M&M RWB series User Manual

&

M&M Refrigeration, Inc.

Computer Control System

Screw Compressor Control

RWB Series

Retro Fit Panel

Standard Screw Compressor - RWB Series

Copyright protection claimed includes all forms and matters now and hereinafter granted protection by statutory or judicial law, including unlimited protection for screen images generated

from the software programs. Such images include but are not limited to windows, icons, and

report displays.

This manual is provided without any warranty of any kind, either expressed or implied. M&M

Refrigeration, Inc., shall not be liable to any person or entity with respect to any liability, loss,

or damage to be caused directly or indirectly by this manual. Information in this document is

subject to change without notice, and does not represent a commitment on the part of the

vendor. The software described in this manual is furnished under a license agreement and

may be used or copied only in accordance with the terms of the agreement. No part of this

document may be reproduced or transmitted in any form or by any means, electrical or

mechanical including photocopying, for any purposes, without permission from M&M Refrigeration, Inc.

M&M Refrigeration Inc., Screw Compressor Manual - RWB Series

Version 200

© M&M Refrigeration, Inc., 1992-2002

All Rights Reserved.

M&M Refrigeration, Inc.

412 Railroad Ave., Suite #1

P.O. Box 449

Federalsburg, MD 21632

Phone (410) 754-8005 FAX (410) 754-5813

Printed in the United States of America.

EFRIGERATION INC

M&M R

.

Revision History

Revision Date Change

- 11/2002 Inital Release

M&M R

EFRIGERATION INC

.

Standard Screw Compressor - RWB Series

M&M R

EFRIGERATION INC

.

Table of Contents

Table of Contents

CHAPTER 1

CHAPTER 2

CCS Introduction

Associated Documents.................................................................. 1-1

Applicable Compressor Models.................................................... 1-1

General Operating Overview

Definitions..................................................................................... 2-1

Keypad Functions ......................................................................... 2-2

Main Screen Overview ................................................................. 2-4

Hot Key Selection ......................................................................... 2-5

Screen Types ................................................................................. 2-5

Menu Screens ........................................................................... 2-6

Data Entry Screens ................................................................... 2-7

Data Entry Procedures.......................................................... 2-8

Field Types....................................................................... 2-8

Selectable Fields.......................................................... 2-9

Numerical Data Input Fields ....................................... 2-9

Absolute Pressure Fields ............................................. 2-9

Time Fields.................................................................. 2-10

Date Fields................................................................... 2-10

String Fields ................................................................ 2-10

Telephone Number Field ............................................. 2-11

Hexadecimal Fields ..................................................... 2-11

Status Screens ........................................................................... 2-12

Confirmation Screens ............................................................... 2-13

Confirmation Screen Procedures.......................................... 2-14

Momentary Screens .................................................................. 2-14

Information Screens.................................................................. 2-15

Access Screens ......................................................................... 2-15

Log Screens .............................................................................. 2-17

Alarms & Failures......................................................................... 2-18

CHAPTER 3

Compressor Controls

Modes Of Operation ..................................................................... 3-1

Lubrication System ....................................................................... 3-2

Oil Pump Configuration ........................................................... 3-2

EFRIGERATION INC

M&M R

. iii

Standard Screw Compressor - RWB Series

Oil Pressure Calculations ......................................................... 3-3

Oil Level Indication.................................................................. 3-3

Starting the Screw Compressor..................................................... 3-3

Manual Mode............................................................................ 3-4

Automatic Mode....................................................................... 3-5

Remote/Auto Remote Mode..................................................... 3-5

I/O Control ........................................................................... 3-5

Network Control................................................................... 3-5

Sequenced Mode ...................................................................... 3-5

Stopping the Screw Compressor................................................... 3-6

Manual Mode............................................................................ 3-6

Automatic Mode....................................................................... 3-6

Remote Mode ........................................................................... 3-6

I/O Control ........................................................................... 3-6

Network Control................................................................... 3-6

Sequenced Mode ...................................................................... 3-7

Capacity Control ........................................................................... 3-7

Computed Slide Valve Position................................................ 3-7

Manual Capacity Control ......................................................... 3-7

Automatic Capacity Control..................................................... 3-7

Control Groups..................................................................... 3-8

Time Proportional Control Strategy..................................... 3-8

Remote Capacity Control ......................................................... 3-11

I/O Control ........................................................................... 3-11

Network Control................................................................... 3-11

Auto-Remote Capacity Control................................................ 3-11

I/O Control ........................................................................... 3-11

Network Control................................................................... 3-12

Sequenced Capacity Control .................................................... 3-12

Low Alarm and Failure Setpoints ........................................ 3-12

Running in Trim Mode......................................................... 3-12

Running in Full Load Mode................................................. 3-13

Anti-Cycle in Sequenced Mode ........................................... 3-13

Forced Unloading & Limiting .................................................. 3-13

Ramp Start ................................................................................ 3-13

Slide Valve Position Ramp Start Limiting................................ 3-14

Unload Solenoid Configuration ........................................... 3-15

Setpoint Scheduling ...................................................................... 3-15

Daily Schedules ........................................................................ 3-15

Weekly Schedule ...................................................................... 3-15

Variable Vi Slide Stop Control...................................................... 3-16

Vi Adjustments..................................................................... 3-16

Manual Vi Adjustment ......................................................... 3-16

Vi Slide Stop and Capacity Slide Valve Interference ............... 3-16

iv

M&M R

EFRIGERATION INC

.

Table of Contents

Oil Temperature Regulation.......................................................... 3-17

Liquid Injection Oil Cooling (Option).......................................... 3-17

Single Port Liquid Injection ..................................................... 3-17

Dual Port Liquid Injection........................................................ 3-17

Anti-Cycle Timer .......................................................................... 3-17

Power Fail Restart......................................................................... 3-18

Remote Status Information....................................................... 3-18

Process Temperature Control (Option) ......................................... 3-18

Economizer Control (Option) ....................................................... 3-19

Automatic Mode ....................................................................... 3-19

Manual On Mode...................................................................... 3-19

Manual Off Mode ..................................................................... 3-19

Sequenced Mode....................................................................... 3-19

Power Assist (Option)................................................................... 3-19

Operational Procedures................................................................. 3-20

START Hot Key ....................................................................... 3-20

STATS Hot Key ........................................................................ 3-22

Compressor Main Status Screen .......................................... 3-22

Status Banner ................................................................... 3-23

System Current State ....................................................... 3-24

Mode Area ....................................................................... 3-24

Alarm & Failure Area ...................................................... 3-25

Compressor Graphics Screen ............................................... 3-25

Energy Status Screen............................................................ 3-26

Operating Hours Screen ....................................................... 3-27

Variable VI Status Screen..................................................... 3-28

Economizer Status Screen (Option) ..................................... 3-29

Active Alarms & Failures Status Screen.............................. 3-30

Auto-Start Warning Screen .................................................. 3-31

MODE Hot Key........................................................................ 3-32

Local Mode .......................................................................... 3-32

Manual Mode ....................................................................... 3-32

Automatic Mode................................................................... 3-32

Remote Mode ....................................................................... 3-33

Auto-Remote Mode.............................................................. 3-33

Sequenced Mode .................................................................. 3-33

SETPT Hot Key ........................................................................ 3-34

Pressure Setpoints ................................................................ 3-34

Suction Pressure Control Groups..................................... 3-34

High Suction Pressure Setpoints...................................... 3-36

Discharge Pressure Setpoints........................................... 3-37

Oil Pressure Setpoints...................................................... 3-38

Oil Filter Pressure Setpoints ............................................ 3-39

M&M R

EFRIGERATION INC

. v

Standard Screw Compressor - RWB Series

Temperature Setpoints.......................................................... 3-40

Discharge Temperature Setpoints .................................... 3-40

Oil Temperature Setpoints (without Liquid Injection) .... 3-41

Oil Temperature Setpoints ( with Liquid Injection)......... 3-42

Process Temperature Control Group................................ 3-43

High Process Temperature Selection ............................... 3-44

Motor Current Setpoints....................................................... 3-45

Slide Valve Setpoints............................................................ 3-46

SCHED Hot Key ...................................................................... 3-47

Control.................................................................................. 3-47

Active Group........................................................................ 3-48

Active Schedule ................................................................... 3-49

Weekly Schedule .................................................................. 3-50

Daily Schedules.................................................................... 3-50

Schedule 1 To Schedule 7................................................ 3-51

CNTRL Hot Key ...................................................................... 3-52

Suction Pressure Control Setpoints...................................... 3-52

Process Temperature Control Setpoints ............................... 3-53

Economizer Control Setpoints (Option)............................... 3-54

Variable VI Setpoints (Option)............................................. 3-55

MISC Hot Key.......................................................................... 3-56

LOGS Hot Key ......................................................................... 3-57

MENUS Hot Key ..................................................................... 3-57

CHAPTER 4 Logging Functions

Logging Functions Technical Overview ....................................... 4-2

Operations Log ......................................................................... 4-2

Trend Log ................................................................................. 4-2

Alarm Log ................................................................................ 4-2

Failure Log ............................................................................... 4-2

User Log ................................................................................... 4-2

KW Log (Optional) .................................................................. 4-3

System Log (Optional) ............................................................. 4-3

Logging Functions Operating Procedures .................................... 4-4

Operations and Trend Logs ...................................................... 4-5

Alarm and Failure Logs............................................................ 4-6

User Log ................................................................................... 4-7

KW Log (optional) ................................................................... 4-8

Clear Logs ................................................................................ 4-9

Clear Std Log ....................................................................... 4-9

Clear System Log (Optional) ............................................... 4-9

Clear All Logs...................................................................... 4-9

Set Log Rates ....................................................................... 4-9

vi

M&M R

EFRIGERATION INC

.

