MJK Automation A/S

Byageren 7

DK-2850 Nærum

Denmark

Tel.: +45 45 56 06 56

Fax: +45 45 56 06 46

mjk@mjk.com

www.mjk.com

Ultrasonic Level Transmitter

and Sensor

GB Shuttle Manual 100316

User Manual

1

New

All MJK’s newest ultrasonic

sensors covered and described

in this manual

New setup procedure.

See page 14 for choosing correct

sensor type at initial setup.

SW 838023

Ultrasonic Level Transmitter and Sensor

IMPORTANT

The first time power is applied to the mounted Shuttle® level transmitter and ultrasonic

sensor, the level transmitter must be configured for the connected sensor type.

The procedure is located on page 14, "Applying power".

If, at a later time, another or a newer sensor type is connected to the transmitter,

the level transmitter must be re-configured accordingly.

The procedure is located on page 69, "Appendix F New sensor / changing sensor".

June 2007

CE Certificate of Conformity

This product complies with the requirements concerning electromagnetic compatibility (EMC)

stipulated in Council directive no. 89/336/EEC of 3rd May 1989, altered at directive no.

92/31/EEC, on the approximation of the laws of the Member States relating to electromagnetic compatibility.

CE approvals

We declare that the Shuttle

®

transmitter and ultrasonic sensors comply with the values stipu-

lated in EN 50081-1 and EN 50082-1.

Ex approval of ultrasonic sensors

®

Shuttle

ultrasonic sensors are approved for mounting in explosive amospheres.

Types 200630/31/40/41: FM Class 1, Div. 1, Group A-G

GB Shuttle Manual 100316

2

SW 838023

Ultrasonic Level Transmitter and Sensor

Table of Contents

Introduction .................................5

About this manual .............................5

Main sections .........................................5

Illustrations .............................................5

Safety instructions .............................6

Repair ....................................................6

Ex equipment .........................................6

Product identification .........................6

Mounting ......................................7

General .............................................7

Explosion hazardous areas ................7

Mechanical mounting ........................7

Level transmitter .....................................7

Ultrasonic sensor ....................................8

Electrical mounting ............................9

Level transmitter .....................................9

Ultrasonic sensor ..................................10

Cutting the cable ..................................10

Display and keyboard ...............11

General ...........................................11

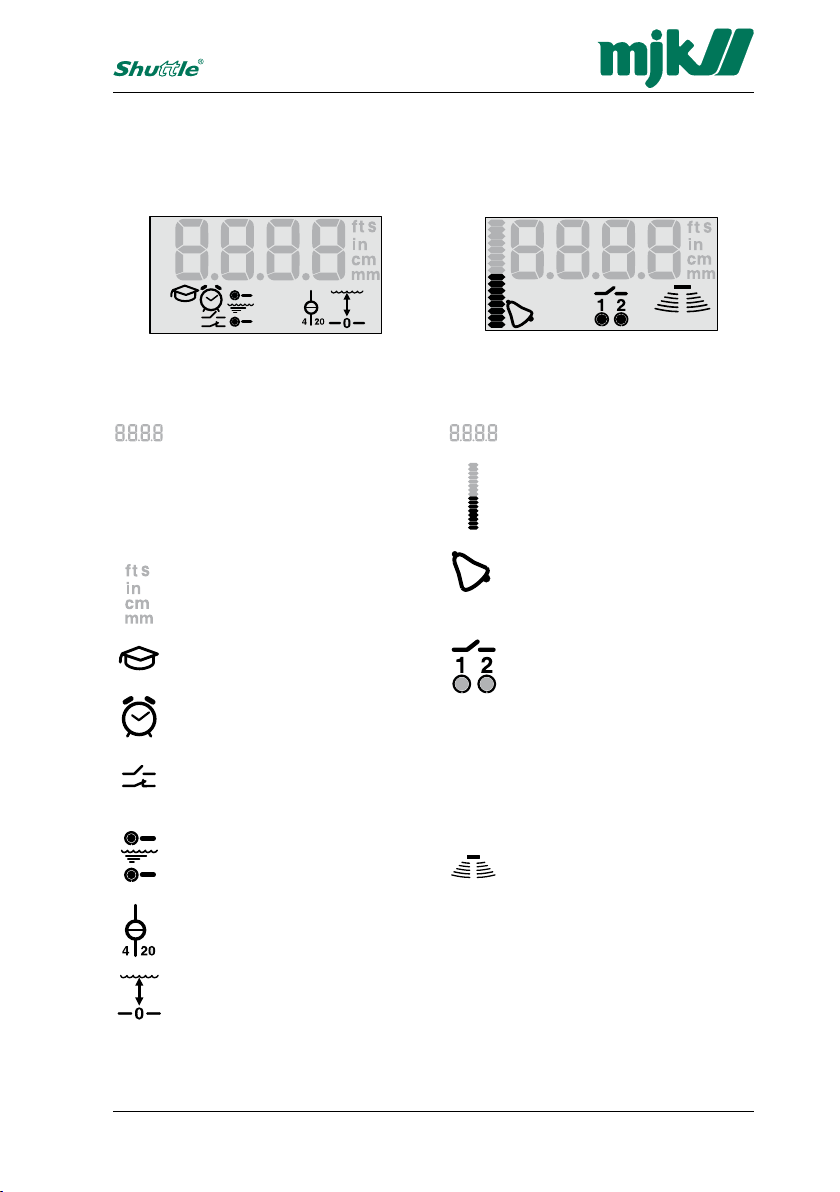

The display symbols ........................12

Displayed during programming .............12

Displayed during normal service ...........12

The keyboard .................................. 13

Basic settings .......................................13

Special settings ....................................13

Get started .................................14

Applying power ...............................14

Sensor type selection ...........................14

- the well is empty… .............................15

- the well is not empty… .......................15

Basic settings ............................16

Units of measurement ..........................17

Sensor to zero point distance ...............18

Level read-out ......................................19

The well is not empty ............................19

mA output ............................................20

Relay outputs .......................................21

Selection of relays 1 and 2 ....................21

Pump control with relays 1 and 2..........22

Level control with relay 1 ......................23

System alarm on relay 1 .......................24

Selection of relay function for relay 2 .....25

Level control with relay 2 ......................26

System alarm on relay 2 .......................27

Start of the learning function ............28

First time activation ...............................28

Activating the learning function ........29

Activation / deactivation ........................29

Settings ......................................30

User settings ................................... 30

User and factory settings ..........30

Factory settings ...............................30

Possible settings .............................31

Fault finding ...............................32

General ...........................................32

Indications on system errors ............32

Normal read-out ...................................32

Too weak or missing echo ....................32

System (sensor) error............................32

Temperature error .................................32

Internal stack error ................................32

EE-PROM error ....................................33

Power failure.........................................33

Fault finding table ............................ 33

GB Shuttle Manual 100316

Ex Instructions ...........................35

3

SW 838023

Ultrasonic Level Transmitter and Sensor

A Technical specifications ............... 37

Dimensions ..........................................37

Shuttle® Ultrasonic Sensors ..................38

Standard Range Version .......................38

Standard Range Version/FM Approved .39

Extended Range Version ......................40

Chemical Resistant Version ..................41

B Changing supply voltage ............. 42

Conversion from 230 to 115 V AC ........42

Conversion from 115 to 230 V AC ........42

C Sensor mounting considerations .43

General ................................................43

Signal spread .......................................43

Measurements......................................44

Along a wall / other surface ................44

Through a concrete deck ....................44

In a tank / container ............................44

Through pipe for foam protection .......44

D Service menu ..............................45

E Special menus ............................46

Bar graph read-out ...............................47

Active measuring range ........................48

Response time .....................................49

Measuring method (application) ............50

mA output signal during system error ...51

Calibration of the level measurement ....52

Offset level readout ...............................53

Indication of echo quality ......................54

Indication of signal amplification ............55

Indication of time period without echo ..56

Select factory settings ..........................57

Access code ........................................58

Readout of version numbers .................59

Find zero level at next power-up ...........60

Fixed mA signal ....................................61

Investigative measurement intervals ......62

System alarm delay ..............................63

Averaging the level measurement .........64

Max. amplification level .........................65

Min. level for accept of ultrasonic echo .66

Sensitivity of the learning function .........67

Changing the access code ...................68

F New sensor / changing sensor .... 69

Open the choose sensor menu.............69

GB Shuttle Manual 100316

4

SW 838023

Introduction

Introduction

Thank you for choosing a Shuttle® Ultrasonic Level Transmitter.

We have done everything possible to make

a level transmitter that can fulfill all your

demands.

®

Shuttle

is suitable for all kinds of level

measurements with ultrasound and can

control and supervise levels in wells and

tanks - including aggressive and polluted

media.

The level meter is both easy to install and

put into service, but read this manual first then you will get the most benefits from the

®

Shuttle

Ultrasonic Level Transmitter right

from the beginning.

You can always contact your representative

or the MJK Service Hotline for advice and

guidance.

Also, take a look at http\\:www.mjk.com.

®

Shuttle

is registered trademark of MJK.

About this manual

Main sections

This manual is divided into the following

three main sections:

1: Introduction

presentation of the Shuttle

manual

2: Mounting

information for performing mechanical

and electrical mounting.

3: Basic settings

a look through the most common set-

tings

®

and this

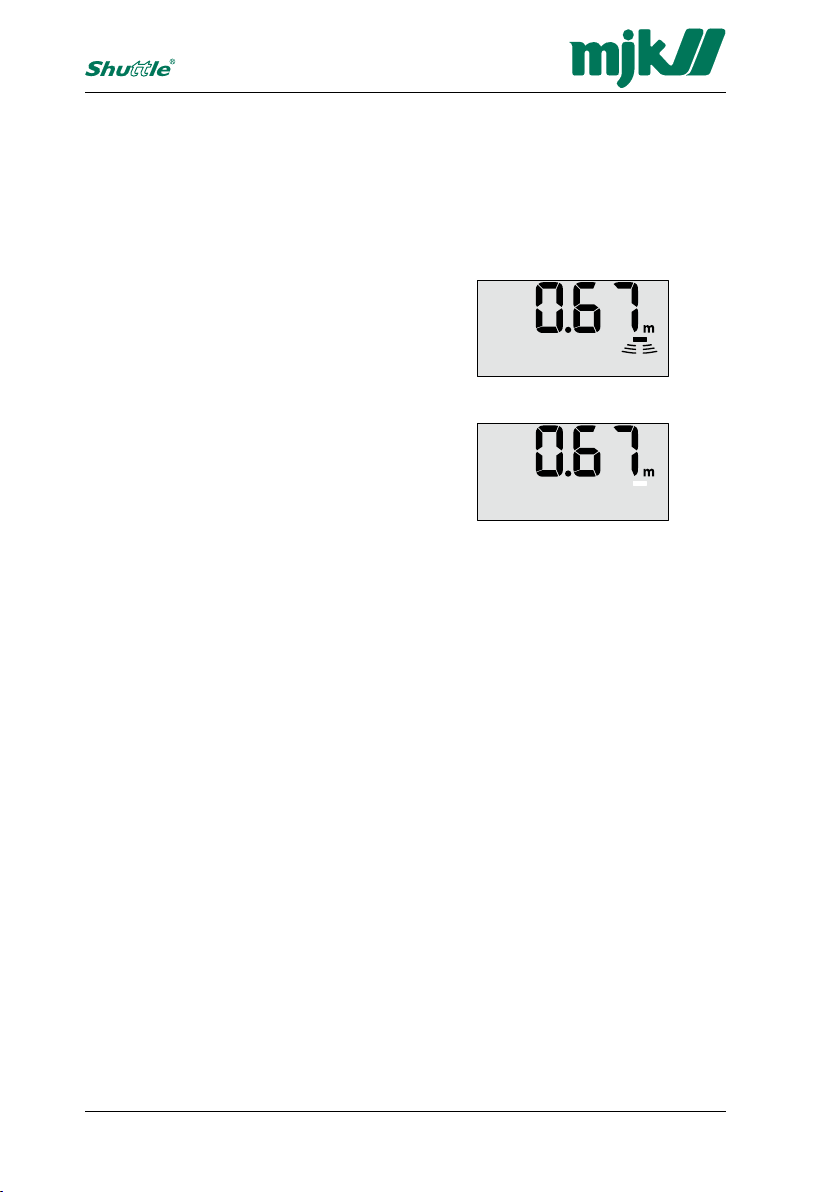

Illustrations

®

All the Shuttle

display read-outs are illustrated in this manual. Some of the display

segments will flash, and in this manual the

display read-outs with flashing segments are

coloured white and the fixed segments are

coloured black.

