Read the operating instructions prior to

commissioning

Operating instructions

Cooker

Unit Type of

energy

Cooker with simmer plate Gas Floor-standing unit OPGHEG1...

Translation from the original document • 2063501-20ABDE-A • 08/06/2017

Unit type Model

Suspended unit OIGHEG1...

2063501-20ABBE-A en-GB

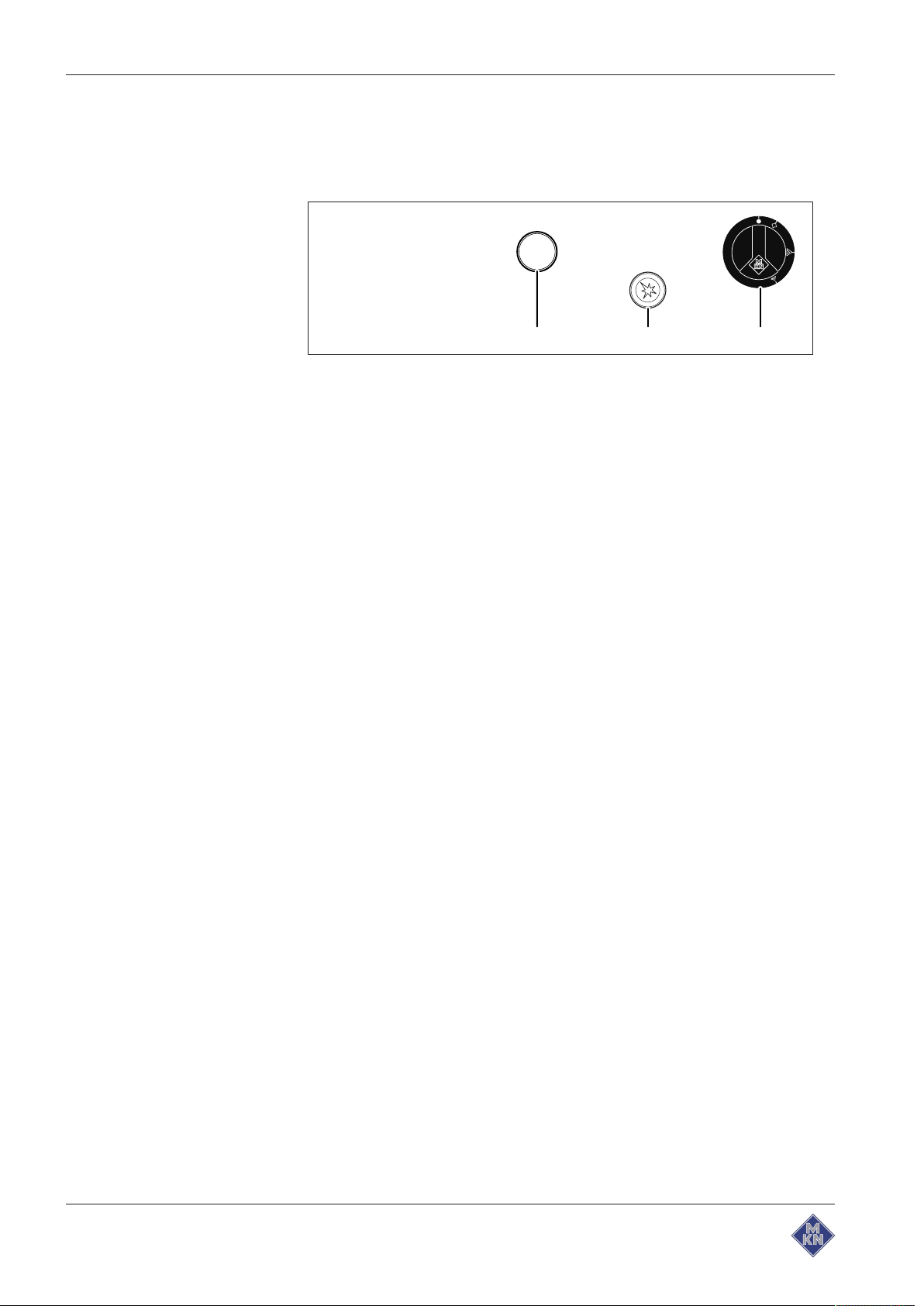

Operating and display elements

ca b

Cooker

a Inspection port c

b

Piezo pilot ignitor

button

Burner

control knob

2 Operating instructions

2063501-20ABBE-A

Manufacturer

MKN Maschinenfabrik Kurt Neubauer GmbH & Co. KG

Halberstädter Strasse 2a

38300 Wolfenbüttel

Germany

Phone +49 5331 89-0

Fax +49 5331 89-280

Internet www.mkn.eu

Copyright

All rights to text, graphics and pictures in this documentation are held by MKN Maschinenfabrik Kurt

Neubauer GmbH & Co. KG. Distribution or duplication is only permitted with the prior written consent

of MKN.

