Instructions for use

Cooling incubator with controlled humidity – EVO line

CLIMACELL

111, 222, 404, 707, 1212

CLIMACELL EVO_np_en_1401_mmm_V1.01

Congratulations on purchase of the new cooling incubator with controlled humidity which is an ideal option for applications in

which you need to maintain or regulate temperature and relative humidity inside of the chamber in various time modes. In case

of optional equipment purchase, it will also allow you to measure and control concentration of CO

2

in the chamber respectively

other gases, intensity of lighting in the visible light zone or UV.

The incubator control uses the newest hardware components and know how in the fi eld of regulation using Fuzzy – logics. The

whole control system arranges high precision of temperature regulation, regulation of humidity and possibly other items and so

it arranges higher reliability of the whole process.

The devices meet the technical and legislative requirements and they are constructed in compliance with relevant EN

standards. They are manufactured from high-quality materials using the newest technologies. Each individual unit passes a

thorough output control and it is tested by testing programs.

If you will follow these instructions, the device will become your reliable and powerful partner.

As from today, all these qualities are at your disposal.

This device is really easy to use, thanks to intuitive control with wizards, but anyway we do recommend you to carefully

read the Instructions for Use to be able to use in full all and any features of the device and to get to know all the information

necessary for its optimal use.

CONTENTS:

31. 1. 2014

1 PRODUCT NAME................................................................................................................................3

2 PURPOSE AND USE.........................................................................................................................3

2.1 B

ASIC CHARACTERISTICS.............................................................................................................................3

3 DEVICE DESCRIPTION.......................................................................................................................4

3.1 G

ENERAL VIEW OF CLIMACELL EVO 111, 222..................................................................................................4

3.2 GENERAL VIEW OF CLIMACELL EVO 404, 707.................................................................................................5

3.3 COMMUNICATION PANEL...............................................................................................................................6

3.4 C

ONTROL PANEL.........................................................................................................................................7

3.5 USEFUL SPACE..........................................................................................................................................7

4 TECHNICAL DATA I..........................................................................................................................8

4.1 GENERAL DATA..........................................................................................................................................8

4.2 ELECTRIC INSTALLATION AND OTHER CONDITIONS............................................................................................8

4.3 C

OMMUNICATION INTERFACE........................................................................................................................9

5 BASIC EQUIPMENT.............................................................................................................................9

6 ADDITIONAL EQUIPMENT..................................................................................................................9

6.1 I

NTERNAL LIGHTING.....................................................................................................................................9

6.2 BUSHINGS WITH DIAMETER 25, 50, 100 MM..................................................................................................10

6.3 MECHANIC LOCK OF THE DOOR.................................................................................................................10

6.4 E

LECTRIC LOCKING (BLOCKING) OF THE DOOR.............................................................................................10

6.5 DOOR HINGED ON THE LEFT.......................................................................................................................10

6.6 INDEPENDENT SENSOR PT 100..................................................................................................................10

6.7 COMMUNICATION SW (WARMCOMM 4) FOR PC WITH WINDOWS......................................................................10

6.8 P

OTENTIAL – FREE CONTACT FOR ALARM REPORTS.......................................................................................10

6.9 INNER SWITCHED SOCKET.........................................................................................................................10

6.10 EXPOSITION LIGHTING...............................................................................................................................11

6.10.1 E

XPOSITION LIGHTING IN DOORS................................................................................................................11

6.10.2 EXPOSITION LIGHTING ON RACKS................................................................................................................11

6.11 SENSORS FOR MEASURING THE INTENSITY OF UV AND VIS EXPOSITION LIGHT IN THE CHAMBER.........................11

6.12 TEMPERATURE RANGE FROM - 20 °C............................................................................................................11

6.13 CHAMBER DE-CONTAMINATION.....................................................................................................................11

6.14 R

EGULATION OF CO

2

CONCENTRATION.........................................................................................................11

6.15 COMMUNICATION MODULE WITH ETHERNET, WIFI, USB HOST.........................................................................11

6.16 PRINTER DPT - 6333...............................................................................................................................11

6.17 ANDROID APPLICATION FOR DEVICE STATUS MONITORING...........................................................................11

7 PUTTING THE DEVICE INTO OPERATION..................................................................................12

7.1 U

NPACKING AND CONTROL.........................................................................................................................12

7.2 IMPORTANT WARNINGS...............................................................................................................................12

7.3 DEVICE PLACEMENT..................................................................................................................................13

7.4 CONNECTION TO WATER SOURCE AND WASTE..............................................................................................13

7.5 C

ONNECTION TO DISTRIBUTION NETWORK...................................................................................................14

8 DEVICE STAFF..................................................................................................................................14

8.1 D

EVICE SWITCH-ON..................................................................................................................................14

8.2 BASIC MENU............................................................................................................................................14

8.3 DEVICE USER MENU.................................................................................................................................14

8.3.1 NATIONAL ENVIRONMENT............................................................................................................................15

8.3.2 USER ADMINISTRATION..............................................................................................................................15

8.3.2.1 W

ITHOUT USER ADMINISTRATION MODE......................................................................................................15

8.3.2.2 ADVANCED USER ADMINISTRATION................................................................................................................15

8.3.2.2.1 A

CTIVATING ADVANCED USER ADMINISTRATION................................................................................................16

8.3.2.2.2 CHANGING USER PASSWORD.......................................................................................................................17

8.3.2.2.3 LOGGING OUT............................................................................................................................................17

8.3.3 W

ARNINGS AND ERRORS..............................................................................................................................17

8.3.3.1 CURRENT ERROR MESSAGES........................................................................................................................17

8.3.3.2 HISTORY OF FAULTS....................................................................................................................................18

8.3.4 DISPLAY AND SOUNDS.................................................................................................................................18

8.3.5 DEVICE MAINTENANCE MENU........................................................................................................................19

8.3.5.1 S

INGLE DEFROSTING....................................................................................................................................19

8.3.5.2 DECONTAMINATION.................................................................................................................................19

8.3.5.3 DRYING...............................................................................................................................................20

8.3.6 C

URRENT DATE AND TIME SETTING..............................................................................................................20

8.3.7 COMMUNICATION – ACTIVATION......................................................................................................................21

8.3.7.1 WIFI CONNECTION ACTIVATION......................................................................................................................21

8.3.7.2 E-MAIL ACCOUNT ACTIVATION........................................................................................................................22

8.3.7.3 WIFI CONNECTION VIA INTERNET BROWSER.................................................................................................22

8.3.8 PRINT..............................................................................................................................................23

8.3.8.1 P

ROTOCOL PRINTING...................................................................................................................................24

8.3.9 B

ACKUP...................................................................................................................................24

8.3.10 S

ERVICE SETTING.......................................................................................................................................24

8.3.10.1 C

OMMUNICATION – SETTINGS.........................................................................................................................24

8.3.10.1.1 ETHERNET SETTING.....................................................................................................................................25

8.3.10.1.2 WIFI SETTING............................................................................................................................................25

8.3.10.1.3 E-MAIL SETTING.........................................................................................................................................26

8.3.10.2 TOUCH PANEL CORRECTION.........................................................................................................................26

8.3.10.3 U

NITS...........................................................................................................................................26

8.3.10.4 RACK..............................................................................................................................................27

8.3.10.5 AUDIT TRAIL..............................................................................................................................................27

8.3.10.6 OVERVIEW OF INPUTS AND OUTPUTS............................................................................................................28

8.3.10.6.1 A

NALOGUE ITEMS.......................................................................................................................................28

8.3.10.6.2 DIGITAL INPUTS AND OUTPUTS.....................................................................................................................28

8.3.11 TESTS................................................................................................................................................28

8.3.11.1 C

OOLING TEST...........................................................................................................................................28

8.4 PROGRAMS.....................................................................................................................................29

8.4.1 LIST OF PROGRAMS.....................................................................................................................................29

8.4.2 DEFINITION OF PROGRAM.............................................................................................................................29

8.4.2.1 SAFETY THERMOSTAT...................................................................................................................................29

8.4.3 P

ROGRAM CONFIGURATION...........................................................................................................................30

8.4.4 SEGMENT SETTINGS....................................................................................................................................31

8.4.4.1 SETTING OF PROGRAMS WITH LIGHT EXPOSITIONÍ..........................................................................................31

8.4.4.2 ALARMS........................................................................................................................................32

8.4.5 TEMPERATURE AND RELATIVE HUMIDITY SETTING AND THEIR LIMITATIONS...............................................................32

8.4.6 P

ROGRAM START MENU..............................................................................................................................33

8.4.7 PROGRAM START........................................................................................................................................33

8.4.7.1 RUNNING PROGRAM GRAPH........................................................................................................................34

8.4.7.2 RUNNING THE PROGRAM WITH LIGHT EXPOSITION............................................................................................34

8.4.7.3 POSTPONED START OF PROGRAM..................................................................................................................34

8.4.7.4 D

OOR OPENING..........................................................................................................................................35

8.4.7.5 DOOR BLOCKING.........................................................................................................................................35

8.4.7.5.1 DOOR BLOCKING IN THE MODE WITHOUT USERS ADMINISTRATION......................................................................35

8.4.7.5.2 D

OOR BLOCKING IN THE MODE OF ADVANCED USERS ADMINISTRATION...............................................................36

8.4.7.6 CURRENTLY RUNNING PROGRAM EDITING.......................................................................................................36

8.4.7.7 POWER SUPPLY OUTAGE..............................................................................................................................37

8.5 HISTORY OF PROTOCOLS..............................................................................................................................37

8.6 SYSTEM INFORMATION.................................................................................................................................38

9 LIST OF ERROR MESSAGES........................................................................................................39

10 DEVICE MAINTENANCE.....................................................................................................................41

10.1 M

AINTENANCE PLAN....................................................................................................................................41

10.2 D

OOR SEALING REPLACEMENT......................................................................................................................42

10.3 DOOR ADJUSTMENT.....................................................................................................................................42

10.4 ACCUMULATION OF CONDENSED WATER STEAM..............................................................................................43

10.5 DEVICE CLEANING AND DECONTAMINATION.....................................................................................................43

10.6 STEAM GENERATOR....................................................................................................................................44

10.7 R

EVISION OF ELECTRO PART S......................................................................................................................44

11 TECHNICAL DATA II.........................................................................................................................45

11.1 O

PERATION D ATA........................................................................................................................................45

11.2 RACKS WITH EXPOSITION LIGHTING............................................................................................................46

12 WARRANTY AND SERVICE...............................................................................................................47

13 TRANSPORT AND STORAGE...........................................................................................................47

14 WAY OF LIQUIDATION.......................................................................................................................47

1 PRODUCT NAME

The Instructions for use apply to the below stated device

models:

Type Model Trade Name ZP Type Construction

Design

CLC - E CLC kkk-c CLIMACELL - Evo automatics –

touch screen

E – EVO (Evolution)

kkk – chamber size 111, 222, 404, 707, 1212

c – cooling up to -20 °C.

2 PURPOSE AND USE

The device CLIMACELL EVO is designed for applications

requiring precise and reproducible simulation of variable

climatic conditions. In its basic version, the incubator allows

simultaneous regulation of temperature and humidity. In

case of additional equipment purchase it offers regulations

of concentration of CO

2

respectively other gases or space

– homogenous lighting in the fi eld of visible or UV light with

adjustable intensity and possibility of intensity measuring

using special sensors. Thanks to the unique combination

the device offers the user with extensive possibilities of use.

CLIMACELL EVO can be used in biology, food processing

industry, chemical industry, electrical technology, histology,

botany, pharmacy and others. A typical example may be the

cultivation of plant and tissue cultures or tests of stability

(photo stability) of materials and medicaments.

2.1 BASIC CHARACTERISTICS

● In the operation space of the device it is possible to

simulate the environment with temperature 0 up to

100 °C (-20 °C up to 100 °C for model „c“), relative

humidity (hereinafter referred to as RH) 10 % up to

95 %. For possible combinations of temperature and RH

see chapter 8.4.5 .

● Possibility of chamber decontamination / sterilization at

160 °C.(this function is not designed for sterilisation of

samples or material).

● Control of space – homogenous lighting with wave

length in visible and UV zone. The light exposition may

be monitored using optional sensors.

● Regulation of CO

2

in the range from 0 up to 20 %

(0-2000 ppm), max. temperature 55 °C. (respectively of

other gases).

● Temperature, RH, lighting and concentration of CO

2

(respectively of other gases) may be regulated in various

time modes.

● Tested samples are stored on racks supplied together

with the device.

● The unique system of air circulation with forced

circulation guarantees space – homogenous distribution

of temperature and RH in the whole operation space of

the device.

● Set speeed of fan from 0 to 100 % in ten – percent

intervals.

● The chamber and all the inner parts are made of

stainless steel. The outer shell is made partially of

zinc-coated and stainless steel material and it is treated

with water-soluble stove enamel (environment - friendly).

● CLIMACELL EVO is equipped with a multi-processor

control with the following characteristics:

o Precise regulation of temperature, humidity, lighting

and CO

2

(gas) with application of the newest trends

in the fi eld of regulation (fuzzy logic), supported by

many years of experience of the company BMT in

this fi eld.

o Graphic display with touch panel allows simple and

intuitive control.

o Wide offer of communication interfaces - Ethernet,

Wifi , USB, RS232. – according to optional equipment

o As many as 100 freely adjustable programs.

