MKN FlexiCombi Classic 6.21, FlexiCombi Classic 10.21, FlexiCombi Classic Series, FlexiCombi Classic 20.21, FlexiCombi Classic 10.15 Operating Instructions Manual

...Page 1

Read the operating instructions prior to

commissioning

Operating instructions

Combisteamer

Unit Model Type of energy Version

FlexiCombi Classic 6.15

6.21

10.15

10.21

20.15

20.21

Translation from the original document • 10014471-0ABDE-A • 23/01/2017

Gas HandClean

WaveClean (optional)

Door with rear-ventilated pane

Door with hygiene glazing

(optional)

1-point core temperature sensor

4-point core temperature sensor

(optional)

Sous-vide core temperature

sensor (optional)

10014471-0ABBE-A en-GB

Page 2

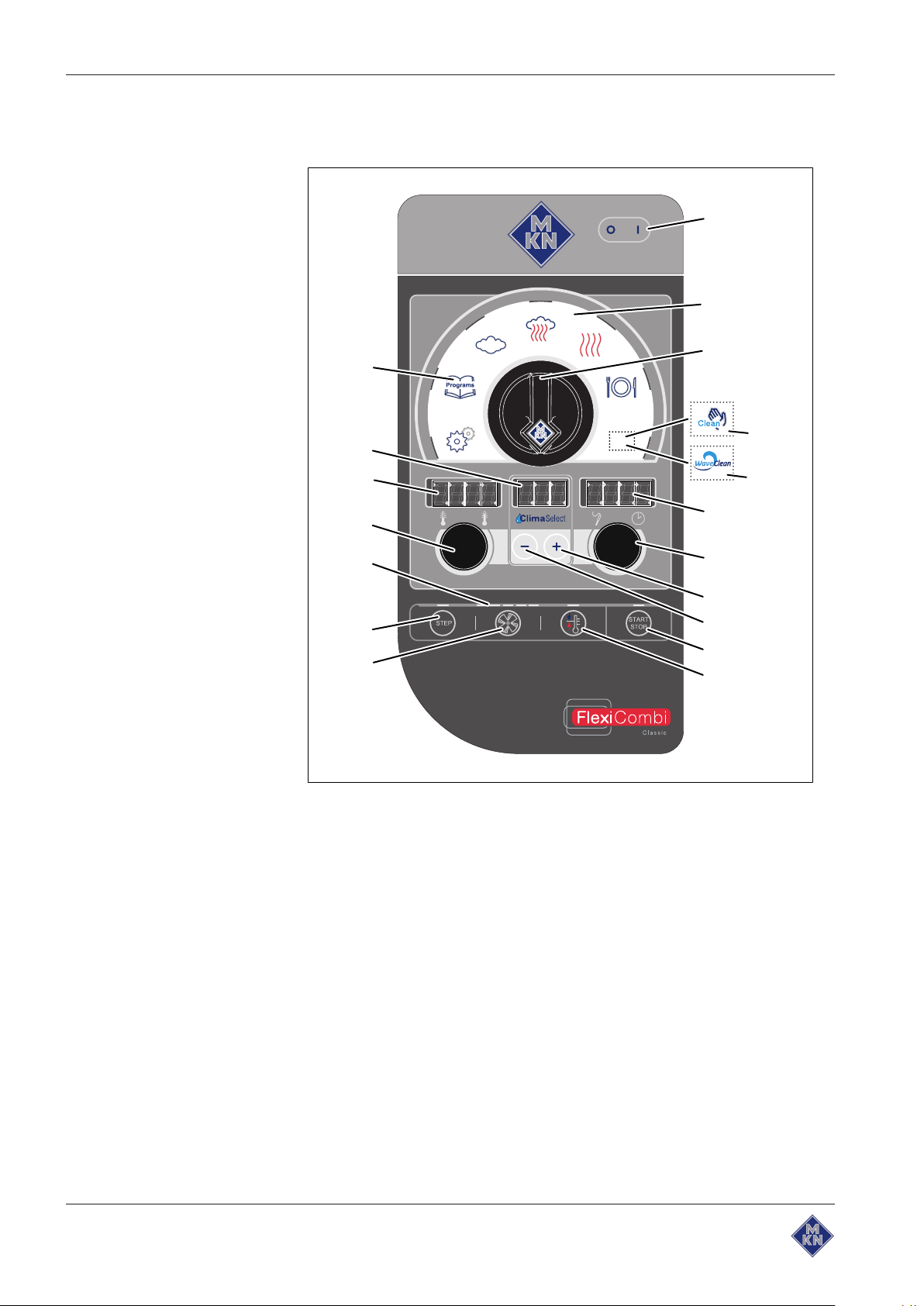

Operating and display elements

MAXI

a

b

c

d

e

f

g

h

i

j

k

l

m

n

o

p

q

r

a

On Off "I O"

b Selection range k

c

Select

d

HandClean

e

WaveClean

f Right display o Left knob

g Right knob p Left display

h

Plus

i

Minus

button j "START STOP" button

knob l

symbol m "STEP" button

symbol n Indicator light

button q Middle display

button r "Programs" button

Ready2Cook

Fan speed

button

button

10014471-0ABBE-A

2 Operating instructions

Page 3

Manufacturer

MKN Maschinenfabrik Kurt Neubauer GmbH & Co. KG

Halberstädter Straße 2a

38300 Wolfenbüttel, Germany

Telephone +49 53 31 / 89-0

Fax +49 53 31 / 89-280

Copyright

All rights to text, graphics and pictures in this documentation are held by MKN Maschinenfabrik Kurt

Neubauer GmbH & Co. KG. Distribution or duplication is only permitted with the prior written consent

of MKN.

Copyright by MKN Maschinenfabrik Kurt Neubauer GmbH & Co. KG.

3Operating instructions

Page 4

Directory of contents

1Introduction......................................................................... 7

1.1About this manual ............................................................................ 7

1.1.1Explanation of signs .................................................................................. 8

1.2Intended use ..................................................................................... 9

1.3Warranty............................................................................................ 9

2Safety information............................................................ 10

3Rules of conduct when the smell of gas is detected .... 13

4Description of the unit ..................................................... 14

4.1Overview of the unit ....................................................................... 14

4.1.1Countertop unit........................................................................................ 14

4.1.2Floor-standing unit................................................................................... 15

4.2Features .......................................................................................... 16

4.2.1Characteristics......................................................................................... 16

4.2.2USB port.................................................................................................. 16

4.2.3HACCP log .............................................................................................. 16

4.2.4WaveClean automatic cleaning (optional)............................................... 16

4.2.5Preheat bridge for models 20.15 and 20.21 ............................................ 17

4.3Operating and cooking modes...................................................... 17

4.3.1Operating modes..................................................................................... 17

4.3.2Types of cooking ..................................................................................... 17

4.3.3Expanded cooking functions ................................................................... 18

4.3.4Core temperature measurement ............................................................. 18

4.4Operating, control and display element functions...................... 19

4.4.1Abbreviations in the displays................................................................... 20

4.5Loading capacity ............................................................................ 21

4.5.1Loading capacity ..................................................................................... 21

4.5.2Plate capacity during regeneration.......................................................... 21

4.6Standard setting values................................................................. 22

4.6.1Temperature standard setting ................................................................. 22

4.6.2Core temperature standard-setting ......................................................... 22

4.6.3Cooking zone humidity standard setting ................................................. 22

4.7Basic settings ................................................................................. 23

5Operating the unit............................................................. 25

5.1Operating the unit in an environmentally responsible manner .......

25

5.2Switching the unit on and off ........................................................ 25

5.2.1Switching on ............................................................................................ 25

5.2.2Switching off ............................................................................................ 25

5.3Opening and closing the cooking zone door .............................. 25

5.3.1Opening the single-stage door latch........................................................ 25

5.3.2Closing the single stage door latch ......................................................... 26

4 Operating instructions

10014471-0ABBE-A

Page 5

Directory of contents

5.3.3Opening the two-stage door latch ........................................................... 26

5.3.4Closing the two-stage door latch ............................................................. 27

5.4Loading and emptying the unit ..................................................... 27

5.4.1Loading and emptying ............................................................................. 27

5.4.2Loading and emptying with a tray rack trolley ......................................... 28

5.4.3Loading and emptying with a tray trolley ................................................. 29

5.5Making the basic settings.............................................................. 30

5.5.1Opening the Setting menu....................................................................... 30

5.5.2Changing the basic setting ...................................................................... 30

5.6Basic functions............................................................................... 31

5.6.1Select cooking mode ............................................................................... 31

5.6.2Setting the cooking temperature ............................................................. 31

5.6.3Setting the cooking zone humidity level .................................................. 31

5.6.4Setting the cooking time .......................................................................... 32

5.6.5Setting the core temperature................................................................... 32

5.6.6Displaying actual values.......................................................................... 33

5.6.7Setting the fan speed .............................................................................. 33

5.6.8Inserting and removing a USB flash drive ............................................... 33

5.6.9Displaying the HAACP log number ......................................................... 33

5.6.10Exporting the HACCP log...................................................................... 34

5.7Using the core temperature sensor.............................................. 34

5.7.1Measuring with a 4-point core temperature sensor ................................. 35

5.7.2Measuring with a sous-vide core temperature sensor............................. 35

5.7.3Measuring the core temperature when cooking frozen food ................... 36

5.8Manual cooking .............................................................................. 36

5.8.1Starting the type of cooking..................................................................... 36

5.8.2Ending the cooking mode........................................................................ 37

5.9User's own cooking programs ...................................................... 37

5.9.1Creating user's own cooking program ..................................................... 37

5.9.2Saving user's own cooking program........................................................ 38

5.9.3Deleting user's own cooking program ..................................................... 38

5.10Automatic cooking ....................................................................... 39

5.10.1Selecting the cooking program.............................................................. 39

5.10.2Starting the cooking program ................................................................ 39

5.10.3Cooking program ends .......................................................................... 39

5.10.4Cancelling the cooking program............................................................ 40

5.10.5Changing the cooking program while cooking....................................... 40

5.11Multi-step cooking program ........................................................ 41

5.11.1Starting .................................................................................................. 41

5.12Expanded cooking functions ...................................................... 41

5.12.1Manual humidification............................................................................ 41

5.12.2Setting the start time delay.................................................................... 41

5.12.3Cancelling the start time delay .............................................................. 42

5.12.4Starting Ready2Cook ............................................................................ 42

10014471-0ABBE-A

5Operating instructions

Page 6

Directory of contents

5.12.5Cancelling Ready2Cook........................................................................ 42

5.13Pausing and finishing use........................................................... 43

5.13.1Perform a hygiene flush after an extended period of idleness .............. 43

6Cleaning and caring for the unit ..................................... 44

6.1Preventing corrosion ..................................................................... 44

6.2Remove rust spots ......................................................................... 44

6.3Cleaning the housing..................................................................... 45

6.4Cleaning the door handle, operating elements and control panel ..

