MKS Granville-Phillips 358 Instruction Manual

Series 358

Granville-Phillips® Series 358 Micro-Ion®

Vacuum Gauge Controller

Instruction Manual

Instruction manual part number 358013

Revision B - November 2014

Series 358

Granville-Phillips® Series 358 Micro-Ion®

Vacuum Gauge Controller

This Instruction Manual is for use with all Granville-Phillips

Series 358 Micro-Ion Vacuum Gauge Controllers.

A list of applicable catalog numbers is provided on the

following page.

For Customer Service or Technical Support 24 hours per day,

7 days per week, every day of the year including holidays:

Phone: +1-800-227-8766 or +1-303-652-4691

MKS, Granville-Phillips Division

6450 Dry Creek Parkway

Longmont, CO 80503 USA

Phone: 1-303-652-4691 or 1-800-776-6543

FAX: 1-303-652-2844

Email: gp-csr@mksinst.com

Corporate Office

MKS Instruments, Inc.

2 Tech Drive, Suite 201

Andover, MA 01810 USA

Phone: 1-978-645-5500

www.mksinst.com

Instruction Manual

© 2014 MKS Instruments, Inc. All rights reserved. Granville-Phillips®, Micro-Ion®, and

Convectron

registered trademarks are the properties of their respective owners.

®

are registered trademarks of MKS Instruments, Inc. All other trademarks and

Granville-Phillips® Series 358 Micro-Ion

Vacuum Gauge Controllerule

Catalog numbers for Series 358 Micro-Ion Controllers

®

Controller for a Micro-Ion gauge, with 3-line display, electron bombardent degas,

and remote input/output interface - CE Marked

(1)

Half-rack mount: 358501 - # # # - # #

Left mount for 19-inch rack: 358502 - # # # - # #

Center mount for 19-inch rack: 358503 - # # # - # #

Black Case & Half-rack mount: 358504 - # # # - # #

Black Case & Left mount for 19-inch rack: 358505 - # # # - # #

Interface options (Slot X):

None 0

RS-232 A

RS-485/422 B

Gauge options (Slot Y):

None 0

Dual Convectron 1

Capacitance Manometer/Convectron

(1)

2

Setpoint options (Slot Z):

None 0

2 setpoint relays for Micro-Ion gauge A

6 setpoint relays, 2 per channel B

Display options (Measurement units):

To rr T

mbar M

Pascal P

Powercord options:

North America 115 V 1

North America 240 V 2

Universal Europe 220 V 3

United Kingdom 240 V 4

NOTE:

(1)

The Capacitance Manometer/Convectron Gauge option is not CE Marked.

Table of Contents

Chapter 1 Before You Begin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.1 Caution and Warning Statements . . . . . . . . . . . . . . . . . . . . 9

1.2 Reading and Following Instructions . . . . . . . . . . . . . . . . . . 9

1.3 Damage Requiring Service . . . . . . . . . . . . . . . . . . . . . . . . . 10

1.4 Pressure Relief Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1.5 Certification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1.6 Warranty Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1.7 Service Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1.8 FCC Verification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Chapter 2 System Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2.1 Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2.2 RS-232 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2.3 RS-485 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

2.4 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

2.5 Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

2.6 Mounting Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Chapter 3 Initial Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

3.1 Controller Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

3.2 Top Cover Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

3.3 Pressure Units Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

3.4 Changing Units of Measure for Electrometer Module . . . . . 28

3.5 Overpressure Shutdown Adjustment . . . . . . . . . . . . . . . . . . 30

3.6 Changing Display Update Rate on Electrometer Module . . . 30

3.7 Changing Units of Measure for Convectron Gauge . . . . . . . 30

3.8 Display Update Rate Switch on Convectron Module . . . . . . 31

3.9 Changing Units of Measure for a Capacitance Manometer . 31

3.10 Process Control Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

3.11 Relay Polarity Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

3.12 RS-232 Computer Interface Setup . . . . . . . . . . . . . . . . . . . . 37

3.13 RS-485 Computer Interface Setup . . . . . . . . . . . . . . . . . . . . 42

3.14 Replacing the Controller Cover . . . . . . . . . . . . . . . . . . . . . . 47

Series 358 Micro-Ion Controller Instruction Manual - 358013 - Rev. B 5

Table of Contents

Chapter 4 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

4.1 Gauge Installation Tips . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

4.2 FCC and EU Installation Requirements . . . . . . . . . . . . . . . . 49

4.3 Cable Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

4.4 Environmental Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . 50

4.5 Controller Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

4.6 Mounting Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . 51

4.7 Line Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

4.8 Fuse Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

4.9 Vacuum Gauge Installation . . . . . . . . . . . . . . . . . . . . . . . . . 53

4.10 Mounting Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

4.11 Grounding the System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

4.12 Connecting Analog Outputs . . . . . . . . . . . . . . . . . . . . . . . . 59

4.13 Connecting a Capacitance Manometer . . . . . . . . . . . . . . . . 60

4.14 Connecting Process Control Relays . . . . . . . . . . . . . . . . . . . 63

4.15 Connecting the RS-232 Computer Interface Handshake Lines 65

4.16 Connecting RS-485 Computer Interface . . . . . . . . . . . . . . . 66

Chapter 5 Preparing for Operation . . . . . . . . . . . . . . . . . . . . . . . . . 67

5.1 Preparing for Pressure Measurement . . . . . . . . . . . . . . . . . . 67

5.2 Alternate ON/OFF Gauge Control . . . . . . . . . . . . . . . . . . . . 68

5.3 Micro-Ion Gauge Remote Input/Output . . . . . . . . . . . . . . . . 68

5.4 Micro-Ion Analog Output Signal . . . . . . . . . . . . . . . . . . . . . 69

5.5 Preparing for Convectron Gauge Operation . . . . . . . . . . . . 71

5.6 Gases other than Nitrogen or Air . . . . . . . . . . . . . . . . . . . . . 71

5.7 Micro-Ion Gauge Auto ON/OFF . . . . . . . . . . . . . . . . . . . . . 80

5.8 Filament Auto ON . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

5.9 Gauge Zero and Atmospheric Pressure Adjustment . . . . . . . 81

5.10 Convectron Gauge Analog Output Signal . . . . . . . . . . . . . . 82

5.11 Preparing for Capacitance Manometer Operation . . . . . . . . 84

5.12 Preparing for Process Control Operation . . . . . . . . . . . . . . . 85

5.13 Preparing to use RS-232 Computer Interface . . . . . . . . . . . . 87

5.14 RS-232 Error Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

5.15 Preparing to Use RS-485 Computer Interface . . . . . . . . . . . 90

5.16 RS-485 Error Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Chapter 6 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

6.1 Controller Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

6.2 Micro-Ion Gauge ON/OFF . . . . . . . . . . . . . . . . . . . . . . . . . 97

6.3 Degas ON/OFF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

6.4 Special Considerations for Use Below 10

6.5 Gauge Electrometer Operation . . . . . . . . . . . . . . . . . . . . . . 98

6.6 Filament Selection for Electrometer Module . . . . . . . . . . . . 100

6 Series 358 Micro-Ion Controller Instruction Manual - 358013 - Rev. B

–3

Torr . . . . . . . . . 98

Table of Contents

Chapter 7 Theory of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

7.1 Micro-Ion Gauge Theory of Operation . . . . . . . . . . . . . . . . 101

7.2 Convectron Gauge Theory of Operation . . . . . . . . . . . . . . . 102

7.3 Microcontrollers and Bus Structure . . . . . . . . . . . . . . . . . . . 103

7.4 Capacitance Manometer Theory of Operation . . . . . . . . . . 103

7.5 Process Control Theory of Operation . . . . . . . . . . . . . . . . . 103

Chapter 8 Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

8.1 Service Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

8.2 Customer service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

8.3 Damage Requiring Service . . . . . . . . . . . . . . . . . . . . . . . . . 106

8.4 Returning a Damaged Product . . . . . . . . . . . . . . . . . . . . . . 106

8.5 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

8.6 Overpressure Shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

8.7 Troubleshooting the Convectron Gauge Module . . . . . . . . . 110

8.8 Capacitance Manometer Troubleshooting . . . . . . . . . . . . . . 112

8.9 Process Control Troubleshooting . . . . . . . . . . . . . . . . . . . . . 112

8.10 RS-232 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

8.11 RS-485 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

8.12 Field Installation of a Module . . . . . . . . . . . . . . . . . . . . . . . 115

Series 358 Micro-Ion Controller Instruction Manual - 358013 - Rev. B 7

Table of Contents

8 Series 358 Micro-Ion Controller Instruction Manual - 358013 - Rev. B

Chapter 1 Before You Begin

CAUTION

WARNING

1.1 Caution and Warning Statements

This manual contains caution and warning statements with which you must

comply to prevent inaccurate measurement, property damage, or personal

injury.

Caution statements alert you to hazards or unsafe

practices that could result in minor personal injury or

property damage.

Each caution statement explains what you must do to prevent or

avoid the potential result of the specified hazard or unsafe

practice.

Warning statements alert you to hazards or unsafe

practices that could result in severe property damage or

personal injury due to electrical shock, fire, or explosion.

Each warning statement explains what you must do to prevent

or avoid the potential result of the specified hazard or unsafe

practice.

Caution and warning statements comply with American Institute of

Standards Z535.1–2002 through Z535.5–2002, which set forth voluntary

practices regarding the content and appearance of safety signs, symbols,

and labels.

Each caution or warning statement explains:

a. The specific hazard that you must prevent or unsafe practice that you

must avoid,

b. The potential result of your failure to prevent the specified hazard or

avoid the unsafe practice, and

c. What you must do to prevent the specified hazardous result.

System Components Initial Setup InstallationBefore You Begin

1.2 Reading and Following Instructions

Series 358 Micro-Ion Controller Instruction Manual - 358013 - Rev. B 9

You must comply with all instructions while you are installing, operating,

or maintaining the module. Failure to comply with the instructions violates

standards of design, manufacture, and intended use of the module. MKS

Instruments, Inc./ Granville-Phillips disclaim all liability for the customer's

failure to comply with the instructions.

• Read instructions – Read all instructions before installing or operating the

product.

• Retain instructions – Retain the instructions for future reference.

Chapter 1

WARNING

• Follow instructions – Follow all installation, operating and maintenance

instructions.

• Heed warnings and cautions – Adhere to all warnings and caution

statements on the product and in these instructions.

• Parts and accessories – Install only those replacement parts and

accessories that are recommended by Granville-Phillips. Substitution of

parts is hazardous.

1.3 Damage Requiring Service

Disconnect the product from the wall outlet and all power sources and refer

servicing to qualified service personnel under the following conditions:

1. When any cable or plug is damaged.

2. If any liquid has been spilled onto, or objects have fallen into, the

product.

3. If the product has been exposed to rain or water.

4. If the product does not operate normally even if you follow the

operating instructions. Adjust only those controls that are covered by

the operation instructions. Improper adjustment of other controls may

result in damage and will often require extensive work by a qualified

technician to restore the product to its normal operation.

5. If the product has been dropped or the enclosure has been damaged.

6. When the product exhibits a distinct change in performance. This

indicates a need for service.

Substitution or modifying parts can result in product

damage or personal injury due to electrical shock or fire.

