Page 1

Bulletin 50-November-02-05

MVT PLASTIFER®

Perchloric Acid Fume Hood

Exhaust System

INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

This publication contains the installation, operation and maintenance instructions for the MVT Plastifer Perchloric Acid

Exhaust System.

M.K. Plastics catalogs and reference material on the above system, provides additional information describin g the

equipment, performance, available accessories, and specifications.

For additional safety information, refer to AMCA publication 410-96, Safety Practices for Users and Installers of

Industrial and Commercial Fans.

For Information on special application requirements, contact M.K. Plastic’s corporate office at (514) 871-9999.

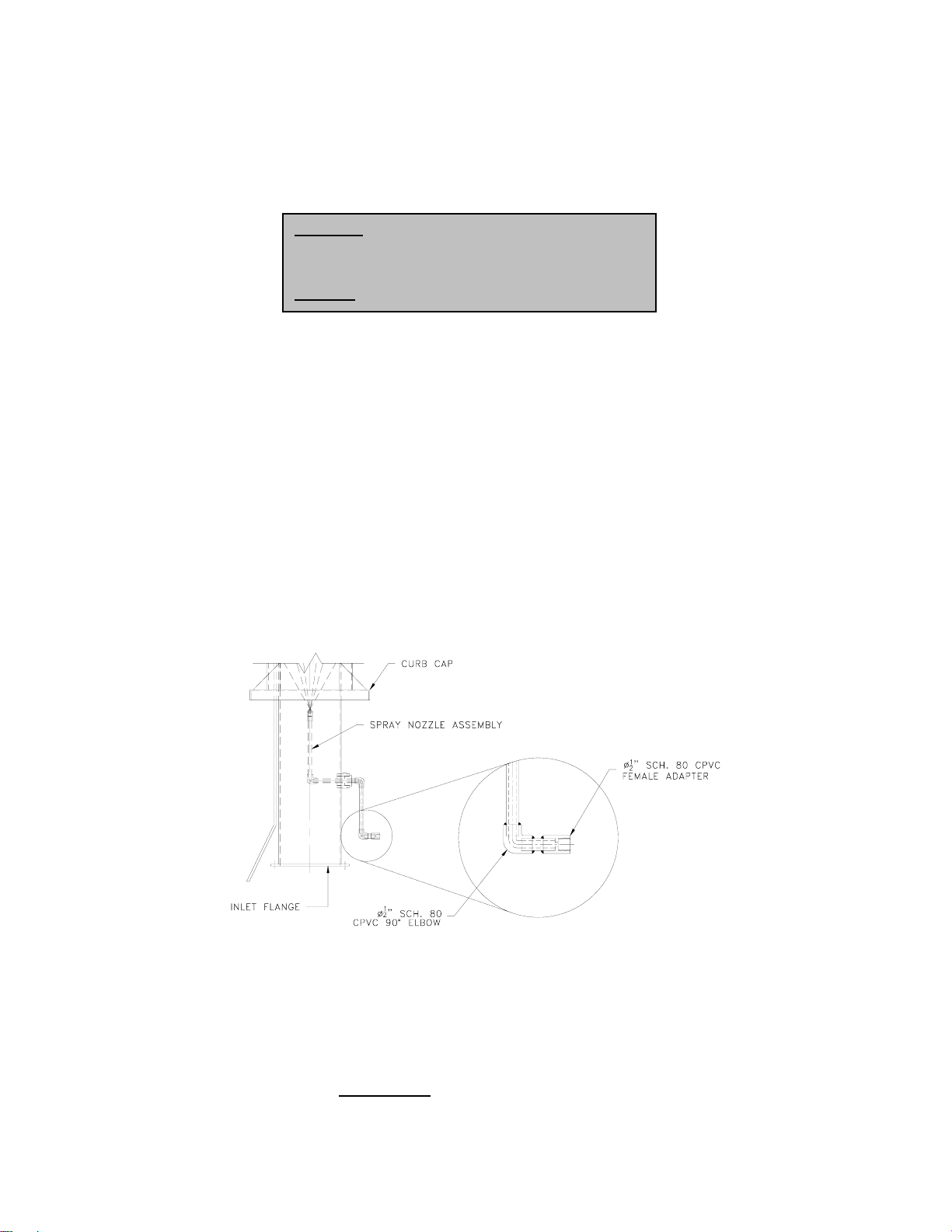

Fig. 1 – MVT Venturi Layout

1

Page 2

Receiving and Inspection

Carefully inspect the venturi/blower and accessories for any damage and shortage immediately upon receipt of the

fan.

• Turn the blower wheel by hand to ensure it turns freely and does not bind.

• Inspect the PVC manual control damper for free operation of all moving parts.

