Page 1

Bulletin 40-02-June 2013

REVISIONS

REV.

DESCRIPTION

Revision DATE

APPROVED

ZONE

E.C.O. No:

REVISED

ALL

0

EMISSION

N.A.

04/27/09

LIU

CORPORATION

SERVING THE NEEDS OF MODERN INDUSTRY

INSTALLATION, OPERATION AND MAINTENANCE MANUAL

Introduction

This bulletin contains the proper installation, operation and

maintenance procedures for the standard DHK & DHK-NW

Medium to High Pressure Centrifugal Fiberglass Fan, to

ensure safe and trouble-free fan operation.

The M.K. Plastics catalog on the above corrosion resistant

FRP fan, provides additional information describing the

equipment, fan performance, available accessories, and

specications.

For additional safety information, refer to AMCA publication

410-96, Safety Practices for Users and Installers of Industrial

and Commercial Fans.

For Information on special fan application requirements,

contact M.K. Plastics corporate ofce at (514) 871-9999.

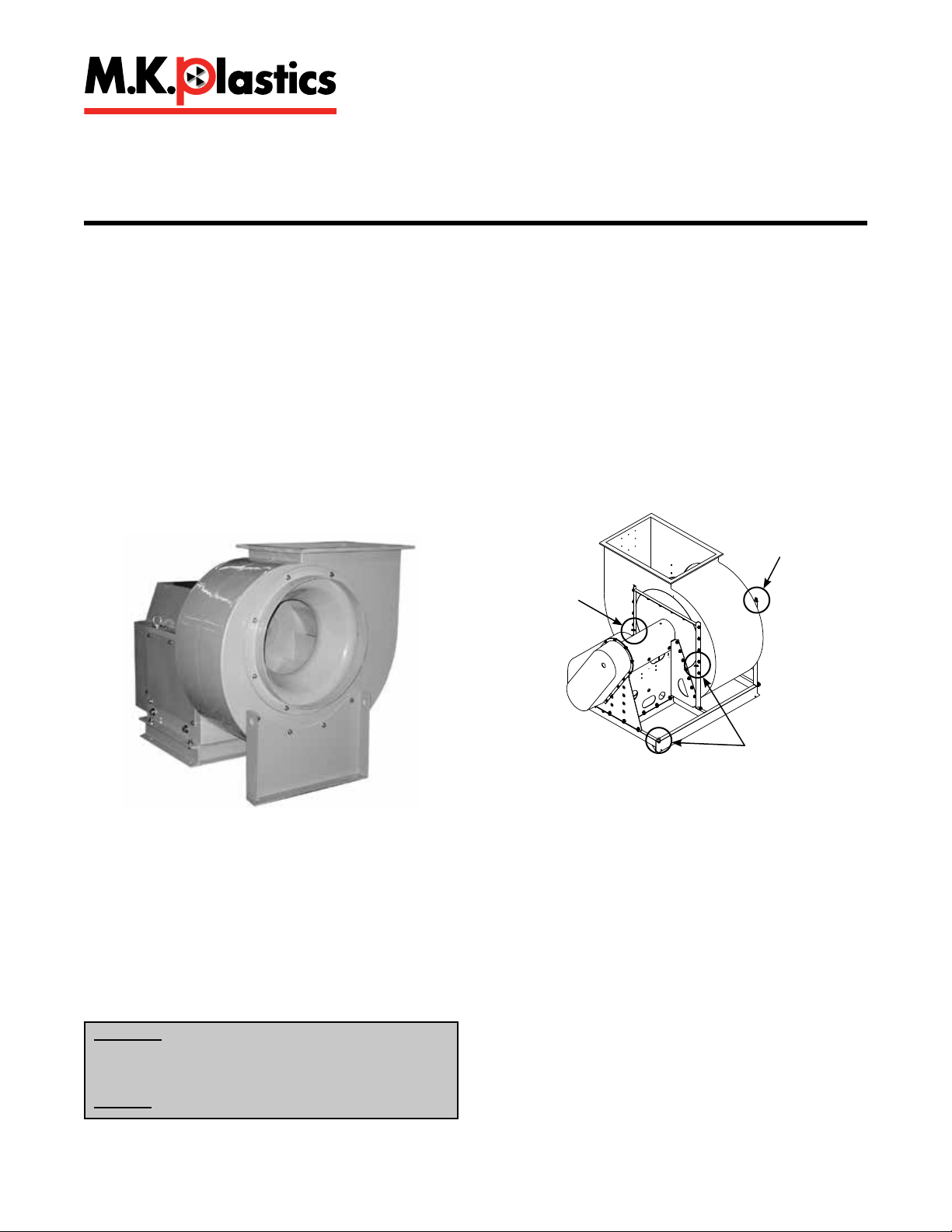

DHK & DHK-NW

Centrifugal Fiberglass Fan

Handling

Fans are to be hoisted and moved by the lifting lugs provided

on the fan (see Figure 1). Location of lugs & brackets varies

by fan size and arrangement. Fans can also be hoisted with

slings placed around the fan housing. When a single hoist

is used, a “spreader” will keep the sling from slipping on the

housing. Large units may have lifting lugs or holes which

should be used only to stabilize the unit while using a sling to

support the weight.

Chain or wire slings should be well-padded where they

contact the fan as not to cause damage to the berglass

surface. Fans should never be lifted by the shaft, fan

housing, motor, belt guard, damper, weather hood, inlet &

outlet anges or any other accessories.

Lifting Lugs

Receiving and Inspection

All M.K. Plastics fans are carefully inspected before leaving

the factory. Compare all components with the bill of lading or

packing list to verify that the proper unit was received. Check

each unit for any damage that may have occurred in transit.

Mishandled units can void the warranty provisions. If units

are damaged in transit, it is the responsibility of the receiver

to make all claims against the carrier. M.K. Plastics is not

responsible for damages incurred during shipment.

WARNING

This unit has rotating parts. Safety precautions

should be exercised at all times during installation,

operation, and maintenance.

ALWAYS disconnect power prior to working on fan.

Lifting Lugs

Lifting Lugs

Figure 1.

Lifting Using the Lifting Lugs

Storage

If the unit cannot be installed and operated immediately,

precautions need to be taken to prevent deterioration of the

unit during storage. The user assumes responsibility of the

fan and accessories while in storage. M.K. Plastics will not be

responsible for damage during storage.

