Laboratory drying ovens and incubators

line Standard

VENTICELL 55, 111, 222, 404, 707

INCUCELL 55, 111, 222, 404, 707

INCUCELL V 55, 111, 222, 404, 707

ECOCELL 55, 111, 222, 404, 707

STERICELL 55, 111, 222, 404

DUROCELL 55, 111, 222

Operating instructions

MMM Medcenter Einrichtungen GmbH producer:

MMM Medcenter

Einrichtungen GmbH

Schulstrasse 29

D – 82 166 Gräfelfing

Tel.: +49 89 89 92 26 20

Fax: +49 89 89 92 26 30

LSI_S_en_np 0402_mmm V 1.09 Blue Line

Operating instructions Ovens line Standard Page

Contents:

10. 2. 2004

1 GENERAL ...................................................................................................................................... 3

1

1.1 P

URPOSE AND USE....................................................................................................................... 3

2 IMPORTANT INSTRUCTIONS ...................................................................................................... 3

2.1 U

2.2 P

NPACKING, CHECKING AND TRANSPORT ....................................................................................... 3

RE-INSTALLATION ....................................................................................................................... 4

2.3 USEFUL SPACE ............................................................................................................................. 6

3 DESCRIPTION OF THE OVEN...................................................................................................... 7

3.1 G

ENERAL VIEW ............................................................................................................................. 7

STERICELL 55~404 - PLACING THE HEPA FILTER, FILTER DIMENSIONS, FUNCTION AND FILTRATION

CHARACTERISTIC OF THE AIR FILTER

....................................................................................................... 8

3.3 POWER CONNECTION AND CONNECTORS........................................................................................ 9

3.4 CONTROL PANEL......................................................................................................................... 10

4 FUNCTION AND OPERATING.................................................................................................... 11

4.1 S

WITCH-ON ................................................................................................................................11

4.2 SWITCH-OFF............................................................................................................................... 12

4.3 U

SER'S SUPPORTING FUNCTIONS................................................................................................. 12

4.4 SETTING-UP REQUIRED VALUES OF TEMPERATURE, TIME-DELAYED SWITCHING-OFF, NUMBER OF

CYCLES

, TIME-DELAYED SWITCHING-ON. ............................................................................................... 12

4.4.1 Sterilization program setting and run - for STERICELL only.......................................... 14

4.5 L

IST OF ERROR MESSAGES .......................................................................................................... 15

4.6 PRINTING THE PROTOCOL............................................................................................................ 15

4.7 F

UNCTION AND SETTING OF THE SAFETY THERMOSTAT.................................................................. 16

4.8 ADJUSTING AND FUNCTION OF THE AIR FLAP ................................................................................. 17

4.9 EXCHANGING THE DOOR SEALING AND ADJUSTING THE DOOR ........................................................ 18

5 PARAMETERS OF THE APPARATUS....................................................................................... 19

5.1 E

LECTRIC CONNECTIONS............................................................................................................. 20

6 CLEANING OF THE OVEN ......................................................................................................... 20

7 MAINTENANCE ........................................................................................................................... 20

8 WARRANTY AND SERVICE ....................................................................................................... 21

9 TRANSPORT AND STORAGE.................................................................................................... 21

10 THE WAY OF LIQUIDATION OF PACKAGE AND DISCARDED APARATUS ......................... 21

11 OPTIONAL EQUIPMENT............................................................................................................. 21

11.1 D

OOR WITH WINDOW AND INNER LIGHTING (EXCEPT IC, ICV).................................................... 22

11.2 BUSHINGS OF DIAMETER 25, 50, 100 MM ................................................................................ 24

11.3 LOCKABLE DOOR .................................................................................................................... 24

11.4 L

EFT DOOR ............................................................................................................................ 24

11.5 INDEPENDENT SENSOR PT100................................................................................................ 24

11.6 C

11.7 HEPA

OMMUNICATION SW DS COM FOR PC UNDER WINDOWS ...................................................... 24

FILTER ........................................................................................................................ 25

11.8 TWO-DOOR PASSING THROUGH VERSION ................................................................................. 25

11.8.1 Two-door STERICELL 404 - installation data ................................................................. 25

11.9 A

DAPTATION AGAINST DRYING-UP OF CULTIVATING MEDIUMS AND TISSUE CULTURES.................. 29

LSI_S_en_np 0402_mmm V 1.09 Blue Line

Operating instructions Ovens line Standard Page

2

V 1.09 Blue Line LSI_S_en_np 0402_mmm

Operating instructions Ovens line Standard Page

1 General

The ovens with electric heating are designed for laboratories, generally for a warming of

various materials by means of hot air at adjustable temperature and optional time. The air

flap enables drying of wet material.

A modern microprocessor (Fuzzy - logic) with a digital display and PT 100 controls the

temperature. Thus exact temperature accuracy and process safety are guaranteed.

The ovens are designed according to EN standards.

They are manufactured of high grade materials with the latest technology.

Each oven is subjected to a strict final test leaving the plant.

1.1 Purpose and Use

VENTICELL (VC) serves for warming of materials by means of hot air with forced-air

circulation by a fan. The ovens are designed for temperatures up to 250 °C, another variant

(+) up to 300 °C.

3

INCUCELL (IC, ICV) serves as an incubator or for cell cultivation in a microbiological

laboratory (see chapter Optional equipment, article Adaptation against drying-up of

cultivating mediums and tissue cultures). The ovens are designed for temperatures up to 70

°C. A quiet operation is characteristic for the variant IC (without a ventilator), more accurate

temperature regulation with small deviations is characteristic for the variant ICV (with

ventilator).

ECOCELL (EC) serves for warming by hot air with natural circulation. The ovens are

designed for temperatures up to 250 °C. They work quietly with lower power consumption

compared with VC units.

STERICELL (SC) serves for sterilizing by hot air with forced-air circulation by a fan. The

ovens are designed for temperatures up to 250 °C. STERICELL uses time-delayed switchoff program for sterilizing, refer to section Set and Running the Sterilizing Program.

DUROCELL (DC) serves for warming by hot air with natural circulation (usefull at procedures

as acid hydrolysis, extraction by nonflammable solvents, thermolysis). The ovens are

designed for temperatures up to 125 °C. Internal surface is covered by a layer of EPOLON,

that protects the chamber against corrosive influence of acids in the form of vapors or liquids.

2 Important Instructions

2.1 Unpacking, checking and transport

Please check after unpacking the oven and its accessories are complete and not damaged.

A possible damage is to be reported to the forwarding agent. An eventual damage must be

immediately reported to the transporting company.

LSI_S_en_np 0402_mmm V 1.09 Blue Line

Operating instructions Ovens line Standard Page

During the manipulation – in case of lifting the cabinet etc. – the cabinet cannot be hold by

the rail or door. The cabinets of volumes 404 and 707 should be lifted by means of delivered

hooks, the rolls are designed for local moving, not for longer transport.

The standard delivery consists of the temperature cabinet, two sieves.

2.2 Pre-installation

♦ Please read carefully the operating instructions before working with the oven!

♦ Install the instrument by plugging the power cord to a line voltage socket. The specified

parameters of the connection are described in chapter Electrical Connection. Adjust the

position of air valve according to chapter Air Valve - Adjustment and Functions. For

VC, SC and ICV types, adjust two air valves – suction and exhaust.

After the first switching-on of the unit the heating bodies and insulation start to be

baked with a typical a smell; after a few operation cycles this smell disappears,

nevertheless it is suitable, during the insulation baking at a temperature above 100°C,

to secure a sufficient air exchange (e.g. by ventilation or exhaustion).

At temperatures above 100 °C the inner chamber surface becomes yellowish. This

coloration is neither the material nor the device defect.

4

The air exhaust in VC, EC a SC types is protected by a cover rear of the unit. This

cover is placed inside the oven while shipping. When installing the unit, insert the

cover into the horizontal openings bellow and above the exhaust to attach it behind

the exhaust.

An air filter can be connected to the suction hole in SC types - see section

Function and filtration characteristics of the air filter.

Ovens are designed to be operated indoor within ambient temperatures from 5 °C to

40 °C and at maximum relative humidity 80 %.

The oven should be installed with a 100 mm distance to the walls at the side and in

back. The temperature of the air coming out of the exhaust may be up to 250 °C

(resp. 300 °C), so the walls near the oven must be inflammable

.

No inflammable or explodable materials may be put into ovens !

Carrying capacity of the floor during installation of the device must correspond to the

weight of the unit itself taking the weight of the maximum charge into consideration

(see chapter Parameters of the unit).

The unit must not be placed on a pad that could cause a danger of fire or smothering

in case of falling some hot object out of the cabinet.

No inflammable, explosive or toxic materials may be put into ovens! The same

applies to materials that could give off such a stuff.

Goods are only to be put on trays into ovens, never directly on the bottom of the oven!

No dangerous goods are permitted. Ovens may not be used for heating of liquids.

V 1.09 Blue Line LSI_S_en_np 0402_mmm

Operating instructions Ovens line Standard Page

Aparatus may not be used in the atmosphere with a possible danger of flammable or

explosive anesthetics.

