MMM VENTICELL, INCUCELL, INCUCELL V, ECOCELL, STERICELL User manual

...

Laboratory drying ovens and incubators

line Standard

VENTICELL 55, 111, 222, 404, 707

INCUCELL 55, 111, 222, 404, 707

INCUCELL V 55, 111, 222, 404, 707

ECOCELL 55, 111, 222, 404, 707

STERICELL 55, 111, 222, 404

DUROCELL 55, 111, 222

Operating instructions

MMM Medcenter Einrichtungen GmbH producer:

MMM Medcenter

Einrichtungen GmbH

Schulstrasse 29

D – 82 166 Gräfelfing

Tel.: +49 89 89 92 26 20

Fax: +49 89 89 92 26 30

LSI_S_en_np 0402_mmm V 1.09 Blue Line

Operating instructions Ovens line Standard Page

Contents:

10. 2. 2004

1 GENERAL ...................................................................................................................................... 3

1

1.1 P

URPOSE AND USE....................................................................................................................... 3

2 IMPORTANT INSTRUCTIONS ...................................................................................................... 3

2.1 U

2.2 P

NPACKING, CHECKING AND TRANSPORT ....................................................................................... 3

RE-INSTALLATION ....................................................................................................................... 4

2.3 USEFUL SPACE ............................................................................................................................. 6

3 DESCRIPTION OF THE OVEN...................................................................................................... 7

3.1 G

ENERAL VIEW ............................................................................................................................. 7

STERICELL 55~404 - PLACING THE HEPA FILTER, FILTER DIMENSIONS, FUNCTION AND FILTRATION

CHARACTERISTIC OF THE AIR FILTER

....................................................................................................... 8

3.3 POWER CONNECTION AND CONNECTORS........................................................................................ 9

3.4 CONTROL PANEL......................................................................................................................... 10

4 FUNCTION AND OPERATING.................................................................................................... 11

4.1 S

WITCH-ON ................................................................................................................................11

4.2 SWITCH-OFF............................................................................................................................... 12

4.3 U

SER'S SUPPORTING FUNCTIONS................................................................................................. 12

4.4 SETTING-UP REQUIRED VALUES OF TEMPERATURE, TIME-DELAYED SWITCHING-OFF, NUMBER OF

CYCLES

, TIME-DELAYED SWITCHING-ON. ............................................................................................... 12

4.4.1 Sterilization program setting and run - for STERICELL only.......................................... 14

4.5 L

IST OF ERROR MESSAGES .......................................................................................................... 15

4.6 PRINTING THE PROTOCOL............................................................................................................ 15

4.7 F

UNCTION AND SETTING OF THE SAFETY THERMOSTAT.................................................................. 16

4.8 ADJUSTING AND FUNCTION OF THE AIR FLAP ................................................................................. 17

4.9 EXCHANGING THE DOOR SEALING AND ADJUSTING THE DOOR ........................................................ 18

5 PARAMETERS OF THE APPARATUS....................................................................................... 19

5.1 E

LECTRIC CONNECTIONS............................................................................................................. 20

6 CLEANING OF THE OVEN ......................................................................................................... 20

7 MAINTENANCE ........................................................................................................................... 20

8 WARRANTY AND SERVICE ....................................................................................................... 21

9 TRANSPORT AND STORAGE.................................................................................................... 21

10 THE WAY OF LIQUIDATION OF PACKAGE AND DISCARDED APARATUS ......................... 21

11 OPTIONAL EQUIPMENT............................................................................................................. 21

11.1 D

OOR WITH WINDOW AND INNER LIGHTING (EXCEPT IC, ICV).................................................... 22

11.2 BUSHINGS OF DIAMETER 25, 50, 100 MM ................................................................................ 24

11.3 LOCKABLE DOOR .................................................................................................................... 24

11.4 L

EFT DOOR ............................................................................................................................ 24

11.5 INDEPENDENT SENSOR PT100................................................................................................ 24

11.6 C

11.7 HEPA

OMMUNICATION SW DS COM FOR PC UNDER WINDOWS ...................................................... 24

FILTER ........................................................................................................................ 25

11.8 TWO-DOOR PASSING THROUGH VERSION ................................................................................. 25

11.8.1 Two-door STERICELL 404 - installation data ................................................................. 25

11.9 A

DAPTATION AGAINST DRYING-UP OF CULTIVATING MEDIUMS AND TISSUE CULTURES.................. 29

LSI_S_en_np 0402_mmm V 1.09 Blue Line

Operating instructions Ovens line Standard Page

2

V 1.09 Blue Line LSI_S_en_np 0402_mmm

Operating instructions Ovens line Standard Page

1 General

The ovens with electric heating are designed for laboratories, generally for a warming of

various materials by means of hot air at adjustable temperature and optional time. The air

flap enables drying of wet material.

