MKS Spectra 138A Instruction Manual

Instruction Manual

MKS Spectra Type 138A

Portable Analytical System

LP101017 Rev 1.02

April 2002

As part of our continuous product improvement policy, we are always pleased to

receive your comments and suggestions about how we should develop our product

range. We believe that the manual is an important part of the product and would

welcome your feedback particularly relating to any omissions or inaccuracies you

may discover.

You can send your comments to:-

MKS Instruments, Spectra Products

Cowley Way

Crewe

Cheshire

CW1 6AG

U.K.

+44 1270 250150 Tel.

+44 1270 251939 Fax.

In North America you can send your comments to:-

MKS Instruments Spectra Products.

380 Woodview Ave.

Morgan Hill

CA 95037

USA

(408) 778-6060 Office

(408) 776-8575 Fax

1-800-VAC CHECK

http://www.spectra-rga.com

Windows and Windows 95 are trademarks of the Microsoft Corporation.

Swagelok is a registered trademark of the Crawford Fitting Company and is fully recognised.

Baratron® is a registered trademark of MKS Instruments, Inc., Andover, MA.

Cajon®, VCR® and VCO® are registered trademarks of Cajon Company, Macedonia, OH.

Channeltron is a registered trademark of the Gallilao Corp.

Viton is a registered trademark of

Conflat is registered trademark of Varian and associates

All other brand or product names are trademarks or registered trademarks of their respective companies.

Copyright © 1999 MKS Instruments Spectra Products.

All rights reserved. No part of this work may be reproduced or transmitted in any form or by any

means, electronic or mechanical, including photocopying and recording, or by any information storage

or retrieval system, except as may be expressly permitted in writing by MKS Instruments Spectra

Products.

EC DECLARATION OF CONFORMITY

Spectra SensorTech Ltd.

Cowley Way

Crewe

Cheshire

CW1 6AG

United Kingdom

DECLARES THAT THE FOLLOWING PRODUCTS:

LM62, LM10 VACSCAN 100

LM63, LM10, LM4 VACSCAN PLUS 100, 200

LM61, LM10, LM4, LM9 SATELLITE 100, 200, 300

LM56 MICROVISION

LM70, LM76 MICROVISION PLUS

LM77 VISION 1000P

LM79 VISION 1000I

LM89 VISION 1000B

LM90 VISION 1000 C / E

LM78 VAC CHECK

LM80 MINILAB

ARE IN CONFORMITY WITH THE FOLLOWING EUROPEAN

DIRECTIVES:

89/336/EEC ELECTROMAGNETIC COMPATIBILITY DIRECTIVE

73/23/EEC LOW VOLTAGE DIRECTIVE AS AMMENDED 93/68 EEC

THE APPLICABLE STANDARDS ARE:

EN 61326:1998 ELECTRICAL EQUIPMENT FOR MEASUREMENT,

CONTROL & LABORATORY USE

EN 61010-1:1993 SAFETY REQUIREMENTS FOR ELECTRICAL

EQUIPMENT FOR MEASUREMENT,

CONTROL & LABORATRY USE.

SIGNED:

T.R.ROBINSON

EUROPEAN OPERATIONS MANAGER

DATE: 1

ST

JULY 2001

Additional Installation Maintenance and Operating Instructions

In order to comply with European regulations, the following procedures must be followed :-

A) INSTALLATION

1) The installation procedures given in the operating and technical manuals must be

followed, in addition to these instructions.

2) The mains power cable must conform to local regulations and must have a protective

earth (PE) conductor securely connected to the power plug protective earth contact.

3) The short earthing braid supplied with some products must be fitted between the

terminal on the RF head and one of the CF40 vacuum flange bolts.

4) Only cables supplied with the equipment may be used for interconnections. If extension

cables are required to obtain a greater separation between control unit and RF head, or if

longer serial communications cables are required, they must be supplied by Spectra

SensorTech Ltd.

5) Cables attached to all other ancillary signal and control ports must have a length of less

than 3 metres. If greater length is required, Spectra SensorTech Ltd must be contacted

for technical guidance on possible EMC and safety issues.

6) The vacuum system on which the analyser/RF head is mounted must be earthed, to a

protective earth, preferably to the same protective earth as the control unit.

B) OPERATION

1) The equipment is not authorised for use as a critical component in a life support or safety

critical system without the express written approval of Spectra SensorTech Ltd.

