Page 1

User Guide (en)

Date: 03/2021

Revision: v.1.4

Page 2

Copyright and disclaimer

All rights reserved. No parts of this document may be reproduced in any form without the

express written permission of Mobile Industrial Robots A/S (MiR). MiR makes no warranties,

expressed or implied, in respect of this document or its contents. In addition, the contents of

the document are subject to change without prior notice. Every precaution has been taken in

the preparation of this document. Nevertheless, MiR assumes no responsibility for errors or

omissions or any damages resulting from the use of the information contained.

Copyright © 2020-2021 by Mobile Industrial Robots A/S.

Contact the manufacturer:

Mobile Industrial Robots A/S

Emil Neckelmanns Vej 15F

DK-5220 Odense SØ

www.mobile-industrial-robots.com

Phone: +45 20 377 577

Email: support@mir-robots.com

CVR: 35251235

MiR250 Shelf Carrier User Guide (en) 03/2021 - v.1.4 ©Copyright 2021: Mobile IndustrialRobots A/S. 2

Page 3

Table of contents

1. About this document 8

1.1 Where to find more information 8

1.2 Version history 9

2. Product presentation 10

2.1 Main features of MiR250 Shelf Carrier 11

2.2 External parts 13

2.3 Internal parts 21

2.4 How MiR Shelf Carrier 250 works 30

3. Warranty 31

4. Safety 32

4.1 Safety message types 32

4.2 General safety precautions 33

4.3 Intended use 38

4.4 Users 39

4.5 Foreseeable misuse 40

4.6 Warning label 41

4.7 Residual risks 41

5. Accessing the internal parts 43

5.1 Front compartment 44

5.2 Rear compartment 45

5.3 Side compartments 46

5.4 MiR Shelf Carrier 250 47

6. Getting started 48

MiR250 Shelf Carrier User Guide (en) 03/2021 - v.1.4 ©Copyright 2021: Mobile IndustrialRobots A/S. 3

Page 4

6.1 In the box 48

6.2 Unpacking MiR250 Shelf Carrier 50

6.3 Connecting the battery 53

6.4 Powering up the robot 55

6.5 Connecting to the robot interface 58

6.6 Driving the robot in Manual mode 59

6.7 Moving the robot by hand 62

6.8 Checking the hardware status 64

6.9 Mounting the nameplate 65

6.10 Enable the MiR250 Shelf Carrier feature 67

6.11 Testing the top module 69

6.12 Shutting down the robot 71

7. Battery and charging 73

7.1 Charging the robot 73

7.2 Disconnecting the battery 74

7.3 Enabling fast swap 75

7.4 Swapping out the lithium-ion battery 77

7.5 Battery storage 79

7.6 Battery disposal 80

8. IT security 82

8.1 Managing users and passwords 82

8.2 Software security patches 82

9. Navigation and control system 84

9.1 System overview 84

MiR250 Shelf Carrier User Guide (en) 03/2021 - v.1.4 ©Copyright 2021: Mobile IndustrialRobots A/S. 4

Page 5

9.2 User input 86

9.3 Global planner 86

9.4 Local planner 88

9.5 Obstacle detection 89

9.6 Localization 94

9.7 Motor controller and motors 97

9.8 Brakes 97

10. Safety system 99

10.1 System overview 99

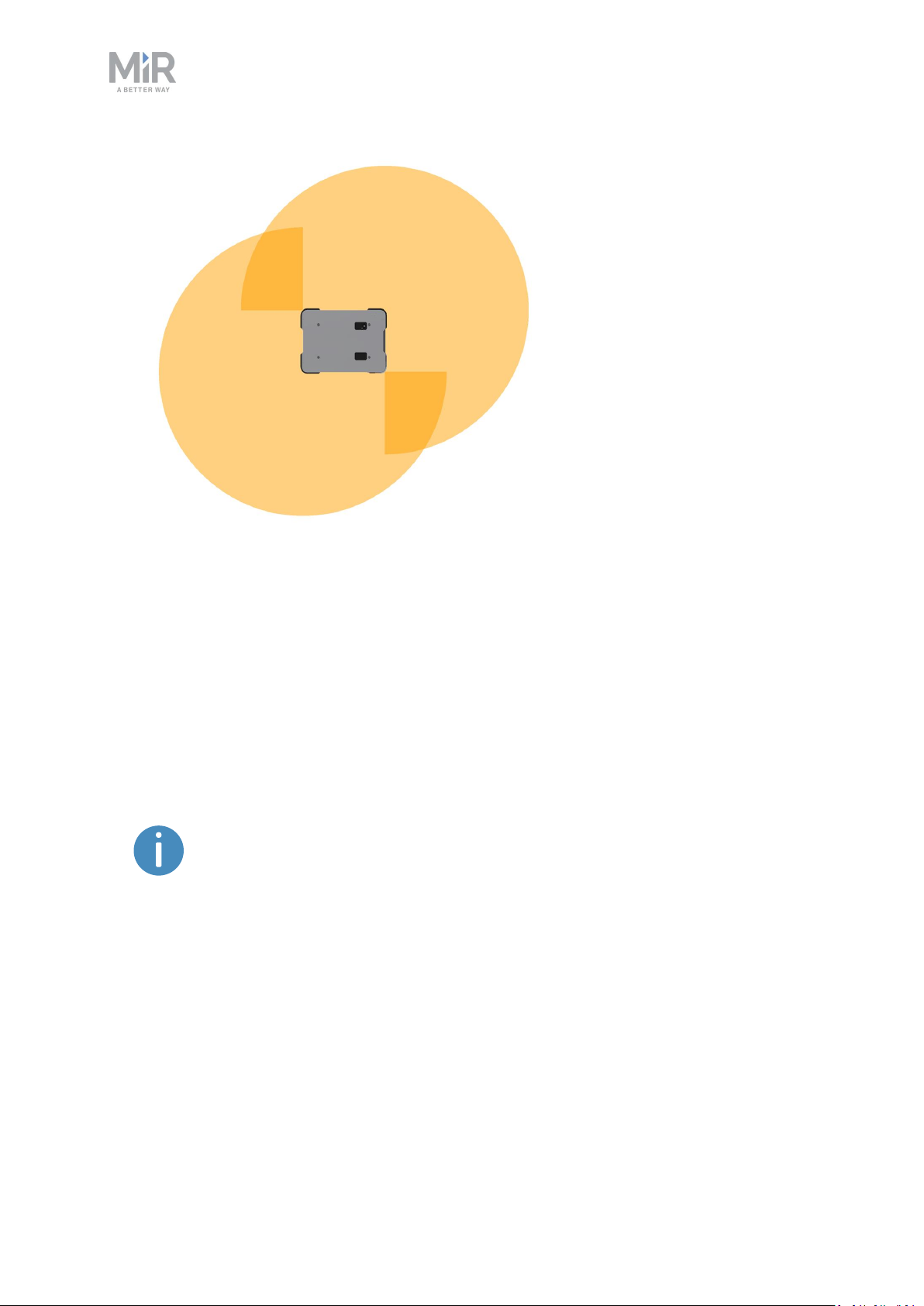

10.2 Personnel detection 104

10.3 Overspeed avoidance 108

10.4 Stability 109

10.5 Emergency stop buttons 109

10.6 MiR Shelf Carrier 250 safety functions 110

10.7 Safety stop 112

10.8 Light indicators and speakers 113

11. Commissioning 117

11.1 Analysis of the work environment 117

11.2 Risk assessment 119

11.3 Shelf specifications 120

11.4 Creating and configuring maps 124

11.5 Markers 135

11.6 Positions 138

11.7 Creating missions 139

MiR250 Shelf Carrier User Guide (en) 03/2021 - v.1.4 ©Copyright 2021: Mobile IndustrialRobots A/S. 5

Page 6

11.8 Creating a footprint 142

11.9 Using operating hazard zones 145

11.10 Making a brake test 150

11.11 Creating user groups and users 151

11.12 Creating dashboards 154

11.13 Updating MiR250 Shelf Carrier software 156

11.14 Creating backups 157

11.15 System settings 157

12. Usage 166

12.1 Creating markers 166

12.2 Creating positions 172

12.3 Creating a marker type 174

12.4 Creating the mission Prompt user 177

12.5 Creating the mission Try/Catch 182

12.6 Creating the mission Variable docking 188

12.7 Creating the mission 80 cm doorway 196

12.8 Creating the mission Pick up and place shelf 203

12.9 Creating the mission Place shelf at VL-marker 208

12.10 Testing a mission 213

13. Unmounting the top module 215

14. Maintenance 220

14.1 Regular weekly checks and maintenance tasks 220

14.2 Regular checks and replacements 222

14.3 Battery maintenance 224

MiR250 Shelf Carrier User Guide (en) 03/2021 - v.1.4 ©Copyright 2021: Mobile IndustrialRobots A/S. 6

Page 7

15. Packing for transportation 226

15.1 Original packaging 226

15.2 Packing the robot for transportation 227

15.3 Battery 227

16. Disposal of robot 228

17. Payload distribution 229

17.1 Side view 230

17.2 Front view 232

17.3 Top view 234

18. Interface specifications 236

18.1 Left side interfaces 236

18.2 Right side interfaces 238

19. Error handling 243

19.1 Software errors 243

19.2 Hardware errors 244

MiR250 Shelf Carrier User Guide (en) 03/2021 - v.1.4 ©Copyright 2021: Mobile IndustrialRobots A/S. 7

Page 8

1. About this document

1. About this document

This user guide explains how to set up and start operating your MiR250 Shelf Carrier robot

and provides examples of simple missions you can expand to your purposes. This guide also

contains information regarding the external and internal components of MiR250 Shelf

Carrier along with instructions for proper maintenance of the robot. You will also find

information regarding safety and specifications needed to commission a safe MiR250 Shelf

Carrier robot application.

NOTICE

Save this manual. It contains important safety and operating instructions.

1.1 Where to find more information

At the MiR website, you can find the following resources under the Manuals tab on each

product page:

• Quick starts describe how you start operating MiR robots quickly. It comes in print in the

box with the robots. Quick starts are available in multiple languages.

• User guides provide all the information you need to operate and maintain MiR robots and

how to set up and use top modules and accessories, such as charging stations, hooks, shelf

lifts, and pallet lifts. User guides are available in multiple languages.

• Commissioning guides describe how to commission your robot safely and prepare it to

operate in the workplace.

• Operating guides describe how to set up and use MiR accessories or supported functions

that are mainly hardware-based, such as charging stations and shelf functions.

• Getting started guides describe how to set up MiR accessories that are mainly software-

based, such as MiR Fleet.

• Reference guides contain descriptions of all the elements of the robot interface and MiR

Fleet interface. Reference guides are available in multiple languages.

• Best practice guides specify how much space MiR robots need to execute common

maneuvers.

• REST API references for MiR robots, MiR hooks, and MiR Fleet. HTTP requests can be

used to control robots, hooks, and MiR Fleet.

• MiR network and WiFi guide specifies the performance requirements of your network

and how you must configure it for MiR robots and MiR Fleet to operate successfully.

MiR250 Shelf Carrier User Guide (en) 03/2021 - v.1.4 ©Copyright 2021: Mobile IndustrialRobots A/S. 8

Page 9

1. About this document

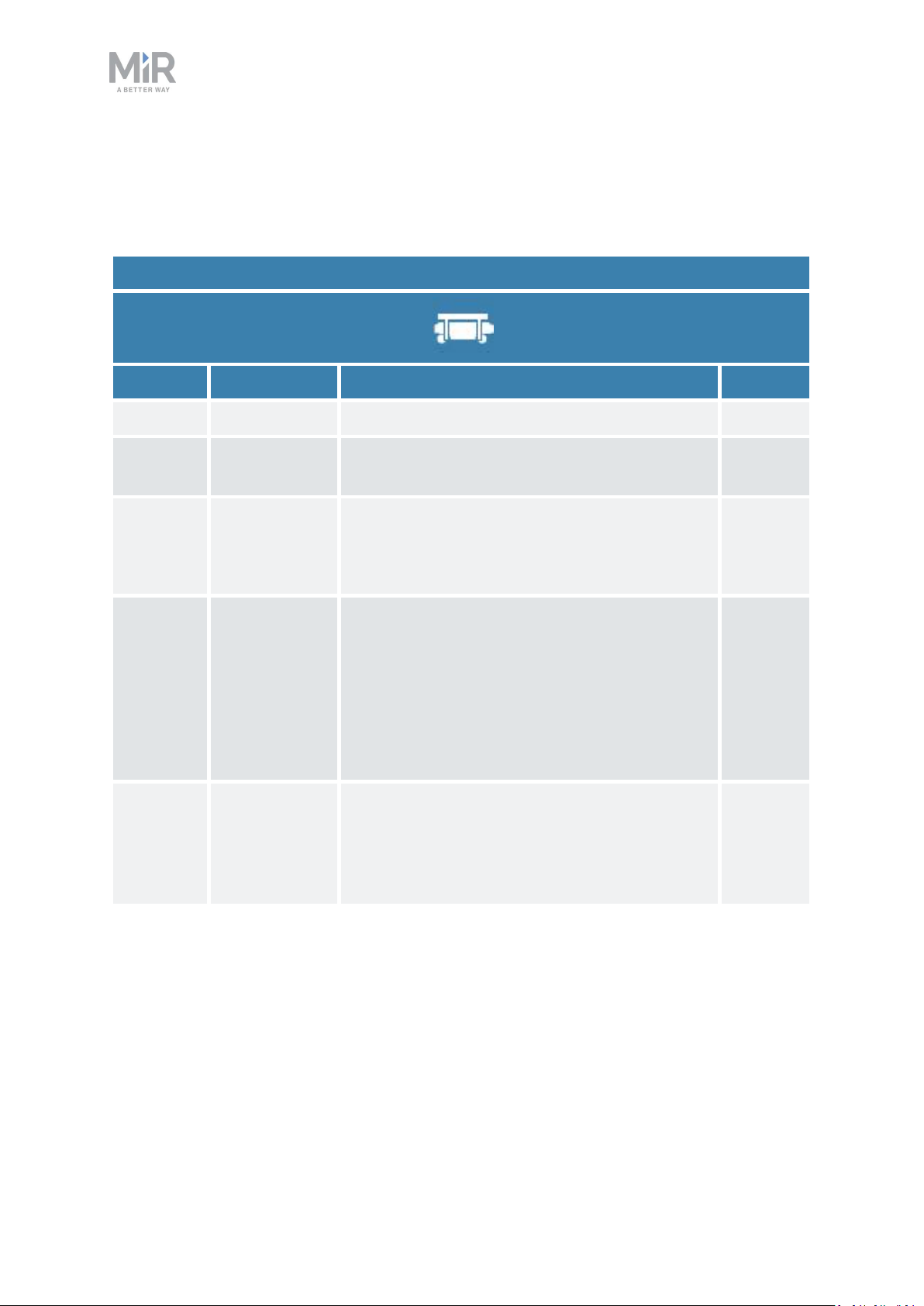

1.2 Version history

This table shows current and previous versions of this document.

MiR250 Shelf Carrier

Revision Release date Description HW

1.0 2020-06-26 First edition 1.0

1.1 2020-07-01 General improvements throughout the

document.

1.2 2020-07-08 Update section: Operating hazard zones

General improvements throughout the

document.

1.3 2020-11-30 Added sections: Warranty, Markers, and

Positions.

Updated section: Battery storage with Power

save mode and Deep sleep mode.

General improvements throughout the

document.

1.4 2021-03-31 Added sections: Enabling fast swap and

Swapping out the lithium-ion battery.

General improvements throughout the

document.

1.0

1.0

1.0

1.0

MiR250 Shelf Carrier User Guide (en) 03/2021 - v.1.4 ©Copyright 2021: Mobile IndustrialRobots A/S. 9

Page 10

2. Product presentation

2. Product presentation

MiR250 Shelf Carrier is an autonomous mobile robot with a top module mounted to it. It is

designed to transport wheeled shelves indoors within production facilities, warehouses, and

other industrial locations where access to the public is restricted.

Users operate MiR250 Shelf Carrier via a web-based user interface, which is accessed

through a browser on a PC, smartphone, or tablet. Each robot has its own network—see

Connecting to the robot interface on page58. The robot can be set up to run a fixed route,

be called on demand, or perform more complex missions.

The robot interface of MiR250 Shelf Carrier can be accessed via Google Chrome, Google

Chromium, Apple Safari, Mozilla Firefox, and Microsoft Edge browsers.

