Page 1

MI114

Batching Controller

User Manual

MI114R2

www.meltrons.com info@meltrons.com

Millennium Mechatronics Limited, PO Box 59187, Dr, Mangere, Manukau, Auckland 2151

Page 2

Page 3

MI114 User Manual

1

Contents

Chapter 1 Profile ---------------------------------------------------------------------------------------------------------------2

Chapter 2 Main Parameters ---------------------------------------------------------------------------------------------------3

Chapter 3 Installation, Interface and Data Format -------------------------------------------------------------------------4

I. Diagram of Front and Back Function Buttons of Indicator ------------------------------------------------------4

II. Connection of Load Cell and Indicator ----------------------------------------------------------------------------6

III. Input and Output Interface -----------------------------------------------------------------------------------------6

IV. Large-screen Display Interface-------------------------------------------------------------------------------------6

V. Serial Communication Interface ------------------------------------------------------------------------------------6

VI. Analog output --------------------------------------------------------------------------------------------------------7

VII. Print and Storage----------------------------------------------------------------------------------------------------8

Chapter 4 Parameter Setting and Calibration-------------------------------------------------------------------------------9

I. [SEt 0] Enquiry Parameter----------------------------------------------------------------------------------------9

II.【SEt 1】General Parameters --------------------------------------------------------------------------------- 11

III. [SEt 2] Control Parameters ----------------------------------------------------------------------------------- 12

IV. Record Print [SEt 3] ------------------------------------------------------------------------------------------- 16

V. Calibration ----------------------------------------------------------------------------------------------------------- 16

Chapter 5 Operating Instructions------------------------------------------------------------------------------------------- 18

I. Startup and zero setting upon startup ----------------------------------------------------------------------------- 18

II. Zero setting manually ---------------------------------------------------------------------------------------------- 18

III. Tare ------------------------------------------------------------------------------------------------------------------ 18

IV. Setting of date and time ------------------------------------------------------------------------------------------- 18

V. Startup/stop ---------------------------------------------------------------------------------------------------------- 18

VI. Peak holding-------------------------------------------------------------------------------------------------------- 18

VII. Input and output function---------------------------------------------------------------------------------------- 18

VIII. Inquiry of common parameters -------------------------------------------------------------------------------- 19

Chapter 6 Explanations of Control Procedure---------------------------------------------------------------------------- 20

I. Mode 0(additive mode with 1 batching material) ----------------------------------------------------------- 20

II. Mode 1(subtracting mode of 1 batching material) --------------------------------------------------------- 21

III. Mode 2(additive scale for two materials) ------------------------------------------------------------------ 24

IV. Mode 3(catchweighing mode) ------------------------------------------------------------------------------- 25

Annex 1 Error Message Prompt -------------------------------------------------------------------------------------------- 29

Annex 2 Large Screen Data Waveform Diagram and Format --------------------------------------------------------- 30

Annex 3 Serial Communication- Data Format of Command Response Mode ------------------------------------- 32

Page 4

MI114 User Manual

2

Chapter 1 Profile

MI114 uses an advanced delta-sigma A/D converter to achieve a higher speed and higher accuracy for batching

or packing systems. The MI114 single chip microprocessor and high-speed Σ-△A/D switch technology

performs conversions and displays weight, with the maximum conversion speed of up to 80 times/second. The

display can be easily connected to the strain gauge based load cells to form batching scales, packing scale,

weighing control systems etc , where high-speed and high precision weighing are required.

Main functions and features of MI114 weighing indicator:

1. Integration of additive scale, subtracting scale, catch weigher function, with 3-channel input of external

control and 3-channel control output;

2. Standard asynchronous serial communication interface (RS232 or RS422/485), with flexible communication

mode (continuous send and command response);

3. 0-20mA/4-20mA (or 0-5V/0-10V) DA precision analogue output, adjustable;

4. Upper and lower limit alarm output setting;

5. High-precision A/D conversion with readability up to 1/30000;

6. 5-point nonlinearity correction;

7. When changing indicator, re-calibration is not required; and you can use the new indicator with

parameters of earlier indicator;

8. Scoreboard output;

9. Flexible peak holding function;

10. Storage, inspection and deletion function of information such as summation of weighing data and

accumulated frequency etc.; power-off data protection is provided;

11. It can be connected to a serial printer to print weighing record, accumulated amounts or parameters;

manual or automatic print is optional;

12. It has tare function; when the automatic control is activated, automatic tare can be selected;

13. Configurable digital filtering of A/D data

14. Selection of printing unit: kg, t, g, lb;

16. Real-time clock, calendar, which is not affected by power off;

17. Factory defaults recovery function;

Page 5

MI114 User Manual

3

Chapter 2 Main Parameters

1. Type: MI114 weighing indicator

2. Accuracy: Class 3, n=3000

3. Input signal range: -19mV~ +19mV

4. Nonlinearity: ≤0.008%F.S

5. No. of connected load cell:

1- 8, 350Ω load cell

6. Power supply for load cell: DC:5V;350mA

7. Load cell wiring: 6 -wire

8. Display: Single-row 7-bit LED, character height 0.5”, and 11 status

indicating lamps

9. Division: 1/2/5/10/20/50/100 optional

10. Clock: Display real time and date.

11. Keyboard: Adopt 5 soft touch buttons

12. Scoreboard interface: Adopt serial output, 20mA constant current source signal.

13 Communication interface: Serial RS422/RS422/RS485, optional; (baud rate 1200~9600)

14. Print interface: Shared with serial port, and can be connected to serial printer.

15. Relay output: Capacity AC:220V; 0.5A

16. External input: Switch contact

17. Power supply: AC 110~230V, 50/60Hz 1A

18. Service temperature,

0~40℃;≤90%RH

19. Storage and transportation

temperature:

-20~50℃

20. External dimension: Housing: 150×76×85mm (width × height × depth)

Panel: 172×93×3mm (width × height × thickness)