CHAPTER 5 Menu Functions

Technical Overview ...................................................................... 5-1

Logon User ............................................................................... 5-1

Logoff User............................................................................... 5-1

Automatic Log Off............................................................... 5-1

Diagnostics Menu ..................................................................... 5-2

System Information.............................................................. 5-2

View Discrete I/O................................................................. 5-2

View Analogs ....................................................................... 5-2

View Dip Switches ............................................................... 5-2

View Network Comm .......................................................... 5-2

Override Discrete I/O (Option) ............................................ 5-3

Setup Menu............................................................................... 5-3

Set Date and Time................................................................ 5-3

Calibrate Sensors.................................................................. 5-3

Dynamic Sensor Calibration............................................ 5-3

Static Sensor Calibration ................................................. 5-4

Password Control ................................................................. 5-4

Adding/Deleting Users .................................................... 5-4

Screen Access Levels....................................................... 5-4

Initialization ......................................................................... 5-5

Power Fail Reset .............................................................. 5-5

Set Factory Configuration................................................ 5-5

Configuration ....................................................................... 5-5

Display Setup................................................................... 5-5

Communication................................................................ 5-5

Motor Configuration ........................................................ 5-5

Set Operating Status......................................................... 5-5

Operational Procedures................................................................. 5-6

Logon User ............................................................................... 5-7

Logoff User............................................................................... 5-7

Diagnostics ............................................................................... 5-8

System Information.............................................................. 5-9

View Discrete I/O................................................................. 5-10

View Analogs ....................................................................... 5-11

View Dip Switches ............................................................... 5-12

View Network Comm .......................................................... 5-13

Override Discrete I/O........................................................... 5-14

Setup ......................................................................................... 5-15

Set Date & Time.................................................................. 5-16

Calibrate Sensors.................................................................. 5-17

Dynamic Sensor Calibration............................................ 5-18

Static Sensor Calibration ................................................. 5-19

Table of Contents

M&M R

EFRIGERATION INC

. vii

Standard Screw Compressor - RWB Series

Password Control ................................................................. 5-19

Add/Delete User .............................................................. 5-20

Screen Access Levels ...................................................... 5-21

Initialization ......................................................................... 5-22

Power Fail Reset .............................................................. 5-23

Set Factory Config........................................................... 5-24

Configuration ....................................................................... 5-25

Display............................................................................. 5-26

Communication Setup ..................................................... 5-27

Motor Configuration........................................................ 5-28

Set Operating Status ........................................................ 5-29

APPENDIX A Alarm and Failure Data

Analog Alarms.............................................................................. A-1

Discrete Alarms ........................................................................... A-3

APPENDIX B Analog and Discrete I/O

Analog Inputs................................................................................ B-1

Discrete I/O RACK 1.................................................................... B-2

APPENDIX C Communication Protocols

Introduction................................................................................... C-1

Applicable Documents.................................................................. C-1

Hardware Interface Description.................................................... C-2

Hardware Requirements ........................................................... C-2

Interface Connections............................................................... C-2

Message Addressing................................................................. C-4

Software Interface Description ..................................................... C-7

Protocol Overview.................................................................... C-7

Status Only or Status and Control Options............................... C-7

Message Categories .................................................................. C-7

MODBUS Protocol Description............................................... C-8

Read Holding Registers........................................................ C-8

Preset Single Register .......................................................... C-9

Preset Multiple Registers ..................................................... C-9

Error Messages..................................................................... C-9

DF1 Protocol Description......................................................... C-11

Protected Typed Logical Read ............................................. C-11

Protected Typed Logical Write............................................. C-12

Word Range Read................................................................. C-12

viii

M&M R

EFRIGERATION INC

.

Table of Contents

Word Range Write................................................................ C-12

Error Messages..................................................................... C-13

Data Formats................................................................................. C-13

Status Message Description .......................................................... C-14

Analog Inputs and Computed Parameters ................................ C-14

Discrete Input and Outputs....................................................... C-15

Alarm and Failure Data ............................................................ C-16

Equipment Data ........................................................................ C-18

Control Message Description........................................................ C-22

Network In Control Command................................................. C-23

Compressor Start/Stop Command ............................................ C-23

Set Compressor Mode Command............................................. C-24

Change Compressor Capacity Command................................. C-24

Acknowledge/Clear Active Alarm Command.......................... C-24

Change Current Setpoint Group Command.............................. C-24

Set Economizer Mode Command............................................. C-25

Auto Start/Stop Control Command .......................................... C-25

Suction Pressure Setpoint Message Description........................... C-26

Process Temperature Setpoint Message Description .................... C-27

M&M R

EFRIGERATION INC

. ix

Standard Screw Compressor - RWB Series

EFRIGERATION INC

x

M&M R

.

CHAPTER 1

CCS Introduction

The Compressor Control System (CCS) is an advanced microprocessorbased control system designed for efficient and automatic control and monitoring of industrial refrigeration systems including screw compressors. The

controller is composed of a microprocessor board, Input/Output boards, a

keypad, and a Liquid Crystal Display (LCD). The system uses the LCD to

present screens to the operator for information review and control.

The Screw Compressor User’s Manual provides the operator with the basic

information needed to configure and operate the compressor. The manual

is divided into several sections beginning with the General Operating Overview which contains system definitions, keypad functions, main LCD screen

layout, screen type designations, and generic alarm & failure information.

The remaining sections of the manual cover the control functions required

for operation of the compressor and detailed descriptions of the display

screens found in the system. Also included are appendices covering standard communications protocols, hardware channel assignments, and alarm

descriptions.

Associated Documents

Familiarity with the following M&M documents is recommended:

• CCS Sequencer Control

Applicable Compressor Models

This document covers the M&M RWB Compressor retrofit.

EFRIGERATION INC

M&M R

. 1-1

Standard Screw Compressor - RWB Series

1-2

M&M R

EFRIGERATION INC

.

CHAPTER 2

General Operating Overview

The following sections will give the user an overview of the general operating procedures for the CCS.

Definitions

CCS System Manager is the person who will assign user passwords,

access levels and screen access requirements.

Cursor is a field indicator used on data entry screens. There are four possible cursor types:

* represents a number field input

•

> represents a selectable field

•

“ represents a string field

•

X represents a hexadecimal field

•

The cursor shows the user which fields are changeable on a data entry

screen.

Display Area is the part of the LCD display that shows system information.

The display area will vary in size depending on whether a large character or

small character screen is being viewed.

Fields are places where the user enters control parameters.

Highlight is when the letters appear light on a dark background instead of

dark on a light background. The highlighted area may flash from light to

dark to stress its importance, and to gain the user’s immediate attention.

Hot Keys are the top-level system functions and menus. The hot keys are

located in a column on the left side of all large character screens.

Large Character Screens are screens that use large, double high characters, and contain the title banner and hot keys.

Main Status Screen is a large character status screen, which is considered

the main system status screen. This screen will also contain the alarm status, mode, and state of the system.

M&M R

EFRIGERATION INC

. 2-1

Standard Screw Compressor - RWB Series

Parameter is a system control value, which is displayed by the system or input by the user.

Examples are suction pressure and high suction pressure alarm setpoint.

Screen is a method of displaying information to the user. The system contains eight types of

possible screens: menu screens, data entry screens, status screens, confirmation screens,

momentary screens, information screens, access screens, and log screens

Small Character Screens utilize the entire LCD display and use small characters to show

system information. These screens do not display the system hot keys.

Toggle is the process of moving from one selectable choice to the next by using the ENTER

key.

User is an individual or group of individuals who will use the system. A user is identified by a

user number ranging from 1 to 10. The user may also be referred to as the operator in this

document.