Store in a dry, protected area being sure fan shaft, bearings

and impeller are protected against dust and corrosion. If it

is necessary to store outdoors or within a building under

construction, special care must be taken to prevent moisture,

dirt or dust accumulation. Coat the shaft with grease or rust

preventative compound. Cover and seal bearings to prevent

entrance of contaminants. Impeller should be rotated at least

once a month to circulate the grease in bearings. If stored

outdoors, cover completely with a tarp or heavy plastic wrap.

Electrical connections and leads must be protected from

moisture. Block impeller to prevent natural rotation. Do not

allow material of any kind to be piled on top or inside of fan.

M.K. Plastics Corp. Montréal, Québec www.mkplastics.com Page. 1

Page 2

Pre-Installation

When the unit is removed from storage after a long duration,

all bearing grease should be purged and replenished with

fresh grease as per the lubrication decal. The motor should be

measured to verify that the resistance is still at a satisfactory

level compared to the value recorded prior to storage.

Inlet & Outlet Fan Installation

Efcient fan performance relies on the proper installation

of inlet and discharge ducts. Installations with poor inlet or

discharge congurations may result in reduced performance.

Restricted or unstable ow at the fan inlet can cause pre

rotation of incoming air or uneven loading of the fan wheel

resulting in increased system losses and sound levels.

Free discharge or turbulent ow in the discharge ductwork

will also result in system losses. Make sure the following

recommendations are followed.

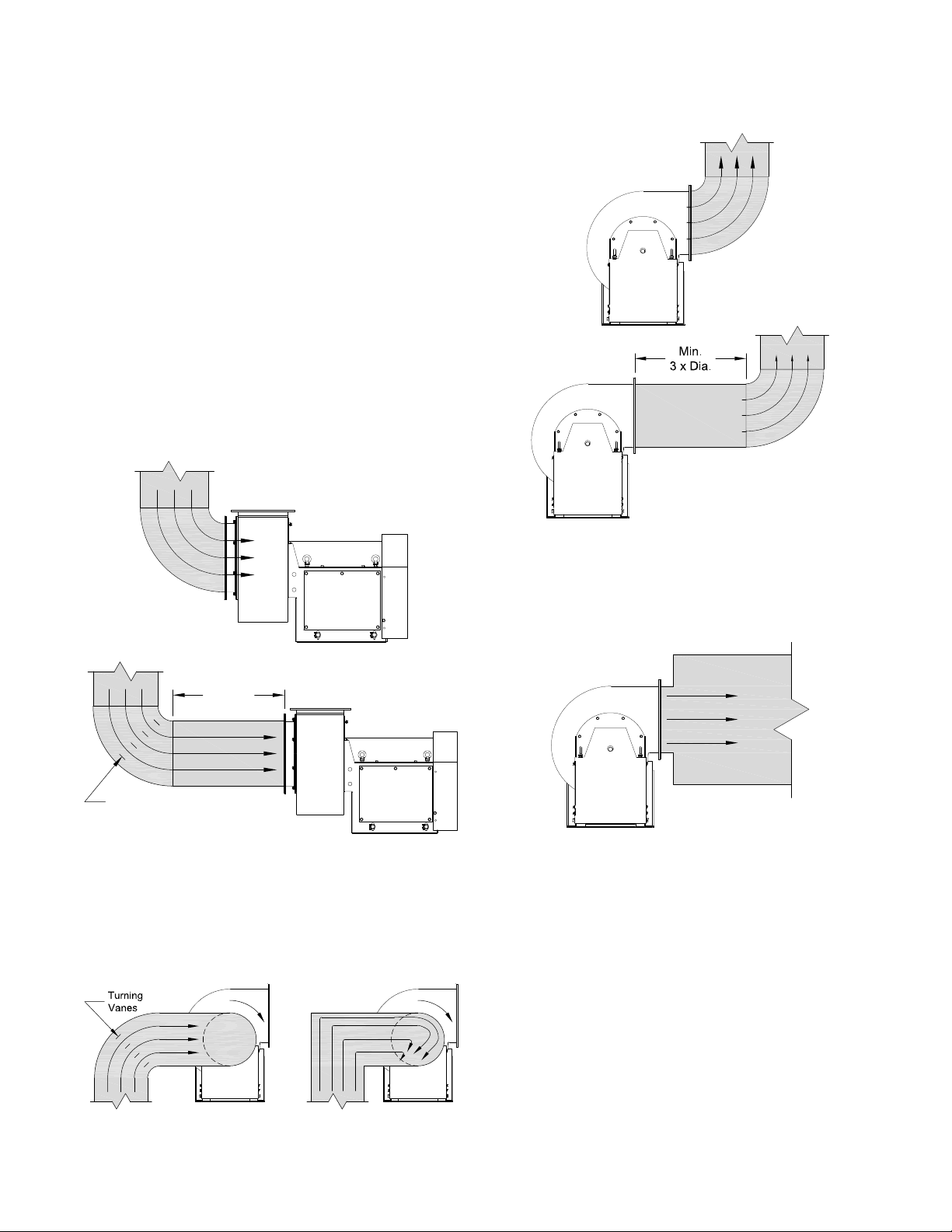

Inlet Duct Turns

Installation of a duct turn or elbow too close to the fan inlet

reduces fan performance. To achieve full fan performance,

there should be at least three effective wheel diameters

between duct turns or elbows and the fan inlet.

Poor

Discharge Duct Turns

Where possible, allow minimum three duct diameters between

turns or elbows and fan outlet. Fan performance is reduced

when turns are made immediately off the fan discharge.

Poor

Good

Min.

3 x Dia.

Turning Vanes

Figure 2 - Inlet Ducting

Good

Inlet Spin

A common cause of reduced fan performance is inlet spin. To

prevent this occurring, it is good practice to use turning vanes

in the duct to reduce the effects.

Good Poor

Figure 3 - Inlet Spin

Figure 4 - Outlet Ducting

Free Discharge

Avoid a free discharge into the plenum. This will result in

lost efciency because it doesn’t allow for a static regain.

Figure 5 - Free Discharge

Fan Installation

Follow proper handling instructions given earlier.

• Move the fan to the nal mounting position.

• Remove skid, crates, and packing materials carefully.

• If supplied, place vibration pads or isolation base on

mounting bolts. Line up holes in fan base with bolts.

• Place fan on mounting structure. Carefully level utilizing

shims as required at all mounting hole locations. Bolt

down the unit.

• Any grout may now be used. Bolt the fan in position

before applying grout. Do not depend upon grout to

support rotating equipment.

• Continue with Operations Checklist.

Additional instructions may be given for some fan sizes,

components and accessories in the submittal.