Any assembling or disassembling may be done only when disconnected from

mains! After the button (button 11, fig. 4) activates the stand-by state, the oven

comes only to a stand-by state, however it is not disconnected from the mains!

♦ If the oven is not used for a longer time, disconnect it from mains by pulling the service

cord from the socket

Power cord can not get to the contact with hot parts of the aparatus – protection

cover of exhaust hole

♦ Safety thermostat assures the protection of the oven, surroundings and goods against

surpassing the rated temperature. Protection through temperature safety class 2

according to EN 61010-2-010 is for VC and EC, protection through temperature

safety class 3 according EN 61010-2-010 cs for IC, ICV. Check regularly – daily – the

function safety thermostat.

♦ The door and the exhaust air flap in SC type are provided with microswitches - see

section Setting and running the sterilizing program.

5

Pull out and consequently push in the upper metal plate piece of internal chamber

carefully, there is a danger of cutting through the rubber gasket of the chamber during

careless manipulation.

The maximum permitted loads: see section Parameters of the unit.

Only for STERICELL

The units of STERICELL 404 are provided with a door lock – for securing the safety.

You can enter the chamber, e.g. because of cleaning, only if the door is locked

(blocked) in an open state. You must keep the key all the time you find yourself inside

the chamber.

When operating the cabinets at high chamber temperature there can be the

maximum allowed temperature of 70 °C at their outer surface (exhaust ports and their

surroundings and the surroundings of the chamber sealing, window and door surface

in case of the optional type with window in door) surpassed and there is a danger of

burns. Please take a high precaution.

During the operation of the devices of 404 and 707 at high temperatures a

deformation of the inner door surface occurs as a consequence of thermal tension,

which makes their closing more difficult. If you open the door in this state, do not

close them until the chamber is cooled down. Otherwise the door mechanism could

be damaged.

LSI_S_en_np 0402_mmm V 1.09 Blue Line

Operating instructions Ovens line Standard Page

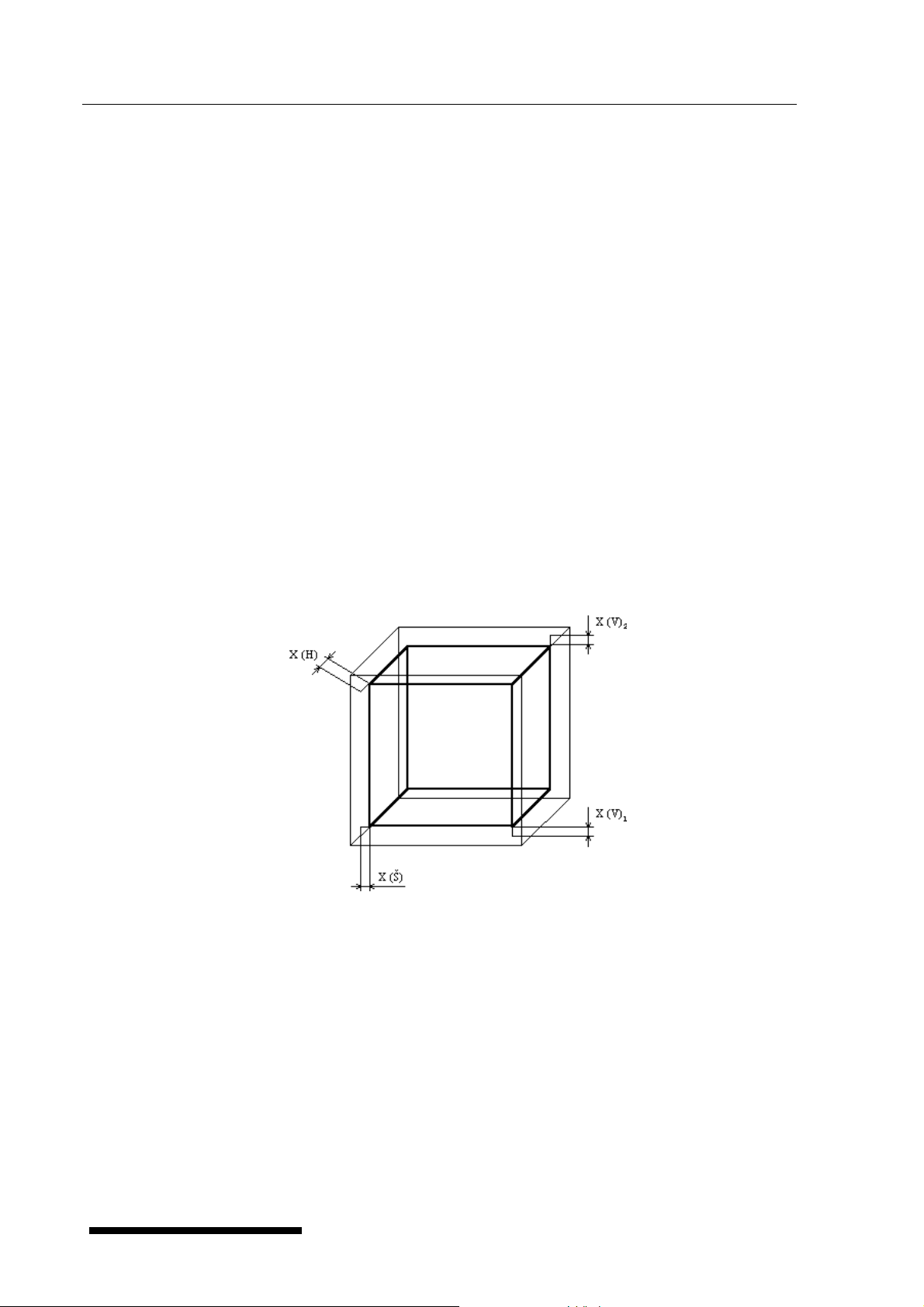

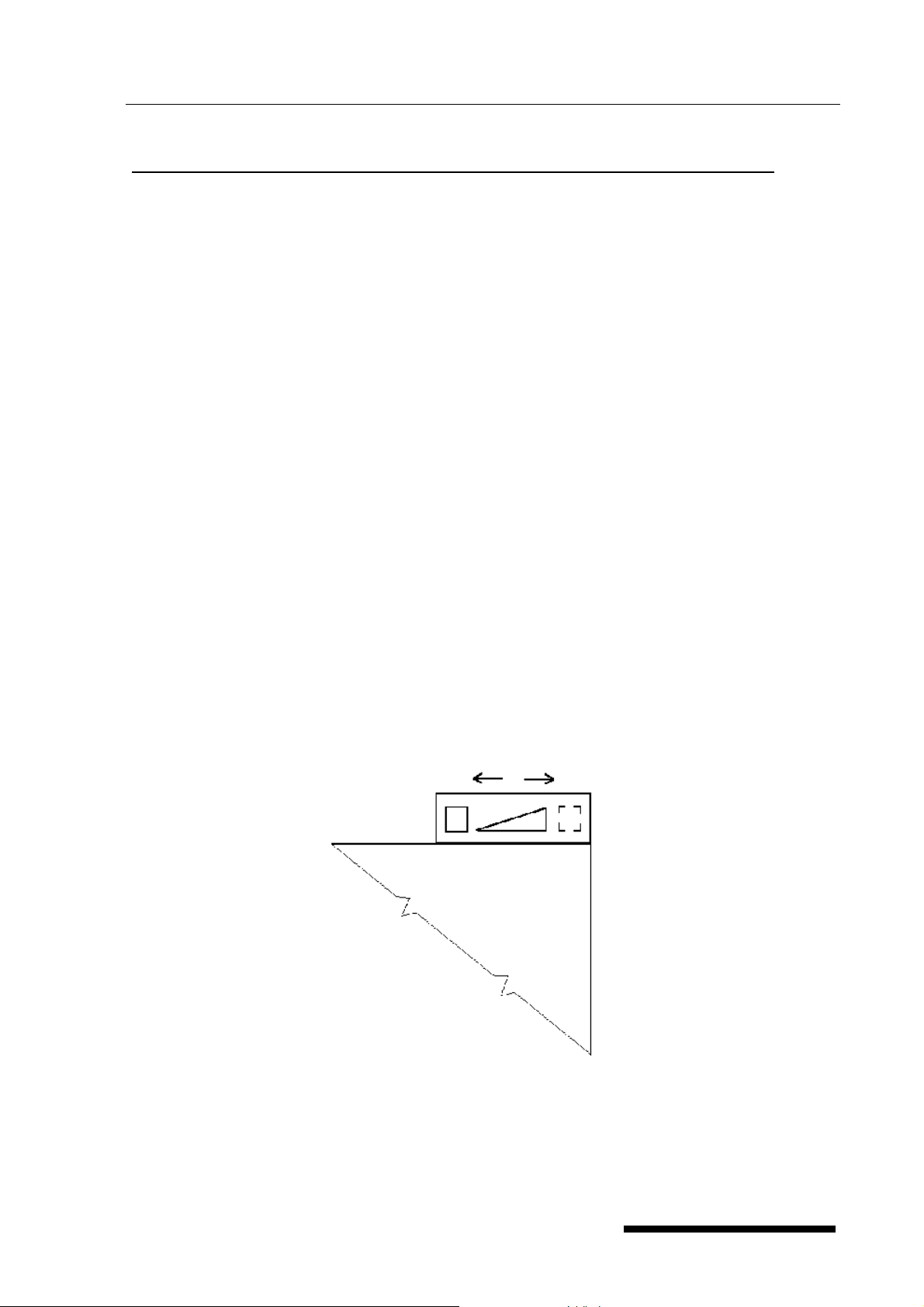

2.3 Useful space

Useful space is illustrated on fig. No. 1, where X(H) = 10 % of the inner chamber depth,

X(Š) = 10 % of the inner chamber width, X(V)

bottom of the inner chamber, X(V)

is the distance from the upper most tray to the ceiling of

2

the inner chamber. The required temperature accuracy - see section Parameters of the unit

- is achieved only in the space defined above (according to DIN 12 880 - marked with thick

lines, thin lines mark inner chamber walls). It means, that over the last upper tray there are

the limits from section 5. not obligatory.