• Install only those replacement parts that are specified by

Granville−Phillips.

• Do not install substitute parts or perform any unauthorized

modification to the controller.

• Do not use the controller if unauthorized modifications

have been made.

10 Series 358 Micro-Ion Controller Instruction Manual - 358013 - Rev. B

Before You Begin

WARNING

1.4 Pressure Relief Devices

Failure to install appropriate pressure relief devices for

high−pressure applications can cause product damage

or personal injury.

For automatic backfilling and other applications in which

malfunction or normal process conditions can cause high

pressures to occur, install appropriate pressure relief devices.

Suppliers of pressure relief valves and pressure relief disks can be located

via an online search, and are listed on ThomasNet.com under “Relief

Valves” and “Rupture Discs. Confirm that these safety devices are properly

installed before installing and operating the product. In addition, check

that:

1. the proper gas cylinders are installed,

2. gas cylinder valve positions are correct on manual systems, and

3. the automation is correct on automated gas delivery systems.

Vacuum gauges with compression fittings may be forcefully ejected if the

vacuum system is pressurized.

1.5 Certification MKS Instruments, Inc./ Granville-Phillips certifies that this product met its

published specifications at the time of shipment from the factory. MKS

Instruments, Inc./ Granville-Phillips further certifies that its calibration

measurements are traceable to the National Institute of Standards and

Technology to the extent allowed by the Institute's calibration facility. See

also CE Declaration of Conformity inside envelope for CE tests performed.

System Components Initial Setup InstallationBefore You Begin

1.6 Warranty Information MKS Instruments, Inc. provides an eighteen (18) month warranty from the

date of shipment for new Granville-Phillips products. The MKS Instruments,

Inc./ Granville-Phillips general terms and conditions of sale provide the

complete and exclusive warranty for MKS,Granville-Phillips Division

products. This document is located on our web site at www.mksinst.com,

or may be obtained by a contacting an MKS. Granville-Phillips Division

customer service representative.

1.7 Service Guidelines If the product requires service, contact the MKS, Granville-Phillips Division

Customer Service Department at +1-800-227-8766 or +1-303-652-4691

for troubleshooting help over the phone.

If the product must be returned to the factory for service, request a Return

Material Authorization (RMA) from Granville-Phillips. Do not return

products without first obtaining an RMA. In some cases a hazardous

materials document may be required. The MKS/Granville-Phillips Customer

Series 358 Micro-Ion Controller Instruction Manual - 358013 - Rev. B 11

Chapter 1

Service Representative will advise you if the hazardous materials document

is required.

When returning a products to Granville-Phillips, be sure to package the

products to prevent shipping damage. Circuit boards and modules

separated from the gauge assembly must be handled using proper anti-static

protection methods and must be packaged in anti-static packaging.

Granville-Phillips will supply return packaging materials at no charge upon

request. Shipping damage on returned products as a result of inadequate

packaging is the Buyer's responsibility.

For Customer Service or Technical Support 24 hours per day, 7 days per

week, every day of the year including holidays:

Phone: +1-800-227-8766 or +1-303-652-4691

Email: gp-csr@mksinst.com

MKS, Granville-Phillips Division

6450 Dry Creek Parkway

Longmont, CO 80503 USA

Phone: 1-303-652-4691 or 1-800-776-6543

FAX: 1-303-652-2844

1.8 FCC Verification This equipment has been tested and found to comply with the limits for a

Class A digital device, pursuant to Part 15 of the U.S. Federal

Communications Commission (FCC) Rules. These limits are designed to

provide reasonable protection against harmful interference when the

equipment is operated in a commercial environment. This equipment uses

and can radiate radio frequency energy and, if not installed and used in

accordance with this instruction manual, may cause harmful interference to

radio communications. However, there is no guarantee that interference

will not occur in a particular installation. Operation of this equipment in a

residential area is likely to cause harmful interference in which case the user

will be required to correct the interference at his own expense. If this

equipment does cause harmful interference to radio or television reception,

which can be determined by turning the equipment OFF and ON, the user

is encouraged to try to correct the interference by one or more of the

following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and the receiver.

• Connect the equipment into an outlet on a circuit different from that to

which the receiver is connected.

• Consult the dealer or an experienced radio or television technician for

help.

For information about FCC and EU compliance, see FCC and EU Installation

Requirements on page 49.

12 Series 358 Micro-Ion Controller Instruction Manual - 358013 - Rev. B

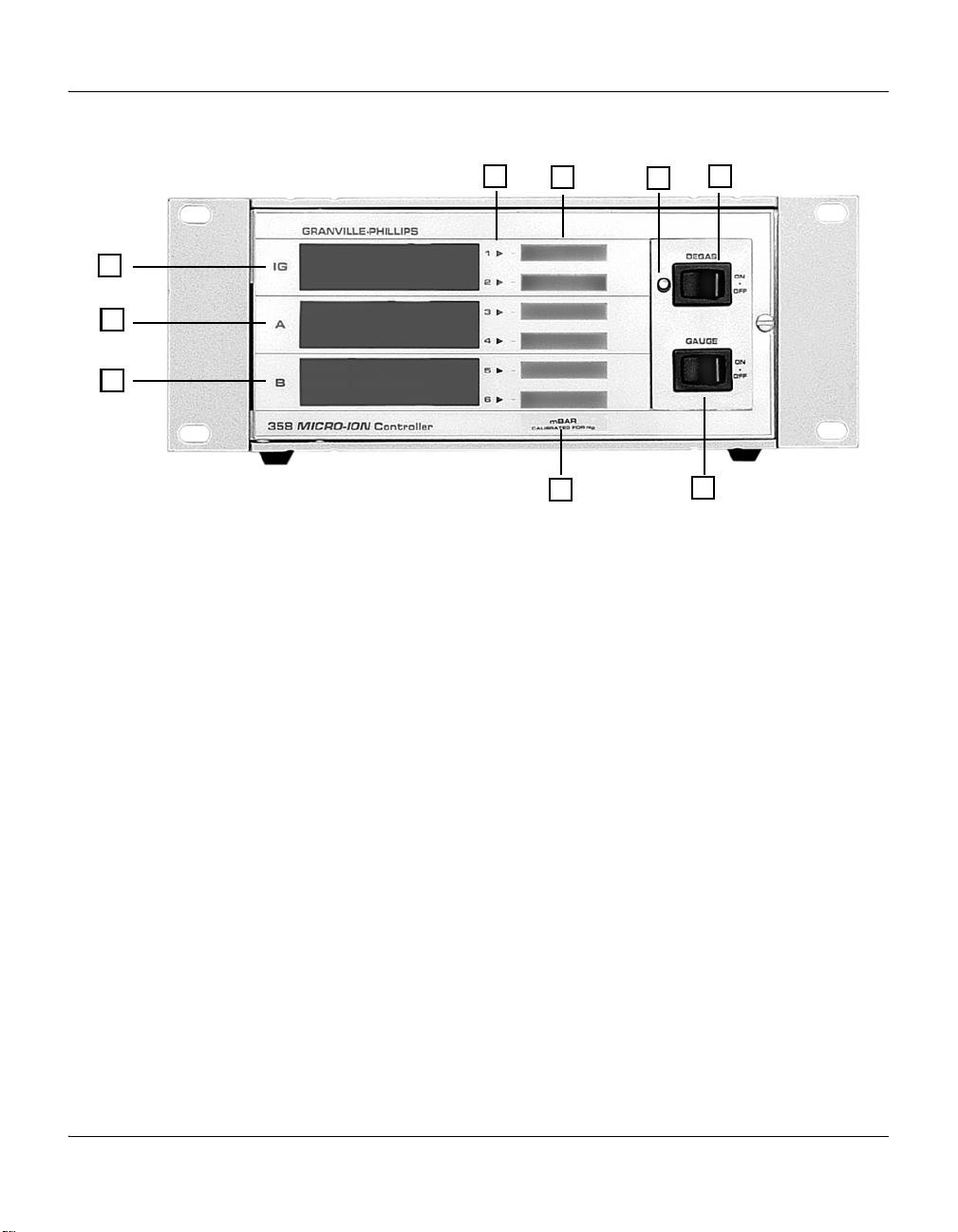

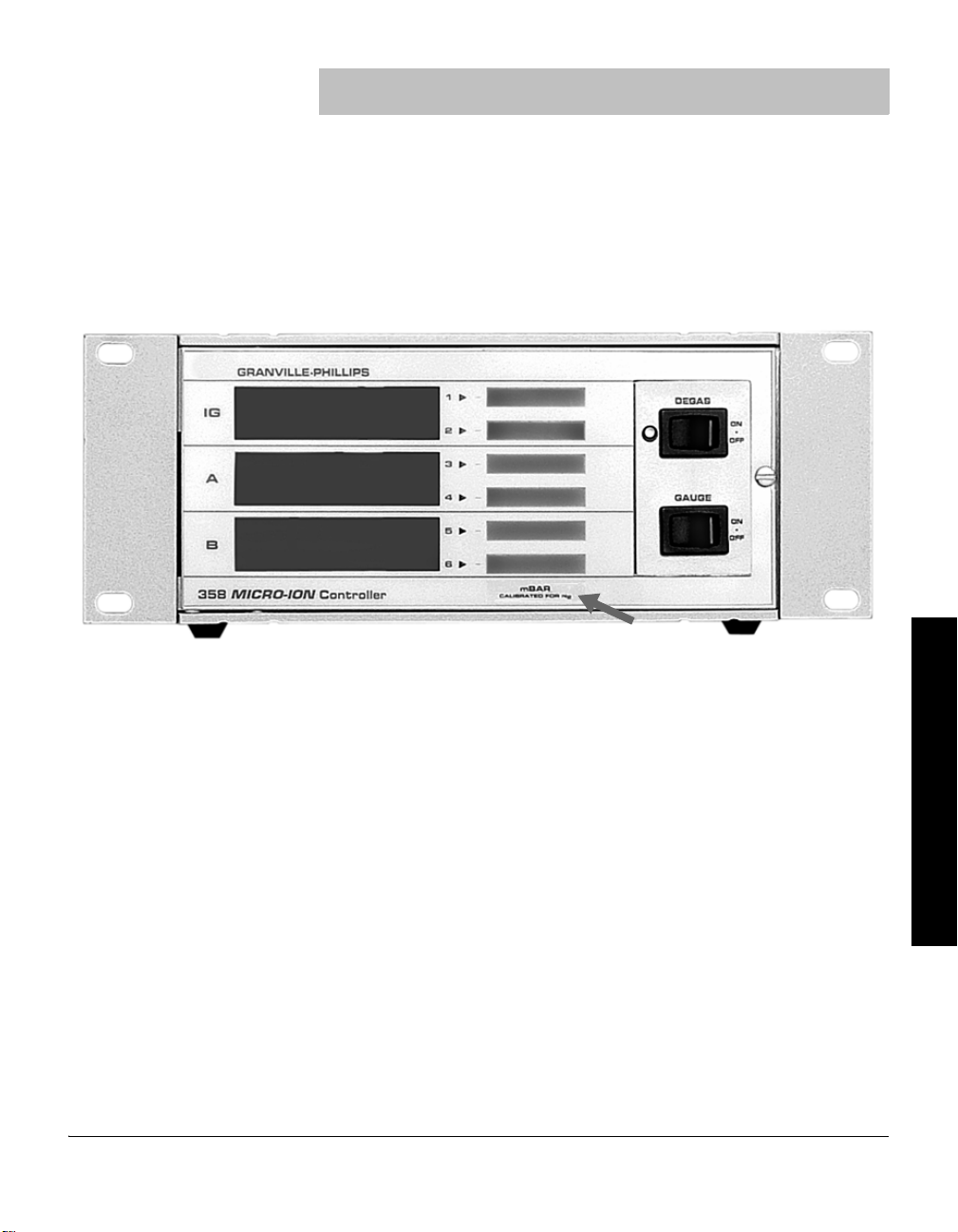

The Series 358 Micro-Ion Vacuum Measurement System can operate one

1

2

3

4

Micro-Ion Gauge along with two Convectron Gauges simultaneously, or

one Micro-Ion Gauge along with one Convectron Gauge and one

Capacitance Manometer Gauge simultaneously.