• Record on the Delivery Receipt any visible sign of damage.

This manual deals primarily with the installation and maintenance of the Venturi system in conjunction with it’s FRP

blower. For further, more complete operational & maintenance details on the FRP blower (fan), please refer to MK

Plastics Bulletin ‘Installation, Operation, and Maintenance Manual’ for FRP centrifugal & Inline fans.

WARNING

The venturi blower has rotating parts. Safety

precautions should be exercised at all times during

installation, operation, and maintenance.

ALWAYS

disconnect power prior to working on fan.

Venturi Installation

1. Set the Venturi carefully on the curb, avoiding damage to the water pipe and the electrical heater strip (if

supplied). Confirm that the Venturi stack is 100% vertical for proper washing operation.

2. The water line for the washing ring, spray nozzle and the 120-volt electrical po wer supply for the heater strip

must be below the roof.

3. Provide piping to the water lines, (washing ring and spray nozzle); install a pressure gauge and a 3-way

solenoid valve per washing line. See page .5 for details on the valves.

4. The Ø1/2” copper pipe for the Venturi washing ring runs down the length of the stack, protrudes through the

curb cap and stops short of the inlet flange for connection. The end of the pipe will be unthreaded. For the

spray nozzle attachment, there will be a Ø1/2” sch. 80 CPVC female adapter for the incoming water line.

Insure there is no debris in the adapter prior to piping connection. See Fig. 2 for details. The heater cable

will have a standard 120-volt plug for outlet electrical connection.

Fig. 2 – Spray Nozzle Detail

5. The installation of the solenoid valves should be as close as possible to the washing units, (spray

nozzles/washing rings), as detailed in the submittal. The control timer can be located as required. F or further

details regarding the washing sequence, see Fig. 4 & Fig .5.

6. Connect the Venturi stack to the perchloric acid hood by means of ductwork. Use 316 stainless steel,

unplasticized PVC or FRP ducting for corrosion resistance. Avoid any metal contact with the exhausted

fumes, such as fastening bolts or screws. Use only gasketing that is resistant to perchloric acid.

7. The weight of the ductwork should not be

used to support the weight, similar to as shown in Fig. 3.

2

supported by the ventruri stack. Additional supports must be

Page 3

Fig. 3 – Support Details (Typ.)

8. Set the Venturi blower on the roof and connect the blower outlet to stack by means of the PVC flexible

connector, PVC manual control damper and PVC reducer (all provided). Refer to MK Plastics Bulletin

‘Installation, Operation, and Maintenance Manual’ for FRP centrifugal & Inline fans on details on how to

mount the FRP blower (fan). The air pressure from the blower in the Venturi will create a vacuum to induce

air to be exhausted from the hood. Note, if an adjustment is required to the exhausted air volume, this can

be done via. the PVC control damper.

Fig. 4 – Washing Schematic (Typ.)

3

Page 4

Venturi Wash Controller (if supplied)

Perchloric acid is extremely dangerous because it is a very strong oxidizer. Dry perchloric acid crystals ar e unstable,

and when subject to shock or vibration, can explode. For this reason the Venturi stack is supplied with a washing ring

and spray nozzle for periodic washing (flushing) of the duct work to remove accumulated wall deposits, which are

soluble in water. The ‘MVT Plastifer Perchloric Acid Wash Controller’ used in conjunction with the Perchloric Acid

Exhaust Venturi system, safely and automatically washes perchlorates from the system. This control package can be

supplied by MK Plastics. See Fig. 4 to Fig. 5 for details.

Through the use of a field programmable microprocessor, wash water is directed via solenoid valv es to each wash

point in the venturi system. When the researcher shuts off the MVT Venturi exhaust fan, the wash system is

energized, sequencing wash water to be directed to the venturi wash ring first, the inlet venturi wash nozzle, second,

and then the auxiliary duct mounted wash rings. This wash cycle continues in descending order (from the top of the

system to the bottom) toward the perchloric fume hood. Wash duration per wash nozzle is fully programmable.

Wash Controller Specification

1. Control unit shall be enclosed in a NEMA 1 enclosure that shall be remotely mounted and located in the

laboratory. The control panel shall house the microprocessor, electronic switches and wiring terminals. The

panel shall have controls consisting of MVT blower Manual/On-Off switch, indicator lights, and

microprocessor display per fan, all mounted on enclosure door. Power input shall be 120 VAC.

2. Interconnecting wiring between the controller and wash solenoid panel, and the water piping between the

wash solenoid panel and the wash rings shall be the responsibility of the installing contractor.

3. A facility safety engineer shall determine the wash cycle duration and the wash duration of each nozzle.

The safety engineer shall then insure the correct programming of the wash cycle.

