Semiautomatic Pallet

Wrapping ROBOT

https://goo.gl/Xm1XrR

BeeWrap

Operation and maintenance

manual

Translation of the “ORIGINAL

INSTRUCTIONS”

Code SBC0032307

ed. 09-2017 - rev. 4

No part of this publication may be reproduced without the written consent of the Manufacturer. Pursuing a policy of continuous improvement, the Manufacturer reserves the right to change this

document without notice, provided that such changes do not create risks to safety.

Summary

Safety information

Purpose of the manual ..................................................................................................................... 3

Glossary of the terms ....................................................................................................................... 4

Attached documentation .................................................................................................................. 5

General safety warnings .................................................................................................................. 5

Safety Warnings for Handling and Installation ................................................................................. 6

Safety Warnings for Operation and Use........................................................................................... 7

Safety Manager Obligations ......................................................................................................... 7

Safety Warnings on Misuse.............................................................................................................. 8

Safety Warnings on Residual Risks ................................................................................................. 8

Safety Warnings for Maintenance and Adjustments......................................................................... 9

Safety warnings for the electrical equipment ................................................................................. 10

Safety warnings for the environmental impact ............................................................................... 10

Safety and information symbols ......................................................................................................11

Technical Specications

general description of the machine ................................................................................................ 13

Description of the main components .............................................................................................. 14

Manufacturer and machine identication ....................................................................................... 16

Cycle .............................................................................................................................................. 17

Types of wrapping .......................................................................................................................... 18

Residual risks ................................................................................................................................. 19

Incorrect uses that are reasonably expected ................................................................................. 20

Optional Accessories ...................................................................................................................... 21

Description of the safety devices ................................................................................................... 22

Specications ................................................................................................................................. 23

Description of outer areas .............................................................................................................. 25

Position of information and safety plates ....................................................................................... 26

IDM 510-032-5_Sommario

Use and functioning

Recommendations on Operation and Use ..................................................................................... 27

Control description ......................................................................................................................... 28

Emergency stop and new start-up ................................................................................................. 32

Stop with activation of the emergency button ............................................................................. 32

Stop with activation of the emergency bumper ........................................................................... 32

(Single or double) automatic wrapping ........................................................................................... 33

Normal stop ................................................................................................................................ 34

(Single or double) automatic wrapping with sheet feeder .............................................................. 35

Normal stop ................................................................................................................................ 37

Setup of parameter values ............................................................................................................. 38

Recipe management ...................................................................................................................... 39

Modifying a recipe ....................................................................................................................... 39

Loading a recipe ......................................................................................................................... 40

Recipe lock/unlock mode ............................................................................................................... 41

Recipe function “P0” ................................................................................................................... 41

Disassembly and reassembly of battery panel ............................................................................... 42

Assembly of battery panel .......................................................................................................... 42

English languageOperation and maintenance manual

1

Maintenance

Recommendations for maintenance interventions ......................................................................... 43

Scheduled maintenance intervals .................................................................................................. 44

Daily check of the safety bumper ................................................................................................... 45

Monthly check of the safety bumper .............................................................................................. 46

Yearly check of the safety bumper ................................................................................................. 48

Recommendations for accumulator batteries ................................................................................. 49

Maintenance of accumulator batteries (GEL) ................................................................................. 50

Maintenance of accumulator batteries (ACID) ............................................................................... 50

Charge of accumulator batteries .................................................................................................... 51

Problems, causes, remedies .......................................................................................................... 53

Alarm message table ..................................................................................................................... 54

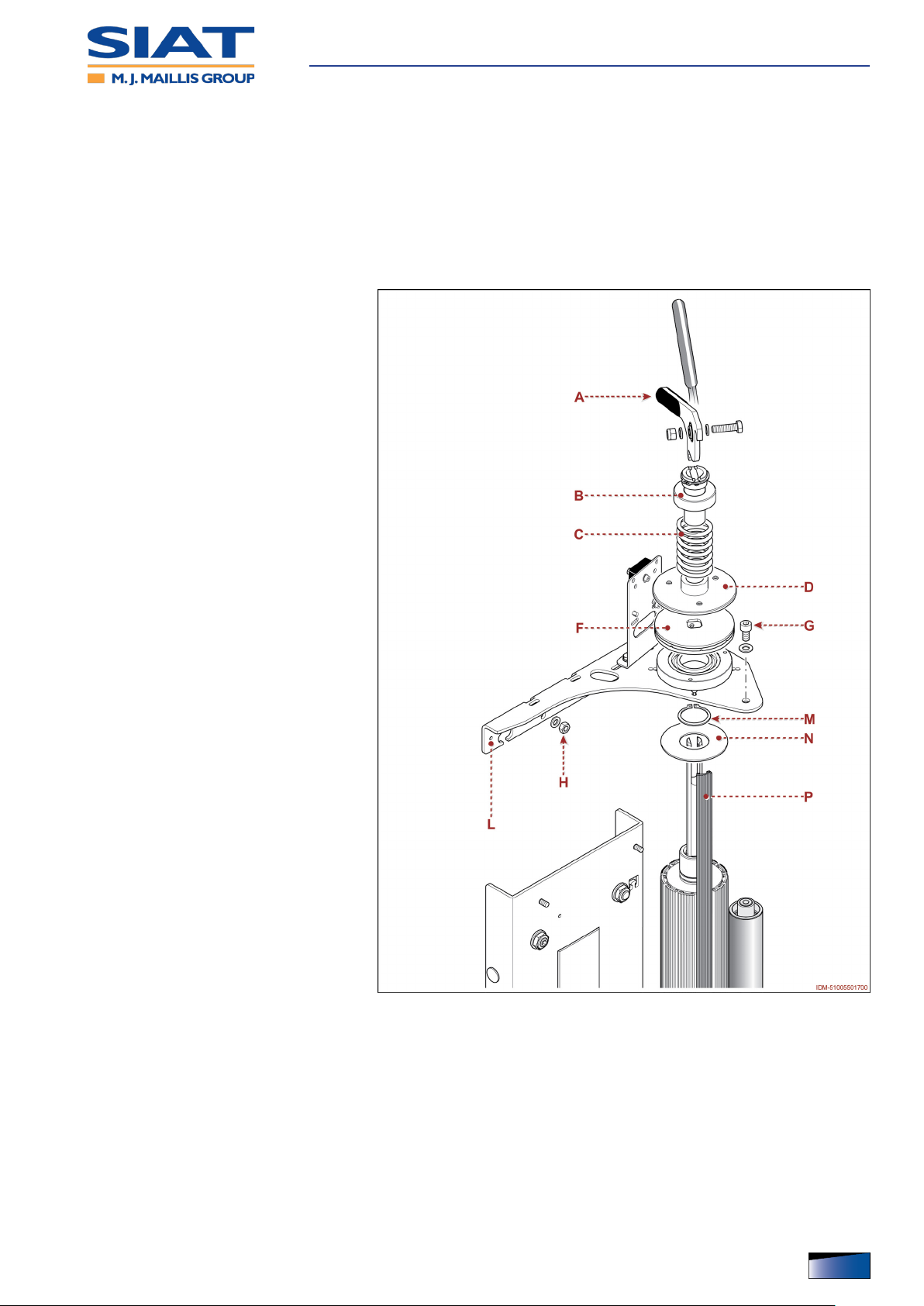

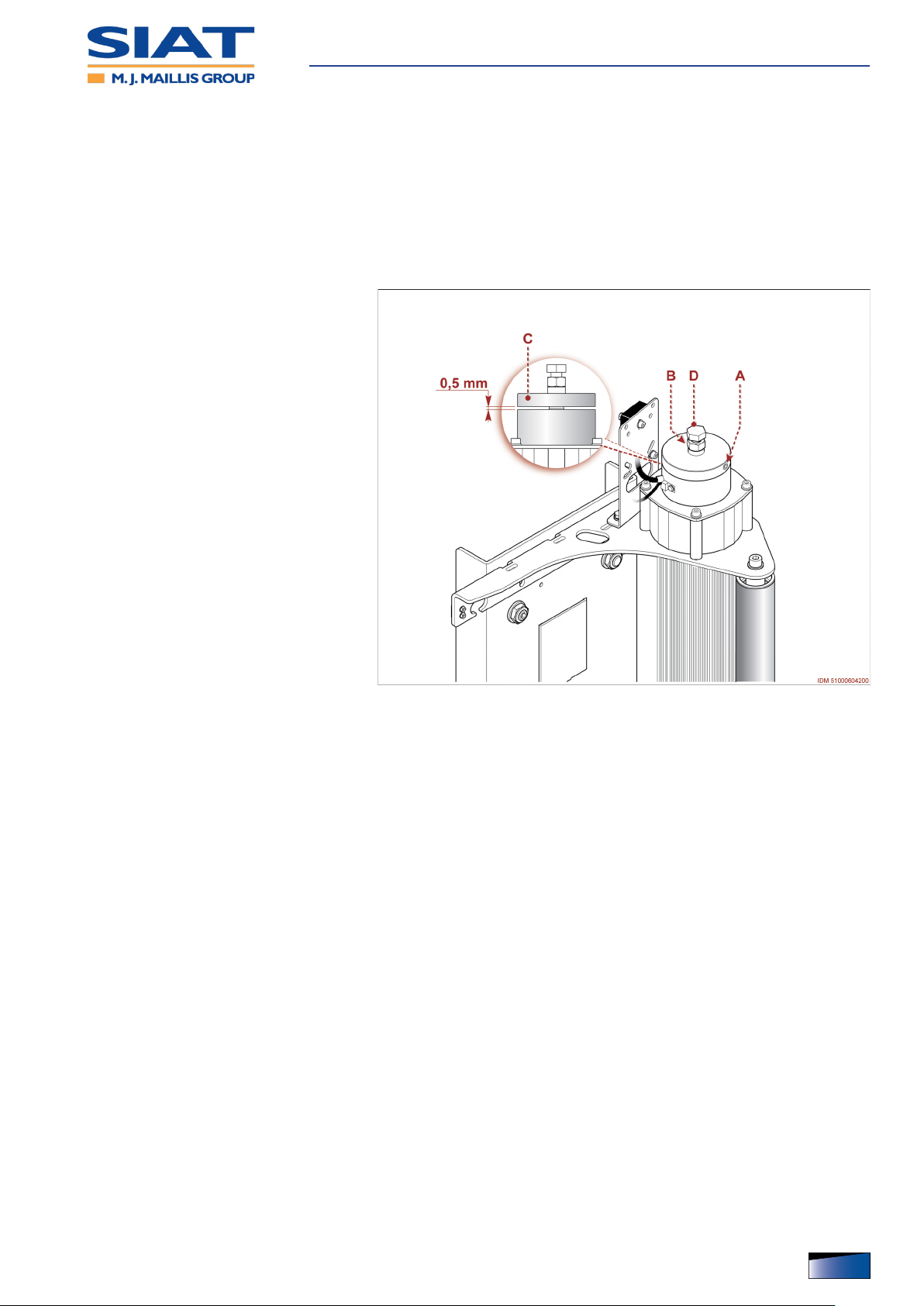

How to adjust the feeler ................................................................................................................. 56

Sensitivity adjustment for the product to be wrapped detection photocell ..................................... 57

Replacing the lifting belt of the carriage ......................................................................................... 58

Battery replacement ....................................................................................................................... 60

Machine Disposal and Scrapping ................................................................................................... 61