M.K. Plastics Corp. Montréal, Québec www.mkplastics.com Page. 2

Page 3

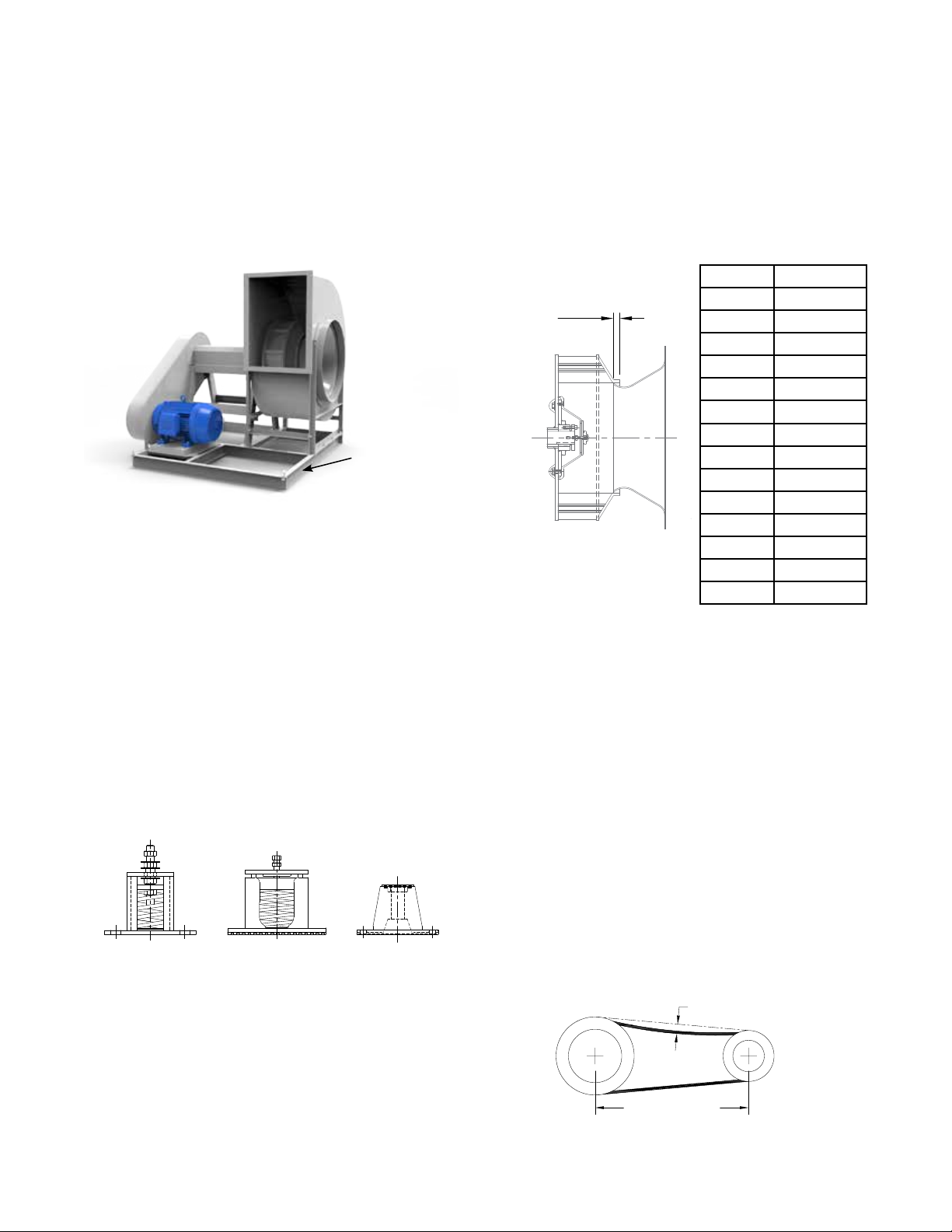

Isolation and Support Foundation

Essential to every DHK fan installation is a strong, level

foundation. A correctly designed concrete foundation with

a structural steel base or inertia base provides the best

means of supporting oor mounted units. Any foundation

size is determined by the fan arrangement, size, weight,

motor weight, position or fan orientation and location of the

installation. The weight of the foundation must be greater

than the weight of the fan and its motor. Roof or oor structure

supports should be per the structural engineer, in accordance

with load requirements and applicable building codes.

Isolation Base

Figure 5 - Isolation (Unitary) Base

Vibration Isolators

To prevent vibration and noise from being transferred to

the building, vibration isolators are recommended. Isolators

should be located between the fan system and the support

structure. M.K. Plastics supplies three main types of isolators

for FRP fans:

• Floor Mounted Seismically Restrained Spring Isolators

(1” to 4” deection)

• Floor Mounted Non-Restrained Housed Spring Isolators

(1” to 3” deection)

• Floor Mounted Rubber-In-Shear Isolators (rubber

mounts)

Refer to the M.K. Plastics submittal for isolator installation

and adjustment instructions. In applications where seismic

installation is required, refer to the M.K. Plastics submittal for

further details.

Seismically Restrained

Spring Isolator

Housed Spring Isolator Rubber-In-Shear

Isolator

Figure 6

Vibration Isolators (Typical)

Wheel-Inlet Overlap

Efcient performance is achieved by having the correct wheel

to inlet overlap and uniform radial gap. This should always be

veried before initial start-up and if possible after the fan has

been in operation for 24 hours.

The overlap is adjusted by loosening the wheel hub on the

shaft and moving the wheel to the correct position - refer to

Table 1. for values. A uniform radial gap (between the edge of

wheel inlet and edge of inlet cone) is achieved by loosening

the bolts on the inlet cone and centering it on the wheel. In

both cases, a trim balance maybe required.

Size Overlap

1225 7/16”

Overlap

Figure 7

Wheel/Inlet Overlap

1500 5/8”

1825 3/4”

2225 15/16”

2450 1”

2700 1-1/16”

3000 1-5/16”

3300 1-3/8”

3650 1-1/2”

4025 1-5/8”

4450 1-13/16”

4900 2”

5425 2-1/8”

6000 2-3/8”

Table 1

Wheel/Inlet Overlap

Drive Maintenance and Installation

V-belt drives need periodic inspection, retensioning, and

occasional belt replacement. When inspecting drives, look for

dirt buildup, burrs or obstructions that can cause premature

belt or drive replacement. If burrs are found, use ne emery

cloth or a stone to remove them. Be careful that dust does

not enter the bearings. Check sheaves for wear. Excessive

slippage of belts on sheaves can cause wear and vibration.