Each program may consist from up to 100 partial

segments.

o Possibility of structuring the users into groups with

differentiated access rights to the operation and

service settings of the device.

o In internal memory of the device there is

automatically saved the record of the course

of regulation including audit trail, total length of

recording up to one year.

o The user has the possibility to make backup of some

device settings and record of the regulation on the

SDHC card, fl ash disc or some other large-capacity

memory USB device.

o Support of WarmComm4 software for regulation

progress recording.

Instructions for use

CLIMACELL EVO_np_en_1401_mmm_V1.01 3

Instructions for use

4 CLIMACELL EVO_np_en_1401_mmm_V1.01

3 DEVICE DESCRIPTION

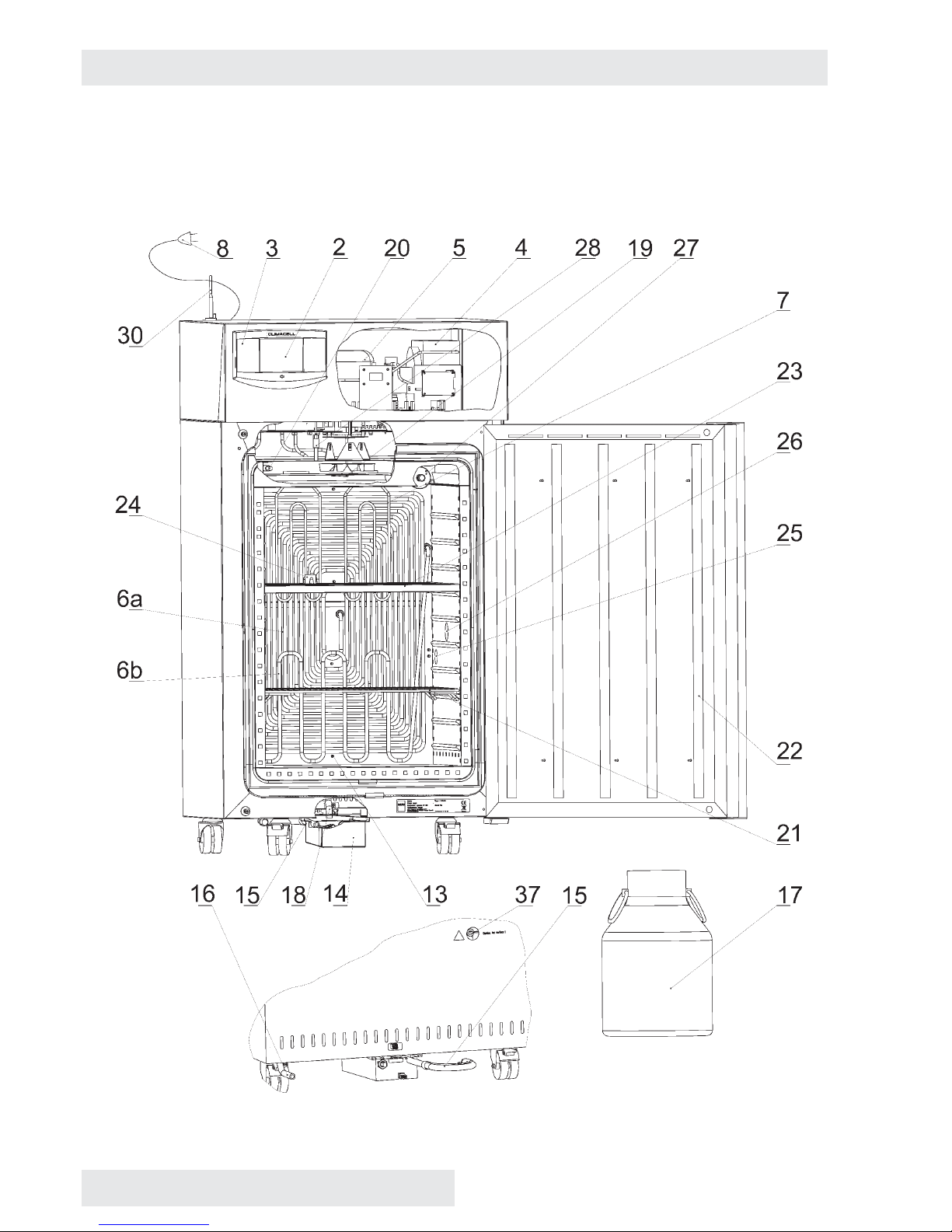

3.1 GENERAL VIEW OF CLIMACELL EVO 111, 222

Fig. 1

Instructions for use

CLIMACELL EVO_np_en_1401_mmm_V1.01 5

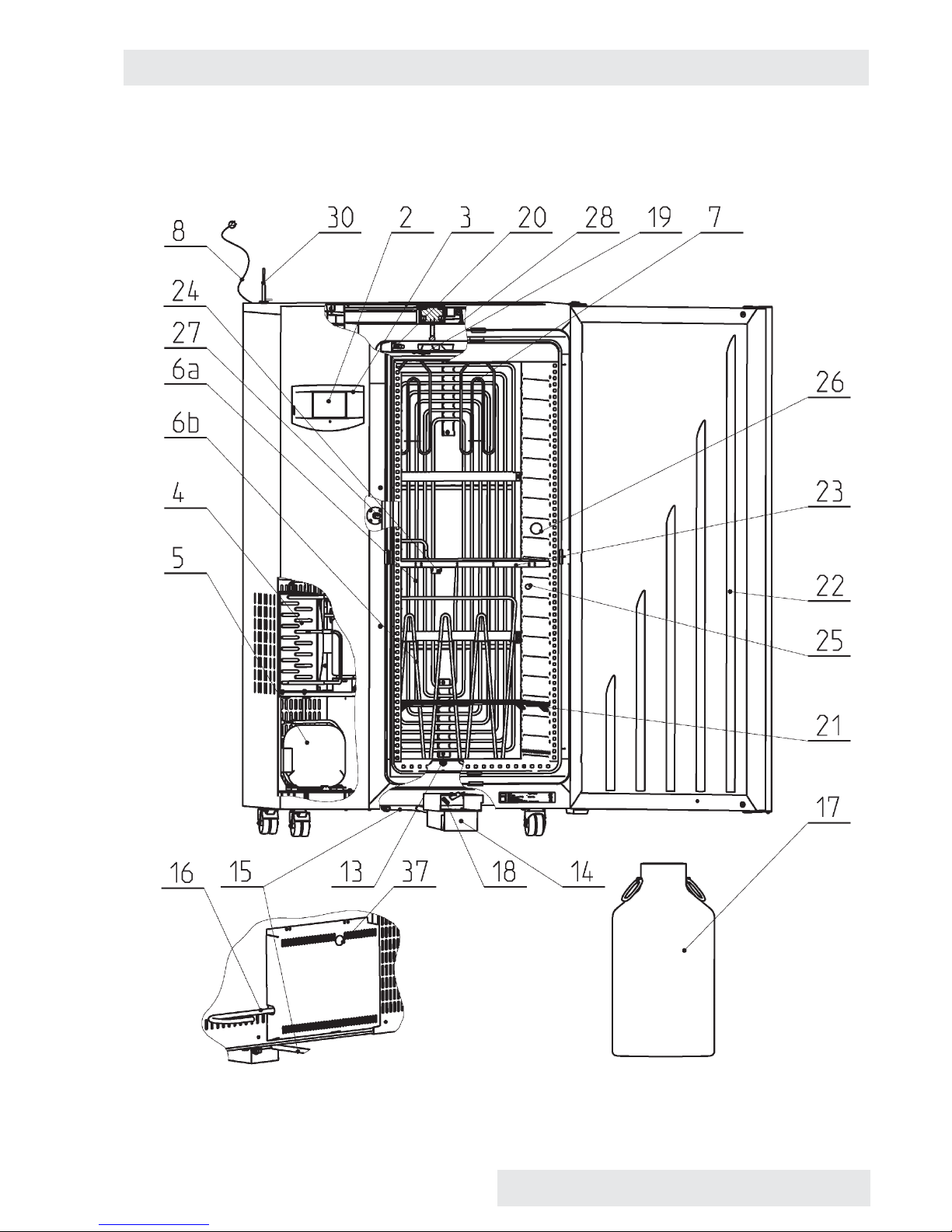

3.2 GENERAL VIEW OF CLIMACELL EVO 404, 707

Fig. 2

6 CLIMACELL EVO_np_en_1401_mmm_V1.01

Instructions for use

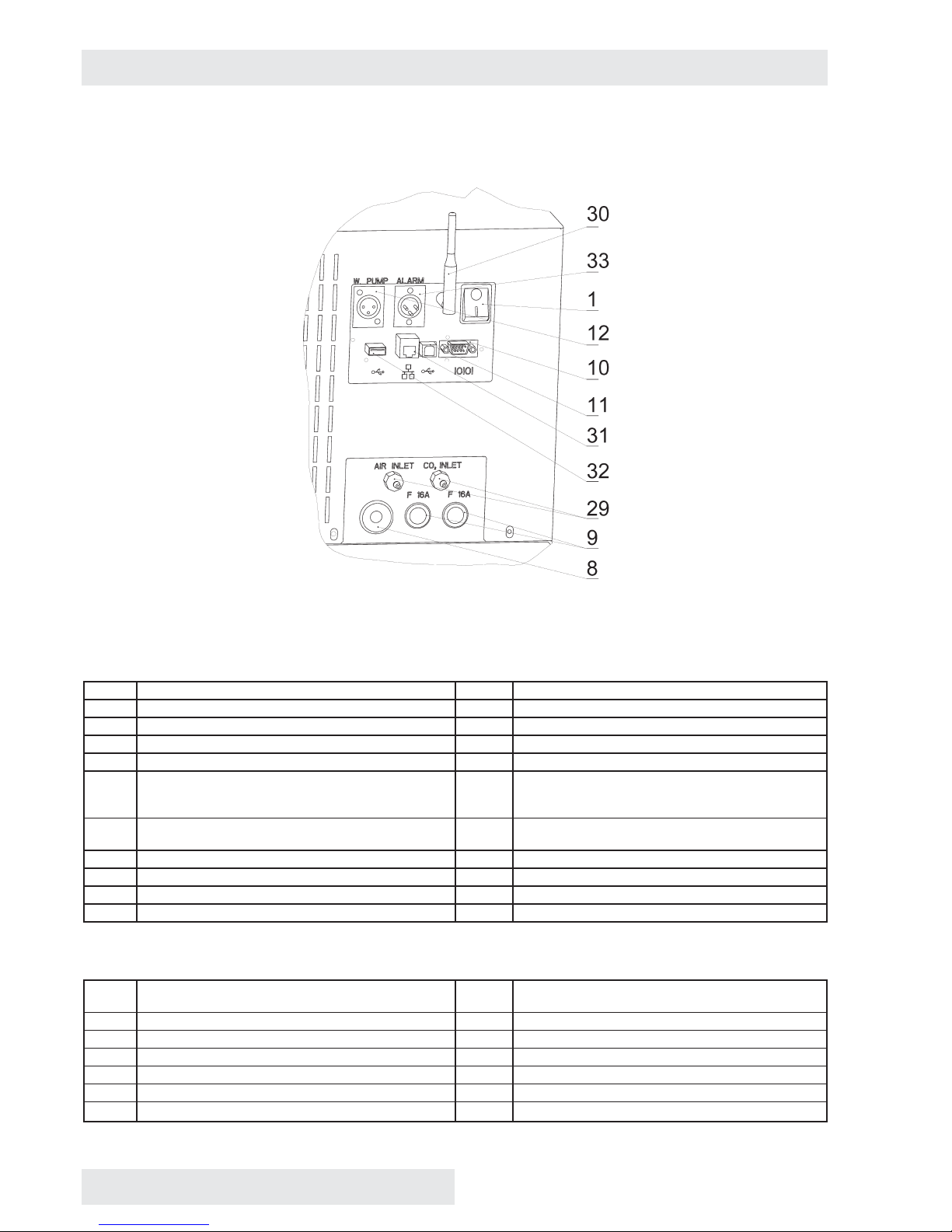

3.3 COMMUNICATION PANEL

Fig. 3

Standard version

1 Network push button 12 Pump connector

2 Control touch panel 13 Input of steam from steam generator

3 Plastic cover of control panel 14 Waste vessel with pump

4 Condenser 15 Waste water discharge

5 Compressor 16 Water inlet from reservoir

6 Cooling tube evaporator -

6a - cooling,

6b - freezing (RH regulation)

17 Distilled water reservoir

7 Heating bodies in heating space 18 Outlet of waste water from chamber and door to the

vessel

8 Network connection 19 Temperature sensor PT 100

9 Fuses T16A/1500 20 Relative humidity sensor

10 Connector RS232 21 Screens (2 pcs)

11 Connector USB device (USB B)

Optional equipment

22 Exposition lighting in the door (LED, fl uorescent

lamps)