For Stericell following definition of the sterilizing space is valid:

at the side to the door is X(D) = 20 % of the inner chamber depth, at the rear side in the

single-door type X(D) = 10 % of the inner chamber depth, X(W) = 10 % of the inner chamber

width, X(H)

is the distance from the lowest tray to the bottom of the inner chamber, X(H)2 is

1

the distance from the upper most tray to the ceiling of the inner chamber. The required

temperature accuracy - see section Parameters of the unit - is achieved only in the space

defined above (according to DIN 12 880 - marked with thick lines, thin lines mark inner

chamber walls). It means, that over the last upper tray there are the limits from section 5. not

obligatory.

is the distance from the lowest tray to the

1

6

Fig. 1

V 1.09 Blue Line LSI_S_en_np 0402_mmm

Operating instructions Ovens line Standard Page

)

3 Description of the oven

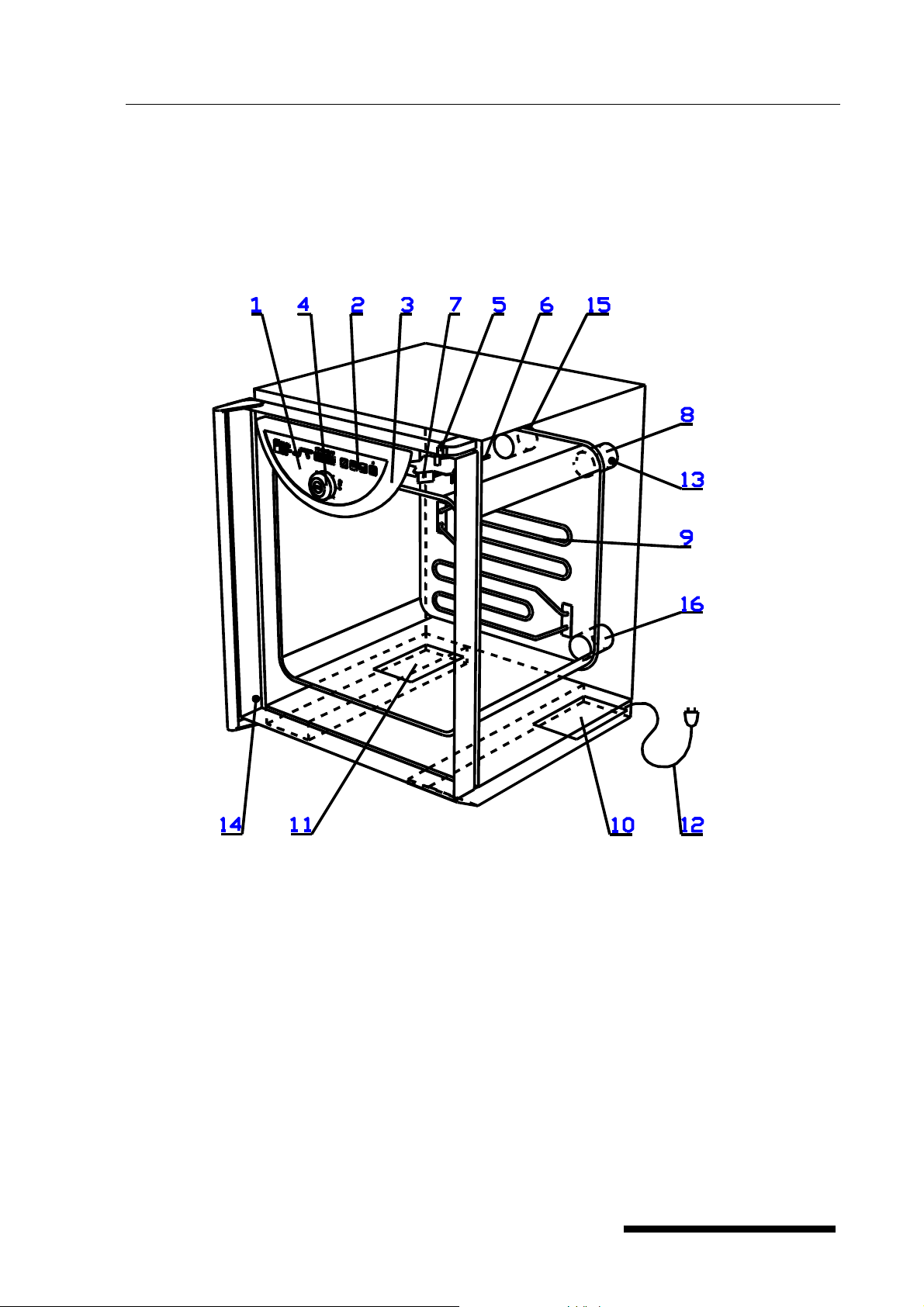

3.1 General view

7

Fig. 2

1 Panel of regulator 2 control buttons

3 Plastic cover of the regulator panel 4 control ring and button of

safety thermostat

5 air flap lever 6 case of sensor Pt 100

7 Ventilator (only for VC, ICV a SC) 8 exhaust with air flap (with

all types)

9 Heating elements 10 Power part I

11 Power part II (only three-phase type) 12 Connection to the mains

13 Sensor for air flap position (only for SC) 14 door sensor (only for SC)

15 Suction hole (only for VC, ICV, SC with air flap) 16 suction opening (with types

EC, IC, DC

LSI_S_en_np 0402_mmm V 1.09 Blue Line

Operating instructions Ovens line Standard Page

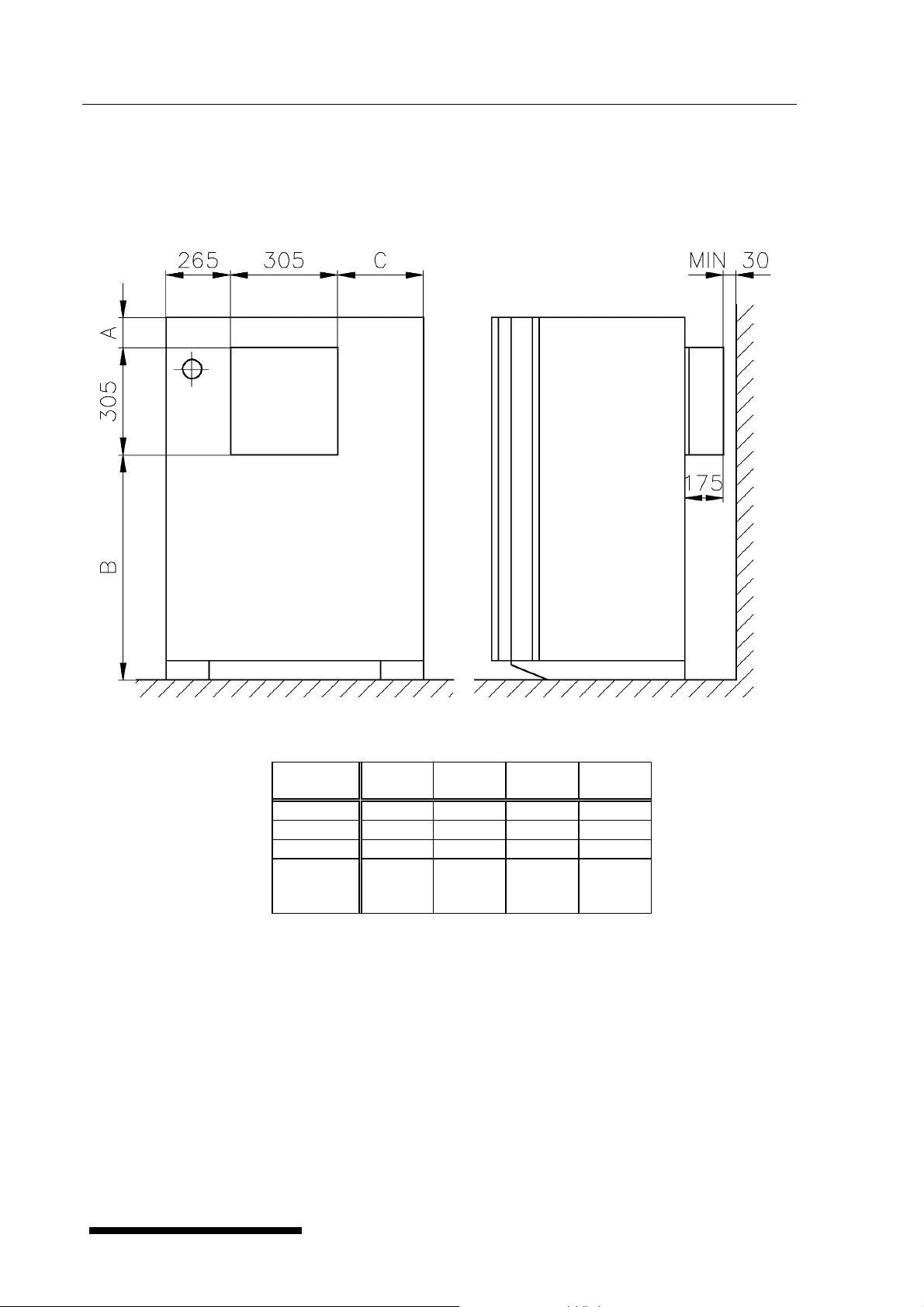

3.2 STERICELL 55~404 - placing the HEPA filter, filter dimensions, function

and filtration characteristic of the air filter

8

fig. 3

Type/

Dimens.