45

6.5Cleaning the door seal................................................................... 45

6.6Cleaning the cooking zone door................................................... 46

6.6.1Cleaning the door with hygienic glazing .................................................. 46

6.6.2Cleaning the door with a back-ventilated window ................................... 46

6.7Cleaning the steam outlet.............................................................. 47

6.8Cleaning the condensation hood (optional) ................................ 47

6.9Removing calcium deposits from the unit................................... 48

6.10Cleaning the cooking zone automatically with WaveClean

(optional) ............................................................................................... 49

6.10.1Preparing for cleaning ........................................................................... 50

6.10.2Selecting the cleaning level................................................................... 50

6.10.3Inserting the cleaning cartridge ............................................................. 51

6.10.4Starting automatic cleaning ................................................................... 52

6.10.5Cancelling automatic cleaning............................................................... 52

6.10.6Ending automatic cleaning .................................................................... 52

6.11Cleaning the cooking zone semi-automatically ........................ 53

6.11.1Preparing the cooking zone................................................................... 53

6.11.2Starting the cleaning program ............................................................... 53

6.11.3Rinsing the cooking zone ...................................................................... 54

6.11.4Drying the cooking zone........................................................................ 54

6.12Swinging the air diverter open and closed ................................ 55

6.13Inspecting the unit........................................................................ 56

6.13.1Performing a visual inspection .............................................................. 56

7Troubleshooting ............................................................... 57

7.1Emergency mode ........................................................................... 57

7.2Causes of errors and remedies..................................................... 57

7.3Nameplate ....................................................................................... 59

8Dispose of unit in an environmentally responsible

manner ................................................................................. 60

9Manufacturer's declaration.............................................. 61

6 Operating instructions

10014471-0ABBE-A

Page 7

1 Introduction

1.1 About this manual

Introduction

The operating instructions are part of the unit and contain information:

• On safe operation,

• On cleaning and care,

• On remedies in case of faults.

Be aware of the following notes and adhere to them:

• Read the operating instructions completely before operating the

unit for the first time.

• Make the operating instructions available to the operator at all

times at the operating site of the unit.

• Insert any supplements from the manufacturer.

• Keep the operating instructions throughout the service life of the

unit.

• Pass on the operating instructions to any subsequent operator of

the unit.

Target group The target group of the instruction manual is the operator, who is

entrusted with the operation, cleaning and care of the unit.

Figures All figures in this manual are intended as examples. Discrepancies

between these and the actual unit can arise.

10014471-0ABBE-A

7Operating instructions

Page 8

Introduction

1.1.1 Explanation of signs

DANGER

Imminent threat of danger

Failure to comply will lead to death or very severe injuries.

WARNING

Possible threat of danger

Failure to comply can lead to death or very severe injuries.

CAUTION

Dangerous situation

Failure to comply can lead to slight or moderately severe

injuries.

ATTENTION

Physical damage

Failure to comply can cause physical damage.

Notes for better understanding and operation of the unit.

Symbol / sign Meaning

• Listing of information.

Action steps, which can be performed

in any sequence.

1.

2.

Action steps, which must be performed

in the specified sequence.

Result of an action performed or

additional information about it.

8 Operating instructions

10014471-0ABBE-A

Page 9

1.2 Intended use

Introduction

This unit is intended to be used solely for commercial purposes,

particularly in commercial kitchens.

This unit may only be used with suitable accessories and for the

cooking of food.

It is forbidden to use the unit for purposes, which include the

following:

• Washing dishes

• Storing supplies

• Drying cloths, paper or dishes

• Heating acids, alkaline solutions or other chemicals

• Heating preserved food

• Heating flammable liquids

• Heating rooms

1.3 Warranty

• Cleaning air filters

The use of the unit is prohibited in the following countries:

• USA

• Canada

The warranty is void and safety is no longer assured in the event of:

• Improper conversion or technical modifications of the unit,

• Improper use,

• Incorrect startup, operation or maintenance of the unit,

• Problems resulting from failure to observe these instructions.

10014471-0ABBE-A

9Operating instructions

Page 10

Safety information

2 Safety information

The unit complies with applicable safety standards. Residual risks

associated with operation or risks resulting from incorrect operation

cannot be ruled out and are mentioned specifically in the safety

instructions and warnings.

The operator must be familiar with regional regulations and observe

them.

Operation During operation, the following group of individuals must be

supervised by an individual who is responsible for safety:

• Individuals with physical, sensory, or mental handicaps, or who

The supervising individual must be familiar with the unit and the risks

associated with it.

Children are not allowed to operate the unit or play with it.

Hot surfaces Risk of burns from hot surfaces

lack the knowledge and experience to operate the unit properly.

• Protect arms and hands by wearing suitable protective gloves.

• Allow surfaces to cool prior to cleaning.

• Remove hot cookware only with suitable protective gloves or

potholders.

• Remove containers and baking sheets only with suitable

protective gloves or potholders.

Hot liquids Risk of burns from hot liquids

• Protect arms and hands by wearing suitable protective gloves.

• Remove, transport and empty containers carefully.

Risk of chemical burns from evaporating cleaners

• Follow the instructions of the cleaning agent manufacturer.

• Allow the cooking so to clean to a temperature below 60 °C and

then clean.

Risk of burns from steam

• Protect arms and hands by wearing protective gloves.

• Do not hold hands in front of the extractor hood.

• First open the cooking zone door slightly and allow the steam to

escape. Then open the cooking zone door completely.

• Dry unit completely after cleaning it.

Defective unit Risk of injury from a defective unit

• Disconnect a defective unit from the electric mains.

• Use gas shut-off valve to isolate unit from gas supply.

• Do not operate a defective unit.

10 Operating instructions

10014471-0ABBE-A

Page 11

Safety information

• Allow only an authorized technician to repair the unit.

Escaping gas or exhaust

gas

Fire prevention Risk of fire from dirt and grease deposits

Risk of asphyxiation and explosion from escaping gas

• Follow the rules of conduct when the smell of gas is detected (see

"Rules of conduct when the smell of gas is detected").

Risk of asphyxiation and poisoning from exhaust gases

• Ensure that air inlet openings are free and that a sufficient amount

of the necessary combustion air is supplied.

• Ensure that the exhaust gas outlet openings are free and that the

exhaust gases are discharged properly.

• Clean the unit when finished using it.

• Do not use the unit as a deep fat fryer.

• Do not store any combustible objects or plastic containers in the

cooking zone.

Risk of fire from objects

• Do not obstruct the exhaust gas duct.

Firefighting

• In the event of a fire, disconnect the unit from the electric mains.

• In the event of a fire, use the gas shut-off valve to isolate the unit

from the gas supply.

• Use a Fire Class F fire extinguisher, never water, to extinguish

grease fires. Other fires, for instance, can be extinguished with fire

extinguishers suitable for Fire Classes A, B, C, CO2 fire

extinguishers or extinguishing media suitable for the fire class

confronted.

Unit on casters Risk of injury from a unit on casters

• Lock casters during operation.

• Only move an empty unit.

Risk of a line breaking if subjected to high tensile load

• Secure the unit with a chain as a strain relief for the power

connection at the installation site so that no tensile load is applied

to the power connection if the unit is moved.

Improper cleaning Risk of chemical burns from cleaning agent

• Follow the instructions of the cleaning agent manufacturer.

10014471-0ABBE-A

• Take appropriate protective measures when handling aggressive

cleaning agents.

11Operating instructions

Page 12

Safety information

Risk of falling on smooth floors

• Keep the floor in front of the unit clean and dry.

Risk of injury from improper cleaning

• Clean the cooking zone carefully. The cooking zone sensor

protrudes into the cooking zone.

Risk of physical damage from improper cleaning

• Clean the unit after using it.

• Do not clean the unit with a high-pressure cleaner or water jet.

• Do not clean the housing with highly abrasive or chemically

aggressive cleaning agents.

• Do not clean the housing with highly abrasive sponges.

• Follow the instructions of the cleaning agent manufacturer.

• Do not cool shock the unit by cooling it abruptly.

• Clean the cooking zone carefully. The cooking zone sensor

protrudes into the cooking zone.

• Do not use any bleaching or chlorine-containing cleaners.

• Remove rust spots with an abrasive.

• Keep the unit free of calcium deposits.

Hygiene Health risk from insufficient hygiene

• Observe applicable regional hygiene regulations.

Core temperature

measurement

Risk of injury from overheated core temperature sensor

• Do not heat the core temperature sensor over an open flame.

Improper use Risk of physical damage from improper use

• Use only original accessories.

• Train operators regularly.

• Do not heat food warmer plates or tins of preserved food.

• Do not cover air inlet and outlet openings.

• Do not operate the unit at temperatures below 4° C.

• Remove the core temperature sensor before the cooked food is

removed.

• Insert the core temperature sensor back into the holder after use.

12 Operating instructions

10014471-0ABBE-A

Page 13

Rules of conduct when the smell of gas is detected

3 Rules of conduct when the smell of gas is detected

DANGER

Risk of asphyxiation and explosion from escaping gas

Follow the rules of conduct when the smell of gas is detected.

• Remain calm.

• Open windows and doors and ventilate rooms.

• Avoid rooms with the smell of gas.

• Do not smoke.

• Do not ignite any flames. Extinguish flames.

• Do not strike any sparks. Do not operate any switches, electrical

devices or use telephones.

• Remove mobile phones and radio-controlled devices from the

hazard area.

• Close gas shut-off valves at the gas meter, at the main feed and, if

possible, at the units.

• Warn other individuals in the building. Call out and knock, do not

ring doorbells.

• Leave the building and prevent entry by others.

• Observed the safety instructions of the gas utility.

