MKN FKECOD615, FlexiCombi MagicPilot Series, FKECOD121, FKECOD621, FKECOD215 Installation Instructions Manual

...Page 1

Read the operating instructions prior to

commissioning

Installation instructions

Combisteamer

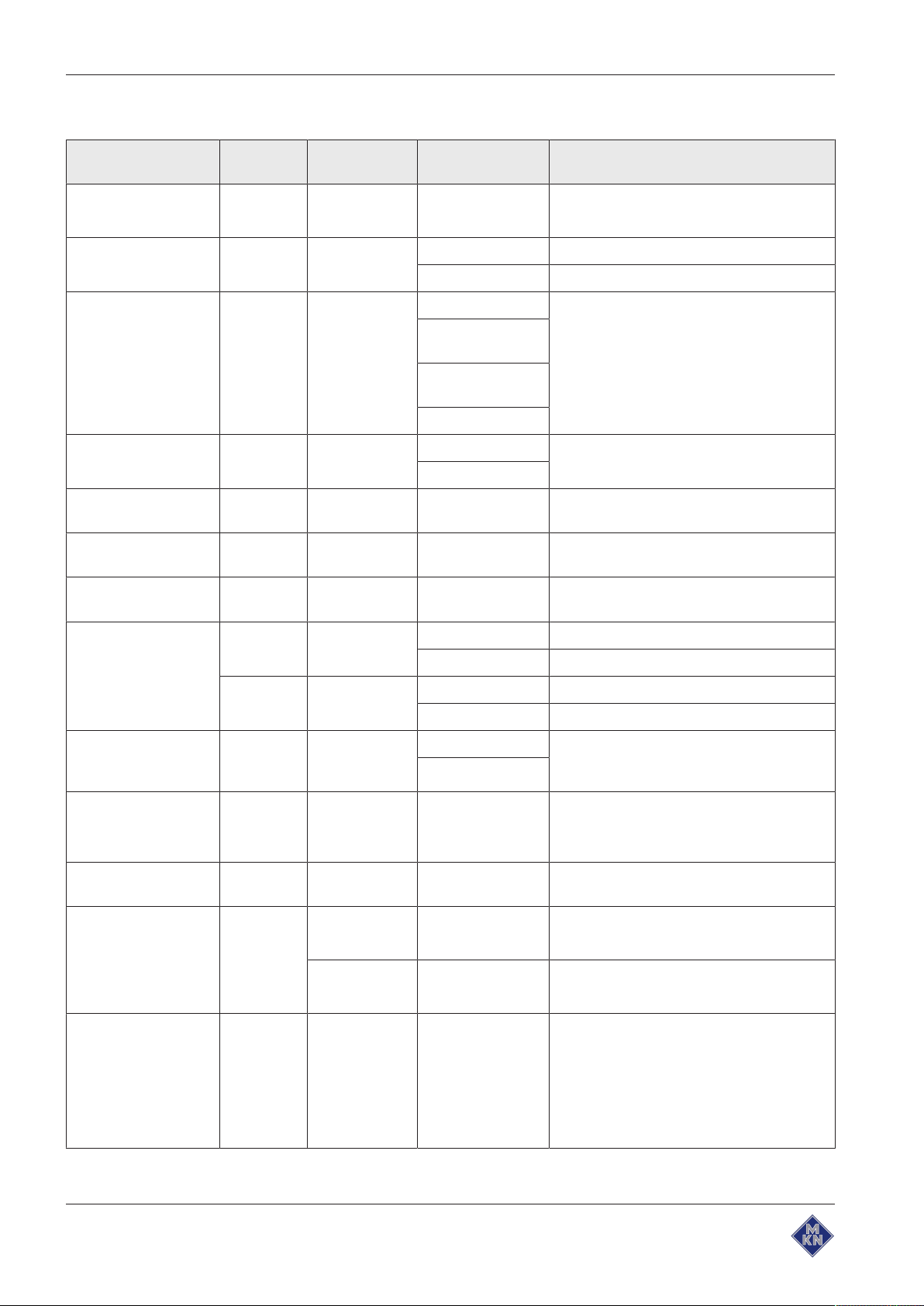

Unit Type of energy Unit type Model

FlexiCombi MagicPilot Electric Countertop unit FKECOD615

Translation from the original document • 10013865-0AIDE-B • 14/10/2016

FKECOD621

FKECOD115

FKECOD121

Floor-standing unit FKECOD215

FKECOD221

10013865-0AIBE-B en-GB

Page 2

Manufacturer

MKN Maschinenfabrik Kurt Neubauer GmbH & Co. KG

Halberstädter Strasse 2a

38300 Wolfenbüttel

Germany

Phone +49 5331 89-0

Fax +49 5331 89-280

Internet www.mkn.eu

Copyright

All rights to text, graphics and pictures in this documentation are held by MKN Maschinenfabrik Kurt

Neubauer GmbH & Co. KG. Distribution or duplication is only permitted with the prior written consent

of MKN.

Copyright by MKN Maschinenfabrik Kurt Neubauer GmbH & Co. KG.

2 Installation instructions

Page 3

Directory of contents

1Introduction......................................................................... 5

1.1About this manual ............................................................................ 5

1.1.1Explanation of signs .................................................................................. 6

1.2Use of the unit................................................................................... 7

1.3Warranty............................................................................................ 7

2Safety information.............................................................. 8

3Description of the unit ..................................................... 10

3.1Overview of the unit ....................................................................... 10

3.2Planning drawing............................................................................ 12

3.3Equipment and connection data................................................... 13

4Transporting the unit ....................................................... 18

4.1Transporting the unit to the installation site ............................... 18

4.2Unpacking the unit ......................................................................... 19

5Setting up the unit............................................................ 20

5.1Maintaining minimum clearances................................................. 21

5.2Lifting the unit off the pallet .......................................................... 22

5.3Setting up the unit on the equipment legs................................... 22

5.4Setting up the unit on a base frame.............................................. 23

5.4.1Installing the support rack ....................................................................... 24

5.5Aligning the unit ............................................................................. 24

5.5.1Aligning countertop unit........................................................................... 24

5.5.2Aligning floor-standing units .................................................................... 24

6Connecting the unit.......................................................... 26

6.1Opening and closing the housing................................................. 26

6.1.1Removing and attaching side wall........................................................... 26

6.2Making the power connection....................................................... 27

6.2.1Matching the unit to the connection voltage ............................................ 29

6.2.2Connecting the power connection cable ................................................. 31

6.2.3Connecting the power optimisation system............................................. 32

6.2.4Connecting to the potential equalisation circuit ....................................... 33

6.3Connecting the kitchen management system ............................. 33

6.4Making the basic control setting................................................... 35

6.4.1Changing the basic control setting .......................................................... 35

6.5Making the water connection ........................................................ 36

6.5.1Connecting the tap water connection line ............................................... 37

6.5.2Connecting softened tap water to both connections ............................... 38

6.6Making the wastewater connection .............................................. 39

6.6.1Connecting the wastewater line to a permanent connection................... 39

6.7Making the exhaust air connection .............................................. 40

6.7.1Connecting the exhaust air line ............................................................... 40

10013865-0AIBE-B

3Installation instructions

Page 4

Directory of contents

7Testing the function ......................................................... 41

7.1Checking the controls.................................................................... 41

7.2Checking the monitoring of the cooking zone door ................... 42

7.3Running the self-diagnosis ........................................................... 42

8Putting the unit into service ............................................ 43

8.1Filling out the Commissioning report........................................... 43

4 Installation instructions

10013865-0AIBE-B

Page 5

1 Introduction

1.1 About this manual

Introduction

The instruction manual is part of the unit and contains information on

safe installation of the unit.

Observe and adhere to the following instructions:

• Read the instruction manual in its entirety prior to installation.

• Make the instruction manual available to the installer at the

operating site at all times.

• Preserve the installation manual throughout the service life of the

unit.

• Insert any supplements from the manufacturer.

• Pass on the installation manual to any subsequent operator of the

unit.

Target group The target group for the installation manual is trained technical

personnel that is familiar with installing and operating the unit.

Figures All figures in this manual are intended as examples. Discrepancies

between these and the actual unit can arise.

10013865-0AIBE-B

5Installation instructions

Page 6

Introduction

1.1.1 Explanation of signs

DANGER

Imminent threat of danger

Failure to comply will lead to death or very severe injuries.

WARNING

Possible threat of danger

Failure to comply can lead to death or very severe injuries.

CAUTION

Dangerous situation

Failure to comply can lead to slight or moderately severe

injuries.

ATTENTION

Physical damage

Failure to comply can cause physical damage.

Notes for better understanding and operation of the unit.

Symbol / sign Meaning

• Listing of information.

Action steps, which can be performed

in any sequence.

1.

2.

Action steps, which must be performed

in the specified sequence.

Result of an action performed or

additional information about it.

6 Installation instructions

10013865-0AIBE-B

Page 7

1.2 Use of the unit

1.3 Warranty

Introduction

This unit is intended to be used solely for commercial purposes,

particularly in commercial kitchens.

The use of the unit is prohibited in the following countries:

• USA

• Canada

The warranty is void and safety is no longer assured in the event of:

• Improper conversion or technical modifications of the unit,

• Improper use,

• Incorrect startup, operation or maintenance of the unit,

• Problems resulting from failure to observe these instructions.

10013865-0AIBE-B

7Installation instructions

Page 8

Safety information

2 Safety information

The unit complies with applicable safety standards. Residual risks

associated with operation or risks resulting from incorrect operation

cannot be ruled out and are mentioned specifically in the safety

instructions and warnings.

The installer must be familiar with regional regulations and observe

them.

The installer must observe the safety instructions in these mounting

instructions and in the "Safety information" chapter of the operating

instructions.

Ensuring conformity with

standards

Improper installation Risk of property damage and personal injury from improper

Transportation and storage Risk of personal injury and property damage from improper

Observe applicable international, European and national laws,

regulations, standards and directives for the unit when transporting,

setting up and connecting it.

installation

• Install the unit only as specified in these installation instructions.

• Do not add anything to the unit or modify the unit.

• Use only original spare parts.

transportation and improper storage

• Store the unit in a dry, frost-free environment.

• Observe the safety regulations for the lifting gear used.

• Attach the unit to the lifting gear securely during transport and

setup, and prevent it from dropping.

