MMM Group ECOCELL 404, ECOCELL 55, ECOCELL 707, DUROCELL 55, DUROCELL 22 Instructions For Use Manual

...

Instructions for use

Laboratory drying ovens and incubators

line Comfort

LSI_K_np_en 1206_mmm_V2.08_B2V

ECOCELL 22, 55, 111, 222, 404, 707

DUROCELL 22, 55, 111, 222

VENTICELL 22, 55, 111, 222, 222/2, 404,

404/2, 707, 707/2

INCUCELL 22, 55, 111, 222, 404, 707

INCUCELL V 22, 55, 111, 222, 404, 707

Congratulations on obtaining a new temperature cabinet, designed for uniform tempering of various

materials by hot air at a selectable temperature and a selectable time mode in laboratories. There is an

air ap installed that enables wet material drying. The temperature course is controlled by an advanced

microprocessor (Fuzzy logic) with a digital display and a temperature sensor PT 100. This system

ensures high accuracy of temperature regulation and tempering process reliability.

The units meet technical and legislative requirements and they are designed according to respective

EN standards. The units are made of high quality materials by using the latest technology. Each piece

undergoes a careful output control.

Provided you will follow the instructions mentioned here the unit becomes your reliable and powerful

partner.

Now these advantages will be available just for you. This unit will help to solve your everyday

problems and it will become powerful assistant for you. This unit is very easy to use, nevertheless, we

recommend you to read the Instructions for use carefully so that you could use all advantages of this

unit and obtain complete knowledge for its optimal use.

CONTENTS:

26. 6. 2012

1 GENERAL................................................................................................................................3

1.1 PurPose and use...............................................................................................................................3

2 IMPORTANT INSTRUCTIONS...........................................................................................................3

2.1 unPacking, checking

and transPort...................................................................................................3

2.2 Pre installation................................................................................................................................3

2.3 useful sPace....................................................................................................................................4

3 DESCRIPTION OF THE OVEN..........................................................................................................5

3.1 general view....................................................................................................................................5

3.2

Power connetion and connectors

......................................................................................................6

3.3 control Panel..................................................................................................................................6

4 FUNCTION AND OPERATING..........................................................................................................7

4.1 Basic setting of the units................................................................................................................7

4.1.1 activating the service mode.....................................................................................................7

4.1.2 service 01 - storing P

1 - P6....................................................................................................7

4.1.3 service 02 - restore/uload the Programs from the chiP card.................................................7

4.1.4 service 03 - set the real time and date...................................................................................8

4.1.5 service 04 - set interval on Printer/communication interface.................................................8

4.1.6 service 05 - select language..................................................................................................8

4.1.7 service

06 -

setting the switching times of inner socket (oPtional)

and the fan run after the Programme termination...............................................................8

4.1.8 service 07 - safety thermostat setting.....................................................................................9

4.1.9 service

41 -

temPerature tolerance.........................................................................................9

4.1.10

service

58 -

door Blocking.

..................................................................................................10

4.1.11 service 62 - sounds setting...................................................................................................10

4.1.12

service

64 -

Programme P6 shifting

.........................................................................................10

4.1.13 service 09 - cancel the service mode.....................................................................................10

4.2 P

rogram P

1....................................................................................................................................10

4.2.1 set P

1...................................................................................................................................10

4.2.2 lcd - read out shown.............................................................................................................11

4.2.3 s

tart P

1................................................................................................................................11

4.2.4 information on the set Parameters during running...............................................................11

4.2.5 stoP P

1.................................................................................................................................11

4.3 Program P

2....................................................................................................................................11

4.3.1 set P

2...................................................................................................................................11

4.3.2 lcd - read out shown.............................................................................................................11

4.3.3 start P

2................................................................................................................................11

4.3.4 information on the set Parameters during oPeration of the unit............................................12

4.3.5 stoP P

2.................................................................................................................................12

4.4 Program P

3....................................................................................................................................12

4.4.1 set P

3...................................................................................................................................12

4.4.2 lcd - read out shown.............................................................................................................12

4.4.3 s

tart P

3................................................................................................................................12

4.4.3.1 P3 and segment 1 in the graPh are active......................................................................12

4.4.3.2 P3 and segment

2

in the are active, the segment

1

is over.............................................12

4.4.3.3 P3 and third segment in the graPh are active............................................................13

4.4.4 information on the set Parameters during oPeration of the unit............................................13

4.4.5 s

toP P

3................................................................................................................................13

4.5 Program P

4...................................................................................................................................13

4.5.1 set P

4..................................................................................................................................13

4.5.2 set the segment for t

1........................................................................................................13

4.5.2.1 set temPerature t

1 ...................................................................................................13

4.5.2.2 set the dwell time of t

1..............................................................................................14

4.5.2.3 read out of t1 and the dwell time...............................................................................14

4.5.2.4 set the ramP at t

1.......................................................................................................14

4.5.2.5 read out of t1 and the ramP...................................................................................14

4.5.2.6 set the fan sPeed at the temPerature t

1......................................................................14

4.5.3 set the segment for t

2.........................................................................................................14

4.5.3.1 set the temPerature t

2...................................................................................................14

4.5.3.2 set the dwell time of t

2..............................................................................................14

4.5.3.3 read out of t2 and the dwell time...............................................................................14

4.5.3.4 set the ramP at t

2.............................................................................................................14

4.5.3.5 read out of t2 and the ramP........................................................................................14

4.5.3.6 set cykles for P

4.............................................................................................................15

4.5.3.7 read out of cycles for P

4.......................................................................................15

4.5.3.8 set the fan sPeed at t

2....................................................................................................15

4.5.4 start P

4...............................................................................................................................15

4.5.4.1 s1 is active, temPerature is heading towards t

1.........................................................15

4.5.4.2 s2 is active, t

1

has Been reached, dwell time is running.............................................15

4.5.4.3 s3 is active, temPerature is heading towards t

2.........................................................15

4.5.4.4 s4 is active, t

2

is reached, dwell time at t

2

is running................................................16

4.5.5 information on set Parameters during oPeration of the unit...............................................16

4.5.6 stoP P

4.................................................................................................................................16

4.6 Program P

5.................................................................................................................................16

4.6.1 descriPtion of P

5

and its control.......................................................................................16

4.7 Program P

6.................................................................................................................................17

4.7.1 descriPtion of P

6................................................................................................................17

4.7.2 Programme setting...............................................................................................................18

4.7.3 Programme start.................................................................................................................19

4.7.4 Power suPPly failure...........................................................................................................19

4.7.5 automatic shifting of P6 Programme during cycling..........................................................19

4.7.6 manual shifting of P6 Programme Beginning - user service

64...............................................20

4.7.7 examPles of P6 Programme setting....................................................................................20

4.7.8 summer/winter time..............................................................................................................21

4.8

measured variaBles disPlay during the Programme run.............................................................21

4.9

keyBoard Blocking.......................................................................................................................21

4.10 error messages..........................................................................................................................21

4.11 Printing the Protocol.................................................................................................................22

4.12 adjusting and function of the air flaP........................................................................................22

4.13 exchanging the door adjusting the door....................................................................................23

5 PARAMETERS OF THE UNIT..........................................................................................................24

5.1 electric connections..................................................................................................................25

6 CLEANING AND DECONTAMINATION OF THE UNIT.................................................................25

7 MAINTENANCE......................................................................................................................26

8 WARRANTY AND SERVICE...........................................................................................................26

9 TRANSPORT AND STORAGE........................................................................................................26

10 THE WAY OF LIQUIDATION OF PACKAGE AND DISCARDED UNIT...................................27

11 OPTIONAL EQUIPMENT..................................................................................................................27

11.1 door with window and inner lighting (for all the tyPes of the volume of

22)...............................27

11.2 Bushings of diameter

25, 50, 100

mm..............................................................................................27

11.3 lockaBle door............................................................................................................................27

11.4 left door...................................................................................................................................28

11.5 indePendent sensor Pt

100 ...........................................................................................................28

11.6 suPPortive sw for Pc...............................................................................................................28

11.6.1 recording sw - warmcomm - for Pc under windows........................................................28

11.6.2 recording Printing sw - Printer archiv - for Pc under windows...........................................28

11.7 h

ePa filter................................................................................................................................28

11.7.1

Placing the hePa filter, filter dimensions, function and filtration

characteristic of the air filter

...........................................................................................28

11.8 Potential - free contact for alarm rePorts...............................................................................29

11.9 inner switched socket...............................................................................................................29

11.10

devices with the door Blocking function

..................................................................................30

11.10.1 one-door model.................................................................................................................30

11.10.2 two-door venticell.................... ........................................................................................30

11.11 Protection of Programme setting By means of a chiP card.........................................................30

11.12 door oPening signalling.............................................................................................................30