The robot uses a map of its work area to navigate and can move to any position on the

map—see Navigation and control system on page84. The map can be created or imported

the first time the robot is used. While operating, the robot avoids obstacles that are not

mapped, like people and furniture.

MiR250 Shelf Carrier is available both in an ESD approved version, which is black, and a nonESD approved version, which is gray.

MiR250 Shelf Carrier transports shelves that are designed according to the specifications in

Shelf specifications on page120. To ensure that the robot has enough traction to transport a

total payload of up to 300 kg, a traction kit is installed within the robot.

MiR250 Shelf Carrier User Guide (en) 03/2021 - v.1.4 ©Copyright 2021: Mobile IndustrialRobots A/S. 10

Page 11

2. Product presentation

The total payload includes both the weight of the shelf and the load on the

shelf.

Specifications for MiR250 Shelf Carrier are available on the MiR website.

2.1 Main features of MiR250 Shelf Carrier

The main features of MiR250 Shelf Carrier are:

• Driving in a populated workspace

The robot is designed to operate among people and maneuvers safely and efficiently in

highly dynamic environments.

• Overall route planning and local adjustments

The robot navigates autonomously to find the most efficient paths to its destinations. The

robot adjusts the path when it encounters obstacles that are not on the map, like

personnel and vehicles.

• Efficient transportation of shelves

The robot is designed to automate transportation of loaded shelves with a weight of up to

300 kg.

• Sound and light signals

The robot continuously signals with light and sounds, indicating where it will drive and its

current status, for example, waiting for a mission, driving to a destination, or destination

reached.

• User-friendly and flexible

The web-based user interface, accessed from a PC, tablet, or smartphone, gives easy

access to operation and monitoring of the robot and can be programmed without any

prior experience. Different user group levels and tailored dashboards can be set up to suit

different users.

• Alert for 'lost'

If the robot enters a situation where it is unable to find a path to its destination, it stops,

turns on the yellow-purple running error light, and a custom defined Try/Catch action

may be used to alert personnel or take other actions—see Creating the mission Try/Catch

on page182.

MiR250 Shelf Carrier User Guide (en) 03/2021 - v.1.4 ©Copyright 2021: Mobile IndustrialRobots A/S. 11

Page 12

2. Product presentation

• Automatic deceleration for objects

The built-in sensors ensure that the robot is slowed down when obstacles are detected in

front of it.

• Internal map

The robot can either use a floor plan from a CAD drawing, or a map can be created by

manually driving the robot around the entire site in which the robot is going to operate.

When the robot is mapping, the robot’s sensors detect walls, doors, furniture, and other

obstacles, and the robot then creates a map based on these input. After you've finished

mapping, you can add positions and other features in the map editor—see Creating and

configuring maps on page124.

MiR250 Shelf Carrier User Guide (en) 03/2021 - v.1.4 ©Copyright 2021: Mobile IndustrialRobots A/S. 12

Page 13

2. Product presentation

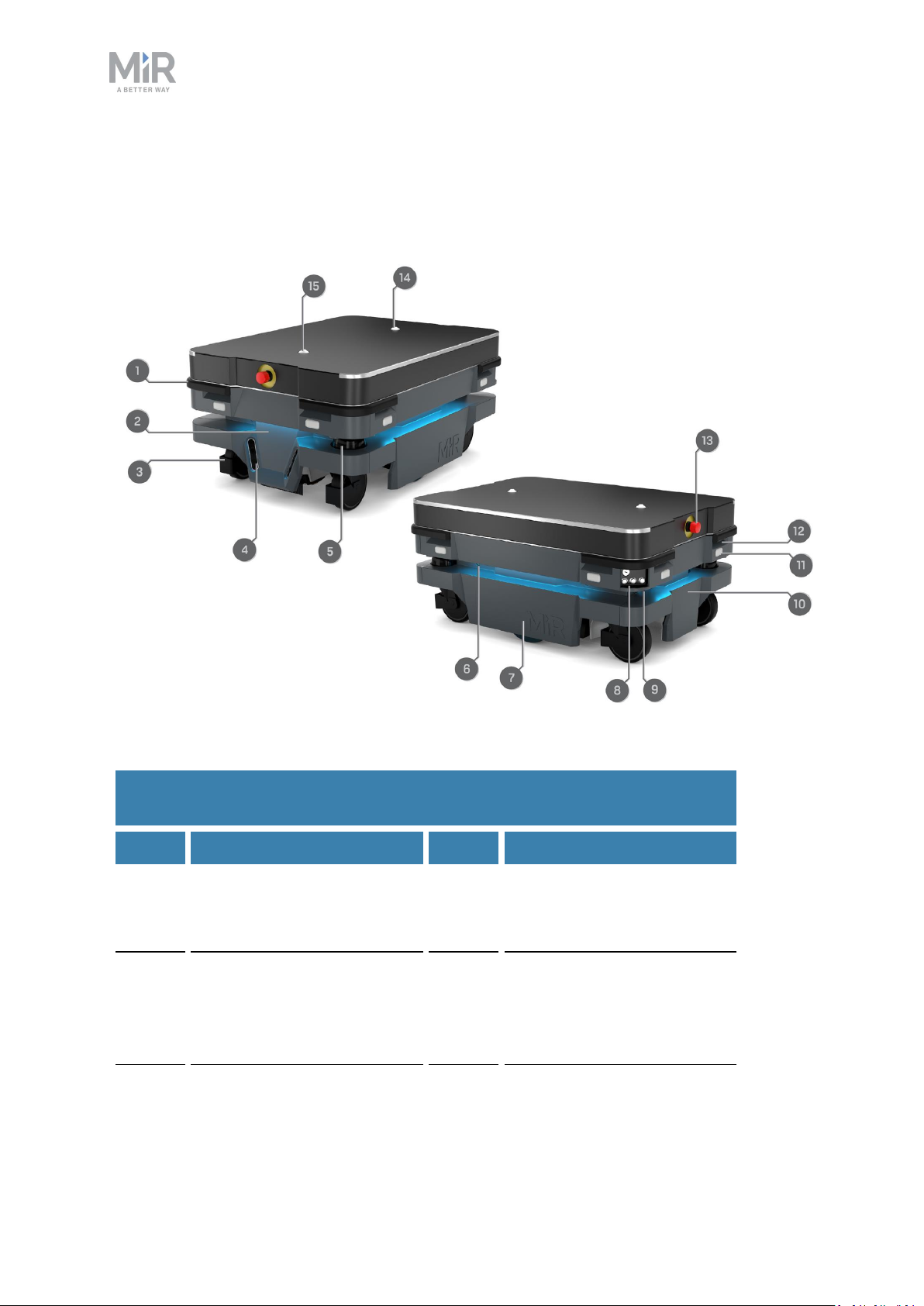

2.2 External parts

This section presents the parts of MiR250 Shelf Carrier that are visible on the outside.

Figure 2.1. MiR250 Shelf Carrier external parts.

Table 2.1.

Identification of the external parts in Figure 2.1

Pos. Description Pos. Description

1 Corner bumper: four pcs,

one on each corner

3 Swivel wheel with foot

guard: four pcs, one in each

corner

2 Front cover: opens to front

compartment—see Internal

parts on page21

4 3D depth camera: two pcs,

both in the front—see

Obstacle detection on

page89

MiR250 Shelf Carrier User Guide (en) 03/2021 - v.1.4 ©Copyright 2021: Mobile IndustrialRobots A/S. 13

Page 14

Pos. Description Pos. Description

2. Product presentation

5 Nanoscan3 safety laser

scanner: two pcs, in

opposite corners—see

Obstacle detection on

page89

7 Side cover: opens to side

compartment—see Internal

parts on page21

9 Manual brake release

switch—see Control panel

on page16

11 Signal light: eight pcs, two

on each corner—see Light

indicators and speakers on

page113

6 Status light: on all four sides

of the robot—see Light

indicators and speakers on

page113

8 Control panel—see Control

panel on page16

10 Rear cover: opens to rear

compartment—see Internal

parts on page21

12 Proximity sensor: eight pcs,

two in each corner behind

corner covers—see

Obstacle detection on

page89

13 Emergency stop button 14 Rear carrier pin

15 Front carrier pin

Identification label

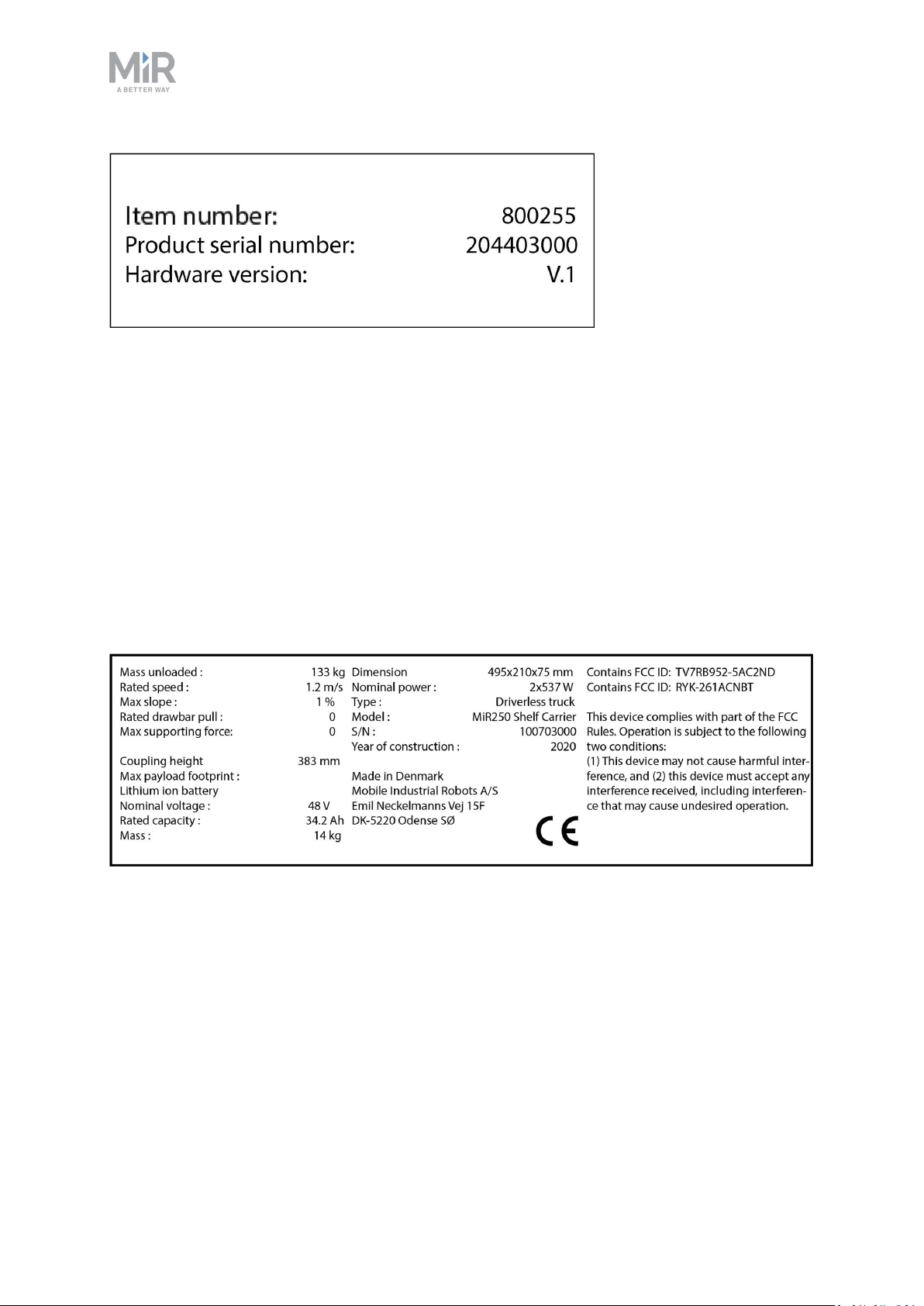

MiR250 Shelf Carrier is delivered with identification labels mounted to each product. The

identification labels identify the product, the product serial number, and the hardware

version of the product.

MiR250 Shelf Carrier User Guide (en) 03/2021 - v.1.4 ©Copyright 2021: Mobile IndustrialRobots A/S. 14

Page 15

2. Product presentation

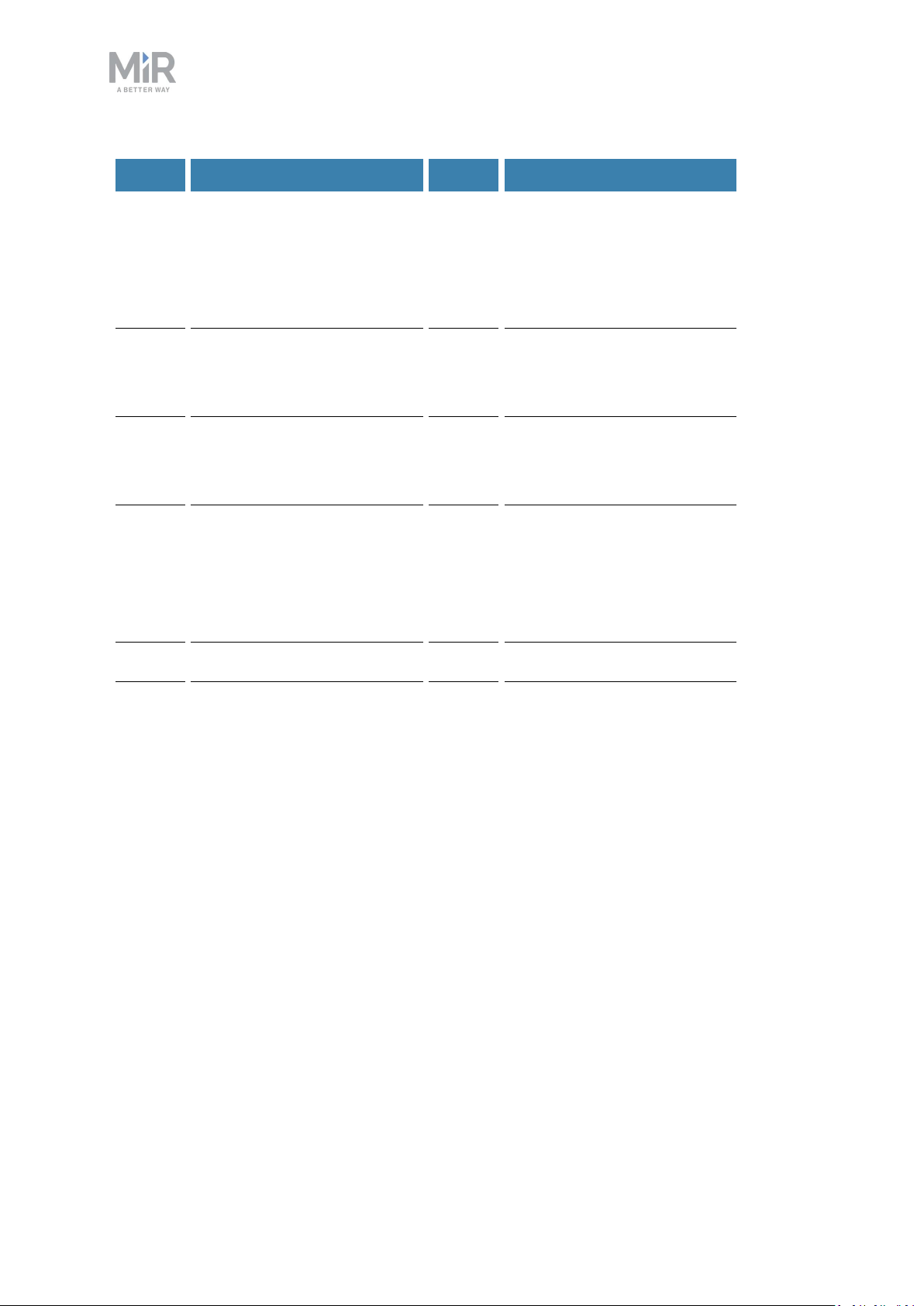

The identification label of MiR250 is located on the rear cover next to the battery.

Figure 2.2. Placement of the MiR250 identification label.

The identification label of MiR Shelf Carrier 250 is located on the left side of the shelf

carrier beneath its cover.

Figure 2.3. Placement of the MiR Shelf Carrier 250 identification label.

MiR250 Shelf Carrier User Guide (en) 03/2021 - v.1.4 ©Copyright 2021: Mobile IndustrialRobots A/S. 15

Page 16

2. Product presentation

Figure 2.4. Example of a MiR Shelf Carrier 250 identification label.