• Transport the unit in an upright position, do not tilt or stack.

• Pay attention to protruding parts when transporting the unit

without packaging.

Fire prevention Risk of fire from combustible surfaces

• Observe general fire prevention regulations.

Organisational measures Risk of property damage and personal injury from lack of

organizational measures

• Identify hazard areas when transporting, setting up and

connecting the unit.

• Prior to starting the installation work, notify any operators present

about the procedure.

• Prior to starting the installation work, discuss how to behave in an

emergency.

• Use equipment and protective gear suitable for the activity.

• Brace housing components to prevent them from falling over and

dropping.

8 Installation instructions

10013865-0AIBE-B

Page 9

Setup Risk of property damage and personal injury from improper

setup

• Ensure that the installation area has adequate load-bearing

capacity.

• Wear safety shoes and protective gloves.

Electrical connection Risk of fire from improper connection

• Observe applicable regional regulations of the electrical utility.

• Ensure that only electricians licensed by the electric utility connect

the unit.

• Ensure that the electrical system is earthed by a protective

earthing conductor.

• Note the information on the nameplate.

Risk of electric shock from live components.

• Prior to working on the electrical system, switch off the unit,

disconnect the electrical system from the mains and prevent

power from being switched on again. Check to ensure absence of

voltage.

Safety information

• Use only insulated tools.

Risk of electric shock

• The unit must be incorporated into the potential equalisation circuit

through use of the specified minimum wire sizes.

Unit on casters Risk of a line breaking if subjected to high tensile load

• Secure the unit with a chain as a strain relief for the power

connection at the installation site so that no tensile load is applied

to the power connection if the unit is moved.

Commissioning Risk of property damage and personal injury from improper

commissioning

• Read the operating instructions prior to commissioning. Observe

the safety instructions in this installation manual and in the "Safety

information" chapter of the operating instructions.

• Put the unit into service only after a successful function test

following assembly.

• Put the unit into service only after it has reached room

temperature.

10013865-0AIBE-B

• Observe the units during operation.

9Installation instructions

Page 10

Description of the unit

s

r

q

p

o

n

m

l

k

j

i h g f

e

d

c

b

a

3 Description of the unit

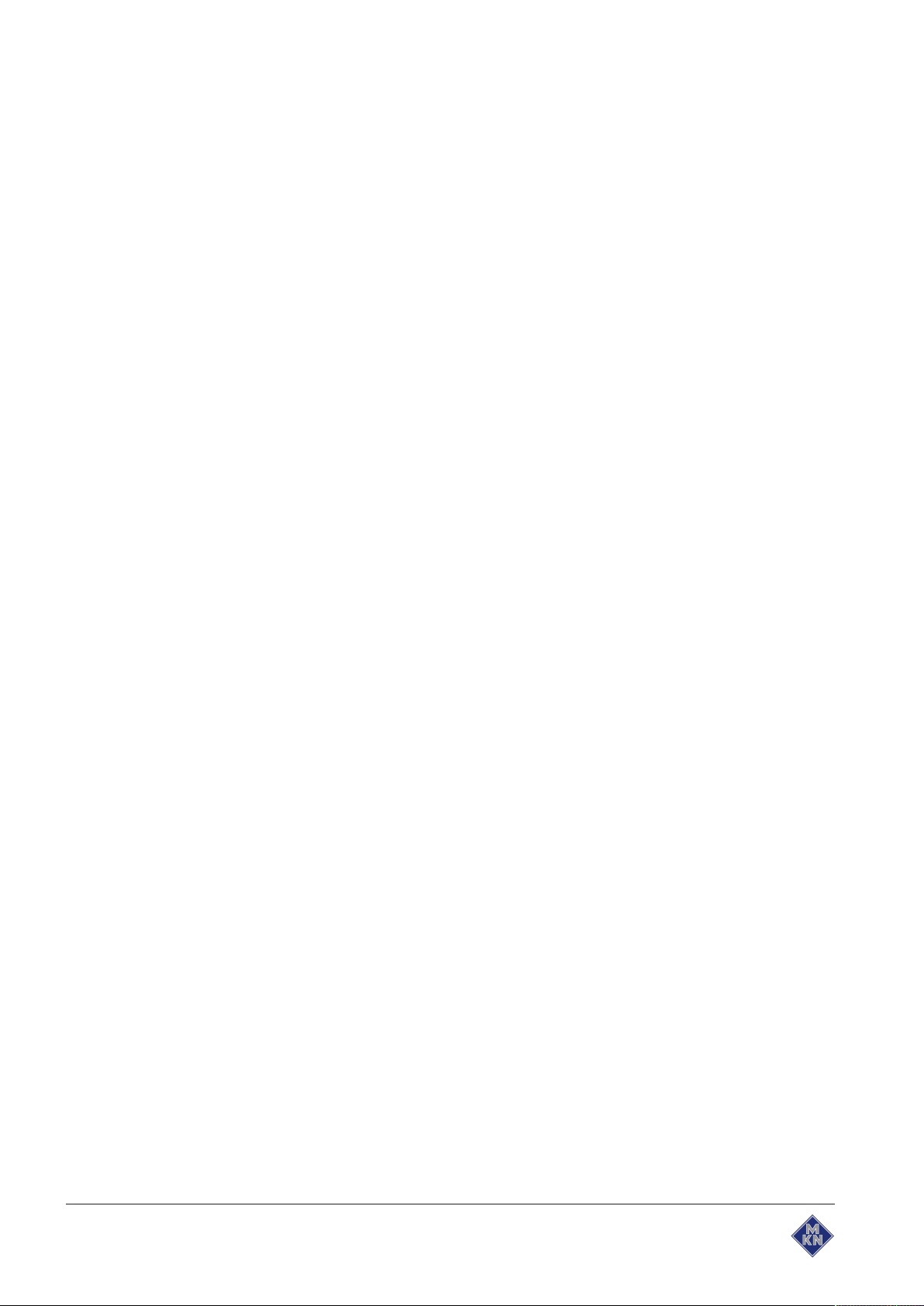

3.1 Overview of the unit

Image: Unit with tray rack trolley

a Tray rack k Nameplate

b Insulated window l Base frame (optional)

c Door handle m Equipment leg

d Cooking zone door n Control unit

e Tray rack trolley (optional) o Housing

f Steam drain channel, door p Air inlet

g Steam drain channel, unit q Steam outlet

h Guide rail for tray rack (optional) r Core temperature sensor

(optional)

i USB port (covered) s Connection for core temperature

sensor (optional)

j Hand shower (optional)

10013865-0AIBE-B

10 Installation instructions

Page 11

Description of the unit

a

d

e

c

b

k

j

i h g f

q

p

o

n

m

l

r

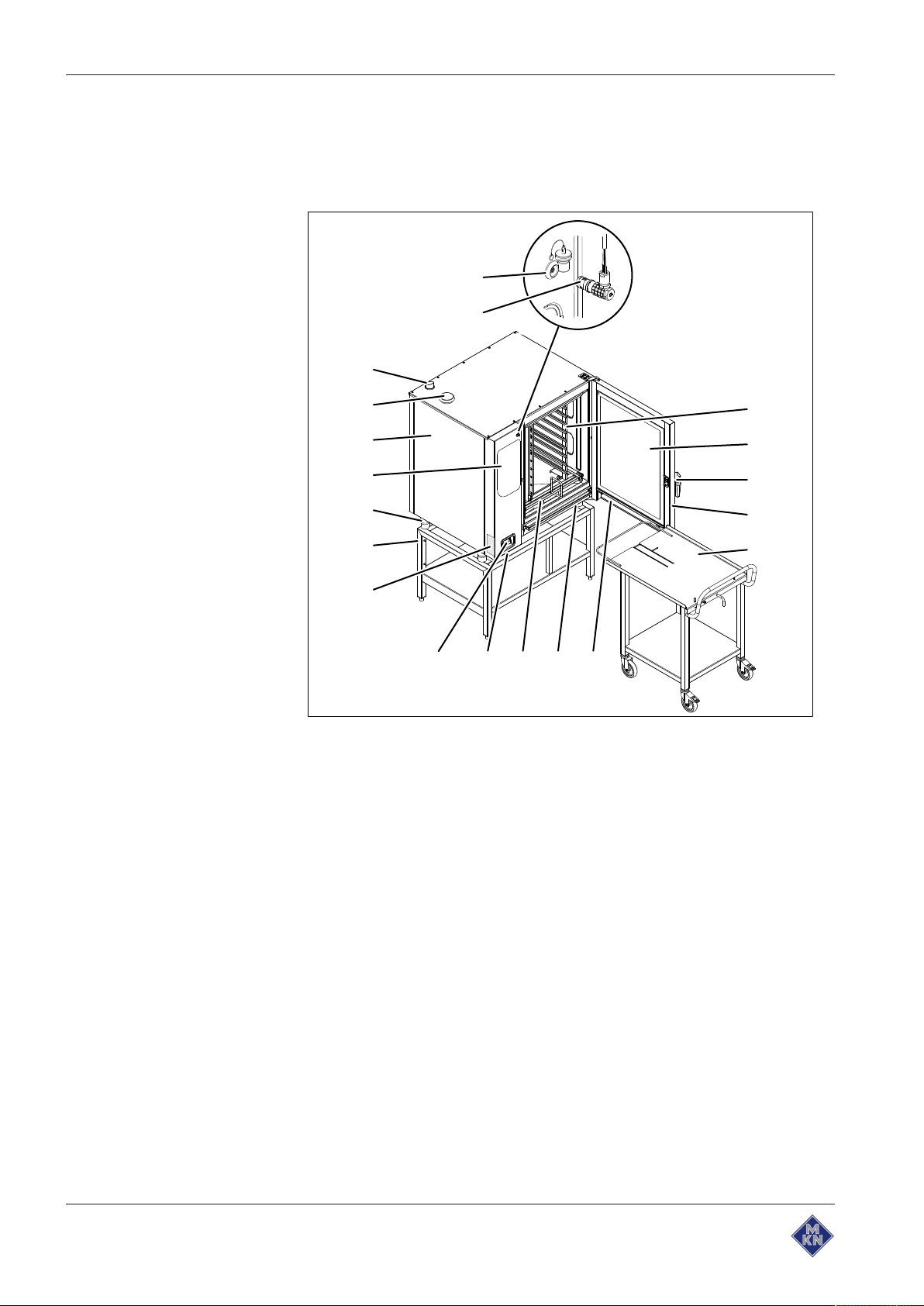

Image: Unit with tray trolley

a Tray rack j Hand shower

b Insulated window k Nameplate

c Door handle l Equipment leg

d Cooking zone door m Control unit

e Guide rail (right) n Housing

f Tray trolley o Air inlet

g Push handle p Steam outlet

h Guide rail (left) q Core temperature sensor

(optional)

i USB port (covered) r Connection for core temperature

sensor (optional)

