Instruction Manual

Manfred Weber

Metra Mess- und Frequenztechnik in Radebeul e.K.

Meissner Str. 58 - D-01445 Radebeul

Phone +49-351-836 2191 Fax +49-351-836 2940

Email: Info@MMF.de Internet: www.MMF.de

Charge

Amplifiers

M68 Series

The latest version of this document can be downloaded from:

http://www.mmf.de/product_literature.htm

© Manfred Weber

Metra Mess- und Frequenztechnik in Radebeul e.K.

Aug. 10 #162

Contents

1.Application................................................................................................................................ 5

2.Function and Operation............................................................................................................. 5

3.Power Supply............................................................................................................................6

3.1.Grounding Concept............................................................................................................6

3.2.External Supply .................................................................................................................6

3.3.Battery Operation (M68D1)...............................................................................................7

4.Inputs........................................................................................................................................ 7

4.1.Charge Input ......................................................................................................................7

4.2.IEPE Input ......................................................................................................................... 7

4.2.1.Switching Off the IEPE Supply .................................................................................9

5.Avoiding Ground Loops............................................................................................................9

6.Amplifier ...............................................................................................................................10

7.Level Indicators.......................................................................................................................10

8.Low Pass Filter .......................................................................................................................11

9.High Pass Filter.......................................................................................................................12

10.Integrators.............................................................................................................................12

11.Rack Cases for Model M68R1..............................................................................................15

12.Technical Data......................................................................................................................16

