User Guide (en)

Date: 12/2020

Revision: v.1.4

Copyright and disclaimer

All rights reserved. No parts of this document may be reproduced in any form without the

express written permission of Mobile Industrial Robots A/S (MiR). MiR makes no warranties,

expressed or implied, in respect of this document or its contents. In addition, the contents of

the document are subject to change without prior notice. Every precaution has been taken in

the preparation of this document. Nevertheless, MiR assumes no responsibility for errors or

omissions or any damages resulting from the use of the information contained.

Copyright © 2019-2020 by Mobile Industrial Robots A/S.

Contact the manufacturer:

Mobile Industrial Robots A/S

Emil Neckelmanns Vej 15F

DK-5220 Odense SØ

www.mobile-industrial-robots.com

Phone: +45 20 377 577

Email: support@mir-robots.com

CVR: 35251235

MiR1000User Guide (en) 12/2020 - v.1.4 ©Copyright 2019-2020: Mobile IndustrialRobots A/S. 2

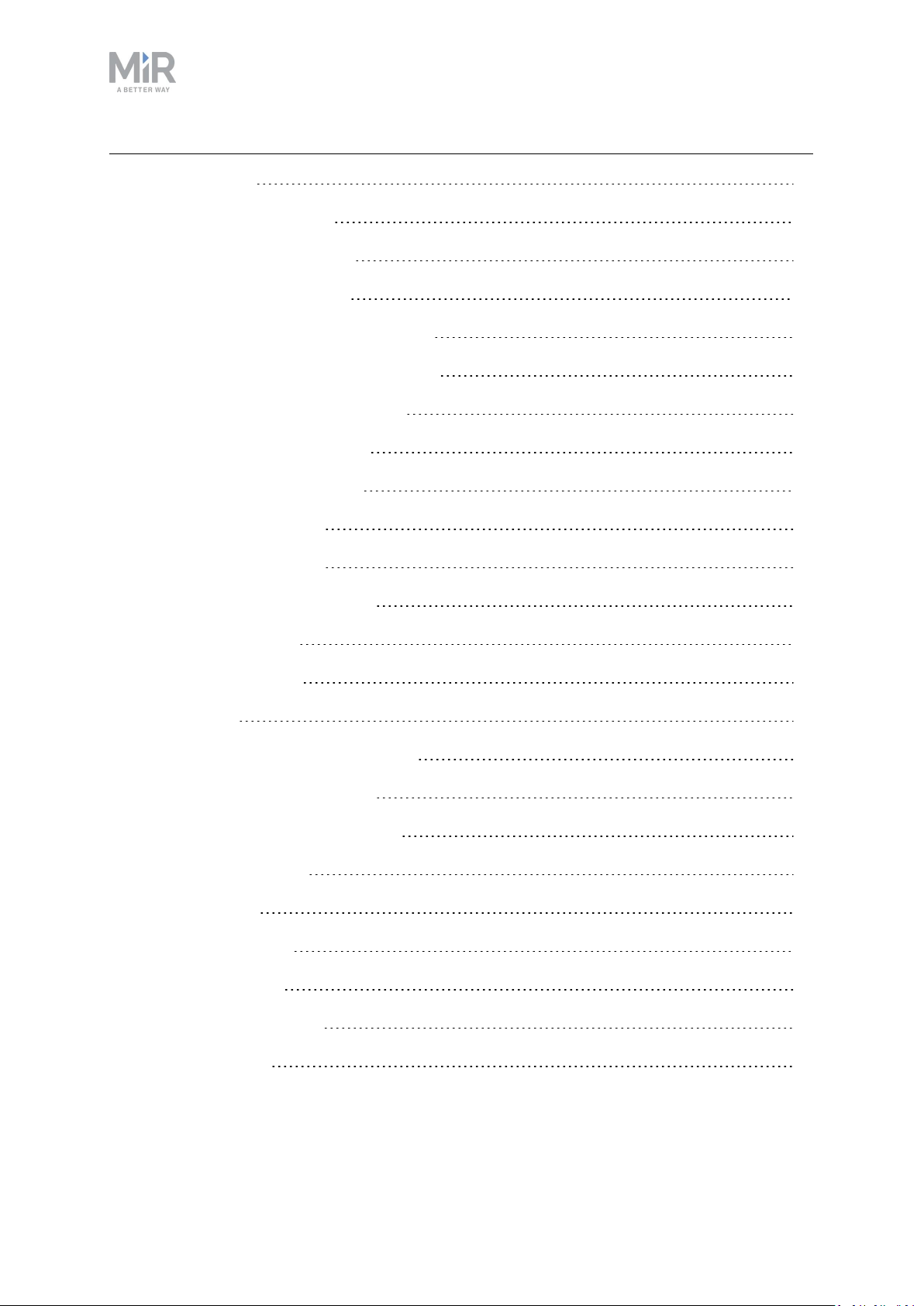

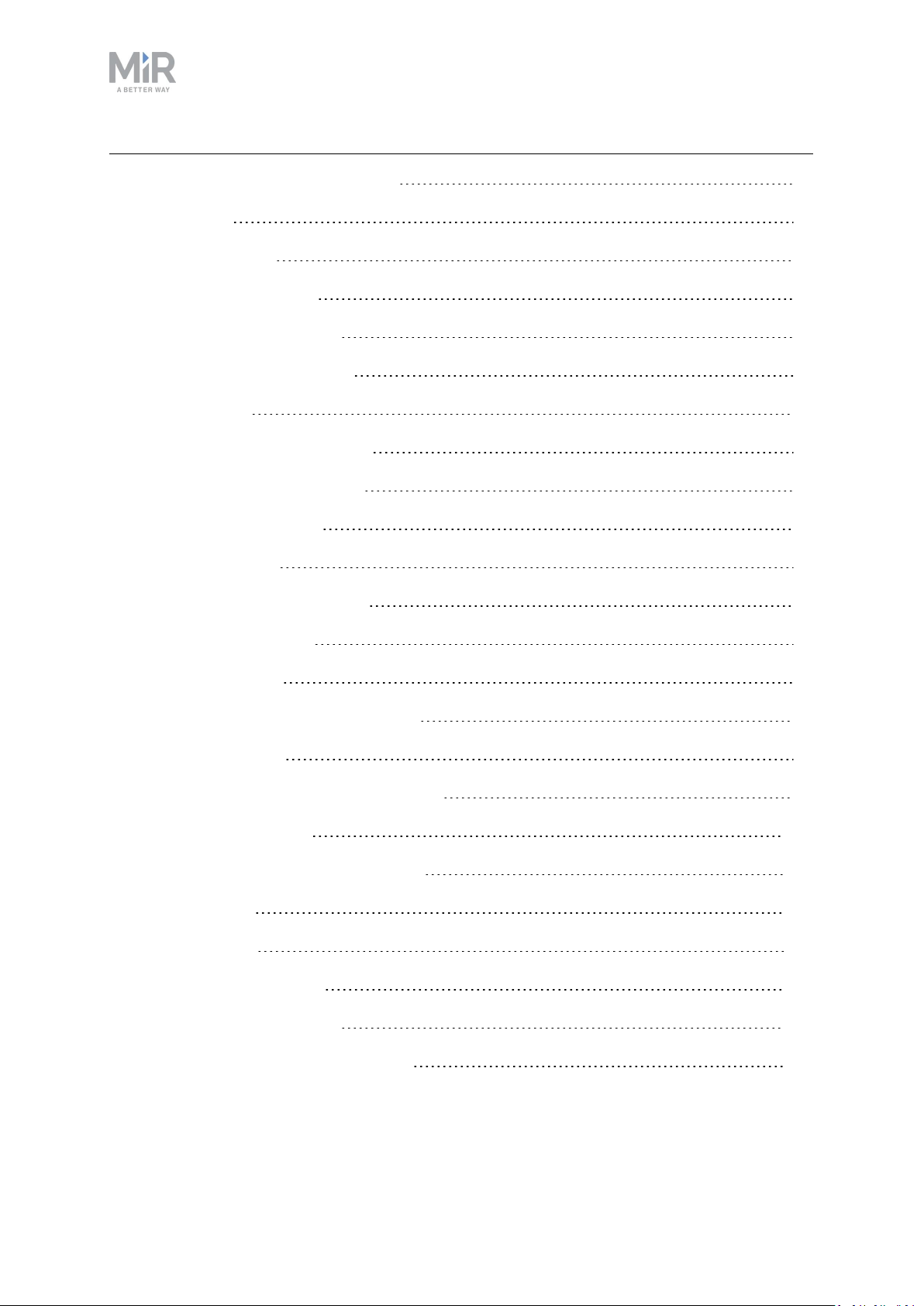

Table of contents

1. About this document 8

1.1 Where to find more information 8

1.2 Version history 9

2. Product presentation 10

2.1 Main features of MiR1000 11

2.2 Top modules 12

2.3 External parts 13

2.4 Internal parts 19

2.5 Manual brake release switch 25

3. Warranty 26

4. Accessing the internal parts 27

4.1 Front compartment 27

4.2 Rear compartment 29

4.3 Side compartments 29

4.4 Top compartments 30

5. Safety 31

5.1 Safety message types 31

5.2 General safety precautions 32

5.3 Intended use 35

5.4 Users 37

5.5 Foreseeable misuse 38

5.6 Residual risks 38

6. Getting started 40

MiR1000User Guide (en) 12/2020 - v.1.4 ©Copyright 2019-2020: Mobile IndustrialRobots A/S. 3