Nameplate

Every MiR application is delivered with a nameplate that must be mounted to the robot. The

nameplate of MiR250 Shelf Carrier identifies the application model and serial number and

includes the CE mark, the technical specifications, and the address of Mobile Industrial

Robots. The nameplate identifies the complete MiR application, for example, a robot with a

top module.

It is the responsibility of the commissioner to mount the nameplate on the application—see

Mounting the nameplate on page65.

Figure 2.5. Example of a MiR250 Shelf Carrier nameplate.

Control panel

MiR250 Shelf Carrier has a control panel in the rear-left corner of the robot.

MiR250 Shelf Carrier User Guide (en) 03/2021 - v.1.4 ©Copyright 2021: Mobile IndustrialRobots A/S. 16

Page 17

The control panel buttons

2. Product presentation

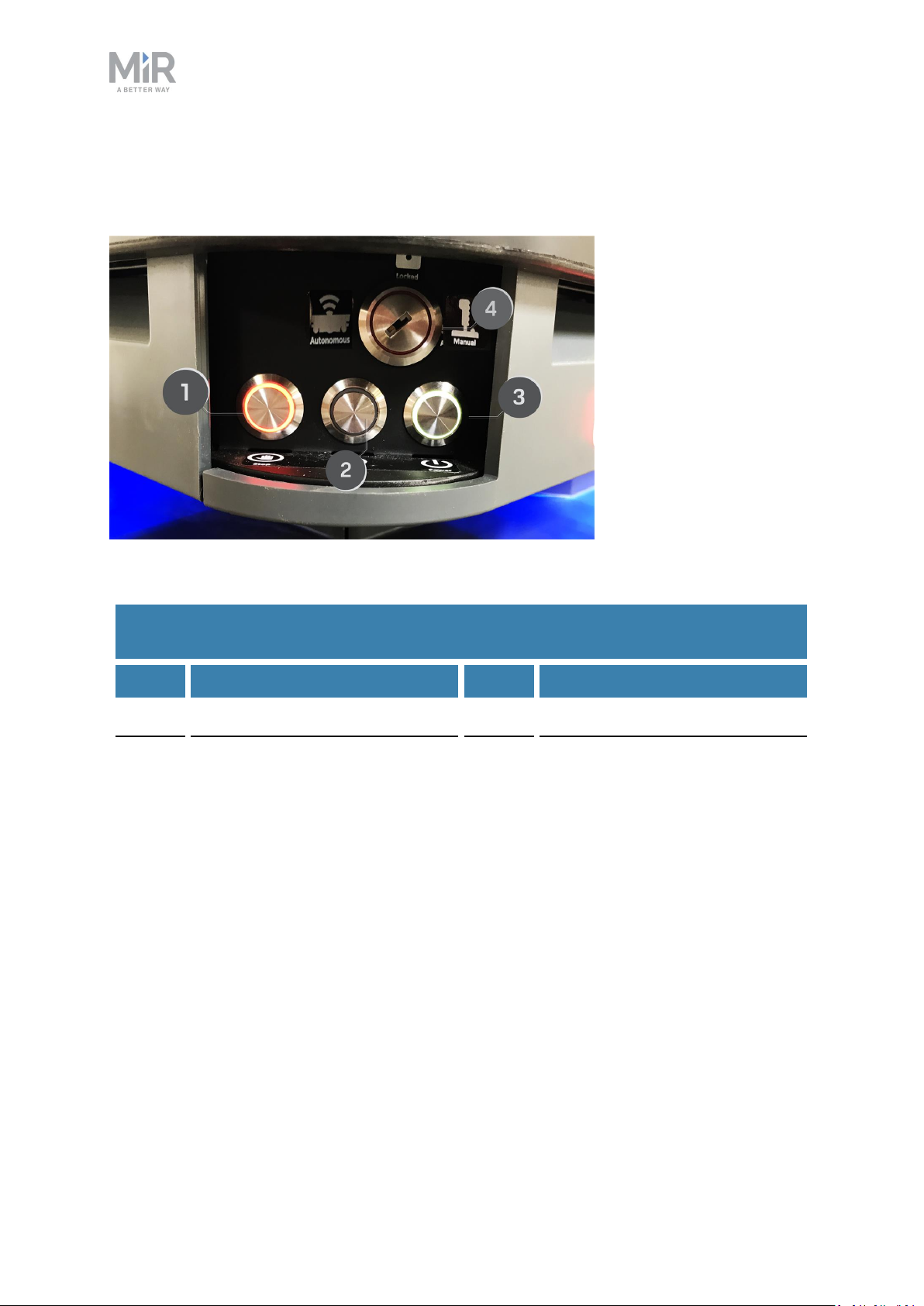

Figure 2.6. The MiR250 Shelf Carrier control panel.

Table 2.2.

Identification of items on the control panel in Figure 2.6

Pos. Description Pos. Description

1 Manual stop button 2 Resume button

3 Power button 4 Operating mode key

Manual stop

Pressing this button stops the robot. After pressing this button, you must press the Resume

button to let the robot continue operating.

Color indication:

• Red: It is possible to engage the Manual stop.

MiR250 Shelf Carrier User Guide (en) 03/2021 - v.1.4 ©Copyright 2021: Mobile IndustrialRobots A/S. 17

Page 18

2. Product presentation

Resume

Pressing this button:

• Clears the Emergency stop state.

• Lets the robot continue operating after the Manual stop button was pressed or after the

operating mode changes.

• Lets the robot start operating after powering up.

Color indication:

• Blinking blue: The robot is waiting for a user action (clear the Emergency stop state,

acknowledge the change of operating mode).

Power

Pressing this button for three seconds turns the robot on or shuts it off.

Color indication:

• Blue: The robot is off.

• Blinking green: The robot is starting up.

• Green: Normal operation.

• Blinking red: The battery level is too low to start without additional charging, or the robot

is shutting down.

The Operating mode key

The Operating mode key lets you switch between operating modes.

• Left position: Autonomous mode

Puts the robot in Autonomous mode.

MiR250 Shelf Carrier User Guide (en) 03/2021 - v.1.4 ©Copyright 2021: Mobile IndustrialRobots A/S. 18

Page 19

2. Product presentation

• Middle position: Locked

Locks the robot. The robot blocks the wheels; you cannot start a mission or drive the robot

manually.

• Right position: Manual mode

Puts the robot in Manual mode.

For more information on operating modes, see Operating modes on the next page.

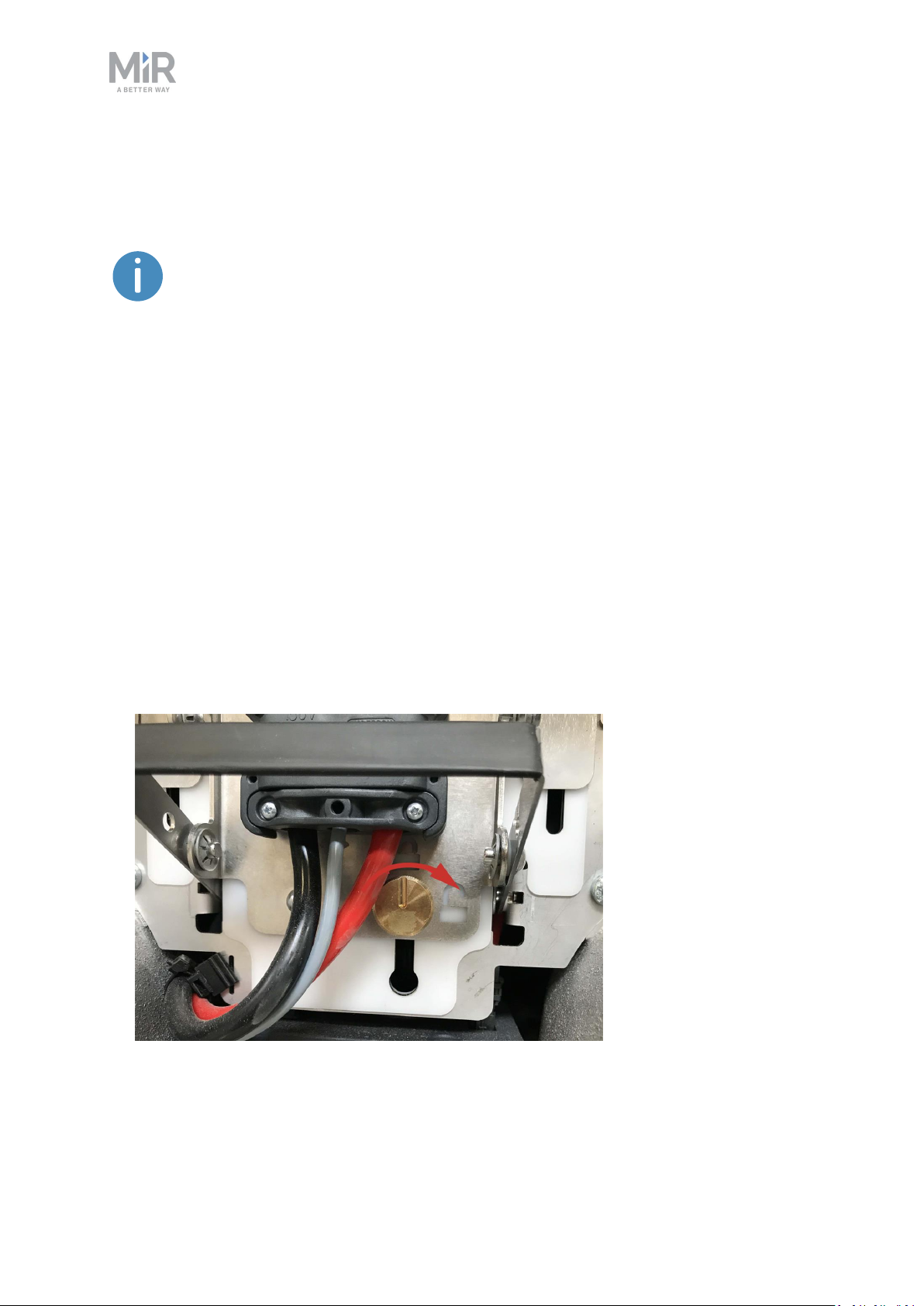

Manual brake release switch

The Manual brake release switch is located below the control panel and releases the

mechanical brakes on MiR250 Shelf Carrier. You release the robot's mechanical brakes by

turning the Manual brake release switch clockwise.

MiR250 Shelf Carrier User Guide (en) 03/2021 - v.1.4 ©Copyright 2021: Mobile IndustrialRobots A/S. 19

Page 20

Figure 2.7. The manual brake release switch is located below the control panel.

2. Product presentation

The mechanical brakes require electrical power to be released, so if the robot is without

power, the mechanical brakes cannot be released. You can see if the robot is powered, by

checking if the Power button on the control panel lights up.

If MiR250 Shelf Carrier shuts down due to low battery percentage, there is still

enough power to release the brakes for approximately a week after.

When driving in Autonomous mode, the robot engages and releases the mechanical brakes

automatically.

The robot cannot operate while the mechanical brakes are released manually.

Operating modes

MiR250 Shelf Carrier has two operating modes: Manual mode and Autonomous mode.

Manual mode

In this mode, you can drive the robot manually using the joystick in the robot interface. Only

one person can control the robot manually at a time. To ensure that nobody else takes

control of the robot, the robot issues a token to the device on which you activate the Manual

MiR250 Shelf Carrier User Guide (en) 03/2021 - v.1.4 ©Copyright 2021: Mobile IndustrialRobots A/S. 20

Page 21

2. Product presentation

mode.

For information about activating this mode, see Driving the robot in Manual mode on

page59.

Autonomous mode

In this mode, the robot executes the programmed missions. After switching the key to this

mode, you can remove the key, and the robot will continue driving autonomously. In

Autonomous mode, the joystick is disabled in the robot interface.

2.3 Internal parts

Most internal parts of MiR250 Shelf Carrier are accessed through covers that open to

different compartments:

• Front compartment

• Rear compartment

• Side compartments

• Top compartments

To access the compartments correctly, see Accessing the internal parts on page43.

WARNING

Removing covers from the robot exposes parts connected to the power supply,

risking damage to the robot from a short circuit and electrical shock to

personnel.

• Before removing any covers, turn off the robot, and disconnect the

battery—see Disconnecting the battery on page74.

Front compartment

The front compartment holds several electronic components, such as the robot computer

and the motor controller carrier board.

MiR250 Shelf Carrier User Guide (en) 03/2021 - v.1.4 ©Copyright 2021: Mobile IndustrialRobots A/S. 21

Page 22

2. Product presentation

To open the front compartment, see Accessing the internal parts on page43.

Front compartment components

The front compartment components are listed in Table 2.3.

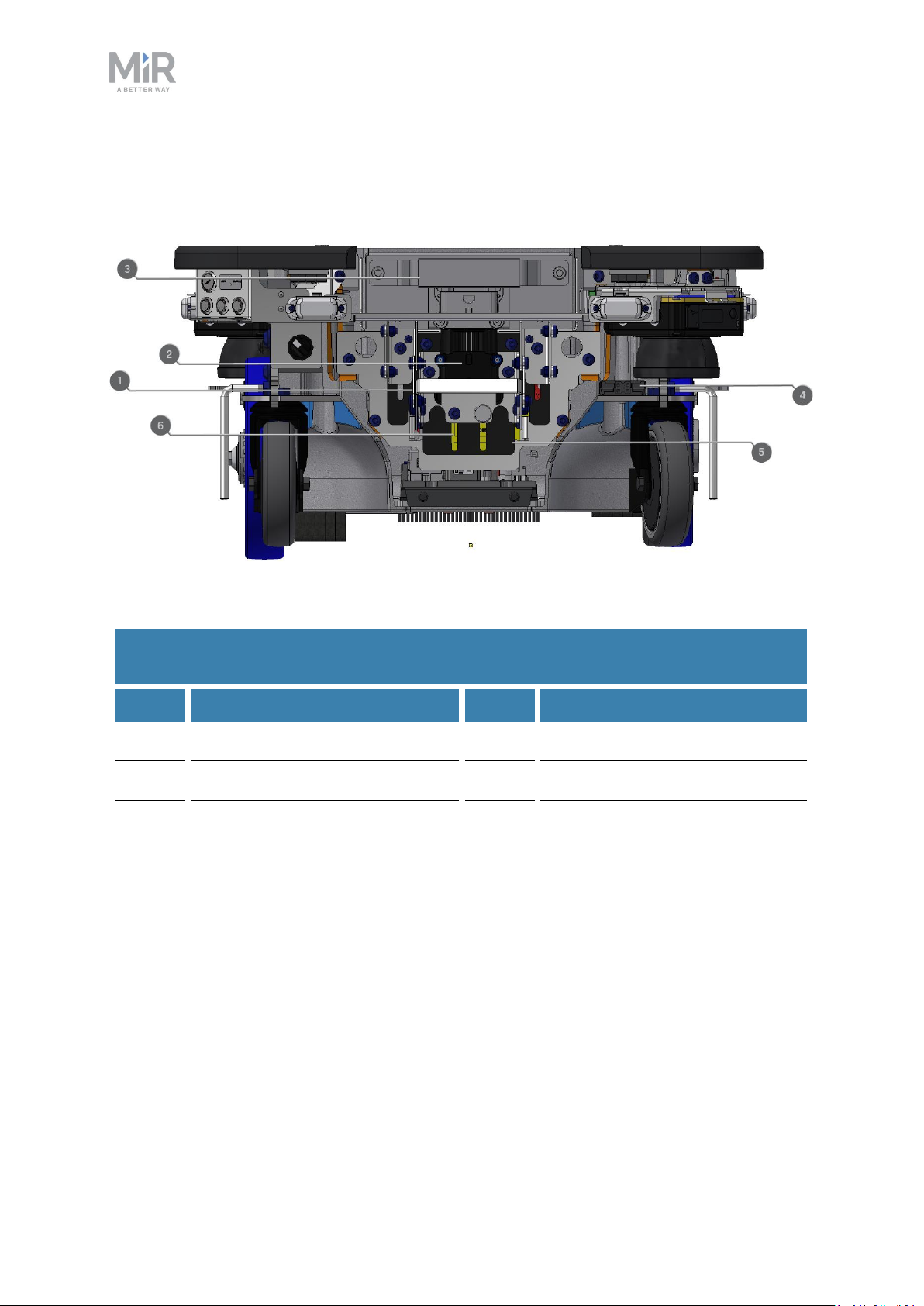

Figure 2.8. Internal parts of the front compartment.