Appendix: Limited Warranty

Declaration of Conformity

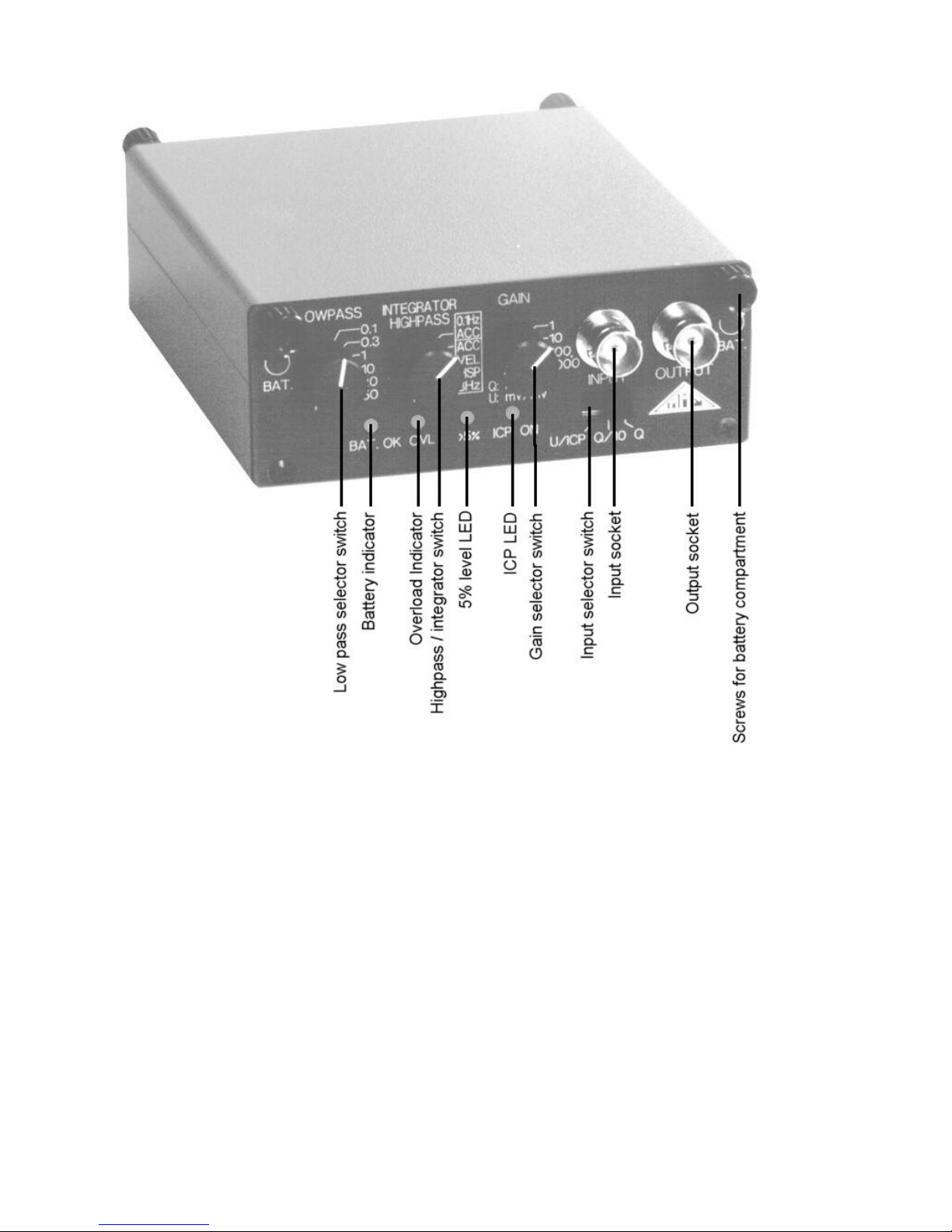

Figure 1: Front view of Model M68D1 with control elements

4

1. Application

The Signal Conditioners of M68 series are intended for connection of piezoelectric acceleration,

force or pressure transducers. The input is suitable for sensors with charge output as well as for

IEPE compatible transducers or microphones.

By means of the M68 the sensor signal can be best possibly adapted to the existing measuring

equipment or PC-based data acquisition systems. The Signal Conditioners provide the following

functions:

• Adaptation of the sensor signal and sensor supply

• Amplification

• High- and low-pass filtering (for example anti-aliasing filter)

• Integration of the sensor signal, for instance, to measure velocity or displacement.

Models M68D1 and M68D3 are housed in a rugged aluminum case. Both models can be used in

laboratory as well as under field conditions. Model M68D1 may also be operated from batteries.

Model M68R1 has been developed for multichannel measuring systems. It fits into 19”-rack

systems.

