Page 1

Operating manual

Deep fat fryer (electric)

Open out the cover page to see the

controls.

Translation of the original operating instructions 2020321-03ABDE-C / 05.04.2011 / TAG-MaBr

Version

London I

London II

Paris

2020321-03ABBE-C / en-GB

Operating manual

Page 2

Controls

123

4

23

5

6

8

O

I

L

P

U

M

P

7

R

E

S

E

T

91011

O

I

L

-

L

E

V

E

L

O

V

E

R

T

E

M

P

-

2

O

V

E

R

T

E

M

P

-

1

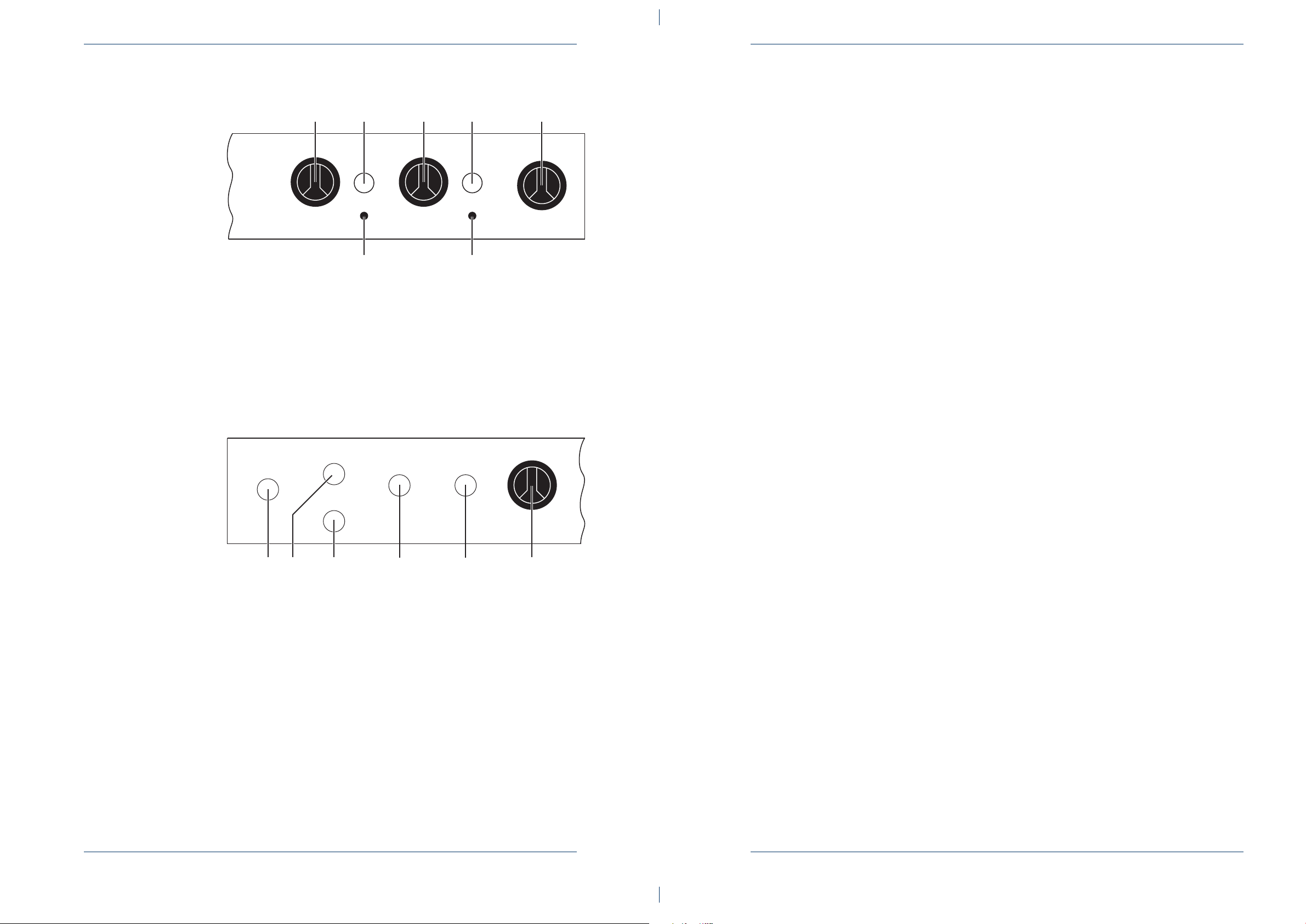

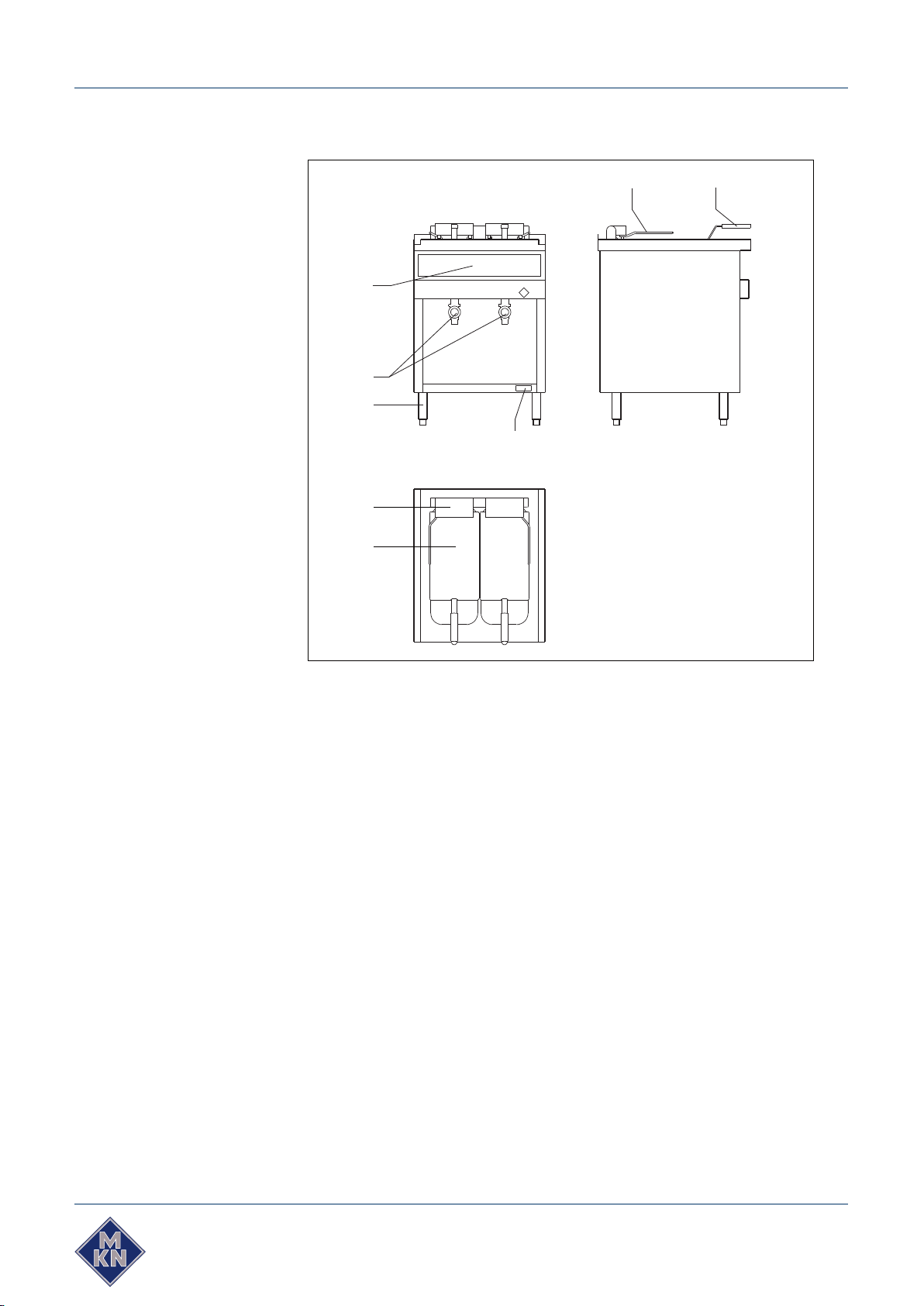

Figure 1: Standard version

1 Unit switch

2 “Heating mode” control lamp

Deep fat fryer (electric)Deep fat fryer (electric)

3 Temperature regulator

4 Safety temperature limiter

(not with marine versions)

5 2. Safety temperature limiter (optional)

Figure 2: Optional equipment

6 Timer

(units with frying basket lifting mechanism)

7 “Reset” button

8 Switch for fat filter system

9 “Over-temperature 2” control lamp

(units with FSC)

10 “Over-temperature 1” control lamp

(units with 2 safety temperature limiters and FSC)

11 “Filling level” control lamp

(units with FSC)

Operating manualOperating manual

Page 3

ContentsDeep fat fryer (electric)

5Introduction ...........................................................1

5Intended use ......................................................................1.1

5About this operating manual ...........................................1.2

6Warnings ............................................................................1.3

6Warranty and liability ........................................................1.4

7Signs and symbols ...........................................................1.5

8Safety information ................................................2

10Construction and function ...................................3

10Description of the unit ......................................................3.1

10Version London I .........................................................................3.1.1

11Version London II ........................................................................3.1.2

12Version Paris ...............................................................................3.1.3

12Features .............................................................................3.2

13Description of the controls ..............................................3.3

14Using frying fat and oil .....................................................3.4