29 Inlet of CO2 (gas) and air (external)

23 Exposition lighting of racks ( LED, fl uorescent lamps) 30 Wifi antenna

24 Lighting sensor (VIS or UV) 31 LAN connector

25 Placement inside of switched socket 32 Connector USB HOST

26 Placement of inner bushing 33 Potential-free contact

27 Sensor of CO

2

(gas) 37 Outlet of steam prom pressure safety lock

28 Inlet of CO2 (gas) to the chamber (internal)

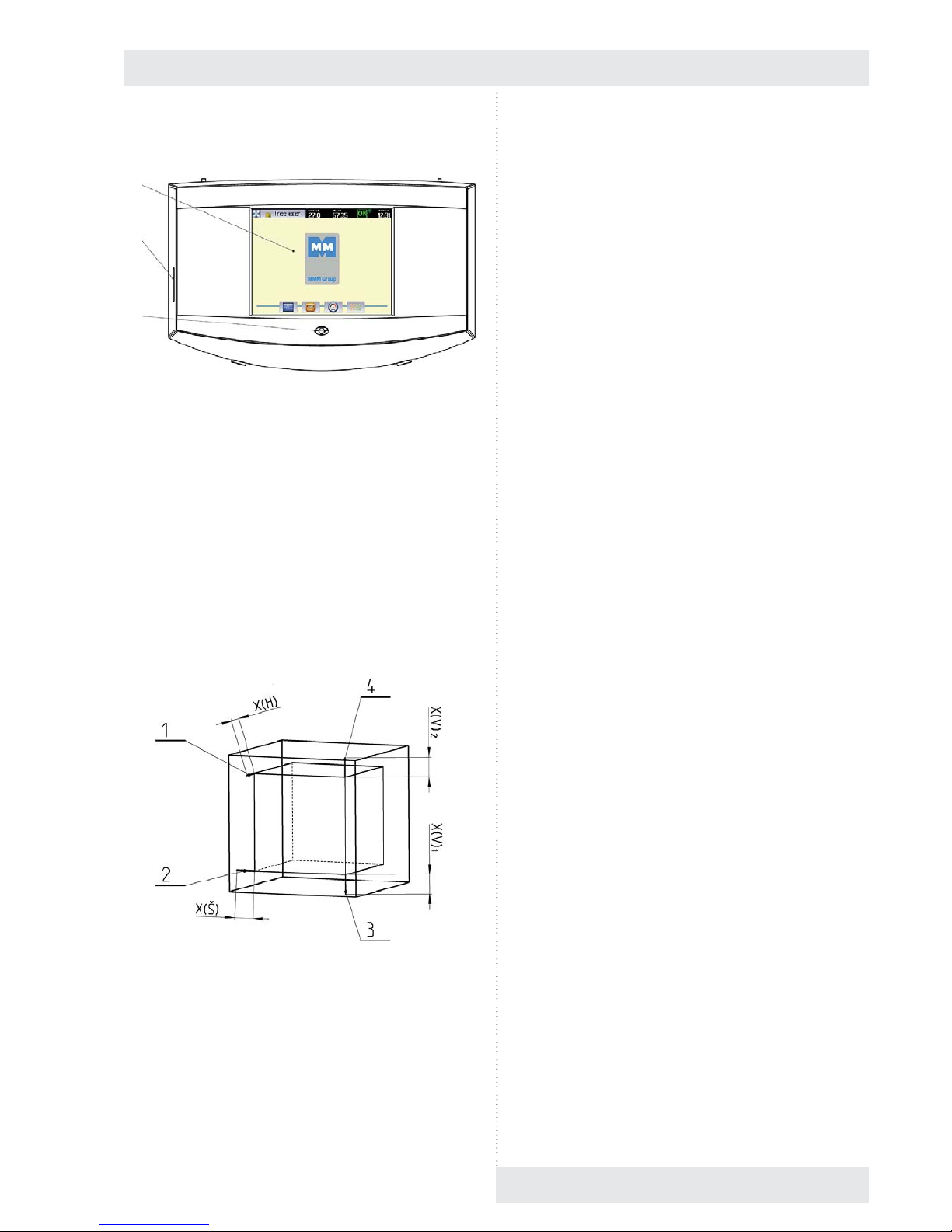

3.4 CONTROL PANEL

Fig. 4

(1) Control touch panel

(2) SD card

(3) Indication LED

3.5 USEFUL SPACE

Useful space is displayed in Fig. 5. In the space delimited

with thick lines in the fi gure there are fulfi lled (in connection

with standard DIN 12 880) the temperature variations as

specifi ed in chapter 11. The thin lines demark inner walls of

the chamber. That means that above the last upper screen,

the values from this chapter are not binding any more.

Fig. 5

(1) X(H) – 10 % of inner chamber depth

(2) X(Š) – 10 % of inner chamber width

(3) X(V)1 – distance of the lowest screen (rack) from the

bottom of the inner chamber

(4) X(V)2 – distance of the top screen (rack) from the

ceiling of the inner chamber

CLIMACELL EVO_np_en_1401_mmm_V1.01 7

Instructions for use

1

2

3

8 CLIMACELL EVO_np_en_1401_mmm_V1.01

Instructions for use

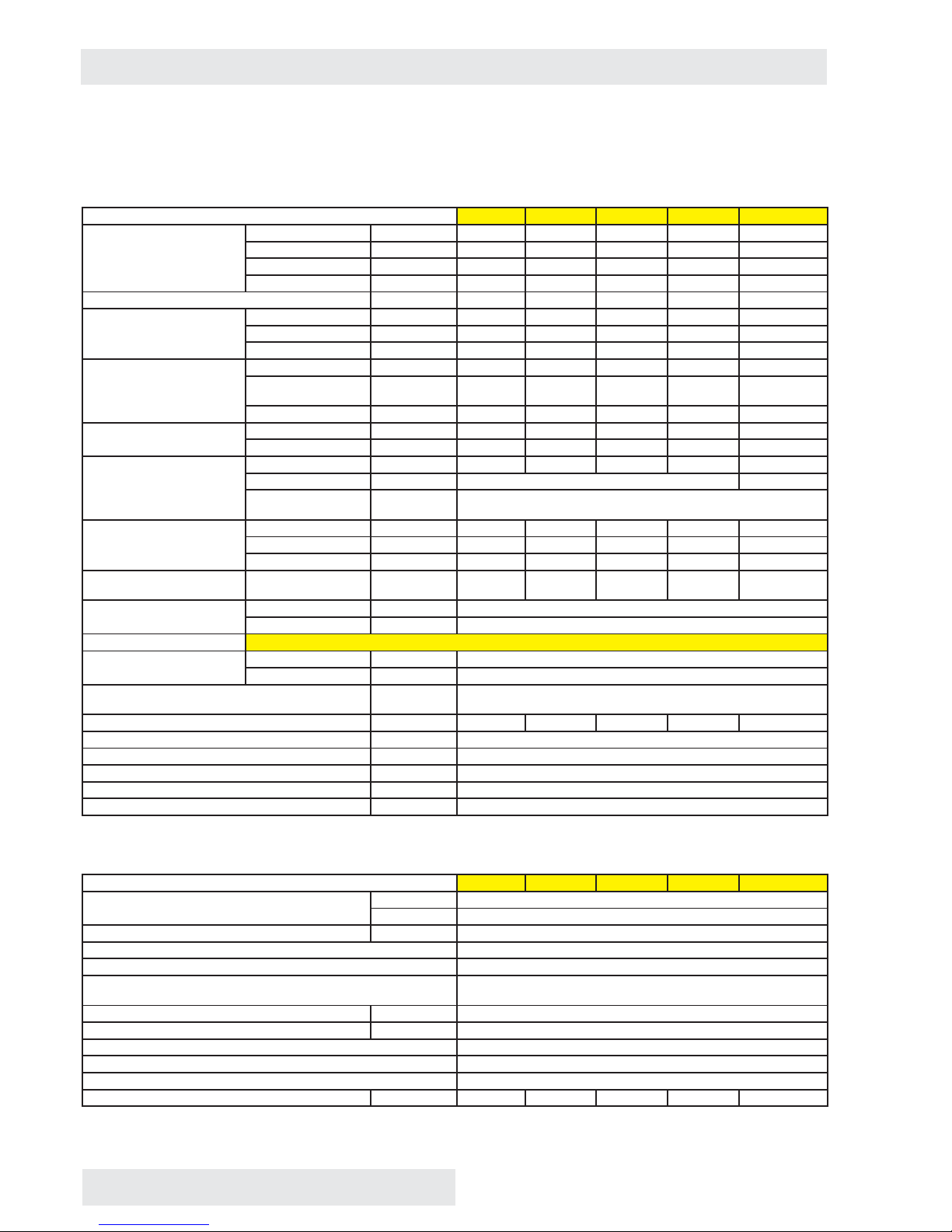

4 TECHNICAL DAT A I

4.1 GENERAL DATA

Name CLIMACELL E 111 / 111-c 222 / 222-c 404 / 404-c 707 / 707-c 1212 / 1212-c

Inner space of the chamber,

stainless steel DIN 1.4301

(AISI 304)

Volume approx. litre 110 219 404 704 1408

Width mm 540 540 540 940 3x540 (1905)

Height mm 535 765 1415 1415 1415

Depth mm 380 530 530 530 530

Steam space volume approx. litre 167 305 530 878 1753

Outer dimensions (including

door, handrail and wheels)

Width mm 780 780 1100 1500 2530

Height mm 1215 1450 1880 1880 1915

Depth mm 755 885 885 885 885

Dimensions with package

(three-layer cartoon)

Width mm 850 850 1170 1570 2600

Height (including

palette)

mm 1360 1630 2070 2070 2105

Depth mm 840 980 950 950 950

Weight net kg 110/120 /153 240/250 280/290

gross kg 140/150 /172 280/290 326/336

Screens

of stainless steel *)

Lead for screens max. No. 7 10 19 19 3x 19

Standard equipment pc 2 6

Pitch between

screens

mm 70

Maximal load Screen kg/screen 20 30 30 50 30

Sheet rack kg/rack 20 30 30 20 30

In total kg/case 50 70 100 130 300

Number of doors External - metal/

internal – glass

pc 1 / 1 1 / 1 1 / 1 2 / 2 3/3

Min. distance of the device

from the walls and objects

Rear and side walls mm 200

Upper wall mm 400

Steam generator connection It is prohibited to use tap water!

Demi water Usual μS/cm ˂ 8

Recommended μS/cm ˂ 3

Pressure from the distribution system for central

distribution

bar ≤ 0,5

Water cask volume litres 20 20 50 50 50

Min. height of water level in cask mm 25

Max. pumping height of waste water mm 1150

Pump cable length mm 4000

Suction hose length mm 4000

Waste hose length mm 4000

4.2 ELECTRIC INSTALLATION AND OTHER CONDITIONS

Electric installation and other conditions 111 / 111-c 222 / 222-c 404 / 404-c 707 / 707-c 1212 / 1212-c

Voltage system standard 1x 230V/ 50(60) Hz

opce 1x 115V/ 50(60) Hz

Network voltage oscillation % ± 10

Class of protection against dangerous touch I

Separation of external circuits Double insulation

Device for type standard CEE-7/VII, IEC-83/CH,16 A/250 V (or other depending on

version)

Intake cable length mm 3000

Socket protection A min. 16

Coverage according to EN 60529 IP 20

Overvoltage category according to (IEC 664 – EN 61010) II with pollution 2

Fuses on rear wall of the superstructure (extension) Safety fuse T 16A/1500

Max. input of the device **) W 2050/1630 2100/1780 3150/2115 3400/2640 xx/3215

Heat losses at 37 °C ca W 70 63 123 148 200

Complete device noise level dB 46 50/56 56/58 58 60

Operation conditions Let the installed device stand still in operation position for 2 hours before its fi rst put

into operation!

Ambient temperature °C +5 up to +40

Max. relative humidity at 31 °C % RH 80

Max. height above sea level m n. m. 3000

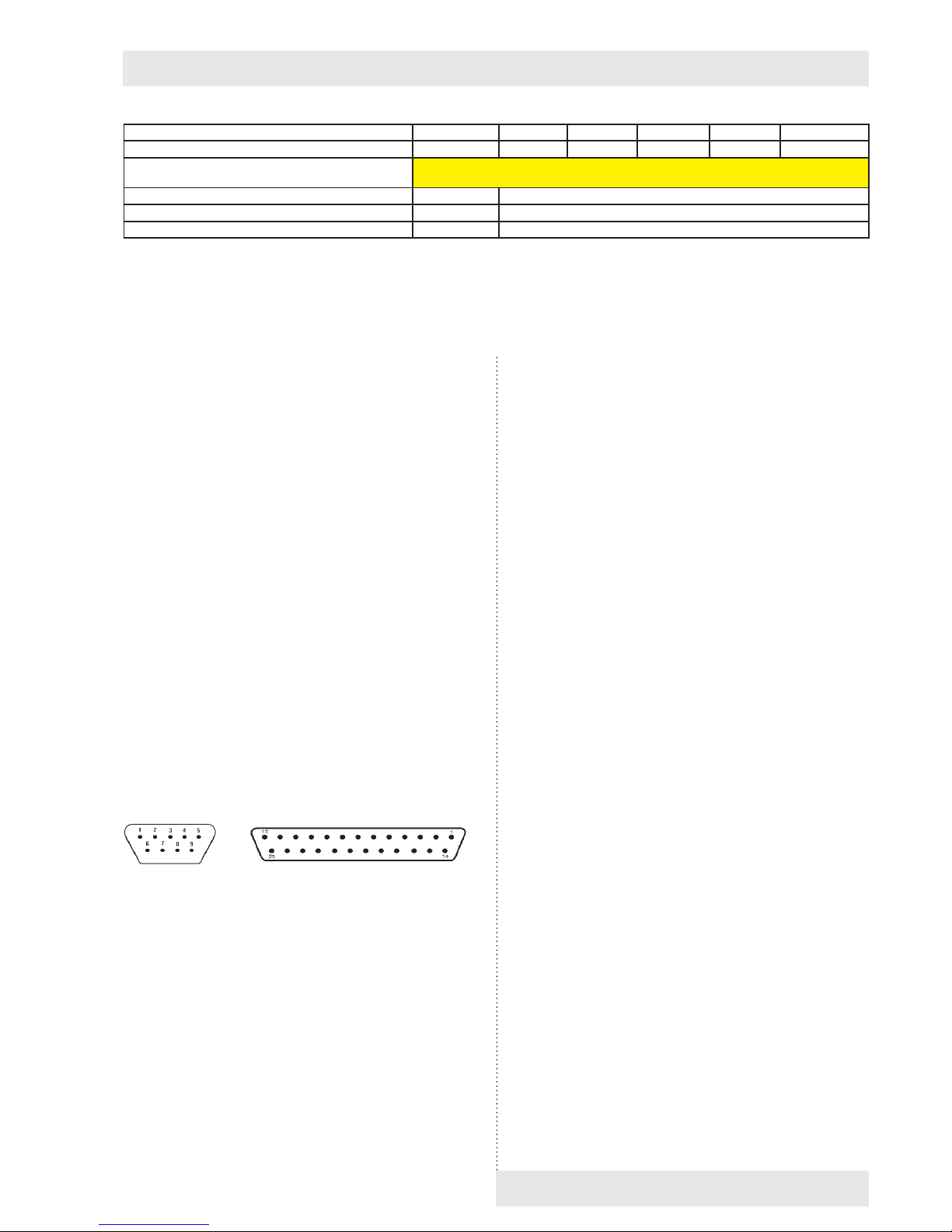

4.3 COMMUNICATION INTERFACE

● Ethernet: 10/100 Mbps

interface 1 x RJ45

standard IEEE 802.3u

half/full duplex

● Wifi : IEEE 802.11b, IEEE 802.11g

Frequency:

