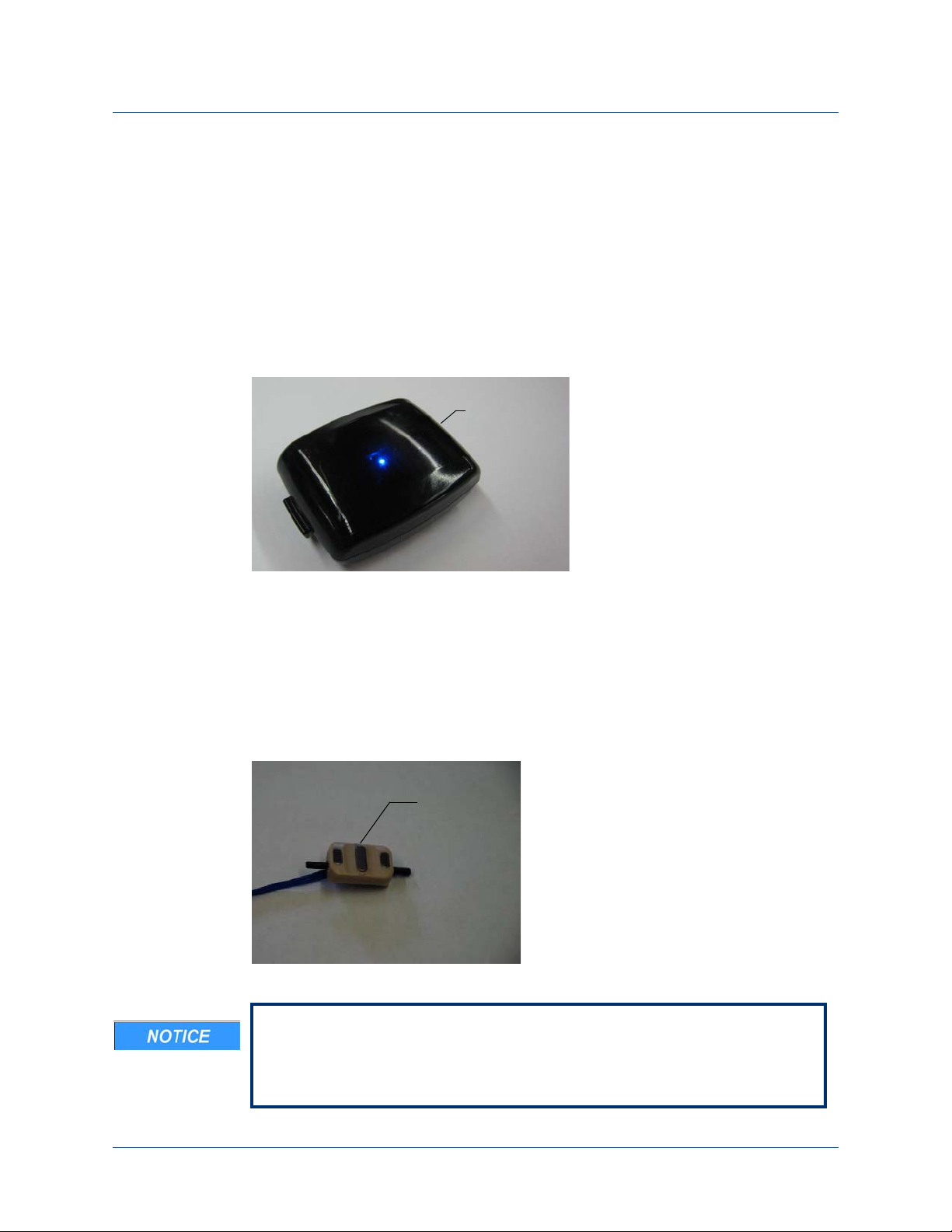

Input and Output Control Devices

Inertial

Measurement

Unit

Surface EMG

Electrodes

The arm uses several input devices and a single output device to control the arm.

The following sections describe these devices.

IMUs (Inertial Measurement Units)

IMUs are placed on top of your shoes and command motion or grip selection by

having you tilt your foot. See

Figure 9. Example Inertial Measurement Unit

Figure 9. To install the IMUs see Installing IMUs.

LUKE Arm System

EMG (Surface EMG Electrodes)

EMGs are placed on your skin or embedded into your socket to maintain contact

against your skin. EMGs are used to read electrical signals from underlying muscle

contractions. EMGs command motion by having you contract the selected muscle.

Figure 10 shows an example of a type of EMG.

Figure 10. Example EMG

When donning the arm system, static electricity discharge to EMGs can

damage them. To minimize the chance of EMG damage, touch any metal on

the arm before touching the EMGs. If you think the EMG is not working

correctly, see

Troubleshooting the Arm.

Rev 1.8 -- Use or Disclosure of Data Contained on this Page is Subject to the Restrictions on the Inside Title Page of this Document 12/5/1627

Page 28

IMU LED Status

The IMU LED shows the functions of the IMU. Pressing the display button for less

than one second causes the IMU battery to blink showing the charge level.

describes the functions of the IMU LEDs.

Table 8. IMU LED Status

User Controls and Wrist Display

Table 8

Function Color Status Description

Normal

Operation

Walk Detect Blue Solid Indicates walk detect mode.

Blue One blink every five (5)

seconds

IMUs are operating normally

and are communicating with

the arm.