21. Dead weight: Approximately 1.2kg

Page 6

MI114 User Manual

4

Chapter 3 Installation, Interface and Data Format

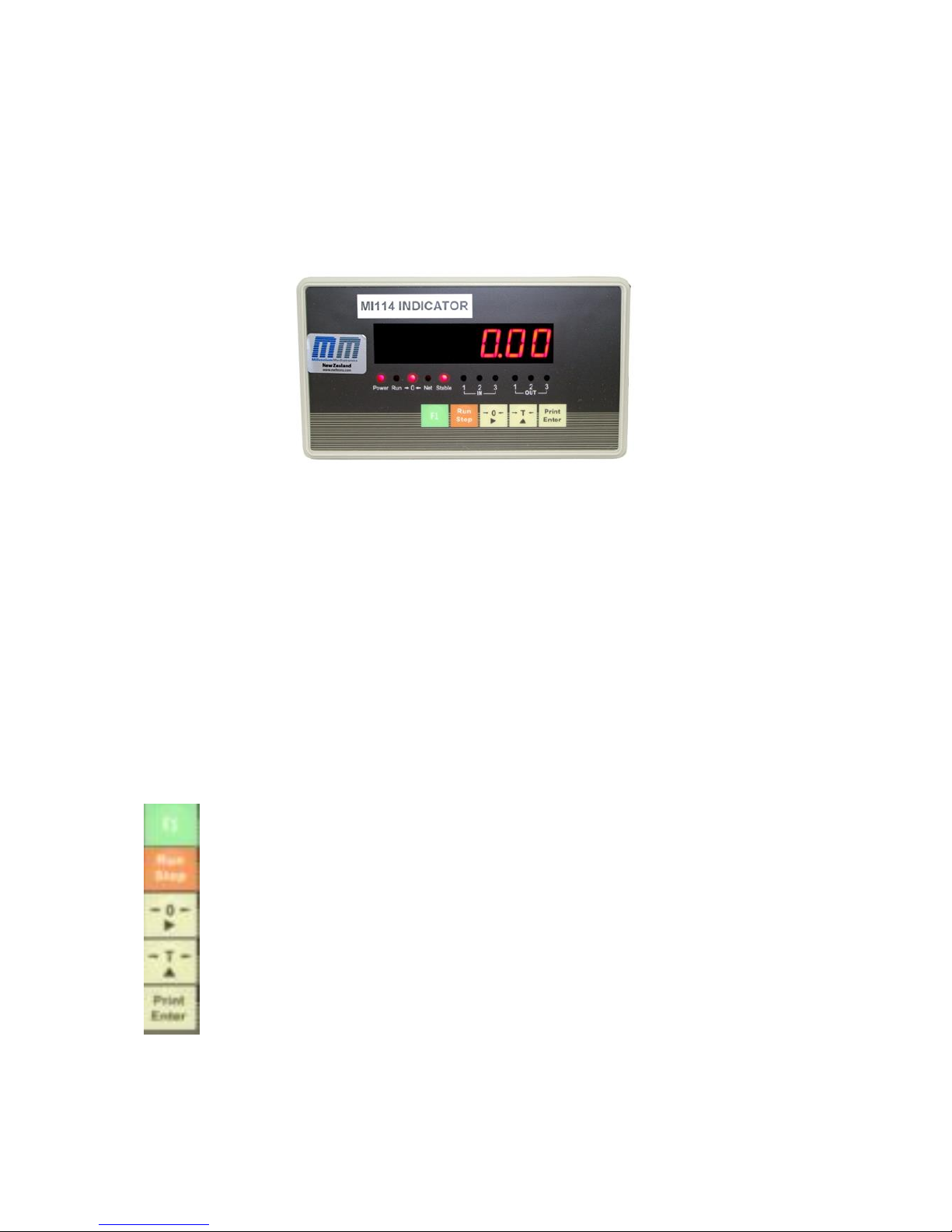

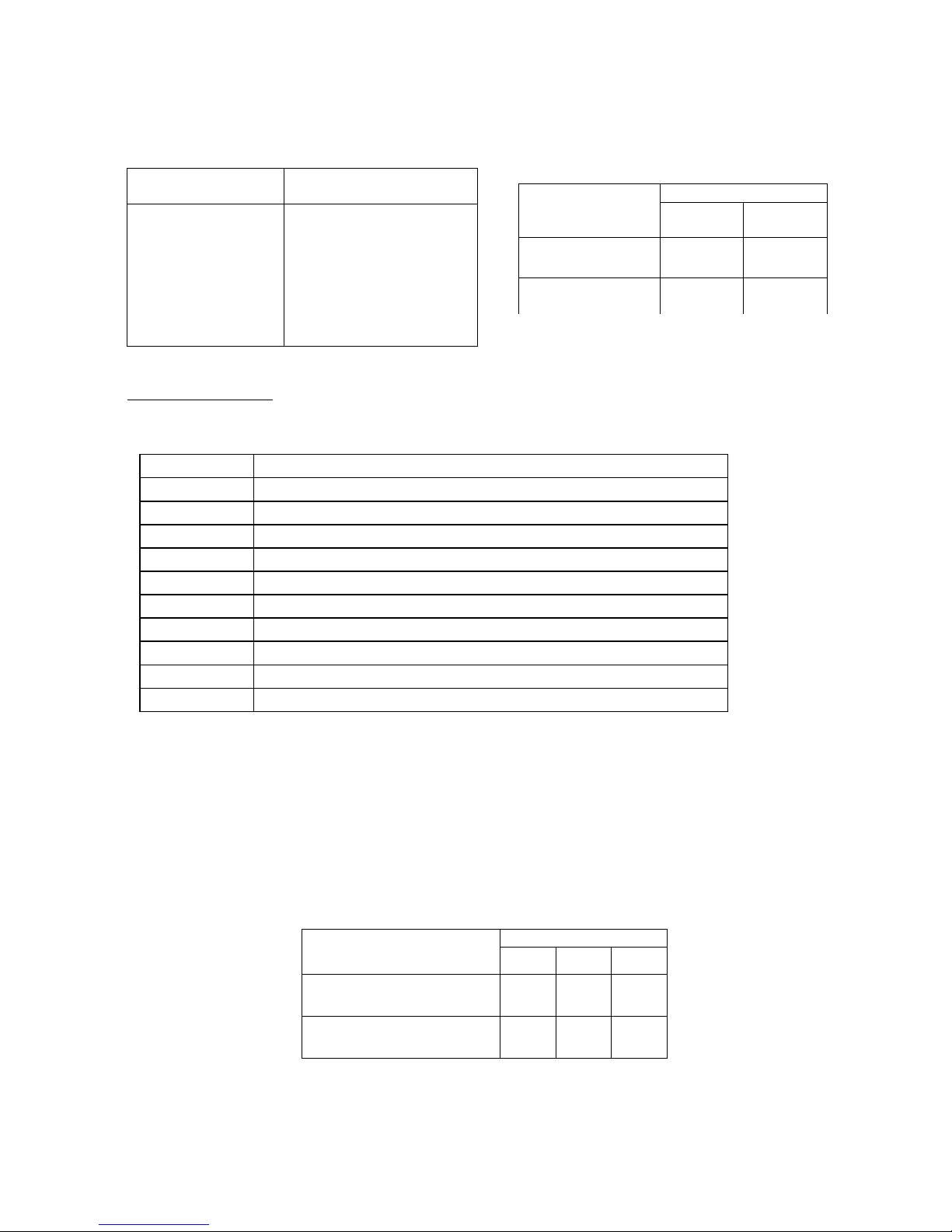

I. Diagram of Front and Back Function Buttons of Indicator

Figure 3-1 Diagram of Front Function Buttons

The meanings of the 11 indicating lamps on display panel are as follows (from left to right):

Power: Power supply indicating lamp

Run: Automatic operation status

>0<: Zero zone indication

Net: Net weight status

Stable: Stabilization status

IN: Three input indications (1, 2, 3 represents three inputs respectively)

OUT: Three output indications (1, 2, 3 represents three outputs respectively)

The five buttons on the display panel have the following functions:

Symbol

Button name

Meaning

[ F1 ] button

Press [F1] and [Operation] buttons simultaneously to examine the inner

code

[Run Stop]

button

It also serves as stop button. It is return button in parameter setting status

[-0-]

button

It is the shift key in parameter setting status.

[-T-] button

It is the “value increase” button in parameter setting

[Print Enter]button

It is the print button for displaying weighing value

Page 7

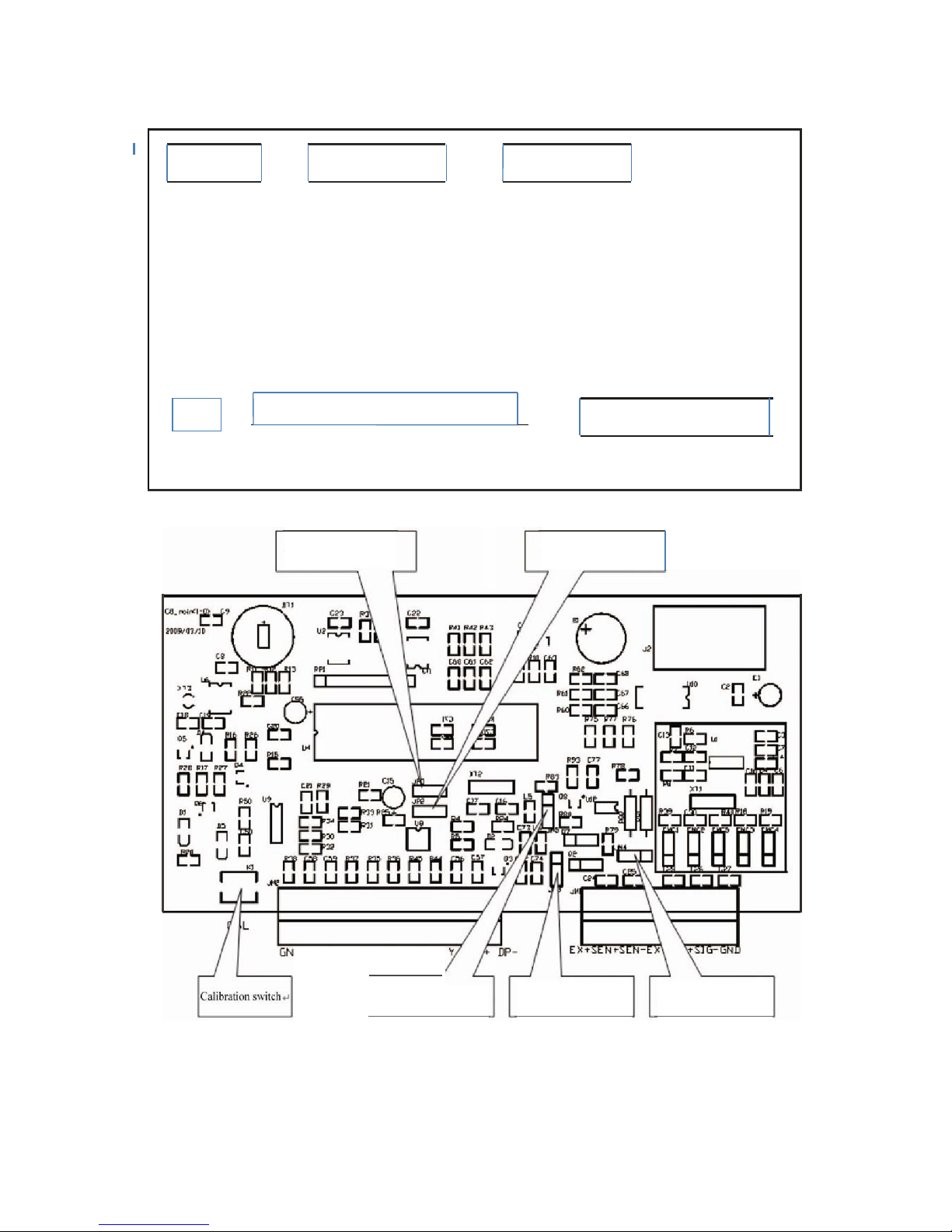

5

L N

GND

l10-230V 50/60Hz

01

02 03

+1

2V 11

12

13 OV

AC power

s

upply Output terminal

lnput terminal

CAL

ON OFF GND RxD TxD Y Z B A OP+

DP-

AO

I

A02

.

