M.K. Morse CSM7NXTB User Manual

248014

INSTRUCTIONS AND SAFETY MANUAL

MODEL: CSM7NXTB /100960

SERIAL # ______________________________________

(FOR YOUR FUTURE REFERENCE PLEASE WRITE IN SERIAL # LOCATED ON MACHINE LABEL)

7” (180mm) STEEL CUTTING CIRCULAR SAW

IMPORTANT! The Metal Devil saw you have purchased is a well–made tool. Used according to the directions it

will give you excellent service for a number of metal-cutting applications. Misuse of this tool, however, could result in

serious or fatal injury. Please read these operating and safety instructions carefully and completely. Read, understand

and follow all safety information. If you are uncertain about any aspect of using this equipment contact your distributor.

THE M. K. MORSE COMPANY | CANTON, OHIO U.S.A. | www.mkmorse.com | SAW MADE IN TAIWAN

IMPORTANT!

READ AND SAVE ALL INSTRUCTIONS FOR FUTURE USE!

The Metal Devil saw you have purchased is a well–made tool.

Used according to the directions it will give you excellent service for a number of

metal-cutting applications. Misuse of this tool, however, could result in serious or

fatal injury. Please read these operating and safety instructions carefully and

completely. Read, understand and follow all safety information. If you are uncertain

about any aspect of using this equipment contact your distributor.

Ear and eye protection must be worn

while operating this equipment.

MODEL CSM7NXTB /100960 SPECIFICATIONS:

MACHINE

Motor: 120V 60Hz 13 Amp Watts 1560

Cutting Capabilities: (Square Tubing) 90 degree cut :1/8” (3mm) wall thickness

Bevel Cut: 0-45˚

Max Cutting thickness: 1/4” (6mm) – mild steel plate

Maximum Cutting Depth: 2.36” (60mm)

RPM No Load Speed: 3800 RPM

Recommended Max.Duty Cyle: 30 minutes

Sound Pressure Level: Under Load DB(A) 88

Weight: 18 lbs / 8.2 kg’s

BLADE DIMENSIONS

Diameter: 7 ” (178mm) 7-1/4˝ (188mm)

Arbor / Bore Diameter: 20mm 20mm

Avergage Blade Kerf: .071“ (1.8mm)

STANDARD EQUIPMENT SUPPLIED WITH SAW

1- Side Handle

1- Fence Guide

1- Pair Safety Goggles

1- Ear Plug Set

1- Carry Case

1-6mm Hex Key

1- Operating Instructions

1- Metal Cutting Blade.

(For Hex Screws)

WARRANTY REPAIRS:

Contact your local Metal Devil Distributor for

assistance with obtaining warranty repairs.

1

NOTICE:

Normal wear and tear and damage caused by misuse

is not covered under the 1 year guarantee.

IMPORTANT SAFETY INFORMATION

READ AND SAVE ALL INSTRUCTIONS FOR FUTURE USE!

BEFORE BEGINNING WORK:

• Check that the voltage is correct and that all handles and

parts are rmly secured.

• This machine is designed for cutting steel. Operate it using

only the recommended M. K. Morse “Metal Devil” brand

TCT (tungsten carbide tipped) blades and accessories.

Do not use blades made of HSS or that do not comply with

the characteristics in these instructions.

• Ensure that the blade is the correct design for the material

being cut.

• Before using any accessories for the Metal Devil Metal

Cutting Machines, always ensure that the RPM of the

accessory matches the RPM of the tool.

• Inspect the machine and blades before each use.

Do not use deformed, cracked or damaged blades.

• Ensure that the blade is properly installed. The direction

arrow on the blade should match rotation of the arbor.

• Do not modify this saw.

• Do not use it for any job for which it was not intended.

Do not use it to power other equipment.

• This tool is equipped with an approved cord and plug for

its intended country of use. Do not try to use it in a country

where it will not be compatible. Never modify the plug.

• Ensure that total work area can be viewed from the

operating position. Make sure the work area is clutter-free.