11.13 two-door Pass-through model..................................................................................................30

11.13.1 venticell

222/2

- installation data........................................................................................30

11.13.2 venticell

404/2

- installation data........................................................................................31

11.13.3 venticell

707/2

- installation data........................................................................................32

11.14 adjustment to Prevent cultivating media and tissue cultures drying.........................................33

11.15 ic and icv with decontaminating function..................................................................................33

11.16 venticell with sterilization function........................................................................................33

11.16.1 Basic sterilization Programme ss.....................................................................................33

11.16.1.1 ss Programme setting

.................................................................................................33

11.16.1.2 lcd - read out shown............................................................................................33

11.16.1.3 ss Programme start.............................................................................................33

11.16.1.4 information on the set Parameters during oPeration of the unit.......................34

11.16.1.5 stoP ss..................................................................................................................34

11.16.1.6 sterilization Programme setting and course.........................................................34

11.16.2 sterilization Programme sP with Preheating Phase..........................................................35

11.16.2.1 sP Programme setting

.................................................................................................35

11.16.2.2 segment setting for t

1..........................................................................................35

11.16.2.3 segment setting for t

2..........................................................................................35

11.16.2.4 sP Programme start..............................................................................................35

11.16.2.5 information on the set Parameters during oPeration of the unit.........................36

11.16.2.6 stoP sP..................................................................................................................36

11.16.3 two-door Pass-through model with automatic door Blocking........................................36

12 EMERGENCY DOOR OPENING.....................................................................................................37

APPENDICES:

EC - DECLARATION OF CONFORMITY

1 general

The ovens with electric heating are designed for

laboratories, generally for a warming of various

materials by means of hot air at adjustable

temperature and optional time. The air ap

enables drying of wet material.

A modern microprocessor (Fuzzy - logic) with

a digital display and PT 100 controls the

temperature. Thus exact temperature accuracy

and process safety are guaranteed. The ovens

are designed according to EN standards. They

are manufactured of high grade materials with

the latest technology. Each oven is subjected to a

strict nal test leaving the plant.

1.1 PURPOSE AND USE

ECOCELL (EC) serves for warming by hot air

with natural circulation. The ovens are designed

for temperatures up to 250 °C. They work quietly

with lower power consumption compared with VC

units.

DUROCELL (DC)

serves for warming by hot air

with natural circulation (usefull at procedures

as acid hydrolysis, extraction by nonammable

solvents, thermolysis). The ovens are designed

for temperatures up to 125 °C. Inner surfaces

of the chamber are covered with an EPOLON

layer which protects the chamber from corrosion

caused by liquid or gaseous acids in case they

leak accidentally from closed vessels. For other

important information see the chapter Before

Putting into Operation.

VENTICELL (VC) serves for warming of

materials by means of hot air with forced-air

circulation by a fan. The ovens are designed for

temperatures up to 250 °C, another variant (+)

up to 300 °C.

INCUCELL (IC, ICV) serves as an incubator or

for cell cultivation in a microbiological laboratory

(see chapter 11 - Optional equipment, article

Adaptation against drying-up of cultivating

mediums and tissue cultures). The ovens are

designed for temperatures up to 70 °C. A quiet

operation is characteristic for the variant IC

(without a ventilator), more accurate temperature

regulation with small deviations is characteristic

for the variant ICV (with ventilator).

2

important

instructions

2.1

UNPACKING, CHECKING AND

TRANSPORT

Please check after unpacking the oven and its

accessories are complete and not damaged.

A possible damage is to be reported to the

forwarding agent. During the manipulation – in

case of lifting the cabinet etc. – the cabinet

cannot be hold by the rail or door. The cabinets

of volumes 404 and 707 should be lifted by

means of delivered hooks, the rolls are designed

for local moving, not for longer transport.

A standard delivery includes the heating cabinet,

2 sieves, 3 chip cards for programme saving, and

1 special operations (SO) card.

2.2

PRE - INSTALLATION

• Please read carefully the Instructions for

use before working with the oven!

• Ovens are designed to be operated indoor

within ambient temperatures from 5 °C to

40 °C and at maximum relative humidity 80 %.

• Install the unit by plugging the power

cord to the mains. However, make sure

at rst that the mains and the electric

connection parameters correspond to the

values specied on the unit type label

and to the data shown in chapter 5 - Unit

Parameters.

• In case of temperatures above 100 °C a

yellowed stain of the inner chamber walls

can occur. This stain is neither the material

nor the unit’s defect.

• After the rst switching-on of the unit the

heating bodies and insulation start to be

baked with a typical a smell; after a few

operation cycles this smell disappears,

nevertheless it is suitable, during the

insulation baking at a temperature above

100 °C, to secure a sufcient air exchange

(e.g. by ventilation or exhaustion).

The air exhaust in VC and EC types is

protected by a cover rear of the unit. This

cover is placed inside the oven while

shipping. When installing the unit, insert the

cover into the horizontal openings bellow

and above the exhaust to attach it behind

the exhaust.

Instructions for use

LSI_K_np_en 1206_mmm_V2.08_B2V 3

DC-type – regarding the fact that it is the

inner chamber only which is resistant to

corrosive effects, the following must be

ensured during the application:

a) Processes specied in the previous

chapter must be performed in the chamber

in closed vessels (corrosive substances

release into the chamber must be

prevented);

b) Exhalations from the exhaust outlet must

be exhausted actively to prevent vapour

condensation on the outlet and its dripping

down to the electric part of the device;

c) The whole device must be placed in a

no-corrosive atmosphere (damage of the

source and regulation electronics must be

prevented).

The oven should be installed with a 100

mm distance to the walls at the side and

in back. The temperature of the air coming

out of the exhaust may be up to 250 °C

(resp. 300 °C), so the walls near the oven

must be inammable

. No inammable

or explodable materials may be put into

ovens !

Carrying capacity of the oor during

installation of the device must correspond

to the weight of the unit itself taking

the weight of the maximum charge into

consideration (see chapter 5 - Parameters

of the unit).

The unit must not be placed on a pad that

could cause a danger of re or smothering

in case of falling some hot object out of the

cabinet.

No inammable, explosive or toxic materials

may be put into ovens! The same applies to

materials that could give off such a stuff!

Goods are only to be put on trays into ovens,

never directly on the bottom of the oven!

No dangerous goods are permitted. Ovens

may not be used for heating of liquids.

Aparatus may not be used in the

atmosphere with a possible danger of

ammable or explosive anesthetics.

Any assembly and disassembly of the

unit parts may only be done after the

unit disconnection from the mains

(unplugging the power cord or switching

the main switch off – see chapter 5)! If

the unit is switched off (button 6, Fig. 4),

the unit will be ready-to-start only but it

is not disconnected from the mains!

• If the oven is not used for a longer time,

disconnect it from mains by pulling the

service cord from the socket.

Power cord can not get to the contact with

hot parts of the aparatus – protection cover

of exhaust hole.

• The temperature cabinet, its surroundings

and the treated material are protected

against an inadmissible temperature

overrun by means of a safety thermostat.

Pull out and consequently push in the

upper metal plate piece of internal chamber

carefully, there is a danger of cutting

through the rubber gasket of the chamber

during careless manipulation.

The maximum permitted loads: see section

5 - Parameters of the unit.

When operating the cabinets at high

chamber temperature there can be the

maximum allowed temperature of 70 °C at

their outer surface (exhaust ports and their

surroundings and the surroundings of the

chamber sealing, window and door surface

in case of the optional type with window in

door) surpassed and there is a danger of

burns. Please take a high precaution.

During the operation of the devices of 404

and 707 at high temperatures a

deformation of the inner door surface

occurs as a consequence of thermal

tension, which makes their closing more

difcult. If you open the door in this state,

do not close them until the chamber is

cooled down. Otherwise the door

mechanism could be damaged.

Regularly – in daily intervals – check by

listening if after the start the fan of the case

is running.