A modern microprocessor (Fuzzy - logic) with a digital display and PT 100 controls the

temperature. Thus exact temperature accuracy and process safety are guaranteed.

The ovens are designed according to EN standards.

They are manufactured of high grade materials with the latest technology.

Each oven is subjected to a strict final test leaving the plant.

1.1 Purpose and Use

VENTICELL (VC) serves for warming of materials by means of hot air with forced-air

circulation by a fan. The ovens are designed for temperatures up to 250 °C, another variant

(+) up to 300 °C.

3

INCUCELL (IC, ICV) serves as an incubator or for cell cultivation in a microbiological

laboratory (see chapter Optional equipment, article Adaptation against drying-up of

cultivating mediums and tissue cultures). The ovens are designed for temperatures up to 70

°C. A quiet operation is characteristic for the variant IC (without a ventilator), more accurate

temperature regulation with small deviations is characteristic for the variant ICV (with

ventilator).

ECOCELL (EC) serves for warming by hot air with natural circulation. The ovens are

designed for temperatures up to 250 °C. They work quietly with lower power consumption

compared with VC units.

STERICELL (SC) serves for sterilizing by hot air with forced-air circulation by a fan. The

ovens are designed for temperatures up to 250 °C. STERICELL uses time-delayed switchoff program for sterilizing, refer to section Set and Running the Sterilizing Program.

DUROCELL (DC) serves for warming by hot air with natural circulation (usefull at procedures

as acid hydrolysis, extraction by nonflammable solvents, thermolysis). The ovens are

designed for temperatures up to 125 °C. Internal surface is covered by a layer of EPOLON,

that protects the chamber against corrosive influence of acids in the form of vapors or liquids.

2 Important Instructions

2.1 Unpacking, checking and transport

Please check after unpacking the oven and its accessories are complete and not damaged.

A possible damage is to be reported to the forwarding agent. An eventual damage must be

immediately reported to the transporting company.

LSI_S_en_np 0402_mmm V 1.09 Blue Line

Operating instructions Ovens line Standard Page

During the manipulation – in case of lifting the cabinet etc. – the cabinet cannot be hold by

the rail or door. The cabinets of volumes 404 and 707 should be lifted by means of delivered

hooks, the rolls are designed for local moving, not for longer transport.

The standard delivery consists of the temperature cabinet, two sieves.

2.2 Pre-installation

♦ Please read carefully the operating instructions before working with the oven!

♦ Install the instrument by plugging the power cord to a line voltage socket. The specified

parameters of the connection are described in chapter Electrical Connection. Adjust the

position of air valve according to chapter Air Valve - Adjustment and Functions. For

VC, SC and ICV types, adjust two air valves – suction and exhaust.

After the first switching-on of the unit the heating bodies and insulation start to be

baked with a typical a smell; after a few operation cycles this smell disappears,

nevertheless it is suitable, during the insulation baking at a temperature above 100°C,

to secure a sufficient air exchange (e.g. by ventilation or exhaustion).

At temperatures above 100 °C the inner chamber surface becomes yellowish. This

coloration is neither the material nor the device defect.

4

The air exhaust in VC, EC a SC types is protected by a cover rear of the unit. This

cover is placed inside the oven while shipping. When installing the unit, insert the

cover into the horizontal openings bellow and above the exhaust to attach it behind

the exhaust.

An air filter can be connected to the suction hole in SC types - see section

Function and filtration characteristics of the air filter.

Ovens are designed to be operated indoor within ambient temperatures from 5 °C to

40 °C and at maximum relative humidity 80 %.

The oven should be installed with a 100 mm distance to the walls at the side and in

back. The temperature of the air coming out of the exhaust may be up to 250 °C

(resp. 300 °C), so the walls near the oven must be inflammable

.

No inflammable or explodable materials may be put into ovens !