Europe: 2.412-2.472GHz

USA: 2.412-2.462GHz

Japan: 2.412–2.484GHz

Channels:

Europe: 13 channels

USA: 11 channels

Japan: 14 channels

● USB host: USB 2.0, full speed

● USB device: USB 2.0, full speed

● SD/MMC card: max. capacity 32 GB

● RS232:

- Printer connection:

Baud: 9600

Stopbit: 1

Parita: none

Databit: 8

Device Printer

Fig. 6

9 pin Canon connector on box DE9 Male

Pin Signal

2 RXD

3 TXD

4 DTR

5 GND

6 DSR

25 Canon connector on printer DB25 Female

Pin Signal

2 TXD

3 RXD

7 GND

20 DTR

Note:

Ethernet, Wifi and USB Host ara available only with devices

with communication module, see chapter 6.15.

5 BASIC EQUIPMENT

The standard supply includes:

● incubator,

● two screens,

● fi lling system (order No. S211567 or S211568),

● waste system (order No. S211558),

● handling hooks (only size 404 and 707),

● instructions for incubator use,

● SD card.

6 ADDITIONAL

EQUIPMENT

6.1 INTERNAL LIGHTING

The lights are placed inside of the chamber on the left. Heatresistant bulbs are used. The light switch is placed on the

door. In combination with the door window there is always

a light placed in the door.

CLIMACELL EVO_np_en_1401_mmm_V1.01 9

Instructions for use

All the data apply in empty chamber (without samples on screens) for ambient temperature of 20 - 22 °C, 100 % fan revolutions,

feeding voltage 230 V ± 10 %.

*) The screens may be fi lled in approximately 50 % of surface and if possible in such a way so as there is allowed equal air

fl ow inside of the chamber space.

**) Compressor + condenser + electromagnetic valves + fan(s) + steam generator heating.

6.7 COMMUNICATION SW

(WARMCOMM 4) FOR PC WITH

WINDOWS

The program WarmComm is designed for recording of the

temperature regulation course in temperature cases. The

data obtained in the course of regulation are displayed

in the form of a graph. The program allows monitoring of

regulation in real time, saving of the regulation progress in a

fi le, watching formerly created fi les, sending e-mails in case

of non-receiving data from the case and sending reports on

extreme values reached in a set time interval.

Instructions for use of the program are supplied together

with the installation program. The hardware requirements

can be managed by a standard PC with operation system

Windows XP or higher.

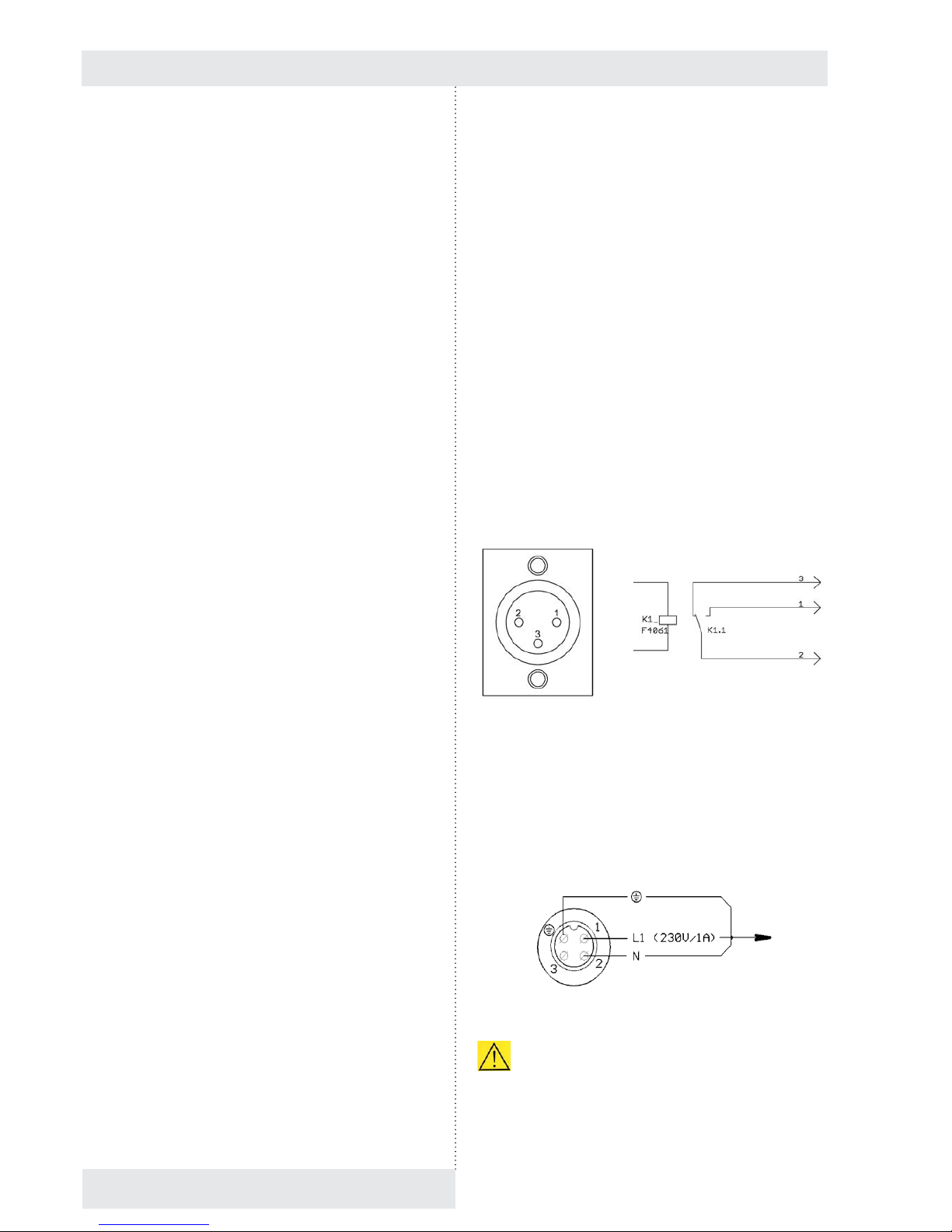

6.8 POTENTIAL – FREE CONTACT

FOR ALARM REPORTS

It is taken out to the connector (33), Fig. 3, in the rear part

of the device. Maximal load of the contact: 24V/1A..

Fig. 7

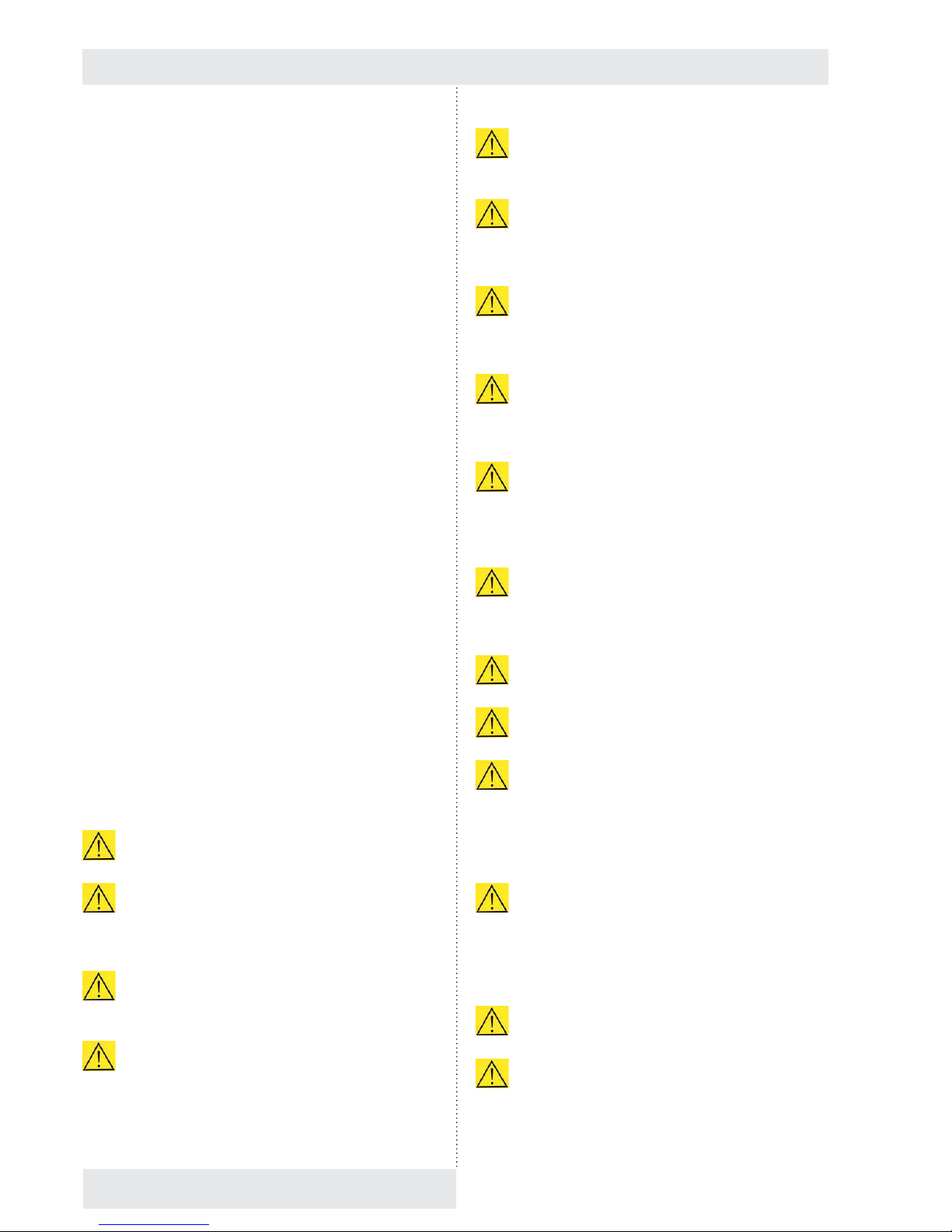

6.9 INNER SWITCHED SOCKET

The socket (nominal voltage 230V, fuse 3 A, coverage IP67)

is located inside of the chamber on the side wall. For details

on switching control see chapter 8.4.3.

Connection of the connector and the built-in device

Fig. 8

The fork may be connected only by a person with

relevant electro technical qualifi cation. When inserting the

fork to the socket and pulling the socket out of the socket or

when handling the inner equipment, it is necessary for the

device to be switched off (network switch in the off position

10 CLIMACELL EVO_np_en_1401_mmm_V1.01

Instructions for use

6.2 BUSHINGS WITH DIAMETER 25,

50, 100

MM

Standard placement of bushings can be found

approximately in the centre of the side (left or right) wall

of the chamber. The bushings are made of metal, they

are closed from the outer side with a special plastic plug

allowing lacing the conductors etc. from the outer space to

the chamber space.

Recommendation: the device used should be equipped with

a dimension-corresponding bushing in case that the user

wants to measure one of the items (T, RH, CO

2

, etc.) with

sensors connected with the external independent measuring

device by conductors; the user pulls the conductors through

the bushing. So as to reach the correct functioning of the

incubator, the conductors, hoses, etc. pulled through the

bushing must be hermetically sealed in the bushing.

6.3 MECHANIC LOCK OF THE DOOR

The lock is placed on the upper front surface of the door

close to the locking mechanism.

6.4 ELECTRIC LOCKING (BLOCKING)

OF THE DOOR

In the course of the material exposition, the door is

blocked by an electromagnetic mechanism so as to avoid

undesirable opening.