Table 2.3.

Identification of internal parts in Figure 2.8

Pos. Description Pos. Description

1 Loudspeaker 2 Carrier board with motor

controller controlling the leftside drivetrain

3 Carrier board with motor

4 Robot computer

controller controlling the rightside drivetrain

5 Charging pads under robot and

broom for keeping dirt away

from the charging pads

MiR250 Shelf Carrier User Guide (en) 03/2021 - v.1.4 ©Copyright 2021: Mobile IndustrialRobots A/S. 22

Page 23

2. Product presentation

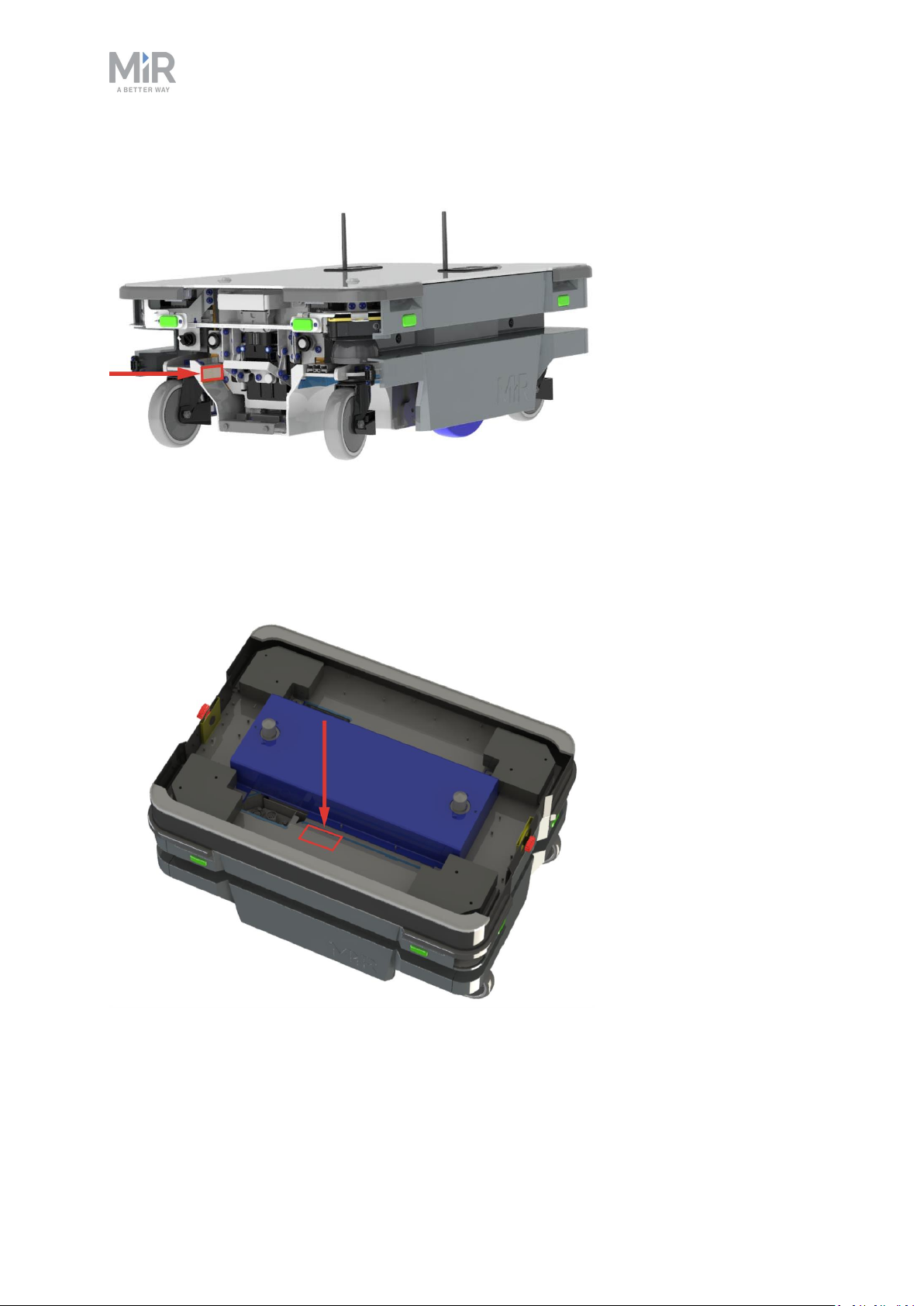

Rear compartment

The rear compartment holds the robot’s battery, Battery disconnect lever, power board, and

safety PLC. The battery and Battery disconnect lever can be accessed without the use of

tools. The other components in the rear compartment are only accessible via use of tools.

To open the rear compartment, see Accessing the internal parts on page43.

NOTICE

The unique nameplate of your robot is to be mounted on the rear

compartment cover—see Mounting the nameplate on page65. Make sure you

do not swap the cover with covers from other robots.

MiR250 Shelf Carrier User Guide (en) 03/2021 - v.1.4 ©Copyright 2021: Mobile IndustrialRobots A/S. 23

Page 24

Rear compartment components

The rear compartment components are listed in Table 2.4.

2. Product presentation

Figure 2.9. Internal parts of the rear compartment.

Table 2.4.

Identification of internal parts in Figure 2.9

Pos. Description Pos. Description

1 Battery disconnect lever 2 Battery connector

3 Battery 4 Cable charging interface

5 Power board for motor

controller, robot computer, and

safety PLC

6 Safety PLC

Side compartments

The side compartments contain the bogies and drive wheels.

To access a side compartment, see Accessing the internal parts on page43.

Side compartment components

The left side compartment components are listed in Table 2.5

MiR250 Shelf Carrier User Guide (en) 03/2021 - v.1.4 ©Copyright 2021: Mobile IndustrialRobots A/S. 24

Page 25

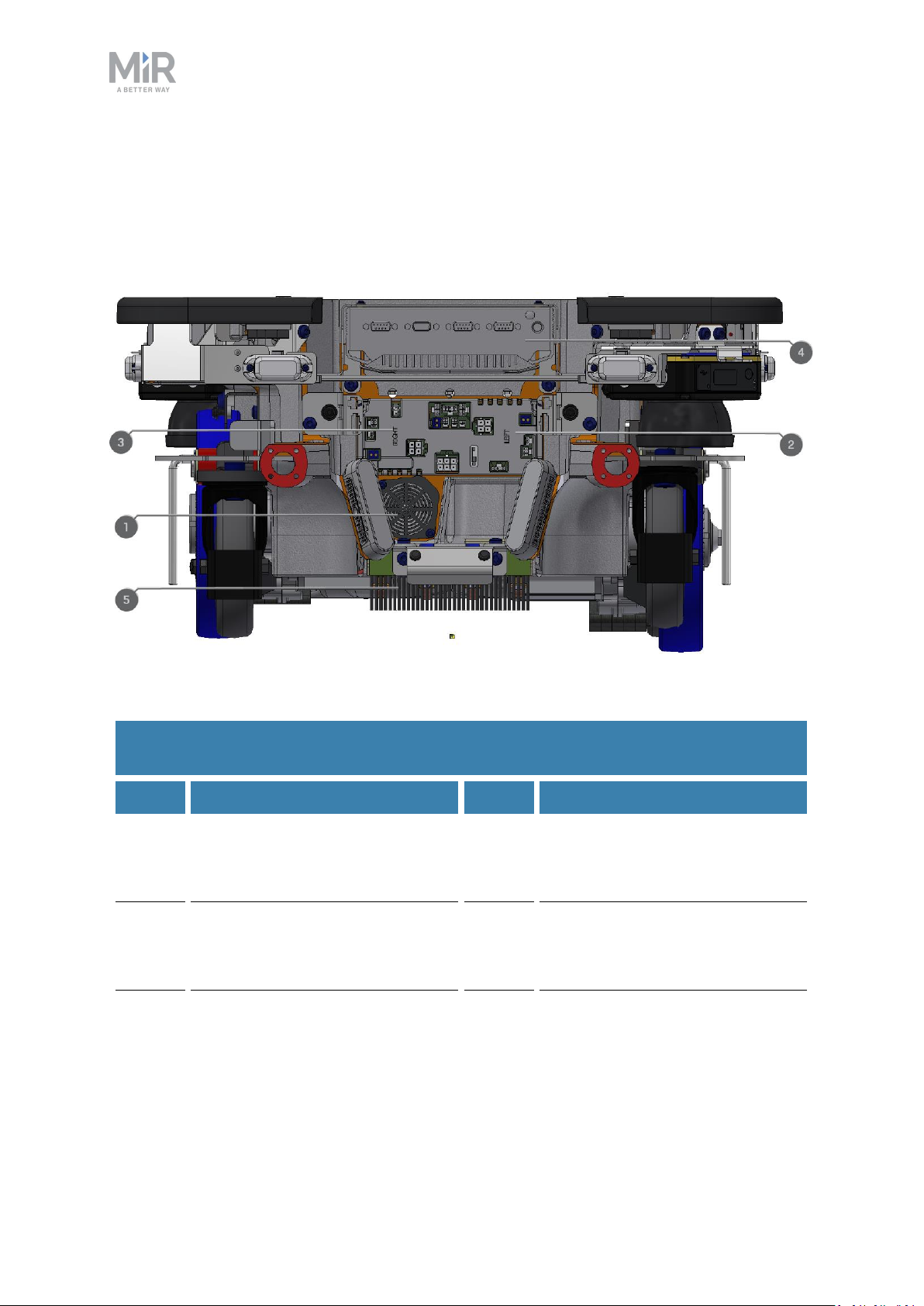

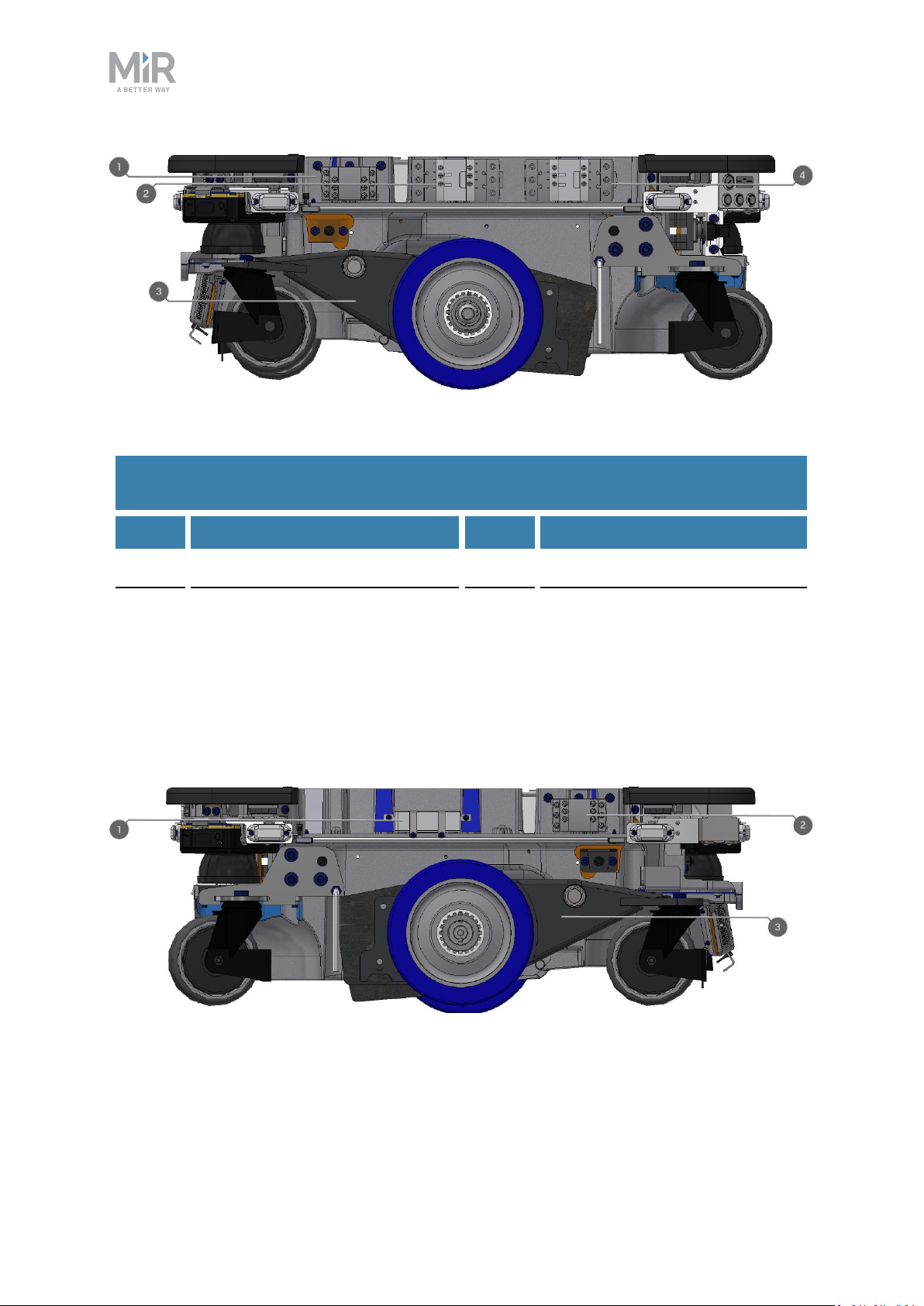

Figure 2.10. Internal parts of the left side compartment.

Table 2.5.

Identification of internal parts in Figure 2.10

2. Product presentation

Pos. Description Pos. Description

1 Safe Stop 1 (SS1) contactor 2 Safe Torque Off (STO) contactor

3 Bogie and drivetrain consisting

4 Safe Torque Off (STO) contactor

of motor, gearbox, encoder,

brake, drive wheel, and

assembly parts

The right side compartment components are listed in Table 2.6

Figure 2.11. Internal parts of the right side compartment.

MiR250 Shelf Carrier User Guide (en) 03/2021 - v.1.4 ©Copyright 2021: Mobile IndustrialRobots A/S. 25

Page 26

2. Product presentation

Table 2.6.

Identification of internal parts in Figure 2.11

Pos. Description Pos. Description

1 Router 2 Safe Stop 1 (SS1) contactor

3 Bogie and drivetrain consisting

of motor, gearbox, encoder,

brake, drive wheel, and

assembly parts

Top compartments

The two top compartments contain electrical interfaces that can be connected to top

modules.

The top compartments are only accessible after the top module has been

removed—see Unmounting the top module on page215.