Replace worn sheaves with new ones. Carefully align

sheaves to avoid premature sheave failure.

Belt tension is determined by the sound the belts make

when the fan is rst started. Belts will produce a loud squeal

which dissipates after the fan is operating at full capacity. If

the belt tension is too tight or too loose, lost efciency and

possible damage can occur. The proper tension for operating

a V-belt is the lowest tension at which the belts will not slip

at peak load conditions. For initial tensioning, the proper belt

deection half-way between pulley centers is 1/60” for each

inch of belt span.

Deflection [inch]

After the fan, isolation base, and isolators are installed,

the entire assembly must be leveled. Position the level on

the isolation base, not the fan shaft, for proper leveling.

Additionally, the motor and fan shafts must be level and

parallel relative to each other for proper alignment.

M.K. Plastics Corp. Montréal, Québec www.mkplastics.com Page. 3

Belt Span [inch]

Figure 8 - Belt Tension

Page 4

Refer to the following procedure for belt tensioning -

C

1. Loosen motor plate adjustment bolts and move motor

plate in order that the belts can easily slip into the

grooves on the pulleys. Never pry, roll, or force the belts

over the rim of the pulley.

2. Adjust the motor plate until proper tension is reached.

For proper tension, a deection of approximately 1/60”

per inch of center distance should be obtained by rmly

pressing the belt. Refer to Figure 8.

3. Lock the motor plate adjustment nuts in place.

4. Ensure pulleys are properly aligned.

When replacing belts, replace the entire set. After initial

replacement and tensioning, recheck belt tension after a few

days. New belts require a break-in period. Never use belt

dressing on any belts.

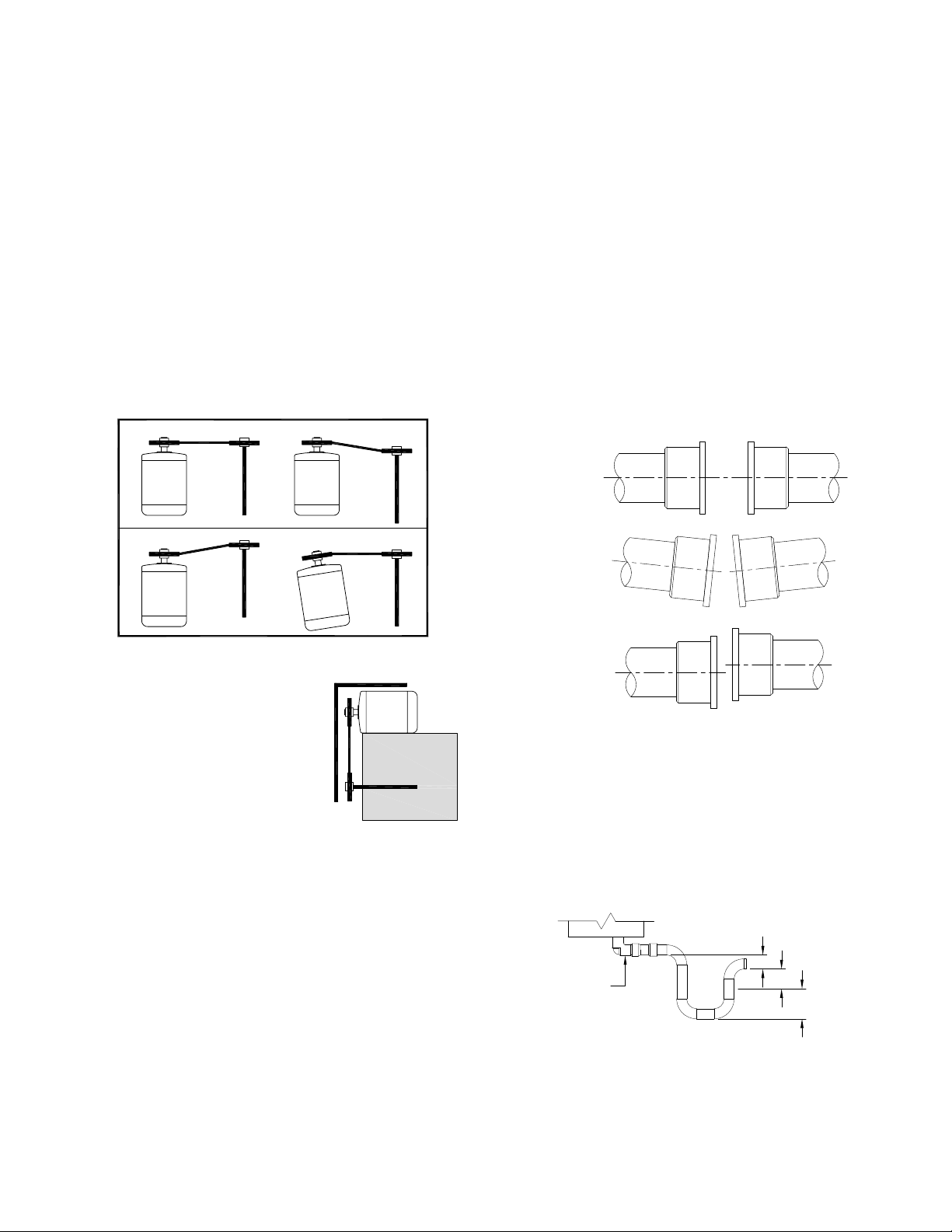

Drive Alignment

Pulley alignment is adjusted by loosening the motor pulley

setscrew and by moving the motor pulley on the motor shaft.

Fig. 9 illustrates correct and incorrect pulley alignment.

Correct Incorrect

Wheel and Shaft Maintenance

Periodically inspect the shaft and wheel for dirt buildup,

corrosion, and signs of excess stress or fatigue. Clean the

components. If the wheel is removed for any reason, make

sure that it is securely attached to the shaft before restarting

the fan.

Arrangement 8 Shaft Flexible Couplings

Coupling alignment should be checked after installation and

prior to start up. Alignment is set at the factory, but shipping,

handling, and installation can cause misalignment. Check

for misalignment between the coupling halves. Parallel

and angular misalignment and separation gap are shown

in Figure 11. Refer to coupling manufacturer’s installation

instructions for allowable misalignment and separation gap

tolerances. When correcting for misalignment using shims,

the shims should only be located under the motor. Do not

place shims under the shaft bearings. A dial indicator or

laser can be used for alignment where greater precision is

required. After aligning procedure, check for tightness of all

coupling component pieces and ensure that they are clean

from dirt and debris.

