Page 1

DNA Engine Opticon® System

For Continuous Fluorescence Detection

PTC-200 DNA Engine® Cycler

™

CFD-3200 Opticon

Operations Manual

Supports Software Version 1.08

Detector

06678 revC.A

Page 2

Page 3

DNA Engine Opticon® System

For Continuous Fluorescence Detection

PTC-200 DNA Engine® Cycler

CFD-3200 Opticon

™

Detector

Operations Manual

Supports Software Version 1.08

Page 4

ii Tech Support: (888) 652-9253 • Sales: (888) 735-8437 • tech@mjr.com • www.mjr.com

Copyright ©2004, Bio-Rad Laboratories, Incorporated. All rights reserved. Reproduction in any form, either print or

electronic, is prohibited without written permission of Bio-Rad Laboratories, Inc.

Chill-out, DNA Engine, DNA Engine Opticon, Hard-Shell, Microseal, MiniCycler, MJ Research and the helix logo,

Multiplate, Opticon, Opticon Monitor and PTC-100 are trademarks belonging to Bio-Rad Laboratories, Inc.

Amplifluor is a trademark of Intergen Company. DyNAzyme is a trademark of Finnzymes Oy. Scorpions is a trademark of DXS Ltd. SYBR is a trademark of Molecular Probes, Inc. TaqMan is a trademark of Roche Molecular Systems,

Inc. Windows is a trademark of Microsoft Corporation.

Practice of the patented polymerase chain reaction (PCR) process requires a license. The DNA Engine Opticon system

includes an Authorized Thermal Cycler and may be used with PCR licenses available from Applied Biosystems. Its use

with Authorized Reagents also provides a limited PCR license in accordance with the label rights accompanying such

reagents .Some applications may also require licenses from other third parties.

This instrument includes an Authorized Thermal Cycler, Serial No __________________. Its purchase price includes the

up-front fee component of a license under United States Patent Nos. 4,683,195, 4,683,202 and 4,965,188, owned by

Roche Molecular Systems, Inc., and under corresponding claims in patents outside the United States, owned by F.

Hoffmann-LaRoche Ltd, covering the Polymerase Chain Reaction ("PCR") process, to practice the PCR process for internal

research and development using this instrument. The running royalty component of that license may be purchased from

Applied Biosystems or obtained by purchasing Authorized Reagents. This instrument is also an Authorized Thermal

Cycler for use with applications licenses available from Applied Biosystems. Its use with Authorized Reagents also

provides a limited PCR license in accordance with the label rights accompanying such reagents. Purchase of this

product does not itself convey to the purchaser a complete license or right to perform the PCR process. Further

information on purchasing licenses to practice the PCR process may be obtained by contacting the Director of Licensing, Applied Biosystems, 850 Lincoln Centre Drive, Foster City, California, 94404, USA.

No rights are conveyed expressly, by implication or estoppel to any patents on real-time PCR.

Applied Biosystems does not guarantee the performance of this instrument.

06678 revCA

Page 5

Tech Support: (888) 652-9253 • Sales: (888) 735-8437 • tech@mjr.com • www.mjr.com iii

Table of Contents

Explanation of Symbols .......................................................................................... iv

Safety Warnings .................................................................................................... iv

Safe Use Guidelines................................................................................................. v

Electromagnetic Interference .................................................................................... v

FCC Warning .......................................................................................................... v

1. Introduction ..................................................................................................... 1-1

2. Layout and Specifications ................................................................................. 2-1

3. Installation and Operation ................................................................................ 3-1

4. Compatible Chemistries, Sample Vessels, and Sealing Options ........................... 4-1

5. Introduction to Opticon Monitor™ Software ...................................................... 5-1

6. Experimental Setup and Programming .............................................................. 6-1

7. Run Initiation and Status ................................................................................... 7-1

8. Data Analysis................................................................................................... 8-1

9. Maintenance ....................................................................................................9-1

10. Troubleshooting ............................................................................................ 10-1

Appendix A .........................................................................................................A-1

Appendix B .......................................................................................................... B-1

Appendix C.......................................................................................................... C-1

Appendix D ......................................................................................................... D-1

Appendix E .......................................................................................................... E-1

Index ..................................................................................................................In-1

Declarations of Conformity ...............................................................................

DoC

-1

Page 6

iv Tech Support: (888) 652-9253 • Sales: (888) 735-8437 • tech@mjr.com • www.mjr.com

Explanation of Symbols

CAUTION: Risk of Danger! Wherever this symbol appears, always consult note

in this manual for further information before proceeding. This symbol identifies components that pose a risk of personal injury or damage to the instrument if improperly

handled.

CAUTION: Risk of Electrical Shock! This symbol identifies components that pose

a risk of electrical shock if improperly handled.

CAUTION: Hot Surface! This symbol identifies components that pose a risk of personal injury due to excessive heat if improperly handled.

Safety Warnings

Warning:Warning:

Warning:Warning:

Warning: Operating the DNA Engine Opticon system before reading this manual can

constitute a personal injury hazard. Only qualified laboratory personnel trained

in the safe use of electrical equipment should operate this instrument.

Warning:Warning:

Warning:Warning:

Warning: Do not open or attempt to repair the Opticon tower or base. Doing so will

void your warranties and can put you at risk for electrical shock. Return the

DNA Engine Opticon system to the factory (US customers) or an authorized

distributor (all other customers) if repairs are needed.

Warning:Warning:

Warning:Warning:

Warning: The sample block can become hot enough during the course of normal opera-

tion to cause burns or cause liquids to boil explosively. Wear safety goggles

or other eye protection at all times during operation.

Warning:Warning:

Warning:Warning:

Warning: The DNA Engine Opticon system incorporates neutral fusing, which means that

live power may still be available inside the machines even when a fuse has

blown or been removed. Never open the Opticon base; you could receive a

serious electrical shock. Opening the base will also void your warranties.

Page 7

Tech Support: (888) 652-9253 • Sales: (888) 735-8437 • tech@mjr.com • www.mjr.com v

Safe Use Guidelines

The DNA Engine Opticon system is designed to operate safely under the following conditions:

• Indoor use

• Altitude up to 2000m

• Ambient temperature 15˚–25˚C

• Maximum relative humidity 80%, noncondensing

• Transient overvoltage per Installation Category II, IEC 664

• Pollution degree 2, in accordance with IEC 664

Electromagnetic Interference

This device complies with Part 15 of the FCC Rules. Operation is subject to the following

two conditions: (1) this device may not cause harmful interference, and (2) this device

must accept any interference received, including interference that may cause undesired

operation.

This device has been tested and found to comply with the EMC standards for emissions

and susceptibility established by the European Union at time of manufacture.

This digital apparatus does not exceed the Class A limits for radio noise emissions from

digital apparatus set out in the Radio Interference Regulations of the Canadian Department of Communications.

LE PRESENT APPAREIL NUMERIQUE N'EMET PAS DE BRUITS RADIOELECTRIQUES

DEPASSANT LES LIMITES APPLICABLES AUX APPAREILS NUMERIQUES DE CLASS A

PRESCRITES DANS LE REGLEMENT SUR LE BROUILLAGE RADIOELECTRIQUE EDICTE PAR

LE MINISTERE DES COMMUNICATIONS DU CANADA.

FCC Warning

Warning: Changes or modifications to this unit not expressly approved by the party

responsible for compliance could void the user’s authority to operate the equipment.

Note: This equipment has been tested and found to comply with the limits for a Class A

digital device, pursuant to Part 15 of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference when the equipment is operated in a

commercial environment. This equipment generates, uses, and can radiate radiofrequency

energy and, if not installed and used in accordance with the instruction manual, may

cause harmful interference to radio communications. Operation of this equipment in a

residential area is likely to cause harmful interference in which case the user will be required to correct the interference at his own expense.

Page 8

Page 9

1-1

1. Introduction

Meet the DNA Engine Opticon System, 1-2

Using This Manual, 1-2

Important Safety Information, 1-3

Page 10

1-2 Tech Support: (888) 652-9253 • Sales: (888) 735-8437 • tech@mjr.com • www.mjr.com

Opticon System Operations Manual

Meet the DNA Engine Opticon® System

Thank you for purchasing a DNA Engine Opticon continuous fluorescence detection system from MJ Research, Incorporated. Designed by a team of molecular biologists and

engineers, the Opticon™ system will meet your needs for a sensitive, easy-to-use, and compact continuous fluorescence detection system. Some of the DNA Engine Opticon system’s

many features include:

• A DNA Engine

®

Peltier thermal cycler delivers superior thermal accuracy and well-to-

well thermal uniformity.

• A 96-well sample block accepts standard consumables (96-well, low-profile microplates and low-profile 0.2ml strip tubes).

• An integrated heated lid permits oil-free cycling.

• Long-lived LEDs excite fluorescent dyes in the 450-495nm range.

• Sensitive optics detect fluorophores with emission spectra in the 515-545nm range

(SYBR Green, FAM).

• Intuitive Opticon Monitor

™

software facilitates experimental setup, run initiation, run

status, and data analysis.

• Dual modes of temperature control include calculated control for maximum speed

and accuracy, or block control for adapting protocols optimized in other cyclers.

• Compact footprint measuring 47cm deep x 34cm wide x 60cm high, allows the

Opticon unit to fit comfortably on any lab bench.

• The Opticon detector is available separately as an upgrade for existing DNA Engine

thermal cyclers.

Using This Manual

This manual contains instructions for operating your DNA Engine Opticon system safely

and productively:

• Chapter 2 acquaints you with the physical characteristics of the Opticon system.

• Chapter 3 presents the basics of installing and operating the Opticon system.

• Chapter 4 discusses the chemistry and sample vessel compatibilities of the

Opticon system.

• Chapters 5-8 step you through the use of the Opticon Monitor software includ-

ing how to enter and run protocols, and analyze collected data.

• Chapter 9 explains the proper maintenance of the Opticon system.

• Chapter 10 offers troubleshooting information for the Opticon system.

Page 11

Tech Support: (888) 652-9253 • Sales: (888) 735-8437 • tech@mjr.com • www.mjr.com 1-3

Introduction

Important Safety Information

Safe operation of the DNA Engine Opticon system begins with a complete understanding of how the instrument works. Please read this entire manual before attempting to operate the DNA Engine Opticon system. Do not allow anyone who has not read this manual

to operate the instrument.

Warning: The DNA Engine Opticon system can generate enough heat to inflict

serious burns and could deliver strong electrical shocks if not used according to the instructions in this manual. Please read the safety warnings

and guidelines at the beginning of this manual on pages iv and v, and

exercise all precautions outlined in them.

Page 12

Page 13

2-1

2. Layout and Specifications

Front View, 2-2

Back View, 2-2

Specifications, 2-3

Gradient Specifications, 2-4

Computer Specifications, 2-4

Page 14

2-2 Tech Support: (888) 652-9253 • Sales: (888) 735-8437 • tech@mjr.com • www.mjr.com

Opticon System Operations Manual

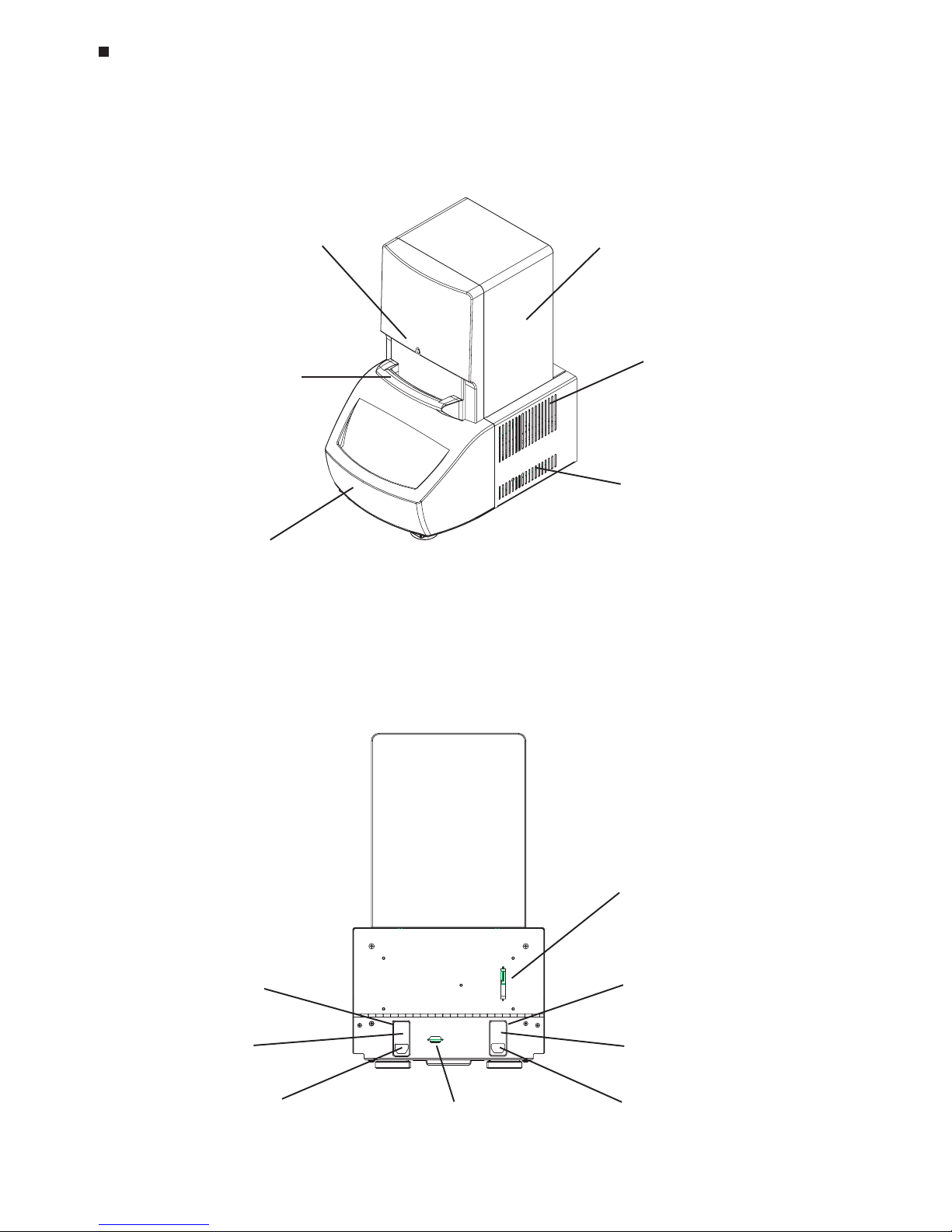

Back View

(Figure 2-2)