Copyright by MKN Maschinenfabrik Kurt Neubauer GmbH & Co. KG.

3Operating instructions

Directory of contents

1Introduction......................................................................... 7

1.1About this manual ............................................................................ 7

1.1.1Explanation of signs .................................................................................. 8

1.2Intended use ..................................................................................... 9

1.3Warranty............................................................................................ 9

2Safety information............................................................ 10

3Rules of conduct when the smell of gas is detected .... 13

4Description of the unit ..................................................... 14

4.1Overview of the unit ....................................................................... 14

4.1.1Floor-standing unit................................................................................... 14

4.1.2Suspended unit ....................................................................................... 16

4.2Function of the operating and display elements......................... 16

5Operating the unit............................................................. 17

5.1Tips for use ..................................................................................... 17

5.2Switching the unit on and off ........................................................ 17

5.2.1Switching on ............................................................................................ 17

5.2.2Switching off ............................................................................................ 18

5.3Burning-in the simmer plate.......................................................... 18

5.4Basic functions............................................................................... 19

5.4.1Adjusting the output................................................................................. 19

5.5Cooking ........................................................................................... 19

5.6Pausing and end of use ................................................................. 20

5.6.1Short pause ............................................................................................. 20

5.6.2Long pause and end of use..................................................................... 21

6Cleaning and caring for the unit ..................................... 22

6.1Preventing corrosion ..................................................................... 22

6.2Removing rust spots...................................................................... 23

6.3Cleaning the housing..................................................................... 23

6.4Opening and closing the simmer plate ........................................ 23

6.4.1Opening the simmer plate ....................................................................... 24

6.4.2Closing the simmer plate......................................................................... 24

6.5Cleaning the simmer plate............................................................. 25

6.6Cleaning the burners ..................................................................... 26

6.7Drying the simmer plate and burner............................................. 27

7Troubleshooting ............................................................... 28

7.1Cause of failure and the remedy................................................... 28

7.2Nameplate ....................................................................................... 28

8Carrying out maintenance ............................................... 29

2063501-20ABBE-A

4 Operating instructions

Directory of contents

9Disposing of the unit in an environmentally responsible

manner ................................................................................. 30

10Manufacturer's declaration............................................ 31

2063501-20ABBE-A

5Operating instructions

Directory of contents

6 Operating instructions

2063501-20ABBE-A

1 Introduction

1.1 About this manual

Introduction

The operating instructions are part of the unit and contain information:

• On safe operation,

• On cleaning and care,

• On remedies in case of faults.

Be aware of the following notes and adhere to them:

• Read the operating instructions completely before operating the

unit for the first time.

• Make the operating instructions available to the operator at all

times at the operating site of the unit.

• Insert any supplements from the manufacturer.

• Keep the operating instructions throughout the service life of the

unit.

• Pass on the operating instructions to any subsequent operator of

the unit.

Target group The target group of the instruction manual is the operator, who is

entrusted with the operation, cleaning and care of the unit.

Figures All figures in this manual are intended as examples. Discrepancies

between these and the actual unit can arise.

2063501-20ABBE-A

7Operating instructions

Introduction

1.1.1 Explanation of signs

DANGER

Imminent threat of danger

Failure to comply will lead to death or very severe injuries.

WARNING

Possible threat of danger

Failure to comply can lead to death or very severe injuries.

CAUTION

Dangerous situation

Failure to comply can lead to slight or moderately severe

injuries.

ATTENTION

Physical damage

Failure to comply can cause physical damage.

Notes for better understanding and operation of the unit.

Symbol / sign Meaning

• Listing of information.

Action steps, which can be performed

in any sequence.

1.

2.

Action steps, which must be performed

in the specified sequence.

Result of an action performed or

additional information about it.

8 Operating instructions

2063501-20ABBE-A

1.2 Intended use

Introduction

This unit is intended to be used solely for commercial purposes,

particularly in commercial kitchens.

This unit may only be used with suitable accessories and for the

cooking of food.