6.1 In the box 40

6.2 Unpacking MiR1000 41

6.3 Connecting the battery 45

6.4 Powering up the robot 46

6.5 Connecting to the robot interface 48

6.6 Driving the robot in Manual mode 50

6.7 Checking the hardware status 52

6.8 Mounting the nameplate 53

6.9 Shutting down the robot 55

7. Battery and charging 56

7.1 Charging the robot 56

7.2 Disconnecting the battery 57

7.3 Battery storage 57

7.4 Battery disposal 58

8. IT security 59

8.1 Managing users and passwords 59

8.2 Software security patches 59

9. Navigation and control system 61

9.1 System overview 61

9.2 User input 63

9.3 Global planner 63

9.4 Local planner 65

9.5 Obstacle detection 66

9.6 Localization 72

MiR1000User Guide (en) 12/2020 - v.1.4 ©Copyright 2019-2020: Mobile IndustrialRobots A/S. 4

9.7 Motor controller and motors 75

9.8 Brakes 75

10. Safety system 77

10.1 System overview 77

10.2 Personnel detection 82

10.3 Overspeed avoidance 87

10.4 Stability 87

10.5 Emergency stop buttons 88

10.6 Emergency stop circuit 89

10.7 Safeguarded stop 90

10.8 Locomotion 91

10.9 Shared emergency stop 92

10.10 Reduced speed 94

10.11 Safety stop 94

10.12 Light indicators and speakers 95

11. Commissioning 99

11.1 Analysis of the work environment 99

11.2 Risk assessment 101

11.3 Creating and configuring maps 102

11.4 Markers 114

11.5 Positions 117

11.6 Creating missions 118

11.7 Creating a footprint 121

11.8 Using operating hazard zones 125

MiR1000User Guide (en) 12/2020 - v.1.4 ©Copyright 2019-2020: Mobile IndustrialRobots A/S. 5

11.9 Making a brake test 127

11.10 Creating user groups and users 128

11.11 Creating dashboards 131

11.12 Updating MiR1000 software 133

11.13 Creating backups 134

11.14 System settings 134

12. Usage 143

12.1 Creating markers 143

12.2 Creating positions 148

12.3 Creating the mission Prompt user 150

12.4 Creating the mission Try/Catch 155

12.5 Creating the mission Variable docking 161

12.6 Testing a mission 169

13. Applications 171

13.1 Mounting a top module 171

14. Maintenance 174

14.1 Regular weekly checks and maintenance tasks 174

14.2 Regular checks and replacements 176

14.3 Battery maintenance 179

15. Packing for transportation 180

15.1 Original packaging 180

15.2 Packing the robot for transportation 181

15.3 Battery 181

16. Payload distribution 182

MiR1000User Guide (en) 12/2020 - v.1.4 ©Copyright 2019-2020: Mobile IndustrialRobots A/S. 6

17. Disposal of robot 189

18. Interface specifications 190

18.1 General purpose interfaces 190

18.2 Safety interfaces 197

18.3 Connector list 201

19. Error handling 203

19.1 Software errors 203

19.2 Hardware errors 204

MiR1000User Guide (en) 12/2020 - v.1.4 ©Copyright 2019-2020: Mobile IndustrialRobots A/S. 7

1. About this document

1. About this document

This user guide explains how to set up and start operating your MiR1000 robot and provides

examples of simple missions you can expand to your purposes. This guide also contains

information regarding the external and internal components of MiR1000 along with

instructions for proper maintenance of the robot. You will also find information regarding

safety and specifications needed to commission a safe MiR1000 robot application.

NOTICE

Save this manual. It contains important safety and operating instructions.

1.1 Where to find more information

At the MiR website, you can find the following resources under the Manuals tab on each

product page:

• Quick starts describe how you start operating MiR robots quickly. It comes in print in the

box with the robots. Quick starts are available in multiple languages.

• User guides provide all the information you need to operate and maintain MiR robots and

how to set up and use top modules and accessories, such as charging stations, hooks, shelf

lifts, and pallet lifts. User guides are available in multiple languages.

• Commissioning guides describe how to commission your robot safely and prepare it to

operate in the workplace.

• Operating guides describe how to set up and use MiR accessories or supported functions

that are mainly hardware-based, such as charging stations and shelf functions.

• Getting started guides describe how to set up MiR accessories that are mainly software-

based, such as MiR Fleet.

• Reference guides contain descriptions of all the elements of the robot interface and MiR

Fleet interface. Reference guides are available in multiple languages.

• Best practice guides specify how much space MiR robots need to execute common

maneuvers.

• REST API references for MiR robots, MiR hooks, and MiR Fleet. HTTP requests can be

used to control robots, hooks, and MiR Fleet.

• MiR network and WiFi guide specifies the performance requirements of your network

and how you must configure it for MiR robots and MiR Fleet to operate successfully.