MiR250 Shelf Carrier User Guide (en) 03/2021 - v.1.4 ©Copyright 2021: Mobile IndustrialRobots A/S. 26

Page 27

2. Product presentation

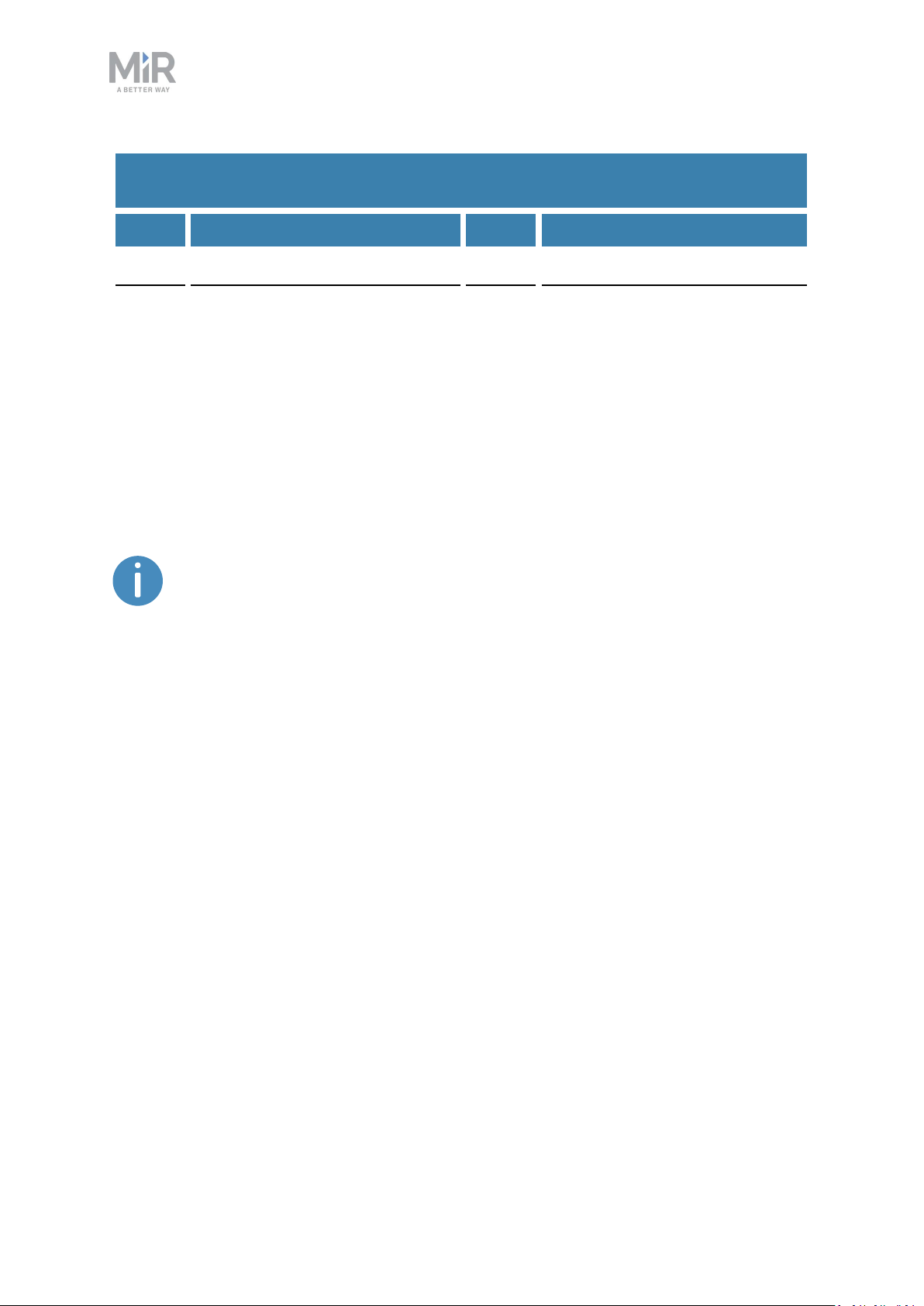

Figure 2.12. The top compartments on the robot.

Top compartment components

The top compartments interfaces are listed in Table 2.7. For detailed information on

electrical interfaces, see Interface specifications on page236.

Figure 2.13. Interfaces in the top compartments.

MiR250 Shelf Carrier User Guide (en) 03/2021 - v.1.4 ©Copyright 2021: Mobile IndustrialRobots A/S. 27

Page 28

2. Product presentation

Table 2.7.

Identification of interfaces in Figure 2.13

Pos. Description Pos. Description

1 Emergency stop 2 Auxiliary power connector

3 Ethernet 4 General purpose I/Os

5 Auxiliary safety functions I/Os

MiR Shelf Carrier 250

Within the shelf carrier top module there is an actuator and a lifting device to raise and

lower the pins, sensor switches, and safety contactors.

To access the internal parts of MiR Shelf Carrier 250, see Accessing the internal parts on

page43.

MiR Shelf Carrier 250 components

The components of MiR Shelf Carrier 250 are listed in Table 2.8.

MiR250 Shelf Carrier User Guide (en) 03/2021 - v.1.4 ©Copyright 2021: Mobile IndustrialRobots A/S. 28

Page 29

2. Product presentation

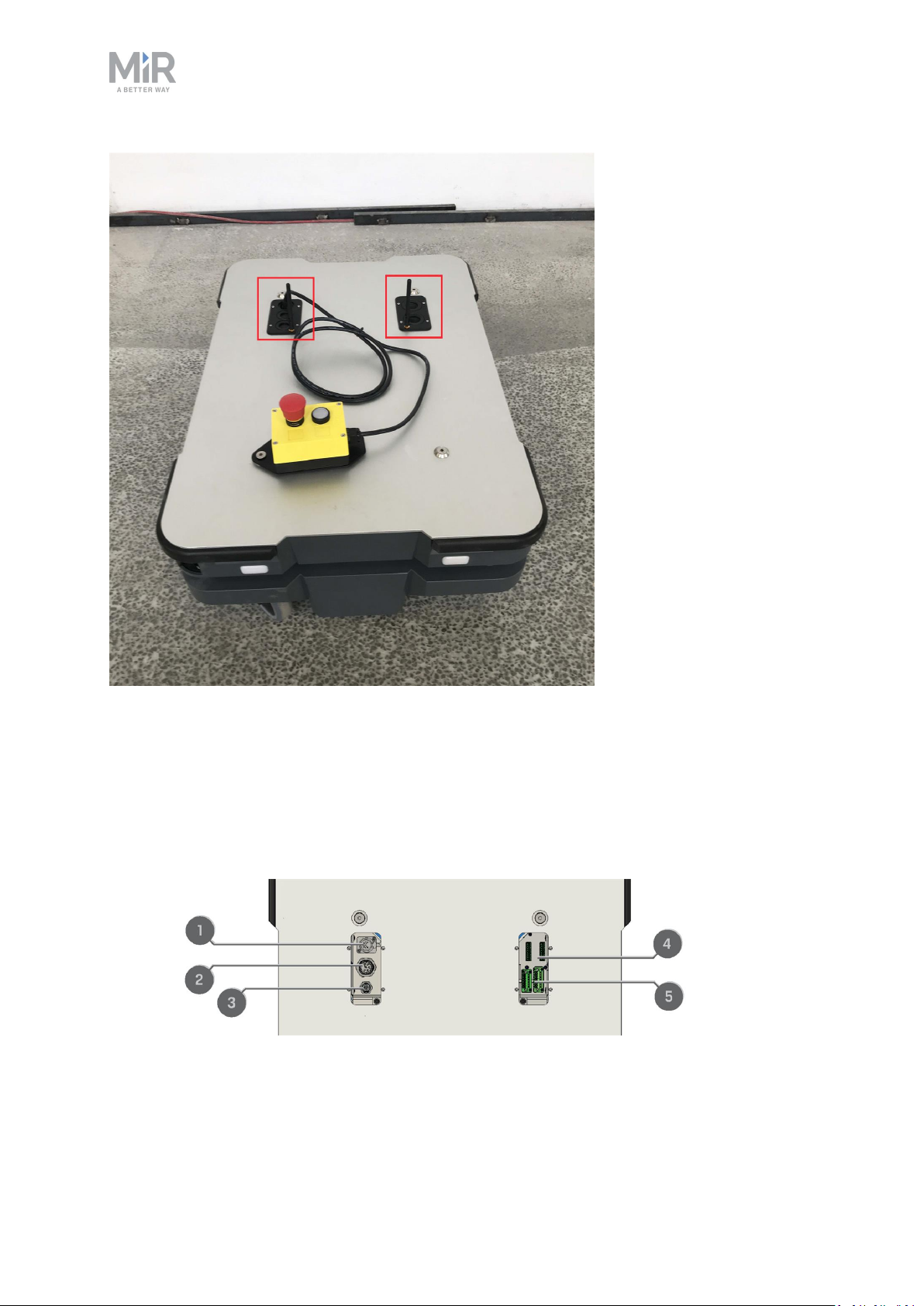

Figure 2.14. Internal parts in MiR Shelf Carrier 250.

Table 2.8.

Identification of internal parts in Figure 2.14

Pos. Description Pos. Description

1 Front Emergency stop button 2 Carrier pins

3 Position switches 4 GPIOconnectors

5 Auxiliary safety IO connectors 6 Safety contactors K1 and K2

7 Rear Emergency stop button 8 Lifting mechanism and actuator

9 Emergency stop connector

MiR250 Shelf Carrier User Guide (en) 03/2021 - v.1.4 ©Copyright 2021: Mobile IndustrialRobots A/S. 29

Page 30

2. Product presentation

2.4 How MiR Shelf Carrier 250 works

When MiR250 Shelf Carrier docks to a shelf, the carrier pins can be raised to pick up a shelf

and lowered to place a shelf at a shelf position.

MiR250 Shelf Carrier uses I/O modules in the safety PLC to control the carrier pins.The

robot uses two inputs and two outputs to communicate with MiR Shelf Carrier 250.

The outputs are used to control the position of MiR Shelf Carrier 250, and the inputs are

used to signal the current position of the MiR Shelf Carrier 250—see Testing the top module

on page69.

To see the menu options for the I/O modules under Setup >IO modules, you must enable

them first—see Enable the MiR250 Shelf Carrier feature on page67.

Table 2.9.

Descriptions of how the robot's internal outputs control the shelf carrier

Output Function

2 Lowers the carrier pins when active.

3 Raises the carrier pins when active.

Table 2.10.

Descriptions of what the robot's internal inputs signal regarding the status of the shelf

carrier

Input Function

2 Is active when the carrier pins are down.

3 Is active when the carrier pins are up.

MiR250 Shelf Carrier User Guide (en) 03/2021 - v.1.4 ©Copyright 2021: Mobile IndustrialRobots A/S. 30

Page 31

3. Warranty

Mobile Industrial Robots offers a standard warranty on all products.

Contact your distributor to see the terms and extend of product coverage.

NOTICE

Mobile Industrial Robots disclaims any and all liability if MiR250 Shelf Carrier

or its accessories are damaged, changed, or modified in any way. Mobile

Industrial Robots cannot be held responsible for any damages caused to

MiR250 Shelf Carrier, accessories, or any other equipment due to

programming errors or malfunctioning of MiR250 Shelf Carrier.

3. Warranty

MiR250 Shelf Carrier User Guide (en) 03/2021 - v.1.4 ©Copyright 2021: Mobile IndustrialRobots A/S. 31

Page 32

4. Safety

4. Safety

Read the information in this section before powering up and operating MiR250 Shelf Carrier.

Pay particular attention to the safety instructions and warnings.

NOTICE

Mobile Industrial Robots disclaims any and all liability if MiR250 Shelf Carrier

or its accessories are damaged, changed, or modified in any way. Mobile

Industrial Robots cannot be held responsible for any damages caused to

MiR250 Shelf Carrier, accessories, or any other equipment due to

programming errors or malfunctioning of MiR250 Shelf Carrier.

4.1 Safety message types

This document uses the following safety message types.

WARNING

Indicates a potentially hazardous situation that could result in death or serious

injury. Carefully read the message that follows to prevent death or serious

injury.

CAUTION

Indicates a potentially hazardous situation that could result in minor or

moderate injury. Alerts against unsafe practices. Carefully read the message

that follows to prevent minor or moderate injury.

NOTICE

Indicates important information, including situations that can result in damage

to equipment or property.

MiR250 Shelf Carrier User Guide (en) 03/2021 - v.1.4 ©Copyright 2021: Mobile IndustrialRobots A/S. 32

Page 33

4.2 General safety precautions

This section contains general safety precautions.

WARNING

If the robot is not running the correct software and is therefore not functioning

properly, the robot may collide with personnel or equipment causing injury or

damage.

• Ensure that the robot is always running the correct software.

WARNING

4. Safety

When the robot is in an operating hazard zone, there is a risk of injury to any

personnel within the zone.

• Ensure that all personnel are instructed to stay clear of operating hazard

zones when the robot is in or approaching the zone.

WARNING

The robot may drive over the feet of personnel, causing injury.

• All personnel must be informed of the side Protective fields of the robot and

be instructed to wear safety shoes near an operating robot—see Personnel

detection on page104.

WARNING

The robot may drive into a ladder, scaffold, or similar equipment that has a

person standing on it. Personnel risk fall injuries and equipment may be

damaged.

• Don't place ladders, scaffolds, or similar equipment in the robot's work

environment.

MiR250 Shelf Carrier User Guide (en) 03/2021 - v.1.4 ©Copyright 2021: Mobile IndustrialRobots A/S. 33

Page 34

WARNING

The robot may drive down staircases or holes in the floor and cause serious

injury to personnel and damage to the robot and to equipment.

• Mark descending staircases and holes as Forbidden zones on maps.

• Keep the maps up to date.

• Inform personnel that the robot cannot detect descending staircases and

holes in the floor in time to stop.

WARNING

Contact with live electrical parts can cause electric shock.

4. Safety

• Do not touch any internal components of the robot while it is powered.

WARNING

Using a charging device different from the one supplied by the manufacturer

can cause a fire and thereby burn injuries to nearby personnel and damage to

the robot and equipment.

• Only use an original MiR charger.

WARNING

Attempting to charge batteries outside the robot can lead to electrical shock

or burns.

• Never charge the batteries outside the robot.

MiR250 Shelf Carrier User Guide (en) 03/2021 - v.1.4 ©Copyright 2021: Mobile IndustrialRobots A/S. 34

Page 35

4. Safety

WARNING

Lithium battery packs may get hot, explode, or ignite and cause serious injury

if they are misused electrically or mechanically.

Observe the following precautions when handling and using lithium-ion

batteries:

• Do not short-circuit, recharge, or connect with false polarity.

• Do not expose to temperatures beyond the specified temperature range or

incinerate the battery.

• Do not crush, puncture, or disassemble the battery. The battery contains

safety and protection devices, which, if damaged, may cause the battery to

generate heat, explode, or ignite.

• Do not allow the battery to get wet.

• In the event the battery leaks and the fluid gets into one’s eye, do not rub

the eye. Rinse well with water, and immediately seek medical care. If left

untreated, the battery fluid could cause damage to the eye.

• Use only an original MiR charger (cable charger or charging station) and

always follow the instructions from the battery manufacturer.

• Do not touch damaged batteries with bare hands. Only personnel using

suitable Personal Protection Equipment (PPE) and tools should handle

damaged batteries.

• Isolate the battery and keep clear if the following conditions are observed:

• The battery exhibits abnormally high temperatures.

• The battery emits abnormal odors.

• The battery changes colors.

• The battery case is deformed or otherwise differs from the normal

electrical or mechanical condition.

• Modifications or manipulations of the battery may lead to considerable

safety risks and are therefore prohibited.

• Do not use the battery for anything other than MiR250 Shelf Carrier.

MiR250 Shelf Carrier User Guide (en) 03/2021 - v.1.4 ©Copyright 2021: Mobile IndustrialRobots A/S. 35

Page 36

4. Safety

WARNING

Load falling or robot overturning if the load on the robot is not positioned or

fastened correctly can cause fall injuries to nearby personnel or damage to

equipment.

• Ensure that the load is positioned according to the specifications and is

fastened correctly—see Payload distribution on page229.

WARNING

Personnel standing next to the robot when it is docking to a shelf risk being

injured by an impact.

• Ensure that docking positions are clearly marked as operating hazard zones

with visible tape or similar marking and that all personnel are instructed

not to stand in the hazard zone when the robot is docking.

WARNING

The robot risks damage and mechanical failure if it is used to transport pallets

or anything other than safely commissioned shelves. Nearby equipment and

personnel risk damage or injury if payloads fall from the robot.

• Only use the robot to transport safely commissioned shelves—see Shelf

specifications on page120.

WARNING

Personnel standing in the blind spot of the robot when it is pivoting with a shelf

risk being struck and injured.

• Ensure that all nearby personnel are instructed not to stand close to the

robot when it is pivoting.

• Inform personnel that the signal lights indicate when the robot is intending

to turn or pivot—see Light indicators and speakers on page113.

MiR250 Shelf Carrier User Guide (en) 03/2021 - v.1.4 ©Copyright 2021: Mobile IndustrialRobots A/S. 36

Page 37

WARNING

Ifa load is positioned incorrectly on a shelf, the load may fall off. Nearby

personnel or equipment risk injury or damage.

• Ensure that each load is positioned correctly on the shelf.It is the

responsibility of the commissioner to determine correct and safe methods

of loading shelves.

• Conduct a brake test while the robot is transporting a fully loaded shelf—

see Making a brake test on page150.

WARNING

If the robot attempts to dock to a shelf and the carrier pins are raised or the

robot is misplaced, the robot may push the shelf. The shelf may collide with

personnel or equipment, resulting in injury or damage.

4. Safety

• Ensure that docking positions are clearly marked as operating hazard zones

with visible tape or similar marking, and that all personnel are instructed

not to stand close to the robot when it is docking.

WARNING

If the robot does not attach to the shelf correctly due to pins being offset from

their correct positions, the shelf can detach at any time. Uncertain control of

the shelf may result in the shelf or its load colliding with personnel or

equipment resulting in injury or damage.

• Ensure the shelf is designed according to specifications—see Shelf

specifications on page120.The laser scanners will then be able to detect if

the shelf is incorrectly positioned and will enter Protective stop before

operating with the shelf.