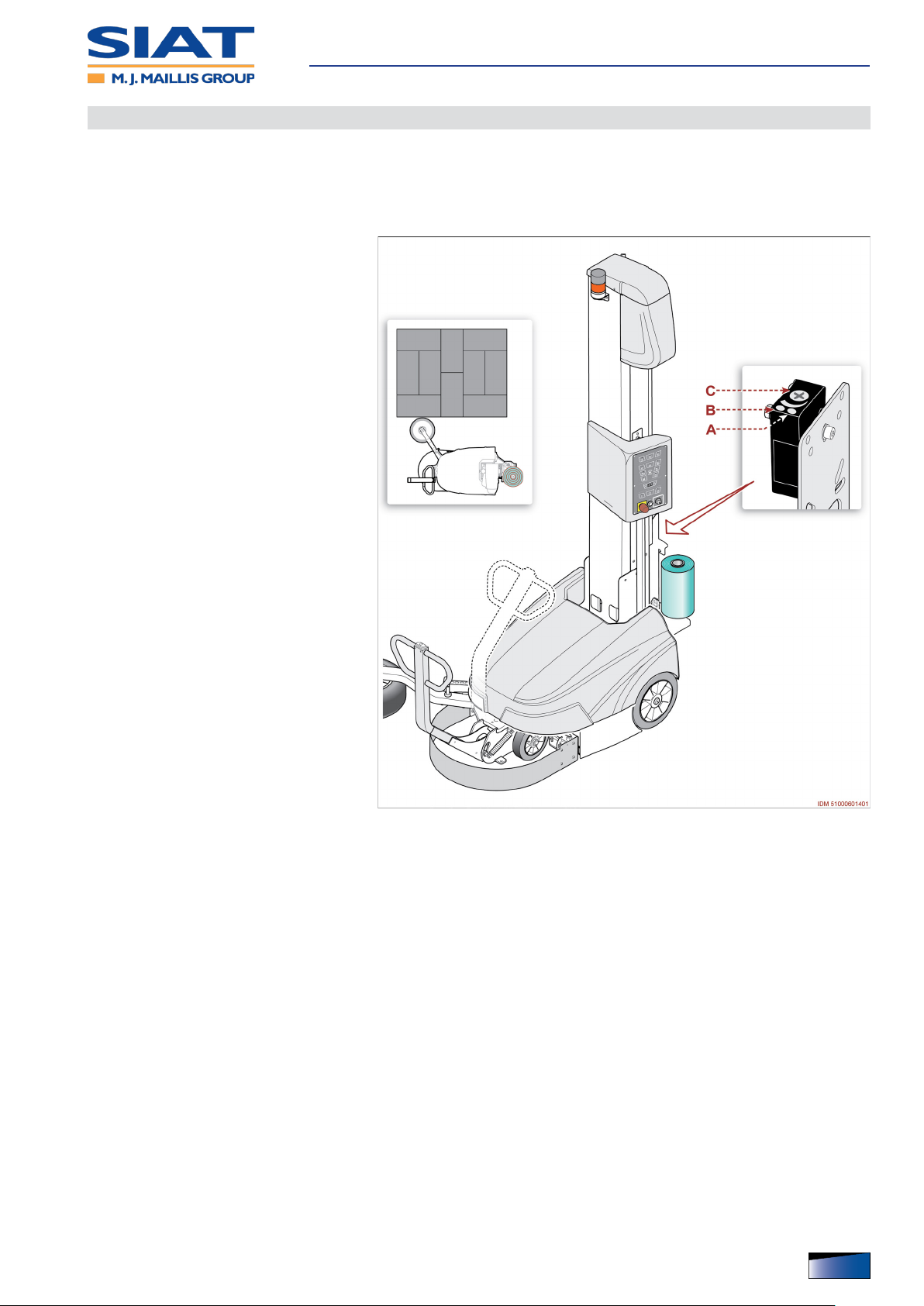

Reel holding carriages

Reel holding carriage (M) ............................................................................................................... 62

Main components ....................................................................................................................... 62

Film Coil Feeding ........................................................................................................................ 63

Tension adjustment of lm .......................................................................................................... 63

Cleaning and replacement of brake disc .................................................................................... 64

Replacing the outer surface of roller ........................................................................................... 65

Reel holding carriage (FM) ............................................................................................................. 66

Main components ....................................................................................................................... 66

Film Coil Feeding ........................................................................................................................ 67

Tension adjustment of lm .......................................................................................................... 67

Cleaning and replacement of brake disc .................................................................................... 68

Adjustment of brake .................................................................................................................... 69

Replacing the outer surface of roller ........................................................................................... 70

Reel holding carriage (LP) ............................................................................................................. 71

Main components ....................................................................................................................... 71

Film Coil Feeding ........................................................................................................................ 72

Tension adjustment of lm .......................................................................................................... 72

Replacement of pre-stretch kit .................................................................................................... 73

Net-type reel holder carriage .......................................................................................................... 75

Main components ....................................................................................................................... 75

Supplying the reel with net .......................................................................................................... 76

Adjustment of net tension ........................................................................................................... 76

Cleaning and replacement of brake disc .................................................................................... 77

Replacement of the net tensioning roller .................................................................................... 78

Analytical index ............................................................................................................................ 79

2

English language Operation and maintenance manual

IDM 510-032-5_Sommario

Purpose of the manual

– The purpose of the manual is to inform and train operators so that they can interact

with the machine in SAFE CONDITIONS.

– Its aim is also to prevent risks, to reduce the social costs resulting from accidents and

damage to the health of people, property and to the environment.

– In some cases, accidents may be due to the Operator using the machine care-

lessly.

– Caution is always necessary. Safety is also the responsibility of all the persons

interacting with the machine throughout its operating life.

– Remember that it is too late to think about safety issues when the accident has

already occurred.

– Reading the Operating Instructions is fundamental in order to minimize the risks

and avoid accidents.

– The content of this manual was originally edited by the Manufacturer in the mother

tongue (ITALIAN), in compliance with the professional writing standards and the regulations in force.

Safety information

– Any translation of the manuals shall be carried out directly and without alterations from

the texts of the ORIGINAL INSTRUCTIONS.

– This applies also to the translations carried out by the agent or by the person who is in

charge of delivering the equipment in the specic linguistic area.

– The Manufacturer reserves the right to make any changes to the content of the manu-

als without prior notice, provided that such changes do not alter the safety level.

– All information supplied by the recipients represents an important contribution to the

improvement of the after-sales service that the manufacturer will offer to his/her customers.

– All supplied information is organised into an index and a table of contents, so as to

easily track specic topics of interest.

– The SAFETY WARNINGS and the INSTALLATION MANUAL are supplied as hard-

copy publications.

– The USE AND MAINTENANCE MANUAL, operation diagrams and all other post-

sale documents can be downloaded from the INTERNET.

– Keep the manual and the attached documents in a place known and easily traceable,

so that you may refer to them whenever necessary.

IDM 510-004-3

English languageOperation and maintenance manual

3

Glossary of the terms

The glossary includes some terms used when processing information, with their

denition, in order to facilitate understanding.

– Training: A process aiming at transferring the knowledge, skills and behaviours re-

quired to work in an autonomous, correct and hazard-free manner.

– Assistant: person chosen, trained and coordinated in an appropriate manner to mini-

mize the risks in carrying out their tasks.

– Emergency stop: voluntary activation of the special control that stops the dangerous

elements of the work unit in the case of imminent risk.

– Stop in alarm conditions: this state causes the components to stop and is activated

when the control system detects a problem in the machine operation.

– General shut down: In addition to the normal stop this state also causes the interrup-

tion of all the power sources (electrical, pneumatic, etc.).

– Operating Stop: state that does not cut off power supply to the actuators, but ensures

control system monitoring in safe conditions.

– Size change: a set of interventions to be carried out before beginning to work with

specications different with respect to the ones previously in use.

Safety information

– Test-run: a series of operations required to ensure compliance to the design speci-

cations, and to commission the machine under safety conditions.

– Installer: a technician chosen and authorized by the manufacturer or his authorized

representative, among those who full the requirements for installation and testing of

the machine or plant in question.

– Maintenance Operator: a technician chosen and authorized, among those who full

the requirements, to carry out routine and extraordinary maintenance operations on

the machine. Therefore, the maintenance operator shall possess precise knowledge

and skills, with particular skills in the relevant eld.

– Routine Maintenance: all the operations necessary to maintain the functionality and

efciency of the machine. Normally, these operations are scheduled by the manufacturer, who denes the necessary skills and methods of action.

– Operator: a person chosen and authorized, among those who full the requirements,

having the knowledge and skills necessary to operate the machine and carry out routine maintenance interventions.

– Person in charge of the installation: a technical expert who must carry out the instal-

lation in compliance with the laws applicable to the workplace and, at the end, assess

its compliance.

– Residual risks: all the risks remain even if all the safety solutions have been adopted

and integrated when the machine has been designed.

– Expert Technician: A person authorised by the Manufacturer and/or his representa-

tive to carry out services that require specic technical skills and abilities.

– Forwarder and Handler: Authorized persons with recognized expertise in the use of

means of transport and lifting devices, in safety conditions.

– Improper use: reasonably foreseeable use different from what is specied in the use

manual, that may be caused by human behaviour.

4

English language Operation and maintenance manual

IDM 510-004-3

Attached documentation

The SAFETY WARNINGS and the INSTALLATION MANUAL are supplied as hardcopy publications.

– The USE AND MAINTENANCE MANUAL, operation diagrams and all other post-sale

documents can be downloaded from the INTERNET.

– The list shows the documentation supplied with the machine.

– CE Declaration of conformity

– Operation and maintenance manual

– Installation manual

– Wiring diagrams

– Pneumatic system diagrams

– Specic Manuals for installed components or sub-assemblies available commercially

General safety warnings

– The machine has been designed and built with all the precautionary measures aimed

at minimising the possible risks over its expected life cycle.

Safety information

– Tampering with and bypassing the safety devices may lead to severe risks for the Op-

erators.

– Before interacting with the machine, and in particular, before its rst use, read the

SAFETY WARNINGS contained in the manual.

– Spend some of your time reading this information to avoid any risk for people’s health

and safety as well as economic damage.

– Respect the SAFETY WARNINGS. Avoid any IMPROPER USE of the machine and

assess the RESIDUAL RISKS.

– When operating the machine, DO NOT wear clothes and/or accessories that could

become caught in the moving or protruding parts.

– Before machine use and/or maintenance, read the information contained in the refer-

ence documents and accurately implement the described procedures.

– Carry out the interventions ONLY according to the modes recommended by the Man-

ufacturer in the “Instructions for use”.

– The personnel in charge of carrying out interventions on the machine must have suit-

able and proven experience in this specic eld.

– Please keep safety signs and information legible and follow the instructions.

– The information signals may be of different shapes and colours, to indicate dangers,

obligations, prohibitions and indications.

– Signals which are no longer legible must be replaced and repositioned in the same

place of origin.

– The non-compliance with the information provided herein may lead to risks for

the safety and health of the persons involved and may also lead to economic

damages.

IDM 510-004-3

English languageOperation and maintenance manual

5

Safety Warnings for Handling and Installation

– The manufacturer has attached special attention to the packaging of the machine, to

minimise the risks associated with the shipping, handling and transport phases.

– The personnel authorised to handle the machine (loading and unloading) must have

acknowledged technical skills and professional ability.

– Before handling, please read the instructions, in particular those on safety, contained

in the installation manual, on the packages and/or on the removed parts.

– In order to make transport easier, the equipment can be shipped with a few disassem-

bled and properly protected and packaged components.

– Loading and transport must be carried out with equipment of adequate capacity by

anchoring it to specic points indicated on the packages.

– DO NOT attempt to by-pass the instructions concerning the lifting requirements and

special points provided for lifting and handling each item and/or disassembled part.