2) All instructions given in the operating manual must be followed.

3) Adjustments are strictly limited to those accessible from the control panel and computer

keyboard and only when running software supplied by Spectra SensorTech Ltd.

C) MAINTENANCE

WARNING-DANGEROUS VOLTAGES EXIST INSIDE THE

EQUIPMENT

1) Maintenance functions must only be carried out by competent persons.

2) During the warranty period, faulty equipment must be returned to Spectra SensorTech

3) There are no user replaceable parts in the electronic equipment. Certain components are

4) Equipment enclosures embody certain special fastening and bonding devices that affect

Ltd., unless special arrangements are made.

EMC and safety critical and must not be substituted. Replacement parts are available

from Spectra SensorTech Ltd.

EMC and safety performance. These must be correctly re-fitted after servicing.

WARRANTY

Type 138A Portable Analytical System

MKS Instruments Spectra Products (MKS Spectra) warrants that the

equipment described in the face of this warranty (the “equipment”)

manufactured by MKS Spectra shall be free from defects in materials and

workmanship for a period of one year from shipment. For the period

commencing with the date of shipment of this equipment and ending one

year later, MKS Spectra will, at its option, either repair or replace any part

which is defective in materials or workmanship without charge to the

purchaser. The foregoing shall constitute the exclusive and sole remedy of

the purchaser for any breach by MKS spectra of this warranty.

The purchaser, before returning any equipment covered by this warranty,

which is asserted to be defective by the purchaser, shall make specific

written arrangements with respect to the responsibility for shipping and

handling the equipment and any other incidental charges with MKS

Spectra UK Global Product Support department.

This warranty does not apply to any equipment that has not been used in

accordance with the specifications recommended by MKS Spectra for the

proper and normal use of the equipment. MKS Spectra will not be liable

under any circumstances for consequential or incidental damages in

connection with or arising out of the sale performance or use of the

equipment covered by this warranty.

INDEMNITY

Where the customer uses the goods or the services supplied by MKS

Instruments Spectra Products either in (MKS Spectra) the

manufacture, supply or distribution of any other goods; or in the

provision of a service; (including without limitation, where the

customer uses the goods or the services supplied by MKS Spectra in

the manufacture and distribution of chemicals or as part of a

manufacturing facility for chemicals) then the customer shall

indemnify and hold harmless MKS Spectra from and against all loss,

damages, costs and expenses awarded against or incurred by MKS

Spectra in respect of such use by the customer or arising out of the

manufacture, supply or distribution of those goods or the provision of

that service (or without limitation arising out of the manufacture and

distribution of those chemicals or the use of the goods or services as

part of that manufacturing facility).

Document Control

Revision 1.00

Date 20 Feb 2001

Change New document based on MKS Instruments UK document

1380004D

Contents

Errata and addenda...............................................................i

Section 1. Safety ..........................................................3

1.1. Symbols used in this manual .................................................................. 3

1.2. Warning symbols.................................................................................... 4

1.2.1. General.........................................................................................4

1.2.2. Other symbols.............................................................................4

1.3. Safety procedures and precautions ......................................................... 5

Section 2. Overview...............................................10

Section 3. Installation........................................... 15

3.1. Environmental Requirements ............................................................... 15

3.2. Electrical Connections.......................................................................... 16

3.3. Testing.................................................................................................. 16

Section 4. Setup and operation.......................................... 19

4.1. Setup..................................................................................................... 19

4.2. Operation.............................................................................................. 19

4.3. Switching on......................................................................................... 20

4.4. Cold Cathode Gauge............................................................................. 20

4.5. Switching Off ....................................................................................... 21

4.6. Bakeout Heater ..................................................................................... 21

PAS Trolley Manual

LP101017 Rev 1.02 Page i

4.7. Inlet System...........................................................................................22

4.8. Operation via flexible connection .........................................................22

4.9. Operation with remote mounted analyser..............................................23

4.10. Operation with atmospheric inlet ........................................................24

Section 5. Troubleshooting ............................27

Section 6. Troubleshooting ............................31

6.1. General..................................................................................................31

6.2. Primary Pump........................................................................................31

6.3. Turbo Pump...........................................................................................31

6.4. Cold Cathode Gauge .............................................................................31

6.5. RGA Head............................................................................................. 32

6.6. Service/Repair.......................................................................................32

Appendix 1. Related documents..................35

Appendix 2. Returns form..................................37

PAS Trolley Manual

LP101017 Rev 1.02 Page ii

Errata and addenda

This page is deliberately left blank.

