MKS GMW-25 Operation Manual

OPERATION MANUAL

GMW-25

RF Plasma Generator

HIGH RF VOLTAGES MAY BE PRESENT AT THE OUTPUT OF THIS

UNIT. All operating personnel should use extreme caution in handling

these voltages and be thoroughly familiar with this manual.

DO NOT USE ANY CFC (CHLOROFLUOROCARBON) SOLVENT IN THE

MAINTENANCE OF THIS PRODUCT. In recognition of our responsibility to protect

the environment, this product has been manufactured without the use of CFC's. The

CFC's

QUALITY

ISO 9001

SYSTEM

The material contained in this manual is subject to change without notice. No part of this manual may be

reproduced or utilized in any form or by any means, electronic or mechanical, including photocopying or

electronic transmission or other means of reproduction or distribution without prior written consent of MKS,

ENI Products. The drawings, specifications and other technical information contained in this manual are the

property of MKS, ENI Products and shall not be copied, reproduced or used in any way, in whole or in part, as

the basis of manufacture or sale of similar items without the prior written consent of MKS, ENI Products.

no-clean flux now used in all soldering operations may leave a small inert residue that

will not affect the performance of the product. The use of CFC's for cleaning or

maintenance may result in partial liquification of the no-clean flux residue, which will

damage the unit and void the warranty.

This product is manufactured at an MKS Instruments’ ISO-9001:2000-QualitySystem-compliant facility.

Notice

Manual Order Number: 1050-001 Copyright © 1996 MKS Instruments, Inc. All rights reserved.

Revision Level: B 10/07/04 MATCHWORK

®

is a registered trademark of MKS Instruments, Inc.

Warranty

MKS, ENI Products warrants to the original purchaser for a period of one year from the date of

delivery, each instrument to be free from defects in materials and workmanship. For a period of one

year, MKS, ENI Products will, at its option, adjust, repair, or replace defective parts, without charge to

the original purchaser, so that the instrument performs according to its specifications.

When warranty service is required, the instrument must be returned, transportation prepaid, to

the factory or to one of MKS, ENI Products' designated service centers. If, in our opinion, the

instrument has been damaged by accident, unreasonable use, buyer-supplied software or interfacing,

improper site preparation or maintenance, or abnormal conditions of operation, repairs will be billed

at standard rates. In this case, an estimate will be submitted before the work is started.

THIS LIMITED WARRANTY IS EXCLUSIVE AND MKS, ENI PRODUCTS MAKES NO OTHER

WARRANTIES, EXPRESS OR IMPLIED, AND ALL OTHER EXPRESS ORAL OR WRITTEN

WARRANTIES AND ALL WARRANTIES IMPLIED BY LAW, INCLUDING ANY WARRANTIES OF

MERCHANTABILITY

QUALITY ARE EXCLUDED

LIABLE FOR SPECIAL, INDIRECT, INCIDENTAL OR CONSEQUENTIAL DAMAGES RESULTING

FROM BREACH OF ANY WARRANTY, WHETHER EXPRESS OR IMPLIED, INCLUDING ANY

IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE, OR

FROM ANY CAUSE WHATSOEVER, INCLUDING NEGLIGENCE. Buyer's sole and exclusive

remedy under this warranty shall be repair or replacement as set forth above, or if MKS, ENI

Products is unable to repair or replace the defective part within a reasonable time, a refund of the

price of the part or goods that give rise to the warranty claim.

OR FITNESS FOR A PARTICULAR PURPOSE OR OTHER WARRANTY OF

AND DISCLAIMED. IN NO EVENT SHALL MKS, ENI PRODUCTS BE

Service And Technical Assistance

For Service or Repair contact the closest Customer Service Department with the following

information:

• Model and serial number

• Purchase order number

• Detailed description of malfunction

• Your company's "Bill To" and "Ship To" address

You will receive a RMA (Return Materials Authorization) number, the warranty status of the unit to be

returned and estimated repair charge, if any. The RMA number is your authorization number. Please

type this number on your purchase order and shipping label. After MKS, ENI Products receives the

unit, a firm quote and estimated date of completion will be given.

For Technical Assistance for your particular application, contact the nearest MKS, ENI Products

Sales and Service Center. The following information will help us provide you with prompt and

efficient service:

• All of the information contained on the unit's nameplate.

• Names and telephone numbers of important contacts.

• Detailed description (i.e. physical damage and/or performance anomalies, quantitative

and/or qualitative deviation from specifications), including miscellaneous symptoms, dates

and times.

• The environment and circumstances under which the issue developed.

• Supporting test data and/or records that can be provided.

• Any previous, related conversations and/or correspondence with MKS, ENI Products.

Sales & Service Locations

ROCHESTER, NY

SAN JOSE, CA

AUSTIN, TX

ENGLAND

GERMANY

JAPAN

KOREA

SINGAPORE

TAIWAN

P.R. of CHINA

MKS Instruments, Inc.

100 Highpower Road

Rochester, NY 14623

Toll Free USA Sales Hotline:

Toll Free USA Service

Hotline:

MKS Instruments, Inc.

70 Rio Robles

San Jose, CA 95134

MKS Instruments, Inc.

1321 Rutherford Lane

Suite 200

Austin, TX 78753

1 Anchorage Court

Caspian Road

Altrincham, Cheshire

WA14 5HH, England

Sielminger Str. 63

D-70771 LeinfeldenEchterdingen (Stetten)

Stuttgart, Germany

1-21-15 Aoyagi Kunitachi

Tokyo 186-0013

Japan

ST

1

Floor, DK Plaza-I

375-1, Geumgok-dong City

Bundangogu, Seongnam

Kyonggi-do, Korea 463-805

Blk 4010 Techplace 1

#01-07/08/09

Ang Mo Ko Ave 10

Singapore 569626

2F, No. 47, Ln. 2, Sect. 2

Kuang Fu Rd.

Hsinchu 300

Taiwan, ROC

West end of 2

No. 3 building (T20-3)

No. 258 Jinzang Rd.,

Shanghai Jin Qiao Export

Processing Zone

Pudong, Shanghai 201206

P.R. of China

nd

floor,

Product and Applications information also available on the Internet at:

Tel:

(585) 427-8300

Fax:

(585) 427-7839

1-800-267-5362

1-800-724-ENI1 (3641)

Tel:

(408) 750-0300

Fax:

(408) 428-0390

Tel:

(512) 719-8000

Fax:

(512) 719-8095

Tel:

44-161-929-5500

Fax:

44-161-929-5511

Tel:

49-711-947700

Fax:

49-711-9477025

Tel:

81-425-229-011

Fax:

81-425-222-636

Tel:

82-31-717-9244

Fax:

82-31-717-9244

Tel:

65-6451-1062

Fax:

65-6451-0172

Tel:

886-3-575-3040

Fax:

886-3-575-3048

Tel:

86-21-5834-7934 or

86-21-5834-7914

Fax:

86-21-5834-7794

http://www.mksinst.com

This page intentionally left blank.

Contents

TABLE OF CONTENTS

Chapter 1 - Introduction................................................................1-1

1.1 About This Manual.......................................................................................1-2

1.1.1 Finding Your Way Around..............................................................1-3

1.1.2 Documentation Conventions..........................................................1-4

Commands .............................................................1-4

Definitions...............................................................1-4

1.2 Safety Considerations .................................................................................1-5

1.2.1 Operating and Maintenance Cautions............................................1-5

1.2.2 Shock Hazard Warnings................................................................1-5

1.2.3 Service ..........................................................................................1-6

1.2.4 Safety Labels.................................................................................1-7

RF Radiation Warning Label...................................1-7

Heavy Object Warning Label..................................1-7

1.2.5 Technical Support..........................................................................1-7

1.3 Name Plate ..........................................................................................1-8

1.4 Generator Options at a glance.....................................................................1-9

1.5 Getting Started Quickly..............................................................................1-12

Chapter 2 - System Installation ....................................................2-1

2.1 Unpacking/Inspection ..................................................................................2-1

2.1.1 Mechanical Inspection ...................................................................2-1

2.1.2 Claim for Damage..........................................................................2-1

2.1.3 Packaging for Reshipment.............................................................2-1

2.2 Installation Requirements............................................................................2-2

2.2.1 Dimension Requirements...............................................................2-2

2.3 Rack Installation..........................................................................................2-3

2.3.1 Installing into a Cabinet Assembly.................................................2-3

GMW-25 i

19-inch Cabinet.......................................................2-3

Contents

2.4 System Interconnect.................................................................................... 2-4

2.4.1 Standard 25-pin Analog I/O Interface (ENI P/N: 1050-235)........... 2-4

2.4.2 37-pin Analog I/O Interface (ENI P/N: 1050-295) .......................... 2-8