Example: Normal display read-out -

none of the segments are flashing.

Example: Missing echo -

the bar on the right hand side is flashing.

Section "Display" gives a more detailed

description of the display symbols shown

during programming and during normal

service. Furthermore, the menu explanations

show all the display indications belonging

to the specific menu during programming of

the Shuttle® Ultrasonic Level Transmitter.

GB Shuttle Manual 100316

5

SW 838023

Introduction

Safety instructions

1: Read this manual carefully.

2: Be aware of the environment at the in-

stallation site. Wear necessary protective

equipment and follow all current safety

regulations.

3: Shuttle

4: There is a risk of lethal electrical shock

Repair

1: Repair of Ex approved equipment (ul-

Ex equipment

1: All current local and national standards,

®

can provide a start signal for

dangerous machinery. Always ensure

that connected machinery and other

equipment are effectively being put

out of service (i.e. removal of main

fuses, lock main- and/or security

switches in off position) before commencing setting, fault finding, service

and maintenance work etc.

from terminal 1 to 5 and L-N. Be careful

not to touch these while Shuttle

service.

trasonic transmitter) must only be made

by MJK or by a service representative

approved by MJK.

regulations regarding installation and use

of Ex approved equipment, certifications

and safety instructions for Ex equipment,

that have been used together with the

installation of Shuttle

observed.

®

must be strictly

®

is in

Product identification

Check that the item(s) delivered corresponds to the ordered item(s). The item

number is printed on a label that is sticked

onto the packing. Shown below is the label

for a delivery including a level transmitter

and a ultrasonic sensor:

➀

➁

➀

➂

➁

➂

➀ Item number

➂ Serial number

➁ Item description

An identical marking can be found on the

right hand side of the level transmitter

cabinet:

GB Shuttle Manual 100316

6

SW 838023

Mounting

Mounting

General

®

Shuttle

measures the level by sending an

ultrasonic signal against the surface and

measuring the delay time of the received

echo.

Although Shuttle

advanced system for eliminating measuring errors, the ultrasonic sensor must - as

much as possible - be mounted so that the

ultrasonic signal is not disturbed by liquid

being pumped in or by mixers, ladders or

other installations in the tank.

The liquid surface should also be calm and

without waves and possibly without foam

that may muffle the ultrasonic echo too

much.

Since the ultrasonic beam is extremely

narrow (between 3 - 7 ° depending on

the sensor type), Shuttle

measurements in very narrow tanks or wells.

This requires that the ultrasonic sensor is

mounted so it points absolutely vertical

against the surface - or the ultrasonic echo

will simply miss the sensor.

Explosion hazardous areas

The ultrasonic sensor is Ex approved in

accordance with EN 50021:1999 and can

be mounted in Zone 2 without the need of

a zener barrier. Please check local requirements before installing in hazarduous

locations.

The level transmitter (= the electronic

box with display) must not be mounted in

explosive hazardous areas.

®

is equipped with a very

®

can be used for

Mechanical mounting

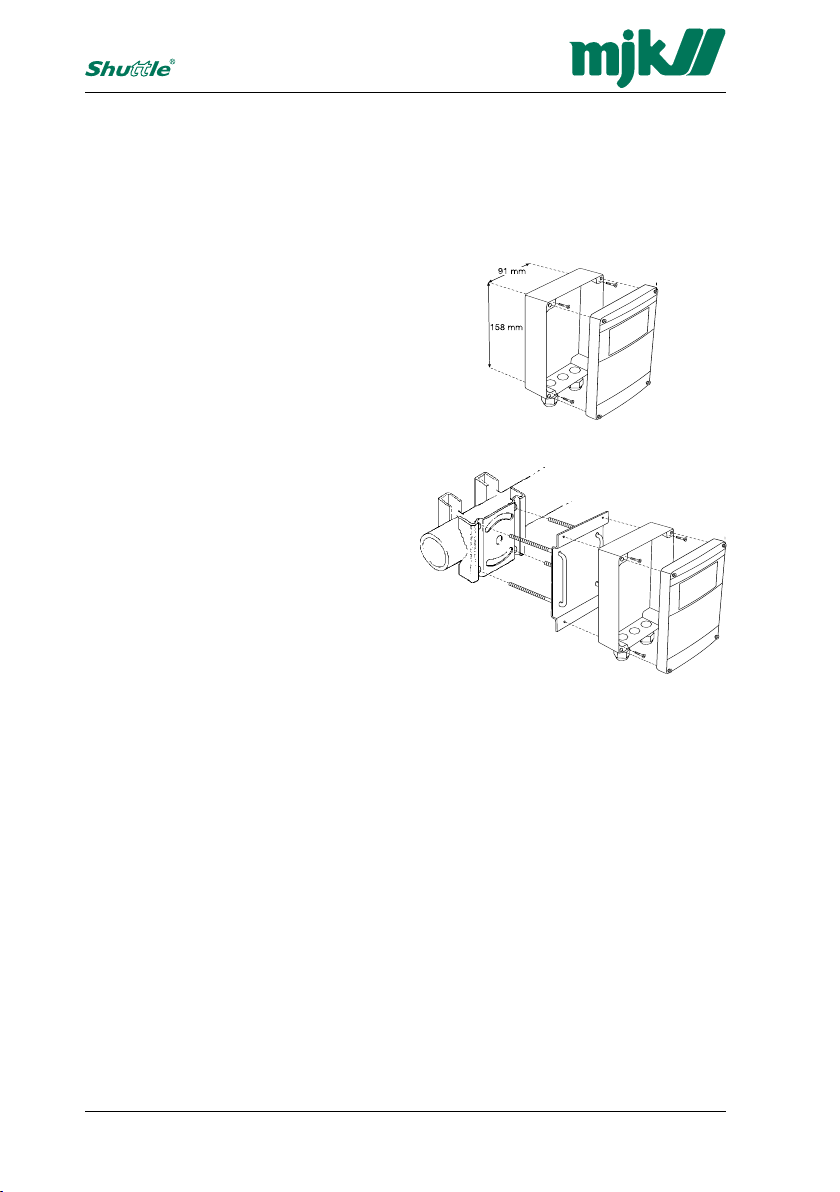

Level transmitter

®

Shuttle

is in IP65 enclosure and can be

mounted outdoors directly on a wall, a

railing or a banister with mounting plate

200240 and universal bracket 200205.

Shuttle® Ultrasonic Level Transmitter

mounted directly on a wall.

Shuttle® Level Transmitter mounted on the plant

with mounting plate 200240 and universal bracket

200205.

Shuttle® must be mounted

vertically in order to observe the

NEMA4X standard.

GB Shuttle Manual 100316

7

SW 838023

Mounting

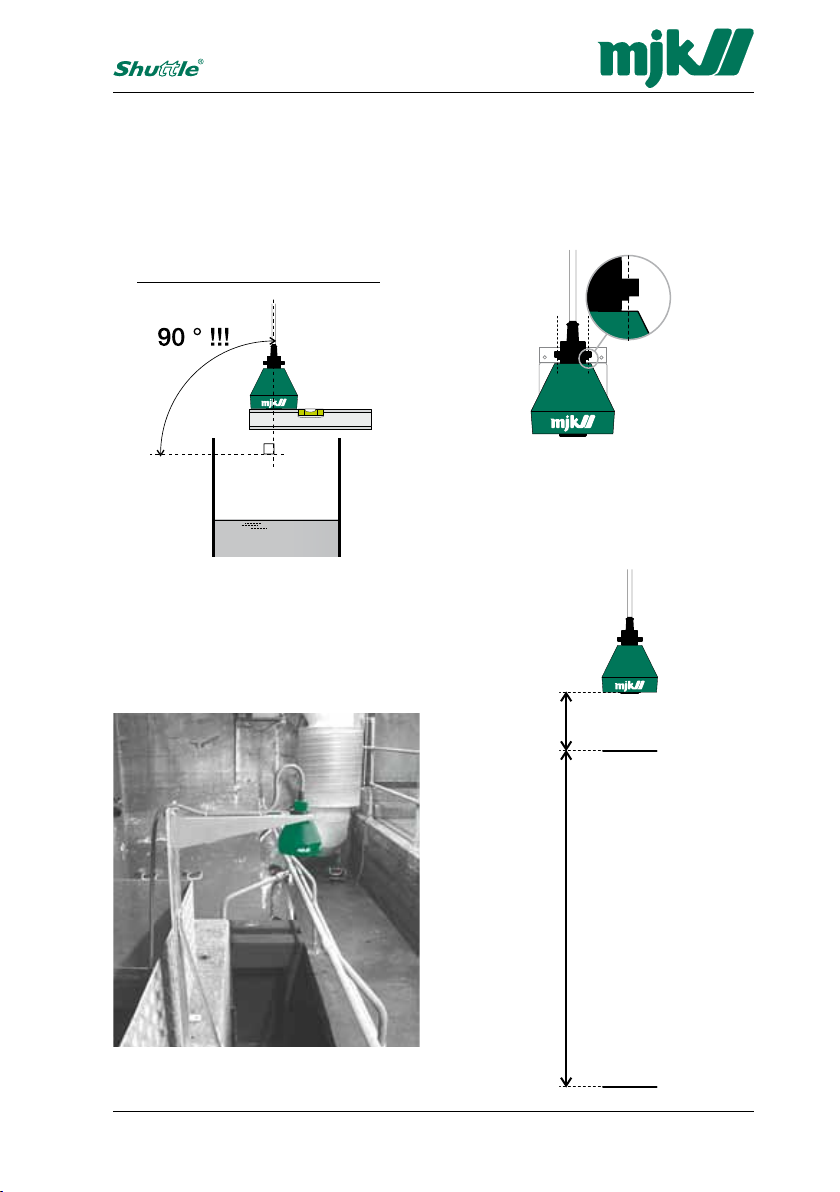

Ultrasonic sensor

Two things are extremely important when

mounting the ultrasonic transmitter: (See

also appendix C!)

1: It should be mounted securely.

2: It should be mounted absolutely vertical.

Use a spirit level in TWO directions.

To ensure a reliable and precise level measurement it

is of vital importance that the ultrasonic sensor points

down absolutely vertical against the liquid surface.

The ultrasonic sensor should be mounted

so the ultrasonic signal has no obstructions

between sensor and surface, i.e. no pipes,

cables, grates etc.

The ultrasonic sensor is equipped with a

nut for bracket mounting. Note the recess

on the nut - it must be fitted safely in the

bracket for firm fixing to the bracket:

For the highest accuracy, the ultrasonic

sensor should be mounted as close as

possible to the highest possible level that

can occur + 35 cm (types 200570, 200640

and 200660) or 80 cm (type 200630). See

below:

Min. 35 cm (200570,

200640,200660)

Highest pos-

sible level

Min. 80 cm (200630)

We deliver two types of sensor brackets that can be

used in almost any installation. The bracket shown is a

standard universal mounting bracket (200220).

GB Shuttle Manual 100316

Max. measuring range:

200570: 15 m

200640: 12 m

200630: 25 m

200660: 10 m

Bottom

8

Total distance: Max. + Min.

SW 838023

Mounting

Electrical mounting

Level transmitter

The Shuttle

the power supply before the ultrasonic

sensor is mounted and connected cor-

When the cover has been removed, the

green plastic film with the menu symbols is

tipped up to gain access to the terminals.

Shuttle

on terminal 10 and 12 or with 230 / 115 V

AC on terminal L and N.

Current regulations for conductor and

fuse dimensions should always be ob-

Always confirm that the Shuttle

rating match the present voltage.

If Shuttle

it will be indicated with a label below the

leftmost terminal block as shown here:

®

must not be connected to

rectly.

®

can be supplied with 10 - 30 V DC

served.

®

voltage

®

is delivered for 115 V AC supply,

Mount the wires according to the terminal

numbers on the reverse side of the green

plastic film:

Terminal: Designation:

1 - 5 Ultrasonic sensor

6 - 7 Relay output 1

(Max. 50 V, 1 A resistive load)

8 - 9 Relay output 2

(Max. 50 V, 1 A resistive load)

10 and 11 4-20 mA output

(Max. 500 Ω load)

10 and 12 10 - 30 V DC supply

L 230 / 115 V AC live

N 230 / 115 V AC neutral

Shuttle® is intended Shuttle® is intended

for 230 V AC. for 115 V AC.