PAS Trolley Manual

LP101017 Rev 1.02 Page i

This page is deliberately left blank.

PAS Trolley Manual

LP101017 Rev 1.02 Page ii

Section 1.

Safety

WARNING

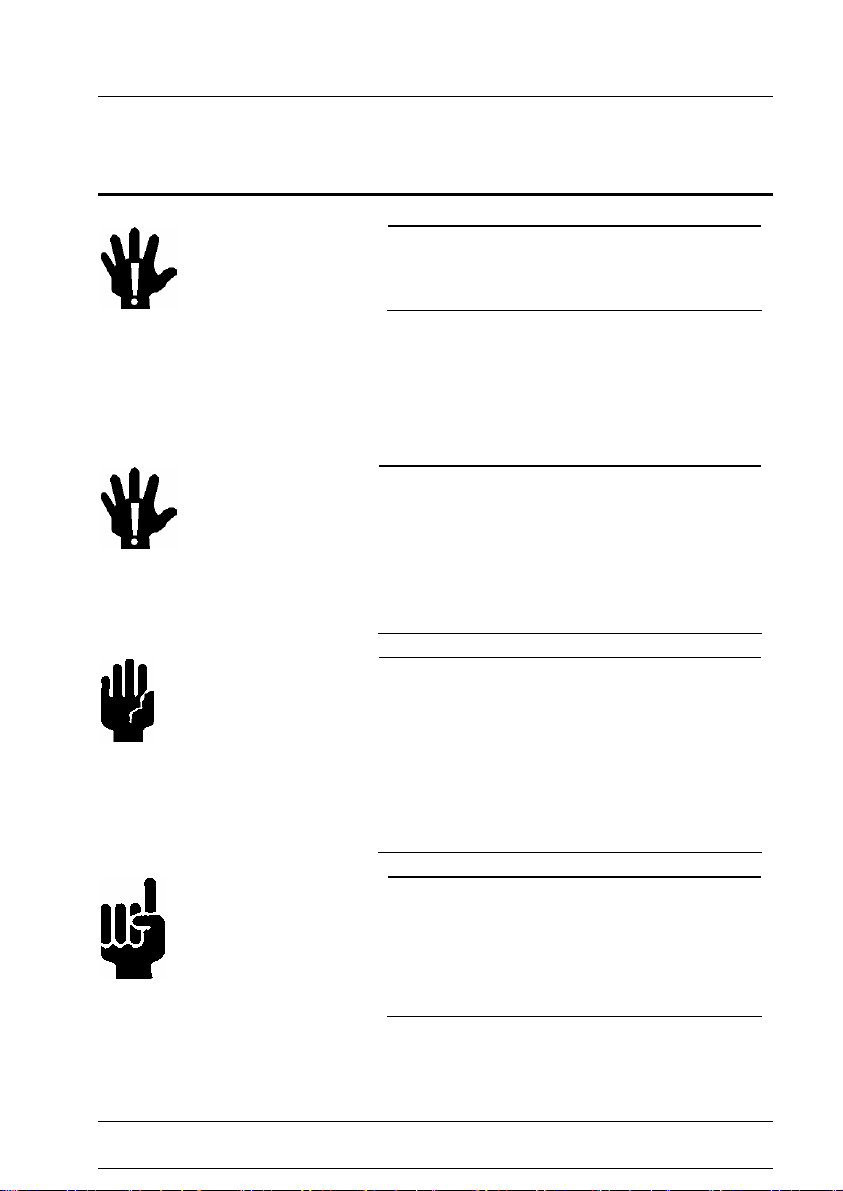

1.1. Symbols used in this manual

Definitions of WARNING, CAUTION and NOTE messages used in this manual.

WARNING

CAUTION

NOTE

Please read this section of the

manual. It contains important

safety information.

The WARNING sign denotes a

hazard to personnel.

WARNING boxes are used where

failure to observe the instructions

could result in personal injury or

death.

The CAUTION sign denotes a

hazard to equipment.

CAUTION boxes are used where

failure to observe the instructions

could result in damage to the

equipment or associated

equipment.

The NOTE sign denotes important

information. It calls attention to a

procedure, practice, condition, or

the like, which is essential to

highlight.