Pressure readout is via three front panel displays, analog output, and

available computer interface.

The Series 358 Micro-Ion Vacuum Measurement Controller is a modular

instrument that can easily be customized to fit most user's exact needs.

Infrequently used controls are housed behind a hinged front panel, reducing

front panel clutter and allowing the Controller to reside in a half rack space.

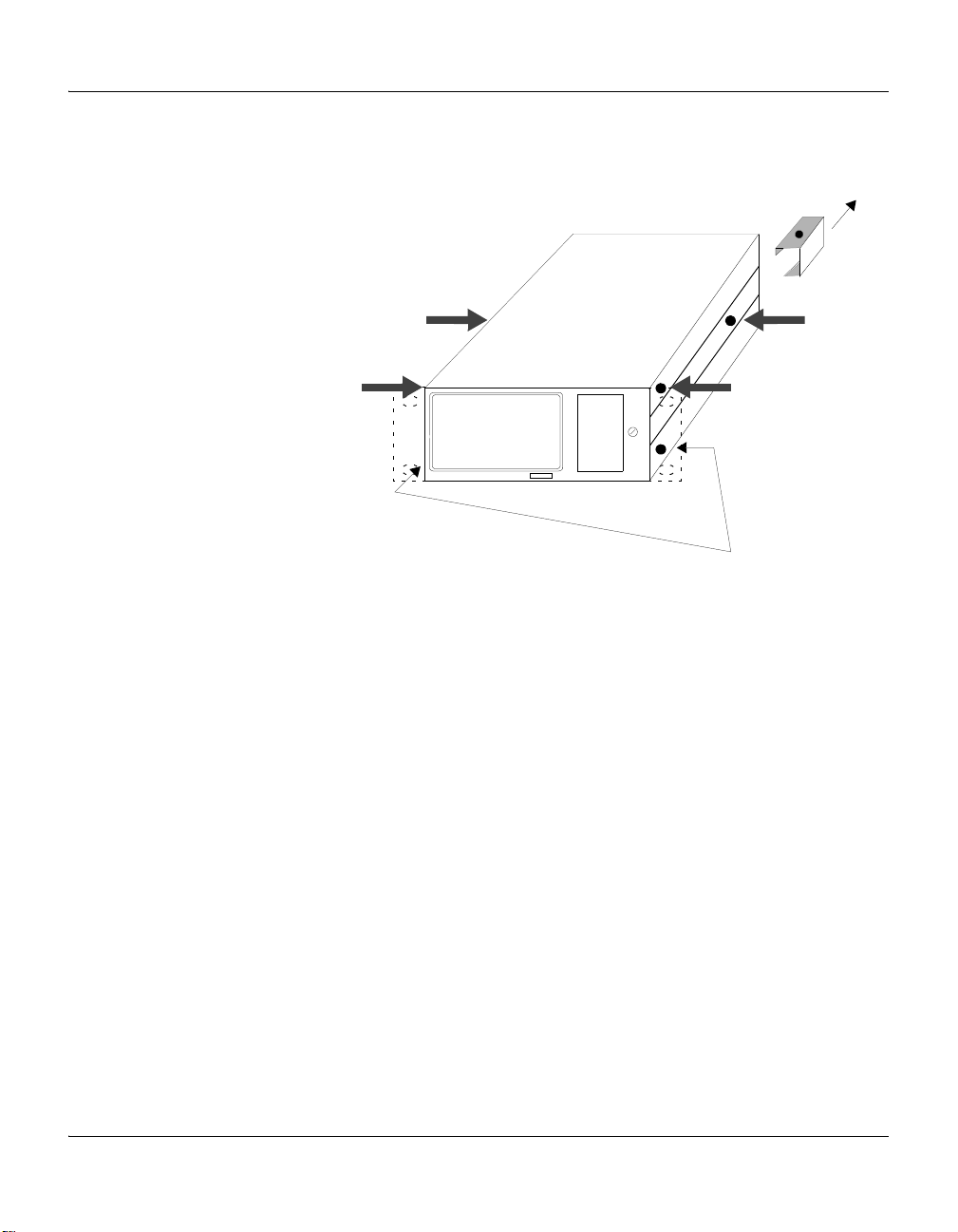

Figure 2-1 Micro-Ion Vacuum Measurement System

Chapter 2 System Components

System Components Initial Setup InstallationBefore You Begin

1. 358 Controller

2. Micro-Ion Gauge

3. Convectron Gauges

4. Capacitance Manometer Gauge

Series 358 Micro-Ion Controller Instruction Manual - 358013 - Rev. B 13

Chapter 2

9

8

6

1

2

3

4

5

7

Figure 2-2 Controller Front Panel

1. Micro-Ion display 6. Degas “momentary” ON/OFF switch

2. Convectron Gauge A display 7. Degas LED

3. Convectron Gauge B or Capacitance

8. Process control channel labels

Manometer display

4. Unit of measure label: Torr, mbar or pascal,

9. Process control channel indicator lights

user selectable

5. Micro-Ion Gauge “momentary” ON/OFF switch

14 Series 358 Micro-Ion Controller Instruction Manual - 358013 - Rev. B

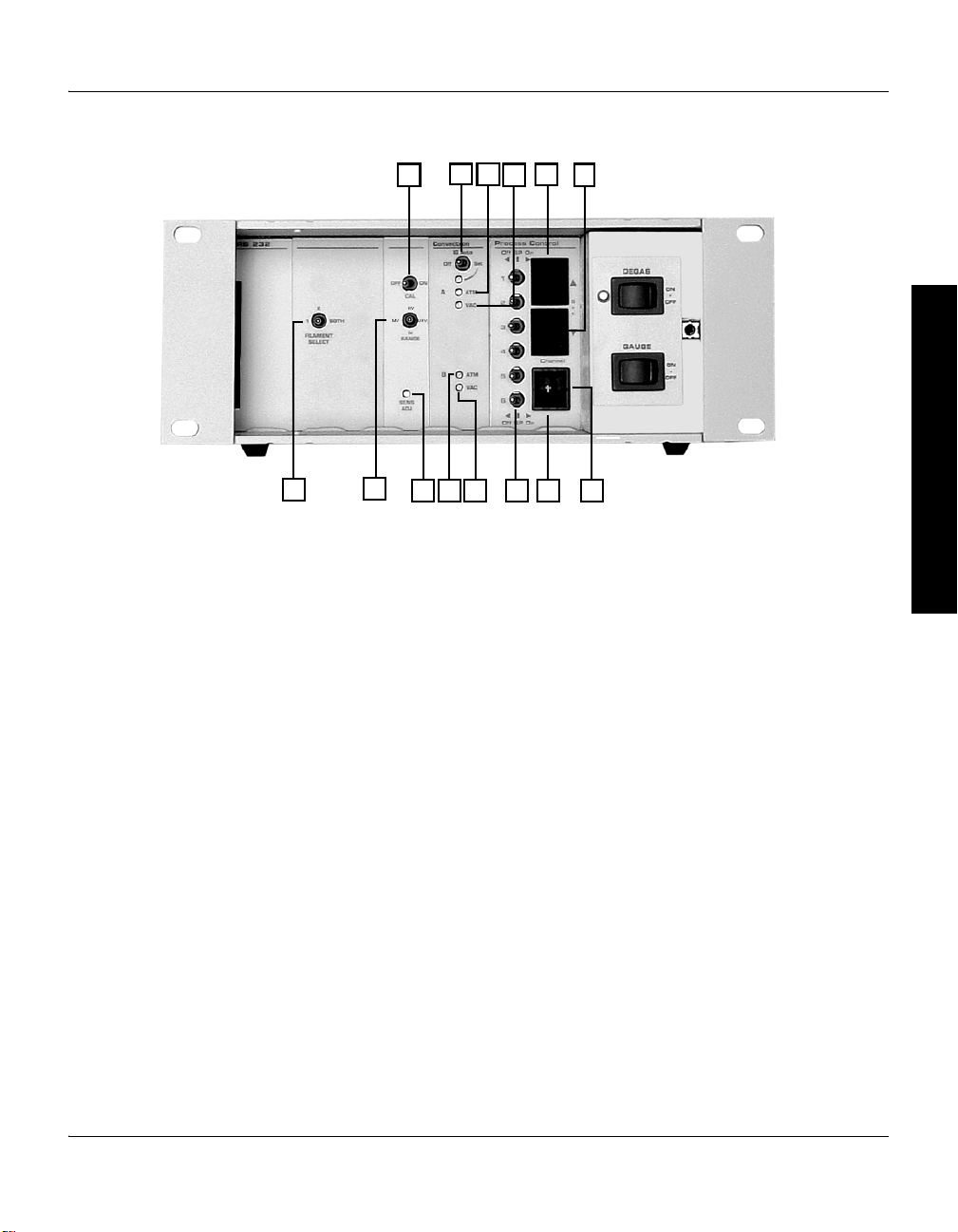

Figure 2-3 Controller Front Panel with Door Open

13

10

9

84 5

2

7

14 11

12

3

1

6

1. Filament select switch: filament 1, filament 2, or both

2. Pressure range selector

3. Sensitivity adjustment

System Components

System Components Initial Setup InstallationBefore You Begin

4. Atmosphere adjustment, Convectron or Capacitance Manometer gauge B

5. Vacuum zero adjustment, Convectron or Capacitance Manometer gauge B

6. Process control setpoint 3-position manual override switches.

Center = relay is controlled automatically.

Left = relay is deactivated.

Right = relay is activated.