– Slowly lift the pack to the minimum necessary height and move it very carefully in order

to avoid dangerous vibrations.

– The packs being shipped must be properly fastened to the means of transport in order

to ensure safe conditions during transfer and the integrity of their contents.

– Certain steps might request one or more operators, who must be previously trained

and informed on the tasks they will have to perform.

– Download packages in the immediate vicinity of the machine setting, which must be

sheltered from bad weather.

– Do not stack the packs onto each other in order to avoid any damage and to avoid the

risk of sudden and dangerous movements.

– In case of prolonged storage, regularly check that the component stocking conditions

do not change.

– The installation area is to be prepared so as to be able to carry out the operations as

specied in the manuals and in conditions of safety.

– Ensure that the installation environment is protected against atmospheric agents, free

of corrosive substances and free of any risk of explosion and/or re.

– Make sure that the installation area has a suitable ventilation to avoid the concentra-

tion of unhealthy air for the Operators.

– Signal and delimit the installation area in a proper way in order to prevent non author-

ised personnel from accessing the installation area.

– The connections to the power sources (electric, pneumatic, etc.) must be performed

correctly, as shown in the diagrams and in compliance with the regulatory and legal

requirements in force.

– ONLY qualied and experienced personnel are allowed to carry out the electrical con-

nections.

– After completing the connections, perform a general check to ensure that all the inter-

ventions have been carried out properly and that the requirements have been met.

– The installation manager, before commissioning, must check that all the safety devices

are properly installed and functioning.

– At the end of operations check that there are no other tools or other material near the

moving parts or in dangerous areas.

– Dispose of all packing in accordance with the laws in force in the country of installation.

– The non-compliance with the information provided herein may lead to risks for

the safety and health of the persons involved and may also lead to economic

damages.

Safety information

IDM 510-004-3

6

English language Operation and maintenance manual

Safety Warnings for Operation and Use

– The machine must be used by one single operator ONLY, who must be trained and

capable of performing the work and be in suitable conditions.

– Certain steps might request one or more operators, who must be previously trained

and informed on the tasks they will have to perform.

– Consult the user manual, in particular during the rst use, and make sure that you

fully understand its content.

– Find out the position and function of the controls and simulate some operations (in

particular start and stop) in order to acquire familiarity.

– The machine shall be used ONLY for the purposes and complying with the procedures

specied by the Manufacturer.

– Make sure that all the safety devices are properly installed and efcient.

– The machine should be used ONLY with the original safety devices installed by the

Manufacturer.

– Ensure the area around the machine, especially the control post, is ALWAYS unob-

structed and in good condition to minimize the risks for the Operator.

Safety information

– According to the type of operation to carry out, wear the Personal Protective Equip-

ment listed in the “Instructions for use” and that indicated by the Labour laws.

– The non-compliance with the information provided herein may lead to risks for

the safety and health of the persons involved and may also lead to economic

damages.

Safety Manager Obligations

▀

– The safety manager must train the operator and help him or her familiarise and interact

with the machine in an independent, adequate and risk-free manner.

– The operator must be informed about reasonably predictable INCORRECT USES and

about the RESIDUAL RISKS that remain.

– The operator must demonstrate that he has acquired the relevant skills and has under-

stood the “User Instructions” in such a way as to carry out his activities safely.

– The operator must be able to recognise the safety signals and demonstrate that he is

in suitable condition to carry out his assigned duties.

– The safety manager must release educational material to trainees and document the

delivered training, so as to be able to produce such documentation in case of litigation.

IDM 510-004-3

English languageOperation and maintenance manual

7

Safety Warnings on Misuse

Improper use: reasonably foreseeable use different from what is specied in the

use manual, that may be caused by human behaviour.

– ONLY trained, documented and authorized Operators are allowed to use the machine.

– DO NOT use or allow other persons to use the machine if the safety devices are faulty,

disabled and/or incorrectly installed.

– DO NOT use or allow other persons to use the machine for purposes and in ways dif-

ferent from what specied by the Manufacturer.

– DO NOT use the machine in home environments.

– DO NOT wear clothes and/or accessories that could become caught in the moving or

protruding parts.

– When operating the machine, ALWAYS wear the Personal Protective Equipment spec-

ied by the Manufacturer and by the current regulations on safety at work.

– If troubles arise, do NOT continue to use the machine. Stop it immediately and restart

only after restoring the normal operating condition.

– DO NOT use the machine if the scheduled routine maintenance interventions have not

been carried out.

Safety information

– DO NOT tamper with, override, bypass or eliminate the safety devices installed on the

machine.

– DO NOT modify the manufacturing and functional characteristics of the machine in any

manner whatsoever.

– DO NOT perform any interventions other than those specied in the Operation Manual

without the explicit authorization of the Manufacturer.

– DO NOT carry out any intervention when the machine is being operated. Stop the

machine and put it in safety condition before carrying out any intervention.

– DO NOT clean or wash the machine using aggressive products that may damage its

components.

– DO NOT replace the components with non-genuine spare parts or other components

with different design and manufacturing specications.

– DO NOT dump in the environment any materials, polluting liquids and maintenance

waste generated during the operations. Dispose of them according to the regulations

in force.

– DO NOT leave the machine unattended during operation and DO NOT leave it at the

end of the work without stopping it to safety conditions.

– The non-compliance with the information provided herein may lead to risks for

the safety and health of the persons involved and may also lead to economic

damages.

Safety Warnings on Residual Risks

Residual risks: all the risks remain even if all the safety solutions have been adopted and integrated when the machine has been designed.

– Upon designing and building the machine, the Manufacturer has paid particular atten-

tion to the RESIDUAL RISKS that may affect the safety and health of the Operators.

– For specic information about residual risks, please refer to the machine user manual.

8

English language Operation and maintenance manual

IDM 510-004-3

Safety Warnings for Maintenance and Adjustments

– Always keep the machine in optimum operating condition and carry out the routine

maintenance according to the intervals and procedures specied by the Manufacturer.

– A good maintenance will ensure a stable performance over time, longer working

life and constant compliance with the safety requirements.

– The personnel authorized to carry out the ordinary maintenance must have qualied

expertise and specic skills in the eld of intervention.

– Any work on the electrical system must ONLY be performed by technicians with ac-

knowledged, eld-specic skills.

– Mark the intervention area and prevent access to the devices that, if activated, may

cause unexpected hazards and jeopardize the safety level.

– According to the type of operation to carry out, wear the Personal Protective Equip-

ment listed in the “Instructions for use” and that indicated by the Labour laws.

– Respect the SAFETY WARNINGS. Avoid any IMPROPER USE of the machine and

assess the RESIDUAL RISKS.

– Before carrying out any intervention, activate all the safety measures, and assess any

residual energy which may still be present.

Safety information

– Interventions to not easily accessible or dangerous areas shall be carried out ONLY

after arranging the required safety conditions.

– Carry out the interventions ONLY according to the modes recommended by the Man-

ufacturer in the “Instructions for use”.

– All operations must be carried out ONLY with suitable tools which shall be in good

condition, in order to avoid damaging any components and parts of the machine.

– Replace the components and/or safety devices ONLY with original spare parts in order

not to alter the required safety level.

– The use of similar but not genuine spare parts can lead to non-compliant repairs, im-

paired performance and economic damage.

– Use the lubricants (oils and greases) recommended by the Manufacturer or lubricants

of equivalent chemical and physical characteristics.

– At work completion, restore all the security conditions aimed to prevent and minimize

the risks during the human-machine interaction.

– At the end of operations check that there are no other tools or other material near the

moving parts or in dangerous areas.

– Refer to the Technical Assistance Service of the Manufacturer, in case interventions

not described in the “Instructions for use” are needed.

– All EXTRAORDINARY MAINTENANCE interventions shall be performed only by au-

thorized Technicians with proven and gained experience in the eld.

– The non-compliance with the information provided herein may lead to risks for

the safety and health of the persons involved and may also lead to economic

damages.

IDM 510-004-3

English languageOperation and maintenance manual

9

Safety warnings for the electrical equipment

The electrical equipment has been built in accordance with the applicable standards and its efciency is ensured if the listed conditions are met.

– Ambient temperature and relative humidity between maximum and minimum permitted

limits.

– Absence of environmental electromagnetic noise and radiation (X-rays, laser, etc.).

– Absence of environment areas with gas and dust concentration levels potentially ex-

plosive and/or at risk of re.

– Use of products and materials free from contaminants and corrosive agents.

– Products containing chemicals, acids, salts, etc. can come into contact with the elec-

trical components and cause irreversible damage.

– Transport and storage temperatures between minimum and maximum permitted limits.

– Altitude not exceeding the maximum permitted limits.

– Installation at altitudes higher than the permitted values will affect the efciency of

electrical and electronic components.

– Power Cable with section suitable for the current power and intensity values indicated

in the data plate.

Safety information

– Protection class in accordance with data plate indications.

– The power supply line to which the machine must be connected must have identical

characteristics to those mentioned in the data plate.

Important

All the listed requirement values are contained in the technical specications table.

– If one or more of the listed requirements cannot be met, alternative solutions

should be agreed at the ordering stage.

Safety warnings for the environmental impact

Each organization is responsible for implementing procedures aimed at identifying, evaluating and controlling the environmental impact of its own activities (products, services, etc.).

– Procedures for identifying signicant environmental impact must take account of the

factors listed.

- Emissions in the atmosphere

- Discharged liquids

- Waste disposal

- Soil contamination

- Use of raw materials and natural resources

- Local problems related to the environmental impact

– In order to minimize the environmental risks during the man-machine interaction follow

the recommended instructions.

- Dispose of all packing in accordance with the laws in force in the country of installation.

- Make sure that the installation area has a suitable ventilation to avoid the concentration of unhealthy air for the Operators.

- Keep noise level to the minimum to reduce noise pollution.

- Select materials on the basis of their composition and provide for differentiated disposal in accordance with the laws in force.

10

English language Operation and maintenance manual

IDM 510-004-3

- Avoid dumping polluting materials and products in the environment (oils, greases,

electrical and electronic apparatus etc.).

- All the components of Electrical and Electronic Apparatus contain dangerous substances and are appropriately marked.

- Dispose of Electrical and Electronic Apparatus Waste properly, at authorised collection centres, to avoid harmful and damaging effects.

- Incorrect disposal of dangerous waste is punishable with sanctions regulated by the

laws in force on the territory in question.

– The non-compliance with the information provided herein may lead to risks for

the safety and health of the persons involved and may also lead to economic

damages.

Safety and information symbols

The gures show safety signs and information and the relevant meaning.

– For more details on the signs actually used, refer to the section on “Position of the

safety signs and information”.

– Electrical shock or electrocution hazard: hazard signal that warns

the operator from accessing the areas under voltage in order to avoid

risks.

Safety information

– Risk of tripping: danger signal indicating that attention should be

paid to projections from the structure.

– Risk of slipping: danger signal indicating that attention should be

paid during transfers on at surfaces.

– Risk of crushing body parts: danger signal warning to stay out of

the active machine work range.

– Risk of crushing upper limbs: danger signal warning to keep upper

limbs out of the active machine work range.

– Risk of projection of objects: it indicates the presence of ying ma-

terials due to high operating speeds or load instability.

IDM 510-004-3

English languageOperation and maintenance manual

11

– Cutting hazard: danger sign warning not to come close to the cutting

parts with the upper limbs.

– Risk of entanglement: danger sign warning not to come close to the

moving parts with the upper limbs.

– Information Signal: indicates the required direction of rotation for

operation.

– Information Signal: indicates the lifting points for fork-type devices.