I

Calibration switch

Communication/Large-screen/

Analog output i nterface

EX+SEN+

SEN-EX-SlG+S I G-GND

Load cell interface

Figure

3-2

Diagram

or

Back Function Buttons

485/232

jumper

JP1

...

485/232

jumper

J

P2

.,

GND R:><.D l:><D

Bv yA

B Z '\'

Analog jumper J MS ., Ana

log jumper

JM3.,

Analog

jumper JM4 .,

Figure 3 - 3 Diagram of Main Board Jumper and Calibration Switch

All interfaces in Figure 3-2 are described in detail below. P lease read the following detailed interface

description while referring to the interface position in Figure 3-2.

Page 8

6

MI114 Manual

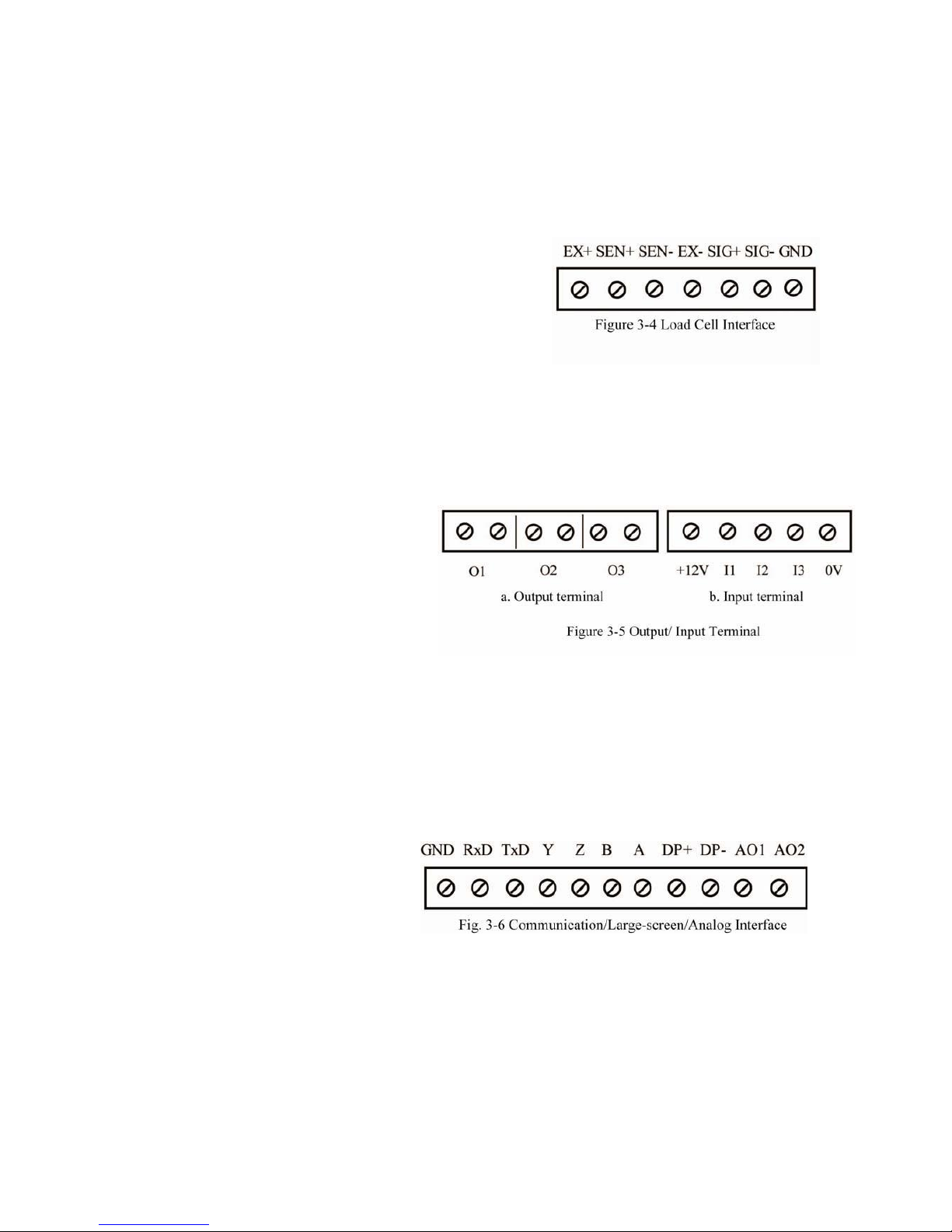

II. Connection of Load Cell and Indicator

The connection with load cell adopts the six wire system connection mode. Please refer to the interfaces in the

Diagram of Back Function Buttons, Figure 3-4. Detailed definitions are given below:

EX+: Positive load cell excitation

SEN+: Positive compensation

SEN-: Negative compensation

EX-: Negative load cell excitation

SIG+: Positive signal

SIG-: Negative signal

GND: Ground

Tip: If a 4 load cell cable is used to connect to MI114, the pins of “EX+” and “SEN+”, “SEN-” and “EX-

” in Figure 3-4 must be short-connected. Otherwise, the indicator cannot be calibrated and weigh

normally.

Ⅲ. Input and Output Interface

The indicator has three channels of optical

isolation input and three channels of relay

output. For interfaces, see Figure

3-5.

① The three outputs are connected to

the external system respectively according to

requirements. O1, O2, O3 terminals have

constant ON built-in relay, which can connect the controlled system directly to the two terminals of

corresponding interface.

Note: Switch contact; effective close control; contact capacity AC: 220V; 0.5A

② The access mode of three inputs is by connecting I1, I2, I3 with +12V, i.e. signal can be entered at the

input terminal. 0V terminal is prepared for customer’s special requirements.

The meaning of interface is different according to different modes. For detailed definition, please see

Chapter 5 Section 7 of this manual.

Note: The +12V terminal and 0V terminal cannot be short connected.

IV. Scoreboard Display Interface

For large-screen interface, see Figure 3-6:

DP+, DP- in the Figure are connected to

the large-screen. For the detailed

communication format, see Annex 2.

V. Serial Communication Interface

Serial communication interface uses RS232C (standard product). According to customer demand, the

RS485 interface can be selected through jumper (the output format is the same with RS232C). For the details

of the interface pin connection, see Table 3-1. For the jumper selection mode, see Table 3-2.

Page 9

7

MI114 Manual

Communication

interface

Jumper Selection

JP1 JP2

RS232C

(Factory defaults)

Left Left

RS485C

Right

Right

Table 3-1 Pin details Table 3-2 Selection of Communication

MI114 indicator can select “continuous send” or “command response”

mode:

Continuous send mode:

The transferred data is the current weight (gross weight or net weight) displayed on the indicator. Each

frame of data is composed of 12 groups of data. The format is as follows:

X

th

Byte

Contents and notes

1

02(XON) Start

2

+ or - Sign bit

3

Weighing data High-order bit

:

Weighing data :

:

Weighing data :

8

Weighing data Low-order bit

9

Decimal scale From right to left (0~4)

10

XOR check High four-bit

11

XOR check Low four-bit

12

03(X0FF) End

NOR=2⊕3⊕……8⊕9

2. Command response mode: For detailed format, please see Annex 3

VI. Analog output

MI114 indicator can choose 3 analog output modes: 0~5V, 0~10V voltage signal output and 4~20 mA

current signal output (It can be also be adjusted to 0~20 mA . The electric current loop adopts the internal

electrical power supply mode, the output mode is selected by jumper JM3~JM5 (See Figure 3-3) on the

main board. For the setting mode, see Table 3-3. The factory setting is 4~20 mA electric current loop. The

switch of analog output is controlled by the C bit of parameter [H ABC] under parameter [SET 1].