For more information see

IMU - Walk Detect and

Zeroing the IMUs.

Fault Amber Blinking Indicates a sensor self-test

has failed. Try resetting the

IMU by removing it from the

charging pad, waiting five (5)

seconds, and then placing

the IMU on the charging

pad. If the condition

continues contact Technical

Support. See

Technical Support

Solid Indicates charging has been

paused. The system should

recover from this condition.

If after 30 minutes charging

does not continue, contact

Technical Support for service

on the charger or the IMU.

See

Contacting Technical

Support

Contacting

.

.

Rev 1.8 -- Use or Disclosure of Data Contained on this Page is Subject to the Restrictions on the Inside Title Page of this Document 12/5/1645

Page 29

Chapter 3: Arm Types and User Controls

Table 8. IMU LED Status

Function Color Status Description

Checking

Battery

Charge

Level or

Shaking to

Wake

Sleep Mode Off No blinks IMU is in sleep mode. See

Blue 5 blinks every 5 seconds

(3 times)

4 blinks every 5 seconds

(3 times)

3 blinks every 5 seconds

(3 times)

2 blinks every 5 seconds

(3 times)

1 blink every 5 seconds

(3 times)

Fully charged (80% to 100%)

Charge level is dropping

(60% to 80%)

Charge level is dropping

(40% to 60%)

Charge level is dropping

(20% to 40%)

Low battery (0% to 20%).

See

Charging the IMU

Battery

.

Waking a Sleeping IMU.

Discharged

Battery

Awake and

Waiting

Off No blinks IMU battery is discharged.

See

Charging the IMU

Battery

Off No blinks IMU is awake and waiting to

connect to the arm.

.

46 Use or Disclosure of Data Contained on this Page is Subject to the Restrictions on the Inside Title Page of this Document -- Rev 1.8

Page 30

Setting Up the Arm

This chapter provides information on how to set up the arm. Based on how your

prosthetist configured your arm, you may need to install some arm parts and then

don the arm to ensure proper fit prior to using the arm.

Topics in this chapter include:

Installing IMUs

•

• Donning (Putting On) the Arm

Before installing the arm parts and donning the arm be sure to visually inspect

all the arm parts and the arm for any sign of damage. If there is any sign of

damage, contact Technical Support. See

4

Contacting Technical Support.

Installing IMUs

If your arm’s control scheme calls for IMUs with shoe clips, you can install them at

this time. There are two steps to installing the IMU:

1. Attaching the IMU to the shoe clip.

2. Attaching the shoe clip to your shoe.

If you need help putting on and taking off the IMUs with shoe clips, have your

caregiver available at this time.

The IMUs have an IP57 rating. The IP rating specifies the strength of an

enclosure against solids (such as dust) and liquids. An IP57 rating provides

resistance to water at depths up to 1 m (39 inches) and resistance to fine dust.

Rev 1.8 -- Use or Disclosure of Data Contained on this Page is Subject to the Restrictions on the Inside Title Page of this Document r49

Page 31

Chapter 4: Setting Up the Arm

The IMUs will not provide data if dramatically tipped (close to vertical). Be sure

to position the IMU as close to level as possible when installing the IMU. If you

attach the IMU to your shoe at a severe angle to begin with, the IMU will not

provide the full range of motion after zeroing.

Installing the IMU to the Shoe Clip

To install the IMU to the shoe clip see Figure 21 and perform the following steps:

Be sure to install the IMU(s) onto the correct foot as configured by your

prosthetist. DO NOT SWAP THE IMU(s) DURING INSTALLATION.

1. Slide the tabbed end of the IMU into the open end of the shoe clip.

When installing the IMU onto the shoe clip, please ensure the following:

• The Front Arrow label on the bottom of the IMU is facing towards your

toes.

• Keep the IMU aligned with the direction of movement. This will prevent any

cross talk from occurring.

2. Press down on the IMU until the shoe clip retention tab snaps into the IMU slot.

Ensure the IMU is fastened securely to the shoe clip.

• The shoe clip can be put on the shoe either before or after the IMU is

installed on the shoe clip.

• You can attach the IMU to the shoe by alternate means (i.e., straps or

pockets) as long as it is securely attached.

50 Use or Disclosure of Data Contained on this Page is Subject to the Restrictions on the Inside Title Page of this Document -- Rev 1.8

Page 32

Figure 21. Attaching the IMU to the Shoe Clip

Open End

of Shoe Clip

IMU Tab

Press Down On IMU

IMU Tab

Open End

of Shoe Clip

Front

P

Part 1

Par t 2

Part 3

Front

Label

Installing IMUs

Rev 1.8 -- Use or Disclosure of Data Contained on this Page is Subject to the Restrictions on the Inside Title Page of this Document 12/5/1651

Page 33

Chapter 4: Setting Up the Arm

Open End of Shoe Clip

NOTE: IMU is shown attached

to shoe clip.

Installing the Shoe Clip to Your Shoe

To install the shoe clip to your shoe see Figure 22 and perform the following steps:

• Note that the shoe clip can be installed onto your shoe with the shoe off

your foot or on your foot.

• Once you have installed the shoe clip, the shoe clip can remain on the

shoe.

1. Orient the shoe clip so that the open end of the clip is facing towards your toes.

2. Slide the shoe clip under the laces of the shoe (left or right).

When installing the shoe clip to the shoe, please ensure the following:

• The shoe clip passes through at least two of the shoe’s laces to ensure the

clip is secure and stable.