PAS Trolley Manual

LP101017 Rev 1.02 Page 3

CAUTION and WARNING instructions MUST be observed. MKS Spectra accepts

no liability for any injury or damage resulting from a failure to observe CAUTION

or WARNING instructions.

1.2. Warning symbols

1.2.1.General

Various warning labels and symbols may be attached to the instrument their

general use is explained below.

The Exclamation Mark (ISO 3864, No.B.3.1) label.

Caution refer to the accompanying documents.

General caution.

Refer to the manual for detailed instructions.

The Electric Shock (ISO 3864, No.B.3.6) symbol.

Caution, risk of electric shock.

This is generally used on the instruments to warn of the

presence of hazardous voltages.

Hot Surface (IEC 417, No.5041) symbol.

Caution risk of burns injury.

Generally used to indicate that the surface may become very

hot during normal operation.

1.2.2. Other symbols

|

On (Supply)

PAS Trolley Manual

LP101017 Rev 1.02 Page 4

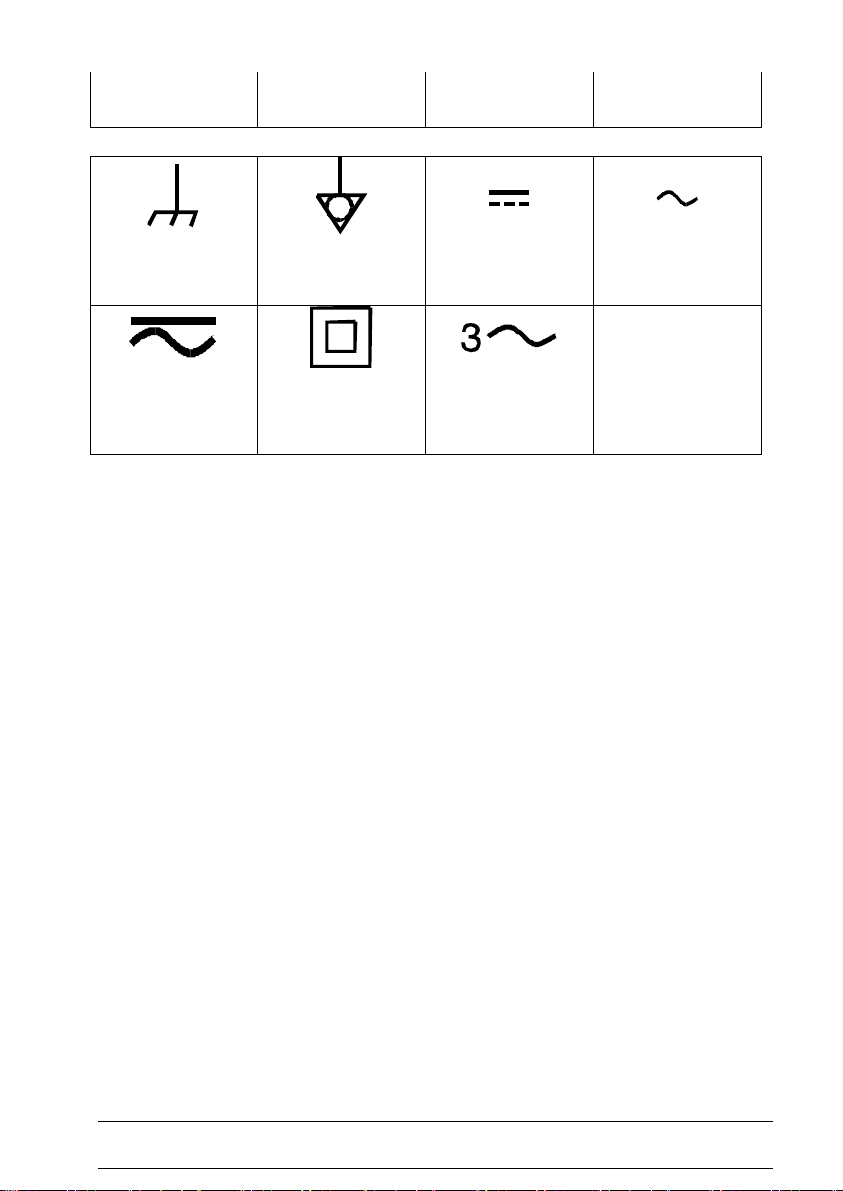

Off (Supply) Earth (ground) Protective earth

IEC 417,

No.5007

IEC 417, No.