6.5 DOOR HINGED ON THE LEFT

This is a mirror-like symmetrical version of the door hinged

on the right. Cases with volumes of 404, 707 and 1212 litres

are not supplied in left version.

6.6 INDEPENDENT SENSOR PT 100

The independent movable sensor is used for measuring the

material temperature directly in the chamber. It is possible to

connect as many as four sensors.

The data on temperature of the sensors are displayed in

system information, see chapter 8.6.

When printing on the printer, each record consists of a

few lines, the fi rst line starting with number 1 shows the

temperature on the regulator sensor, the other lines starting

with letters display the temperature on movable sensors.

Fork

To the device

6.13 CHAMBER DE-CONTAMINATION

The chamber is heated to 160 °C and the temperature is

kept for specifi ed time period. Everything is controlled by the

given program and it is not possible to change the values.

6.14 REGULATION OF CO2

CONCENTRATION

Using the regulation system and the CO2 sensor it is

possible to correct and measure the CO

2

concentration in

the chamber. Allowed temperature range is from -20 °C

to 60 °C, the humidity is not limited, but water must not

condensate on the sensor. The range of CO

2

concentration

is from 0 to 20 % or 0-2000 ppm respectively it may also be

different – it depends on the CO

2

sensor type used and on

device confi guration by the manufacturer.

6.15 COMMUNICATION MODULE WITH

ETHERNET, WIFI, USB HOST

● The communication module allows connection of the

device to local network using LAN connector or Wifi .

● It provides an active web server accessible via LAN.

The web server allows remote monitoring of current

regulation progress on the device, viewing the history of

protocols and audit trail.

● It is possible to use the communication module for

sending e-mails in case of error status occurrence or in

case of any warning.

● It provides the user with communication interface USB

host, via which it is possible to connect USB fl ash disk

respectively some other large capacity memory device

doer data saving.

6.16 PRINTER DPT- 6333

The thermo printer connectible via RS232, paper width

58 mm, is supplied with a cable and feeding source.

6.17 ANDROID APPLICATION FOR

DEVICE STATUS MONITORING

The CLC Monitor application is designed for monitoring

of device activity at mobile devices with operation system

Android. The application provides the user with information

on current status of remote device within the reach of WIFI.

CLIMACELL EVO_np_en_1401_mmm_V1.01 11

Instructions for use

– „0“). The connection socket – fork must be appropriately

tightened so as not to decrease the declared degree of

protection (IP 67). After disconnection of the fork and the

socket carefully screw the protection covers on the socket

and the fork so as impurities and humidity cannot penetrate

into them.

Note:

In this version, the maximal operation temperature of the

device is limited to 60 °C.

6.10 EXPOSITION LIGHTING

6.10.1 EXPOSITION LIGHTING IN DOORS

The exposition fl uorescent or LED lighting is placed in the

door. Its intensity is controlled from 0 % to 100 % in steps of

10 %, see chapter 8.4.4.

6.10.2 EXPOSITION LIGHTING ON RACKS

The chamber may house racks with exposition fl uorescent

or LED lighting, its intensity is controlled from 0 % to 100 %

in steps of 10 %, see chapter 8.4.4.

6.11 SENSORS FOR MEASURING

THE INTENSITY OF UV AND

VIS EXPOSITION LIGHT IN THE

CHAMBER

The measured values may be displayed on the display

and they are saved in the program protocol. Both types of

sensors may be simultaneously used in one device (six

sensors as a maximum).

Notes:

Sensors for measuring the intensity of UV and VIS light

have the range of operation temperature from -20 °C to

80 °C. So as to avoid their damage, the temperature in the

chamber is limited as follows:

o maximal operation temperature of the device is limited to

75 °C,

o in case of the temperature in the chamber to reach

80 °C, all the heating elements and exposition lighting is

switched off and an alarm is announced.

6.12 TEMPERATURE RANGE FROM -

20 °C

The RH is not regulated in the temperature range from

-20 °C to +10 °C.

This version cannot be combined with exposition lighting on

the door (in switched on and off status) and on the racks (in

switched on status).

Instructions for use

12 CLIMACELL EVO_np_en_1401_mmm_V1.01

The devices are not designed for environment

with risk of fl ammable or explosive substances

(e.g. anaesthetics).

If the device is used with CO2, it is necessary to

protect the premises in case of excessive gas

leakage (well ventilated room, sensors of CO

2

with alarm, etc.).

Any assemblage or disassembly of parts of the

device may only be performed after the device

disconnection from electric network by pulling

the feeding cable from the socket!

In case of temperatures below 0 °C or above

60 °C there is a risk of injury caused by metal

handles on inner glass doors. Use protective

aids.

When operating a device with pre-set

temperature above 70 °C be extremely careful

when opening the door. As the pre-set RH is kept,

hot steam develops in the chamber and it may

cause scalding.

The protection of the temperature case, its

surroundings and processed material against

prohibited temperature exceeding is arranged by a

protective thermostat according to EN 61010-2-010.

The network connection must not get in touch with

hot parts of the device.

You can fi nd all and any installation conditions of the

device in tables, see chapter 4.

The cases stand on the fl oor, they are space saving,

equipped with castor wheels. It is necessary for the

cooling incubator to stand on fl at fl oor (because of

the device functionality). And we recommend a waste

canal to be located in the room for any case of water

leakage.

After the device placement to the desired location,

turn and set the brake of the castor wheels. The front

one in the front direction and the rear ones in the rear

direction, in parallel with sides of the device in such a

way so as the device gets maximal possible stability

in forward and backward directions.“

Always place the material on screens in the device,

never put it on the bottom of the device!

If you want to start the chamber decontamination, it

must be empty (only the RH sensor may stay).

7 PUTTING THE

DEVICE INTO

OPERATION

7.1 UNPACKING AND CONTROL

After unpacking please check whether the device and its

accessories are complete and undamaged.

Any possible damage must be immediately reported

to the carrier! Do not lift up the case for the handrail or

door in the course of handling (e.g. case lifting, etc.). Lift

the case up using the enclosed hooks. When removing the

case from the palette take care of the device bottom. Lift the

case up using the hooks and move the palette completely

out. Then put the case carefully on the wheels designed for

local movements on smooth fl oor – not for any prolonged

transport. Pay attention mainly to door steps and entries

to lifts. In such cases it is also necessary to lift the case up

using the hooks. In the course of any handling of the case,

the door must be closed and the case must be disconnected

from power mains. When moving the case be always very

careful and handle the case in such a way so as not tip it

over. In case of sizes 404, 707 and 1212 it is necessary to

protect the case against possible tipping over by fastening it

to the wall see chapter 7.3.

7.2 IMPORTANT WARNINGS

CLIMACELL is designed and manufactured in compliance

with requirements of EU regulations No. 2006/95/EC and

2004/108/EC and it is individually tested according to

EN 61010-1.

Let the installed device stand still in operation position

for at least two hours before putting it into operation for

the fi rst time.

Read these Instructions for Use carefully before

starting the use of the device!

The load capacity of the fl oor for the device

placement must correspond with the weight of

the device, taking into consideration the maximal

charge weight (see chapter 4.1).

It is not allowed to place the device on a mat that

may cause a risk of fi re or smouldering in case of

hot objects to fall out of the device.

It is not allowed to insert any fl ammable,

explosive or poisonous substances or materials

that could release such substances to the device!

Fig. 9

7.4 CONNECTION TO WATER

SOURCE AND WASTE

The device may be connected to the cask supplied by us

or to water distribution system. In both case, the water and

water mains must meet the parameters as per chapter 4.1.

Fig. 10

a) Take the cask (1) out of the chamber.

b) Connect the cable connector (3) to the socket (4) back

on the superstructure, see chapter 3.3.

c) The waste vessel (5) is placed in the chamber. After

unpacking, insert it to the holder above the device.

Connect the cable connector (6) to the socket (7).

Connect the free end of the waste hose (8) to the

discharge.

Instructions for use

CLIMACELL EVO_np_en_1401_mmm_V1.01 13

It is not possible to start decontamination in devices

with a window in the door.

The temperature and RH regulation is negatively

affected by reduction of fan speed, exposition lighting

and measuring of CO

2

. There do not apply the values

from chapter 11.1.

The RH regulation is also negatively affected in case

of any other humidity source but the generator to be

in the chamber.

If you use the device for long-term several days

lasting tests at low temperatures, the ice in the

chamber will grow up similarly to a refrigerator or a

freezer.

Devices connected via communication interface

must meet valid regulations from the point of view of

electrical safety and electromagnetic compatibility.

If you do not use the incubator for prolonged time,

disconnect it from the network by pulling the feeding

cable form the socket.

In case of the device to be used in any other but

designed way, the protection provided by the device

may be affected.

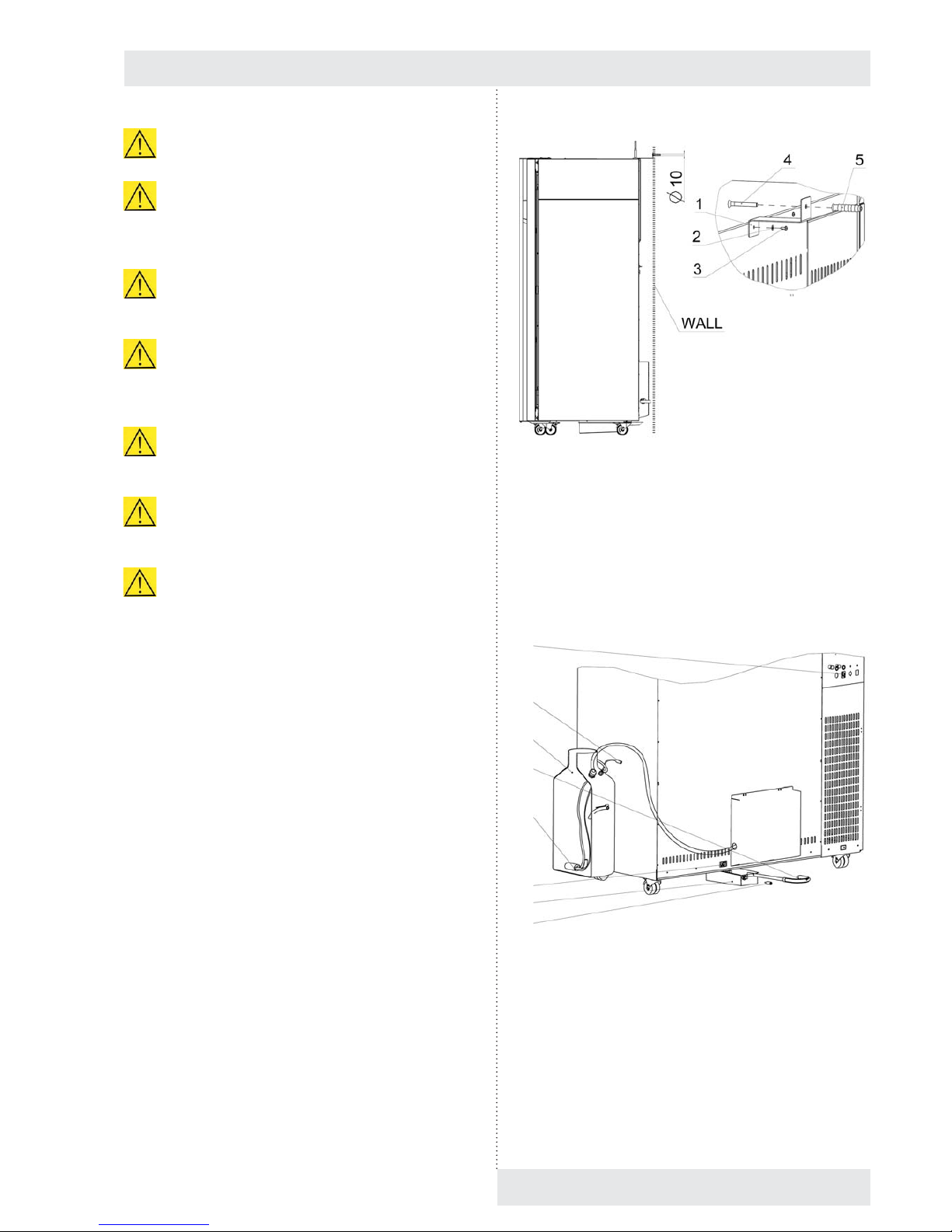

7.3 DEVICE PLACEMENT

Cases with volumes of 404, 707 and 1212 l must be fi xed to

the wall in the room using the enclosed fi xation set. Place

the device to the required location and mark the place for

drilling a hole in the wall. Drill the hole according to the wall

plug used. The wall plug supplied is designed for ordinary

bricks – in case of any special bricks it is necessary to use

corresponding wall plug type.

a) Drill a hole to a fi xed wall and place the wall plug into it

(5).

b) Fix the fi xation set (1), (2), (3) on the device.

c) Fasten the device to the wall using the enclosed screw

(4).

4

3

1

8

2

7

5

6

Fig. 11

d) Pull the hose from the generator (P1) through the

bushing in the cask and apply the submersible pump (2),

(P2). Then tighten the bushing in such a way so as the

hose (P3) is sealed.

e) Fill the cask with distilled water and the device is ready

for operation.

Note:

It is not allowed to prevent fl ow of let-in and let-out water in

hoses.