10013865-0AIBE-B

11Installation instructions

Page 12

Description of the unit

F

BA

C

D

E

H

G

A

H

B C D

E

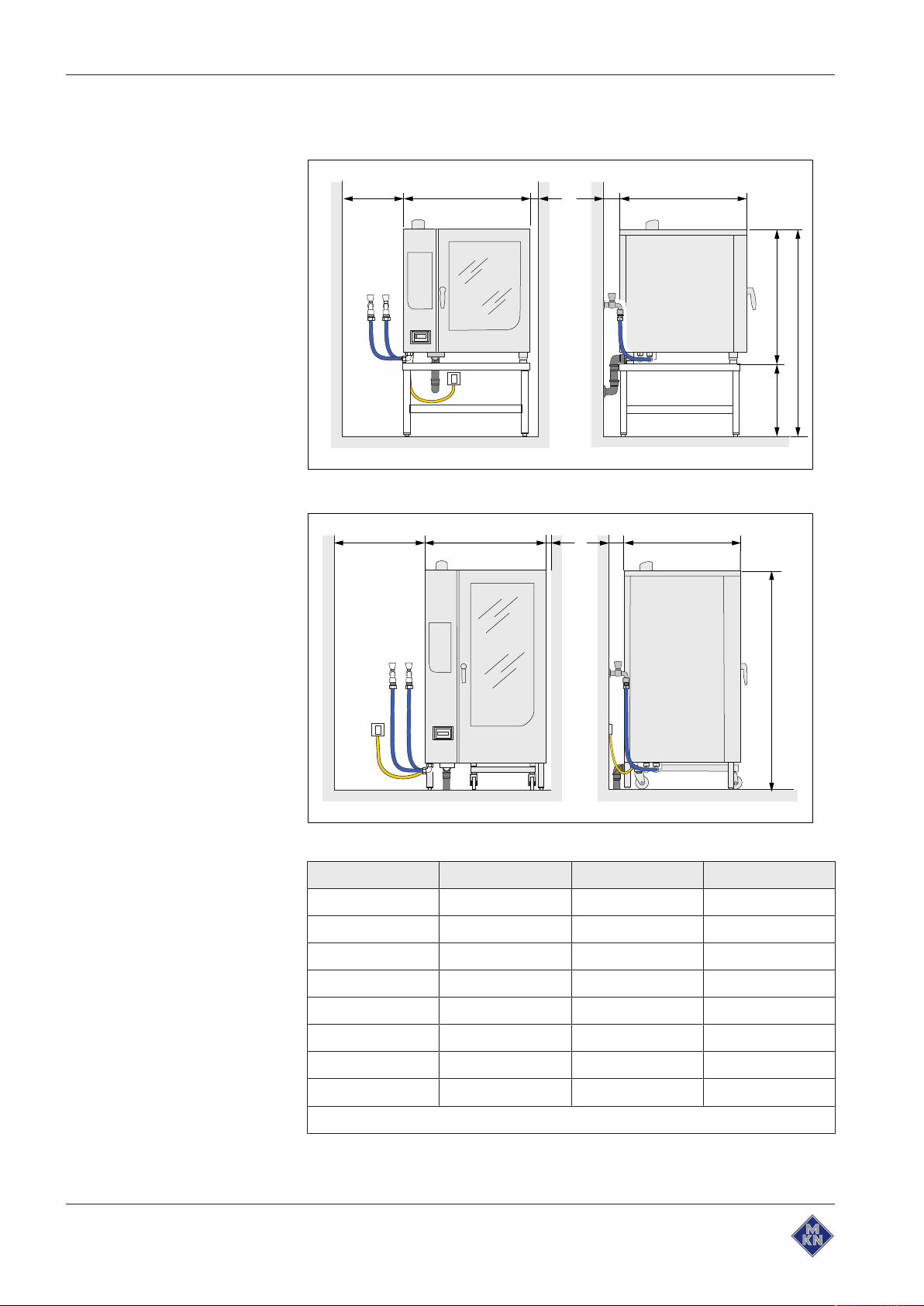

3.2 Planning drawing

Image: Size 6XX and 1XX

Image: Size 2XX

Size 615, 621 115, 121 215, 221

A 50 50 50

B 997 997 1075

C 50 50 50

D 50 50 50

12 Installation instructions

E 799 799 813

F 790 1060 ---

G 850 580 ---

H 1640 1640 1960

All dimensions in mm

10013865-0AIBE-B

Page 13

Description of the unit

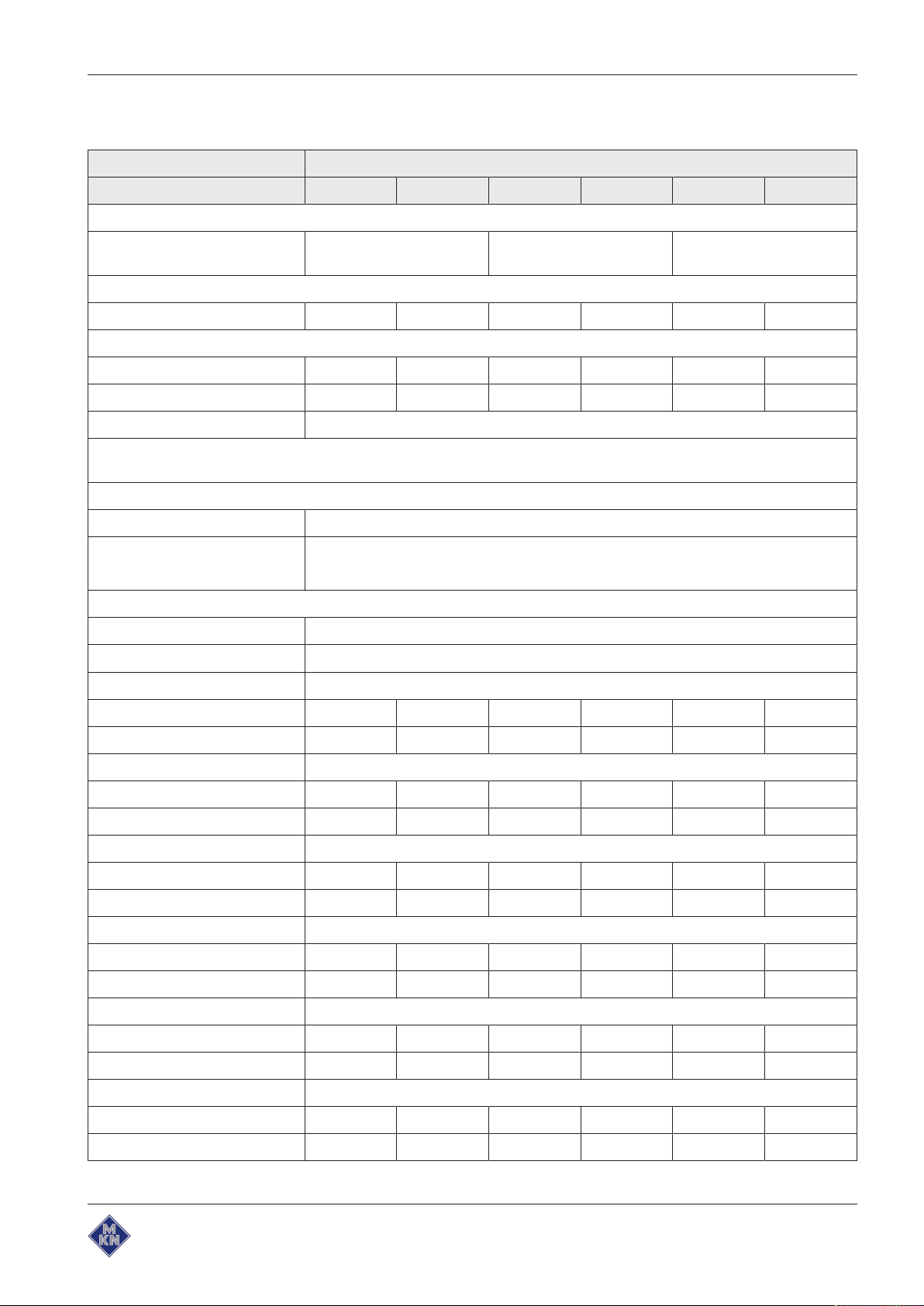

3.3 Equipment and connection data

Model: FKECOD

Size 615 621 115 121 215 221

Dimensions

Unit

Length x Width x Height (mm)

Weight

(kg) unit 120 125 140 145 305 313

Emissions

Latent heat (W) 1780* 3670* 2750* 5400* 5510* 10200

Sensible heat (W) 1190 2450 1840 3600 3670 7100

Noise level (db(A)) < 70

* The stated value is reduced by 80% when operating with a condensation hood; the sensible heat is increased by the

amount of the reduction.