2. Function and Operation

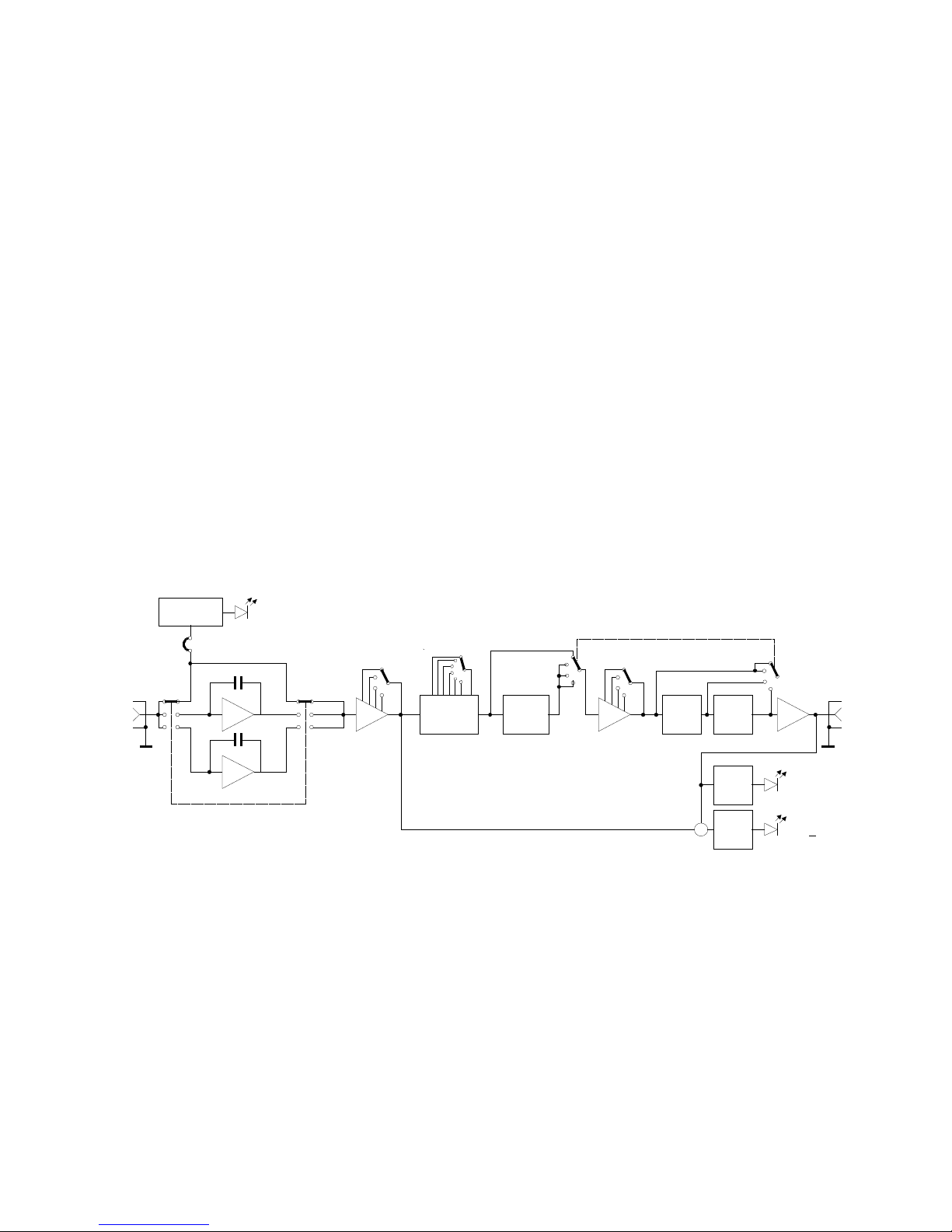

Figure 2 shows the block diagram of Model M68 with its most important functional groups.

Depending on the position of the input switch, the input signal passes the impedance converter

Q1 or Q2. If IEPE operation is selected, the signal is directly connected to the amplifier. At

IEPE operation a constant current is fed into the input socket to supply the sensor electronics.

The constant current source can be switched off by the internal jumper J1, in case an AC voltage

shall be connected to the input.

The input circuit is followed by the first amplifier stage, low pass and high pass filters. The low

pass filter has 6 selectable limiting frequencies. The high pass filter has a limiting frequency of 3

Hz, which can be bypassed by the switch “HIGH PASS / INTEGRATOR”. In this case the full

5

Figure 2: Block diagram

U

Q/10

Q

U

Q/10

Q

Q1

Q2

IEPE

supply

J1 (ICPon/off)

Low pass

Frequency

High

pass

0.1Hz

3Hz

V2 1. Int. 2. Int.V1

Gain

a

v

d

Gain

Input

Overload

Output

IEPE

+

Compa-

rator

>5%

V=1

Compa-

rator

bandwidth down to 0.1 Hz comes into effect. The filters are followed by the second amplifier

stage. The divided gain before and after filtering provides sufficient dynamic range, even for signal components outside the filter range. At the same time a high signal-to-noise ratio is achie ved.

Before reaching the output driver the signal may pass one or two integrating stages. The output

is DC coupled.

A control LED for the output modulation indicates an output signal higher than 5 % of full-scale

modulation. An overload LED shows if the output signal exceeds 90 % of full-scale modulation.

It also indicates overload before the filter stages.

Models M68D1, M68D3, and M68R1 have identical electronic circuits.