• The Front Arrow label on the bottom of the IMU is facing towards your

toes.

3. Tighten the laces to secure the IMU and shoe clip to the shoe.

4. If you have not already done so put on the shoe.

5. Once you have installed the IMUs you can don (put on) the arm. See

(Putting On) the Arm

.

Figure 22. Attaching the Shoe Clip to the Shoe

Donning

52 Use or Disclosure of Data Contained on this Page is Subject to the Restrictions on the Inside Title Page of this Document -- Rev 1.8

Page 34

The IMUs do not contain an ON/OFF button. An IMU that is awake and set

up to communicate with an arm will do so once the arm is powered ON. See

Waking a Sleeping IMU and Initializing the Arm.

Location and Orientation of the IMUs

During the configuration process your prosthetist will have located and oriented the

IMUs to ensure proper operation of the arm. Be sure to locate and orient the IMUs

per your prosthetist’s instructions.

Waking a Sleeping IMU

When an IMU has not communicated with the arm for more than 30 minutes, the

IMU reverts to a sleep mode to conserve the battery. When in sleep mode the IMU

is not listening for arm communication.

Waking a Sleeping IMU

As a result, if the IMU is in sleep mode when the arm is turned on, it will not

connect with the arm. This results in the Grip Select LEDs sweeping while the arm

is trying to find the IMUs. If no IMUs are found, the System Fault Icons on the wrist

display blink along with an “IMU Comm Lost” fault code. Shaking your foot with

the IMU attached wakes the IMU from sleep mode so that the IMU is ready to

communicate with the arm once the arm system is powered up.

An IMU that has been shaken awake is waiting to communicate with the arm. IMUs

that are not actively communicating with an arm blink the battery state of charge

whenever they are shaken, regardless of whether they are sleeping or not.

If the IMU does not communicate with the arm within five (5) minutes of being

shaken awake, the IMU reverts back to sleep mode to conserve the battery.

Rev 1.8 -- Use or Disclosure of Data Contained on this Page is Subject to the Restrictions on the Inside Title Page of this Document 12/5/1653

Page 35

Chapter 5: Using the Arm

IMU - Walk Detect

The IMUs are designed to detect rapid foot movements (such as those seen while

walking) and not use these movements as arm commands. For example, if you

shake your feet the IMUs would detect this as motion other than a normal

command. When walk detect is active, the white Arm Mode LED blinks rapidly and

the blue IMU LED is solid. Note that when walk detect is active you will not be able

to move the arm using the IMUs, however, non-IMU controls will continue to

function as configured. If you are concerned about arm movement while walking (or

at other times) put the arm in Standby mode prior to walking.

When you stop walking and the IMUs come to rest, the arm reverts back to the

previous mode (Arm or Hand) the arm was in prior to entering walk detect and

resumes normal operation. This happens automatically when the IMU commands

return to zero. If the walk detect LED continues to blink, this indicates that the arm

is still receiving a command from one of your inputs. To resolve this issue, make

sure your IMUs are positioned correctly, your feet are flat/normal to the ground and

you are not activating any other inputs.

If you cannot resume normal operation of the arm and the white Arm Mode LED

continues blinking with your feet flat on the ground, the IMU zero point is incorrect

and the current signal level is above a set threshold. To fix this issue you need to

re-position the IMUs on your feet or zero the IMUs by going into Standby mode.

Zeroing the IMUs.

See

IMU - Angle Limit Detect

The IMUs are designed to detect when you exceed the IMUs’ angle limit. This

occurs when you tip the IMUs more than 45 degrees since the last time the IMUs

were zeroed or were out of range. As a result, the white Arm Mode LED on the

Wrist Display blinks rapidly informing you of the problem.

If the IMUs exceed 45 degrees, you will not be able to move the arm with the IMUs,

however, non-IMU controls will continue to function as designed. To resume normal

operation you need to return your foot/feet to the rest or zero position.

If the white Arm Mode LED continues to blink, you need to reposition the IMUs,

re-position your feet, or zero the IMUs by going into Standby mode. See

the IMUs

.

Zeroing

58 Use or Disclosure of Data Contained on this Page is Subject to the Restrictions on the Inside Title Page of this Document -- Rev 1.8

Page 36

Mode Change Interlock

If you are in the process of switching modes (Standby to Hand mode or Hand to

Arm mode) and the system detects a command to move, the mode change

interlock becomes active. As a result, the white Arm Mode LED on the Wrist

Display blinks rapidly informing you of the problem.

You can switch modes when mode change interlock is active, however you will not

be able to command the arm. When the IMUs are returned to the zero position or

the wired input falls below the activation threshold you will be able to command the

arm.

If the problem does not clear automatically and the white Arm Mode LED continues

to blink, you need to re-position the IMUs/feet or zero the IMUs by going into

Standby mode (See

not activated.

Zeroing the IMUs

Zeroing the IMUs establishes a neutral position. When you take the arm out of

Standby mode the system zeros the IMUs by taking a snapshot of the IMU’s

position and identifies that position as neutral. For example, if you should take the

arm out of Standby mode while your feet and attached IMUs are in an inclined

position the IMUs will be zeroed at that position. If you should then place your feet

and IMUs in a different position without zeroing the IMUs the result could be

unintended arm motion. To ensure this does not occur re-zero the IMU s by

performing the following steps:

1. Using the designated mode input place the arm in the Standby mode.

2. Place your feet at the position you want to zero the IMUs (usually feet flat on the

ground).