Operating environment

Temperature (°C) 5 — 40

Relative humidity (%)

Non-condensing

Power connection

Protection class IPX5, IPX6 (optional)

Type of connection 3PE / AC 50/60Hz, 3NPE / AC 50/60Hz

Voltage (V) 200

997 x 799 x 790 997 x 799 x 1060 1075 x 813 x 1960

95

Connected load (kW) 10.1 16.3 14.7 25.5 29.4 50.9

Fuse (A) 3 x 35 3 x 50 3 x 50 3 x 80 3 x 100 3 x 180

Voltage (V) 208

Connected load (kW) 10.2 17.4 15.7 27.3 31.4 54.6

Fuse (A) 3 x 35 3 x 50 3 x 50 3 x 80 3 x 100 3 x 180

Voltage (V) 220

Connected load (kW) 11.6 19.7 17.7 30.8 35.4 61.4

Fuse (A) 3 x 35 3 x 63 3 x 63 3 x 100 3 x 125 3 x 180

Voltage (V) 230

Connected load (kW) 12.6 21.4 19.3 33.6 38.6 67

Fuse (A) 3 x 35 3 x 63 3 x 63 3 x 100 3 x 125 3 x 180

Voltage (V) 240

Connected load (kW) 13.7 23.3 21 36.5 42 72.9

Fuse (A) 3 x 35 3 x 63 3 x 63 3 x 100 3 x 125 3 x 180

Voltage (V) 380

Connected load (kW) 9.4 18.9 14.4 27.6 28.7 55

Fuse (A) 3 x 16 3 x 35 3 x 25 3 x 50 3 x 50 3 x 100

10013865-0AIBE-B

13Installation instructions

Page 14

Description of the unit

Model: FKECOD

Size 615 621 115 121 215 221

Voltage (V) 400

Connected load (kW) 10.4 20.9 15.9 30.5 31.7 60.9

Fuse (A) 3 x 16 3 x 35 3 x 25 3 x 50 3 x 50 3 x 100

Voltage (V) 415

Connected load (kW) 11.2 22.5 17.1 32.8 34.1 65.5

Fuse (A) 3 x 16 3 x 35 3 x 25 3 x 50 3 x 50 3 x 100

Voltage (V) 440

Connected load (kW) 10.4 20.9 15.8 30.5 31.5 60.9

Fuse (A) 3 x 16 3 x 35 3 x 25 3 x 50 3 x 50 3 x 100

Voltage (V) 480

Connected load (kW) 12.3 20.9 18.9 32.6 37.6 65.1

Fuse (A) 3 x 16 3 x 35 3 x 25 3 x 50 3 x 50 3 x 100

Soft water connection

Type of water Soft water, cold

Carbonate hardness

CaCO3(mmol/l (°dH))

Chloride Cl (mg/l) < 50

Iron Fe (mg/l) < 0.1

Connection pressure (kPa

(bar))

Connection (") R 3/4

Tap water connection

Type of water Tap water, cold

Carbonate hardness

CaCO3(mmol/l (°dH))

Connection pressure (kPa

(bar))

Connection (") R 3/4

Water consumption for steaming

Soft water (l/h) 16 21 18 24 36 48

Water consumption for Combisteaming

Soft water (l/h) 3,5 4,6 4 5,3 8 10,6

< 0,9 (5)

200 (2) — 600 (6)

< 4 (22)

200 (2) — 600 (6)

Water consumption for WaveClean cleaning program

Soft water (l) 3

Tap water (l) 32

Wastewater connection

Wastewater type Dirty water, maximum 80 °C

Connection to unit (mm) 50

Maximum length (m) 1

14 Installation instructions

10013865-0AIBE-B

Page 15

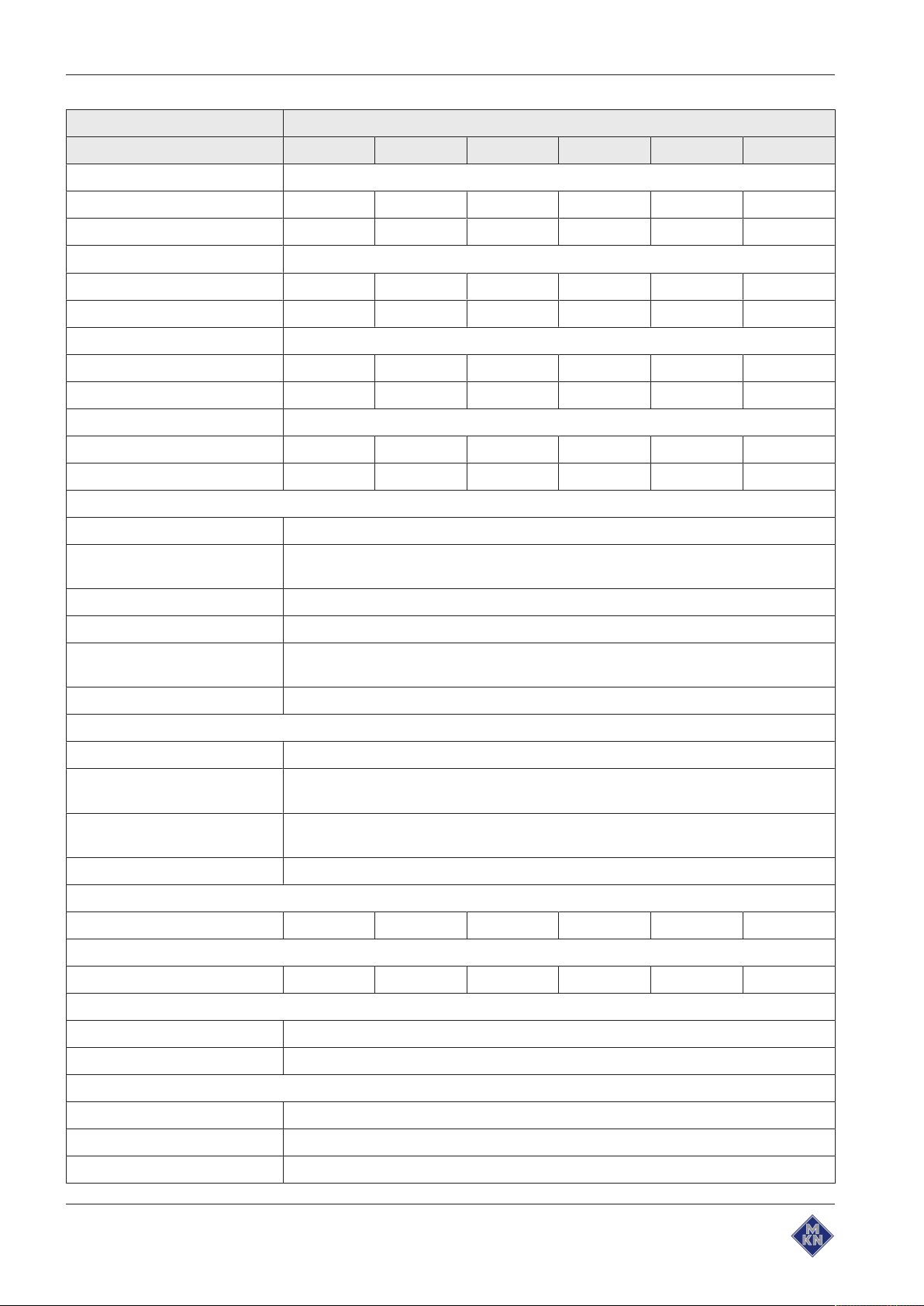

Description of the unit

Model: FKECOD

Size 615 621 115 121 215 221

Temperature resistance (°C) 95

Maximum flow rate (l/min) 10

Exhaust air connection

Connection to unit (mm) 53 73

Maximum length (m) 2,5

Temperature resistance (°C) 180

Transformer voltage

Type of connection 3NPE / AC 50/60Hz

Voltage range (V) 200 — 240

Transformer T1

Marking or colour of the cores Blue Red

Voltage measured (V) Voltage at the transformer (V)

190 — 200 0 200

201 — 220 0 220

221 — 230 0 230

231 — 240 0 240

241 — 250 0 250

Type of connection 3NPE / AC 50/60Hz

Voltage range (V) 380 — 415

Transformer T1

Marking or colour of the cores Blue Red

Voltage measured (V) Voltage at the transformer (V)

370 — 380 0 220

381 — 400 0 230

401 — 420 0 240

Type of connection 3PE / AC 50/60Hz

Voltage range (V) 380 — 480

Transformer T0 T1

Marking or colour of the cores T0 - 0V T0 - 230V T0 - 400V Blue Red

Voltage measured (V) Voltage at the transformer (V)

370 — 380 0 219 400 0 230

381 — 415 0 230 400 0 230

416 — 450 0 230 440 0 230

451 — 490 0 230 480 0 230

10013865-0AIBE-B

15Installation instructions

Page 16

Description of the unit

Basic control setting

Basic setting ParametersStandard

value

Date / time yyyy - mm - dd

Unit of temperature 1 °C °C Celsius (°C)

Altitude 2 0—999 0—999 m Request the altitude above sea level from

80% power 3 100 80% Power can be limited to 80% (for special

Actual voltage 14 400 100 — 500V Set the local, mean voltage between the

Audible signal

volume

Signal tones Sound 1 Sound 1 — 4 There are 4 sets of different sounds

33 Medium Individual Sets the volume.

Adjustment

range

hh : mm

°F Fahrenheit (°F)

1000 m—1999

m

2000 m—2499

m

2500 m or higher

100%

Explanation

Year - Month - Day

Hour : Minute

the local weather station. If the altitude is

unknown, set 0 – 999 m.

applications).

line conductors.

available.

Unit of volume 34 ml (ml) Millilitre (ml)

(fl.oz.) Fluid ounce (fl.oz.)

35 Imperial

(fl.oz.)

Power optimisation

system

Water filter

maintenance

Network DHCP Network address

Kitchen management

system

Settings parameters 1. Set parameters via the roller.

42 Off On If a power optimisation system is

44 0 0 — 99900 l Water quantity up to the maintenance

Disabled Active

Ethernet Ethernet

Imperial (fl.oz.) Imperial fluid ounce

U.S. (fl.oz.) U.S. fluid ounce

Off

and DHCP

Disabled

Serial

connected, "On" must be selected for the

unit to heat.

message.

0 = No maintenance message

Select and set interface.

Port and unit address can be set.

Type of signal transmission

2. Tap the "Read" button to display the

set value.

3. Specify another value via the button

panel.

4. Press the "Write" button to save the

new value.