14Recommended frying temperatures and times ..............3.5

15Filling quantities ...............................................................3.6

16Operation ...............................................................4

16Commissioning .................................................................4.1

16Filling with frying fat .........................................................4.2

16Switching on/switching off unit .......................................4.3

16Switching on ...............................................................................4.3.1

17Switching off ...............................................................................4.3.2

17Basic functions .................................................................4.4

17Setting the temperature ..............................................................4.4.1

18Setting the time ...........................................................................4.4.2

18Deep frying ........................................................................4.5

19Frying (with the frying basket lifting mechanism) .........4.6

20End of operation and breaks ...........................................4.7

21Emptying the unit ..............................................................4.8

21Draining off the frying fat .............................................................4.8.1

21Filtering frying fat with the integrated fat filtering system ............4.8.2

23Cleaning ................................................................5

23Avoiding corrosion ...........................................................5.1

3Operating manual

Page 4

Deep fat fryer (electric)Contents

23General cleaning ...............................................................5.2

24Cleaning the housing .......................................................5.3

24Cleaning the frying basin .................................................5.4

25Cleaning the tubular heating elements ...........................5.5

26Faults .....................................................................6

26Correcting faults ...............................................................6.1

26Safety temperature limiter (STL) triggered .....................6.2

6.2.1

6.2.2

Switching the STL back on after exceeding the maximum

operating temperature ................................................................