It is forbidden to use the unit for purposes, which include the

following:

• Operating without simmer plate

• Frying directly on the simmer plate

• Heating rooms

• Heating flammable liquids

• Heating acids, alkaline solutions or other chemicals

• Heating of warmer plates, containers and tins

• Drying cloths, paper or dishes

1.3 Warranty

• As set-down area or working surface

The use of the unit is prohibited in the following countries:

• USA

• Canada

The warranty is void and safety is no longer assured in the event of:

• Improper conversion or technical modifications of the unit,

• Improper use,

• Incorrect startup, operation or maintenance of the unit,

• Problems resulting from failure to observe these instructions.

2063501-20ABBE-A

9Operating instructions

Safety information

2 Safety information

The unit complies with applicable safety standards. Residual risks

associated with operation or risks resulting from incorrect operation

cannot be ruled out and are mentioned specifically in the safety

instructions and warnings.

The operator must be familiar with regional regulations and observe

them.

Operation During operation, the following group of individuals must be

supervised by an individual who is responsible for safety:

• Individuals with physical, sensory, or mental handicaps, or who

The supervising individual must be familiar with the unit and the risks

associated with it.

Hot surfaces Risk of burns from hot surfaces

• Protect arms and hands by wearing suitable protective gloves.

lack the knowledge and experience to operate the unit properly.

Hot liquids Risk of chemical burns from evaporating cleaners

Defective unit Risk of injury from a defective unit

Escaping gas or exhaust

gas

• Do not touch heating elements, hot surfaces or accessories

immediately after use.

• Allow surfaces to cool prior to cleaning.

• Follow the instructions of the cleaning agent manufacturer.

• Use gas shut-off valve to isolate unit from gas supply.

• Do not operate a defective unit.

• Allow only an authorized technician to repair the unit.

Risk of asphyxiation and explosion from escaping gas

• Follow the rules of conduct when the smell of gas is detected (see

"Rules of conduct when the smell of gas is detected").

Risk of asphyxiation and poisoning from exhaust gases

• Ensure that air inlet openings are free and that a sufficient amount

of the necessary combustion air is supplied.

• Ensure that the exhaust gas outlet openings are free and that the

exhaust gases are discharged properly.

Fire prevention Risk of fire from dirt and grease deposits

• Clean the unit when finished using it.

Risk of fire from overheating

• Observe the unit during operation.

10 Operating instructions

2063501-20ABBE-A

Risk of fire from objects

• Do not obstruct the exhaust gas duct.

Firefighting

• In the event of a fire, use the gas shut-off valve to isolate the unit

from the gas supply.

• Use a Fire Class F fire extinguisher, never water, to extinguish

grease fires. Other fires, for instance, can be extinguished with fire

extinguishers suitable for Fire Classes A, B, C, CO2 fire

extinguishers or extinguishing media suitable for the fire class

confronted.

Improper cleaning Risk of chemical burns from cleaning agent

• Follow the instructions of the cleaning agent manufacturer.

• Take appropriate protective measures when handling aggressive

cleaning agents.

Risk of falling on smooth floors

Safety information

• Keep the floor in front of the unit clean and dry.

Risk of physical damage from improper cleaning

• Clean the unit after using it.

• Do not clean the unit with a high-pressure cleaner or water jet.

• Do not clean the housing with highly abrasive or chemically

aggressive cleaning agents.

• Do not clean the housing with highly abrasive sponges.

• Follow the instructions of the cleaning agent manufacturer.

• Do not cool shock the unit by cooling it abruptly.

• Do not block the openings in the simmer plate.

Hygiene Health risk from insufficient hygiene

• Observe applicable regional hygiene regulations.

• Follow the cleaning instructions.

Improper use Risk of physical damage from improper use

• Do not operate the unit outdoors.

2063501-20ABBE-A

• Use only original accessories.

• Train operators regularly.

• Do not heat food warmer plates or tins of preserved food.

• Observe the unit during operation.

• Use only cookware that is dry outside.

• Use only appropriate and undamaged cookware.

• Remove spices, overcooked food or the like immediately.

11Operating instructions

Safety information

• Do not fry directly on the simmer plate.

• Do not operate the unit without the simmer plate.

12 Operating instructions

2063501-20ABBE-A

Rules of conduct when the smell of gas is detected

3 Rules of conduct when the smell of gas is detected

DANGER

Risk of asphyxiation and explosion from escaping gas

Follow the rules of conduct when the smell of gas is detected.

• Remain calm.

• Open windows and doors and ventilate rooms.

• Avoid rooms with the smell of gas.