• Once outside the building, notify responsible parties:

– If the smell of gas comes from the unit, notify customer service.

– If the source of the smell of gas cannot be localised

immediately, notify the gas utility.

– If the escaping gas is audible, leave the building immediately,

prevent others from entering and notify the fire brigade, police

and gas utility.

– If the smell of gas comes from inaccessible rooms, notify the

fire brigade, police and gas utility.

10014471-0ABBE-A

13Operating instructions

Page 14

Description of the unit

t

s

q

p

o

n

m

l

k

j

i h g f

e

d

c

b

a

r

4 Description of the unit

The unit is a hot air steamer, which is suitable for most cooking

methods used in commercial kitchens. It can be used with either hot

air or unpressurised live steam, either individually, in sequence, or in

conjunction with moist or dry heat.

4.1 Overview of the unit

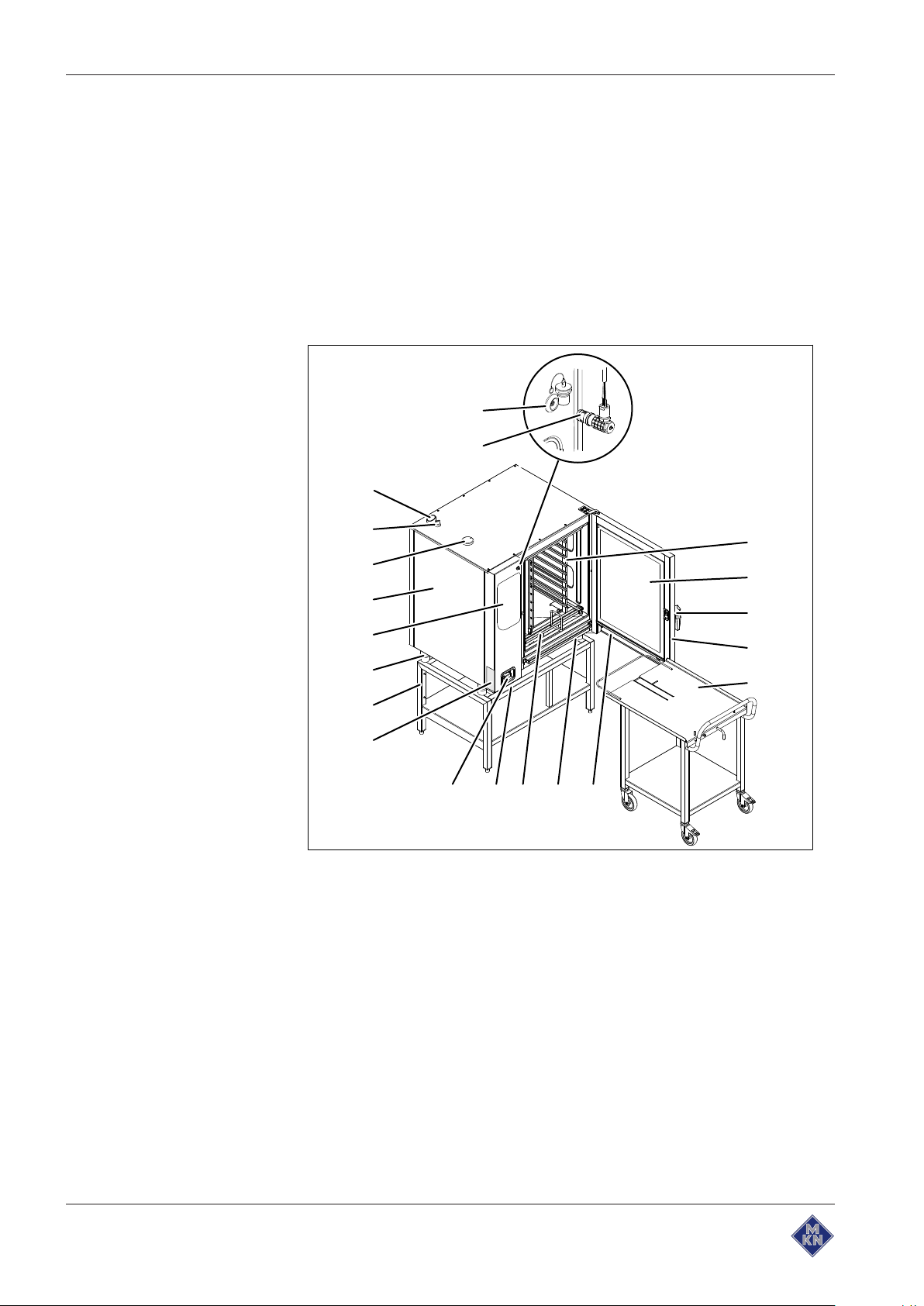

4.1.1 Countertop unit

Image: Unit with tray rack trolley

a Tray rack k Nameplate

b Insulated window l Base frame (optional)

c Door handle m Equipment leg

d Cooking zone door n Control unit

e Tray rack trolley (optional) o Housing

f Steam drain channel, door p Air inlet

g Steam drain channel, unit q Waste gas connection

h Guide rail for tray rack (optional) r Steam outlet

i USB port (covered) s Core temperature sensor

j Hand shower t Connection for core temperature

14 Operating instructions

(optional)

sensor (optional)

10014471-0ABBE-A

Page 15

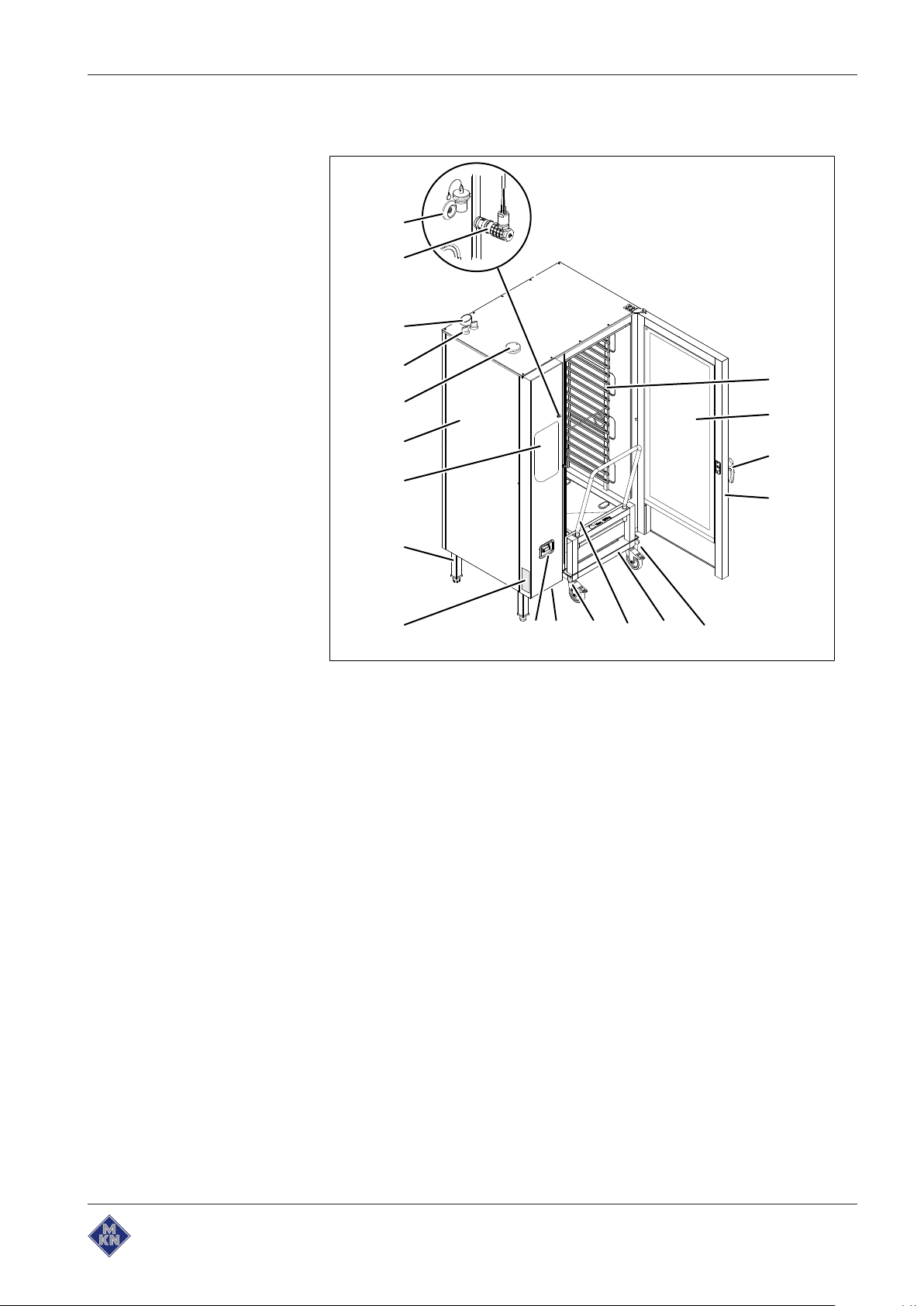

4.1.2 Floor-standing unit

s

r

q

p

o

n

m

l

k

i

j

h g f e

d

c

b

a

Description of the unit

Image: Unit with tray trolley

a Tray rack k Nameplate

b Insulated window l Equipment leg

c Door handle m Control unit

d Cooking zone door n Housing

e Guide rail (right) o Air inlet

f Tray trolley p Waste gas connection

g Push handle q Steam outlet

h Guide rail (left) r Core temperature sensor

(optional)

i USB port (covered) s Connection for core temperature

sensor (optional)

j Hand shower

10014471-0ABBE-A

15Operating instructions

Page 16

Description of the unit

4.2 Features

4.2.1 Characteristics

• 1-point core temperature sensor

• 4-point core temperature sensor (optional)

• Sous-vide core temperature sensor (optional)

• Hand shower (optional)

• Back-ventilated cooking zone door

• Cooking zone door with hygienic glazing (optional)

• Single-stage door latch

• Two-stage door latch (optional); this feature is standard on size 20

units

• Power optimizing system (optional)

• Cooking zone door hinged at right

• Cooking zone door hinged at left (optional)

• HandClean

• WaveClean (optional)

4.2.2 USB port

The unit is equipped with a USB port (USB 2.0).