7. Process control channel indicator

8. Process control channel selector thumbwheel

9. “Down” process control setpoint pressure set pushbutton

10. “Up” process control setpoint pressure set pushbutton

11. Vacuum zero adjustment, Convectron gauge A

12. Atmosphere adjustment, Convectron gauge A

13. Micro-Ion gauge auto ON switch (via Convectron gauge)

14. Calibration / sensitivity ON switch

Series 358 Micro-Ion Controller Instruction Manual - 358013 - Rev. B 15

Chapter 2

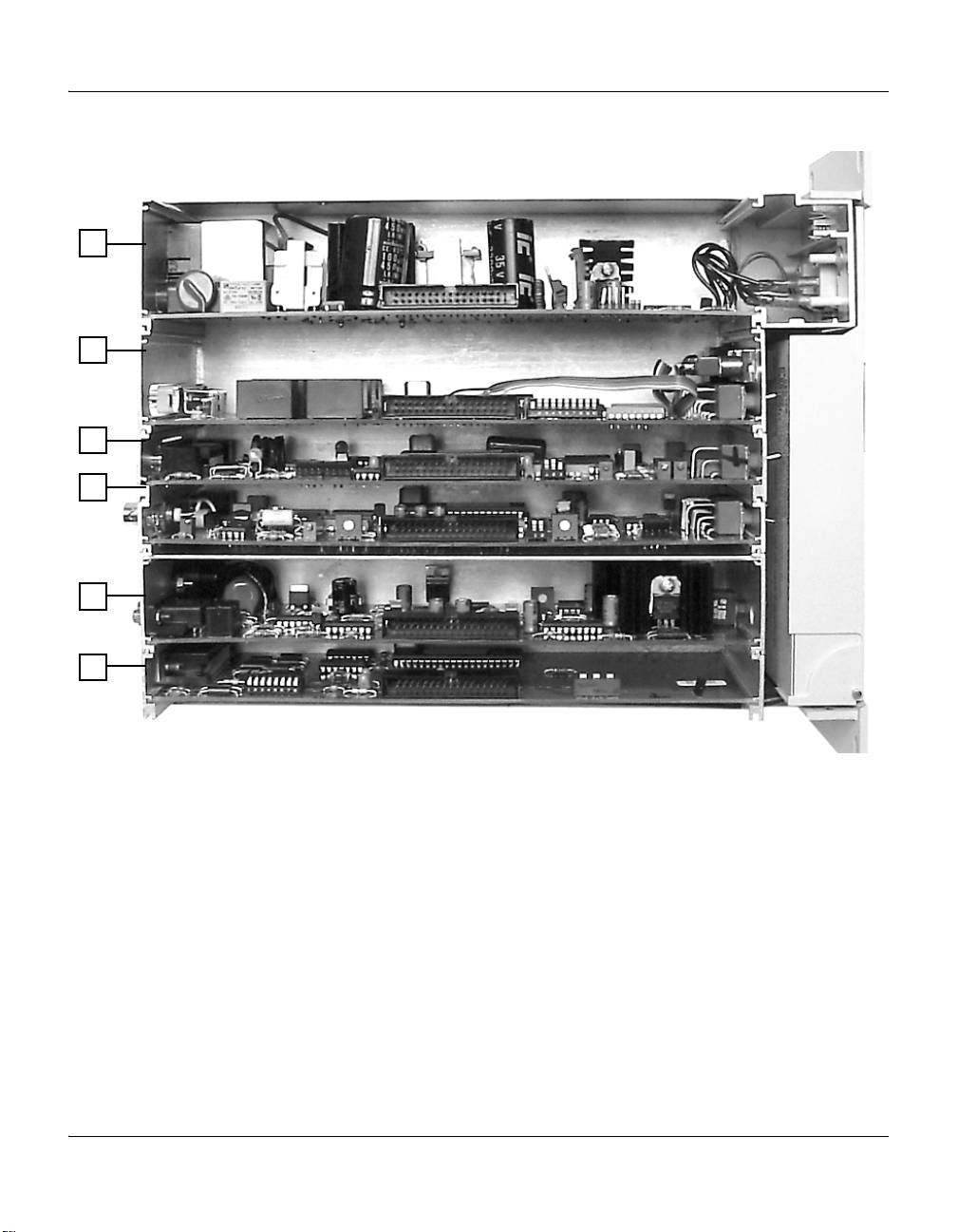

1

2

3

4

5

6

Figure 2-4 Controller Top View with Cover Removed

1. Power supply board

2. Process control setpoint option board

3. Convectron or Capacitance Manometer gauge option board

4. Electrometer board

5. Filament/grid supply board

6. Interface option board (RS-232 or RS-485)

16 Series 358 Micro-Ion Controller Instruction Manual - 358013 - Rev. B

2.1 Options

1

12

2

3 54 8

9

7

10

1113

6

System Components

Process Control Relay

A 2-setpoint or 6-setpoint relay option can either be factory installed or

added at any time by the user. The set points are adjustable from

atmosphere to 1 x 10

indication.

RS-232 or RS-485/422 Computer Interface Module

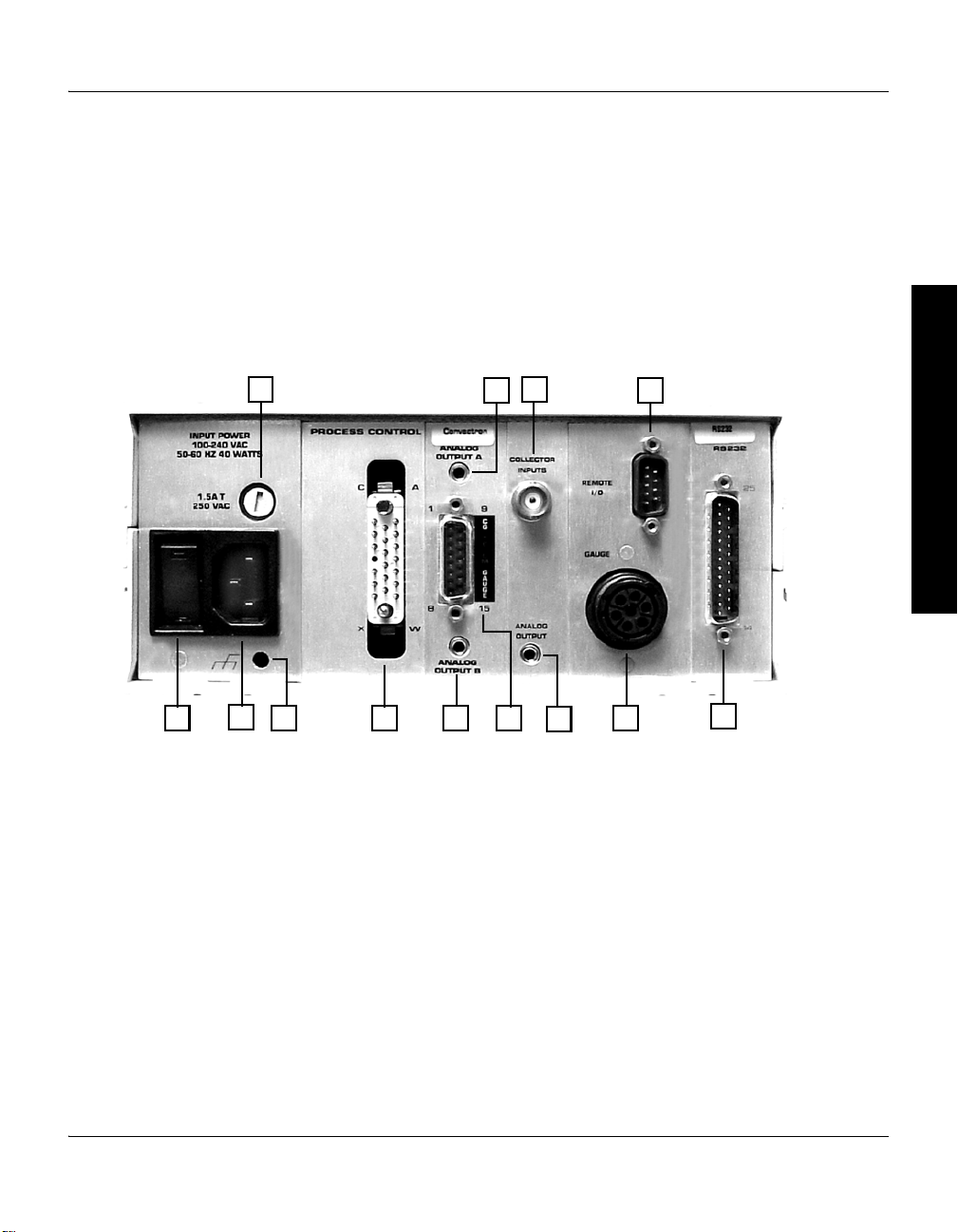

Figure 2-5 Controller Rear Panel (with RS-232 Option)

Provides readout of pressure, process control relay status, and Micro-Ion

Gauge control.