• Do not smoke.

• Do not ignite any flames. Extinguish flames.

• Do not create any sparks. Do not operate any switches, electrical

devices or use telephones.

• Remove mobile phones and radio-controlled devices from the

hazard area.

• Close gas shut-off valves at the gas meter, at the main supply

and, if possible, at the units.

• Warn other individuals in the building. Call out and knock, do not

ring doorbells.

• Leave the building and prevent entry by others.

– Notify the gas utility stand-by service.

– Do not try to eliminate damage to the gas system by yourself.

• Observe the safety instructions of the gas utility.

• Once outside the building, notify the responsible parties:

– If the smell of gas comes from the unit, notify Customer

service.

– If the source of the gas smell can not be localised immediately,

notify the gas utility.

– If the escaping gas is audible, leave the building immediately,

prevent others from entering and notify the fire brigade, police

and gas utility.

– If the smell of gas comes from inaccessible rooms, notify the

fire brigade, police and gas utility.

2063501-20ABBE-A

13Operating instructions

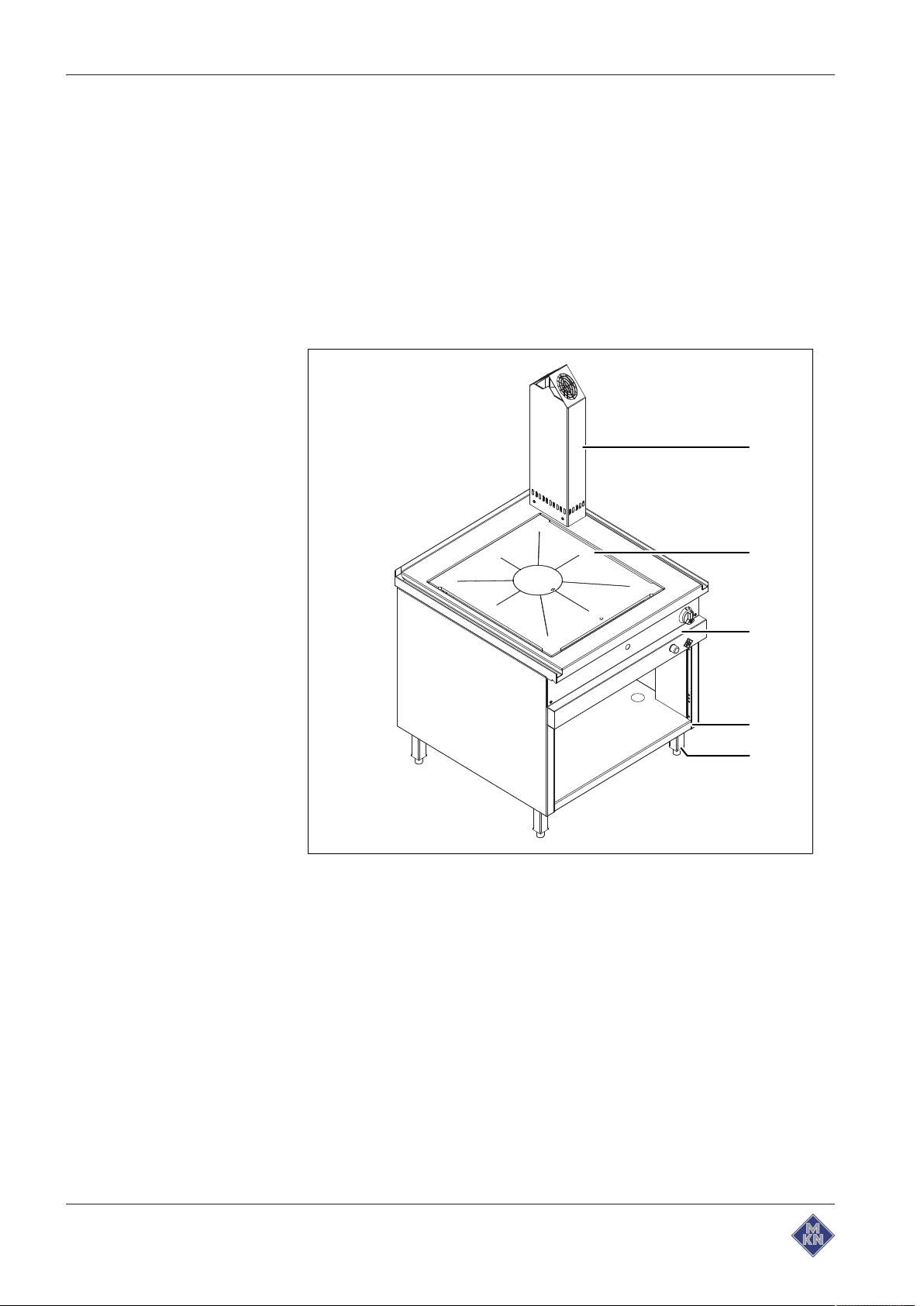

Description of the unit

a

b

d

c

e

4 Description of the unit

4.1 Overview of the unit

The unit is intended for universal use in commercial kitchens for

cooking food in pots and pans on a surface. Possible uses are

cooking, stewing, frying, braising, boiling and combined frying and

cooking.

4.1.1 Floor-standing unit

Image: Cooker with simmer plate

a Exhaust gas duct d Nameplate and gas type

b Simmer plate e Equipment leg (optional)

c Control panel

14 Operating instructions

supplemental label

2063501-20ABBE-A

e

a

a

d

c

b

Image: Cooker with simmer plate, "open" simmer plate

a Lifting handle d Burner

b Insert plate e Pilot burner

c Swivel mechanism locking lever

Description of the unit

2063501-20ABBE-A

15Operating instructions

Description of the unit

a

b

d

c

e

4.1.2 Suspended unit

Image: Cooker with simmer plate

a Exhaust gas duct d Nameplate and gas type

supplemental label

b Simmer plate e Suspension mounting

c Control panel

4.2 Function of the operating and display elements

Operating/display element Symbol Designation Function

Burner

control knob Off Switch off gas supply

Ignition Gas supply for pilot burner is released, the

burner is switched off

...

Piezo pilot ignitor

Flame monitoring

port

Inspection port Monitor ignition and flame pattern

button Ignite pilot burner

inspection

Output Set the burner output

Monitor flame

16 Operating instructions

2063501-20ABBE-A

5 Operating the unit