2.4.3 9-pin PL-2HF Analog I/O Interface (ENI P/N: 1050-290)............. 2-11

2.4.4 15-pin Analog I/O Interface .......................................................... 2-12

2.4.5 DeviceNet Pin Out....................................................................... 2-13

2.5 Remote Digital Interface............................................................................ 2-14

2.5.1 Communication Configuration ..................................................... 2-15

2.5.2 RS-422 Bussing........................................................................... 2-16

2.6 MATCHWORK

2.6.1 MATCHWORK

®

Interconnection............................................................... 2-17

®

Power Requirements......................................... 2-18

2.6.2 AC Power Cable Connections..................................................... 2-18

2.6.3 RF Power Connections................................................................ 2-19

2.6.4 Fiber Optic Control and Debug Cables........................................ 2-19

2.7 Safety Interlocks........................................................................................ 2-20

2.8 Panels and Controls.................................................................................. 2-22

2.8.1 Front Panel..................................................................................2-23

Display.................................................................. 2-23

LEDs..................................................................... 2-24

Controls................................................................ 2-25

2.8.2 Front Panel Options..................................................................... 2-26

Fully Functional Front Panel................................. 2-27

Remote Front Panel ............................................. 2-28

2.8.3 Rear Panel................................................................................... 2-29

Connections ......................................................... 2-29

Rear Panel Drawing ............................................. 2-30

2.9 Power Requirements................................................................................. 2-31

2.9.1 AC Mains Connection.................................................................. 2-31

2.10 Cooling Water Requirements .................................................................. 2-32

2.10.1 Water Fittings Connection ......................................................... 2-33

2.11 Maintenance & Cleaning ......................................................................... 2-34

2.12 System Check ........................................................................................ 2-35

2.13 Initial Power Up....................................................................................... 2-36

ii GMW-25

Contents

Chapter 3 - GMW-25 Operation.....................................................3-1

3.1 Basic Operation ..........................................................................................3-1

3.1.1 Generator Operation through the Front Panel ...............................3-1

Turning on AC Mains Power...................................3-1

Ensuring that the Front Panel/Remote Front Panel is

unLOCKed..............................................................3-2

Setting the RF power..............................................3-3

Entering the frequency menu..................................3-3

3.1.2 Generator Operation through the ENI Monitor...............................3-5

Turning on the generator........................................3-5

Ensuring that the ENI Monitor has control..............3-5

Selecting the mode of operation.............................3-5

Changing the requested power...............................3-7

3.1.3 Matching Network Configuration for Generator Control.................3-8

Setting the MATCHWORK

control.....................................................................3-8

3.1.4 Matching Network Operation through the Generator ...................3-10

Activating the front panel to display MW

status/Readbacks.................................................3-10

3.1.5 Changing the Matching Network parameters...............................3-11

®

up for Generator

3.2 ENI Monitor Software Commands.............................................................3-12

3.2.1 Basic Monitor...............................................................................3-13

3.2.2 Generator Control........................................................................3-14

3.2.3 Generator Readback....................................................................3-15

3.2.4 MATCHWORK

3.2.5 MATCHWORK

®

Control...............................................................3-18

®

Readback via the Generator..............................3-19

3.3 Advanced Operation..................................................................................3-20

3.3.1 Generator Front Panel Operation ................................................3-20

Changing between Auto-Tune and Manual Tune

Mode.....................................................................3-21

Setting the Minimum Search Threshold................3-22

Setting the delay time...........................................3-22

Setting the start frequency....................................3-23

Menu Navigation and Exit.....................................3-23

3.3.2 ENI Monitor Generator Operation................................................3-23

3.3.3 MATCHWORK

®

Network Operation using the Generator

Front Panel.....................................................................3-23

3.3.4 MATCHWORK Operation using the ENI Monitor......................... 3-23

GMW-25 iii

Contents

3.4 Remote Control Interface Communication Protocol .................................. 3-24

3.4.1 Space Characters........................................................................ 3-24

3.4.2 Illegal Commands........................................................................ 3-25

3.4.3 Leading Zeros and Missing User Arguments............................... 3-25

3.4.4 Special Characters ...................................................................... 3-25

3.4.5 Power-up Message...................................................................... 3-26

3.4.6 Backspace Characters................................................................. 3-26

3.4.7 Escape from Indefinite Loops...................................................... 3-26

3.4.8 Link Release Character............................................................... 3-27

3.4.9 XON and XOFF........................................................................... 3-27

3.4.10 Key Level................................................................................... 3-27

3.4.11 Link Integrity Checking .............................................................. 3-28

Chapter 4 - Troubleshooting.........................................................4-1

4.1 Hardware Faults.......................................................................................... 4-2

4.2 System Faults .......................................................................................... 4-3

4.3 Analog Remote Interface Faults.................................................................. 4-4

4.3.1 RF OVERHEAT (Hard Fault)......................................................... 4-4

4.3.2 MAX POWER (Soft Fault).............................................................. 4-4

Appendix A - GMW-25 Specifications .........................................A-1

Appendix B - Glossary of Symbols .............................................B-1

Appendix C - Glossary of Terms .................................................C-1

iv GMW-25

Introduction

Chapter 1

Introduction

The GMW-25 Plasma Generator is a rugged, highly reliable RF power

source for plasma etching, CVD, and sputtering applications. Featuring

precise power control and digital interfacing and increased load-power

capability, the GMW-25 generator provides the exceptional reliability

and repeatability required for today’s demanding plasma processes.

Operating at a customer-specified frequency in the range of 1.8 MHz to

2.17 MHz, the GMW-25 generator produces 2500 W of power into a

50Ω load. The DSP-based control module automatically measures

forward RF power and reflected RF power, maintaining constant power

output within ±1% of set point over a Dynamic Power Range of 25 to

2500 watts.

Precise power calibration is traceable to NIST (National Institute of

Standards and Technology) through the ENI Power Standard. Low

harmonic distortion and spurious-free performance complement the

unit’s RF power output control and unconditional RF stability.

An extremely rugged and highly efficient RF power section ensures

greater power delivery into fixed match systems. The DSP-based

control constantly monitors internal subsystem status to maximize

system availability. Extensive built-in diagnostics and internal fail-safe

memory simplify maintenance requirements and increase system

uptime.

A new 9-pin digital interface provides remote control, monitoring and

diagnostic capability via the RS-232 serial link to a computer or host

terminal. Optional custom interface cards are also available.

GMW-25 1-1

Introduction

1.1 About This Manual

The manual provides all of the information required to safely install,

setup, and operate your generator. While every attempt has been

made to provide a concise set of installation and operating procedures

in the Getting Started Quickly section, detailed instructions are also

available.

It is essential that you become thoroughly familiar with the contents of

this manual prior to using your generator. If used properly, the

information contained in this manual will not only promote reliable

generator performance but will also encourage a safe operating or

service environment for all individuals.

1-2 GMW-25

Introduction

1.1.1 Finding Your Way Around

This manual is divided into five chapters and three appendices. The

main Table of Contents will help you to quickly locate the chapter that

contains the information you may be seeking. The following is a brief

description of each chapter.

Chapter 1

Chapter 2

Chapter 3

Chapter 4

Chapter 5

Appendix A

Appendix B

Appendix C

The chapter you are reading. This chapter provides information

on the content of the manual, the documentation conventions

used, safety considerations that need to be observed, and a

concise Getting Started Quickly section.

This chapter acquaints the user with the GMW-25 Plasma

Generator. It covers major features and front and rear panel

descriptions.

This chapter covers everything needed to install and set up your

generator from Unpacking and Inspection to Initial Power up.

This chapter covers in more detail how to operate your generator

and take advantage of all of its features.

This chapter details common troubleshooting situations and

solutions you may encounter when using your generator.

This appendix provides complete physical and electrical

characteristics of your generator.

This appendix provides a glossary of all the symbols used in this

manual and on the generator per UL, CSA, TUV, and CE

certifications.

This appendix provides a glossary of new terms that have been

used throughout this manual.

GMW-25 1-3

Introduction

1.1.2 Documentation Conventions

To better emphasize important information in this manual, the below

methods of formatting have been used to call attention to this

information.

Commands

Many parts of this manual refer to computer commands and data. It is

important to recognize the conventions used in this manual in order to

understand the meaning of these commands.

Angle Brackets

Rounded Brackets

Square Brackets

< >

( )

[ ]

These brackets are shown for command parameters.

They are not part of the command and should not be

entered.

These brackets contain hex-equivalent numbers for

printable or non-printable characters. The lower-case "h

(h) stands for hexadecimal.

These brackets indicate a symbol name for special

control codes or non-printable characters. Examples of

commonly used control codes are listed below.