–10

Torr with override switches and front panel status

System Components Initial Setup InstallationBefore You Begin

1. Power switch 8. Micro-Ion Gauge power connector

2. Power input connector 9. DB25S connector for RS-232 computer interface

3. Grounding lug to be connected to Earth ground

with 12 AWG conductor

4. 20-pin connector for process control relay

contacts

5. Connector for analog output voltage from

Convectron or Capacitance Manometer gauge B

6. DA15P connector for Dual Convectron or

10. DE9S connector for remote parameter selection

inputs/outputs

11. Collector connector for Micro-Ion gauge

12. Connector for analog output voltage from

Convectron gauge A

13. Fuse holder

Capacitance Manometer gauge cable

7. Connector for analog output voltage from

Micro-Ion Gauge

Series 358 Micro-Ion Controller Instruction Manual - 358013 - Rev. B 17

Chapter 2

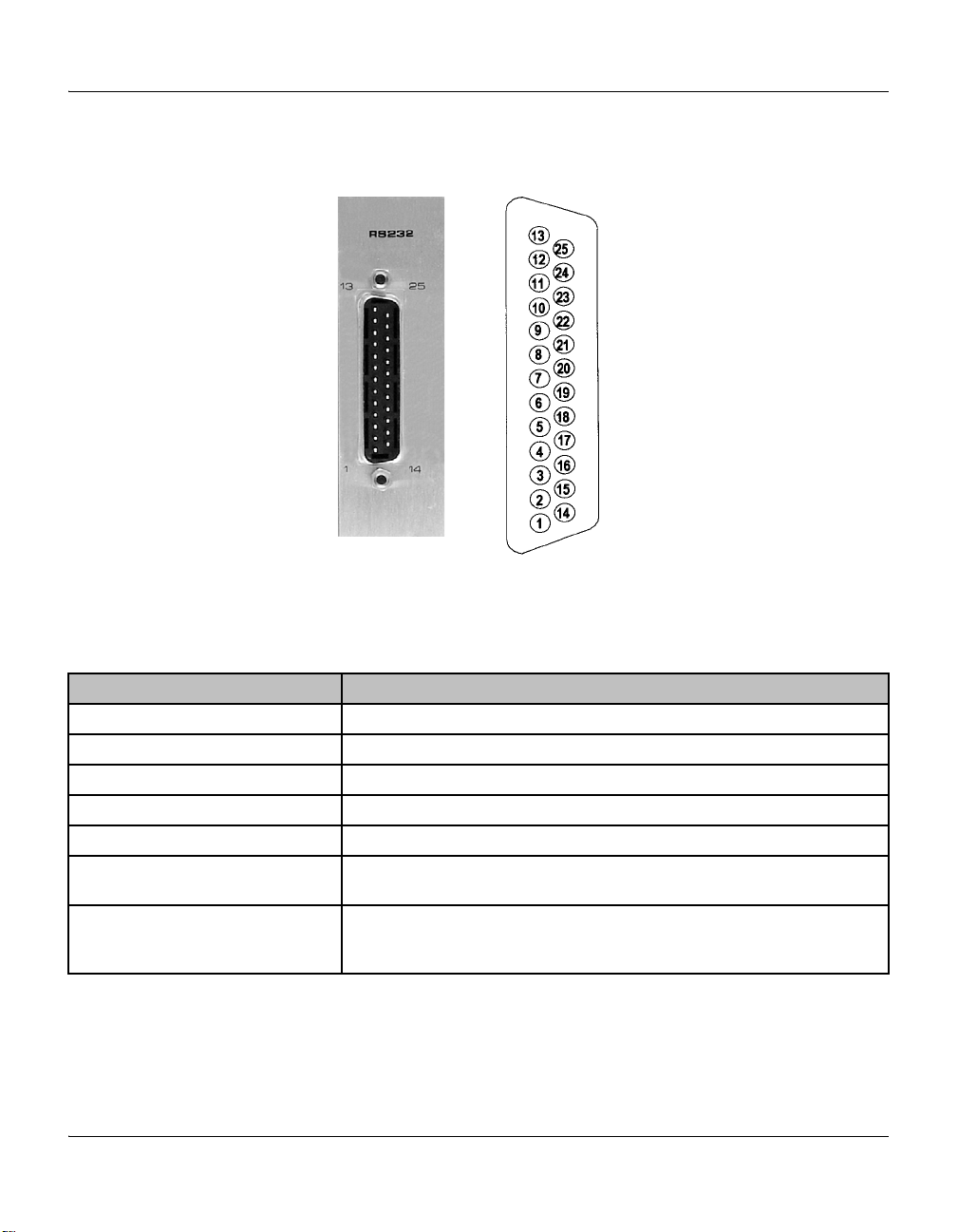

DB–25S connector

See Section 3.12 for

connector pin assignments.

2.2 RS-232 Specifications

Figure 2-6 RS-232 Wiring Connector

Table 2-1 RS-232 Specifications

Item Specification

Format EIA standard RS-232-C, half duplex, asynchronous

Data Rates 75,150,300,600,1200,2400,4800,9600 baud

Character length 7 or 8 bit ASCII, switch selectable

Parity Odd, even, or none, switch selectable

Stop bits 1 or 2. 8 character bits plus parity allows only 1 stop bit

Handshake Outputs: DTR,RTS. RTS polarity selectable. Inputs: DSR, CTS, DCD. May be

forced to logic “TRUE” with switches

Logic levels Inputs: Logic 1, 2.0 Vdc minimum,15 Vdc maximum, logic 0, –15 Vdc minimum,

18 Series 358 Micro-Ion Controller Instruction Manual - 358013 - Rev. B

0.75 VDC maximum

Input Current: 4.0 mA max @ Vin = +15 Vdc, –4.0 mA max @ Vin = –15 Vdc

2.3 RS-485 Specifications

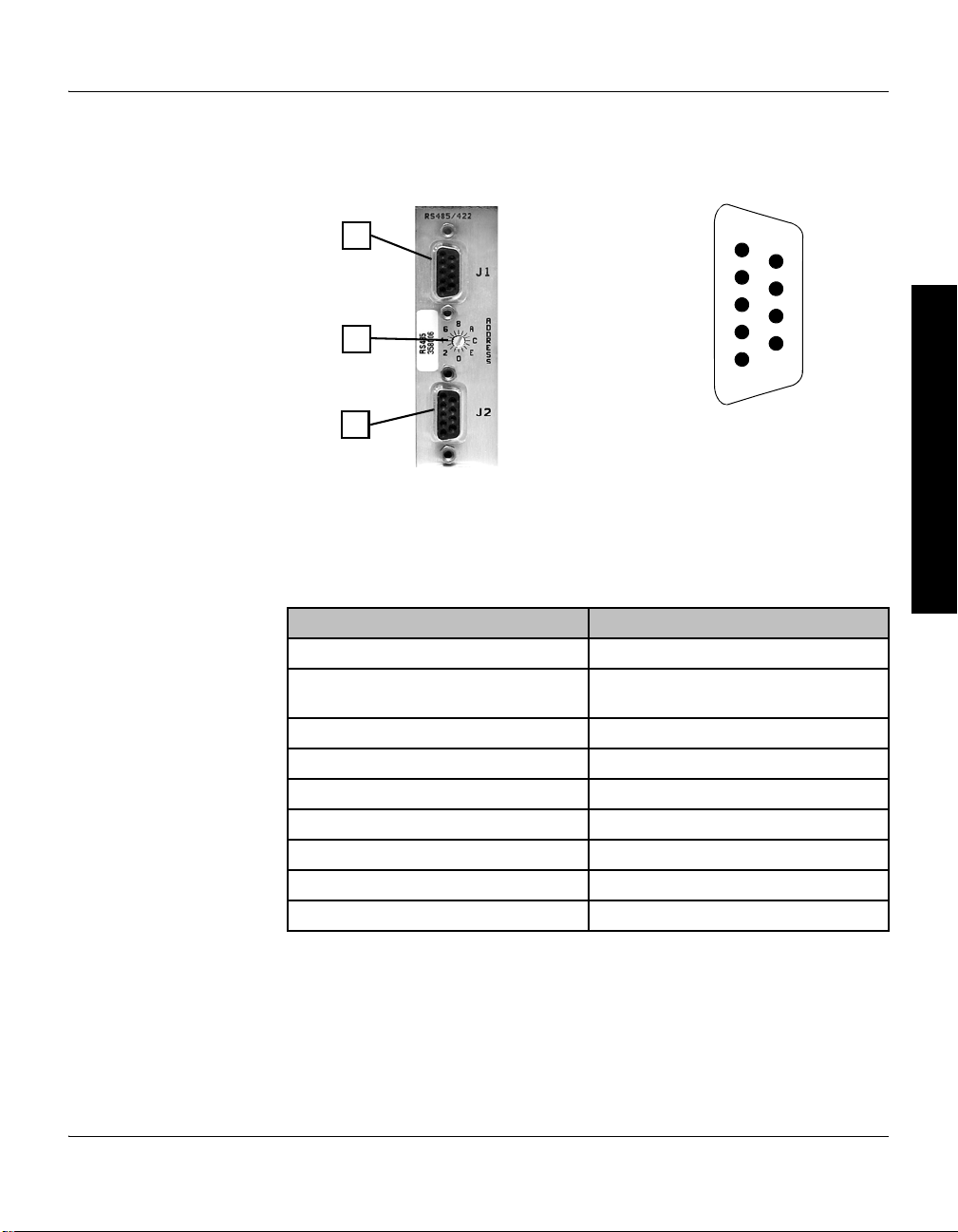

1

3

2

1) J 1 DE9P

Connector for

RS-485/422

computer interface

2) Address dial

3) J 2 DE9P

Connector for

RS-485/422

computer interface

5

9

1

6

See Section 3.12 for connector pin assignments

Figure 2-7 RS-485 Wiring Connector

Table 2-2 RS-485 Specifications

Item Specification

Format Half duplex, asynchronous.

Data Rates 19200, 9600, 4800, 2400, 1200, 600, 300,

Character Length 8 bit or 7 bit ASCII

Parity No parity, even, or odd

Stop Bits 1 or 2

Handshake None.