4. The wash cycle can be fully programmable, or have manual override by pressing the stop button.

5. Upon blower shut down, the wash system sequence shall be initiated, energizing the respective solenoid

valve, starting the wash cycle at the highest wash nozzle, and continuing down through all the wash nozzles

and rings in the perchloric exhaust system. The user has the option to have the blower operational during

the wash.

6. The total wash cycle duration and the wash duration of each nozzle shall be based upon the correct

programming of the MVT wash cycle timer by the facility safety engineer.

7. Upon completion of the wash cycle, the system shall reset itself to the OFF mode.

8. Refer to MK Plastics programming guide for specific programming information. A detailed ‘T raining Guide’

booklet will be included with each timer; this gives information on wiring, istallation and programing.

Fig. 5 – Control Timer

Wiring (TYP.)

4

Page 5

The 3-Way Solenoid Valves

These valves are 3-way, diaphragm operated, solenoid pilot controlled. T hey are made of brass with only four moving

parts: a core assembly, two diaphragm assemblies, and a disc holder sub-assembly.

Normally Closed – see Fig. 6

Solenoid De-energized: Flow is from cylinder ‘A’ to exhaust ‘E’. Pressure ‘P’ connection is closed.

Solenoid Energized: Flow is from pressure ‘P’ to cylinder ‘A’. Exhaust ‘E’ connection is closed.

The valve is designed to perform properly when mounted in any position. Ho wever, for optimum life and performance,

the solenoid should be mounted vertically and upright to reduce the possibilit y of foreign matter accumulating in the

solenoid base sub-assembly area. The flow direction and pipe con nection of the valves are indicated on the body;

pipe connections have to be in accordance with the size indicated on the nameplate and fitted accordingly. To protect

the solenoid valves, install a strainer or filter at the inlet side as close to the valve as possible.

Clean the valves periodically; in general, if the voltage to the solenoid is correct, sluggish valve operation, excessive

noise, or leakage will indicate that cleaning is required. Clean valve strainer or filter when cleaning the valve. Causes

of improper operation are as follows –

1. Incorrect Pressure: check valve pressure, the pressure to the valve must be within the range specified on

the nameplate. Pressure recommended for the Venturi washing is stated on the submittal, and may vary

depending on a particular job.

2. Excessive Leakage: Disassemble the valve and clean all parts. Replace worn or damaged parts.

Fig. 6 – 3-Way Solenoid Valve Flow Diagram

Operation and Maintenance Instructions

1. The blower must be in operation when perchloric acid exhaust hood is being utilized.

2. Program the timer to open the solenoid valves for the duration as required by the facility safety engineer. Set

washing intervals as often as necessary depending on the frequency of use of the perchloric acid hood by

examining for sediments at the back of the hood.

3. Connect the heater strip at the bottom of the Venturi to the 120-volt – 0.5A electrical supply. It must be on a

different circuit than the disconnect switch. The heater comes with a thermostat, which is built in and

maintenance free. The heater strip, (or cable), remains wrapped around the washing ring water pipe all year

round, but it is recommended disconnecting the power at the end of the season when the temperature

remains above 50ºF. The thermostat turns the cable on when exposed to temperatures below 38ºF. It will

shut off when the pipe has been heated to 45ºF. At the end of the cable, bottom of venturi stack, is a

standard electrical plug for an outlet. We strongly recommend the use of a GFCI protected circuit and not to

overload the outlet. If an extension cord is necessary, use only a properly sized, grounded, CSA/UL C ertified

cord suitable for outdoor service.

4. Water to the washing ring/nozzle must be made available and a pressure gauge installe d to assure sufficient

pressure and flow.

5. At start of system read the pressure gauge on the water pipe to confirm that it agrees with MK Plastics

specifications.

6. Verify at set periods that the wash controller is operational and functioning properly.

7. The disposal of the perchloric acid washing liquid must be done according to municipal codes and

regulations governing polluting containments.

5

3-Way Solenoid Valve

Page 6

Auxiliary Washing Rings

As part of the Perchloric Acid Exhaust System, M.K. Plastics supplies (if required) auxiliary washing rings for both

vertical and horizontal sloping duct runs from the Venturi stack to the fume hood. The auxiliary washing ri ngs should

be located every 10’-12’ on vertical ductwork and every 4’-5’ on the horizontal ductwork. See Fig. 7 for typical detail of

the auxiliary washing rings. Spray nozzles (similar to the spray nozzle on the Venturi stack) shoul d also be installed

up and down stream on each elbow. It is recommended, however, that the Venturi stack should be located as close

as possible to the perchloric fume hood, without elbows and horizontal duct runs.

Fig. 7 – Auxiliary Washing Rings

6

Loading...

Loading...