Carrying capacity of the floor during installation of the device must correspond to the

weight of the unit itself taking the weight of the maximum charge into consideration

(see chapter Parameters of the unit).

The unit must not be placed on a pad that could cause a danger of fire or smothering

in case of falling some hot object out of the cabinet.

No inflammable, explosive or toxic materials may be put into ovens! The same

applies to materials that could give off such a stuff.

Goods are only to be put on trays into ovens, never directly on the bottom of the oven!

No dangerous goods are permitted. Ovens may not be used for heating of liquids.

V 1.09 Blue Line LSI_S_en_np 0402_mmm

Operating instructions Ovens line Standard Page

Aparatus may not be used in the atmosphere with a possible danger of flammable or

explosive anesthetics.

Any assembling or disassembling may be done only when disconnected from

mains! After the button (button 11, fig. 4) activates the stand-by state, the oven

comes only to a stand-by state, however it is not disconnected from the mains!

♦ If the oven is not used for a longer time, disconnect it from mains by pulling the service

cord from the socket

Power cord can not get to the contact with hot parts of the aparatus – protection

cover of exhaust hole

♦ Safety thermostat assures the protection of the oven, surroundings and goods against

surpassing the rated temperature. Protection through temperature safety class 2

according to EN 61010-2-010 is for VC and EC, protection through temperature

safety class 3 according EN 61010-2-010 cs for IC, ICV. Check regularly – daily – the

function safety thermostat.

♦ The door and the exhaust air flap in SC type are provided with microswitches - see

section Setting and running the sterilizing program.

5

Pull out and consequently push in the upper metal plate piece of internal chamber

carefully, there is a danger of cutting through the rubber gasket of the chamber during

careless manipulation.

The maximum permitted loads: see section Parameters of the unit.

Only for STERICELL

The units of STERICELL 404 are provided with a door lock – for securing the safety.

You can enter the chamber, e.g. because of cleaning, only if the door is locked

(blocked) in an open state. You must keep the key all the time you find yourself inside

the chamber.

When operating the cabinets at high chamber temperature there can be the

maximum allowed temperature of 70 °C at their outer surface (exhaust ports and their

surroundings and the surroundings of the chamber sealing, window and door surface

in case of the optional type with window in door) surpassed and there is a danger of

burns. Please take a high precaution.

During the operation of the devices of 404 and 707 at high temperatures a

deformation of the inner door surface occurs as a consequence of thermal tension,

which makes their closing more difficult. If you open the door in this state, do not

close them until the chamber is cooled down. Otherwise the door mechanism could

be damaged.