Address 256 selectable combinations

Number of Connections Up to 32 devices

Total Cable Length 4000 ft. maximum

System Components

System Components Initial Setup InstallationBefore You Begin

150 baud

Series 358 Micro-Ion Controller Instruction Manual - 358013 - Rev. B 19

Chapter 2

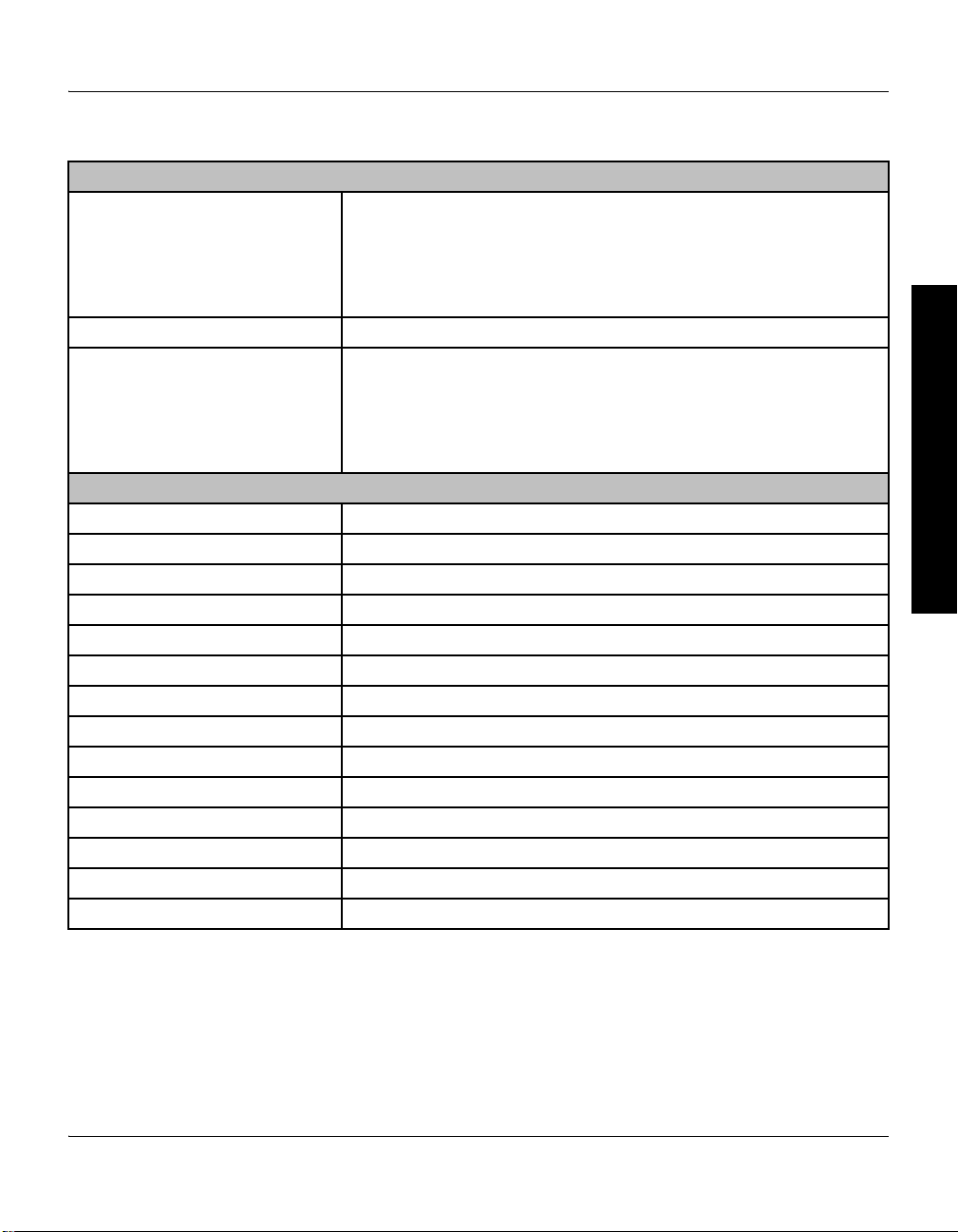

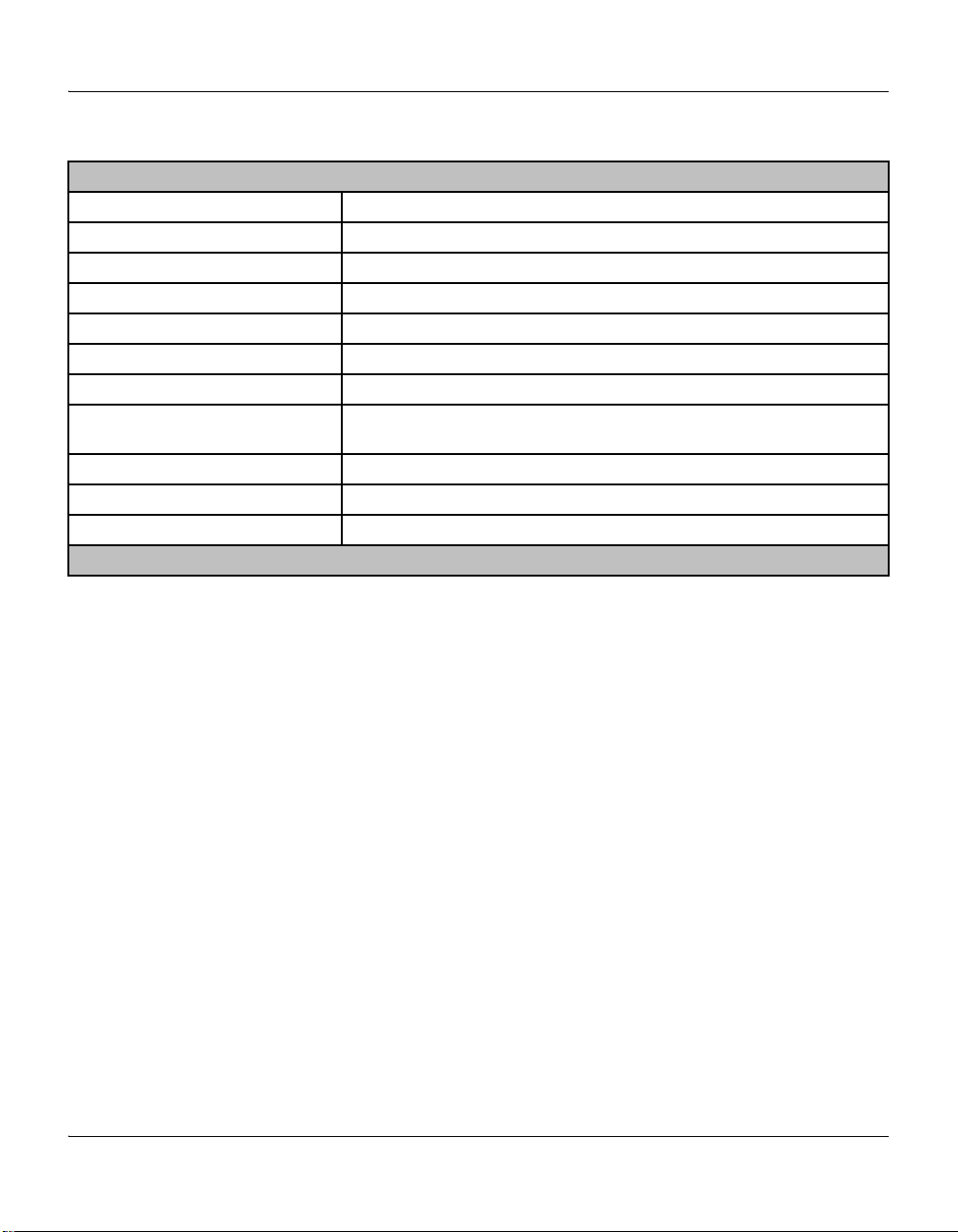

2.4 Specifications

Table 2-3 Specifications

Micro-Ion System

Pressure Range for N

Lower Measurement Limit

Upper Measurement Limit

or air*

2

< 1 x 10–9 Torr (1.3 x 10–9 mbar) (1.3 x 10–7 pascal) at 4 mA emission

Atmosphere

Controller

Electronic accuracy Typical ± 3% of reading at ambient temperature of 25 ± 5

Display

Units

Update Rate

Digital, green LED, 2 digits plus exponent

Torr, mbar, pascal (user selectable)

0.5 sec. typical as shipped. Internal switch selectable to 3 sec./reading averaged

°C

Filament Control Switch selectable: filament 1, filament 2, or both

Degas Electron bombardment, approximately 4 W with 2 minute timer

Maximum Micro-Ion Gauge

Cable Length 15 m (50 ft) with standard cable

Remote I/O

Gauge and Degas On/Off Inputs

Momentary ground controls filament selection and degas

Less than 0.4 Vdc @ 10 μA for 25 msec (minimum). Must be greater than 3.5 Vdc

for 105 msec (minimum) before next low state

Filament Status Relay Contact Rating

Micro-Ion gauge status relay rated at 1.0 A, 30 Vdc

Environment Indoor use

Altitude up to 2000 meters

Temperature 0

°C to 40 °C

Maximum relative humidity 80% for temperatures up to 31 °C decreasing linearly

to 50% relative humidity at 40 °C

Transient overvoltages according to installation category (overvoltage category) II

Pollution degree 2 in accordance with IEC 664

Operating Temperature 0 °C to +40 °C ambient, noncondensing

Non-operating Temperature –40 °C to +70 °C

Analog Output 0 to 10 Vdc, logarithmic, 1 V/decade

Overpressure Protection Gauge turns OFF if pressure rises above factory set upper pressure limit

Emission Current Settings 0.02 mA (MV), 1 mA (HV), 4 mA (UHV)

Operating Voltage and Power 100 to 240 VAC, 50 to 60 Hz, 50 W maximum

Fuse Rating 250 V, 1.6 A, 5 x 20mm Time Lag (T), low breaking capacity

Weight 1.8 kg (4 lb)

* Measurement limits are determined by the controller emission current setting and X-ray limit of the gauge.

20 Series 358 Micro-Ion Controller Instruction Manual - 358013 - Rev. B

System Components

Table 2-3 Specifications

Controller Options

Process Control

Relay Configuration

Contact Rating

Channels

Hysteresis

Setpoint adjustment

SPDT, Form C

5A @ 120 VAC, 4A @ 240 VAC resistive or 5A @ 30 Vdc

6 maximum, 2 per operating gauge maximum

10%

Digital, 2 significant digits plus exponent

Digital Interfaces RS-232 or RS-485/422

Dual Convectron Gauge

Pressure Range

Display Units

Maximum Cable Length

Analog Output

Display Resolution

999 to 1 x 10

Torr, mbar, pascal (user selectable)

150 m (500 ft)

0 to 7 V, logarithmic, 1 V/decade, adjustable offset of +1 to –7 Vdc

2 significant digits, except for lowest two decades

–4

Torr for N2 or air

Micro-Ion Gauge

Sensitivity 3/Torr to 50/ Torr (factory setting is 20/Torr)

Emission Current 20 μA, 1 mA, 4 mA

Collector Potential 0 V

Grid Potential +180 Vdc

Filament Potential +30 Vdc

Degas Electron bombardment: 15 mA DC, 250 Vdc, auto shutoff, 2 minutes

Analog Output 0 to 10 Vdc, logarithmic, 1 V/decade

Filaments Dual yttria-coated iridium, or tungsten

†

Operating Temperature 0 °C to +50 °C ambient, noncondensing

Gauge Bakeout Temperature +200 °C maximum

Cable Bakeout Temperature +150 °C maximum

Materials Exposed to Vacuum Vacuum fired, UHV compatible

Internal Volume 10.8 cm

Weight 0.1 kg (4 oz.) (with 1 5/16 in. Conflat

3

(0.66 in.3)

®

type flange)

† Tungsten filaments are for applications involving gases containing fluorine, chlorine, or other gas species that poison

yttria-coated iridium filaments. Tungsten filaments are not recommended for general vacuum applications because they may

burnout when exposed to high pressures.

System Components Initial Setup InstallationBefore You Begin

Series 358 Micro-Ion Controller Instruction Manual - 358013 - Rev. B 21

Chapter 2

Table 2-3 Specifications

Convectron Gauge

Pressure Range 1 x 10

Display Resolution 2 significant digits, except for 1 significant digit in 1 x 10

Gas Type N

–4

Torr to 990 Torr, N2 equivalent

, air (for direct reading)

2

–4

Torr decade

Display Update Time 0.5 sec. typical. Switch selectable to 3 sec./reading, averaged

Analog Output 0 – 7 Vdc, logarithmic, 1 V/decade

Ion Gauge Turn-On Range Less than or equal to 100 mTorr (1 x 10

-1

Torr)

Sensor Material Gold-plated tungsten

Mounting Orientation Gauge axis must be horizontal to provide accurate measurement above about

1 Torr

Operating Temperature +4 °C to +50 °C ambient, noncondensing

Bakeout Temperature +150 °C maximum, nonoperating, cable disconnected

Cable Bakeout Temperature +105 °C maximum

Ion Gauge Pressure Range* See Table 3-1 on page 30

22 Series 358 Micro-Ion Controller Instruction Manual - 358013 - Rev. B

System Components

Table 2-3 Specifications

Capacitance Manometer Specifications

Gauge Type Any capacitance manometer transducer that requires ± 15 Vdc power at < 250 mA

Accuracy 0.01% of full scale (as limited by display resolution)

Display Resolution Highest 3 decades – 2 digits, lowest decade – 1 digit, scientific notation

Maximum Pressure Scales 1, 10, 100, 1000 Torr max heads, 4 decades of pressure

Display Update Time Unfiltered: 0.5 sec. typical. Switch selectable filtering: 3 sec. (average of 6

Output to Head ± 15 V ± 2% at 250 mA

Input from Head 0 to 10 Vdc into 100 k

Analog Output 5 mA maximum

Analog Output Speed Limited by transducer speed

Cable Connection Cable termination is bare tinned wire, user terminates to transducer