3. Power Supply

3.1. Grounding Concept

The inputs and outputs of the signal conditioners are single ended, i.e. asymmetrical. In case an

additional signal ground connection is required, ground is available via a separate connector at

the rear of the instruments. For the Models M68D1 and M68D3 this connector is a 4 mm banana jack. The signal ground of Model M68R1 can be found at the 4-pole frame connector.

The case of the instruments is internally connected to ground.

If model M68R1 is used with the rack cases M68B6 and M68B12 a connection is made between

signal ground and protective earth potential via the case.

The power supply is separated from signal ground. In some cases it may be of advantage to

connect the minus pole of the power supply to signal ground, to avoid ground loops. For this

purpose you can plug in the 4 mm jumper (delivered with the instruments) at the rear of Models

M68D1 and M68D3. At Model M68R1 the terminals of the power supply socket can be connec ted by a wire.

3.2. External Supply

The Signal Conditioners M68 are powered by an external DC voltage

Models M68D1 and M68D3 come with a mains plug adapter for 115/230 VAC. The power supply socket according to DIN 45323 is located at the rear of the instruments. Any other voltage of

5 V to 15 V DC and about 300 mA (for M68D1) or 1 A (for M68D3) may be connected to this

socket. The positive supply terminal is connected to center pin (tip). The POWER ON/OFF

switch is located at the rear.

The M68R1 also has its power supply connector at the rear. It is a 4-pole frame connector type

WAGO 232. The pin designation is shown in Figure 3.

Figure 3: Power supply socket of Model M68R1

6

+ 5 .. 15 V

0 V

Signal ground

0 V

The supply voltage is connected to the terminals “+ 5 .. 15 V“ and “0 V”. A special plug with

screwed contacts for the rear socket is delivered together with the instrument. This way the

power supply can be wired manually. In case you use the offered 19”-mounting racks with internal power supply unit, this connection is realized by the backplane. Model M68R1 has no

power on/off switch.

The instruments are protected against false polarization and short-time excess voltage up to

60 V. All models of M68 series have an LED “BAT O.K.” indicating sufficient supply voltage.

It lights up green, as long as the voltage is above 5 V. It works for battery operation as well as

for external power supply (M68D1).

3.3. Battery Operation (M68D1)

Model M68D1 has a battery compartment for four “AA” size batteries (type LR 6). It is opened

by unscrewing four plastic knobs and removing the cover. The right polarity is shown on the

battery holder. To ensure long battery life it is recommended to use alkaline batteries. Accumulators may be used as well. You can operate the instrument on NiMH or NiCd. However, by reason of the lower voltage of accumulators, the battery control will not work exactly.

Please take discharged batteries out of the instrument to avoid damage by leakage. Also, remove

the batteries if the unit is not in use for a longer period.

4. Inputs

The Signal Conditioners M68 are designed for both sensors with charge output and with inte grated impedance converters to IEPE standard as well. You can switch from one to the other

type of transducer by means of the slide switch next to the input socket. Both input types use the

same BNC input socket.

4.1. Charge Input

Capacitive signal sources, usually piezoelectric sensors with charge output, are connected to the

charge input (Q). The input is fed to an amplifier with capacitive feedback. All M68 instruments

have two input stages for charge. In the position “Q/10” of the switch the gain is divided by 10.

The advantage of charge measurement is, that cable capacitance and insulation resistance have

almost no influence to the measuring result. For sensors with charge output it is strongly recommended to use special low-noise cables. Ordinary cable will cause a considerable measuring error at mechanical stress, as a result of the so-called triboelectrical effect. Cables with low insulation resistance, for example caused by humid connectors, reduce the accuracy of measurement at

lower frequencies. A desirable insulation resistance is higher than 10 G Ω. Cables longer than

10 m are not recommended at the charge input.