[LF] Line Feed (0Ah)

[CR] Carriage Return (0Dh)

[ESC] Escape (1Bh)

Definitions

This icon is used to set off a definition of a new term used in this

manual. Appendix C provides a complete list of all the new terms used

here.

1-4 GMW-25

Introduction

1.2 Safety Considerations

Certain safety considerations must be observed before operation of

this generator can be attempted. Safety labels are used in both the

manual and on the generator to alert operating and service personnel

to conditions that may cause personal injury or damage to the

equipment from misuse or abuse. Please read the labels and

understand their meaning.

1.2.1 Operating and Maintenance Cautions

The caution label is used in this manual to caution the reader that

failure to follow important operating or maintenance instructions could

adversely affect equipment reliability.

1.2.2 Shock Hazard Warnings

The warning label is used in this manual to warn the reader of a

procedure or practice that could result in personal injury if not followed

carefully.

The lightning bolt within a triangle is used to alert operating and service

personnel to the presence of un-insulated voltage within the enclosure

of sufficient magnitude to cause dangerous electric shock. Only

authorized service personnel with a schematic diagram and knowledge

of the voltages existing within the equipment shall remove covers or

panels bearing this symbol.

GMW-25 1-5

Introduction

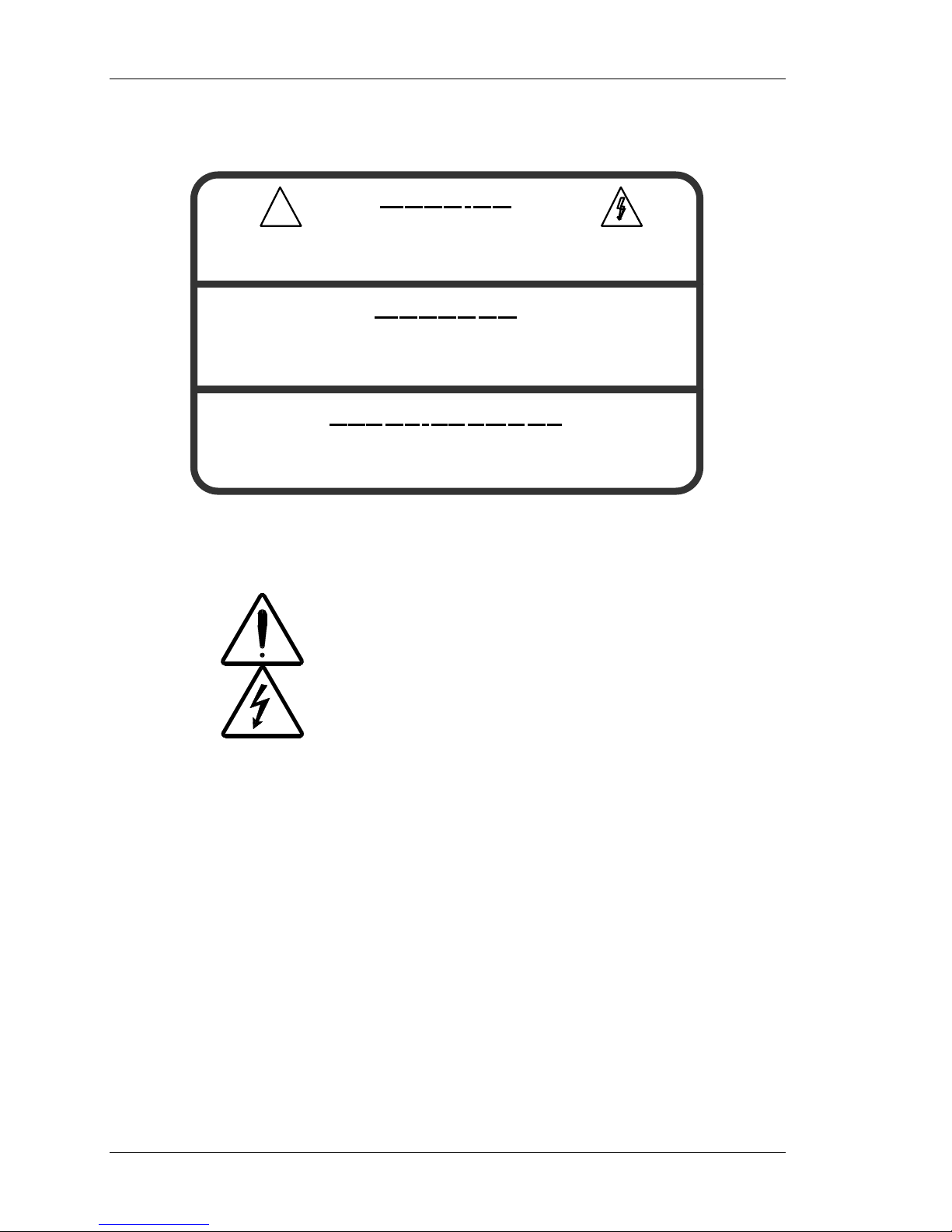

1.2.3 Service

!

-- SERVICE BY AUTHORIZED PERSONNEL ONLY

-- REFER TO INSTALLATION AND OPERATING INSTRU CTIONS

-- DISCONNECT POW ER FOR ANY SERV ICE WORK

-- SERVICE NUR VON FACHPERSONAL

-- INSTA LLATIONS - UND G EBRAUCHSANWEISUNG B EACHTEN

-- BEI SERVICE ARBEITEN VOM NETZ TRENNEN

-- CONFIER LA MAINTEN ANCE A` UNE PERSONNE QUALIFEE

-- CO NSULT ER LA NOTICE D'INS TALLA TION E T D'UTI LISATION

-- COUPER L' ALIMENTATION AVANT TOUTE MAINTENANCE

WARNING

WARNUNG

AVERTISSEMENT

Service Warning Marking

Figure 1.2.3

MKS, ENI Products is responsible for safety, reliability, and

performance of the equipment only if:

• Assembly operations, extensions, readjustments,

modifications, or repairs are carried out by authorized

personnel.

• The electrical installation is made in accordance with the

installation instructions provided and the room in which the

equipment is installed complies with the environmental

requirements.

• The equipment is used in accordance with the instructions

for use.

1-6 GMW-25

Introduction

1.2.4 Safety Labels

RF Radiation Warning Label

This label is used to caution the user that the unit produces RF

radiation that can be harmful.

Heavy Object Warning Label

This label is used to caution the user that the unit weighs over 35 lbs

(16 kg) and should be moved by two people.

1.2.5 Technical Support

On the back of the generator is a label with an "800" number for MKS,

ENI Products’ Technical Support. Should you have any difficulties with

your generator and have exhausted all possibilities in the

Troubleshooting Chapter, please feel free to call us.

1- 800- 724- ENI1 (3641)