Front View

(Figure 2-1)

Power cord jack

(some models)

Power switch

(fuses, some

models)

DAQ (data acquisition)

cable port

Serial cable port

Power module,

left configuration

(standard)

Power cord jack

Power switch

(fuses)

Power module,

right configuration

(some models)

Optical tower

Cycler drawer

Air exhaust vents

(also on other side)

Air intake vents

(also on other side)

Blue protocolindicator light

Blue trigger handle

(door mechanism)

Page 15

Tech Support: (888) 652-9253 • Sales: (888) 735-8437 • tech@mjr.com • www.mjr.com 2-3

Layout and Specifications

Specifications

Thermal range: 0˚ to 105˚C, but not more than 30˚C

below ambient temperature

Accuracy: ±0.3˚C of programmed target @ 90˚C,

NIST-traceable

Thermal homogeneity: ±0.4˚C well-to-well within 30 seconds of

arrival at 90˚C

Ramping speed: Up to 3.0˚C/sec

Sample capacity: 96-well microplate (low-profile) or

96 x 0.2ml strip tubes (low-profile)

Line voltage: 100-240VAC

Frequency: 50-60Hz

Power: 850W maximum

Fuses: Two 6.3A, 250V Type S505, fast acting

(user changeable)

Two 8.0A, 250V Type S505, fast acting

(inaccessible)

Weight: 27kg (excluding computer and

monitor)

Size: 47cm deep x 34cm wide x 60cm high

(excluding computer and monitor)

Fluorescence Excitation Range: 450-495nm

Fluorescence Detection Range: 515-545nm

Page 16

2-4 Tech Support: (888) 652-9253 • Sales: (888) 735-8437 • tech@mjr.com • www.mjr.com

Opticon System Operations Manual

Gradient Specifications

Accuracy: +0.3°C of target at end columns within

30 seconds (NIST-traceable)

Column uniformity:

+0.4°C, in column, well–to–well, within

30 seconds of target attainment

Calculator accuracy:

+0.4°C of actual column temperature

(NIST-traceable)

Lowest programmable 30°C

temperature:

Highest programmable 105°C

temperature:

Gradient range: from 1°C up to 24°C

(temperature differential)

Computer Specifications

(minimum specifications for the computer provided with the Opticon system)

Processor: 2.4GHz processor

Operating System: Windows XP Pro

Display: 15 inch flat-screen monitor

Memory: 256 MB RAM

Storage: 40GB hard drive

Data Acquisition Board: National Instruments PCI-6036E

200kS/s (samples per second)

Page 17

3-1

3. Installation and Operation

Unpacking the Opticon Unit, 3-2

Packing Checklist, 3-2

Setting Up the DNA Engine Opticon System, 3-3

Environmental Requirements, 3-3

Power Supply Requirements, 3-4

Air Supply Requirements, 3-4

Ensuring an Adequate Air Supply, 3-4

Ensuring That Air Is Cool Enough, 3-4

Troubleshooting Air Supply Problems, 3-5

Turning the Opticon Unit and Computer On and Off, 3-5

Opening and Closing the Cycler Drawer, 3-6

Loading Sample Vessels into the Block, 3-6

Page 18

3-2 Tech Support: (888) 652-9253 • Sales: (888) 735-8437 • tech@mjr.com • www.mjr.com

Opticon System Operations Manual

Unpacking the Opticon™ Unit

Please follow these instructions for unpacking the Opticon unit to reduce the risk of personal injury or damage to the instrument.

Important: DO NOT lift the instrument out through the top of the box.

Important: DO NOT use the blue handle to lift the instrument at any time.

• Cut the band securing the cardboard cover to the support base.

• Open the top of the cardboard cover.

• Remove the top foam insert.

• Remove the accessory box (contents listed below).

• Lift the cardboard cover up and off of the instrument.

• Firmly grasp the sides of the instrument from beneath to support the weight of the

cycler and the optical tower. Carefully lift the instrument off of the shipping support. Do not lift the instrument by the blue handle or the cycler drawer.

Packing Checklist

After unpacking the DNA Engine Opticon® continuous fluorescence detection system, check

to see that you have received the following:

1. One DNA Engine Opticon unit (Opticon detector with DNA Engine

®

thermal cycler)

2. One computer with keyboard, mouse, monitor, cables, & installed software (Opticon

Monitor and Windows XP pro)

• One serial cable for connecting the Opticon unit’s serial port (figure 2-2) to the

computer serial port

• One data acquisition cable for connecting the Opticon unit’s DAQ port (figure 2-

2) to the data acquisition card in the computer

3. One Opticon accessory pack including:

• One power cord for the Opticon unit

• Two spare fuses

•

DNA Engine Opticon® Continuous Fluorescence Detection System Operations

Manual

(this document)

• Opticon Monitor

™

software CD ROM

• Consumables samples including 0.2ml low-profile strip tubes in opaque white

(MJ Research catalog no. TLS-0851), optical flat caps for 0.2ml tubes and plates

(MJ Research catalog no. TCS-0803), and low-profile Multiplate

™

96-well micro-

plates in opaque white (MJ Research catalog no. MLL-9651)

Page 19

Tech Support: (888) 652-9253 • Sales: (888) 735-8437 • tech@mjr.com • www.mjr.com 3-3

Installation and Operation

If any of these components are missing or damaged, contact MJ Research, Incorporated or

the authorized distributor from whom you purchased the DNA Engine Opticon system to

obtain a replacement. Please save the original packing materials in case you need to return

the DNA Engine Opticon system for service. See Appendix C for shipping instructions.

Setting Up the DNA Engine Opticon System

The Opticon system requires a location with three power outlets to accommodate the

Opticon unit, the computer, and the monitor. A location with network access (Ethernet

10/100BaseT) is recommended if you wish to transfer setup and analysis files between

the computer running the Opticon unit and other computers.

The DNA Engine Opticon system requires only minimal assembly. Insert the power cord

plug into its jack at the back of the instrument, just below the power switch (see figure 22 for the location of the jack). Then, plug the power cord into a standard 110V or 220V

electrical outlet. The Opticon unit will accept 220V automatically, as does the monitor.

However, you must set the voltage on the computer. See the “Power Supply Requirements”

section below for more information.

Before launching the Opticon Monitor software (see Chapter 5), be sure that the Opticon

unit is connected to the computer. There are two cables that connect the Opticon unit to

the computer. Connect the serial cable to the serial cable port on the Opticon unit (see

figure 2-2) and serial port #2 on the computer. Connect the data acquisition cable to the

DAQ port on the Opticon unit (see figure 2-2) and the data port on the computer.

Note: The DAQ cable has high-density connectors; take care not to bend any of the pins.

Environmental Requirements

For reasons of safety and performance, ensure that the area where the DNA Engine

Opticon system is installed meets the following conditions:

• Nonexplosive environment

• Normal air pressure (altitude below 2000m)

• Ambient temperature 15˚–31˚C

• Relative humidity above 10% and up to 80%

• Unobstructed access to air that is 31˚C or cooler (see below)

• Protection from excessive heat and accidental spills. (Do not place the DNA Engine

Opticon system near such heat sources as radiators, and protect it from danger of

having water or other fluids splashed on it, which can cause electrical short circuits.)

Page 20

3-4 Tech Support: (888) 652-9253 • Sales: (888) 735-8437 • tech@mjr.com • www.mjr.com

Opticon System Operations Manual

Power Supply Requirements

The DNA Engine Opticon unit requires 100-240VAC, 50-60Hz and a grounded outlet.

The DNA Engine Opticon unit can use current in the specified range without adjustment,

so there is no voltage-setting switch. The monitor can also accept either 110 or 220V

power without adjustment.

Important! For 220V operation of the computer, the red voltage-setting

switch located on the back of the computer, near the power cord

jack, must display 230V rather than 115V.

The Opticon unit is equipped with a power-entry module that accepts cordsets with an

IEC 60320-1 type C13 connector (this is the same standard configuration used by many

computer manufacturers for their equipment). All cordsets used with the Opticon unit must

be rated to carry at least 10A at 125V or 250V, the latter specification depending upon

the supply voltage used. Additionally, the cordset must meet all other applicable national

standards—thus at a minimum, the cordset should carry the mark of a nationally recognized testing agency appropriate to your nation.

Note: Do not cut the supplied 120V power cord and attach a different connector. Use a one-

piece molded connector of the type specified above.

Air Supply Requirements

The DNA Engine Opticon unit requires a constant supply of air that is 31˚C or cooler in

order to remove heat from the heat sink. Air is taken in from the lower vents located on

the sides of the instrument and exhausted from the upper vents on both sides (see figure

2-1). If the air supply is inadequate or too hot, the instrument can overheat, causing performance problems and even automatic shutdowns.

Ensuring an Adequate Air Supply

• Do not block air intake vents (see figure 2-1).

Position the DNA Engine Opticon unit at least 10cm from vertical surfaces and other thermal

cyclers or heat-generating equipment (greater distances may be required; see below).

• Do not allow dust or debris to collect in the air intake vents.

Ensuring That Air Is Cool Enough

• Do not position two or more DNA Engine Opticon units (or other instruments) so that hot

exhaust air blows directly into the air intake vents.

• Confirm that the DNA Engine Opticon unit receives air that is 31˚C or cooler by measuring the temperature of air entering the machine through its air intake vents.

Page 21

Tech Support: (888) 652-9253 • Sales: (888) 735-8437 • tech@mjr.com • www.mjr.com 3-5

Installation and Operation

Place the DNA Engine Opticon unit where you plan to use it, and turn it on. Try to

reproduce what will be typical operating conditions for the machine in that location,

particularly any heat-producing factors (e.g., nearby equipment running, window blinds

open, lights on). Run a typical protocol for 30 minutes to warm up the DNA Engine

Opticon unit, then measure the air temperature at the air intake vents. If more than one

machine is involved, measure the air temperature for each.

If the air intake temperature of any machine is warmer than 31˚C, consult Table 3-1 for

possible remedies. After implementing possible remedies, verify that the temperature of

the air entering the air intake vents has been lowered, using the procedure outlined above.

Table 3-1 Troubleshooting Air Supply Problems

Cause Possible Remedies

Air circulation is poor. Provide more space around instrument or adjust room

ventilation.

Ambient air temperature Adjust air conditioning to lower ambient air

is high. temperature.

Instrument is in warm part Move instrument away from, or protect instrument from,

of room. such heat sources as radiators, heaters, other equip-

ment, or bright sunlight.

Instruments are crowded. Arrange machines so that warm exhaust air does not

enter intake vents.

Turning the Opticon Unit and Computer On and Off

Locate the power switch on the back, left-side of the Opticon unit (back, right-side on

some models) just above the power cord (see figure 2-2). To turn the Opticon unit on,

press the switch so that the side marked “1” is depressed. The thermal cycler requires

several minutes to warm up after the Opticon unit is powered up. To turn the Opticon unit

off, depress the “0” side of the power switch.

Be sure that the Opticon unit is connected to the computer and turned on prior to launching the Opticon Monitor software. The blue protocol-indicator light on the front of the

Opticon unit (see figure 2-1) is illuminated only during a protocol run.

Press the power button on the front of the computer once to turn the computer on. Select

Shutdown

from the

Start

menu to turn the computer off. Press the power button on the

front of the monitor once to turn it on, and press it again to turn the monitor off.