GB Shuttle Manual 100316

9

SW 838023

Mounting

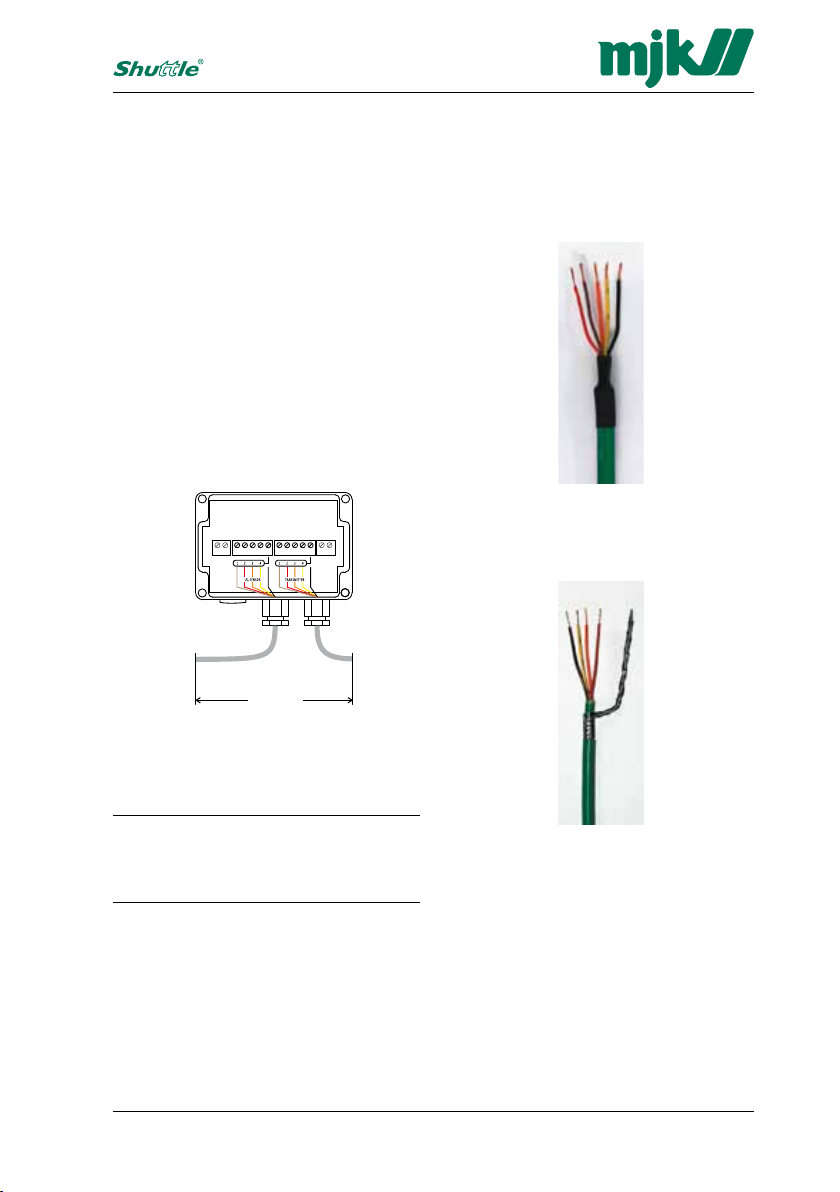

Ultrasonic sensor

The ultrasonic sensor is delivered as standard with 12 metres of cable. The ultrasonic

sensor can be delivered with up to 100 m of

cable on order, or the standard 12 m cable

can be extended to max. 100 m.

The cable is a special low capacity cable,

so extensions should always

be made with the same type of cable.

On of the most common faults on a Shuttle

installation is bad or faulty cable connections or using cables that dose not meet the

required specifications.

It is recommended to use connection

box 200590 if the sensor cable must be

extended.

To ultrasonic

sensor

Max.

To Shuttle

level

transmitter

100 m !

Cutting the cable

The cable is delivered with the wires

stripped as shown with the black wire (no.

5) soldered to the shield:

®

When the cable is cut, only 4 wires will

appear:

®

The ultrasonic sensor cable has 5 wires with

both color code and number:

Number: Color: Designation:

1 Brown Ultrasonic pulse

2 Red

3 Orange Temperature compensation

4 Yellow

5 Black Shield ➀

➀ This wire is connected to the cable shield.

The wires are mounted according to the

terminal markings on the connection box

PCB and on the Shuttle® respectively.

GB Shuttle Manual 100316

When the cable has been cut, the shield

should be mounted in terminal 5 instead

of the black wire !

When the ultrasonic sensor is mounted and

connected correctly, the Shuttle

®

can be

connected to the power supply.

See section 'Get started'.

10

SW 838023

Display and keyboard

Display and keyboard

General

The keyboard is used only for the initial programming of the Shuttle

behind the front lid. The keys are marked with symbols indicating their function.

The same symbols are used throughout this manual under the explanation of the individual

menus.

LCD-display with

symbols for indica-

tion during program-

ming, servicing and

normal operation.

®

, and is therefore hidden

Keyboard for

programming the

Shuttle

A brief program-

ming instruction.

The lower part can

be tipped up to

show the connec-

tion terminals and

their designations.

Interface used during

®

manufacturing and

for test purposes.

GB Shuttle Manual 100316

11

SW 838023

Display and keyboard

The display symbols

The different display segments indicates the actual level, the state of the output relays etc.

during normal service and indicates limit values, selection of measuring unit and other settings during programming.

The segments shown will be lit during

programming of the Shuttle®.

Displayed during programming

Numerical read-out of limit values.

delays and other numerical settings

and selections. Is also used to show

an initial letter code at start up of the

special settings.

See also pages 46 - 69.

Displayed when selecting the desired measuring unit (see page 17)

and when selecting time delays.

Start / activation of the learning

function. See also pages 28 - 29.

Flashes when setting the time

delays.

See also pages 22 - 24, 26 and 27.

Displayed when programming the

output relays.

See also pages 23 - 24, 26 and 27.

Displayed when setting the start and

stop levels for the output relays.

See also pages 21 - 23 and 25 -26.

Displayed when setting the zero

point and span for the mA output.

See also page 20.

Displayed when setting the distance

between sensor and zero point and

setting of level read-out.

See also pages 18 - 19.

The segments shown will be lit when

®

are in normal service.

Shuttle

Displayed during normal service

Numerical read-out of the actual

level.

Bar graph for indication of the signal

level on the mA-output or for indication of the actual level.

Alarm symbol. The symbol is shown

if a system error should occur on the

®

Shuttle

.

See also pages 24 and 27.

Indication of the status of the output

relays and whether the output relays

are in use. The round dot below

the relay number will appear steady

when the relay is activated and will

appear flashing when the relay is

about to be activated after a preset

time delay.

See also pages 22 - 24, 26 and 27.

This group of symbols indicates the

strength of the received ultrasonic

echo. A good measuring signal is

indicated by three or more sets of

archs.

See also page 32.

GB Shuttle Manual 100316

12

SW 838023

Display and keyboard

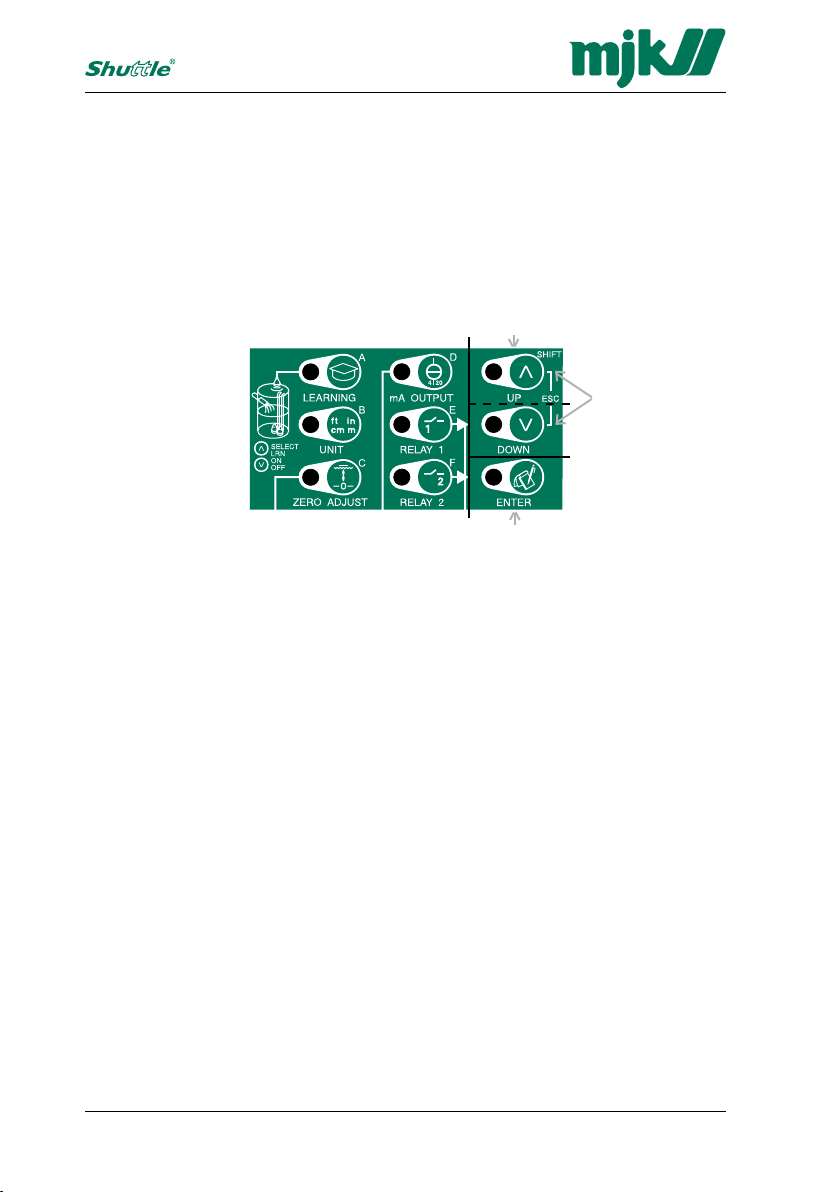

The keyboard

From the Shuttle

6 basic settings and 15 special settings.

There is direct access to the menus for basic settings by pressing one the keys A to F.

See appendix E for instructions for access to the special settings.

When a menu has been selected, settings are made with the UP and DOWN keys and

the selection is confirmed with the ENTER key (

read-out. To leave any menu without changing the settings, press the UP and DOWN keys

simultaneously (ESCape, ➂).

®

keyboard the keys marked A - F (➀) gives access to 21 menus divided in

➃) whereafter Shuttle

®

reverts to normal

➀ ➁

➂

➃

Basic settings

A (LEARNING)

Start and activation/deactivation of the

learning function.

B (UNIT)

Selection of measuring unit.

C (ZERO ADJUST)

Setting of sensor distance and zero

point.

D (mA OUTPUT)

Setting of the mA output.

E (RELAY 1)

Setting of the functions for relay

output # 1.

F (RELAY 2)

Setting of the functions for relay

output # 2.