TECHNI CAL SUPPORT

Technical Support Label

Figure 1.2.5

GMW-25 1-7

Introduction

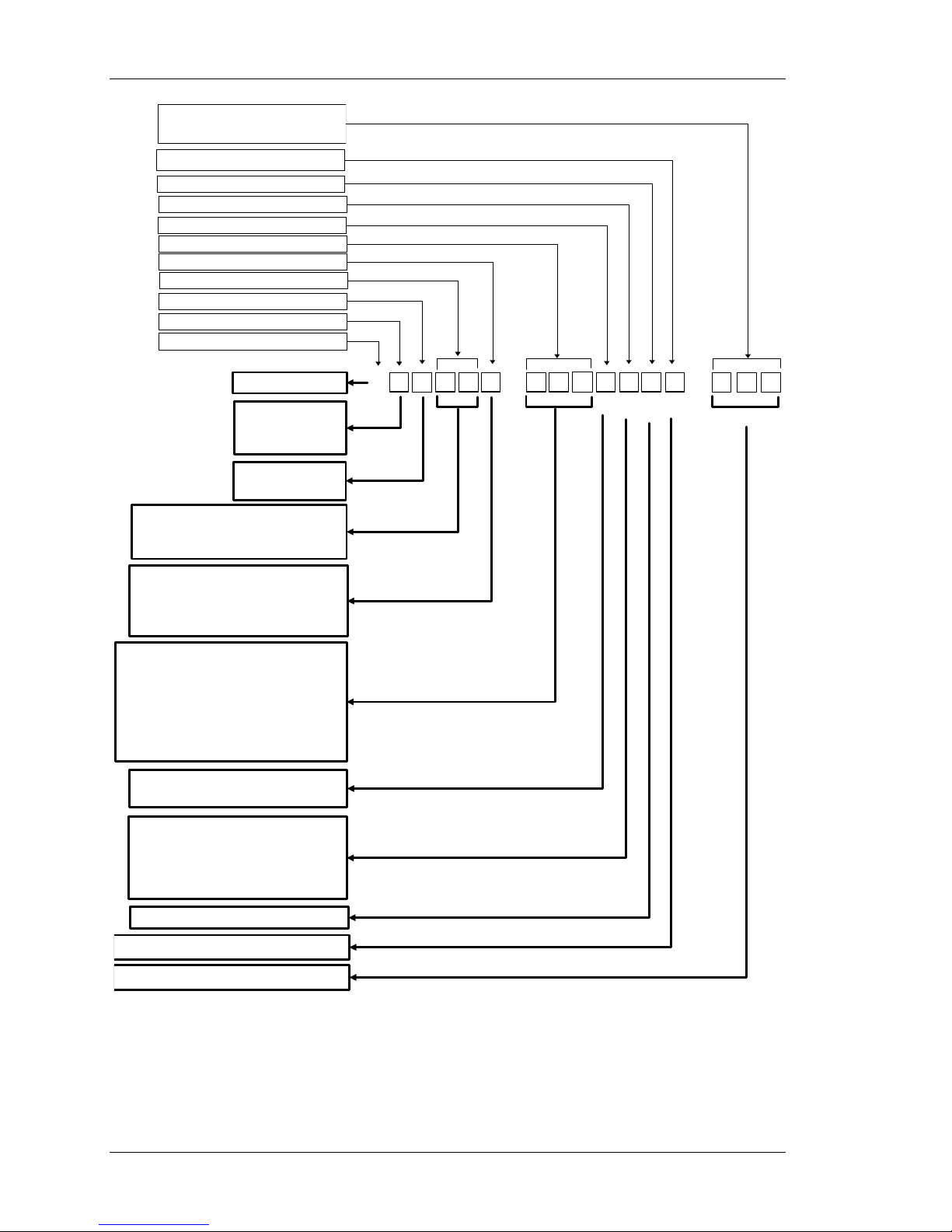

1.3 Nameplate

The GMW-25 Plasma Generator can be identified by a nameplate on

the back of the unit that contains the following information:

GMW-25 Serial Tag Label

A.

ENI MODEL NUMBER:

The model number that uniquely

identifies the unit.

B.

PART NO:

The assembly number that uniquely

identifies the product configuration.

(See section 1.4 for more information

on the model number.)

C.

SERIAL NO:

The number that is sequentially

assigned as the product is

manufactured.

D.

SOFTWARE VERSION:

The version number that identifies the

software configuration.

E.

WEIGHT:

The weight of the unit.

Figure 1.3

I

F.

RF OUTPUT:

The output of the unit in watts and its

operating frequency.

G.

CUST P/N:

A number that is specific to the

customer who ordered the unit and

that contains the customer's own part

number and revision level.

H.

ENI REV:

The revision letter that identifies the

product configuration. Revision A is

the initial revision level.

I.

DATE:

The date of manufacture in

MM/DD/YY format.