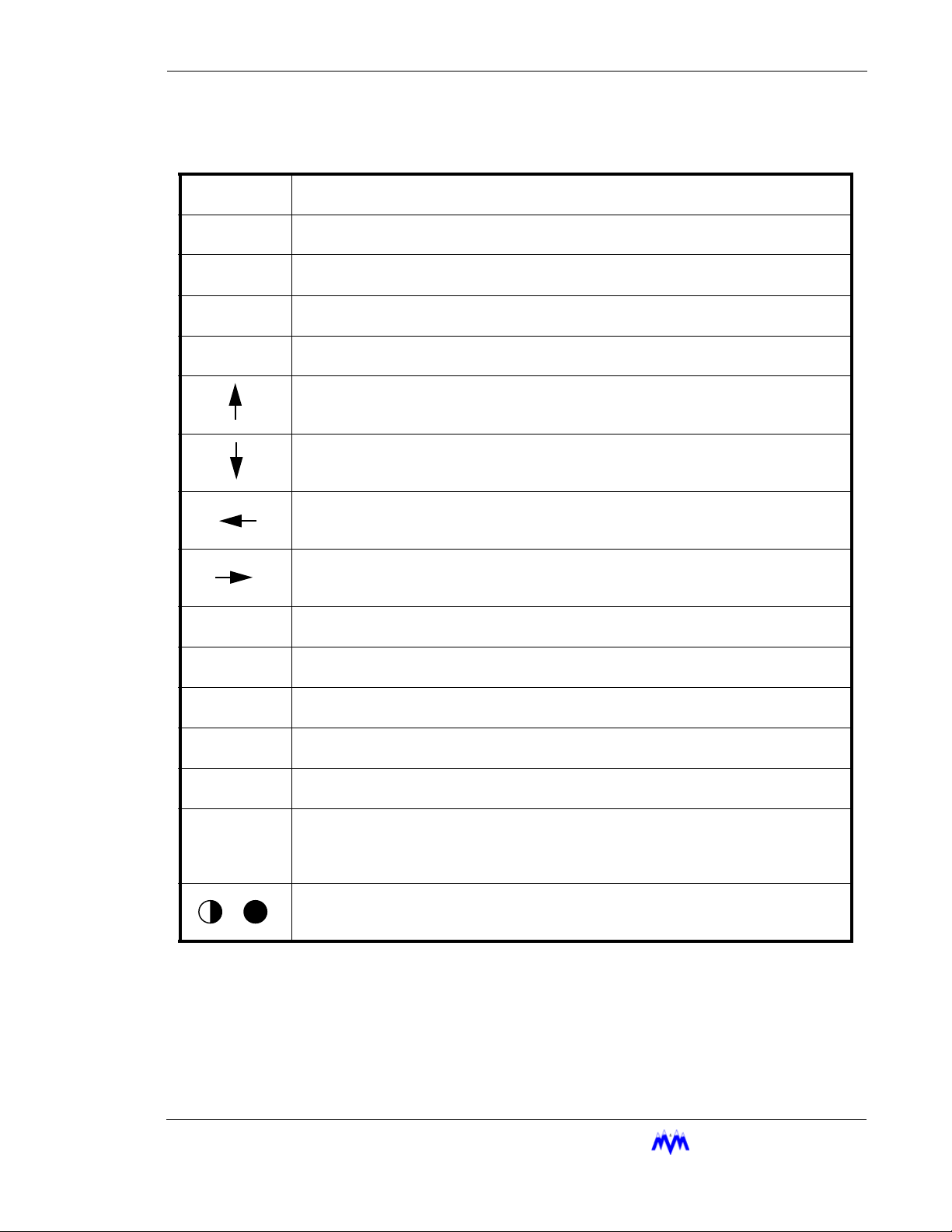

Keypad Functions

The following is a brief summary of the CCS keypad along with a description of its individual

keys. Below is a drawing of the CCS keypad layout.

2-2

M&M R

EFRIGERATION INC

Keypad Diagram

.

Chapter 2: Keypad Functions

STOP

SHIFT

0 – 9

•

-

PG UP

PG DN

QUIT

SAVE

CLEAR

ENTER

The red STOP key causes an immediate and orderly shutdown of a compressor. This

key usually has no effect on master panels.

The SHIFT key is used to switch control back and forth from the display area to the hot

keys. This key may also be used to scroll between the horizontal pages of a log screen.

The NUMBER keys select menu or hot key options. On data entry screens the number

keys are used to enter numerical data.

The DOT key allows decimal point entry on data entry screens. This key also permits

the user to page forward one full screen at a time on log and status screens.

The MINUS key allows negative number entry on data entry screens. This key also permits the user to page back one full screen at a time on log or status screens.

On data entry or menu screens, the UP ARROW key moves the cursor up to the next

item on the screen.

On data entry or menu screens, the DOWN ARROW key moves the cursor down to the

next item on the screen.

On data entry or menu screens, the LEFT ARROW key moves the cursor left to the next

item on the screen. This key also permits the user to page forward one full screen at a

time on log and status screens.

On data entry or menu screens, the RIGHT ARROW key moves the cursor right to the

next item on the screen. This key also permits the user to page back one full screen at

a time on log and status screens.

The PG UP key is used to page back one full screen at a time for status screens or to

page up to more current data on log screens.

The PG DN key is used to page forward one full screen at a time for status screens or to

page down to older data on log screens.

The QUIT key exits the current screen and displays the previous screen. Pressing the

QUIT key to exit from a data entry screen will result all changed data being lost.

The SAVE key is used with data entry screens to save any changed information. It also

exits the current screen and displays the previous screen.

The CLEAR key within data entry screens will erase the current number field. On the

main status or alarm status screen it acknowledges and clears alarms and failures.

The ENTER key is used within data entry screens on a number field to accept numerical

data or on a selectable field to toggle through the available choices. On menu screens,

the ENTER key will select the highlighted menu item. The ENTER key may also be

used to scroll forward through the status screens.

The CONTRAST keys are used to adjust the display for proper viewing depending on

the ambient light levels. When the desired contrast is achieved, pressing any other key

will lock the current contrast value into memory.

M&M R

EFRIGERATION INC

. 2-3

Standard Screw Compressor - RWB Series

Main Screen Overview

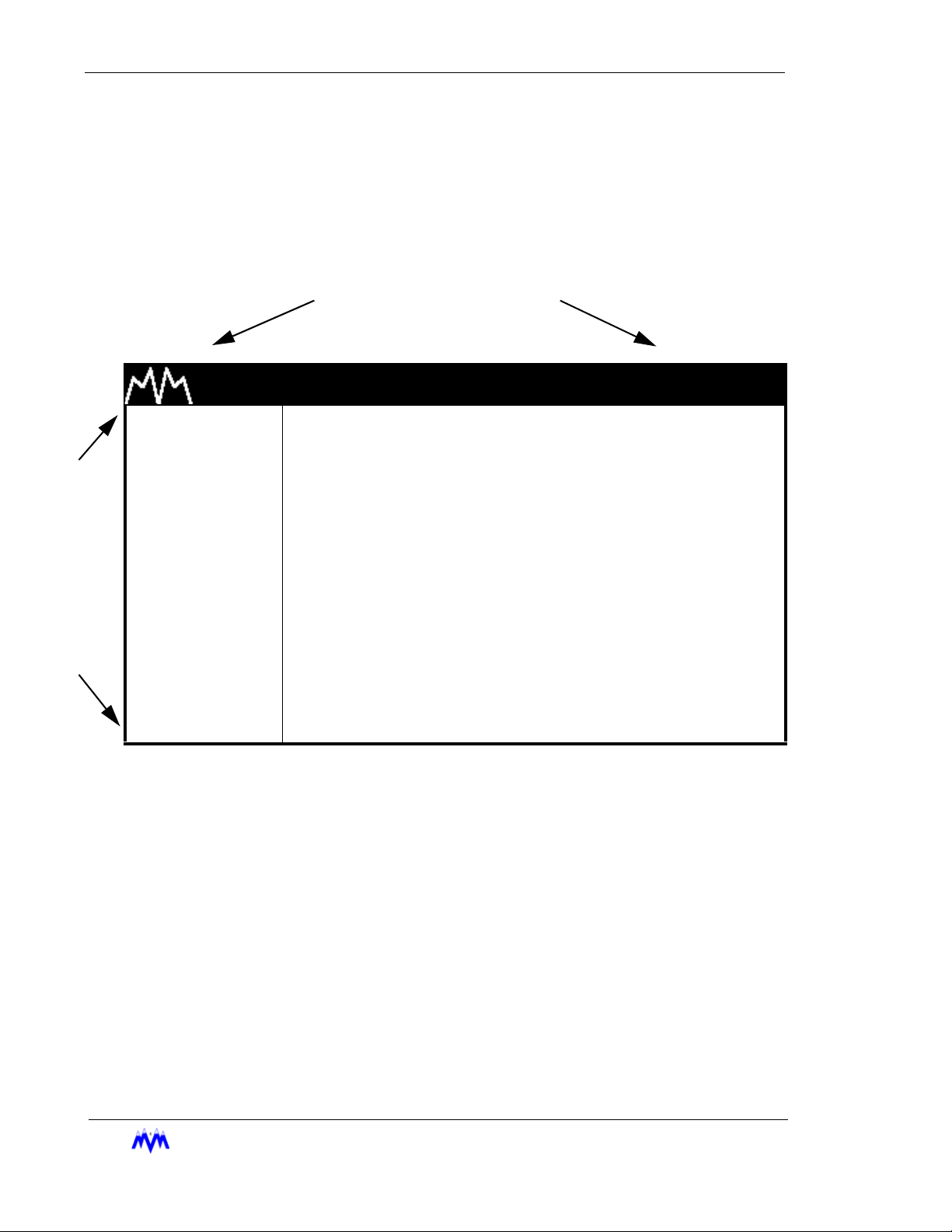

The Main Screen is the name for a set of features common to all large character screens. The

Main Screen is broken down into three areas: display area, hot keys, and title banner. The following drawing shows a representation of the main screen layout and labels each of its various areas.