5017

IEC 417,

No.5017

(ground)

IEC417, No.5019

Frame or chassis

IEC 417,

No.5020

Both direct and

alternating current

IEC 417, No.5033-a

Equipotentiality

IEC 417,

No.5021

Class II equipment

IEC 417, No. 5172a

Direct current

IEC417, No.5031

Three phase

alternating current

IEC 617-2

No.020206

Alternating

current

IEC417, No.5032

1.3. Safety procedures and precautions

Observe the following general safety precautions during all phases of

operation of this instrument. Failure to comply with these precautions or with

specific warnings elsewhere in this manual violates safety standards of

intended use of the instrument and may impair the protection provided by the

equipment. MKS Instruments assumes no liability for the customer’s failure

to comply with these requirements.

SERVICE BY QUALIFIED PERSONNEL ONLY

Operating personnel must not attempt component replacement and

internal adjustments. Any service must be performed by qualified

service personnel only.

GROUNDING THE PRODUCT

This product is grounded through the grounding conductor of the

power cord. To avoid electrical shock, plug the power cord into a

properly wired receptacle before connecting it to the product input or

output terminals. A protective ground connection by way of the

grounding conductor in the power cord is essential for safe operation.

DANGER ARISING FROM LOSS OF GROUND

PAS Trolley Manual

LP101017 Rev 1.02 Page 5

Upon loss of the protective-ground connection, all accessible

conductive parts (including knobs and controls that may appear to be

insulating) can render an electrical shock.

GROUND AND USE PROPER ELECTRICAL FITTINGS

Dangerous voltages are contained within this instrument. All

electrical fittings and cables must be of the type specified, and in

good condition. All electrical fittings must be properly connected

and grounded.

USE THE PROPER POWER CORD

Use only a power cord that is in good condition and which meets the

input power requirements specified in the manual.

Use only a detachable cord set with conductors that have a crosssectional area equal to or greater than 1.5 mm2. The power cable

should be approved by a qualified agency such as VDE, Semko, or

SEV.

USE THE PROPER POWER SOURCE

This product is intended to operate from a power source that does not

apply more voltage between the supply conductors, or between either

of the supply conductors and ground, than that specified in the

manual.

USE THE PROPER FUSE

Use only a fuse of the correct type, voltage rating, and current rating,

as specified for your product.

KEEP AWAY FROM LIVE CIRCUITS

Do not replace components with power cable connected. Under

certain conditions, dangerous voltages may exist even with the power

cable removed. To avoid injuries, always disconnect power and

discharge circuits before touching them.

USE CAUTION WHEN OPERATING WITH HAZARDOUS MATERIALS

If hazardous materials are used, observe the proper safety

precautions, completely purge the instrument when necessary, and

ensure that the material used is compatible with the materials in this

product, including any sealing materials.

PAS Trolley Manual

LP101017 Rev 1.02 Page 6

DO NOT OPERATE IN AN EXPLOSIVE ENVIRONMENT

To avoid explosion, do not operate this product in an explosive

environment unless it has been specifically certified for such

operation.

USE PROPER FITTINGS AND TIGHTENING PROCEDURES

All instrument fittings must be consistent with instrument

specifications, and compatible with the intended use of the

instrument. Assemble and tighten fittings according to

manufacturer’s directions.

CHECK FOR LEAK-TIGHT FITTINGS

Carefully check all vacuum component connections to the instrument

to ensure leak-tight installation.

OPERATE AT SAFE INLET PRESSURES

Never operate at pressures higher than the rated maximum pressure

(refer to the product specifications for the maximum allowable

pressure).

INSTALL A SUITABLE BURST DISC

When operating from a pressurized gas source, install a suitable burst

disc in the vacuum system to prevent system explosion should the

system pressure rise.

KEEP THE UNIT FREE OF CONTAMINANTS

Do not allow contaminants to enter the unit before or during use.

Contamination such as dust, dirt, lint, glass chips, and metal chips

may permanently damage the unit or contaminate the process.

ALLOW THE UNIT TO WARM UP

If the unit is used to control dangerous gases, they should not be

applied before the unit has completely warmed up. Use a positive

shutoff valve to ensure that no erroneous flow can occur during

warm up.

AVOID EXPLOSIVE GAS MIXTURES

PAS Trolley Manual

LP101017 Rev 1.02 Page 7

Loading...

Loading...