1-8 GMW-25

Introduction

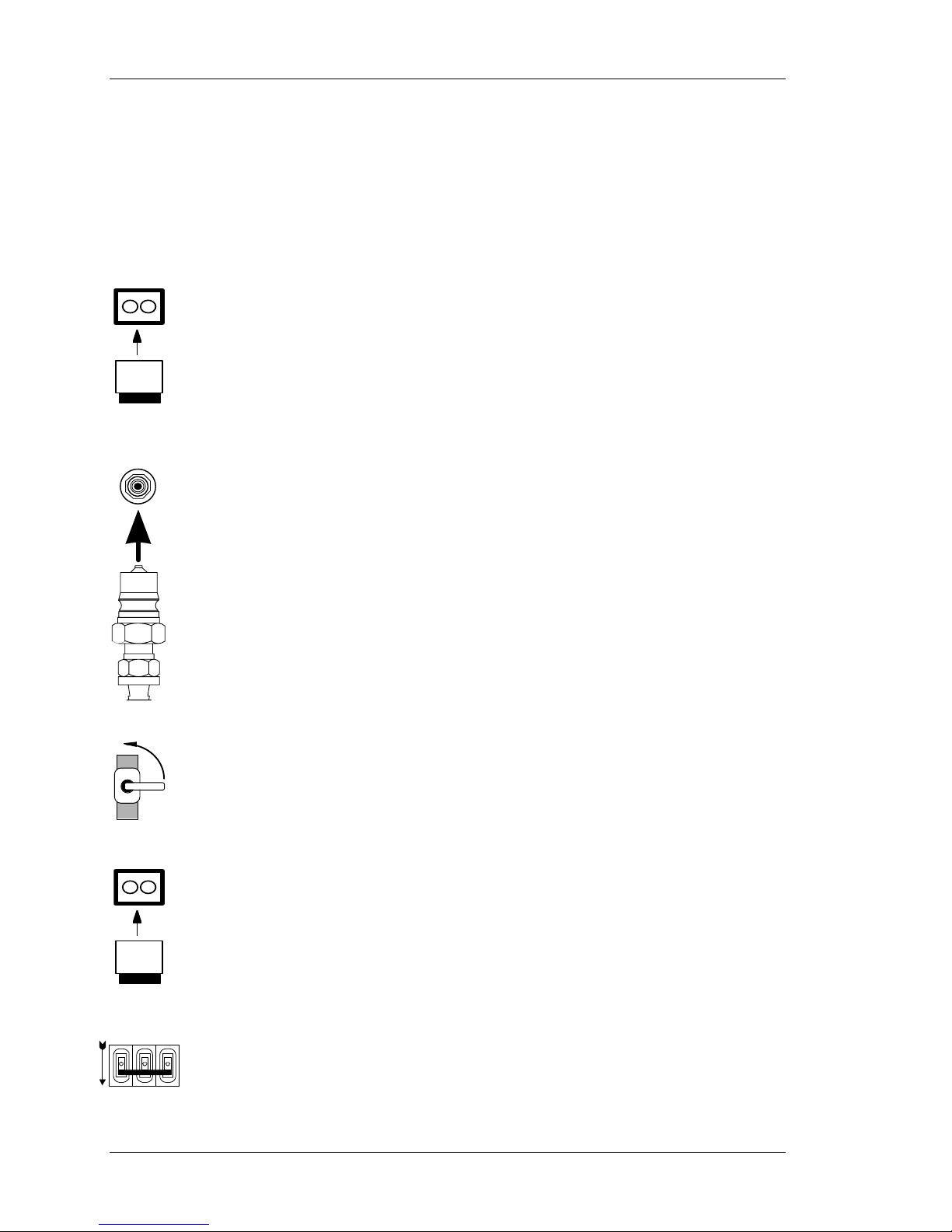

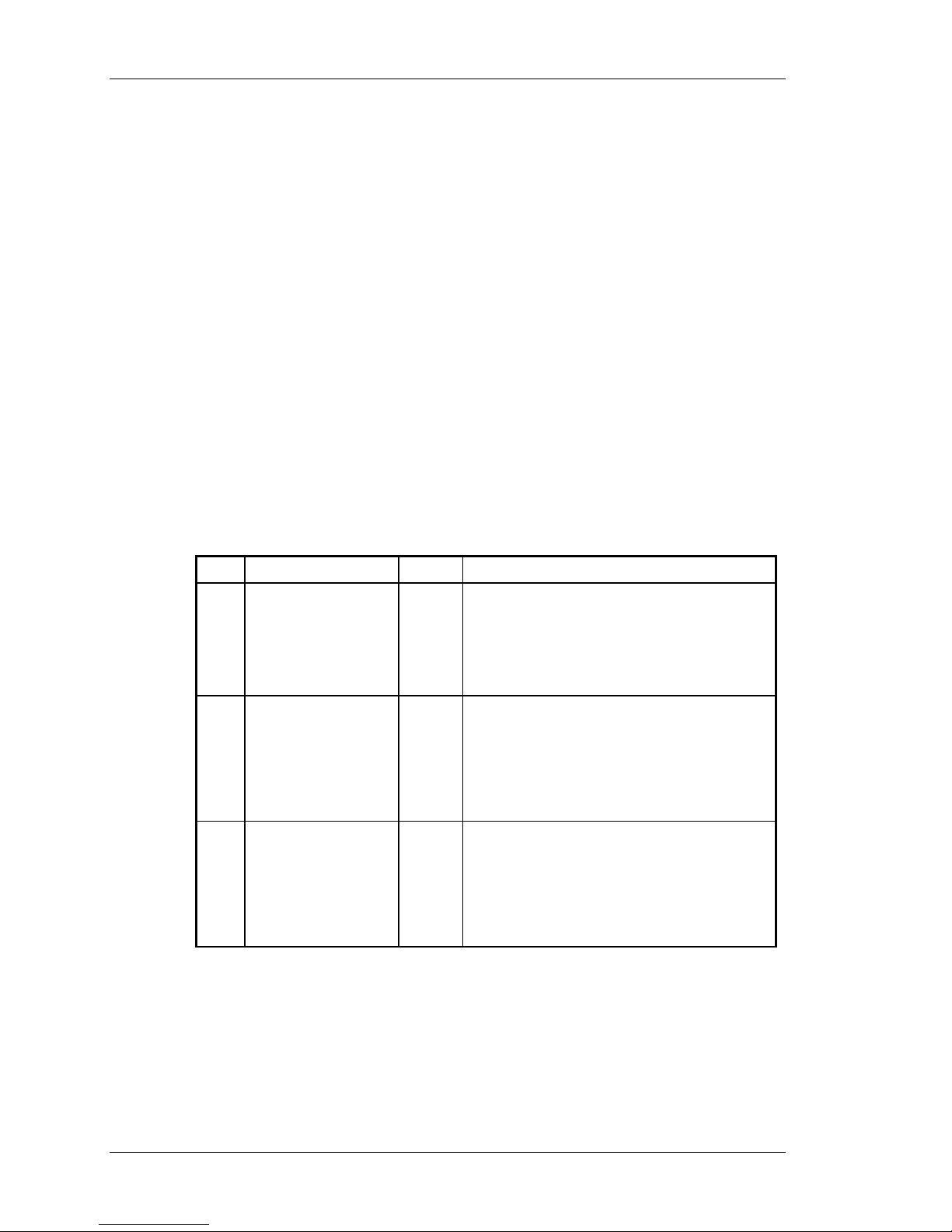

1.4 Generator Options at a glance

Before the unit is installed and powered up, it is important to ensure

that the correct unit was received. The model numbers of the Genesis

line of generators have been configured in such a way that it is easy to

tell what option has been installed on a specific unit. The number

generated from this matrix defines the configuration of that unit and

results in a part number that will be utilized throughout the

manufacturing process.

This matrix should be used to compare the configuration of the unit

that was initially ordered to the configuration of the unit received. If

they are different, contact the nearest MKS, ENI Products’ Sales or

Service location for assistance.