HACCP logs can be exported to the USB flash drive and archived on

an external PC as necessary.

4.2.3 HACCP log

All cooling programs run are recorded in the HACCP log.

The data are exported via the USB port.

4.2.4 WaveClean automatic cleaning (optional)

With WaveClean automatic cleaning,the cooking zone is cleaned with

the aid of a cleaning cartridge intended specifically for the program

and then rinsed clean.

16 Operating instructions

10014471-0ABBE-A

Page 17

4.2.5 Preheat bridge for models 20.15 and 20.21

Image: Preheat bridge

In the case of the 20.15 and 20.21 models of Combisteamer, the

preheat bridge is attached to the bottom edge of the cooking zone

opening, if the cooking zone is heated or cleaned with WaveClean,

and if there is no tray trolley in the Combisteamer.

Description of the unit

4.3 Operating and cooking modes

4.3.1 Operating modes

Manual cooking

In the Manual cooking mode, individual cooking programs and

equipment functions can be activated directly. The various cooking

modes and equipment functions can be modified individually.

Automatic cooking

In the Automatic cooking mode, saved cooking programs can be

activated and modified if necessary.

4.3.2 Types of cooking

Steaming

Steaming is a cooking mode, in which the food to be cooked is

cooked gently by means of steam in a temperature range of 30 °C to

130 °C.

Combisteaming

Combisteaming is a cooking mode, in which large roasts, casseroles

and baked goods can be cooked in a temperature range of 30 °C to

250 °C.

10014471-0ABBE-A

Hot air

Hot air is a cooking mode, in which the food to be cooked is cooked

without additional moisture in a temperature range of 30 °C to 250 °C.

17Operating instructions

Page 18

Description of the unit

Regeneration

Regeneration is a cooking mode, in which the food being cooked can

be kept warm and prepared in a temperature range of 30 °C to 155

°C.

4.3.3 Expanded cooking functions

Expanded cooking functions can be used to modify individual cooking

steps for the particular food being cooked.

The following expanded cooking functions are available:

Manual humidification Manual humidification allows the cooking zone humidity to be

increased during operation.

Start time delay

When using the start time delay, temperatures that promote the

growth of harmful microorganisms on the food being cooked can

occur in the cooking zone. Observe food processing regulations.

The start time delay can be used to set a waiting period until the

program starts.

In this way, bottlenecks in production and preparation can be

avoided.

The prepared food to be cooked can be loaded into the unit and the

desired cooking program selected.

Heat (Ready2Cook)

The function can be selected when starting the cooking

program.

For many cooking programs such as baking, for instance, the correct

starting temperature is important.

The expanded heating function can be used to warm the cooking

zone to the correct starting temperature.

4.3.4 Core temperature measurement

When using core temperature measurement, the temperature inside

the food being cooked is measured by means of a core temperature

sensor.

As soon as the target core temperature is reached, the cooking

process is ended automatically or, in the case of a multi-step cooking

program, the next cooking step starts.

The use of core temperature measurement offers the following

benefits:

• Reduced energy and water consumption

• No overcooking

• Less weight lost by the food being cooked

• High HACCP safety

18 Operating instructions

10014471-0ABBE-A

Page 19

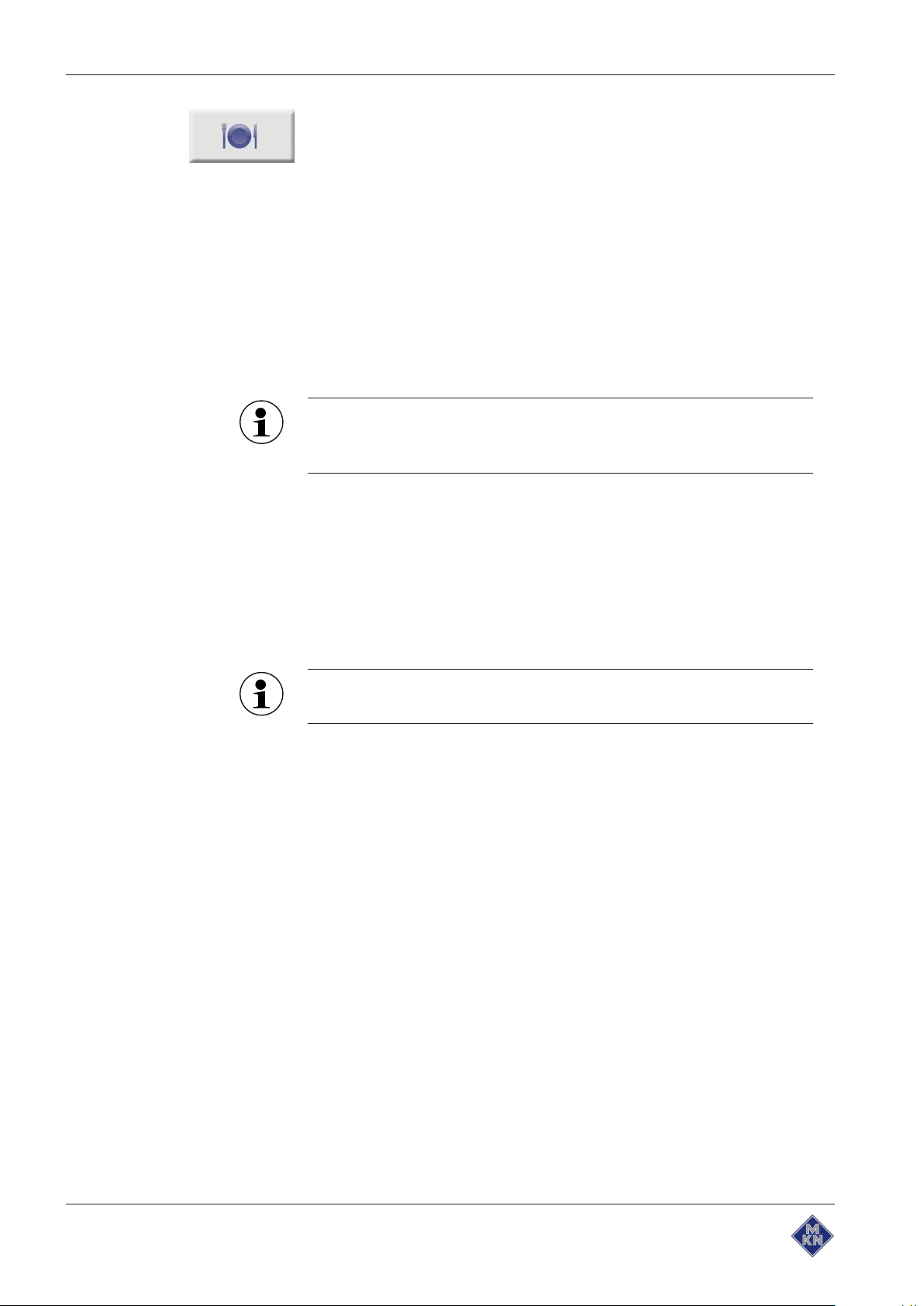

4.4 Operating, control and display element functions

Programs

SymbolOperating and display element Function

Description of the unit

On Off"I O"

Select

Steaming

Combisteaming

Hot air

Regeneration

Programs

"Programs" button • Saves a cooking program

HandClean

button • Switch unit on "I"