A (mm) 85 85 85 135

B (mm) 290 470 710 1470

C (mm) 50 190 190 190

Height

A+B+305

(mm)

55 111 222 404

680 860 1100 1910

Note: The minimum distance from the filter to the wall is 30 mm.

The air filter is a part of the optional accessories, it is installed when cooling STERICELL by

forced air circulation.

Class of the HEPA filter according to DIN 24 184 is S, according to EUROVENT it is EU 12.

V 1.09 Blue Line LSI_S_en_np 0402_mmm

Operating instructions Ovens line Standard Page

3.3 Power connection and connectors

Fig. 5 Foot of the unit with power supply - rear view (with the power part I)

9

1 Socket for printer

2 Supply lead

3 Screws attaching the power part

4 The power part panel (placed in foot)

Fig. 6 Interface for protocol printer

Pin Signal

2 TX

3 RX

5 GND

6 DTR

Ovens connected by RS-232C connector must meet the regulations and be approved

by the testing laboratory. Ovens are designed for connecting a CITIZEN printer, type iDP

3110-24 RF-A which can be ordered with the oven.

Interface parameters

Baud: 9600

Stopbit: 1

Parity: none

Databit: 8

LSI_S_en_np 0402_mmm V 1.09 Blue Line

Operating instructions Ovens line Standard Page

p

g

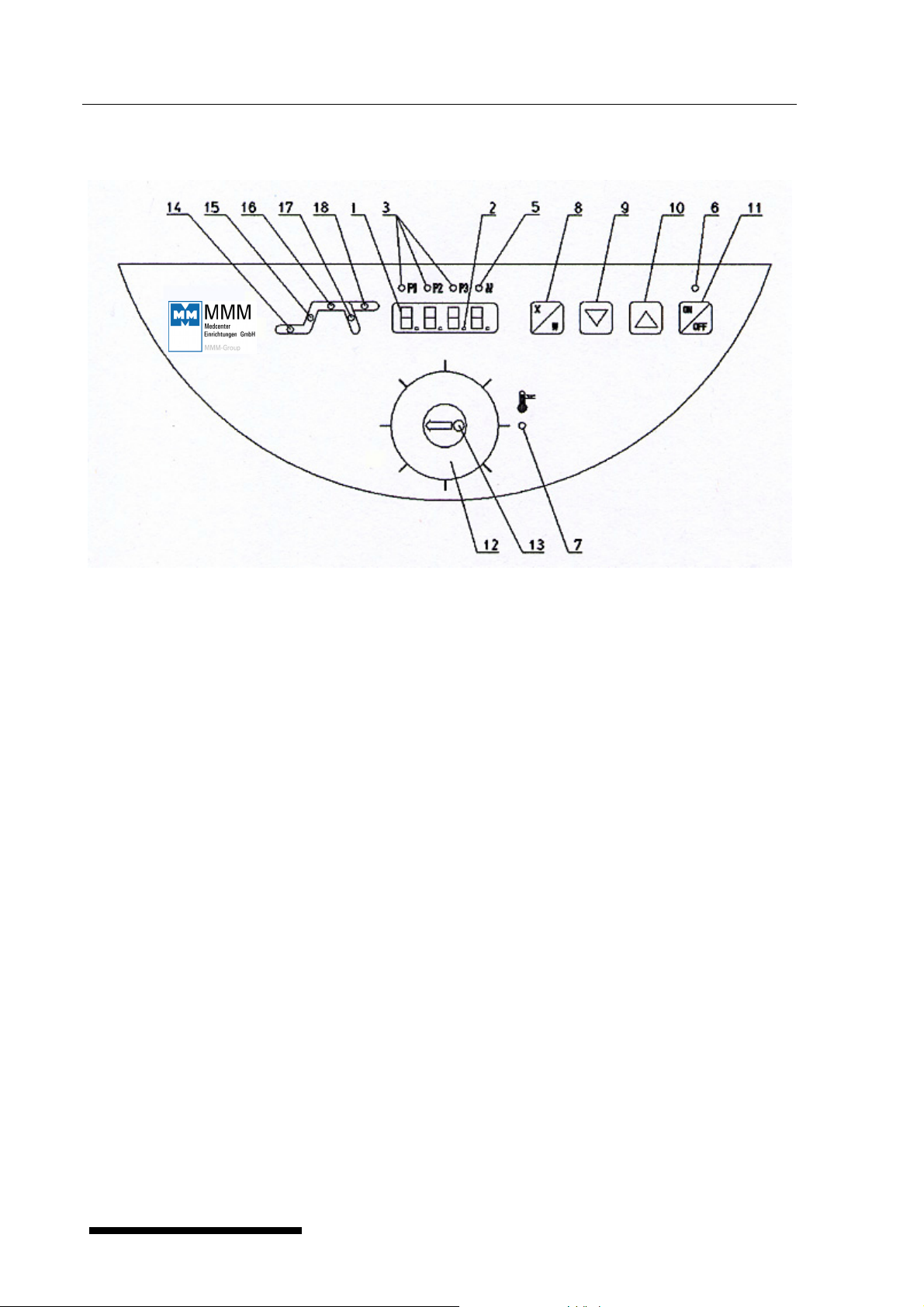

3.4 Control panel

10

Fig. 4

1 Display

2 decimal point - lights (the unit is connected to the mains - stand-by condition)

3 preselected programs indicator lamps- lights: program is active

- blinks: program will be active in 5 sec.

5 heating indicator lamp - lights:condition of temperature regulator - heating active

6 switching-on indicator lamp - lights after switching the unit on by the depression of

ON/OFF

7 protection thermostat indicator lamp - lights:temperature exceeds the selected setting

limit of the protecting thermostat - heating is off/further information see

chapter 4.8.Protecting thermostat function and setting-up

8 Setting-up mode activation button

9 setting the value downwards

10 setting the value upwards

11 switch ( ON – switched on, OFF - stand by condition)

12 adjustable protecting thermostat - outer rotary ring

13 button (RESET) to set the protecting thermostat in operation again

14 Indicator lamp: blinks - setting-up mode, lights - active part of the program is time-

delayed switching-on

15 Indicator lamp: blinks - setting-up mode, lights - active part of the program is heating

upto set temperature

16 Indicator lamp: blinks - setting-up mode, lights - active part of the program is time-

delayed switching-off

17 Indicator lamp: blinks - setting-up mode, lights - decrease of temperature after

switching-off

18 Indicator lamp: blinks - seting-up mode, lights - active part of the program is infinite

stay on set-up temperature

Indicator lam

s 14-18 blink - mode of number of cycles settin

V 1.09 Blue Line LSI_S_en_np 0402_mmm

Operating instructions Ovens line Standard Page

4 Function and operating

The unit can be set to various modes according to the required function, i.e. the unit’s cycle

can be modified, as described below. In Fig. a complete course of one cycle with its

segments is shown.

11

Segment Function

0 time-delayed switching,

a rise onto the temperature,

b time-delayed switching-off,

c temperature drop after switching off

Function of the control lights is described in section Description of the unit, in paragraph

Control panel.

4.1 Switch-on

1. After connection to the mains a green dot in the right lower part of the display lights

(stand-by condition) in case that the unit was in the stand-by mode before switching-off;

in contrary case the program continues by the part of the program which was

interrupted before switching-off.

2. Before switching-off.Depress button

lamp of one of preselected programs and indicator lamp of initial active phase of the

program light up; if preset temperature is higher than that in the chamber,the heating

indicator lamp lights also - either permanently or intermittently (depending on switched on

or switched off heating regulator).

3. The display displays real data relating to active phase of the program.

indicator lamp above the button, indicator

LSI_S_en_np 0402_mmm V 1.09 Blue Line

Operating instructions Ovens line Standard Page

4.2 Switch-off

Press the key . The display turns off, only the green control light in the lower right part is

on (stand by). The total unplugging from mains (in case of a long-term putting out of

operation or a maintenance) is achieved by pulling the service cord from a socket – see also

chapter Pre-installation.