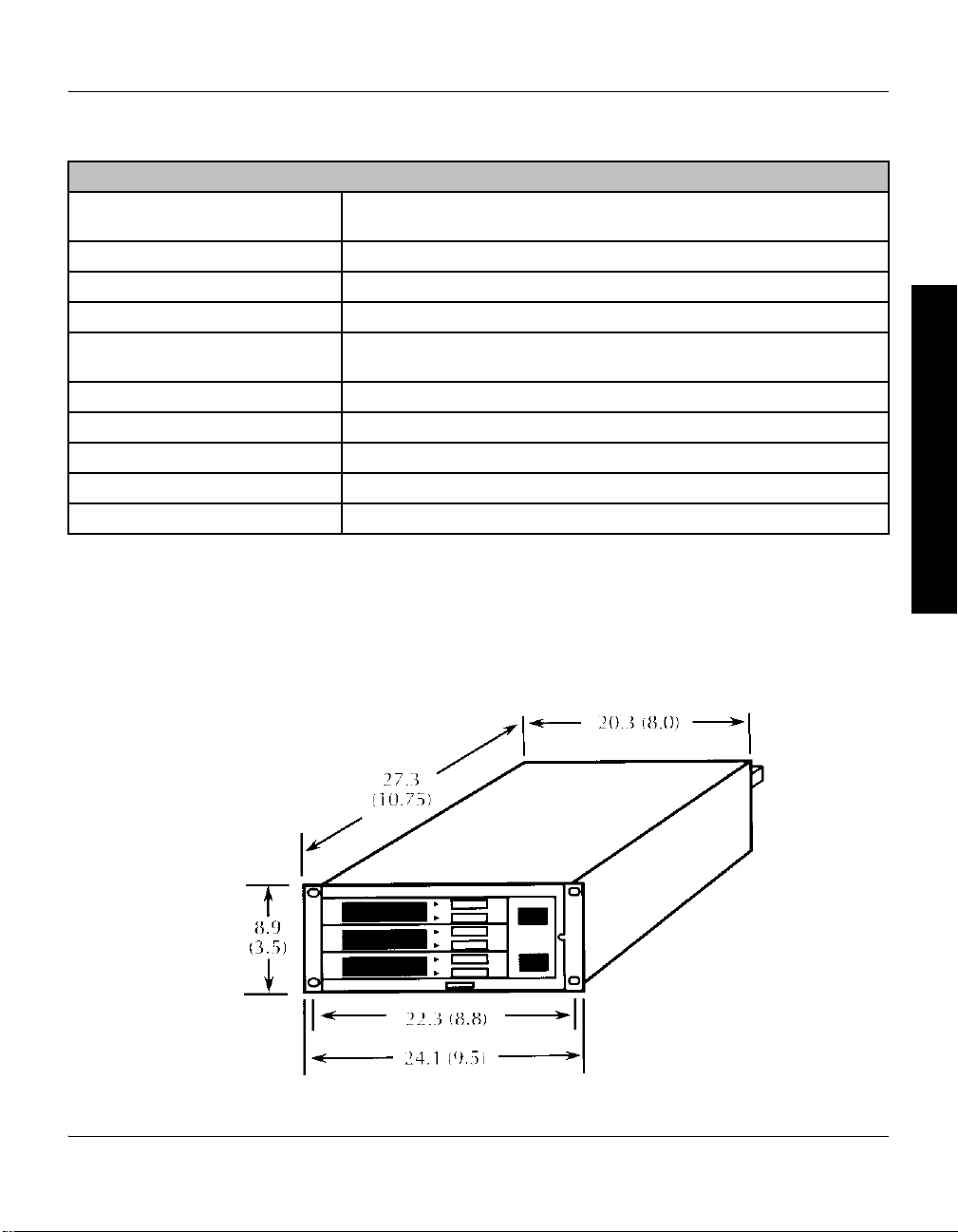

2.5 Dimensions The dimensions of the controller in a half rack (standard) mounting are

and outputs 0–10 Vdc proportional to pressure

readings)

Ω

shown in Figure 2-8.

Dimensions are in centimeters (inches).

System Components Initial Setup InstallationBefore You Begin

Figure 2-8 Controller Dimensions

Series 358 Micro-Ion Controller Instruction Manual - 358013 - Rev. B 23

Chapter 2

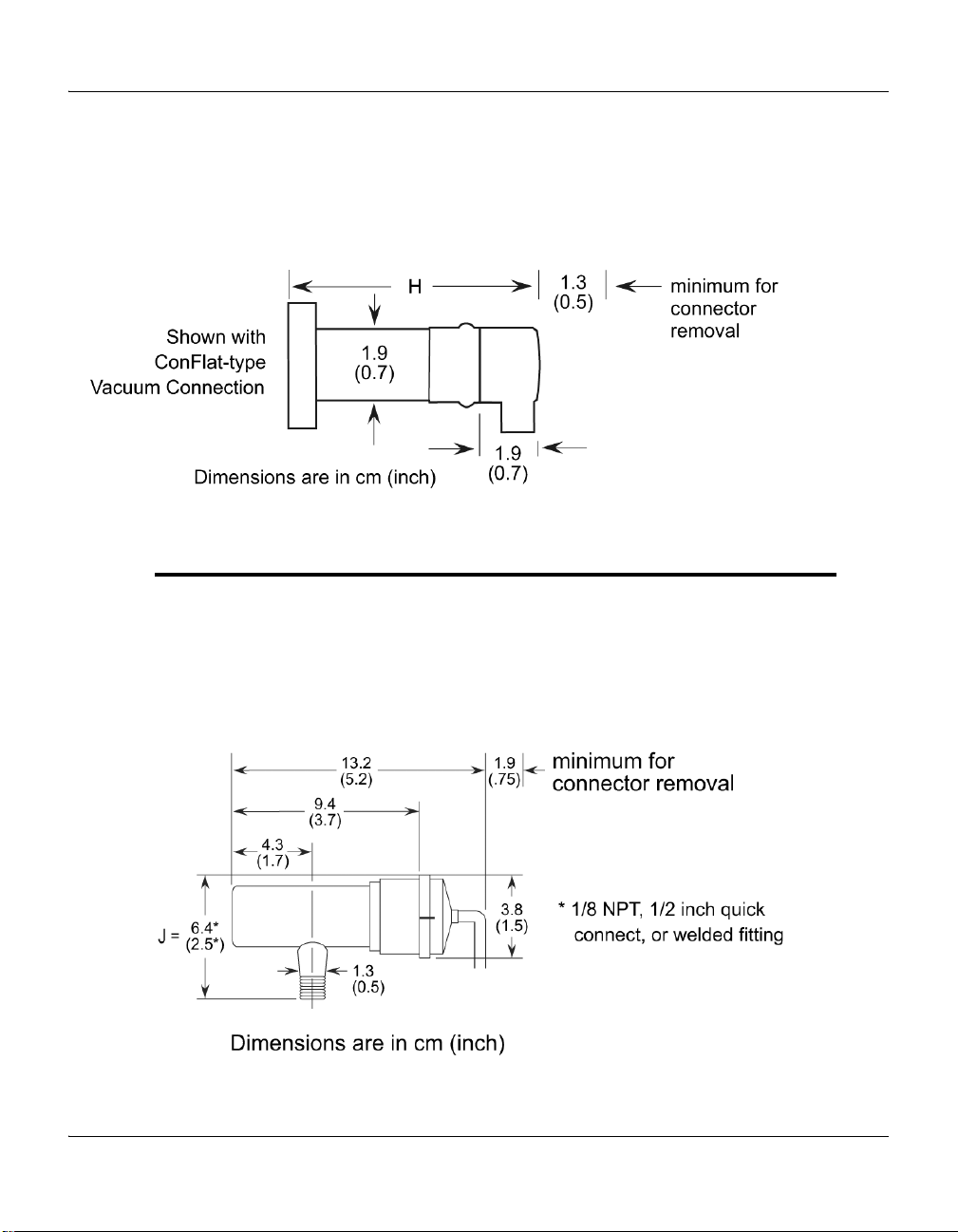

Figure 2-9 Micro-Ion Gauge with Connector

The dimensions of the Micro-Ion gauge are shown in Figure 2-9.

Dimensions are in cm (in.).

H dimensions are given in Table 2-4.

The dimensions of the Convectron gauge are shown Figure 2-10.

Dimensions are in cm (in.).

J dimensions are given in Table 2-4.

Figure 2-10 Convectron Gauge with Connector

24 Series 358 Micro-Ion Controller Instruction Manual - 358013 - Rev. B

Table 2-4 Fittings

Fitting Description Dimension H Dimension J

0.75 inch port diameter

1.0 inch port diameter

15 mm port diameter

18 mm port diameter

9.4 cm (3.7 in.)

9.4 cm (3.7 in.)

9.4 cm (3.7 in.)

9.4 cm (3.7 in.)

Not applicable

Not applicable

Not applicable

Not applicable

System Components

1/4 inch VCR

1/2 inch VCR type

NW16KF flange

NW25KF flange

NW40KF flange

1.33 inch ConFlat

2.75 inch ConFlat

®

type

Not applicable

8.6 cm (3.4 in.)

7.3 cm (2.9 in.)

7.3 cm (2.9 in.)

7.3 cm (2.9 in.)

®

7.3 cm (2.9 in.)

7.3 cm (2.9 in.)

VCR® is a registered trademark of Swagelok Company

8.1 cm (3.2 in.)

8.1 cm (3.1 in.)

6.9 cm (2.7 in.)

6.9 cm (2.7 in.)

Not applicable

6.4 cm (2.5 in.)

6.4 cm (2.5 in.)

2.6 Mounting Options The controller can be ordered with a variety of mounting options to fit your

needs. This includes half rack (standard), full rack, or two units in a full rack.

See Controller Installation on page 50 and Figure 4-1 on page 52.

System Components Initial Setup InstallationBefore You Begin

Series 358 Micro-Ion Controller Instruction Manual - 358013 - Rev. B 25

Chapter 2

26 Series 358 Micro-Ion Controller Instruction Manual - 358013 - Rev. B

Chapter 3 Initial Setup

3.1 Controller Setup Now is a convenient time to make any required switch changes before

mounting the Controller in its desired location.

If the pressure display units of measure are correct (see Figure 3-1), and you

do not want to change the degas power timer from the factory setting of 10

minutes, skip to Process Control Setup on page 32.

Figure 3-1 Units of Measure Label

System Components Initial Setup InstallationBefore You Begin

If you want to change the units of measure, the display rate, or the degas

timer, you must remove the top cover of the Controller.

3.2 Top Cover Removal 1. With power OFF, remove any cables from Controller rear panel.

2. Observe antistatic precautions to avoid damaging static sensitive

components inside the chassis. Use a grounded, conductive work

surface. Do not handle integrated circuits (IC) devices more than

necessary, and only when wearing a high impedance ground strap.

(A high impedance helps protect human life in case of inadvertent

contact with high voltage.)

3. Remove the four Phillips head screws identified in Figure 3-2. If the

unit is equipped with a rear bracket, remove the Phillips head screw on

the bracket, and slide the bracket off.

Series 358 Micro-Ion Controller Instruction Manual - 358013 - Rev. B 27

Chapter 3

Bracket

Do not remove the two

lower front screws

Figure 3-2 Location of Screws for Top Cover Removal

3.3 Pressure Units Setup

If units of measure are as desired (see Figure 3-1), skip to Changing Display

Update Rate on Electrometer Module on page 30.

3.4 Changing Units of Measure for Electrometer Module

Your unit will have been shipped from the factory preset to display the unit

of measure, Torr, mbar, or pascal, that you requested. Selection between

Torr and mbar units is done by adjusting the Micro-Ion gauge tube

sensitivity to the appropriate units. For example, a tube has a sensitivity of

20/Torr or 15/mbar. Thus, for this tube, adjusting the sensitivity for a display

reading of 2.0+1 will result in display of pressure in Torr (see Sensitivity

Adjustment on page 99). Adjusting to 1.5+1 will result in display in mbar.