• "O" switches off the unit

knob • Selects the cooking mode,

cooking programs, cleaning

and settings

symbol • Indicates that the Steaming

cooking modecan be selected

here

symbol • Indicates the the Combisteam-

ing cooking modecan be selected here

symbol • Indicates that the Hot air cook-

ing mode can be selected here

symbol • Indicates that the Regeneration

cooking mode can be selected

here

symbol • Selects a cooking program

symbol • Indicates that the semi-auto-

matic

HandClean

be selected here

program can

WaveClean

Settings

Left display • Displays the cooking temperat-

Cooking temperature symbols • Indicate that settings for the

Left knob • Sets the temperature

Middle display • Shows the cooking zone hu-

ClimaSelect

Minus

symbol • Indicates that the automatic

WaveClean

selected here

symbol • Selects the settings and ser-

vice functions

ure

temperature can be made here

midity

symbol • Indicates that settings for the

cooking zone humidity can be

made here

button • Reduces the cooking zone hu-

midity

program can be

10014471-0ABBE-A

Plus

button • Increases the cooking zone hu-

midity

19Operating instructions

Page 20

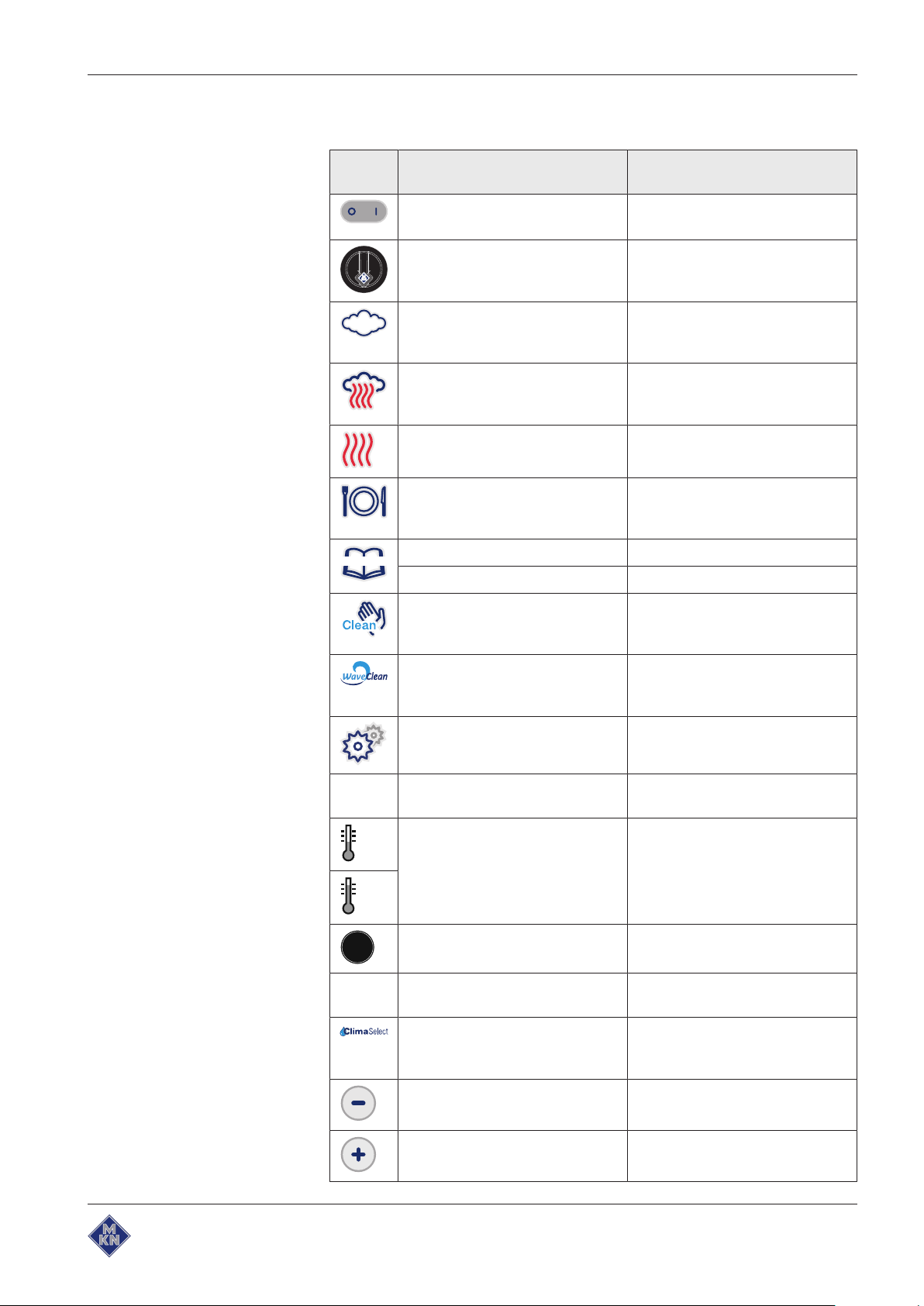

Description of the unit

STEP

START

STOP

SymbolOperating and display element Function

Right display • Shows the cooking time or core

temperature

Core temperature

symbol • Indicates that settings for the

core temperature can be made

here

Cooking time

symbol • Indicates that settings for the

time can be made here

Right knob • Sets the cooking time or core

temperature

"STEP" button • Advances to the next step in

the cooking program

• Acknowledges an error message

Fan speed

button • On Model 6.10: Sets the fan

speed

Ready2Cook

button • Starts and stops the heating or

cooling process

"START STOP" button • Starts and stops the cooking

programs or the cleaning

Indicator light • Illuminates if active

• Confirms the setting or selection

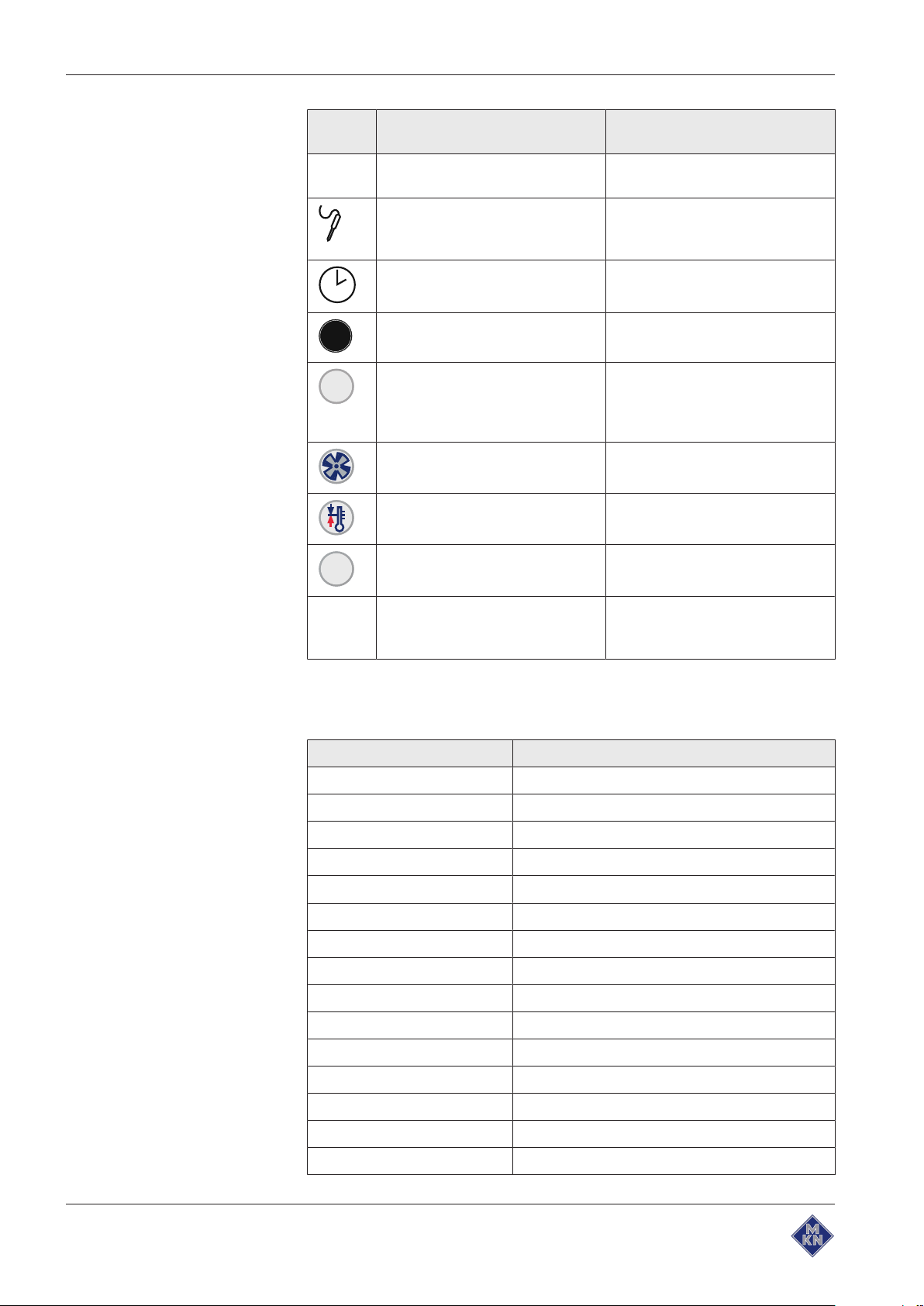

4.4.1 Abbreviations in the displays

Information appears in the displays only in the form of abbreviations.

Abbreviation Explanation

Calc Calcium deposit removal

CAr Cartridge

CLE Manual cleaning

CL1 Cleaning for about 1 hour

CL2 Cleaning for about 2 hours

CL3 Cleaning for about 3 hours

dLAY Start time delay

dIA Diagnostic error display

End End

Err Error

HAC HACCP

HOt Too hot

OPn Open

OPt Option

PASS Password entry

10014471-0ABBE-A

20 Operating instructions

Page 21

4.5 Loading capacity

Description of the unit

Abbreviation Explanation

Prot Log number

Pro Program number

rdY Ready

SEr Service

SHO Rinse

SOF Software

SPr Spray

SPU Forced rinse

STEP Step

USb USB

X-Y Step X of Y

4.5.1 Loading capacity

Tray rack trolley and tray trolley

Version Per shelf maximum (kg) Per unit maximum (kg)

6.15 15 50

6.21 15 50

10.15 15 80

10.21 15 80

20.15 15 150

20.21 15 150

4.5.2 Plate capacity during regeneration

Cooking time and cooking temperature depend on the number of

plates.

Version Plate diameter

6.15 30 24 22

6.21 30 24 22

26 cm 28 cm 32 cm

10014471-0ABBE-A

10.15 50 40 40

10.21 50 40 40

20.15 100 80 80

20.21 120 120 80

on 1/1 GN grate Tray rack or tray trolley

21Operating instructions

Page 22

Description of the unit

4.6 Standard setting values

4.6.1 Temperature standard setting

The setting range for the cooking zone temperature depends on the

cooking mode.

Cooking mode Standard value

(°C)

Steaming 100 30 - 130 1

Combisteaming 150 30 - 250 1

Hot air 180 30 - 250 1

Regeneration 50 30 - 150 1

4.6.2 Core temperature standard-setting

The adjustment range for the core temperature depends on the

cooking mode.

Cooking mode Standard value

(°C)

Steaming 70 0 - 99 1

Combisteaming 70 0 - 99 1

Hot air 70 0 - 99 1

Regeneration 50 0 - 99 1

4.6.3 Cooking zone humidity standard setting

Adjustment

range (°C)

Adjustment

range (°C)

Alteration

increments (°C)

Alteration

increments (°C)

The setting range for the cooking zone humidity depends on the type

of cooking.

Type of

cooking

Steaming 100 90 - 110 90 - 100 - 110

Combisteaming 90 20 - 100 20 - 40 - 70 - 90 -

Hot air 100 0 - 100 0 - 25 - 50 - 75 -

Regeneration 100 0 - 100 0 - 25 - 50 - 75 -

Standard value

(%)

Setting range

(%)

Change

increments (%)

100

100

100

22 Operating instructions

10014471-0ABBE-A

Page 23

4.7 Basic settings

Description of the unit

The unit is already preset, when it is delivered.

The values in the following list can be modified.

Basic setting No. Standard

value

Password 7 111 0 – 500 Individual passwords can be set in this

Start-time preselection with

or without fan

Steam elimination 48 1 0 = Low

Displays

Temperature display 1 0 0 = °C

Water quantity display 34 0 0 = ml

Water quantity display in fl.

oz.

13 0 0 = Without fan

35 0 0 = Imperial

Adjustment

range

1 = With fan

1 = Normal

2 = High

1 = °F

1 = fl.oz.

fl.oz.

1 = US fl.oz.

Explanation

area.

If the "0" setting is selected, the fan

remains off during the preset time period.

If the "1" setting is selected, the fan runs at

intervals during the preset time period.

The intensity of steam elimination can be

adjusted in three levels.

The temperature can be displayed in °C or

°F.

The water quantity can be displayed in ml

or fl.oz.

The fl.oz. water quantity can be displayed

in Imperial or US.