16 Installation instructions

10013865-0AIBE-B

Page 17

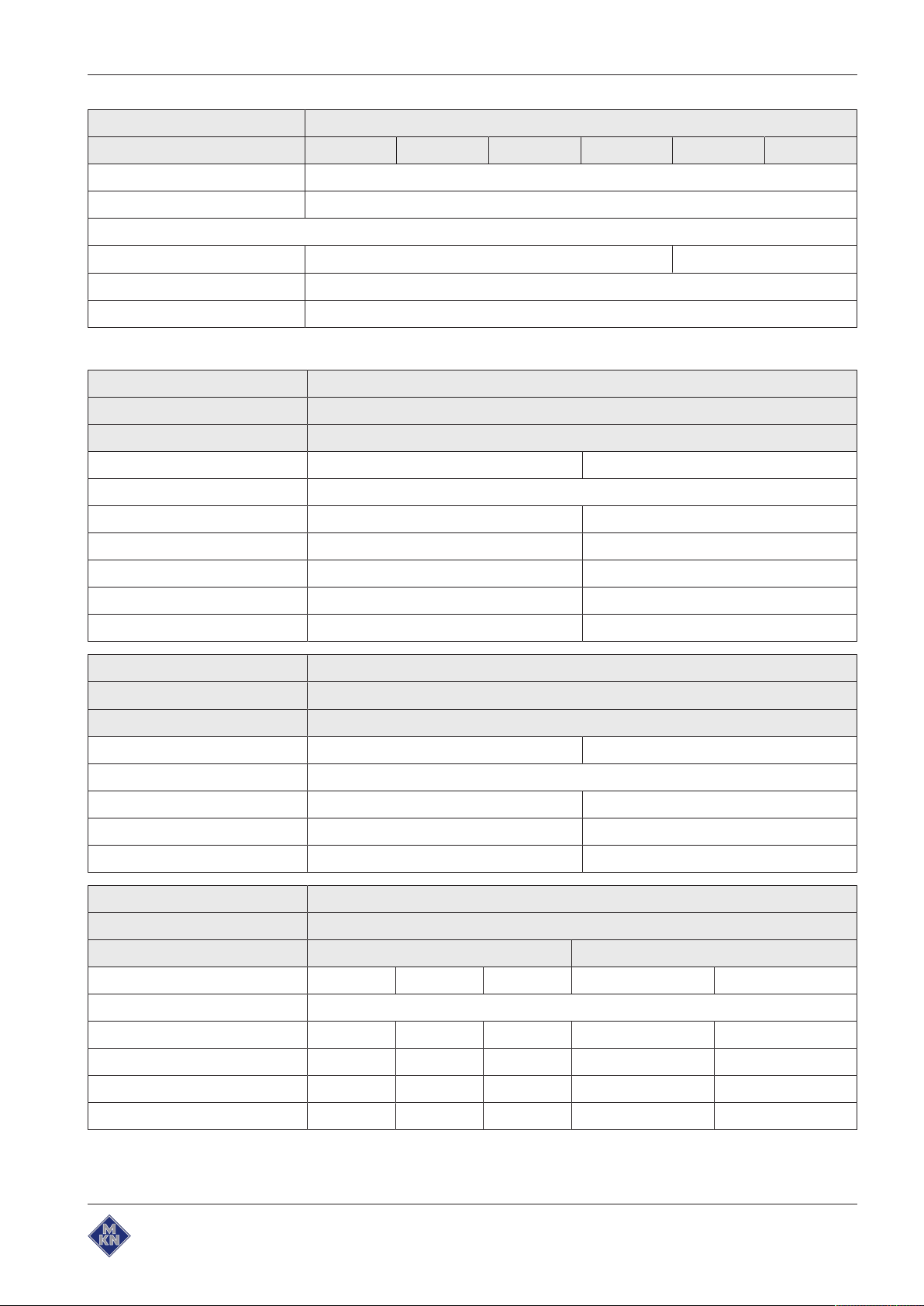

Basic control setting (Advanced)

Description of the unit

Basic setting ParametersStandard

value

Ready2Cook

preheating

temperature

Time extension for

condensation hood

Preselect steaming

temperature

Preselect

Combisteaming

temperature

Preselect hot air

temperature

Preselect

regeneration

temperature

Maximum waiting

time after

Ready2Cook, for T <

250 °C

4 15 0 — 30% If the unit is fully loaded with a large mass

5 60 0 – 600s Time extension for the condensation hood,

9 100 30 °C — 130 °C Preset temperature for steaming

10 150 30 °C — 250 °C Preset temperature for Combisteaming

11 180 30 °C — 250 °C Preset temperature for hot air

12 130 30 °C — 150 °C Preset temperature for regeneration

37 120 0 — 300min Maximum waiting time after the

Adjustment

range

Explanation

(roasts, loaves of bread), increase the

preheat temperature so that the cooking

zone temperature does not drop too

suddenly.

after the cooking zone door has been

opened

Ready2Cook temperature is reached, for

set value < 250 °C

Maximum waiting

time after

Ready2Cook, for T >

250 °C

Generator mode 45 0 0 = No

Cleaning monitoring 46 0 0 = No

Steam elimination 48 1 0 = Low

Time format 675 0 0 = 24h

38 30 0 — 60min Maximum waiting time after the

1 = Yes

1 = Yes

1 = Normal

2 = High

1 = 12h

Ready2Cook temperature is reached, for

set value > 250 °C

If a generator is used to supply electricity

When cleaning monitoring is activated, a

message appears if the cleaning program

has not been started for more than 1 day.

Sets the steam elimination level

Sets the 12h or 24h time format

10013865-0AIBE-B

17Installation instructions

Page 18

Transporting the unit

4 Transporting the unit

CAUTION

Risk of property damage and personnel injury from tipping

equipment

• Do not linger next to or behind raised equipment.

• Move raised equipment carefully.

ATTENTION

Risk of physical damage from improper transport

• Transport the unit upright.

• Do not tilt or stack the unit.

• Pay attention to protruding parts when transporting the

unpacked unit.

Prior to transporting the unit to the installation site, ensure that:

• The roadway has adequate load-bearing capacity.

• Wall openings are large enough.

4.1 Transporting the unit to the installation site

Image: Lengthwise and crosswise transport on pallet

Use suitable transport means to move unit to installation site.

18 Installation instructions

10013865-0AIBE-B

Page 19

4.2 Unpacking the unit

Transporting the unit

CAUTION

Risk of injury from sharp edges

• Wear protective gloves.

When unpacking the unit, inspect it for transport damage.

Do not install damaged units or put into service.

1. Remove the packaging.

2. Pull the protective film off the unit.

3. Remove the packaging material from the cooking zone

completely.

4. Clean the unit (see "Cleaning and maintaining the unit" in the

operating instructions).

5. Enter the information from the nameplate into the commissioning

report.

10013865-0AIBE-B

19Installation instructions

Page 20

Setting up the unit

5 Setting up the unit

WARNING

Risk of burns from spraying hot fat

• Set up deep fat fryers outside the range of the hand shower.

CAUTION

Risk of crushing from improper setup

• Protect the unit and work area during setup and alignment.

CAUTION

Risk of fire from failure to observe applicable regional fire

prevention regulations

• Observe applicable regional fire prevention regulations.

ATTENTION

Risk of physical damage from overheating of the unit

• Do not set up the unit close to heat sources.

20 Installation instructions

10013865-0AIBE-B

Page 21

5.1 Maintaining minimum clearances

A

C

B

D

Image: Minimum clearances to walls, ceiling or units

Setting up the unit

A B C D *

50 100 500 50

All dimensions in mm

* Recommended for service work 500 mm

The following clearances from walls, ceilings or other equipment must

be maintained when setting up the unit:

• Left, right and rear at least 50 mm.

• For service work, 500 mm on the left is recommended.

• For parking the tray trolley, 800 mm on the left.

• Clearance from heat sources (baking oven), 500 mm on the left.

• Clearance to deep-fat fryers, at least one length of the hand

shower on the left and right.

• There must be no water, gas or electric lines in the ceiling above

the unit.

10013865-0AIBE-B

21Installation instructions

Page 22

Setting up the unit

5.2 Lifting the unit off the pallet

CAUTION

Risk of property damage and personnel injury from tipping

equipment

• Do not linger next to or behind raised equipment.

• Move raised equipment carefully.

ATTENTION

Risk of physical damage from lifting the unit incorrectly

• Place the forks of the lift truck next to the waste trap.

Requirement Unit unpacked

Protective film removed

Unit cleaned

Image: Lifting the unit off the pallet

1. Slide the forks of the pallet truck under the unit and to the right of

the waste trap.

2. Lift the unit off the pallet.

5.3 Setting up the unit on the equipment legs

Requirement The floor must carry the weight of the unit

1. Lift the unit with the pallet truck.

2. Move the unit to the installation site.

3. Place the unit on the floor.

4. Set up the unit in accordance with the planning drawing (see

"Planning drawing").

22 Installation instructions

10013865-0AIBE-B

Page 23

5.4 Setting up the unit on a base frame

ab

d

c

e

f

Image: Setting up the unit on a base frame

Setting up the unit

a Lifting fork d Stud bolt

b Waste trap on the unit e Equipment leg

c Base frame f Unit

Requirement The base frame must carry the weight of the unit

Base frame levelled

Base frame must be set up in accordance with the planning drawing

1. Lift the unit.

2. Place the unit over the stud bolts and onto the base frame.

CAUTION

Risk of scalding due to spillage of hot cooked food

• Attach sticker if the upper slide-in rails are higher than 1.60

m.

Image: Attach a warning sign about the shelf height

3. Clean the adhesive surface for the sticker.

10013865-0AIBE-B

4. Attach the sticker to the cooking zone door at a height of 1,6 m.

23Installation instructions

Page 24

Setting up the unit

c

b

d

A

B

c

a

5.4.1 Installing the support rack

Depending on the version, the base frame can be equipped with a

support rack.

The support rack is used to hold containers, metal trays and grates.

Image: A Stop profile, B Support rack

Requirement Pins installed in the uprights of the base frame

a Stop profile c Outboard support rack

b Pin d Inboard support rack

1. Place the stop profiles on the pins (at the back).

2. Install the support racks.

5.5 Aligning the unit

5.5.1 Aligning countertop unit

Requirement Base frame levelled

Level the unit by screwing the equipment legs in or out.

Fill out the Commissioning report.

5.5.2 Aligning floor-standing units

ATTENTION

Risk of water discharge from leaking cooking zone

The cooking zone will leak if the tray trolley is not aligned.

• Operate a floor-standing unit only with the tray trolley.

• Align the tray trolley carefully.

The tray trolley is needed to align a floor-standing unit.

Prepare the tray trolley.

Aligning tray trolley

Requirement The floor under and in front of the unit is flat

1. Level the unit by screwing the equipment legs in or out.

2. If the floor conditions are poor, insert spacers on the casters of the

tray trolley.

24 Installation instructions

10013865-0AIBE-B

Page 25

Setting up the unit

a

c

b

d

e

f

3. Open the cooking zone door.

4. Move the tray trolley into the unit until it stops and check the

alignment.