Switching the STL back on if the ambient temperature falls below

0 °C .............................................................................................

26

27

27Control lamp is defective .................................................6.3

28Cause of errors and troubleshooting ..............................6.4

29Service ...................................................................7

29Disposal .............................................................................7.1

30Declarations of Conformity ..................................8

Operating manual4

Page 5

1 Introduction

1.1 Intended use

MKN deep fat fryers are appliances solely intended to be used for

commercial purposes, especially in commercial kitchens.

The unit may only be used with suitable frying fats for the purpose of deep

frying food.

It is not permitted to use the unit for the following purposes, among others:

●

Drying towels, paper or dishes

●

Heating acids, brines or other chemicals

●

Heating inflammable liquids

●

Melting fats or salts

●

As a food warmer

●

Cooking noodles, potatoes, vegetables or other food in salt water

●

Cooking soups or sauces

●

Defrosting frozen foods

IntroductionDeep fat fryer (electric)

1.2 About this operating manual

Target group

This operating manual is part of the equipment and contains information

required by the persons operating the unit to enable them to operate it

safely, for cleaning and looking after the unit and for handling faults.

●

The employees engaged to perform any tasks with the unit must have

read the operating manual, especially the section “Safety information”,

before beginning work.

●

Keep this operating manual stored safely during the life of the unit.

●

Make sure that this operating manual is constantly available for the

staff at the place where the unit is used.

●

Supply this operating manual to any subsequent owner or user of the

unit.

●

Include any supplements received from the manufacturer.

●

Supplement the instructions, including supervisory or notification

requirements, to take account of special operational circumstances

e.g. work organisation, workflows or deployed staff.

●

This operating manual is intended for employees who are responsible

for operating, cleaning and looking after the unit as well as handling

faults.

●

Repairs to the unit may only be carried out by specially trained

technical staff.

5Operating manual

Page 6

●

Adults may not use the unit without supervision if

-

they are unable to do so due to their physical, sensory or mental

capabilities,

-

they do not have the knowledge and experience required to

operate the unit safely and in the manner intended.

1.3 Warnings

Warnings are indicated with a pictogram and a signal word.

The type and source of the risk as well as the consequences are described

together with instructions for avoiding the danger. The meanings of the

pictograms and signal words used are explained in section “Signs and

symbols” (see Chapter “Signs and symbols”, Page 7).

1.4 Warranty and liability

The unit may not be modified or technically changed.

Deep fat fryer (electric)Introduction

All guarantees or warranties cease to exist if technical changes are made.

Furthermore, the safety of the unit is no longer guaranteed.

Claims for warranty or liability for damages to persons or property are

excluded if they arise from one or more of the following causes:

●

Improper use of the unit

●

Incorrect installation, commissioning, operation or servicing of the

unit

●

Technical changes to the unit without the binding agreement of the

manufacturer

●

Use of spare parts or accessories not approved by MKN

●

Faults resulting from the failure to comply with these operating

instructions

Operating manual6

Page 7

1.5 Signs and symbols

DANGER

Imminent danger

→

Non-compliance poses a threat of death or serious injury.

WARNING

Possible danger

→

Non-compliance may pose a threat of death or serious injury.

CAUTION

Dangerous situation

→

Non-compliance may result in slight injuries.

IntroductionDeep fat fryer (electric)

CAUTION

Dangerous situation

→

Non-compliance may result in equipment damage.

Provides helpful information regarding use.

ExplanationMeaningSymbol

These must be fulfilled before you can

follow the instructions.

An action is required here.Instruction, single

Instructions must be followed in the order given.

Emphasises the name of the controlControlOn/Off

1.

2.

RequirementsRequirements

step

Instruction, multiple

steps

7Operating manual

Page 8

Deep fat fryer (electric)Safety information

2 Safety information

MKN appliances comply with the relevant safety standards. However,

this does not exclude all possible dangers from arising, e.g. due to

improper use.

Therefore, when installing and operating the unit, the operating personnel

must be familiar with and observe local regulations, including BGR 111

“Working in catering kitchens”.

The following safety measures must also be observed:

Hot surfaces, steam and

liquids

Electricity Risk of electric shock

Risk of burns due to hot surfaces

●

Wear insulated protective gloves during operation.

●

Allow surfaces to cool before cleaning.

●

Do not touch the heating elements immediately after operation.

Risk of scalding due to hot steam

●

Hot fat causes traces of water to evaporate in an explosive manner;

dry the unit completely after cleaning.

Risk of scalding due to hot fat

●

Observe the effective capacity.

●

Whenever possible, thaw frozen food before deep frying.

●

Dry foods containing a lot of water before deep frying.

●

Do not mix frying fats and oils or different kinds of frying fats.

●

Units with rollers:

-

Only move the unit when the basin is empty.

-

Lock the rollers during operation.

●

To avoid damaging the electronics, do not operate the unit if the

controls are damaged.

●

Only put a defective unit back into operation after it has been repaired.

Risk of fire Risk of fire due to self-igniting fat, soiling and greasy films

●

Clean the unit after each use.