TITLE BANNER

H

O

T

K

E

Y

S

M & M REFRIGERATION 8:32

1. START

2. STATS

3. MODE

DISPLAY AREA

4. SETPT

5. SCHED

6. CNTRL

7. MISC

8. LOGS

9. MENUS

Main Screen Layout

Title Banner - The top highlighted bar contains the M&M logo and the current time of day and

may only be found on large character screens.

AM

2-4

Display Area - Contains all of the detailed screen information. Large character screens will

use only the designated display area, while small character screens use the entire LCD display.

Hot Keys - The hot keys are a set of system functions, which are found in a column on the left

side of all large character screens. They are the most frequently used functions on the CCS

and allow access to all lower level menus and functions.

EFRIGERATION INC

M&M R

.

Chapter 2: Hot Key Selection

Hot Key Selection

1. Verify Number next to a Hot Key is Highlighted - one of the numbers next to a hot

key should be highlighted and flashing. (This is not the same as having the hot key

command highlighted.)

If there are no numbers highlighted, switch control from the display area to the hot

keys by pressing the SHIFT key.

2. Select Option - use the key pad to select a corresponding option number or use the

arrow keys to move the highlighted area to the desired selection and press ENTER.

3. Alternate Select Option - whenever a status screen is being displayed, a hot key

may be activated by typing the hot key number. This also works on small character

status screens even though the hot keys are not visible.

Screen Types

CCS information is presented to the operator using eight different types of screens. The differ-

ent screen types each use specific data entry and control procedures. The screen types let the

user know which screen type heading to refer to for information on the specific screens' procedures. The following is a list of the eight different screen types.

• Menu Screen - displays a numbered list of options.

• Data Entry Screen - used to modify system control parameters.

• Status Screen - displays real-time system summary data.

• Confirmation Screen - used for verification, gives a choice for a yes or no option.

• Momentary Screen - displays a message for three seconds.

• Information Screen - used to display system information

• Access Screen - a menu type screen with an number input field.

• Log Screen - displays a record of system parameters and actions.

M&M R

EFRIGERATION INC

. 2-5

Standard Screw Compressor - RWB Series

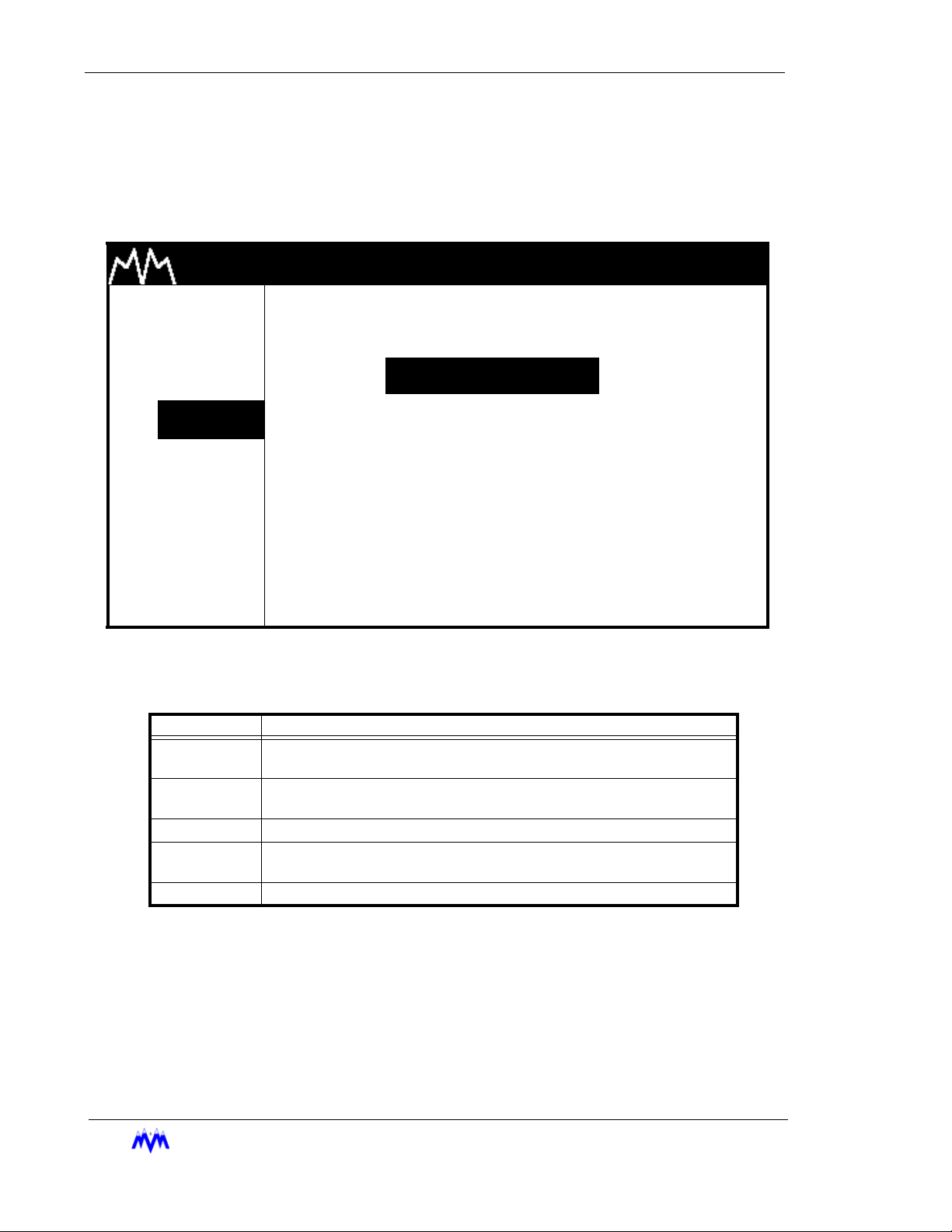

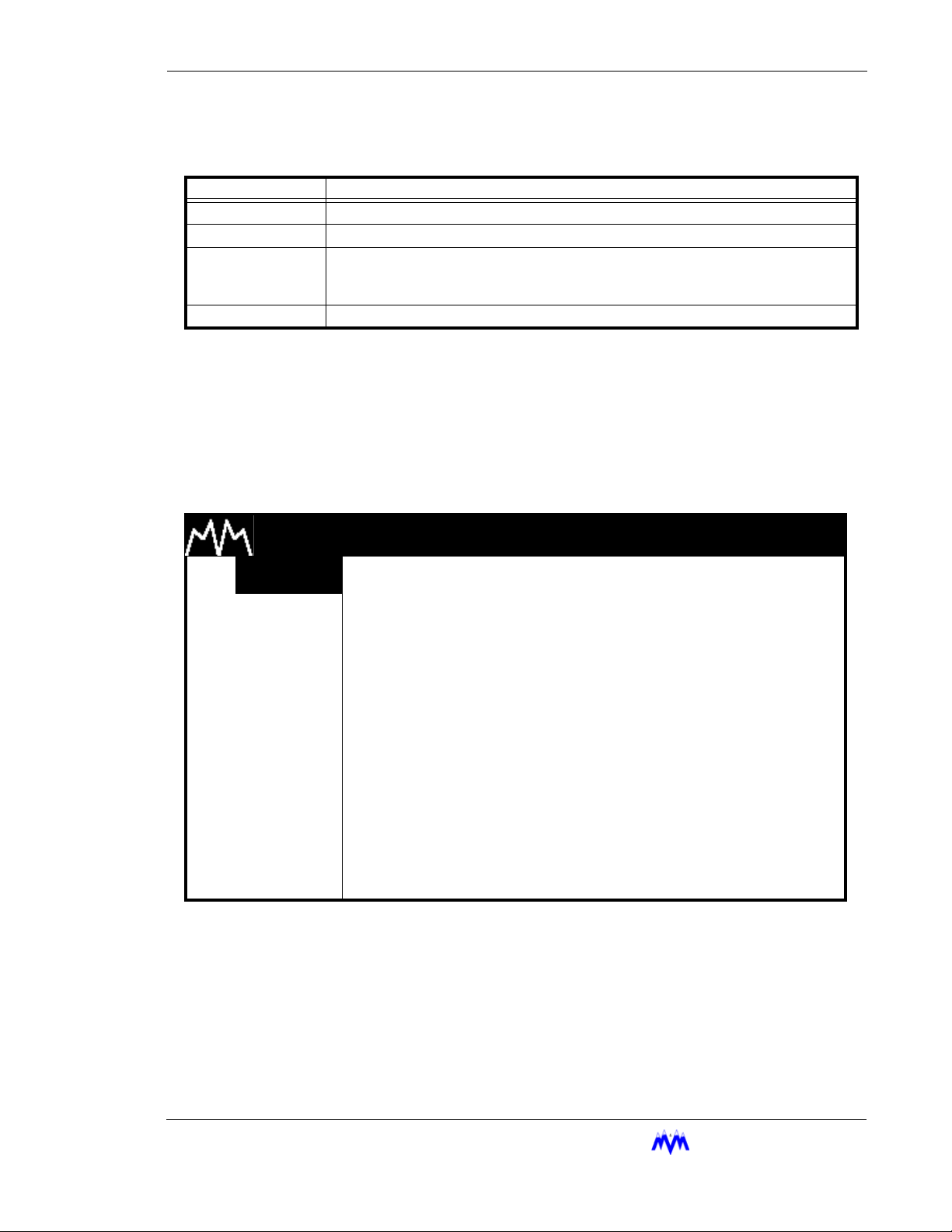

Menu Screens

The Menu screen is used to present the user with choices for various system operations.

