Page 1

MK-1080 BLADE ALIGNMENT PROCEDURE

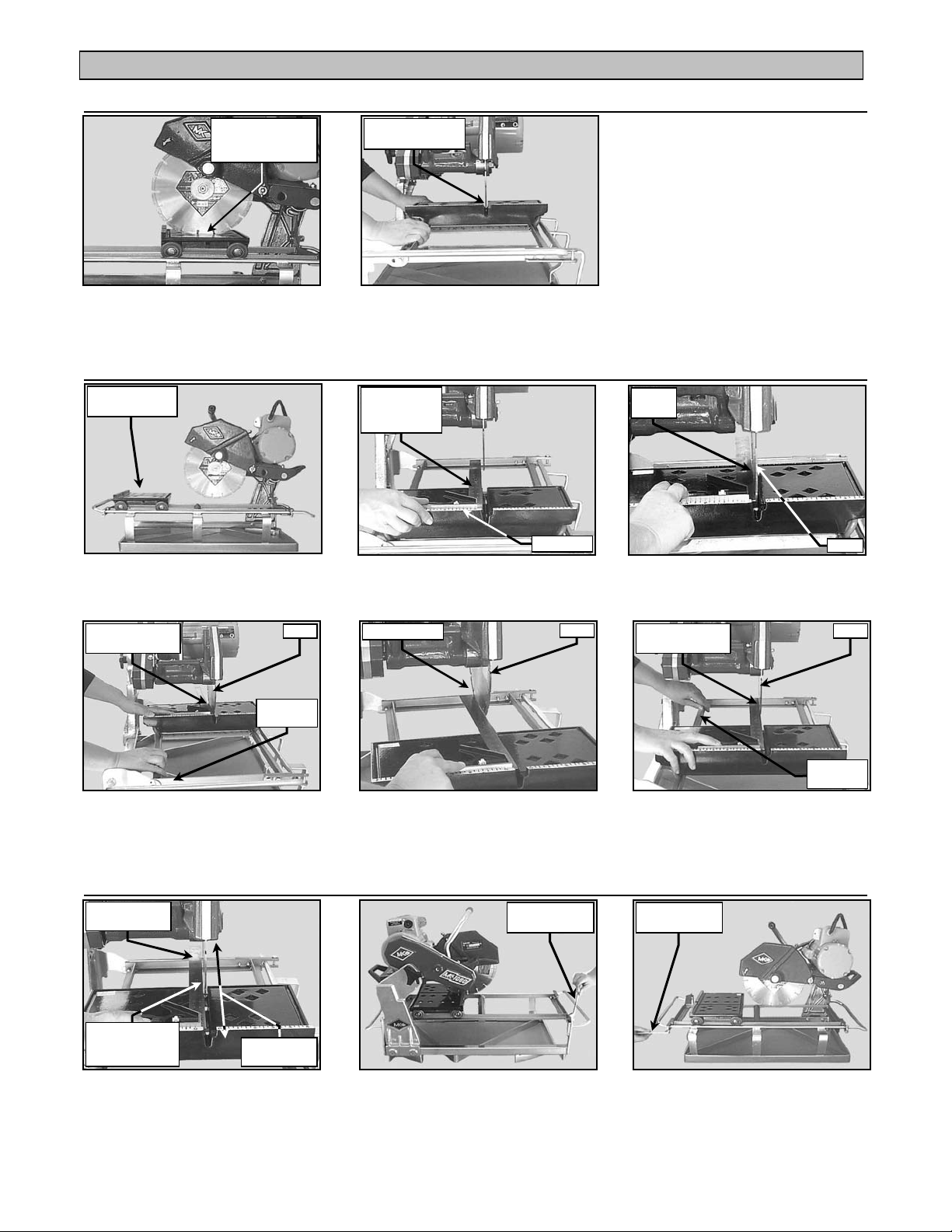

Disconnect Saw

Remove Pan

Blade

The Movable Cutting Table of the MK-1080 may become misaligned with the Cutting Head of the Tile Saw over

time. Should misalignment occur, perform the following steps to realign the Tile Saw.

NOTE: If alignment problems are the result of a warped blade, a bent frame or bent support arm, or, if alignment

is off by more than 1/8-inch, contact the MK Diamond Service Center – (800) 474-5594

Tools Needed:

Combination Square (Square)

12-inch or Greater

1/4-inch Wrench

or

MK Dual Hole Box Wrench

Preparation:

Inspect Cutting HeadInspect Frame

Inspect Cutting Table

Inspect

(A)

Remove Tile Saw

from Power Source

Remove Water Pan

Turn Counter-

clockwise

to Loosen

(B)

(C)

Inspect Tile Saw

for damage

Turn Counter-

clockwise

to Loosen

(D)

Inspect Diamond Blade

for damage

(E)

Loosen front and rear

Adjustable Frame

Retaining Clamp Bolts

(F)

Loosen front and rear

Adjustable Frame

Adjusting Bolts

Page 2

MK-1080 BLADE ALIGNMENT PROCEDURE

Blade

Flush with Blade

Blade

Table

Frame

Blade

Flush with Blade

Frame

Blade

Blade

Rough Alignment:

Adjust Cutting

Head to Cut Depth

of Approx _”

Center Blade

In Cutting Groove

(A)

Position Cutting Head

to normal Cut Depth

Move Adjustable Frame

until Blade is centered in

(B)

Cutting Groove

Final Alignment:

Position Cutting

Table to Front

(A)

Pull Movable Cutting Table

to front of Tile Saw

Front of Square

Adjustable

Place Square

Against

Ruler/Stop

Ruler/Stop

(B)

Position Square flat on Movable

Cutting Table against Ruler/Stop

End of Square

Front of

Square

(C)

Position front of Square

against Blade

End of Square

Adjustable

(D)

Move Adjustable Frame until

Square rests evenly across Blade

(E)

Position end of Square

against Blade

Move Adjustable Frame until

Square rests evenly

(F)

across Blade

Verification:

Set Square Off

Verify Gap Even

Along Length

of Square

Move Cutting

(A)

Move the Cutting Table back and

forth to verify Blade is even

across all points of Square

Turn Clockwise

to Tighten

(B)

Tighten front and rear

Adjustable Frame

Adjusting Bolts

Turn Clockwise

to Tighten

(B)

Tighten front and rear

Adjustable Frame

Retaining Clamp Bolts

Page 3

MK-1080 BLADE ALIGNMENT PROCEDURE

Blade

Table

Set Square Off

Verify Gap Even

Along Length

of Square

(D)

Move the Cutting Table back and

forth to re-verify Blade is even

across all points of Square

Move Cutting

Loading...

Loading...