DANGER

Risk of burns from escaping hot food being cooked

Ensure that cookware can not tilt.

CAUTION

Risk of burns from hot surfaces

• Protect arms and hands by wearing suitable protective

5.1 Tips for use

In order to use the unit to its optimum and avoid heat loss:

• Use suitable cooking utensils.

Operating the unit

gloves.

– Suitable cooking utensils are those made of metal, such as for

example steel, stainless steel, copper or cast iron, and they

should have a flat bottom.

– Unsuitable cooking utensils are those made of plastic, glass or

ceramics.

• The shape and size of the cooking utensil can be freely selected.

• Utilize stored heat by switching back at an early stage.

• Avoid overcooking.

• Place the pan lid on when cooking.

5.2 Switching the unit on and off

5.2.1 Switching on

Requirements Gas shut-off valve on the unit is closed

1. Open the gas shut-off valve on the unit.

2. Press the

3. Keep the

Gas flows to the pilot burner.

4. After about 5 seconds also press the

The pilot burner is ignited.

5. Observe the ignition procedure through the inspection port.

Burner

Burner

control knob and turn it to the " " setting.

control knob pressed on the " " setting.

Piezo pilot ignitor

button.

2063501-20ABBE-A

Ignition flame is burning.

6. After 10 seconds let go of the

The pilot burner continues to burn automatically.

Unit switched on and ready for use.

Burner

control knob.

17Operating instructions

Operating the unit

If there is no ignition, repeat the procedure.

7. Press the

The burner is ignited.

The burner burns at full load.

Heat zone is on.

5.2.2 Switching off

During operation the

unintentional shifting to the "

Press the

The gas supply is disconnected.

The burner is switched off.

The pilot burner is switched off.

The unit is off.

5.3 Burning-in the simmer plate

When using for the first time, heat the simmer plate to maximum

output in order to eliminate unpleasant smells.

Burner

Burner

control knob and turn it to the " " setting.

Burner

control knob and turn it to the " " setting.

control knob is safeguarded against

" setting.

Smoke can develop when particles are incinerated on the heat

zone.

• Ventilate the room well.

The simmer plate can turn a bluish colour during operation. Do

not remove the oxide layer. It provides additional corrosion

protection.

Requirement Simmer plate without cooking utensils

1. Switch on the unit (see "Switching the unit on and off").

2. Heat at maximum output for approx. 10 minutes.

3. Switch off the unit (see "Switching the unit on and off").

4. Clean the unit (see "Cleaning the unit").

Simmer plate is burned-in.