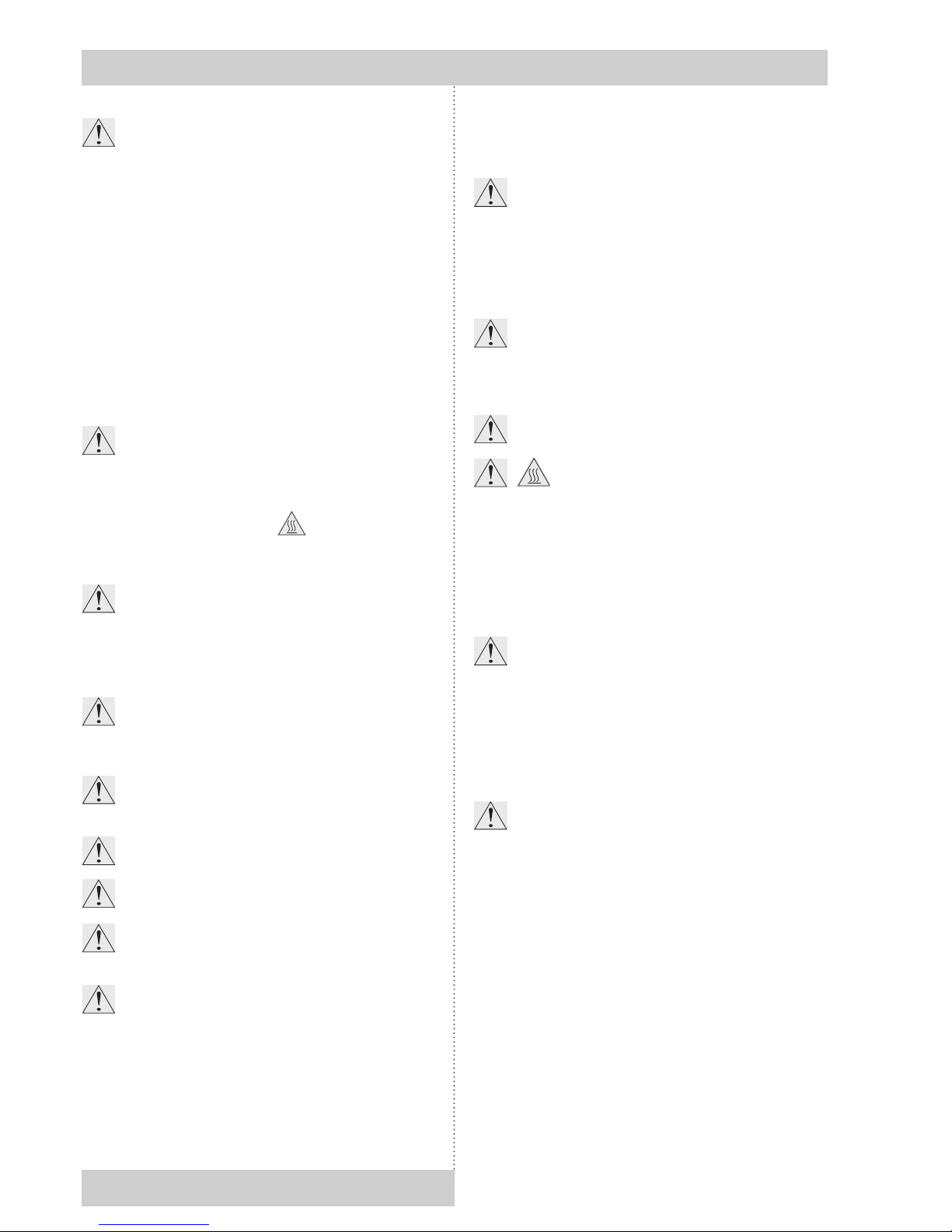

2.3 USEFUL SPACE

Useful space is illustrated on g. No. 1, where

X(H) = 10 % of the inner chamber depth, X(Š)

= 10 % of the inner chamber width, X(V)

1

is the

distance from the lowest tray to the bottom of

the inner chamber, X(V)

2

is the distance from

the upper most tray to the ceiling of the inner

chamber. The required temperature accuracy see section Parameters of the unit - is achieved

only in the space dened above (according

to DIN 12 880 - marked with thick lines, thin

lines mark inner chamber walls). It means, that

over the last upper tray there are the limits

from section 5 - Parameters of the unit not

obligatory.

Instructions for use

4 LSI_K_np_en 1206_mmm_V2.08_B2V

Fig. 1

3 description of the

oven

3.1

GENERAL VIEW

Fig. 2

1 - controller panel

2 - control keys

3 - plastic cover of the controller panel

4 - control ring and safety thermostat key

5 - lever for air ap positioning

6 - case of PT 100 sensor

7 - fan (only for VC, ICV)

8 - exhaust with air ap (with all types)

9 - heating elements

10 - power board I

11 - power board II (only three-phase type)

12 - mains cord

14 - door sensor (see chapter Optional

Accessories)

15 - suction hole (only for VC, ICV, with air ap)

16 - suction hole (with types EC, DC, IC).

ECOCELL 22

Instructions for use

LSI_K_np_en 1206_mmm_V2.08_B2V 5

X (H)

X (V)

2

X (V)

1

X (Š)

VENTICELL 22

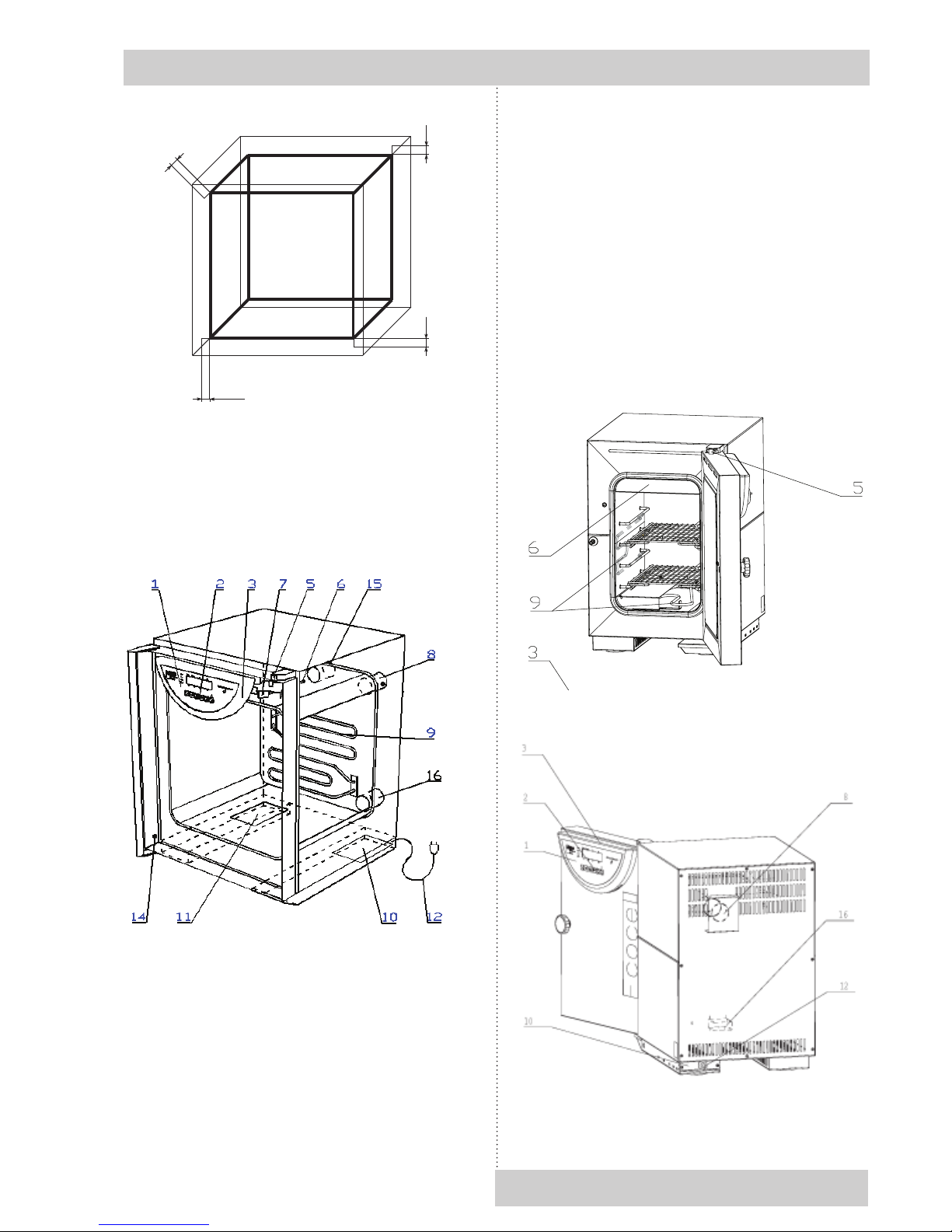

1 Connector RS-232C (Canon) for printer

2 Supply lead

3 Screws attaching the power part

4 The power part panel (placed in foot)

9 pin Canon connector on the case

Pin Signal

2 RXD

3 TXD

5 GND

6 DSR

1

2

3

4 5

6

7

8 9

Fig. 6: 9 pin Canon - Interface for protocol printer

25 pin Canon connector on the printer

Pin Signal

2 TXD

3 RXD

7 GND

20 DTR

The appliances, which are connected with the

connector RS-232C, must comply with valid

regulations in terms of electric safety and

electromagnetic compatibility.