4.3 User's supporting functions

Enter the function by simultaneous depressing +

By means of set on the display

12

a) U1 - setting the period of print of the printer from 0 up to 255 min by means of

enter the setting by means of

b) U2 - ON or OFF - set permission or prohibition of cycles by means of (for all

pre-selections at the same time), enter the setting by depressing

multiple repetition of the program with set time-delayed switching-off and switchingon.

Leave the setting by depressing

c) U3 – Prn or PC – data transfer via interface RS 232 either on the printer (Prn) or, in case

of using the program Warmcomm, on the computer (PC); set the sign Prn or PC by means

of.

d) U4 – reserve

e) U5 – permission (Y) or prohibition (n) of the acoustic signalizing at the exposure end (in

case of cycling after the end of the last cycle). The acoustic signal consists of three

consequent tones (between individual cycles one short high beep is heard). The primary

setting prohibits the acoustic signalizing.

and leave the function by depressing .

; a cycle means

,

4.4 Setting-up required values of temperature, time-delayed switching-off,

number of cycles, time-delayed switching-on.

1. Set preselection of program 1 or 2 or 3 by means of or , after depressing or

the control lamp of further program starts to flicker. This program will be activated

within ca. 5 sec, if no other button is depressed during this time. Setting by means of

or will cause the stop of the running cycle and starting a new cycle with the preselected parameters.

Setting-up cycle begins with setting required temperature.

V 1.09 Blue Line LSI_S_en_np 0402_mmm

Operating instructions Ovens line Standard Page

13

2. Depress , indicator lamps 15, 16 (Fig.4) begin to flicker, by means of set

required temperature in °C on the display

The lowest adjustable and displayable temperature interval with VC, EC, SD, DC is

1 °C with IC, ICV it is 0,1 °C.

Indicator lamps of the segments flicker permanently.

3. By depressing

off, by means of

change to the segment of setting the time-delayed switching-

set required value in hours and minutes from 1 to 99 hrs 59

min on the display, indicator lamps 16, 17 (Fig.4) flicker. The symbol --- corresponds to

the unlimited exposure.

4. By depressing

means of

change to the segment of setting the number of cycles and by

set the number of cycles from 1 up to 255 (more information on the

cycles see 4.3) - all indicator lamps flicker during setting up.

This function can be used with time-delayed switching-off ≠ 0 only.

Set the possibility to select the cycles by means of the user's supporting function.

5. By depressing

on and by means of

change to the segment of setting the time-delayed switching-

set the required value in minutes from 0 up to 99 hrs 59

min, indicator lamp 14 (Fig.4) flickers.

6. Start the program by double depressing

(start of the program is announced by an

acoustic signal). Data on real temperature with time count-down flickers on the display

during the phase of time-delayed switching on. The heating is switched on after

reaching the time of zero and the display shows the real temperature in the chamber.

After reaching the required temperature

a) in case of setting the time-delayed switching-off, the chamber temperature with the

set time count-down begins to flicker on the display

b) or in case of unlimited switching-off, the chamber temperature with the rising time

flicker on the display.

Permanently lighting indicator lamps give information on just active program segment.

7. Individual set values can be checked during the run of the program - by depressing

the required value is shown on the display, indicator lamps flicker, by another

depressing

within 5 seconds you change to the next segment, in this way all

settings can be checked successively.

Original program continues if you use no control element within 5 seconds.

8. Similarly, during the course of the program, you can change the already set values,

when

a) after setting the last value - time-delayed switching-on - you wait approximately 5

seconds, the program continues with changed values from the point of interruption,

b) after setting the value you start the program by double depressing

, the program

starts with new values from the beginning.

LSI_S_en_np 0402_mmm V 1.09 Blue Line

Operating instructions Ovens line Standard Page

4.4.1 Sterilization program setting and run - for STERICELL only

Data in previous paragraphs hold for setting and run.

Temperature °C Sterilization exposition in minutes

160 60

170 30

180 20

1. After the last depressing of the setting button the unit starts the first set segment

automatically. During this program phase (segment 0 and a ) the automatics permanently

checks the condition of the door and of the air flap. If the door or the air flap is open,

temperature and the message open flicker on the display. After closing the door and/or

the flap the message disappears.

2. A few seconds after reaching the sterilization temperature (this may be even with a

certain delay as compared with the data on the display) the set sterilization time begins to

be counted down – time-delayed switching-off (phase b). During this phase the

automatics permanently checks the condition of the door and of the air flap. If the door

or the air flap is open, the phase continues and the display shows the message open

and chamber temperature data alternately.

If the door or the flap is not closed, the unit switches off after the set exposure time is

reached and the display shows open/end and the temperature alternately, you can

14

cancel the message by double depressing

.

After closing the door or the air flap, segment b (or a - according to the real temperature

in the chamber) starts automatically from the beginning again.

If the temparture drops during this phase below the set value, the display indicates error

2.

3. The heating switches off after reaching the set time, indicator lamp 17 lights, the unit

starts to cool down (phase c) and the display shows the value of real temperature

and the note end alternately. Function of all buttons except of the switch (button 11, Fig.

4) is locked. Unlocking is done by opening the door or the air flap or by depressing

Then the note end disappears and the unit is in the stand-by mode.

4. If we want to repeat such set cycle, we activate the unit without setting by single

depressing

. The unit starts to run.

5 Warning! When starting a sterilization cycle - or in case of a set time-delayed switching-off,

the temperature in the chamber must be lower than the required one. Otherwise you

induce an error 3 message.

Note:

a) Because the STERICELL ovens are especially designed for sterilizing purposes, the

sterilization temperature within the sterilization space (definition see chapter Useful

space) is maintained with accuracy from -1 to +5 °C. The information on the display and

on the printer agrees with the real chamber temperature.

b) For sterilization of greater amount of small packed objects special holders of these objects

can be ordered.

.

V 1.09 Blue Line LSI_S_en_np 0402_mmm

Operating instructions Ovens line Standard Page

15

c) After reaching the set sterilization temperature and after the start neither the temperature

can be changed nor the program switched over.

d) In case of messages Err 2 and Err 3 you can cancel them by depressing

for ca. 2

seconds; the display shows brk (break) and the chamber temperature data alternately.

You can change the parameters or switch over the program or let the chamber cool down

in this condition. Start the new setting by depressing

.

Ventilator run and program end:

With all types containing ventilator the ventilator runs for 5 minutes after the program end

and then it is switched off.

4.5 List of error messages

Err 1 - not calibrated (the service engineer performs compensation of measuring conduits

of the sensor).

Err 2 - drop of temperature below sterilization temperature (only in case of SC, the function

is activated only with set time-delayed switching-off , deactivate setting by

cancelling)

Err 3 - rise of temperature above sterilization temperature (only in case of SC, the function

is activated only with set time-delayed switching-off, deactivate setting by

cancelling), or real temperature in the chamber is above set temperature.

Err 4 - Err 10 - HW error (report this event to the producer)

4.6 Printing the protocol

Printing the protocol with the help of CITIZEN printer, type iDP 3110-24 RF-A. Setting the

interval on a printer will decide at what interval the actual value of the chamber temperature

will be printed. The time of the interval will be printed on the head of the extract.

The interval of the printer can be set within: t

after 1 minute.

1. The display indicates the actual temperature. Connect the printer to the cabinet by the

RS-232C connector into the printer’s receptacle (see fit, 4), connect the other ending of

the cable to the connector rear of the printer. Connect the printer to mains by connecting

the adapter AC 230 V, 50 Hz, 0,1 A/DC 7 V, 1,6 A into the socket on the back side of the

printer and plugging the adapter into the wall socket. Turn the switch on the right side of

the printer off. The control light POWER and SEL is turned on. The printer is in ON-LINE

mode. Paper will start moving on by pressing the key LF (only in mode OFF-LINE, that is

after pressing the key SEL, the control light SEL switches off. To restore the mode ONLINE press the key SEL, the control light SEL switches on). The printer prints only in the

mode ON-LINE!

2. Set the required interval upwards or downwards according to Setting-up required

values of temperature.

3. The printer prints the heading containing type of the unit, set temperature and

selected time interval. Values of the following data are printed in one line under this

heading: time from starting the program and actual temperature in the chamber.

4. Switching the print off is performed by setting the print interval to 0 (symbol ---).

5. In case of change of set operation conditions of the oven or in case of change of print

interval a new heading will be printed (this is not valid when set interval is 0 (symbol---).

LSI_S_en_np 0402_mmm V 1.09 Blue Line

= 1 minute, t

min

= 255 minutes (4 hr. 15 min.),

max

Operating instructions Ovens line Standard Page

6. If the power supplying the apparatus fails , after the power recovery the printer prints the

sign Æ Power recovery! and the actual temperature value. Time intervals start counting

immediately after power recovery. After the unit has been turned off and turned on again,

a new head is printed.

7. If the power supplying the printer fails or the printer is turned off, no message is printed

after turning the printer on again or after power recovery .

Setting of the DIP / switches of the printer: all four pins are in lower position OFF.

4.7 Function and setting of the safety thermostat

The safety thermostat protects the oven, its surrounding and the goods against surpassing

the set temperature (for example it prevents the goods samples to be damaged or destroyed

when the temperature regulator is damaged or when you set unintendedly a chamber

temperature, which the sample cannot withstand).