(see pages 14 - 29)

Special settings

Shift + A (bA - bar graph readout)

Shift + B (rA - Active measuring range)

Shift + C (rE - response time for level

changes)

Shift + D (AP - Application setup)

Shift + E (S. Err - System error indication)

Shift + F (LE - Level readout calibration)

Esc + A (nAP - Setting of reference level)

Esc + B (Qu - Indication of signal quality)

Esc + C (Sh - Indication of signal amplifi-

cation)

Esc + D (dE - Period without echo)

Esc + E (Choose sensor)

Esc + F (FA - Factory settings)

AxsC + A (S. Ln - HW/SW/Serial numbers)

AxsC + B (S.St - Find zero level at next

power-up)

AxsC + C (12nA - Constant mA signal out)

AxsC + D (nS - Investigative measurements

interval)

AxsC + E (S. Al - System alarm delay)

(see Appendix E)

GB Shuttle Manual 100316

13

SW 838023

Display and keyboard

Get started

Applying power

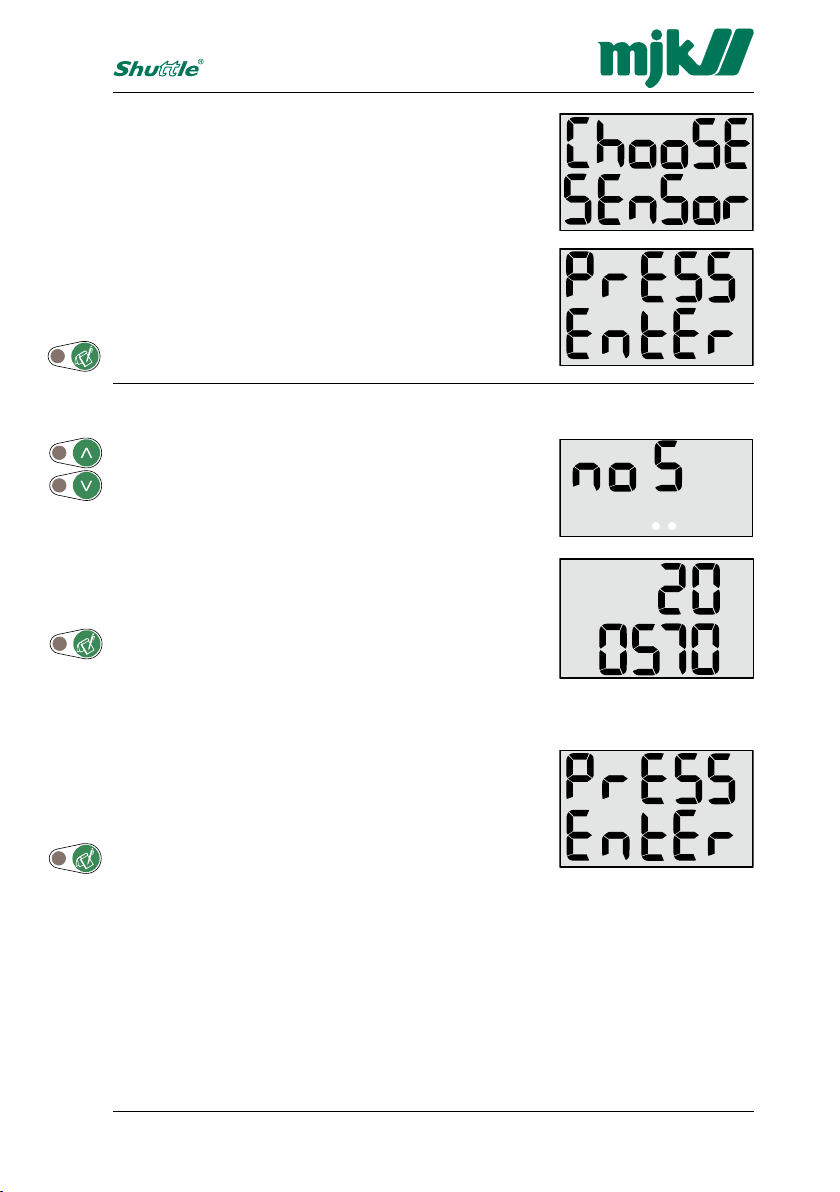

When Shuttle

lowing texts (Choose Sensor Press Enter) will appear across

the display:

Press "Enter" once to select the required sensor type.

Sensor type selection

When "No Sensor" (no S) is displayed, press the 'Up' or

'Down' arrow key to leaf through the different sensor types:

2005xx and 2006xx.

When the required sensor type appears on the display (here:

200570), press "Enter" once.

®

is connected to power for the first time, the fol-

The sensor type is now registered by the level transmitter,

and "Press Enter" passes across the display to indicate that

you may continue with setting/measuring a level of 0 meter

(nil, empty tank).

Press "Enter" once to proceed with the initial settings.

Notes:

When a sensor type has been selected, the factory settings will have no influence on this selection.

If you choose "No Sensor" (no S), the Shuttle will

invoke the choose sensor menu at start-up. From this

point the correct sensor type can be selected.

GB Shuttle Manual 100316

14

SW 838023

Display and keyboard

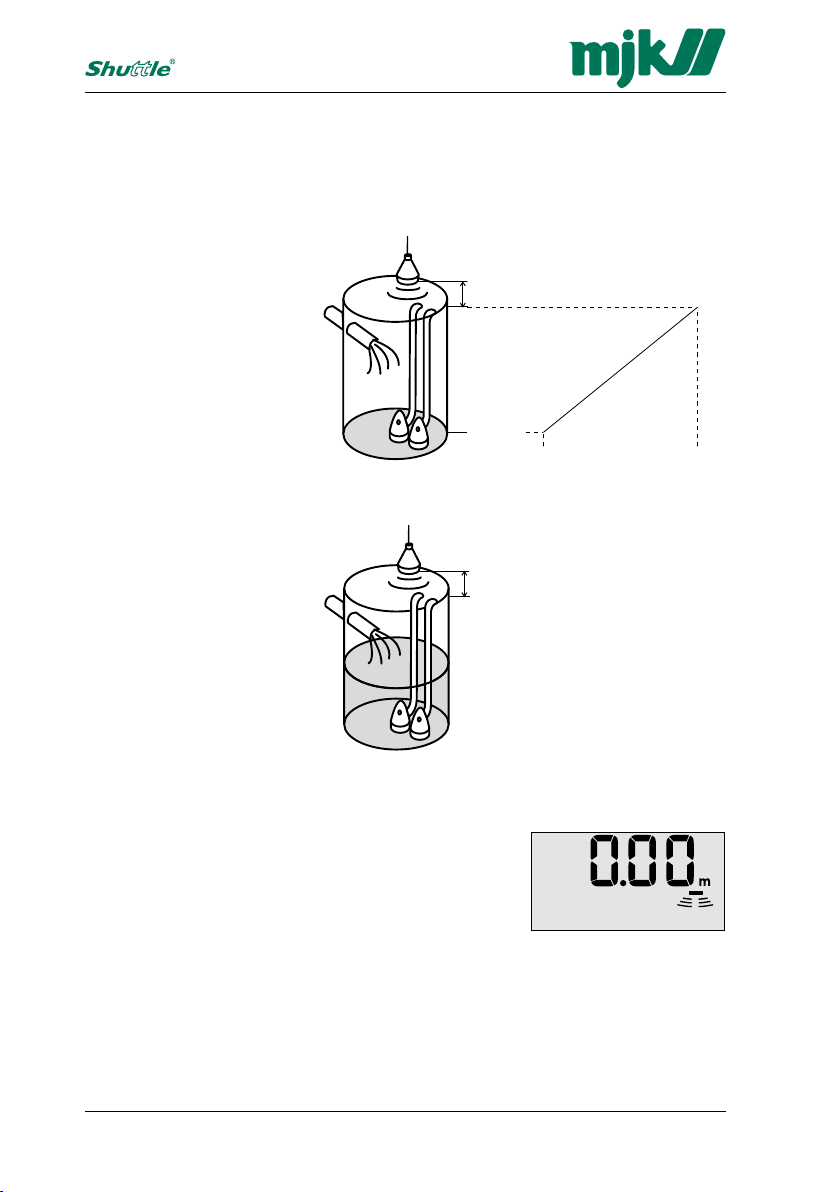

®

At the same moment Shuttle

level that is present in the tank or well.

Furthermore, the mA output is set to 4 mA at the current zero point and 20 mA at a level corresponding to a distance of 35 cm from the ultrasonic sensor.

- the well is empty…

Level read-out = distance

between sensor and bottom

- (minus) the distance between sensor and surface.

- the well is not empty…

registers an echo, the zero point is automatically set to the

35 cm from sensor (types 200570,

200640 and 200660)

80 cm from sensor (type 200630)

0.00 m

4 mA 20 mA

The distance from the sensor to the zero point or the

35 cm from sensor

level read-out must be set

manually - see page 18.

Note: The dead band

varies for the different

sensor types: 35 cm for

types 200570, 200640 and

200660, and 80 cm for type

200630.

See also Appendix A, Technical Specifications begining on

page 37.

Shuttle® will now indicate the current level in the tank or well

(0 m immediately after initial startup) and is now in service

as a regular level meter, i.e. without the use of the relays and

the analog output for control / alarm.

See the next section for basic settings.

GB Shuttle Manual 100316

15

SW 838023

Display and keyboard

Basic settings

The automatic setting of the zero point and the mA output made by Shuttle® during initial

startup may be adequate.

If changes of the zero point read-out and mA output setting should be necessary, and when

®

Shuttle

is to be used as a pump controller or for level monitoring, an additional 5 settings

should be made. These settings are described in detail on the following pages.

Proceed with set-up in the order listed below:

1: Setting units of measurement See page 17.

2: Setting the distance from sensor to zero point and

Setting the level read-out: See pages 18 - 19.

3: Setting the mA output: See page 20.

4: Setting the the relay limits: See page 21.

5: Start of the learning function: See pages 28 - 29.

When the settings are made, Shuttle® is ready to be put into service.

Bar graph

The bar graph can

be set to indicate

either the level

read-out or the mA

output.

Alarm

A flashing bell

indicates, that a

level is exceeded

or that Shuttle

®

is

not certain that the

measured level is

correct.

MJK

will always be at

your disposal.

Display

®

Shuttle

continuosly reads

out the current level with

bright and easy-to-read

figures.

Echo strength

®

Shuttle

indicates

that the ultrasonic

echo is sufficient

for a reliable level

measurement.

Relay outputs

When Shuttle

®

measures a level

that has exceeded

a setpoint limit, the

relays are activated

and their current position are indicated

here. (Relay no. 2 is

activated.)

GB Shuttle Manual 100316

16

SW 838023

Display and keyboard

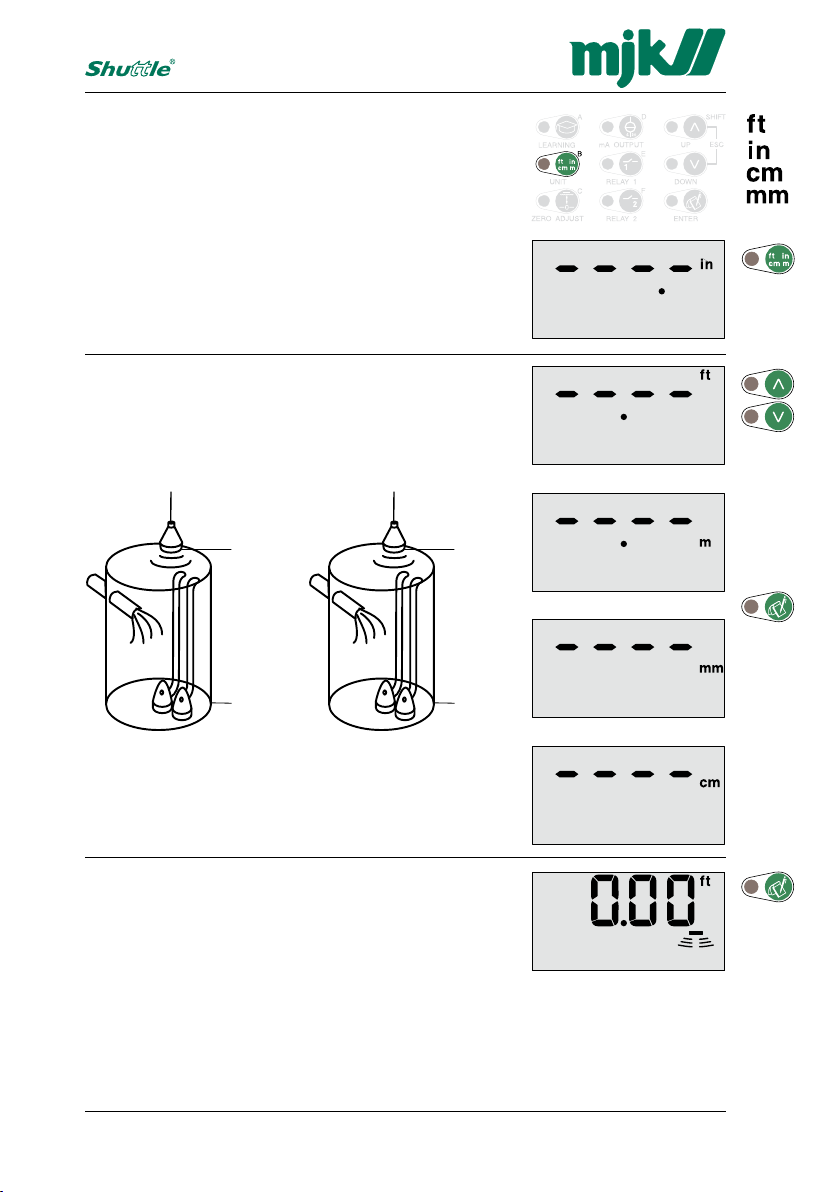

Units of measurement

If the measuring unit is changed, all other values in menus

and settings will automatically be converted to the new

measuring unit.

In this example the measuring unit is changed from metres

to feet.

The settings will be rounded off automatically.

Select unit with the arrow keys.

The dot indicates the position of the decimal separator.