●

Observe the instructions regarding cleaning.

●

Do not leave the unit unattended during operation.

●

Observe the effective capacity.

●

Consider the lower flash point when using old frying fat.

Operating manual8

Page 9

Safety informationDeep fat fryer (electric)

Firefighting

●

Disconnect the unit from the mains immediately in the event of fire.

●

Never attempt to put out a fire with water. Use a class F fire

extinguisher to put out oil and fat fires. For other fires, use ABC fire

extinguishers.

Hygiene Personal injury and damage to equipment due to inadequate cleaning

●

Observe the cleaning instructions.

Cleaning Risk of burns caused by cleaning agents

●

Wear protective gloves and glasses when using caustic cleaning

agents.

●

Observe the information provided by the manufacturer of the cleaning

agent.

Risk of injury due to slippery floors

●

Clean the floor in front of the unit regularly to remove splattered

grease.

Damage to equipment due to incorrect cleaning

●

Do not cool the unit abruptly after operation.

●

Do not clean the unit with a high-pressure cleaner.

●

Do not clean the surfaces with abrasive cleaners, scouring pads or

chemically aggressive cleaners.

●

Observe the reaction times for cleaning agents.

●

Clean the unit regularly.

●

Collect used fat in suitable containers and dispose of properly

according to the harmful substance ordinances.

Improper use Damage to equipment due to improper use

●

Only use the unit with standard frying fats or oils. Liquid and semi-solid

frying fats are suitable.

●

Do not melt solid frying fat in the frying basin.

Liquify solid frying fat before filling.

●

Do not operate the unit without the oil clarifying tray.

●

Only use original accessories.

9Operating manual

Page 10

2

3

4

56 7

8

1

Deep fat fryer (electric)Construction and function

3 Construction and

function

3.1 Description of the unit

3.1.1 Version “London I”

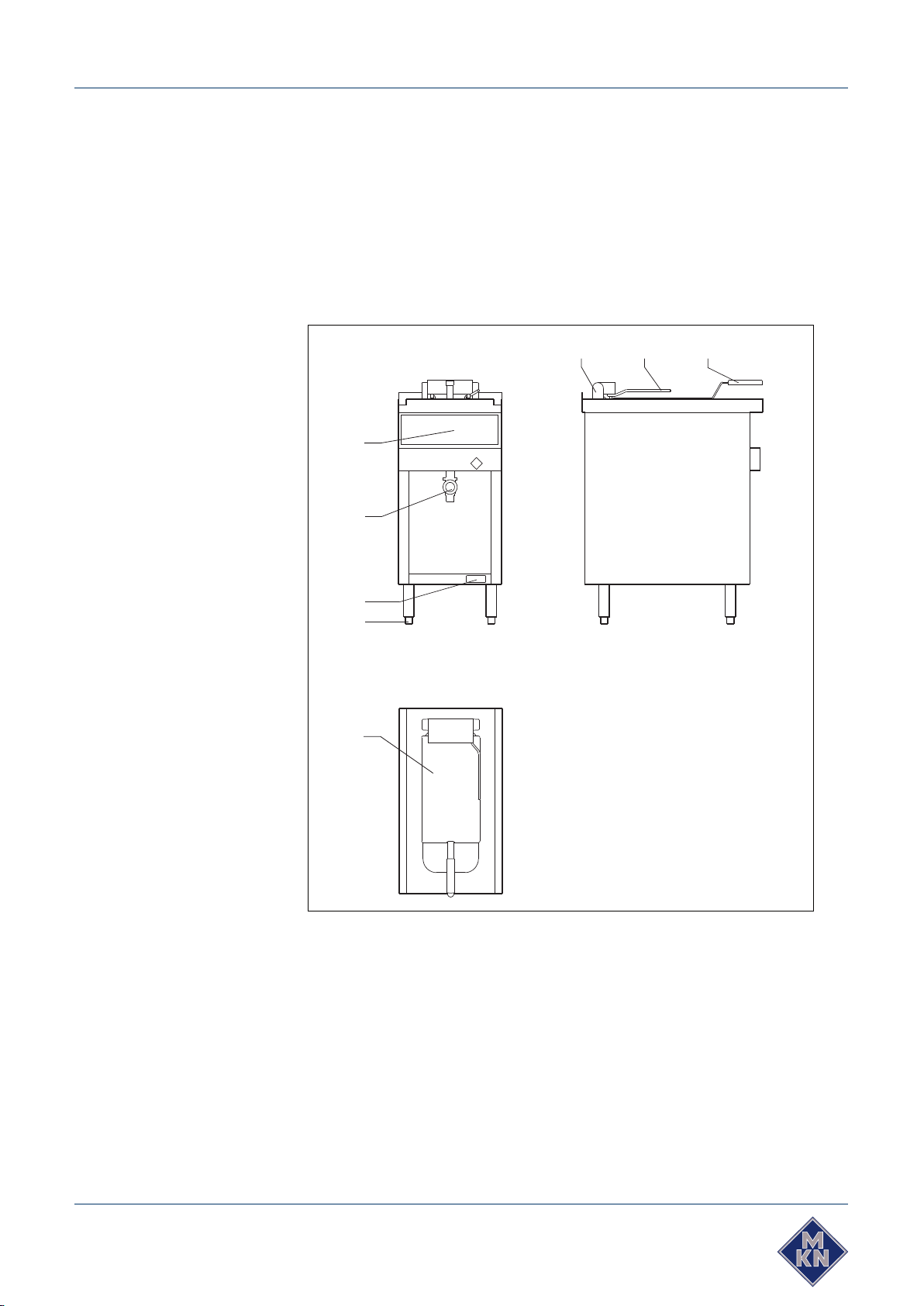

Figure 3: Version “London I”