GMW-25 1-9

Introduction

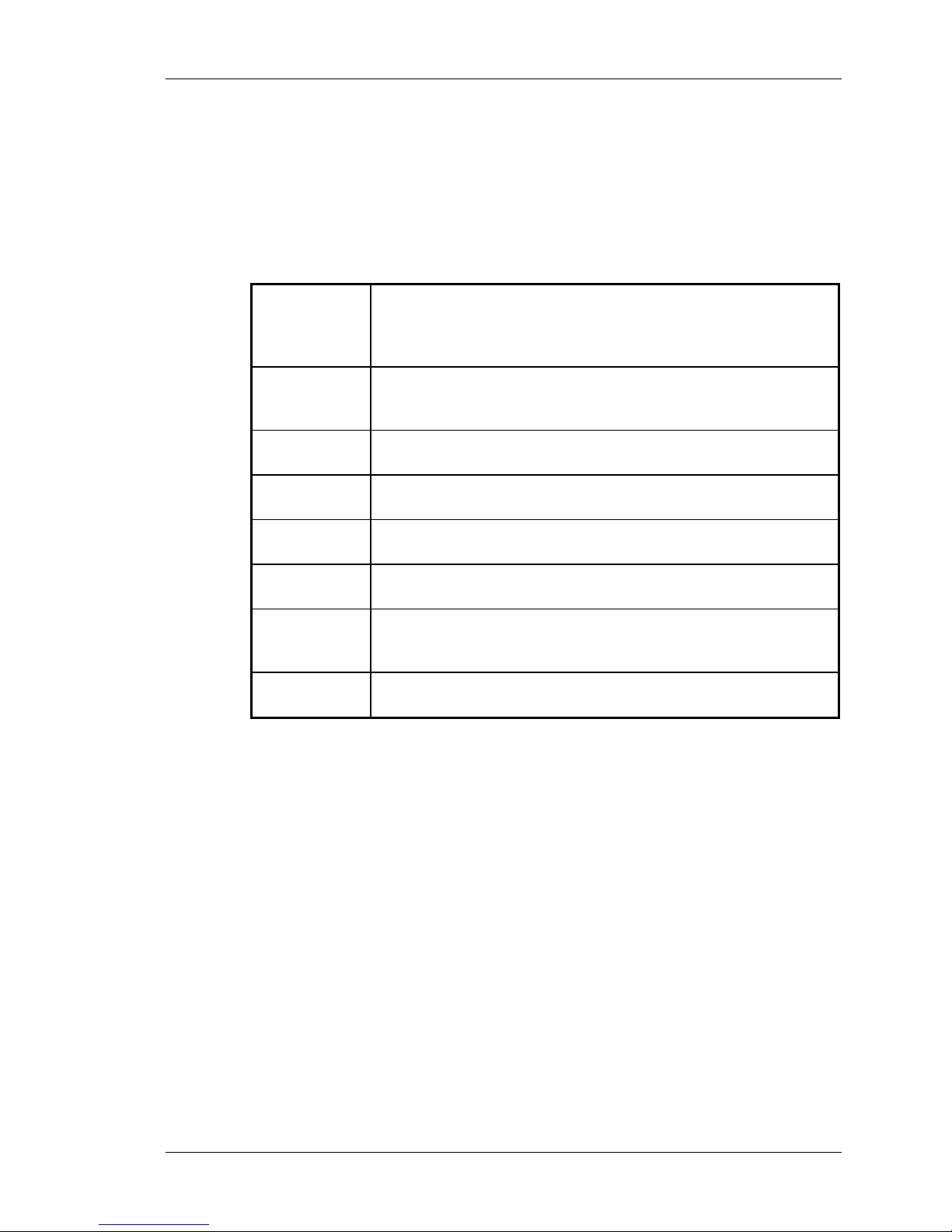

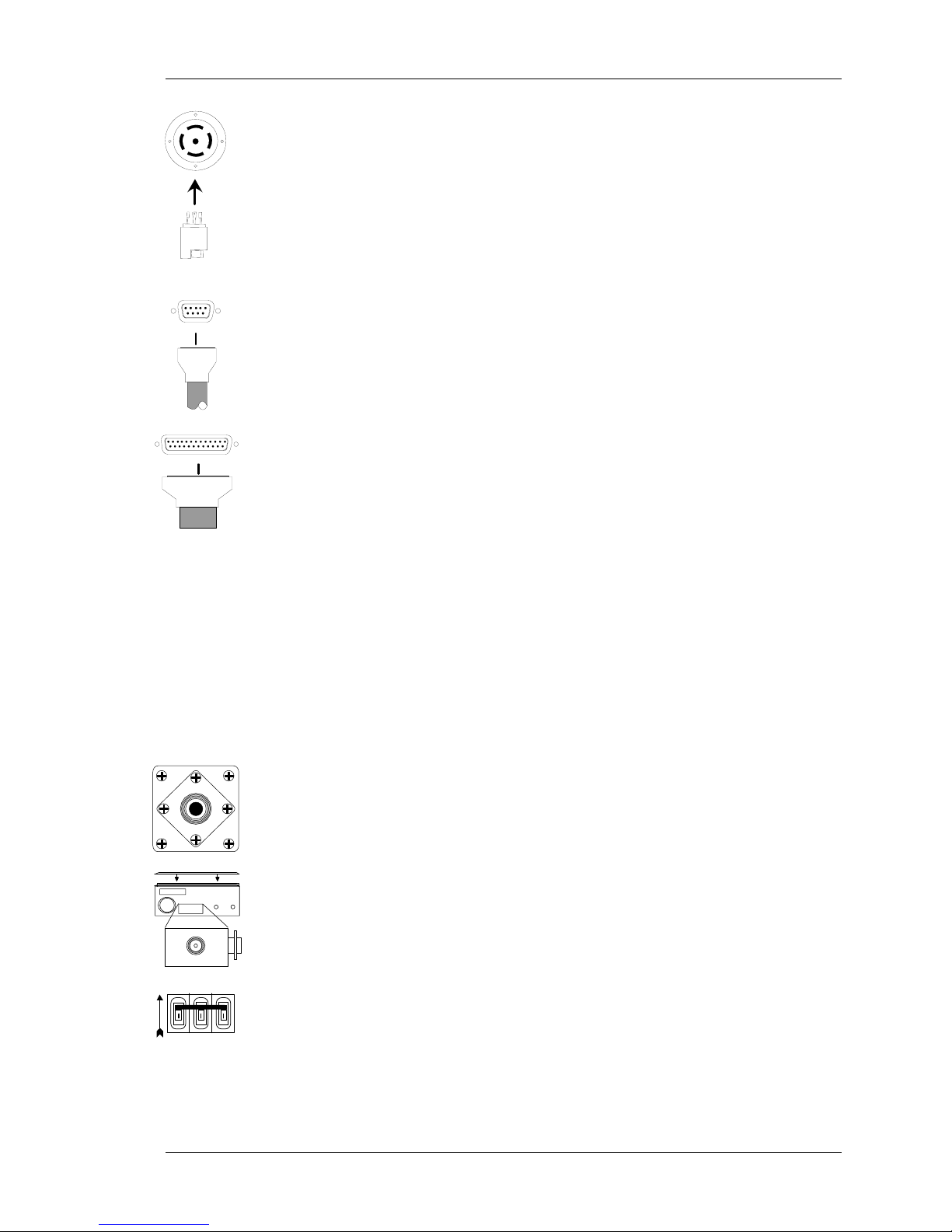

Interface Card Configuration

For ENI Inte r nal Use Only

Blank

Output RF Connector

Front Panel Configuration

Frequency

AC Input Phase

Power

Cooling

Frequency Range

Product Series

G

L

M

H

W

A

1.25kW

12

2.5kW

25

5.0kW

50

Single Phase North American

X

3 Phase North American

A

Single Phase Europe

Y

3 Phase Europe

E

0.2MHz

D20

0.27MHz

D27

0.38MHz

D38

0.4MHz

D40

0.8MHz

D80

1.0MHz

1D0

2.0MHz

2D0

Blank

B

Full Featured

F

None

0

9 Pin PL2-HF Emulation

1

15 Pin Analog

2

25 Pin Analog Emulation

3

37 Pin Analog Emulation

4

70

1D

2D9

4D0

12D

13D

27D

40D

2.9MHz

4.0MHz

12.56MH

13.56MHz

27.12MHz

40.68MHz

GENESIS

LOW FREQ

MID FREQ

HIGH FREQ

Water

Air

7.0kW

10.0kW

G

-

-

N, H, C, L

Reserved for Future Use

For ENI Internal Use Only

Genesis Part Number Interpreter

1-10 GMW-25

Figure 1.4

Introduction

This part number interpreter is comprised of 18 separate fields. In

these fields, letters and numbers are used to define the final

configuration of a unit.

The unit you have received should have the value “25“ in the fourth

and fifth fields of the final part number. Check the serial tag on the

back of the generator. If it doesn’t have “25” in the part number,

contact the nearest MKS, ENI Products’ Sales or Service location for

assistance.

GMW-25 1-11

Introduction

1.5 Getting Started Quickly

This section is intended to provide you with a set of instructions to

enable you to quickly set up and start running your generator.

References to more detailed information are provided at the end of

each step.

To quickly set up your GMW-25 generator, follow the procedure below:

1. Connect the solenoid valve plug.

(See section 2.10 for a description of the solenoid valve.)

2. Connect the water inlet and outlet hoses securely to the water

inlet and outlet connections on the rear panel of the generator.

(See section 2.10 for more information on the connectors.)

3. Once they are securely connected, turn both water valves to the

open position.

4. Insert the External Interlock plug into the interlock connector on

the rear panel marked “INTERLOCK.” AC Power will not engage

until this interlock is defeated (plugged).

(See section 2.7 for more information about the safety

interlocks.)

5. Make sure the AC Mains Circuit Breaker is in the OFF position

(The

O symbol should be showing).

1-12 GMW-25

Introduction

6. For units without a hard-wired line cord, plug the AC Main line

cord into the AC receptacle in the back of the unit. Make sure the

line voltage matches the voltage you selected when the unit was

ordered.

(See section 1.4 for the available line voltages and section 2.9

for more information on AC Power Requirements.)

7. Connect the 9-pin male serial digital interface to the female serial

interface connector on the rear panel.

See Table 2.5.1 for pin outs.

8. Connect an analog control cable, if you’re not running a remote

front panel, to the analog interface connection on the rear panel.

There is a safety interlock in Pins 10 and 23. This interlock must

also be defeated (in this case shorted) for the unit to work (see

section 2.4 for Interlock Pin Outs). The AC power contactor will

not engage unless this interlock is defeated.

This interface will vary depending on what type of interface was

selected when the unit was ordered.

If your unit does not have a fully functional front panel or you are

using a remote front panel or a terminal, connect the interface

input. This connection is either a 9-pin, 15-pin, 25-pin, or 37-pin

plug. (See section 2.4 for analog interface types.)

9. Connect the load from the plasma chamber to the RF output

connection. This will vary depending upon the application you

are using.

10. Make sure that the unit covers and the RF output cover are on.

There are safety interlocks in all these locations that must be

engaged or the unit will not work. (See section 2.7 for more

information about the safety interlocks.)

11. Flip the AC mains switch up to the ON position (The

should be showing). You should hear the contactor engage. The

GMW-25 1-13

front panel display should appear like the following:

I symbol

Introduction

AUX LEV MODE

REVFWD

ENI

Genesis Generator

SET POINT STATUS

The display will clear and show the following:

AUX LEV MODE

0 FP 0 0

REVFWD

0W NORMAL

or:

SET POINT STATUS

AUX LEV MODE

REVFWD

3W FP 3 1

46W 2000000 Hz

SET POINT STATUS

(This display is only shown on auto-tune generators)

12. From the terminal, you should see the following message:

Power up delay in effect-please wait

Then the terminal will show the following:

ENI monitor on

13. The generator is now ready to run RF.

1-14 GMW-25

System Installation

Chapter 2

System Installation

2.1 Unpacking/Inspection

2.1.1 Mechanical Inspection

If damage to the shipping carton is evident, request the carrier’s agent

be present when the unit is unpacked. Check for equipment damage

and inspect the cabinet and panels for dents and scratches.

2.1.2 Claim for Damage

Please notify MKS, ENI Products directly or your authorized MKS, ENI

Products’ representative if the product is mechanically damaged or

fails to meet specifications upon receipt. Retain our shipping carton

and packing material for the carrier's inspection, as well as for

subsequent use to return the unit should this become necessary.

2.1.3 Packaging for Reshipment

Whenever possible, the original shipping carton and packing material

should be used for reshipment. If the original packing material is not

available, wrap the instrument in heavy paper or plastic. Use a strong

shipping container. If a cardboard carton is used, it should be at least

200-lb. test material.

Use shock-absorbing material around all sides of the instrument to

provide a firm cushion and to prevent movement inside the container

wall on each side. Protect the front panel by means of cardboard

spacers inserted between the front panel and the shipping carton.

Make sure that the instrument cannot move in the container during

shipping. Seal the carton with a good grade of shipping tape and mark

the container: FRAGILE! ELECTRONIC INSTRUMENT

GMW-25 2-1

Drain water before shipment.