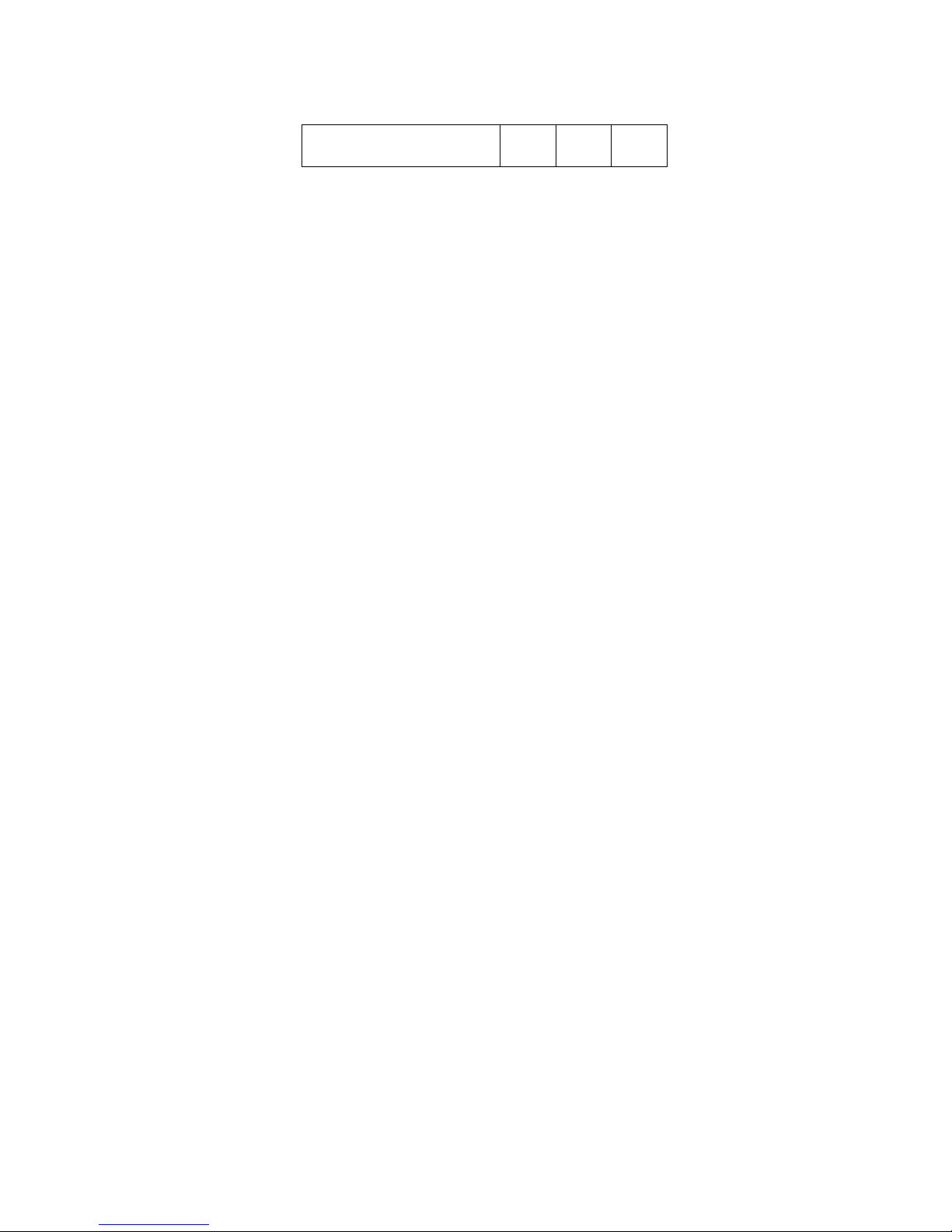

Table 3-3 Setting of Analog output

Analog output

Selection of jumper

JM3

JM4

JM5

4—20mA (Factory defaults)

Up

——

Down

0—5V

Down

Right

Up

232 Communication

485 Communication

GND: Grounded

RXD:

Receiving end of

indicator

TXD:

Sending end of

indicator

A: RXD+

receiving positive data

B: RXD-

receiving negative data

Z: TXD-

sending negative data

Y: TXD+

sending positive data

Page 10

8

MI114 Manual

0—10V

Down

Left

Up

Calibration method for analog output

The zero point value of analog output and full scale value are in direct proportion to corresponding DA

code (See Table 4-3, instructions of [SEt 1] parameter 12 and 13). The parameter 12 and parameter 13 can be

corrected by calculation according to the analog output error.

Note: At the mode of voltage output, short circuit of the analog output terminal is strictly

prohibited, and the load of 4-20mA electric current loop output cannot be disconnected, or otherwise

the analog output circuit may be damaged.

VII. Print and Storage

Print

The serial port communication RS232 connection mode is adopted. By means of selecting connection to

serial printer in indicator parameter Set 1, the weighing data can be printed through the serial port. Hand

print and automatic print are available, which are introduced below:

1. Hand print

Single print: In weighing status, press “Print/Enter” button to print the current time, date, net weight, tare

weight, accumulated frequency and accumulated weight.

Print record: At the mode of 0, 1, 2, all weighing records, including the time, date, net weight, tare weight,

accumulated frequency and accumulated weight for each weighing, can be stored and printed. For concrete

operations, see [Set 3].

2. Automatic print

After selecting printer and automatic print in parameter settings, information such as the current time,

date, net weight, tare weight, accumulated frequency and accumulated weight will be printed automatically

when a process is completed each time during the automatic control process.

Note: New prints cannot be made until it returns to zero after every print; if printer or hand peak

holding function is not selected, the hand print function is invalid; when communication in [Set 1] is not

selected or communication is selected but the serial printer is not selected, print is not valid; when the set baud

rate is not 9600, [Err P] will be prompted.

Storage

Storage is often used together with print, and is divided into hand storage and automatic storage.

Automatic storage should be enabled in parameter settings. Attention must be paid to several points during

storage:

1. Hand storage cannot be conducted in catch weighing mode.

2. The next storage cannot be executed until it returns to zero after each time of storage.

3. After the control mode (i.e. additive scale, subtracting scale, catch weigher) is changed, it needs to enter

the parameter setting 0 to eliminate the accumulated results, or otherwise an error may occur.

Page 11

9

MI114 Manual

Chapter 4 Parameter Setting and Calibration

If there is no special instruction for parameter setting, the button functions are as follows:

[F1] button: exit from parameter setting

[Operation] button: the current setting is not saved, and return to the previous parameter

[Zero setting] button: move the current flicker bit

[Tare] button: modify the current flickering value

[Enter] button: make sure to save the current parameter setting, and enter the next

parameter setting

Press [F1] button and [Zero setting] button simultaneously to enter parameter setting selection

interface. The setting catalogues are:

【SEt 0】 : enquiry parameter;

【SEt 1】 : general parameter;

【SEt 2】 : control parameter;

【SEt 3】 : print record (no such function in catch weighing mode)

[Note] Please note the instruction in remarks for each parameter. Part of parameters will only be

displayed under specific mode or conditions.

I. [SEt 0] Enquiry Parameter

Table 4-1 Non-Catch Weigher Mode

Para-

meter

Indicator

Display

Parameter Specification

Remarks

1 [n ****]

Accumulated frequency

It can only be inquired, but not changed.

2 [A******]

Accumulated weight

It can only be inquired, but not changed.

3 [dEL *]

Delete the selection of

accumulated frequency and

accumulated weight

0: no-operation

1: execute deletion operation

Page 12

10

MI114 Manual

4 [d**.**.**]

Current date setting

Press [Zero setting] button to move the current

flicker bit, press [Tare] button to modify parameter

value

5 [t**.**.**]

Current time setting

Press [Zero setting] button to move the current

flicker bit, press [Tare] button to modify parameter

value

6 [A ****]

Zero position calibration

Restricted parameter. The calibration switch must

be opened (turn the calibration switch CAL to the

left ON position) when changing, and input the

correct password.

Press [Enter] button to check the parameter

value one by one;

Before pressing [Tare] button to modify

parameter value, first enter the password

protection interface in Step 18!

These parameters can be modified only by entering

the correct password for one time.

When checking the parameters, the indicator will

return to weighing status after Step 16 is displayed.

7 [b ****]

CAL Coefficient

8 [C ****]

Nonlinear correction point 1

9 [d ****]

CAL Coefficient 2

(nonlinear correction)

10 [E ****]

Nonlinear correction point 2

11 [F ****]

CAL Coefficient 3

(nonlinear correction)

12 [L ****]

Nonlinear correction point 3

13 [H ****]

CAL Coefficient 4

(nonlinear correction)

14 [P ****]

Nonlinear correction point 4

15 [ t ****]

CAL Coefficient 5 (nonlinear

correction)

16 [ r ****]

Nonlinear correction point 5

17 [HF *]

Whether to restore factory

setting:

0: not restore; 1: restore

If recovery of factory setting is selected, it will

come into effect after re-startup, and the calibration

parameters will not be changed.

18

[PAS 000]

Password protection status

Password protection interface. Input the correct

password (111) and enter Step 6 to modify

parameters. If the password is wrong, it will return

to weighing status.

Table 4-2 Catch Weigher Mode

Para-

meter

Indicator

Display

Parameter Specification

Remarks

1 [n 1 ****]

Accumulated frequency of

Channel 1

It can only be inquired, but not changed.

2 [A******]

Accumulated weight of Channel

1

It can only be inquired, but not changed.

3 [n 2 ****]

Accumulated frequency of

Channel 2

It can only be inquired, but not changed.

4 [A******]

Accumulated weight of Channel

2

It can only be inquired, but not changed.

Page 13

11

MI114 Manual

5 [n 3 ****]

Accumulated frequency of

Channel 3

It can only be inquired, but not changed.

6

[A******]

Accumulated weight of Channel

3

It can only be inquired, but not changed.

7 [d**.**.**]

Setting of current date

The following parameters are same with the latter

part of Table 1.

II.【SEt 1】General Parameters

Table 4-3

Parameter

Indicator

Display

Parameter Specification

Remarks

1

[H ABC]

Hardware selection

A - Communication (0: communication is not

required, 1: communication is required)

B-Large-screen (0: large-screen is not required, 1:

large-screen is required)

C-Analog (0: analog is not required, 1: analog is

required)

For example: When

communication is required,

large-screen and analog are not

required, set it to [H 100].