MiR1000User Guide (en) 12/2020 - v.1.4 ©Copyright 2019-2020: Mobile IndustrialRobots A/S. 8

1. About this document

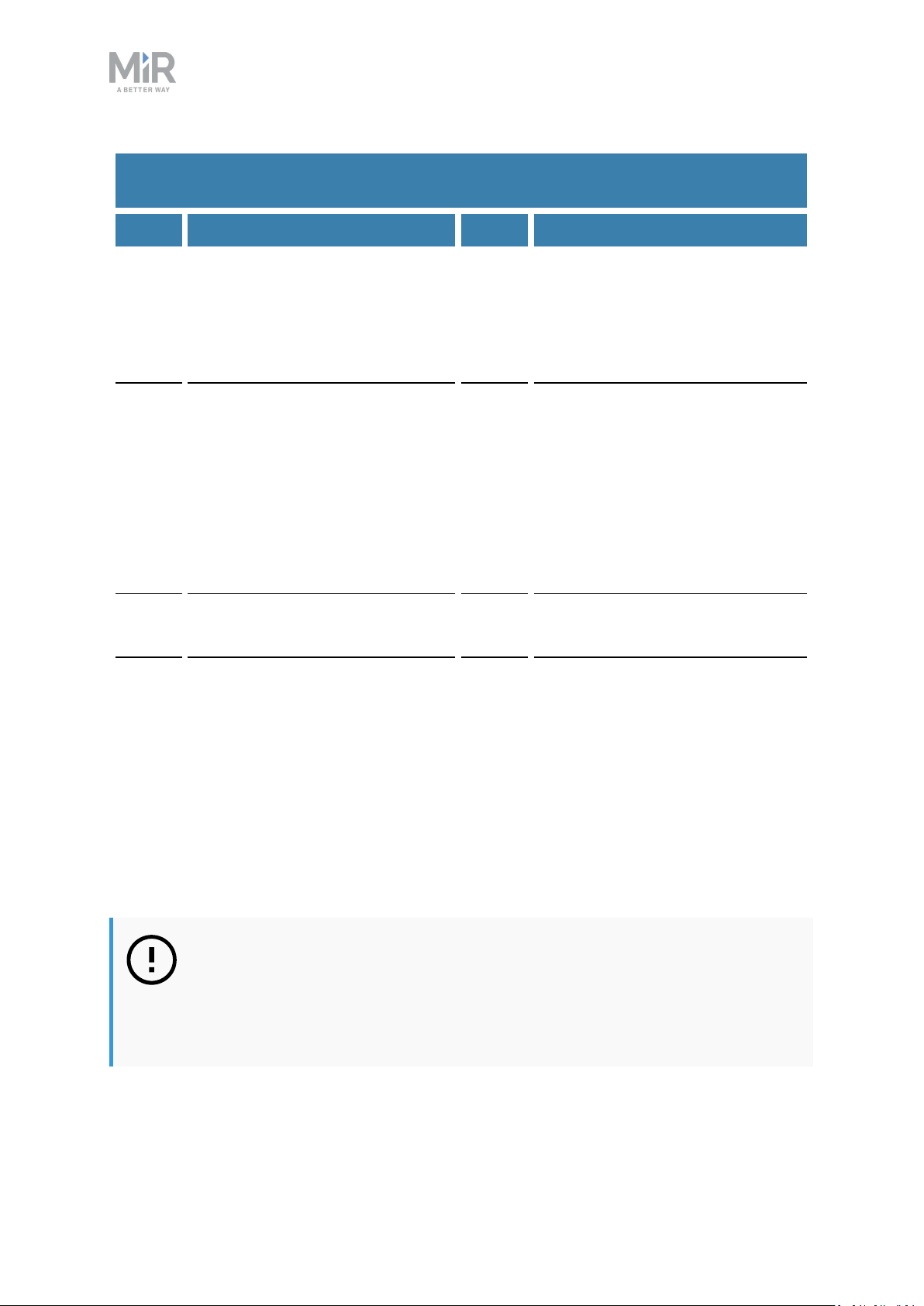

1.2 Version history

This table shows current and previous versions of this document.

MiR1000

Revision Release date Description HW

1.0 2019-05-31 First edition. 1.0

1.1 2019-07-11 New sections: Create mission, Mission editor, Lift

modifications

Updated section: Status lights.

1.2 2019-10-08 New section: Updating MiR1000 software. 1.0

1.3 2020-06-11 New section: IT Security

Added new information about payload

1.4 2020-12-01 New chapters: Warning label, Mounting the

nameplate, Accessing the internal parts, Battery

and charging, IT security, Navigation and control

system, Safety system, Usage, Disposal of robot,

Error handling and Glossary.

General improvements throughout the document.

1.0

1.0

1.0

MiR1000User Guide (en) 12/2020 - v.1.4 ©Copyright 2019-2020: Mobile IndustrialRobots A/S. 9

2. Product presentation

2. Product presentation

MiR1000 is an autonomous mobile robot that can transport loads up to 1000 kg indoors

within production facilities, warehouses, and other industrial locations where access to the

public is restricted.

Users operate MiR1000 via a web-based user interface, which is accessed through a browser

on a PC, smartphone, or tablet. Each robot has its own network—see Connecting to the robot

interface on page 48. The robot can be set up to run a fixed route, be called on demand, or

perform more complex missions.