Menu screens are found throughout the CCS system. The following is an example of a

menu screen.

M & M REFRIGERATION 8:32

1. START

2. STATS

3. MODE

4. SETPT

5. SCHED

SETPOINT SELECTIONS

1.PRESSURE

2.TEMPERATURE

3.MOTOR CURRENT

6. CNTRL 4.SLIDE VALUE POS

7. MISC

8. LOGS

9. MENUS

Menu Screen

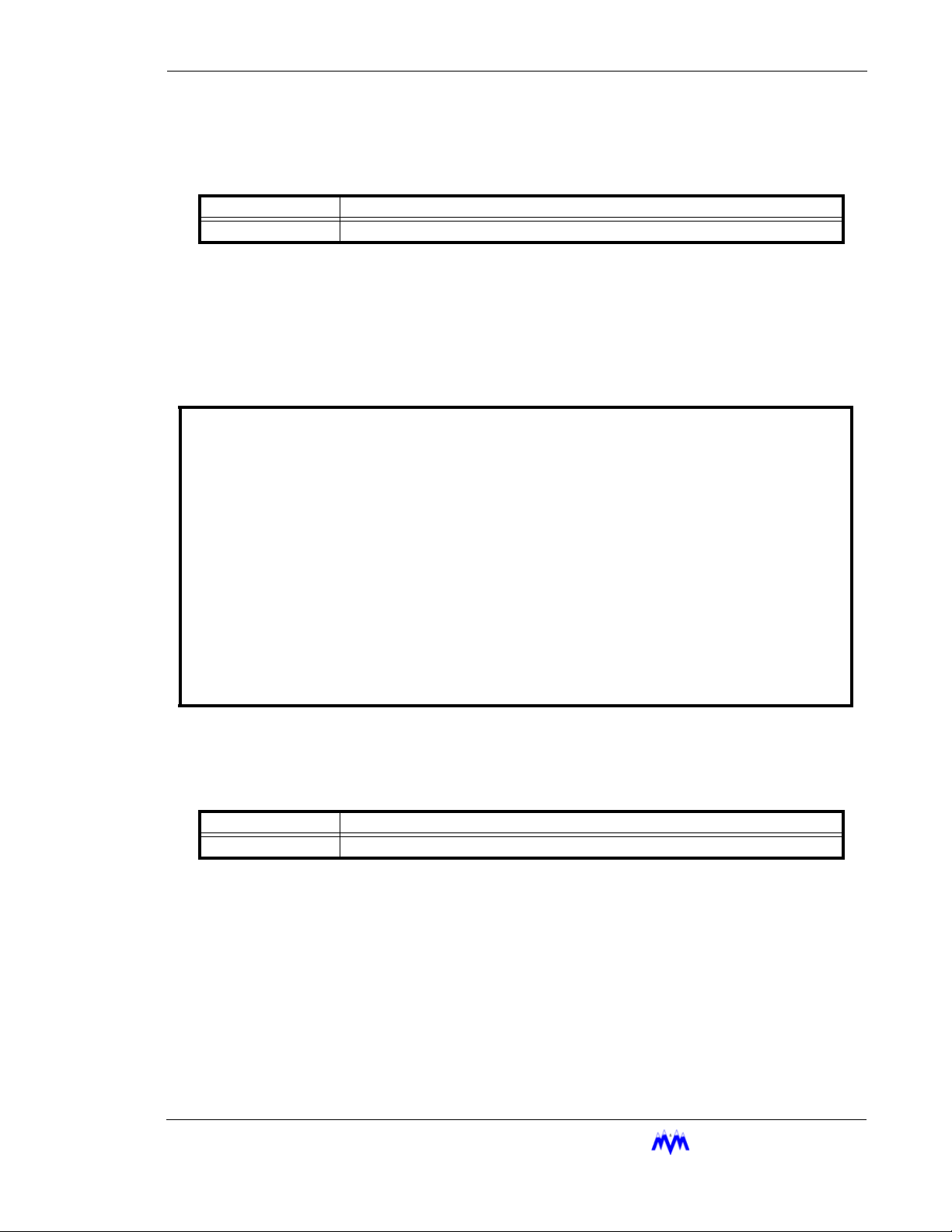

The following table contains a list of the active keys on a menu screen and their function.

AM

2-6

KEYS FUNCTION

SHIFT

NUMBER

KEYPAD

ENTER Used to choose the selection number that is highlighted.

UP/DOWN

ARROW

QUIT Exits from current screen to the previous screen.

EFRIGERATION INC

M&M R

Switches control back and forth between the display area and the hot

keys.

Used to choose a selection number.

Moves the cursor from one selection to the next either up or down.

Menu Screen Keys Table

.

Chapter 2: Screen Types

Menu Selection Procedures - Menu options are chosen similar to hot key options.

1. Verify Cursor Control - Verify that a menu option number is highlighted. If not

use the SHIFT key to transfer cursor control from the hot keys to the display area.

2. Menu Option Selection - Use the number keys corresponding to the desired

menu item or the arrow keys and press ENTER to select the desired menu item.

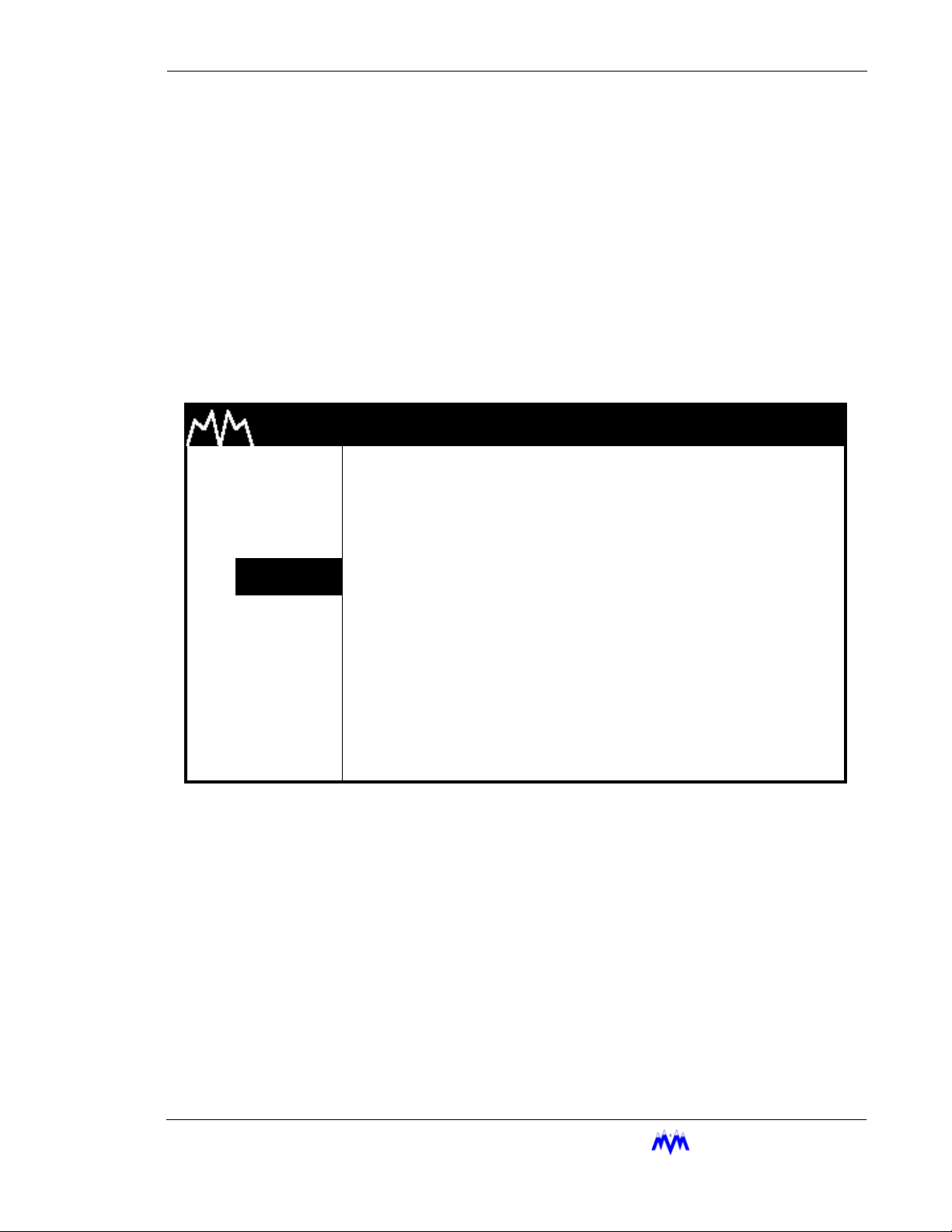

Data Entry Screens

Data Entry screens are user interactive screens, which allow the user to change or input

system data. These screens contain a special cursor to signify the field type at the cursor

location. The cursor can be moved throughout the screen to indicate each field location.