Safety information

– Information sign: it indicates the points where to attach the hooks of

the lifting device.

– Information Signal: indicates the earthing point.

– Information warning sign: read the operation and maintenance

manual carefully before performing any operations.

– Information signal: before performing any operation, disconnect the

power plug to avoid electric shock hazards.

12

English language Operation and maintenance manual

IDM 510-004-3

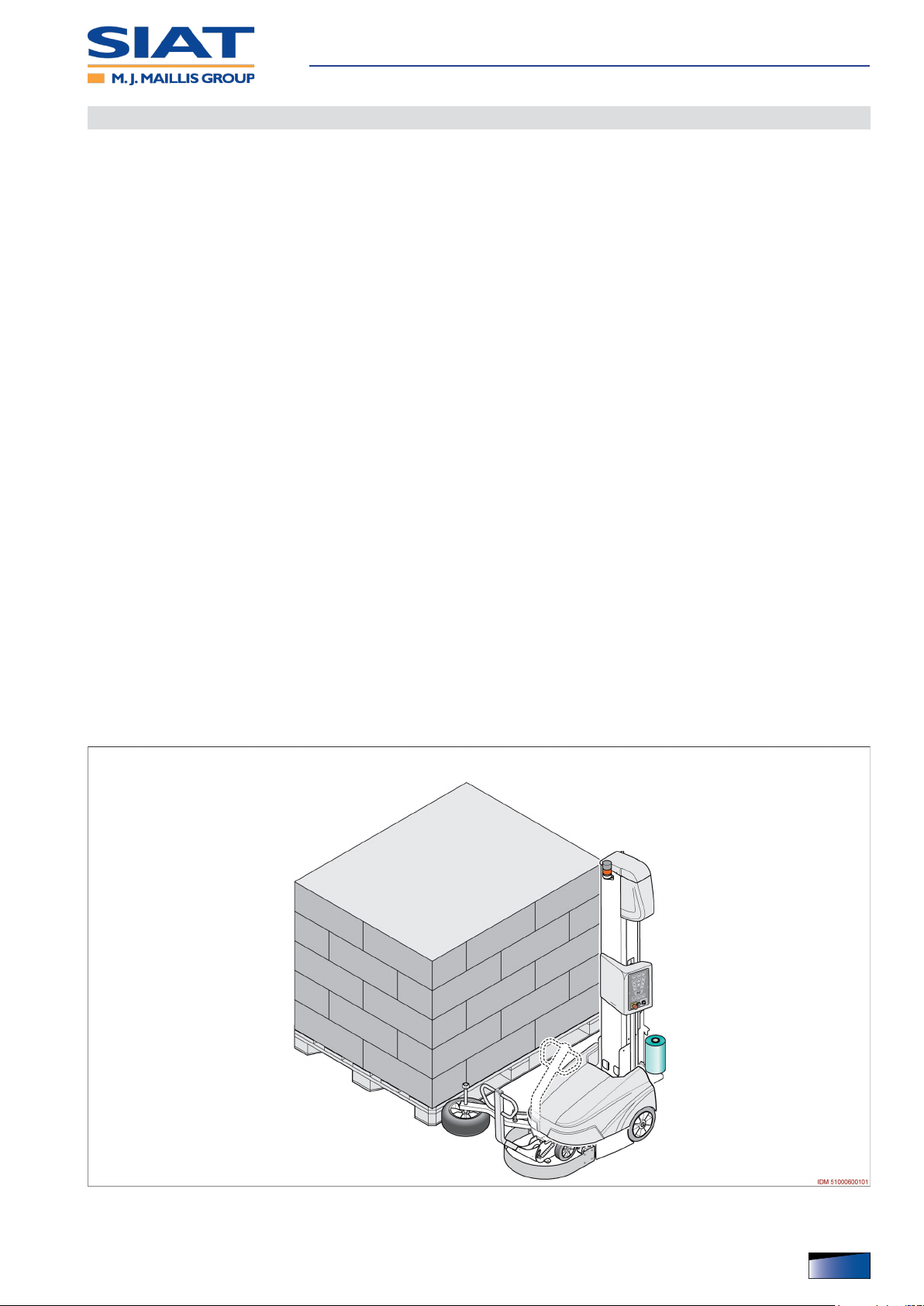

Technical Specications

general description of the machine

The semiautomatic robot series BeeWrap is a machine designed and built to stabilise palletised products with stretch lm.

– The products to be wrapped must be contained in packages (cases, containers for

liquids, etc.) having a regular shape or in any case, such as to allow for stable palletising.

– The containers of liquids or uids should be hermetically sealed and with suitable char-

acteristics to avoid spilling any content.

– To wrap loads, commercially available reels of stretch lm are used.

– The machine has been designed, built and equipped by applying integrated safety

principles.

– The machine is for professional use only and must be used in industrial-type settings

- factories or workshops.

– The premises must have no areas with gas and dust concentration levels that are po-

tentially explosive and/or at risk of re.

– The working area must be at (no slopes), compact and smooth to allow for easy and

safe movement of the machine.

– On request, the machine may be equipped with accessories, either when it is ordered

or later.

See “Optional Accessories” for further details.

– The machine must be used by one single operator ONLY, who must be trained and

capable of performing the work and be in suitable conditions.

– The operator must programme the wrapping cycle, start and monitor the operating

cycle and control the machine stops (pause, emergency, etc.).

– The operator must also change the lm reel, carry out the battery charge procedures

and the scheduled maintenance operations.