18 Operating instructions

2063501-20ABBE-A

5.4 Basic functions

5.4.1 Adjusting the output

Operating the unit

5.5 Cooking

During operation the

unintentional shifting to the "

Increase output: Turn the

direction.

Reduce output: Turn the

direction.

The output can be freely adjusted between the maximum and

minimum output.

Requirements Heat zone is on

1. Press the

The burner is ignited.

The unit operates at maximum output.

2. Turn the

The unit operates at minimum output.

Burner

Burner

Burner

control knob and turn it to the " " setting.

control knob to the " " setting.

control knob is safeguarded against

" setting.

Burner

Burner

control knob in the " "

control knob in the " "

CAUTION

Risk of burns from hot surfaces

The temperature of the simmer plate is very hot in the area of

the exhaust gas routing.

• Protect arms and hands by wearing suitable protective

gloves.

CAUTION

Risk of scalding from hot steam or hot food that is being

cooked

Scalding from hot escaping steam or hot food being cooked can

occur, when cooking utensils are being opened, closed or

moved.

• Cooking utensils must be carefully opened, closed and

moved.

• Protect arms and hands by wearing suitable protective

gloves.

Cooking encompasses a number of cooking modes, such as for

example cooking, frying and braising.

2063501-20ABBE-A

19Operating instructions

Operating the unit

Requirements Simmer plate without cooking utensils

Image: Temperature distribution, exhaust gas duct on the right (dark colour = high

temperature)

1. Switch on the unit (see "Switching the unit on and off").

2. Set the maximum output (see "Basic functions").

3. Set up the cooking utensil.

4. Use the

functions") or regulate the cooking temperature by moving the

cooking utensil.

5. Depending on the desired cooking mode, continue with the

cooking of the food.

6. Switch off the unit (see "Switching the unit on and off").

7. Remove the cooking utensil from the heat zone.

5.6 Pausing and end of use

Switch off the unit during pauses and at end of use.

5.6.1 Short pause

WARNING

Risk of injury from flash fire

The heat zone is heated.

The heat zone is completely heated after approx. 30 minutes.

The cooking utensil is heated.

Burner

control knob to adjust the output (see "Basic

The heat zone cools down.

When switching on the burner after a pause in operation, check

the function of the pilot burner to ensure that it ignites properly.

1. Press the

Burner

control knob and turn it to the " " setting.

The burner is switched off.

The pilot burner remains on.

2. Continuing after a pause in operation:

20 Operating instructions

2063501-20ABBE-A

Operating the unit

3. Press the

Heat zone is on.

5.6.2 Long pause and end of use

After being out of operation for a longer period of time, the unit

must be checked by an expert, who is approved by the gas

utility.

1. Press the

2. Close the gas shut-off valve on the unit.

Unit not in operation.

Burner

control knob and turn it to the " " setting.

The burner is ignited.

The burner burns at full load.

Burner

control knob and turn it to the " " setting.

The burner is switched off.

The pilot burner is switched off.

The unit is off.

2063501-20ABBE-A

21Operating instructions

Cleaning and caring for the unit

6 Cleaning and caring for the unit

CAUTION

Risk of burns from hot surfaces

• Allow surfaces to cool prior to cleaning.

ATTENTION

Risk of physical damage from extremely abrupt cooling

• Do not cool shock the unit by cooling it abruptly.

ATTENTION

Risk of physical damage from improper cleaning

• Do not clean the unit with a high-pressure cleaner or water

jet.

ATTENTION

Risk of physical damage through penetration of water

Image: Discharge channel

6.1 Preventing corrosion

• Keep the surfaces of the unit clean and with access to air.

• Remove lime, grease, starch and protein deposits from the

• Remove salt accumulations.

• Only expose parts made from non-rusting steel to brief contact

• Avoid damaging the stainless steel surface with other metal items,

• Do not close the discharge channel and do not fill with water.

surfaces of the unit.

with highly acidic foods, spices, salts or the like.

such as for example steel spatulas or steel wire brushes.

• Avoid contact with iron and steel, such as for example steel wool

and steel spatulas.

• Do not use bleaching or chlorine-containing cleaning agents.

• Clean the contact surfaces with water.

• Always keep the simmer plate dry.

22 Operating instructions

2063501-20ABBE-A

• If the simmer plate is not to be used for a longer period of time,

6.2 Removing rust spots

• Remove fresh rust spots with a mild abrasive or fine sandpaper.

• Always remove rust spots completely.