2,00 m

0,00 m

6,59 ft

0,0 ft

Note: 'mm' or 'in' cannot be selected if it could cause

overrun in the display read-out.

Shuttle® reverts to normal read-out with the new measuring

unit.

GB Shuttle Manual 100316

17

SW 838023

Display and keyboard

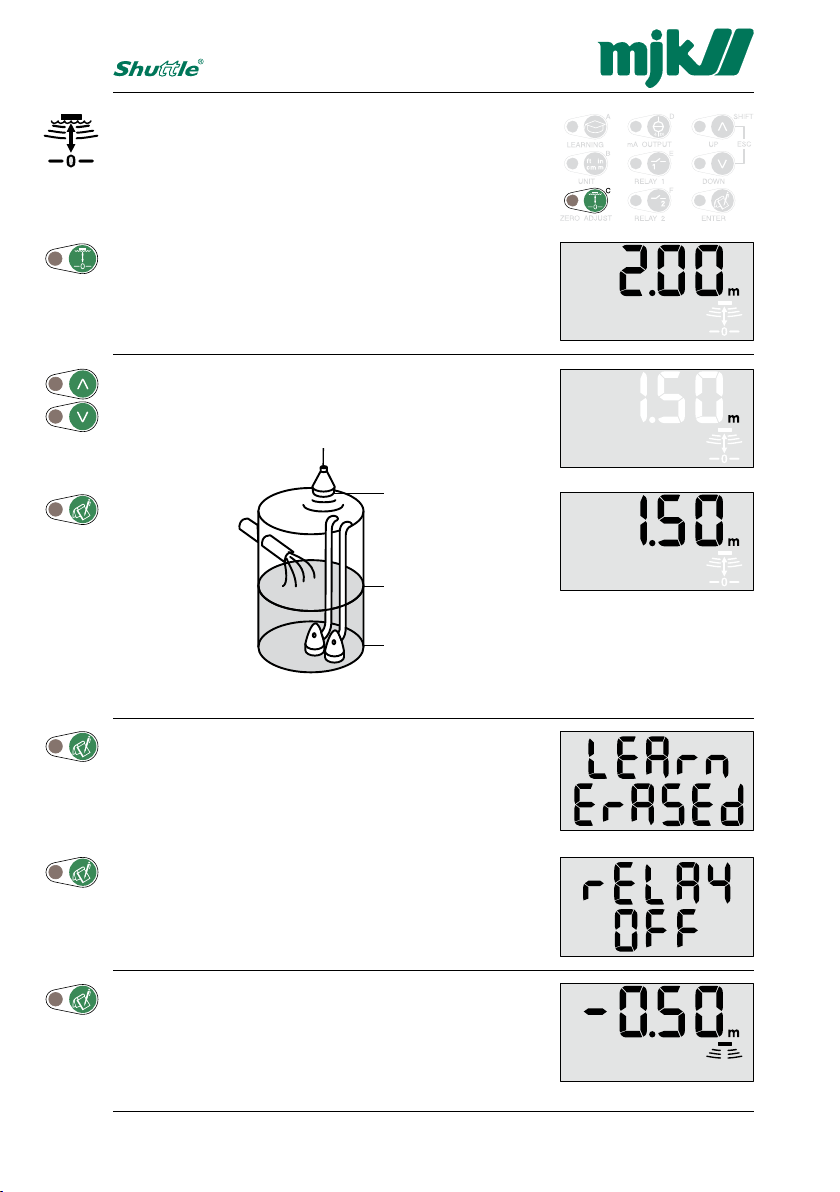

Sensor to zero point distance

The level read-out (zero point) can be adjusted as required.

This is almost always required if the well was not empty during initial startup.

Note: The learning function settings will be erased and

In this example, the level read-out is changed to be 1.50 ft

from the bottom of the well / tank.

Set the new zero point with the arrow keys.

the relays will be deactivated if the zero point setting is changed.

2,00 m

0,50 m

0,00 m

If the learning function has been activated, Shuttle® will deactivate the learning function and erase the suspicious levels

that were found last time the learning function was activated.

The learning function must therefore both be started and

reactivated again.

If the relay outputs are configured for pump control, the

relays will be deactivated, but their limit settings will not be

erased. Also, delay settings and other settings will not be

erased.

Shuttle® will now read out - 0,50 m when the well is empty.

GB Shuttle Manual 100316

18

SW 838023

Display and keyboard

Level read-out

The well is not empty

With this function the level read-out can be increased or

decreased on demand. This is almost always required if the

well was not empty during initial startup.

Note: The learning function settings will be erased and

In this example, the actual level is 80 cm, but Shuttle

out 0 m.

Select the desired level read-out with the arrow keys.

Shuttle

the relays will be deactivated if the zero point setting is changed.

®

®

will now read out 0,00 m when the well is empty.

reads

1,20 m

0,00 m

- 0,80 m

2,00 m

0,80 m

0,00 m

If the learning function has been activated, Shuttle® will deactivate the learning function and erase the suspicious levels

that were found last time the learning function was activated.

If the relay outputs are configured for pump control, the

relays will be deactivated, but their limit settings will not be

erased.

Also, delay settings and other settings will not be erased.

Shuttle® will now revert to normal level read-out with a

increased read-out value.

GB Shuttle Manual 100316

19

SW 838023

Display and keyboard

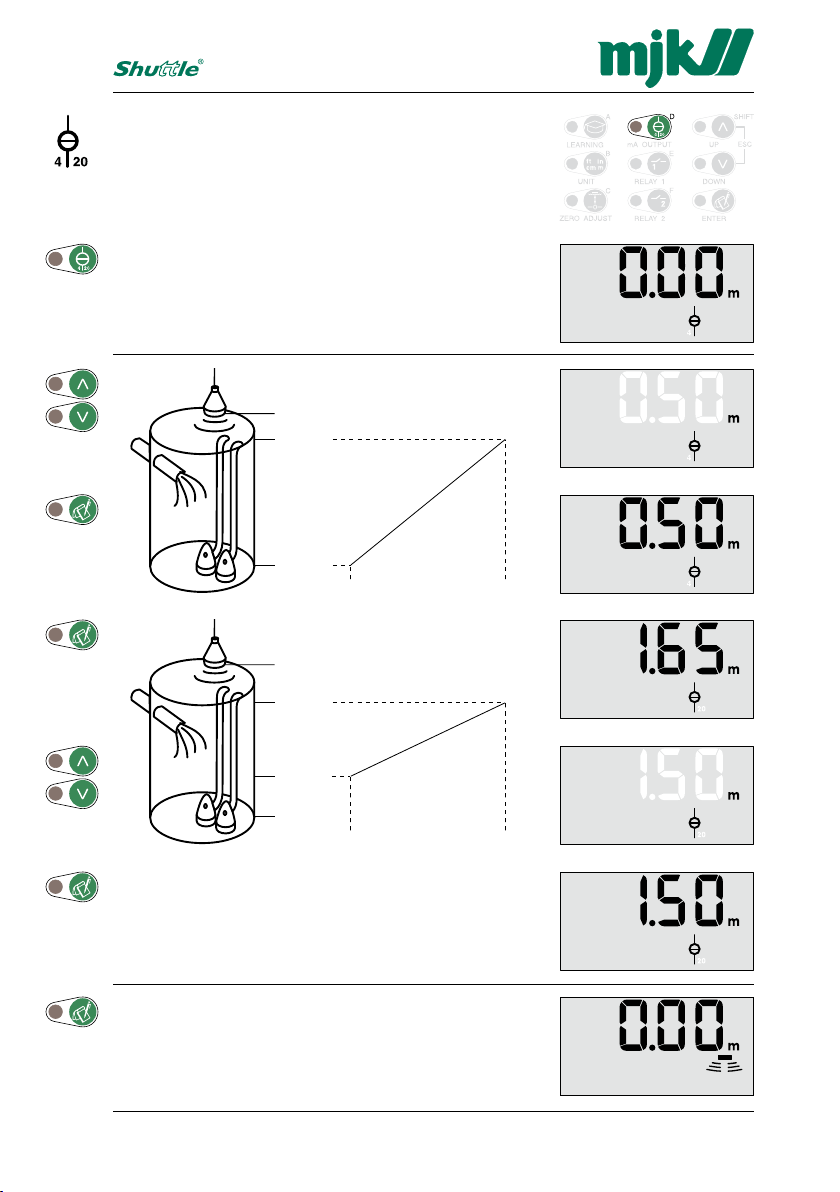

mA output

When Shuttle

®

is connected to the power supply for the first

time, the mA-output is automatically set to provide 4 mA

at zero level and 20 mA at a level corresponding to 35 cm

below the ultrasonic transmitter.

In this example the range of the mA output is changed from

0 - 1,65 m to 0,5 - 1,5 m. Changes made will not affect the

relay settings.

Note: Both values can be set over the whole range thus

making it possible to decrease the mA signal at

rising levels and vice versa.

2,00 m

1,65 m

0,00 m

4 mA 20 mA

2,00 m

1,50 m

0,50 m

0,00 m

4 mA 20 mA

Shuttle® reverts to normal read-out.

GB Shuttle Manual 100316

20

SW 838023

Display and keyboard

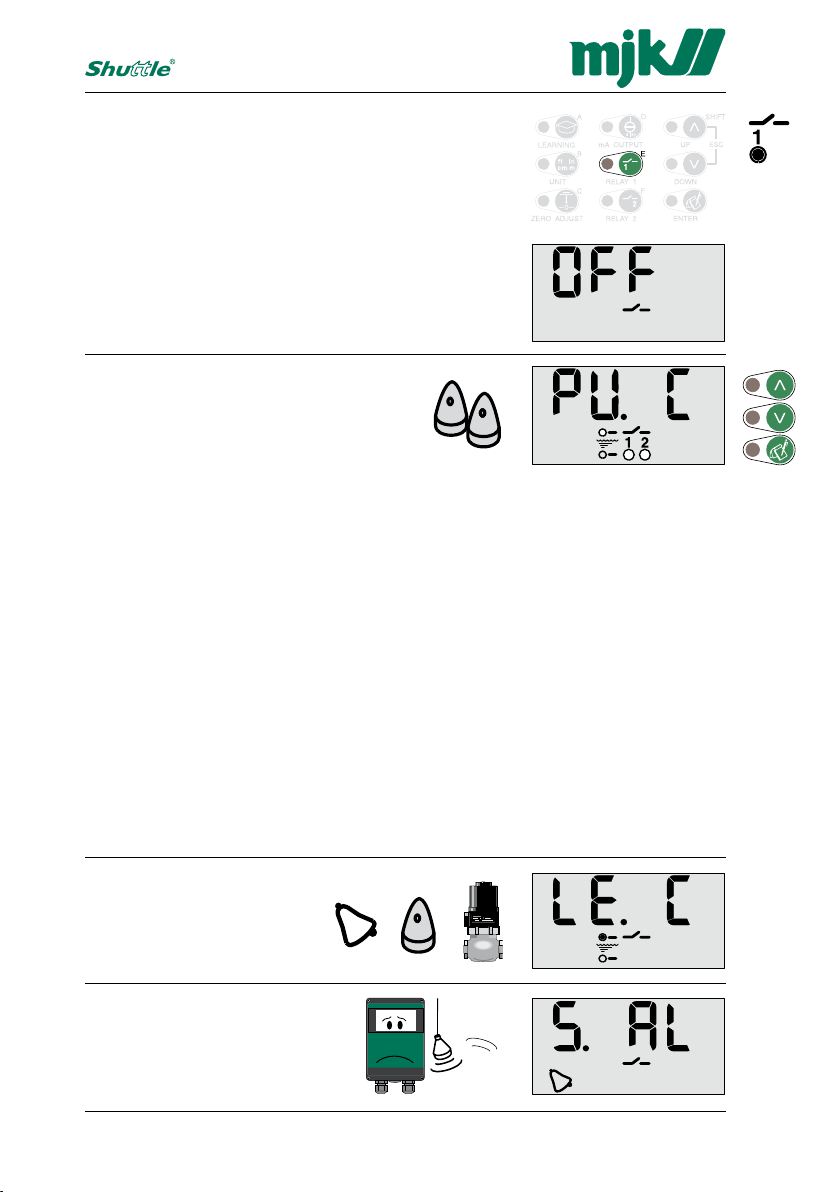

Relay outputs

Selection of relays 1 and 2

Three functions are available:

- pump control with alternation of two pumps

- level control

- system alarm

Note: If Pump Control is selected, the start and stop

If Level Control is selected, the start and stop set-

Select the desired function with the arrow keys.