Note: This setting will affect

the following display menu.

2

[n ABC]

Relevant Parameters of Zero Zone A-

zero setting range upon startup (0~5) B-

zero setting range by hand (0~5)

For example: if set the zero

setting range upon startup to

20%, the zero setting range by

hand to 4%, and the zero tracking

to 0.5e, it will be set to [n

421].

A,B

0 1 2 3 4

5

F .S%

0 2 4

10

20

100

C-zero tracking range (0~8)

When it is set to 0, the tracking function is closed.

For other values, see the following table:

C 1 2 3 4 5 6 7

8

(e

1

1.5 2 2.5 3 3.5

4

3

[FLt *]

AD Filtering Intensity (0~4)

The smaller the value is, the

faster the weight changes, but

the stability is worse; The bigger

the value is, the slower the

weight changes, but the stability

is better. The user should adjust

the parameter according to

requirements.

Value

0 1 2 3 4

Filtering

Intensity

weak

Compar

atively

weak

medium

Compar

atively

strong

Strong

4

[Adr **]

Communication Address of Indicator (01~26)

When several indicators send data to the same PC,

this communication address is required to

distinguish each of the indicators.

It won’t be displayed when

communication is not required.

5

[bt *]

Communication Baud Rate (0~4)

It won’t be displayed when

communication is not required.

BPS

0 1 2 3 4

BPS

600

1200

2400

4800

9600

Page 14

12

MI114 Manual

6

[tod *]

Communication Mode:

0-command response mode (Refer to Chapter 3);

1-continuous send mode

2-connect to serial printer

It won’t be displayed when

communication is not required.

7

[AtP *]

Automatic accumulated print:

0-automatic accumulation

1-automatic accumulation without print

2-automatic accumulation and automatic print

Accumulation and print conditions

should be set appropriately .

8

[Unit *]

Print Unit:

0-kg (kilogram)

1-g (gram)

2-t (ton)

3 – lb (lbs)

It is effective only when printing.

It won’t be displayed when

communication is not required.

9

[F *]

Peak Holding:

0-Peak holding is closed.

1-Peak holding is effective, and the holding will

be cancelled automatically after returning to zero.

2 - Peak holding is effective; press the button to

manually cancel holding.

Hand mode includes pressing the

input button and input terminal to

obtain input signal.

10 [AL*****]

The corresponding weight of analog output zero

point

Will not be displayed when analog

output is not required.

11 [A******]

The corresponding weight of analog output full

range

Will not be displayed when analog

output is not required.

12

[PL ***]

DA inner code (0-30000) when analog output is at

zero point

(Output 4-20mA signal is about 12520;

output 0-5V/0-10V is 0)

The zero point of analog output of

can be modified by editing this

code.

13

[PH ***]

DA inner code (30000-65535) when analog output

is at full range

(4-20mA output is about 62590;

0-5V/0-10V output is about 65200)

The full load point for calibration of

analog output can be modified by

editing this code.

14 [Prt *]

Whether to print this set parameter:

0: No.

1: Yes.

This item won’t be displayed when

there is no printer.

III. [SEt 2] Control Parameters

Table 4-4

Parameter

Indicator

Display

Parameter Specification

Remarks

1

[CP *]

Control Mode

0: 1 kind of additive mode of batching

1: 1 kind of subtraction mode of

batching

2: 2 kinds of additive mode of

batching

3:catchweighing mode

For work flows of all kinds of mode, see

Chapter 6.

2

[Pt 0]

Number of cycles

The number of control process (0 ~ 99, 0

stands for indefinite times)

Please select the corresponding parameter setting according to the set [Control Mode].

Page 15

13

MI114 Manual

Mode 0, 1 (Additive mode or subtraction mode for 1 kind of batching material)

3

[C ABCDE]

Advanced Control Parameters

A-quick or slow feed status

0: When quick feeding, only the

quick feed is opened.

1: When quick feeding, both the

quick and slow feed are opened

simultaneously.

B - automatic tare status before

feeding

0: no automatic tare

1: automatic tare

C -self-correction selection for lead

0: no correction

1: correction

D - out-of-tolerance treatment

selection

0: no treatment, the cycle

continues

1: wait for treatment until

qualified

E-material shortage gradual feed

0: no gradual feed

1: gradual feed

This parameter will change the control flow,

so generally no modification should be made.

Some parameters are invalid at subtraction

mode.

4

[A******]

Batching value

5

[b******]

Quick feed lead

6

[c******]

Slow feed lead

7

[d******]

Allowance

8

[L******]

Zero zone

1. When the indicator is discharging, if the net

weight is less than that of zero zone value, it

will be deemed as discharge completion;

2. The indicator print and accumulation

cannot be conducted until the gross weight is

greater than the zero zone value.

9

[t0 **]

0.0~9.9 seconds feed measurement

delay

To avoid weight misjudgment caused by

weight impact when starting.

10 [t1 **]

0.0~9.9 seconds delay of quick feed

over

11 [t2 **]

0.0~9.9 seconds delay of slow feed

over

12 [t3 **]

0.0~9.9 seconds gradual feed output

time

It won’t be displayed when there is no gradual

feed.

13 [t4 **]

0.0~9.9 seconds gradual feed interval

time

It won’t be displayed when there is no gradual

feed.

Page 16

14

MI114 Manual

14 [t5 **]

0.0~9.9 seconds time

Mode 0: discharge over delay

Mode 1: qualified output time

15 [t6 **]

0.0~9.9 seconds re-feed delay

16 [Prt *]

Whether to print this parameter:

0:No.

1: Yes.

It won’t be displayed when there is no printer.

Mode 2 (Additive mode for 2 kinds of batching)

3

[C ABCD]

Advanced Control Parameters

A - automatic tare status before

feeding

0: no automatic tare

1: automatic tare

B -self-correction selection for lead

0: no correction

1: correction

C -out-of-tolerance treatment

selection

0: no treatment, the cycle

continues

1: wait for treatment until qualified

D- material shortage gradual feed

0: no gradual feed

1: gradual feed

This parameter can change the control flow,

so it should be modified according to the

actual control needs.

4

[A******]

Material 1 quantitative value.

5

[b******]

Material 1 feed lead.

6

[C******]

Material 1 allowance.

7

[P******]

Material 2 quantitative value.

8

[d******]

Material 2 feed lead.

9

[t******]

Material 2 allowance.

10

[L******]

Zero zone

1. The gross weight is judged when the

indicator is discharging, if the net weight is

less than the zero zone value, it will be

deemed as discharge completion;

2. The indicator print and accumulation

cannot be conducted until the gross weight is

greater than the zero zone value.

11 [t0 **]

0.0~9.9 seconds feed measurement

delay

To avoid weight misjudgment caused by

weight impact during startup.

12 [t1 **]

0.0~9.9 seconds material 1 feed over

delay

Page 17

15

MI114 Manual

13 [t2 **]

0.0~9.9 seconds material 2 feed over

delay

14 [t3 **]

0.0~9.9 seconds gradual feed output

time

This item won’t be displayed when there is no

gradual feed.

15 [t4 **]

0.0~9.9 seconds gradual feed interval

time

It won’t be displayed when there is no gradual

feed.

16 [t5 **]

0.0 ~ 9.9 seconds discharge finish

delay

17 [t6 **]

0.0~9.9 seconds re-feed delay

18 [Prt *]

Whether to print this parameter:

0: No.

1: Yes.

It won’t be displayed when there is no printer.

Mode 3 (Catch Weighing Mode)

Parameter

Indicator

Display

Parameter Specification

Remarks

3

[FodE *]

Catch Weighing Mode:

0-Self-testing mode

1-External control mode

2-Upper and lower limit mode

Self-testing mode: When the weight is greater

than zero zone value, it starts catch weighing

automatically.

External control mode: Only when the

external control signal is triggered, the

indicator begins catch weighing.

Upper and lower limit mode: The real-time

upper, medium, lower limit relay output.

4

[H******]

Upper limit setting: Input a weight

value that is between zero and full

range.

When the weight value is smaller than the

lower limit, O1 is output;

When the weight value is between the lower

limit and upper limit, O2 is output;

When the weight value is greater than the

upper limit, O3 is output.

5

[L******]

Lower limit setting: Input a weight

value that is between zero and full

range.

6

[Lq*****]

Zero zone

1. Enter the next cycle only after sending out

the catch weighing signal and the indicator

weight is less than this value;

2. Enter t1 only when the indicator weight is

greater than this value at self-checking mode.

7

[t0 **]

Judgment Delay (0~9.9) Seconds:

At external control mode, data

calculation is conducted only after the

external control is triggered for t0

second;

At self-checking mode, data

calculation is conducted after the

weight leaves zero zone for t0 second.

8

[t1 **]

Calculation Time for Average

Weight (0~9.9) Seconds:

The indicator will accumulate,

average the weight within t1 after t0,

and the obtained value will serve as

catch weighing basis.

Page 18

16

MI114 Manual

9

[t2 **]

Calculation Delay (0~9.9) Seconds:

The indicator has no action within t2

after t1 is calculated, wait with delay.