Interface parameters: Baud: 9600

Stopbit: 1

Parity: none

Databit: 8

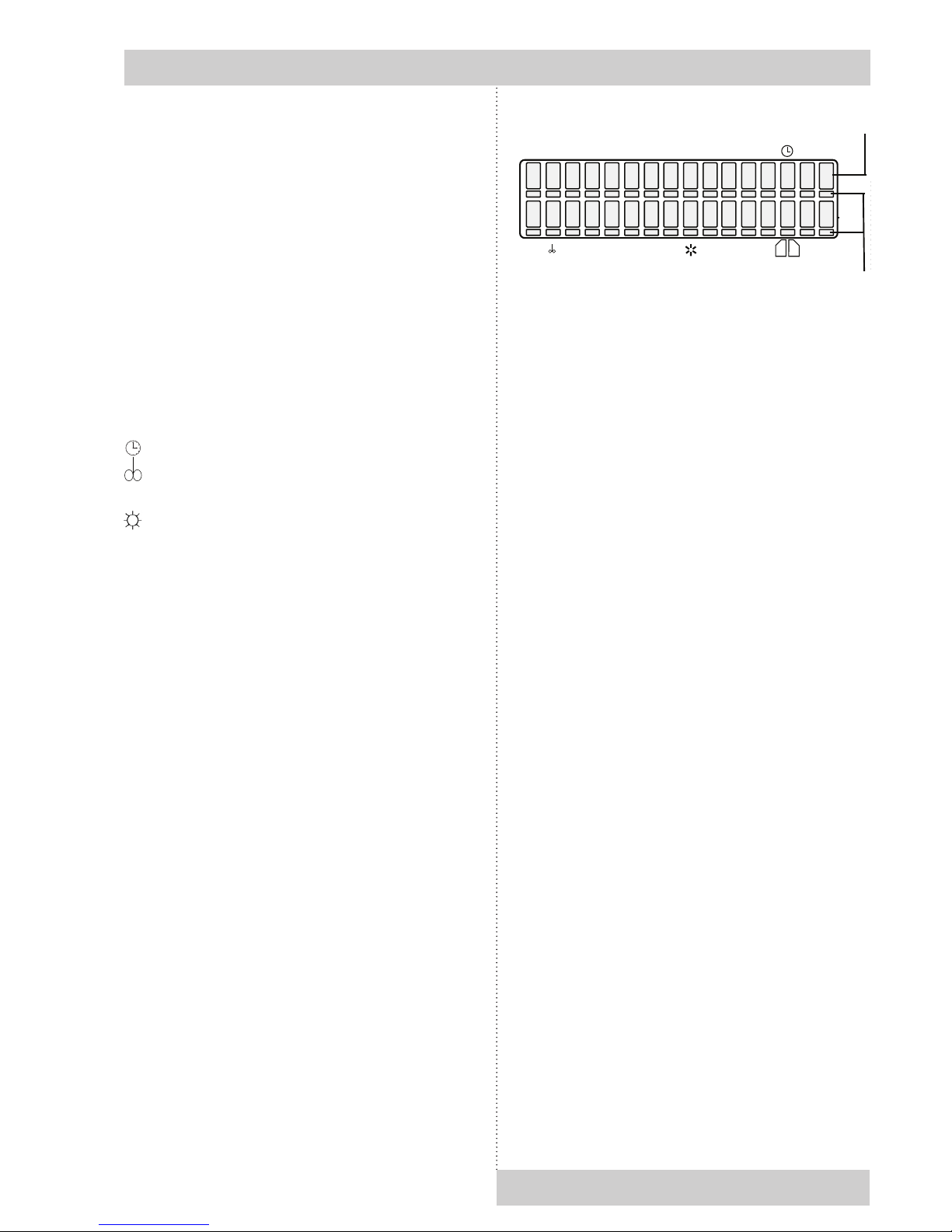

3.3

CONTROL PANEL

Fig. 5

1. key of activation of setting-up mode

2/4. cursor steering turning to the left/right

3. setting-up value in parameter

5. key starting the program

6. switch (ON - on, OFF - stand by)

Instructions for use

6 LSI_K_np_en 1206_mmm_V2.08_B2V

VENTICELL 22

3.2

POWER CONNETION AND CONNECTORS

1 2

3

4

Fig. 5 Foot of the unit with power supply - rear view

(with the power part I)

ON

OFF

X

W

START

STOP

RH

5 6

Program Segment

°C

*

1 2

3 4

5 6

7

8

9

10

11

12

13

Instructions for use

LSI_K_np_en 1206_mmm_V2.08_B2V 7

Positions

Návod k použití

Pozice na displeji:

Program: zobrazení programu

Segment: Dílčí nebo úplné gracké zobrazení

průběhu programu

°C: Zobrazení teploty

: Čas procesu

: Ukazatel rychlosti ventilátoru v %

(kroky po 10 %)

RH: relativní vlhkost v %

☼ Nastavení intenzity expozičního světla

ve dveřích

56 Pozice jsou použity pro specické účely

– viz popisy v textu.

4 FUNKCE A OBSLUHA

Funkce jednotlivých kontrolek a ovládacích

tlačítek je popsána v kapitole 3 - Popis přístroje,

a 3.4 - Ovládací panel.

Připojení k elektrorozvodné síti:

Hodnoty jmenovitého napětí a příkonu přístroje,

které jsou uvedeny na výrobním štítku,

porovnejte s přívodem napětí. Pokud parametry

přívodu odpovídají parametrům přístroje, zapojte

vidlici přístroje do zásuvky přívodu.

Zapnutí přístroje:

Stiskněte tlačítko

O

N

O

F

F

, (nad kterým se rozsvítí

kontrolka), displej se rozsvítí, tímto je přístroj

připraven k provozu, pokračujte podle bodů

uvedených níže.

Displej zobrazuje všechny parametry najednou.

Kurzor se pohybuje pod všemi 32 místy displej

v tzv. kurzorové lince a je vždy umístěn pouze

pod jedním z 32 znaků.

4.1 ZÁKLADNÍ NASTAVENÍ PŘÍSTROJŮ

Přístroje teplotní techniky s regulátorem Komfort

– nabízí zákazníkovi širokou škálu využití.

Základem pro správné spuštění systému je jeho

optimální počáteční nastavení. K tomu slouží

následující servisní režim obsahující 10 různých

služeb.

4.1.1 AKTIVACE SERVISNÍHO REŽIMU

Zmáčkněte současně tlačítka ▲► a držte je

po dobu 2 s. Na displeji se objeví informace

Service 01. Pomocí tlačítka ▲ můžete přepínat

mezi jednotlivými službami Service 01 – Service 07,

Service 41 a 59.

4.1.2 SERVICE 01 - ULOŽENÍ PROGRAMŮ

P1 - P4, NEBO P5, NEBO P6 NA

ČIPOVOU KARTU

Pomocí této služby můžete uložit programy P1 –

P4, nebo P5, nebo P6 na čipovou kartu výrobce

přístroje. Před vlastním zápisem parametrů na

čipovou kartu je nejdříve nutné vložit do štěrbiny

v panelu přístroje správnou kartu. Tyto karty je

možné přiobjednat u dodavatele přístroje.

Ujistěte se, že se čipová karta nachází ve

čtecím zařízení!

Uložení proveďte stiskem

X

W

. Správnost

uložení je potvrzena sdělením “Provedeno” na

displeji. Stiskněte podruhé START/STOP, tím

umožníte přechod do jiné služby.

Pokud je na displeji sdělení “Spatna MMM

CCard”, zkontrolujte čipovou kartu a činnost

opakujte.

Základní postup je následující:

Stiskem START/STOP nejdříve otevřete službu

ukládání programů.

K dispozici jsou možnosti P1 – P4, nebo P5,

nebo P6. Výběr proveďte pomocí ▲.

Vlastní uložení programu proveďte stisknutím

X

W

. (Detailně: Před spuštěním: na displeji je

nápis: „Servis 01““Zapis na kartu“

°c

Program Segment

RH

5

6

Pozice

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

Cursor line

(32 digits)

Parameter change:

Move the cursor horizontally by pressing ◄►.

Parameter below which there is the cursor can

be changed by means of button ▲.

4.1 bASIC SETTING OF THE UNITS

Thermal technology units with the Comfort

regulator offer a wide range of utilisation for the

customer. In order to make them active, there are

fundamental inputs required. To achieve this the

following service mode.

4.1.1 ACTIVATING THE SERVICE MODE

Press simultaneously buttons ▲► for 2 seconds.

The display displays the information Service 01.

You can change between individulal services by

means of button ▲.

4.1.2 SERVICE 01 – STORING P1- P

6

With help of this service you can store programs

P1 – P6 on the chip card. Before storing the

parameters to the chip card it necessary to insert

the right card to the unit panel. These cards can

be ordered optionally.

Make sure that the chip card is in the card

reader!

Press START/STOP to open the programme

saving service.

