MKS HPS Service Manual

tm

HPS

Two-Stage Valve

Service Manual

651 Lowell Street

Methuen, MA 01844

Main Telephone: (800) 227-8766 p/n 1061054

www.mksinst.com

Rev. 001

Copyright © 2015 by MKS Instruments, Inc.

All rights reserved. No part of this work may be reproduced or transmitted in any form or by any means,

electronic or mechanical, including photocopying and recording, or by any information storage or retrieval

system, except as may be expressly permitted in writing by MKS Instruments, Inc.

Printed in the United States of America

DeviceNet™ is a trademark of Open DeviceNet Vendor Association, Inc., Coral Springs, FL.

®

SEMI

is a registered trademark of Semiconductor Equipment and Materials International, Mountain View,

CA.

®

Swagelok

and VCR® are registered trademark of Swagelok Marketing Co., Solon, OH.

Table of Contents

Valve Safety Information .................................................................................................................................. 1

Symbols Used in This Instruction Ma nual .................................................................................................................... 1

Symbols Found on the Unit ........................................................................................................................................... 1

Safety Procedures and Precautions ................................................................................................................................ 1

Sicherheitshinweise für das Ventil.................................................................................................................... 3

In dieser Betriebsanleitung vorkommende Symbole ..................................................................................................... 3

Erklärung der am Gerät angebrachten Symbole ............................................................................................................ 3

Sicherheitsvorschrift en und Vorsichtsmaßnahmen ....................................................................................................... 3

Informations de sécurité relatives au manomètre ........................................................................................... 5

Symboles utilisés dans ce manuel d’utilisation ............................................................................................................. 5

Symboles figurant sur l’unité ........................................................................................................................................ 5

Mesures de sécurité et précautions ................................................................................................................................ 5

Medidas de seguridad del manómetro ............................................................................................................. 7

Símbolos usados en este manual de instrucciones ......................................................................................................... 7

Símbolos hallados en la unidad ..................................................................................................................................... 7

Procedimientos y precauciones de seguridad ................................................................................................................ 7

How This Manual is Organized ..................................................................................................................................... 9

Customer Support .......................................................................................................................................................... 9

Chapter One: General Information .............................................................................................................. 10

Introduction ................................................................................................................................................................. 10

Chapter Two: Servicing an HPS Products Two-Stage Valve ..................................................................... 11

Disassembly of the main valve .................................................................................................................................... 11

Disassembly and Inspection of Internal Assembly ...................................................................................................... 12

Disassembly of the bypa ss valve ................................................................................................................................. 14

Disassembly and Inspection of the Bypass Valve ....................................................................................................... 15

Assembly of Main and Bypass Valves ........................................................................................................................ 15

List of Figures

No table of figures entries found.

List of Tables

Table 1: Definition of Symbols Found on the Unit............................................................................................. 1

Tabelle 2: Bedeutung der am Gerät angebrachten Symbole ............................................................................... 3

Tableau 3: Définition des symboles sur l’unité ................................

Tabla 4: Definición de los símbolos hallados en la unidad ................................................................................. 7

Table 5: Definitions .......................................................................................... Error! Bookmark not defined.

.................................................................. 5

iii

Valve Safety Information

The WARNING sign denotes a hazard. It calls attention to a procedure, practice,

condition, or

in injury to personnel.

The CAUTION sign denotes a hazard. It calls attention to an operating procedure,

practice, or the like, which, if not correctly performed or adhered to, could result in

damage to or destruction of all or part of the product.

The NOTE sign denotes important information. It calls attention to a procedure, practice,