10

[t3 **]

Signal Sending Time (0 ~ 9.9)

Seconds:

The indicator sends catchweighing

signal, with duration of t3 second.

11 [Prt *]

Whether to print this parameter:

0: No.

1: Yes.

It won’t be displayed when there is no printer.

★Please confirm H≥L during setting, or otherwise the indicator cannot work normally, and may cause

unexpected errors. The above time doesn’t take reaction time, such as relay action, into consideration.

IV. Record Print [SEt 3]

(This function is only effective at Mode 0, 1, 2)

Table 4-5

Parameter

Indicator

Display

Parameter Specification

Remarks

1

[n ***]

The sequence number of records to be printed

The sequence number of records

is corresponding to accumulated

frequency.

2

[Prt *]

Whether to print record:

0: No.

1: Yes.

It won’t be displayed when there

is no printer.

The form of printed record sheet is shown as Table 4-6:

Table 4-6

Date:

Feb 11, 2009

Time:

16:18:36

Net Weight:

5.00kg

Gross Weight:

0.00kg

Accumulated

Frequency:

0011

Accumulated

Weight:

115.00kg

V. Calibration

Turn the calibration switch CAL to the left ON position to open the calibration switch. Then press [F1]

button and [Enter] button simultaneously, the indicator displays [--CAL--], indicating entering calibration

status. Press [Enter] button to enter. For specific calibration parameter instructions and operation, refer to the

following table (* stands for the original set value):

Table 4-7

Step

Parameter

Display

Parameter Instruction

Operation Instruction

1

[E *]

Division: 1/2/5/10/20/50/100 optional

Press [Enter] after modifying parameters

2

[dC *]

Digits of decimal point (0-3)

Press [Enter] after modifying parameters

Page 19

17

MI114 Manual

3

[F******]

Full value (The limit set automatically is

full value plus 8 division)

Press [Enter] after modifying parameters

4

[r 0]

Save the original zero position:

0: S a v e the current zero position.

1: Skip over the current zero position

confirmation.

Input 0 to enter Step 5 (reco mmended),

Input1 to enter Step 7.

5

[noLoAd ]

Zero position confirmation

Confirm that the current weighing

platform has no load and the stability

light is ON, then press [Enter].

6

[*******]

Display the current AD code

Press [Enter] after the AD code is stable.

7

[AdLoAd1]

Load weights

Press [Enter] after the weight is loaded.

8

[*******]

Display the current AD code

Press [Enter] after the AD code is stable.

9

[ *******]

The weight of current loaded weights

Change to the weight value of current

weights, press [Enter] button to enter Step

12 and complete the calibration;

Change to the weight value of current

weights, press [F1] button to enter the

nonlinear correction flow of Step 10;

10 [AdLoAd* ]

th

Load weights, calibrate the weight of n

point (n<=5)

Press [Enter] to enter the next step after

weights are loaded.

11

[*******]

Display the current AD code

Press [Enter] to enter Step 9 cyclically

after the AD code is stable. (At most five

-point nonlinear correction can be

conducted)

12 [*******]

Display the current weight value

The calibration is finished. Return to

weighing status.

Please put the calibration switch at OFF position after calibration is finished

Page 20

18

MI114 Manual

Chapter 5 Operating Instructions

I. Startup and zero setting upon startup

After connecting to the power supply, the display performs self-check of strokes “0-9”, then shows the

version No.. After that, it enters into weighing mode. After startup, if the weight of empty scale deviates from

zero point, but remains within the zero range, the display will perform zero setting upon startup. If the weight is

out of the zero setting range, the display shows the weight based on the calibrated zero point. For information

on the zero setting, please refer to the setting of parameter B in the parameters 1:[n ABC] as described in

Chapter 1

【SEt 1】.

II. Zero setting manually

When the display value deviates from zero point, but remains within the range of zero setting manually,

and the light is steady, press the button【Zero setting】to make the display value reset to zero. The

zero point light will turn ON. For setting the zero range manually, refer to the setting of parameter A in the

parameters 1:[n ABC] as described in Chapter 1 【SEt 1】.

III. Tare

Under weighing status, when the displayed weight is a positive value and weighing is stable, press the

button 【Tare】to deduct the displayed value as tare. Then the displayed net weight is 0, with the net weight

indicator light ON.

IV. Setting of date and time

Set the date through the contents [d**.**.**] and the time through [t**.**.**] in parameters setting 【SEt

0】. Press the button【Zero setting】to change the flicker bit, and【Tare】to change the size. After completion

of setting, press the button【Enter】for setting of other parameters or exit from setting by pressing the button

【 F1 】.

V. Startup/stop

For startup or stop, press directly the button【Run】on key board, or input an impulse signal from the

“Startup” end of back panel. The indicator is ready to enter into control mode or exit from control mode.

VI. Peak holding

By means of setting the param eter [F *] in parameters【SEt 1, select the peaking holding mode:

0-peak holdings is off.

1-peak holding is valid, and it is cancelled automatically after zero setting.

2-peak holding is valid. Press the button【Enter】to enable peak holding; press the button【Enter】once

again to disable peak holding (under this status, the button【Enter】has no save manually/print function).

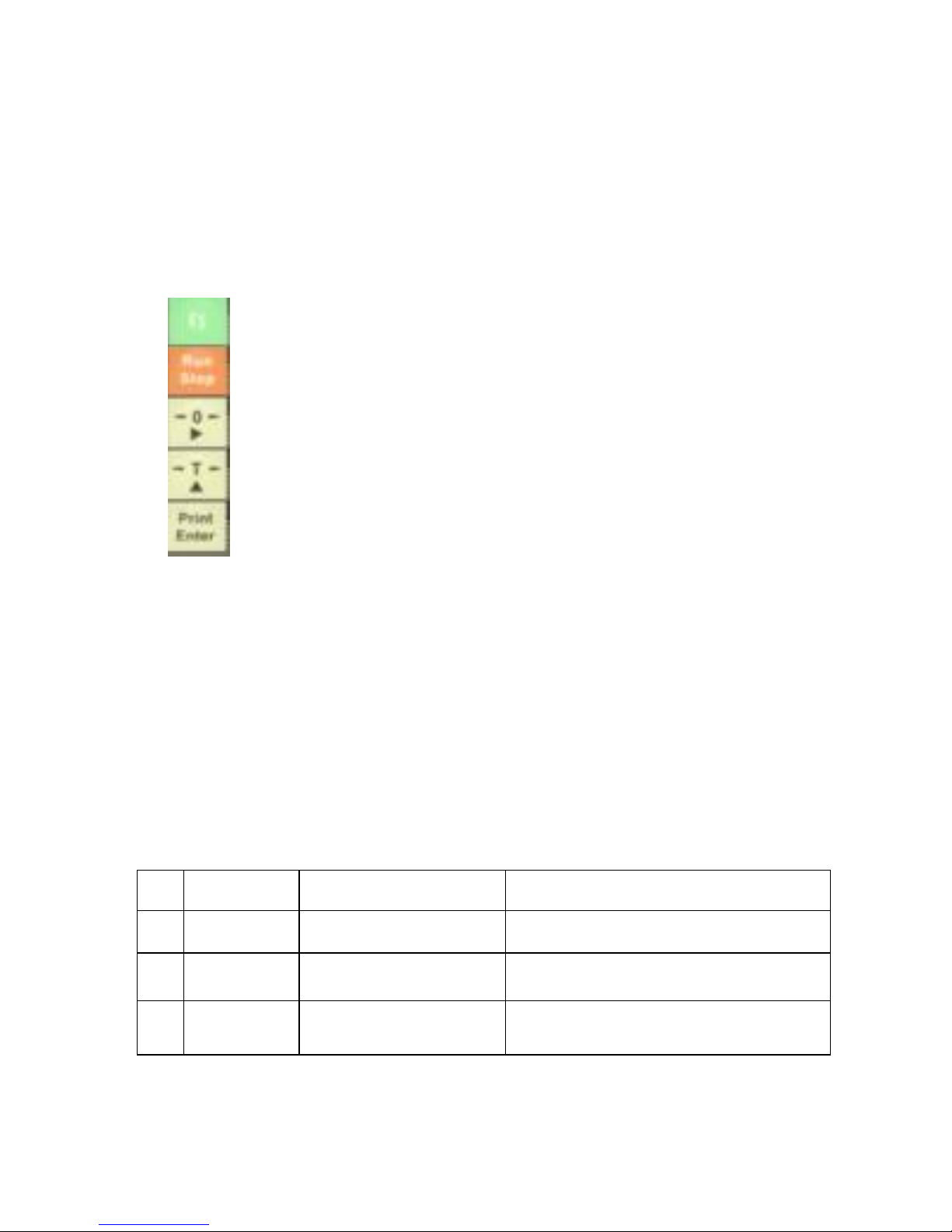

VII. Input and output function

The input and output has the following meanings under different modes:

Mode

Input

Output

I1

I2

I3

O1

O2

O3

Mode 0

startup/stop

feed

discharge

Quick feed

Slow feed

discharge

Mode 1

startup/stop

discharge

——

Quick discharge

Slow discharge

complete

Mode 2

startup/stop

feed

discharge

Feed material 1

Feed material 2

discharge

Mode 3

startup/stop

External

control

input

——

Net weight≤

lower limit

Lower limit < net

weight < upper

limit

Net weight ≥

upper limit

Page 21

19

MI114 Manual

Input and output test:

Press the button【F1】and【Run】simultaneously to enter internal code status. At this moment, if level

signal is given to the input end 1, 2 and 3, the output end 1, 2, and 3 will output corresponding signal, and the

light indicator on the front panel will turn on.