IDM 510-006-5

English languageOperation and maintenance manual

13

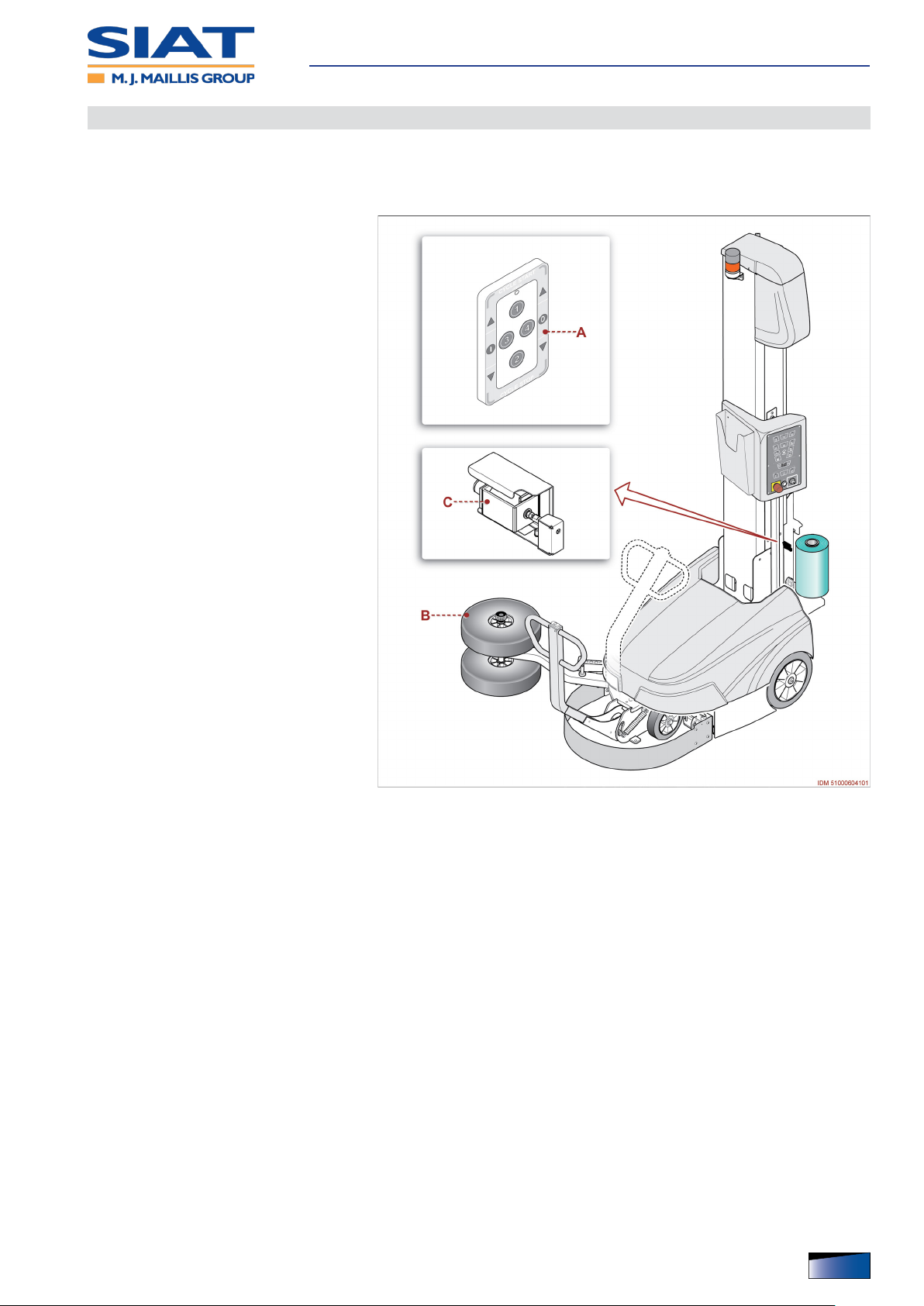

Technical Specications

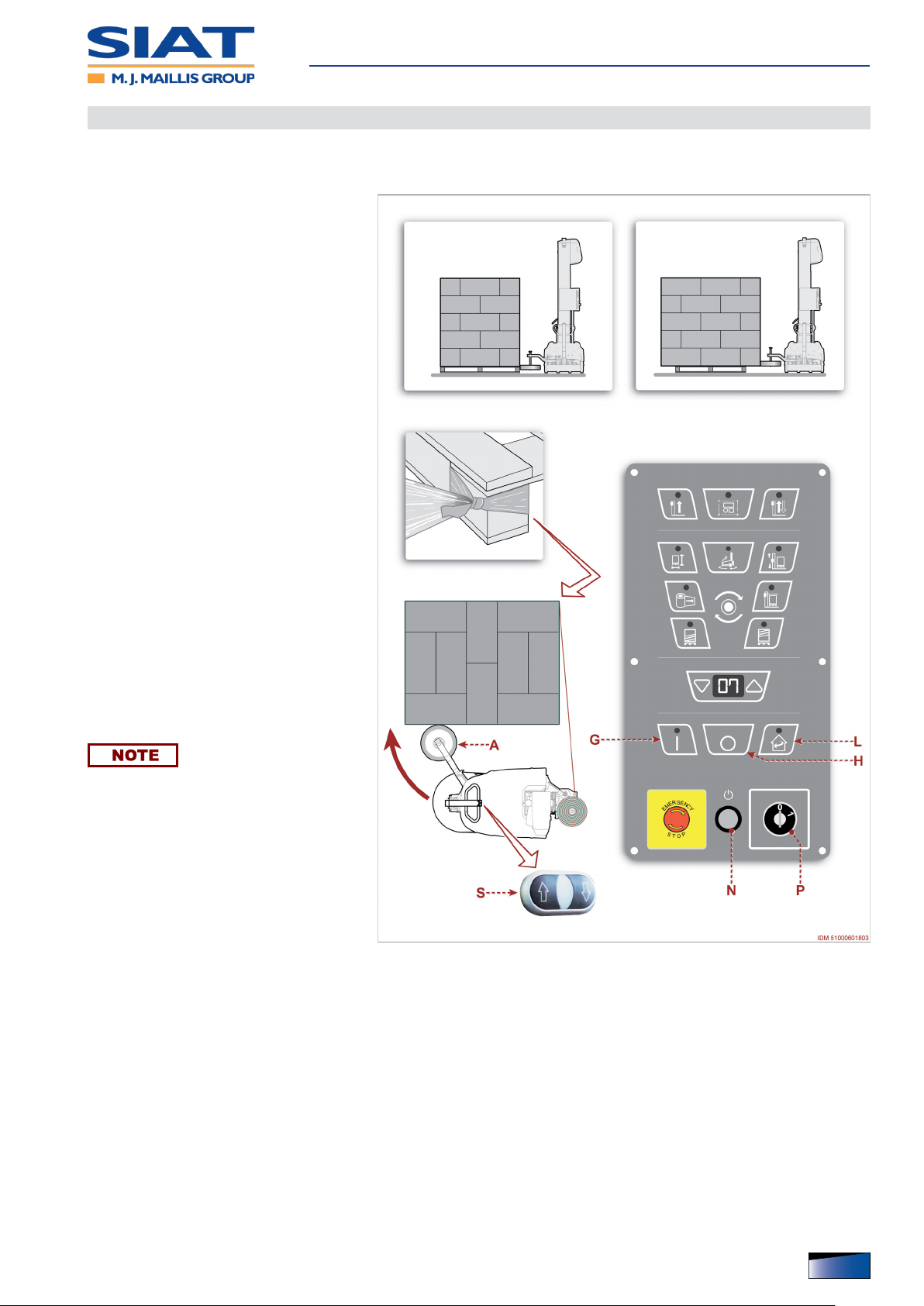

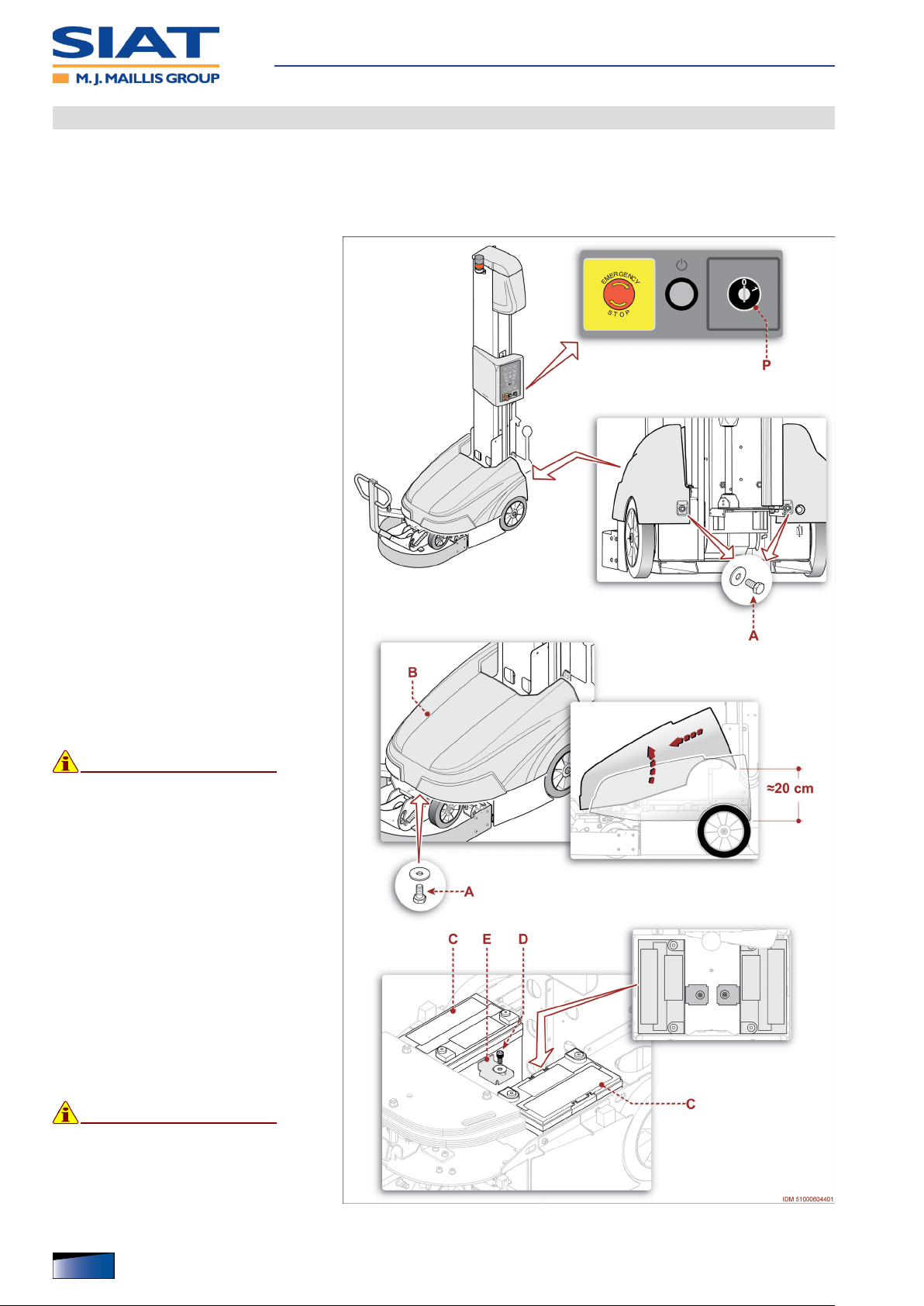

Description of the main components

The image shows the main components and the list reports their description and

function.

14

English language Operation and maintenance manual

IDM 510-006-5

Technical Specications

A) Handlebar: control that drives the machine during the movement.

– The controls installed in the handlebar start the movement.

B) Feeler: it helps keeping the machine in contact with the perimeter of the load to be

wrapped.

C) Accumulator batteries: they supply the circuit and electric motors with power.

D) Battery charger: This electronic device is used to recharge the batteries C.

– To charge battery , connect the power supply cable to power outlet E.

– The charging status is shown on display of control panel E.

E) Electrical power outlet: it is used to connect battery charger to the power supply

network.

F) Control panel: it contains the devices to start and control all the operation functions.

G) Column: it is used for vertical movement of reel holding carriage H.

H) Reel holding carriage

– According to production requirements, in the ordering phase the machine can be

equipped with one of the listed carriages.

– Reel holder carriage (type M): suitable for wrapping, allows the operator to adjust the

lm tension manually using the ring nut of the mechanical brake.

– Reel-holder carriage (type FM): suitable for wrapping, allows the operator to adjust

the lm tension from the control panel.

– Reel-holder carriage (type LP): suitable for wrapping, with motorised lm pre-stretch-

ing and electronic tension adjustment from the control panel.

– Net-type reel holder carriage (type ): suitable for wrapping, allows the operator to

adjust the lm tension manually using the ring nut of the mechanical brake.

L) Document holder: it contains the use and maintenance manual.

IDM 510-006-5

English languageOperation and maintenance manual

15

Manufacturer and machine identication

The identication plate (pictured) is afxed directly to the machine.

– In addition to the references for iden-

tication provided by the Manufacturer, they also list all the essential

information for a safe operation.

A) Manufacturer identication

B) Space reserved for CE compliance

marking

C) Machine model

D) Machine type

E) Serial number

F) Serial number

G) Year of fabrication

H) Power supply voltage

Technical Specications

L) Electrical power consumption

M) Power supply frequency

N) Absorbed power

P) Power supply phases

16

English language Operation and maintenance manual

IDM 510-006-5

Technical Specications

Cycle

The gures show the operating cycle with indication of the main operating areas.

Stage Ê

– Approach the machine to the pallet until touching the

feeler.

– Tie the trailing end of the lm to the base of the prod-

uct to be wrapped.

Stage Ë

– Start the wrapping cycle that will be performed based

on the previously set parameters.

– The machine moves clockwise around the product

and stops once it nishes wrapping it.

Stage Ì

– Manually cut the lm and cause it to adhere to the

wrapped product.

– The machine is ready for a new wrapping cycle.

IDM 510-006-5

English languageOperation and maintenance manual

17

Types of wrapping

The gure shows the types of wrapping available.

– Single wrapping: it starts at the base of the load to

be wrapped (with stabilisation wraps) and ends at

the top of the load, after completing the closing

wrapping.

– Move the reel carriage to fully lowered position from

the control panel to start a new wrapping.

The operator can decide whether to cut the lm

when the carriage is in the high position or in the

low position.

– Double wrapping: it starts at the base of the load to

be wrapped (with stabilisation wraps) and ends at

the top of the load.

– After completing the reinforcement at the top of the

load, the wrapping continues downwards and stops

after the closing wrapping.

Technical Specications

– Single wrapping with sheet feeder: it starts at the

base of the load to be wrapped (with stabilisation

wraps) and stops temporarily at the top of the load.

– After inserting the covering sheet the operator must

enable the control to restart the wrapping.

– After completing the upper reinforcement, the wrap-

ping stops.

– Move the reel carriage to fully lowered position from

the control panel to start a new wrapping.

The operator can decide whether to cut the lm

when the carriage is in the high position or in the

low position.

– Double wrapping with sheet feeder: it starts at the

base of the load to be wrapped (with stabilisation

wraps) and stops temporarily at the top of the load.

– After inserting the covering sheet the operator must

enable the control to restart the wrapping.

– After completing the reinforcement at the top of the

load, the wrapping continues downwards and stops

after the closing wrapping.

IDM 510-006-5

18

English language Operation and maintenance manual

Technical Specications

Residual risks

Residual risks are dened as: “Any risk that remains notwithstanding the safety solutions adopted and integrated during the design phase”.

– Each residual risk is signalled with a special sign. Some of them are applied close to

the areas where the risk is present, others are placed in an easily visible position.

– The list includes the residual risks that may persist on this type of machine.

– Risk of crushing body parts: do

not stay or pass through the operating area during wrapping.

– Risk of crushing body parts: pay

attention that there are no obstacles

during the manual reverse movement.

– Risk of crushing body parts and

lower limbs: do not stay within the

operating area while the reel holding

carriage is lowering.

IDM 510-006-5

English languageOperation and maintenance manual

19

– Risk of crushing upper limbs: do

not introduce or place upper limbs in/

next to any machine moving parts

during operation.

– The risk mainly relates to the area

between the sliding column and the

reel holding carriage.

Technical Specications

Incorrect uses that are reasonably expected

Improper use: reasonably foreseeable use different from what is specied in the use

manual, that may be caused by human behaviour.

– ONLY trained, documented and authorized Operators are allowed to use the machine.

– DO NOT use or allow other persons to use the machine for purposes and in ways dif-

ferent from what specied by the Manufacturer.

– NEVER use the tool if the scheduled maintenance interventions have not been carried

out accordingly

– DO NOT use the machine in unstable, uneven, sloping and unsuitably protected areas

to prevent the risk of capsizing or falling.

– DO NOT enable the wrapping cycle during road, rail or sea transport (even if the

means is not moving).

To be used on naval means, carefully assess its stability to be able to operate in

safe conditions.

– DO NOT use the machine in places that are at risk of re and / or explosion.

– Do not use the machine as a means to transport people or things.

– When the products are wrapped, the radius of action of the machine must be kept free

from people.

– DO NOT carry out any intervention when the machine is being operated. Stop the

machine and put it in safety condition before carrying out any intervention.

– DO NOT clean or wash the machine using aggressive products that may damage its

components.

– DO NOT leave the machine unattended during operation and DO NOT leave it at the

end of the work without stopping it to safety conditions.