condit

|

IEC 417, No. 5007

IEC 417, No. 5008

IEC 417, No. 5017

IEC 417, No. 5019

IEC 417, No. 5020

IEC 417, No. 5021

IEC 417, No. 5031

IEC 417, No. 5032

IEC 417, No. 5033-a

IEC 617-2, No. 020206

ISO 3864, No. B.3.1

ISO 3864, No. B.3.6

Valve Safety Information

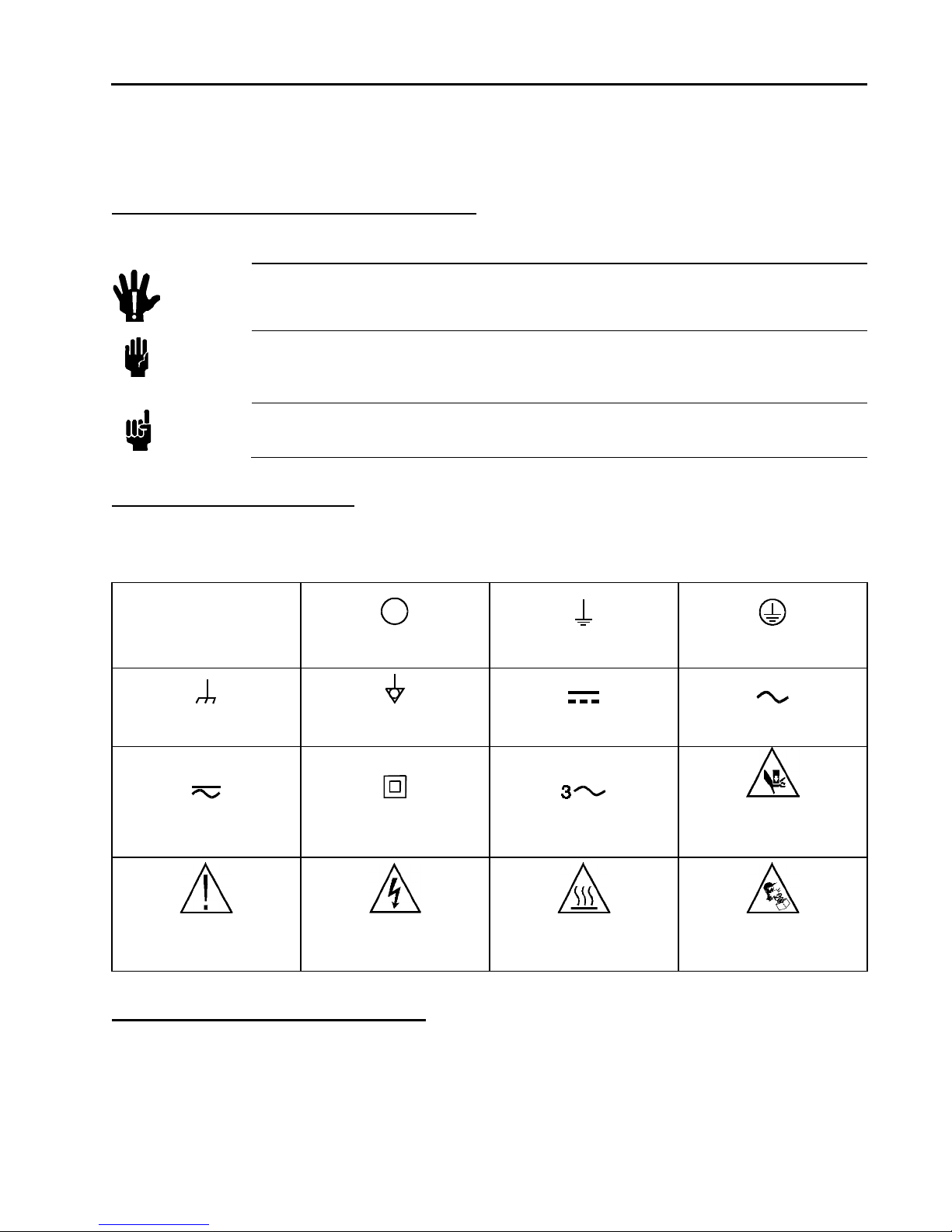

Symbols Used in This Instruction Manual

Definitions of WARNING, CAUTION, and NOTE messages used throughout the manual are:

Warning

the like, which, if not correctly performed or adhered to, could result

Caution

Note

ion, or the like, which is essential to highlight.

Symbols Found on the Unit

The following table describes symbols that may be found on the unit.

Table 1: Definition of Symbols Found on the Unit

On (Supply)

Frame or Chassis

Both Direct and Alternating

Current

Caution (refer to

accompanying documents)

Off (Supply)

Equipotentiality

Class II Equipment

IEC 417, No. 5172-a

Caution, Risk of Electric

Shock

Safety Procedures and Precautions

Earth (ground)

Direct Current

Three Phase

Alternating Current

Caution, Hot Surface

IEC 417, No. 5041

Protective Earth (ground)

Alternating Current

Caution, Hand Crush

ISO 3864

Caution, Spring Loaded

ISO 3864

Observe the following general safety precautions during all phases of operation of this instrument.

Failure to comply with these precaution s or with sp eci fic warnin gs else wh ere in this manu a l viola tes

safety standards of intended use of the instrument and may impair the protection provided by the

equipment. MKS Instruments, Inc. assumes no liability for the customer ’s fail ure to comp ly with thes e

requirements.

1

Valve Safety Information

Moving parts in the valve create a risk of personal injury until the valve is securely

incorporated into a system. To avoid injury, keep all body

valve opening.