7.5 CONNECTION TO DISTRIBUTION

NETWORK

Compare the nominal voltage and device input values

as specifi ed in the production plate of the device with the

voltage intake. If the intake parameters correspond with the

device parameters, connect the fork of the device to the

intake socket.

8 DEVICE STAFF

8.1 DEVICE SWITCH-ON

After switching the network switch (1), Fig. 3, to position „I“

the display of the control panel displays the basic menu of

the device. The indication LED (3), Fig. 4 lights green.

Instructions for use

14 CLIMACELL EVO_np_en_1401_mmm_V1.01

(1) (2) (3) (4)

(5) (6) (7) (8) (9) (10) (11) (12)

(13)

8.2 BASIC MENU

Fig. 12

(1) Programs (8.4).

(2) Protocol history (8.5).

(3) System information (8.6).

(4) Device user menu (8.3).

(5) Help.

(6) User login icon (8.3.2).

(7) Name of logged-in user

(8) Current temperature in the working part of the device.

(9) Current relative humidity (RH) in the working part of

the device.

(10) Warning and error indication (8.3.3.1).

(11) Device status information (8.4.7).

(12) Current date and time.

(13) Device identifi cation number (8.3.7).

8.3 DEVICE USER MENU

In order for the device to be operated precisely as the user

requires, it must fi rst be set up. Click

(Fig. 12) to

open the device settings screen.

Note:

Only colour-highlighted icons may be used for user

settings; the grey icons are inactive (only accessible by the

administrator).

Instructions for use

CLIMACELL EVO_np_en_1401_mmm_V1.01 15

Fig. 13

(1) Selection of national environment (8.3.1)

(2) Error and report history (8.3.3.2)

(3) Display and sounds (8.3.4)

(4) User administration (8.3.2)

(5) Device maintenance (8.3.5)

(6) Date and time (8.3.6)

(7) Communication (8.3.7)

(8) Print (8.3.8)

(9) Backup (8.3.9)

(10) User administration (8.3.2)

(11) System tests (8.3.11)

(12) Service and system settings (8.3.10).

8.3.1 NATIONAL ENVIRONMENT

By clicking on the icon (Fig. 13) you will open the

menu for national environment selection.

Fig. 14

8.3.2 USER ADMINISTRATION

→

The device controls can be accessed in two different modes:

● Without user administration

See 8.3.2.1.

● With advanced user administration

See 8.3.2.2.

8.3.2.1 WITHOUT USER ADMINISTRATION

MODE

This mode is the factory default setting. The user has

access to all the device’s menus with the exception of

special service functions. This mode is particularly suitable

for users who do not require the device to be secured

against unauthorised access. It is not necessary to log in to

control the device.

The without user administration mode recognises two

different types of users:

● Free user:

o User with unrestricted access to the device controls

(except for special service functions).

o The fi eld (7), Fig. 12, displays the words free user.

● Administrator:

o May activate (deactivate) advanced user

administration, see 8.3.2.2.

o The fi eld (7), Fig. 12 displays the word admin.

8.3.2.2 ADVANCED USER ADMINISTRATION

Allows the user structure to be defi ned with different rights

for access to controls and device settings.

Advanced user administration mode recognises three

different types of users:

● Administrator:

o Activates (deactivates) advanced user administration.

o Defi nes individual operator-type users, allocates

them access rights and passwords and places them

into groups.

o Hass access to all device settings except for service

functions.

o Access the device using his username and password

o The fi eld (7), Fig. 12, displays the word admin.

● Operator:

o User with limited access rights, subordinate to the

administrator.

o Is allocated a username and password which are

used whenever operating the device

(1) (2) (3) (4)

(9) (10) (11) (12)

(5)

(6)

(8)

(7)

16 CLIMACELL EVO_np_en_1401_mmm_V1.01

Instructions for use

Select advanced user administration after logging in in the

user menu :

→

Fig. 16

(1) Selection of user administration mode.

(2) Automatic logout time.

- If inactive for longer than the set time, the user will

be automatically logged out.

- Entering a time of 0 will cancel the automatic

logout time.

(3) Defi nition of groups.

- The administrator may place operators in up to

four groups with different user rights, see Fig. 17

(4) Defi nition of users.

- This button displays a list of all users. See Fig.

18. Login names and passwords may then be

allocated for individual users (Fig. 19).

Defi nition of group, See (3), Fig. 16.

Fig. 17

(1) Group name.

- Maximum permissible length of group name is

0 – 10 characters.

(2) Defi nition of group access rights.

(3)

(1)

(2)

(4) (5) (6) (7)

(1)

(2)

(3)

(4)

(1)

(2)

o Operator-type users may be placed into four groups,

depending on their rights, see 8.3.2.2.1.

o The fi eld (7), Fig. 12, displays the operator name.

● Without login:

o No user is logged into the device.

o The device cannot be operated.

o There is allowed only viewing of program protocols

and viewing of status information, see 8.6.

o The fi eld (7), Fig. 12, displays the word login.

8.3.2.2.1 ACTIVATING ADVANCED USER

ADMINISTRATION

Only the administrator has access to advanced user

administration. Clicking the

(Fig. 12) icon opens

the login screen.

Factory default fi rst time login details:

Name: admin

Password: password

Fig. 15

(1) Username.

(2) User password.

(3) Cancel.

(4) Numerical keyboard.

(5) Clear button

- Inserts a blank character.

(6) Delete.

(7) Confi rm.

CLIMACELL EVO_np_en_1401_mmm_V1.01 17

Instructions for use

User editing. See (4), Fig.16.

Fig. 18

(1) Button for defi ning administrator password.

- The fi rst button in the list is reserved for the

administrator.

(2) Buttons for defi ning operator names and passwords.

- Buttons 2 – 100 are used to defi ne operator login

names and passwords. See Fig. 19.

User editing. See (2), Fig. 18.

Fig. 19

(1) Operator name

- Maximum permissible length of name is 1 – 10

characters

(2) Operator password.

- Maximum permissible length of name is 1 – 14

characters.

(3) Allocating operator to group

- See Fig. 16, Fig. 17.

(1)

(2)

8.3.2.2.2 CHANGING USER PASSWORD

Under the icon the user (administrator or operator)

an change his access password.

Fig. 20

Note:

Maximum permissible length of password is 5 – 14

characters.

8.3.2.2.3 LOGGING OUT

If the user is logged in and clicks a logout request

will be displayed.

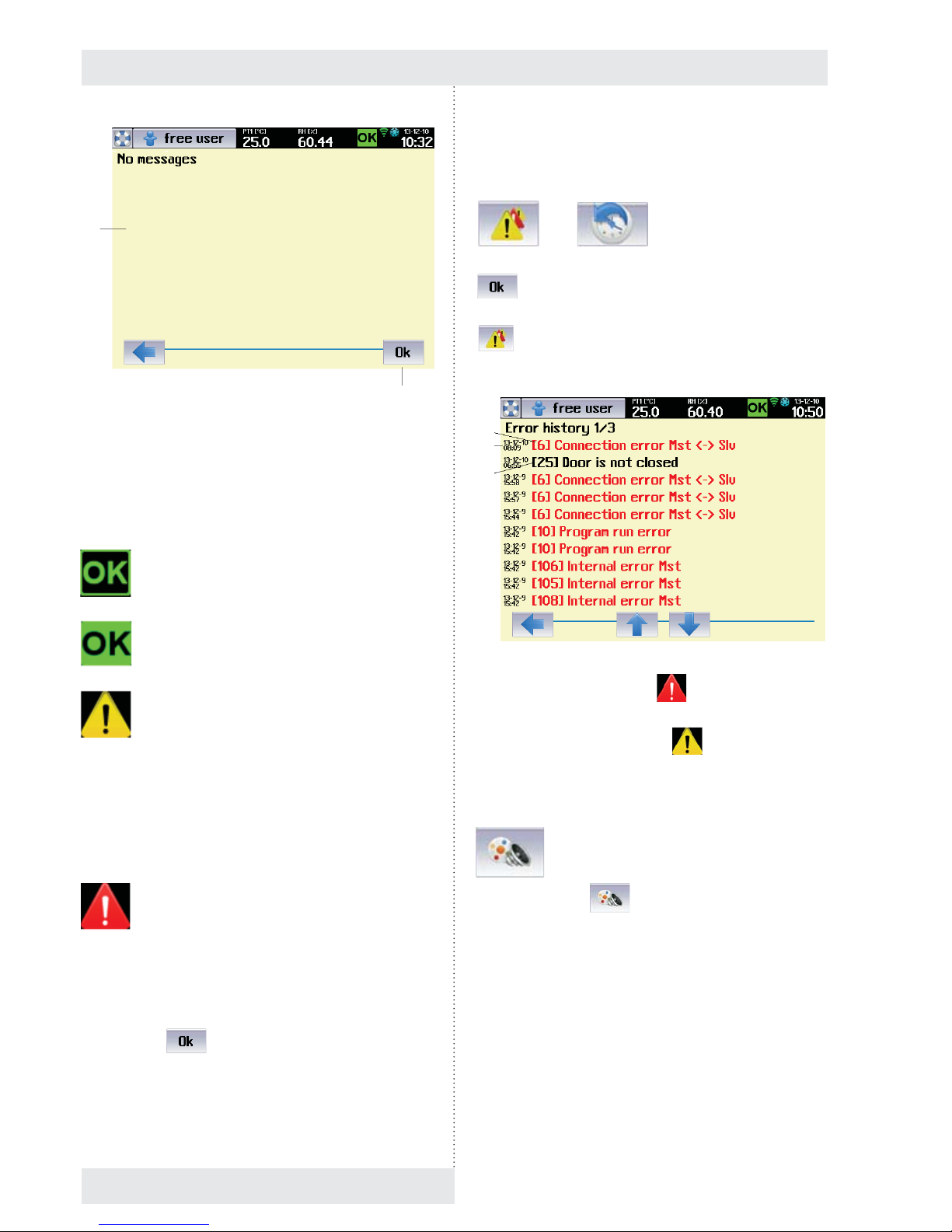

8.3.3 WARNINGS AND ERRORS

8.3.3.1 CURRENT ERROR MESSAGES

CLIMACELL EVO automatically monitors a series of

parameters that are important for the program to run

properly and safely. If a fault or hazardous situation is

detected, the user is given a visual (or audible) notifi cation

– all faults detected are displayed in the form of a list (list

of current error messages, Fig. 21). This list shows all

warnings or errors whose cause has not yet been rectifi ed.

(1)

(2)

(3)

Fig. 21

(1) Current error messages.

(2) Button for confi rming all displayed errors.

The list of current error messages can also be displayed

by clicking the icon (10), Fig. 12; the icon can have the

following meanings:

No error messages - program is not running.

● ED signal light is green (3), (Fig. 4).

No error messages - program is running.

● LED signal light is green.

Warning.

● The fl ashing symbol is displayed if a

non-critical fault occurs, i.e. a fault which does

not prevent the program from running. After

pressing OK to confi rm, the symbol will stop

fl ashing, although it remains on the toolbar if

the fault is still present.

● The LED signal light acts the same as the

symbol – it fl ashes (lights up) orange.

Error.

● The fl ashing symbol warns the user that a

serious fault has occurred while the program

is running. Upon this kind of error the program

is stopped and the system awaits

confi rmation from the user. After pressing

. the symbol will stop fl ashing,

although it remains on the toolbar if the

fault is still present. The program may only be

restarted once the cause of the error has

been rectifi ed. These errors are displayed in

red in the list.

(1)

(4)

● The LED signal light fl ashes (lights up) red.

8.3.3.2 HISTORY OF FAULTS

→

After fault elimination and after confi rmation by push button

the fault is transferred to the history of faults

(Fig. 22). You can display the history of faults by pressing

in the menu for device setting (Fig. 13). The list

displays last thirty fault events.

Fig. 22

(1) Fault occurrence record ( ).

(2) Date and time of occurrence

(3) Warning occurrence record (

).

8.3.4 DISPLAY AND SOUNDS

By clicking on icon (Fig. 13), you will display the

menu for setting the display appearance and selections for

sound signals.

(1)

(2)

(3)

Instructions for use

18 CLIMACELL EVO_np_en_1401_mmm_V1.01

Fig. 23

(1) Colour profi le setting.

(2) Volume level setting.

(3) Acoustic indication options.

8.3.5 DEVICE MAINTENANCE MENU

Fig. 24

8.3.5.1 SINGLE DEFROSTING

→ Defrosting

It is suitable to use single defrosting mainly in programs

with long-term intensive cooling, when the condensate

gets frostbitten in the chamber and on the cooling system

of the device. In the course of single defrosting, the forst is

effi ciently removed. The operation cannot be activated when

(1) (2)

(3)

the program is running. Defrosting is ctivated in the device

maintenance menu.

Warning:

In case of single defrosting the temperature in the

chamber of the device increases to 50 °C, so take the

tested samples out of the incubator so as to avoid their

damage.

Note:

It is necessary to distinguish between automatic defrosting

of cooling system (see 8.4.3) and single defrosting of the

whole device. Automatic defrosting removes icing from the

cooling system of the device only (and so it increases its

effi ciency) and it is performed automatically in the course of

the program operation. Single defrosting removes icing from

the whole device and it cannot be run while the rpogramn is

running.

Fig. 25

(1) Defrosting program parameters.

(2) Warning regarding objects that must be taken out of

the device.

- This option must be ticked, otherwise it is not

possible to start the program.

(3) Defrosting program start.