Setting the thermostat:

Set the safety thermostat to a temperature higher then the rated temperature. The thermostat

turns off 5 to 10 °C higher than the set temperature (because of the temperature inertia of the

chamber material, and according to the heating-up time to the “switch-off’ temperature whether it is slow or quick).

16

Follow these steps to set the thermostat:

1. Push the outer revolving ring towards the operating panel. While slightly pressing rotate to

the right (clockwise) to the maximum. Together with the outer ring the center with the

button is rotating.

2. Heat the oven up to the working temperature and leave it for 10 minutes at this

temperature.

3. Now rotate the ring to the left - counterclockwise - (the same way as in the step 1) until the

control light protective thermostat comes on. At this moment the set temperature is

reached.

4. After that turn the ring to the right a little and press the thermostat button. You will hear a

“click“ and the control light protecitve thermostat comes off. If you do not hear the “click“

and the control light does not come off turn the ring a little more to the right and press the

button again - repeat so until the control light comes off; only in this case the thermostat is

set to the rated temperature.

If the oven is set to the maximum temperature, rotate to the right according to the step 1.

5. The oven continues working.

WARNING:

The safety thermostat is class 2 or class 3 (by EN 61010-2-010) - according to the type of the

oven. This distinguishes its function as follows:

In VENTICELL, ECOCELL and STERICELL there is a class 2 type - marked TWB

When exceeding the set temperature in the chamber, the thermostat turns the heating

elements off and the control light protective thermostat comes on (the oven does not heat

even if the control light heating is on). If the temperature drops below the limit of the safety

thermostat, the heating stays disconnected. It is necessary to press the safety thermostat

button to start the heating again. The control light protective thermostat comes off.

V 1.09 Blue Line LSI_S_en_np 0402_mmm

Operating instructions Ovens line Standard Page

17

In INCUCELL and in INCUCELL with ventilator there is a class 3 type - marked TWW

When exceeding the set temperature in the chamber, the thermostat turns the heating

elements off and the control light protective thermostat comes on (the oven does not heat

even if the control light heating is on). If the temperature in the chamber drops below the limit

of the safety thermostat, the heating is automatically turned on. The control light protective

thermostat comes off.

4.8 Adjusting and function of the air flap

Function description:

The air flap serves for ventilating the chamber space of the oven, for example when drying

wet material.

Adjusting the air flap:

Adjust the air flap when installing the unit. Put the operating lever of the air flap to the close

position and put the air flap in the exhaust rear of the oven so that it closes the entire

ventilating hole. Hold the shaft of the flap with pliers to prevent turning over.

Note:

In STERICELL, VENTICELL and INCUCELL WITH VENTILATOR it is necessary to adjust

the sucking air flap besides the exhaust air flap.

The air flap control:

If you put wet goods into an oven to dry it before warming (sterilization), put the air flap in

the position open so that the steam could freely leave the chamber. After drying put the air

flap in the position closed.

Note:

Operating the unit with an open air flap when no goods are being dried increases power

consumption and moreover the maximum temperatures may not be reached.

CLOSE

DOOR

OPEN

LSI_S_en_np 0402_mmm V 1.09 Blue Line

Operating instructions Ovens line Standard Page

4.9 Exchanging the door sealing and adjusting the door

Take off the sealing completely, start in the middle lower part.

Fix the new sealing on the edge of the chamber, start in the middle lower part. Squeeze the

sealing between the chamber and the outer cover.

To check up the tightness place a sheet of paper between the door and the chamber when

closing the door. Pull it out slowly, you should feel a relatively strong resistance.

The door is adjustable at four points:

- in the left upper part by means of bolts and nuts – sketch position 3

- in the left lower part by means of bolts and nuts – sketch position 4

- in the right upper part by means of screw with internal hexagon – sketch position 2

- in the right lower part after loosening the screw with internal hexagon adjusting in frontback direction of the door hinge is possible – sketch position 1

Adjust the door so that when closed the rubber sealing of the chamber would fit to the sheet

of the floating door along the whole perimeter. To check it up place a sheet of paper between

the sealing and the metal sheet of the floating door before it is closed, it is possible to take

the paper out against a small resistance.

18

V 1.09 Blue Line LSI_S_en_np 0402_mmm

Operating instructions Ovens line Standard Page

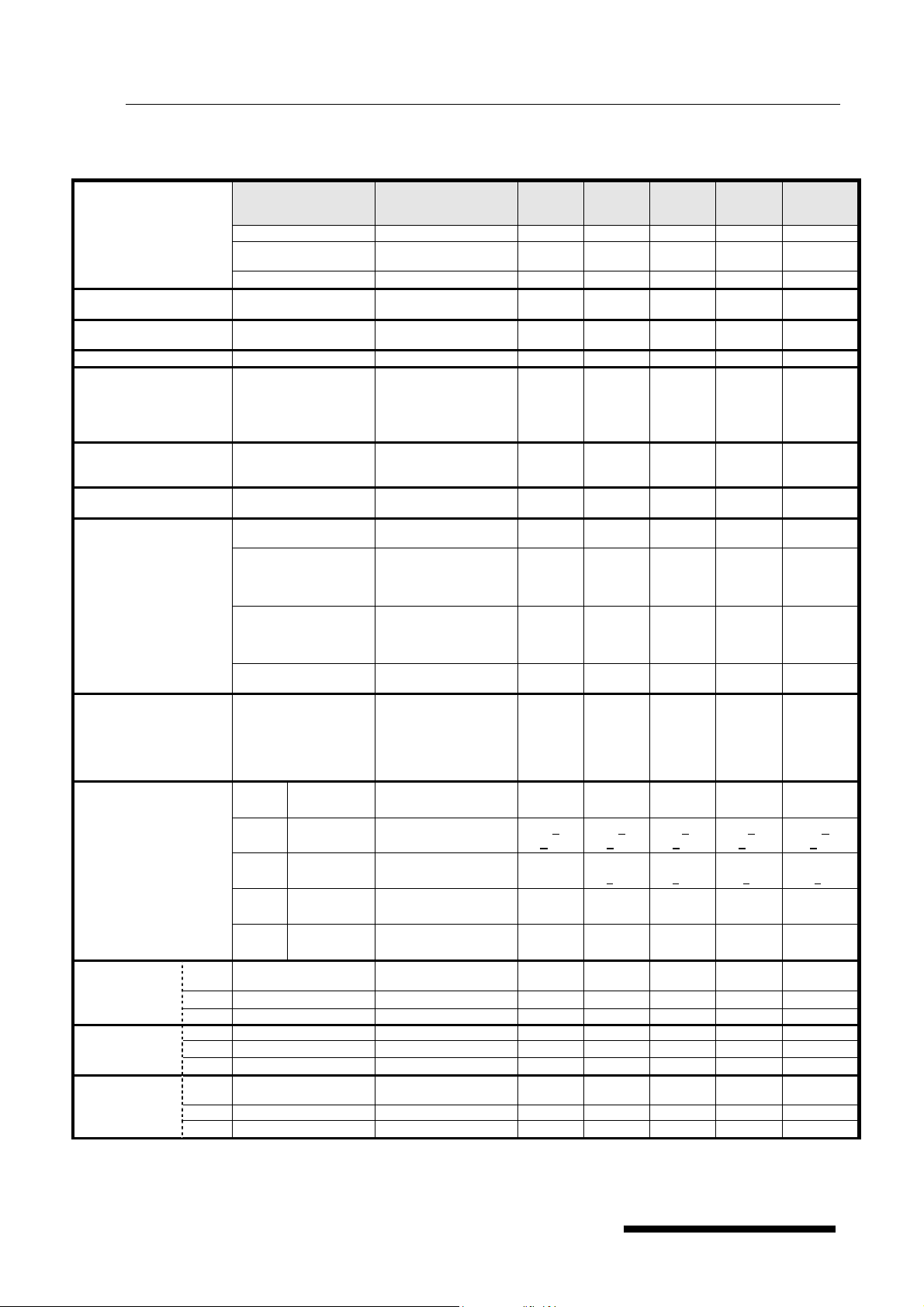

5 Parameters of the apparatus

Technical data

Interior

of stainless steel

material DIN No 1.4301

volume VC, IC / ICV, EC

SC

DC

width cca mm 400 540 540 540 940

depth VC, EC, SC, DC

IC / ICV

height cca mm 350 530 760 1410 1410

Tray

racks

standard equipment

Maximal weight of the

load *)

per tray

inside the oven

Door No. 1 1 1 1 2

External dimensions

(including door and handle)

width

depth

t (incl.Foots and Rolls)

heigh

diameter of the air branch

outer / inner

Package dimensions

(three layers carton)

width

depth

height (incl.palette)

Mass nett

brutt

Electricity

- mains 50/60 Hz

power W

input

[stand by]

max. power kW VC, SC

current A VC, SC

nominal voltage V VC, SC, DC, EC

Temperature

data

Working temperature

(beginning of the

regulation

Temperature accuracy

according to DIN 12 880 T2, at

working temperature with closed

air flap and door

Time required to

reach with closed air

flap and voltage

230 V

Heat emission at

250 °C

100 °C DC 41 48 50 41/38 59/51

37 °C IC/ICV 49 / 41 57 / 51 79 / 66 - 250 °C VC, EC, SC cca W 590 760 990 1940 2550

from 10 °C above ambient

temp. to °C

from 5/10 °C above ambient

temp. to °C

from 5 °C above ambient

temp. to °C

VC

( >50 °C)