• Use barriers to keep people away from the work area.

• Do not operate the tool in explosive environments.

Power tools create sparks that may ignite ammable

materials, dusts or gases.

• Do not operate in damp or wet conditions or areas –

electric sparks may occur. You could suffer serious injury,

or death from electrocution, burns or electrical shock.

• Do not wear loose clothing or jewelry when operating the

saw. Tie back long hair that might get into the blade.

• Always securely clamp the material to be cut.

• Never attempt to use this or any power tool while under

the inuence of alcohol or any drug that might aect your

perceptions or judgment.

• Be sure there are no children in the area where you will

operate this saw. Never allow children near a power saw.

Improper use of this saw can result

in serious injury or death. Do not

use without proper training. READ,

UNDERSTAND AND FOLLOW ALL

INSTRUCTIONS & WARNINGS IN

THIS MANUAL AND ON THE SAW.

Some dust created by power

sanding, sawing, grinding, drilling,

and other construction activities

contains chemicals known [to the

State of California] to cause cancer,

birth defects or other reproductive

harm. Some examples of these

chemicals are:

• Lead from lead-based paints.

• Crystaline silica from bricks and

cement and other masonry

products.

• Arsenic and chromium from

chemicall-treated lumber.

Your risk from these exposures

varies, depending on how often you

do this type of work. To reduce your

exposure to these chemical: work in

a well ventilated area, and work with

approved safety equipment, such as

those dust masks that are specially

designed to lter out microscopic

particles.

Ear and eye protection must be worn

while operating this equipment.

2

DO NOT OPERATE IN WET

OR DAMP CONDITIONS

MACHINE IS

DOUBLE INSULATED

RECYCLE MACHINE

PROPERLY

IMPORTANT SAFETY INFORMATION

READ AND SAVE ALL INSTRUCTIONS FOR FUTURE USE!

WHILE OPERATING THE SAW

• Always use the safety glasses and hearing protection provided, or their

equivalent, when using this saw. A ying chip could cause blindness.

Cutting noise could seriously impair hearing.

• Never use the tool without the original protection guard system. Ensure that

moveable guards operate freely without restrictions.

• Do not try to defeat any safety device. Do not lock the moving guard in the

open position.

• Ensure that the cutting depth adjustment handle/angle adjustment handle and

parallel blade guide are rmly xed while using the tool.

• Support the work piece properly. Never hold the work piece in your hand or put

it across your legs.

• Always use both hands to operate the saw. Keep hands out of path of blade.

• Never reach around, under or behind the saw blade when operating the

machine. The guard cannot protect your hand if you do so.

• Do not touch the blade while it is in motion. Do not try to stop the blade by

lateral pressure on the blade.

• Never reach for a saw blade until the blade has completely stopped rotation

and the machine has been disconnected from the power source.

• When cutting wood, use suitable dust extraction and breathing apparatus.

• Remove the plug from main power supply before replacing the blade,

making adjustments or performing other maintenance work.

• Always keep the power cord away from the moving parts of the tool.

• Do not operate in damp or wet conditions or areas – electric sparks may occur.

You could suffer serious injury, or death from electrocution, burns or electrical

shock.

• In case of saw jamming, immediately switch off the saw and disconnect the plug.

Remove the saw from the material and inspect the blade for damage.

• Use only the anges and washers that are supplied with the tool. Replace them

with original (OEM) replacement parts if they become damaged or scored.

• When storing the tool, switch off the motor, unplug the cord from the power

source and ensure that all moving parts have come to a complete stop.

3

MACHINE PREPARATION and OPERATION

READ AND SAVE ALL INSTRUCTIONS FOR FUTURE USE!

BLADE REMOVAL AND INSTALLATION

1 Unplug machine from power source before doing any

servicing or blade replacement.