Page 22

3-6 Tech Support: (888) 652-9253 • Sales: (888) 735-8437 • tech@mjr.com • www.mjr.com

Opticon System Operations Manual

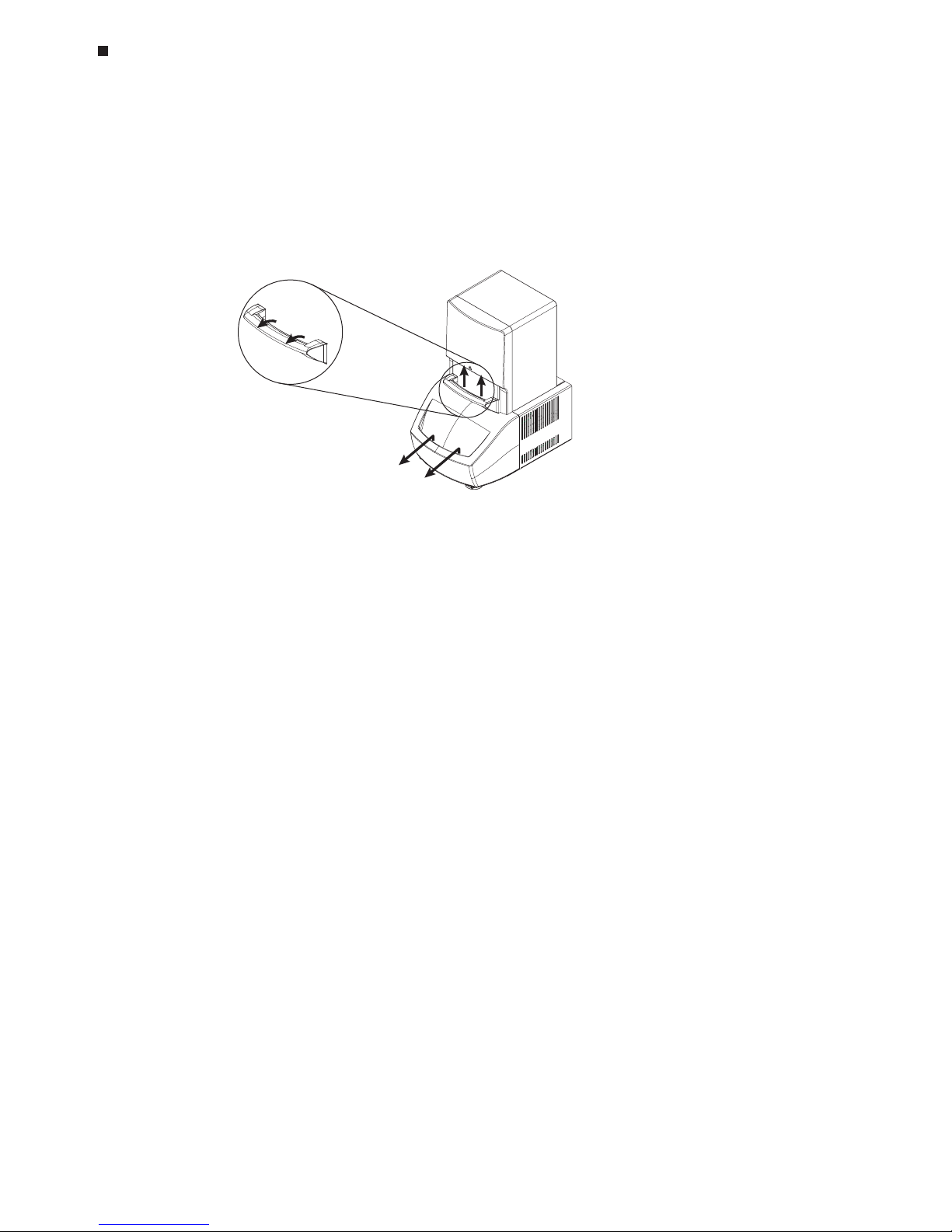

Opening and Closing the Cycler Drawer

To gain access to the Opticon unit’s thermal cycling block, first squeeze the blue trigger

handle (1) and allow the spring-loaded door to lift up (2). Then, use the hand hold on the

drawer front to slide the cycler drawer out toward you exposing the 96-well thermal cycler block (3).

To return the Opticon unit to the closed position, slide the cycler drawer back into the

instrument and lower the blue handle to secure the cycler drawer. It is not necessary to

squeeze the trigger handle.

Note: Do not open the cycler drawer while the blue protocol-indicator light is illuminated.

Opening the door, particularly during a scan of the plate, may interrupt the software’s

control of the protocol.

Loading Sample Vessels into the Block

Important! Do not use full height 0.2ml tubes or full height unskirted

microplates. Refer to the “Selecting the Correct Sample Vessel” section

in Chapter 4 for tube and microplate recommendations.

To ensure uniform heating and cooling of samples, sample vessels must be in complete

contact with the block. Adequate contact is ensured by doing the following:

• Ensure that the block is clean before loading samples (see Chapter 9 for cleaning

instructions).

• Firmly press strips of 0.2ml low-profile tubes, or a 96-well, low-profile microplate into

the block wells (see the “Selecting the Correct Sample Vessel” section in Chapter 4).

• MJR strongly recommends that oil not be used to thermally couple sample vessels to

the block.

Tip: Spin down reactions in tubes or microplates prior to loading into the thermal-cycler

block. Air bubbles in samples or liquid on the plate deck can adversely affect results.

1.

2.

3.

Page 23

4-1

4. Compatible Chemistries,

Sample Vessels, and Sealing

Options

Optical System, 4-2

Compatible Chemistries, 4-2

SYBR Green I, 4-2

Molecular Beacons, 4-3

Hydrolysis Probes (TaqMan Probes), 4-3

Scorpions Probes, 4-4

Amplifluor Universal Detection System, 4-4

Selecting the Correct Sample Vessel, 4-5

Vessels Optimized for Fluorescence Detection and Thermal Cycling, 4-5

Sealing Sample Vessels, 4-5

Sealing with Optical Caps and the Heated Lid, 4-6

Sealing with Chill-out™ 14 Liquid Wax, 4-6

Sample Vessel and Sealing Selection Chart for Optical Assays, 4-7

Reaction Volume Recommendations, 4-8

Page 24

4-2 Tech Support: (888) 652-9253 • Sales: (888) 735-8437 • tech@mjr.com • www.mjr.com

Opticon System Operations Manual

Optical System

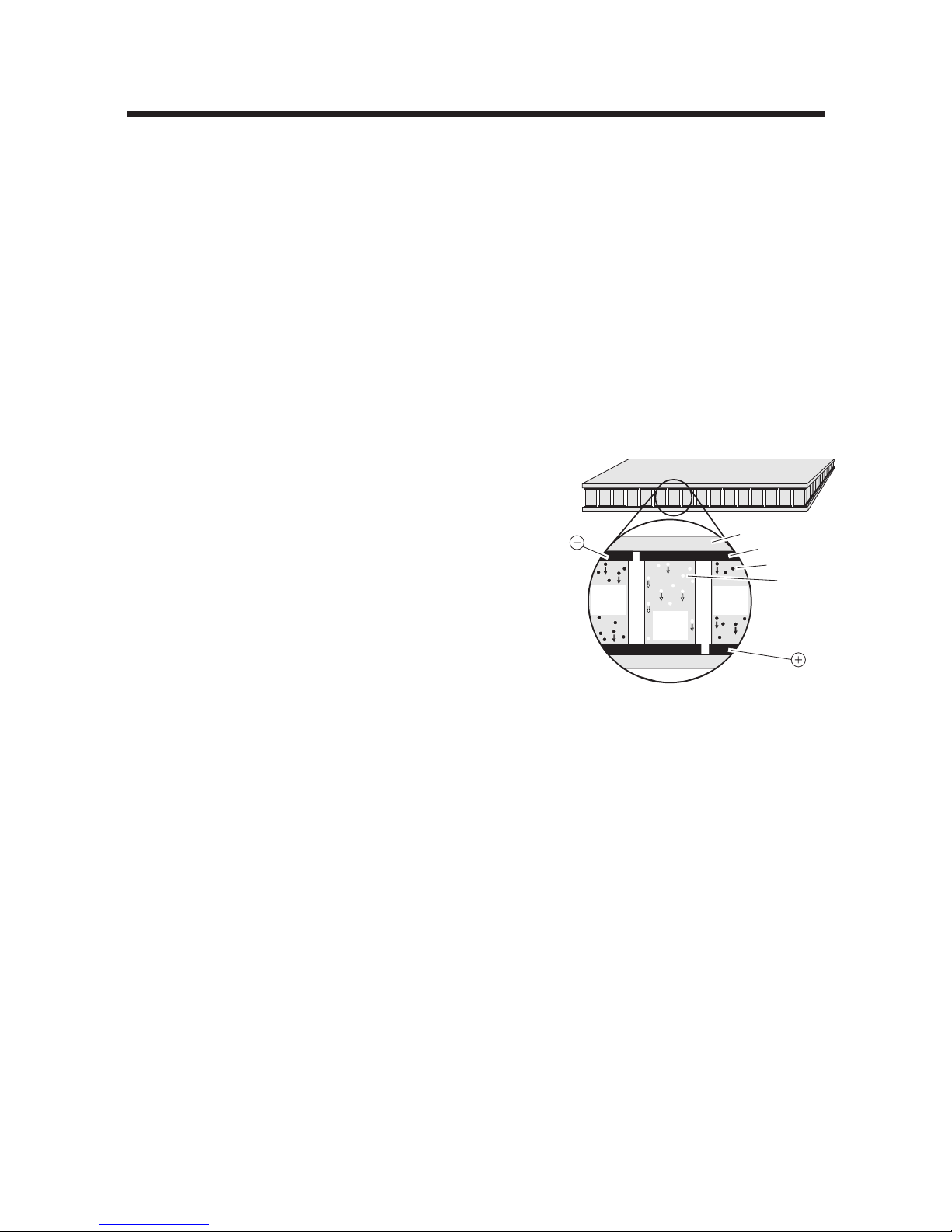

The Opticon™ detector uses an array of 96 blue LEDs to sequentially illuminate each of

the 96 wells in the cycler block. The LEDs efficiently excite fluorescent dyes with excitation spectra in the 450 to 495nm range. The Opticon detector is optimized to detect dyes

with emission spectra in the 515 to 545nm range, such as SYBR Green and FAM.

The Opticon detector is calibrated at the factory and requires no calibration before use.

See Chapter 10, “Troubleshooting” for instructions on testing detector calibration and

recalibrating.

Compatible Chemistries

The Opticon detector is compatible with popular dye chemistries including SYBR Green

I, molecular beacons, hydrolysis probes (TaqMan probes), Scorpions probes, and the

Amplifluor system. In addition to performing real-time quantification and DNA melting

profiles, the Opticon system is also useful as a temperature-controlled fluorimeter for a

number of applications including ligand binding and protein structure studies. If you have

questions regarding the compatibility of a particular chemistry with the Opticon detector,

contact MJ Research technical support at 888-652-9253.

SYBR Green I

SYBR Green I (available from Molecular Probes, Inc. of Eugene, Oregon) is a dsDNA

binding dye thought to bind in the minor groove. The fluorescence of SYBR Green I is

greatly enhanced upon binding dsDNA. This characteristic makes it ideal for detection

of amplification products. The maximum absorbance of SYBR Green I is ~497nm and

the emission maximum is ~520nm*.

SYBR Green I has several advantages for detection of nucleic acids in real time. Because

SYBR Green I binds to all dsDNA, it does not have to be customized for individual templates thereby providing the advantages of quick protocol adaptation and relatively low

cost. Further, SYBR Green I is very sensitive because multiple dye molecules bind to a

single amplification product. However, because SYBR Green I binds to all dsDNA, false

positive signals from primer-dimers, secondary structure, or spurious priming can interfere with accurate quantification. Measuring fluorescence at elevated temperatures may

help reduce the detection of nonspecific products

1

. Performing a melting curve to analyze product homogeneity can also aid in analyzing quantification results obtained with

SYBR Green I.

MJR recommends using buffers containing 5% dimethyl sulfoxide (DMSO) with a concentration of 1X or less SYBR Green I with the Opticon detector. For additional information

on optimizing protocols using SYBR Green I with thermostable enzymes available from

MJ Research, contact MJ Research technical support at 888-652-9253.

1

Morrison, T.B., J.J. Weis and C.T. Wittwer. 1998. Biotechniques 24:954-962.

*Molecular Probes, Inc.

Page 25

Tech Support: (888) 652-9253 • Sales: (888) 735-8437 • tech@mjr.com • www.mjr.com 4-3

Compatible Chemistries, Sample Vessels, and Sealing Options

Molecular Beacons

Molecular beacons are dual-labeled oligonucleotide probes designed to form stem-loop

structures in the absence of target. In the hairpin configuration, the fluorophore at one

end of the molecule is brought into close proximity with a quenching moiety at the other

end of the molecule. When the fluorophore is excited in this configuration, it transfers

energy to the quencher rather than emitting that energy as light, in a process known as

fluorescence resonance energy transfer (FRET). A “dark” quencher is often used, so the

energy transferred from the fluorophore is emitted in the infrared as opposed to the visible range. If a second fluorophore is used as a quencher, the transferred energy is emitted as light at the quenching fluorophore’s characteristic wavelength.