Swivel housing5Height-adjustable feet1

Swivel lever6Type plate2

Frying basket “L”7Drain3

Lid8Controls4

Operating manual10

Page 11

3.1.2 Version “London II”

1

3

2

4

56

7

8

Construction and functionDeep fat fryer (electric)

Figure 4: Version “London II”

Swivel lever5Type plate1

Frying basket “L”6Height-adjustable feet2

Swivel housing7Drain3

Lid8Controls4

11Operating manual

Page 12

3.1.3 Version “Paris”

1

3

4

57

8

9

2

6

Deep fat fryer (electric)Construction and function

Figure 5: Version “Paris”

Frying basket “P”6Type plate1

Frying basket “L”7Height-adjustable feet2

Swivel housing8Drain3

Lid9Controls4

Swivel lever5

3.2 Features

Main components

Electrical features

●

Self-supporting housing made of chrome nickel steel (material no.

1.4301)

●

Frying basin with deeper, cooler fat zone and drainage at the bottom

(front drainage optional)

●

Direct heating with swivelling tubular heating elements

●

Unit switch

●

Temperature regulator

●

Control lamps (visual signal)

Operating manual12

Page 13

●

Buzzer (audible signal)

●

Safety temperature limiter

-

Optional Fryer Safety Control (FSC) system

-

Optional second Safety Temperature Limiter (STL)

●

Heating contactors

Construction and functionDeep fat fryer (electric)

Units with frying basket

lifting mechanism

Units with fat filter system

Accessories and optional

equipment

3.3 Description of the controls

●

Drive motor

●

End switch

●

Timer

●

Pull-out fat collection receptacle

●

2 fat-filter inserts

●

Pump with removable intake and return flow nozzles.

●

Return flow line with self-closing coupling

●

Lid

●

Oil clarifying tray

●

Frying baskets

●

Fat collection receptacle

●

Connection rails for setting up several units

●

Side connection rails

Open out the cover page to see the controls.

“Filling level” control lamp

“Over-temperature” control lamp

Safety temperature limiter

DescriptionControl

Switch on/offUnit switch

Lights up when heating is activated“Heating mode” control lamp

Lights if the oil/fat level is below the

minimum.

Lights when the maximum operating

temperature is exceeded.

Units with FSC:

●

“Over-temperature 1” lights if the

FSC has detected a fault.

●

“Over-temperature 2” lights if the

maximum operating temperature is

exceeded (STL has triggered)

Sets the frying temperatureTemperature regulator

Switches the safety temperature limiter

back on

13Operating manual

Page 14

Deep fat fryer (electric)Construction and function

DescriptionControl

Activate heating“Reset” button

Switches the fat filter system on/offSwitch for fat filter system

Sets the frying timeTimer

3.4 Using frying fat and oil

Frying fat as a food The food being fried absorbs frying fat during frying, e.g. French fries

7-12%, doughnuts 20-25%. The fat is eaten along with the food; this is

why frying fat also counts as a food in terms of nutritional physiology.

Suitability for consumption Frying fat must be suitable for consumption, this means that it must be

replaced in good time before it becomes spoiled.

The period of use given by the manufacturer is always decisive. Good

frying fat can be used for about 30-40 hours depending on the method

of use and the food being fried.

Extending the usable life

of the fat

Used frying fat Do not top up used frying fat with new fat; replace completely instead.

3.5 Recommended frying temperatures and

To determine whether the fat is suitable for consumption, quick tests (e.g.

3M Oil Testing Strips) are available from specialised suppliers.

The fat will stay suitable for consumption for longer by taking the following

measures:

●

Store frying fat cool when not in use

●

Choose foods for frying that contain only small amounts of water

●

Use the frying fat for only one type of food.

●

Do not overheat the fat (160-180 °C is sufficient)

●

Do not fry breadcrumbed food

Collect used fat in suitable containers and dispose of properly according

to the harmful substance ordinances.

times

Frying time (minutes)Frying temperature (°C)Food

3–4170Doughnuts

2–3170Cauliflower

2–6170Fish fillet

2–4160Trout

3–8170Chicken, portioned

2–4170Pan fried items

Operating manual14

Page 15

and deep frozen

and thawed

Table 1: Recommended frying temperatures and times

3.6 Filling quantities

Table 2: Filling quantities (food to be fried)

Construction and functionDeep fat fryer (electric)

Frying time (minutes)Frying temperature (°C)Food

3–5180French fries, blanched

2–3180French fries, blanched

2–3180Crullers

1–3170Onion rings

Filling quantity (kg)Version

1.2London I

2 x 1.2London II

2.5Paris

Table 3: Filling quantities (frying fat)

Filling quantities min./max. (l)Version

6.5/12.5London I

2 x 6.5/2 x 12.5London II

15/30Paris

15Operating manual

Page 16

4 Operation

4.1 Commissioning

The unit was tested for functioning and safety after manufacture.