The robot interface of MiR1000 can be accessed via Google Chrome, Google Chromium,

Apple Safari, Mozilla Firefox, and Microsoft Edge browsers.

The robot uses a map of its work area to navigate and can move to any position on the

map—see Navigation and control system on page 61. The map can be created or imported

the first time the robot is used. While operating, the robot avoids obstacles that are not

mapped, like people and furniture.

Specifications for MiR1000 are available on the MiR website.

MiR1000User Guide (en) 12/2020 - v.1.4 ©Copyright 2019-2020: Mobile IndustrialRobots A/S. 10

2. Product presentation

2.1 Main features of MiR1000

The main features of MiR1000 are:

• Driving in a populated workspace

The robot is designed to operate among people and maneuvers safely and efficiently in

highly dynamic environments.

• Overall route planning and local adjustments

The robot navigates autonomously to find the most efficient paths to its destinations. The

robot adjusts the path when it encounters obstacles that are not on the map, like

personnel and vehicles.

• Efficient transportation of heavy loads

The robot is designed to automate transportation of loads up to 1000 kg.

• Sound and light signals

The robot continuously signals with light and sounds, indicating where it will drive and its

current status, for example, waiting for a mission, driving to a destination, or destination

reached.

• User-friendly and flexible

The web-based user interface, accessed from a PC, tablet, or smartphone, gives easy

access to operation and monitoring of the robot and can be programmed without any

prior experience. Different user group levels and tailored dashboards can be set up to suit

different users.

• Alert for 'lost'

If the robot enters a situation where it is unable to find a path to its destination, it stops,

turns on the yellow-purple running error light, and a custom defined Try/Catch action

may be used to alert personnel or take other actions—see Creating the mission Try/Catch

on page 155.

• Automatic deceleration for objects

The built-in sensors ensure that the robot is slowed down when obstacles are detected in

front of it.

• Internal map

The robot can either use a floor plan from a CAD drawing, or a map can be created by

manually driving the robot around the entire site in which the robot is going to operate.

When the robot is mapping, the robot’s sensors detect walls, doors, furniture, and other

obstacles, and the robot then creates a map based on these input. After you've finished

mapping, you can add positions and other features in the map editor—see Creating and

configuring maps on page 102.

MiR1000User Guide (en) 12/2020 - v.1.4 ©Copyright 2019-2020: Mobile IndustrialRobots A/S. 11

2. Product presentation

2.2 Top modules

The following top modules are available for MiR1000:

• MiR Pallet Lift 1000

A lift platform may be mounted on MiR1000 enabling it to automate the internal

transport of US standard 40x48 pallets.

• MiR EU Pallet Lift 1000

A pallet lift for EU pallets may be mounted on MiR1000 enabling it to automate the

internal transport of EU pallets.

• MiRPalletRack

Use a MiRPalletRack with MiR Pallet Lift 1000. The lift places and picks up US standard

40 x 48 in (1016 x 1219 mm) pallets from the rack autonomously.

• MiREUPalletRack

Use a MiREUPalletRack with MiR EU Pallet Lift 1000. The lift places and picks up EU

pallets from the rack autonomously.

To learn more about the top modules, go to the MiR website.

MiR1000User Guide (en) 12/2020 - v.1.4 ©Copyright 2019-2020: Mobile IndustrialRobots A/S. 12

2.3 External parts

This section presents the parts of MiR1000 that are visible on the outside.

2. Product presentation

Figure 2.1. MiR1000 external parts.

Table 2.1.

Identification of the external parts in Figure 2.1

Pos. Description Pos. Description

1 Left cover plate: access to

Power interface, GPIO

interface, and Ethernet

interface—see Interface

specifications on page 190

3 Signal light: eight pcs., two

on each corner—see Light

indicators and speakers on

page 95

2 Right cover plate: access to

Aux. safety functions

interface and Aux.

Emergency stop interface—

see Interface specifications

on page 190

4 Rear maintenance hatch:

opens to the rear

compartment—see Internal

parts on page 19

MiR1000User Guide (en) 12/2020 - v.1.4 ©Copyright 2019-2020: Mobile IndustrialRobots A/S. 13

Pos. Description Pos. Description

2. Product presentation

5 Rear safety laser scanner—

see Obstacle detection on

page 66

7 Emergency stop button: four

buttons, two on each side—

see Emergency stop circuit

on page 89

9 3D depth cameras: two pcs,

detect objects in front of the

robot— see Obstacle

detection on page 66

11 Front safety laser scanner—

see Obstacle detection on

page 66

6 Right side maintenance

hatch: opens to the right side

compartment—see Internal

parts on page 19

8 Proximity sensors: eight pcs.,

two in each corner behind

the corner covers—see

Obstacle detection on page

66

10 Front maintenance hatch:

opens to the front

compartment— see Internal

parts on page 19

12 Left side maintenance hatch:

opens to the left side

compartment—see Internal

parts on page 19

13 Status light: on all four sides

of the robot— see Light

indicators and speakers on

page 95

Identification label

MiR1000 is delivered with an identification label mounted to the product. The identification

label identifies the product, the product serial number, and the hardware version of the

product.