Separation

Incorrect Incorrect

Figure 9 - Pulley Alignment

A recommended method of inspecting

the pulley alignment is shown in

Figure 10. With the shorter leg of a

carpenter’s square or other straight

edge lying along the case of the

motor, adjust the position of the motor

pulley (or the motor) until the longer

leg of the square is parallel to the belt.

Motor Maintenance

The three basic rules of motor

maintenance are:

Figure 10

1. Keep the motor clean.

2. Keep the motor dry.

3. Keep the motor properly lubricated.

Blow dust off periodically (with low pressure air) to prevent

motor from overheating.

Some smaller motors are lubricated for life. Lubrication

requirements are normally attached to the motor. Use the

motor manufacturer’s recommendations for relubrication. If

this information is not available, the following schedule may

be used. Motors less than 10 HP running about eight hours a

day in a clean environment should be lubricated once every

ve years; motors 15 to 40 HP, every three years. For motors

in dusty or dirty environments or running 24 hours a day:

divide the service interval by 4. Do not over lubricate.

Angular

Misalignment

Parallel

Misalignment

Figure 11 - Flexible Couplings

Drainage Detail

All DHK fans come as standard with outlet drains due to the

possibility of water or condensation that may occur. Proper

disposal of water must occur by connection of drain outlet to

a drainage system (by others). Piping must have adequate

pitch for proper runoff and be supported (if needed) to prevent

the possibility of sagging and overow. The trap should be

lled before start-up.

A

Fan Drain

Dimension of A, B, C: Inches

Figure 12 - Drainage Detail

A: Must be greater than system static pressure.

B: Must be greater than 1/2 of the system static pressure.

C: 1” water seal.

B

M.K. Plastics Corp. Montréal, Québec www.mkplastics.com Page. 4

Page 5

Speed [rpm] 500 1000 1500 2000 2500 3000

Size

1225

1500

1825

2225

1225

6 6 5 3 3 2

1500

6 6 5 3 3 2

1825

6 6 5 3 3 2

2225

6 6 5 3 3 -

2450

6 4 4 3-1/2 2-1/2 -

2700

6 4 4 3-1/2 2-1/2 -

3000

5 4 3 2-1/2 - -

3300

5 4 3 2-1/2 - -

3650

5 4 3 - - -

4025

5 4 2-1/2 - - -

4450

4-1/2 3-1/2 2-1/2 - - -

4900

4-1/2 3-1/2 - - - -

5425

4-1/2 3-1/2 - - - -

6000

4-1/2 3-1/2 - - - -

Relubrication Schedule [Months]

For Bearings With No Grease Fittings

For Bearings With Grease Fittings

Relubrication is not required. Bearings are factory charged with the

correct amount of grease and do not require further grease charge.

Table 2 - Relubrication Schedule [Months]

Fan Bearing Lubrication

Proper lubrication of the fan drive bearings helps assure

maximum bearing life. DHK fans come with three types of

fan bearings:

1. Self-Lube pillow block ball bearings (1225-2225), which

do not require re-greasing. No grease ttings.

2. Air Handling Heavy Duty ball bearing pillow blocks

(1225-2225), which do require re-greasing. With grease

ttings - see schedule on Table 2.

3. Spherical split pillow block bearings (2450-6000), which

do require re-greasing through a grease tting on the

outer housing and should be lubricated by the schedule,

Table 2.

However, every installation is different and the frequency

of relubrication should be adjusted accordingly. On high

moisture applications, the lubrication frequency may need

to be doubled or tripled to adequately protect the bearings.

Double the relubrication frequency on fans with vertical

shafts.

Observation of the conditions of the grease expelled from the

bearings at the time of relubrication is the best guide as to

whether regreasing intervals and amount of grease added

should be altered.

Greases are made with different bases. There are synthetic

base greases, lithium base, sodium base, etc. Avoid mixing

greases with different bases. They could be incompatible

and result in rapid deterioration or breakdown of the grease.

All bearings are lled with a lithium-based grease before

leaving the factory. When the fans are started, the bearings

may discharge excess grease through the seals for a short

period of time. Do not replace the initial discharge because

leakage will cease when the excess grease has worked out.

Sometimes the bearings have a tendency to run hotter during

this period. There is no reason for alarm unless it lasts over

48 hours or gets very hot (over 200°F). When relubricating,

use a sufcient amount of grease to purge the seals. Rotate

bearings by hand during relubrication.

Table 2 is for shaft bearings on belt drive and direct drive

arrangement #8 fans, motor bearing lubrication should be per

the motor manufacturers instructions.

Suggested initial greasing interval - remove bearing cap

and observe condition of used grease after lubricating.

Adjust lubrication frequency as needed. Hours of operation,

temperature, and surrounding conditions will affect the

relubrication frequency required. ‘If bearings need to be re

packed, remove old grease, pack bearing full and ll housing

reservoirs on both sides of bearing to bottom of shaft.’

Lubricate with a multipurpose roller bearing NLGI No. 2 having

rust inhibitors and antioxidant additives, and a minimum oil

viscosity of 500 SSU at 100ºF. Some greases having these

properties are:

1. Shell - Alvania No. 2 Mobil

2. Mobilith AW2/Mobilith SHC100

3. Texaco - Premium RB2

4. American - Rykon Premium 2

Lubricate bearings prior to extended shutdown or storage

and rotate shaft monthly to aid corrosion protection.

Fan Bearing Replacement

Figure 13

Split Pillow Block

Figure 14

Solid Pillow Block

M.K. Plastics Corp. Montréal, Québec www.mkplastics.com Page. 5

Page 6

Removal of Wheel, Shaft & Bearings -

1. Mark the position on the shaft of both bearing races,

setscrews (if applicable) and the wheel and sheave. If

you are replacing the shaft as well, these marks will give

you reference.

2. Mark the location and orientation of the inlet cone and

sleeve to the casing and remove, this will give you

access to the wheel. Remove the drive sheave from the

shaft

3. Start wheel removal by unscrewing the front protective

cap and then the nut, washers and threaded stud

assembly that holds the cap to the fan shaft. The exposed

bushing has hex screws that secure the bushing to the

shaft; they are situated on the front face of the bushing.

Unscrew the hex screws, remove and screw back into

the other exposed holes of the bushing. By doing this

you are pushing the bushing out. Remove and then use

a 2-jaw puller to extract the bushing if needed. When the

bushing is out, the wheel and hub assembly can now be

removed from the fan shaft. Note: DHK 1225 to 1500

sizes do not have bushings, the wheel is held in place to

the shaft with the threaded rod assembly only.