Signal output

Duration of signal output 6 20 0 – 180s Duration of the audible signal

0 = Signal off

Volume of signal output 33 0 0 = Quiet

1 = Loud

Cooking modes

Steaming temperature 9 100 30 – 130 °C The cooking temperature for this cooking

Combisteaming temperature 10 150 30 – 250 °C The cooking temperature for this cooking

Hot air temperature 11 180 30 – 250 °C The cooking temperature for this cooking

Regeneration temperature 12 130 30 – 150 °C The cooking temperature for this cooking

Ready2Cook

Volume of the audible signal

mode can be selected within the range of

settings.

mode can be selected within the range of

settings.

mode can be selected within the range of

settings.

mode can be selected within the range of

settings.

10014471-0ABBE-A

23Operating instructions

Page 24

Description of the unit

Basic setting No. Standard

value

Ready2Cook preheating

temperature in percent

Max. waiting time in minutes

after the Ready2Cook

temperature has been

reached, if set T > 250 °C

Max. waiting time in minutes

after the Ready2Cook

temperature has been

reached, if set T <= 250 °C

FlexiCombi Air

Time extension for the

condensation hood

4 15 0 – 30% If the unit is fully loaded with a large mass

37 120 0 - 300 Here you can set, how long the preheating

38 30 0 - 60

5 60 0 – 600s Time extension for the condensation hood,

Adjustment

range

Explanation

(roasts, loaves of bread), increase the

preheating temperature, so that the

cooking zone temperature does not drop

too suddenly.

temperature is to be held after it has been

reached, without a cooking process being

started.

after the cooking zone door has been

opened

24 Operating instructions

10014471-0ABBE-A

Page 25

Operating the unit

5 Operating the unit

5.1 Operating the unit in an environmentally responsible manner

If used correctly, this Combisteamer achieves very low energy

consumption.

You can assist low energy consumption by:

• Avoiding continuous operation - the Combisteamer heats up very

quickly, which means that continuous operation is not necessary.

• Loading the cooking zone as full as possible - if practical, use a

Combisteamer with a smaller cooking zone.

5.2 Switching the unit on and off

5.2.1 Switching on

Press the

The unit is now on.

On Off"I O"

button to "I".

5.2.2 Switching off

Press the

The unit is now off.

On Off"I O"

button to "O".

5.3 Opening and closing the cooking zone door

The single-stage door latch is standard on sizes 6 and 10.

The two-stage door latch is standard on size 20, and optional on

sizes 6 and 10.

5.3.1 Opening the single-stage door latch

10014471-0ABBE-A

Image: Opening the single-stage door latch

1. Rotate the door handle anti-clockwise or clockwise.

The cooking zone door opens.

If the door handle is released, it returns automatically to its initial

position.

2. Open the cooking zone door completely.

25Operating instructions

Page 26

Operating the unit

A

B

5.3.2 Closing the single stage door latch

Image: Closing the single stage door latch

Requirement Door handle in initial position

Close the cooking zone door with pressure.

The cooking zone door is closed.

5.3.3 Opening the two-stage door latch

Image: Opening the two-stage door latch

On size 6 and size 10, first rotate the door handle anticlockwise.

1. Rotate the door handle to a horizontal position.

The cooking zone door opens, but is still held.

2. Continue rotating the door handle upwards.

The cooking zone door is no longer held.

If the door handle is released, it returns automatically to its initial

position.

3. Open the cooking zone door completely.

10014471-0ABBE-A

26 Operating instructions

Page 27

5.3.4 Closing the two-stage door latch

A B

Image: Closing the two-stage door latch

Requirement Door handle in initial horizontal position

1. Close the cooking zone door with pressure.

The cooking zone door latches.

2. Rotate the door handle downwards.

The cooking zone door is closed.

Operating the unit

5.4 Loading and emptying the unit

CAUTION

Risk of burns from hot liquid

• Never insert a food-carrying tray with cooking liquid above

eye level.

• Use only suitable trays to hold food. The food-containing

trays must rest securely on the support brackets.

• Always insert the food-containing trays into the U-rails.

CAUTION

Risk of physical damage and personnel injury from

exceeding the loading capacity

• Do not exceed the maximum loading capacity.

To not use bent or damaged support racks.

5.4.1 Loading and emptying

10014471-0ABBE-A

Loading

1. Open the cooking zone door.

2. Insert food-containing trays into the support racks.

3. Close the cooking zone door.

4. Start the cooking process.

Emptying

1. Open the cooking zone door.

2. Remove the food-containing trays.

3. Remove all food residues from the drain screen.

27Operating instructions

Page 28

Operating the unit

a

b

c

d

e

f

g

4. Leave the cooking zone door slightly ajar.

This extends the service life of the door seal.

No moisture builds up in the cooking zone.

5.4.2 Loading and emptying with a tray rack trolley

Image: Loading and emptying with a tray rack trolley

a Tray rack e Tray rack trolley

b Push handle f Tray rack support plate

c Lever g Guide rail

d Locking casters

Loading with a tray rack trolley

Requirement Remove support racks and place guide rails on pins.

Food-containing trays resting securely on the tray rack

1. Open the cooking zone door.

2. Rotate the lever on the tray rack trolley.

The tray rack is secured to prevent its rolling down.

Check that the tray rack is locked in place by pulling on it

slightly.

3. Load the tray rack.

4. Position the tray rack trolley at the unit.

Lock the casters to prevent the trolley's rolling away.

5. Rotate the lever.

The tray rack is now free to move.

6. Insert the tray rack completely until the rollers rest in the openings

in the guide rail.

7. Retract the tray rack support plate and secure in place with the

lever.

8. Move the tray rack trolley away from the unit.

9. Close the cooking zone door.

10.Start the cooking process.

28 Operating instructions

10014471-0ABBE-A

Page 29

Emptying with a tray rack trolley

a

b

c

d

e

f

g

1. Open the cooking zone door.

2. Position the tray rack trolley at the unit.

Lock the casters to prevent the trolley's rolling away.

3. Insert the tray rack support plate and secure the tray rack on the

plate.

4. Pull the tray rack onto the tray rack trolley and secure in place.

5. Release the locking casters and move the tray rack trolley away

from the unit.

6. Remove all food residues from the drain screen.

7. Leave the cooking zone door slightly ajar.

This extends the service life of the door seal.

No moisture builds up in the cooking zone.

5.4.3 Loading and emptying with a tray trolley

Operating the unit

10014471-0ABBE-A

Image: Loading and emptying with a tray trolley

a Tray rack e Cleaning cartridge holder

b Push handle f Guide rail (left)

c Tray trolley g Guide rail (right)

d Locking casters

Loading with a tray trolley

Requirement Checked that food-containing trays are sitting securely in the tray

trolley

1. Load the tray trolley.

2. Move the tray trolley in completely.

3. Withdraw the push handle from the tray trolley.

4. Close the cooking zone door.

5. Start the cooking process.

29Operating instructions

Page 30

Operating the unit

Emptying with a tray trolley

1. Open the cooking zone door.

2. Insert the push handle into the tray trolley.

3. Retract the tray trolley.

4. Remove all food residues from the drain screen.

5. Leave the cooking zone door slightly ajar.

5.5 Making the basic settings

The basic settings for operation can be displayed and changed by

entering the password "111".

The list of adjustable parameters can be found in the chapter on

"Description of the unit".

5.5.1 Opening the Setting menu

This extends the service life of the door seal.

No moisture builds up in the cooking zone.

Each basic setting of the unit is stored under a number that can

be displayed.

Requirement The unit is on

1. Turn the

2. Use the right not to set the password.

3. Press the "START STOP" button.

4. Use the left knob to select OPt.

The basic settings can be changed.

5.5.2 Changing the basic setting

1. Press the "START STOP" button.

Select

The indicator light illuminates.

The left display shows "PASS".

The right display flashes "0000".

The right display shows the set password.

The left display flashes "HAC".

The left display flashes "OPt".

knob to the

Settings

symbol.

Left display flashes the basic setting parameter (see

"Equipment and connection data").

"OPt" appears on the centre display.

The right display shows the first set value.

2. Turn the left knob.

Set number.

3. Press the "START STOP" button.

The basic setting can be adjusted.

30 Operating instructions

10014471-0ABBE-A

Page 31

5.6 Basic functions

180°C 100 85°C

5.6.1 Select cooking mode

Requirement The unit is on

Operating the unit

4. Turn the right knob.

Set new value.

5. Press the "START STOP" button.

Accept changes.

6. Press and hold the "STEP" button for 3 seconds.

Changes are saved.

"OPt" flashes on the left display.

The centre display shows "Stor".

7. Press the "STEP" button to leave the Settings menu.

8. Fill out the commissioning report.

Use the

The indicator light above the selected type of cooking

illuminates.

The left display flashes the preset cooking time.

The right display flashes the cooking time.

The centre display shows the cooking zone humidity for the

selected cooking mode.

5.6.2 Setting the cooking temperature

Requirement Cooking mode selected

Turn the left rotary knob.

Turning to the left lowers the cooking temperature.

Turning to the left raises the cooking temperature.

The left display shows the cooking temperature.

Select

knob to select the type of cooking desired.

Image: Cooking temperature set

5.6.3 Setting the cooking zone humidity level

Requirement Cooking mode selected

Press the

The cooking zone humidity level is increased or decreased.

The centre display shows the cooking zone humidity.

10014471-0ABBE-A

Plus

button or the

Minus

button.

31Operating instructions

Page 32

Operating the unit

180°C

100 00:45

180°C

100 00:45

180°C 100 85°C

Image: Cooking zone humidity set

5.6.4 Setting the cooking time

Requirement Cooking mode selected

The cooking time can be set for up to 23 hours and 59 minutes

in 1-minute increments.

Continuous operation is stopped automatically after 23 hours

and 59 minutes.

The hours and minutes appear in the display.

Turn the right knob.

Image: Cooking time set

5.6.5 Setting the core temperature

Requirement Cooking mode selected

Turn the right knob to the left beyond continuous operation to core

temperature.

Turn the right knob.

The right display shows the cooking time.

Rotate to the left, unit switches to continuous operation, right

display indicates "- - - -".

Rotate to the right, increase cooking time.

The right display shows the standard value for the core

temperature.

Turning clockwise increases the core temperature.

Turning anti-clockwise lowers the core temperature.

The right display shows the core temperature.