The identification label of MiR1000 is located on the rear-right side of the chassis.

MiR1000User Guide (en) 12/2020 - v.1.4 ©Copyright 2019-2020: Mobile IndustrialRobots A/S. 14

Figure 2.2. Placement of the identification label.

2. Product presentation

Figure 2.3. Example of a MiR1000 identification label.

MiR1000User Guide (en) 12/2020 - v.1.4 ©Copyright 2019-2020: Mobile IndustrialRobots A/S. 15

2. Product presentation

Nameplate

Every MiR application is delivered with a nameplate that must be mounted to the robot. The

nameplate of MiR1000 identifies the application model and serial number and includes the

CE mark, the technical specifications, and the address of Mobile Industrial Robots. The

nameplate identifies the complete MiR application, for example, a robot with a top module.

It is the responsibility of the commissioner to mount the nameplate on the application—see

Mounting the nameplate on page 53.

Figure 2.4. Example of a MiR1000 nameplate.

Control panel

MiR1000 has a control panel in the rear-left corner of the robot.

MiR1000User Guide (en) 12/2020 - v.1.4 ©Copyright 2019-2020: Mobile IndustrialRobots A/S. 16

The control panel buttons

2. Product presentation

Figure 2.5. The MiR1000 control panel.

Table 2.1.

Identification of items on the control panel in Figure 2.5

Pos. Description Pos. Description

1 Manual stop button 2 Resume button

3 Power button 4 Operating mode key

Manual stop

Pressing this button stops the robot. After pressing this button, you must press the Resume

button to let the robot continue operating.

Color indication:

• Red: It is possible to engage the Manual stop.

Resume

Pressing this button:

• Clears the Emergency stop state.

• Lets the robot continue operating after the Manual stop button was pressed or after the

MiR1000User Guide (en) 12/2020 - v.1.4 ©Copyright 2019-2020: Mobile IndustrialRobots A/S. 17

2. Product presentation

operating mode changes.

• Lets the robot start operating after powering up.

Color indication:

• Blinking blue: The robot is waiting for a user action (clear the Emergency stop state,

acknowledge the change of operating mode).

Power

Pressing this button for three seconds turns the robot on or shuts it off.

Color indication:

• Blue: The robot is off.

• Blinking green: The robot is starting up.

• Green: Normal operation.

• Blinking red: The battery level is too low to start without additional charging, or the robot

is shutting down.

The Operating mode key

The Operating mode key lets you switch between operating modes.

• Left position: Autonomous mode

Puts the robot in Autonomous mode.

• Middle position: Locked

Locks the robot. The robot blocks the wheels; you cannot start a mission or drive the robot

manually.

• Right position: Manual mode

Puts the robot in Manual mode.

For more information on operating modes, see Operating modes below.

Operating modes

MiR1000 has two operating modes: Manual mode and Autonomous mode.

MiR1000User Guide (en) 12/2020 - v.1.4 ©Copyright 2019-2020: Mobile IndustrialRobots A/S. 18

2. Product presentation

Manual mode

In this mode, you can drive the robot manually using the joystick in the robot interface. Only

one person can control the robot manually at a time. To ensure that nobody else takes

control of the robot, the robot issues a token to the device on which you activate the Manual

mode.

For information about activating this mode, see Driving the robot in Manual mode on page

50.

Autonomous mode

In this mode, the robot executes the programmed missions. After switching the key to this

mode, you can remove the key, and the robot will continue driving autonomously. In

Autonomous mode, the joystick is disabled in the robot interface.

2.4 Internal parts

Most internal parts of MiR1000 are accessed through maintenance hatches that open to

different compartments:

• Front compartment

• Rear compartment

• Side compartments

• Top compartments

To access the compartments correctly, see Accessing the internal parts on page 27.

Front compartment

The front compartment holds several electronic components, such as the robot computer

and the motor controller carrier board.

To open the front compartment, see Accessing the internal parts on page 27.

Front compartment components

The front compartment components are listed in Table 2.1.

MiR1000User Guide (en) 12/2020 - v.1.4 ©Copyright 2019-2020: Mobile IndustrialRobots A/S. 19

2. Product presentation

Figure 2.6. Internal parts of the front compartment.

Table 2.1.

Identification of internal parts in Figure 2.6

Pos. Description Pos. Description

1 Cable chain: contains a group of

cables that connect with robot

components outside of the front

compartment.

3 Access point/Router: access point

that broadcasts the robot's WiFi

signal so you can connect to the

2 Safe Torque Off contactors: cuts

power to the robot's motor when

the robot enters Protective or

Emergency stop.

4 Robot computer: processes data

from the sensors and controls

the robot's navigation.

robot wirelessly.