The display shows: „P1 ÷ 6 → MMM CCard”,

Press X/W to do storing. The transmission is

conrmed by the read out „Done“ on LCD. Press

START/STOP again to enter another service.If

the read out on the LCD is „Bad MMM CCard“,

check the chip card and repeat the procedure.

4.1.3 SERVICE 02 - RESTORE

/

UPLOAD THE

PROGRAMS FROM THE CHIP CARD

Using this service you can record programs

P1 - P6 previously stored on the chip card into

the memory of the unit again. The programs

entered into the memory before will be deleted.

7. indicator light - shines after switching on the

switch

8. indicator light heating - shines: state of

temperature regulator - heating active

9. indicator light cooling - shines: state of

temperature regulator - cooling active

10. indicator light – failure

11. indicator light of safety thermostat - shines:

temperature surpassed the limit set on

the safety thermostat - heating is off / see

paragraph 4.1.8 - Set safety thermostat

12. display

13. port for inserting the chip card.

Position on the display:

Program: displaying the program

Segment: partial or full graphic representation of

the program coarse

°C: temperature display

: process time

: fan speed display in % (steps of 10 %)

RH: % relative humidity

: setting-up intensity of exposition light in the

door

56 : positions are used for specic purposes -

see descriptions in text.

4

function and

operating

Function of the control lights is described

in section 3 - Description of the unit, in

paragraph 3.3 - Control panel.

Connecting to mains:

Compare the nominal voltage input values

indicated on the index plate with the supply

voltage. If the supply parameters correspond with

the unit parameters, connect the unit’s plug with

the supply socket.

Switching the device on:

Press the ON/OFF button. An indicator above

it lights up. The device is ready for operation,

follow the below given instructions.

The display displays all parameters together for

your information. The cursor moves below all

32 places along the so called cursor line and

it is located always below only one of the 32

characters.

8 LSI_K_np_en 1206_mmm_V2.08_B2V

Instructions for use

The programs in the memory will be recorded

over (erased). Make sure the chip card is in

the card reader. Press START/STOP to open

the programme download service. The display

shows: „MMM CCard → P1 ÷ 6”,

Press X/W to record. The transmission is

conrmed by the read out „Done“ on LCD. Press

START/STOP again to enter another service. If

the read out on the LCD is „Bad MMM CCard“,

check the chip card and repeat the procedure.

ATTENTION!

The original chip card delivered by the

manufacturer should be used only. Cards whose

type ends with the gure 1024 (AT24C1024) may

only be used. Older cards ending with the gure

16 may not be used.

4.1.4 SERVICE 03 - SET THE REAL TIME

AND DATE

Pressing START/STOP you enter the service.

Set the real time and date by pressing buttons

◄► and ▲. Enter the date format setting by

shifting the cursor behind the display edge,

using the buttons ◄►. The date format is

selected by pressing ▲ while the cursor is

on the position 7. The possible formats are

(in Czech): RRRR-MM-DD, RRRR-DD-MM,

MM-DD-RRRR, and DD-MM-RRRR. The default

format is RRRR-MM-DD. (In other languages:

YYYY-MM-DD, JJJJ-MM-TT, or AAAA-MM-JJ).

The data delimiter is selected by pressing ▲

while the cursor is on the position 6. The key ◄

takes you back to the time setting.

To quit the service press START/STOP again.

4.1.5 SERVICE 04 - SET INTERVAL

ON PRINTER/COMMUNICATION

INTERFACE

To print the protocols the units of thermal

technology may be provided (optional) with a

printer, which is connected by a cable to the

printer interface – see chapter 4.8 - Printing the

protocol by START/STOP and set the interval:

Pressing ▲ select one of the following choices:

- printer OFF

- switched over to PC (application of SW

WarmComm – data are sent to PC)

- interval 10 s

- interval 01 min

- interval 01 hr.

By pressing ◄ move the cursor to the position

10/01 seconds, minutes or hours. By pressing

▲ you can change the printer interval within the

following range:

-10 to 50 s (step 10 s)

- 01 to 59 min (step 1 min)

- 01 to 12 h (step 1 h).

One unit only is active, either seconds, or

minutes, or hours.

By further move of the cursor to the display edge,

you enter printer selection. Select the printer type

by means of ▲

Printer=1 ... Citizen

Printer=2 ... Thermal printer DPT 6333-V.24

To quit the service press START/STOP again.

4.1.6 SERVICE 05 - SELECT LANGUAGE

Pressing START/STOP you enter the service.

To select the language use button ▲ To quit the

service press START/STOP again.

4.1.7 SERVICE

06 –

SETTING THE

SWITCHING TIMES OF INNER SOCKET

(

OPTIONAL

)

AND THE FAN RUN AFTER

THE PROGRAMME TERMINATION

A) Switching times setting

ATTENTION!

Using this service you can set the time of

periodical switching on and off of the inner

socket.

Open the service by pressing START/STOP. The

bottom line of LCD states:

“on: XXPP off: YYQQ”,

where XXPP is the time for which the socket is

switched on for one part of the period (00 – 99),

YYQQ is the time when it is switched off (00 –

99).

PP is the abbreviation of time unit (minutes or

hours) for switching on, QQ for switching off.

The following applies: XXPP + YYQQ = whole

period.

Use ◄ and ► to move the cursor, use ▲ to

change the numbers of time units or units.

If XX = 00, then the socket never switches

on, if XX ≠ 00 and YY = 00, then the socket is

permanently switched on after the start up to

termination.

B) Setting the fan run after the programme

termination

Leave the “inner socket” setting by means of

◄► and by pressing ▲, set:

a) “Prog” – the fan runs only during the P1-P6

run;

b) „T50C“-„T250“ – the fan runs even after

program termination, up to temperature

decrease below pre-set value (it is possible

to set the value from 50 °C to 250 °C in 10 °C

increments),

c) “Door” - the fan keeps running after the

programme termination and switches off after

the door opening (applied only for units with a

closed door sensor);

d) “alws” – the fan keeps running till the cabinet is

switched off by the ON/OFF button.

Other options are available to VH only:

e) “Off“ – fan switched off,

f) „End“ – the fan starts after program termination

and switches off only when the device

is switched of. In the course of program

operation the fan stops, which positively

affects the thermo homogeneity.

4.1.8 SERVICE

07

- SAFETY THERMOSTAT

SETTING

Safety thermostat serves to protect the

thermal technology cabinet, its surrounding

and treated material against inadmissible rise

of set temperature (e.g. prevents damage

or destruction of material samples in case of

damage to the temperature regulator or in case

of unintentional setting of a temperature in the

chamber of the unit higher than the sample is

able to withstand).The service is opened by the

depression of the START/STOP button.

Set the upper limiting temperature selected

by you on the bottom line of the display – on

the position 12, 13, and 4 (symbols XXX on the

display). The minimum difference from the preset

regulated temperature is +5°C. Set the safety

thermostat type on the position 16 (symbol Y on

the display):

Type 2 – It is used for the types VC, EC, and

DC. If the preset temperature in the chamber

is exceeded, the display shows the error 04

– “Therm.protect.activated”. The thermostat

switches off the heating elements; the indicator

“safety thermostat” and the acoustic alarm are

switched on. The unit does not heat although the

indicator “heating” shines.

To restart the activity, the safety thermostat must

be reset – the error message and the acoustic

alarm are cancelled by pressing the button

START/STOP. The safety thermostat is also reset

after each pressing the button X/W in the service

07.

Type 3 – It is used for the IC and ICV types. If the

preset temperature in the chamber is exceeded,

the thermostat switches off the heating elements;

the indicator “safety thermostat” and the acoustic

alarm are switched on and the display shows the

alternating messages “Therm.protect.activated”

and the previous information. The unit does not

heat although the indicator “heating” shines.

After the temperature in the chamber drops

below the preset limit of the safety thermostat,

the unit continues its work (e.g. the heating

is switched on again) – the indicator “safety

thermostat” turns off. The acoustic alarm is still

active and the display shows the alternating

messages “Ochr.term.aktiv” and the previous

information. Cancel these two non-standard

status signals by pressing the button START/

STOP.

To conrm set temperature and type of the

thermostat, insert the chip card „SO“ in the card

reader and press X/W.

Terminate the service and close by the

depression of START/STOP button again.

Check of the safety thermostat function:

According to the procedure described in Service

07 – setting the safety thermostat - set the

temperature limit to 85 °C and conrm with the

chip card SO. In P1 set the temperature 60 °C

and start the program. After reaching the set

temperature wait for about 10 minutes, stop the

program and select the Service 07; in Service

07 - set the temperature limit to 50 °C and

conrm with the chip card SO. The unit operates

according to the description in Service 07

– Setting the safety thermostat: report ”Safety

Thermost.” on the display etc.