IC/ICV

IC/ICV

EC

SC ****)

DC

temperature :

- accuracy in space

- accuracy in time

temperature :

- accuracy in space

- accuracy in time

temperature :

- accuracy in space

- accuracy in time

temperature :

- accuracy in space

- accuracy in time

temperature :

- accuracy in space

- accuracy in time

VC, SC

EC

100 °C DC 380 490 630 - 37 °C IC/ICV 30 45 45 65 85

Air exchange

speed at

150 °C VC, SC

EC

100 °C DC 8 12 5

37 °C IC/ICV 5 / 45 5 / 49 5 / 24 5 / 18 5 / 12

cca ltrs 55

55

55

cca mm 390

370

max. No

pcs. included

max. kg

max. kg

cca mm

cca mm

cca mm

cca mm

cca mm

cca mm

cca mm

cca kg

cca kg

20

50

620

640

680F

52/49

700

730

880

55

61

1,3

DC

IC / ICV

EC

1,2

0,3 / 0,7

1,2

5,6

DC

IC / ICV

EC

5,2

1,3 / 3

5,2

230

IC / ICV

VC **)

SC

IC / ICV ***)

EC

DC

cca (±) % of the reached

temperature

cca (±) °C

cca (±)°C

cca (±) °C

cca (±) % of the reached

temperature

cca (±) °C

cca °C

do °C

cca (±) % of the reached

temperature

cca (±) °C

cca min.

230

250 / 300

250

70 / 99,9

250

125

0,4

<0,5/<0,3

<0,2

0,3

+5 / -1

+3 / -1

0,3

49

59

cca/h 45

111

111

111

390

370

4

2

7

2

20

50

760

640

860F

52/49

830

730

1050

75

84

222

222

222

540

520

10

2

30

70

760

790

1090F

52/49

830

860

1280

100

117

404

404

-

540

520

19

2

30

100

760

790

1910R

52/49

830

860

2070

150

165

1160

1910R

52/49

1350

2080

5555 5

1,9

1,8

0,3 / 0,7

1,8

8,3

8,3

1,3 / 3

7,8

230

230

250 / 300

250

70 / 99,9

250

125

1

1

0,4

<0,5/<0,3

<0,2

2

2

<0,8

+5 / -1

+3 / -1

2

2

0,3

53

60

49

8

12

1,9

1,9

0,5 / 0,7

1,8

8,3

7,8

2 / 3

7,8

230

230

250 / 300

250

70 / 99,9

250

125

1

0,4

<1/ <0,3

<0,2

2

<0,8

+5 / -1

+3 / -1

2

0,3

70

99

24

5

3,7

-

0,9 / 1,3

3,6

5,2; 5,2; 5,2

-

3,9 / 5,6

3,9; 3,9;7,8

400/3N

230

250 / 300

250

70 / 99,9

250

-

1,5

0,4

<1/ <0,8

<0,2

2,5

<1

+5 / -1

+3 / -1

-

-

58

85

18

4

0,9 / 1,3

5,2; 7,8;7,8

3,9 / 5,6

73,9; 7,8;7,8

400/3N

250 / 300

70 / 99,9

<1,5/<1,5

<0,2

19

707

-

-

540

520

19

2

50

130

790

860

215

233

4,9

-

4,5

-

230

-

250

-

2,5

0,4

3,5

<1

-

-

-

-

64

95

12

3

Note: All technical data are related to 22 °C ambient temperature and ± 10 % voltage swing (if not specified). For other parameters see section Electric connections

*) Approx. 50 % of the tray area can be filled in a way a uniform air circulation is enabled inside the chamber.

**) Standard type is up to 250 °C, optional type is up to 300 °C ****) The definition of the sterilizing space given in chapter Useful space is valid

***) Standard type is up to 70 °C, optional type is up to 99,9 °C

LSI_S_en_np 0402_mmm V 1.09 Blue Line

Operating instructions Ovens line Standard Page

5.1 Electric connections

Basic data for connection:

Mains connection 1x230V/50(60)Hz

3x400V/50(60)Hz+N+PE;

(standard types are marked with bold face)

1x110-125V/230-240V//50(60)Hz;

3x110-125V/230-240V//50(60)Hz;

protection against dangerous contact - class I

external circuits isolation double isolation (tested by 4 kV voltage)

type of unit plug as a standard CEE-7/VII, IEC-83/CH, 16

A/250 V (or another according to the type)

socket protection 10 A – 32 A (acc. tech. parameters in the

Operating instructions of the unit)

protection according to EN 60529 IP 20

overvoltage category according to

(IEC 664 – EN 61010) II in case of pollution degree 2

used fuses according to corresponding schemes in

the Service instructions

Ambient conditions:

ambient temperature: +5 °C to + 40 °C

max.relative humidity: 80 % at 31 °C

20

6 Cleaning of the oven

Clean the oven while cold and when the power supply cord is disconnected from the mains.

Clean the interior walls of the chamber as well as the exterior of the oven with water and

detergent, resp. with suitable chemicals. Abrasive cleaning agents may scratch the metal

sheets. If you want to clean the outer jacket of the chamber, take the inner walls of the

chamber out as follows:

Shift the upper wall of the chamber out of the oven, take out the side walls, the bottom and

the rear wall. Put the oven together in a reverse sequence after it has been cleaned, be

concerned with the bottom and the side walls which should be slid in behind the four

projections in the front part of the chamber.

In case some contaminated material escapes into the chamber the user is responsible for

proper decontamination of all contaminated surfaces with suitable and approved disinfecting

agent.

Before using some other cleaning or decontamination method different from our

recommendation, it is suitable for the user to be informed by with the producer whether the

intended method cannot cause a damage to the device.

7 Maintenance

No special maintenance is necessary. If you have any troubles, please, call the service.

V 1.09 Blue Line LSI_S_en_np 0402_mmm

Operating instructions Ovens line Standard Page

21

8 Warranty and service

Warranty is guaranteed by MMM for satisfactory delivery and functioning of the ovens within

the contractual regulations and the period of the warranty.

MMM does not cover any deficiencies or damages due to normal wear and tear, chemical or

physical attack, excessive overload, incorrect handling or due to the ovens being used in a

way in which it was not intended to be used, particularly in case of non-observance of the

enclosed operating instructions, incorrect installation resp. start-up by the customer or a third

party, as well as in the case of damage to the system caused by foreign objects or

inadequate maintenance and repairs In the case of sending back to the producer (to repair or

exchange at claim), use the original package. In the other case you accept the responsibility

for eventuel damage during transport and the producer will exact from you a compensation of

necessary coherent repairs. In the case of sending back to the producer (to repair or

exchange at claim), use the original package. In the other case you accept the responsibility

for eventuel damage during transport and the producer will exact from you a compensation of

necessary coherent repairs.

.

For a correct connection to the mains observe the technical data and Operating

instructions

Important:

MMM (the producer) covers the safety and technical qualities of the oven only in case the

repairs and adjustments are done by the producer or by an organization commissioned by

the producer and the components are replaced with parts allowed by the producer and of

the MMM standard.

After a repair has been done, the company recommends the user to demand a certificate

from the repairer describing the kind and extent of the repairs, resp. describing a change of

nominal data or an extent of the work, containing the date of the repair, name of the firm and

a signature,

9 Transport and storage

Device will be prepared for transport by a competent person (who also disconnects the

device from the mains). Device must be transported and stored in original wrapping. If you

send the device back (for reparation or change in case of reclamation), use the original

wrapping. Otherwise you overtake the responsibility for event. damaging during the transport

and the producer will reclaim compensation for event. additional reparations. Device can be

stored in the ambient temperatures of 0 °C to 40 °C.

10 The way of liquidation of package and discarded aparatus

a) palette – liquidation in the incinerator

b) carton – recyclable waste

c) unit out of action -the liquidation shall be performed by a firm that is authorized to dispose

waste and that secures the disposal in accordance with legal environmental standards.

The unit does not include any environmentally harmful components.

LSI_S_en_np 0402_mmm V 1.09 Blue Line

Operating instructions Ovens line Standard Page

11 Optional equipment

11.1 Door with window and inner lighting (except IC, ICV)

The door is provided with three-layer thermally resistant windows; layout and dimensions are

shown in the picture on the following side.

Caution!

During the operation of the cabinet do not touch the glass surface. This surface cannot

be heat-insulated like the metal sheet door. That is why the temperature of the glass surface

is higher than that of other surfaces and there is a danger of burns. The inner space is

illuminated with heat resistant bulbs – their switch is placed on the door. For types IC, ICV

the door with window is not available.

The surface of the door with windows causes larger thermal losses, which increases spatial

temperature deviations in the chamber (compared with common door without windows).