If you want to change pascal units, change the switch on the electrometer

module as follows:

1. Shut OFF power to the Controller.

2. Remove the top cover as described in Top Cover Removal on page 27.

3. Locate the Micro-Ion gauge electrometer module. See Figure 2-4 and

Figure 3-3.

4. Locate the Unit of Measure display units control switch.

28 Series 358 Micro-Ion Controller Instruction Manual - 358013 - Rev. B

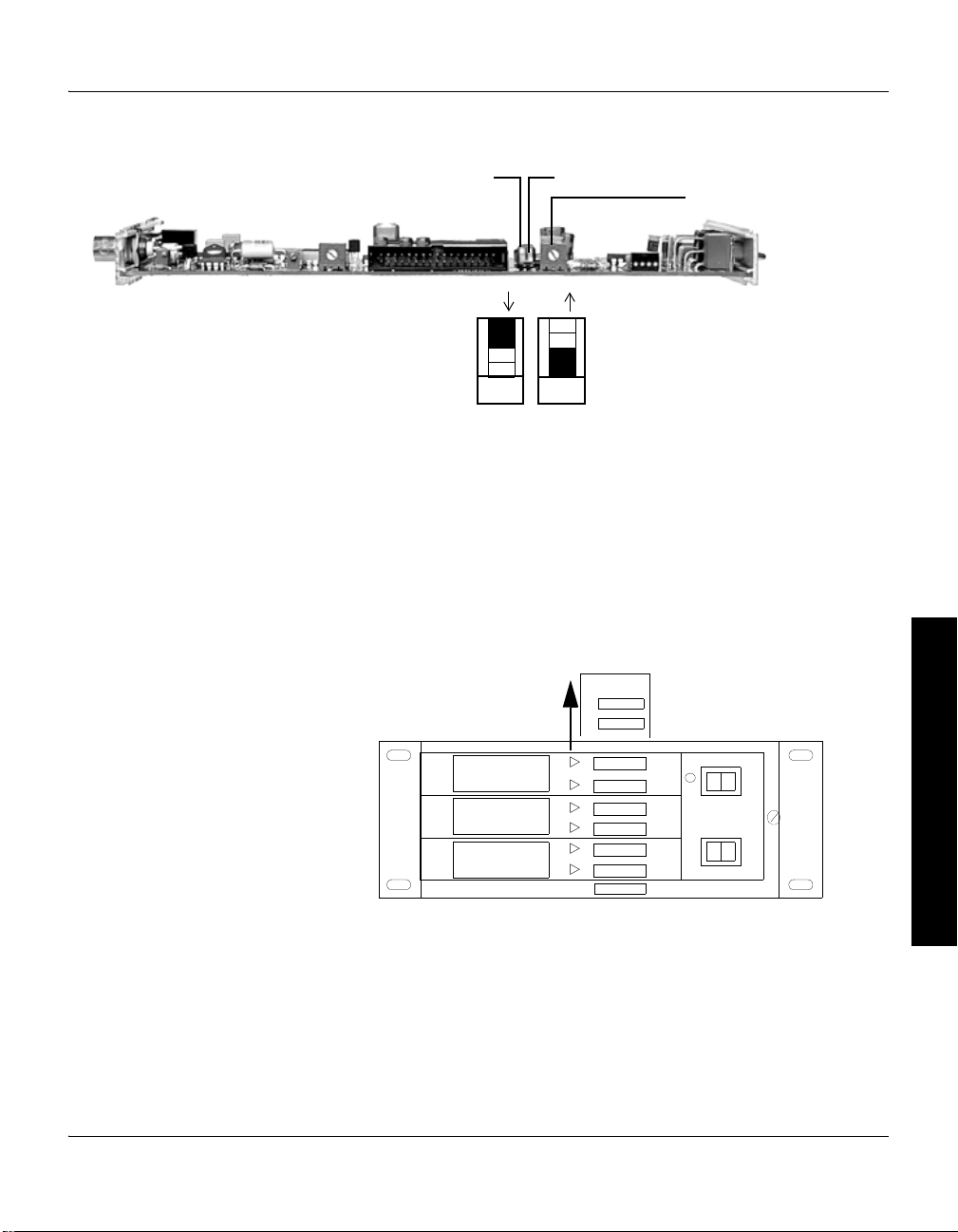

Figure 3-3 Ion Gauge Electrometer Module TopView

Unit of Measure

Slow Update

Overpressure Shutdown

Potentiometer

Units of measure switch

ON and OFF positions

X

OFF

X

ON

1

2

IG

7.5 – 6

A

B

6.4 – 2

3.2 + 2

1

DEGAS

-

2 -

3 -

ON

OFF

GAUGE

ON

OFF

358 Micro-Ion Controller

4 -

5 -

6 -

TORR

5. Set the switch to the desired position: Off = Torr/mbar units;

On = pascal units.

You must also change the setting of the unit of measure switch on the

Dual Convectron gauge as described in Changing Units of Measure for

Convectron Gauge on page 30.

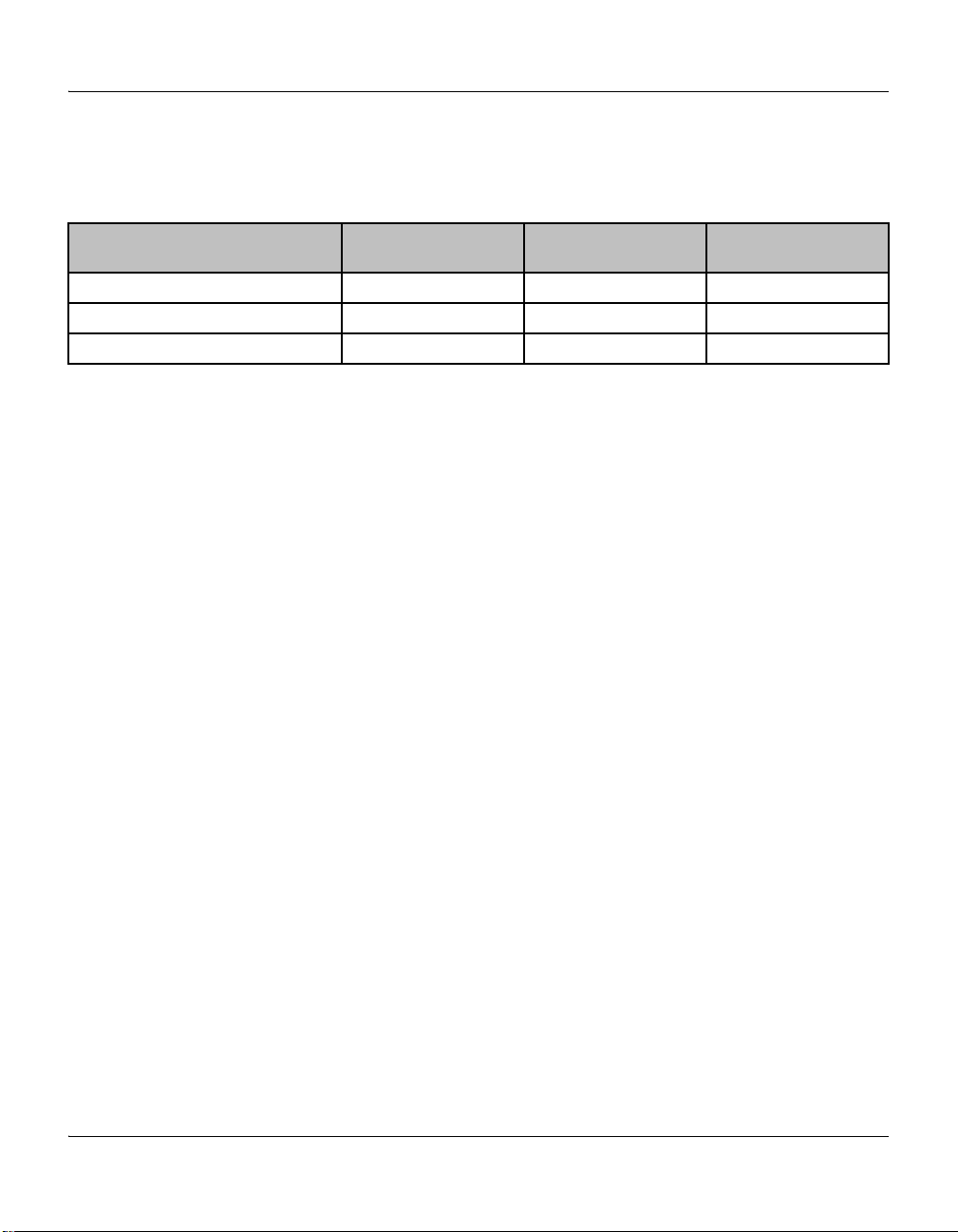

6. To change the units of measure label on the front of the Controller,

open the door and lift the label card from its slot in the top of the front

panel. Units of measure labels are included in the mounting hardware

kit.

Initial Setup

System Components Initial Setup InstallationBefore You Begin

Figure 3-4 Removing the Units of Measure Label Card

Series 358 Micro-Ion Controller Instruction Manual - 358013 - Rev. B 29

Chapter 3

3.5 Overpressure Shutdown Adjustment

Table 3-1 Pressure Range Settings

Pressure Range

Designation

Emission Current 20 μA 1 mA 4 mA

Recommended Upper Limit, Torr 5 x 10

Recommended Lower Limit, Torr 1 x 10

This control is factory set so the ion gauge will shut down when the pressure

rises above the levels given in Table 3-1.

MV

(Medium Vacuum)

–2

–6

HV

(High Vacuum)

–4

8 x 10

–7

1 x 10

To adjust the overpressure shutoff point to a different level:

1. Maintain system pressure at the desired shutoff point.

2. Rotate the overpressure adjustment potentiometer fully

counterclockwise.

3. Turn ON the ion gauge.

4. Rotate the adjustment potentiometer clockwise slowly until the ion

gauge turns OFF.

3.6 Changing Display Update Rate on Electrometer Module

When “ON”, the Slow Update switch on the electrometer module enables

pressure averaging. The display will be updated approximately every 3

seconds. When “OFF”, the update period is approximately 0.5 seconds.

Refer to Figure 3-3 on page 29.

UHV

(Ultrahigh Vacuum)

–4

2 x 10

Less than 1 x 10

–9

3.7 Changing Units of Measure for Convectron Gauge

The Series 358 Controller is shipped from the factory preset to display the

units of measure, Torr, mbar, or pascal, that you requested. To change the

units of measure for the Convectron Gauge:

1. Turn OFF power to the Controller.

2. Remove the top cover as described in Top Cover Removal on page 27.

3. Locate the Convectron gauge module. See Figure 2-4 and Figure 3-5.

4. Locate the mbar and pascal units switches.

5. Leave both switches “OFF” for Torr units. Turn ON the switch for either

mbar or pascal units.

6. Modify the units of measure of the electrometer module to be

consistent with the Convectron gauge. (See Changing Units of Measure

for Electrometer Module on page 28.)

7. Slip the label card out of the top of the front panel and apply the

appropriate pressure units label. See Figure 3-4.

8. Replace the top cover as described on page 47.

30 Series 358 Micro-Ion Controller Instruction Manual - 358013 - Rev. B

Loading...

Loading...