20

English language Operation and maintenance manual

IDM 510-006-5

Technical Specications

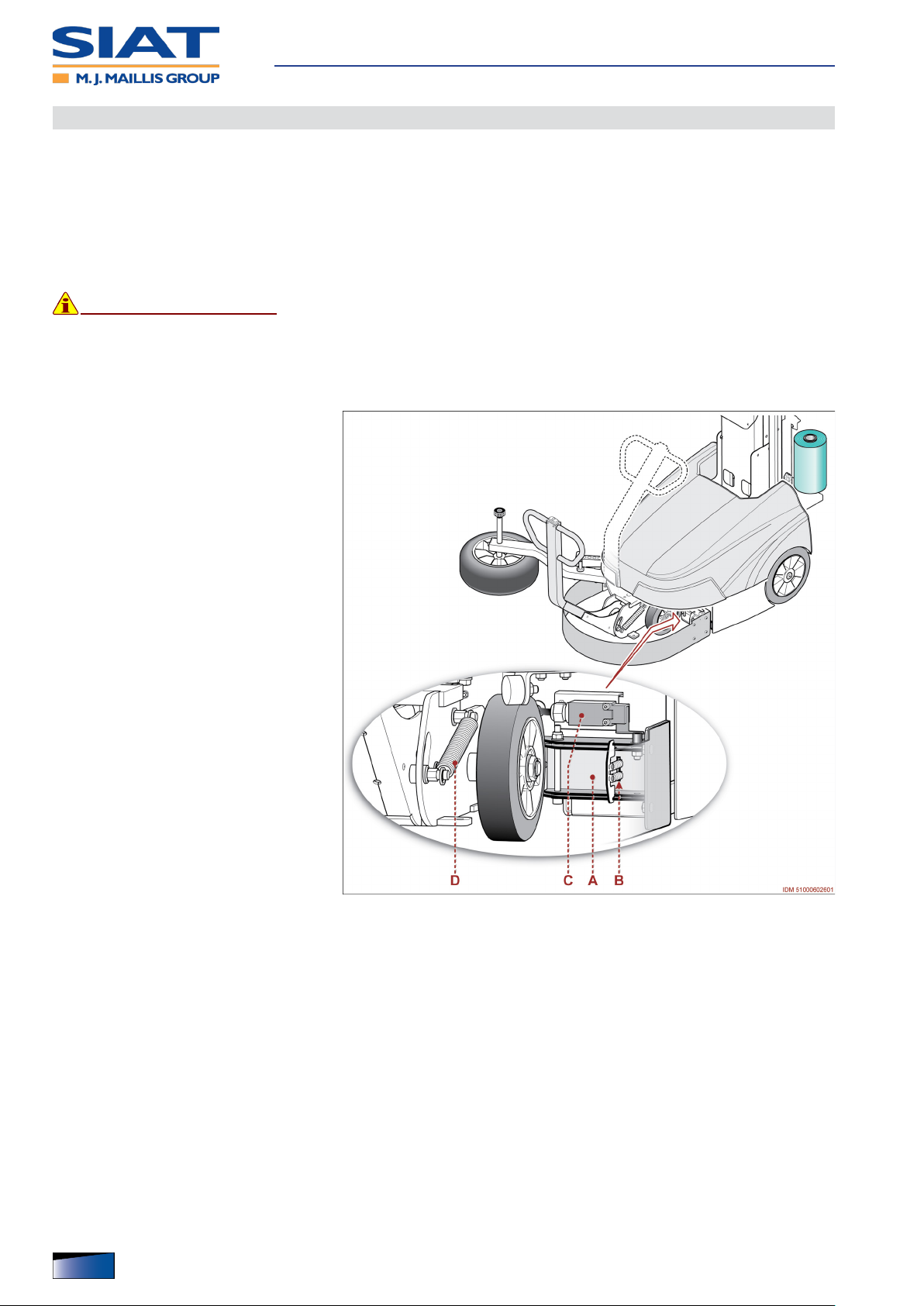

Optional Accessories

Some accessories designed to improve the performance and versatility of the machine are available from the manufacturer. This list contains a description of the

main ones.

A) Radio control: optional device that

is used as a remote control.

B) Double wheel feeler: compared to

the single wheel version, it increases

the contact with the perimeter of the

load to be wrapped.

C) Film cutting device: it cuts the lm

automatically at the end of wrapping

(only for reel holding carriage of type

“LP”).

IDM 510-006-5

English languageOperation and maintenance manual

21

Technical Specications

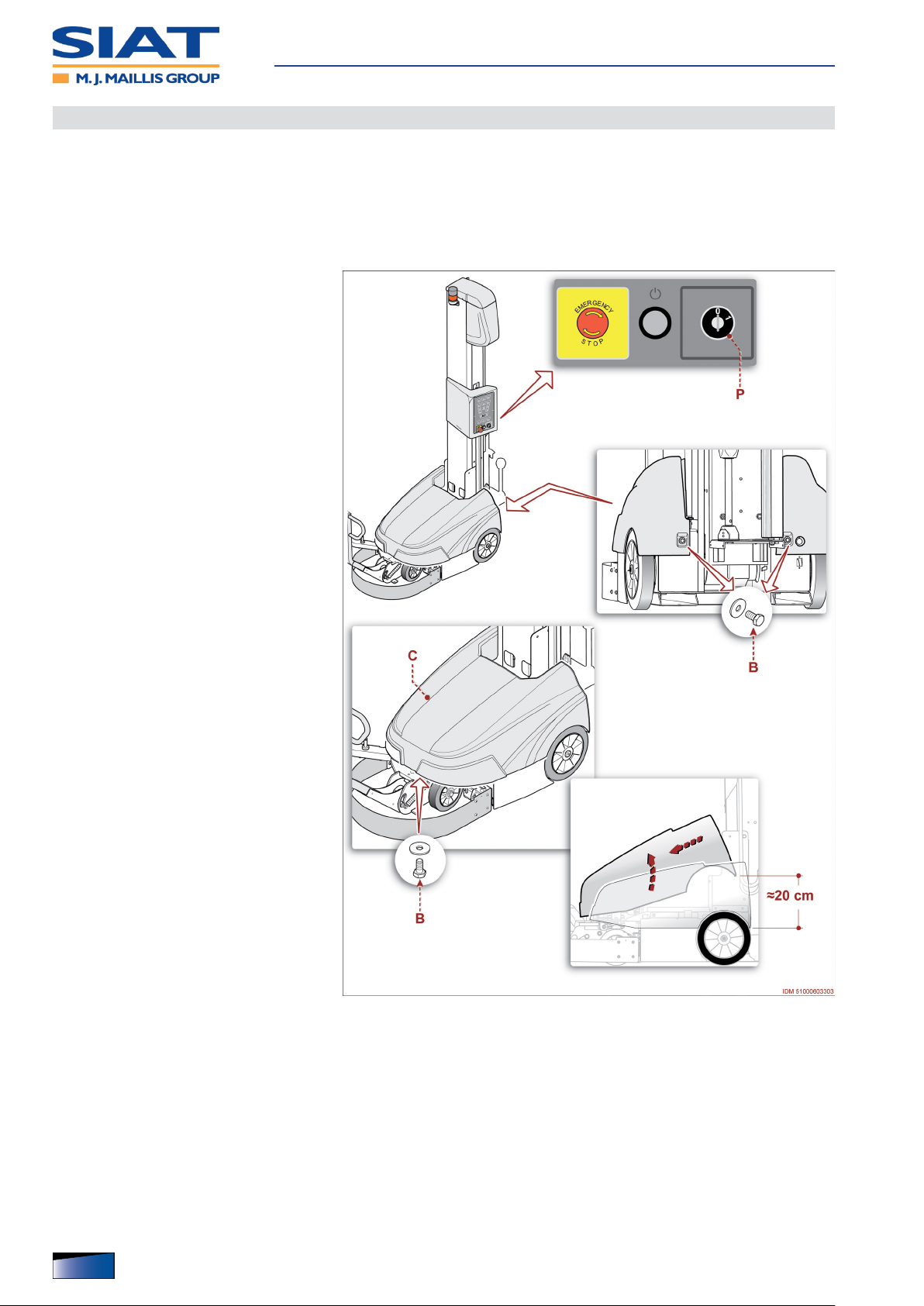

Description of the safety devices

The machine is equipped with safety devices that reduce the risks during the

man-machine interaction.

A) Emergency stop button: safety

control that, in case of an imminent

risk, stops all parts whose function

might constitute a risk.

See “Control description” for further

details.

B) Key selector switch: safety control

that connects and disconnects the

power supply of battery.

C) Fall arrest system: safety device

that prevents the risk of a fall of the

carriage in the event of lifting strap

breaking.

– System is equipped with spring de-

vice that locks reel holding carriage

in its position in case of failure of

belt.

D) Key selector: control to activate and

deactivate brake of the machine infeed electric motor.

– The key of control must be hand-

ed over to the maintenance technician in order to avoid any interference by non-authorised

personnel.

– When the machine stops and display

shows “b0”, it means that batteries

are completely exhausted.

Important

ONLY the maintenance technician is allowed to release the brake of the electric

motor in order to move the machine to the charge area.

E) Warning light (yellow light): safety device that signals the operating conditions of the

machine.

F) Audible warning device: safety device indicating the wrapping or machine conveying

process with manual control.

G) Fixed guard: safety device that prevents access to the parts whose operation may be

dangerous.

– The device is secured and it can be opened only by means of tools.

– Guard can be removed only when the machine is stopped under safe conditions and

must be installed before starting it.

H) Emergency bumper: safety device that stops the operation in emergency conditions,

in case of collision against an obstacle.

22

English language Operation and maintenance manual

IDM 510-006-5

Specications

Technical Specications

Table: Technical data of the machine

Description

Electric supply

The power supply specications are those shown in the identication plate applied to the machine.

Features of the machine (C=2100)

LxWxH (Length, width, height). mm 1600 x 1200 x 2410

E - Wrapping start value mm 50

F - Wrapping end value mm 2260

Weight (with acid-type batteries 90 A) kg 330

traverse speed m/min. 50 ÷ 80

Features of the machine (C=2600)

LxWxH (Length, width, height). mm 1600 x 1200 x 2910

E - Wrapping start value mm 50

F - Wrapping end value mm 2760

Weight (with acid-type batteries 90 A) kg 340

traverse speed m/min. 50 ÷ 80

Features of accumulator batteries

- Quantity no. 2

Batteries ¹)

- Current intensity (gel type)

- Current intensity (acid type) A 90

- Gel type (82 A) kg 27

Weight of every battery

- Gel type (105 A) kg 37

- Acid type (90 A) kg 29

Features of battery charger

See the technical specications on the identication plate of battery charger.

IDM 510-006-5

Characteristics of the load to be wrapped (C=2100)

AxBxC (Length, width, height).

- Min dimensions mm 400 x 500 x 600

- Max dimensions mm 6000 x 7000 x 2100

Maximum perimeter m 26

Unit of

measure-

ment

A 82

A 105

Value

English languageOperation and maintenance manual

23

Technical Specications

Description

Unit of

measure-

ment

- With film tensioning power from 2 kg kg 20

Minimum weight

- With film tensioning power from 6 kg kg 45

- With film tensioning power from 10 kg kg 55

Characteristics of the load to be wrapped (C=2600)

AxBxC (Length, width, height).

- Min dimensions mm 400 x 500 x 600

- Max dimensions mm 6000 x 7000 x 2600

Maximum perimeter m 26

- With film tensioning power from 2 kg kg 20

Minimum weight

- With film tensioning power from 6 kg kg 45

- With film tensioning power from 10 kg kg 55

Dimensions of lm reel

D - (Max.) diameter mm 250

d - Diameter of paperboard core (internal)mm mm 76

h - (Maximum height).mm mm 500

Film thickness µm 17 ÷ 23

Maximum weight kg 17

Environmental conditions

Maximum operating height (asl) m 1000

Relative humidity (detected at a temperature included between 20°C and 40°C) % 50

Ambient functioning temperature °C +5 ÷ 40

Environmental brightness LUX 150

Maximum level of noise dBa 72

¹) Accumulator batteries are installed as already ready for use (charged).