5 Loudspeaker:emits sounds

programmed in missions.

6 Power board: controls the power

distribution for the motor

controller, robot computer, and

safety PLC.

MiR1000User Guide (en) 12/2020 - v.1.4 ©Copyright 2019-2020: Mobile IndustrialRobots A/S. 20

2. Product presentation

Pos. Description Pos. Description

7 Motor controller carrier board:

contains the motor controllers

and the controller for proximity

sensors and light indicators.

8 Safety PLC:controls the safety

system—see Safety system on

page 77.

Rear compartment

The rear compartment holds the robot’s battery, Battery disconnect switch, and charging

interface.

To open the rear compartment, see Accessing the internal parts on page 27.

Rear compartment components

The rear compartment components are listed in Table 2.2.

Figure 2.7. Internal parts of the rear compartment.

MiR1000User Guide (en) 12/2020 - v.1.4 ©Copyright 2019-2020: Mobile IndustrialRobots A/S. 21

2. Product presentation

Table 2.2.

Identification of internal parts in Figure 2.7

Pos. Description Pos. Description

1 Connectors for the proximity

sensors.

3 Connector for the status light

band.

5 Charging connection interface:

for external MiR cable charger.

7 Connection interface for MiR

Controller: connect a MiR

controller to drive the robot with

a joystick.

2 Battery disconnect switch:

disconnects the battery from the

robot. Shown in the Off position

where the battery is

disconnected.

4 Manual brake release switch:

releases the brakes so the robot

can be pushed manually. Shown

in the Off position, where the

robot engages and releases the

brakes automatically—see

Manual brake release switch on

page 25.

6 Battery with connector: main

power to the robot.

Side compartments

The side compartments contain the bogies and drive wheels.

To access a side compartment, see Accessing the internal parts on page 27.

NOTICE

The unique nameplate of your robot is to be mounted on the right side

compartment hatch—see Mounting the nameplate on page 53. Make sure you

do not swap the hatch with hatches from other robots.

MiR1000User Guide (en) 12/2020 - v.1.4 ©Copyright 2019-2020: Mobile IndustrialRobots A/S. 22

Side compartment components

The left and right side compartment components are listed in Table 2.3.

2. Product presentation

Figure 2.8. Internal parts of the MiR1000 left and right side compartments.

Table 2.3.

Identification of internal parts in Figure 2.8

Pos. Description Pos. Description

1 Connector for status light band 2 Drive wheel

Top compartments

The two top compartments contain electrical interfaces that can be connected to top

modules.

MiR1000User Guide (en) 12/2020 - v.1.4 ©Copyright 2019-2020: Mobile IndustrialRobots A/S. 23

2. Product presentation

Figure 2.9. The top compartments on the robot.

Top compartment components

The top compartments interfaces are listed in Table 2.4. For detailed information on

electrical interfaces, see Interface specifications on page 190.

Figure 2.10. Interfaces in the top compartments.

MiR1000User Guide (en) 12/2020 - v.1.4 ©Copyright 2019-2020: Mobile IndustrialRobots A/S. 24

2. Product presentation

Table 2.4.

Identification of interfaces in Figure 2.10

Pos. Description Pos. Description

1 Ethernet 2 GPIO: General purpose I/O

3 Power 4 Auxiliary Emergency stop

5 Auxiliary safety functions

2.5 Manual brake release switch

The Manual brake release switch is located in the rear maintenance hatch below the Battery

disconnect switch. You release the robot's mechanical brakes by turning the Manual brake

release switch counter-clockwise.

Figure 2.11. The manual brake release switch is located below the control panel.

The mechanical brakes require electrical power to be released, so if the robot is without

power, the mechanical brakes cannot be released.

When driving in Autonomous mode, the robot engages and releases the mechanical brakes

automatically.

The robot cannot operate while the mechanical brakes are released manually.

MiR1000User Guide (en) 12/2020 - v.1.4 ©Copyright 2019-2020: Mobile IndustrialRobots A/S. 25

3. Warranty

Mobile Industrial Robots offers a standard warranty on all products.

Contact your distributor to see the terms and extend of product coverage.

NOTICE

Mobile Industrial Robots disclaims any and all liability if MiR1000 or its

accessories are damaged, changed, or modified in any way. Mobile Industrial

Robots cannot be held responsible for any damages caused to MiR1000,

accessories, or any other equipment due to programming errors or

malfunctioning of MiR1000.