Before putting into service:

1. Remove any remaining production residues and packaging.

2. Clean the unit (see Chapter “Cleaning”, Page 23).

4.2 Filling with frying fat

Requirements Unit is switched off and is cool

CAUTION

Deep fat fryer (electric)Operation

Risk of fire caused by frying fat

The fat or oil can ignite if the filling quantity is below the minimum level.

→

Observe the filling mark.

1. Liquify solid frying fat in a saucepan before filling the unit.

2. Remove the lid.

3. Close the drain.

4. Fill with fat or oil according to the amount of food to be fried (see

Chapter “Filling quantities”, Page 15).

You will find the filling marks on the rear wall of the frying basin: Observe

the minimum and maximum quantities!

4.3 Switching on/switching off unit

4.3.1 Switching on

Requirements Unit is filled with frying fat or oil at least up to the lower filling mark

WARNING

Risk of fat fires

The fat or oil can ignite if the filling quantity is below the minimum level.

→

Observe the filling mark.

Operating manual16

Page 17

1. Turn the unit switch (1).

Unit is switched on.

2. Press Reset (7).

Heating is switched on.

3. Set the temperature with the temperature regulator (3).

Control lamp (2) lights up, frying fat is being heated.

Units with frying basket lifting mechanism: Lifting bars will move to the

upper end position and a signal will sound.

The unit is ready for operation once the control lamp goes out.

4.3.2 Switching off

CAUTION

Damage to equipment due to switching off incorrectly

OperationDeep fat fryer (electric)

Switching on again with cold, solidified fat blocks the frying tray lifting

mechanism.

→

Do not switch the unit off when the basket holding bracket is lowered.

→

Turn the unit switch (1) to the setting “0”.

Unit is switched off.

4.4 Basic functions

4.4.1 Setting the temperature

→

Turn the temperature regulator (3) to the desired temperature.

The control lamp (2) lights up.

17Operating manual

Page 18

4.4.2 Setting the time

→

Turn the timer (6), to set the frying time.

Minimum: 1 minute, maximum: 15 minutes

4.5 Deep frying

Requirements Unit is filled with frying oil or fat

Unit is switched on and pre-heated

WARNING

Risk of fire

→

Never leave the unit unattended during operation.

→

Observe information about fighting fires in chapter “Safety

information”.

Deep fat fryer (electric)Operation

CAUTION

Risk of burns due to frying oil or fat frothing over

→

Whenever possible, thaw or partly thaw frozen food before adding.

→

Observe the specified filling quantities.

Observe the information about using frying fats and oils (see Chapter

“Using frying fat and oil”, Page 14).

1. Dry damp food before frying.

2. Place the food to be fried in the frying basket, observing the maximum

filling quantity (see Chapter “Filling quantities”, Page 15).

3. Check the temperature.

The control lamp (2) goes dark as soon as the set temperature is reached.

4. Place the frying basket in the frying basin.

Version “Paris”: When frying with the frying basket “L”, use the frying

basket “P” as well.

Observe the recommended frying temperatures and times (see Chapter

“Recommended frying temperatures and times”, Page 14).

Operating manual18

Page 19

OperationDeep fat fryer (electric)

Figure 6: Positioning the frying basket

5. After frying, place the frying basket in the swivel housing and allow

the fat to drain off.

4.6 Frying (with the frying basket lifting mechanism)

Requirements Unit is filled with frying oil or fat

Unit is switched on and pre-heated

WARNING

Risk of fire

→

Never leave the unit unattended during operation.

→

Observe information about fighting fires in chapter “Safety

information”.

CAUTION

Risk of burns due to frying oil or fat frothing over

→

Whenever possible, thaw or partly thaw frozen food before adding.

→

Observe the specified filling quantities.

The frying basket lifting mechanism lowers the frying basket into the frying

basin automatically and lifts it out again after a pre-set time.

1. Dry damp food before frying.

2. Place the holding bracket for the basket on the lifting bars behind the

swivel housing.

3. Position the frying basket on the holding bracket.

Version “Paris”: When frying with the frying basket “L”, use the frying

basket “P” as well.

19Operating manual

Page 20

6

5

4

3

7

8

9

10

11

Deep fat fryer (electric)Operation

4. Place the food to be fried in the frying basket, observing the maximum

filling quantity (see Chapter “Filling quantities”, Page 15).

5. Setting the time.

Observe the recommended frying temperatures and times (see Chapter

“Recommended frying temperatures and times”, Page 14).

6. Check the frying temperature.

The control lamp (2) goes out as soon as the frying temperature is

reached.

7. Press timer (6), to start frying.

The frying basket will be lowered into the frying basin.

At the end of the pre-set time, the frying basket will be raised from the

frying basin and a signal will sound.

To interrupt frying, press timer (6) again.

4.7 End of operation and breaks

Switch off the unit at the end of operation and during breaks.

1.

Turn temperature regulator to “Δ”.

2. Turn the unit switch to “0”.

The unit is switched off.

Operating manual20

Page 21

4.8 Emptying the unit

4.8.1 Draining off the frying fat

Requirements Frying fat is liquid

Unit is switched on

CAUTION

Risk of scalding due to hot fat

→

Wear heat-resistant protective gloves.

Observe the information about using frying fats and oils (see Chapter

“Using frying fat and oil”, Page 14).

When transporting, use a heat-resistant container with handles and

sealable lid.

OperationDeep fat fryer (electric)

Observe the effective filling capacity of the unit.