4.2. IEPE Input

IEPE stands for "Integrated Electronics Piezo Electric". It has been established as industrial

standard for piezoelectric transducers. Other brand names for the same principle are ICP®, Isotron®, Deltatron®, Piezotron® etc. The integrated sensor circuit transforms the charge signal of

the piezo-ceramics, with its very high impedance and high EMI sensitivity, into a voltage signal

with low impedance. The converted signal can be easier transmitted. The cable length at this in put may be more than one hundred meters. Ordinary low cost coaxial cable can be used.

7

A peculiarity of IEPE is, that power supply and measuring signal use the same line. So, an IEPE

transducer needs, like a transducer with charge output, only one single-ended line.

Figure 4 shows the circuit diagram. To separate the low impedance sensor signal from the power

supply, the integrated circuit is supplied with constant current.

This constant current must be fed into the measuring line and simultaneously separated from the

following amplifier stages. The yellow LED “IEPE ON” indicates the flow of constant current.

By supplying the sensor with constant current a positive DC voltage arises over its terminals.

This static bias voltage depends on manufacturer and specimen and amounts to about 5 through

14 V. The sensor signal is superposed on this bias voltage. The output voltage of the transducer

never changes to negative values. Its minimum value is the saturation voltage of the integrated

impedance converter (0.5 V to 1 V). The supply voltage of the constant current source determines the maximum value of the output voltage. For the M68 this voltage amounts up to 24 V and

guarantees an optimum dynamic range for all available sensors.Figure 5 shows these relations.

8

Figure 4: IEPE principle

Integrated amplifier

U

I

const

s

Q

U

Piezo

ceramics

C

C

R

I

C

C

I

const

R

I

Coupling capacitor

Constant supply current

Input resistance

U

s

Supply voltage of

constant current source

coaxial cable,

> 100 m

IEPE Transducer Signal Conditioner

Figure 5: Dynamic range of IEPE compatible transducers

4.2.1. Switching Off the IEPE Supply

In some cases it may be necessary to switch off the constant current supply, in order to use the

input for normal AC sources. For this purpose, please change the position of the jumper, which

you will find at Models M68D1 and M68R1 behind the front panel. Remove the cover of Model

M68D1 by unscrewing the four plastic screw heads. To remove the cover of Model M68R1,

four screws at the side and two at the back are unscrewed. Jumper J1 is located left at the front

side of the printed circuit board. Plug it into the position “OFF” to switch off the constant cur rent source.

After removing the front cover of Model M68D3 you will see only the jumper of channel 1. To

reach the jumpers of channels 2 and 3, please remove front and rear panel.

5. Avoiding Ground Loops

Earthing or ground loops are often the reason for measuring errors in multichannel measuring

systems. In most cases you will find a superimposed 50 Hz or 100 Hz voltage on the measuring

signal. One reason for this effect may be, that the transducers are connected to ground not only

via their cable at the signal conditioner, but also in addition at the measuring point through their

case. Vibration transducers are often mounted at grounded machine parts. Within earthing systems transient currents may appear. These transient currents cause a potential drop across the

earthing or grounding wires. Via the signal input of the amplifier they may result in a considerable measuring error.

To avoid this, insulated attachment of the transducers is recommended.

Metra offers several industrial vibration transducers with insulated mounting base and different

insulating flanges for non-insulated sensors.

9

Max. output voltage =

supply voltage of

constant current source

Min. output voltage =

saturation voltage

(see data sheet)

Sensor bias voltage

(see data sheet)

negative overload

0V

positive overload

24 V

0.5..1 V

5 .. 14 V

A star-shaped grounding network is the ideal solution to avoid ground loops. Star-shaped means

that all grounding wires of the sensors and the amplifier outputs are tied to ground at the signal

conditioners, without any transverse connections. In many cases this is more difficult to realize

for the outputs than for the inputs, because the following measuring equipment may have singleended, inputs. If you have the choice to use differential inputs, which can be found on many

data acquisition boards, you should preferably use them.