4. Unbolt the bearing housing hold-down bolts and remove

the shaft and bearings as one unit. Keep any existing

shims in place.

5. Unbolt the top housing section and remove the bearing

assemblies from the shaft. A suitable puller may be

required, or tap on the bearing with a wood block and

hammer to remove. If the bearings are attached with

set screws, unscrew and slide the assembly off as one

piece.

6. If the existing shaft is being used, check the shaft for

nicks, burrs and damage. Remove any anti-corrosion

coating with a suitable degreaser and wipe clean.

Bearing Replacement [Split Housing Bearings With

Adapter Sleeves] -

1. Split pillow block bearings come in kits with bearings,

adapter sleeve, locknut, lock washer and xing rings for

the rear xed bearing. NOTE: replacement bearings will

be shipped temporarily assembled on a shaft.

2. Remove the top half of the bearing housing to expose

the bearing seat.

3. Place the lower half of the bearing housings in position

on the stand and tighten the xing bolts.

4. Spherical split pillow block bearings use synthetic rubber

seals that come in split (half) sections. One half should

be inserted into the lower bearing housing on both sides

and some grease applied prior to the bearing assembly.

5. Place the bearings in the lower half of the housings with

the larger sides of the bores facing towards the shaft

ends.

6. Slide the adapter sleeves through the bearings, ensuring

that the threads are facing each other.

7. Install the lock washers on the adapter sleeves with

inner prong of washer in a slot on the adapter sleeve.

Install the locknut on both bearings with the chamfered

face facing the bearing, but do not tighten.

8. Slide shaft through both bearing assemblies. If the

bearing locks to the shaft, tap gently on the adapter

sleeve to loosen.

9. To hold the shaft in place during wheel mounting, clamp

the sheave end of the shaft to the edge of the stand.

10. Install the wheel and bushing on the shaft. Install the inlet

cone in its original location. Position the wheel correctly

by moving the shaft axially in the bearing assemblies.

11. Install xing rings on the rear bearing (closest to sheave).

Move shaft axially so that the xing ring may be inserted

between housing shoulder and bearing outer ring.

12. Tighten locknuts to fasten the bearings to the shaft,

using a spanner. While tightening, regularly measure

the internal bearing clearance between the most vertical

unloaded roller and outer ring with a feeler blade. When

required clearance is obtained (check table), tighten

locknut until the closest washer tab meets a slot on the

locknut.

13. Fill the lower housings with grease until the rollers are

covered.

14. Carefully align the top part of the housing with the dowel

pins and tighten bolts, ensuring that the upper seals

are in place. Make sure that the split housing is paired

only with its original top half, as these parts are not

interchangeable from one housing to another.

Bearing Replacement [Closed Housing Bearings With

Setscrews] -

1. Making sure that the set screws are not protruding from

the inner bearing rings, slide the bearings directly onto

the shaft. If using an old shaft, make sure the bearings

are not mounted on a worn section. Tapping the inner

ring face with a soft driver might be required.

2. The outer ring of the bearing is spherical and swivels

in the housing to compensate for misalignment. Secure

the housing to the stand with the xing bolts, but do not

fully tighten.

3. Install the wheel on the shaft. Install the inlet cone in its

original location. Position the wheel correctly by moving

the shaft axially in the bearing assemblies.

4. Tighten the setscrews on the bearings to secure the

shaft. Refer to torque chart on Page 7.

5. Rotate the shaft by hand to allow the bearing outer rings

to nd their center of free movement.

Test Run -

1. Re-install the sheave and adjust the belt tension.

2. Test run and retighten all setscrews and xing bolts; trim

balance as necessary.

Changing Shaft Speed

All belt driven fans with motors up to and including 5 HP

are equipped with variable pitch pulleys. To change the fan

speed, perform the following:

1. Loosen setscrew on driver (motor) pulley and remove

key, if equipped.

2. If the pulley has multiple grooves, all must be adjusted

to the same width.

3. After adjustment, inspect for proper belt tension.

4. To reduce speed, open the pulley in order that the belt

rides deeper in the groove (smaller pitch diameter).

5. To increase speed, close the pulley so that the belt rides

higher in the groove (larger pitch diameters). Make sure

the maximum fan RPM and motor HP is not reached.