MiR250 Shelf Carrier User Guide (en) 03/2021 - v.1.4 ©Copyright 2021: Mobile IndustrialRobots A/S. 37

Page 38

4. Safety

WARNING

If the robot drives on a slope and looses grip of the attached shelf, the shelf or

its load may collide with personnel or equipment causing injury or damage.

• Do not operate MiR250 Shelf Carrier on slopes.

WARNING

If the robot transports a shelf with a load that extends the footprint of the

robot, the load may collide with personnel or equipment causing injury or

damage.

• Do not load the shelves with loads that exceed the robot's footprint.

CAUTION

Robot malfunctions can cause an electrical fire, causing damage and injury to

equipment and personnel.

• Personnel operating near the robot must be informed on how to use an ABC

fire extinguisher to put out an electrical fire should the robot malfunction

and catch on fire.

CAUTION

Risk of trapping or injury to personnel if robots malfunction or if personnel

enter operating hazard zones.

• Personnel operating near the robot must be informed on how to engage the

robot's Emergency stop function in emergency situations.

4.3 Intended use

MiR250 Shelf Carrier is intended to be commissioned and used in indoor industrial

environments where access for the public is restricted. For details about the environmental

conditions in which MiR250 Shelf Carrier should operate, see specifications for MiR250 Shelf

MiR250 Shelf Carrier User Guide (en) 03/2021 - v.1.4 ©Copyright 2021: Mobile IndustrialRobots A/S. 38

Page 39

4. Safety

Carrier on the MiR website.

MiR250 Shelf Carrier is intended to be commissioned according to the guidelines in

Commissioning on page117. This is a prerequisite for safe usage of MiR250 Shelf Carrier.

MiR250 Shelf Carrier is equipped with safety-related features that are purposely designed

for collaborative operation where the robot operates without a safety enclosure or together

with people.

MiR250 Shelf Carrier is designed for and all risks are considered when it is used to transport

shelves that fulfill the specification and design requirement described in Shelf specifications

on page120.

MiR250 Shelf Carrier is a completed MiR application that consists of a MiR250 with a

mounted MiR Shelf Carrier 250. The application is CE marked as long as it is not modified or

altered. However, a CE marked application does not guarantee a CE marked setup. It is the

responsibility of the commissioner to commission MiR250 Shelf Carrier safely.

NOTICE

A safe machine does not guarantee a safe system. Follow the guidelines in

Commissioning on page117 to ensure a safe system.

4.4 Users

MiR250 Shelf Carrier is only intended to be used by personnel that have received training in

their required tasks.

There are three types of intended users for MiR250 Shelf Carrier: commissioners, operators,

and direct users.

Commissioners

Commissioners have thorough knowledge of all aspects of commissioning, safety, use, and

maintenance of MiR250 Shelf Carrier and have the following main tasks:

• Commissioning of the product. This includes creating maps and restricting the user

interface for other users and making brake tests with a full payload.

• Conducting the risk assessment.

MiR250 Shelf Carrier User Guide (en) 03/2021 - v.1.4 ©Copyright 2021: Mobile IndustrialRobots A/S. 39

Page 40

4. Safety

• Determining the payload limit, weight distribution, safe fastening methods, safe loading

and unloading of loads on MiR250 Shelf Carrier, and ergonomic loading and unloading

methods if relevant.

• Ensuring the safety of nearby personnel when the robot is accelerating, braking, and

maneuvering.

• Marking operating hazard zones.

Operators

Operators have thorough knowledge of MiR250 Shelf Carrier and of the safety precautions

presented in this user guide. Operators have the following main tasks:

• Servicing and maintaining MiR250 Shelf Carrier.

• Creating and changing missions and map features in the robot interface.

Direct users

Direct users are familiar with the safety precautions in this user guide and have the

following main tasks:

• Assigning missions to MiR250 Shelf Carrier.

• Fastening loads to MiR250 Shelf Carrier securely.

• Loading and unloading from a paused robot.

All other persons in the vicinity of MiR250 Shelf Carrier are considered indirect users and

must know how to act when they are close to the robot. For example, they must be aware

that visibly marked operating hazard zones must be respected.

4.5 Foreseeable misuse

Any use of MiR250 Shelf Carrier deviating from the intended use is deemed as misuse. This

includes, but is not limited to:

• Using the robot to transport people

• Using the robot on steep surface grades, such as ramps

• Making changes to the SICK configuration

• Driving the robot on cross slopes

• Exceeding the total payload

• Positioning or fastening loads incorrectly according to the specifications—see Payload

distribution on page229

MiR250 Shelf Carrier User Guide (en) 03/2021 - v.1.4 ©Copyright 2021: Mobile IndustrialRobots A/S. 40

Page 41

4. Safety

• Using Emergency stop buttons for anything other than emergency stops

• Driving the robot with anything other than safely commissioned shelves

• Using the robot in medical and life critical applications

• Operating the robot outside the permissible operating parameters and environmental

specifications

• Using the robot in potentially explosive environments

• Using the robot outdoors

• Using the robot in hygiene zones

4.6 Warning label

MiR250 Shelf Carrier is supplied with a warning label that specifies that it is strictly

prohibited to ride on the robot.

The label must be placed on the robot or top module so that it is clearly visible.

Figure 4.1. The warning label must be placed on the robot or top module.

4.7 Residual risks

Mobile Industrial Robots has identified the following potential hazards that commissioners

must inform personnel about and take all precautions to avoid when working with MiR250

Shelf Carrier:

• You risk being run over, drawn in, trapped, or struck if you stand in the path of the robot

or walk towards the robot or its intended path while it is in motion.

• You risk being run over, drawn in, trapped, or struck if you stand in the path of the robot

or walk towards it while it is driving in reverse. The robot only drives in reverse when

undocking from a marker, such as a charging station or load transfer station.

• You risk being crushed or trapped if you touch the robot while it is in motion.

MiR250 Shelf Carrier User Guide (en) 03/2021 - v.1.4 ©Copyright 2021: Mobile IndustrialRobots A/S. 41

Page 42

4. Safety

• You risk being run over, drawn in, trapped, or struck if you stand in the path of the robot

or walk towards it while it is docking to a shelf.

• You risk being crushed or trapped between the robot and a shelf while the carrier is

picking up a shelf.

• You risk being crushed or trapped if the robot places a load outside a designated drop-off

area due to faulty localization.

• You risk losing control of the robot if it is accessed by unauthorized users. Consider

increasing the IT security of your product—see IT security on page82.

NOTICE

Other significant hazards may be present in a specific robot installation and

must be identified during commissioning.

MiR250 Shelf Carrier User Guide (en) 03/2021 - v.1.4 ©Copyright 2021: Mobile IndustrialRobots A/S. 42

Page 43

5. Accessing the internal parts

5. Accessing the internal parts

Most internal parts of MiR250 Shelf Carrier are accessed through covers that open to

different compartments:

• Front compartment

• Rear compartment

• Side compartments

• Top compartments

For more information on how to remove the covers on MiR250, see the video

How to remove and attach the covers on MiR250 on MiR Academy at the MiR

website. Contact your distributor for access to MiR Academy.

WARNING

Removing covers from the robot exposes parts connected to the power supply,

risking damage to the robot from a short circuit and electrical shock to

personnel.

• Before removing any covers, turn off the robot, and disconnect the

battery—see Disconnecting the battery on page74.

MiR250 Shelf Carrier User Guide (en) 03/2021 - v.1.4 ©Copyright 2021: Mobile IndustrialRobots A/S. 43

Page 44

5. Accessing the internal parts

5.1 Front compartment

To open the front compartment, follow these steps:

1. Unscrew the two screws holding the front cover with a T30 Torx screwdriver.

2. Pull the front cover off of the robot.

MiR250 Shelf Carrier User Guide (en) 03/2021 - v.1.4 ©Copyright 2021: Mobile IndustrialRobots A/S. 44

Page 45

5. Accessing the internal parts

5.2 Rear compartment

To open the rear compartment, follow these steps:

1. Push the two white buttons at the same time.

2. Loosen the cover by first loosening the bottom corners one at the time, then the two top

corners. Pull down and then out on each top corner.

MiR250 Shelf Carrier User Guide (en) 03/2021 - v.1.4 ©Copyright 2021: Mobile IndustrialRobots A/S. 45

Page 46

3. Pull off the cover.

5. Accessing the internal parts

5.3 Side compartments

The front and rear covers have to be removed before you can remove the side

covers.

To open a side compartment, follow these steps:

1. Turn the two screws counterclockwise with a T30 Torx screwdriver.

MiR250 Shelf Carrier User Guide (en) 03/2021 - v.1.4 ©Copyright 2021: Mobile IndustrialRobots A/S. 46

Page 47

2. Pull the cover off.

5.4 MiR Shelf Carrier 250

5. Accessing the internal parts

To access the internal parts of MiR Shelf Carrier 250, remove the top plate of the shelf

carrier by unscrewing all 14 screws from the top plate and lifting off the plate.

MiR250 Shelf Carrier User Guide (en) 03/2021 - v.1.4 ©Copyright 2021: Mobile IndustrialRobots A/S. 47

Page 48

6. Getting started

This section describes how to get started with MiR250 Shelf Carrier.

NOTICE

To be able to use MiR250 Shelf Carrier, your robot must be running software

version 2.9.0 or higher.

NOTICE

Read Safety on page32 before powering up MiR250 Shelf Carrier.

6. Getting started

In some images in this section, the robot is shown without a MiR Shelf Carrier

250 top module.

6.1 In the box

This section describes the contents of the MiR250 Shelf Carrier box.

MiR250 Shelf Carrier User Guide (en) 03/2021 - v.1.4 ©Copyright 2021: Mobile IndustrialRobots A/S. 48

Page 49

6. Getting started

Figure 6.1. The box containing the robot and accessories.

The box contains:

• The MiR250 Shelf Carrier robot

• A MiR250 Shelf Carrier document folder containing a USB flash drive and the following

printed documents:

• MiR250 Shelf Carrier Quick Start

• The CE Declaration of Conformity for your robot

• The CE Declaration of Conformity for your application

• Getting the robot online

• Passwords

• The unique nameplate for your application

• The USB flash drive in the document folder has the following content:

• MiR250 Shelf Carrier User Guide

• MiR250 Shelf Carrier Quick Start

• MiR Network and WiFi Guide

• MiR Robot Reference Guide

• MiR Robot REST API Reference

• Getting the robot online

MiR250 Shelf Carrier User Guide (en) 03/2021 - v.1.4 ©Copyright 2021: Mobile IndustrialRobots A/S. 49

Page 50

6. Getting started

6.2 Unpacking MiR250 Shelf Carrier

This section describes how to unpack the robot.

Keep the original packaging for future transportation of MiR250 Shelf Carrier.

To unpack the robot, follow these steps:

1. Place the box with the robot so that there is at least three meters of free space at the

front or the back of the box. This is necessary as the robot drives out of the box on a

ramp.

2. Cut the protective straps surrounding the box.

MiR250 Shelf Carrier User Guide (en) 03/2021 - v.1.4 ©Copyright 2021: Mobile IndustrialRobots A/S. 50

Page 51

3. Remove the lid from the box.

6. Getting started

4. Take the folder with the printed documents and the USB flash drive out of the box.

MiR250 Shelf Carrier User Guide (en) 03/2021 - v.1.4 ©Copyright 2021: Mobile IndustrialRobots A/S. 51

Page 52

5. Remove the walls of the box and the protective foam blocks.

6. Getting started

6. Place the lid of the box so that you can use it as a ramp. Align the lid so that it is flush

with the base of the box.

MiR250 Shelf Carrier User Guide (en) 03/2021 - v.1.4 ©Copyright 2021: Mobile IndustrialRobots A/S. 52

Page 53

6. Getting started

6.3 Connecting the battery

To connect the battery to the robot, you need to open the rear compartment—see Accessing

the internal parts on page43.

To connect the battery to the robot, follow these steps:

1. Turn the battery lever lock clockwise to unlock the battery lever.

2. Pull up the lever to connect the battery connector to the battery. Then turn the battery

lever lock counterclockwise to secure the battery lever.

MiR250 Shelf Carrier User Guide (en) 03/2021 - v.1.4 ©Copyright 2021: Mobile IndustrialRobots A/S. 53

Page 54

6. Getting started

3. Reattach the rear cover by tilting it slightly so that the bottom point forward and insert it

into the two attachment sockets. Press the two white buttons while attaching the cover to

the robot.

4. Click the cover in place one corner at the time.

MiR250 Shelf Carrier User Guide (en) 03/2021 - v.1.4 ©Copyright 2021: Mobile IndustrialRobots A/S. 54

Page 55

6.4 Powering up the robot

To power up the robot, follow these steps:

6. Getting started

MiR250 Shelf Carrier User Guide (en) 03/2021 - v.1.4 ©Copyright 2021: Mobile IndustrialRobots A/S. 55

Page 56

6. Getting started

1. Press the Power button for three seconds to turn on the robot.

The status lights waver yellow, and the robot starts the software initialization process.

MiR250 Shelf Carrier User Guide (en) 03/2021 - v.1.4 ©Copyright 2021: Mobile IndustrialRobots A/S. 56

Page 57

When the initialization process ends, the robot goes into Protective stop.

6. Getting started

2. Press the Resume button to clear the Protective stop. The robot is now ready for

operation.

MiR250 Shelf Carrier User Guide (en) 03/2021 - v.1.4 ©Copyright 2021: Mobile IndustrialRobots A/S. 57

Page 58

6. Getting started

6.5 Connecting to the robot interface

When the robot is turned on, it enables the connection to its WiFi access point. The name of

the access point appears in the list of available connections on your PC, tablet, or phone.

NOTICE

The original username and password for the robot’s web interface are in the

document Getting the robot online.

The unique password for the WiFi access point is in the Passwords document.

Both documents are in the box with the product.

To connect to the robot interface, follow these steps:

1. Using your PC, tablet, or phone, connect to the WiFi access point of the robot using the

unique password for the WiFi access point. The access point name has the following

format: MiR_20XXXXXXX.

The access point name is derived from the robot application's model serial

number.

MiR250 Shelf Carrier User Guide (en) 03/2021 - v.1.4 ©Copyright 2021: Mobile IndustrialRobots A/S. 58

Page 59

2. In a browser, go to the address mir.com and sign in.

6. Getting started

3. Switch to Manual mode, and drive the robot down the ramp—see Driving the robot in

Manual mode below.

6.6 Driving the robot in Manual mode

CAUTION

When driving the robot in Manual mode, it is possible to mute the Protective

fields and drive the robot into Forbidden zones and Unpreferred zones on the

map. This means that the robot will only stop when it is very close to an

obstacle and will not respond to zones on the map. This can result in injury to

personnel or damage to equipment if the robot is not driven carefully.

• Drive carefully to avoid collisions with any personnel or objects when

driving the robot in Manual mode.

• Avoid driving the robot manually without a clear visual of the robot.

MiR250 Shelf Carrier User Guide (en) 03/2021 - v.1.4 ©Copyright 2021: Mobile IndustrialRobots A/S. 59

Page 60

6. Getting started

To drive the robot in Manual mode, follow these steps:

1. On the robot, turn the Operating mode key to Manual mode (turn it to the right).

2. In the robot interface, select the joystick icon. The joystick control appears.

MiR250 Shelf Carrier User Guide (en) 03/2021 - v.1.4 ©Copyright 2021: Mobile IndustrialRobots A/S. 60

Page 61

3. Select Manual control. The Resume button on the robot starts blinking.

6. Getting started

4. On the robot, press the Resume button. The status lights turn blue, indicating that the

robot is in Manual mode.