System Installation

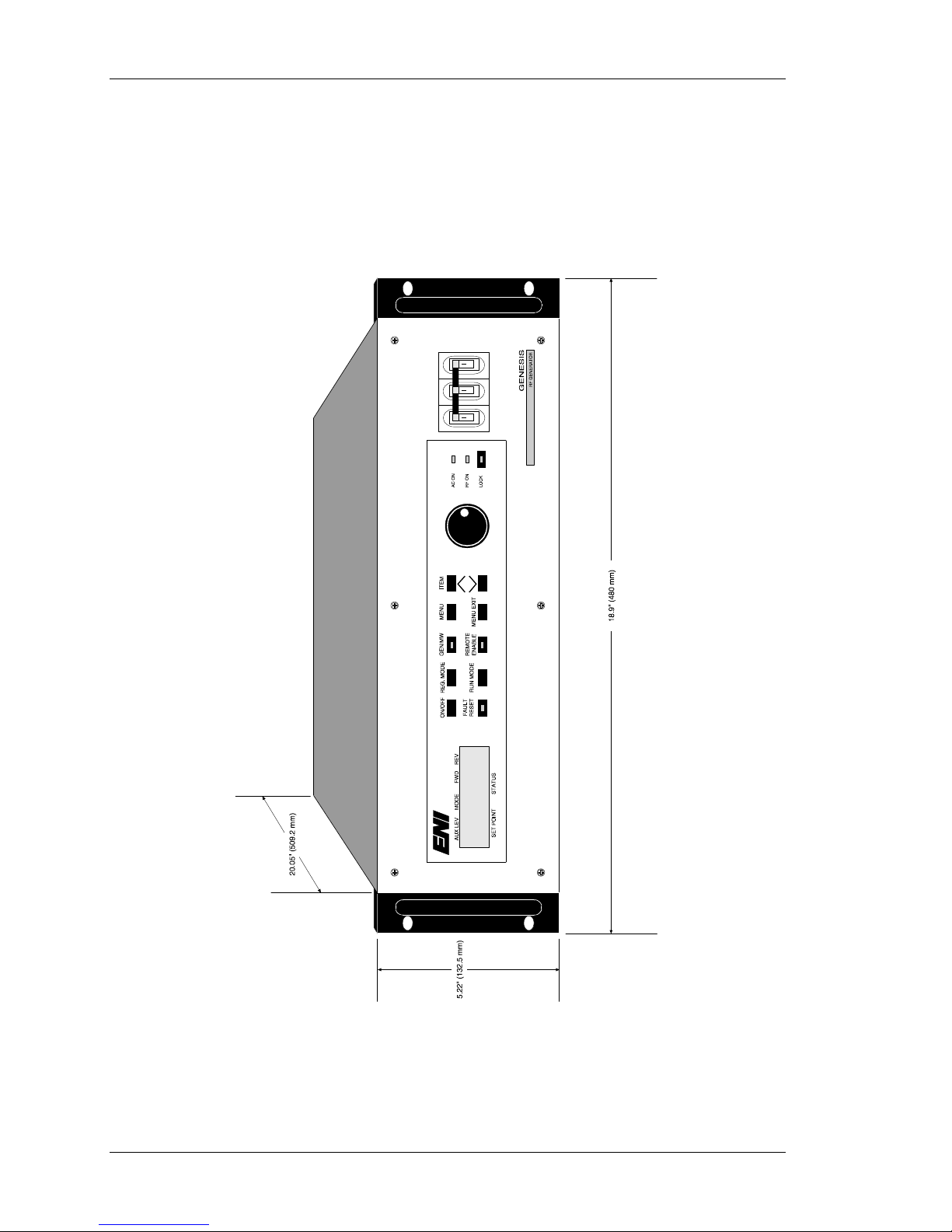

2.2 Installation Requirements

2.2.1 Dimension Requirements

The following figure shows the dimension requirements for standard

19-inch rack mountings.

Front & Side Dimension Requirements

w/ Fully Functional Front Panel

2-2 GMW-25

Figure 2.2.1

System Installation

2.3 Rack Installation

To ensure proper operation of the GMW-25, it is important to provide

correct mechanical support within a rack installation.

2.3.1 Installing into a Cabinet Assembly

The GMW-25 generator can be installed in a cabinet assembly. The

procedures for this depend upon the type of cabinet used. At the time

the unit was ordered, the cabinet type was specified. Information is

given below on installing the unit into the most common cabinet

assembly.

19-inch Cabinet

The front panel can be ordered with a hole pattern for mounting in a

19" EIA rack. However, the generator must be supported on a rack

shelf since the front panel is not strong enough to support the weight of

the generator. Ground braid must be connected from the generator

ground stud to the chassis ground on the cabinet.

Because of the weight of the generator, extreme caution

should be used during installation. Steps should be taken

to ensure that the rack will not tip when the unit is

extended out of the rack.

GMW-25 2-3

System Installation

2.4 System Interconnect

The GMW-25 generator is available with four options for the analog

interface:

• No interface card

• 25-pin analog

• 37-pin analog emulation

• 9-pin emulation for ENI’s PL-2HF generator

In order to maintain EMC compliance, I/O cables should be

constructed using shielded cable (Alpha Supra-Shield or equivalent)

and metallized backshells providing 360° shield termination.

Each of these options is described in detail below and the appropriate

pin out table is also given.

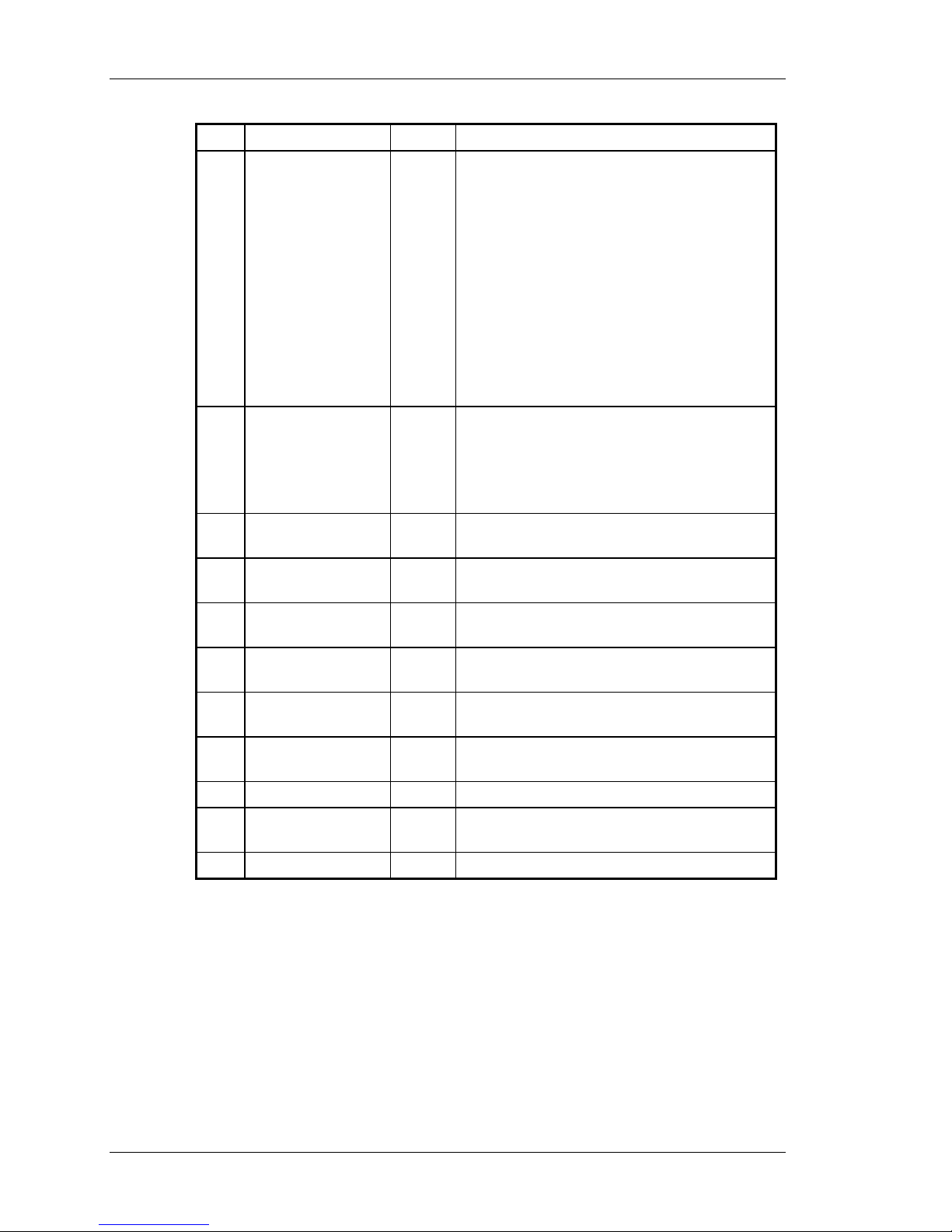

2.4.1 Standard 25-pin Analog I/O Interface (ENI P/N: 1050-235)

The analog I/O Interface for the GMW-25 generator provides:

Pin Name Type Description

1

2

3

DI = Digital Input DO = Digital Output AI = Analog

Max. Power (E) DO Emitter side of isolated transistor switch.

(See Note 1)

Transistor ON - Indicates a max. reverse

power or max. current fault.

Transistor OFF - No fault.

Reflected power (+) AO A linear DC voltage that represents the

reflected power output level.

0 V = 0 W and the max. value is adjustable

between 0 and 12 VDC. Typically

calibrated to 10 VDC = Maximum Reflected

Power Limit.

Forward power (+) AO A linear DC voltage that represents the

forward power output level.

0 V = 0 W and the max. value is adjustable

between 0 and 12 VDC. Typically

calibrated to 10 VDC = Maximum Rated

Power.

AO = Analog Output

Input

25-pin Analog I/O Interface Pin Outs

2-4 GMW-25

Table 2.4.1

System Installation

Pin Name Type Description

4

5

6

7

8

9

10

DI = Digital Input DO = Digital Output AI = Analog Input AO = Analog Output

RF ON/OFF

Control (+)

Power set point (+) AI A linear DC voltage to set the output power

+28 VDC User voltage for interface purposes. Rated

RF ON (E) DO Emitter side of isolated transistor switch.

Analog remote

enable

Overheat (E) DO Emitter side of isolated transistor switch.

Interlock This pin should connect to Pin 23 to

DI A voltage between this and Pin 17 will turn

RF power ON.

Leaving it open or applying zero voltage will

turn RF power OFF.

The nominal voltage to turn RF ON is

selectable between +5 V or +24 V via a

jumper on the control board, however it

should not exceed 30 VDC.

level.

0 V = 0 W and the max. value is adjustable

between 0 and 12 VDC. Input impedance is

100 k ohms balanced differential to ground.

50 mA max.

(See Note 1)

Transistor ON - RF ON.