5. Close the cooking zone door.

The sheet metal seal on the tray trolley should make full

contact (no gaps) with the door seal.

The shelves in the unit should be horizontal.

6. Fill out the Commissioning report.

Aligning tray trolley with insertion system

The Combisteamer can be equipped with the

system(optional).

Image: Aligning the tray trolley with the insertion system

a Tray trolley d Equipment leg

b Distance e Support roller

c Guide rail f Push handle

EasyIn

insertion

10013865-0AIBE-B

1. Level the unit by screwing the equipment legs in or out.

2. Open the cooking zone door.

3. Place the tray trolley against the guide rails.

4. Screw the equipment legs in or out, until the support rollers are 1

mm — 5 mm above the guide rails.

5. Retract the tray trolley.

6. Level the guide rails.

7. Move the tray trolley into the unit until it stops and check the

alignment.

The casters of the inserted tray trolley should no longer have

floor contact.

8. Remove the push handle.

9. Close the cooking zone door.

10.Fill out the Commissioning report.

25Installation instructions

Page 26

Connecting the unit

A B

6 Connecting the unit

DANGER

Risk of personal injury and physical damage from electric

shock

• Prior to working on the unit, ensure that the unit has been

• Do not operate the unit with the housing open.

CAUTION

Risk of injury from sharp edges

• Wear protective gloves.

ATTENTION

Risk of physical damage from damage to the lines

• Remove and attach housing components carefully.

disconnected from the mains.

6.1 Opening and closing the housing

6.1.1 Removing and attaching side wall

Removing the side wall

Image: A Size 6XX and 1XX; B Size 2XX

1. Unscrew the screws on the side wall.

2. Pull the bottom edge of the side wall forwards.

3. Remove the side wall.

26 Installation instructions

10013865-0AIBE-B

Page 27

Attaching side wall

ATTENTION

Risk of physical damage from leaky housing

• Check seals when attaching the housing parts.

• Replace damaged gaskets.

1. Insert the top edge of the side wall.

2. Carefully push the bottom of the side wall inwards.

3. Fasten the side wall with the screws.

4. Check that the side wall is in contact with the unit on all sides.

6.2 Making the power connection

The unit must be connected on the basis of the information on the

nameplate and this manual.

ATTENTION

Risk of physical damage from incorrect connection voltage

Connecting the unit

• Before making the connection, measure the connection

voltage and check the set voltage on the transformers in the

unit.

Wiring diagram

The wiring diagram is included with the unit.

The wiring diagram and additional documents are available on the

manufacturer's Internet page by entering the serial number of the unit

(see Impressum).

Installation work

Electrical installation work must be carried out by an electrician.

Comply with the local regulations of the electrical utility company.

Power connection cable

Minimum requirements for the unit's power connection cable to the

electric mains:

Connection Power connection cable

Permanent connection for fixed

installation with a cable from the unit to

a separate connection box.

Connection of the unit with a plug.

Rubber sheath cable, oil-resistant,

shrouded and flexible in accordance

with IEC 60245-57 (for example

H05RN-F).

10013865-0AIBE-B

Permanent connection for fixed

installation with a permanently laid

cable and direct connection to the unit.

PVC sheathed cable for permanent

ducting in buildings or damp and wet

rooms.

27Installation instructions

Page 28

Connecting the unit

Permanent connection

CAUTION

Risk of property damage and personal injury from improper

installation

• In the case of a permanent electrical connection, install an

all-phase disconnect switch before the unit.

Install an all-phase disconnect switch if the unit will be connected

permanently to the electric mains.

Plug-in connection

CAUTION

Risk of property damage and personal injury from improper

installation

• The plug-in connection must be readily accessible.

If the unit is connected with a plug to the power-supply mains, use

plugs and sockets according to IEC60309.

The socket must be readily accessible so that the unit can be

disconnected from the electric mains at any time.

Insulation monitoring

If there is an unearthed network (IT network), the unit can be

incorporated into the insulation monitoring.

Fault current device

Image: RCD switch type A, circuit symbol

The unit can be connected to a fault current device.

If a fault current device is used, a fault current device type A (RCD

type A) must be installed, to ensure that AC fault currents and

pulsating DC currents are detected.

28 Installation instructions

10013865-0AIBE-B

Page 29

Equipotential bonding

Image: Equipotential bonding symbol

The unit must be included in a potential equalisation system by

means of appropriately sized wiring.

6.2.1 Matching the unit to the connection voltage

DANGER

Risk of personal injury and physical damage from electric

shock

Connecting the unit

• Prior to working on the unit, ensure that the unit has been

disconnected from the mains.

• Do not operate the unit with the housing open.

ATTENTION

Risk of physical damage from incorrect connection voltage

• Before making the connection, measure the connection

voltage and check the set voltage on the transformers in the

unit.

When the unit is delivered, it is preset to a certain connection voltage

or voltage range.

If the connection voltage on site differs from the preset connection

voltage, damage to the unit can arise.

Before connecting the unit, the connection voltage must be measured

and the transformers in the unit checked, and if necessary they must

be reconnected.

10013865-0AIBE-B

29Installation instructions

Page 30

Connecting the unit

A B

Nnc110 V

120 V

200 V

208 V

220 V

230 V

240 V

250 V

X1

X2

T1

480 V

440 V

400 V

242 V

230 V

219 V

0 V

A B

T0

Image: A Transformer position T1; B Connection for transformer controls

Requirement Unit not live

Image: A Transformer position T0, only for unit without neutral wire; B Transformer

connection

Left side wall removed

1. Measure the connection voltage with a suitable measuring device.

The voltage range must match that on the nameplate.

If there are voltage fluctuations, the maximum expected

voltage must be taken into account.

2. Check whether the transformer voltage is within the specified

range (see "Equipment and connection data").

If the set voltage differs, match the transformer voltage by

reconnecting.

Document the new voltage set on the sticker.

3. In the case of units with several transformers, repeat the

procedure for each transformer.

4. Close the housing (see "Opening and closing the housing").

5. Fill out the Commissioning report.

10013865-0AIBE-B

30 Installation instructions

Page 31

6.2.2 Connecting the power connection cable

a

b

c

d

DANGER

Risk of personal injury and physical damage from electric

shock

• Prior to working on the unit, ensure that the unit has been

disconnected from the mains.

• Do not operate the unit with the housing open.

DANGER

Risk of personal injury and physical damage from electric

shock

• Before connecting, ensure that the power connection cable

has been disconnected from the power supply.

• Ensure that the power connection cable is undamaged.

Connecting the unit

Image: Connecting the electric power cable

a Connection terminals c Electric power cable

10013865-0AIBE-B

b Cable tie d Cable gland

31Installation instructions

Page 32

Connecting the unit

Requirement Unit not live

Power connection cable not live

Unit matched to the connection voltage

Side wall open

1. Route the power connection cable into the unit through the cable

gland.

2. Connect the power connection cable in accordance with the wiring

diagram.

3. Secure the power connection cable with cable ties.

4. Tighten the cable gland securely to provide strain relief.

5. Close the housing (see "Opening and closing the housing").

6. Fill out the Commissioning report.

6.2.3 Connecting the power optimisation system

DANGER

Risk of personal injury and physical damage from electric

shock

• Prior to working on the unit, ensure that the unit has been

disconnected from the mains.

• Do not operate the unit with the housing open.

DANGER

Risk of personal injury and physical damage from electric

shock

• Before connecting, ensure that the power connection cable

has been disconnected from the power supply.

• Ensure that the power connection cable is undamaged.

The unit can be connected to a power optimisation system.

Requirement Unit not live

Power connection cable not live

Housing opened

1. Pull the power connection cable into the unit through the cable

gland.

2. Bring the power connection cable to the connection terminals.

3. Connect the power connection cable in accordance with the wiring

diagram.

4. Secure the power connection cable with cable ties.

5. Register the power optimisation system in the basic control

settings (see "Making the basic control settings").

6. Fill out the Commissioning report.

32 Installation instructions

10013865-0AIBE-B

Page 33

6.2.4 Connecting to the potential equalisation circuit

Image: Connecting the potential equalisation circuit

1. Run and attach potential equalisation line to the identified

terminal.

2. Fill out the commissioning report.

Connecting the unit

6.3 Connecting the kitchen management system

The units can be connected with a RJ45 plug to a kitchen

management system.

DANGER

Risk of personal injury and physical damage from electric

shock

• Prior to working on the unit, ensure that the unit has been

disconnected from the mains.

• Do not operate the unit with the housing open.

10013865-0AIBE-B

33Installation instructions

Page 34

Connecting the unit

a

b

c

d

e

Minimum requirements for the network cable

Type of network Ethernet

Cable quality 4-pair, shrouded patch cable

Cat-6 S/FTP

Connection to unit Shrouded RJ45 plug

Image: Connecting the kitchen management system

a RJ45 socket d Cable tie

b RJ45 plug e Ferrite ring

c Network cable

Requirement Unit not live

Housing opened

1. Pull the network cable into the unit through the cable gland.

2. Lead the network cable through the two ferrite rings, with one

winding through each.

3. Connect the network cable to the unit with the RJ45 plug.

4. Register the network in the basic control setting (see "Making the

basic control setting").

5. Fill out the Commissioning report.

10013865-0AIBE-B

34 Installation instructions

Page 35

6.4 Making the basic control setting

a b

cd

e

Image: Main menu

Connecting the unit

a Main menu d "Equipment functions" button

b

FlexiHelp

c Language selection

6.4.1 Changing the basic control setting

By entering the password "2100", the basic settings for the installation

can be displayed and changed.

The basic settings are made in the dialogue.

Advanced settings are made via the parameters for the settings.

Requirement The unit is switched on

The Main menu is displayed

1. Tap the "Equipment functions" button.

The

Equipment functions

2. Tap the "Equipment settings" field.

The

PIN

3. Enter the password.

4. Tap the

Confirm

button e

menu is displayed.

window opens.

button.

Back

button

10013865-0AIBE-B

The

Equipment settings

The basic settings can be changed (see "Equipment and

connection data").

5. Fill out the Commissioning report.

menu is displayed.

35Installation instructions

Page 36

Connecting the unit

6.5 Making the water connection

Installation work involving drinking water must be performed by an

authorised plumbing contractor.

Observe applicable regional regulations with regard to drinking water

installations and connection data (see "Equipment and connection

data").