1. Place a suitable container underneath.

2. Slowly open the drain.

3. Collect used fat in suitable containers and dispose of properly

according to the harmful substance ordinances.

4. Close the drain.

4.8.2 Filtering frying fat with the integrated fat filtering system

Requirements Frying fat is liquid

CAUTION

Risk of scalding due to hot fat

→

Wear heat-resistant protective gloves.

Observe the information about using frying fats and oils (see Chapter

“Using frying fat and oil”, Page 14).

With the London II version, filter the fat in the two frying basins separately.

1. Switch off the unit.

2. Pull out the fat collection receptacle as far as possible.

3. Insert the fine frying fat filter.

21Operating manual

Page 22

Deep fat fryer (electric)Operation

4. Insert the coarse frying fat filter.

5. Push the fat collection receptacle back in completely.

The intake nozzle must engage in the pump.

6. Open the drain slowly and let the fat run into the container.

7. Close the drain.

8. Insert the return pump nozzle into the coupling of the return line.

9. Turn the switch for the fat filter system to the right and hold it.

The fat will be pumped into the frying basin.

10. London II version: To filter the second frying basin, pull out the return

pump nozzle and refit it.

Operating manual22

Page 23

5 Cleaning

5.1 Avoiding corrosion

●

Keep the surfaces of the unit clean and well aired.

●

Regularly remove accumulated layers of scale, grease, starch and

protein.

●

Regularly remove salt deposits.

●

Only allow parts made of stainless steel brief contact with

concentrated acids, spices, salts or similar substances.

●

Avoid damaging the stainless steel surface with other metallic items

(steel spatulas, steel wire brushes).

●

Avoid contact with iron and steel (steel wool, steel spatulas, chippings

from the water pipes, iron-containing water).

●

Eliminate newly rusted points, which may have formed due to contact

with iron for example, using a mild scouring agent or fine sandpaper.

●

Do not use any bleaching or chlorine-containing cleansers.

●

Clean contact surfaces with fresh water.

CleaningDeep fat fryer (electric)

5.2 General cleaning

CAUTION

Risk of burns due to hot surfaces

→

Allow surfaces to cool before cleaning.

CAUTION

Equipment damage due to water penetrating the electronic controls

→

Do not spray the outside of the housing with water jets.

CAUTION

Damage to surfaces caused by incorrect cleaning

→

Do not use abrasive cleaners or cloths.

→

Do not use aggressive cleaners (e.g. grill cleaner).

CAUTION

Damage caused by incorrect cooling

→

Allow the unit to cool before cleaning.

→

Do not use ice or cold water for cooling.

23Operating manual

Page 24

1. Clean the unit after each use.

2. Switch off unit and allow to cool before cleaning.

3. Wipe the outside of the housing with a standard stainless steel cleaner

and fresh water.

5.3 Cleaning the housing

→

Clean the housing daily with warm water and a standard detergent.

5.4 Cleaning the frying basin

Requirements Frying fat drained off

CAUTION

Risk of burns due to hot surfaces

→

Allow surfaces to cool before cleaning.

Deep fat fryer (electric)Cleaning

CAUTION

Risk of scalding due to hot steam

Hot frying fat causes traces of water to evaporate in an explosive manner.

→

Dry the unit completely after cleaning.

1. Turn off the unit and allow it to cool.

2. Close the drain.

3. Remove the frying basket.

4. Units with frying basket lifting mechanism: Remove the holding bracket

for the basket from the lifting bars.

5. Swivel out the heating coil using the swivel lever and lock in place.

6. Carefully remove the oil clarifying tray from the frying basin and empty

it.

7. Thoroughly clean the frying basin, frying basket and oil clarifying tray

with warm water and dishwashing detergent.

8. Rinse thoroughly with clear water.

9. Wipe dry with a lint-free cloth.

Ensure that no water remains in the drain.

10. Lift the heating coil slightly with the swivel lever and fold in the

supporting bracket.

Operating manual24

Page 25

11. Swivel the heating coil back into the frying basin using the swivel

lever.

12. Replace the oil clarifying tray.

13. Units with frying basket lifting mechanism: Place the holding bracket

for the basket on the lifting bar.

14. Replace the frying basket.

15. Put the lid on.

5.5 Cleaning the tubular heating elements

Requirements Frying fat drained off

CAUTION

Risk of burns due to hot surfaces

→

Allow surfaces to cool before cleaning.

CleaningDeep fat fryer (electric)

CAUTION

Risk of scalding due to hot steam

Hot frying fat causes traces of water to evaporate in an explosive manner.

→

Dry the unit completely after cleaning.

1. Turn off the unit and allow it to cool.

2. Close the drain.

3. Place a suitable container underneath.

4. Fill with water up the maximum filling level mark.

5. Switch on the unit and heat the water to 90 °C.

6. Switch off the unit.

7. Allow encrustation to soften for 30 minutes.

8. Open the drain slowly and let the water run into the container.

9. Close the drain again.

10. Swivel the tubular heating element outward with the swivel lever and

allow it to lock in place.

11. Allow tubular heating element to cool down.

12. After allowing to cool, push the supporting plate under the heating

unit in its swivelled-out position.

13. Clean the tubular heating element with a soft brush.

25Operating manual

Page 26

Deep fat fryer (electric)Faults

6 Faults

6.1 Correcting faults

This section describes the steps to be taken in the event that faults occur

on the unit during operation.