5. Drive the robot off the ramp using the joystick.

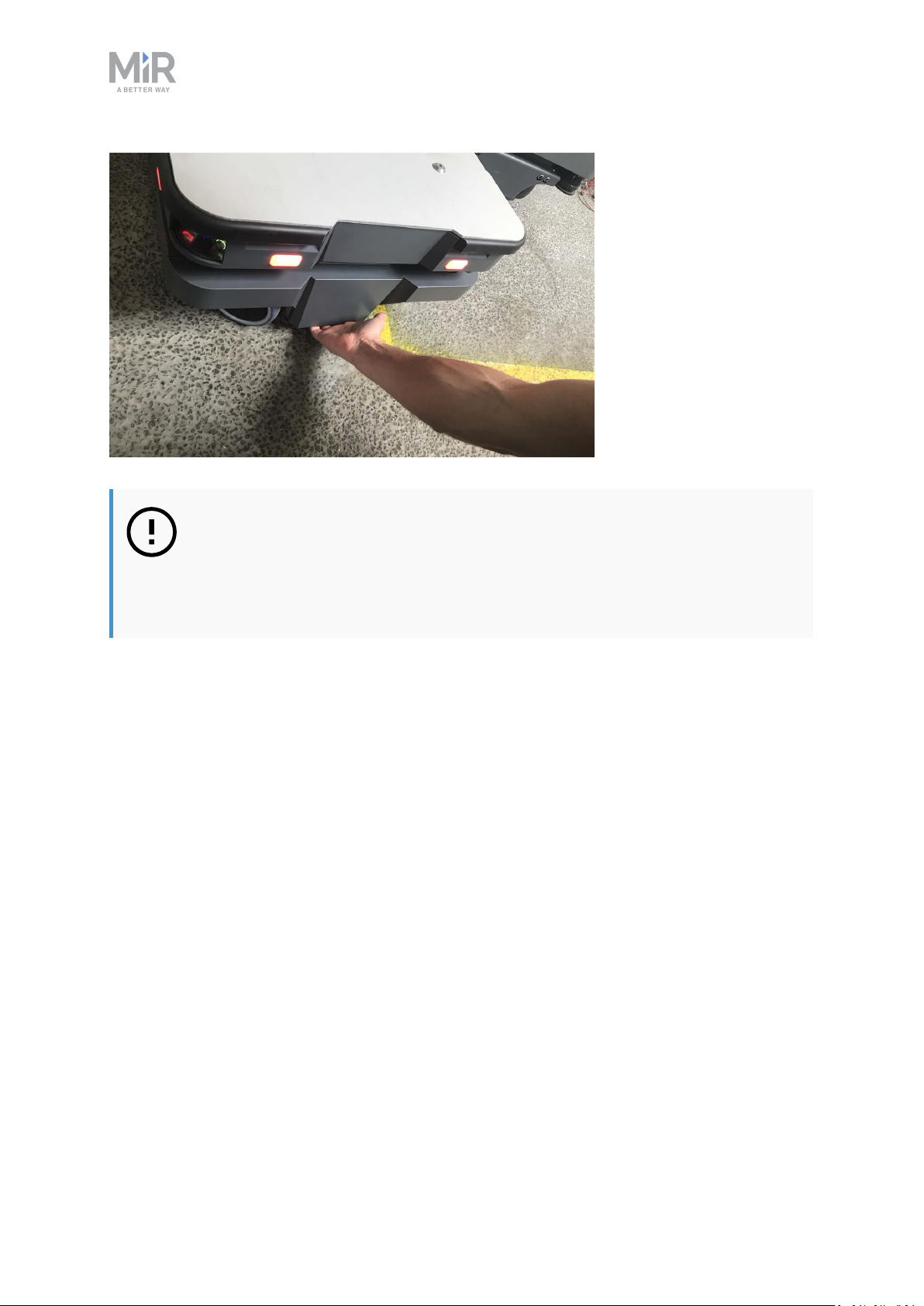

Place your foot in front of the ramp while the robot drives on it to keep the

ramp from slipping.

MiR250 Shelf Carrier User Guide (en) 03/2021 - v.1.4 ©Copyright 2021: Mobile IndustrialRobots A/S. 61

Page 62

6. Getting started

6.7 Moving the robot by hand

You should generally avoid moving the robot by hand, but if, for example, the robot gets

stuck near an obstacle and cannot be moved by manual control, it is possible to do so.

Before moving the robot by hand, make sure the mechanical brakes are released.

To release the brakes, the robot must be turned on—see Connecting the

battery on page53. When the robot shuts down due to low battery, there is

still enough power to use the manual brake release for a week or more.

MiR250 Shelf Carrier User Guide (en) 03/2021 - v.1.4 ©Copyright 2021: Mobile IndustrialRobots A/S. 62

Page 63

6. Getting started

Release the brakes by turning the Manual brake release switch located below the control

panel clockwise.

Figure 6.2. The Manual brake release switch is located below the control panel.

To move the robot by hand, either push or pull it.

When pushing or pulling the robot, grip the MiR Shelf Carrier 250 top module.

You can also pull the robot using the designated pull handles beneath the front and rear

covers.

MiR250 Shelf Carrier User Guide (en) 03/2021 - v.1.4 ©Copyright 2021: Mobile IndustrialRobots A/S. 63

Page 64

6. Getting started

NOTICE

When handling the robot, do not push or pull the robot sideways, and do not

use the covers for pushing or pulling. Only use the designated pull handles or

the top module.

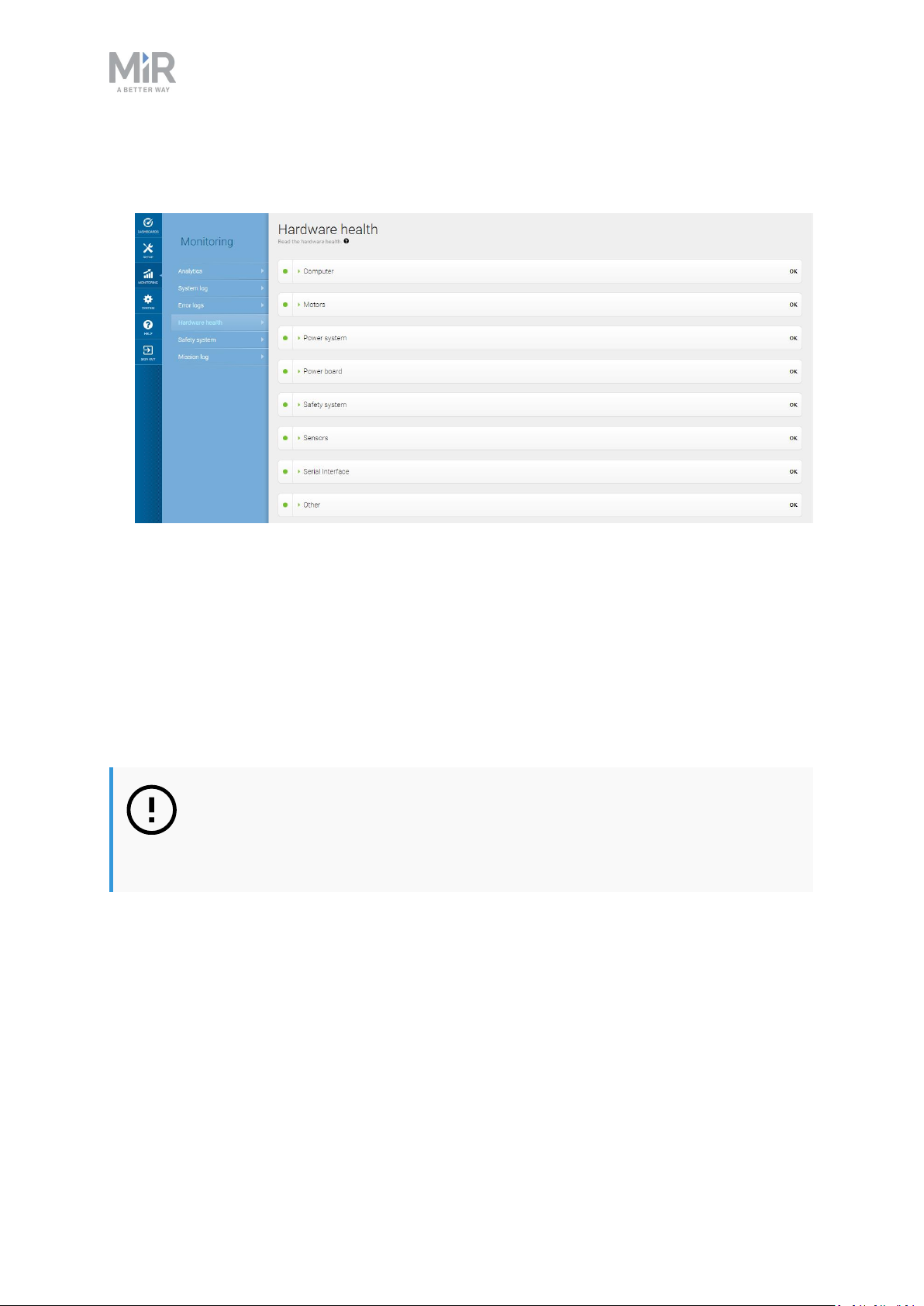

6.8 Checking the hardware status

To check that all hardware components work as intended, follow these steps:

1. Sign in to the robot interface—see Connecting to the robot interface on page58.

2. Go to Monitoring > Hardware health.

MiR250 Shelf Carrier User Guide (en) 03/2021 - v.1.4 ©Copyright 2021: Mobile IndustrialRobots A/S. 64

Page 65

6. Getting started

3. Check that all elements on the page have the OK status and that they have green dots on

the left.

For more information, see Hardware health in MiR Robot Reference Guide on the MiR

website.

6.9 Mounting the nameplate

Before using MiR250 Shelf Carrier, you must mount its unique nameplate to it. The

nameplate contains information specific to your MiR application—see Nameplate on

page16.

NOTICE

The nameplate must be mounted as described in the following steps. If

mounted incorrectly, the CEmark is invalid.

MiR250 Shelf Carrier User Guide (en) 03/2021 - v.1.4 ©Copyright 2021: Mobile IndustrialRobots A/S. 65

Page 66

To mount the nameplate correctly, follow these steps:

1. Locate the rear cover—see External parts on page13.

2. Clean the area marked in the image below with a degreasing agent.

6. Getting started

3. Mount the nameplate on the cleaned area.

MiR250 Shelf Carrier User Guide (en) 03/2021 - v.1.4 ©Copyright 2021: Mobile IndustrialRobots A/S. 66

Page 67

6. Getting started

6.10 Enable the MiR250 Shelf Carrier feature

To access the MiR250 Shelf Carrier settings and mission menus, the MiR250 Shelf Carrier

features must be enabled.To check that they are enabled, follow these steps:

1. Sign in to the robot interface, and go to System > Settings > Features.

MiR250 Shelf Carrier User Guide (en) 03/2021 - v.1.4 ©Copyright 2021: Mobile IndustrialRobots A/S. 67

Page 68

2. Under ShelfPallet Lift and Shelf, select True.

6. Getting started

3. Under I/O modules, select True. The MiR Shelf Carrier 250 top module communicates

with the robot through I/O modules, so they must be activated for the shelf carrier to

work.

MiR250 Shelf Carrier User Guide (en) 03/2021 - v.1.4 ©Copyright 2021: Mobile IndustrialRobots A/S. 68

Page 69

6. Getting started

6.11 Testing the top module

To test that the top module of MiR250 Shelf Carrier is configured and connected correctly,

follow these steps:

1. Sign in to the robot interface, and go to Setup > I/O modules.

MiR250 Shelf Carrier User Guide (en) 03/2021 - v.1.4 ©Copyright 2021: Mobile IndustrialRobots A/S. 69

Page 70

6. Getting started

2. Under MiR internal I/Os, complete the following sequence, and verify that the robot

executes the expected action:

a. Under Outputs, select 3. Verify that the carrier pins rise up.

b. Once the pins are raised, verify that 3 under Inputs is green.

c. Under Outputs, select 2. Verify that the carrier pins lower into the robot.

MiR250 Shelf Carrier User Guide (en) 03/2021 - v.1.4 ©Copyright 2021: Mobile IndustrialRobots A/S. 70

Page 71

6. Getting started

d. Once the pins are lowered, verify that 2 under Inputs is green.

If the lift was raised and lowered as expected and the correct input feedback was received,

MiR Shelf Carrier 250 is correctly installed.

If MiR Shelf Carrier 250 did not operate correctly, verify that you have enabled the feature

as described in Enable the MiR250 Shelf Carrier feature on page67. If MiR Shelf Carrier 250

continues to fail, contact your distributor.

6.12 Shutting down the robot

To shut down MiR250 Shelf Carrier, follow these steps:

1. Ensure that the robot is not moving or executing an action.

2. Press the Power button for three seconds.

MiR250 Shelf Carrier User Guide (en) 03/2021 - v.1.4 ©Copyright 2021: Mobile IndustrialRobots A/S. 71

Page 72

6. Getting started

3. The robot starts the shutdown process. The status lights waver yellow, and the Power

button blinks red.

4. When the robot finishes the shutdown process, the status and the signal lights go off, and

the Power button turns blue.

When you shut down the robot for transportation, service, or repair, the battery must be

disconnected—see Disconnecting the battery on page74.

MiR250 Shelf Carrier User Guide (en) 03/2021 - v.1.4 ©Copyright 2021: Mobile IndustrialRobots A/S. 72

Page 73

7. Battery and charging

7. Battery and charging

The robot is powered by a fast swap lithium-ion battery that can be charged inside the robot

with a MiR cable charger or a MiR Charge48V charging station.

7.1 Charging the robot

This section describes how to charge MiR250 Shelf Carrier using a MiR cable charger.

A MiR cable charger is not part of the MiR250 Shelf Carrier standard delivery.

Contact your distributor for more information.

The robot is delivered 40-60% charged.

The rear compartment holds the robot’s battery. To access the rear compartment, see

Accessing the internal parts on page43.

To charge MiR250 Shelf Carrier using the cable charger, connect the cable charger to the

charging interface on the robot in the bottom-right corner.

Use only an original MiR cable charger.

MiR250 Shelf Carrier User Guide (en) 03/2021 - v.1.4 ©Copyright 2021: Mobile IndustrialRobots A/S. 73

Page 74

7. Battery and charging

If the robot has been inactive for more than a week or if its battery

percentage has been below 5% for more than four hours, the battery goes into

Power save mode, which disables the power to the robot—see Battery storage

on page79.

To disable Power save mode, disconnect the battery connector for 30 seconds

and then reconnect it and wait 30 seconds before turning on the robot, or

connect a MiR cable charger to the robot.

For information about the charging time, see specifications on the MiR website.

7.2 Disconnecting the battery

Whenever the robot is to be transported, undergo maintenance, or stored for long periods of

time, you should always disconnect the battery.

The rear compartment holds the robot’s battery. To access the rear compartment, see

Accessing the internal parts on page43.

To disconnect the battery, follow these steps:

1. Turn the battery lock clockwise to release it.

MiR250 Shelf Carrier User Guide (en) 03/2021 - v.1.4 ©Copyright 2021: Mobile IndustrialRobots A/S. 74

Page 75

2. Press down on the battery lever to disconnect the battery.

3. Turn the battery lock counterclockwise to lock it.

7. Battery and charging

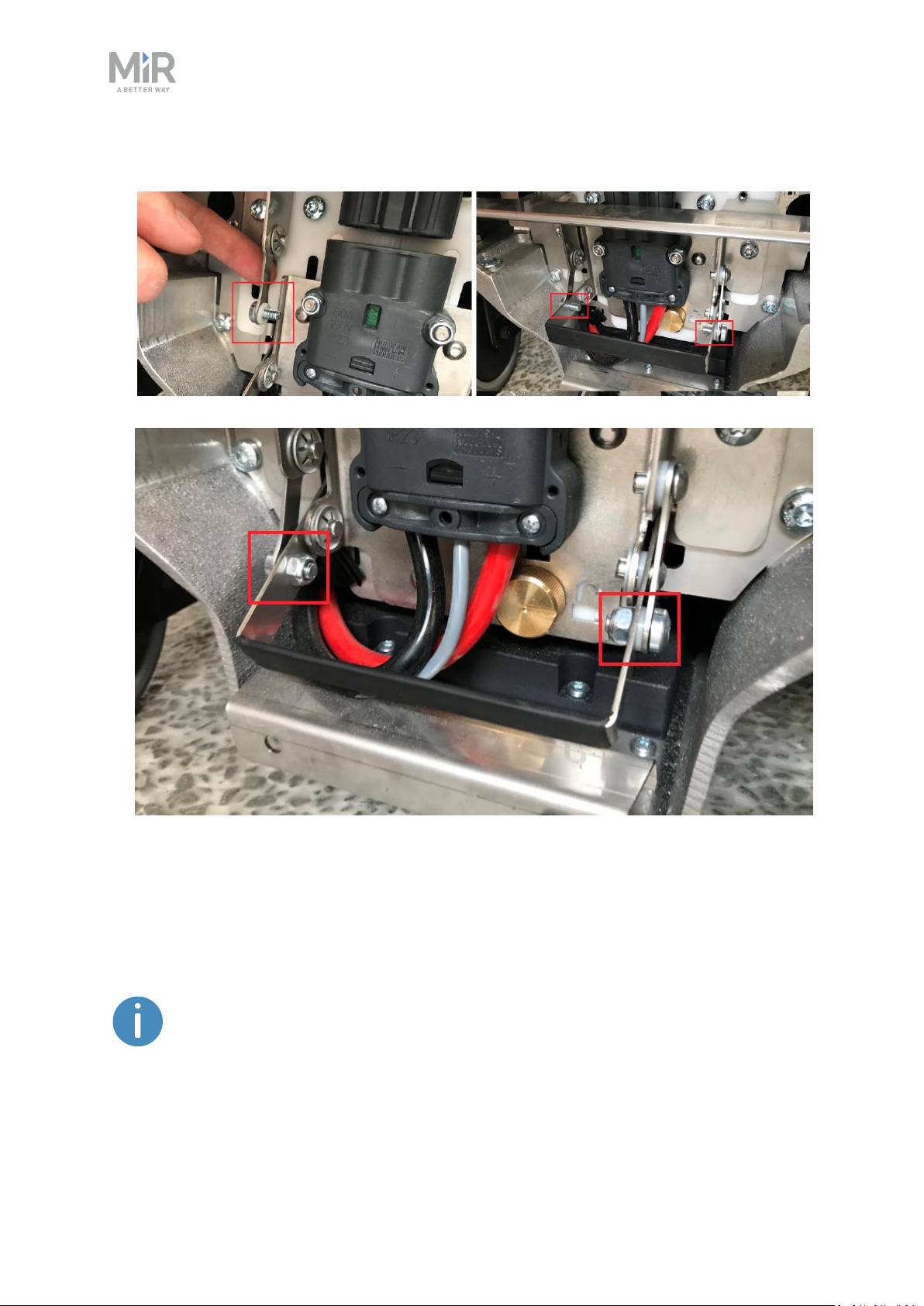

7.3 Enabling fast swap

If you wish to enable the fast swap-option on the robot, you must modify the battery

disconnect assembly.