Pump control:

Continue on the facing page.

settings cannot be set any closer than 10 cm.

tings cannot be set any closer than 1 cm.

Note: If pump control is selected, both relays are set in this menu and relay 2 will not be

The relays can control both pumping in and pumping out, but both relays will have

If it is later desired to change the setting, simply change the setting for relay 1 after

If the relays are configured for pump control, they will always be deactivated on

Level control:

See page 23.

System alarm:

See page 24.

available for other functions.

the same function. The function is selected automatically when relay 1 is set according to the start and stop levels. If the start level is set higher than the stop level,

both relays will then be configured for pumping in. On the other hand, if the start

level is set lower than the stop level, both relays will be configured for pumping in.

which the start and stop setting for relay 2 will be switched automatically.

system errors after 30 seconds independent of the selected time delay to prevent

dry run of the pumps.

GB Shuttle Manual 100316

21

SW 838023

Display and keyboard

Pump control with relays 1 and 2

Start and stop level for pump no. 1 is set to

1,00 and 0,75 m respectively.

1,00 m

0,75 m

Select the time delay for relay 1 with the arrow keys.

Start and stop level for pump no. 2 is set to 1,25

and 0,50 m respectively.

3.75 ft

1.50 ft

Select the time delay for relay 2 with the arrow keys.

With these start and stop levels Shuttle® is now configured

for pumping out and reverts to normal read-out.

GB Shuttle Manual 100316

22

SW 838023

Display and keyboard

Level control with relay 1

In this menu the level for activation (set) of relay 1 is changed from 1,65 to 1,00 m and deactivation (reset) of the relay output is changed from 0,00 to 0,50 m.

Select the activation (set)

level for relay 1 with the

arrow keys.

1,00 m

(activate)

0,50 m

(deactivate)

Select the deactivation (reset)

level for relay 1 with the arrow keys.

Select the time delay.

Select relay mode.

('n.c' = normally closed,

'n.o' = normally open).

Shuttle® reverts to normal read-out.

GB Shuttle Manual 100316

23

SW 838023

Display and keyboard

System alarm on relay 1

In this menu the time delay is set for the activation of relay 1 when a system error occurs

together with the reset position of the relay (normally open / normally closed):

Select the time delay.

Select relay mode.

('n.c' = normally closed,

'n.o' = normally open).

®

Note: If 'n.c' is selected, Shuttle

will also give alarm in case of power failure.

®

Shuttle

reverts to normal read-out.

GB Shuttle Manual 100316

24

SW 838023

Display and keyboard

Selection of relay function for relay 2

Two functions are available:

- level control

- system alarm

Note: Both relays are already in use if pump control has

Select the desired function.

Level control:

Continue on the facing page.

System alarm:

See page 27.

been selected earlier.

GB Shuttle Manual 100316

25

SW 838023

Display and keyboard

Level control with relay 2

In this menu the level for activation (set) of relay 1 is changed from 1,65 to 1,00 m and deactivation (reset) of the relay output is changed from 0.00 to 1.50 ft.

Select the activation (set)

level with the arrow keys.

1,00 m

0,50 m

Select the deactivation

(reset) level with the arrow

keys.

Select the time delay.

Select relay mode.

('n.c' = normally closed,

'n.o' = normally open).

Shuttle® reverts to normal read-out.

GB Shuttle Manual 100316

26

SW 838023

Display and keyboard

System alarm on relay 2

In this menu the time delay is set for the activation of relay 1 when a system error occurs

together with the reset position of the relay (normally open / normally closed):

Select the desired time delay.

Select relay mode.

('n.c' = normally closed,

'n.o' = normally open).

®

Note: If 'n.c' is selected, Shuttle

will also give alarm in case of power failure.

Shuttle® reverts to normal read-out.

GB Shuttle Manual 100316

27

SW 838023

Display and keyboard

Start of the learning function

First time activation

With this function Shuttle

bances in the well or tank that could appear as a true echo.

Disturbances can result from inlet pipes, the pump installation, a slanted bottom, etc.

®

Shuttle

stores the levels of the false echoes, which will

practically eliminate the chance of locking on a false echo.

®

Shuttle

will look for a maximum of 15 echos.

Select the function with the arrow keys.

Note: Only this selection is available if the learning

function settings have been erased earlier or the

function has never been activated before.

Shuttle® starts to investigate the tank / well for disturbances.

The investigation is finished when all segments in the bar

graph are lit.

Note: According to the number of disturbing elements,

this process may take several minutes.

®

learns if there are any distur-

In this example, Shuttle®

has found two false echos

➀ (the inlet) and ➁ (from the

pump intallation) and also

2,00 m

the correct echo from the

bottom of the well / tank.

Select the level closest to

1,75 m

the correct level +/- 15 cm

(➂).

If none of the echoes are

from a true level meas-

0,18 m

0,00 m

urement, but are all false

echoes (e.g. a slanted well

bottom), select 'nf'

(= none found).

Shuttle® now reverts to normal read-out.

Note: If 'nf'was selected as explained above, Shuttle

will normally indicate system error until a varying

echo from a true level surface is detected.

GB Shuttle Manual 100316

28

➀

➁

➂

®

SW 838023

Display and keyboard

Activating the learning function

Activation / deactivation

This function activates or deactivates the learning function.

Select with the arrow keys.

If 'OFF' (deactivation) is selected, Shuttle

®

will still remember the levels of the false echos but will not take them into

consideration.

If 'ON' (activation) is selected, Shuttle

®

will take the false

echo levels into consideration.

If 'LRN' is selected, Shuttle

®

will start a new learning proc-

ess.

Note: All levels found earlier will be erased.

If 'OFF' (or later 'ON') is selected, Shuttle® will revert to

normal read-out.

GB Shuttle Manual 100316

29

SW 838023

User and factory settings

Settings

User settings

Learning function:

Measuring unit:

Sensor / zero point distance:

Level read-out setting:

mA output: 4 mA =

20 mA =

Relay outputs: 1 2

Off:

Pump control: ❒

Level control: ❒ ❒

System alarm: ❒ ❒

Start level:

Stop level:

Relay delay: sec.

NO/NC:

❒ Off ❒ On

❒ m ❒ in ❒ ft ❒ mm ❒ cm

❒ ❒

❒ (NC) ❒ (NC)

Factory settings

❒ Off

❒ m

± 0

± 0

Zero point

35 cm from sensor

1 2

❒ ❒

-

- -

- -

- -

- -

30 sec. 30 sec.

❒ (NC) ❒ (NC)

bA

rA

rE

AP

S.Err

LE

Bar graph read-out:

Active measuring

range:

Response tme: mm/s

Measuring method:

mA signal at

system error:

Calibration of

level readout:

❒ Off ❒ mA output ❒

read-out

❒ 1 (Fluid) ❒ 2

❒ Freeze ❒ Fixed signal, mA

User and factory settings

GB Shuttle Manual 100316

Level

(Sludge and

granulate)

30

❒ mA output

From zero point to

35 cm from sensor

100 mm/s

❒ 1 (Fluid)

❒ Freeze

± 0

SW 838023

User and factory settings

Possible settings

Learning function: On / Off

Measuring unit: m / in / ft / mm / cm

Sensor / zero point distance: ± 60 m

➀

Level read-out setting: ➀ ± 60 m

mA output: ➀ ± 14,64 m

➁

➁ ± 15 m

Start level: From (zero point + distance to sensor) to (max. range - zero point)

Stop level: From (zero point + distance to sensor) to (max. range - zero point)

Relay delay: 0 to 300 sec.

NO/NC: NO / NC

Bar graph read-out: Off / mA output / level read-out

Active

measuring range:

Response time: 0,1 to 300 mm/s

Measuring method 1 (Fluid) / 2 (Sludge and granulate)

mA signal at

system error:

Calibration of level readout: - 30 til 0,29 m

GB Shuttle Manual 100316

Freeze / Fixed signal. (Fixed signal can be set from 3,5 to 20,5 mA)

0,1 to max. range

31

SW 838023

Fault finding

Fault finding

General

Almost all system errors are due to the echo from the ultrasonic sensor being either too weak

or missing. This is normally caused by incorrect installation of the ultrasonic sensor, a faulty

ultrasonic sensor or by faults on the cable between the ultrasonic sensor and the Shuttle

level meter. Other factors also have an influence on the ultrasonic level measurement. But

always check first that the ultrasonic sensor is installed correctly and is working properly. See

also the fault finding table on the facing page.

Indications on system errors

First, Shuttle

®

will indicate that the echo is too weak or missing. After 5 minutes Shuttle® displays 'S.Err', and if one of the relays is set to be activated on a system error, the relay will be

activated after the delay time. At the same time the signal from the mA output will be either

locked on the last known value or provide a preset signal value (3.5 - 20.5 mA). Other valid

error types are temperature errors, internal stack errors and EE-PROM errors (see below).

If the problem disappears, Shuttle

®

will change back to normal read-out. At the same moment, the relay output set as alarm output will switch back to its normal position and the mA

output will provide a normal signal.

Normal read-out

®

Shuttle

receives an echo

that has sufficient strength

for a safe and reliable level

measurement.

Too weak or missing echo

The received echo is too

weak for Shuttle

®

to perform a safe and reliable level

measurement.

®

System (sensor) error

If echo is still weak after 5

minutes, Shuttle

®

enters

system error mode and

sends an alarm. Also, relays

configured for pump control

will be deactivated.

Temperature error

Contack an MJK service

representative, if a temperature error appers.

Internal stack error

Contack an MJK service

representative, if an internal

stack error appers.

GB Shuttle Manual 100316

32

SW 838023

Fault finding

EE-PROM error

Contack an MJK service

representative, if an EEPROM error appers.

Power failure

If one of the relay outputs is

set to NC (normally closed),

an external alarm is immediately sent out at power

failure.

Fault finding table

Problem Cause Remedies

The display

is not lit

Shuttle

indicates

system error

Power supply W ire mounting Is min. 10 mm of the insulation removed and firmly

®

Liquid

surface

Ultrasonic

sensor

mounted?

AC supply Is correct live voltage present between terminals L and

N?

Is the right-hand fuse (40 mA@230 VAC, 100 mA@115

VAC) intact? Exchange if necessary.

DC supply Is 10 - 30 VAC present between terminals 10 and 12,

and is the polarity correct?

Is the left-hand fuse (200 mA) intact? Exchange if

necessary.

Measuring Is the liquid surface foamy? Try changing the setting

method for measuring method from 'AP 1' to 'AP 2'.

(Shift + D)

Wire mounting Is a minimum of 10 mm of the insulation removed and

the wires firmly mounted?

Are the wires connected to the correct terminals? See

the connection diagram.

Cable Are there water in the connections, and are the

extensions extensions made correctly?

Condition Is the black part of the sensor miscoloured or

cracked? Miscolouring indicates that the sensor is not

suited for the environment on the installation site.

Function Is the sensor transmitting clicking sounds? If not, the

sensor is faulty.

Sensor Is the sensor mounted ABSOLUTELY VERTICAL?

mounting It is extremely important that the sensor is firmly

mounted in a vertical position. See the section

'Mechanical mounting of sensor'.

Measuring Is the sensor mounted so that the measuring distance

distance is less than the deadband and more that the max.

range? The max./min. measuring range must not be

exceeded.

GB Shuttle Manual 100316

33

SW 838023

Fault finding

Shuttle®

indicates

system error

constantly

Level readout is not

changing

Level readout is wrong

Level

read-out is

unstable

®

Shuttle

Ultrasonic

sensor

Ultrasonic

sensor

®

Shuttle

Ultrasonic

sensor

®

Shuttle

Setting Is the setting of the active measuring range (Shift + B)

correct? The active measuring range must not be set

lower than the max. possible level.

Sensor Is the sensor mounted ABSOLUTELY VERTICAL?

mounting It is extremely important that the sensor is firmly

mounted in a vertical position. See the section

'Mechanical mounting of sensor'.

Installation Are there for example bit, fatty accumulations or other

site objects disturbing the ultrasonic signal?

Setting Has the learning function been activated? If the

learning function has not been activated, Shuttle

lock on a false echo.

®

may

Sensor Is the sensor mounted ABSOLUTELY VERTICAL?

mounting It is extremely important that the sensor is firmly

mounted in a vertical position. See the section

'Mechanical mounting of sensor'.

Cable Is the sensor cable extended with a not-approved

cable type and/or extended beyond 100 m?

Installation Does the ultrasonic sensor have the same temperature

as the ambient air? Deviations will produce measuring

errors!

Setting Shuttle® level readout may need adjustment.