4.1.9 SERVICE

41

- TEMPERATURE

TOLERANCE

The bottom line of the display shows the

message “+XX.X °C -YY.Y °C”, where “+XX.X”

means the upper deviation of the temperature

(adjustable range 0 to +20) and “-YY.Y”

means the lower deviation of the temperature

(adjustable range 0 to -20). If a situation occurs

during the programme run that the temperature

in the chamber is lower than the preset

temperature minus the lower deviation,

error 2 is shown. If a situation occurs during

the programme run that the temperature in the

chamber is higher than the preset temperature

plus the upper deviation, error 3 is shown. If

a 00.0 deviation is set, the deviation is not

controlled.

The type of the errors no. 2 and 3 when the

temperature goes out of the preset range is

selected on the last character. There are the

possibilities “H” (the errors are “critical”) –

the programme run is stopped; or “S” (the errors

are “soft”) – the programme keeps running. The

default value (after RAM initialization) is “H”

(critical error).

LSI_K_np_en 1206_mmm_V2.08_B2V 9

Instructions for use

4.1.10 SERVICE 58 - DOOR bLOCKING

This service is available only in models equipped

with the door blocking function.

One-door model:

Press START/STOP and open the service.

Select one of the following possibilities by means

of ▲:

1. Inactive – the door is unblocked permanently

2. Manual – the door can be blocked and

unblocked by means of ▲ and ►

3. Automatic – the door is blocked automatically

after a pre-set period of time elapses after the

door closing.

The time can be set within the range from 2 to 9

seconds. Unblock the door by pressing ▲ and ►

buttons for 2 seconds.

You can select “C” on the last display position. In

such case, the door can be unblocked only after

inserting the SO card.

S e r v i c e 5 8

A u t o m . a f t e r 2 s C

Two-door VENTICELL models:

After the service is started, the cursor is placed

on the rst left position; four statuses can be preset on the bottom line by means of ▲:

S t r : A

=

O p n B

=

L c k

This status denes the door blocking after the

programme start by means of START/STOP.

S t p : A

=

O p n B

=

L c k

This status denes the door blocking after the

programme interruption by means of START/

STOP.

E n d : A

=

L c k B

=

O p n

This status denes the door blocking after the

programme termination (the panels show “Konec

Px” and “End”.

U n l o c k a l l ( X / W )

Press X/W to unblock both doors.

Use ◄ and ► to move the cursor between “A” =

loading door, and “B” = unloading door.

Three values are dened for these options (the

tables show the initial setting):

• „Opn“ – unblocked

• „Lck“ – blocked

• „Txyz“ – the door will be unblocked after the

temperature in the chamber drops below

“xyz”. “xyz” can be pre-set by means of ▲ in

the range from 50 to 200 °C.

It is recommended to pre-set the same “xyz”

value as in Service 06 (duration of the ventilator

run after the programme termination).

“A=Lck” cannot be pre-set if the device is in “Stp”

status. “A=Lck” only can be pre-set if the device

is in “End” status.

The device will be in “Stp” status only if the

programme run is interrupted by means of

START/STOP; however, this shall not be applied

if an error status is cancelled by means of

the said button. The door blocking will remain

unchanged after the error status cancellation.

See more in the Chapter Optional Accessories.

4.1.11 SERVICE

62 –

SOUNDS SETTING

This service allows individual switch-on and -off

of the following events:

- Device switch-on;

- Device errors;

- Operator’s errors;

- Buttons pressing;

- Programme start;

- Programme end;

- Door opening during the programme run.

4.1.12 SERVICE

64 –

PROGRAMME P

6

SHIFTING

This service shifts the programme start to a new

time. See more in chapter Programme P6.

4.1.13 SERVICE

09 -

CANCEL THE SERVICE

MODE

By pressing START/STOP, the service mode is

cancelled. You can then modify programmes and

start them freely.

4.2 PROGRAM P

1

Constant temperature is required.

P 1 =

The cabinet operates continuously at set

temperature until switching the unit off.

4.2.1 SET P

1

Put cursor to the position Program with help of

◄► and switch to P1 with help of ▲. Set the

temperature at the position of °C within the range

10 LSI_K_np_en 1206_mmm_V2.08_B2V

Instructions for use

of the type of the unit - see item Purpose and use

– with VC, EC, DC cabinets it is possible to set

in 1 °C steps, with IC and ICV in 0.1 °C steps.

Set the fan speed (type VC ICV) at the position

from 10, 20....up to 100 % (these are the

percentages of maximum speed).

ATTENTION!

Do not reduce the fan speed if it is not

necessarily needed. Reduced fan speed may

cause reduced accuracy!

4.2.2 LCD - READ OUT SHOWN

°c

Program Segment

RH

5

6

P /1

1

0 0

0 0

. 0 0 0 : 0 0

–

–

– – – –

4.2.3 START P

1

Press START/STOP, a sound will appear and the

“windmill“ in the rst digit of LCD starts running

clockwise.

See the following LCD read out:

°c

Program Segment

RH

5

6

*

/1

1

°C °C °C

0 0

.

h h

m m

:

–

Digit 1 (windmill running) = program running

Digit 7 to 10 = actual temperature in °C.

Digit 12 to 16 = time from the start in hr:min.

As soon as the set values are reached, then run

down time is shown.

4.2.4 INFORMATION ON THE SET

PARAMETERS DURING RUNNING

Press X/W and all information on the set

parameters are shown at once. All possible

parameters in all possible programs can be set

including the one which is presently active, as

long as the change is effective.

4.2.5 STOP P

1

Press START/STOP again.

4.3 PROGRAM P

2

SETUP-temperature is reached rst, dened

time will run down and when nished the heating

is turned off.

P 2 =

The unit operates at set temperature until the

lapse of set time (max. 99 hr 59 min).

4.3.1 SET P

2

With help of buttons ◄► put the cursor to the

position Program and switch to the program P2.

Set the temperature at the position of °C.

Move the cursor to the position

¹ and set the

run down time between 00hr:00min to 9999 hr,

at the position

(type VC, ICV) change the fan

speed between 10, 20...100 %.

ATTENTION!

Do not reduce the fan speed if it is not

necessarily needed. Reduced fan speed may

cause reduced accuracy!

4.3.2 LCD - READ OUT SHOWN

°c

Program Segment

RH

5

6

P /

/

2

1

0 0

0 0

. 0 0 0 : 0 0

–

–

–

–– –

4.3.3 START P

2

Press START/STOP, a sound will appear and

the “windmill“ in the rst digit of LCD starts

running clockwise.

See the following LCD read out:

°c

Program Segment

RH

5

6

*

/

/

2

1

°C °C °C

0 0

.

h h

m m

:

–

°C°C°C = actual temperature

hh:mm = time to reach the set temperature, if

the set-up is reached, the rest of the run down

time is indicated.

After the programme ends, temperature in the

chamber and the text “End” are displayed.

LSI_K_np_en 1206_mmm_V2.08_B2V 11

Instructions for use

Programme end indication and temperature in

the chamber disappear after pressing any panel

key.

4.3.4 INFORMATION ON THE SET

PARAMETERS DURING OPERATION

OF THE UNIT

See item 4.2.4.

4.3.5 STOP P

2

Press START/STOP.

4.4 PROGRAM P

3

Delayed start begins after given time.

[The function starts for example at the weekend.

Thus your goods are ready on the rst day of

return to work.]

P 3 =

Starts running after the delayed time has run

down (max. 9999 hr) and the unit operates at

the set temperature. The duration of the set

temperature can be limited or unlimited in time.

4.4.1 SET P

3

By pressing ◄► put the cursor to the Program

position and switch to P3. By pressing ◄► put

the cursor to the graph and make sure that the

segment 1 in the graph is activated (otherwise

change by buttons ▲.

Set the time of delay between 00hr:00min to

9999 hr position

¹. By pressing ◄► move

to the graph and with help of ▲ change to the

segment 2 in the graph _/¯. Set the temperature

in elds °C.

Move the cursor to position

¹ and set the time

of process duration between 00 hr:00 min. up

to 9999 hr. or unlimited ∞∞:∞∞ (set the innity in

the following way: set 9999 hr, put the cursor to

the nine in units and depress ▲. Set the cursor

(with types VC, ICV to position

and set the

fan speed between 10 up to 100 %.

ATTENTION!

Do not reduce the fan speed if it is not

necessarily needed. Reduced fan speed may

cause reduced accuracy!

4.4.2 LCD - READ OUT SHOWN

4.4.3 START P

3

Press START/STOP, a sound will appear and the

“windmill“ in the rst digit of LCD starts running

clockwise. See the following LCD read out:

4.4.3.1

P3 AND SEGMENT 1 IN THE GRAPH

ARE ACTIVE

°c

Program Segment

RH

5

6

*

/3

1

°C °C °C

0 0

.

h h

m

m

:

–

–

–

= první segment

°C°C°C = actual temperature

hh:mm = the programmed time, counting ⇒

down towards zero.