LSI_S_en_np 0402_mmm V 1.09 Blue Line

Operating instructions Ovens line Standard Page

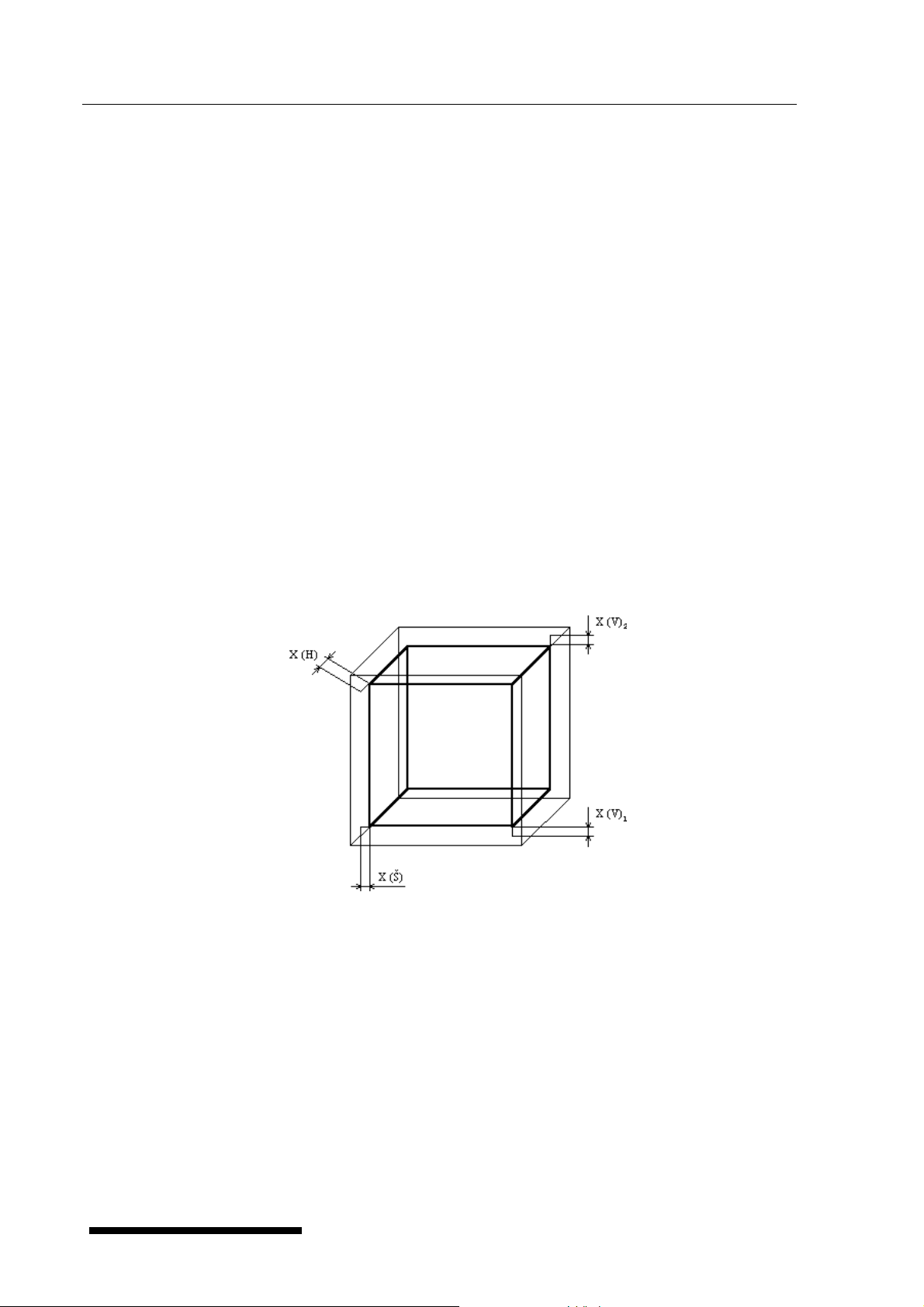

2.3 Useful space

Useful space is illustrated on fig. No. 1, where X(H) = 10 % of the inner chamber depth,

X(Š) = 10 % of the inner chamber width, X(V)

bottom of the inner chamber, X(V)

is the distance from the upper most tray to the ceiling of

2

the inner chamber. The required temperature accuracy - see section Parameters of the unit

- is achieved only in the space defined above (according to DIN 12 880 - marked with thick

lines, thin lines mark inner chamber walls). It means, that over the last upper tray there are

the limits from section 5. not obligatory.

For Stericell following definition of the sterilizing space is valid:

at the side to the door is X(D) = 20 % of the inner chamber depth, at the rear side in the

single-door type X(D) = 10 % of the inner chamber depth, X(W) = 10 % of the inner chamber

width, X(H)

is the distance from the lowest tray to the bottom of the inner chamber, X(H)2 is

1

the distance from the upper most tray to the ceiling of the inner chamber. The required

temperature accuracy - see section Parameters of the unit - is achieved only in the space

defined above (according to DIN 12 880 - marked with thick lines, thin lines mark inner

chamber walls). It means, that over the last upper tray there are the limits from section 5. not

obligatory.

is the distance from the lowest tray to the

1

6

Fig. 1

V 1.09 Blue Line LSI_S_en_np 0402_mmm

Operating instructions Ovens line Standard Page

)