8.3.5.2 DECONTAMINATION

→ Decontamination

In the course of decontamination, the operation space of the

chamber faces high temperature. The initial parameters for

exposition are 160 °C and 30 minutes. These values may

be adjusted according to client´s requirements (a service

intervention is necessary).

(1)

(2)

(3)

Instructions for use

CLIMACELL EVO_np_en_1401_mmm_V1.01 19

Instructions for use

20 CLIMACELL EVO_np_en_1401_mmm_V1.01

Notes:

- Decontamination is not possible in some versions of the

device as the high temperature could damage some

parts of the device and that is why it is factory blocked.

- Decontamination is blocked for the version with

exposition lighting.

Warning:

Before start of the decontamination program it is

absolutely necessary to take out of the device all and

any objects and accessories that could be damaged or

destroyed by high temperature infl uence!

These include mainly:

● tested samples

● racks with exposition lighting

● lighting intensity sensors

● CO

2

sensor.

After selection of decontamination (Fig. 24) there will be

displayed a menu for the decontamination program start:

Fig. 26

(1) Decontamination program parameters.

(2) Warning regarding objects that must be taken out of

the device.

(3) Decontamination program start.

Note:

Options (1), (2) must be ticked, otherwse it is not possible to

start the program..

8.3.5.3 DRYING

→ Drying

Drying removes in an optimal way all and any residuals of

condensed humidity from the chamber of the device.

● In the course of drying, the fan revolutions are set to

100 % and temperature in the chamber is kept around

40 °C. Before start of drying it is necessary to take out of

the device all and any material that could be damaged

by the above stated temperature.

Fig. 27

(1) Drying parameters.

(2) Warning of the material that must be taken out of the

device.

(3) Start of drying.

Note:

So as to reach intensive chamber ventilation it is required

for the door of the device to be open before start of drying.

Fig. 28

8.3.6 CURRENT DATE AND TIME

SETTING

(1)

(2)

(3)

(1)

(2)

(3)

CLIMACELL EVO_np_en_1401_mmm_V1.01 21

Instructions for use

Fig. 29

(1) Current date.

(2) Winter time.

(3) Time delay in hours in case of transfer to summer time.

- Here you can easily move time to summer (winter)

time. Change in this position means a change

of time in upper bar. It is not possible to perform

such movement when the program is running or in

delayed program start mode.

(4) Current time.

8.3.7 COMMUNICATION – ACTIVATION

In the Communication menu there is set the communication

interface for the application WarmComm4, there is also

performed activation of Wifi connection and e-mail account.

Note:

Selections LAN, E-mail sending of reports and Wifi are

available only at devices with communication module, see

6.15.

Fig. 30

(1) Communication interface for WarmComm4

(2) Identifi cation number of the device

- The number allows distinguishing of individual

devices in cases when a user uses several

CLIMACELL EVO devices at once.

- Displaying the device identifi cation number on the

device display - see 8.4.7.

(3) E-mail account activation, see 8.3.7.2.

(4) Wifi options

- When this option is selected, there are found

access points of available WLAN.

- A red cross means that Wifi connection is not

active.

8.3.7.1 WIFI CONNECTION ACTIVATION

By clicking the push button (3), see Fig. 30, you will display

a list of available access points.

Fig. 31

(1) Example of the list of access points found.

- In our case there was selected TechLink01

WEP64.

After selecting the access point there is required a password

for access to WLAN.

Fig. 32

(1)

(2)

(3)

(4)

(1)

(2)

(3)

(4)

(1)

(1)

(2)

Instructions for use

22 CLIMACELL EVO_np_en_1401_mmm_V1.01

(1) Password Index.

- The user may have as many as four passwords

for access to the access point. The password

index defi nes which of the passwords is used.

(2) Password.

- It is provided by WLAN administrator.

After password entering there is displayed the access point

which the connection has been established with.

Fig. 33

(1) Access point which the connection has been

established with.

8.3.7.2 E-MAIL ACCOUNT ACTIVATION

By pushing the push button (2), Fig. 30, there will be

displayed a screen for e-mail account login.

Fig. 34

(1) Name for e-mail account login.

(2) Password for e-mail account login.

Note:

- The proper e-mail account activation must be preceded

by its creation. It is possible to create the account on any

server providing e-mail services. Contact your system

administrator to create an account, respectively use

services of any of public e-mail service providers (www.

gmail.com, www.yahoo.com, etc).

- When creating an e-mail account, the user obtains a

unique name and password for his/her account. Enter

the data to positions (1) and (2), Fig. 34.

- For e-mai communication setting, see also 8.3.10.1.3.

After successful login there is a green tick in the e-mail

account push button and the name of then account is

displayed (Fig. 35).

Fig. 35

(1) E-mail account.

8.3.7.3 WIFI CONNECTION VIA INTERNET

BROWSER

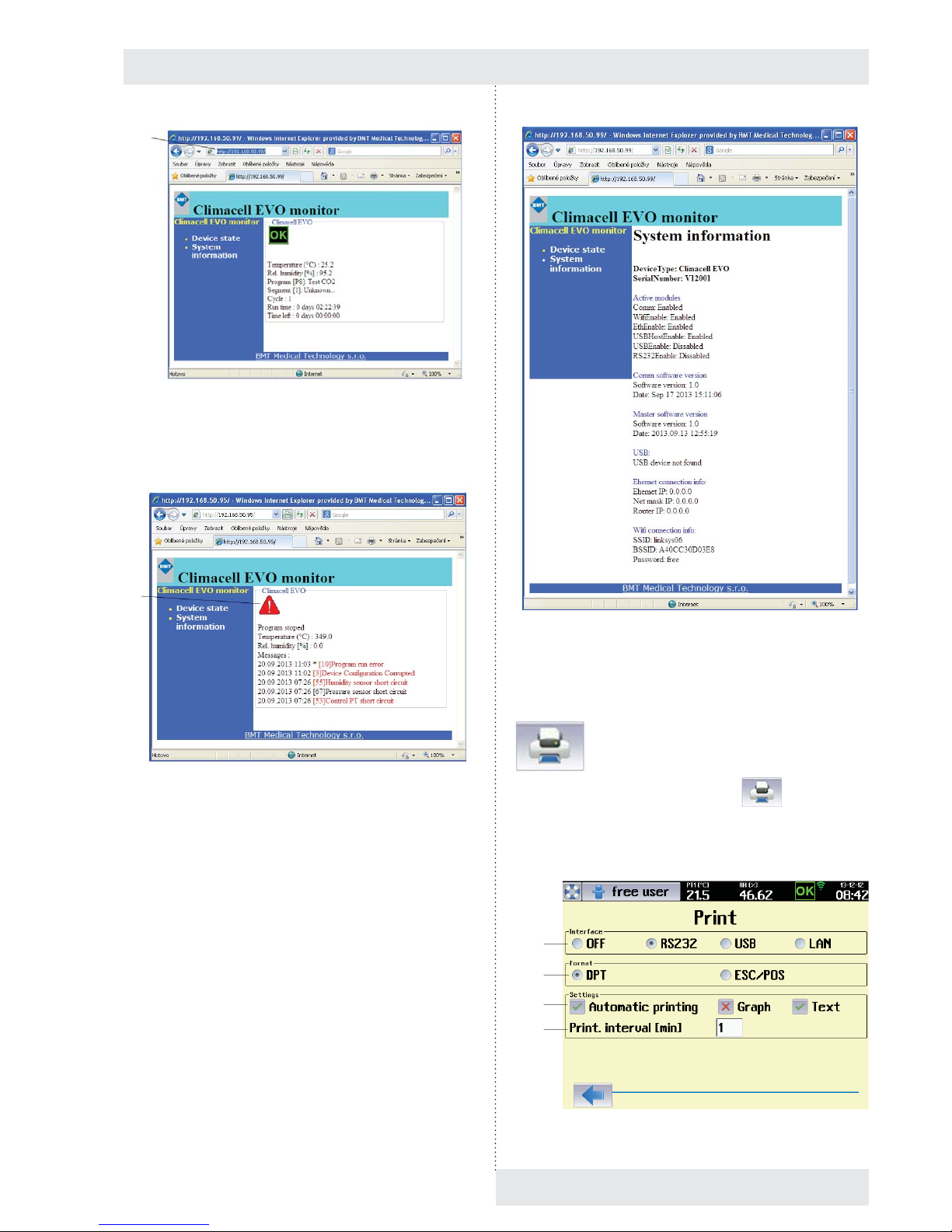

CLIMACELL EVO provides the possibility of remote

monitoring of the device status. The wifi web server runs on

communication module and it is possible to connect to it via

ordinary Internet browser.

To establish connection with CLIMACELL EVO proceed as

follows:

1. Connect the device to local network and confi gure it

correctly - see 8.3.7.1 a 8.3.10.1.2.

2. From the system information panel 2/2 (Fig. 74) read the

pre-set IP address for WIFI.

3. Insert the address to the address line of the web browser

in PC, connected to the same local network as the

device.

4. The status of the device will be read on the web site, see

Fig. 36.

5. The last error message will be displayed after clicking on

the icon

, see Fig. 37.

6. System information will be displayed by clicking on

“System Information”.

See Fig. 38.

(1)

(1)

(2)

(1)

Instructions for use

CLIMACELL EVO_np_en_1401_mmm_V1.01 23

Fig. 36

(1) IP address of Wifi .

Fig. 37

(1) Icon for faults displaying.

Fig. 38

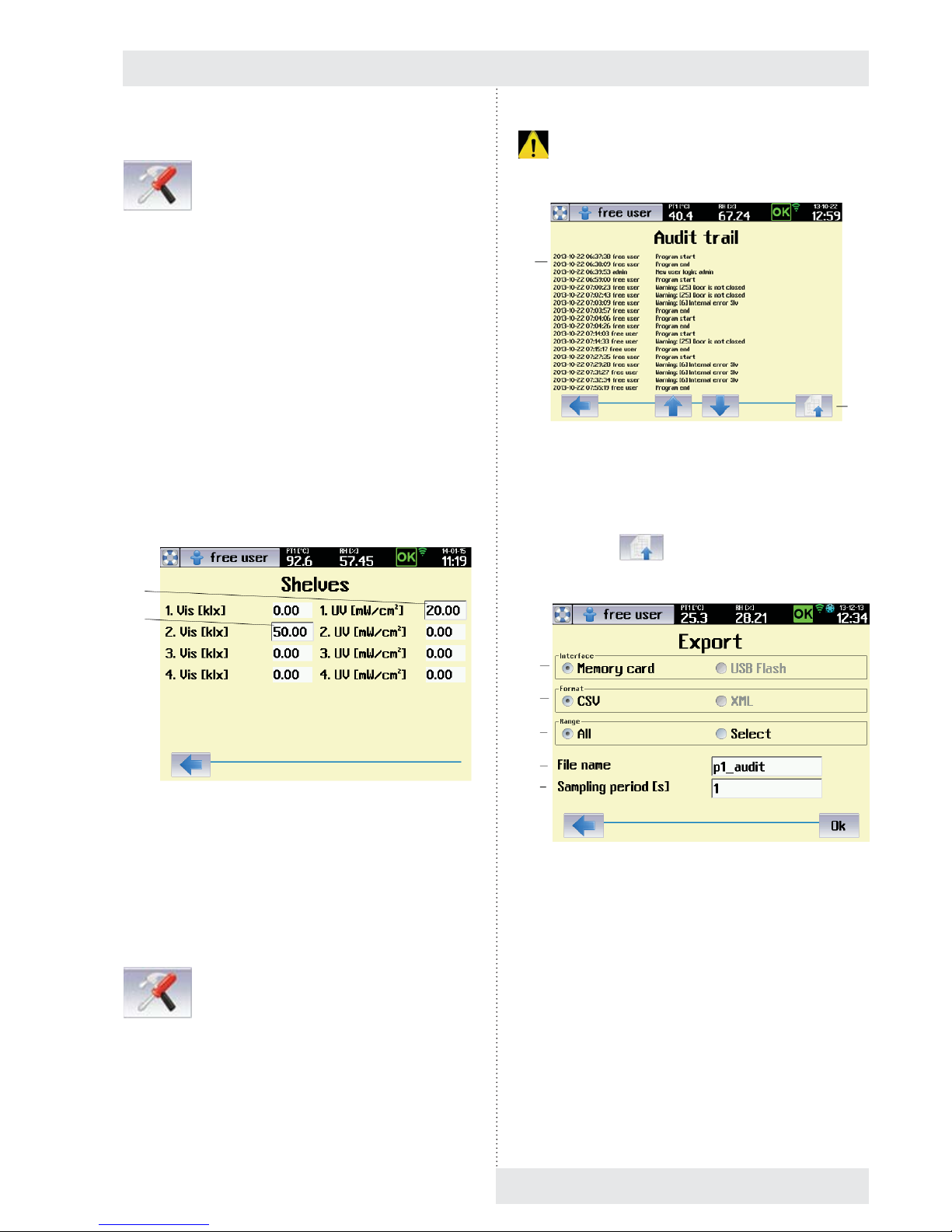

8.3.8 PRINT

The menu is displayed using the icon (Fig. 13).

Note:

We recommend use of the printer DPT6333, see 6.16.

Fig. 39

(1)

(1)

(1)

(2)

(3)

(4)

Instructions for use

24 CLIMACELL EVO_np_en_1401_mmm_V1.01

(1) Communication interface selection.