M.K. Plastics Corp. Montréal, Québec www.mkplastics.com Page. 6

Page 7

Size

Set Screw /

Bolt Torque

Size

Pillow Block

Bearing

Set Screw /

Bearing Cap

Bolt Torque

Mounting Bolt

304 SS Bolt

Torque

316 SS Bolt

Torque

1225 RHP, MP1 60 in-lbs 3/8-16UNC, 1.75L 236 in-lbs 247 in-lbs

1500 RHP, MP1 60 in-lbs 3/8-16UNC, 1.75L 236 in-lbs 247 in-lbs

1825 RHP, MP1-7/16 110 in-lbs 1/2-13UNC, 2.25L 517 in-lbs 542 in-lbs

2225 RHP, MP1-7/16 110 in-lbs 1/2-13UNC, 2.25L 517 in-lbs 542 in-lbs

2450 NSK,SNN,1-11/16 389 in-lbs 1/2-13UNC, 1.75L 517 in-lbs 542 in-lbs

2700 NSK,SNN,1-11/16 389 in-lbs 1/2-13UNC, 2.25L 517 in-lbs 542 in-lbs

3000 NSK,SNN,2-3/16 673 in-lbs 5/8-11UNC, 2.5 L 1110 in-lbs 1160 in-lbs

3300 NSK,SNN,2-3/16 673 in-lbs 5/8-11UNC, 2.5 L 1110 in-lbs 1160 in-lbs

3650 NSK,SNN,2-3/16 673 in-lbs 5/8-11UNC, 2.5 L 1110 in-lbs 1160 in-lbs

4025 NSK,SNN,2-7/16 673 in-lbs 5/8-11UNC, 2.75L 1110 in-lbs 1160 in-lbs

4450 NSK,SNN,2-15/16 1682 in-lbs 3/4-10UNC, 3 L 1530 in-lbs 1582 in-lbs

4900 NSK,SNN,2-15/16 1682 in-lbs 3/4-10UNC, 3 L 1530 in-lbs 1582 in-lbs

5425 NSK,SNN,3-7/16 3275 in-lbs 1-8UNC, 3.75L 3400 in-lbs 3595 in-lbs

6000 NSK,SNN,3-7/16 3275 in-lbs 1-8UNC, 3.75L 3400 in-lbs 3595 in-lbs

MSK

Bushing

Cap Screw Torque

H 1/4 x 3/4 95 in-lbs

P 5/16 x1 192 in-lbs

Q 3/8 x 1-1/4 348 in-lbs

R 3/8 x 1-3/4 348 in-lbs

S 1/2 x 2-1/4 840 in-lbs

U 5/8 x 2-3/4 1680 in-lbs

W 3/4 x 3 3000 in-lbs

P1-P3 5/16-18 UNC 80 in-lbs

Q1-Q3 3/8-16 UNC 143 in-lbs

Bushing Tightening for Aluminum Hub

304 SS Bolt

Torque

316 SS Bolt

Torque

1225 RHP, MP1 60 in-lbs 3/8-16UNC, 1.75L 236 in-lbs 247 in-lbs

1500 RHP, MP1 60 in-lbs 3/8-16UNC, 1.75L 236 in-lbs 247 in-lbs

1825 RHP, MP1-7/16 110 in-lbs 1/2-13UNC, 2.25L 517 in-lbs 542 in-lbs

2225 RHP, MP1-7/16 110 in-lbs 1/2-13UNC, 2.25L 517 in-lbs 542 in-lbs

2450 NSK,SNN,1-11/16 389 in-lbs 1/2-13UNC, 1.75L 517 in-lbs 542 in-lbs

2700 NSK,SNN,1-11/16 389 in-lbs 1/2-13UNC, 2.25L 517 in-lbs 542 in-lbs

3000 NSK,SNN,2-3/16 673 in-lbs 5/8-11UNC, 2.5 L 1110 in-lbs 1160 in-lbs

3300 NSK,SNN,2-3/16 673 in-lbs 5/8-11UNC, 2.5 L 1110 in-lbs 1160 in-lbs

3650 NSK,SNN,2-3/16 673 in-lbs 5/8-11UNC, 2.5 L 1110 in-lbs 1160 in-lbs

4025 NSK,SNN,2-7/16 673 in-lbs 5/8-11UNC, 2.75L 1110 in-lbs 1160 in-lbs

4450 NSK,SNN,2-15/16 1682 in-lbs 3/4-10UNC, 3 L 1530 in-lbs 1582 in-lbs

4900 NSK,SNN,2-15/16 1682 in-lbs 3/4-10UNC, 3 L 1530 in-lbs 1582 in-lbs

5425 NSK,SNN,3-7/16 3275 in-lbs 1-8UNC, 3.75L 3400 in-lbs 3595 in-lbs

6000 NSK,SNN,3-7/16 3275 in-lbs 1-8UNC, 3.75L 3400 in-lbs 3595 in-lbs

Pillow Block

Bearing

Bearing Cap

Mounting Bolt

304 SS Bolt

Torque

316 SS Bolt

Table 3 - Fan Bearing Torque

Tapered

Bushing

QT 1/4-20UNC 108 in-lbs

JA No.10-24UNC 60 in-lbs

SH-SDS-SD 1/4-20UNC 108 in-lbs

SK 5/16-18UNC 180 in-lbs

SF 3/8-16UNC 360 in-lbs

E 1/2-13UNC 720 in-lbs

F 9/16-12UNC 1320 in-lbs

J 5/8-11UNC 1620 in-lbs

M 3/4-10UNC 2700 in-lbs

N 7/8-9UNC 3600 in-lbs

P 1-8UNC 5400 in-lbs

W 1-1/8-7UNC 7200 in-lbs

S 1-1/4-7UNC 9000 in-lbs

Cap Screw Torque

MSK

Bushing

Bushing Tightening for Aluminum Hub

Cap Screw Torque

H 1/4 x 3/4 95 in-lbs

P 5/16 x1 192 in-lbs

Q 3/8 x 1-1/4 348 in-lbs

R 3/8 x 1-3/4 348 in-lbs

S 1/2 x 2-1/4 840 in-lbs

U 5/8 x 2-3/4 1680 in-lbs

W 3/4 x 3 3000 in-lbs

P1-P3 5/16-18 UNC 80 in-lbs

Q1-Q3 3/8-16 UNC 143 in-lbs

Table 4 - Bushing and Pulley Torque

Torque

F Ensure belt touches only the pulleys.

F Ensure fan and ductwork are clean and free of debris.

F Inspect wheel-to-inlet clearance.

F Close and secure all access doors.

F Restore power to the fan.

Start Up

Turn the fan on. In variable speed units, set the fan to its

lowest speed and inspect for the following:

F Direction of rotation.

F Excessive vibration.

F Unusual noise.

F Bearing noise.

F Improper belt alignment or tension (listen for squealing).

F Improper motor amperage or voltage.

If a problem is discovered, immediately shut the fan off. Lock

out all electrical power and check for the cause of the trouble.

See Troubleshooting.

Inspection

Inspection of the fan should be conducted at the rst

30 minute, 8 hour and 24 hour intervals of satisfactory

operation. During the inspections, stop the fan and inspect.

F 30 Minute Interval: Inspect bolts, setscrews, and motor

mounting bolts. Adjust and tighten as necessary.

F 8 Hour Interval: Inspect belt alignment and tension.

Adjust and tighten as necessary.

F 24 Hour Interval & 30 Days: Inspect belt tension. Adjust

and tighten as necessary.

Grounding Straps

Static Grounding Strap

If supplied with a Graphite Liner, a

grounding strap is provided on the

bottom of the scroll housing for the

removal of static electricity. This strap

must be connected to the building

electrical grounding circuit or the

roof steel structure. If an Aegis shaft

grounding ring is supplied on the

motor, the motor support stand should

also be grounded.

Operational Checklist

Final Installation

F Inspect fasteners and setscrews, particularly fan

mounting and bearing fasteners, and tighten according

to the recommended torque shown in Tables 3 & 4.

F Inspect for correct voltage with voltmeter.

F Ensure all accessories are installed.

Pre-Start Checks

F Shut off all primary and secondary power sources.

F Ensure fasteners and setscrews are tightened.

F Inspect belt tension and pulley alignment.

F Inspect motor wiring.

Figure 15

Grounding Strap

General Fan Maintenance

WARNING

Disconnect and secure to the ‘Off’ position all electrical power to the fan prior to inspection and servicing.

Failure to comply with this safety precaution could

result in serious injury or death.

Once the unit has been put into operation, a routine

maintenance schedule should be set up to accomplish the

following:

1. Lubrication of bearings and motor.

2. Wheel, housing, bolts and set screws on the entire fan

should be checked for tightness.