3 Description of the oven

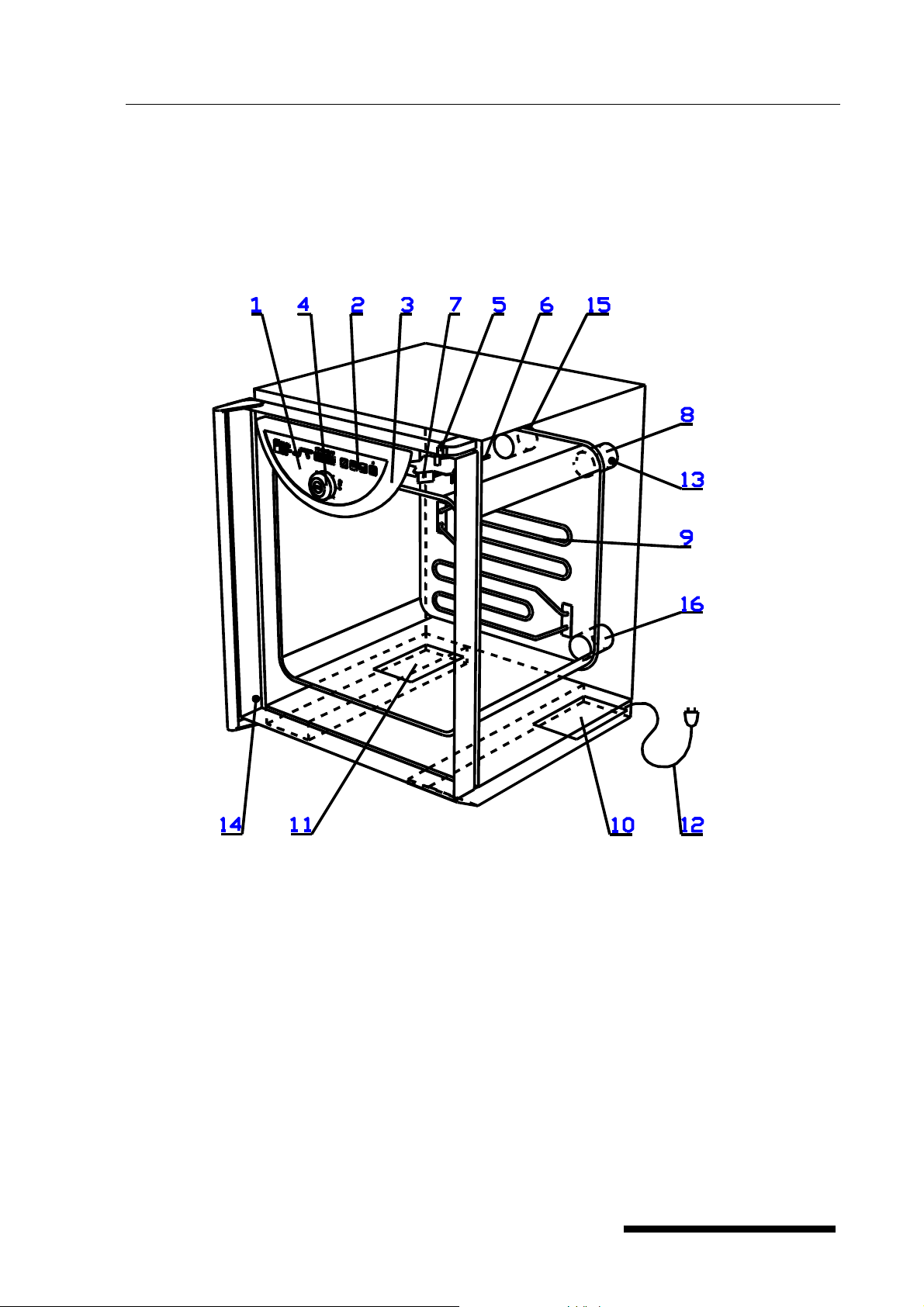

3.1 General view

7

Fig. 2

1 Panel of regulator 2 control buttons

3 Plastic cover of the regulator panel 4 control ring and button of

safety thermostat

5 air flap lever 6 case of sensor Pt 100

7 Ventilator (only for VC, ICV a SC) 8 exhaust with air flap (with

all types)