2 Remove the chip collection unit. (Instructions Page 7)

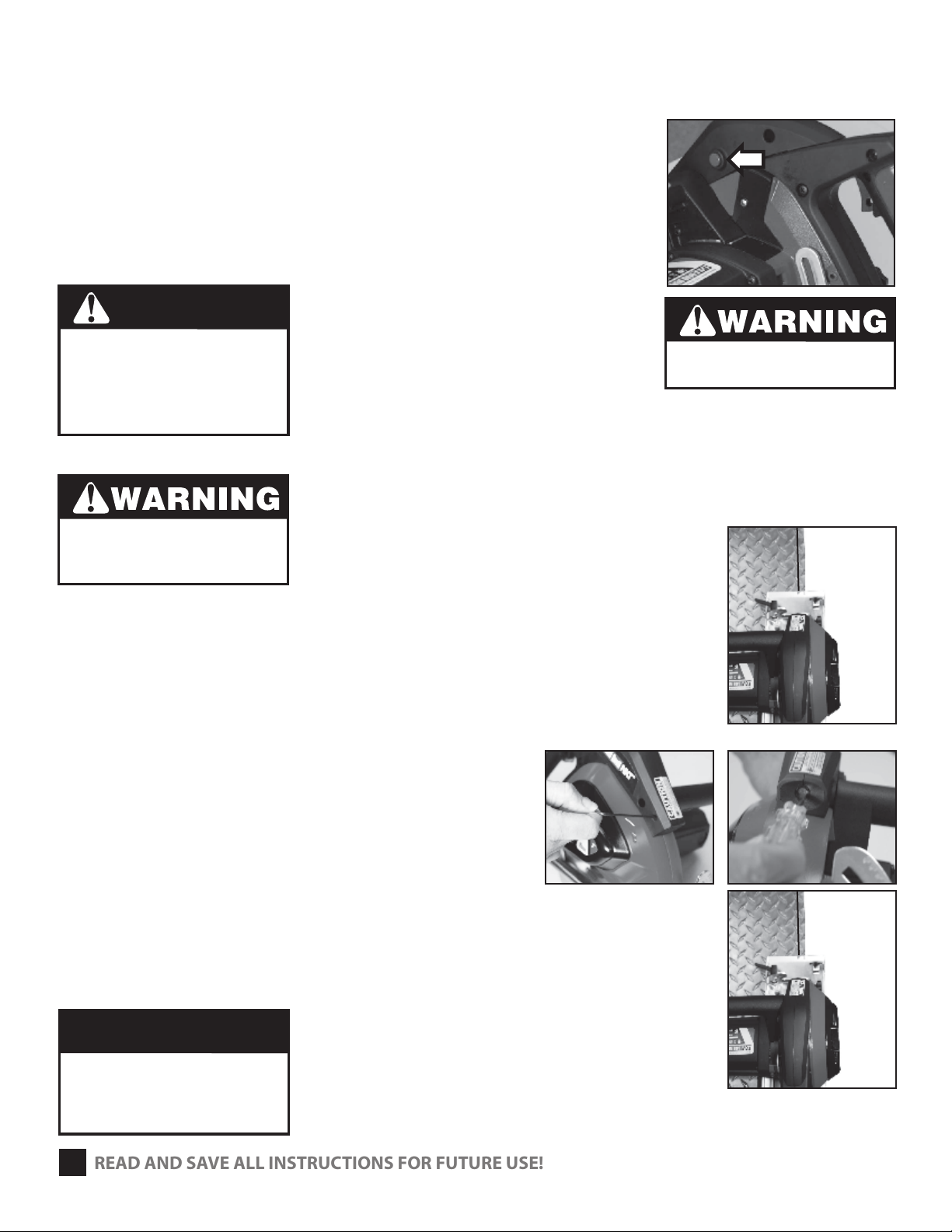

3 Depress spindle lock to stop blade/spindle rotation. (Fig. 1)

4 Use the supplied 6mm hex key to remove the bolt / washer

and ange holding the blade. (Fig. 2 & 3)

5 Rotate the blade guard away from the blade.

Remove used blade. (Fig. 4)

6 Replace with new Morse Metal Devil Blade.

7 Replace ange / washer and bolt.

8 Depress spindle lock and securely tighten the bolt.

9 Make sure that the arrow on the blade and the teeth are

rotating counterclockwise.