3. Any dirt accumulation on the wheel or in the housing

should be removed to prevent unbalance and possible

damage.

4. Isolation bases should be checked for freedom of

movement and the bolts for tightness. Springs should be

checked for breaks and fatigue. Rubber isolators should

be checked for deterioration.

5. Inspect fan impeller and housing looking for fatigue,

corrosion or wear.

6. Check V-belt drives on a regular basis for wear, tension,

alignment and dirt accumulation.

7. If drive belts have been replaced, new belts will stretch.

Belt tension needs to be checked & adjusted after 1

week, and again after 30 days of operation. Refer to

Figure 8. on Page 3 for details.

M.K. Plastics Corp. Montréal, Québec www.mkplastics.com Page. 7

Page 8

Troubleshooting

Excessive Noise or Vibration

• Damaged wheel.

• Wheel rubbing inlet; adjust wheel or inlet cone.

• Verify wheel balance, rebalance if necessary.

• Belts misaligned.

• Belts too loose; worn or oily belts.

• Loose fasteners.

• Speed too high.

• Incorrect direction of rotation. Make sure the fan rotates in same direction as the arrows on the motor or belt

drive assembly.

• Bearing collars or hardware loose.

• Bearings need lubrication or replacement.

• Debris in impeller; clean all dirt off wheel, check wheel balance and rebalance if necessary.

• Fan surge.

• Check alignment of shaft and motor drives.

Low Volume or Pressure

• Incorrect direction of rotation. Make sure the fan rotates in same direction as the arrows on the motor or belt

drive assembly.

• Poor fan inlet or outlet conditions. There should be a straight clear duct at the inlet or outlet.

• Improper wheel alignment.

• Check duct system, see Page 2. For recommendations.

Motor Problems (Overheating)

• Motor improperly wired.

• Incorrect direction of rotation. Make sure the fan rotates in same direction as the arrows on the motor or belt

drive assembly.

• High horsepower; resize the ductwork. Check proper operation of face and bypass dampers. Check lters

and access doors.

• Cooling air diverted or blocked.

• Improper inlet clearance.

• Incorrect fan speed.

• Incorrect voltage.

Bearing Problems (Overheating)

• Improper bearing lubrication; check for excessive or insufcient grease in bearings.

• Excessive belt tension.

• Check for bent shaft.

• Align bearings.

M.K. Plastics Corp. Montréal, Québec www.mkplastics.com Page. 8

Page 9

DHK - Parts List - Belt Drive (Arrangement #1)

5

6

7

8

9

1234

15

16

Item No. Item Description

1 Inlet Sleeve

2 Inlet cone

3 Impeller

4 Fan Casing

5 Bearing

6 Shaft

7 Shaft / Bearing Guard

8 Pulleys

9 Belts

10 Belt Guard

11 Motor Base

12 Motor

13 Unitary Base (Standard)

14 Motor Cover (Optional)

15 Control Damper

16 Gravity Backdraft Damper

13 14

1110

12

M.K. Plastics Corp. Montréal, Québec www.mkplastics.com Page. 9

Page 10

DHK - Parts List - Belt Drive (Arrangement #10)

56

7

10

8

9

11

1234

14

15

12

Item No. Item Description

1 Inlet Sleeve

2 Inlet cone

3 Impeller

4 Fan Casing

5 Shaft

6 Bearing

7 Shaft / Bearing Guard

8 Pulleys

9 Belts

10 Motor

11 Belt Guard

12 Motor Base

13 Unitary Base (Optional)

14 Control Damper

15 Gravity Backdraft Damper

13

M.K. Plastics Corp. Montréal, Québec www.mkplastics.com Page. 10

Page 11

DHK - Parts List - Direct Drive

5

6

1

(Arrangement #4)

12

7

4

11

10

6

7

89

3

2

5

(Arrangement #8)

Item No. Item Description

1 Inlet Sleeve

2 Companion Flange

3 Inlet Cone

4 Impeller

5 Fan Casing

6 Motor

7 Unitary Base (Standard)

8 Shaft / Bearing Guard

9 Bearings

10 Coupling

11 Shaft Guard

12 Motor Cover (Optional)

M.K. Plastics Corp. Montréal, Québec www.mkplastics.com Page. 11

Page 12

Warranty

M.K. Plastics will not be responsible for damage to equipment or materials through improper installation, storage, improper

servicing, or through attempts to operate it in excess of its rated capacity or recommended use, intentional or otherwise. We will

not be responsible for consequential damage.

Based on the fact that M.K. Plastics has no direct control over the actual handling and use of its products in the eld, M.K.

Plastics does not assume any liability for any loss to the customer or any personnel or any physical damages that are claimed

by anyone due to a failure or cause attributed to the use of its products. In no event shall M.K. Plastics be responsible for

consequential damages of any such defective material or workmanship, including but not limited to the buyer’s loss of material

or prot, increase expense of operation, downtime or reconstruction of the work and in no event shall M.K. Plastics obligation

under this warranty exceed the original contract price of the defective item.

M.K. Plastics warrants its equipment, products and parts, to be free from defects in workmanship and material under normal

use and service for one (1) year after delivery to the rst user. Our obligation under this warranty being limited to repairing or

replacing, at our option, without cost at our factory any part, or parts which shall, within such warranty period, be returned to us

with transportation charges prepaid, and which our examination shall disclose to our satisfaction to have been defective.

M.K. Plastics will not be responsible for the cost of removal of a defective product or parts or the installation of a replaced product

or parts, or for costs due for its removal, crating or shipping.

On account of variables including but not limited to, vibration, system noise characteristics, motor overloading or change in

voltage condition, the specics of customer application of equipment or other system conditions, M.K. Plastics does not expressly

warrant its equipment for any specic purpose.

The customer and its agents are responsible for the selection and application of M.K. Plastics products, including their tness

for the purpose and performance intended. Consequently, the customer on behalf of its agents assumes all liability related to the

use/misuse, application and selection of the M.K. Plastics Products.

Bulletin 40-02-June 2013

CORPORATION

SERVING THE NEEDS OF MODERN INDUSTRY

M.K. Plastics Corp. Montréal, Québec www.mkplastics.com Page. 12

4955 de Courtrai Ave., Montréal, Québec, H3W 1A6 ● TEL: (514) 871-9999

Trimex Building, Route 11, Mooers, N.Y., 12958 ● TEL: (888) 278-9988

FAX: (514) 871-1753

Email: mkfans@mkplastics.com

Loading...

Loading...