Sensor Is the sensor mounted ABSOLUTELY VERTICAL?

mounting It is extremely important that the sensor is firmly

mounted in a vertical position. See the section

'Mechanical mounting of sensor'.

Is the sensor mounted firmly? The sensor should be

mounted on a suitable bracket.

Installation Turbulence on the surface.

site Objects on the surface that disturb the measurement.

Strong winds can bend off the echo, so it misses the

ultrasonic sensor.

Setting Response time (Shift + C) is set too low.

GB Shuttle Manual 100316

34

SW 838023

Ex Instructions

Ex Instructions

Quick Installation Guide - FM-approved MJK Ultrasonic Sensors

MJK Ultrasonic Sensor Installation

MJK Automation A/S offers a variety of FM-approved ultrasonic sensors for the MJK Shuttle® Level Converter, the

MJK 704 Pump Controller and the MJK 713 Open Channel Flow Converter.

This quick guide solely covers mounting and installation of the FM-approved MJK Shuttle sensors in hazardous

locations.

Shuttle® Ultrasonic Sensor Type 200630 - Extended Range w/ 39 ft. cable

•

Shuttle® Ultrasonic Sensor Type 200631 - Extended Range w/ 150 ft. cable

•

Shuttle®Ultrasonic Sensor: 200630 (200631)

Range: 75 ft. (fluids), 30 ft. (solids)

Frequency: 30 kHz

Spread: 6°

Deadband: 32"

Temperature: - 5 °F to + 150 °F

Shuttle® Ultrasonic Sensor Type 200640 - Standard Range w/ 39 ft. cable

•

Shuttle® Ultrasonic Sensor Type 200641 - Standard Range w/ 150 ft. cable

•

Shuttle® Ultrasonic Sensor Type 200650 - Short Range w/ 39 ft. cable

•

Shuttle® Ultrasonic Sensor Type 200651 - Short Range w/ 150 ft. cable

•

Materials: PBF/ceramic

Shuttle®Ultrasonic Sensor: 200640 (200641)

Range: 35 ft. (fluids), 15 ft. (solids)

Frequency: 40 kHz

Spread: 7°

Deadband: 14"

Temperature: - 5 °F to + 150 °F

Materials: PBF/ceramic

Shuttle®Ultrasonic Sensor: 200650 (200651)

Range: 10 ft. (fluids), 4 ft. (solids)

Frequency: 75 kHz

Spread: 7°

Deadband: 14"

Temperature: - 5 °F to + 150 °F

Materials: PBF/ceramic

-40

-30

-20

-10

-40

-30

-20

-10dB

-40

-30

-20

-10dB

dB

0

0

0

3030

3030

3030

9090

6060

9090

6060

9090

6060

See comprehensive information about the MJK Shuttle® Level Converter, the MJK 704 Pump Controller and the

MJK 713 Open Channel Flow Converter in their respective data sheets, installation and user manuals.

Sensor Installation in Class I, II and III, Div. 1 & 2, A, B, C, D, E, F, G Hazardous Locations

UltraSonic Sensor Installation DWG 5049 070327

GB Shuttle Manual 100316

Page 1 of 2

35

MJK North America, Inc.

37 Sherwood Terrace, #126

Lake Bluff, IL 60044

Tel: 847-482-8655

877 MJK LINK

Fax: 847-482-8654

mjkusa@mjk.com

www.mjk.com

SW 838023

Ex Instructions

Quick Installation Guide - FM-approved MJK Ultrasonic Sensors

Class I, II and III, Div. 1 & 2,

A, B, C, D, E, F, G

hazardous location

User supplied conduits

and materials, see notes.

Max. 18 inches

User supplied conduit and

connection box, see notes.

To MJK ultrasonic

sensor

To MJK transmitter

Optional MJK

extension cable

p/n 690010

Integral sensor cable,

see notes.

Required for Class I, II and III,

Div. 1 & 2 locations sealing fittings,

sealing cement and fiber kit.

See notes

Class I, II and III, Div. 1 & 2,

A, B, C, D, E, F, G

hazardous location

Required for Class I, II and III,

Div. 1 & 2 locations sealing fittings,

sealing cement and fiber kit.

See notes

Notes for customer supplied materials and services

Cables, fittings and conduits must be installed by the customer in accordance with NEC 501-4, 502-4 or 503-3.

1.

In Class I, II and III, Div. 1 & 2, A, B, C, D, E, F, G hazardous (classified) locations all seal fittigs, sealing com-

2.

pounds, connections boxes, conduits, fittings, etc. must be certified and approved for use in the above mentioned locations.

Minimum thread engagement between all threaded joints must be a maximum of 5 full threads.

3.

Interconnecting cable conduits and fittings must be grounded to a proper electrical ground. Bonding between all

4.

conduit connections must be provided and installed by the customer as part of installation.

The sensors are provided with an integral cable. An extension cable must MJK cable, part no. 690010.

5.

The cable must be run in accordance with NEC (ANSI/NFPA 70), CEC pt. I and/or applicable local code require-

6.

ments.

This installation guide is under MJK control, and modifications are not allowed without consent from the certifying

7.

authority.

GB Shuttle Manual 100316

Page 2 of 2

36

Denmark

www.mjk.dk

mjk@mjk.dk

+45 45 56 06 56

Norway

www.mjk.no

mjk@mjk.no

+47 69 20 60 70

MJK offices:

The Netherlands

www.mjk.com

mjknl@mjk.com

+31 251 672171

Sweden

www.mjk.se

kontoret@mjk.se

+46 53 31 77 50

North America

www.mjk.com

mjkusa@mjk.com

+1 847 482 8655

Australia

www.mjk.com

mjk@mjk.com

+61 3 9755 1529

SW 838023

Appendix

A Technical specifications

Shuttle® Level Transmitter

Measuring range 0 - 25 m

Span From 0 - 10 cm to 0 - 25 m

Power supply 230 / 115 V AC, 10 - 30 V DC

Consumption 2 W

Temperature - 20 to + 60 °C

Input From ultrasonic sensor

Accuracy

Outputs Analogue: 1 pc. 4 - 20 mA, max. 500 Ω loop impedance.

Display LCD with 4 digits and symbols

Operation Function keys behind the front cover

Enclosure IP65

CE approvals EN 50081-1, EN 50082-1

The accuracy is stated for the selected measuring range with the sensor mounted 35 cm above highest possible

➀

level and with subsequent calibration of level readout as explained on page 52 and when measuring on an even

surface without foam build-up or other disturbing objects.

Dimensions

Better than ± 0,2% ➀

Digital: 2 pcs. relays with connect or disconnect function (NO/NC).

Max. 50 V DC, 1 A ohmic / 50 V AC, 50 VA.

Shuttle® Level Transmitter

Universal bracket

Short sensor bracket

GB Shuttle Manual 100316

Standard sensor bracket

37

Shuttle® Ultrasonic Sensor

500 mm

50 mm

115 mm

550 / 950 mm

Sensor bracket for channel or flume

SW 838023

Appendix

9090

6060

3030

0

-40

-30

-20

-10

dB

Shuttle® Ultrasonic Sensors

Standard Range Version

Shuttle® Ultrasonic Sensor Type 200570

Measuring range 15 m (liquids), 6 m (solids)

Frequency 30 KHz

Spread 3 °

Dead band 35 cm

Sensitivity See figure below

Temperature - 20 to + 60 °C

Materials PP (green), POM (black)

Cable Shielded, insuated with oil resistant PVC,

length 12 m

(Max. 100 m with 690010 cable)

Enclosure IP 68, water-proof, withstands sub-

merging, max. 1 bar

CE approvals EN 50081-1, EN 50082-1

GB Shuttle Manual 100316

38

SW 838023

Appendix

Standard Range Version/FM Approved

Shuttle® Ultrasonic Sensor Types 200640 / 200641

Measuring range 12 m (liquids), 6 m (solids)

Frequency 40 KHz

Spread 7 °

Dead band 35 cm

Sensitivity See figure below

Temperature - 20 to + 60 °C

Materials VALOX

Cable 200640:

Cable 200641:

Enclosure IP 68, water-proof, withstands sub-

CE approvals EN 50081-1, EN 50082-1

Ex approvals FM Class 1, Div. 1, Group A-G

Shielded, insuated with oil resistant PVC,

length 12 m.

Shielded, insuated with oil resistant PVC,

length 50 m

(Max. 100 m with 690010 cable)

merging, max. 1 bar

9090

GB Shuttle Manual 100316

39

-10

-40

-30

-20

6060

dB

3030

0

SW 838023

Appendix

Extended Range Version

Shuttle® Ultrasonic Sensor Types 200630 / 200631

Measuring range 25 m (liquids), 10 m (solids)

Frequency 30 KHz

Spread 6 °

Dead band 80 cm

Sensitivity See figure below

Temperature - 20 to + 60 °C

Materials VALOX

Cable 200630:

Cable 200631:

Enclosure IP 68, water-proof, withstands sub-

CE approvals EN 50081-1, EN 50082-1

Ex approvals FM Class 1, Div. 1, Group A-G

Shielded, insuated with oil resistant PVC,

length 12 m.

Shielded, insuated with oil resistant PVC,

length 50 m

(Max. 100 m with 690010 cable)

merging, max. 1 bar

9090

GB Shuttle Manual 100316

40

-40

-30

-20

-10dB

0

6060

3030

SW 838023

Appendix

Chemical Resistant Version

Shuttle® Ultrasonic Sensor Type 200660

Measuring range 10 m (liquids), 5 m (solids)

Frequency 50 KHz

Spread 6 °

Dead band 35 cm

Sensitivity See figure below

Temperature - 20 to + 60 °C

Materials PP, PVDF

Cable Shielded, insuated with oil resistant PVC,

length 12 m

(Max. 100 m with 690010 cable)

Enclosure IP 68, water-proof, withstands sub-

merging, max. 1 bar

CE approvals EN 50081-1, EN 50082-1

GB Shuttle Manual 100316

41

SW 838023

Appendix

B Changing supply voltage

1: Remove the lid, detach the wires from

the terminal blocks and remove the four

screws that hold the electronics in the

cabinet.

2: Take out the electronics and turn it

around.

Look at the upper left corner and look

if two soldering branches (pos. B) are

mounted and if the conducting branch

(pos. A) is broken or not.

- no soldering branches is mounted

(pos B) and the conducting branch

(pos. A) is not broken: Shuttle

®

is

intended for 230 V AC.

- two soldering (lus) are mounted (pos.

B) and the conducting branch (pos. A)

is broken: Shuttle

®

is intended for

115 V AC.

Conversion from 230 to 115 V AC

Mount two soldering brackets between

the soldering points (pos. B) and break

the conducting branch or drill out the

soldering point (pos A).

Turn around the electronics and ex-

change the left fuse to a 100 mA fuse.

Conversion from 115 to 230 V AC

Remove the two soldering brackets

between the soldering points (pos. B).

Close the conducting branch (pos A).

Turn around the electronics and ex-

change the right fuse to a 40 mA fuse.

The rightmost fuse should be rated

40 mA @ 230 VAC or 100 mA @ 115 VAC.

3: Mount the electronics in the cabinet,

mount the wires in the terminal blocks

and mount the lid.

A A

230 V AC 115 V AC

GB Shuttle Manual 100316

BB

42

SW 838023

Appendix

C Sensor mounting considerations

General

The ultrasonic sensor is characterized by a

very narrow spread of the ultrasonic signal

(3 ° - 7 ° depending on the type of sensor),

which makes it possible to use the ultrasonic sensor under very tight conditions, i.e. in

narrow wells or tanks. 80 % of the ultrasonic

signal is concentrated within this area, which

will give a sufficient echo that is sufficient in

the far most cases.

It is required, though, that the ultrasonic

signal is not being muffled or disturbed by

gratings, pipes, cables etc., and that the

ultrasonic sensor is not mounted so the

ultrasonic signal is sent too close to a tank

wall or well wall.

Signal spread

The illutration to the left shows the spread

of the ultrasonic sensor in conjunction with

the measuring distance, the ultrasonic signal

spread will be 57 cm at a measuring distance of 9 m. It will appear, that increasing

the measuring distance the distance from

the center line to a smooth wall should be

increased accordingly.

Distance

Table 1: The ultrasonic signal spread along a smooth

Spread (cm) Min. dist. from wall (cm)

(m)

3° 6° 7° at 3° at 6° at 7°

15 20 22 8 10 11

1

20 31 34 10 15 17

2

26 41 47 13 21 23

3

31 52 59 15 26 29

4

36 62 71 18 31 36

5

41 73 83 21 36 42

6

47 83 96 23 42 48

7

52 94 108 26 47 54

8

7 104 120 29 52 60

5

9

62 115 132 31 57 66

10

68 125 145 34 63 72

11

73 136 157 36 68 78

12

78 146 169 39 73 85

13

83 157 181 42 78 91

14

89 167 194 44 84 97

15

wall and minimum distance to center line in

conjunction to the measuring distance.