Key Concepts

Zeroing the IMUs) or you need to ensure the wired inputs are

3. Using the designated mode input take the arm out of Standby mode.

4. The IMUs are now zeroed for that position and the IMU LED blinks blue once

every five (5) seconds.

If you have to continually re-zero the IMUs while not changing the neutral

position you should check to ensure the IMUs and shoe clips are securely

attached to your shoes.

Rev 1.8 -- Use or Disclosure of Data Contained on this Page is Subject to the Restrictions on the Inside Title Page of this Document 12/5/1659

Page 37

Chapter 6: Charging the Batteries

Power Cord

Charging Pad

IMUs

Charging Pad

Status LEDs

Charging the IMU Battery

To charge the IMU battery you need to remove the IMU from its shoe mounting clip

and place the IMU on the charging pad. Note the following when charging the IMU

battery:

• IMUs cannot be charged during use. The prosthesis stops functioning

and the System Fault Icon on the wrist display illuminates if this is

attempted.

• Do not place any objects on the charging pad other than the IMUs.

• Mobius Bionics suggests that you charge the IMU battery overnight.

• The estimated time to recharge an empty IMU battery to 80% capacity is

less than 2.0 hours.

• You can charge up to two IMUs at a time on the charging pad.

Figure 43 to see how the IMU is placed on the charging pad and Table 17 for a

See

description of the IMU charging status LEDs.

Figure 43. Charging the IMU Battery

90 Use or Disclosure of Data Contained on this Page is Subject to the Restrictions on the Inside Title Page of this Document -- Rev 1.8

Page 38

Charging the IMU Battery

Table 17. IMU Battery Charging LED Status

Function Color Status Description

Charging Blue Slow Blinking IMU is performing a self-test.

Fast Blinking Battery is charging.

NOTE: A fully discharged

IMU may need to partially

charge before the LED will

blink blue. When the IMU is

on the charging pad, the

charging pad’s status LEDs

will be blue.

Solid Battery is fully charged.

Fault Amber Blinking Indicates a sensor self-test

has failed. Try resetting the

IMU by removing it from the

charging pad, waiting five (5)

seconds, and then placing

the IMU on the charging

pad. If condition continues

contact Technical Support.

See

Contacting Technical

Support

.

Amber Solid Indicates charging has been

paused. The system should

recover from this condition.

If after 30 minutes charging

does not continue, contact

Technical Support for service

on the charger or the IMU.

See

Contacting Technical

Support

.

To charge the IMU battery perform the following steps:

1. Turn OFF the arm.

2. Plug the charging pad’s AC Adapter into an electrical outlet.

3. Remove the IMU from its shoe mounting clip.

4. Set the IMU on the charging pad circle. (One IMU per circle).

Ensure the IMU is placed on the pad with the LED facing up, so you can view

the IMU LEDs.

Rev 1.8 -- Use or Disclosure of Data Contained on this Page is Subject to the Restrictions on the Inside Title Page of this Document 12/5/1691

Page 39

Chapter 6: Charging the Batteries

5. Ensure the charging pad status LEDs are ON when charging the IMUs. See

Figure 43.

6. View the status of the IMU battery charge status LEDs. See

Table 17.

7. Reattach the IMU to its shoe clip. The IMU is now ready for use.

You cannot replace the IMU battery. If there is a problem with the IMU

battery, turn the arm power OFF, doff the arm, and contact Technical

Support. See

Contacting Technical Support.

IMUs are awake and waiting for communication from the arm once it is

removed from the charging pad. However, the IMU goes into sleep mode if it

has not communicated with the arm within 30 minutes. See

Sleeping IMU

.

Waking a

92 Use or Disclosure of Data Contained on this Page is Subject to the Restrictions on the Inside Title Page of this Document -- Rev 1.8

Page 40

Chapter 7: Maintaining and Troubleshooting the Arm

Troubleshooting the Arm

This section provides basic troubleshooting steps to help you find and resolve

possible problems that may occur with the arm. It also describes how alerts are

generated and indicated to identify possible problems.

If at any time you feel the arm is not in proper working order (e.g., slow to

move, hard to control, making odd sounds, etc.) turn the battery power OFF

and contact Technical Support at once. See

LUKE Arm System Alerts

The arm system generates alerts to indicate possible problems. Many of these alerts

are indicated by LEDs. The LED may blink or turn a certain color to indicate the

alert. The arm system may also sound a tone to indicate an alert.

All alerts are low priority alarms and technical alarms.

Contacting Technical Support.

Alerts may be generated when:

• A battery is discharged

• Hardware is damaged

Alerts are generated when:

• Communication with an IMU is lost

• You attempt to charge an IMU when the prosthesis is in operation

To learn more about these alerts see

Chapter 6, “Charging the Batteries”.