The following is an example of a data entry screen.

M & M REFRIGERATION 8:32

1. START

2. STATS

3. MODE

4.

SETPT

5. SCHED

6. CNTRL

7. MISC

8. LOGS

9. MENUS

NOTE: D

ata Entry screens may also contain information for reference purposes that is not

changeable.

OIL TEMP SETPTS

HIGH FAILURE XXX.X

HIGH ALARM XXX.X

HEATER CONTROL XXX.X

LOW ALARM XXX.X

LOW FAILURE XXX.X

Data Entry Screen

AM

DEGF

DEGF

DEGF

DEGF

DEGF

M&M R

EFRIGERATION INC

. 2-7

Standard Screw Compressor - RWB Series

The following table contains a list of the active keys on a data entry screen and their function.

KEYS FUNCTION

NUMBER

KEYPAD

ENTER

ARROW

KEYS

CLEAR

SAVE Exits from the current screen and all new data is saved.

QUIT Exits from the current screen and all new data is lost.

Used to enter numerical data.

Toggles through the available choices on a selectable field. On a number field the

ENTER

Moves the cursor from one field to the next either up, down, left or right. Any of the

arrow keys can also be used to accept the data entered on a number field.

Will clear the current numerical field. The

key is used to accept entered data and move to next field.

A data entry screen may contain both numerical input and selectable fields, which are identified by different cursors as shown in the following table.

CLEAR

Data Screen Keys

key is not active on selectable fields.

CURSOR FUNCTION

> Selectable cursor, indicates a selectable field.

* Numerical input cursor, indicates a number field.

“ String input cursor, indicates an alphanumeric string field.

X Hexadecimal input cursor, indicates hexadecimal number field.

Data Entry Screen Cursor Table

Data Entry Procedures

1. Verify Screen Type - One of the special cursors must appear on the screen. If

the cursor did not appear you are not on a data entry screen.

2. Change Fields - Use the arrow keys to move the cursor to the desired field.

3. Enter Data - Enter the desired numerical data or select the desired selectable

depending on field type.

4. SAVE OR QUIT - Upon completing the changing of data the user may press

SAVE to save all newly entered data and return to the previous screen. If the

user presses QUIT the entered data will not be saved. After pressing QUIT, a

confirmation screen will ask the user to verify the desire to lose all changes

entered.

Field Types

2-8

M&M R

This section discusses the procedures used to work with each of the field types

as well as the general procedures that apply to all number entry fields. The following information applies to any field when entering numerical data:

Decimal Number Entry - If the data you wish to enter has a zero in the decimal

place there is no need to enter " .0 ". Simply enter the whole number value.

EFRIGERATION INC

.

Chapter 2: Screen Types

Arrow Keys - The arrow keys will accept the entered data and move the cursor to

the next field.

Errors - A flashing error message tells the user that the entered data is not within

an acceptable range for the field. The user must clear the error before proceeding. To clear an error message the operator presses the CLEAR key.

Restoring Valid Data - The user can clear and re-enter data from any field prior

to leaving the field. If the arrow key or the ENTER key is used to move off the

field after it has been cleared, the previously entered valid data will be restored to

the field.

Selectable Fields

A selectable field gives the user a choice of inputs from which to toggle

through, and is recognized by the ">" cursor preceding it.

1. Verify Cursor Type - locate the ">" selection cursor.

2. ENTER Key - cycles the user through the available selections.

3. Arrow Keys - move to the next field and accept the selection.

Numerical Data Input Fields

A numerical field is used to enter control data, and is recognized by the "*"

cursor preceding it.

1. Verify Cursor Type - locate the "*" numeric input cursor.

2. Number Keypad - press the number keys that correspond to the

number you wish displayed. Use the decimal and minus keys where

applicable. Each field will limit the user to a maximum number of

whole and decimal numbers for that specific field.

3. ENTER/Arrow Keys - move to the next field and accept the entered

number.

4. Verify Cursor Type - Upon pressing the ENTER or DOWN ARROW

key, if the cursor moves across to the units column and changes to

the ">" selectable cursor, the user is in a suction pressure field which

is described in the next section.

Absolute Pressure Fields

This field is actually a combination of numerical and selectable fields. The

selectable or units section of the field allows the user to adjust the units to

select vacuum or non-vacuum ranges.

1. Verify Cursor Type - locate the "*" numeric input cursor.

2. Number Keypad - press the number keys that correspond to the

number you wish displayed. Use the decimal and minus keys where

applicable. If the numeric field already has the correct data and only

the units need to be adjusted, re-enter the existing numerical data

and press ENTER.

EFRIGERATION INC

M&M R

. 2-9

Standard Screw Compressor - RWB Series

3. ENTER/Arrow Keys - locks in the numerical data and moves the

cursor across to the units section of the field.

4. Verify Cursor Type - locate the ">" selection cursor next to the units

section.

5. ENTER - cycles between possible units selections.

6. Arrow Keys - move to the next field and accept the entered data.

7. Errors - If an error occurs because the value entered is out of range

the CLEAR key will clear the field and return the user to the number

portion of the field.

Time Fields

The time field is a special case numerical field used to enter time data.

1. Verify Cursor Type - locate the "*" numeric input cursor.

2. Number Keypad - use the number keys to enter the time you wish

displayed. For example, to input the time 5:59 press 0559, the system automatically moves from hours to the minutes. The ":" is automatically entered in a time field. This field will allow for whole number

acceptance. For example to set the time 8:00 the user may type 08

and press ENTER. The time on the screen will appear as 08:00. It

should be noted that time fields may be entered in 12-hour or 24hour format depending on the system configuration. If the system is

in 12-hour format the user will be prompted to select "AM" or "PM"

using a selectable field after a number is entered.

3. Arrow Keys - move to the next field and accept the entered time.

Date Fields

The Date field is a special case numerical entry field used to enter the date.

1. Verify Cursor Type - locate the "*" numeric input cursor.

2. Number Keypad - use the number keys to enter the date you wish

displayed. For example, to enter the date 1/1/91 the user would type

in 010191, the system automatically moves from the month to the

day and then to the year. The "/" slash symbol is entered for you.

3. Arrow Keys - move to the next field and accept the entered date.

String Fields

The String field is a special case alphanumeric entry field. It is similar to a

selectable field but each character in the string may be selected from the list

of all-possible letters, numbers, and special characters.

1. Verify Cursor Type - locate the " “ " string input cursor.

2. Enter Key - Pressing the ENTER key first will clear the current contents and start entering characters. The ENTER key is primarily used

to cycle through the available selections for the current character

positions.

2-10

M&M R

EFRIGERATION INC

.

Chapter 2: Screen Types

3. “.” Key - Selecting the Period (.) key puts the field into edit mode

and allows the current contents of the field to be entered.

4. Arrow Keys - Allows you to move within a field to different charac-

ters.

5. Number Keys - These keys are used to enter numbers into a charac-

ter.

6. Clear Key - This key is used to clear the contents of the entire field.

7. Entering a space - If a space is allowed in the field, an “_” will be

available in the character list. Selecting this character will result in a

space being inserted in the string. All trailing spaces are eliminated.

Telephone Number Field

The Telephone Number field is a special case alphanumeric entry field. It is

similar to a string field but only allows numbers and several special characters

required for telephone numbers.

1. Verify Cursor Type - locate the " “ " string input cursor.

2. Enter Key - Pressing the ENTER key first will clear the current contents and start entering characters. The ENTER key is primarily used

to cycle through the available selections for the current character

positions.

3. “.” Key - Selecting the Period (.) key puts the field into edit mode

and allows the current contents of the field to be entered.

4. Arrow Keys - Allows you to move within a field to different charac-

ters.

5. Number Keys - These keys are used to enter numbers into a charac-

ter.

6. Clear Key - This key is used to clear the contents of the entire field.

7. Entering a space - If a space is allowed in the field, an “_” will be

available in the character list. Selecting this character will result in a

space being inserted in the string. All trailing spaces are eliminated.

Hexadecimal Fields

The Hexadecimal Field is a special case alphanumeric entry field. It is similar

to a string field but only allows numbers and several special characters

required for hexadecimal numbers.

1. Verify Cursor Type - locate the " “ " string input cursor.

2. Enter Key - Pressing the ENTER key first will clear the current contents and start entering characters. The ENTER key is primarily used

to cycle through the available selections for the current character

positions.