10 Release spindle lock. Check to be sure that it has fully

released by manually rotating the blade.

11 Replace chip collection unit and securely latch.

(FIG. 1)

(FIG. 2)

12 Replace hex key to holder.

MAKING A CUT

Where possible, always clamp the work piece on a rigid

1

support.

2 Before starting the saw motor:

• Place front edge squarely on the work piece.

• Ensure that the blade is not touching the material to be cut.

• Sight the cutting line with the line of the cut guide.

3 Allow the machine to come to full start.

4 Introduce the blade slowly so as not to damage the teeth

of the blade. DO NOT FORCE THE TOOL. Allow the speed of the

saw blade to do the work.

5 Using both hands, move the saw forward through the work

piece. Applying more pressure on the tool will not improve

cutting performance, but will reduce blade life.

SIGHT LINE NOTCH

1 Use the sight-line notch at front of base plate as guide. (FIg. 5)

The notch represents the kerf of the cut.

(FIG. 3)

(FIG. 4)

2 Align your cut line to the left or the right center of the sight line notch. (Depending on the nal length of the cut piece

required)

4

(FIG. 5)

MACHINE PREPARATION and OPERATION (Cont.)

READ AND SAVE ALL INSTRUCTIONS FOR FUTURE USE!

LASER SIGHT GUIDE SYSTEM

1 The laser sight system is intended as a guide only

and should not be used for accuracy of the cut.