In case of shipment by air, the machine is delivered with non-installed batteries.

Value

24

English language Operation and maintenance manual

IDM 510-006-5

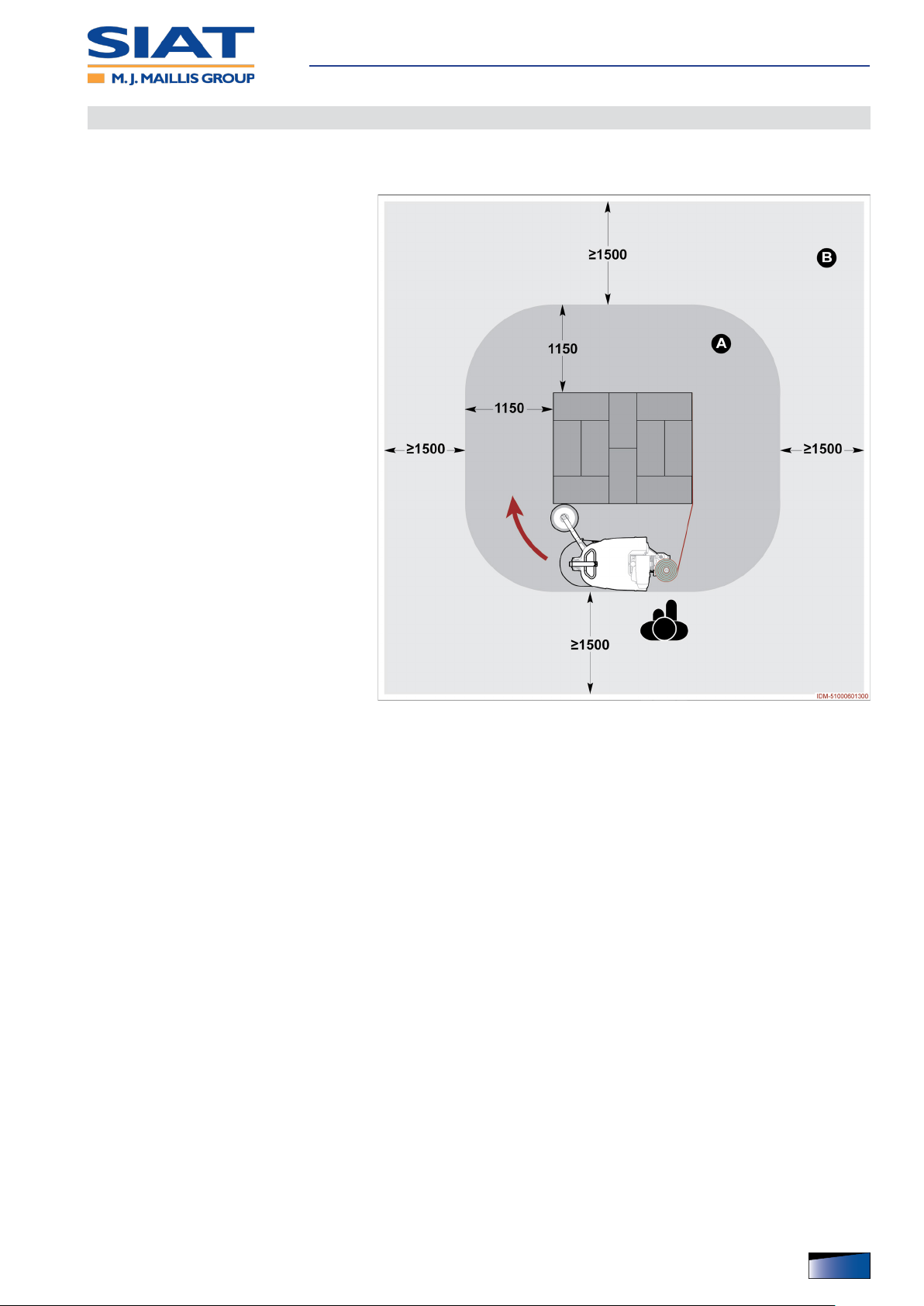

Technical Specications

Description of outer areas

The gure shows different areas to be considered in the planning of the installation

area.

A) Machine working area

B) Perimeter area

IDM 510-006-5

English languageOperation and maintenance manual

25

Position of information and safety plates

The gure shows the position of the

signals applied on the machine.

– Please keep safety signs and infor-

mation legible and follow the instructions.

– Signals which are no longer legible

must be replaced and repositioned in

the same place of origin.

– For more details on the signs used,

refer to the section on “Safety signs

and information”.

Technical Specications

26

English language Operation and maintenance manual

IDM 510-006-5

Use and functioning

Recommendations on Operation and Use

– The machine must be used by one single operator ONLY, who must be trained and

capable of performing the work and be in suitable conditions.

– According to the type of operation to carry out, wear the Personal Protective Equip-

ment listed in the “Instructions for use” and that indicated by the Labour laws.

– Consult the user manual, in particular during the rst use, and make sure that you

fully understand its content.

– Find out the position and function of the controls and simulate some operations (in

particular start and stop) in order to acquire familiarity.

– The machine shall be used ONLY for the purposes and complying with the procedures

specied by the Manufacturer.

– Make sure that all the safety devices are properly installed and efcient.

– Ensure the area around the machine, especially the control post, is ALWAYS unob-

structed and in good condition to minimize the risks for the Operator.

– Keep the reel suitably relled to prevent to avoid interrupting the wrapping due to ab-

sence of lm.

IDM 510-006-5

English languageOperation and maintenance manual

27

Use and functioning

Control description

The illustration shows the main commands and their description and function are

listed.

A) Key: control that selects the type of

load to be wrapped (signalled by the

LED switching-on mode).

Press control repeatedly until you select the LED switching-on mode corresponding to the load to be wrapped.

– LED off: rectangular standard-sized

load to be wrapped.

– LED with steady light: circular load

to be wrapped.

– LED with ashing light: large-size

load to be wrapped.

B) Button: control that enables single

automatic wrapping (rise of the reel

holder carriage).

– Single automatic wrapping with-

out sheet feeder: press control

once (LED with solid light).

– Single automatic wrapping with

sheet feeder: press control twice

(blinking LED).

C) Button: control that enables double

automatic wrapping (rise and descent of the reel holder carriage).

– Double automatic wrapping with-

out sheet feeder: press control

once (LED with solid light).

– Double automatic wrapping with

sheet feeder: press control twice

(blinking LED).

D) Key: control for selecting the wrapping parameter to set and for enabling recipe selec-

tion.

– Recipe enabling: press control and keep it pressed (about 5 seconds).

– Parameter selection: press control repeatedly and release it when the LED corre-

sponding to the icon to be programmed turns on.

– Ê -

Setup of wrapping speed

– The number shown on display E refers to a value scale from 0 to 10.

– Ë - Setup of the size of the load to be wrapped

– The value is expressed in metre and it can be measured with a tolerance of ±10%.

28

English language Operation and maintenance manual

IDM 510-006-5

Use and functioning

– LED on with steady light combined with LED on with steady light of key A: program-

ming of the diameter of the load to be wrapped.

– Flashing LED: programming of the height of the load to be wrapped.

– Set up value 0 to allow special photocell to detect the height without measuring the

load to be wrapped.

– Ì - Setup of the speed of reel holding carriage

– LED on with steady light: programming of the lifting speed of the reel holding carriage.

– Flashing LED: programming of the lowering speed of the reel holding carriage.

– The number shown on display E refers to a value scale from 0 to 10.

– Í - Setup of the tension of lm (only for reel holding carriage of type FM - LP).

– The number shown on display E refers to a value scale from 0 to 99.

– Î - Setup of the detection delay of photocell

– Led on: programming time (in seconds) from the detection of the end of the load until

the stop of the reel holder carriage.

– Blinking LED: programming of the descent (in seconds) of the reel holder carriage in

order to allow the insertion of the protection sheet.

– Ï - Setup of the number of wrapping revolutions for bottom reinforcement.

– The number shown on display E refers to the number of wrapping revolutions to be

carried out for the reinforcing bands.

– Ð - Setup of the number of wrapping revolutions for upper reinforcement.

– The number shown on display E refers to the number of wrapping revolutions to be

carried out for the reinforcing bands.

E) Digital display: it displays different functions (value of the selected parameter, active

alarm, selected recipe, etc.).

– At the end of every wrapping cycle, display shows the charge level of accumulator

batteries.

After 30 seconds from the last control activation, the brightness intensity of display

decreases.

F) Keys: controls that increase or reduce the value shown in the display E.

– Controls (held pressed) are used to lift or lower reel holding carriage.

The operation mode is possible ONLY if the wrapping cycle is completed and/or all

LEDs are off.

G) Key: control to start the wrapping phase.

– LED on: function activated.

– LED on with ashing light: reel holding carriage not timed.

H) Key: control to stop the wrapping phase at a different point than the pre-set one.

L) Key: control that is used to reset the position of reel holding carriage.

IDM 510-006-5

– LED on: press control to perform the reset.

English languageOperation and maintenance manual

29

M) Emergency stop button: safety

control that, in case of an imminent

risk, stops all parts whose function

might constitute a risk.

– The control must stay “locked” until

all the normal operating conditions

have been restored.

– After having normalised running con-

ditions, unblock the button with a deliberate action to authorise restart.

N) Illuminated button (blue light):

control designed to activate electric

power supply.

– Control enabled only when selector

P is in position “1” (ON).

– Blue light off: activated power supply

line.

Use and functioning

– Blue light on: power supply deacti-

vated.

P) Key selector switch: safety control

that connects and disconnects the

power supply of battery.

– Position “1” (ON): power supply on

– Position “0” (OFF): power supply off

Q) Key selector: control to activate and

deactivate brake of the machine infeed electric motor.

– The key of control must be hand-

ed over to the maintenance technician in order to avoid any interference by non-authorised personnel.

– Position “0”: brake of electric motor activated and machine functions enabled.

– Control rotated to the right: brake of electric motor deactivated and machine functions

disabled.

– When the machine stops and display E shows “b0”, it means that batteries are com-

pletely exhausted.

Important

ONLY the maintenance technician is allowed to release the brake of the electric

motor in order to move the machine to the charge area.

R) Buttons: non-release controls that manually move the machine.

Controls are enabled only when reel holding carriage is in its lowest position.

30

English language Operation and maintenance manual

IDM 510-006-5

Use and functioning

S) Warning light (yellow light): safety device that signals the operating conditions of the

machine.

T) Audible warning device: safety device indicating the wrapping or machine conveying

process with manual control.

Z) Radio control: optional device that is used as a remote control.

Z1) Switching-on control

Z2) LED showing that device is on

Z3) Switching-off control

Z4) Control that starts wrapping

Z5) Control that interrupts the wrapping process in a point other than the pro-

grammed point.

IDM 510-006-5

English languageOperation and maintenance manual

31

Emergency stop and new start-up

Stop with activation of the emergency button

▀

1. In the presence of an imminent risk press emergency

button M.

– All moving devices immediately stop.

– The pilot light of button N turns on.

2. Identify the causes that have caused the stop.

3. Restore normal running conditions

Important

The recovery operations that are not within the operator’s eld of competence shall be carried out by authorised personnel and with recognised skills.