3. “.” Key - Selecting the Period (.) key puts the field into edit mode

and allows the current contents of the field to be entered.

EFRIGERATION INC

M&M R

. 2-11

Standard Screw Compressor - RWB Series

4. Arrow Keys - Allows you to move within a field to different charac-

ters.

5. Number Keys - These keys are used to enter numbers into a char-

acter.

6. Clear Key - This key is used to clear the contens of the entire field.

7. Entering a space - If a space is allowed in the field, an “_” will be

available in the character list. Selecting this character will result in a

space being inserted in the string. All trailing spaces are eliminated.

Status Screens

Status screens are used to display a summary of significant system information. The main

Status screen in a system is usually a large character text screen or graphics screen and

is the default screen displayed on the LCD. The main Status screen will be replaced by

the Active Alarm and Failure screen when a new alarm or failure exists or by the AutoStart Warning screen if the compressor is online and ready to start.

The operator may view each of the system's available status screens by scrolling through

using the ENTER, PG UP, PG DN, Right Arrow, or Left Arrow keys. The number of status

screens on a system will vary depending upon the individual system's configuration.

Another feature of the system is that it will automatically return to the main status screen

after 10 minutes of no keyboard activity. Below is an example of a Status screen.

M & M REFRIGERATION 8:32

1. START SY XXX.X

2.

STATS

SP XXX.X

3. MODE DP XXX.X

4. SETPT OP XXX.X

5. SCHED OF XXX.X

6. CNTRL

7. MISC

OF 0.1

SV XXX

PSIG |

PSIG |

PSIG |

PSIG |

PSIG |

PSIG |

PCT |

MA XXX.X

ST XXX.X

DT XXX.X

OT XXX.X

OS XXX.X

PT XXX.X

AMPS

DEGF

DEGF

DEGF

DEGF

DEGF

8. LOGS

9. MENUS RUN-TRIM SEQ NORM

Status Screen

AM

2-12

M&M R

EFRIGERATION INC

.

Chapter 2: Screen Types

The following table contains a list of the active keys on a status screen and their function.

KEY FUNCTION

SHIFT Switches control between the display area and the hot key options.

ENTER Scrolls through the set of available status screens.

PG UP/PG DN/

RIGHT/LEFT

ARROWS

QUIT Returns the user to the main status screen.

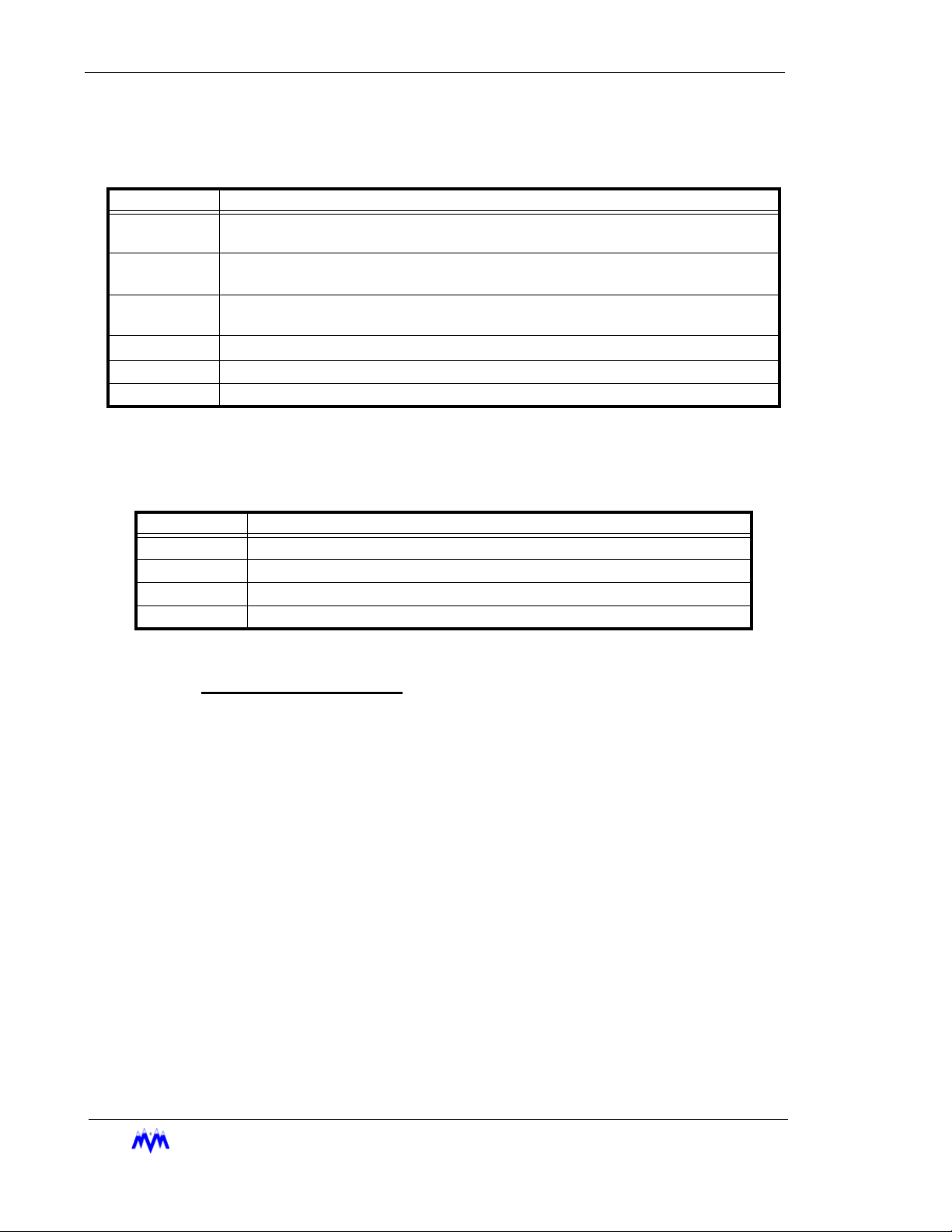

Confirmation Screens

A Confirmation screen is used to ask the user to confirm a selection by answering a question. This screen usually appears after the user has altered system parameters and then

presses the QUIT key or, to verify a system control request. Below is an example of a con-

firmation screen.

Pages forward or back through the available status screens.