User Controls and Wrist Display and

100 Use or Disclosure of Data Contained on this Page is Subject to the Restrictions on the Inside Title Page of this Document -- Rev 1.8

Page 41

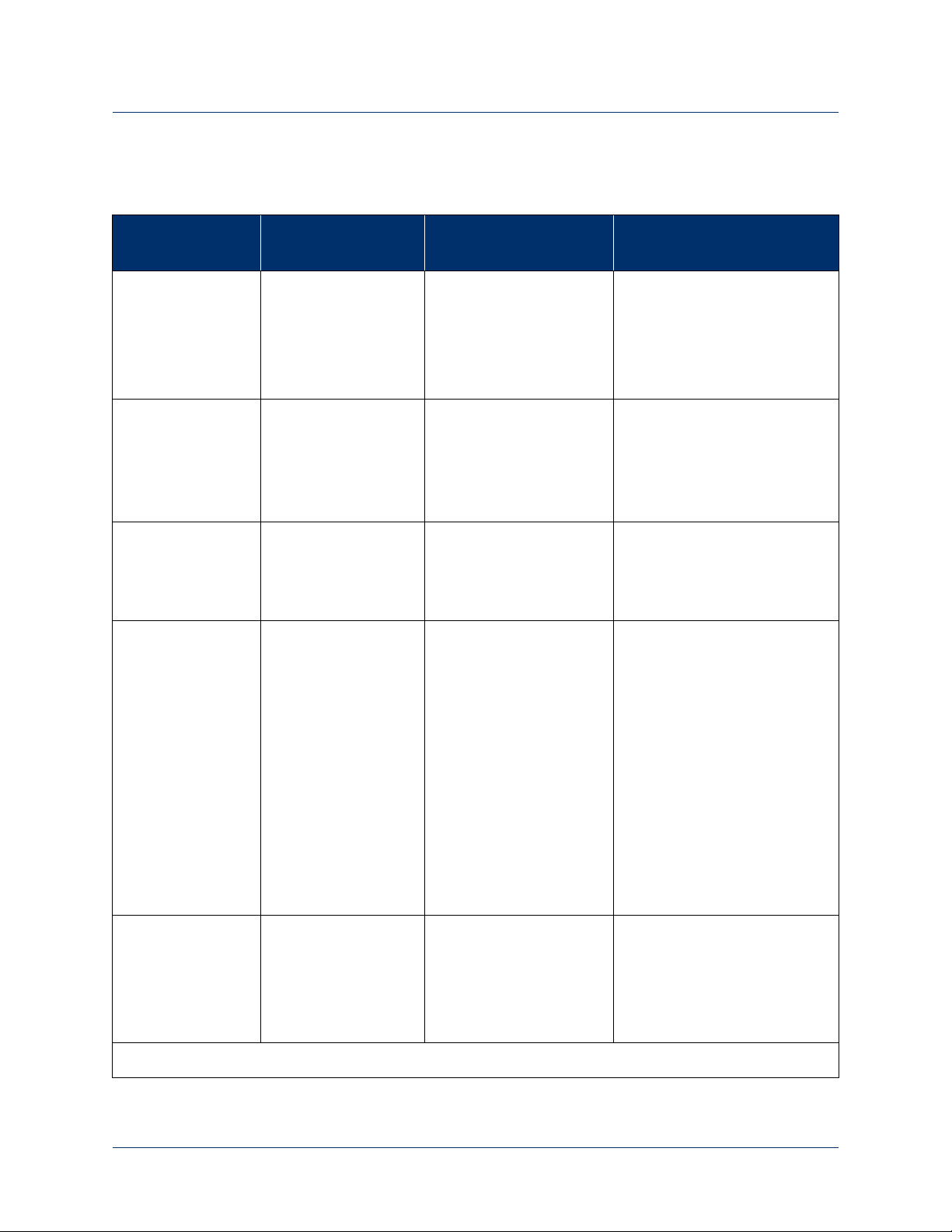

Troubleshooting

The following tables provide solutions to solving problems with the arm.

Table 18. Troubleshooting - Try This First

TRY

THIS

FIRST

Troubleshooting the Arm

These basic tips may help you quickly solve problems with the arm:

1. Put the arm into Standby Mode.

2. Check and secure the IMUs on your feet.

3. Take the arm out of Standby Mode.

1. Power the arm off.

2. Shake the IMUs to wake them. Look for the blinking blue

LEDs.

3. Make sure all cables are securely connected.

4. Put your feet flat on the ground

5. Power the arm on.

See the tables below to help you in troubleshooting problems with the arm system:

•

Table 19, Troubleshooting - Wrist Display and System Faults

– Use this table for help when Wrist Display LEDs are on or flashing

•

Table 20, Troubleshooting - Arm Function

– Use this table for help with moving the arm or changing grips

•

Table 21, Troubleshooting - Power and Battery Charging

– Use this table for help with powering the arm on and charging batteries

If the solutions in these troubleshooting tables do not solve the problem with the

arm, contact Technical Support. See

Contacting Technical Support.

Rev 1.8 -- Use or Disclosure of Data Contained on this Page is Subject to the Restrictions on the Inside Title Page of this Document

12/5/16101

Page 42

Chapter 7: Maintaining and Troubleshooting the Arm

Table 19. Troubleshooting - Wrist Display and System Faults

Problem Cause Solution

System Fault Icons Blinking

Fault Code: 3

System Fault Icons Blinking

Fault Code: 36

IMU not awake

IMU battery low

Ham radios, walkie

talkies, theft detectors, or

metal detectors are

affecting the arm

ACI not talking to arm

1. Power the arm off

2. Shake the IMUs to wake them

3. Power the arm on

1. Power the arm off

2. Shake the IMU to check the IMU

battery charge level and charge if

necessary

3. Power the arm on

1. Power the arm off

2. Move the arm at least 0.5 m (20 inches)

away from any ham radios, walkie

talkies, theft detectors, or metal

detectors

3. Power the arm on

1. Power the arm off

2. Check and tighten all system cables

3. Power the arm on

System Fault Icons Blinking

Fault Codes: 25, 26, 34,

256

System Fault Icons Blinking

Fault Code Not Listed

Arm motors warm

1. Power the arm off

2. Move to a cooler location if possible

3. Wait 15 minutes

4. Power the arm on

Contact Technical Support. See

Contacting Technical Support.