Molecular beacons are designed such that the loop, which is usually 15-30 nucleotides in

length, is complimentary to the target sequence. The arms flanking the loop, which are

usually 5–7 nucleotides in length, are designed such that they are complementary and

favor formation of a stem structure. A fluorophore is attached to the end of one arm, and a

quencher is attached to the other. Molecular beacons must be carefully designed such that

at the annealing temperature of the reaction hairpins form in the absence of template, but

that in the presence of template, the annealing of the loop sequence to the target is energetically favorable. When the loop of a molecular beacon hybridizes to the target sequence,

the conformational change of the probe separates the fluorophore and the quencher.

When the fluorophore is excited, it now emits light at its characteristic wavelength.

One advantage of molecular beacons is that unlike SYBR Green, molecular beacons specifically detect the target of interest. Great sensitivity, including detection of single

nucleotide polymorphisms (SNPs), is possible with carefully designed molecular beacons

and optimized reaction conditions (temperature, buffer). However, each probe must be

carefully and uniquely designed for the detection of a specific target.

Molecular beacons are a technology patented by the Public Health Research Institute of

New York, NY and are available from a number of licensed suppliers. When designing

molecular beacons for use with the Opticon detector, fluorophores with excitation and

emission spectra falling within the Opticon detector’s excitation (450-490nm) and detection (515-545nm) ranges, such as FAM, can be used. Either dark quenchers or a quenching fluorophore may be used with the Opticon detector. However, because the Opticon

detector is a single-color detection system, light from a quenching fluorophore can not be

separately monitored. Dark quenchers tend to give cleaner signal because there is no

overlapping signal from light emitted by the quenching fluorophore.

Hydrolysis Probes (TaqMan Probes)

TaqMan probes are a patented technology available from a number of licensed suppliers. They are oligonucleotide probes whose fluorescence is dependent on the amplification of a target sequence. TaqMan probes are designed to anneal to the target sequence

between the forward and reverse primers. A reporter fluorophore is attached to the 5’

end of the probe and a quencher to the 3’ end.

Page 26

4-4 Tech Support: (888) 652-9253 • Sales: (888) 735-8437 • tech@mjr.com • www.mjr.com

Opticon System Operations Manual

When the intact probe anneals to the target sequence, excitation of the reporter is quenched

because of its proximity to the 3’ quencher. However, as extension proceeds, the 5’ exonuclease activity of the polymerase cleaves the probe, separating the reporter from the

quencher. TaqMan probes work well with enzymes derived from Thermus species, such

as DyNAzyme™ II DNA polymerase from Thermus brockianus, available from MJ Research,

Inc. Liberated reporter molecules accumulate as the number of cycles increases, such that

the increase in fluorescence is proportional to the amount of amplified product.

One advantage of TaqMan probes, particularly for quantification, is that fluorescence is

dependent not only on the presence of a specific target, but also on amplification of that

target. However, like molecular beacons, TaqMan probes must be individually designed

for specific targets. See the “Molecular Beacons” section above for recommendations on

the use of specific fluorophores and quenchers with the Opticon detection system.

Scorpions Probes

Scorpions probes (available from licensed suppliers) contain both an amplification primer

and a target-specific probe separated by an amplification blocker. The probe portion is

flanked by complementary sequences favoring formation of a stem structure which brings

a fluorophore and a quencher into close proximity.

During amplification, extension of the target sequence proceeds from the primer portion

of the Scorpions probe. As the reaction cools following denaturation, a uni-molecular

rearrangement occurs such that the Scorpions probe sequence binds to the amplified target sequence, separating the complementary stem sequences and thus the fluorophore

and quencher. Since the Scorpions probe is integrated into the product, there is a direct

relationship between the number of targets generated and the amount of fluorescence.

See the “Molecular Beacons” section above for recommendations on the use of specific

fluorophores and quenchers with the Opticon detection system.

Amplifluor Universal Detection System

The Amplifluor system (available from Intergen Company of Purchase, NY) makes use of

a universal primer that emits a fluorescence signal only following incorporation of the

primer into an amplification product. The universal primer consists of a 18 base primer

tail ("Z sequence") coupled to a hairpin sequence labeled with a fluorophore and a

quencher. First, the target is amplified using target-specific primers, one of which has the

Z sequence added to its 5' end. In the following round of amplification, the complement

to the Z sequence is incorporated into the product. The universal primer then anneals to

the complement of the Z sequence and extension proceeds. In the next cycle, extension

proceeds through the universal primer incorporating it into the amplification product. In

the process, the hairpin is unfolded separating the fluorophore and quencher and emitting a fluorescence signal that is proportional to the amount of amplified product.

See the “Molecular Beacons” section above for recommendations on the use of specific

fluorophores and quenchers with the Opticon detection system.

Page 27

Tech Support: (888) 652-9253 • Sales: (888) 735-8437 • tech@mjr.com • www.mjr.com 4-5

Compatible Chemistries, Sample Vessels, and Sealing Options

Selecting the Correct Sample Vessel

Important! Do not use full height 0.2ml tubes or full height unskirted

microplates. Full height 0.2ml tubes and most unskirted microplates do

not provide sufficient clearance between the sample block and lid-heater

assembly. Do not force the cycler drawer closed.

For proper clearance in the Opticon unit, the distance from the bottom of a tube/plate to

the cap rim can not exceed 17.5mm. In general, fully-skirted 96-well microplates, such

as MJ Research Microseal

®

and Hard-Shell® microplates, provide sufficient clearance when

sealed with either domed or flat optical caps (see the "Sample Vessel and Sealing Selection Chart for Optical Assays" below). If unskirted microplates are used, low-profile plates,

such as the MJ Research MLL-series Multiplate

™

microplates, are required.

Low-profile 0.2ml strip tubes, such as MJ Research TLS-series tubes, are recommended

for small numbers of samples. Full-height 0.2ml tubes do not provide sufficient clearance.

Vessels Optimized for Fluorescence Detection and Thermal

Cycling

For optimal sensitivity in fluorescence-detection assays, we recommend thin-walled 0.2ml

tube strips and microplates with opaque-white wells. MJ Research, Inc. offers microplates

and tubes with opaque white or clear wells designed for fluorescence detection assays

and optimized to ensure a precise fit in the cycler block (see the "Sample Vessel and

Sealing Selection Chart for Optical Assays" below).

Microplates and tubes with black wells may be useful in applications requiring very low

levels of background. However, signal strength is significantly reduced when plates and

tubes with black wells are used.

Note: In-factory calibration of the Opticon detector is performed with opaque-white plates.

If you are using natural (clear) or black plates, refer to Chapter 10 for instructions on

performing a calibration test and recalibrating.

Sealing Sample Vessels

Steps must be taken to prevent the evaporation of water from reaction mixtures during thermal cycling so as to avoid changing the concentration of reactants. Only a layer of oil or

wax, such as Chill-out liquid wax, will completely prevent evaporation from sample vessels. However, an adequate degree of protection can be achieved by sealing with optical

caps, then cycling the samples using the heated lid to prevent condensation/refluxing.

Page 28

4-6 Tech Support: (888) 652-9253 • Sales: (888) 735-8437 • tech@mjr.com • www.mjr.com

Opticon System Operations Manual

Sealing with Optical Caps and the Heated Lid

The heated inner lid maintains the upper part of sample vessels at a higher temperature

than the reaction mixture. This prevents condensation of evaporated water vapor onto

the vessel walls, so that solution concentrations are unchanged by thermal cycling. The

heated lid also exerts pressure on the tops of vessels loaded into the block, helping to

maintain a vapor-tight seal and to firmly seat tubes or microplates in the block for the

most efficient transfer of heat to and from the samples.

Optical caps must be used along with the heated lid to prevent evaporative losses. Ultraclear, optical cap strips (available from MJ Research, Inc.) provide high light transmission for fluorescence detection and vapor-tight sealing. Tight-fitting caps do the best job

of preventing vapor loss.

Note: When tubes are cooled to below-ambient temperatures, a ring of condensation may

form in tubes above the liquid level but below the top of the sample block. This is not a

cause for concern since it occurs only at the final cool-down step when thermal cycling is

finished.

Sealing with Chill-out™ Liquid Wax

Clear Chill-out liquid wax (available from MJ Research, Inc.) may be used to seal sample

vessels for optical assays. Clear Chill-out liquid wax is the same easy-to-use alternative to

oil as the standard, red-colored Chill-out wax. However, clear Chill-out wax provides excellent light transmission for optimal performance in optical assays. Chill-out liquid wax

provides 100% prevention of condensation and vapor loss. At room temperature and

above, this overlay is transparent and can be applied by pipet. Chill-out liquid wax solidifies below 14°C. Use only a small amount of Chill-out liquid wax; 1-3 drops (15-50µl)

are usually sufficient. (Include this volume in the total volume when setting up a calculated-control protocol.) Be sure to use the same amount of wax in all samples vessels to

ensure a uniform thermal profile.

Page 29

Tech Support: (888) 652-9253 • Sales: (888) 735-8437 • tech@mjr.com • www.mjr.com 4-7