• Expose treated areas to fresh air for at least 24 hours. During this

6.3 Cleaning the housing

Cleaning and caring for the unit

protect it with a special care product or thinly applied film of oil.

time, do not allow any contact with greases, oils or foods so that a

new protective layer can form.

ATTENTION

Risk of physical damage from improper cleaning

• Do not clean the housing with highly abrasive or chemically

aggressive cleaning agents.

• Do not clean the housing with highly abrasive sponges.

Requirement Unit switched off and cooled down

Clean the housing with warm water and commercially available

washing-up liquid.

6.4 Opening and closing the simmer plate

CAUTION

Risk of squashing when opening and closing the simmer

plate

• Open and close the simmer plate carefully with the lifting

handle.

• Always secure the simmer plate by means of the swivel

mechanism locking lever.

2063501-20ABBE-A

23Operating instructions

Cleaning and caring for the unit

a

b

c

a

b

c

d

6.4.1 Opening the simmer plate

Image: Opening the simmer plate

Requirements Unit switched off and cooled down

1. Open the simmer plate with the lifting handle.

2. Secure the simmer plate in the "open" position with the swivel

6.4.2 Closing the simmer plate

a Extraction handle c Swivel mechanism locking lever

b Simmer plate

mechanism locking lever.

Image: Closing the simmer plate

a Extraction handle c Swivel mechanism locking lever

b Simmer plate d Adjusting screw

24 Operating instructions

2063501-20ABBE-A

Requirements Unit switched off and cooled down

1. Hook the lifting handle into the simmer plate.

2. Raise the simmer plate slightly with the lifting handle.

3. Release the swivel mechanism locking lever.

4. Put the simmer plate down.

5. Unhook the lifting handle from the simmer plate.

6.5 Cleaning the simmer plate

CAUTION

Risk of squashing when opening and closing the simmer

plate

• Open and close the simmer plate carefully with the lifting

handle.

• Always secure the simmer plate by means of the swivel

mechanism locking lever.

Cleaning and caring for the unit

ATTENTION

Risk of physical damage from distortion of the simmer plate

The simmer plate can become distorted if the openings are

blocked.

• Always keep the openings in the simmer plate free and

clean.

Image: Simmer plate openings

Requirements Unit switched off and cooled down

1. Clean the top of the simmer plate.

2. Wipe off light contamination with a damp cloth.

Use a mild cleaning agent.

3. Remove heavy contamination with a stainless steel spatula or

steel wire pad.

4. Rinse thoroughly with clear water.

5. Wipe dry with a lint-free cloth.

6. If required, poke a suitable tool into the simmer plate openings to

free them.

2063501-20ABBE-A

Always keep the openings in the simmer plate free and clean.

7. Lift the insert plate out with the lifting handle.

Clean the insert plate support in the same way.

25Operating instructions

Cleaning and caring for the unit

a

b

8. Open the simmer plate (see "Opening and closing the simmer

plate").

9. Clean the burner (see "Cleaning the burner").

10.Close the simmer plate (see "Opening and closing the simmer

plate").

11.Put in the insert plate.

6.6 Cleaning the burners

CAUTION

Risk of squashing when opening and closing the simmer

plate

• Open and close the simmer plate carefully with the lifting

• Always secure the simmer plate by means of the swivel

Clean the underside of the simmer plate in the same way.

handle.

mechanism locking lever.

The pilot burner discharge openings must be free.

To ensure the reliable function of the unit, clean the burner and pilot

burner.

Image: Burner with pilot burner

a Burner

b Pilot burner

Requirements Unit switched off and cooled down

1. Open the simmer plate (see "Opening and closing the simmer

plate").

2. Clean the pilot burner and burner nozzles with a soft brush.

3. Clean the burner chamber.

Remove dry particles with a soft brush and vacuum cleaner.

4. Wipe off light contamination with a damp cloth.

Use a mild cleaning agent.

5. Remove heavy contamination with a steel wire pad.

6. Rinse thoroughly with clear water.

7. Wipe dry with a lint-free cloth.

26 Operating instructions

2063501-20ABBE-A

8. Close the simmer plate (see "Opening and closing the simmer

plate").

6.7 Drying the simmer plate and burner

Dry the burner and pilot burner by heating them up.

Dry the simmer plate and insert plate by heating them.

Requirements Burner and pilot burner cleaned

Simmer plate cleaned and closed

Insert plate put in

1. Switch on the unit (see "Switching the unit on and off").

2. Heat the burner at maximum output for several minutes.

3. Switch off the unit.

Cleaning and caring for the unit

Tip

The burner and simmer plate are dry.