The levers holding the battery in place are fastened with screws from the

factory to ensure that the battery stays disconnected during transportation.

The rear compartment holds the robot’s battery. To access the rear compartment, see

Accessing the internal parts on page43.

MiR250 Shelf Carrier User Guide (en) 03/2021 - v.1.4 ©Copyright 2021: Mobile IndustrialRobots A/S. 75

Page 76

7. Battery and charging

To enable the fast swap-option on the robot, follow these steps:

1. Disconnect the battery—see Disconnecting the battery on page74.

2. Unscrew the screw shown in the image below with a T20 Torx screwdriver. Do this on

both sides of the lever.

3. Unscrew the screw shown in the image below with a 10 mm Hex screwdriver. Do this on

both sides of the lever.

MiR250 Shelf Carrier User Guide (en) 03/2021 - v.1.4 ©Copyright 2021: Mobile IndustrialRobots A/S. 76

Page 77

4. Fasten the two levers to the lever controlling the connector.

7. Battery and charging

7.4 Swapping out the lithium-ion battery

MiR250 Shelf Carrier is supplied with a removable lithium-ion battery. The battery can be

charged inside the robot with a MiR cable charger.

The robot is delivered with one lithium-ion battery. Contact your distributor if

you need more batteries.

MiR250 Shelf Carrier User Guide (en) 03/2021 - v.1.4 ©Copyright 2021: Mobile IndustrialRobots A/S. 77

Page 78

7. Battery and charging

To be able to remove the battery, you must first enable the fast swap-option in your robot—

see Enabling fast swap on page75.

The rear compartment holds the robot’s battery. To access the rear compartment, see

Accessing the internal parts on page43.

To swap out the battery, follow these steps:

1. Disconnect the battery—see Disconnecting the battery.

2. Pull out the battery.

You can now replace the battery.

3. Do these steps in reverse when putting in the battery.

MiR250 Shelf Carrier User Guide (en) 03/2021 - v.1.4 ©Copyright 2021: Mobile IndustrialRobots A/S. 78

Page 79

7. Battery and charging

7.5 Battery storage

The battery should be stored in an area at room temperature with a non-condensing relative

air humidity—see specifications on the MiR website. Temperatures and humidity below or

above the specifications will shorten the service life of the battery.

The battery should not be exposed to nor submerged in any liquid as this may damage the

battery.

Charge the battery before storage to preserve the service life of the battery.

NOTICE

If you store the battery for a longer period of time when it is almost depleted,

you may not be able to get it running again. Contact your distributor if this

occurs.

To preserve the battery, disconnect the battery from the robot before storing the robot.

Power save mode

If the battery is not used for a period of time, it enters Power save mode. When the battery

is in Power save mode, it will not power the robot until the battery is activated again.

To activate the battery after it has been in Power save mode, disconnect it from the robot

for 30 seconds, reconnect it to the robot, wait 30 seconds, and then turn on the robot. If the

robot cannot turn on, contact your distributor.

The amount of time it takes for the battery to enter Power save mode depends on the state

of charge of the battery. The best state to store the battery at is when it is 80% charged.

Table 7.1 provides best practice values for storage time and the time it takes for the battery

to enter Power save mode depending on the battery percentage.

Table 7.1.

Time taken for the battery to enter Power save mode and maximum storage time at

various battery percentages

Battery state of charge Power save mode timeout Maximum storage time

100% 1 week 18 months

MiR250 Shelf Carrier User Guide (en) 03/2021 - v.1.4 ©Copyright 2021: Mobile IndustrialRobots A/S. 79

Page 80

7. Battery and charging

Battery state of charge Power save mode timeout Maximum storage time

75% 1 week 15 months

50% 1 week 12 months

25% 1 week 6 months

5% 4 hours 2 months

0% 4 hours 1 month

The battery percentage displayed in the robot interface is based on when the

robot will shut down due to low voltage. When the interface displays 0%

battery percentage, the actual state of charge is around 5%

Deep sleep

When the battery is completely depleted, the battery enters Deep sleep mode. It can be

stored for six weeks in this state before the battery shuts down completely, and the battery

cells may begin to take damage.

When you connect the battery to a charger, it should be brought out of Deep sleep mode,

but if not, apply the same method as when it goes into Power save mode.

7.6 Battery disposal

Return unserviceable batteries to relevant facilities in accordance with local statutory

regulations.

A crossed-out wheeled bin indicates that the product needs to be disposed separately and

not as municipal waste—see Figure 7.1.

You are legally obliged to return used batteries and rechargeable batteries. Disposing used

batteries in the household waste is prohibited. Batteries containing hazardous substances are

marked with the crossed-out wheeled bin. The symbol indicates that it is forbidden to

dispose the product via the domestic refuse. The chemical symbols for the respective

hazardous substances are Cd= Cadmium, Hg = Mercury, Pb = Lead.

MiR250 Shelf Carrier User Guide (en) 03/2021 - v.1.4 ©Copyright 2021: Mobile IndustrialRobots A/S. 80

Page 81

Figure 7.1. Battery disposal symbols.

7. Battery and charging

MiR250 Shelf Carrier User Guide (en) 03/2021 - v.1.4 ©Copyright 2021: Mobile IndustrialRobots A/S. 81

Page 82

8. IT security

8. IT security

ITsecurity is a set of precautions you can take to prevent unauthorized personnel from

accessing MiR250 Shelf Carrier. This section describes the main IT-security related risks and

how to minimize them when commissioning MiR250 Shelf Carrier.

MiR250 Shelf Carrier communicates all data over the network that it is connected to. It is

the responsibility of the commissioner to ensure that it is connected to a secure network.

MiR recommends conducting an IT-security risk assessment before commissioning the robot.

Contact your distributor for a list of FAQs about IT security.

8.1 Managing users and passwords

Managing your users and passwords is the main way you can control access to MiR250 Shelf

Carrier.

There are three default users with predefined passwords for you to start using. These are

described in the MiR Robot Reference Guide along with instructions to create new users,

user groups, and passwords. MiR advises you to:

• Change the default password for all predefined users if you choose to continue to use

them. Make sure to choose a strong password since MiR250 Shelf Carrier does not

enforce any password rules nor expire the password.

• Create new user groups if more levels of access are necessary.

• Create dedicated user accounts under the relevant user group for each person accessing

MiR250 Shelf Carrier, and ensure that the users change the password on their first signin. It is not recommended to have several users share the same account.

• Only enable users with a minimum level of access to use a pin code to sign in. Users with

a higher level of access are recommended to use a strong password to sign in instead.

8.2 Software security patches

To improve the security of MiR250 Shelf Carrier, MiR supplies security patches to the

operating system in new MiR software update files. When you install a security patch, it

takes approximately 10-15 minutes longer to update a MiR product.

MiR250 Shelf Carrier User Guide (en) 03/2021 - v.1.4 ©Copyright 2021: Mobile IndustrialRobots A/S. 82

Page 83

8. IT security

Understanding MiR software versions

MiR uses the Major.Minor.Patch.Hot fix format to version software. For example, 2.8.1.1

means that the software is based on the second major release, the eighth minor release of

the major version, the first patch release of the minor version, and, in this example, a single

hot fix is included too.

• Major releases include the most significant changes that affect the entire robot software.

• Minor releases often include new features and smaller changes that only affect parts of

the software.

• Patch releases focus on fixing small issues in the software and introducing quality

improvements.

• Hot fix releases are only created when a patch release has introduced a critical issue that

needs to be fixed immediately.

Security patch policy

MiR applies the following policy when supplying security patches:

• New security patches are distributed per every minor release.

• All patch releases under a minor release include the previous security patches also. In

other words, if you chose not to install the first software version in a minor release, such

as version 2.9.0, the security patches will still be installed when you update to 2.9.1 or

higher.

MiR250 Shelf Carrier User Guide (en) 03/2021 - v.1.4 ©Copyright 2021: Mobile IndustrialRobots A/S. 83

Page 84

9. Navigation and control system

9. Navigation and control system

The navigation and control system is responsible for driving the robot to a goal position

while avoiding obstacles. This section describes the processes and components involved in

the robot's navigation and control system.

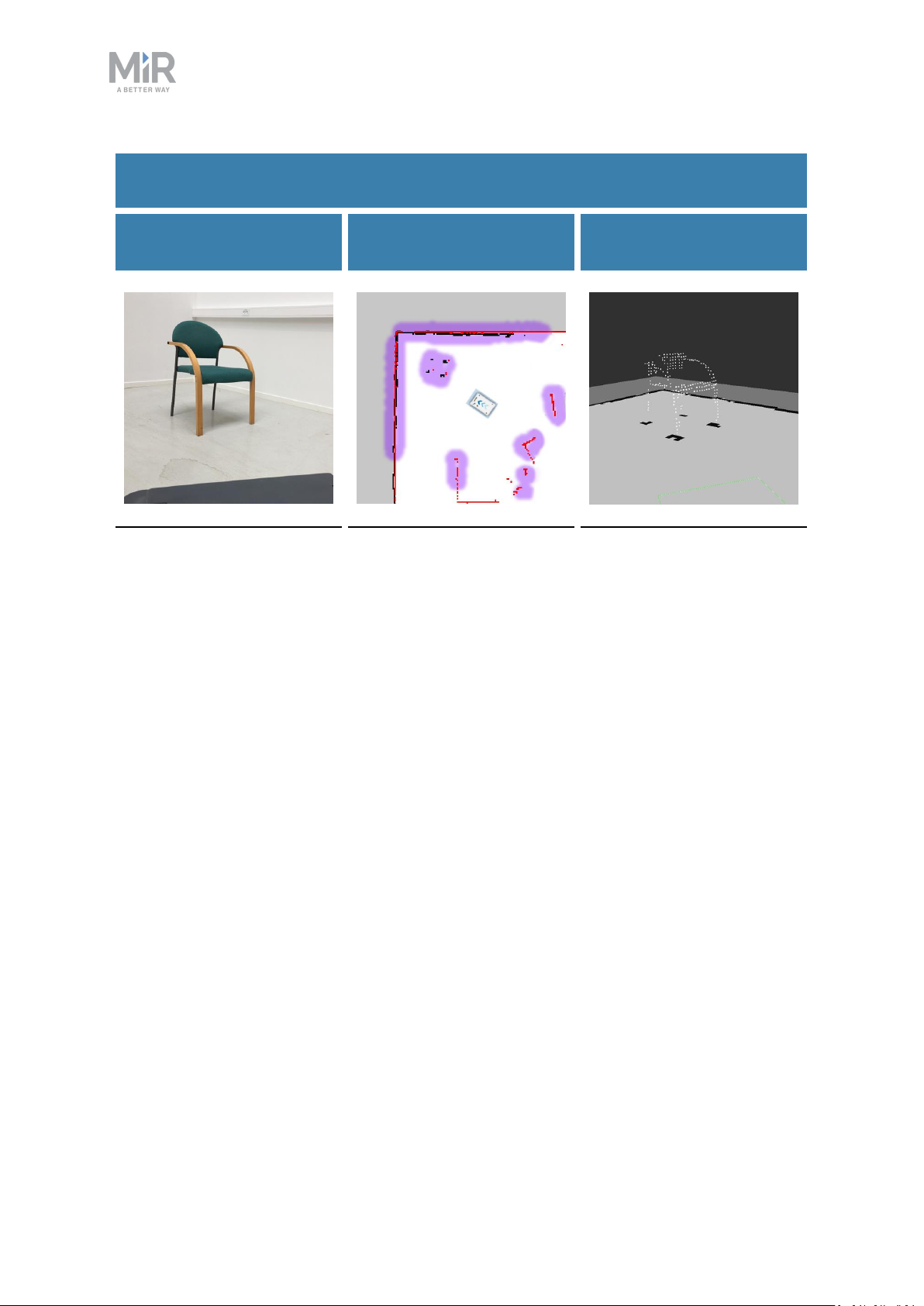

9.1 System overview

The purpose of the navigation and control system is to guide the robot from one position on

a map to another position. The user provides the map and chooses the goal position the

robot must move to. The diagram in Figure 9.1 describes the processes in the navigation and

control system.

The main processes involved in the navigation system are:

• Global planner

The navigation process starts with the global planner determining the best path for the

robot to get from its current position to the goal position. It plans the route to avoid walls

and structures on the map.

• Local planner

While the robot is following the path made by the global planner, the local planner

continuously guides the robot around detected obstacles that are not included on the

map.

• Obstacle detection

The safety laser scanners, 3D cameras, and proximity sensors are used to detect obstacles

in the work environment. These are used to prevent the robot from colliding with

obstacles.

• Localization

This process determines the robot's current position on the map based on input from the

motor encoders, inertial measurement unit(IMU), and safety laser scanners.

• Motor controller and motors

The motor controller determines how much power each motor must receive to drive the

robot along the intended path safely. Once the robot reaches the goal position, the brakes

are engaged to stop the robot.

Each part of the process is described in greater detail in the following sections.

MiR250 Shelf Carrier User Guide (en) 03/2021 - v.1.4 ©Copyright 2021: Mobile IndustrialRobots A/S. 84

Page 85

9. Navigation and control system

Figure 9.1. Flow chart of the navigation and control system. The user provides the necessary input for the robot

to generate a path to the goal position. The robot executes the steps in the navigation loop until it reaches the

goal position and stops by engaging the brakes.

MiR250 Shelf Carrier User Guide (en) 03/2021 - v.1.4 ©Copyright 2021: Mobile IndustrialRobots A/S. 85

Page 86

9. Navigation and control system

9.2 User input

To enable the robot to navigate autonomously, you must provide the following:

• A map of the area, either from a .png file or created with the robot using the mapping

function—see Creating and configuring maps on page124.

• A goal destination on that map—see Markers on page135.

• The current position of the robot on the map. This usually only needs to be provided when

a new map is activated.

Figure 9.2. On the map, the current position of the robot is identified by the robot icon , and the goal

destination in this example is the robot position . The robot computer now determines a path from the

current position to the goal position.

Once the robot computer has a map with the robot's current position and a goal destination,

it begins planning a route between the two positions on the map using the global planner.

9.3 Global planner

The global planner is an algorithm in the robot computer that generates a path to the goal

position.This path is known as the global path.

MiR250 Shelf Carrier User Guide (en) 03/2021 - v.1.4 ©Copyright 2021: Mobile IndustrialRobots A/S. 86

Page 87

9. Navigation and control system

Figure 9.3. The global path is shown with the blue dotted line that leads from the start to the goal position.