Compatible Chemistries, Sample Vessels, and Sealing Options

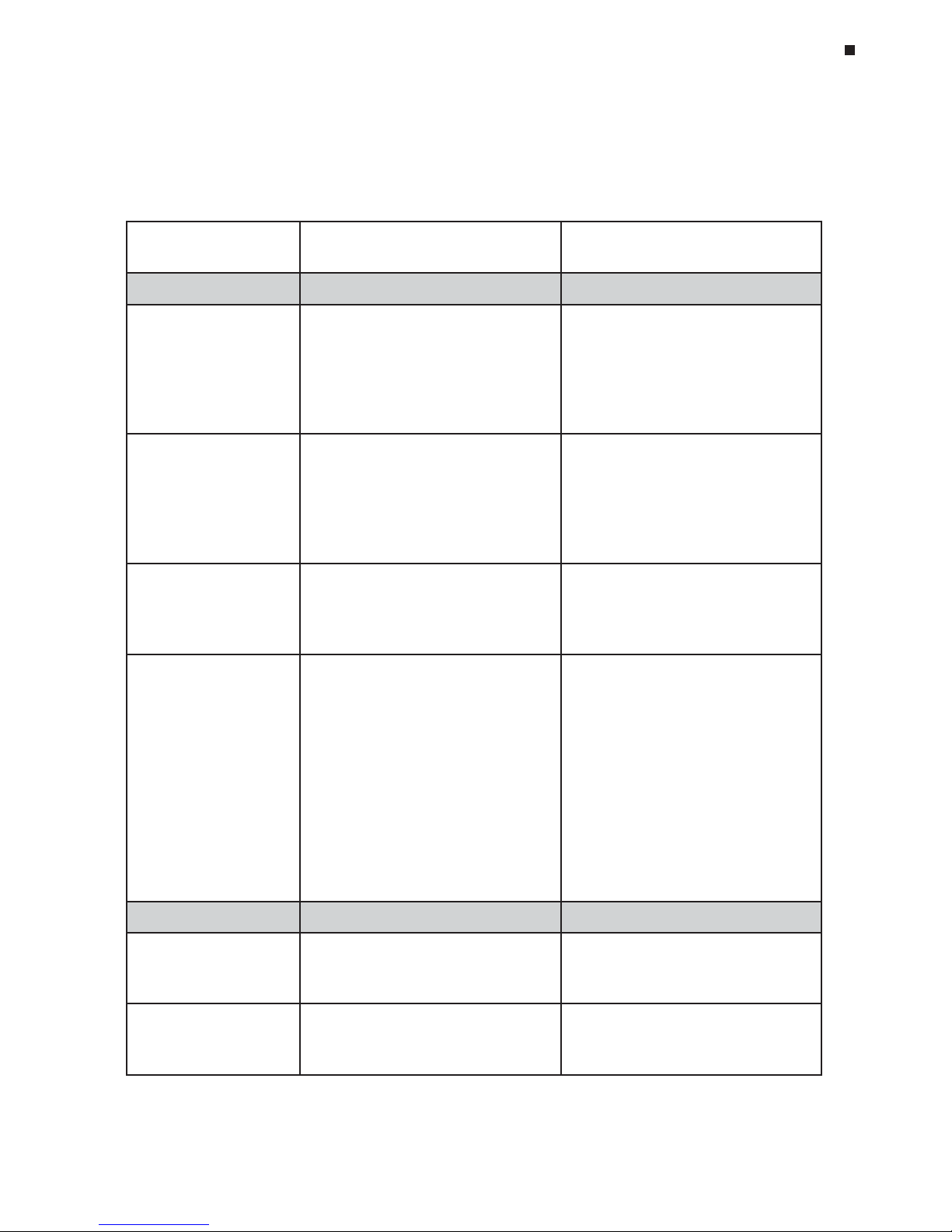

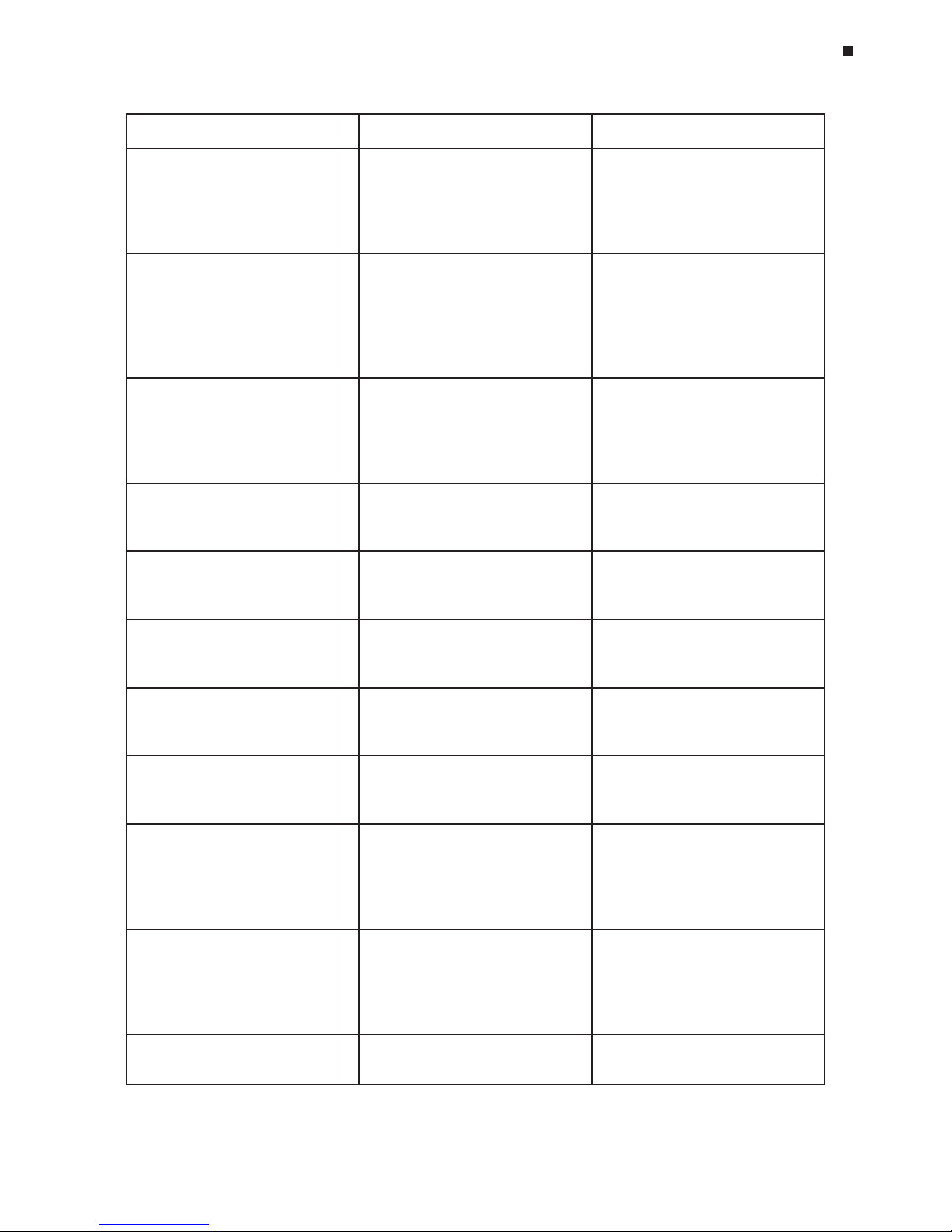

Sample Vessel and Sealing Selection Chart for Optical Assays

The following sample vessels and sealing options are recommended for use with the DNA

Engine Opticon® system and are available from MJ Research, Inc. To place an order, call

888-729-2165 or fax 888-729-2166.

tcudorP

golataChcraeseRJM

rebmuN

sthgilhgihtcudorP

slesseV

eliforP-woL

sebutlm2.0

8fospirts

)etihweuqapo(1580-SLT

)raelc(1080-SLT

fosrebmunllamsroflaedI•

selpmas

mumixamofsllewetihwesU•

langis

mrofinurofsllewraelcesU•

gniweivelpmasdnalangis

™etalpitluMeliforP-woL

detriksnu

llew-69

setalporcim

)etihweuqapo(1569-LLM

)raelc(1069-LLM

selpmas69nahtrewefroflaedI•

ezisottucebnacsetalporcim---

mumixamofsllewetihwesU•

langis

mrofinurofsllewraelcesU•

gniweivelpmasdnalangis

llew-69®laesorciM

s

etalporcimdetriks

)etihweuqapo(1569-PSM

)raelc(1069-PSM

mumixamofsllewetihwesU•

langis

mrofinurofsllewraelcesU•

gniweivelpmasdnalangis

llew-69®llehS-draH

setalporcimdetriks

sllewetihw/llehsetihw5569-PSH

sllewetih

w/llehskcalb5669-PSH

sllewetihw/llehsder5169-PSH

sllewetihw/llehswolley5269-PSH

sllewetihw/llehseulb5369

-PSH

sllewetihw/llehsneerg5469-PSH

sllewraelc/llehsetihw1069-PSH

sllewraelc/llehskcalb1669-PSH

sllewraelc

/llehsder1169-PSH

sllewraelc/llehswolley1269-PSH

sllewraelc/llehseulb1369-PSH

sllewraelc/llehsneerg1469-

PSH

selpmas69roflaedI•

talfyletulosbasniameretalP•

rof,gnilcyclamrehtgnirud

noitcellocthgilmrofinu

rofdoog

erasllehsderoloC•

gnidoc-roloc

snoitpOgnilaeS

.spactalflacitpO

8fospirts

3080-SCT

thgilhgihrofraelc-artlU•

noissimsnart

lµ5>semulovgnilcyclamrehT•

diuqiL

™tuO-llihC

edarg-lacitpo,xaW

1141-OHC

yalrevoliolarenimsecalpeR•

noissimsnartthgilhgiH•

lµ2>semulovgnilcyc

-lamrehT•

Page 30

4-8 Tech Support: (888) 652-9253 • Sales: (888) 735-8437 • tech@mjr.com • www.mjr.com

Opticon System Operations Manual

Reaction Volume Recommendations

Reaction volumes of 20-100µl are recommended for most applications. However, it is

beneficial to empirically optimize reagent concentrations and sample volumes with the

Opticon detector as the sensitivity of the optical system often allows a cost-saving reduction in reagent concentrations. Volumes as low as 10µl can be used, though sensitivity is

slightly reduced.

The maximum recommended sample volume is 100µl. Volumes exceeding 100µl do not

maintain adequate contact with the wells of the sample block resulting in nonuniform

heating and cooling within the sample.

The reaction volume is used to calculate the temperature of the samples during a calculated-control run (see the “Temperature Control Method” section in Chapter 6). Therefore,

thermal accuracy is optimized when all samples contain identical volumes.

Page 31

5-1

5. Introduction to Opticon

Monitor™ Software

How Opticon Monitor Software Works, 5-2

Launching and Navigating Opticon Monitor Software, 5-3

Exiting Opticon Monitor Software, 5-5

Opticon Monitor File Extensions, 5-6

Which Version of Opticon Monitor Software Are You Running?, 5-6

Viewing Usage and Message Logs, 5-6

Page 32

5-2 Tech Support: (888) 652-9253 • Sales: (888) 735-8437 • tech@mjr.com • www.mjr.com

Opticon System Operations Manual

Opticon Monitor software controls all operations on the DNA Engine Opticon® continuous fluorescence detection system. This chapter will introduce you to the Opticon Monitor software and discuss the basics of launching and navigating the software. Chapter 6

describes experimental setup and programming. Chapter 7 discusses run initiation and

status, and Chapter 8 focuses on data analysis. This manual documents version

1.08 of the Opticon Monitor software.

How Opticon Monitor Software Works

The intuitive Opticon Monitor software is structured such that there are just three phases

from protocol creation to analyzed results.

1. Experimental setup and programming. All setup and programming operations are accessed from the master file window. The master file orchestrates the run by

specifying which combination of plate and protocol files to apply to a particular run.

Users can create new files or apply existing files, in their current form or after editing.

2. Run initiation and status. After creating a plate and a protocol setup, or select-

ing a plate and a protocol file, a run can be initiated. The user has the option to stop the

run at any time and to skip protocol steps. The status screen can be used to monitor the

progress and thermal profile of the run. Data collection can be monitored during the run

by plotting fluorescence intensity vs. cycle number.

3. Data analysis. Starting copy number can be quantified by using the software to set

the c(t) (cycle threshold) line, view and adjust an automatically-generated standard curve,

and apply unknowns to the curve. Products can be identified by melting profile using the

software to plot fluorescence vs temperature, and/or the negative first derivative (-dI/dt)

of that graph.

Page 33

Tech Support: (888) 652-9253 • Sales: (888) 735-8437 • tech@mjr.com • www.mjr.com 5-3

Introduction to Opticon Monitor Software

Launching and Navigating Opticon Monitor Software

Opticon Monitor software is pre-installed on the computer provided with the Opticon

™

unit. The Opticon Monitor software is compatible with Windows 2000 and Windows XP

operating systems. Opticon Monitor software can control the Opticon unit only when running on the computer supplied with the system, which has special hardware required for

data acquisition. Nonetheless, Opticon Monitor software can be installed on any computer running Windows 2000 or Windows XP for the purposes of setting up protocols or

analyzing data.

To launch the Opticon Monitor software, choose

Programs

from the Windows

Start

menu,

and then

Opticon Monitor

. Upon launching the Opticon Monitor software, the Opticon

Monitor window will appear displaying a new master file template. Alternatively, double

click on an existing Opticon Monitor master, plate, protocol, or data file to launch Opticon Monitor and display the chosen file.

4. Log box

1. Toolbar 2. Pull-down menus

3. Setup/analysis display window

(master file)

Page 34

5-4 Tech Support: (888) 652-9253 • Sales: (888) 735-8437 • tech@mjr.com • www.mjr.com

Opticon System Operations Manual

Opticon Monitor window features include:

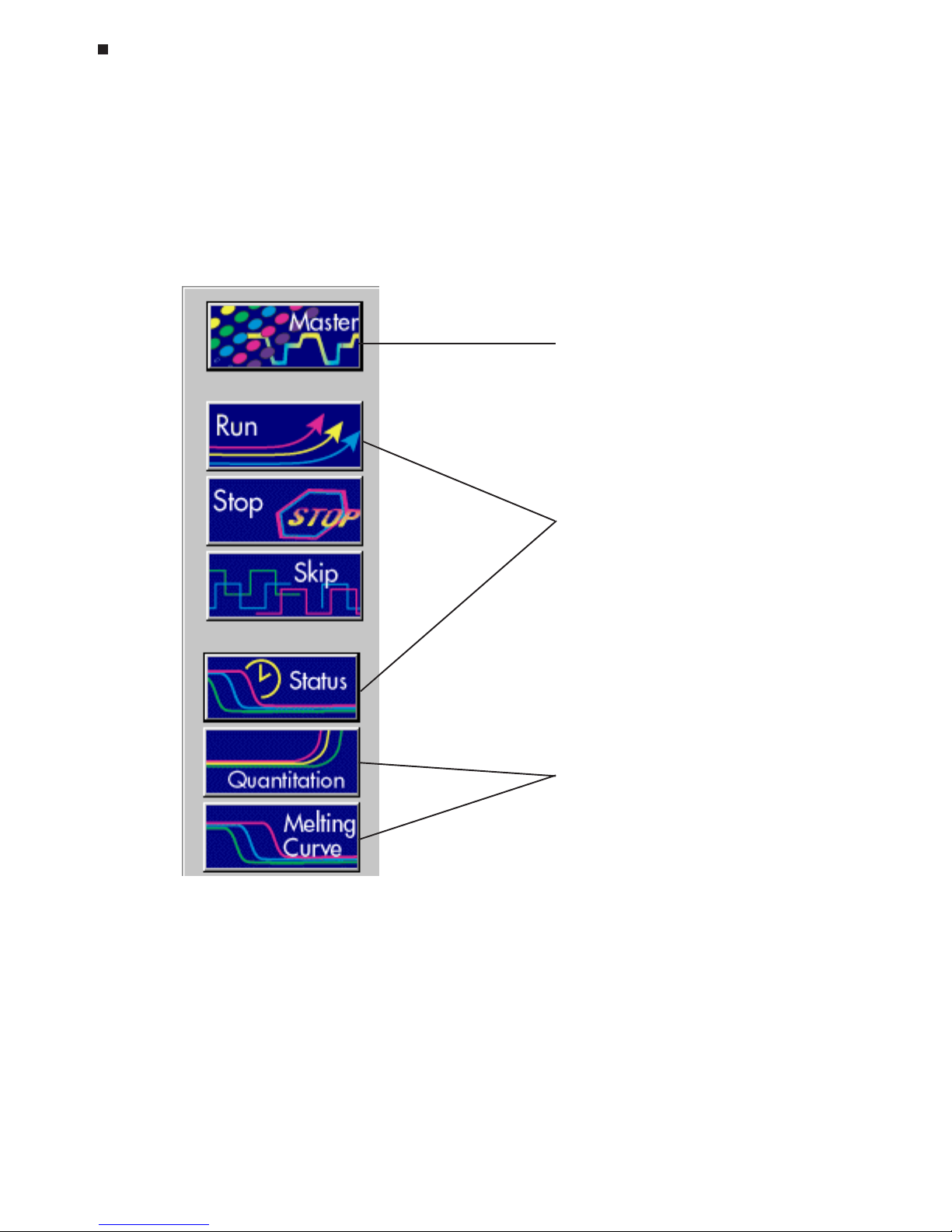

1. Toolbar: The toolbar contains both menu buttons and run status information. The

menu buttons located on the toolbar are the primary means of navigation between

the setup/programming, run/status and analysis windows:

Experimental setup & programming

Run initiation and monitoring

Data analysis

Page 35

Tech Support: (888) 652-9253 • Sales: (888) 735-8437 • tech@mjr.com • www.mjr.com 5-5

Introduction to Opticon Monitor Software

The run status box on the toolbar indicates if a protocol or infinite incubation step is

running. It lists the time remaining in the run, the current step and cycle counts, and

the current temperatures.