Transistor OFF - RF OFF.

DI Ground referenced logic input. (See Note 2)

LOW - Selects analog remote control mode.

HIGH - Disables analog remote control

mode.

Leaving this pin disconnected will ensure a

configurable HIGH or LOW state (Rev. A

Interface only).

Note: If the generator is in digital remote

mode, it cannot switch to analog remote

mode until the digital remote mode is

disabled. Therefore, setting this pin low will

have no effect until the digital remote mode

is disabled.

(See Note 1)

Transistor ON - Overheat fault.

Transistor OFF - No fault.

complete the interlock chain.

If the interlock chain is broken, the AC

contactor will open. External circuit should

be capable of switching 100 mA at 24 VAC.

25-pin Analog I/O Interface Pin Outs (Cont’d)

GMW-25 2-5

Table 2.4.1

System Installation

Pin Name Type Description

11

12

13

14

15

16

17

18

19

20

21

Leveling select DI Ground referenced logic input. (See Note 2)

LOW - Selects forward-power leveling.

HIGH - Selects an alternative power-leveling

mode.

Leaving this pin disconnected will ensure a

configurable HIGH or LOW state.

Note: The alternate power-leveling mode is

selected via a software switch in a

CALIBRATION menu. Either load-power

leveling or an external source such as DC

Bias may be selected. The default is Load

Power Leveling.

Load power (+) AO A linear DC voltage that represents the load

power output level.

0 V = 0 W and the max. value is adjustable

between 0 and 12 VDC. Typically calibrated

to 10 VDC = Maximum Rated Power.

+15 VDC User voltage for interface purposes. Rated

10 mA max.

Max. power (C) DO Collector side of isolated transistor switch

for Pin 1.

Reflected power

return (-)

Forward power

return (-)

RF ON/OFF

Control (-)

Power set point

return (-)

GND Signal / Chassis ground.

RF ON (C) DO Collector side of isolated transistor switch

GND Signal / Chassis ground.

AO Signal return for Pin 2.

AO Signal return for Pin 3.

DI Signal return for Pin 4.

AI Signal return for Pin 5.

for Pin 7.

25-pin Analog I/O Interface Pin Outs (continued)

2-6 GMW-25

Table 2.4.1

System Installation

Pin Name Type Description

22

23

24

25

DI = Digital Input DO = Digital Output AI = Analog Input AO = Analog Output

Note 1: For all isolated transistor outputs.

Transistor OFF (switch open) - VCEmax = 40 VDC (IC < 500 µA)

Transistor ON (switch closed) - ICmax = 10 mA (VCE < 1 V)

Overheat (C) DO Collector side of isolated transistor switch

for Pin 9.

Interlock This pin should connect to Pin 10 to

complete the interlock chain.

If the interlock chain is broken, the AC

contactor will open.

Option V User voltage for interface purposes. This

voltage is configurable for

+5 VDC or -15 VDC via a jumper on the

control board. Rated 10 mA max.

Load power return

(-)

AO Signal return for Pin 12

Note 2: For all ground referenced logic level inputs.

HIGH = 2 VDC min. to 30 VDC max.

LOW = -0.2 VDC min. to 1 VDC max.

25-pin Analog I/O Interface Pin Outs (continued)

Table 2.4.1

GMW-25 2-7

System Installation

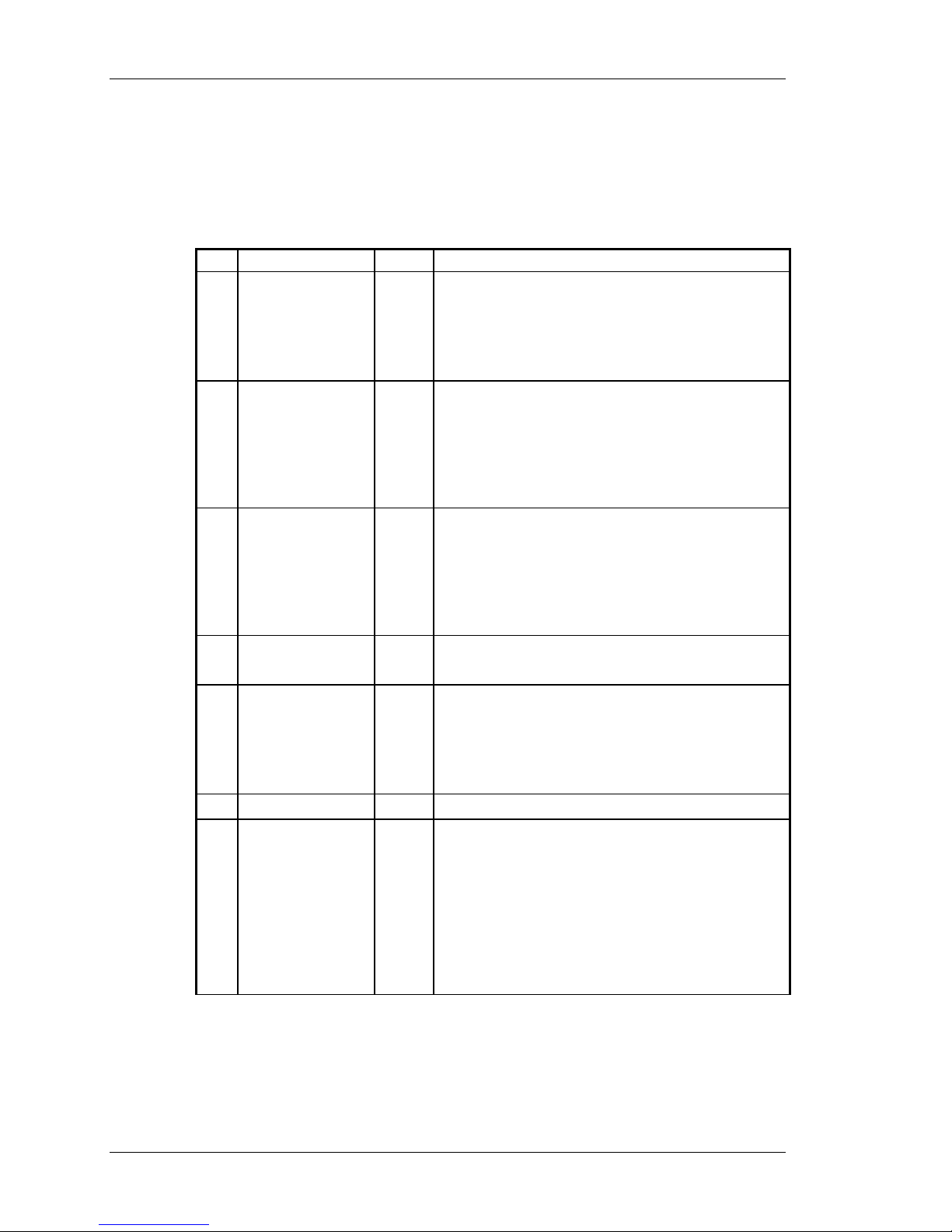

2.4.2 37-pin Analog I/O Interface (ENI P/N: 1050-295)

The 37-pin Analog I/O Interface is optically insulated from the

generator at the interface board interconnect point. Therefore, to use

this interface card, the customer system needs to source power to the

interface board on Pins 36 and 37.

Pin Name Type Description

MAX POWER (E) DO Emitter side of isolated transistor switch. (See

1

Note 1)

Transistor ON - Indicates a max. reverse power

or max. current limit.

Transistor OFF - No limit reached.

2

3

4

5

6

7

DI = Digital Input DO = Digital Output AI = Analog Input AO = Analog Output

REFLECTED

POWER (+)

FORWARD

POWER (+)

RF ON/OFF

RETURN

POWER

SETPOINT (+)

No Connect N/A NONE

GENERATOR

READY (E)

AO A linear DC voltage that represents the reflected

power output level.

0 V = 0 W and the max. value is adjustable

between 0 and 12 VDC.

Typically calibrated to 10 VDC = Maximum

Reflected Power Limit.

AO A linear DC voltage that represents the forward

power output level.

0 V = 0 W and the max. value is adjustable

between 0 and 12 VDC.

Typically calibrated to 10 VDC = Maximum Rated

Power.

DI Signal return for Pin 29.

AI A linear DC voltage to set the output power level.

0 V = 0 W and the max. value is adjustable

between 0 and 12 VDC.

Input impedance is 100 k ohms balanced

differential to ground.

DO Emitter side of isolated transistor switch. (See

Note 1)

Transistor ON - GENERATOR READY

Transistor OFF - GENERATOR NOT READY

Signal Definition:

Generator Ready = interlock chain complete (see

Pins 10 & 35) as well as no present generator

overheat condition.

2-8 GMW-25

37-pin Analog I/O Interface

Table 2.4.2

Loading...

Loading...