22

V 1.09 Blue Line LSI_S_en_np 0402_mmm

Operating instructions Ovens line Standard Page

Door with glass window

23

LSI_S_en_np 0402_mmm V 1.09 Blue Line

Operating instructions Ovens line Standard Page

11.2 Bushings of diameter 25, 50, 100 mm

The bushings are normally placed cca in the middle of the side (right or left) wall of the

chamber. The bushes are metallic, closed with a special plastic plug from the outer side,

which enables passing through of wires etc. from the outer space to the chamber.

Recommendation: the used unit should be provided with a bushing with corresponding

dimensions, if user wishes to measure temperature inside the chamber by means of sensors,

that are connected with an independent measuring device by means of wires; the user pulls

the wires through the bushing.

11.3 Lockable door

The lock is placed on the upper part of door's surface near the closing mechanism.

24

11.4 Left door

This is the symmetric mirror version of the right door. The cabinet of 404 liter is not delivered

in this version.

11.5 Independent sensor PT100

Another additional sensor - movable inside the chamber, by means of which the temperature

in the chamber or in the treated probe can be measured. The wires of the sensor are

connected to a connector located at the back in the device foot. The measuring apparatus,

used for evaluating the sensor signal, is not part of the delivery and the customer must get it

by himself.

Notice: the sensor wires can also be lead through a bushing according to 11.2 without using

a connector.

11.6 Communication SW Warmcomm for PC under Windows

The program Warmcomm is designed to record the temperature course in the thermal

cabinets. Data obtained during the regulation are displayed in form of a graph (with time on

the horizontal axis and obtained data on the vertical axis). The program enables to follow the

regulation in real time, to store the regulation course to a file on a disc and to view the

already stored files, to send e-mails in case of not receiving data from the cabinet and to

send reports of extreme values being reached within the specified time interval.

Operation instructions of this program are delivered together with the installation program,

minimal requirements on PC hardware for the program Warmcomm are:

• Operation system Windows 95 and above, Windows NT 4 and above

• CPU min. 200 MHz

• RAM min. 32 MB (for shorter measurement of one unit)

• one-hour-record of data requires free space of about 150 KB on the hard disc

V 1.09 Blue Line LSI_S_en_np 0402_mmm

Operating instructions Ovens line Standard Page

25

• maximal length of the connecting cable is 15 m (specified by RS 232 standard)

• free serial port

11.7 HEPA filter

See par 3.2 Stericell – placing the HEPA filter.

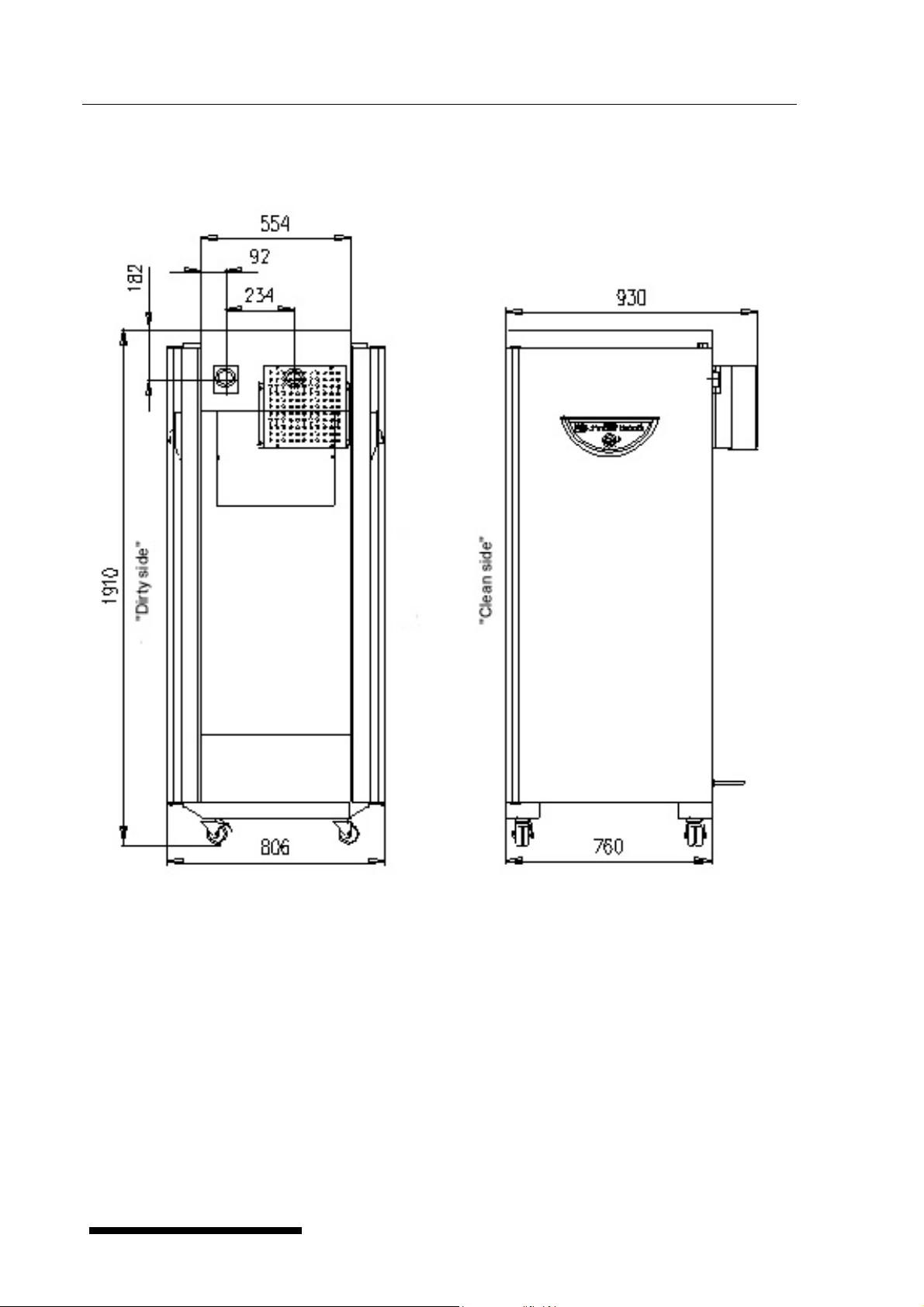

11.8 Two-door passing through version

This version is only in VC and SC 404 available. It enables to load the material in one space

and unload it in the other space after the heat treatment (for instance in case of SC: loading

in an unsterile - ”dirty” – space and unloading in the sterile - “clean” – space after

sterilization).

The passing through Stericell is provided with additional options as follows:

• mechanical door lock on both doors,

• microswitches of locks on both doors – display on the panels of both doors reports

opening of any door during the sterilization with “open”

• LED graph on the panels of both doors informs about the active program phase

This equipment helps to ensure a safe sterilization course.

Caution!

When using the passing through variant of SC (except for cleaning and maintenance)

only one door can by opened simultaneously.

If the material still has not been sterilized, the door on the “clean” side must not be

opened.

Otherwise there is a danger of the clean space contamination!

In case the rules of safe work are not followed, following nonstandard states can occur:

a) if you unlock and open the door on the “clean” side during the sterilization, a message

“open” is shown on the display – it means, that you have caused a risk of contaminating

the “clean” place, after closing the door the sterilization cycle is repeated,

b) if you unlock and open the door on the “dirty” side during the sterilization, a message

“open” is shown on the display – you have caused a risk of contaminating the sterilized

material, after closing the door the sterilization cycle is repeated.

11.8.1 Two-door STERICELL 404 - installation data

1) input power 3700 W

2) electrical installation – connection of the device:

- plug VDE 0623, DIN 4962/63, CEE 17, IEC 309, 3P + N + PE, 16A/380-415 VAC

- supply to the socket from the switchboard 5x2.5 mm

16 A – place near the unit

- cable length 3 m

3) heat emission at 200 °C: 1900 W

4) weight: 150 kg

2

Cu, protection by circuit breaker

LSI_S_en_np 0402_mmm V 1.09 Blue Line

Operating instructions Ovens line Standard Page

Main dimensions of STERICELL 404 - passing through

26

V 1.09 Blue Line LSI_S_en_np 0402_mmm

Operating instructions Ovens line Standard Page

27

LSI_S_en_np 0402_mmm V 1.09 Blue Line

Operating instructions Ovens line Standard Page

Cover sheets

28

Detail A

6x screw ∅ 4x40 with countersink head with cross groove for fixing to a wall insert dowels

with a size of 8 to the wall

Detail B

19x screw for a metal sheet ∅3,9x9 with a half-round head and a cross groove necessary

to screw with cover sheets with holes of ∅3.2

Detail C

By beating the pins to the rectangular holes of the sheet borders secure them together.

V 1.09 Blue Line LSI_S_en_np 0402_mmm

Operating instructions Ovens line Standard Page

11.9 Adaptation against drying-up of cultivating mediums and tissue cultures

This mechanical and program adaptation reduces considerably the drying-up of cultivating

mediums and tissue cultures when using INCUCELL with ventilator. Basically there is

increased the chamber tightness, it is not possible to open the valves of air holes, there is a

humidity tray added, the ventilator is closed when the door is opened.

29

LSI_S_en_np 0402_mmm V 1.09 Blue Line

Loading...

Loading...