2. Pull-down menus: The pull-down menus provide access to numerous functions

including the ability to print and export data as well as set the default options for

data analysis.

3. Setup/analysis display window: The window displays the selected setup, sta-

tus, or analysis screen.

4. Log box: The log box lists the instrument operation log including any errors encoun-

tered.

Exiting Opticon Monitor Software

Exit Opticon Monitor software by selecting

Exit

from the

File

menu, or by clicking the

close button in the upper-right corner of the title bar. If a protocol is running, it must be

stopped prior to exiting Opticon Monitor software.

Page 36

5-6 Tech Support: (888) 652-9253 • Sales: (888) 735-8437 • tech@mjr.com • www.mjr.com

Opticon System Operations Manual

Opticon Monitor File Extensions

When saving files, the Opticon Monitor software automatically adds one of the following file

extensions:

.mast Master file: Controls a run by specifying which plate and protocol

files to apply during the run.

.plate Plate file: Specifies the contents of the 96 wells, any descriptive well labels that

were assigned, and the amounts of any quantitation standards for use in generating a standard curve.

.prot Protocol file: Specifies the order and parameters of protocol steps including

temperature incubations, plate reads, temperature gradients, goto steps, and

melting curves.

.tad Data file: Contains the fluorescence and temperature data collected during the

run, and any selected options and analysis parameters.

Which Version of Opticon Monitor Software Are You

Running?

To determine which version of Opticon Monitor software is currently installed on your

computer, choose

About

from the

Help

menu. The About window will appear displaying

the Opticon Monitor version number. This manual documents Opticon Monitor software,

version 1.08.

Select

Close

to return to the current setup or analysis screen, or click the X in the upper-

right corner.

Viewing Usage and Message Logs

To view a record consisting of the dates and times that runs were initiated and successfully completed, as well as a record of the master, plate, and protocol files applied during those runs, select

Logs

from the

View

pull-down menu and click the

Usage Log

toggle

tab. The dates and times that the software was launched and quit will also be displayed.

To view a record of operations performed by the Opticon Monitor software, including

any error messages, select

Logs

from the

View

pull-down menu and click the

Message

Log

toggle tab.

Page 37

6-1

6. Experimental Setup and

Programming

Creating a Master File, 6-2

Specifying a User, 6-3

Adding New Users, 6-3

User Password Protection, 6-4

Removing Users, 6-4

Assigning New Plate and Protocol Files to a Master File, 6-4

Creating a Plate File, 6-4

Assigning Well Contents, 6-5

Selecting Wells Using the Plate Diagram, 6-5

Selecting Wells Using the Plate Information Table, 6-6

Specifying Quantitation Standards, 6-7

Assigning Well Descriptions, 6-8

Saving a Plate File, 6-8

Creating a Protocol File, 6-9

Choosing a Temperature and a Lid Control Mode, 6-10

Temperature Control Method, 6-10

Lid Control, 6-11

Saving Temperature and Lid Control Settings, 6-12

Designing and Entering a Protocol, 6-12

Entering a New Protocol, 6-13

Temperature Step, 6-13

Gradient Step, 6-15

Gradient Calculator, 6-17

Plate Read Step, 6-17

Adding Multiple Temperature Steps, Gradient Steps, or Plate Reads, 6-17

Goto Step, 6-18

Melting Curve Step, 6-19

Editing a Protocol Step, 6-20

Deleting a Protocol Step, 6-20

Inserting a Protocol Step Between Existing Steps, 6-20

Melting Curve Analysis, 6-21

Saving a Protocol File, 6-23

Saving a Master File, 6-23

Assigning Existing Plate and Protocol Files to a Master File, 6-23

Reusing Master Files, 6-24

Using the Quick Load Feature, 6-25

Page 38

6-2 Tech Support: (888) 652-9253 • Sales: (888) 735-8437 • tech@mjr.com • www.mjr.com

Opticon System Operations Manual

All setup and programming operations can be accessed from the master file window.

Before running a protocol on the DNA Engine Opticon® system, a master file specifying

all of the parameters for the run can be created. The master file orchestrates the run by

specifying which plate and protocol files to apply to a run. The first section of this chapter

will describe how to create and assign new plate and protocol files to a master file. The

second section will describe how to assign existing plate and protocol files, with or without modifications, to a master file. Finally, instructions for reusing and editing existing

master files will be discussed.

Creating a Master File

Upon launching the Opticon Monitor™ software (see Chapter 5), the Opticon Monitor

window will appear displaying a new master file template.

New master file

Page 39

Experimental Setup and Programming

Tech Support: (888) 652-9253 • Sales: (888) 735-8437 • tech@mjr.com • www.mjr.com 6-3

A master file consists of two component files:

1. Plate file: specifies the contents of the 96 wells, any descriptive well labels that were

assigned, and the amounts of any quantitation standards for use in generating a

standard curve.

2. Protocol file: specifies the order and parameters of temperature incubations, plate

reads, temperature gradients, goto steps, and melting curves.

The

New, Edit, Open

, and

Save

buttons located in the Plate Setup and Protocol Setup

sections of the master file can be used to assign new or existing files to the master file as

described below. The Quick Load feature can be used to quickly assign existing plate

and protocol files to the master file (see the "Using the Quick Load Feature" section at the

end of this chapter).

Specifying a User

The user feature allows users to organize master, plate, protocol and data files by placing them in a

Shared

folder to which all users have read/write access, or into personal

folders which can be password protected. Files in a password-protected folder cannot be

edited or deleted through Opticon Monitor, nor can files be placed in the folder without

the password. However, password-protected files can be read by all users. These files

can be edited by any user if a Save as is first performed and the file is assigned to the

shared folder or that user's folder. This provides all users access to all files, but ensures

that the files in an individual user's password-protected folder are only altered by that

user.

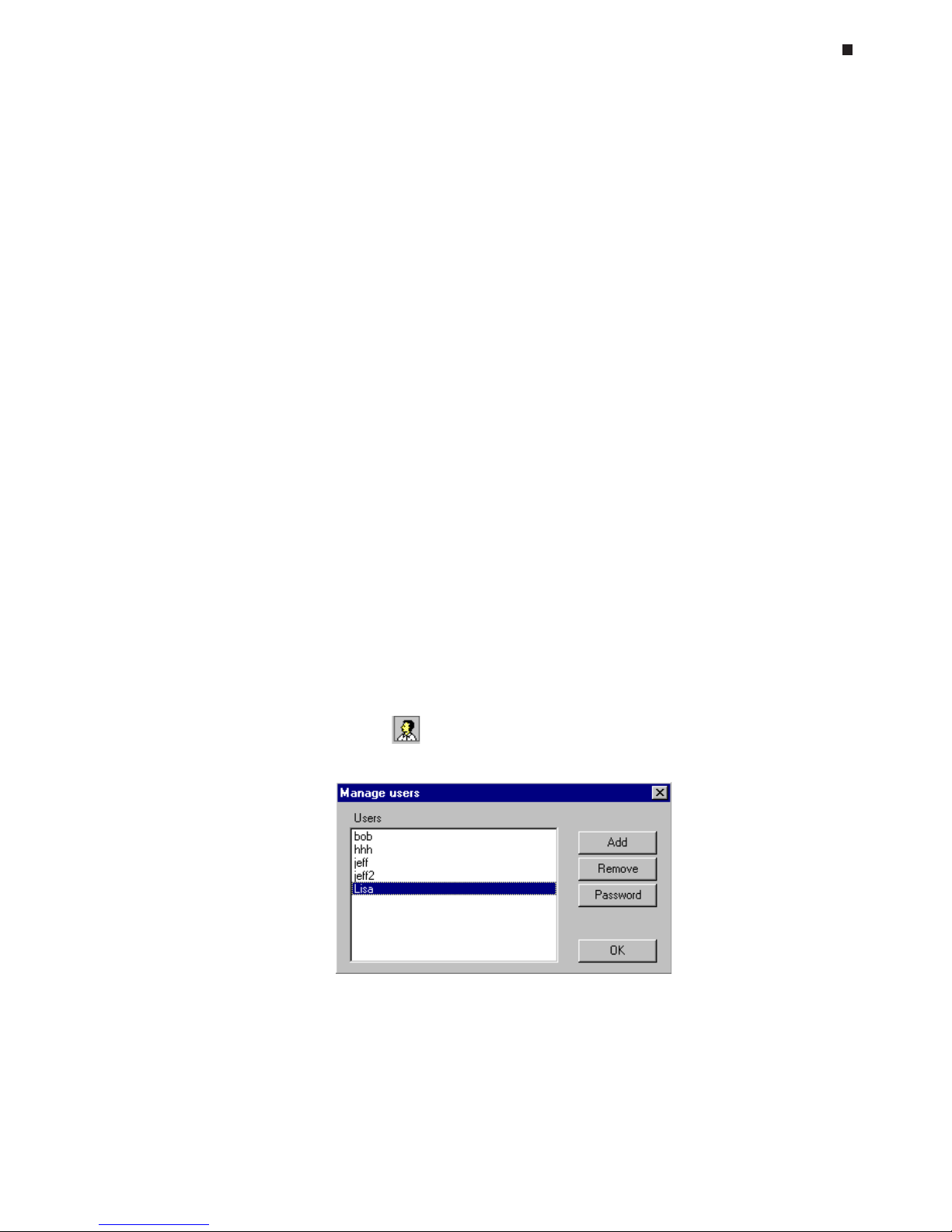

Adding New Users

To add a new user, click the icon in the master file window.

Page 40

6-4 Tech Support: (888) 652-9253 • Sales: (888) 735-8437 • tech@mjr.com • www.mjr.com

Opticon System Operations Manual

In the Manage users window that appears, select

Add

. Enter the new user's name in the

New User window that appears and select

OK

.

User Password Protection

To password protect a user's files, select the name from the Users list in the Manage users

window and then select

Password

. To assign a password, enter the password in the

New

Password

field and again in the

Confirm New Password

field. To change an existing

password, first enter the existing password in the

Old Password

field, and then enter and

confirm the new password. The user will be prompted to enter their password when their

name is selected from the drop-down

User

list in the master file window.

Removing Users

To remove a user from the Opticon Monitor software, select the user's name in the Manage users window and then select

Remove

. You will be asked to confirm deletion of the

user as all data associated with the user will also be deleted.

Assigning New Plate and Protocol Files to a Master

File

Creating a Plate File

A plate file functions to identify the contents of the 96 wells as empty (ignored), blank (for

background subtraction), quantitation standard (for standard-curve generation), or sample

(for unknown and control reactions). A plate file may also contain user-specified well

descriptions, and the amounts and units of any quantitation standards.

Click the

New

button in the Plate Setup section of the master file to create a new plate

file.

In the plate file window, begin by entering the volume of your reactions (in µl) in the

Reac-

tion Volume

field. See the "Reaction Volume Recommendations" section in Chapter 4 for

additional information.