Image: Core temperature set

32 Operating instructions

10014471-0ABBE-A

Page 33

5.6.6 Displaying actual values

Temperature setpoint

Remaining time or actual core temperature

5.6.7 Setting the fan speed

Operating the unit

The actual cooking zone temperature, elapsed cooking time or

actual core temperature can be displayed during cooking.

Turn the left knob.

The left display shows the current cooking zone temperature

for 5 seconds. Then, the temperature setpoint is displayed.

Turn the right knob.

The right display shows the elapsed cooking time for 5

seconds. Then, the remaining time or actual core temperature

is displayed.

The fan speed is adjusted in up to five steps. Each step is

displayed by an indicator light.

The number of steps depends on the type of cooking.

Press the

is reached.

The indicator lights illuminate.

Fan speed

5.6.8 Inserting and removing a USB flash drive

Inserting a USB flash drive

Requirement USB flash drive with a minimum of 2 GB and maximum of 32 GB

available storage capacity (not included with delivery)

USB flash drive not write-protected

Insert the USB flash drive.

The USB flash drive is ready after at most 20 seconds.

Removing the USB flash drive

Requirement Exporting or importing of data completed

button several times until the desired speed

Remove the USB flash drive.

5.6.9 Displaying the HAACP log number

Requirement The cooking process is running

1. Press the Minus button.

The current log number is displayed.

2. Record the log number.

10014471-0ABBE-A

33Operating instructions

Page 34

Operating the unit

5.6.10 Exporting the HACCP log

Briefly pressing the "START STOP" button transfers the

selected logs.

Pressing the "START STOP" button for longer (3 seconds)

transfers all the available logs.

Requirement USB flash drive inserted

Registered with password under Settings

1. Turn the left rotary knob.

2. Press the "START STOP" button.

3. Turn the left and right knobs and select the log range.

4. Press the "START STOP" button.

The left display flashes "HAC".

The left display shows the lowest log number.

"HAC" appears on the centre display.

The right display flashes the highest log number.

"HAC" appears on the left display.

The centre display shows USb".

The right display shows a continuous stream of characters.

The HACCP log is exported to the USB flash drive.

5. Press the "STEP" button.

This returns you to the Setting menu.

5.7 Using the core temperature sensor

WARNING

Risk of injury from a bursting core temperature sensor

• The core temperature sensor can burst as the result of

overheating of the measuring tip.

• Never heat a core temperature sensor with a cigarette lighter

or other heat source.

Measuring the core temperature is recommended for all types of

cooking to achieve an optimal result.

The unit has a core temperature sensor in the cooking zone and

can be equipped with an optional connection for an external

core temperature sensor.

34 Operating instructions

10014471-0ABBE-A

Page 35

5.7.1 Measuring with a 4-point core temperature sensor

b

c

b

d

a

a

b

Image: Core temperature sensor with one and four measuring points

Insert the core temperature sensor completely into the food being

cooked.

Insert the core temperature sensor into the thickest point of the

food being cooked.

If there is a bone in the food being cooked, insert the core

temperature sensor close to the bone.

If the food being cooked is elongated, insert the core temperature

sensor across the food to avoid a hole in the centre of the slice.

When cooking poultry, insert the core temperature sensor into the

inside of the leg.

Operating the unit

5.7.2 Measuring with a sous-vide core temperature sensor

The sous-vide core temperature sensor, which is available as an

accessory, is connected to the

10014471-0ABBE-A

sensorconnection

Image: Sous-vide core temperature sensor with sous-vide pads

Attach foam rubber or expanded rubber sous-vide pads to the

vacuum-packed food to be cooked.

Always insert the core temperature sensor through the sous-vide

pads completely into the food to be cooked.

Insert the core temperature sensor into the thickest section of the

food to be cooked.

When food with a bone is being cooked, insert the core

temperature sensor close to the bone.

When elongated pieces of food are being cooked, insert the core

temperature sensor across the food to avoid a hole in the centre

of the slice.

outside the unit.

Core temperature

35Operating instructions

Page 36

Operating the unit

When cooking poultry, insert the core temperature sensor into the

inside of the leg.

5.7.3 Measuring the core temperature when cooking frozen food

When cooking frozen food, measuring with a sous-vide core

temperature sensor is not possible.

Image: Drilling a hole with a hand drill

1. Use a hand drill to make a hole for inserting the sensor.

2. Place the food to be cooked on the baking sheet or into the

cooking pan.

3. Place the cooking sheet or cooking pan into the unit.

4. Insert the core temperature sensor into the food being cooked.

5.8 Manual cooking

5.8.1 Starting the type of cooking

Requirement The unit is on

1. Use the

2. Set the cooking temperature.

3. Set the cooking time or core temperature.

4. Set the cooking zone humidity.

5. Set the fan speed.

6. Load the unit.

7. If necessary, insert the core temperature sensor into the food

being cooked.

Select

The indicator light above the selected cooking mode

illuminates.

The left display flashes the preset cooking temperature.

The centre display flashes the preset cooking zone humidity.

The right display flashes the cooking time.

knob to select the desired cooking mode.

36 Operating instructions

10014471-0ABBE-A

Page 37

8. Press the "START SROP" button.

The indicator light for the "START STOP" button flashes.

Operating the unit

The number of indicator lights above the

displays the speed level.

The left display shows the set cooking temperature.

The centre display shows the set cooking zone humidity.

The right display shows the cooking time remaining or the core

temperature.

5.8.2 Ending the cooking mode

1. Press the "START STOP" button.

The cooking program is cancelled.

The indicator light for the selected cooking mode illuminates.

The left display shows the preset cooking temperature.

The right display shows the preset cooking time.

2. Open cooking zone door.

5.9 User's own cooking programs

5.9.1 Creating user's own cooking program

Requirement The unit is on

Fan speed

button

1. Use the

cooking step.

2. Set the cooking temperature.

3. Set the cooking zone humidity.

4. Set the fan speed.

5. Set the cooking time or core temperature.

6. Press the "STEP" button.

7. Use the

cooking step.

8. Set the cooking temperature.

9. Set the cooking zone humidity.

10.Set the fan speed.

11.Set the cooking time or core temperature.

12.Add more cooking steps as required.

Select

The indicator light illuminates.

The displays flash the preset standard values.

The indicator light illuminates.

"STEP" appears on the left display for the step.

The centre display shows "2" for the second cooking step.

Select

The indicator light illuminates.

The displays flash the preset standard values.

knob to select the cooking mode for the first

knob to select the cooking mode for the second

10014471-0ABBE-A

37Operating instructions

Page 38

Operating the unit

To correct the settings, press the "STEP" button several times to

return to the desired cooking step. Set the values again.

5.9.2 Saving user's own cooking program

Requirement Cooking program entered

1. Press the "Programs" button for 3 seconds.

"Pro" appears on the left display.

The indicator light flashes.

The centre display is off.

The right display shows the first free program position.

2. Turn the right knob and select the number of the program position.

The centre display does not show anything if the program

position is unoccupied, or it shows "===" if the program

location is occupied.

3. Press the "Programs" button for 3 seconds.

A signal sounds.

The centre display shows "===".

The cooking program is saved.

5.9.3 Deleting user's own cooking program

Deleting all programs

Turn the

Press and hold the

for 3 seconds.

All the program space is free again.

Deleting individual cooking programs

Turn the

Select

"Pro" appears on the left display.

All the cooking programs are deleted.

Select

"Pro" appears on the left display.

The right display shows the number of the current cooking

program selected.

knob to the

Plus

button and

knob to the

Programs

Minus

Programs

symbol.

button at the same time

symbol.

Using the right knob, select the number of the cooking program to

be deleted.

Press and hold the

The cooking program is deleted.

The program space is free again.

38 Operating instructions

Minus

button for 3 seconds.

10014471-0ABBE-A

Page 39

5.10 Automatic cooking

5.10.1 Selecting the cooking program

Requirement No cooking program selected

Operating the unit

Rotate the

"Pro" appears on the left display.

The right display shows the number of the saved cooking

program or it shows "1" if no cooking program is saved.

Turn the right knob and select the number of the program position.

The centre display does not show anything if the program

position is unoccupied, or it shows "===" if the program

location is occupied.

For immediate start: Press the "START STOP" button. To start

Ready2Cook: Press the

The program is loaded and starts.

5.10.2 Starting the cooking program

Requirement No cooking program selected

Rotate the

"Pro" appears on the left display.

The right display shows the number of the saved cooking

program or it shows "1" if no cooking program is saved.

Select

Select

knob to the

Ready2Cook

knob to the

Programs

button.

Programs

symbol.

symbol.

5.10.3 Cooking program ends

1. The cooking program ends automatically.

2. Press the "START STOP" button or open the cooking zone door.

Turn the right knob and select the number of the program position.

The centre display does not show anything if the program

position is unoccupied, or it shows "===" if the program

location is occupied.

For immediate start: Press the "START STOP" button. To start

Ready2Cook: Press the

The program is loaded and starts.

The cooking program ends once the cooking time has elapsed

or the core temperature has been reached.

A signal sounds.

"End" appears on the right display.

The indicator lights go off.

The signal is switched off.

Ready2Cook

button.

10014471-0ABBE-A

39Operating instructions

Page 40

Operating the unit

5.10.4 Cancelling the cooking program

1. Press the "START STOP" button.

The cooking program is cancelled.

The indicator light for the selected cooking mode illuminates.

The left display shows the preset cooking temperature.

The right display shows the preset cooking time.

2. Open cooking zone door.

5.10.5 Changing the cooking program while cooking

The cooking time, cooking zone humidity, fan speed, cooking

temperature and target core temperature can be changed during

cooking. These changes apply only to the currently running

cooking program and are not retained as presets.

In the case of multi-step cooking programs, press the "STEP"

button repeatedly until the centre display shows the desired

cooking step.

1. Press the "STEP" button.

The indicator light for the cooking mode illuminates.

The left display flashes the set cooking temperature.

The centre display flashes the set cooking zone humidity.

The right display flashes the set cooking time.

The number of indicator lights above the

Fan speed

button

displays the speed level.

2. Set the cooking time, cooking zone humidity level, fan speed,

cooking temperature or target core temperature.

The displayed values are saved automatically after 2 seconds.

40 Operating instructions

10014471-0ABBE-A

Page 41

5.11 Multi-step cooking program

5.11.1 Starting

Requirement Multi-step cooking program entered

Press the "START STOP" button to start the cooking program.