102 Use or Disclosure of Data Contained on this Page is Subject to the Restrictions on the Inside Title Page of this Document -- Rev 1.8

Page 43

Troubleshooting the Arm

Sweeping

Table 19. Troubleshooting - Wrist Display and System Faults

Problem Cause Solution

Low Battery Icon On Battery is low Replace the external battery in the holster

with a fully charged battery.

Plug the AC Adapter into the forearm

charging port

External battery not

connected

1. Check that the external battery is properly seated in the holster

2. Check and tighten the cables between

the arm and the holster

Grip Select LEDs Sweeping IMU not talking to arm Shake the IMUs to wake them

IMU battery is low Charge the IMUs

Ham radios, walkie

talkies, theft detectors, or

metal detectors are

Move the arm at least 0.5 m (20 inches)

away from any ham radios, walkie talkies,

theft detectors, or metal detectors

affecting the arm

Arm Mode LED Blinking Walk Detect

1. Stop walking

2. Put your feet flat on the ground

3. Check that the Arm Mode LED has

stopped blinking

IMU tilted too far

1. Put the arm into Standby Mode

2. Check and secure the IMUs on your

feet

3. Put your feet flat on the ground

4. Take the arm out of Standby Mode

Input device not working Contact Technical Support. See

Contacting Technical Support.

Rev 1.8 -- Use or Disclosure of Data Contained on this Page is Subject to the Restrictions on the Inside Title Page of this Document

12/5/16103

Page 44

Chapter 7: Maintaining and Troubleshooting the Arm

Table 20. Troubleshooting - Arm Function

Problem Cause Solution

Arm moving without

command

Arm not moving

IMU zero position

changed

Sweat near EMGs

Ham radios or walkie

talkies are affecting the

arm

Arm is in Standby Mode Put the arm into Hand Mode

Arm is off

Arm is faulted

1. Put the arm into Standby Mode

2. Check and secure the IMUs on your

feet.

3. Put your feet flat on the ground

4. Take the arm out of Standby Mode

1. Put the arm into Standby Mode

2. Wipe the sweat from the EMG

electrode and skin with a dry cloth

3. Take the arm out of Standby Mode

1. Put the arm into Standby Mode

2. Move the arm at least 0.5 m (20 inches)

away from any ham radios or walkie

talkies

3. Take the arm out of Standby Mode

1. Shake the IMUs to wake them

2. Power the arm on

See

Table 19, Troubleshooting - Wrist

Display and System Faults

.

Input device not

connected

Cannot change Modes Input device not

connected

Input device not working Contact Technical Support. See

Cannot change grips Hand is not fully open

Input device not working Contact Technical Support. See

1. Power the arm off

2. Check and tighten all connections at the

ACI

3. Power the arm on

1. Power the arm off

2. Check and tighten all connections at the

ACI

3. Power the arm on

Contacting Technical Support.

1. Put the arm into Hand Mode

2. Fully open the hand

3. Change grips

Contacting Technical Support.

104 Use or Disclosure of Data Contained on this Page is Subject to the Restrictions on the Inside Title Page of this Document -- Rev 1.8

Page 45

Table 21. Troubleshooting - Power and Battery Charging

Problem Cause Solution

Troubleshooting the Arm

Arm does not power on Internal battery too low

External battery too low

External battery not

connected

Internal Battery Charging

Charging Status Icon Blinking

Ye l l ow

Internal battery charging

paused

1. Plug the AC Adapter into the forearm

charging port

2. The charging status icon first blinks

yellow for a few minutes. Wait until the

charging status icon blinks blue.

3. Power the arm on

1. Replace the external battery in the hol-

ster with a fully charged one

2. Power the arm on

1. Check that the external battery is prop-

erly seated in the holster

2. Check and tighten the cables between

the arm and the holster

3. Power the arm on

1. Move the arm to a cooler location

2. Wait up to 2 hours. You can keep the

arm on and the AC adapter connected

while waiting.

3. Charging should continue on its own. If

it does not, contact Technical Support.

See

Contacting Technical Support.

Charging Status Icon On

Solid Yellow

Rev 1.8 -- Use or Disclosure of Data Contained on this Page is Subject to the Restrictions on the Inside Title Page of this Document

Internal battery charging

fault

Contact Technical Support. See

Contacting Technical Support.

12/5/16105

Page 46

Chapter 7: Maintaining and Troubleshooting the Arm

Table 21. Troubleshooting - Power and Battery Charging

Problem Cause Solution

External Battery Charging

Charging Dock Fault Status

Blinking Yellow

Charging Dock Fault Status

On Solid Yellow

IMU Charging

IMU Yellow LED On Solid Charging paused

IMU Yellow LED Blinking Self test failure

Charging paused

Charging fault Contact Technical Support. See

1. Wait up to 2 hours. You can keep the

charging dock on and the battery in the

charging dock while waiting.