NB!

Max. measuring

distance is

31½ ft when us-

ing a standard

sensor bracket !

For greater

distances the

bracket should

be extended

further out over

the well or tank.

Figure 1: The signal spread in conjunction with the

measurement distance. The spread value

should be increased by 50 - 100 % if the

surface is not smooth!

GB Shuttle Manual 100316

43

SW 838023

Appendix

Measurements

Along a wall / other surface

The values in table 1 assume the ultrasonic

signal is sent along a smooth surface like

a wall or plane without any projections,

joints, butts etc.

If the surface is not smooth or has projections (i.e. joints on prefab elements), the

ultrasonic signal will be impedeaded too

much, and for that reason

the values for minimum distance to wall in

table 1 should be increased with

50 - 100 % !

Through a concrete deck

When the ultrasonic sensor is measuring

through a concrete deck, the dimension

of the opening should be made as shown

below: (See table 1 for the sensor spread.)

Min. diameter (D)

= sensor spread +

100 %

In a tank / container

If the ultrasonic sensor is mounted for

measurement of the level in a closed tank or

container, it should measure through a pipe

with a cutoff as shown below:

Min. diameter (D) =

sensor spread + 100 %

Min. 14 in

30 - 45 °

Measurement in a closed container or tank.

Through pipe for foam protection

When measuring on liquids prone to building

up foam on the surface, it is often necessary

to measure through a pipe, since the build

up of foam rarely will occur inside the pipe.

Measurement through a concrete deck with

Measurement through a concrete deck with

GB Shuttle Manual 100316

sharp edge.

Min. diameter (D) =

45 - 60 ° edge cutoff.

sensor spread

+ 50 %

Min. diameter (D) =

sensor spread + 100 %

Measurement through a pipe for foam protection.

44

SW 838023

Appendix

D Service menu

®

Shuttle

has a service menu that gives access to settings that normally are not altered

by the user and therefore are protected by a

password.

The service menu includes:

- adjustment of the 4-20 mA output

- adjustment of the temperature compen-

sation

- functional control of keyboard and

display

- relay check

- changing of serial number and hard-

ware/software numbers

- self test function

Refer to 'Shuttle

information of the functions in the service

menu.

®

Service Manual' for further

GB Shuttle Manual 100316

45

SW 838023

Appendix

E Special menus

Under certain circumstances it may be necessary to make adjustments and to make

readings in the following special menus.

It is recommended that only experienced

users and MJK service technicians make

alterations in these menus.

The following menus are not protected with

an access code:

Bar graph read-out

Active measuring range

Response time

Measurement method

mA output value during system error

Calibraton of level readout

Offset level readout

Indication of echo signal quality

Indication of signal amplification

Indication of period length without echo

Selection of factory presets

The following menus are protected with an

access code:

Readout of version numbers

Find zero level on next power-up

Fixed mA signal

Interval between investigative

measurements

System alarm delay

Averaging the level measurement

Max. amplification level

Min. level for accept of ultrasonic echo

Sensitivity of the learning function

Changing the access code

GB Shuttle Manual 100316

46

SW 838023

Appendix

Bar graph read-out

This function is used to select whether the bar graph should

follow the analog output or the level read-out.

Changes will not have influence on the relay settings.

The bargraph follows the analog output.

Note: If the mA settings are inverted (the level reference

The bar graph follows the level read-out.

Note: If the active measuring range has been decreased

The bar graph is deactivated.

at 4 mA is set higher than the level reference at

20 mA), the bar graph will increase when the level

decreases and vice versa.

to e.g. 1,45 - 3 m (see next page), the range of

the bar graph will be changed accordingly (all segments lit at 3 m and all segments off at 1,45 m.)

Shuttle® reverts to normal read-out.

GB Shuttle Manual 100316

47

SW 838023

Appendix

Active measuring range

®

Shuttle

's measuring range is normally set automatically to

a distance corresponding to the ultrasonic sensor's distance

to zero level + 45 cm.

It may become necessary to decrease the active measuring

range so it corresponds to the highest and lowest possible

levels in the well /tank - especially if the ultrasonic sensor is

mounted above a steel grating or an opening in a well cover.

In this example, the Shuttle

®

's active measuring range are

decreased from 0,35 cm - 15 m to 1,45 - 3m measured

from the sensor - that is 3,00 m from the bottom to 10 cm

below the grating or cover.

Set the start distance of the measuring range measured

from the ultrasonic sensor (i.e. the highest possible level).

0 m

0,35 m

Normal

measuring

range

15,00 m

0 m

(1,35 m)

1,45 m

Reduced

measuring

range

3,00 m

Set the stop distance of the measuring range measured from the

ultrasonic sensor (i.e. the lowest possible level).

Shuttle® reverts to normal read-out.

GB Shuttle Manual 100316

48

SW 838023

Appendix

Response time

When the level changes, the display read-out will change

accordingly with a pre-programmed delay.

The response time is set to 100 mm/sec. from the factory,

which means that an actual level change will not be shown

in the display at a faster rate than 4 in per second.

When measuring on turbulent surfaces, it may become

necessary to increase the response time in order to obtain a

more stable level measurement and also relay function.

Select the desired response time with the arrow keys.

Note: Changing the response time will also change the

Shuttle® reverts to normal read-out.

response time for the mA output and the time for

exceeding the set/reset levels.

GB Shuttle Manual 100316

49

SW 838023

Appendix

Measuring method (application)

®

Shuttle

's high accuracy is partly obtained by controlling the

strength of the ultrasonic pulse based on the strength of the

received echo. (AP 1)

When performing level measurements on foaming surfaces,

granulate, sludge etc., the received echo is generally so

weak that it would be better to let Shuttle

ultrasonic pulses with full strength constantly. (AP 2)

Also, when performing level measurements on surfaces with

very rapid level changes, it can be necessary to moderate

the influence of the learning function (see also page 28) to

prevent Shuttle

®

from locking on false echos. (AP 3)

Select measuring method with arrow keys.

If 'AP 1' is selected, the ultrasonic pulse will be controlled in

accordance with the strength of the received echo.

'AP 1' should normally be selected for fluid applications.

®

send out the

If 'AP 2' is selected, Shuttle

®

will transmit with full strength

constantly.

'AP 2' should normally be selected for sludge / granulate

applications.

If 'AP 3' is selected, Shuttle

®

will be better to catch rapid

level changes.

'AP 3' should normally be selected for measuring in sludge

containers, grating matter or other aqueous matter.

Shuttle® reverts to normal read-out.

GB Shuttle Manual 100316

50

SW 838023

Appendix

mA output signal during system error

This function determines how the mA output should act in

case of a system error.

System errors are most often caused by a weak or missing

ultrasonic echo, but may also occur by failure of the ultrasonic sensor or failure in Shuttle

Select the desired condition with the arrow keys.

The mA output will be locked on the last known value when

a system error occurs.

The mA output will give a fixed signal when a system error

occurs.

Select the desired value (0.35 to 20.5 mA) of the fixed signal

with the arrow keys.

®

's internal circuits.

Shuttle® reverts to normal read-out.

GB Shuttle Manual 100316

51

SW 838023

Appendix

Calibration of the level measurement

If the distance of the ultrasonic sensor above the surface is

known, it will be possible make a calibration of Shuttle

level read-out.

The calibration will only have influence on the level read-out

- not on relay setpoints for pump control, alarms etc.

Note: Because of the built-in temperature compensation,

it is important that the ultrasonic sensor has the

same temperature as the surrounding air. Leave

the sensor in the surrounding air for minimum 1

hour.

Select the desired correction with the arrow keys.

If the learning function has been activated, Shuttle® will deactivate the learning function and erase the suspicious levels

that were found last time the learning function was activated.

The learning function must therefore both be started and

reactivated again.

If the relay outputs are configured for pump control, the

relays will be deactivated, but their limit settings will not be

erased. Also, delay settings and other settings will not be

erased.

®

's

®

Shuttle

reverts to normal read-out.

GB Shuttle Manual 100316

52

SW 838023

Appendix

Offset level readout

®

Shuttle

can display the levels with reference to a selectable

offset level.

This means that the normal zero level (when the tank is

empty) is displaced up or down.

Note: It is very important, that the distance from sensor

Shuttle® wil now display the

level as the distance from

sensor to zero.

to zero is set correctcly (see page 18), and that the

active measuring range (see page 48) is set to a

distance, that corresponds to the longest meaasuring distance that can occur.

2,00 m

Zero refer-

Select the desired zero reference with the arrow keys

and confirm with 'Enter'.

Zero refer-

Shuttle® reverts to normal

read-out. Every 5 seconds

the display indicates that

the level readouts are displaced from zero.

GB Shuttle Manual 100316

ence

ence

53

m

0,00

1,00 m

0,00 m

-1,00 m

SW 838023

Appendix

Indication of echo quality

This menu is used to indicate the strength of the received

ultrasonic echo.

If there are frequent system errors (see page 32), this function can be used to check if the ultrasonic echo is being

weakened too much under the current working conditions

- i.e. foam, waves etc.

There are no specific limits indicating that the echo is too

weak, since it depends highly on the current working conditions. Please contact MJK for advice.

The strength of the received ultrasonic echo is displayed

immediately.

(The strenght is shown in percent.)

Shuttle® reverts to normal read-out.

GB Shuttle Manual 100316

54

SW 838023

Appendix

Indication of signal amplification

This menu is used to display the amplification level of the

received ultrasonic echo. The function can give an indication

og the strength of the received echo.

If the amplification level is low (below. 20 dB), the echo

strength is good and vice versa.

A high amplification level (max. 50 dB) indicate that the

ultrasonic echo is weak (foam or waves).

High amplification may in certain situations create other

problems with electrical noise from other equipment at the

installation site.

The amplification level is displayed immediately.

(The level is displayed in dB)

Shuttle® reverts to normal read-out.

GB Shuttle Manual 100316

55

SW 838023

Appendix

Indication of time period without echo

This menu is used to display the longest time period during

which Shuttle

also how many days has passed since this occurred.

®

has been missing an acceptable echo, and

The longest time period that Shuttle

®

has been missing an

acceptable echo is displayed immediately.

(In seconds.)

Next, the number of days since the occurrence is displayed.

The longest period with echo failure will be erased after 14

days.

Shuttle® reverts to normal read-out.

GB Shuttle Manual 100316

56

SW 838023

Appendix

Select factory settings

All settings - except calibration of the level measurement

- made after initial startup will be reset to factory settings

with this function.

The zero point setting will also be adjusted to the immediate

level in the well / tank. Furthermore, the mA output is set to

4 mA at the current zero point and 20 mA at a level corresponding to a distance of 14 in from the ultrasonic sensor.

Note: The function will cause Shuttle

same way it did when the supply power was

turned on for the first time..

Select 'ON' with the arrow keys.

®

to start up the

This is shown in the display until Shuttle

®

detects a valid

echo again.

... after which Shuttle® returns to normal read-out.

GB Shuttle Manual 100316

57

SW 838023

Appendix

Access code

To gain acces to the remaining menus, an access code is

required.

Press and hold 'Escape' at least for 5 seconds:

The access code can now be selected:

Use the arrow keys to select…

(Standard access code is 100:)

…and confirm with 'ENTER':

All password protected menus can now be selected.

®

Shuttle

will display the current level readings between menu

selections.

Shuttle® will revert to normal readout if:

1: the keyboard has not been used within 5 minutes.

2: 'Escape' is pressed.

The acces code must then be entered again for access to

the password protected menus.

GB Shuttle Manual 100316

58

SW 838023

Appendix

Readout of version numbers

Enter the access code (see page 58) and press'A':

This menu is used to display version numbers for software

and hardware and the unit's serial number.

The hardware version number

is displayed first:

(Ex.: HW version 838003)

Use the up-arrow to proceed.

The software version number is

displayed next:

(Ex.: SW version 838014)

Use the arrows to proceed.

At last the Shuttle

®

's serial

number is displayed:

(Ex.: serial no. 029400)

Use the down-arrow to proceed.

®

Shuttle

is ready for a new selection of a password protect-

ed menu after pressing 'Enter'.

(Re-entering the access code is not necessary if a menu

selection is made within 5 minutes.)

Press 'Escape' if no further password protected menu

selections are needed …