The

last program step.

The

The indicator light for the type of cooking used in the currently

active program step illuminates.

The left display shows the cooking temperature for the

currently active program step.

The right display shows the total cooking time or "--;--L if a later

cooking step with core temperature follows.

The right display shows the actual core temperature if the core

temperature is selected for the currently active program step.

START STOP

STEP

indicator light illuminates.

indicator light flashes until the end of the

Operating the unit

5.12 Expanded cooking functions

5.12.1 Manual humidification

This function is not programmable.

Requirement Cooking program selected and started

Press and hold the

The centre display shows a slowly increasing bar. The cooking

zone humidity level is increased.

5.12.2 Setting the start time delay

If the fan option is selected at the start time delay, the fan

switches on in short intervals until the start time is reached.

Requirement Cooking program selected or a manual cooking program set

1. Press the "START STOP" button for 3 seconds.

"dLAY" appears on the left display.

Plus

button.

10014471-0ABBE-A

The right display flashes "00:01".

2. Turn the right knob anti-clockwise or clockwise.

The right display shows the selected time.

3. Press the

The centre indicator light for the

Fan speed

button.

Fan speed

button illuminates.

41Operating instructions

Page 42

Operating the unit

4. Press the "START STOP" button.

Start-time preselection starts.

The indicator light for the "START STOP" button illuminates.

The right display shows the remaining time before starting and

the colon in the time display flashes.

After the remaining time before starting has expired, the set

cooking program starts automatically.

5.12.3 Cancelling the start time delay

Press the "START STOP" button.

The start time delay is cancelled.

The cooking zone light illuminates.

5.12.4 Starting Ready2Cook

The unit is brought to the correct starting temperature with

Ready2Cook.

Requirement Cooking program selected or a manual cooking program set

1. Briefly press the

Temperature of the cooking chamber is set at 15% via set-up

start temperature.

The indicator light for the

The indicator light for the "START STOP" button flashes.

The left display shows the current cooking zone temperature.

The right display shows the starting temperature.

A signal sounds when the starting temperature is reached.

"rdY" appears on the left display.

2. Open cooking zone door.

The signal is switched off.

The indicator light for the

The displays show the current settings for the selected cooking

program.

3. Load the unit.

4. Close the cooking zone door.

The set cooking program starts automatically.

Ready2Cook

button.

Ready2Cook

Ready2Cook

button flashes.

button goes out.

5.12.5 Cancelling Ready2Cook

Briefly press the

Ready2Cook stops.

The indicator light for the

The set cooking program starts automatically.

42 Operating instructions

Ready2Cook

button.

Ready2Cook

button goes out.

10014471-0ABBE-A

Page 43

5.13 Pausing and finishing use

Switch off the unit during pauses and at end of use.

5.13.1 Perform a hygiene flush after an extended period of idleness

For reasons of hygiene, flush the water lines in the unit and on-site

water lines before using the unit.

Pause in operation lasting more than 2 days

Requirement GN containers, baking trays and grates removed from the cooking

zone

The cooking zone contains no food to be cooked

1. Operate the hand shower for 1 minute.

2. Run the "Steaming" cooking mode for 7 minutes at 100 °C.

Idle period for more than 7 days

Requirement GN containers, baking trays and grates removed from the cooking

zone

There is no food to be cooked in the cooking zone

Operating the unit

1. Operate the hand shower for 5 minutes.

2. Run the "Steaming" cooking mode for 1 hour at 100 °C.

10014471-0ABBE-A

43Operating instructions

Page 44

Cleaning and caring for the unit

6 Cleaning and caring for the unit

CAUTION

Risk of burns from hot surfaces

• Allow surfaces to cool prior to cleaning.

CAUTION

Risk of chemical burns from cleaning agent

• Follow the instructions of the cleaning agent manufacturer.

• Take appropriate protective measures when handling

aggressive cleaning agents.

ATTENTION

Risk of physical damage from extremely abrupt cooling

• Do not cool shock the unit by cooling it abruptly.

6.1 Preventing corrosion

• Keep the surfaces of the unit clean and with access to air.

• Remove lime, grease, starch and protein deposits from the

• Remove salt accumulations.

• Only expose parts made from non-rusting steel to brief contact

• Avoid damaging the stainless steel surface with other metal items,

• Avoid contact with iron and steel, such as for example steel wool

• Do not use bleaching or chlorine-containing cleaning agents.

ATTENTION

Risk of physical damage from improper cleaning

• Do not clean the unit with a high-pressure cleaner or water

jet.

surfaces of the unit.

with highly acidic foods, spices, salts or the like.

such as for example steel spatulas or steel wire brushes.

and steel spatulas.

• Clean the contact surfaces with water.

6.2 Remove rust spots

• Remove fresh rust spots with a mild abrasive or fine sandpaper.

• Always remove rust spots completely.

• Expose treated areas to fresh air for at least 24 hours. During this

time, do not allow any contact with greases, oils or foods so that a

new protective layer can form.

44 Operating instructions

10014471-0ABBE-A

Page 45

Cleaning and caring for the unit

6.3 Cleaning the housing

Requirement Unit switched off and cooled down

Clean the housing with warm water and commercially available

washing-up liquid.

6.4 Cleaning the door handle, operating elements and control panel

ATTENTION

Risk of physical damage from improper cleaning

• Do not clean the surface with highly abrasive or chemically

aggressive cleaning agents.

• Do not clean the surface with highly abrasive sponges.

Requirement Unit disconnected from the electric mains

Clean the door handle, operating elements and control panel with

a damp cloth and commercially available detergent.

6.5 Cleaning the door seal

ATTENTION

Risk of physical damage from improper cleaning

Animal fats in combination with high temperatures can damage

the door seal very quickly if it is not maintained properly.

• Clean the door seal regularly.

• Do not use aggressive cleaners.

During automatic cleaning and semi-automatic cleaning, the

outside surface of the door seal is not cleaned.

The door seal must be cleaned separately.

If the unit is used primarily for roasting, also clean the door seal

during pauses in use.

When finished using the unit, clean the door seal with warm water

and a commercially available detergent.

10014471-0ABBE-A

45Operating instructions

Page 46

Cleaning and caring for the unit

a

b

b

6.6 Cleaning the cooking zone door

CAUTION

Risk of burns from hot surfaces

• Allow surfaces to cool prior to cleaning.

ATTENTION

Risk of physical damage from improper cleaning of the

surface

• Do not use abrasive cleaners or cloths.

• Do not use grill cleaners.

6.6.1 Cleaning the door with hygienic glazing

Remove residual calcium deposits from the glass window with

vinegar or citric acid.

6.6.2 Cleaning the door with a back-ventilated window

Image: Swing open the inner window on the cooking zone door

a Inner window b Retaining spring

1. Open the cooking zone door 90°.

2. Release the retaining spring and swing open the inner window

90°. Do not lift the inner window when swinging it open. Do not

swing the inner window open completely. Hold the inner window

securely during cleaning.

3. Remove residual calcium deposits from the glass window with

vinegar or citric acid.

4. After cleaning the inner window, swing it in again and engage the

retaining spring.

46 Operating instructions

10014471-0ABBE-A

Page 47

6.7 Cleaning the steam outlet

Image: Cleaning the steam outlet

ATTENTION

Risk of physical damage from deposits

• Check the steam outlet and connected piping for deposits.

Use a liquid cleaner containing at most 20% sodium or

potassium hydroxide.

Cleaning and caring for the unit

Flushing with water is not necessary.

1. Examine the steam outlet and connected piping for deposits.

2. Spray liquid cleaner into the steam outlet.

6.8 Cleaning the condensation hood (optional)

CAUTION

Risk of fire from dirt and grease accumulation

• Clean the hood after use.

• Follow the cleaning instructions.

CAUTION

Risk of burns from hot surfaces

• Allow surfaces to cool prior to cleaning.

CAUTION

Risk of injury from sharp edges

• Wear protective gloves.

10014471-0ABBE-A

Image: Cleaning the condensation hood

47Operating instructions

Page 48

Cleaning and caring for the unit

Requirement Unit and hood disconnected from the electric mains

Unit and hood cool

1. Clean the housing daily with warm water and a commercially

available cleaner.

2. Push the grease filter upwards.

3. Pull the grease filter on the underside of the hood forward to

remove it.

4. Clean the grease filter and hood with a commercially available

cleaning agent.

5. Rinse and dry the grease filter, and replace it in the hood.

6.9 Removing calcium deposits from the unit

To remove calcium deposits manually, fill a manual spray gun

with a special decalcifier.

Requirement Cooking zone temperature less than 40 °C

Cooking zone cleaned

1. Dilute special decalcifier with water in a ratio of 1:2.

2. Fold open the air diverter.

3. Spray the diluted special decalcifier into the cooking zone.

4. Allow to act for 30 minutes.

5. Flush the cooking zone thoroughly.

6. Examine the cooking zone for any remaining calcium deposits.

7. If necessary, repeat the decalcification.

8. Open the cooking zone door and leave it open with a slight gap

until the unit is used again.

This extends the service life of the door seal.

No moisture builds up in the cooking zone.

48 Operating instructions

10014471-0ABBE-A

Page 49

Cleaning and caring for the unit

6.10 Cleaning the cooking zone automatically with WaveClean (optional)

CAUTION

Risk of chemical burns

Keep the cooking zone door closed during the cleaning

procedure.

CAUTION

Risk of chemical burns

In the case of the 20.15 and 20.21 models, put the preheat

bridge on the bottom edge of the cooking zone opening, if there

is no tray trolley in the Combisteamer.

The use of unsuitable cleaning agents often causes damage to

units. MKN makes great efforts to be able to offer a cleaning

agent, which on the one hand achieves an outstanding cleaning

performance, but which on the other hand does not attack and

damage the hot air steamer. We therefore recommend that only

our cleaning agent is used. MKN does not assume any

responsibility or liability for damage, which is caused by

unsuitable cleaning agents. Claims against MKN that are due to

this can not be upheld, not even within the scope of the

guarantee or warranty.

It is not permitted to cool the temperature sensor down in order

to start the cleaning procedure more quickly. The whole cooking

zone must be cooled down to 60 °C for effective cleaning.

Depending on the cleaning level selected, the fan may come to

a standstill for up to 60 minutes. This is not a cancellation of