6. Amplifier

The instruments of M68 Series have the following measuring ranges:

Charge mode: 0.1 / 1 / 10 / 100 / 1000 mV/pC

IEPE mode: 1 / 10 / 100 / 1000 times

The gain selection switch ”GAIN” has four positions. In position “Q/10” of the input selection

slide switch the measuring range of all charge ranges is divided by 10. This may be advanta geous for measurement with high sensitivity transducers or for shock measurement.

After connecting a sensor and occasionally after changing the measuring range, the amplifier

needs a certain settling time because of a short term overload. Therefore it may take up to 30 s,

until the output voltage is free of DC components.

The amplifier output is buffered and DC-coupled. Therefore, possible offset currents fed into the

amplifier output by the following equipment (for instance a PC data acquisition board), do not

cause a DC offset.

7. Level Indicators

LEDs indicate minimum modulation and overload condition.

The LED “>5%” lights up at an output voltage higher than 0.7 V. The LED “OVL” lights up if

the output voltage exceeds 9 V.

The optimum gain range is selected, if the LED “>5%” lights up and the LED “OVL” remains

dark. If both LEDs remain dark, the gain should be increased. If both LEDs light up the gain

should be reduced.

The overload detector monitors both the amplifier output and the filter input (see Figure 2). By

that means overload condition will also be indicated when high signal components beyond the

filter pass band occur.

An overload detector at the integrator input is not provided. In some cases high level components at higher frequencies may overload the amplifier stage before the integrator while at the

integrator output no overload condition can be detected. To avoid this, make sure to check the

signal level in the switch position “ACC” (integrator off) before switching on the integrators.

When the LED indicates overload you can use the low pass filter to attenuate high frequencies.

10

8. Low Pass Filter

To eliminate disturbing noise or to comply with the Shannon theorem: “Signal frequency should

be less than half of the sampling frequency”, it can be advantageous, to use a low pass filter. For

higher accuracy in the time domain it is recommended to set the low pass at 1/10 the sampling

frequency.

The instruments of M68 series have 6 internal low pass filters. The scale at the positions of the

filter switch “LOW PASS” is shows the 3 dB limiting frequencies in kHz. The following table

shows the 3 dB and the 10 % limiting frequencies of the low pass filters:

3 dB Frequency

100 Hz

300 Hz

1 kHz

10 kHz

20 kHz

50 kHz

10 % Frequency

70 Hz

200 Hz

700 Hz

7 kHz

14 kHz

35 kHz

The slope of the low pass filters is 40 dB per decade.

11

180°

-180°

-90°

90°

0

0,1 1 10 100

kHz

0 dB

-20 dB

-40 dB

0,1 1 10 100

kHz

1 kHz

1 kHz

10 kHz

10 kHz

20 kHz

50 kHz

20 kHz

50 kHz

Figure 6: Typical frequency and phase response of the low pass filters

180°

-180°

-90°

90°

0

0 dB

-20 dB

-40 dB

10 100 1000 10000

Hz

10 100 1000 10000

Hz

100 Hz

300 Hz

100 Hz

300 Hz

9. High Pass Filter

The M68 signal conditioners have a high pass filter with a lower limiting frequency of 3 Hz (3 dB). By means of this filter low frequency noise can be removed. Low frequency noise may

occur, for example, by the influence of temperature transients to piezoelectric compression type

accelerometers. The slope of the 3 Hz high pass filter is 40 dB / frequency decade. The 3 Hz

high-pass filter is switched on by turning the “INTEGRATOR HIGH PASS” switch into positi on “ACC 3 Hz”. If the high pass filter is switched off (switch position “0.1 Hz ACC”), the lower

limiting frequency of the amplifier is 0.1 Hz.

With the integrators the high pass filter is always switched on.

As the filters are located between the amplifier stages (see Figure 2) the instrument does not become overloaded, even if the measured signal has higher spectral components outside the filter

range.

10. Integrators

The M68 can integrate the measuring signal one or two times. Integration can be useful for vi bration measurement by means of accelerometers on rotating machinery.

Single integration of vibration acceleration results in velocity, double integration in displace ment.