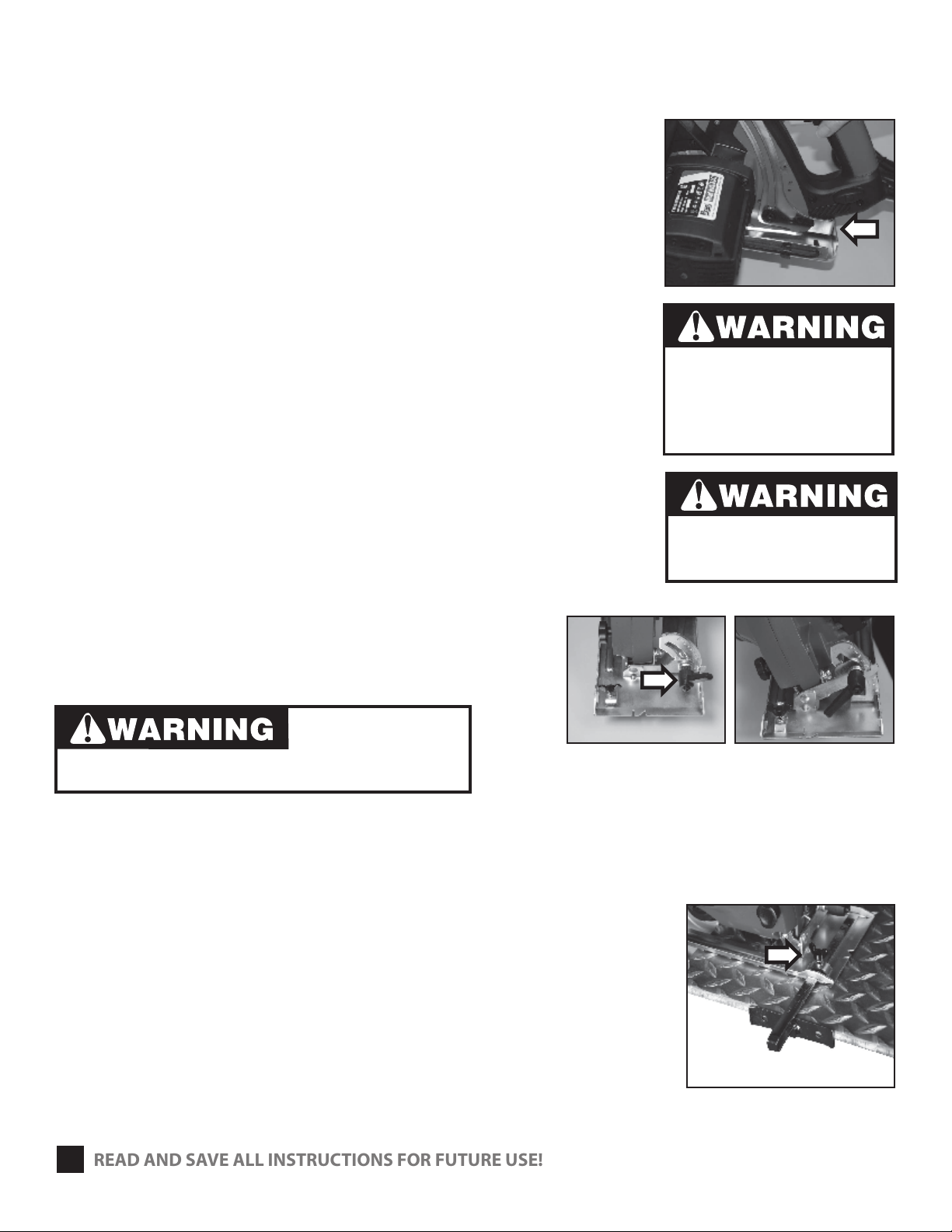

2 Depress Laser power switch (Fig. 6)

3 Laser Beam follows the angle of the base plate.

4 Alight laser beam with your cut line.

5 After completing the cut depress the laser power

switch to disconnect power to laser.

DANGER

LASER RADIATION

Avoid direct eye contact

with light source.

Do not point laser at anyone.

Never look into the laser light.

ALIGNMENT TIPS FOR LASER SIGHT GUIDE

Do not turn on saw

for this adjustment!

Serious injury could result.

(FIG. 6)

Turning the laser o does not turn

power o to the saw.

(FIG. 7)

1 Find a square, at work piece of either steel or plywood

and place the work piece on a table. (Fig. 7)

2 Push the blade guard up and away from the blade.

3 Place the saw on the top of the work piece.

The blade should touch the edge of the work piece. (Fig. 7)

ADJUSTING FOR PARALLEL

Depress power laser power switch. If the laser line does not

line up with the edge of work piece then:

a. For small adjustments use a M2 hex key and loosen

or tighten the screw adjustment. (Fig. 8) to bring

the beam back to parallel.

b. For larger adjustments use a small at head screw

driver to the slot in the front of the light (Fig. 9)

to realign the beam. Then use the M2 hex key and

loosen or tighten the screw in order to do the nal

positioning. (Fig. 10)

c. The laser light and the 2 sight line markings, on the

base plate should now be in the same plane.

CAUTION

(FIG. 8)

(FIG. 9)

(FIG. 10)

Do not overturn the adjustment

screw on the front of the light.

You could damage threads or the

plastic housing for the laser.

5

READ AND SAVE ALL INSTRUCTIONS FOR FUTURE USE!

MACHINE PREPARATION and OPERATION (Cont.)