Status Screen Keys

M & M REFRIGERATION 8:32

1. START

2. STATS

3. MODE

4. SETPT

5. SCHED

6. CNTRL

7. MISC

8. LOGS

9. MENUS

AM

VERIFY

COMPRESSOR ONLINE

1.NO

2.YES

Confirmation Screen

M&M R

EFRIGERATION INC

. 2-13

Standard Screw Compressor - RWB Series

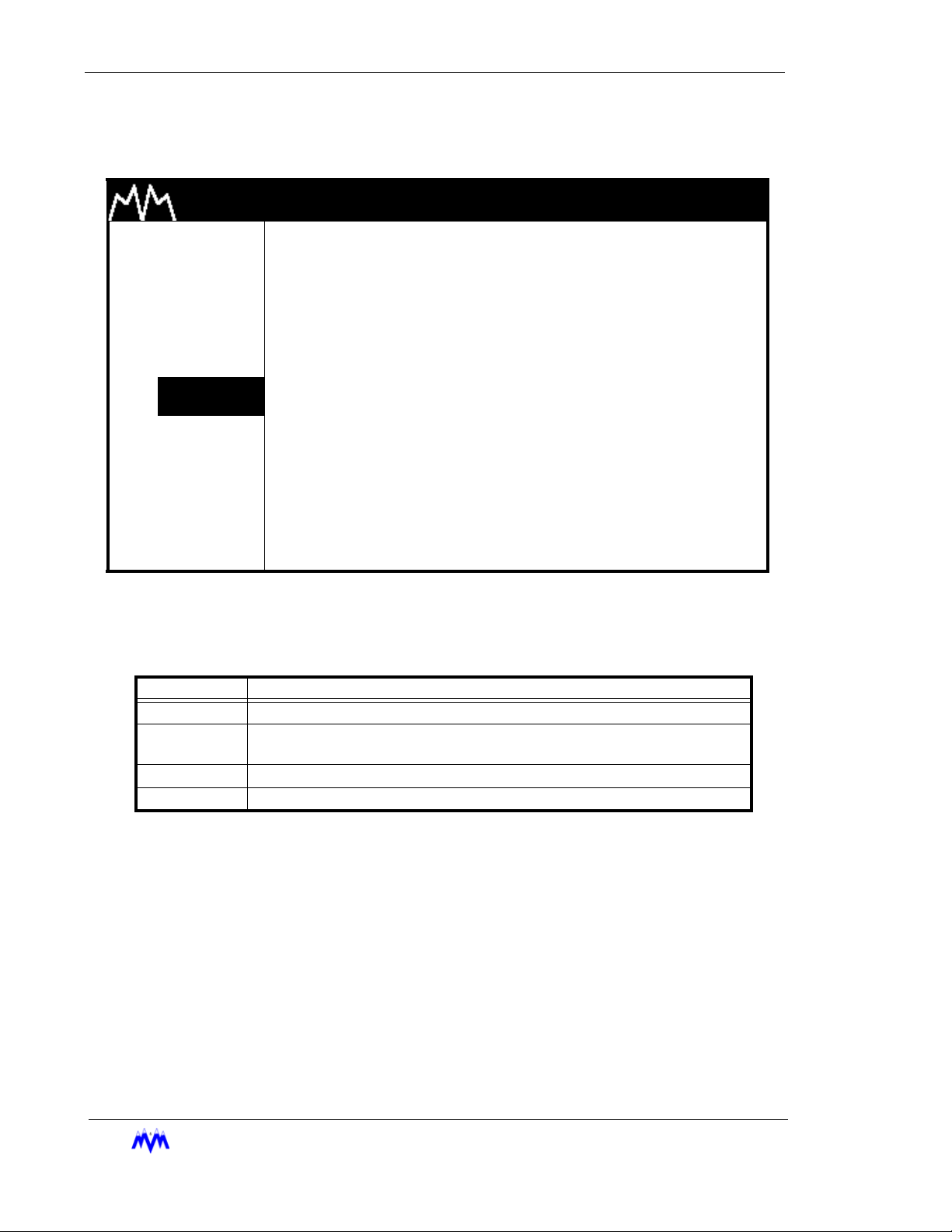

The following table contains a list of the active keys on a confirmation screen and their

function.

KEYS FUNCTION

NUMBER

KEYPAD

ENTER Used to select the highlighted response number.

UP/DOWN

ARROWS

QUIT

Confirmation Screen Procedures

Number Keypad - Use the keypad to match your response with the numerical

choices shown on the screen or press QUIT to exit the screen.

Used to select a response number.

Moves the cursor from one selection to the next, either up or down.

Exits from the current screen to the previous screen. Same as selecting NO for

most screens or YES when quitting from a data entry screen after making

changes.

Confirmation Screen Keys

Momentary Screens

The Momentary screen is used to verify certain user selections by displaying an informative message for three seconds. Rather than waiting for the entire three second time to

elapse, the operator may press the QUIT key to end viewing of the message. The follow-

ing is an example of a momentary screen.

M & M REFRIGERATION 8:32

1. START

2. STATS

3. MODE

4. SETPT

5. SCHED

6. CNTRL

7. MISC

8. LOGS

AM

AUTOMATIC MODE

ENABLED

9. MENUS

2-14

M&M R

EFRIGERATION INC

Momentary Screen

.

Chapter 2: Screen Types

The following table contains a list of the active keys on a momentary screen and their

function.

KEY FUNCTION

QUIT Stops display of the message before the three second time limit expires.

Momentary Screen Keys

Information Screens

Information screens are used to display system data to the user. The information on

these screens may be real-time data or a snapshot of data at the time the screen is

first displayed.

SYSTEM INFORMATION day mm/dd/yy hh:mm:ss

M & M REFRIGERATION INC, COPYRIGHT 1991-2001 FRAME STATISTICS

F0 F1 F2 F3

M&M SCREW day mm dd yyyy hh:mm:ss v1.00 ---- ---- ---- --- MEMORY INITIALIZED : mm/dd/yy hh:mm:ss MAX : xxxx xxxx xxxx xxxx

SYSTEM LAST RESET : mm/dd/yy hh:mm:ss AVG : xxxx xxxx xxxx xxxx

CURRENT TIME : mm/dd/yy hh:mm:ss day MIN : xxxx xxxx xxxx xxxx

TIMER STATUS : 0 of 0 MAX: 0

REFRIGERANT : R717 SEQUENCED : NO LUBE SYSTEM : NO PUMP

NETWORK CONTROL : NO REMOTE : NO UNLOAD SOL : N/OPEN

BYPASS SOL : NO AUTO-REMOTE : NO

ECONOMIZER SOL : NO PROCESS TEMP : NO

VARIABLE VI : NONE MODEM : NO

Information Screen

The following table contains a list of the active keys on an information screen and their

function.

KEY FUNCTION

QUIT Exits from current screen to the previous screen.

Information Screen Keys

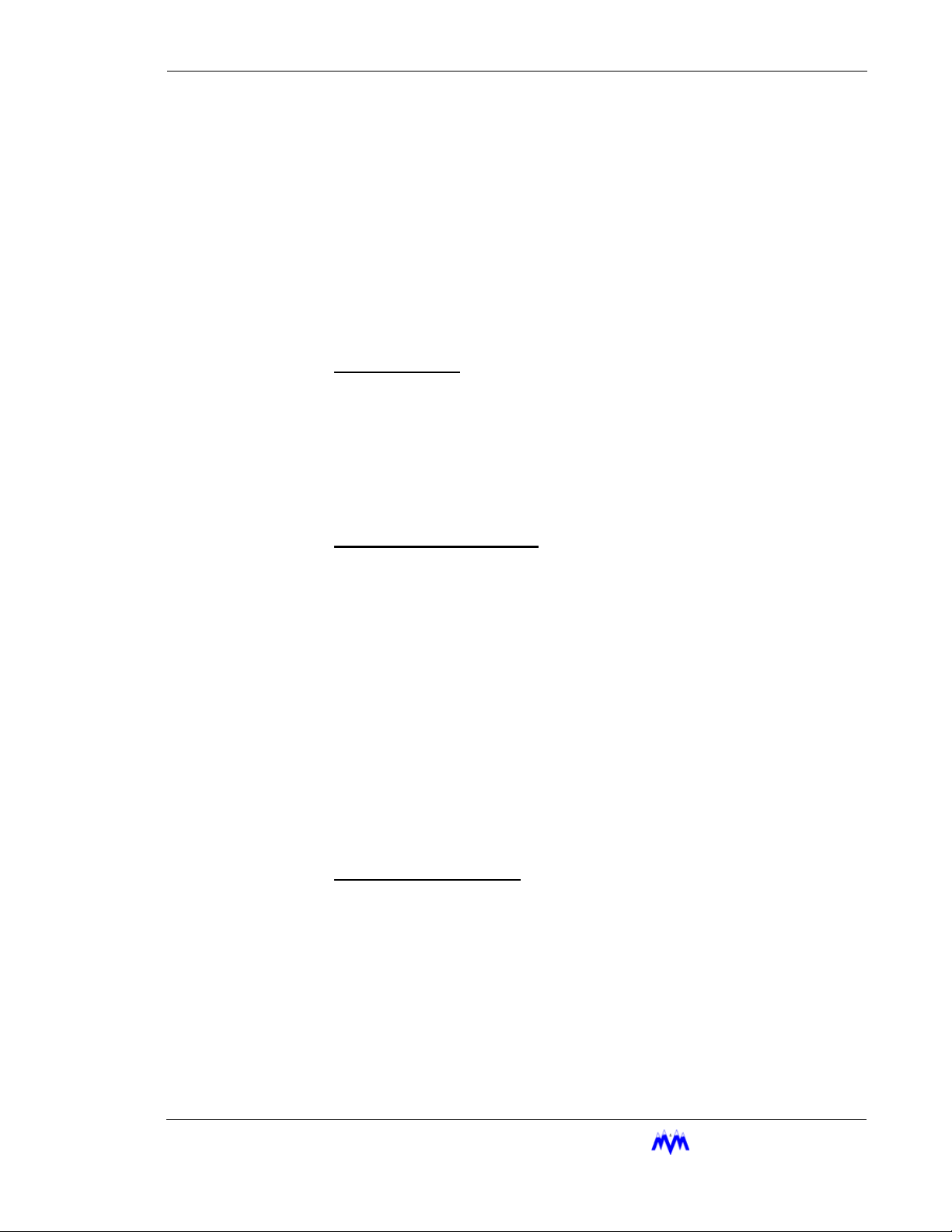

Access Screens

The Access screen is used to index the user into a larger set of screens. This screen is

typically used in cases where more than eight screens are available for a particular option.

The Access screen will perform error checking on the number entered. For example, if the

screen is used to access the daily schedules and the number eight is entered, the input

area will flash ERROR since there are only seven possible schedules. The user will be

M&M R

EFRIGERATION INC

. 2-15

Standard Screw Compressor - RWB Series

required to clear the error and enter a correct value. The data entry process is described

in more detail in the data entry section. The following is an example of an access screen.

M & M REFRIGERATION 8:32

1. START

2. STATS

3. MODE

4. SETPT

5. SCHED

6. CNTRL

7. MISC

8. LOGS

9. MENUS

The following table contains a list of the active keys on an access screen and their function.

AM

DAILY SCHEDULES

ENTER SCHEDULE (1-7) xxx

Access Screen

KEYS FUNCTION

SHIFT Switches control back and forth between the display area and the hot keys.

NUMBER

KEYPAD

ENTER Used to accept the selection number that is entered.

QUIT Exits from current screen to the previous screen.

Used to enter a number selection.

Access Screen Keys

2-16

M&M R

EFRIGERATION INC

.

Loading...

Loading...