The „INTEGRATOR HIGH PASS“ switch activates the integrators. In position “ACC“ (acceleration) the measuring signal passes without integration. At the position “VEL” (velocity) the si gnal is integrated once, in position “DISP” (displacement) twice.

With switched on integrators the 3 Hz high pass filter is always activated.

The following calculations show how the M68 output u

out

corresponds to the three vibration

quantities. The selected gain range of the M68 is G and the accelerometer sensitivity (see transducer data sheet) is Bua.

12

Figure 7: Frequency and phase response of the high pass filter

0 dB

-20 dB

-40 dB

0,1 1 10 100

Hz

180°

-180°

-90°

90°

0

0,1 1 10 100

Hz

Vibration acceleration a (without integration):

a=

u

out

G⋅B

ua

(a in m/s²; u

out

in mV; G in mV/mV; B

ua

in mV/ms-2)

Vibration velocity v (single integration):

v=

u

out

G⋅B

ua

⋅10

(v in mm/s; u

out

in mV; G in mV/mV; B

ua

in mV/ms-2)

Vibration displacement d (double integration):

d =

u

out

G⋅B

ua

⋅100

(d in µm; u

out

in mV; G in mV/mV; B

ua

in mV/ms-2)

The equations above apply for IEPE compatible accelerometers. For accelerometers with charge output,

G is replaced by the selected charge amplifier range in pC/g and Bua is replaced by the transducer’s charge sensitivity Bqa.

Example:

Vibration velocity is measured using an accelerometer with a sensitivity of Bqa= 5 pC/ms-2. The M68 is

operated in the range G=100 mV/pC. Its output voltage is 300 mV

rms

. What is the corresponding vibrati-

on velocity?

Solution:

v=

300

100⋅5

⋅10=6 mm / s

RMS

Often a direct connection between the output voltage of the M68 and the measured physical

quantity (for example “1 mV corresponds to 1 mm/s”) is desired.

This can be achieved by adjusting the connected measuring equipment or by typing in a correction factor

in a PC based data acquisition system. In the example given above this correction factor would be 0.02.

At higher frequencies the output voltage will have only small amplitudes after integration. The dynamic

range and the signal-to-noise ratio therefore become lower in the kHz-range (Figure 8).

13

In some cases signal components with high frequency and magnitude may overload the amplifier although no overload can be detected at the M68 output. The overload LED remains dark.

This can occur due to the attenuation of higher frequencies by the integrator (compare Figure 8).

To avoid possible overload, make sure to check the signal level in the switch position “ACC”

(integrator off) before using the integrator. If an overload condition should be indicated, reduce

high frequency components by an appropriate low pass frequency.

14

Figure 8: Frequency response of the integrators

100

10

1

%

dB

Hz

D

o

u

b

l

e

i

n

t

e

g

r

a

t

i

o

n

S

i

n

g

l

e

i

n

t

e

g

r

a

t

i

o

n

Modulation limits

Max.

modulation

0.1 1 10 100 1000

20

0

-20

-40

Figure 9: Pase response of the integrators

180°

-180°

0

90°

-90°

0.1 1 10 100 1000

11. Rack Cases for Model M68R1

For the 19” unit M68R1 the following rack mounting cases are available:

Model

M68B6

M68B12

Channels

6

12

Built-in power supply

yes

yes

The rack cases Models M68B6 and M68B12 supply the plugged-in modules via a backplane.

They can be operated with both 115 VAC and 230 VAC without changing any settings.

15

Figure 10: Front view of rack case M68B12

Figure 11: Rear view of rack case Model M68B6

The fuse holder of the rack cases M68B6 and M68B12 with mains power supply is located inside the mains socket at the rear. It can be pulled out using a screw driver. The fuse facing to the

back of the drawer is a spare fuse. The rear one is the mains fuse.

Important: Unplug the device from the mains voltage before replacing the fuse.

Make sure that the fuse to be replaced has the rating T 800 mA.