(2) Data format supported by the printer

- The data format is set in the technical specifi cation

of the printer. For the printer DPT6333 select

„DPT“.

(3) Options for printing.

- Automatic printing – a protocol is automatically

printed after the prograam termination.

- Graph – only the graph is printed.

- Text – only the text is printed.

(4) Print interval.

- It sets the printing period – it is possible to set 1

up to 999 minutes.

8.3.8.1 PROTOCOL PRINTING

Connect the printer and the device using the cable

according to 4.3. The connector for RS232 can be found on

the communication panel in the rear part of the device

(Fig. 3).

Connect the printer to power supply and switch on the

power switch (proceed according to instructions for use of

the printer). The printer may receive data from the device

while being in ON-LINE mode (push button SEL).

Select the interface (RS232).

Set the printing mode.

The printout contains:

- Printout heading:

o device type,

o serial number,

o batch number,

o program parameters,

o printing interval.

- Program data:

o program start time,

o values of items in given time.

Notes:

- A new heading is printed in case of program parameters

change.

- In case of device feeding cut off there is printed a

message after power supply restoration

→ Network

cut off.

- Setting of DIP switches on the printer DPT-6333:

1 - OFF

2 - OFF

3 - ON

4 - OFF

5 - OFF

6 - OFF.

8.3.9 BACKUP

CLIMACELL EVO allows performance of backup of some

important settings of the device (list of programs, list of

users, device confi guration). It is possible to use saved

data for consequent restoration of original setting or for

confi guration of another device. The menu is activated by

the icon

(Fig. 13). As a recording medium it is

possible to use SDHC card or USB fl ash disc. The card is

inserted to the appropriate slot on the control panel, the

USB fl ash disc is connected via the USB Host connector in

the rear part of the device.

Note:

For the USB fl ash disc connection the device must be

equipped with the communication module (optional

equipment of the device).

Fig. 40

8.3.10 SERVICE SETTING

8.3.10.1 COMMUNICATION – SETTINGS

→ Communication

Notes:

- Setting the communication interface of the device

supposes basic knowledge in the fi eld of computer

networks. In case of any unclear matters please contact

your information system administrator.

Instructions for use

CLIMACELL EVO_np_en_1401_mmm_V1.01 25

- The settings described in this chapter suppose that the

device is equipped with communication module, see

6.15.

8.3.10.1.1 ETHERNET SETTING

The communication interface of the device allows its

inclusion to LAN. An example of setting is shown in Fig. 41.

Fig. 41

(1) Ethernet activation.

(2) DHCP

- The user has two possibilities to get the IP

address of the device within LAN:

o IP address is assigned by the network

administrator (see below).

o the DHCP option is ticked – then, the

IP address is assigned to the device

automatically through the DHCP server.

(3) IP address of the device.

- Assigned by the LAN administrator.

(4) Sub-net mask.

- The sub-net mask is provided by the LAN

administrator.

(5) Initial gate.

- IP address of the router.

- Get information from the LAN administrator.

(6) DNS

- Address of Local DNS (Domain Name System).

- Get information from the LAN administrator.

(7) MAC

- A unique address of each network device.

- It is factory adjusted but it can be changed if

necessary.

- If there is set the MAC address 00-00-00-00-0000, the device uses the MAC address pre-set

from the factory. The address is stated in system

information, see 8.6.

- If the user wants to use aome other address but

the initial one, he may re-type it in this fi eld.

- After editing, you must switch the device on and

off using the push button ON/OFF!

(8) Ethernet setting.

(9) Wifi setting.

(10) E-mail setting.

(11) Web site setting.

8.3.10.1.2 WIFI SETTING

Fig. 42

(1) Wifi activation

(2) Automatic assignment of the IP address by the DHCP

server.

- See 8.3.10.1.1.

(3) IP address of the device.

- IP address of the device within WLAN.

- Assigned by the WLAN administrator

(4) Sub-net mask.

- Get information from the WLAN administrator.

(5) Initial gate.

(6) DNS.

- Address of Local DNS (Domain Name System).

- Get information from the WLAN administrator.

(7) Web server activation.

- On the communication module it is possible to

activate web server, allowing the user to monitor

the status of the device, see 8.3.7.3.

(8) Roaming.

- The device automatically connects to the access

point with the strongest signal.

(1)

(3)

(4)

(5)

(6)

(7)

(2)

(8) (9) (10)

(2)

(1)

(3)

(4)

(5)

(7)

(8)

Instructions for use

26 CLIMACELL EVO_np_en_1401_mmm_V1.01

8.3.10.1.3 E-MAIL SETTING

Fig. 43

(1) Sending

- Switched off / via Wifi / via Ethernet.

(2) SMTP.

- The address of the SMTP server – the address

of the server where the user´s e-mail account

is created. In case of a request for e-mail

communication CLIMACELL EVO connects with

the server and the user logins to his account (see

8.3.7.2), then it is possible to send e-mails to any

address.

- For address of the e-mail server contact your

information system administrator respectively you

can use any of public providers of e-mail services,

e.g. www.gmail.com etc.

(3) E-mail address.

- Target address, to which the e-mails are to be

sent.

- There may be any address for which the

e-mail server defi ned by address (2) sends the

messages from CLIMACELL EVO.

8.3.10.2 TOUCH PANEL CORRECTION

→ Touch Surface Offset

In this menu it is possible to calibrate the touch panel in

such a way so as the push buttons displayed on the display

exactly match the active area on the touch panel. With any

touch of the relevant push button, the active touch area on

the touch panel moves in one pixel in specifi ed direction.

Maximal adjustable variation is 100 pixels in any direction.

The initial value is x = 0, y = 0.

Note:

Display resolution is 640 x 480 pixels.

(1)

(2)

(3)

Fig. 44

(1) Current value of calibration in pixels for axis x

and y

(2) Push buttons for movement of active fi eld of touch

panel in given direction.

(3) New touch surface after movement downwards

(Δx = 0, Δy = -20).

- The fi eld where push buttons react to touch was

moved in 20 pixels downwards.

8.3.10.3 UNITS

→ Units

Selection of units for temperature and pressure.

Fig. 45

(1)

(2)

(3)

Instructions for use

CLIMACELL EVO_np_en_1401_mmm_V1.01 27

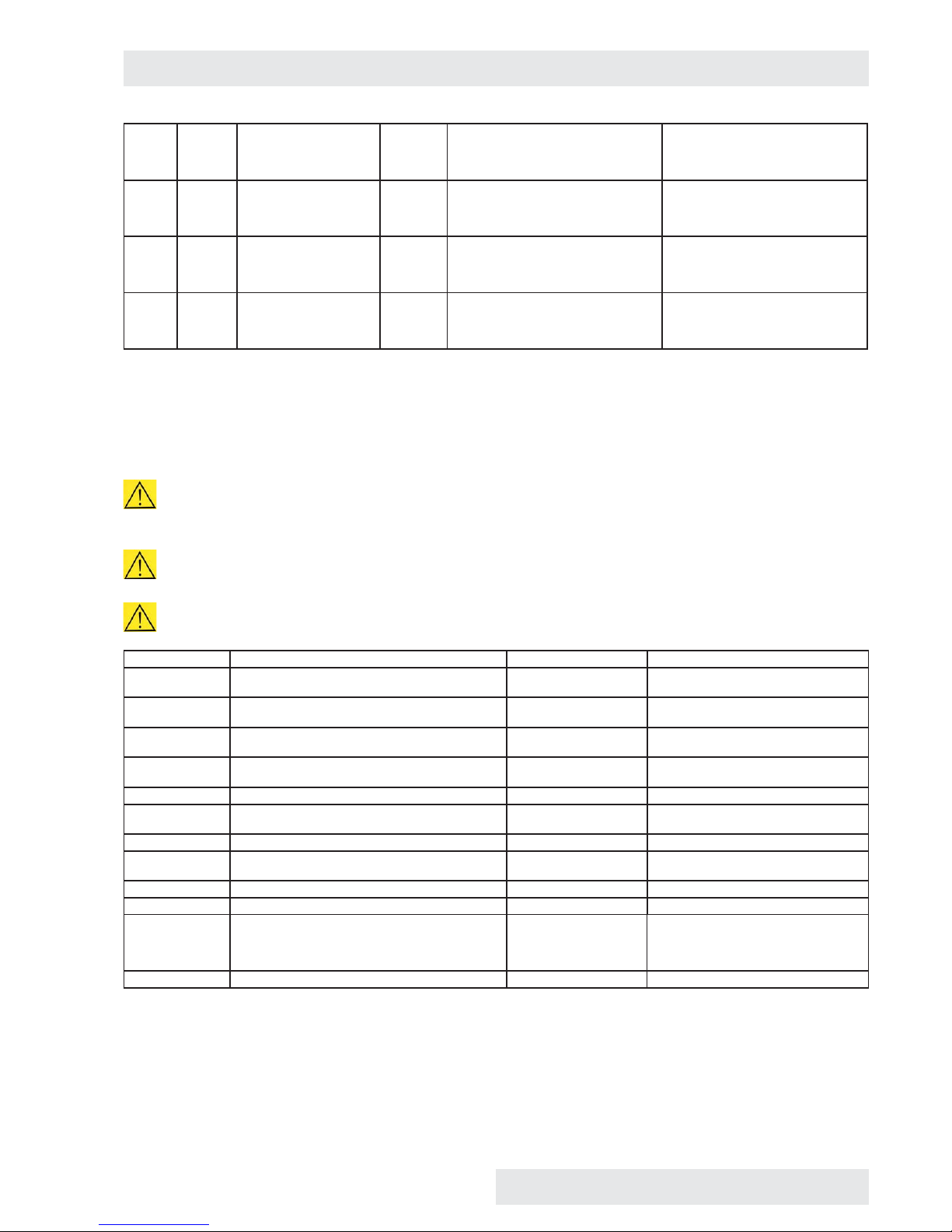

8.3.10.4 RACK

→ Rack

This service menu serves for entering the value of VIS and

UV light intensity under individual light racks in case that

the device is not equipped with sensors for light intensity

measuring (optional equipment, see 6.11).

The procedure is as follows:

1. The relevant rack is lit to maximal intensity (100 %).

2. The user uses an external measuring gauge for

measuring the intensity of visible light IVIS [k.lx],

respectively intensity of UV radiation IUV [mW/cm2]

below the relevant rack, on the exposed material

position.

3. The measured value is entered to the menu according to

Fig. 46 and it is saved in the device memory.

4. The saved value of light intensity will be used for

calculation of exposition time in programs with light

exposition (8.4.4.1).

Fig. 46

(1) Intensity of UV radiation measured below the fi rst UV

rack.

(2) Intensity of visible light measured below the second

rack.

8.3.10.5 AUDIT TRAIL

→ Audit trail

The audit trail contains a chronological record of all action

performed using the device. The minimum length of each

recorded section is ten years, although this may be longer

depending on the frequency of the work. Once the memory

capacity allocated for the audit trail reaches 90 %, a warning

. is issued. A service call-out is required to restore full

capacity.

Fig. 47

(1) Audit trail records.

(2) Button for export.

The push button

displays a menu for the audit trail

export.

Fig. 48

(1) Memory medium selection.

- USB fl ash disk is allowed only with devices with

communication module, see 6.15.

(2) Record format.

- Format CSV is suitable for export to the

application Microsoft Excel.

- XML is a universal format supported by many

applications.

(3) Export range.

- Everything – there is performed the export of

complete audit trail.

- Selection - export starts from the fi rst record on

current page. Number of exported records is set

by the item (5).

(1)

(2)

(1)

(2)

(1)

(2)

(3)

(4)

(5)

Instructions for use

28 CLIMACELL EVO_np_en_1401_mmm_V1.01

(4) File name.

- 8 characters as a maximum.

(5) Number of exported records.

8.3.10.6 OVERVIEW OF INPUTS AND OUTPUTS

This menu provides information on statuses of all the

sensors and action elements within the whole device. It

serves mainly for service purposes and it may be used in

remote diagnostics of the device. There are displayed the

data from all the sensors and current statuses of all the

action elements in the device.

8.3.10.6.1 ANALOGUE ITEMS

Fig. 49

(1) Analogue Inputs

- A set of analogue items measured within the

whole device (temperature, pressure, humidity,

concentration CO

2

, backup battery voltage, data

from light sensors).

(2) Analogue Outputs.

- Analogue outputs mean the level of analogue

control signals, i.e. mainly signals for lighting

intensity control.

(3) Digital inputs and outputs displaying.

8.3.10.6.2 DIGITAL INPUTS AND OUTPUTS

Fig. 50

(1) Digital Outputs.

- Output signals for control of individual action

elements of the device.

(2) Digital Inputs

- In1 up to In8 are digital inputs. The information

on statuses of terminal switches and comparators

within the scope of the device.

(3) Transfer to analogue items displaying.

8.3.11 TESTS

The tests serve for checking the correct function of the

device.

8.3.11.1 COOLING TEST

We recommend for the cooling test to be performed in case

of any suspicion of impaired effi ciency of the cooling system.

The proper test is performed on an empty device and it

consists of three phases:

Test phase Description

1 Start up to temperature 22 °C.

2 Lead time at temperature of 22 °C for the period of

10 minutes

3 Cooling from 22 °C to 10 °C. The cooling is

switched on to maximal output

(1)

(2)

(3)

(1) (2)

(3)

Instructions for use

CLIMACELL EVO_np_en_1401_mmm_V1.01 29

Fig. 51