VIII. Inquiry of common parameters

Press the button【 F1 】under weighing mode to enquire the following parameters respectively:

Mode 0, 1:batching value, date, time

Mode 2 :batching value 1, batching value 2, date, time

Mode 3 :upper limit, lower limit, date, time

Page 22

20

MI114 Manual

Chapter 6 Explanations of Control Procedure

The four working modes of the indicator are explained in details as below:

I. Mode 0(additive mode with 1 batching material)

The double-speed batching of 1 kind of material mainly involves the following parameters: batching value

A1, quick feed lead b, slow feed lead C, allowance, zero value L. Please refer to the following figure for

understanding of the functions, meanings and time sequence of control input and output of various parameters

during the process:

Additive mode of 1 batching material:

Note: A—batching value; b—quick feed lead value; C—slow feed lead value; L—zero zone value. t0—

measurement delay;t1—quick feed over delay;t2—slow feed over delay;t3—gradual feed output

time;t4—interval time of gradual feed;t5—discharge over delay.

The schematic diagram of slow feed 1 shows the slow feed output when both the quick feed and slow

Page 23

21

MI114 Manual

feed are ON during quick feed process, and gradual feed exists.

The schematic diagram of slow feed 2 shows the slow feed output when only the quick feed is ON

during quick feed process, and without gradual feed.

The control procedure in the above diagram is consist of 4 processes including quick feed, slow feed,

gradual feed and discharge.

(1) Quick feed-- When the control procedure starts, the quick feed output gives out a signal, and the

corresponding O1 relay is closed. When the weight is added to the quick feed stop value A-b, the

quick feed output signal is cancelled, the corresponding O1 relay is switched off.

(2) Slow feed-- After a period of delay time t1 (quick feed over delay), the slow feed output gives out a

signal, and the corresponding O2 relay is closed. When weight is added to the slow feed stop value AC, the slow feed output signal is cancelled, the corresponding O2 relay is switched off. If the

parameter is set to both quick feed and slow feed ON, the slow feed output gives out a signal since

the beginning, and the corresponding O2 relay is closed until the weight reaches up to the slow feed

stop value A-C.

(3) Gradual feed-- If the parameter is set with gradual feed, the O2 relay corresponding to slow feed will

be closed for a period of t3, and switched off for a period of t4. Gradual feed is carried out through

such repeated cycle, until the weight reaches up to the allowance range of batching value, i.e. the

qualified area.

(4) Discharge-- Discharge output sends out a signal, and the corresponding O3 relay is closed. After the

weight is deducted from the value L in zero zone, the discharged is considered completed, which

corresponds to point M in the figure. At this moment, after another delay of t5, the discharge output

signal is cancelled, and the corresponding O3 relay is switched off. A complete control procedure is

finished.

Note: during the above process, if the slow feed lead is bigger than that of quick feed lead, i.e. C>b, then

the slow feed output won’t give out signal, and the corresponding O2 relay remains switched off. If no

gradual feed is set for parameters, the above gradual feed process (3) is not included. The turning off of

discharge should meet the conditions that the weight is less than zero zone value.

II. Mode 1(subtracting mode of 1 batching material)

Please refer to the following figure for understanding of the functions, meanings and time sequence of

control input and output of various parameters during the process:

Note: A—batching value; b—quick subtraction lead value; C—slow subtraction lead value;

t1—quick subtraction over delay;t2—slow subtraction over delay;t3—gradual feed output time;

t4—interval time of gradual feed;t5—discharge over delay

The schematic diagram of slow subtraction 1 shows the slow subtraction output when both the quick

subtraction and slow subtraction are ON during quick subtraction process, and gradual feed exists.

The schematic diagram of slow subtraction 2 shows the slow subtraction output when only the quick

Page 24

22

MI114 Manual

subtraction is ON during quick subtraction process, and without gradual feed.

The control procedure in the above diagram consists of 4 processes including quick subtraction, slow

subtraction, gradual feed allowance treatment and discharge.

(1) Quick subtraction -- When the control procedure starts, the quick subtraction output gives out a

signal, and the corresponding O1 relay is closed. When the weight is reduced to the quick

subtraction stop value A-b, the quick subtraction output signal is cancelled, the corresponding O1

relay is switched off.

(2) Slow subtraction -- After a period of delay time t1 (quick subtraction over delay), the slow

subtraction output gives out a signal, and the corresponding O2 relay is closed. When the weight is

reduced to the slow subtraction stop value A-C, the slow subtraction output signal is cancelled, the

corresponding O2 relay is switched off. If the parameter is set to both quick subtraction and slow

subtraction ON, the slow subtraction output gives out a signal since the beginning, and the

corresponding O2 relay is closed until the weight reaches up to the slow subtraction stop value A-C.

(3) Gradual feed -- If the parameter is set with gradual feed, the O2 relay corresponding to slow

subtraction will be closed for a period of t3, and switched off for a period of t4. Gradual feed is

carried out through such repeated cycle, until the weight reaches up to the allowance range of

batching value, i.e. the qualified area.

Page 25

23

MI114 Manual

(4) Discharge-- Discharge output sends out a signal, and the corresponding O3 relay is closed. After the

delay of t5, the discharge output signal is cancelled, and the corresponding O3 relay is switched off.

A complete control procedure is finished.

Note:

1. During the above process, if the slow subtraction lead value is bigger than the quick subtraction lead

value, i.e. C>b, the slow subtraction output won’t give out signal, and the corresponding O2 relay

maintains switched off. If no gradual feed is set for the parameters, the above gradual feed process

(3) is not included.

2. When the residual weight doesn’t reach to the batching value, the indicator stops subtraction, and

waits for feed signal. After receiving the feed signal, the indicator starts to feed material, and make

judgment to the weight during feeding process. When the batching value is obtained, material

feeding is stopped. At this moment, the weight can finish a subtraction cycle, then material

subtraction is continued. For example, if the batching value is 50Kg, when the remaining material in

the hopper is only 20kg, no subtraction will be performed until the hopper is added with material up

to 50Kg.

3. The discharge process in the subtracting scale can be used to remove the container loaded with

Page 26

24

MI114 Manual

material, just like a discharge process.

III. Mode 2(additive scale for two materials)

Note: A—batching value of material 1; b—lead value of material 1; P—batching value of material 2; d—lead

value of material 2; L—zero zone value.

t0—measurement delay;t1—feed over delay of material 1;t2—feed over delay of material 2;t3—gradual feed

output time; t4-interval time of gradual feed; t5-discharge over delay time.

The control procedure in the above diagram is composed of 5 processes including feed of material 1,

gradual feed out-of-allowance treatment of material 1, feed of material 2, gradual feed out-of-allowance

treatment of material 2 and discharge.

(1) Feed of material 1-- When the control procedure starts, the feed output of material 1 gives out a

signal, and the corresponding O1 relay is closed. When the weight is added to the feed stop value of

material 1 A-b, the feed output signal of material 1 is cancelled; the corresponding O1 relay is

switched off.

Page 27

25

MI114 Manual

(2) Gradual feed out-of-allowance treatment of material 1-- After the delay for a period of t1 (feed over

delay of material 1), if the parameter is set with gradual feed, the O2 relay corresponding to feed of

material 1 will be closed for a period of t3, and switched off for a period of t4. Gradual feed is

carried out through such repeated cycle, until the weight reaches up to the allowance range of

batching value of material 1, i.e. the qualified area.

(3) Feed of material 2-- The feed output of material 2 gives out a signal, and the corresponding O1 relay

is closed. When the weight is added to the feed stop value of material 2 P-d, the feed output signal of

material 2 is cancelled, the corresponding O1 relay is switched off

(4) Gradual feed out-of-allowance treatment of material 2 -- After the delay for a period of t2 (feed over

delay of material 2), if the parameter is set with gradual feed, the O2 relay corresponding to feed of

material 2 will be closed for a period of t3, and switched off for a period of t4. Gradual feed is

carried out through such repeated cycle, until the weight reaches up to the allowance range of

batching value of material 2, i.e. the qualified area.

(5) Discharge -- Discharge output sends out a signal, and the corresponding O3 relay is closed. After the

weight is less than the value L in zero zone, the discharged is considered completed, which

corresponds to point M in the figure. At this moment, after another delay of t5, the discharge output

signal is cancelled, and the corresponding O3 relay is switched off. A complete control procedure is

finished.

Note: If no gradual feed is set for parameters, the above gradual feed process (2), (4) is not included.