12. Technical Data

Measuring inputs

Charge and IEPE compatible, R

I

> 5 MΩ

BNC socket, single-ended

IEPE sensor supply

3.8 .. 5.6 mA constant current,

compliance voltage 24 V,

switched off by internal jumper,

LED indicator

Gain

0.1 / 1 / 10 / 100 / 1000 mV/pC (charge)

1 / 10 / 100 / 1000 (IEPE)

Accuracy

± 1 % typical, referred to full scale output

± 2 % maximum, referred to full scale output

Low pass filter (-3 dB)

0.1 / 0.3 / 1 / 10 / 20 / 50 kHz, two poles, 40 dB/decade

High pass filter (-3 dB)

3 Hz, two poles, 40 dB/decade, can be switched off

Frequency range

of integrators

Single integration: 3 .. 1000 Hz

Double integration: 3 .. 100 Hz

Output

± 10 V

PEAK

, DC coupled, DC offset < 10 mV,

R

OUT

= 100 Ω, BNC socket, single-ended

Cross-talk attenuation

> 60 dB (M68D3 at 1 kHz / V=1000)

Output noise with

charge input

< 15 mV

rms

(0.1 Hz .. 50 kHz bandwidth) and

< 8 mV

rms

(3 Hz .. 20 kHz bandwidth)

Output noise with

IEPE input

< 10 mV

rms

(0.1 Hz .. 50 kHz bandwidth) and

< 6 mV

rms

(3 Hz .. 20 kHz bandwidth)

LED indicators

Minimum modulation: > 0.7 V

PEAK

Overload: > 90 % of full-scale output

Battery: supply voltage > 5 V

16

External supply

5 .. 15 VDC

< 300 mA (M68D1, M68R1)

< 1 A (M68D3)

connector to DIN 45323 (M68D1 / M68D3)

4 pin frame connector (M68R1)

Battery supply

(only M68D1)

4 x “AA” size (LR6)

> 10 h lifetime with alkaline cells

Mains supply

(only M68B6 / M68B12)

Wide range input 85 .. 264 VAC

Socket for IEC 320 mains cord

Grounding required

Power consumption: < 40 W

Fuse: 800 mA (slow) in mains socket

Mains plug adapter

(only M68D1 / M68D3)

Wide range input 100 .. 240 VAC, 50 / 60 Hz

with two pole Euro plug

Output: 12 VDC / 0.5 A (M68D1) / 1 A (M68D3)

Warm-up time

15 minutes

Operating temperature

-10 .. 50 °C, 95 % rel. humidity without condensation

Dimensions

(width x height x

depth)

105 x 40 x 150 mm³ (M68D1)

105 x 90 x 140 mm³ (M68D3)

7 width units x 3 height units x 190 mm (M68R1)

17

Limited Warranty

Metra warrants for a period of

24 months

that its products will be free from defects in material or workmanship

and shall conform to the specifications current at the time of shipment.

The warranty period starts with the date of invoice.

The customer must provide the dated bill of sale as evidence.

The warranty period ends after 24 months.

Repairs do not extend the warranty period.

This limited warranty covers only defects which arise as a result

of normal use according to the instruction manual.

Metra’s responsibility under this warranty does not apply to any

improper or inadequate maintenance or modification

and operation outside the product’s specifications.

Shipment to Metra will be paid by the customer.

The repaired or replaced product will be sent back at Metra’s expense.

18

19

Declaration of Conformity

Products: Charge Amplifiers

Models: M68D1, M68D3, M68R1, M68B6, M68B12

It is hereby certified that

the above mentioned products

comply with the demands

pursuant to the following standards:

• EN 50081-1

• EN 50082-1

• EN 61000-3

• EN 60950

Responsible for this declaration is the producer

Metra Mess- und Frequenztechnik

Meißner Str. 58

D-01445 Radebeul

Declared by

Manfred Weber

Radebeul, 29th of May, 2001

Loading...

Loading...