Page 41

Experimental Setup and Programming

Tech Support: (888) 652-9253 • Sales: (888) 735-8437 • tech@mjr.com • www.mjr.com 6-5

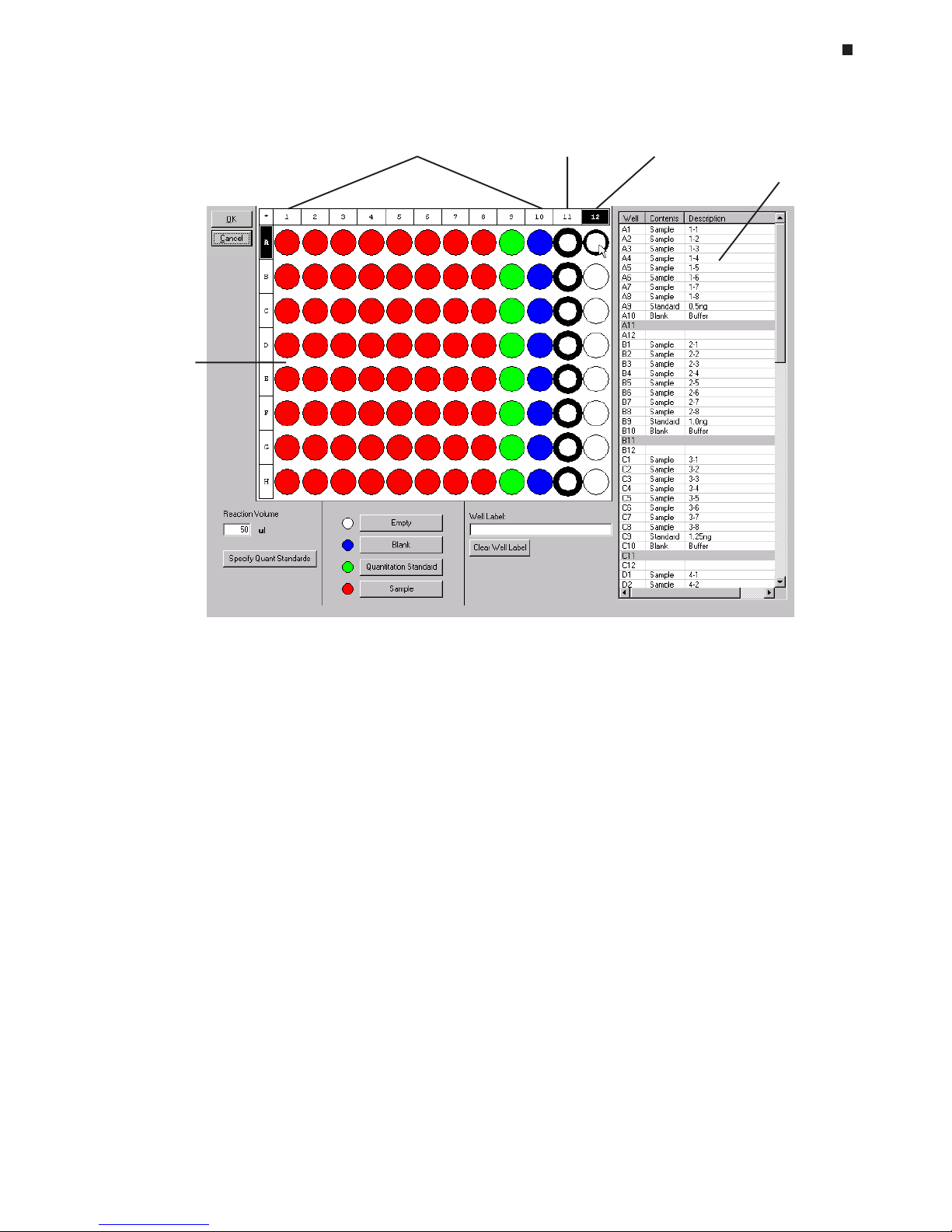

Assigning Well Contents

Follow these steps to characterize the contents of wells as empty, blank, quantitation standard, or sample:

1. Select the well or grouping of wells to which a specific content is to be assigned. You

can select wells by using either the plate diagram or the plate information

table to the right of the diagram.

Selecting Wells Using the Plate Diagram

Move the cursor over an individual well, row letter, or column number to highlight the

well or wells with a thin outline and darken the corresponding well coordinates (see

well A12 in the diagram above). Clicking on highlighted wells will select them. Selected wells appear heavily outlined, and the fields of the corresponding wells are

highlighted in the plate information table (see wells in column 11 in the diagram above).

• Select all wells in the plate by clicking on the * in the upper-left corner of the plate

diagram.

• Select all wells in a column by clicking on the numbered box at the top of the

column. To select multiple columns, hold down the control key and click on the

numbered box at the top of each column to be selected.

Plate

diagram

Wells with assigned

contents

Selected

wells

Highlighted

well

Plate

information

table

Plate file window

Page 42

6-6 Tech Support: (888) 652-9253 • Sales: (888) 735-8437 • tech@mjr.com • www.mjr.com

Opticon System Operations Manual

• Select all wells in a row by clicking on the lettered box at the start of the row. To

select multiple rows, hold down the control key and click on the lettered box at

the start of each row to be selected.

• Select an individual well by clicking on the well.

• Select multiple wells in an arbitrary pattern by holding down the left mouse button and dragging the cursor over the wells to be selected, or hold down the

control key and click on the individual wells you wish to select.

To deselect all wells, click on any blank space in the plate diagram or on another

well. To deselect a well, click on the well again.

Selecting Wells Using the Plate Information Table

• Select an individual well by clicking on the well’s coordinates (e.g., A1) in the table.

• Select multiple adjacent wells by left clicking on the coordinates of the first well to

be included, holding down the shift key, and left clicking on the coordinates of

the last well to be included in the group.

• Select multiple, non-adjacent wells by holding down the control key and left

clicking on each well’s coordinates to select it.

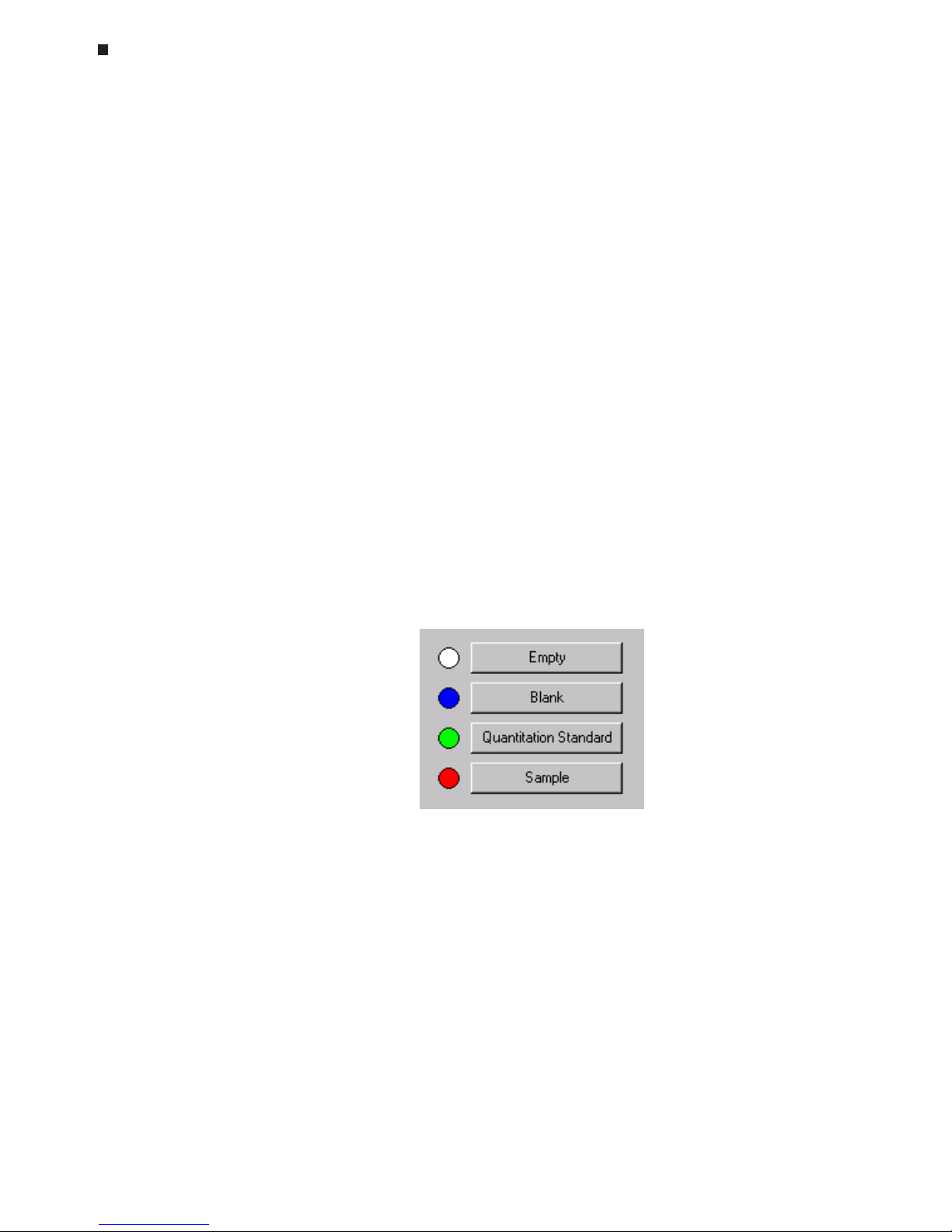

2. Assign the appropriate contents to selected wells by clicking on one of the four

contents buttons:

• Empty (white) – The well is empty. The Opticon™ detector will not measure the

fluorescence in the well. Unspecified wells are considered empty.

• Blank (blue) – The well contains a blank reaction (e.g., buffer only). Fluorescence

intensity measurements from blank wells can be used in background subtraction

calculations.

• Quantitation Standard (green)- The well contains a user-specified standard of

known quantity (see the “Specifying Quantitation Standards” section below).

Fluorescence intensity readings from quantitation standards are used to plot a

standard curve.

• Sample (red) –The well contains an experimental sample (unknown or control).

Page 43

Experimental Setup and Programming

Tech Support: (888) 652-9253 • Sales: (888) 735-8437 • tech@mjr.com • www.mjr.com 6-7

The color of assigned wells in the plate diagram should correspond to the color of the

content specified, and each content assignment should appear in the corresponding

Contents

column of the plate information table.

3. To change the content assignment of a well, select the well as described in step 1,

and click on the desired content button. The well’s color and corresponding content

information in the plate information table will reflect the content change. If a well is

not designated as empty prior to the run, the content assignment for the well can be

changed post run. Changing a "non-empty" well to "empty" post-run will

result in the irreversible loss of fluorescence data for that well.

Specifying Quantitation Standards

If you are using quantitation standards, click the

Specify Quant Standards

button

after you have designated which wells contain standards. A pop-up window will

appear listing all of the wells to which quantitation standards have been assigned.

The scroll bar will become active if the number of standards assigned is greater than

the number that can be displayed in the window.

Enter the quantity of each standard in the

Value

box. Then, specify the

Units

of the

standard by choosing either ng, moles, molecules, ge (genome equivalents), or copies from the pull-down menu, or define your own units by selecting the

Manage

but-

ton. Select

Add

in the Manage Standards window that appears, and type the desired unit designation in the Add Item window that appears. To remove unit designations from the

Units

menu, highlight the designation and click the

Remove

button.

Select

Save

to save the standard specifications, or click

Cancel

to undo any changes

to the standard specifications.

Page 44

6-8 Tech Support: (888) 652-9253 • Sales: (888) 735-8437 • tech@mjr.com • www.mjr.com

Opticon System Operations Manual

A standard curve will be automatically generated using the values supplied during

analysis of the data. You will have the option to adjust the standard curve by deselecting points (see Chapter 8).

Assigning Well Descriptions

To aid in sample identification, you can enter descriptive well labels for individual wells

or groups of wells. Begin by selecting the well(s) using the plate diagram or plate information table as specified in the “Assigning Well Contents” section above. Then, type a

description in the

Well Label

field. The well label will be applied to the selected well or

wells and appear in the Description column in the plate information table. Alternatively,

double click on an individual row in the plate information table and type a well label

directly into the well’s Description field. You can also copy and paste a well label from

one Description field in the table to a second Description field by first double-clicking on

the field and then using either (control c) to copy or (control v) to paste. To simultaneously

paste a well label into the Description fields of multiple wells, select the wells as described

above and use (control v) to paste into the

Well Label

field.

Use the

Clear Well Label

button to delete the well labels for selected wells from the

Description column.

Once you have finished entering plate file parameters, click the

OK

button in the upperleft corner of the plate file window to return to the master file window. A picture and

summary of the assigned plate contents will appear in the Plate Setup section of the master

file window.

Alternatively, if you wish to discard the plate file information and return to the master file,

click

Cancel

.

Saving a Plate File

To save the newly created plate file, select the

Save

button from the Plate Setup section in

the master file window. Enter an appropriate name in the

File Name

field of the Save

Plate File As window.

Then, specify the location to which the plate file should be saved. If a specific user has

been designated in the master file window, the plate file may be saved to that user's

personal folder

(Save to Personal Folder)

, to the shared folder (

Save to Shared Folder)

,

or to an alternate location (S

pecify Other Save Location)

. If the designated user is

Shared

,

Page 45

Experimental Setup and Programming

Tech Support: (888) 652-9253 • Sales: (888) 735-8437 • tech@mjr.com • www.mjr.com 6-9

only the last two options are available. If the

Specify Other Save Location

option is cho-

sen, select the

Browse

button to access a standard Windows browse screen, and select

the location to which you wish to save the file.