1. Observe the instructions in Chapter “Cause of errors and

troubleshooting”, Page 28.

2. Contact customer service.

6.2 Safety temperature limiter (STL) triggered

CAUTION

Damage of the safety temperature limiter due to improper switching

back on

→

Allow unit to cool down.

→

Determine the cause of the triggering and eliminate it.

The safety temperature limiter is a safety device that prevents the unit

from being damaged.

It is triggered when

●

the unit exceeds its maximum operating temperature

●

the ambient temperature falls below 0 °C

If the maximum operating temperature is exceeded, the unit's heating

switches off.

6.2.1 Switching the STL back on after exceeding the maximum operating temperature

1. Allow unit to cool down.

2. Determine the cause of the STL triggering.

3. Eliminate the cause.

4. Remove the cap in the switch cover.

5. Press the red unlocking button.

6. Replace the cap in the switch cover.

Operating manual26

Page 27

FaultsDeep fat fryer (electric)

6.2.2 Switching the STL back on if the ambient temperature falls below 0 °C

If the ambient temperature falls below 0 °C (e.g. during storage in a

warehouse or operation in a mobile sales cart), the STL triggers. The unit

cannot be switched on.

DANGER

Risk of injury due to the sensor bursting

The sensor tip may burst if it becomes overheated.

→

Never heat sensors with a lighter or similar source of heat.

1. Warm the sensors to room temperature (20 °C).

2. Remove the cap in the switch cover.

3. Press the red unlocking button.

4. Replace the cap in the switch cover.

6.3 Control lamp is defective

CAUTION

Equipment damage due to penetration of water

→

Replace control lamps according to the applicable replacement parts

list.

An unsealed lens or control lamp could allow penetration of cleansers.

Only put the defective unit back into service after replacing the defective

lens or control lamp with an original component.

27Operating manual

Page 28

Deep fat fryer (electric)Faults

6.4 Cause of errors and troubleshooting

Open out the cover page to see the controls.

RemedyPossible causesError

●

Control is defective.Control does not respond

Disconnect the unit from the mains.

●

Contact customer service.

up; signal sounds.

(units with FSC)

“Over-temperature” control

lamp lights up during operation;

signal sounds.

Unit shuts off

cracked

Ambient temperature is below 0 °C.

Safety temperature limiter (STL) has

triggered.

Not enough frying fat.“Filling level” control lamp lights

Maximum operating temperature exceeded. STL has triggered.

Temperature regulator at “Δ”

Power supply disrupted

Unit is defective

Unit is defectiveInsufficient heat output

Operating temperature exceeded, STL

has triggered

Control lamp is defectiveControl lamp not working or is

Check the STL (see Chapter “Safety

temperature limiter (STL) triggered”,

Page 26)

●

Switch off unit and top up the frying

fat. Observe the filling mark.

Switch unit on again after 2 minutes.

●

Allow the unit to cool down again if

the “filling level” control lamp does not

go out.

●

Turn off the unit and allow it to cool

down.

Switch unit on again after 2 minutes.

●

Allow the unit to cool down again if

the “over-temperature” control lamp

does not go out.

●

Switch on the unit.Unit is switched offUnit does not heat up

●

Press “Reset” button.Heating is not activated

●

Set the temperature.

●

Connect the unit to the mains.

●

Check the STL (see Chapter “Safety

temperature limiter (STL) triggered”,

Page 26)

●

Disconnect the unit from the mains.

●

Contact customer service.

●

Disconnect the unit from the mains.

●

Contact customer service.

●

Check the STL (see Chapter “Safety

temperature limiter (STL) triggered”,

Page 26)

●

Disconnect the unit from the mains.

●

Contact customer service.

Operating manual28

Page 29

7 Service

MKN GmbH & Co D-38300 Wolfenbüttel

SN: XXXXXXX Typ: XXXXXXXXXX

XX,X kW IP XX

21 3

When contacting the service department, please always provide the serial

number (1) and device type (2) of your unit.This information can be found

on the type plate (3).

Figure 7: Type plate

Enter the data in the provided table.

ServiceDeep fat fryer (electric)

Serial numberDevice type

7.1 Disposal

Used electric and electronic appliances, in addition to valuable materials,

also contain harmful substances which were necessary for their functioning

and safety.

Do not dispose of the unit with regular non-recyclable waste.These

substances can be damaging to your health or to the environment if

incorrectly handled or disposed of with regular waste. Observe local

regulations for used appliances and dispose of accordingly. If you have

any questions, please contact the responsible authorities (e.g. the offices

of waste management).

29Operating manual

Page 30

Deep fat fryer (electric)Declarations of Conformity

8 Declarations of

Conformity

Operating manual30

Page 31

Declarations of ConformityDeep fat fryer (electric)

31Operating manual

Page 32

Deep fat fryer (electric)

Operating manual32

Page 33

Deep fat fryer (electric)

33Operating manual

Page 34

Deep fat fryer (electric)

Operating manual34

Page 35

Deep fat fryer (electric)

Page 36

Deep fat fryer (electric)

MKN Maschinenfabrik

Kurt Neubauer GmbH & Co.

Halberstaedter Strasse 2

D-38300 Wolfenbuettel (Germany)

Phone +49 (0) 53 31 / 89-0

Fax +49 (0) 53 31 / 89-280

Loading...

Loading...