3. Warranty

MiR1000User Guide (en) 12/2020 - v.1.4 ©Copyright 2019-2020: Mobile IndustrialRobots A/S. 26

4. Accessing the internal parts

4. Accessing the internal parts

Most internal parts of MiR1000 are accessed through maintenance hatches that open to

different compartments:

• Front compartment

• Rear compartment

• Side compartments

• Top compartments

4.1 Front compartment

To open the front compartment, follow these steps:

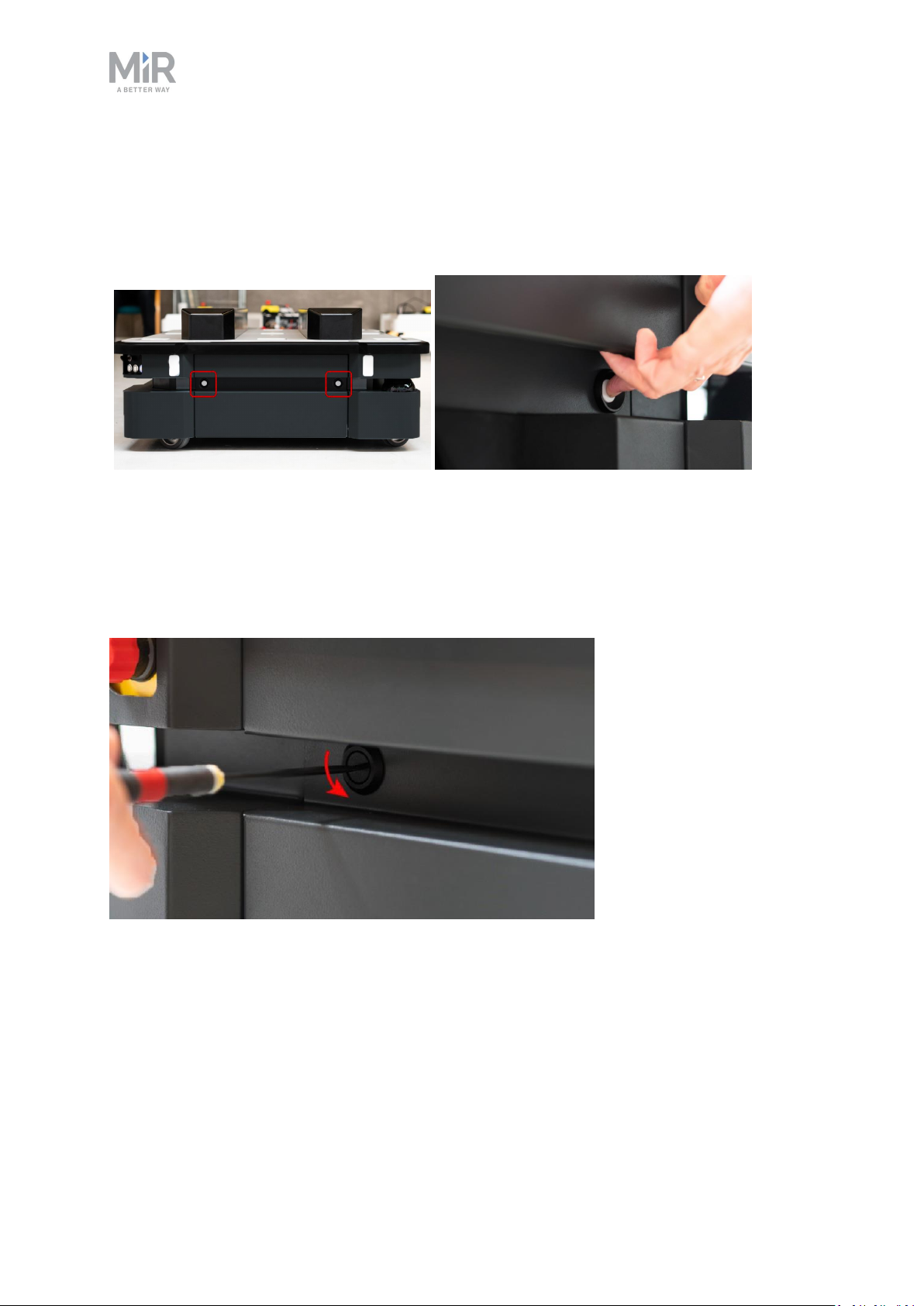

1. Push the two white buttons and pull the hatch.

MiR1000User Guide (en) 12/2020 - v.1.4 ©Copyright 2019-2020: Mobile IndustrialRobots A/S. 27

2. Turn the two levers 180°.

4. Accessing the internal parts

3. Pull out the compartment drawer while holding underneath it and lifting slightly.

MiR1000User Guide (en) 12/2020 - v.1.4 ©Copyright 2019-2020: Mobile IndustrialRobots A/S. 28

4. Accessing the internal parts

4.2 Rear compartment

To open the rear compartment, push the two white buttons at the same time and pull the

hatch.

4.3 Side compartments

To open a side hatch, turn the two screws 90° with a flat-head screwdriver, and pull open the

hatch.

MiR1000User Guide (en) 12/2020 - v.1.4 ©Copyright 2019-2020: Mobile IndustrialRobots A/S. 29

4. Accessing the internal parts

4.4 Top compartments

To open a top compartment, remove the four screws and lift off the top cover.

MiR1000User Guide (en) 12/2020 - v.1.4 ©Copyright 2019-2020: Mobile IndustrialRobots A/S. 30

Loading...

Loading...