9 Heating elements 10 Power part I

11 Power part II (only three-phase type) 12 Connection to the mains

13 Sensor for air flap position (only for SC) 14 door sensor (only for SC)

15 Suction hole (only for VC, ICV, SC with air flap) 16 suction opening (with types

EC, IC, DC

LSI_S_en_np 0402_mmm V 1.09 Blue Line

Operating instructions Ovens line Standard Page

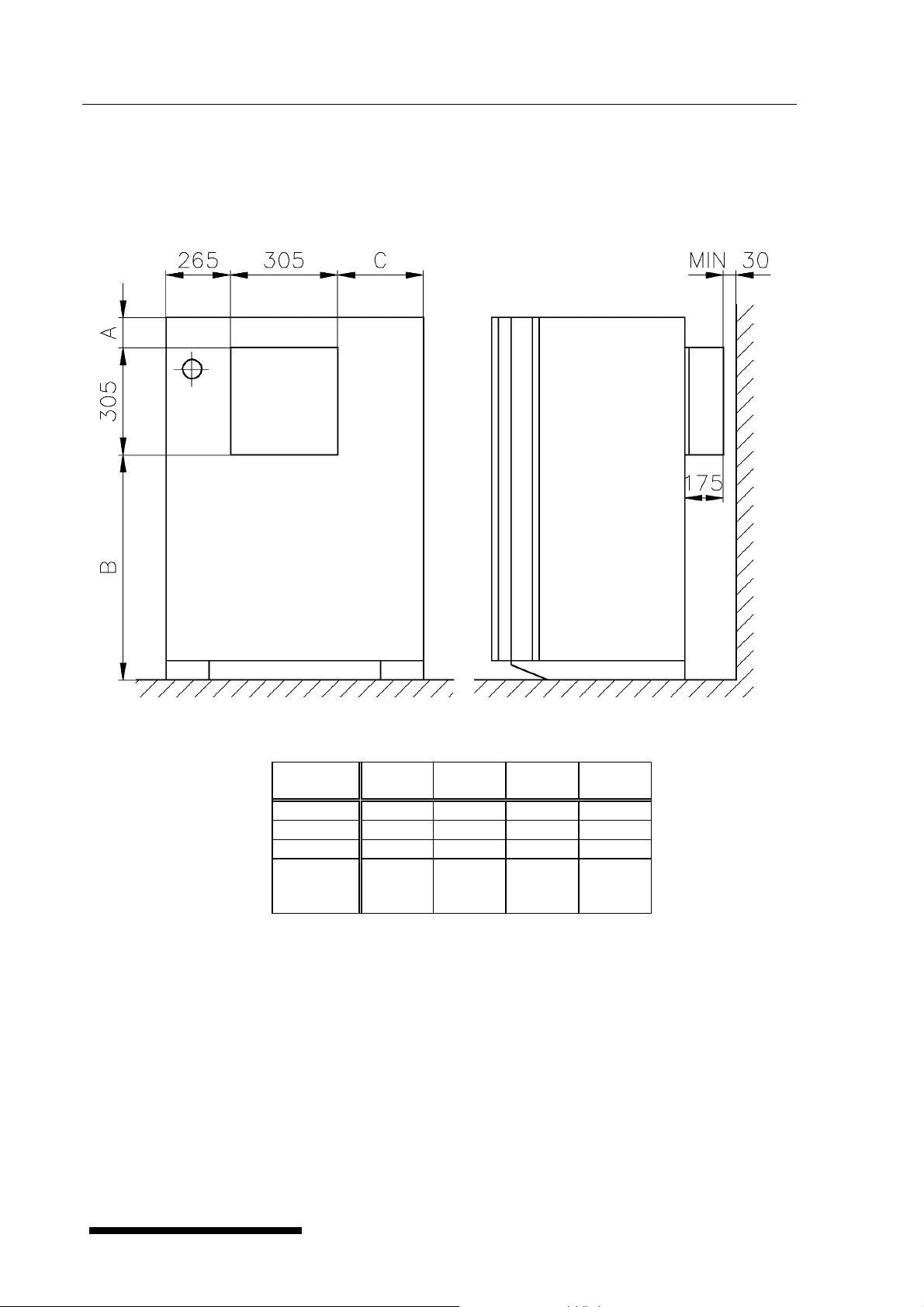

3.2 STERICELL 55~404 - placing the HEPA filter, filter dimensions, function

and filtration characteristic of the air filter

8

fig. 3

Type/

Dimens.

A (mm) 85 85 85 135

B (mm) 290 470 710 1470

C (mm) 50 190 190 190

Height

A+B+305

(mm)

55 111 222 404

680 860 1100 1910

Note: The minimum distance from the filter to the wall is 30 mm.

The air filter is a part of the optional accessories, it is installed when cooling STERICELL by

forced air circulation.

Class of the HEPA filter according to DIN 24 184 is S, according to EUROVENT it is EU 12.

V 1.09 Blue Line LSI_S_en_np 0402_mmm

Loading...

Loading...