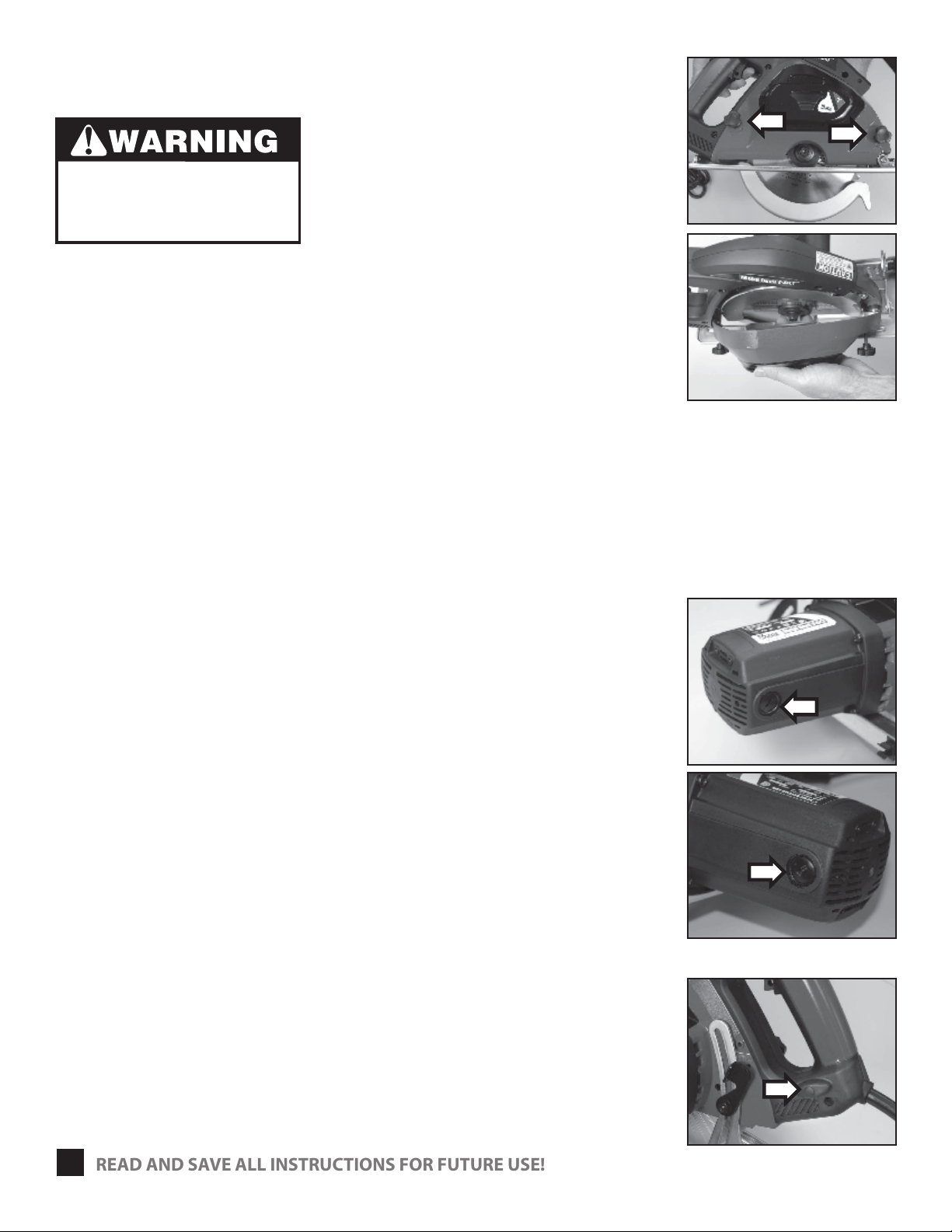

ADJUSTMENT OF THE CUTTING DEPTH

With power to the saw turned “OFF”:

1 Release the lock to adjust to the required cutting depth.

(Fig. 11)

2 Make sure that the blade protrudes at the maximum

cutting depth that the saw is capable of in the material

being cut.

3 Tighten to lock into position. Check to ensure that the

lock will not loosen while being used.

NOTE: Metal cutting blades work best while having the maximum

amount of blade engaged in the cutting action. This distributes the

cutting load among the teeth on the blade. This is the opposite of

how a wood cutting blade is used, where minimal blade protrusion

allows the operator to make a cut while minimizing the potential for

the blade to become bound in the cut and produce material tearout.

EXCEPTION: Metal grating is best cut by having the blade protrude

very minimally beyond the depth of the grating. The interrupted cuts

that occur when cutting grating are very hard on the blade and

carbide tips.

BEVEL CUTTING ADJUSTMENTS

(g…)

(FIG. 11)

Adjusting a saw with the power

connected could lead to an injury

if the saw started suddenly.

Never connect the saw to a power

source until all adjustment steps

are completed.