Creating a Protocol File

A protocol file contains a program that controls the thermal-cycling parameters of a run

and specifies when during the run the Opticon detector will measure the fluorescence in

the wells designated as samples, quantitation standards, and blanks. Protocol steps can

be entered and edited in the protocol file window and a listing and graphical representation of the protocol is displayed for easy review.

Click the

New

button in the

Protocol Setup

section of the master file to create a new pro-

tocol file.

Protocol file window

Insert

protocol

steps

Select methods

of temperature

and lid control

Protocol

listing

Protocol

graphical

representation

Edit

protocol

steps

Page 46

6-10 Tech Support: (888) 652-9253 • Sales: (888) 735-8437 • tech@mjr.com • www.mjr.com

Opticon System Operations Manual

Choosing a Temperature and a Lid Control Mode

Click the

Edit

button in the Temperature and Lid Mode panel to specify the temperature

Control Method and the Lid Control method to be used in the run. The Protocol Options

window will be displayed.

Temperature Control Method

The DNA Engine Opticon system can control block temperature in two different ways,

each of which has implications for the speed and accuracy of sample heating.

1. Calculated Control is the default method of temperature control. Calculated

control is the method of choice for most protocols, yielding consistent, reliable,

and fast programs. When using calculated control, the DNA Engine Opticon

system maintains a running estimate of sample temperatures based on the block’s

thermal profile, the rate of heat transfer through the sample tube, and the sample

volume. Since this estimate is based on known quantities and the laws of thermodynamics, sample temperatures are controlled much more accurately than with

block temperature control.

Hold times can be shortened significantly when protocols are run under calculated control. In addition to the simple convenience of spending less time running

reactions, shorter protocols also help preserve enzyme activity and minimize

false priming. Cycling denaturations run under calculated control are usually

optimal at five to 30 seconds, though optimization of denaturation time may be

beneficial for quantitative protocols. Annealing/extension steps can also be shortened—but the periods for these will be reaction specific.

Calculated control provides for shorter protocols in three ways:

Page 47

Experimental Setup and Programming

Tech Support: (888) 652-9253 • Sales: (888) 735-8437 • tech@mjr.com • www.mjr.com 6-11

• Brief and precise block-temperature overshoots are used to bring samples

to temperature rapidly.

• Incubation periods are timed according to how long the samples, not the

block, reside at the target temperature.

• The instrument automatically compensates for vessel type and reaction

volume.

2. When using Block Control, the DNA Engine Opticon system adjusts the block’s

temperature to maintain the block at programmed temperatures independent of

sample temperature. Block control provides less precision in control of actual

sample temperature than calculated control provides. Under block control, the

temperature of samples always lags behind the temperature of the block. The

length of the time lag depends on the vessel type and sample volume but is

typically between 10 and 30 seconds. Block control is used chiefly to run protocols developed for other thermal cyclers that use block control including the PTC100

®

cycler and the MiniCycler® personal cycler from MJ Research.

Lid Control

When a sample is heated, condensation on the tube cap or the plate cover can occur. This changes the volume of the sample, the concentration of components and thus

the kinetics of the enzymatic reaction. Use of a heated lid minimizes condensation by

keeping the upper surface of the reaction vessel at a temperature slightly greater than

that of the sample itself.

The DNA Engine Opticon system can control lid temperature in three possible ways:

Constant, Tracking

, or

Off

.

• Constant: Keeps the inner lid at a specified temperature (˚C). This is the default

method of control. To use constant lid-temperature control, select

Constant

and

enter a

Lid Temperature

between 30°C and 110°C or use the arrows to scroll to

the desired temperature. A temperature of 5°C to 15°C above the highest temperature in a protocol is recommended. You can also specify a sample-block

temperature below which the heated lid will turn off. Enter a

Lid Shutoff Tempera-

ture

between 1°C and 50°C or use the arrows to scroll to the desired tempera-

ture.

• Tracking: Offsets the temperature of the heated inner lid a minimum specified

number of degrees Celsius in comparison to the temperature of the sample block.

Tracking is useful for protocols with long incubations in the range of 30-70°C,

where it may be undesirable to keep the lid at a very high temperature. An offset

of 5°C above block temperature is adequate for most protocols. To use tracking

lid-temperature control, select

Tracking

and enter the number of degrees, from

1°C to 45°C, the lid temperature should be maintained above the block temperature, using the format

Lid Temperature = Block Temperature +

. You can also use

the arrows to scroll to the desired temperature. To specify a sample-block temperature below which the heated lid will turn off, enter a

Lid Shutoff Temperature

between 1°C and 50°C or use the arrows to scroll to the desired temperature.

Page 48

6-12 Tech Support: (888) 652-9253 • Sales: (888) 735-8437 • tech@mjr.com • www.mjr.com

Opticon System Operations Manual

Note: Because there is no active cooling of the lid, a decrease in the lid temperature may not be observed during rapid cycling. In addition, the lid heats more

slowly than the sample block as a result of its additional thermal mass.

• Off: No power is applied to the heated lid. In this mode, condensation will occur

at a rate consistent with the incubation temperature and the type of tube or plate

sealant being used. This option is recommended only when using an oil or wax

overlay.

Saving Temperature and Lid Control Settings

Click the OK button to apply your temperature and lid control settings to the protocol,

or choose

Cancel

to close the window without changing the settings applied to the

protocol. The settings should appear in the Temperature Control and Lid Settings fields

above the protocol listing and graphical display.

Designing and Entering a Protocol

Programming the DNA Engine Opticon system consists of entering a series of steps encoding a protocol. This section will present a sample protocol and describe how to enter

the protocol steps. Additional protocol options will also be described.

Consider the following example protocol:

1. Incubate at 94°C for 30 seconds

2. Optimize annealing temperature by incubating at a range of 55°C to 65°C across

the 12 columns of the sample block

3. Read the fluorescence intensity of the Blank, Quantitation Standard, and Sample

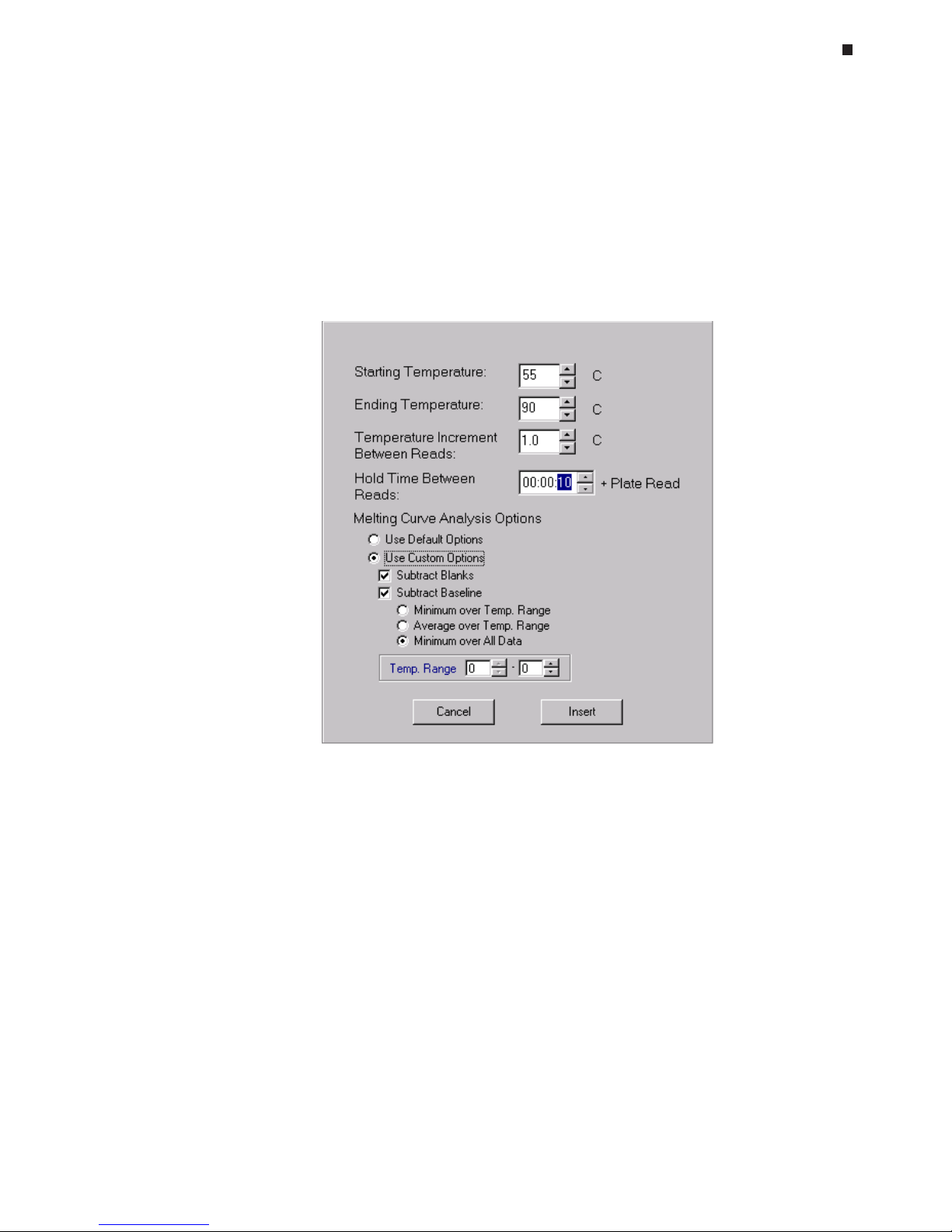

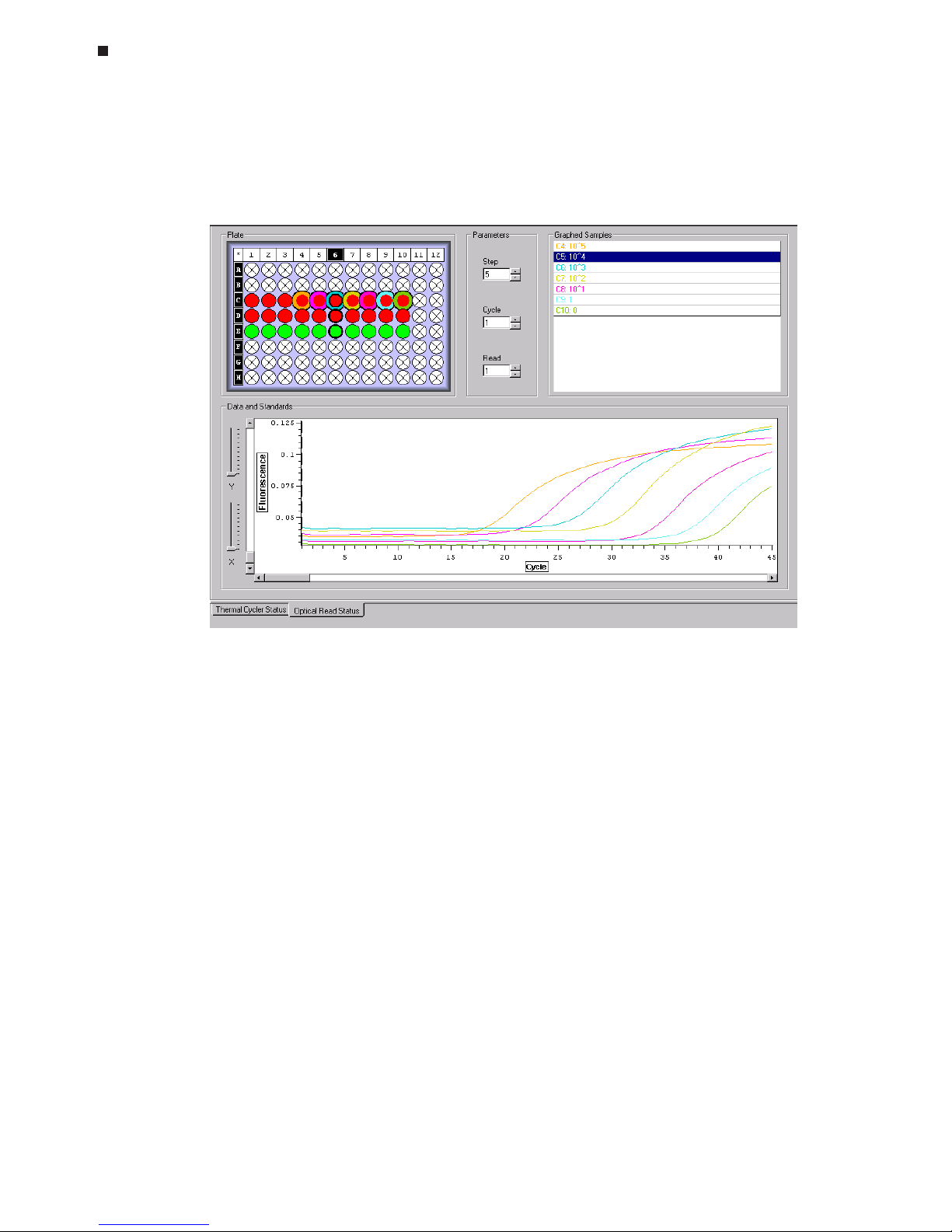

wells