1.

2.

Warning

parts away from any

Do not insert objects into openings where contact with moving parts is

possible.

Isolate the valve from any electrical or pneumatic power supply before

handling the valve.

DO NOT SUBSTITUTE PARTS OR MODIFY VALVE

Do not install substitute p arts or perform any unaut horized mod ification to the valve. Return the valve to an MK S

Calibration and Service Center for service and repair to ensure that all safety features are maintained.

SERVICE BY QUALIFIED PERSONNEL ONLY

Operating personnel must not attempt component replacement and internal adjustments. Qualified service personnel

must perform any service only.

USE CAUTION WHEN OPERATING WITH HAZARDOUS MATERIALS

If hazardous materials are used, observe the proper safety precautions, completely purge the valve when necessary, and

ensure that the material used is compatible with the wetted materials in this product, including any sealing materials.

PURGE THE VALVE

After installing the unit, or befor e removing it from a system, purge the unit completely with a clean, dry gas to eliminate

all traces of the previously used flow material.

USE PROPER PROCEDURES WHEN PURGING

This valve must be purged under a ventilation hood and gloves must be worn for protection.

DO NOT OPERATE IN AN EXPLOSIVE ENVIRONMENT

To avoid explosion, do not operate this product in an explosive environment unless it has been specifically certified for

such operation.

USE PROPER FITTINGS AND TIGHTENING PROCEDURES

All valve fittings must be consistent with valve specifications and compatible with the intended use of the valve.

Assemble and tighten fittings ac c ording to manufacturer’s directions.

CHECK FOR LEAK-TIGHT FITTINGS

Carefully check all vacuum component connections to ensure leak-tight installation.

OPERATE AT SAFE INLET PRESSURES

Never operate the valve at pressures higher than the rated maximum pressure (refer to the product specifications for the

maximum allowable pressure).

INSTALL A SUITABLE BURST DISC

When operating from a pressurized gas source, install a suitable burst disc in the vacuum system to pr e vent system

explosion should the sys t em pressure rise.

KEEP THE UNIT FREE OF CONTAMINANTS

Do not allow contaminants to enter the unit before or during use. Contamina tion such as dust, dirt, lint, glass chips, and

metal chips may permanently damage the unit or contaminate the process.

KEEP AWAY FROM VALVE OPENING

Keep fingers, other body parts, and other materials away from the valve opening when the valve is in operation.

2

Sicherheitshinweise für das Ventil

Das Symbol WARNUNG! weist auf eine Gefahr für das B

macht auf einen Arbeitsablauf, ei n e Arbeitsweise, einen Zustand oder eine

sonstige Gegebenheit aufmerksam, deren unsachgemäße Ausführung bzw.

ungenügende Berücksichtigung zu Verletzungen führen kann

Das Symbol VORSICHT! weist auf eine Gefahr für das Gerät hin. Es macht auf

einen Bedienungsablauf, eine Arbeitsweise oder eine sonstige Gegebenheit

aufmerksam, deren unsachgemäße Ausführung bzw. ungenügende

Berücksichtigung zu einer Besch

Teilen des Gerätes führen kann

Das Symbol HINWEIS macht auf wichtige Informationen bezüglich eines

Arbeitsablaufs, einer Arbeitsweise, eines Zustands oder einer so

aufmerksam.