2. Charging should continue on its own. If

it does not, contact Technical Support.

See

Contacting Technical Support.

Contacting Technical Support.

1. Wait up to 30 minutes. You can keep

the charging pad on and the IMU on the

charging pad while waiting.

2. Charging should continue on its own. If

it does not, contact Technical Support.

See

Contacting Technical Support.

1. Remove the IMU from the charging pad

2. Wait 5 seconds

3. Place the IMU on the charging pad

4. If the error persists, contact Technical

Support. See

Support

Contacting Technical

.

IMU LED off IMU not talking to

charging pad

1. Clean the top of the charging pad.

2. Clean the bottom of the IMU.

3. Place the IMU, LED side up, on the

charging pad’s center circle.

If the solutions in these troubleshooting tables do not solve the problem with the

arm, contact Technical Support. See

106 Use or Disclosure of Data Contained on this Page is Subject to the Restrictions on the Inside Title Page of this Document -- Rev 1.8

Contacting Technical Support.

Page 47

Technical Specifications

This appendix provides technical specifications for the LUKE arm, battery, AC

Adapter and charging pad.

Arm Specifications

:

Table 22. Arm System Specifications

Parameter Range/Explanation

Compliance The LUKE arm system complies with IEC 60601-1:2005

Power Type The arm is internally powered when under battery power

Designation The arm is designated Class II when plugged into the AC Adapter

A

Parts Type The arm and all body worn accessories are Type BF applied parts

:

Table 23. Operating Environmental Range

Parameter Range/Explanation

Operating Temperature

Humidity 15% to 93% (non-condensing)

Pressure 700 hPa to 1060 hPa

Arm and body worn Mobius

Bionics supplied accessories IP

rating

Rev 1.8 -- Use or Disclosure of Data Contained on this Page is Subject to the Restrictions on the Inside Title Page of this Document 107

• 10 °C to 40 °C (50 °F to 104 °F) with no degradation in

performance

• -10 °C to 50 °C (14 °F to 122 °F) with reduced arm speed

and/or load capacity

IP52

Page 48

Appendix A: Technical Specifications

Table 23. Operating Environmental Range (Continued)

Parameter Range/Explanation

IMU IP Rating IP57

When using the arm continuously in a hot environment (40°C, 104°F) and

while charging the internal battery, portions of the forearm and upper arm (if

applicable) could reach temperatures of 54°C - 57°C (130°F - 135°F), when

evaluated as directed in IEC60601-1: 2005-12.

:

Table 24. Transport and Storage Environmental Range

Parameter Range

Storage Temperature (excluding

-25 °C to 70 °C (-13 °F to 158 °F)

battery)

Humidity 15% to 93% (non-condensing)

Pressure 700 hPa to 1060 hPa

:

Table 25. Service Life Specifications

Part Service Life

Arm Expected to function for up to three (3) years with an 18 month

service interval

Internal and External Batteries Expected to provide at least 80% of new capacity for up to a year of

typical use

IMU Battery Expected runtime is at least 18 hours for up to a year of use

AC Adapter and Charging Pad Expected to function for up to three (3) years

External Battery Holster and

Expected to function for up to three (3) years

External Battery Charging Dock

ACI and Cables Expected to function for up to three (3) years

108 Use or Disclosure of Data Contained on this Page is Subject to the Restrictions on the Inside Title Page of this Document -- Rev 1.8

Page 49

:

Table 26. Mass of Arm Configurations

Arm Configuration Mass

Arm Specifications

Shoulder Configuration (SC)

4.7 kg

Humeral Configuration (HC) 3.4 kg

Radial Configuration (RC) 1.4 kg

:

Table 27. Dimensions of Arm Configurations

Arm Configuration Dimensions

Shoulder Configuration (SC) See Figure 48

Humeral Configuration (HC) See Figure 49

Radial Configuration (RC) See Figure 50

Rev 1.8 -- Use or Disclosure of Data Contained on this Page is Subject to the Restrictions on the Inside Title Page of this Document 12/5/16109

Page 50

Appendix A: Technical Specifications

23.2323

23aa

23

4.3

26.4

23.4

26.4

9.8

38.6

14.5

19.5

See Note 1

See Note 2

Figure 48. Dimensions of Shoulder Configuration (In Centimeters)

• NOTE 1: Upper arm length configurations in 1 cm increments from 26.4 to

31.4 cm. See

Arm Types.

• NOTE 2: Forearm length configurations in 1 cm increments from 23.4 cm to

27.4 cm. See

Arm Types

110 Use or Disclosure of Data Contained on this Page is Subject to the Restrictions on the Inside Title Page of this Document -- Rev 1.8

Page 51

Arm Specifications

14.5

19.5

23.4

12.7

17.3

See Note 3

12.1

14.5

31.6

Figure 49. Dimensions of Humeral Configuration (In Centimeters)

• NOTE 3: Forearm length configurations in 1 cm increments from 23.4 cm to

27.4 cm. See

Arm Types.