Do not use machine for

plunge cutting.

Serious injury could occur.

1 Loosen bevel handle (Fig. 12)

2 Adjust to the required cutting angle by lining up the bar

on the bevel handle with the degree needed on the scale.

3 Tighten bevel handle.

For certain compound cuts it

may be necessary to manually

retract the guard to allow the

blade to enter into and / or through the cut. Be extremely careful when

PARALLEL BLADE GUIDE

making these cuts,as the guard will not protect you from injury.

PARALLEL BLADE GUIDE

To set the guide:

1 Loosen the retaining screw. (Fig 13)

2 Slide the guide up snugly against the side of the work piece.

3 Using a measuring tape, check that the distances from the

front and the back of the blade to the edge of the blade

guide are equal. This will ensure that the guide is parallel

to the blade. The guide should be parallel to the blade,

and not to the base of the tool, to avoid damage to both

blade and motor.

4 Retighten the screw.

(FIG. 12)

(FIG. 3)

6

MACHINE PREPARATION and OPERATION (Cont.)

READ AND SAVE ALL INSTRUCTIONS FOR FUTURE USE!

CHIP COLLECTION AND REMOVAL CHAMBER

Metal chips may be very hot and sharp.

Wear eye protection whenever you open

the collection chamber.

Never touch metal refuse with bare hands.

Removal:

1 Loosen the two knob bolts holding the collection unit

to the saw (Fig. 14)

a. The chips accumulating can be seen in the

collection chamber window.

b. Chips should always be emptied when chamber is

approximately half full.

2 Tilt saw so collection unit is face down.

3 Pull collection unit away from saw. (Fig. 15)

4 Gently shake chips out of chamber into proper disposal bin.

NOTE: The knob bolts remain fastened to the collection chamber.

Re-Attaching:

(FIG. 14)

(FIG. 15)

1 Place the saw upright

2 Place collection unit on to saw and tighten knob bolts.

MAINTENANCE and TROUBLESHOOTING

• In case of electrical or mechanical malfunction,

immediately turn o the machine and disconnect the

plug. Ensure that the saw is unplugged and the blade

has stopped rotating before doing any maintenance.

• Keep your Metal Devil Circular Saw and cord clean.

Use only a damp cloth and very mild soap to clean the

saw.