The burner and simmer plate are protected against corrosion.

In order to care for the rust protection, or if it has been worn

away, apply a special care product or thin oil film.

2063501-20ABBE-A

27Operating instructions

Troubleshooting

7 Troubleshooting

DANGER

Risk of fatal injury from escaping gas

• Gas installation work on the gas system and unit may only

be performed by an expert approved by the gas utility. The

applicable regional regulations of the gas utility must be

observed.

7.1 Cause of failure and the remedy

Failure Possible causes Remedy

Operating element does not

react

The unit does not heat up Gas supply interrupted • Restore gas supply.

Insufficient heat output

Burner

control knob is defective • Close the gas shut-off valve on the

unit.

• Contact Customer service.

• Open the gas shut-off valve on the

unit.

• Contact Customer service.

Burner

control knob is on the " " setting

Burner

control knob is defective • Close the gas shut-off valve on the

Piezo pilot ignitor

Unit defective • Close the gas shut-off valve on the

Burner

control knob is defective • Close the gas shut-off valve on the

Unit defective • Close the gas shut-off valve on the

button is defective • Close the gas shut-off valve on the

• Set the output.

unit.

• Contact Customer service.

unit.

• Contact Customer service.

unit.

• Contact Customer service.

unit.

• Contact Customer service.

unit.

• Contact Customer service.

Smell of gas Gas is escaping • Follow the rules of conduct when the

smell of gas is detected.

7.2 Nameplate

When contacting Customer service, please always provide the

following data from the nameplate:

Serial number

(SN)

Type number

(TYP)

28 Operating instructions

2063501-20ABBE-A

8 Carrying out maintenance

The unit is maintenance-free, there are no maintenance

requirements.

In order that the value of the unit is retained, the manufacturer

recommends that maintenance is carried out on a needs basis by a

maintenance company, which is approved by the gas utility.

Carrying out maintenance

2063501-20ABBE-A

29Operating instructions

Disposing of the unit in an environmentally responsible manner

9 Disposing of the unit in an environmentally responsible manner

Do not dispose of unit or the unit's components together with nonrecyclable waste. If the unit is disposed of together with nonrecyclable waste or treated improperly, toxic substances contained in

the unit can damage health and pollute the environment.

Dispose of the unit in accordance with local regulations for used

appliances. Clarify any open questions with the responsible agencies

(for instance, solid waste management).

Cleaning agents Dispose of leftover cleaning agents and cleaning agent containers in

accordance with the information provided by the cleaning agent's

manufacturer. Observe applicable regional regulations.

30 Operating instructions

2063501-20ABBE-A

10 Manufacturer's declaration

EC Declaration of Conformity

1 / 1

2063501--0KOBE-B en-GB

Manufacturer

MKN Maschinenfabrik Kurt Neubauer GmbH & Co. KG • Halberstädter Straße 2a • 38300 Wolfenbüttel,

Germany

We hereby declare, that the following product:

Description of the unit

Unit for cooking food in commercial applications

Designation / Unit type

Gas cooker with simmer plate / XXGHEG...

Unit number

0763501 10014100 1463501 2063501 3063501

complies with the relevant provisions of the following directives and regulations, but does not contain any

assurance of properties:

• Directive 2009/142/EC, dated 30 November 2009, relating to appliances burning gaseous fuels

• Directive 2011/65/EU (RoHS) dated 01 July 2011

• REGULATION (EC) No. 1935/2004 dated 27 October 2004 on materials and objects, which are intended to

come into contact with food

We hereby declare, that the listed units comply with the type of construction described in the EU Type

Examination Certificate, and that they meet the requirements of the specified Gas Appliances Directive.

Product identification number of the EU type examination certificate:

CE-0085CL0515

Adduced basis for verification

EN 203-1:2014

EN 203-2-9:2006

EN 203-3:2009

The manufacturer bears the sole responsibility for issuing this Declaration of Conformity. This Declaration of

Conformity becomes invalid, if changes are made which are not agreed with us.

Wolfenbüttel, 14/03/2017

Person authorised to compile the technical documents: ppa. Peter Helm,Chief Technical Officer (address as

manufacturer)

Translation from the original document • 2063501--0KODE-B

Manufacturer's declaration

2063501-20ABBE-A

31Operating instructions

Manufacturer's declaration

32 Operating instructions

2063501-20ABBE-A

www.mkn.eu

Loading...

Loading...