4.4.3.2 P

3

AND SEGMENT 2 IN THE ARE

ACTIVE, THE SEGMENT

1

IS OVER

°C°C°C = actual temperature

hh:mm = time running from the start till the set

temperature has been reached.

After the set temperature has been reached,

the run down time is shown if the time of the

procedure is unlimited. If the time is limited, the

rest of the run down time is shown.

12 LSI_K_np_en 1206_mmm_V2.08_B2V

Instructions for use

segment 1

Program Segment

°C

RH

5 6

*

3

//

–

°C

°C

°C

.

1

0

0

h

h :

min

=

=

//

–

= druhý segment

segment 2

°c

Program Segment

RH

5

6

P /3

1

0 0

0 0

. 0 0 0 : 0 0

–

–

–

–

––

–– – –

r = ramp value, can be set on digits 12 – 16 and

corresponds with temperature change speed

in °C/min max. value is +3.2 °C/min, when

T0 < T1, or T1 > T2 If r = 00.0, no ramp

active! (The numerical value of the ramp has

an orientation character, the real speed can

be affected by the amount of goods in the

chamber and maximum speed of temperature

change may not be met, taking the limited

heating power into account)

t = time available in position

¹ (00hr:00min –

9999 hr), at T2 the dwell time can be

unlimited

c = cycles shown in position ¹, digits 12 – 13 on

LCD (available only at T2, if the dwell time is

unlimited) Possible number of cycles is 2 to

9999 (eventually ∞- which is the next position

after 99).

The value of cycle number is a global value that

does not relate to individual segments, it relates

to the complete programmed sequence. It can

be displayed while displaying any segment on

the display, however it does not concern only

the displayed segment, but the whole sequence!

Minimum number of cycles is 1. If only one cycle

is chosen, the programme runs as if it has been

switched on without cycles.

The program can be started by depressing

START; no matter which segment is shown on

the display, the program always runs from the

segment 0 or 1, if the time of the zero segment

is zero. For successful inserting of the cycling

process into an already started process it is

essential that at the moment of the start “cXX” is

shown on the display, where XX is the number

of intended runs of the whole sequence. E.g.

number two means, that the sequence is carried

out and then repeated completely, i.e. it runs

twice around. If “cXX” is not shown on the display

at the moment of the START and there is shown

data on time or on the ramp of the actually

displayed program instead, the whole sequence

runs once and is not repeated, i.e. there are no

cycles.

4.5.2 SET THE SEGMENT FOR T

1

4.5.2.1 SET TEMPERATURE T

1

Put cursor to the position Program and switch

to P4. By pressing ◄► place the cursor on the

graph and make sure that T1 (/¯\_) is activated. If

not, activate it with buttons ▲.

Change to the position of °C - temperature setting

- and set the temperature.

4.4.3.3 P3 AND THIRD SEGMENT IN THE

GRAPH ARE ACTIVE

The preset temperature has been reached. If the

procedure duration is unlimited, time passed is

displayed. If the procedure duration is limited,

time remaining till the end is displayed. After the

programme ends, temperature in the chamber

and the text “End” are displayed. Programme

end indication and temperature in the chamber

disappear after pressing any panel key.

4.4.4 INFORMATION ON THE SET

PARAMETERS DURING OPERATION OF

THE UNIT

See item 4.2.4.

4.4.5 STOP P

3

Press START/STOP.

4.5 PROGRAM P

4

With 2 temperature levels T1 and T2, with a

controlled speed of the temperature change

(ramps) and with cycling.

P4 =

T1 T2

Operates at 2 temperature levels T1 and T2, the

dwell time on the level T1 is limited, on the level

T2 can be limited or unlimited.

4.5.1 SET P

4

Index: T0 = initial chamber temperature

T1 = temperature level 1

T2 = temperature level 2

Digit 11 on LCD = (placed between temperature

and dwell time values), shows the following

information:

LSI_K_np_en 1206_mmm_V2.08_B2V 13

Instructions for use

Program Segment

°C

RH

5 6

*

3

//

–

°C

°C

°C

.

1

0

0

h

h :

min

=

=

/

–

= druhý segment

segment 3

4.5.3 SET THE SEGMENT FOR T

2

4.5.3.1 SET THE TEMPERATURE T

2

Place the cursor on the graph and make sure

that T2 ( /¯\_ ) is activated. If not, activate

with help of ▲. Switch over to position °C -

temperature setting - and set the temperature.

4.5.3.2 SET THE DWELL TIME OF T

2

Put the cursor on the digit 11 on LCD and ask

for parameters by pressing ▲. Either „t“ or „r“ or

„c“ will appear. Select „t“. Enter the position

¹

and set the dwell time between 00hr:00min and

9999 hr, unlimited ∞∞:∞∞ (set the innity in the

following way: set 9999 hr, put the cursor to the

nine in units and depress▲.

4.5.3.3 READ OUT OF T2 AND THE DWELL

TIME

°c

Program Segment

RH

5

6

P /

/

4

1

0 0

0 0

. 0 0 . 0 0

–

–

–

r

+/-

4.5.3.4 SET THE RAMP AT T

2

Return the cursor to the digit 11 on LCD and by

pressing buttons ▲ select „r“. Switch to position

¹ and set the required ramp (max. value

+3.2 °C/min for T1 < T2). If the ramp is not

needed, leave „r“ on 0.00. In this case the

temperature will be changed at maximum

speed. The symbol ± appears automatically

in accordance to T1 and T2 relation (see item

4.5.2.4.).

4.5.3.5 READ OUT OF T2 AND THE RAMP

°c

Program Segment

RH

5

6

P /

/

4

1

0 0

0 0

. 0 0 . 0 0

–

–

–

r

+/-

4.5.2.2 SET THE DWELL TIME OF T

1

Move cursor to the digit 11 on LCD and ask for

parameters by pressing simultaneously ▲ Either

„r“ or „t“ will appear (see above). Select „t“. Move

to the position

¹ and set the dwell time between

00 hr:00 min and 9999 hr.

4.5.2.3 READ OUT OF T

1

AND THE DWELL

TIME

°c

Program Segment

RH

5

6

P /

/

4

1

0 0

0 0

. 0 0 0 : 0 0

–

–

–

–

–

–

–

– –– – –

t

4.5.2.4 SET THE RAMP AT T

1

Return the cursor to the digit 11 on LCD and by

pressing ▲ select „r“.

Switch to the position

¹ and set the required

ramp (max. value +3.20 °C/min for T0 < T1).

If the ramp is not needed, leave „r“ on 0.00.

In this case the temperature will be changed

at maximum speed. The symbol ± appears

automatically in accordance to T0 and T1 relation

(the ramp with negative value of temperature

change speed may be set in case that the speed

of spontaneous cooling of the cabinet is higher).

4.5.2.5 READ OUT OF T1 AND THE RAMP

°c

Program Segment

RH

5

6

P /

/

4

1

0 0

0 0

. 0 0 . 0 0

–

–

–

r

+/-

4.5.2.6 SET THE FAN SPEED AT THE

TEMPERATURE T1

Put the cursor to the position and change the

fan speed between 10, 20...100 %.

ATTENTION!

Do not reduce the fan speed if it is not

necessarily needed. Reduced fan speed may

cause reduced accuracy!

14 LSI_K_np_en 1206_mmm_V2.08_B2V

Instructions for use

LSI_K_np_en 1206_mmm_V2.08_B2V 15

4.5.3.6 SET CYCLES FOR P

4

Return the cursor to the digit 11 on LCD and with

▲ select „c“. Switch to the position

¹, set the

number of cycles between 02 and 99 (eventually

∞). The number of cycles means, how many

times will the cycle run, i.e. value 03 means,

that at the end of the rst cycle will be the whole

process still twice repeated. Cycles are not

applied in case when the display does not display

„c“ in the moment of program start and after the

exposure termination at T2 drop of temperature

in the cabinet below the level of T1 must take

place.

4.5.3.7 READ OUT OF CYCLES FOR P

4

°c

Program Segment

RH

5

6

P /

/

4

1

0 0

0 0

. 0 10

–

–

–

c

4.5.3.8 SET THE FAN SPEED AT T

2

Put the cursor to the position and change the

fan speed between 10 to 100 %.

ATTENTION!

Do not reduce the fan speed if it is not

necessarily needed. Reduced fan speed may

cause reduced accuracy!

4.5.4 START P

4

ATTENTION!

If cycling is required, „c“ must be on LCD when

starting the program.

Press START/STOP, a sound will appear and the

“windmill“ in the rst digit of LCD starts running

clockwise. See the following LCD read out:

The graph shows the actual state of the program.