Figure 50. Dimensions of Radial Configuration (In Centimeters)

Rev 1.8 -- Use or Disclosure of Data Contained on this Page is Subject to the Restrictions on the Inside Title Page of this Document 12/5/16111

Page 52

Appendix A: Technical Specifications

Battery Specifications

:

Table 28. Battery Charge and Operation Times

Arm System

Configuration

Battery Type One (1) Hour Charge

Operation Time

1

Full Charge2

Operation Time

1

SC/HC Internal Battery One (1) Hour Two (2) Hours

SC/HC External Battery Two (2) Hours

RC External Battery Four (4) Hours

IMU

Not Applicable Not Applicable

Five (5) Hours

Ten (10) Hours

One (1) Day

NOTES:

1. Actual use time may vary from stated figures based on use patterns, battery age, and arm configuration.

Contact Technical Support for additional information. See

2. See

Chapter 6, “Charging the Batteries” for charging time.

:

Contacting Technical Support.

Table 29. Power Specifications - Internal Battery

Parameter Range/Explanation

Battery Type Lithium-Ion

Capacity 30 Watt-Hours

Charging time (approximate) 80% capacity in less than 2.0 hours

Storage Life Three (3) months without recharging

Storage Temperature Short Term (24 Hours Maximum): -25°C to 70°C (-13°F to 158°F)

Long Term: -10°C to 50°C (14°F to 122°F)

:

Table 30. Power Specifications - External Battery

Parameter Range/Explanation

Battery Type Lithium-Ion

Capacity 74 Watt-Hours

Charging time (approximate) 80% capacity in less than 2.0 hours

Storage Life Three (3) months without recharging

112 Use or Disclosure of Data Contained on this Page is Subject to the Restrictions on the Inside Title Page of this Document -- Rev 1.8

Page 53

AC Adapter Specifications

Table 30. Power Specifications - External Battery (Continued)

Parameter Range/Explanation

Storage Temperature Short Term (24 Hours Maximum): -25 °C to 70 °C (-13 °F to

158 °F)

Long Term: -10 °C to 50 °C (14 °F to 122 °F)

:

Table 31. Power Specifications - IMU Battery

Parameter Range/Explanation

Battery Type Lithium-Polymer

Capacity 190 mAh

Charging time (approximation) 80% capacity in less than two (2.0) hours

Storage Life Three (3) months without recharging

Storage Temperature Short Term (24 Hours Maximum): -25 °C to 70 °C (-13 °F to

158 °F)

Long Term: -10 °C to 50 °C (14 °F to 122 °F)

AC Adapter Specifications

:

Table 32. AC Adapter Specifications

Parameter Range/Explanation

Input Voltage 100 VAC - 240 VAC

Input Frequency 50/60 Hz

Input Current 1.5 Amps

Operating Temperature 0 °C to +70 °C (32 °F to 158 °F)

Operating Humidity 10% to 95% RH, non-condensing

Storage Temperature -40 °C to +80 °C (-40 °F to 176 °F)

Rev 1.8 -- Use or Disclosure of Data Contained on this Page is Subject to the Restrictions on the Inside Title Page of this Document 12/5/16113

Page 54

Appendix A: Technical Specifications

Charging Pad Specifications

:

Table 33. Charging Pad Specifications

Parameter Range/Explanation

Input Voltage 100 VAC - 240 VAC

Input Frequency 50/60 Hz

Current Rating 1 Amp Maximum

Transmit Frequency Range 100 kHz - 205 kHz

Transm i t P ower <5 W

Protocol Qi version 1.1, Wireless Power Consortium

Effective Range 10 mm or less

Wireless Security Qi version 1.1

Quality of Service Provisions Any debris or clutter between the bottom of the IMU and the

Charging Pad may prevent IMU charging. Any increase in the

distance between the IMU and Charging Pad will increase

communication interference. This interference, however, will not

cause any incorrect data to be sent and will not cause any harm to

the LUKE arm system.

Loss or corruption of data between the IMU and Charging Pad for

more than 2 seconds can result in the interruption of charging.

In these cases, communication problems can usually be resolved by

ensuring the top of the Charging Pad is clean and clear of clutter,

the IMU is clean and its label is free of wrinkles, and that IMUs are

placed label side down and placed as close as possible to the center

of the charging pad targets.

114 Use or Disclosure of Data Contained on this Page is Subject to the Restrictions on the Inside Title Page of this Document -- Rev 1.8

Page 55

Arm Radio Specifications

:

Table 34. Arm Radio Specifications

Parameter Range/Explanation

Arm Radio Specifications

Transmit and Receive Frequency

Range

Effective Radiated Power <10 mW

Modulation Direct Sequence Spread Spectrum per IEEE 802.15.4-2006

Protocol Proprietary Frequency Hopping Communication Protocol

FCC Compliance This device complies with part 15 of the FCC Rules. Operation is

Effective Range (Arm/IMU) 3 m or less

Effective Range (Arm/Dongle) 1 m or less

Wireless Security Proprietary Frequency Hopping Communication Protocol

2.4 - 2.5 GHz

subject to the following two conditions: (1) This device may not

cause harmful interference, and (2) this device must accept any

interference received, including interference that may cause

undesired operation.

Pursuant to FCC 15.21 of the FCC rules, changes not expressly

approved by Mobius Bionics might cause harmful interference and

void the FCC authorization to operate this product.

This product complies with FCC OET Bulletin 65 radiation

exposure limits set forth for an uncontrolled environment.

Rev 1.8 -- Use or Disclosure of Data Contained on this Page is Subject to the Restrictions on the Inside Title Page of this Document 12/5/16115

Page 56

Appendix A: Technical Specifications

Table 34. Arm Radio Specifications (Continued)

Parameter Range/Explanation