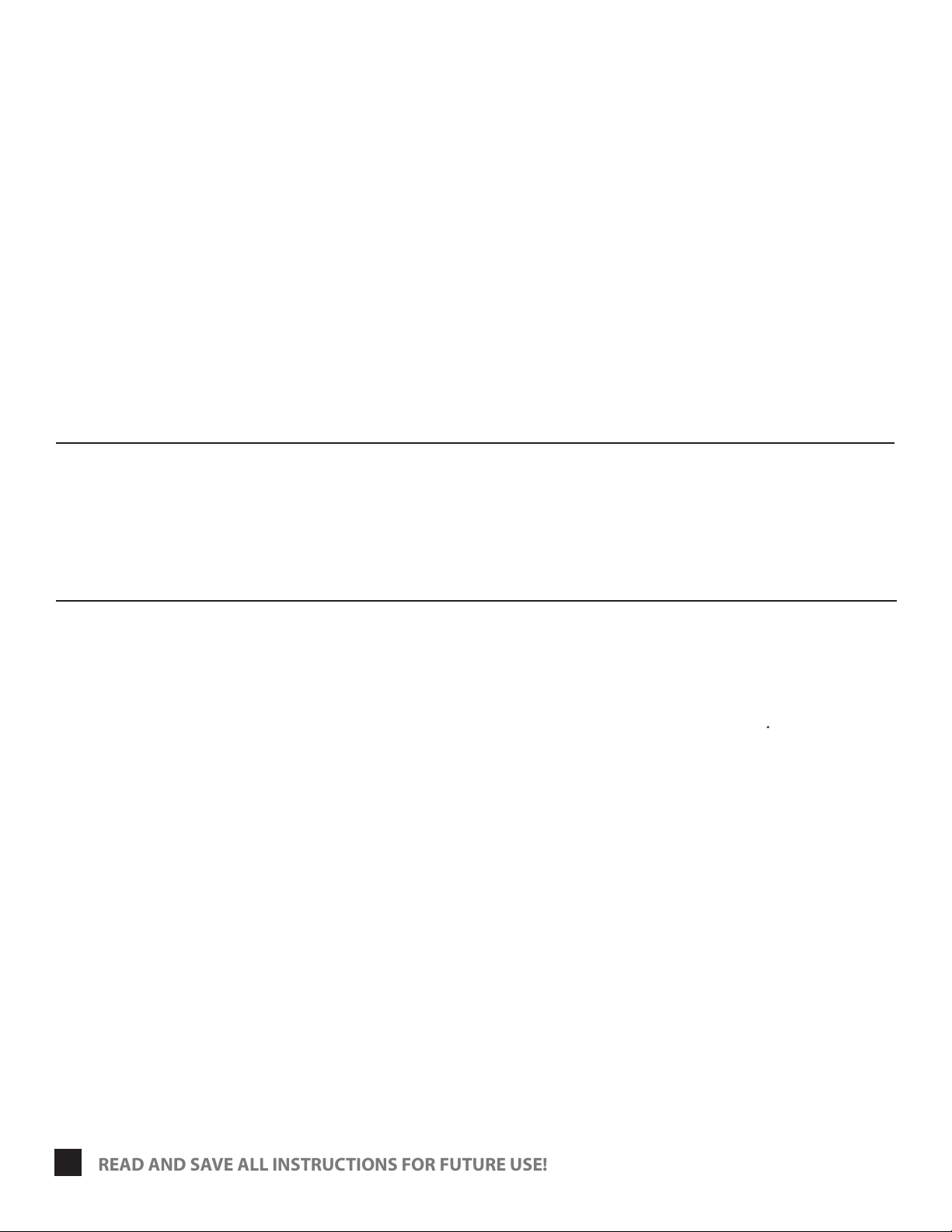

• Excessive sparking can indicate the presence of dirt in

the motor or worn carbon brushes. Check for wear.

(Fig. 16A & 16B) Replace brushes when they reach 1/4”

(6mm).

• For all other service and maintenance take machine to

an authorized service center.

MACHINE LUBRICATION

This machine is lubricated during its manufacturing with

sucient lubricant to last approximately 72 hours of operation.

To add lubricant, it is necessary to dismantle the tool. This

procedure is best accomplished by an authorized service center.

(FIG. 16A)

(FIG. 16B)

(FIG. 17)

TOOL OVERLOAD / RESET

If the tool overload protection device activates, allow the motor

to cool, (approximately 3 minutes) then press the reset button to

continue operation. (Fig. 17)

7

READ AND SAVE ALL INSTRUCTIONS FOR FUTURE USE!

TROUBLESHOOTING

SYMPTOM POSSIBLE CAUSE CORRECTIVE ACTION

Saw will not start No supply of power Check that saw is plugged in

And that there is power to source.

Brushes are worn or sticking Disconnect power, open brush caps

and ensure brushes move freely in

the holders. Check whether brushes

require replacing.

(Cont.)

Cord Damage Contact Repair Center

Motor Components Open Contact Repair Center

Or short circuited.

Overload Switch is Activated Push switch to reset

Saw produces Dull, damaged blade or Replace the blade

poor cuts incorrect blade for the

application.

Motor is overloaded Reduce the amount of force being used

to push the blade through the cut..

Saw produces an Mechanical obstruction Contact repair center.

unusual sound

Armature has shorted out Contact repair center.

Blade is out of balance Replace blade.

Excessive sparking occurs Brushes are not moving Disconnect power, remove brushes,

Inside motor housing freely Clean or replace.

Switch is faulty Contact Repair Center

Armature short circuited, Contact repair center.

open circuitt, or commutator

is dirty

8

Loading...

Loading...