|

IEC 417, No.5007

IEC 417, No.5008

IEC 417, No.5017

IEC 417, No.5019

IEC 417, No.5020

IEC 417, No.5021

IEC 417, No.5031

IEC 417, No.5032

IEC 417, No.5172-a

IEC 617-2, No.020206

ISO 3864

Sicherheitshinweise für das Ventil

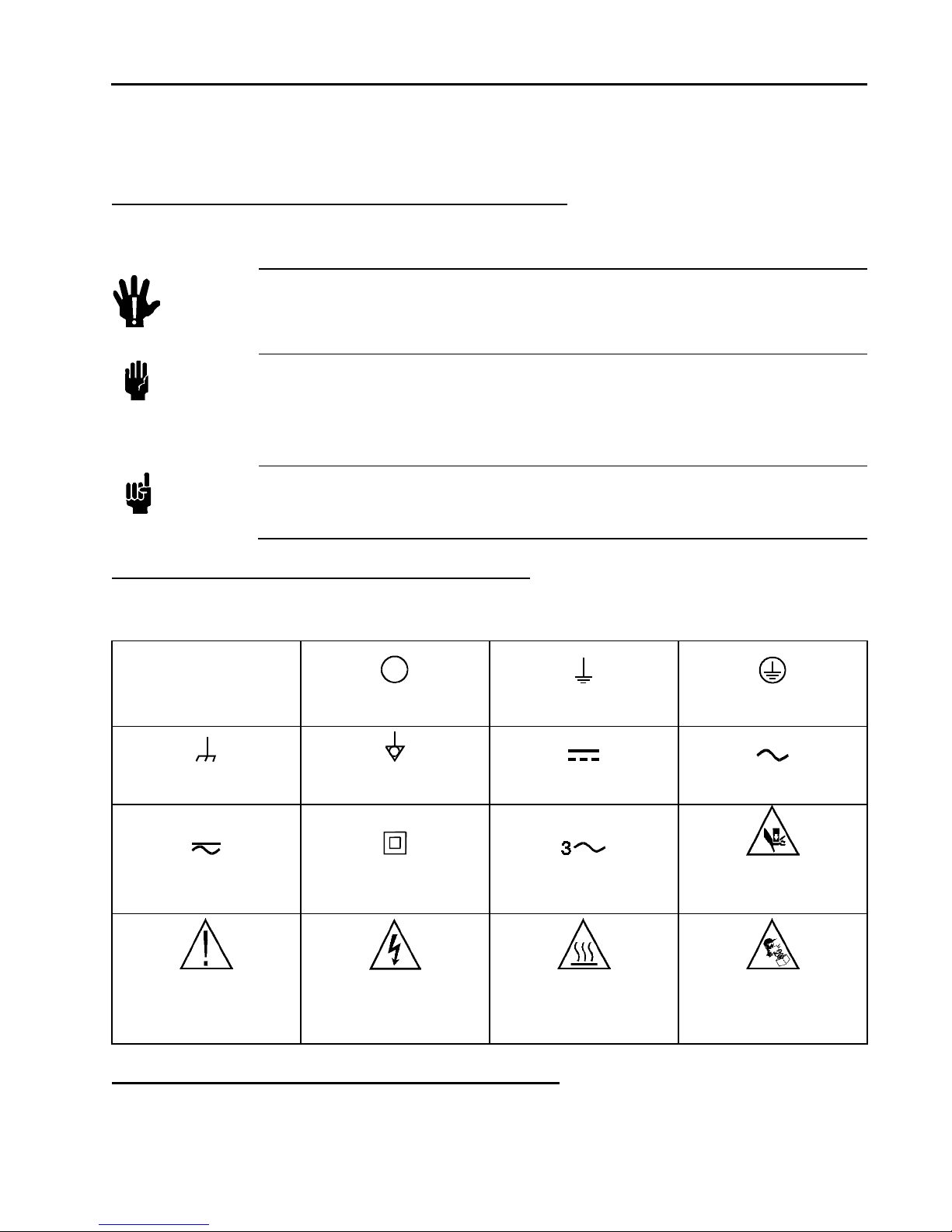

In dieser Betriebsanleitung vorkommende Symbole

Bedeutung der mit WARNUNG!, VORSICHT! und HINWEIS gekennzeichneten Absätze in dieser

Betriebsanleitung.

Warnung!

Vorsicht!

edienpersonal hin. Es

.

ädigung oder Zerstörung des Gerätes oder von

.

Hinweis

nstige Gegebenheit

Erklärung der am Gerät angebrachten Symbole

Nachstehender Tabelle sind die Bedeutungen der Symbole zu entnehmen, die am Gerät angebracht sein können.

Tabelle 2: Bedeutung der am Gerät angebrachten Symbole

Ein (Energie)

Aus (Energie)

Erdanschluss

Schutzleiteranschluss

Masseanschluss

Gleich- oder Wechselstrom

IEC 417, No.5033-a

Warnung vor einer

Gefahrenstelle (Achtung,

Dokumentation beachten)

ISO 3864, No.B.3.1

Aquipotentialanschluss

Durchgängige doppelte

oder verstärkte Isolierung

Warnung vor gefährlicher

elektrischer Spannung

ISO 3864, No.B.3.6

Gleichstrom

Dreileiter-Wechselstrom

(Drehstrom)

Höhere Temperatur an

leicht zugänglichen Teilen

IEC 417, No.5041

Sicherheitsvorschriften und Vorsichtsmaßnahmen

Folgende allgemeine Sicherheitsvorschriften sind während allen Betriebsphasen dieses Gerätes zu

befolgen. Eine Missachtung der Sicherheitsvorschriften und sonstiger Warnhinweise in dieser

3

Wechselstrom

Vorsicht: Quetschgefahr für

die Hand

Vorsicht: Federspannung

ISO 3864

Loading...

Loading...