The unit has a connection for permanent attachment the drinking

water system.

The unit is equipped with a permanent connection for:

• Softened drinking water for steam generation

• Drinking water for cooling, rinsing and cleaning

CAUTION

Hygiene risk from contaminated drinking water

• The connection to the drinking water supply must be

equipped with a backflow preventer.

ATTENTION

Risk of physical damage from the wrong water quality

• Ensure that the water quality complies with the equipment

and connection data.

Always connect both water connections to the unit.

36 Installation instructions

10013865-0AIBE-B

Page 37

6.5.1 Connecting the tap water connection line

a

b

e

c

d

f

Image: Water connection

a Soft water d Tap water connection

b Backflow preventer e Tap water connection line

c Soft water connection f Tap water

Connecting the unit

Requirement Water pressure complies with the specified range (see "Equipment

and connection data")

Backflow preventer installed

The connection lines are pressure-tight and suitable for tap water

1. Connect the connection lines to the tap water valves using seals.

2. Flush the connection lines thoroughly.

3. Insert dirt filters into the water connections on the unit.

4. Connect the tap water connection line to the unit.

5. Connect the soft water connection line to the unit.

6. Open the tap water valves and check the threaded connectors for

leaks.

7. Fill out the Commissioning report.

10013865-0AIBE-B

37Installation instructions

Page 38

Connecting the unit

a

b

c

d e

f

g

h

6.5.2 Connecting softened tap water to both connections

If only softened tap water is available at the installation site, use a Tpiece to connect both water connections on the unit to each other.

Image: Connecting softened tap water to both connections

a Softened tap water e Tap water connection

b Backflow preventer f Dirt filter

c Connection line g T-piece

d Softened tap water connection h Seal

Requirement Water pressure complies with the specified range (see "Equipment

and connection data")

Backflow preventer installed

The connection line is pressure-tight and suitable for tap water

1. Connect the connection line to the tap water valve for soft water

using a seal.

2. Flush the connection line thoroughly.

3. Insert dirt filters into the water connections on the unit.

4. Connect the T-piece to the unit.

5. Connect the connection line for soft water to the T-piece using a

seal.

6. Open the tap water valve and check the threaded connectors for

leaks.

7. Fill out the Commissioning report.

38 Installation instructions

10013865-0AIBE-B

Page 39

6.6 Making the wastewater connection

a

b

c

d

e

c

b

a

f

Installation work involving wastewater must be performed by an

authorised plumbing contractor.

Observe the applicable regional regulations of the sewage utility

involved.

6.6.1 Connecting the wastewater line to a permanent connection

Connecting the unit

Image: Wastewater line to a permanent connection

a Wastewater connection d Sewer system waste trap

b Wastewater line e Pipe clamp

c Sewer system f Vacuum breaker

If a waste trap is installed in the wastewater system, a vacuum

breaker must be installed in the wastewater line.

Requirement Wastewater line complies with the specifications (see "Equipment

and connection data")

1. Install the wastewater line up to the connection at the sewer

system.

2. Secure the wastewater line with pipe clamps.

3. Fill the waste trap on the unit with tap water.

4. Fill out the Commissioning report.

10013865-0AIBE-B

39Installation instructions

Page 40

Connecting the unit

6.7 Making the exhaust air connection

When setting up the unit under a ventilation system, observe the

regional regulations for heating, ventilation and air conditioning

systems.

ATTENTION

Risk of physical damage from fouling of the exhaust air

ducts

• Do not connect the exhaust air line directly to the ventilation

system.

ATTENTION

Risk of corrosion damage from condensate

• Install the exhaust air line such that condensate cannot

collect.

6.7.1 Connecting the exhaust air line

Image: Connecting the exhaust air line

Requirement Exhaust air line complies with the specifications (see "Equipment and

connection data")

1. Connect the exhaust air line to the steam outlet.

2. Route the exhaust air line with a 3° rise as far as the ventilation

system.

3. Fasten the end of the exhaust air line 50 mm — 200 mm

underneath the ventilation system.

4. Fill out the Commissioning report.

40 Installation instructions

10013865-0AIBE-B

Page 41

7 Testing the function

DANGER

Risk of personal injury and physical damage from

unsuccessful operational check

• Do not put the unit into service.

• Contact customer service.

Requirement Power connection made

Water connection made

Wastewater connection made

Unit cleaned

7.1 Checking the controls

1. Switch on the unit and start any cooking program (see Operating

instructions).

Testing the function

Set the cooking zone temperature to a higher temperature than

the current cooking zone temperature.

The unit heats up.

Once the set temperature is reached, heating switches off.

The temperature no longer increases.

The controls are functioning.

2. Switch off the unit.

3. Fill out the Commissioning report.

10013865-0AIBE-B

41Installation instructions

Page 42

Testing the function

7.2 Checking the monitoring of the cooking zone door

1. Switch on the unit and start any cooking program (see operating

instructions).

The unit starts to heat.

The fan wheel is turning.

2. Open the cooking zone door during operation.

The unit shuts off the heating function.

The fan wheel comes to a stop.

The monitoring of the cooking zone door is functioning.

3. Close the cooking zone door.

4. Switch off the unit.

5. Fill out the commissioning report.

7.3 Running the self-diagnosis

1. Switch on the unit.

2. Start the "CombiDoctor" self-diagnosis program (see "Checking

the unit" in the Operating instructions).

If no errors are displayed, the unit is OK.

3. Switch off the unit.

4. Fill out the Commissioning report.

42 Installation instructions

10013865-0AIBE-B

Page 43

8 Putting the unit into service

If the unit is not put into service immediately after being

connected and the function check, all inspections must be

repeated.

Requirement Power connection made

Water connection established

Wastewater connection established

Exhaust connection made (if required by the customer)