4.5.4.1 S1 IS ACTIVE, TEMPERATURE IS

HEADING TOWARDS T

1

°c

Program Segment

RH

5

6

*

/

/

4

1

°C °C °C

0 0

.

h h

m

m

:

–

–

= S1

°C°C°C = actual temperature

hh:mm = time since start to reaching T1.

4.5.4.2 S2 IS ACTIVE, T1 HAS bEEN

REACHED, DWELL TIME IS RUNNING

°c

Program Segment

RH

5

6

*

/

/

4

1

°C °C °C

0 0

.

h h

m

m

:

–

–

–

= S2/T2

°C°C°C = actual temperature

hr:mm = dwell time at T1 running down

towards zero.

4.5.4.3 S3 IS ACTIVE, TEMPERATURE IS

HEADING TOWARDS T

2

°c

Program Segment

RH

5

6

*

/

/

4

1

°C °C °C

0 0

.

h h

m

m

:

–

–

= S3

°C°C°C = actual temperature

hr:min = time running since the end of T1 till it

reaches T2.

Instructions for use

P4 =

S1 S2 S3 S4

T1 T2

4.5.4.4 S4 IS ACTIVE, T2 IS REACHED, DWELL

TIME AT T

2

IS RUNNING

°c

Program Segment

RH

5

6

*

/

/

4

1

°C °C °C

0 0

.

h h

m

m

:

–

–

–

= S4/T2

°C°C°C = actual temperature

hr:mm = in case the time of the procedure is

unlimited the time of running is shown, in case of

the limited time the rest of this time is shown.

4.5.5 INFORMATION ON SET PARAMETERS

DURING OPERATION OF THE UNIT

See item 4.2.4.

4.5.6 STOP P

4

Press START/STOP.

4.6 PROGRAM P

5

4.6.1 DESCRIPTION OF P5 AND ITS

CONTROL

T

tn=max 15

t7t6t5t4t3t2t1t0

T7

T4

T3

T5 T6

T1 T2

S0

S1

S2

S3

S4

S5

S6

S7

Sn

t

tn=max. 39

The program consists of 40 segments. Segment

0 is for the delayed start, it is dened only by

the time t0. If t0 is 0, there is no delayed start.

Segments 1 to 39 are of the same qualities, each

of them is dened only by the end temperature,

time or speed (ramp), fan rotation speed and

depending on the type of the unit also by relative

humidity and chamber light.

Each of the segments 1 to 39 can be set as

the last and innite, that is the program at this

segment must be nished by START/STOP

button.

Instructions for use

16 LSI_K_np_en 1206_mmm_V2.08_B2V

If the cycle selection is active on LCD at the

moment of the start, see g. Display - state of the

program selection - E: cXX, the program comes

again to the start after the last segment is over

and the whole program is repeated. The denite

number of program cycles corresponds with the

number behind the letter “c“. The segment 0 can

be counted into the cycle as well even when it is

zero.

Range of parameters:

time t0 0 hr, 0 min to 9999 hr

time t1 to t39 0 hr, 0 min. to 9999 hr, or

innite ramp

Rampe r1 to r39 to 3.2 °C/min for heating

(negative sign for an

eventual cooling down)

temperature T1 toT39 range according to the

device parameters

fan speed V1 to V39 10 to 100 % with 10 % steps

number of

cycles

C 2 to 99 eventually ∞- which

is the next position after 99

DISPLAY - STATE OF THE PROGRAM SELECTION

A

B C D E

G H IF

A: P5 name of the program

B: XX number of the set segment

C: X type of the set segment:

x time of the zero segment is set to zero,

segment will be skipped over

> not the last, the end length - see E

>I the last, the end length - see E

∞ the last, innite length

D: XX . X required temperature of the set segment

(! the end temp.)

E: TXX : XX Hour and minute of the end of the set

segment; or

R ± X .XX The ramp = the required speed of the set

segment;deciding is the time; or

t ± X . XX The calculated hour and minute of the

end of the set segment; ramp is default;

or

r ± X .XX The calculated speed of the set segment;

time is default; or

cXX the number of cycles of the whole

program

F: XXX the fan speed of the set segment

G: XX the relative humidity of the set segment

device continues automatically from the point

before interruption.

4) If the device is switched off by the button

START/STOP or ON/OFF, the programme

starts running from the beginning after

reswitching-on.

Ventilator operation after a programme end:

The operation can be set in Service 06.

Immediate ventilator switch-off after programme

termination is pre-set in all ventilator types.

4.7 PROGRAM P

6

4.7.1 DESCRIPTION OF P

6

Programme P6 works with segments whose

duration is determined by real time and calendar

date.

1. Programme P6 consists of 40 segments

and is determined strictly by real time, i.e. it

follows the preset programme independently

of the switch-on time, power failures, restarts

after an error, etc.

2. Segment 0 (so called “delayed start”) is

compulsory; time and date must be set in it.

It may even be set to the past and means the

“beginning of the programme”. Segments 1 to

39 have the same properties. Each of them

is determined by the end temperature, time

or speed of temperature rise, and ventilator

speed.

3. If cycling is switched on, segment end times

are shifted after each cycle end (forward

by the programme duration). Updated

parameters are thus displayed when you

check the parameters during the device

operation (after X/W pressing).

4. The whole P6 programme (all segments at

once) can be shifted by service 64 by any

time interval to both the future and past and

there is no need to rewrite all segments

before a new programme start.

H: XXX the light of the set segment

I: XX . XX the month and day at the moment (at P5

impossible to be set )

DISPLAY - RUNNING OF THE PROGRAM

A

B C D E

G HF

A: ∗ 5

the rotating symbol and the program

number

B: X the number of the relevant segment

C: X the type of the set segment:

> not the last, the end length - see E

>Ι I the last, the end length - see E

∞ the last, innite length

D: XX . X the temperature in the chamber at the

moment

E: XX : XX the segment time at the moment -

hours, minutes

all segments - counting down from the

set value towards zero,

in case of an innite length of the last

segment counting up from zero

in case the time is higher than 9999 hr.

>>:>> is indicated

F: XXX the fan speed at the moment

G: XX not used

H: XXX not used

Programme P5 continuation after preset

parameters change or programme interruption:

1) The programme is running e.g. in segment 5.

You want to change the setting in a passed

already segment (e.g. segment 4) or in a

future segment (e.g. segment 6). Press

X/W and change the setting according to

your needs. Meanwhile, the programme

will continue running in segment 5. Wait for

several second. The programme returns from

the setting mode to the working segment 5

and continues working.

2) The programme is running e.g. in segment 5.

You want to change the setting of the running

programme 5. Press X/W and change the

programme 5 setting according to your needs.

Wait for several seconds. The programme

returns from the setting mode to the beginning

of segment 5 and starts running.

3) The programme is running. Power supply is

interrupted either by switching the main device

switch off or due to power supply system

failure. After the power supply is renewed, the

LSI_K_np_en 1206_mmm_V2.08_B2V 17

Instructions for use

T

tn=max 15

t7t6t5t4t3t2t1t0

T7

T4

T3

T5 T6

T1 T2

S0

S1

S2

S3

S4

S5

S6

S7

Sn

t

tn=max. 39

4.7.2 PROGRAMME SETTING

Segment 0 is compulsory, i.e. it cannot be

switched off. This condition must be met to

allow denition of the beginning, thus the whole

programme duration, which is necessary for

cycling.

When setting the delayed start, year is set on the

bottom line. Programme start can thus be preset

even to the past. Year will always be displayed at

the same place (7th position on the bottom line);

the sequence month-day (DD-MM or MM-DD) is

determined by setting in service 3.

P 6 0 0

>

2 2 . 5 0 9 : 0 0

1 0 0 2 0 0 9 1 8 - 0 2

or

P 6 0 0

>

2 2 . 5 0 9 : 0 0

1 0 0 2 0 0 9 0 2 - 1 8

In other segments, year is not displayed on

the bottom line; years are calculated at the

programme start.

Each of segments S 1 to S 39 may be set as the

last one, i.e. the programme either ends after the

nal temperature Ti reaching and concurrent time

ti elapsing, or another cycle may follow.

Each of segments 1 to 39 may be set as the

last one and innite, i.e. the programme must

be ended by means of START/STOP in this

segment.

If there is an active cycle selection displayed in

the moment of programme start (see the gure

Display – programme selection status – E: cXX),

then the programme passes to the beginning

again after the last segment ending and the

whole programme is repeated. The overall

number of the whole cycle runs equals to the

gure following the letter “c”. Segment 0 is not

included in the cycle.

The number of cycles is related to the whole

programmed sequence. It can be displayed in

presence of any segment on the display but it

does not refer to the displayed segment only but

to the whole sequence!