4. Manually cut the lm and cause it to adhere to the

wrapped product.

Use and functioning

Decide whether to remove or to leave the already

wrapped lm.

5. Unlock the emergency stop button with a voluntary ac-

tion.

6. Press the push-button N.

– The push-button lamp N shuts off.

7. Press key L.

8. Wait until reel holding carriage automatically reaches its end-of-cycle position.

9. Tie the trailing end of the lm to the base of the product to be wrapped.

10. Start the wrapping process.

Stop with activation of the emergency bumper

▀

– Operation stops automatically in emergency conditions when the bumper collides

against an obstacle.

– In case of emergency conditions, the pilot light of button N is on and audible warning

device is off.

1. Remove the obstacle.

2. Manually cut the lm and cause it to adhere to the wrapped product.

Decide whether to remove or to leave the already wrapped lm.

3. Press the push-button N.

– The push-button lamp N shuts off.

4. Press key L.

5. Wait until reel holding carriage automatically reaches its end-of-cycle position.

6. Tie the trailing end of the lm to the base of the product to be wrapped.

7. Start the wrapping process.

32

English language Operation and maintenance manual

IDM 510-006-5

Use and functioning

(Single or double) automatic wrapping

The gure shows the points of intervention and the description shows the procedures to be adopted.

1. Check whether the wrapping lm has

the same chemical-physical properties as that installed in the reel holder

carriage.

– If lm characteristics appear to be

different, consider whether you

should adjust the lm tension.

2. Rotate selector P to position “1”

(ON) in order to activate the battery

power supply.

– The pilot light of button N turns on.

3. Press the push-button N.

– The pilot light of button N turns off.

4. Use the buttons S to lean the roller

feeler A against the load to be

wrapped.

5. Before commissioning, check that

roller feeler is next to the upper surface of the pallet.

– If the pallet is smaller than the load to

be wrapped, roller feeler must be positioned on the lowest side of the

load.

The support area must be sufciently

regular to allow roller feeler to rotate

properly.

6. Tie the trailing end of the lm to the

base of the product to be wrapped.

7. Select and activate the recipe of interest.

See “Recipe management” for furcther details.

8. Press button G to start the wrapping cycle.

– If the LED of key L is ashing, press key L to move reel holding carriage to its end-of-

cycle position.

– When reel holding carriage is timed, the LED of key L turns off.

– To restart the wrapping cycle, press key G again.

– Audible warning device is activated to warn that the machine is operating.

IDM 510-006-5

– The machine stops as previously described, based on the selected type of wrapping.

English languageOperation and maintenance manual

33

Press button H to stop wrapping;

press button G to continue.

Wrapping will start at the point where

it has been stopped.

– Single mode: the wrapping stops

automatically with the reel holder

carriage at the upper side of the load.

Press button L to move reel holder

carriage to the start of the cycle (lower part).

– Double mode: the wrapping stops

automatically with the reel holder

carriage at the starting point (lower

side of the load).

9. Manually cut the lm and cause it to

adhere to the wrapped product.

Use and functioning

Important

Keep the reel suitably relled to prevent to avoid interrupting the wrapping due to absence of lm.

10. Use the buttons S to lean the roller

feeler A against the load to be

wrapped.

11. Press button G to start the wrapping

cycle.

– Audible warning device is activated

to warn that the machine is operating.

– The machine performs the new

wrapping and, at the end of the set

cycle, stops automatically.

12. Repeat the same steps for the rest of

the loads.

13. At the end of the working activity, adjust the buttons S to park the machine within the

battery charging area.

14. Carry out battery recharge (See “Charge of accumulator batteries”).

Normal stop

▀

– Make sure that the wrapping process has been completed.

– DO NOT control a machine stop if the wrapping cycle has not been completed.

– Manually cut the lm and cause it to adhere to the wrapped product.

– Remove the wrapped product.

– Rotate electric selector P to position “O” (OFF).

– The power supply of batteries is deactivated.

34

English language Operation and maintenance manual

IDM 510-006-5

Use and functioning

(Single or double) automatic wrapping with sheet feeder

The gure shows the points of intervention and the description shows the procedures to be adopted.

1. Check whether the wrapping lm has

the same chemical-physical properties as that installed in the reel holder

carriage.

– If lm characteristics appear to be

different, consider whether you

should adjust the lm tension.

2. Rotate selector P to position “1”

(ON) in order to activate the battery

power supply.

– The pilot light of button N turns on.

3. Press the push-button N.

– The pilot light of button N turns off.

4. Use the buttons S to lean the roller

feeler A against the load to be

wrapped.

5. Before commissioning, check that

roller feeler is next to the upper surface of the pallet.

– If the pallet is smaller than the load to

be wrapped, roller feeler must be positioned on the lowest side of the

load.

The support area must be sufciently

regular to allow roller feeler to rotate

properly.

6. Tie the trailing end of the lm to the

base of the product to be wrapped.

7. Select and activate the recipe of interest.

See “Recipe management” for furcther details.

8. Repeatedly press the button D until selecting the parameter Î.

9. Use one of controls F to dene the descent of reel holder carriage with regard to the

upper part of the product.

– The greater is the value, the greater is the movement of the reel holder carriage.

10. Press button G to start the wrapping cycle.

– If the LED of key L is ashing, press key L to move reel holding carriage to its end-of-

IDM 510-006-5

cycle position.

– When reel holding carriage is timed, the LED of key L turns off.

– To restart the wrapping cycle, press key G again.

English languageOperation and maintenance manual

35

– Audible warning device is activated

to warn that the machine is operating.

– The machine stops as previously de-

scribed, based on the selected type

of wrapping.

Press button H to stop wrapping;

press button G to continue.

Wrapping will start at the point where

it has been stopped.

– Single mode: the wrapping stops

automatically with the reel holder

carriage at the upper side of the load.

– Insert the covering sheet.

– Press the key G to complete the

wrapping of the covering sheet.

Press button L to move reel holder

carriage to the start of the cycle (lower part).

Use and functioning

– Double mode: the wrapping stops

automatically with the reel holder

carriage at the upper side of the load.

– Insert the covering sheet.

– Press key G.

– The machine completes the wrap-

ping cycle and stops automatically

with the reel holder carriage at the

lower side of the load.

11. Manually cut the lm and cause it to

adhere to the wrapped product.

Important

Keep the reel suitably relled to prevent to avoid interrupting the wrapping due to absence of lm.

12. Use the buttons S to lean the roller feeler A against the load to be wrapped.

13. Press button G to start the wrapping cycle.

– Audible warning device is activated to warn that the machine is operating.

– The machine performs the new wrapping and, at the end of the set cycle, stops auto-

matically.

14. Repeat the same steps for the rest of the loads.

15. At the end of the working activity, adjust the buttons S to park the machine within the

battery charging area.

16. Carry out battery recharge (See “Charge of accumulator batteries”).

36

English language Operation and maintenance manual

IDM 510-006-5

Normal stop

▀

– Make sure that the wrapping process has been completed.

– DO NOT control a machine stop if the wrapping cycle has not been completed.

– Manually cut the lm and cause it to adhere to the wrapped product.

– Remove the wrapped product.

– Rotate electric selector P to position “O” (OFF).

– The power supply of batteries is deactivated.

Use and functioning

IDM 510-006-5

English languageOperation and maintenance manual

37

Use and functioning

Setup of parameter values

The gure shows the points of intervention and the description shows the procedures to be adopted.

1. Press control D repeatedly and release it when the

LED corresponding to the icon to be programmed turns

on.

– The value of the selected parameter appears on dis-

play E.

2. Press one of buttons F to modify the value.

– With the parameter Ê selected: the number shown re-

fers to a value scale from 0 to 10.

– With parameter Ë selected: the displayed value refers

to the diameter or height of the load to be wrapped.

- Diameter of the load to be wrapped: from 0,8 to 0,9

metre

- Height of the load to be wrapped: from 0,6 to 2,6 metre

– With parameters Ì selected: the number shown refers

to a value scale from 0 to 9.

– With parameters Í selected: the number shown refers

to a value scale from 0 to 99.

– With the parameter Î selected: the number shown re-

fers to the time expressed in seconds (from 0 to 9.9).

– With the parameters Ï - Ð selected: the number

shown refers to the number of revolutions to be performed for the reinforcing wrappings (from 0 to 10).

38

English language Operation and maintenance manual

IDM 510-006-5

Use and functioning

Recipe management

The gure shows the points of intervention and the description shows the procedures to be adopted.

– The described procedures refer to how to modify and/

or activate a recipe.

Modifying a recipe

▀

1. Rotate selector P to position “1” (ON) in order to activate the battery power supply.

– The pilot light of button N turns on.

2. Press the push-button N.

– The pilot light of button N turns off.

– The number of the last used recipe appears on display

E.

3. Select the wrapping of interest by means of one of buttons B-C.

4. Keep button D pressed (about 5 seconds) in order to

enable programming.

5. Press one of buttons F to select the number of the rec-

ipe to be modied.

6. Set up all parameters of recipe one at a time.

7. Press control D repeatedly and release it when the

LED corresponding to the desired icon turns on.

– The value of the selected parameter appears on dis-

play E.

8. Press one of buttons F to modify the value.

– With the parameter Ê selected: the number shown refers to a value scale from 0 to

10.

– With parameter Ë selected: the displayed value refers to the diameter or height of the

load to be wrapped.

- Diameter of the load to be wrapped: from 0,8 to 0,9 metre

- Height of the load to be wrapped: from 0,6 to 2,6 metre

– With parameters Ì selected: the number shown refers to a value scale from 0 to 9.

– With parameters Í selected: the number shown refers to a value scale from 0 to 99.

– With the parameter Î selected: the number shown refers to the time expressed in

seconds (from 0 to 9.9).

– With the parameters Ï - Ð selected: the number shown refers to the number of rev-

olutions to be performed for the reinforcing wrappings (from 0 to 10).

IDM 510-006-5

English languageOperation and maintenance manual

39

Loading a recipe

▀

1. Rotate isolator switch P to position

“I” (ON) in order to activate the bat-

tery power supply.

– The pilot light of button N turns on.

2. Press the push-button N.

– The pilot light of button N turns off.

– The number of the last used recipe

appears on display E.

3. Use the buttons S to lean the roller

feeler A against the load to be

wrapped.

4. Tie the trailing end of the lm to the

base of the product to be wrapped.

5. Keep button D pressed (about 5 sec-

onds) in order to enable programming.

Use and functioning

6. Press one of buttons F to select the

number of the recipe to be loaded.

7. Press button G to start the wrapping

cycle.

– If the LED of key L is ashing, press

key L to move reel holding carriage

to its end-of-cycle position.

– When reel holding carriage is timed,

the LED of key L turns off.

– To restart the wrapping cycle, press key G again.

– Audible warning device is activated to warn that the machine is operating.

40

English language Operation and maintenance manual

IDM 510-006-5

Use and functioning

Recipe lock/unlock mode

The lock mode is used to avoid that the parameters of the stored recipes are

changed.

– The gure shows the points of intervention and the

description shows the procedures to be adopted.

1. Press and hold control H (about 7 seconds).

– Message “n. 0” appears on display E.

2. Press key D.

3. Press one of keys F until parameter “19” is displayed.

4. Press the key D to conrm.

– Display E shows message “c.9”.

5. Press key D.

6. Press one of keys F to select value “0” or “1”.

– Value “0”: recipes unlocked.

The parameters of the stored recipes can be changed.

– Value “1”: recipes locked.

The parameters of the stored recipes cannot be

changed.

7. Press the key D to conrm.

Recipe function “P0”

▀

– Recipe “P0” is used to programme the wrapping pro-