Operation successfully checked

Housing closed

1. Instruct the operator.

2. Fill out the commissioning report.

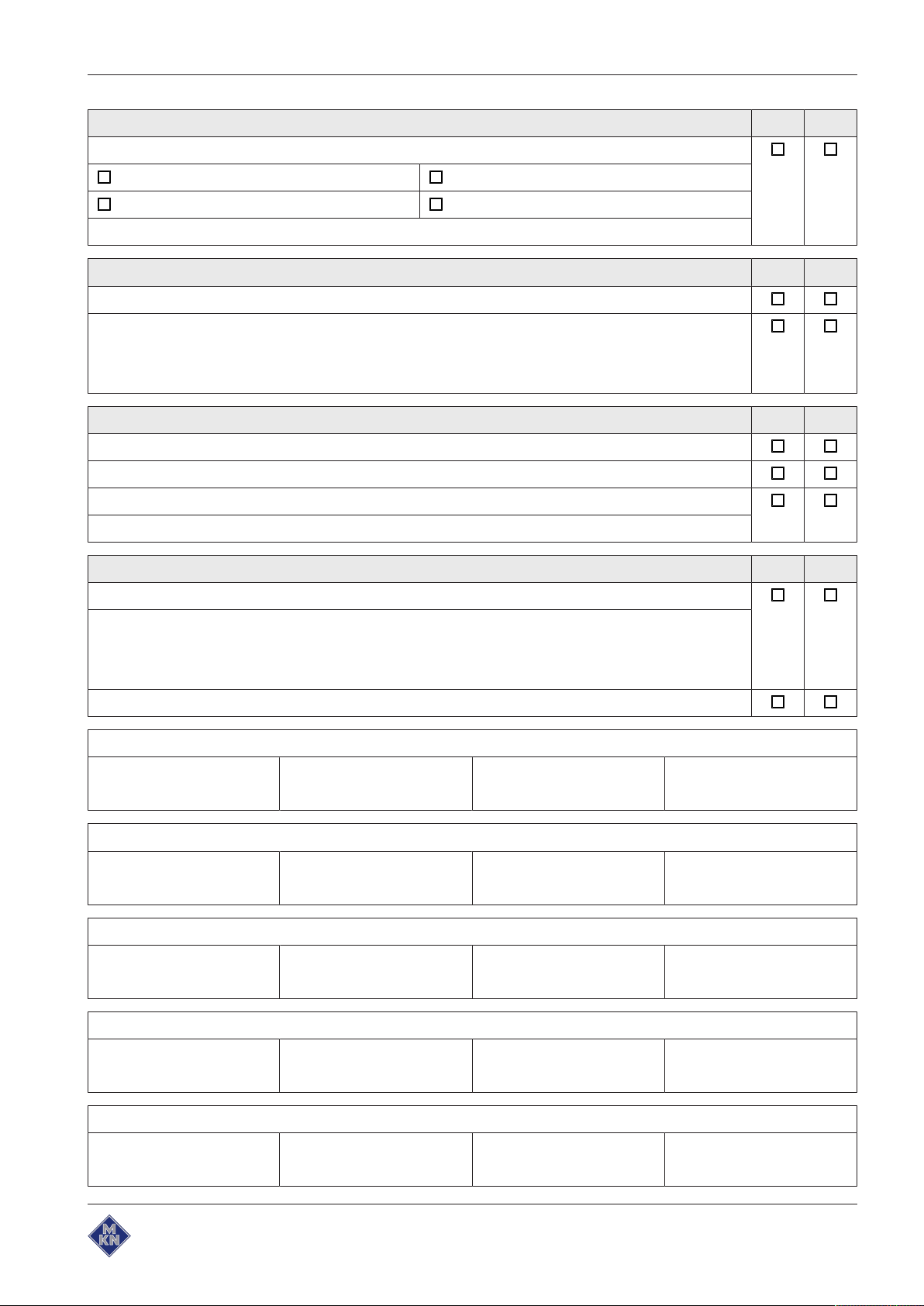

8.1 Filling out the Commissioning report

Putting the unit into service

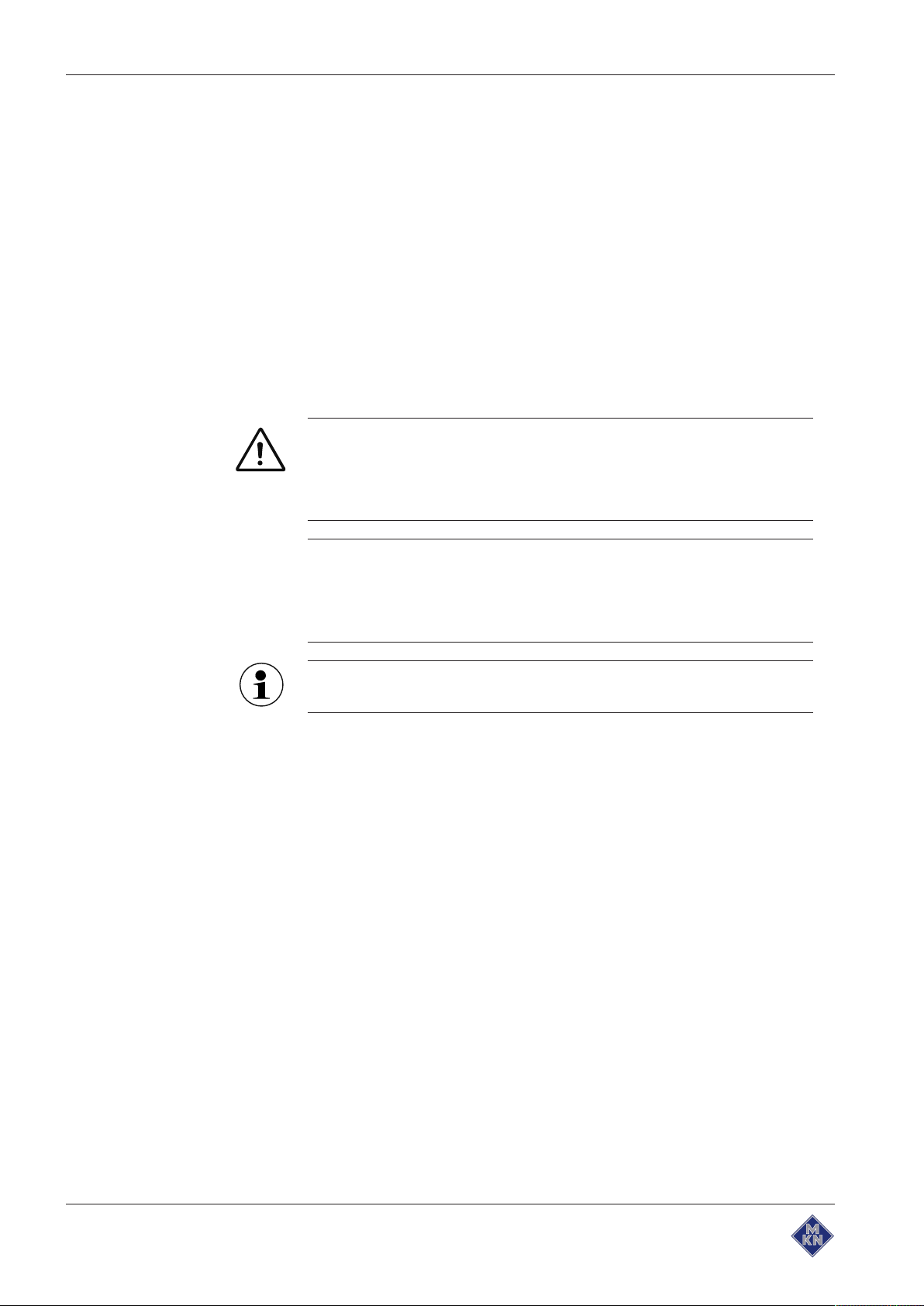

General Yes No

Information from the nameplate entered?

SN: _____________________________ Typ: _____________________________

E: ________________________________________________________________

Bez: ______________________________________________________________

Item-Nr.: _____________________________ (if listed)

Obvious damage to the unit?

What and where?:

______________________________________________________________________________

Unit levelled?

Electrical connection Yes No

Power connection made properly?

Equipotential bonding Power optimizing system

Floating contact …

Electrical connections made properly?

Residual-current protective device connected immediately before this unit?

Residual-current protective device connected before this and other units?

Connection voltage measured?

Connection voltage: _______________ (V)

Set transformer voltage

T0: 0 V | ______ V | ______ V; T1: blue 0 V | red ______ V; T2/T3: blue ______ V | red ______ V

Kitchen management system Yes No

Has the kitchen management system been connected properly?

10013865-0AIBE-B

43Installation instructions

Page 44

Putting the unit into service

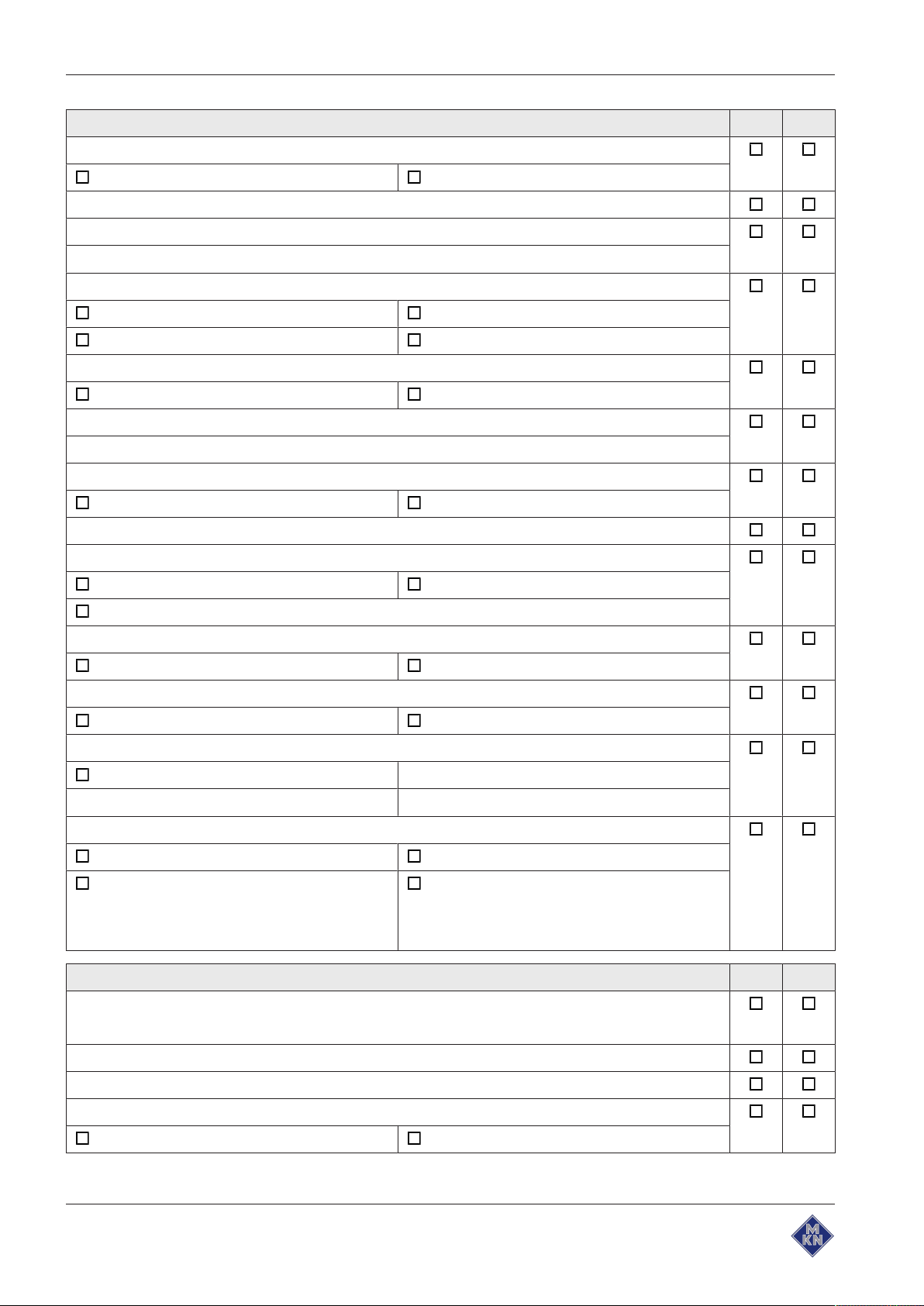

Basic control setting Yes No

Unit of temperature set?

°C °F

Have date and time been set?

Has software version been identified?

Version: __________

Altitude set?

0—999 m 1000 m—1999 m

2000 m—2499 m 2500 m or higher

80% power set?

100 % 80 %

Current voltage set?

Voltage: ________ V

Audible signal volume set?

quiet loud

Has signal tone been selected?

Volume unit set?

ml fl.oz. (Imperial)

fl.oz. (U.S.)

Power optimisation system set?

On Off

Water filter maintenance set?

No maintenance message Maintenance message at: _______________ l

Has network configuration been set?

DHCP IP address: ____________________________

Subnet mask: ____________________________ Gateway: ____________________________

Has kitchen management system been set?

Active Disabled

Ethernet

TCP port: __________

Unit address: __________

Water connection Yes No

Serial

Unit address: __________

Connection pressure within indicated range?

Connection pressure: _______________ ( _______________ ) kPa (bar)

Water connection made properly?

Lines and connections leak-tight?

Water connections connected with T-piece?

Connected only to softened tap water Connected only to tap water

44 Installation instructions

10013865-0AIBE-B

Page 45

Wastewater connection Yes No

Wastewater connection made properly?

Waste trap in the building Aerator

Funnel drain Floor gutter

Connection dimension of wastewater line: ____________________ mm

Exhaust air connection Yes No

Setting up below ventilation system?

Connected to exhaust air duct?

Connection dimension of exhaust air line: ____________________ mm

Length of exhaust air line: ________________________ mm

Function check Yes No

Controls are functioning?

Monitoring of the cooking zone door is functioning?

Self-diagnostic program run without faults?

Putting the unit into service

Fault: _______________________________________________________________________

Final notes Yes No

Was the unit put into service?

Comments:

Operator trained?

Electrical installation was provided by:

Company Installer City, date Signature

The connection to a kitchen management system was made by:

Company Installer Place, date Signature

Water installation was provided by:

Company Installer City, date Signature

Wastewater installation was provided by:

Company Installer City, date Signature

Exhaust air connection was provided by:

Company Installer City, date Signature

10013865-0AIBE-B

45Installation instructions

Page 46

Putting the unit into service

The function check was performed by:

Company Installer City, date Signature

Operator training was provided by:

Company Installer City, date Signature

46 Installation instructions

10013865-0AIBE-B

Page 47

Page 48

www.mkn.eu

Loading...

Loading...