IV. Mode 3(catch weighing mode)

1. Self-check mode of catch weigher

Application examples:

Supposing a belt weigher is provided at the site, 3 kinds of cargoes of different weight 5Kg, 10Kg and

15Kg respectively need to be catch weighed through the belt user, which are transferred by the belt once every

10 seconds; the time for loading and unloading the weighing platform is about 2seconds, and the cargoes stay

on the platform for about 4 seconds, based on these conditions, we can make the following parameters setting

in 【SET--2】(2-digit decimal number is assumed to set during calibration). The cargoes less than 7.5kg are

sorted to channel 1, the cargoes between 7.5kg and12.5kg are sorted to channel 2, while those more than

12.5kg are sorted to channel 3.

Parameters

Indicator display

Parameters setting

Setting instructions

1

[CP *]

3

3 catch weighing modes are set hereof.

2

[Pt 0]

00

the times of control process (0~99,0 means

indefinite times)

Mode 3(catch weighing mode)

Page 28

26

MI114 Manual

Parameters

Indicator display

Parameters instructions

Remark

3

[FodE *]

0

Self-check mode: automatic catch weighing is

started when the weight is bigger than that in

zero zone

Upper and lower limit mode: real time upper

limit, intermediate limit and lower limit

relay output

4

[H******]

12.50

Set to the intermediate value of 2 cargoes to

facilitate catch weighing

5

[L******]

7.50

Set to the intermediate value of 2 cargoes to

facilitate catch weighing

6

[Lq*****]

4.00

A bigger value in zero zone to remove other

interference

7

[t0 **]

20

about 2 seconds for loading the weighing

platform

8

[t1 **]

40

about 4 seconds in staying on weighing

platform

9

[t2 **]

20

about 2 seconds waiting for the cargoes to be

unloaded from weighing platform

10 [t3 **]

20

send a channel signal with duration of 2

seconds

Please refer to the following diagram for control time sequence:

Schematic Diagram of Control Process 4

Page 29

27

MI114 Manual

Brief description of control process ( please understand in combination with the time sequence

diagram):

(1) The indicator is put into operation and judges if the weight is bigger than the value in zero zone. If so,

t0 delay is started, waiting for cargo to be loaded on the weighing platform.

(2) The time t0 is over, and starts to calculate the average weight of cargoes, with time duration of t1.

The value obtained from calculation serves as foundation for later catch weighing signals.

(3) The time t1 is over, t2 delay starts, waiting for the cargo to be unloaded from the weighing platform.

(4) The time t2 is over, and the catch weighing channel signal is sent, to make the cargo enter into the

corresponding channel. The time for sending channel signal is t3.

(5) The time t3 is over, and signal is sent, and the indicator judges once again if the weight returns to

zero zone. The next cycle can only begin when the weight stays within zero zone.

2. External mode of catch weigher

Application example:

It is assumed that a high speed catch weigher is used at site: the industrial control PLC together with this

indicator performs quick catch weighing to the cargo. PLC controls the transportation of cargo to the weighing

platform, and gives out a trigger signal to the indicator when it reaches there to make it calculate the weight.

The weight range of the qualified product of user is between 9.90Kg~10.10Kg. Channel signal is sent as per

weight, to make the PLC control and send to different channels. 1 cycle takes approximately 3-5 seconds.

The indicator and PLC should coordinate well. The parameters can be set in【SET--2】according to the

following table (2-digit decimal is assumed during calibration).

Param

eter

Indicator display

Parameter setting

Setting instruction

1

[CP *]

3

3 is set, catch weighing mode

2

[Pt 0]

00

Times of control procedure (0~99,0 for

indefinite times)

3

[FodE *]

1

External control mode: only when the

external control signal is triggered will the

indicator start the catch weighing

4

[H******]

10.10

Qualified upper limit

5

[L******]

9.90

Qualified lower limit

6

[Lq*****]

5.00

Zero area is big, other interference can be

removed

7

[t0 **]

02

The cargo is on the weighing platform when

receiving the trigger signal, no long delay is

required.

8

[t1 **]

20

2 seconds are sufficiently enough to calculate

the weight.

9

[t2 **]

00

After completing the calculation, PLC can be

notified at once to remove the cargo. No delay

is required.

10 [t3 **]

10

The channel signal with duration of 1 second

is sent to ensure the receipt by PLC.

Page 30

28

MI114 Manual

Please refer to following diagram for control of time sequence

Schematic Diagram of Control Process 5

Brief description of control process(In combination with the time sequence diagram)

(1) The indicators starts to run, waiting for trigger signal;

(2) The trigger signal is received, t0 delay occurs, waiting for cargo to be loaded stable.

(3) The time t0 is over; the indicator starts to calculate the average weight of cargo, with time duration

of t1. The value obtained from calculation serves as foundation for later catch weighing signal

(4) The time t1 is over, waiting for activation of t2.

(5) The time t2 is over, the channel signal for catch weighing is sent to make the cargo enter into

corresponding channels. The time for sending channel signal is t3.

(6) The time t3 is over, and the signal is sent and the indicator judges once again if the weight returns to

zero zone. The next cycle can’t be started only when the weight stays within zero zone

3. Upper and lower limit mode

After setting the upper and lower limit value, the instruction under operation will send real time the signal

at the output end according to the actual weight.

Page 31

29

MI114 Manual

Annex 1 Error Message Prompt

Err 01

Fail to meet tare requirements

Err 02

Fail to meet zero setting requirement

Err 03

The weight upon startup exceeds zero setting range

Err 04

Memory storage is full

Err 05

The input full value is 0 during calibration

Err 06

The calibrated loaded weight is too small

Err 07

The calibration switch is invalid

Err 08

Wrong input time or date

Err P

The baud rate setting does not meet requirements during printing

OL

The weight exceeds the full value

Page 32

30

MI114 Manual

Annex 2 Large Screen Data Waveform Diagram and Format

1. The large screen signal is the 20mA constant current loop signal, with binary code serial output, and

baud rate of 600. Every frame of data has 11 bits, including 1 start bit (0), 8 data bits (low-order bit in

front), 1 flag bit, and 1 stop bit (1).

2. A set of data is set every 100ms. Every set of data includes 3 frames of data, with meaning as follows:

Large Screen Data Frame Waveform Diagram

Page 33

31

MI114 Manual

The first frame data: flag bit is 0;

X:d0, d1, d2 are position of decimal point(0-3);

Y:d3-weight signal(1-negative;0-positive);

d4-gross/net weight(1-net weight;0-gross weight);

G17, G16:binary data;

The second frame data: flag bit is 0;

G15 ~ G8:binary data;

The third frame data: flag bit is 1;

G7 ~ G0:binary data;

G0 ~ G17: 18-bit binary code of weight in order from low to high

Page 34

32

MI114 Manual

Annex 3 Serial Communication-Data Format of Command

Response Mode

AD: indicator address(for example: A(ASCII code is41))

XH: check high four-bit

; XL: check low four-

bit. Note:

(1) The address is 1~26 when setting the indicator, and the corresponding address during communication

is A~Z;

(2) The command A~H is also sent in ASCII format.

Please refer to the following table in respect of the meaning of various letter command and

their communication format:

Command

Meaning

Format

Example

A

Send by PC

Handshake

02 AD 41 XH XL 03

02 41 41 30 30 03

Send by

indicator

Handshake

02 AD 61 XH XL 03

02 41 61 32 30 03

B

Send by PC

Read gross weight

02 AD 42 XH XL 03

02 41 42 30 33 03

Send by

indicator

Send gross weight

02 AD 62 ** ** ** ** ** **

** ** XH XL 03

02 41 62 2B 30 30 31 2E 30 30

30 32 37 03(1.000)

C

Send by PC

Ret net weight

02 AD 43 XH XL 03

02 41 43 30 32 03

Send by

indicator

Send net weight

02 AD 63 ** ** ** ** ** **

** ** XH XL 03

02 41 63 2B 30 30 30 2E 30 30

30 32 37 03(0.000)

D

Send by PC

Read tare

02 AD 44 XH XL 03

02 41 44 30 35 03

Send by

indicator

Send tare

02 AD 64 ** ** ** ** ** **

** ** XH XL 03

02 41 64 2B 30 30 31 2E 30 30

30 32 31 03(1.000)

E

Send by PC

Tare

02 AD 45 XH XL 03

02 41 45 30 34 03

Send by

indicator

Tare

02 AD 65 XH XL 03

02 41 65 32 34 03

F

Send by PC

Zero setting

02 AD 46 XH XL 03

02 41 46 30 37 03

Send by

indicator

Zero setting

Zero setting successful:

02 AD 66 XH XL 03

Zero setting conditions not

satisfied:

02 AD 69 XH XL 03

Zero setting successful:

02 41 66 32 37 03

Zero setting conditions not

satisfied:

02 41 69 32 38 03

G

Send by PC

Startup

02 AD 47 XH XL 03

02 41 47 30 36 03

Send by

indicator

Startup

02 AD 67 XH XL 03

02 41 67 32 36 03

H

Send by PC

Stop

02 AD 48 XH XL 03

02 41 48 30 39 03

Send by

indicator

Stop

02 AD 68 XH XL 03

02 41 68 32 39 03

Loading...

Loading...